Method for simplifying analysis of elastic-plastic fractures of RPV under extreme accident conditions based on RCC-M specification

An analysis method and technology for accident conditions, applied in the direction of analyzing materials, strength characteristics, measuring devices, etc., can solve the problems of simple form and lack of theoretical basis, and achieve the effect of improving accuracy and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

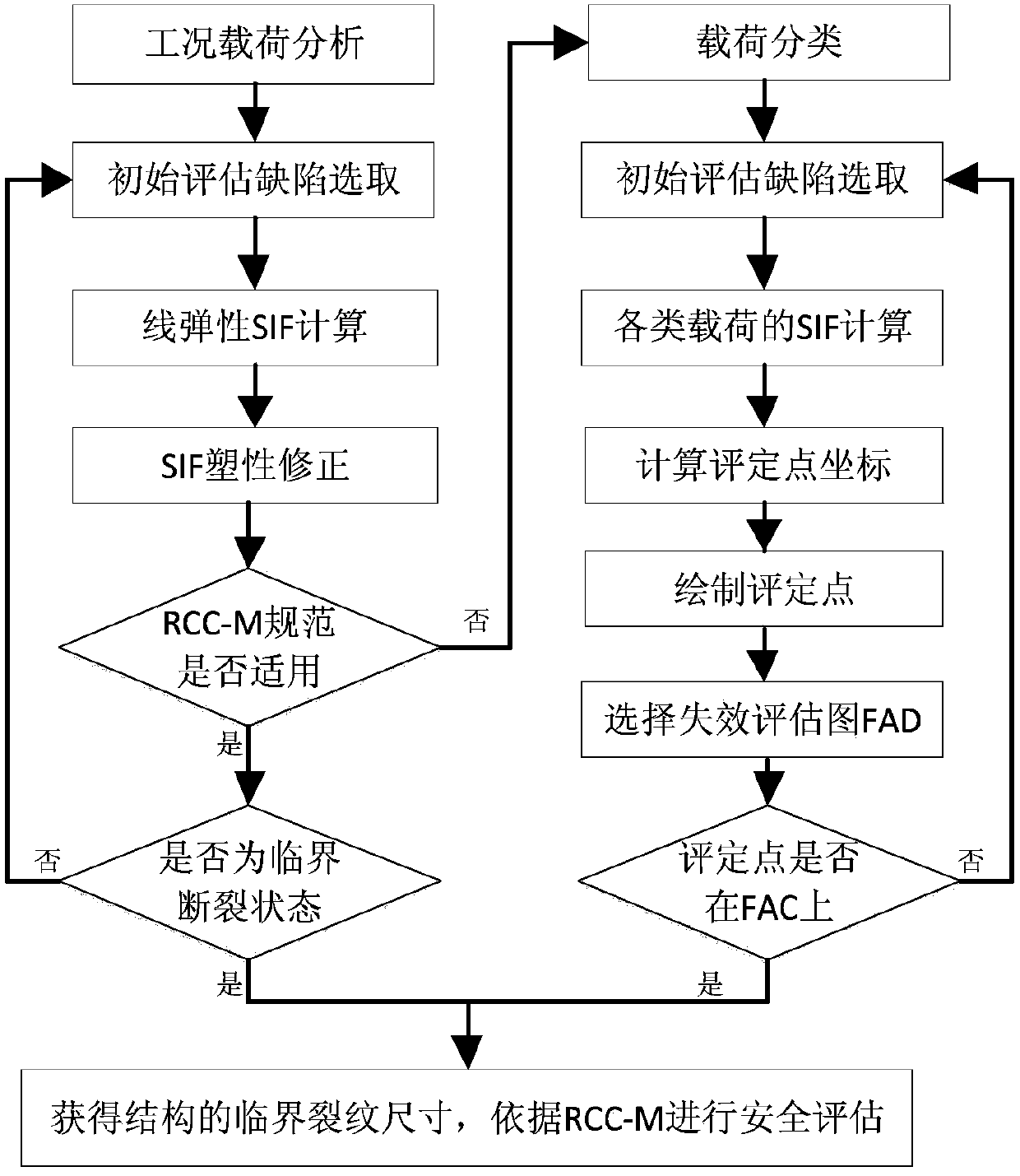

Method used

Image

Examples

Embodiment 1

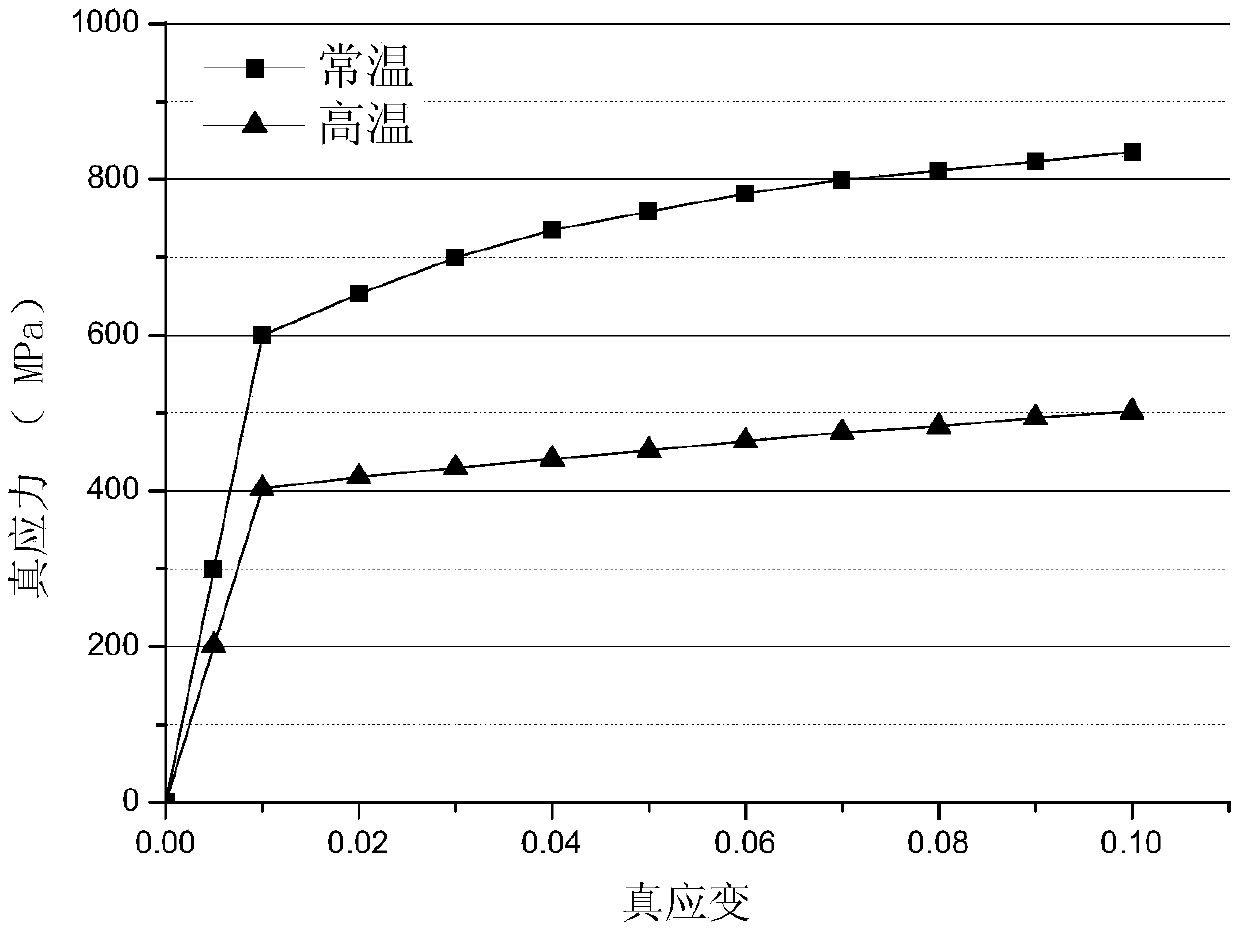

[0055] RPV core area inner diameter Ri=1994.5mm, shell wall thickness t=200mm, surfacing layer thickness t c = 7.5 mm. The analysis process of simplified elastic-plastic fracture mechanics under an extreme accident condition is given here. Under an extreme accident condition, the RPV is rapidly cooled to room temperature under normal operating conditions. At the initial moment of the extreme accident, the internal pressure load was 15.5MPa, and the average temperature of the RPV cylinder was 300°C.

[0056] 1) Load analysis

[0057] Under this extreme accident condition, the RPV core barrel bears internal pressure load and thermal shock load, in which the internal pressure load belongs to the primary load, and the thermal shock load belongs to the secondary stress load.

[0058] 2) Defect characterization

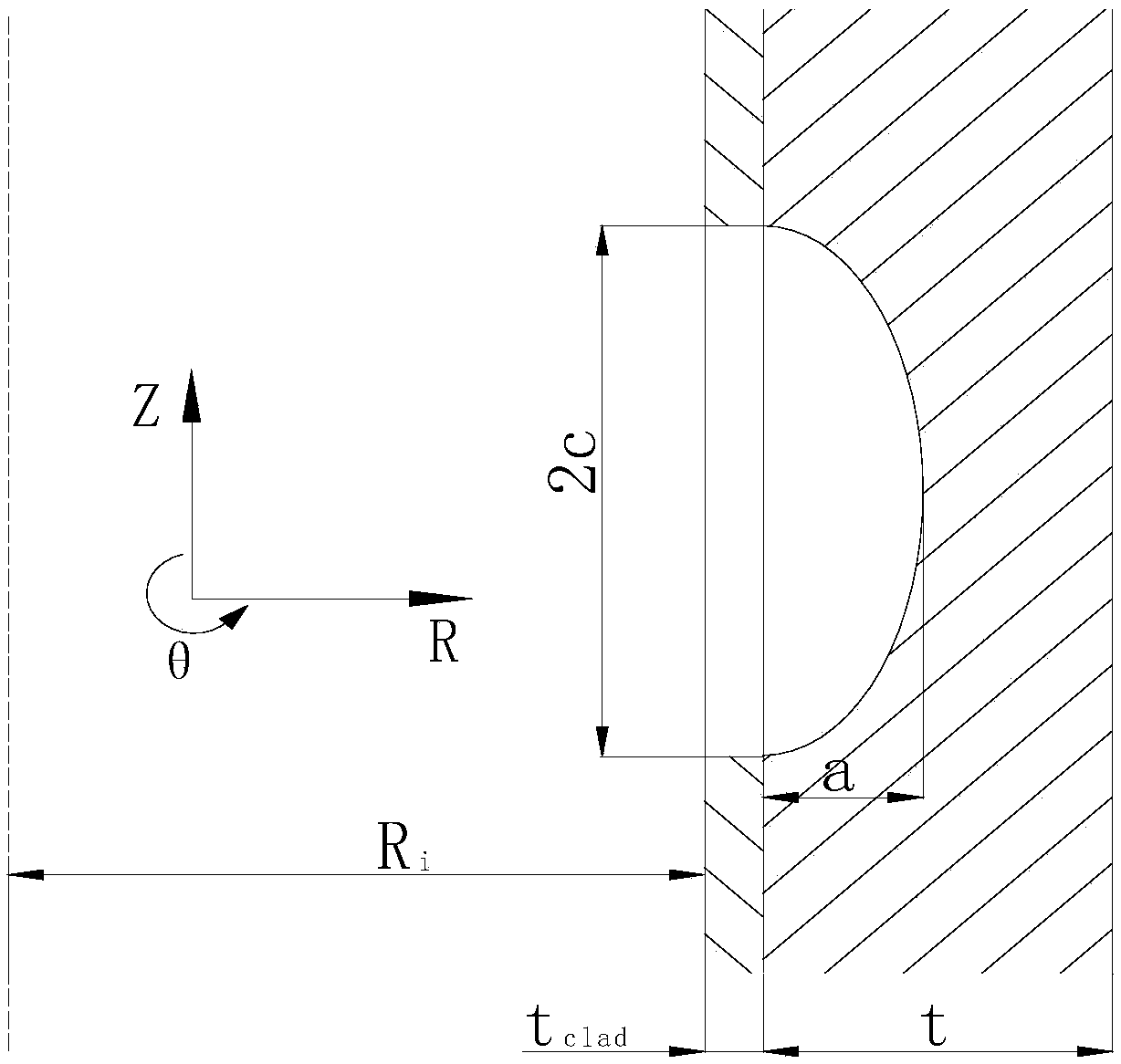

[0059] Characterization of RPV defects according to the RCC-M specification, figure 2 To characterize the defect at the RPV core barrel, the defect is an axial crack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com