Patents

Literature

60 results about "Strength factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Factor of Strength (FOS) As a general definition, FOS can be termed as a factor which, when applied to the elastic stresses from FEA at a node, will produce the corresponding design life at the node. The significant advantage of using FOS comes from the ability of user to calculate safety factor based on target life of the component.

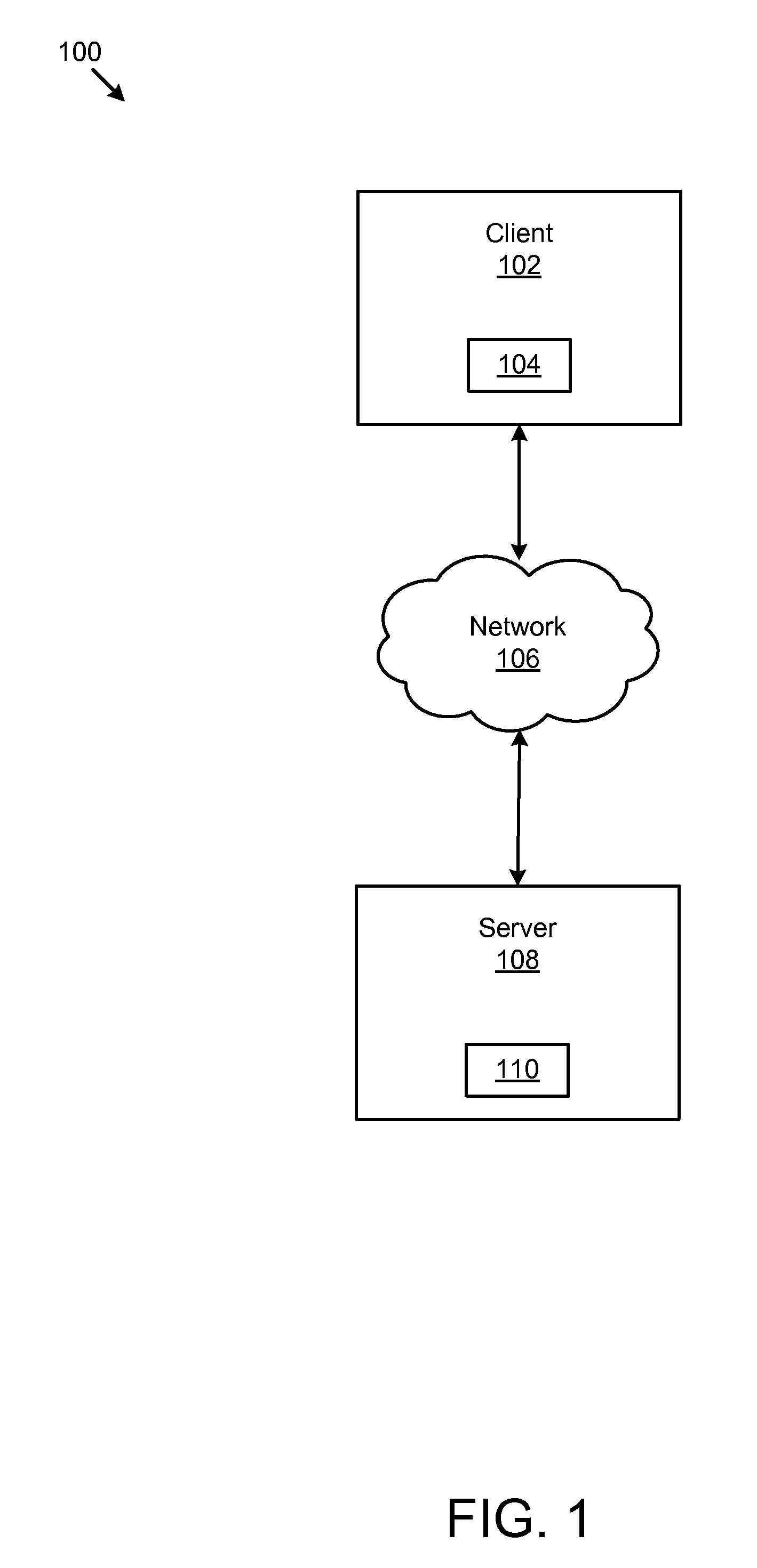

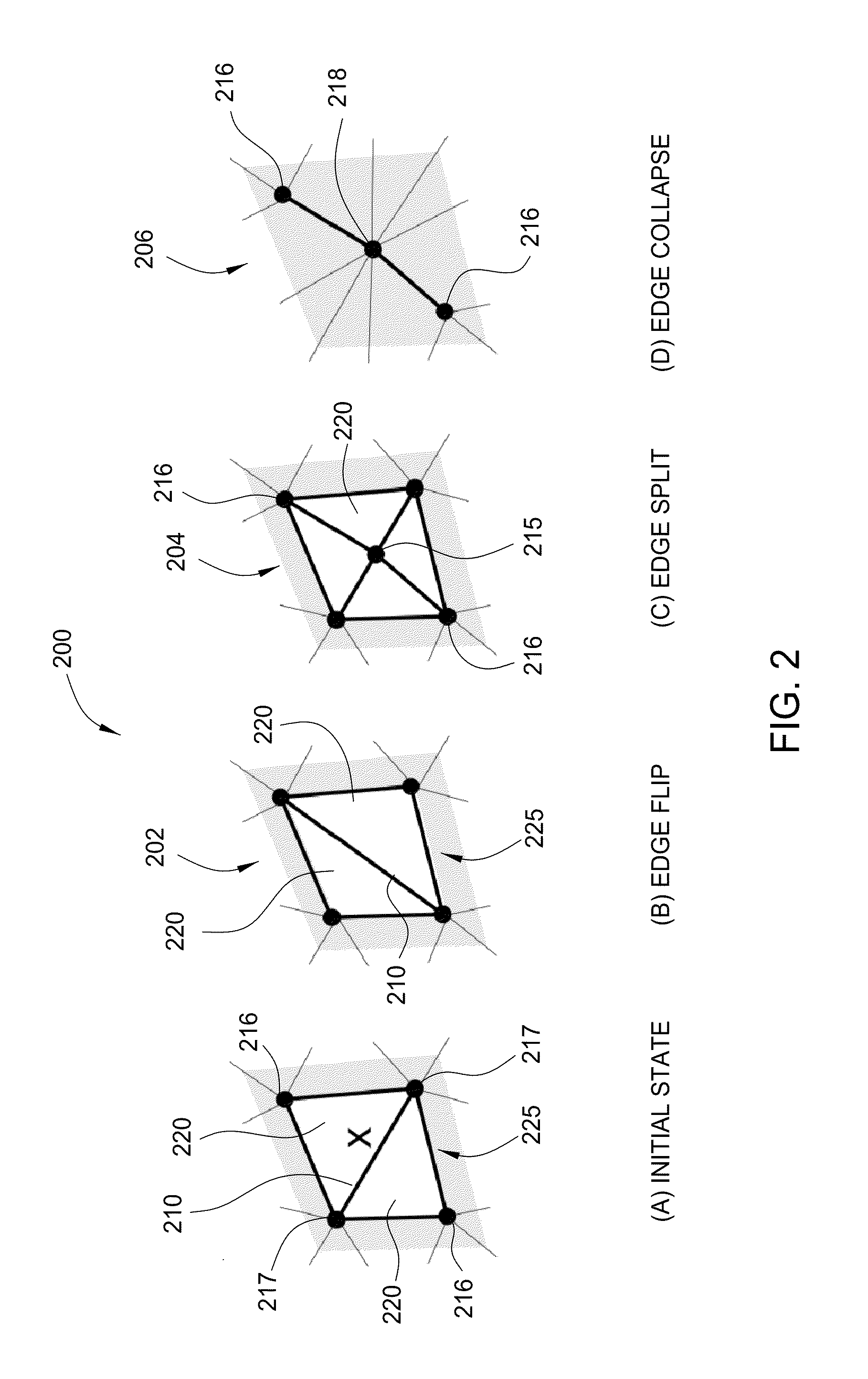

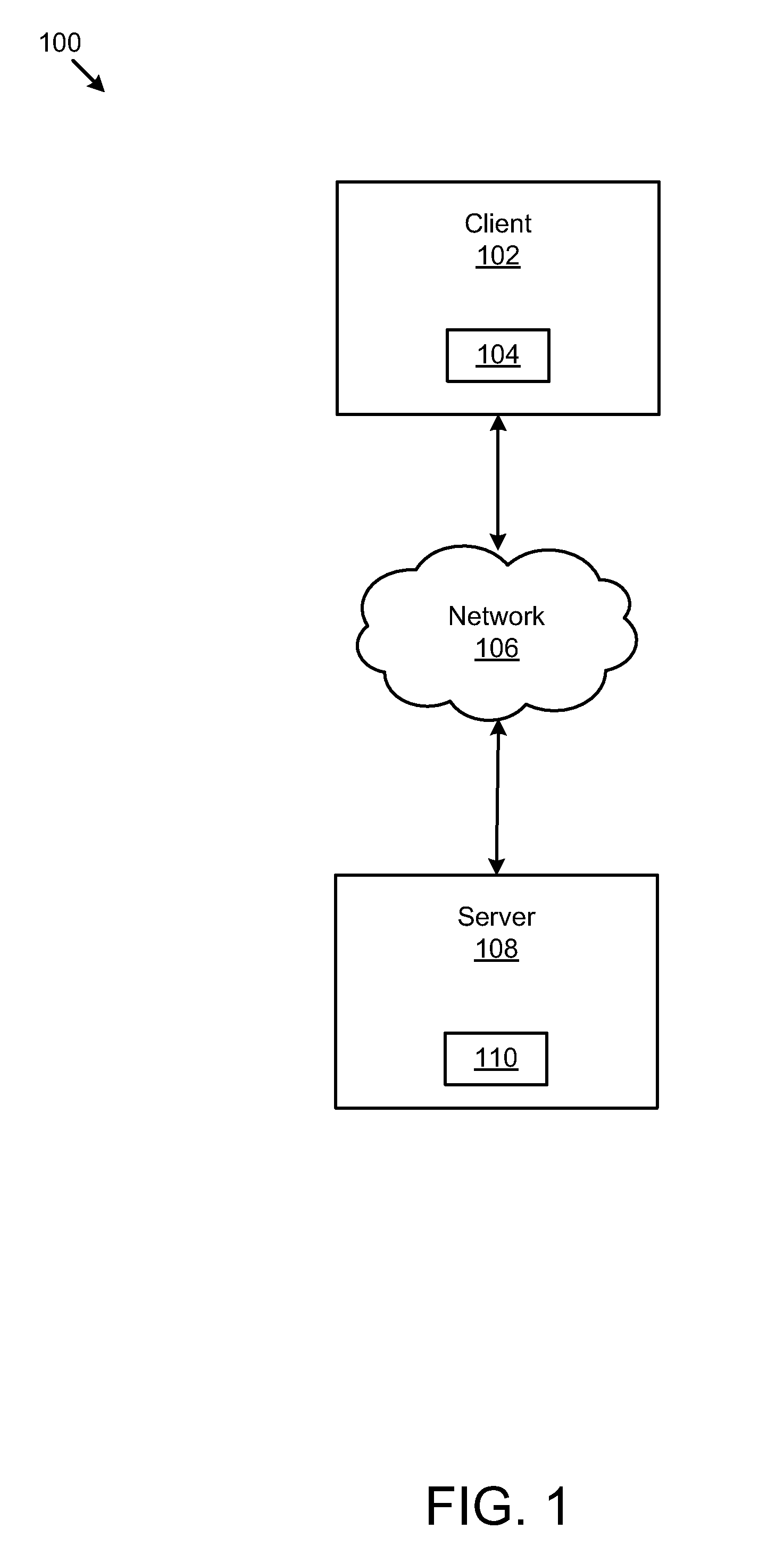

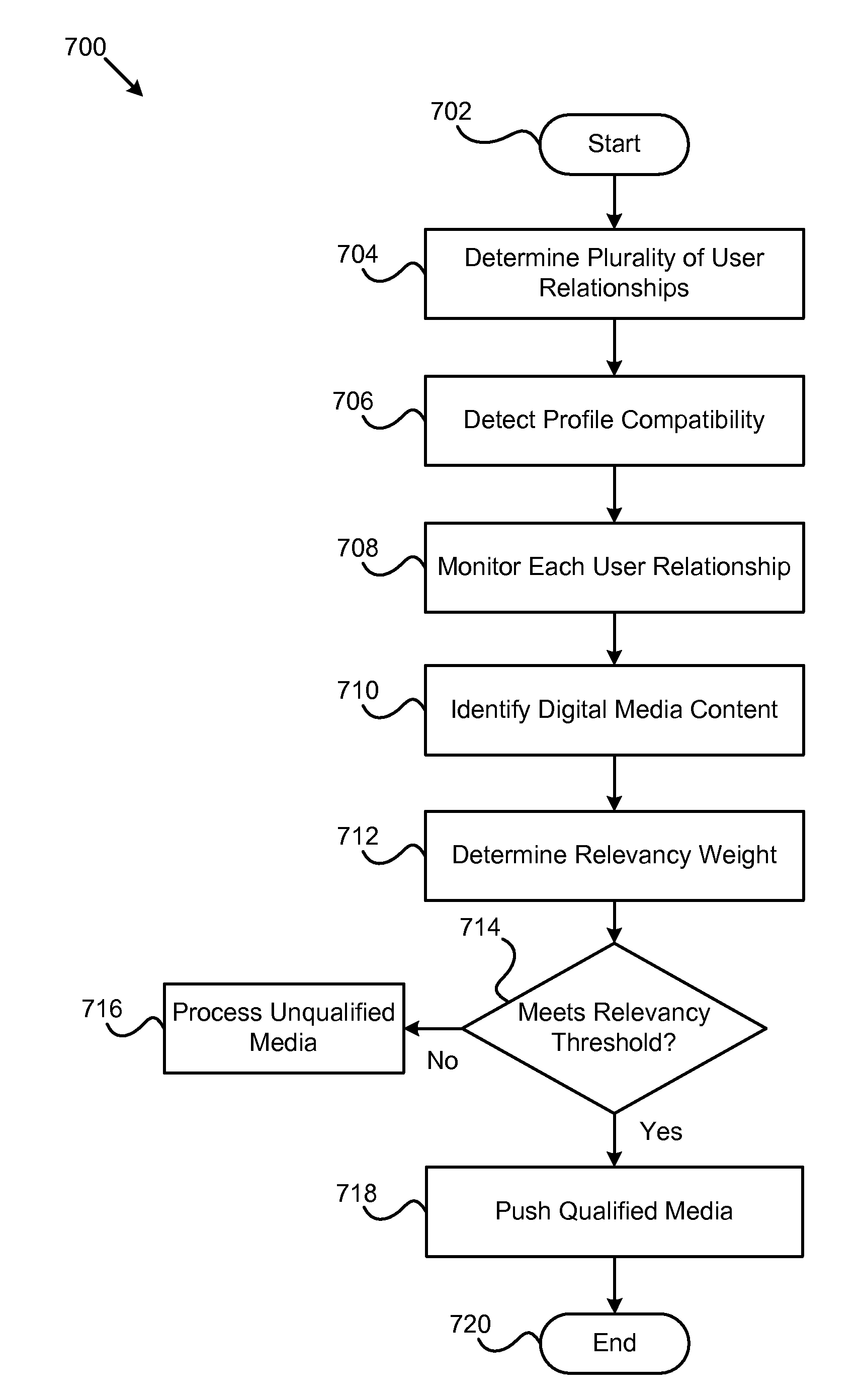

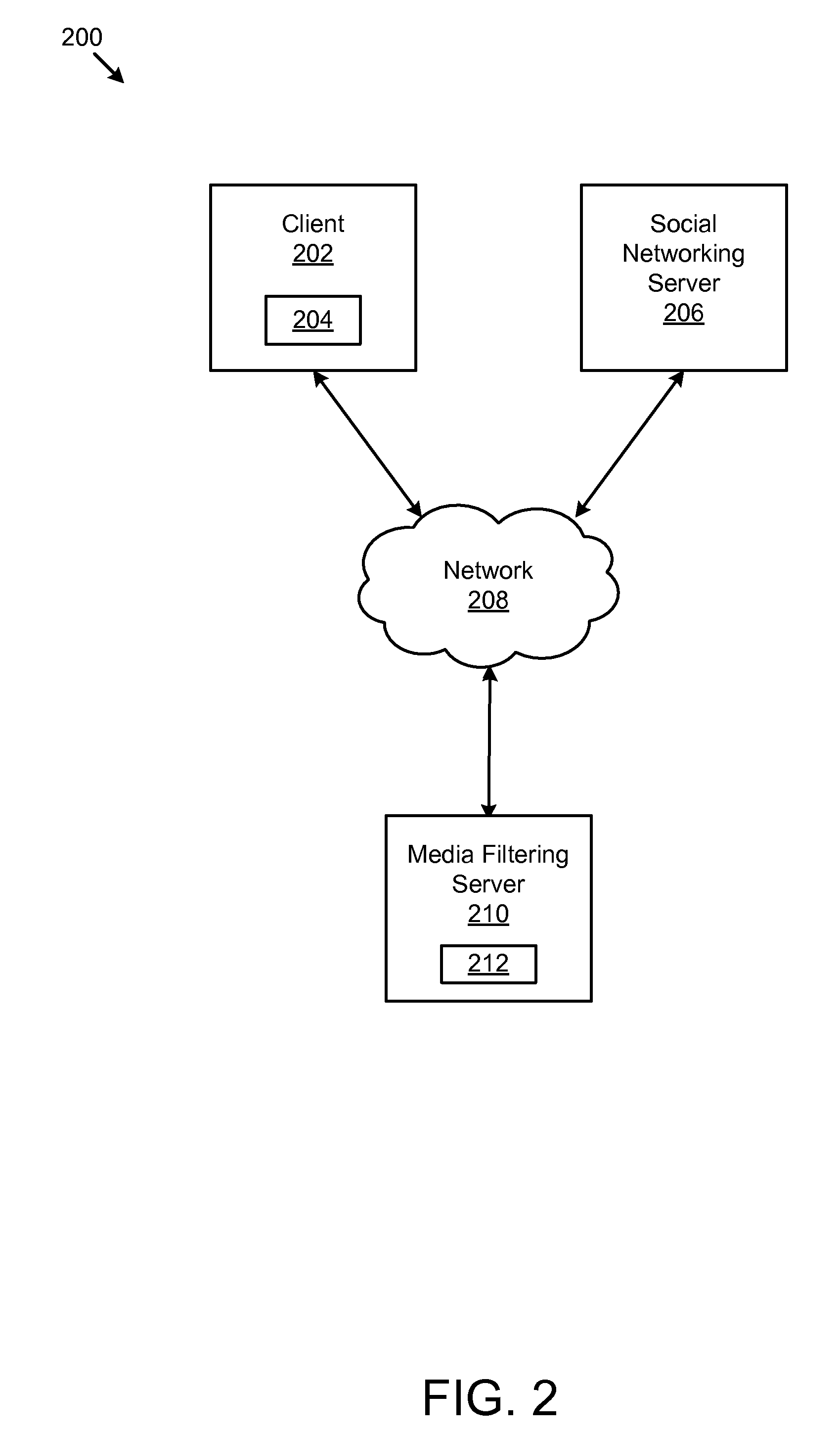

Automated digital media content filtration based on relationship monitoring

An apparatus, system, and method are disclosed for automated digital media content filtration based on relationship monitoring. The method determines a plurality of user relationships based at least in part on an online association between a user and a content producer. The method monitors each user relationship with each content producer for a relationship interaction between the user and the content producer. Furthermore, the method also identifies digital media content published by a content producer having a relationship with the user. A determined relevancy may be based on a strength factor derived at least in part on monitored relationship interactions between the user and the content producer that published the digital media content. The digital media content is presented to the user, with that having a greater relevancy weight having a higher priority than other digital media content available to the user from other content producers.

Owner:IBM CORP

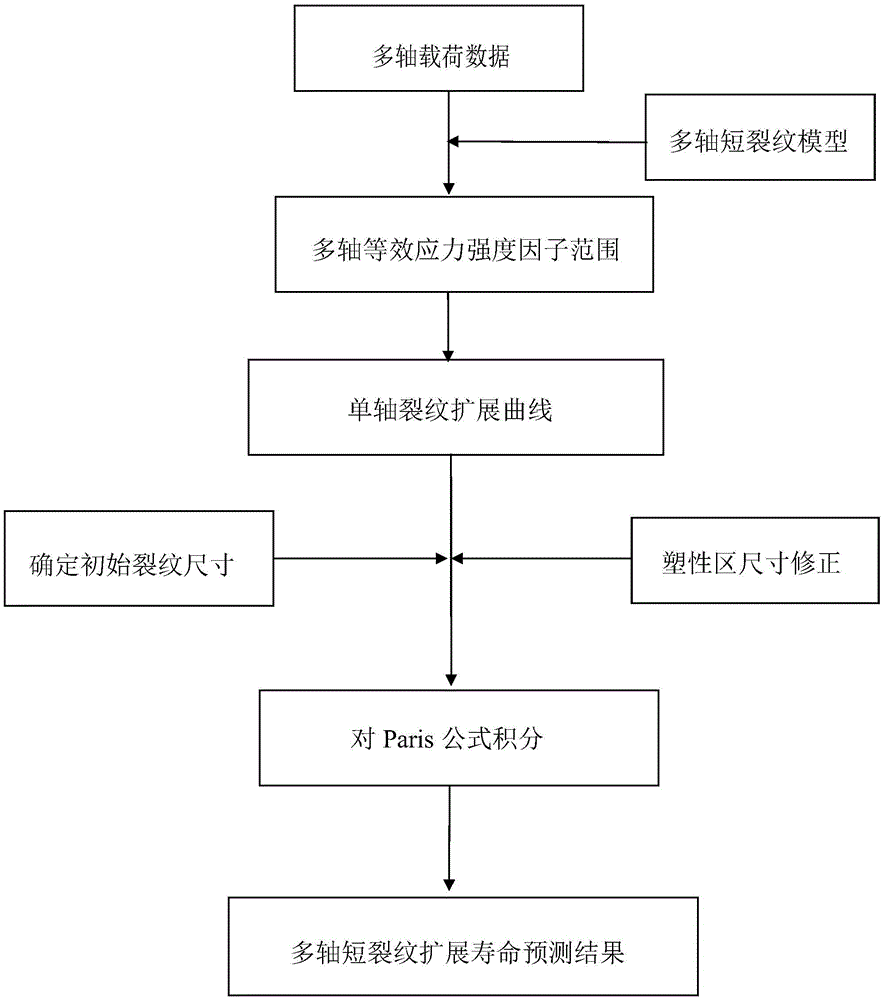

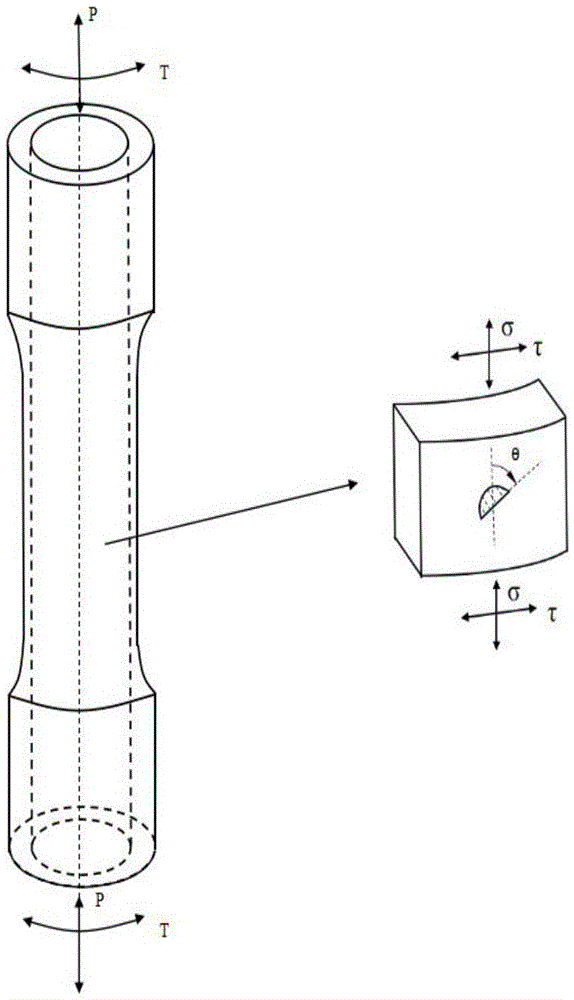

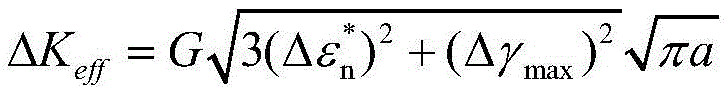

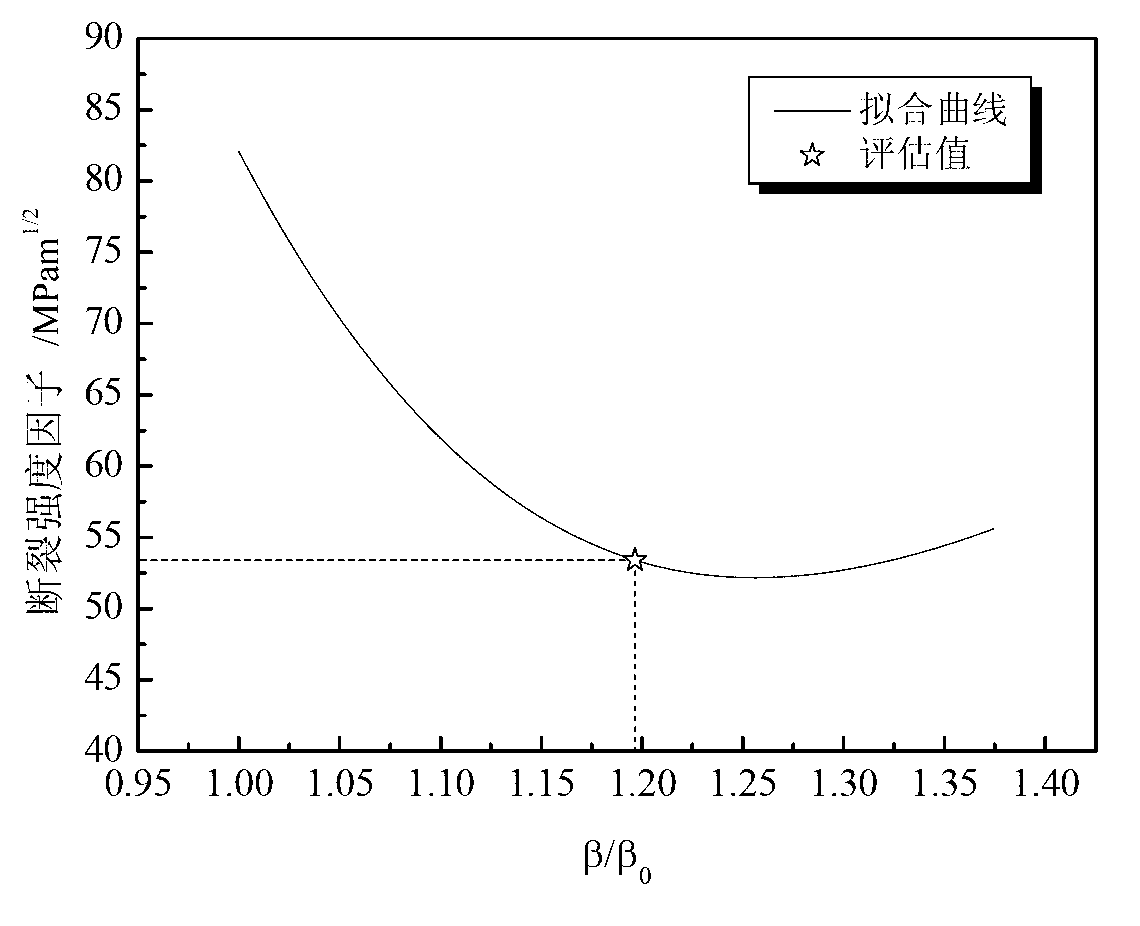

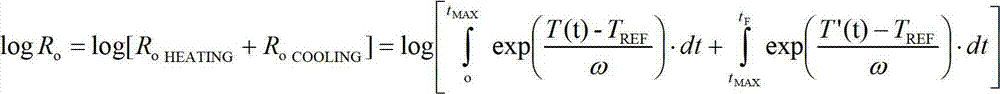

Multiaxial short crack propagation life prediction method based on critical surface method

ActiveCN105466772APromote engineering applicationMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesFatigue damageEngineering

The present invention provides a multiaxial short crack propagation life prediction method based on a critical surface method, and relates to the field of multiaxial fatigue strength theory. The algorithm comprises the steps of: (1) selecting a plane, which contains the maximum shearing strain range, as a critical surface, and using the damage parameters on the critical surface to characterize a short crack propagation driving force; (2) based on the shear-type multiaxial fatigue damage parameters, establishing an equivalent crack stress intensity factor applicable to the multiaxial stress state; (3) fitting the short crack propagation rate data under uniaxial loading to obtain an uniaxial short crack propagation curve; and (4) carrying out plastic zone size correction on the crack tip, and calculating the short crack propagation life by a fracture mechanics method. The method can well descript the influence of non-proportional loading on crack propagation. The results show that the method can well predict the short crack propagation life under multiaxial proportional and non-proportional loading.

Owner:BEIJING UNIV OF TECH

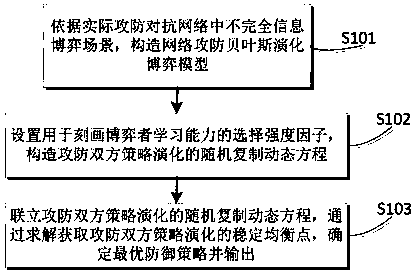

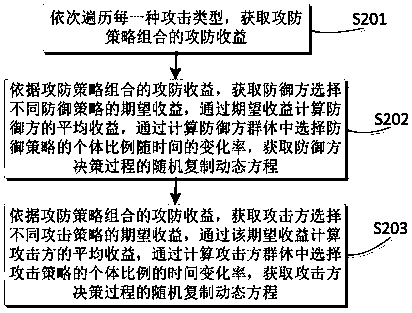

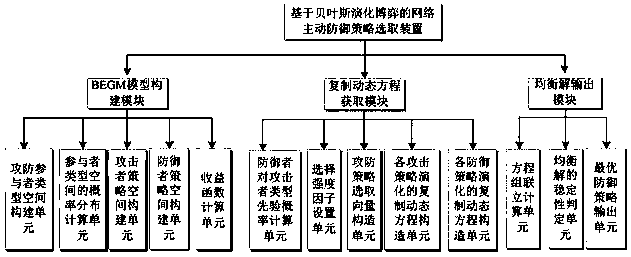

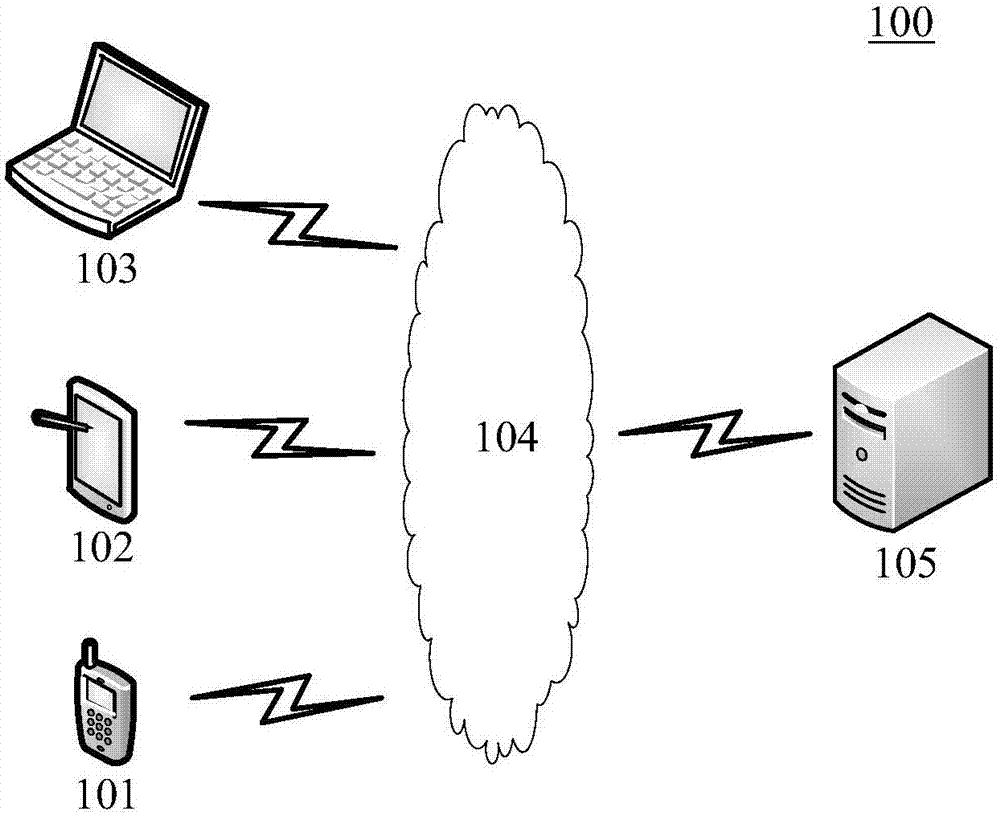

Network active defense policy selection method and device based on Bayesian evolutionary game

InactiveCN108833401APractical applicationImprove versatilityData switching networksDynamic equationInformation networks

The invention belongs to the technical field of the network security, and especially relates to a network active defense policy selection method and device based on Bayesian evolutionary game. The method comprises the following steps: constructing a network attack Bayesian evolutionary game model according to an incomplete information game scene in an actual attack-defense adversarial network; setting a selection strength factor for describing gamer learning capacity, and constructing a random replicate dynamic equation about the attacker-defender policy evolution; combining the random replicate dynamic equations about the attacker-defender policy evolution, solving to acquire a stable balance point of the attacker-defender policy evolution, and determining and outputting an optimal defense policy. From the limited intellectual visual angle of the participant, a replicate dynamic equation about the participant decision process is constructed and solved by means of the replicate dynamicmechanism for describing the biological evolution, the method is suitable for incomplete information network attack-defense adversarial network and more suitable for the actual application, the generality and operability in the network decision implementation process are enhanced, and the effective guidance is provided for selecting the active defense policy.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

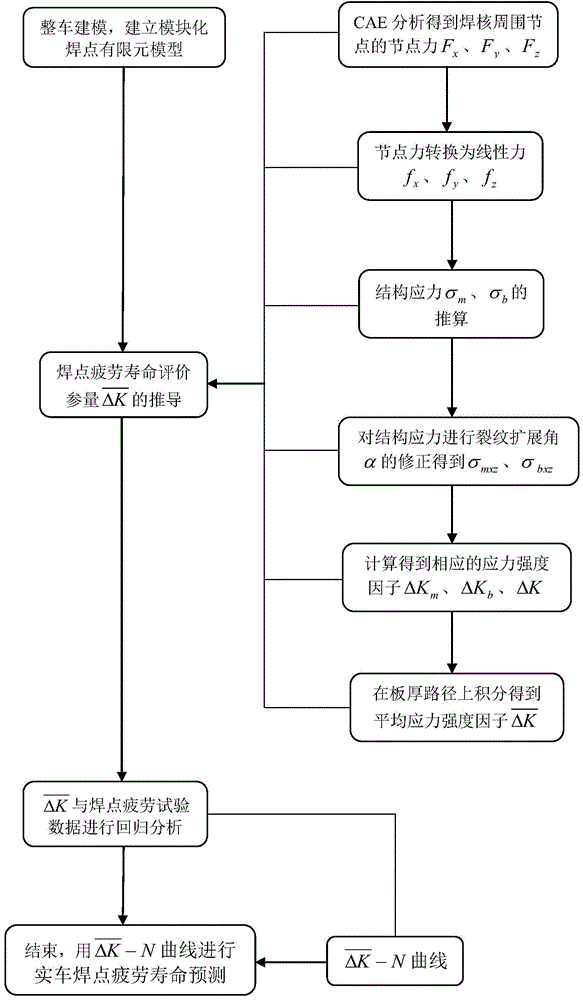

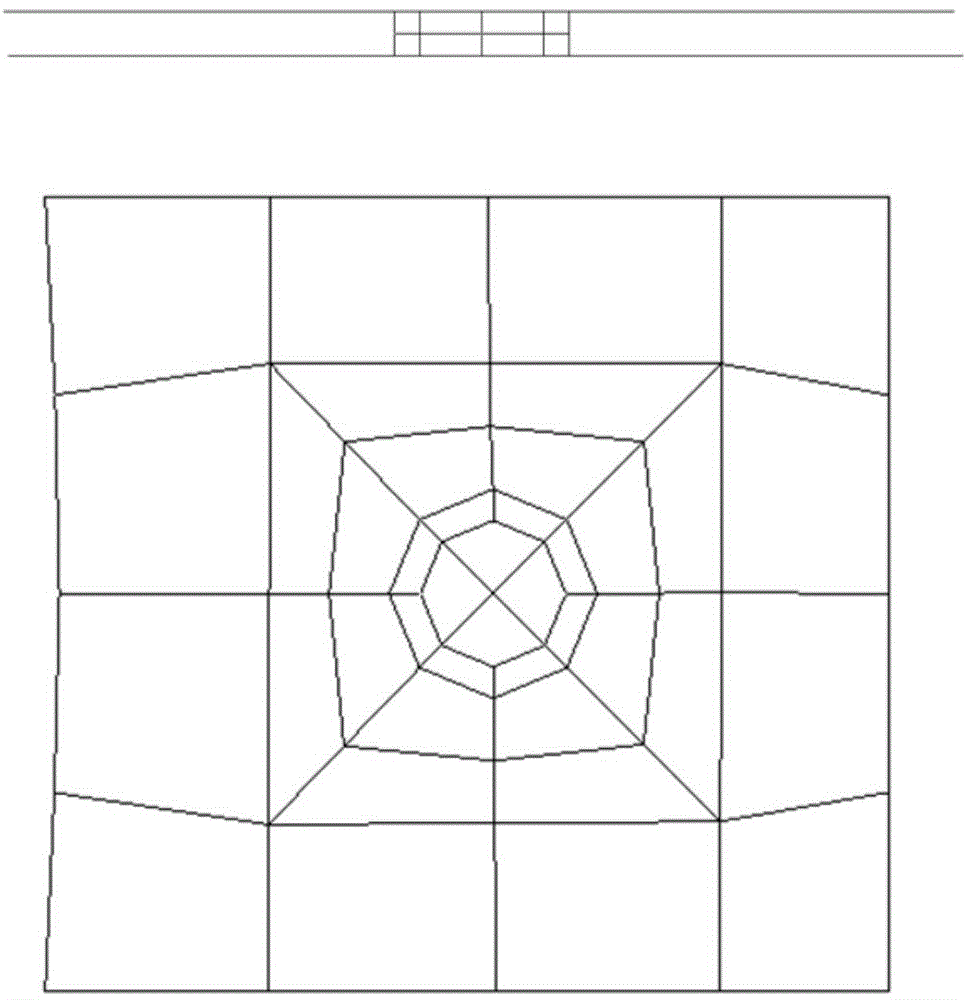

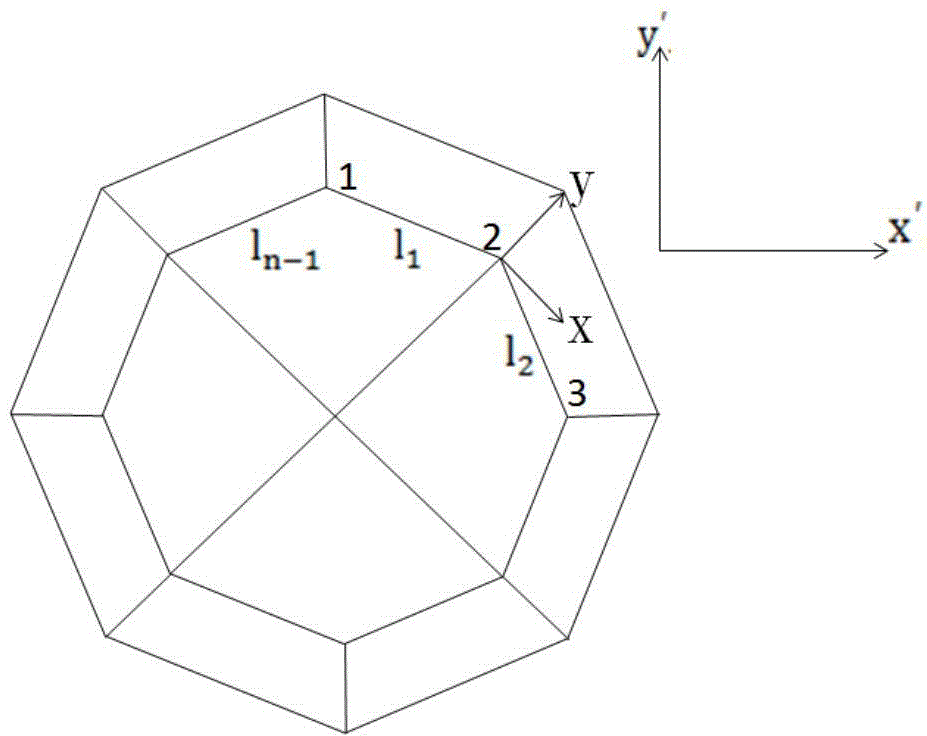

Spot-weld fatigue life predicting method

InactiveCN104573392AImprove efficiencyConform to the physical geometrySpecial data processing applicationsElement modelRegression analysis

The invention relates to a spot-weld fatigue life predicting method. The spot-weld fatigue life predicting method includes steps of 1, modeling a full vehicle and establishing a modularized spot-weld finite element model; 2, deducing spot-weld fatigue life evaluation parameter, mean stress strength factor; 3, subjecting spot-welded joints of different materials to systematic fatigue test, and subjecting the mean stress strength factor and fatigue test data of the spot-welded joints of different materials to regression analysis to obtain a curve of the spot-welded joints of different materials. The spot-weld fatigue life predicting method adopts the modularized spot-weld model to predict the spot-weld fatigue life, in actual application, only nodes of a border unit of the modularized spot-weld model are superposed with nodes of a welding structure unit, and spot-weld modeling efficiency in the full-vehicle modeling is improved.

Owner:HUNAN UNIV

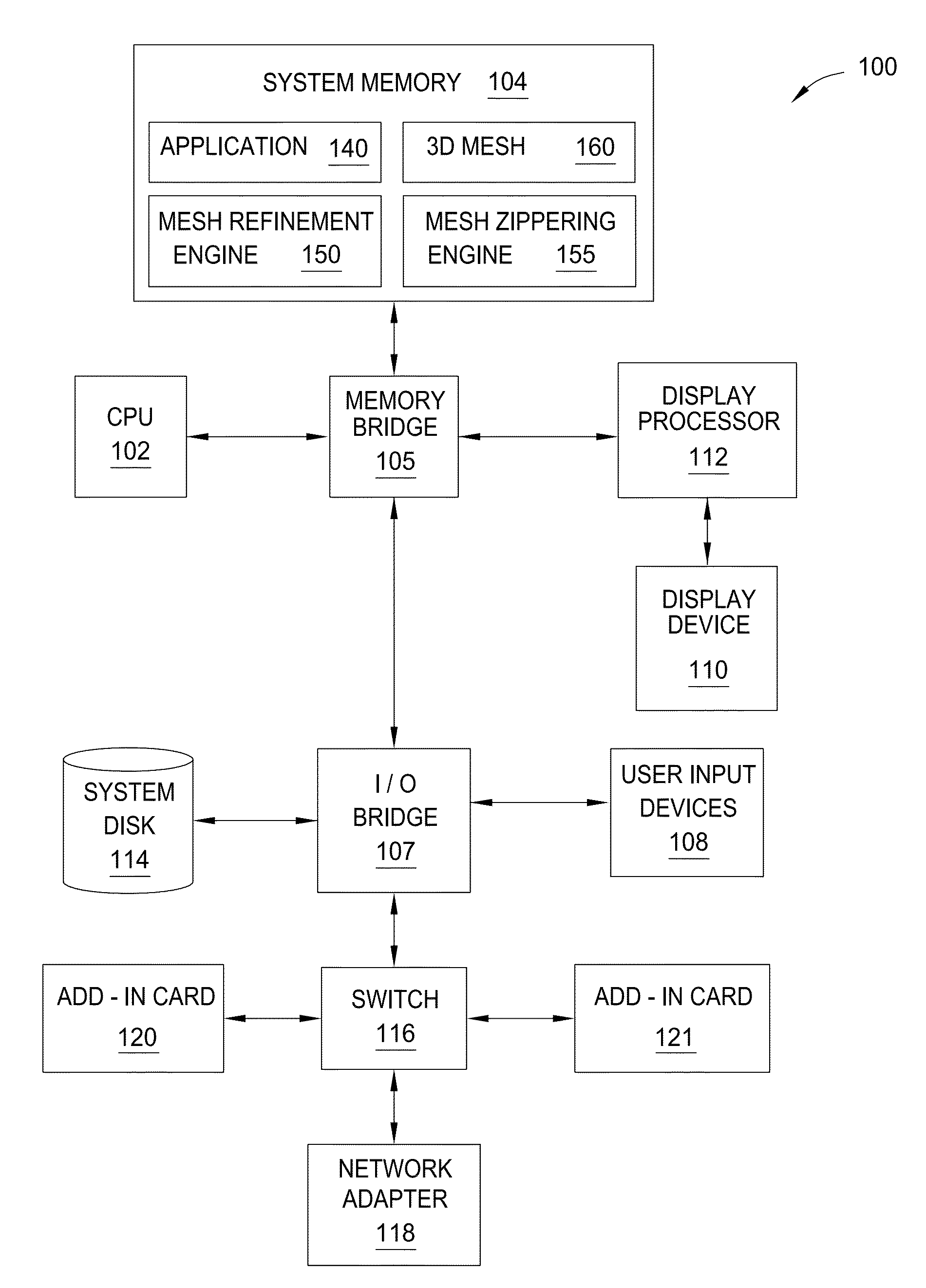

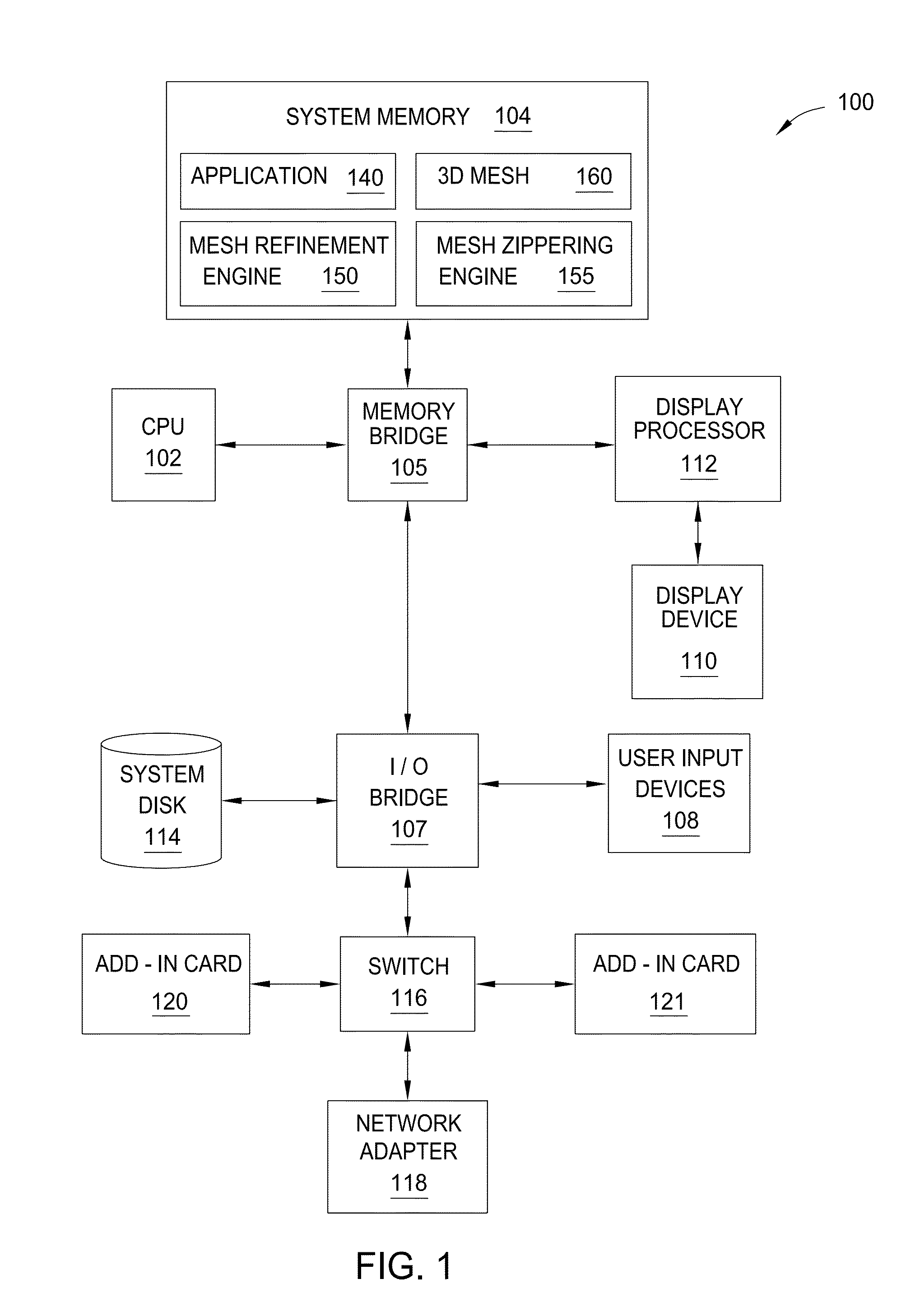

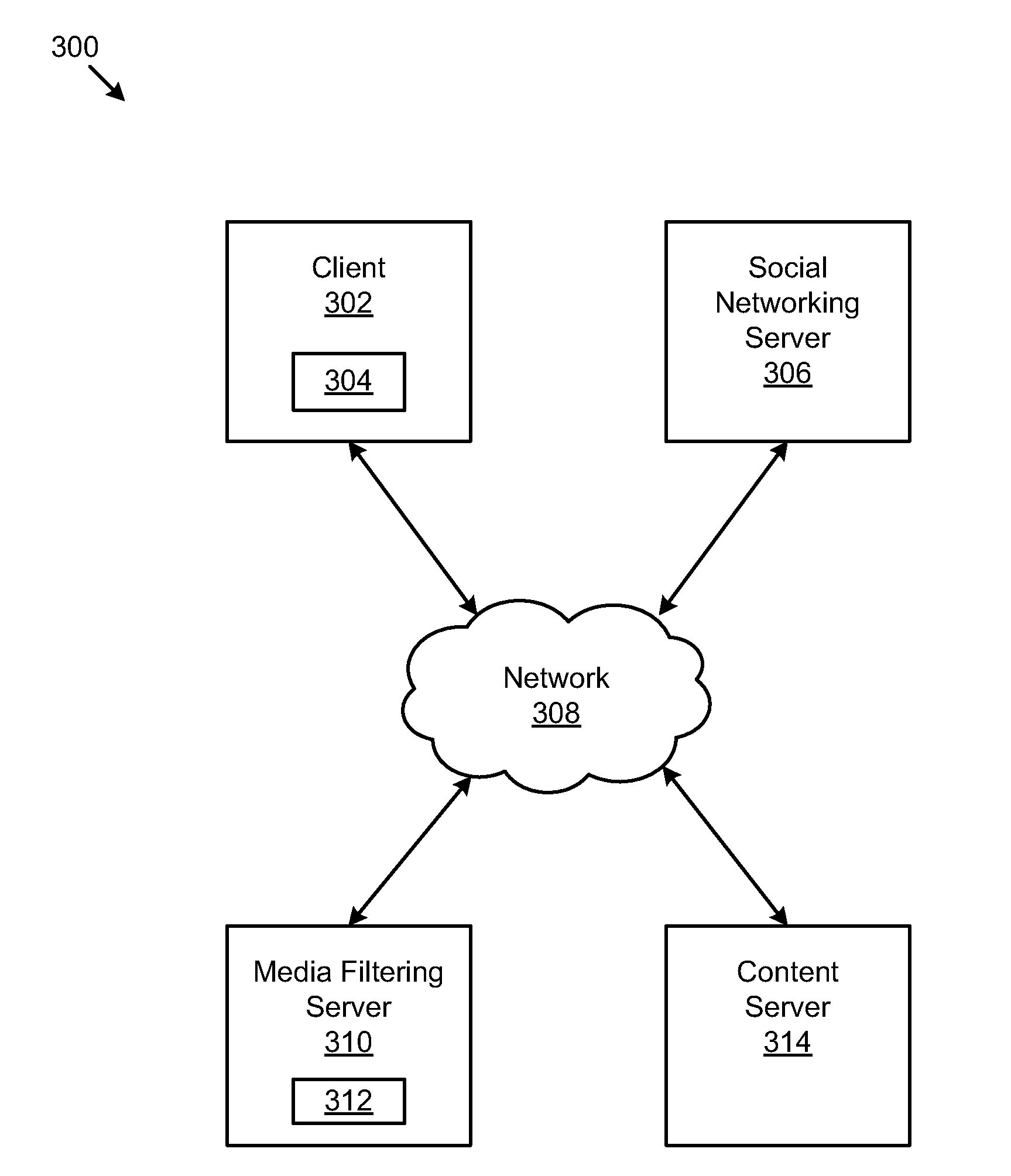

Adaptively zippering meshes

ActiveUS20130300734A1Easy to specifyEfficient merge3D-image renderingComputer scienceStrength factor

One embodiment of the present invention sets forth a technique for zippering meshes of primitives. The technique involves identifying a first vertex associated with a first mesh boundary and having a first position and identifying a second vertex that is proximate to the first vertex and associated with a second mesh boundary, where the second vertex has a second position. The technique further involves determining a third position based on the first position, the second position, and a zippering strength factor, where the third position is located in a region between the first position and the second position. Filially, the technique involves moving the first vertex to the third position.

Owner:AUTODESK INC

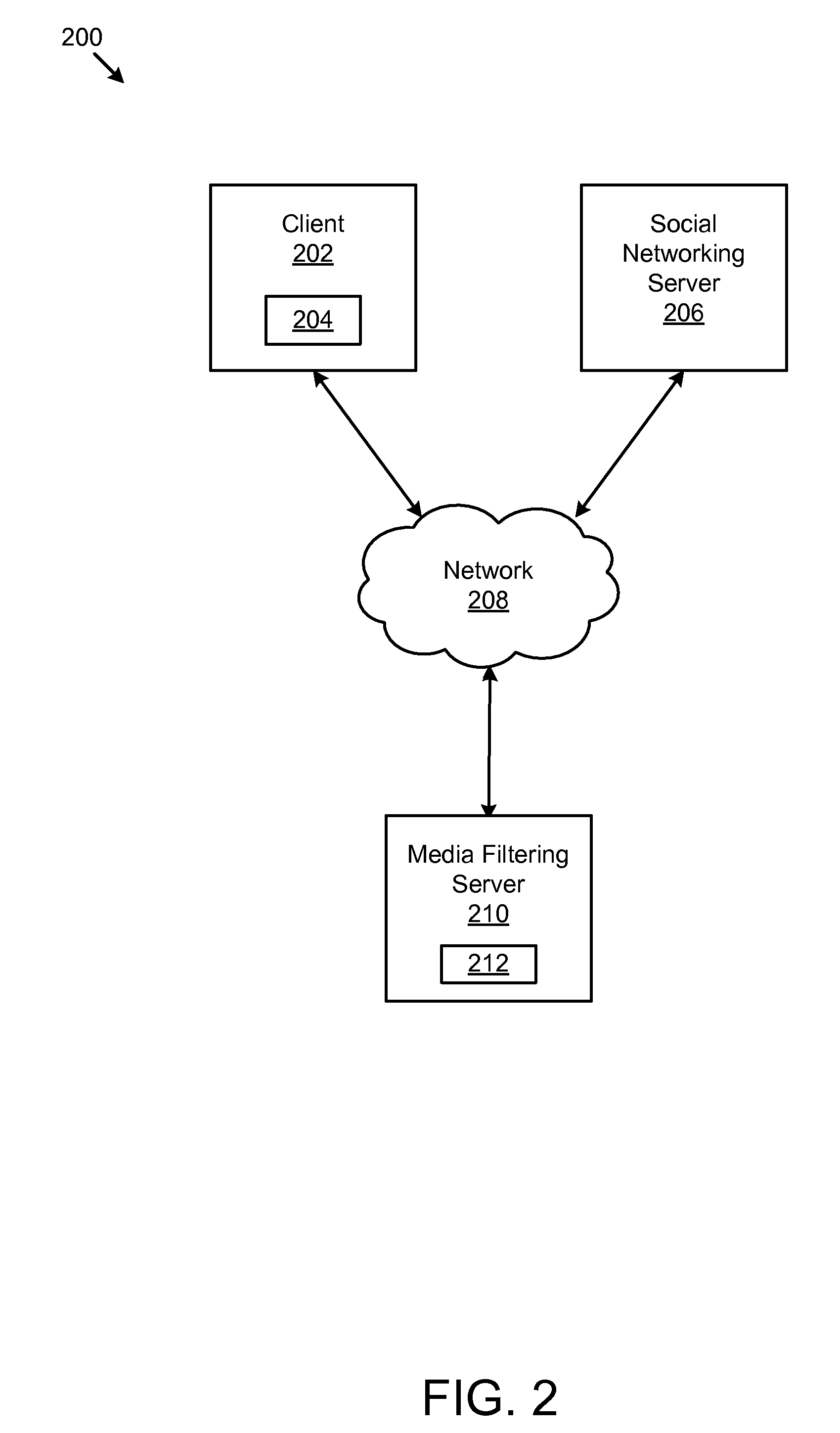

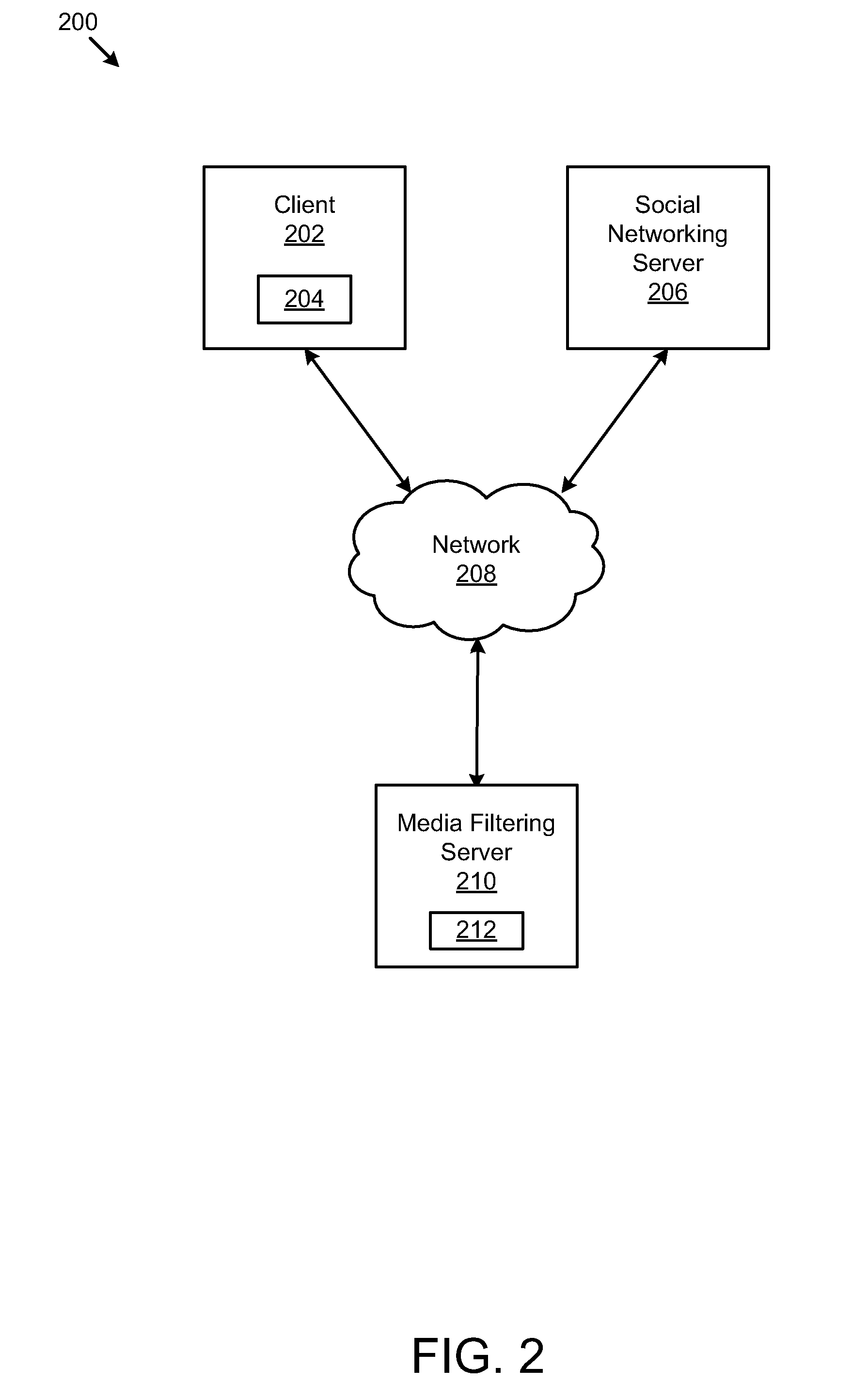

Automated digital media content filtration based on relationship monitoring

Automated digital media content filtration is performed by establishing automatically, according to a tolerance parameter, a plurality of user relationships, each user relationship based on monitoring an online association between a user and a content producer. Filtration is also performed by monitoring determined user relationships, interacting with a plurality of independent servers to identify digital media content published by content producers having a user relationship with the user and determining a relevancy weight for each published digital media content item, the relevancy based on a strength factor. Filtration is still further performed by presenting the digital media content published by one or more of the content producers to the user such that digital media content having a greater relevancy weight receives a higher priority than other digital media content available to the user from the plurality of content producers.

Owner:INT BUSINESS MASCH CORP

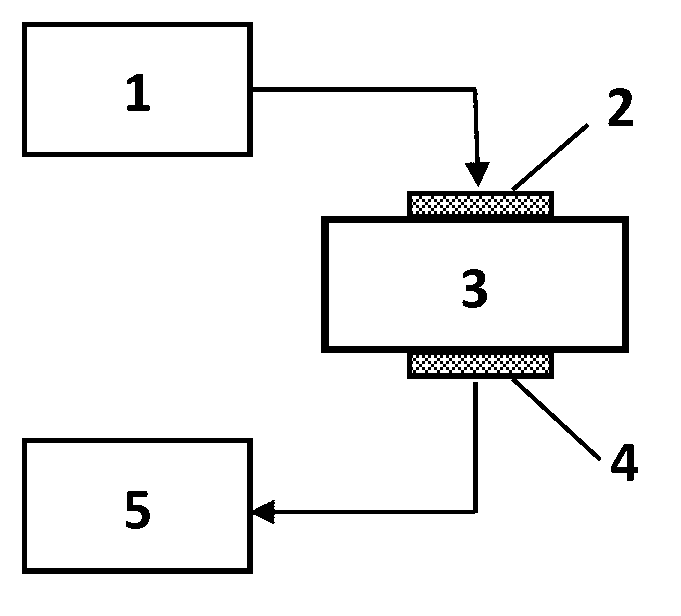

Nondestructive testing method for metal material fracture toughness

InactiveCN103063508ANo damageThe detection process is fastStrength propertiesMaterial under testMetallic materials

The present invention discloses a nondestructive testing method for metal material fracture toughness, and the method mainly includes: performing Charpy impact tests to samples of different damage degrees to obtain the brittle transition temperatures of the samples; performing ultrasonic secondary harmonic measurement to the samples of each type of the damage degrees to obtain the second harmonic ultrasound nonlinearity parameter normalized value of the samples of the type of the damage degree; obtaining the fracture strength factor of the samples of each type of the damage degrees via the fracture toughness tests or by reference of fracture empirical formulas, and making a calibration curve for nondestructive testing fracture toughness; performing ultrasonic secondary harmonic measurement to a metal material under test to obtain the second harmonic ultrasound nonlinearity parameter normalized value of the metal material under test; and obtaining the fracture toughness value of the metal material under test by using the calibration curve. The nondestructive testing method for metal material fracture toughness of the invention is capable of performing testing and evaluation of material fracture toughness of in-service metallic components, and providing a reliable basis for the security service of the metal materials.

Owner:EAST CHINA UNIV OF SCI & TECH

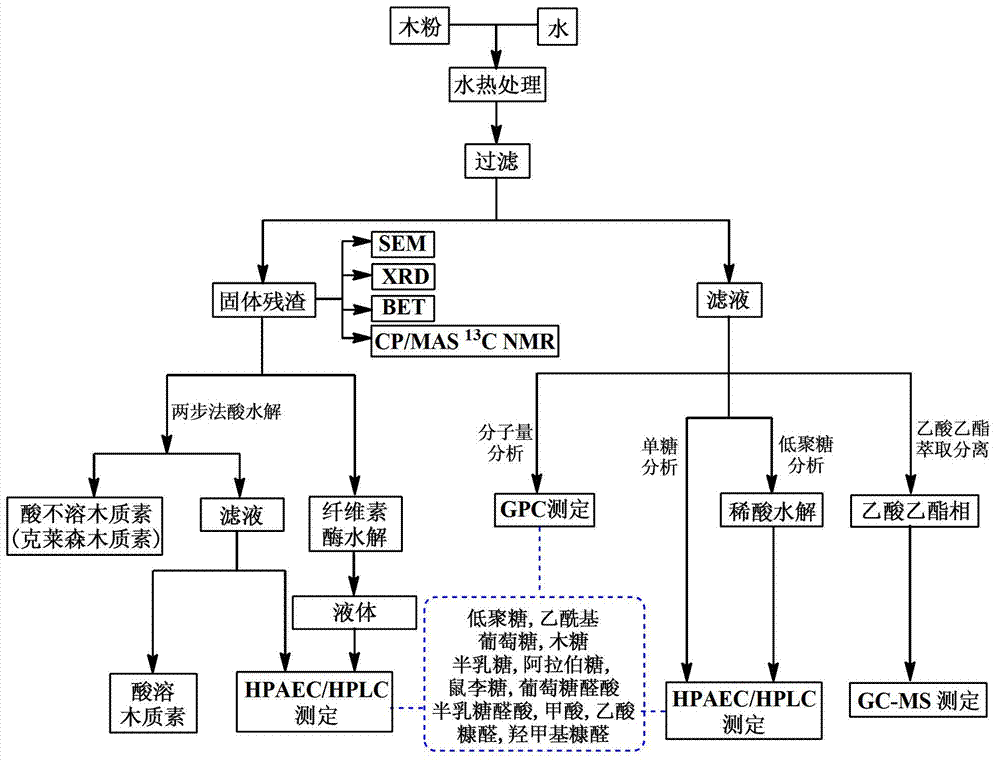

Preprocessing method for lignocellulose raw material

ActiveCN102864668AIncrease hydrolysis rateHigh recovery rateFibrous raw materialsFermentationPretreatment methodHigh pressure

The invention discloses a preprocessing method for a lignocellulose raw material, which comprises the following steps: (1) fully mixing the crashed lignocellulose raw material with water, and then standing for 2-4 hours, and transferring a mixture into a high-pressure reactor; heating the high-pressure reactor from room temperature to 180-240 DEG C under the protection of inert gases, and then immediately and quickly cooling the reactor to the room temperature through condensate water, wherein the strength factor is 2.40-4.17 and the pressure is a saturated vapor pressure at 1.19-3.45MPa at corresponding temperature; and (2) performing solid-liquid separation on the product obtained in the step (1), thereby obtaining a solid-phase product and a liquid-phase product. The preprocessing method for the lignocellulose raw material has the advantages of low cost, no pollution to environment, low energy consumption, high hydrolysis rate of hemicellulose, high recovery rate, and the like.

Owner:BEIJING FORESTRY UNIVERSITY

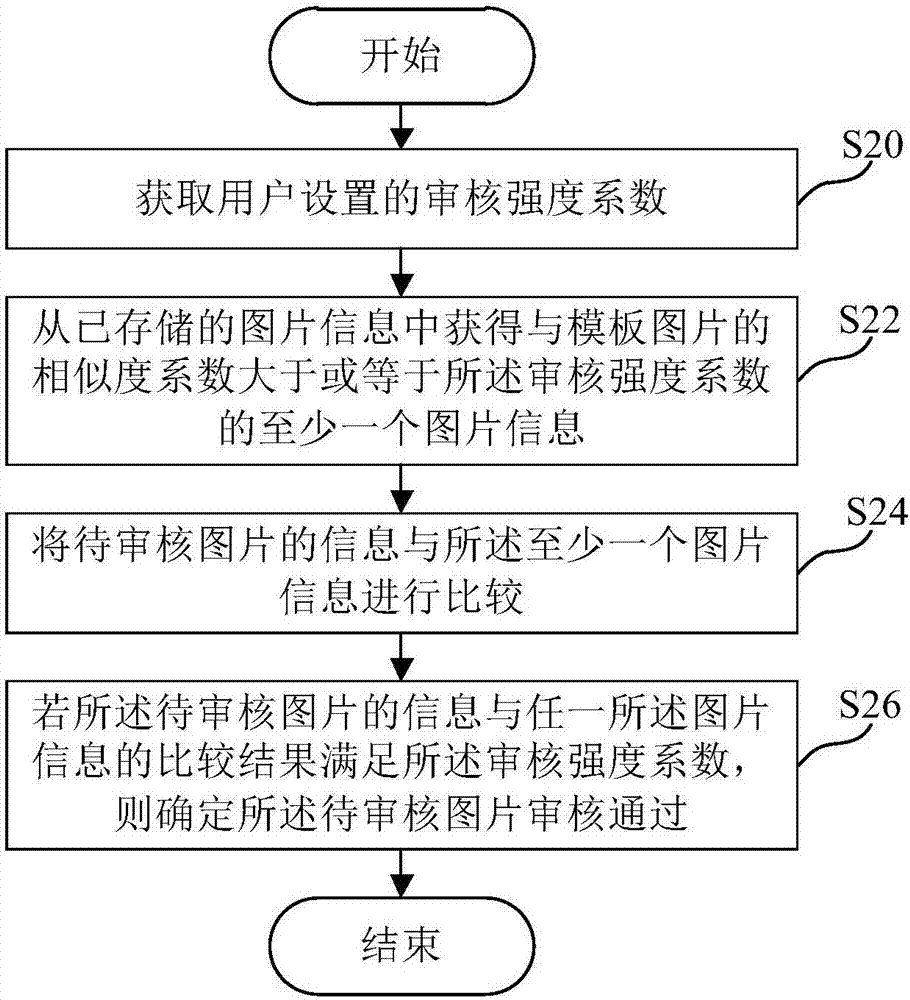

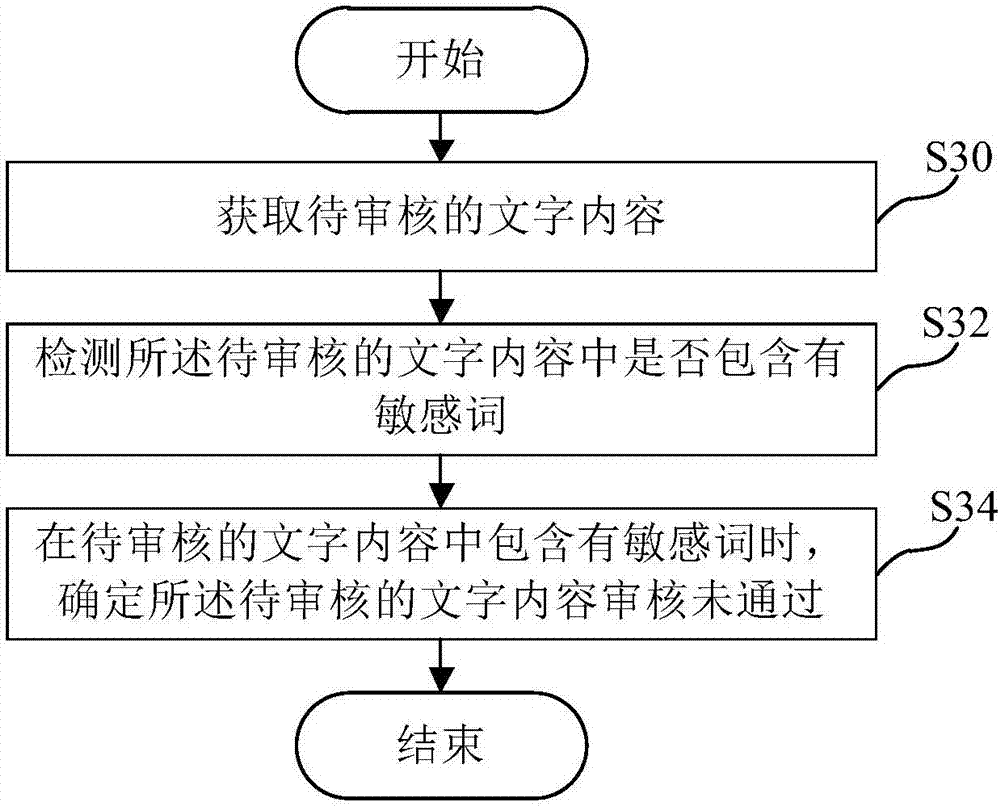

Information auditing method, information auditing device, computer-readable medium and electronic equipment

InactiveCN107133221AAudit results are controllableSolve the speed problemSemantic analysisCharacter and pattern recognitionSoftware engineeringInformation device

The invention provides an information auditing method, an information auditing device, a computer-readable medium and electronic equipment. The information auditing method comprises the steps of acquiring an auditing strength factor set by a user; acquiring at least one piece of picture information from stored picture information, wherein the similarity coefficient of the picture information and a template picture is greater than or equal to the auditing strength factor; comparing information of a picture to be audited with the at least one piece of picture information; if the comparison result of the information of the picture to be audited and any picture information meets the auditing strength factor, determining that the picture to be audited passes the audit. After the technical scheme is adopted, the picture can be automatically audited, and the problems of slow audit speed and uncontrollable audit results which are caused by a manual audit way can be solved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

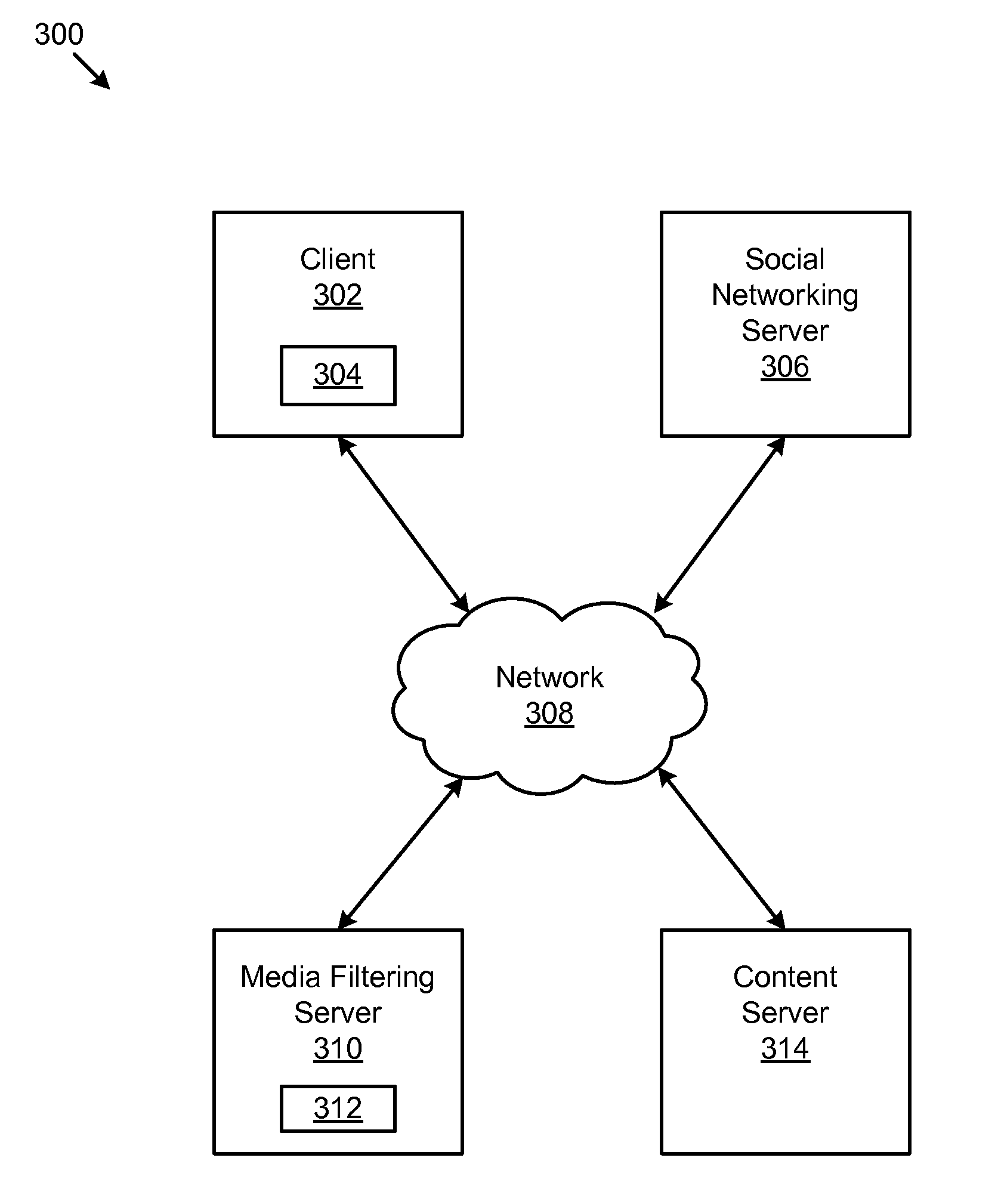

Automated digital media content filtration based on relationship monitoring

An apparatus, system, and method are disclosed for automated digital media content filtration based on relationship monitoring. The method determines a plurality of user relationships based at least in part on an online association between a user and a content producer. The method monitors each user relationship with each content producer for a relationship interaction between the user and the content producer. Furthermore, the method also identifies digital media content published by a content producer having a relationship with the user. A determined relevancy may be based on a strength factor derived at least in part on monitored relationship interactions between the user and the content producer that published the digital media content. The digital media content is presented to the user, with that having a greater relevancy weight having a higher priority than other digital media content available to the user from other content producers.

Owner:IBM CORP

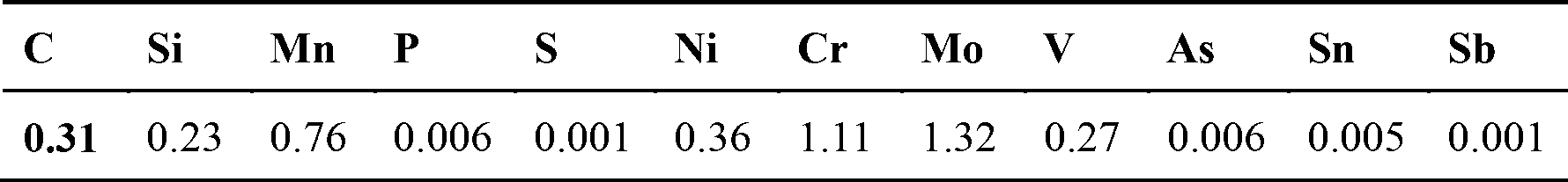

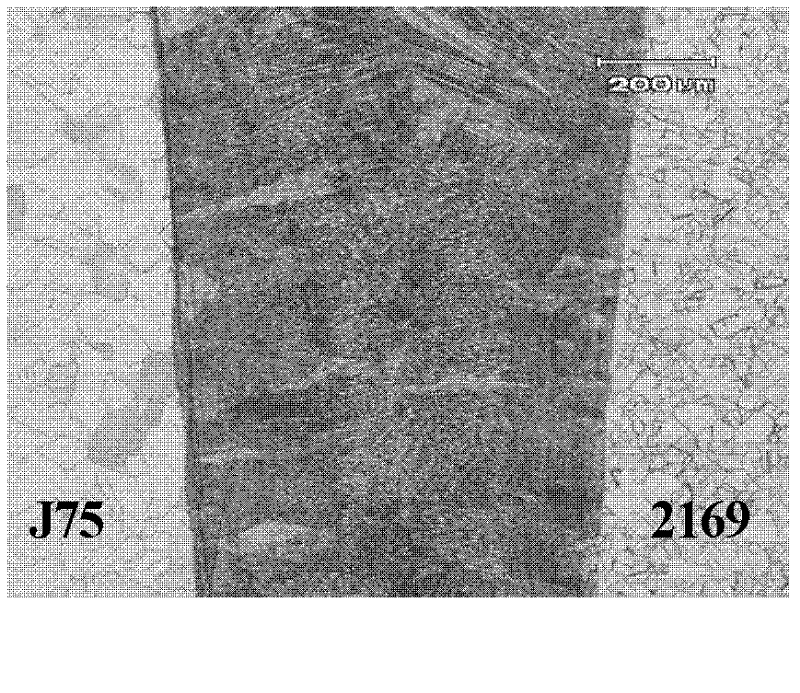

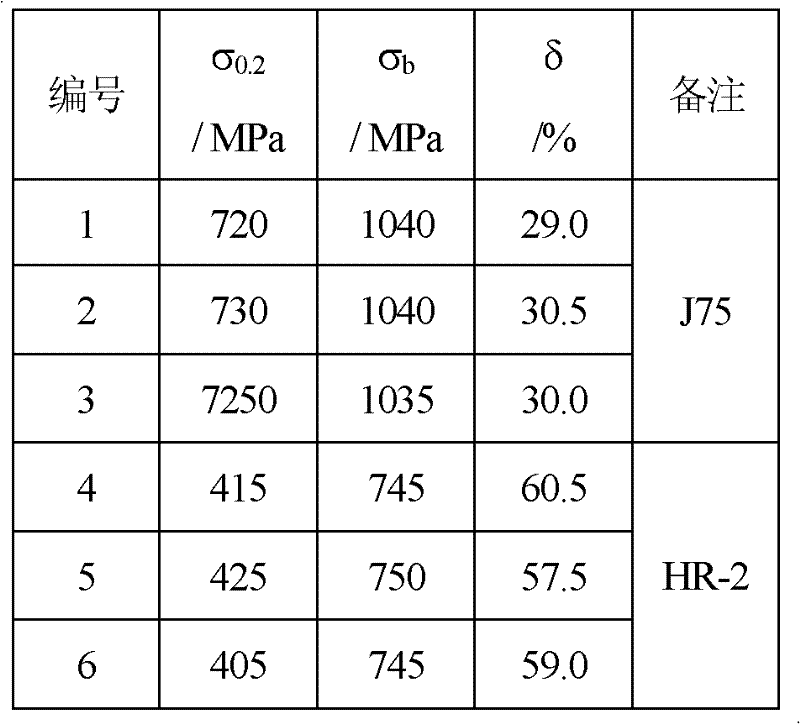

Method for welding heterogeneous austenitic stainless steel plates

InactiveCN102500906APrevent dent defectsControl welding deformationElectron beam welding apparatusHeat-affected zoneAlloy

The invention relates to the field of heterogeneous steel welding, in particular to a vacuum electron beam welding method for single-phase austenitic stainless steel (HR-2) and precipitation strengthening austenitic stainless steel (J75) heterogeneous plates (which have the thickness of between 2.0 and 5.0 millimeters). According to the vacuum electron beam welding method for the HR-2 and J75 stainless steel heterogeneous plates, a process comprises the following steps of: performing pre-welding treatment on parent metals, clamping and fixing in a vacuum welding chamber, vacuumizing the welding chamber, welding in a positioning mode, welding by using electron beams in a single circulation mode (the electron beams scan in a deflection mode) and scanning weld joints by using the electron beams in a defocusing mode after welding. According to HR-2 and J75 heterogeneous metal joints, the defects of pores, entrainment and the like are overcome in the joints, and poor gama' areas are not formed in a welding molten pool and a heat affected zone on one side of J75 alloy. The joints of the HR-2 and J75 stainless steel heterogeneous plates welded by the method have good formed surfaces, the strength of the joints is higher than 680 to 700 MPa, and the strength factor of the HR-2 stainless steel can reach over 0.9.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

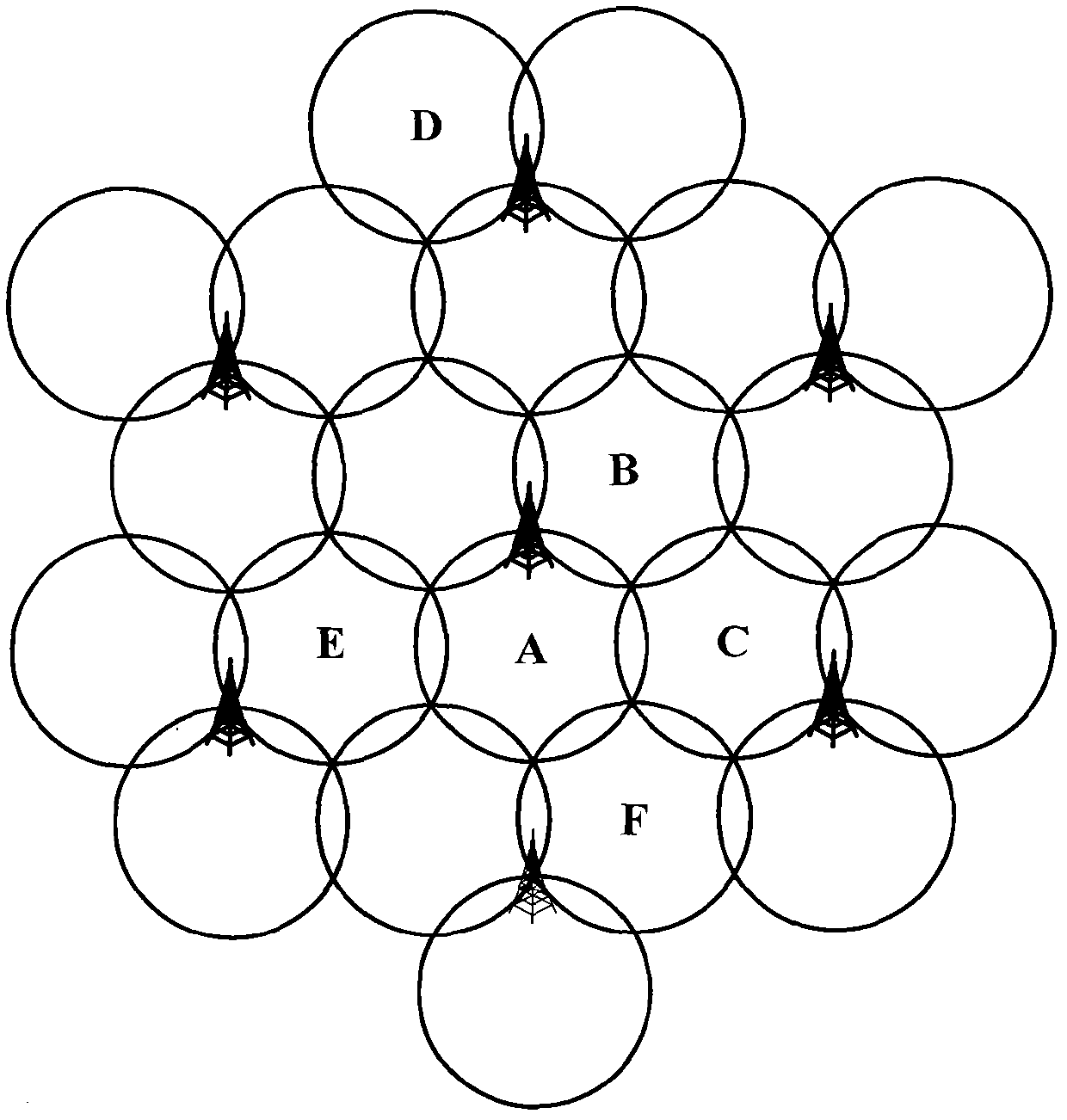

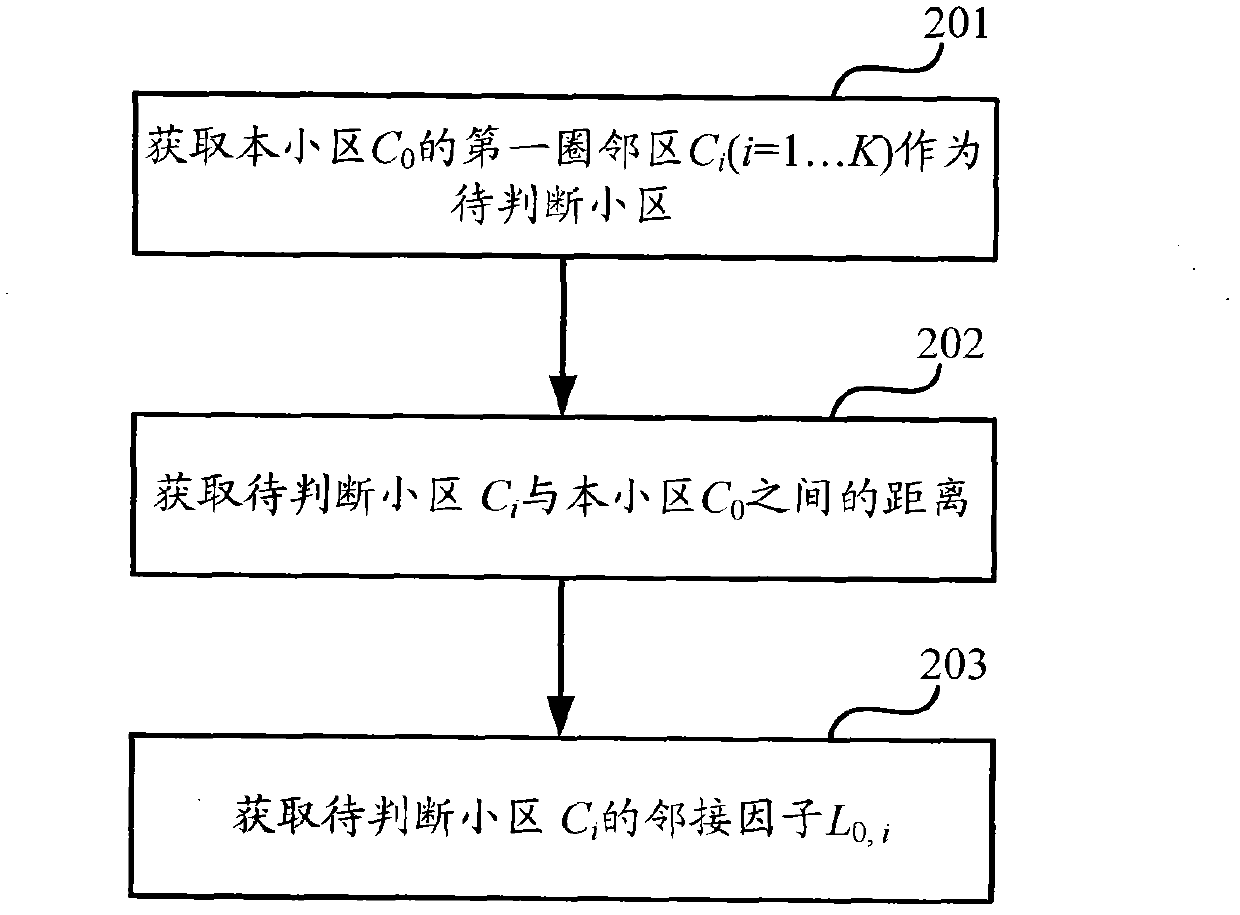

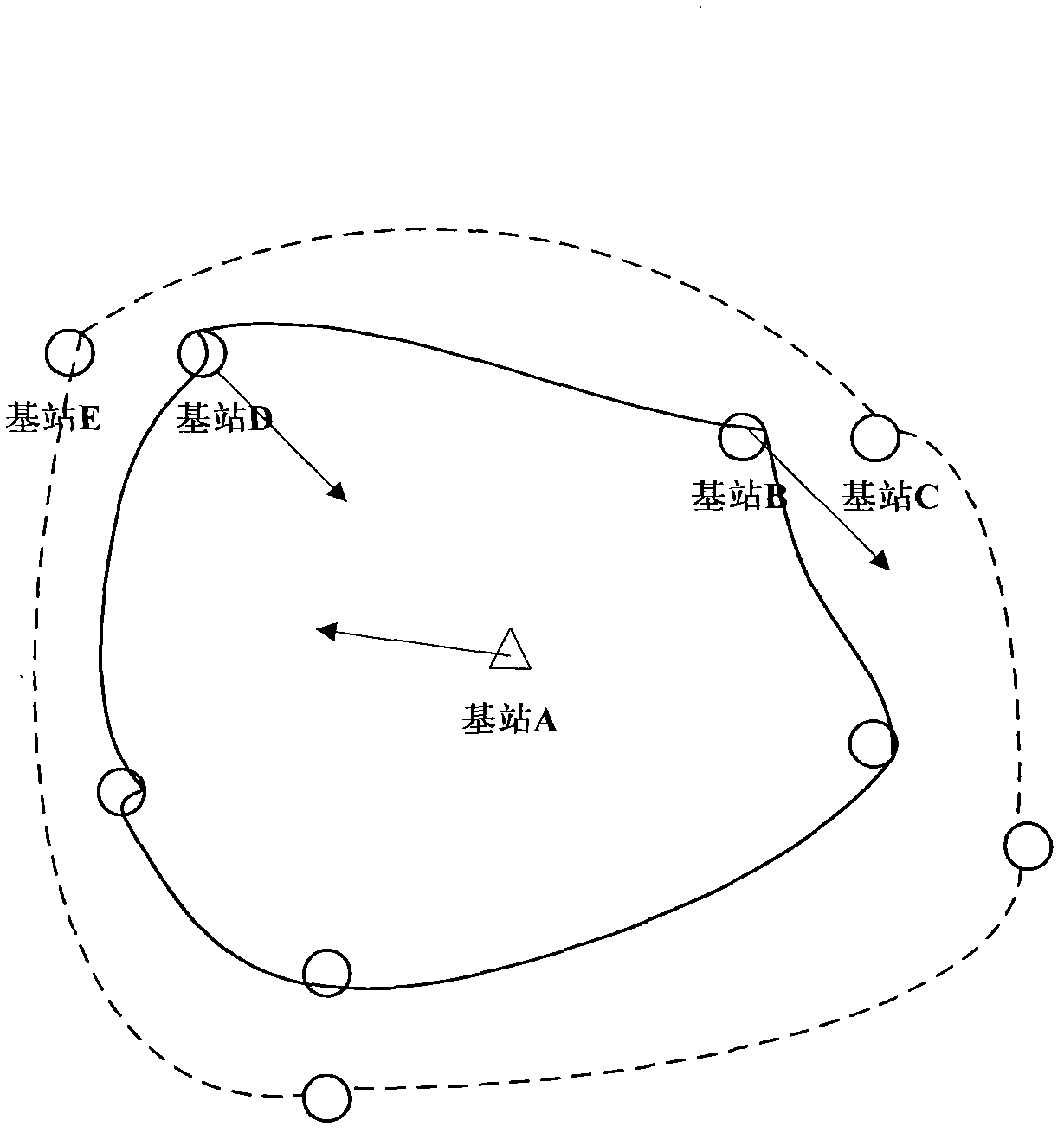

Method and device for determining cell adjacent relation

The invention discloses a method for determining cell adjacent relation. The method includes: obtaining information of a cell and a cell to be judged; determining distance factor of the cell to be judged according to the information the cell and the cell to be judged; determining topology strength factor of the cell to be judged according to the information the cell and the cell to be judged; determining adjacent relation factor of the cell to be judged according to the distance factor and the topology strength factor; and determining adjacent relation of the cell to be judged and the cell according to the adjacent relation factor. The method and a device can determine the adjacent relation between the cells accurately.

Owner:POTEVIO INFORMATION TECH

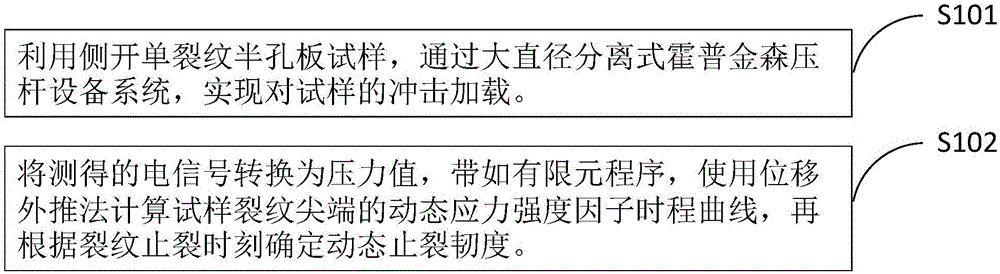

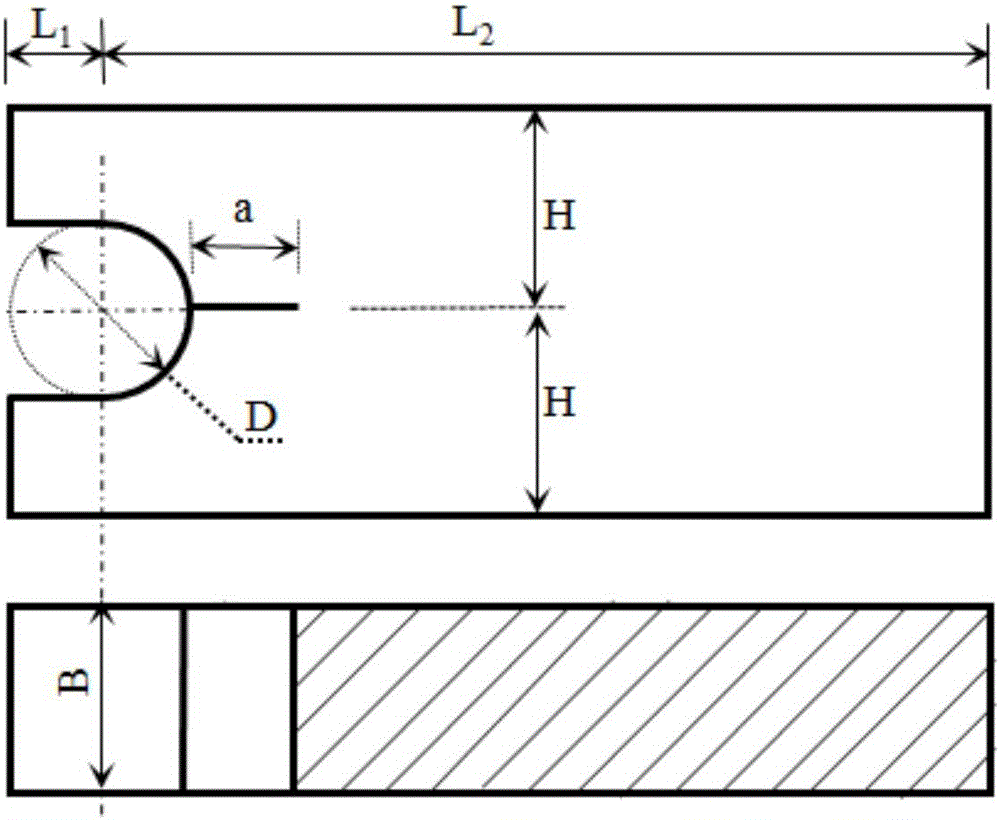

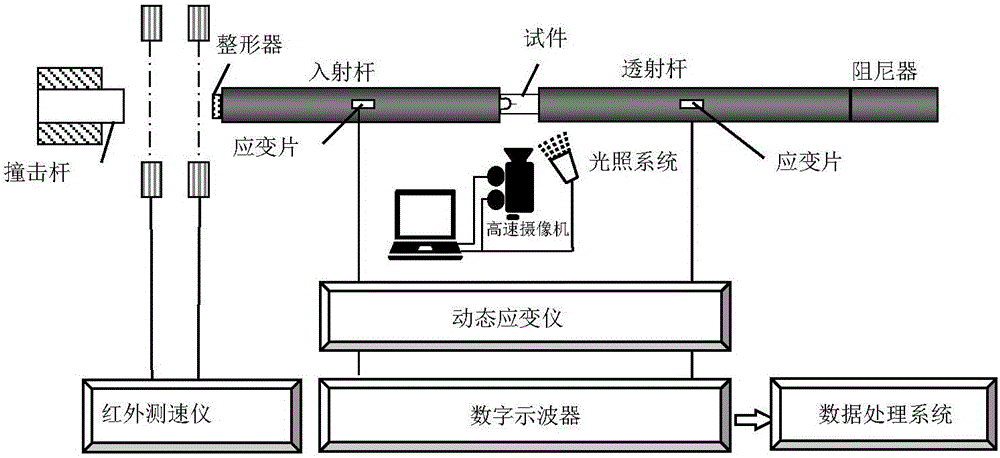

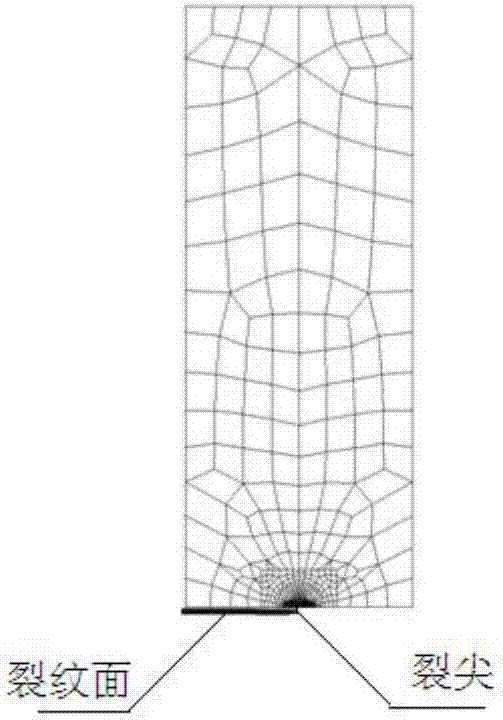

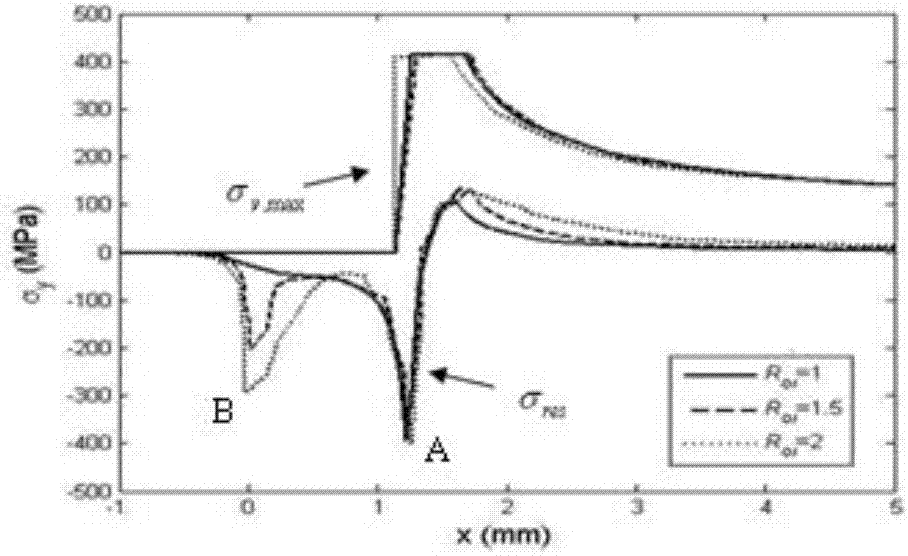

Testing method for dynamic crack arrest toughness of I-type crack under impact load

InactiveCN106290012ASimple methodEasy to operateMaterial strength using single impulsive forceConfiguration designStress intensity factor

The invention discloses a testing method for the dynamic crack arrest toughness of an I-type crack under the impact load, and belongs to the technical field of geotechnical engineering. The method includes the steps of conducting impact test research through a large-diameter separated type Hopkinson pressing rod and a test configuration designed by an inventor, determining the dynamic crack toughness of a sample through an experiment-numerical value method, calculating the load borne by the sample and the moment of crack arrest through strain signals obtained through a test, inputting an obtained time travel curve to a finite element program Ansys, calculating the near-field displacement of a crack tip through a 1 / 4 node unit, obtaining the time travel curve of the I-type dynamic rupture stress strength factor of the sample through a displacement extrapolation method, obtaining the strain strength factor value corresponding to the crack arrest moment as the dynamic crack arrest toughness of the material, and then obtaining the pure I-type crack dynamic crack arrest toughness under the effect of the impact load. The method is simple and convenient to operate and should have more practical application meaning in research of the dynamic crack arrest characteristic of rock under the impact dynamic load.

Owner:SICHUAN UNIV

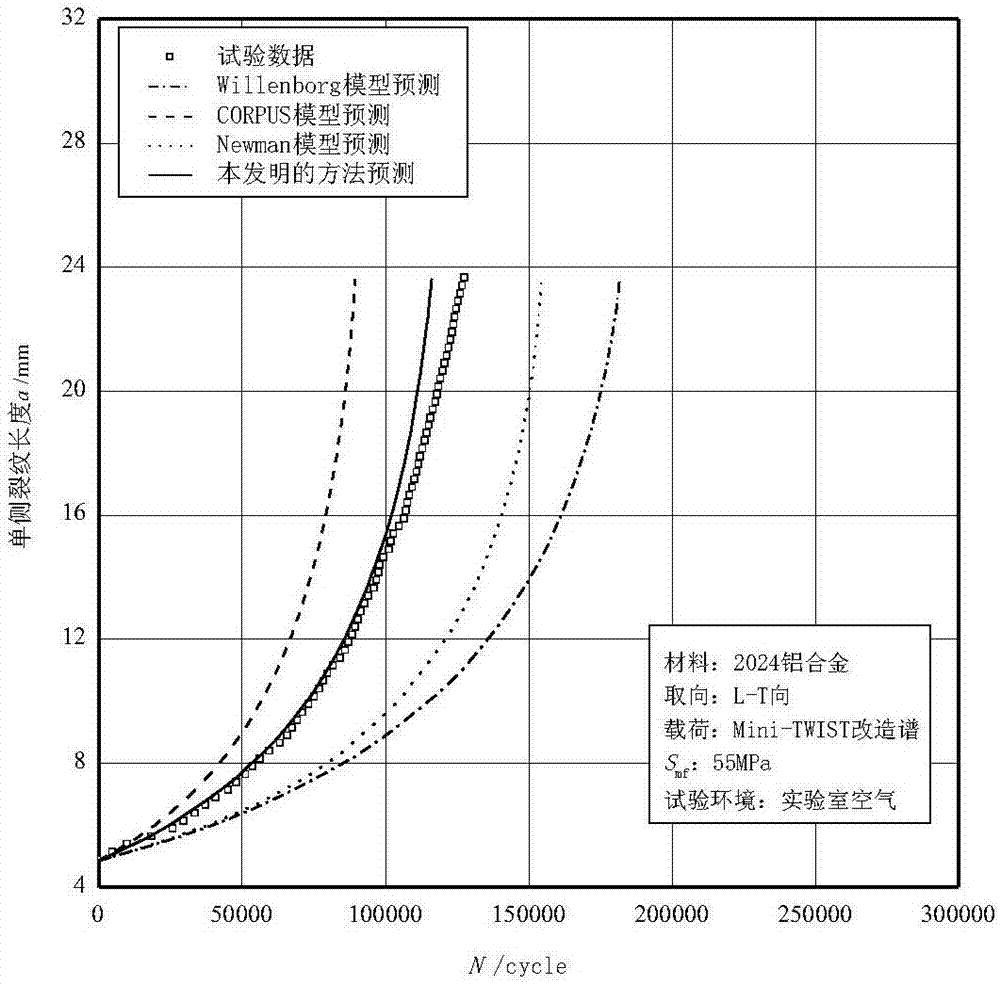

Metal material fatigue crack propagation prediction method

ActiveCN107506544AImprove forecast accuracyMeet the needs of structural designUsing mechanical meansSpecial data processing applicationsJet aeroplanePredictive methods

The invention belongs to a metal material damage tolerance design technology and relates to a metal material fatigue crack propagation prediction method. The fatigue crack propagation prediction method comprises the following steps of determining residual stress strain field distribution near a crack tip in crack propagation; calculating a residual stress strength factor; determining a processing method for variable amplitude loading; and building a fatigue crack propagation model. According to the metal material fatigue crack propagation prediction method provided by the invention, the fatigue crack propagation prediction precision is improved; the application range is expanded; and the needs of modern airplane structure design are met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

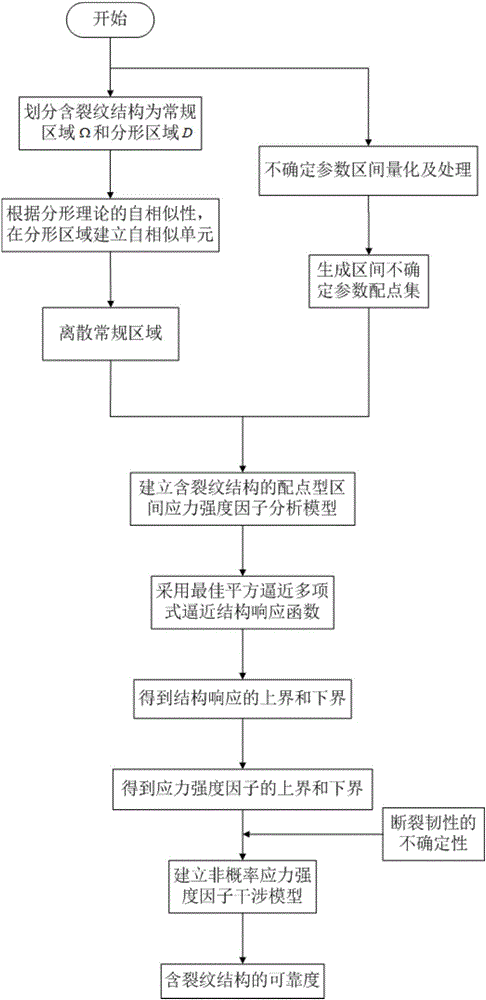

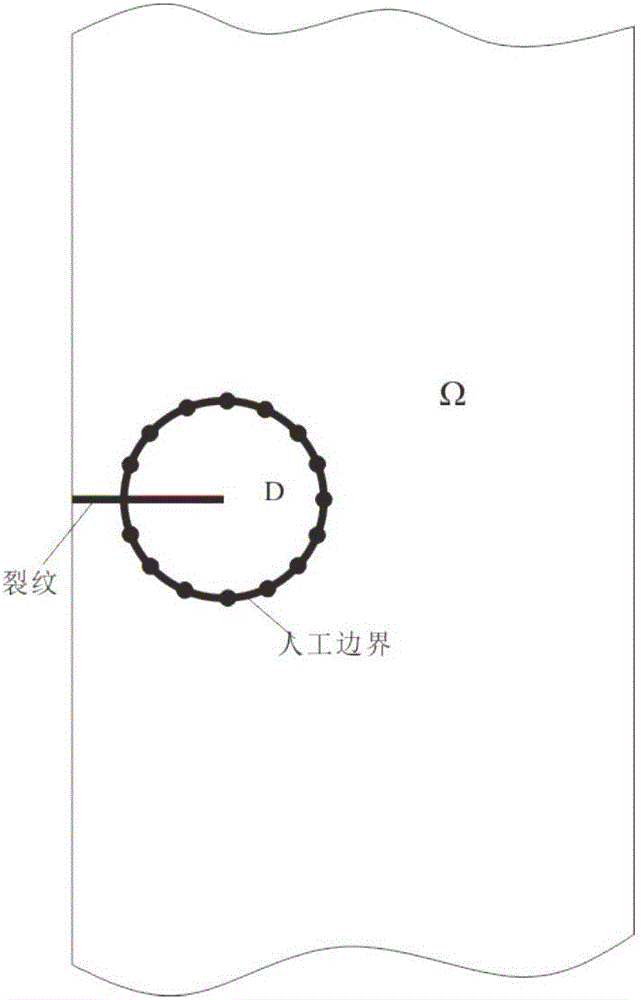

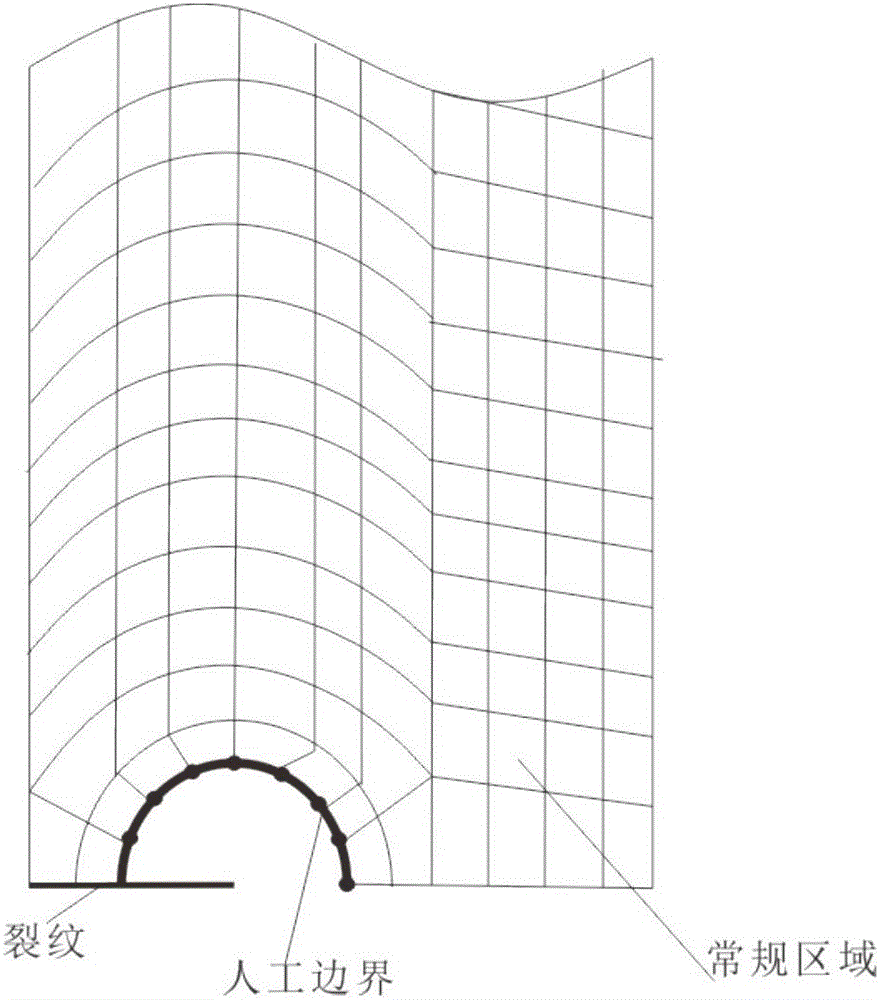

Structure fracture non-probability reliability analysis method based on fractal theory

InactiveCN105893716AHigh precisionOvercome the shortcomings of low precisionGeometric CADSpecial data processing applicationsStress intensity factorDiscretization

The invention discloses a structure fracture non-probability reliability analysis method based on the fractal theory. The method includes the steps that the uncertainty effect of parameters such as load, material characteristics and geometric dimensions under limited sample conditions is considered first, an uncertainty parameter section is quantified, and points are collocated in the uncertainty parameter section; a self-similarity grid and a conventional grid discretization cracked structure are adopted, a point collocation section stress intensity factor analysis model of the cracked structure is set up, and the section range of stress intensity factors is obtained through solution; the uncertainty effect of fracture tenacity is considered, and a non-probability stress intensity factor intervene model is set up to obtain reliability of the cracked structure. The structure reliability is obtained accurately and efficiency, and objective and effective data is provided for structural design.

Owner:BEIHANG UNIV

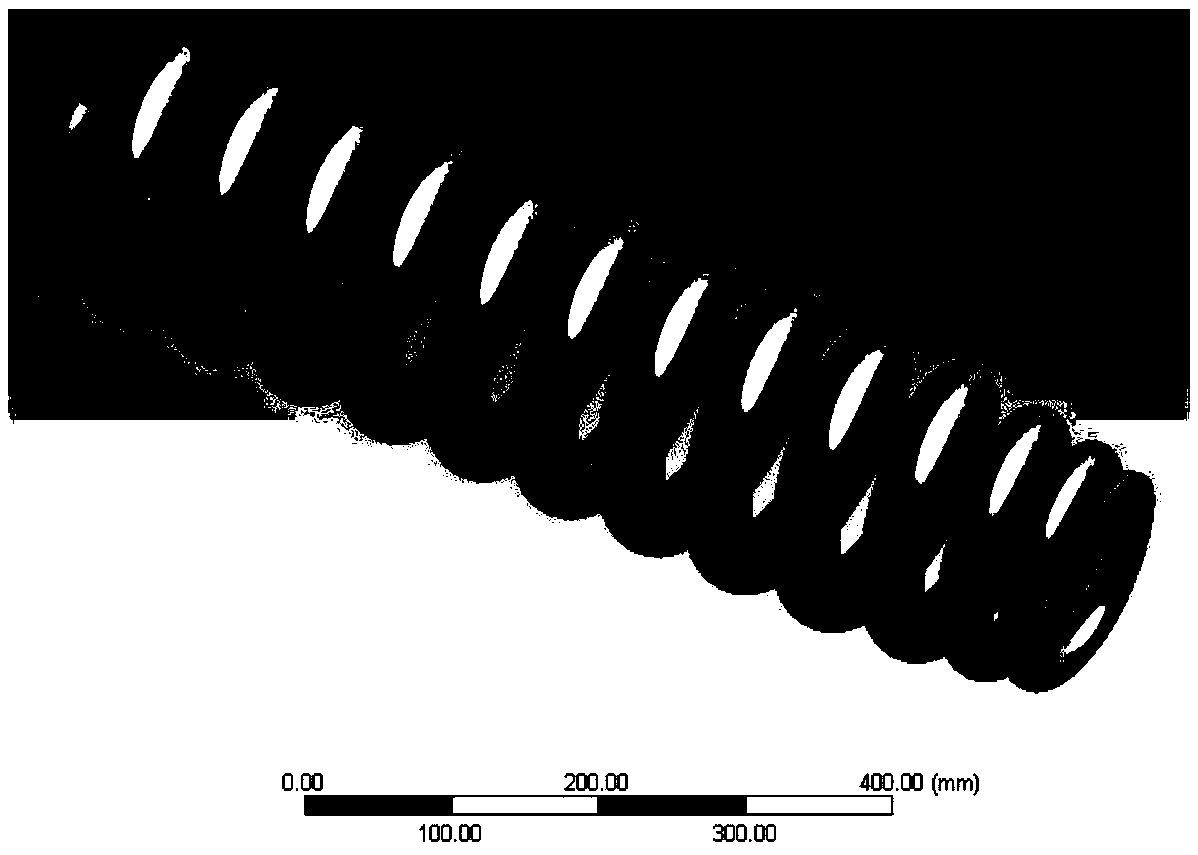

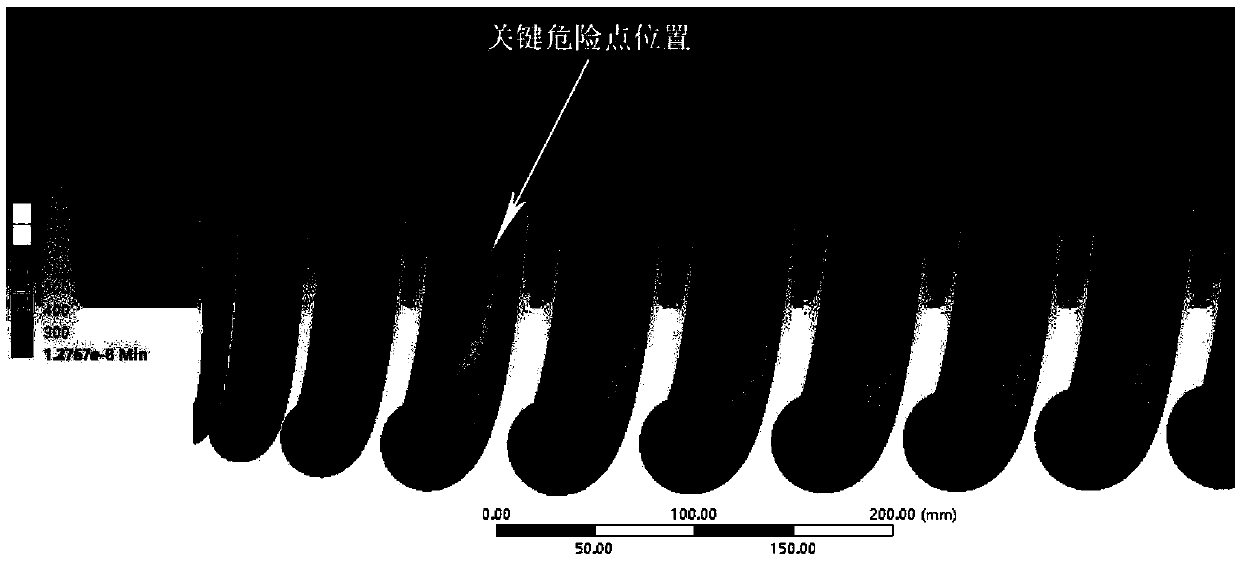

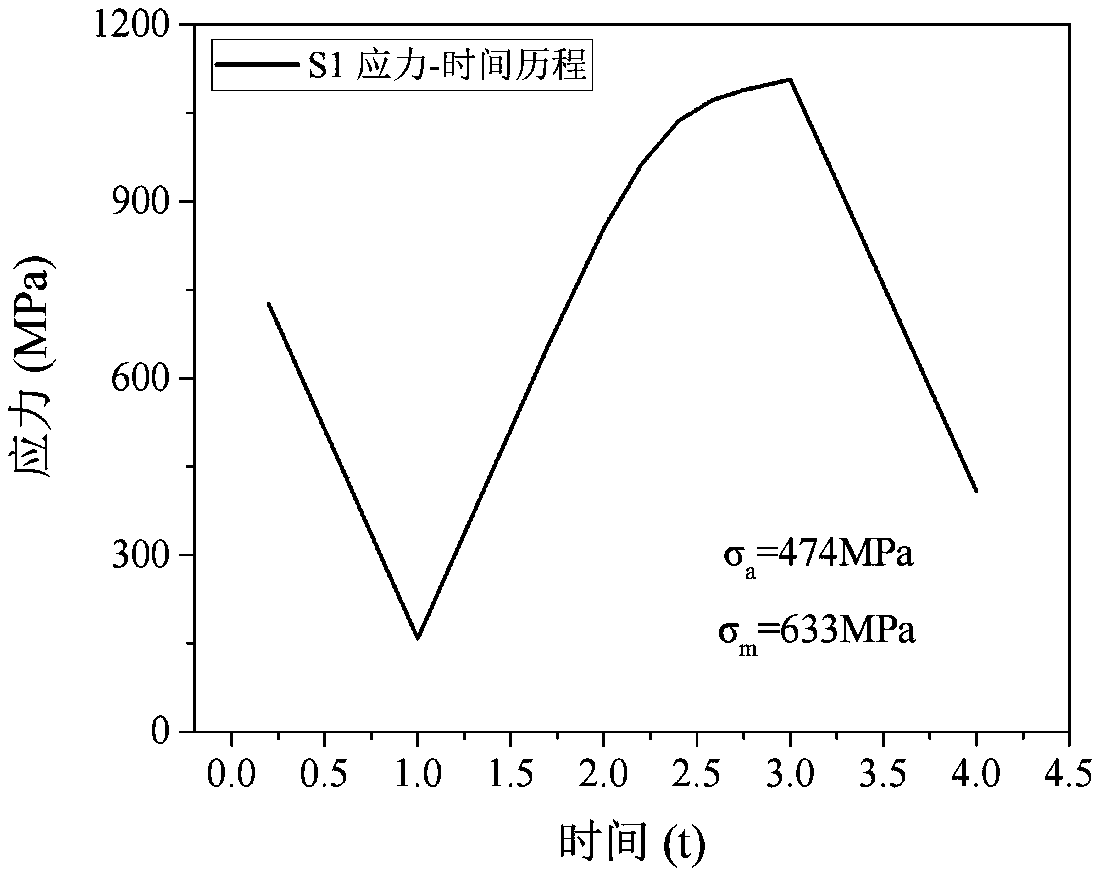

Part service life prediction method comprehensively considering fatigue strength influence factors

ActiveCN109635385AAvoid trial volumeSimplify the design processGeometric CADDesign optimisation/simulationResponse processFatigue damage

The invention discloses a part service life prediction method comprehensively considering fatigue strength influence factors, and relates to the field of fatigue strength design, and the method comprises the following steps: (1) carrying out static analysis on a part structure by utilizing a finite element method, and determining a key dangerous point position with weak strength; (2) simulating acyclic load borne by the part, and obtaining a stress response process at a dangerous point; (3) calculating stress amplitude and average stress as damage parameters; (4) carrying out average stress correction by utilizing a Goodman equation; (5) determining a comprehensive fatigue strength factor; (6) predicting the fatigue life of the part; and (7) accumulating the fatigue damage of the materialby utilizing a Miner theorem, and when the fatigue damage of the material reaches 1, enabling the parts to fail. According to the method, the comprehensive fatigue strength factor is utilized to comprehensively consider the influence of the size and the surface state on the fatigue strength, the huge test amount for determining the size coefficient and the surface state coefficient can be avoided, and the design cost is reduced.

Owner:BEIJING UNIV OF TECH

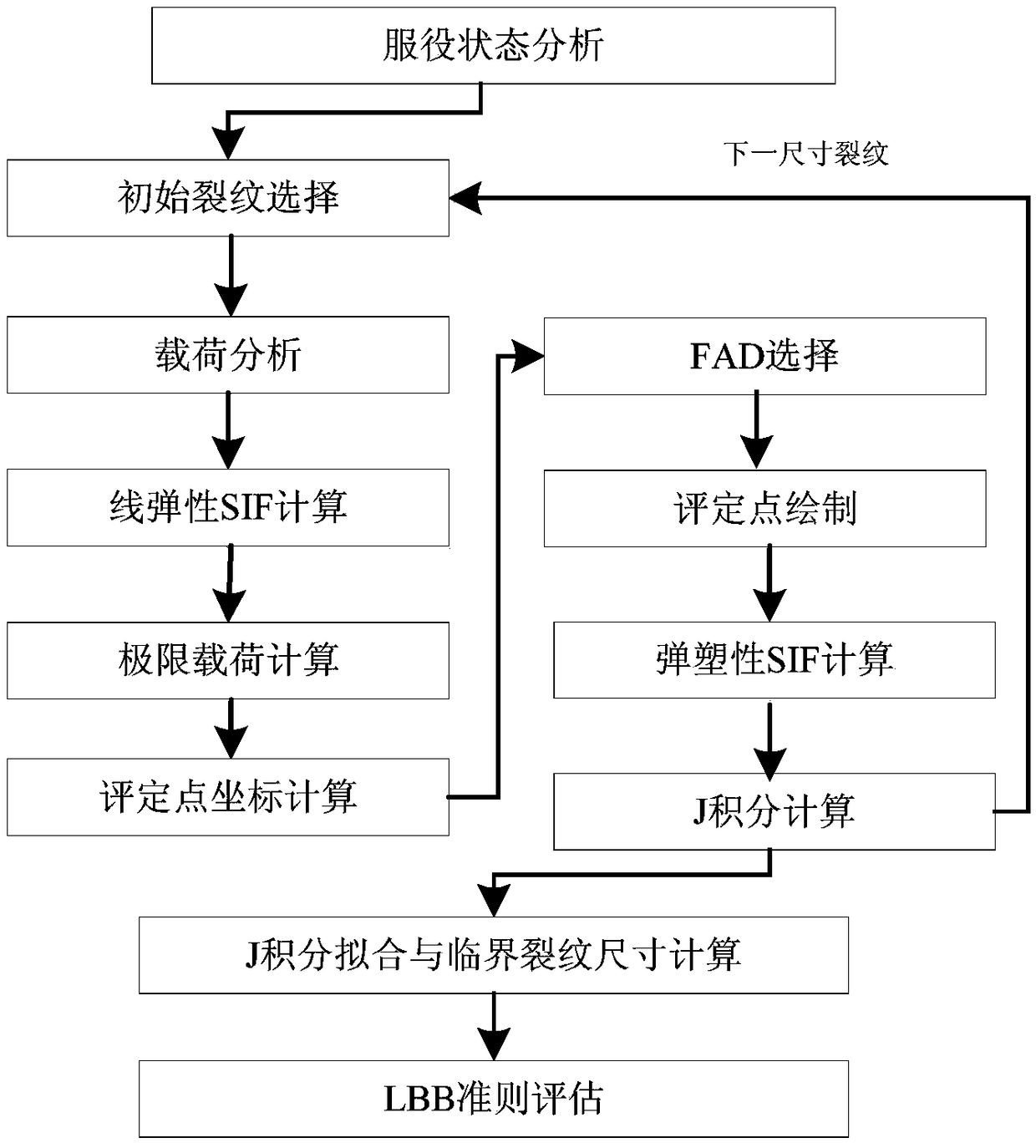

Leak before burst analysis method based on failure assessment diagram

ActiveCN108710721ADesign optimisation/simulationSpecial data processing applicationsFailure assessmentElement model

The present invention relates to a leak before burst (LBB) analysis method based on a failure assessment diagram (FAD). The method comprises the following steps: (a) service state analysis; (b) initial crack selection; (c) load analysis; (d) line elastic stress intensity factor (SIF) calculation; (e) ultimate load analysis; (f) evaluation point coordinate calculation; (g) FAD selection; (h) evaluation point drawing; (i) elastoplastic SIF calculation; (j) J-integral calculation; (k) calculation and fitting of the J-integral of different cracks; (l) calculation of the structural failure criticalcrack size; (m) calculation of the structural critical leakage crack size; and (n) LBB criterion evaluation. According to the method provided by the present invention, based on the FAD theory, defects that the theoretical basis of elastoplastic analysis in the existing norms is insufficient, the existing J-integral calculation manual has a limited application scope, the finite element modeling analysis process is complicated, and the processes for calculating the structural failure critical crack size and the structural critical leakage crack size are complicated, and the like are overcome, and a FAD-based LBB analysis basis is provided.

Owner:SUZHOU NUCLEAR POWER RES INST +4

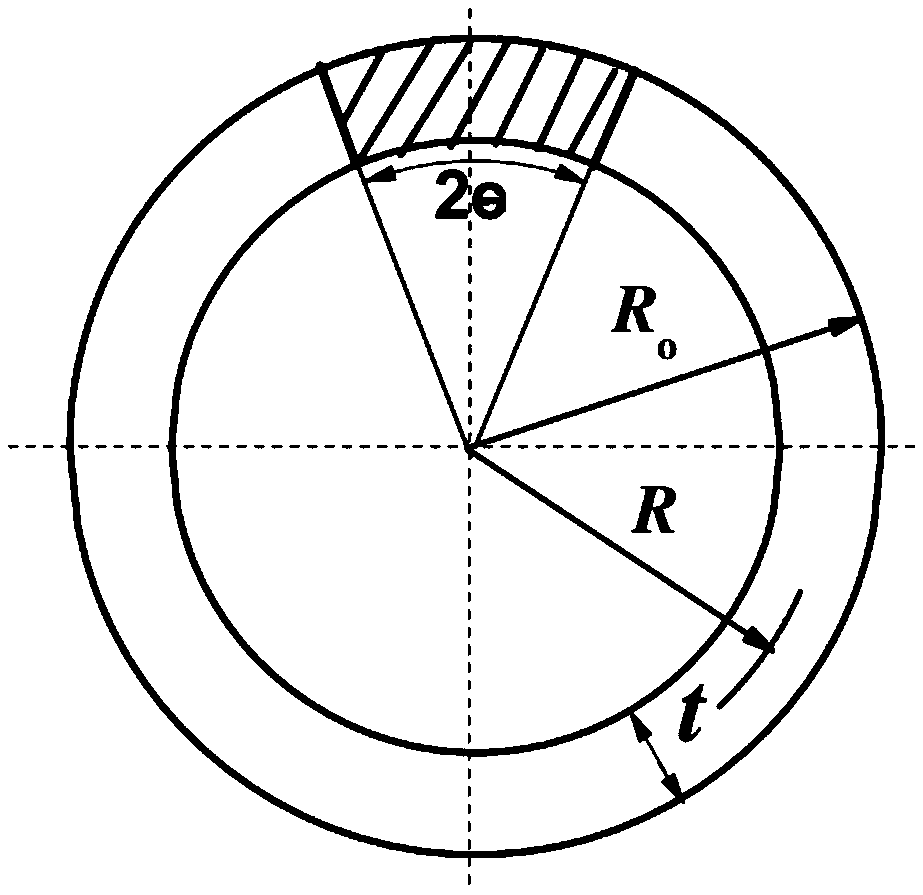

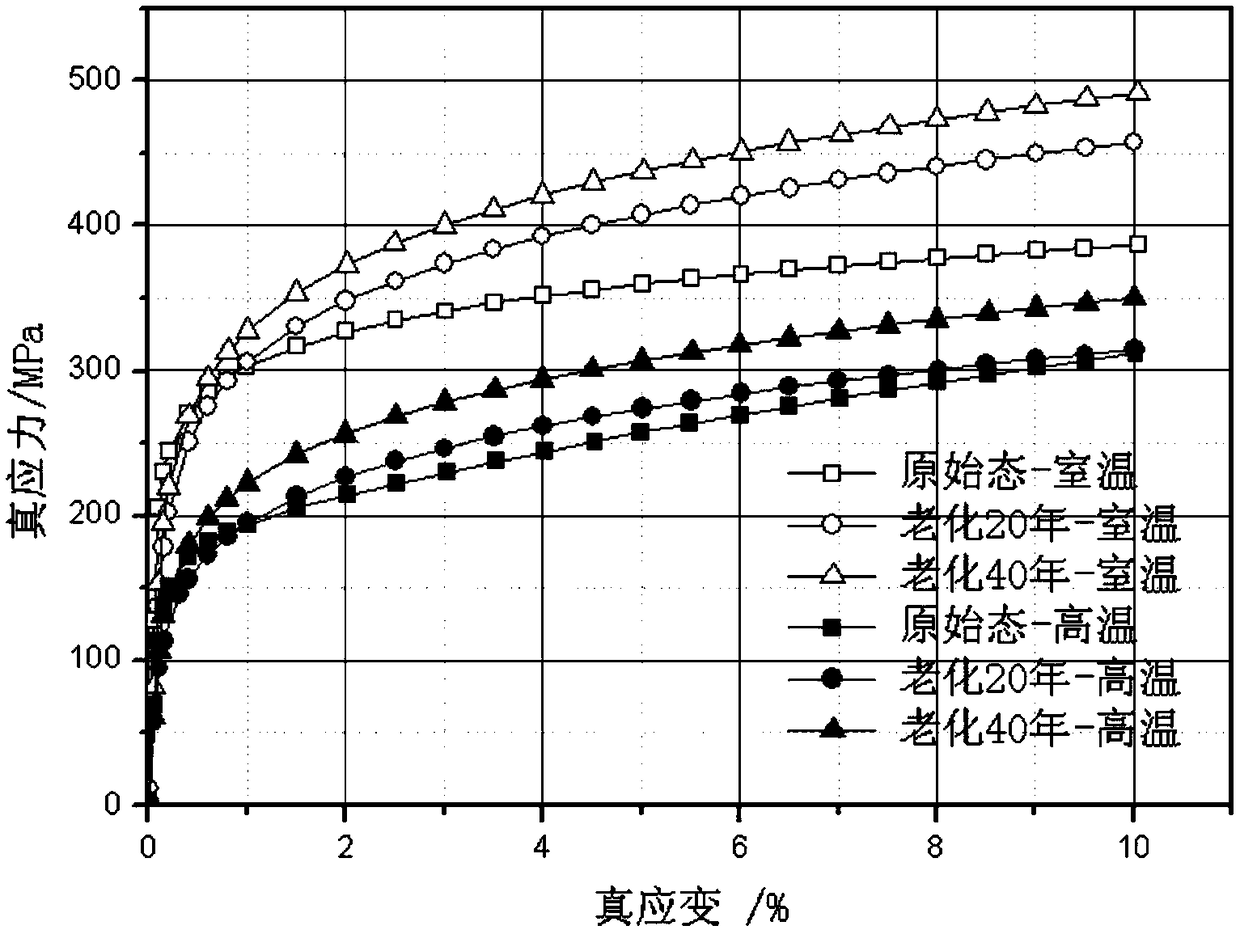

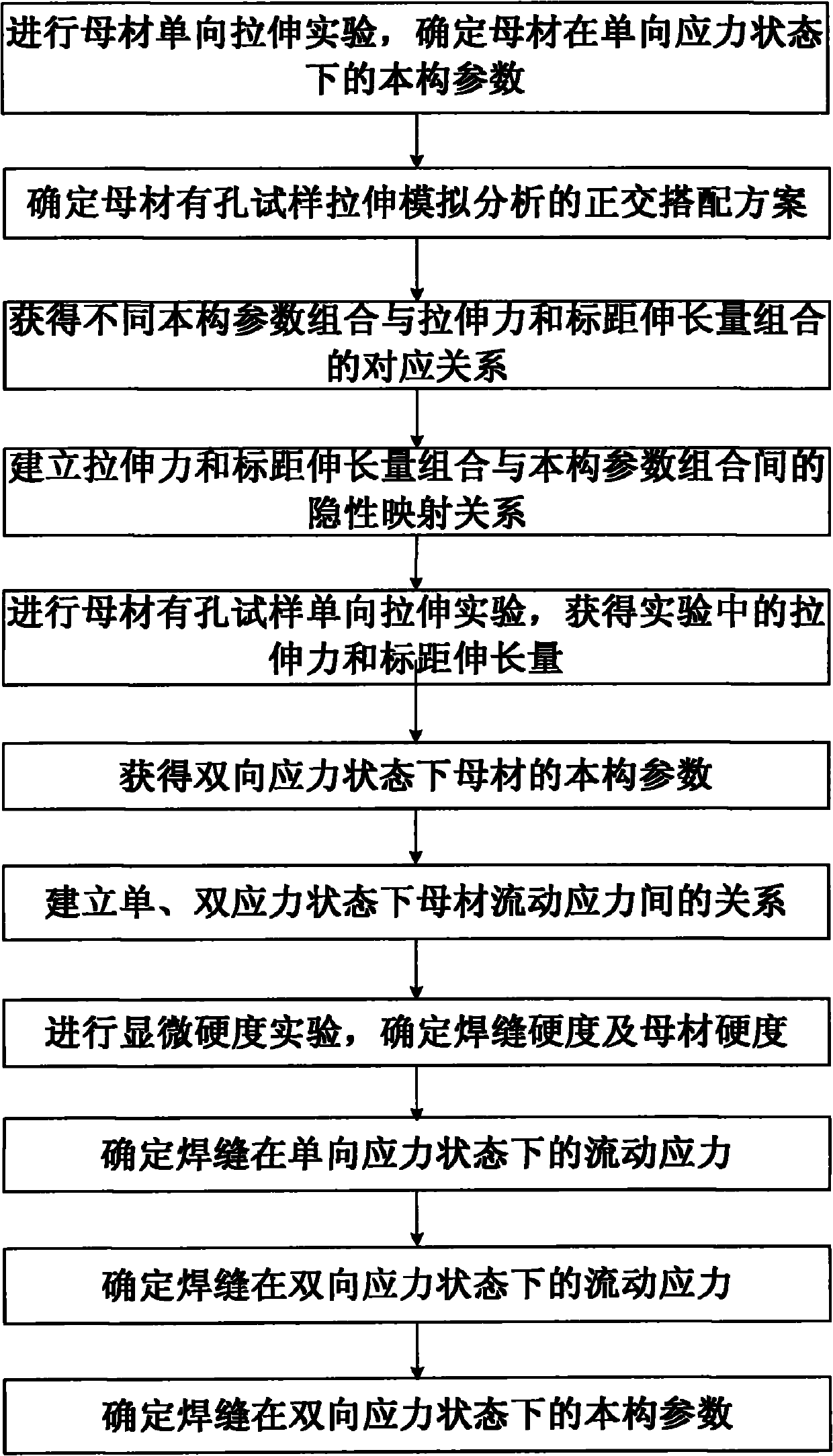

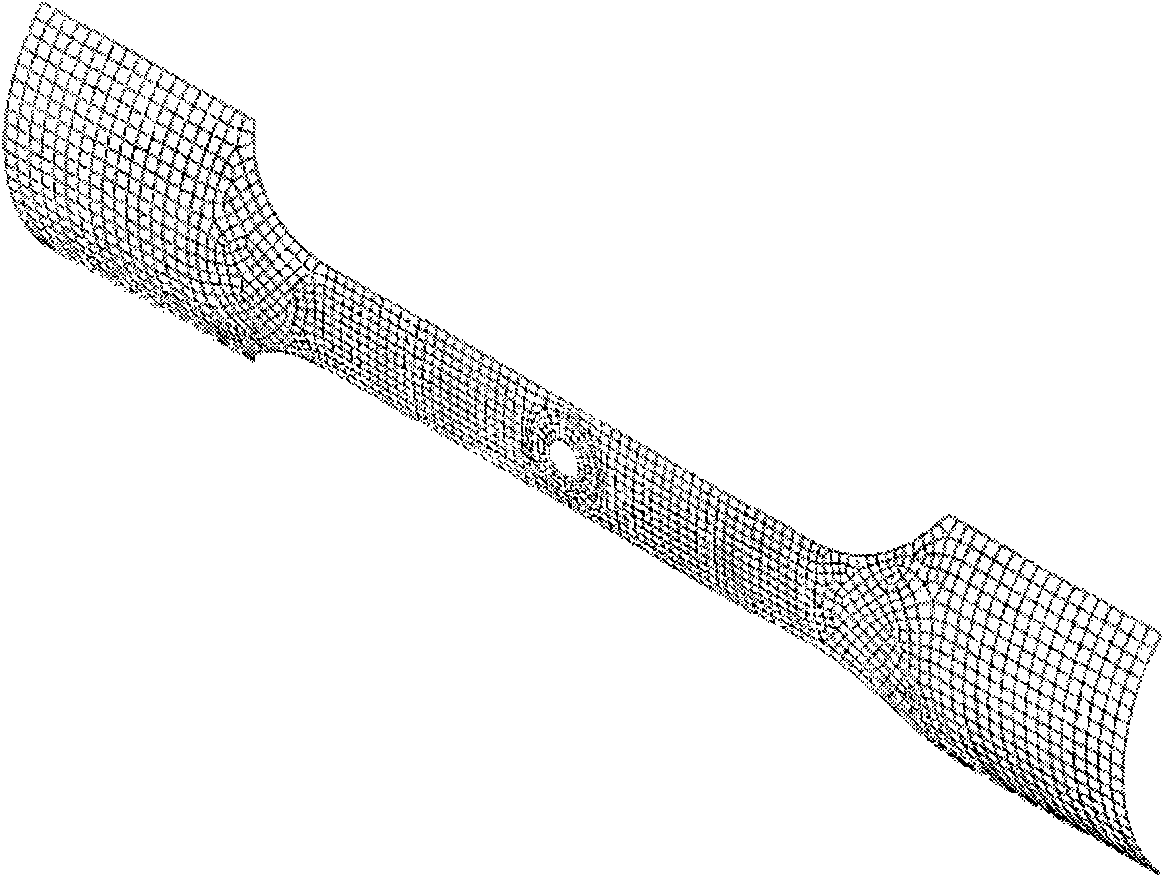

Method for determining constitutive parameters of butt welded pipe welding seam in biaxial stress state

ActiveCN102004819AImprove forming qualityRaise the forming limitSpecial data processing applicationsWeld seamStressed state

The invention relates to a method for determining constitutive parameters of a butt welded pipe welding seam in the biaxial stress state, which comprises the following steps of: determining the constitutive parameters of the parent metal in the uniaxial stress state, thereby determining the range of the parent metal strength factor K<sim> in the perforated sample tensile finite element analogy, and the range of the hardening index n<sim>; and by determining the variation ranges of the strength factor and the hardening index, obtaining the relationship between different constitutive parameter combinations (K<sim>, n<sim>) and the combinations (F<sim>, Delta l<sim>) of tensile force and gauge length elongation, and establishing a recessive mapping relationship between the combination (F, Delta l) of tensile force and gauge length elongation and the constitutive parameter combination (K, n), thereby obtaining the constitutive parameters of the welding seam in the biaxial stress state. The method induces the planar biaxial tension stress state, which is more approximate to the true stress state of pipe deformation, in the uniaxial tension process of a perforated sample, can be used for accurately and efficiently determining the constitutive parameters of the welding seam ductility of a butt welded pipe, and is beneficial to enhancing the forming quality and the forming limit of the welded pipe.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

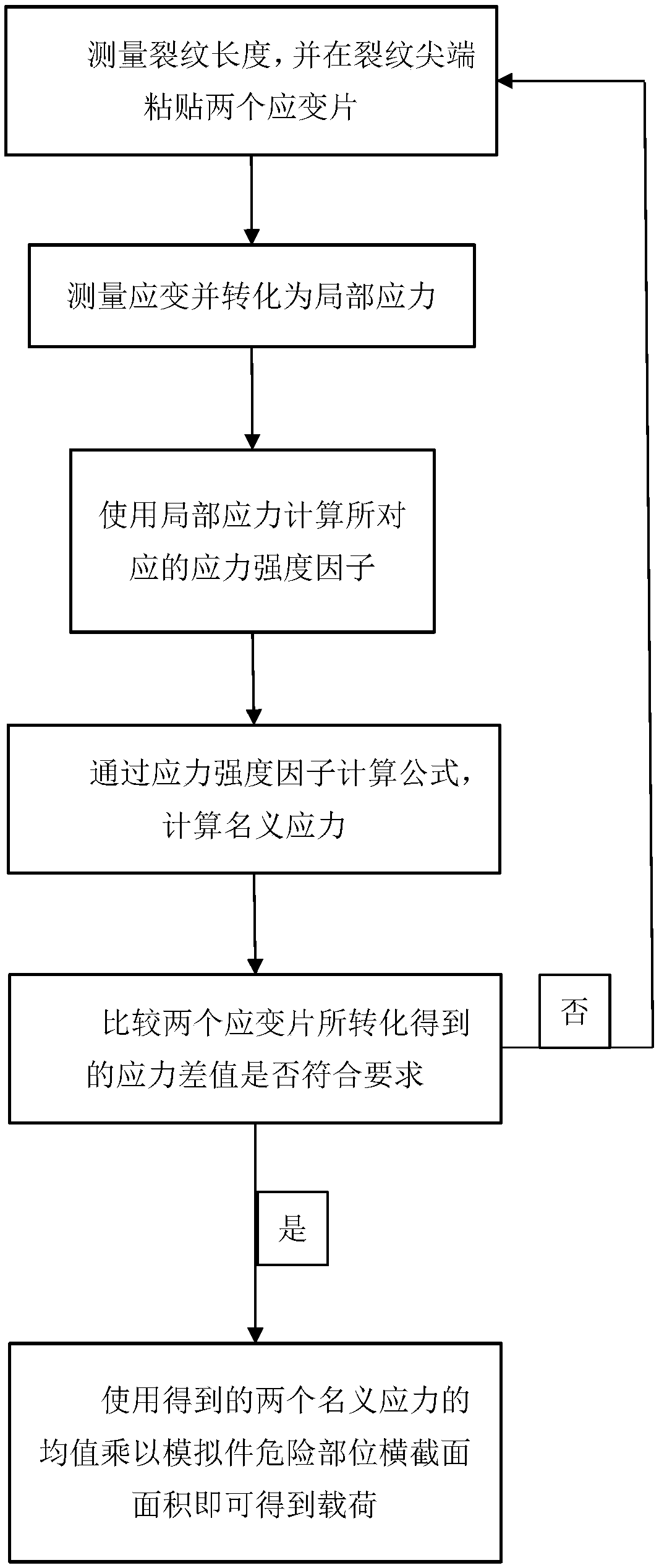

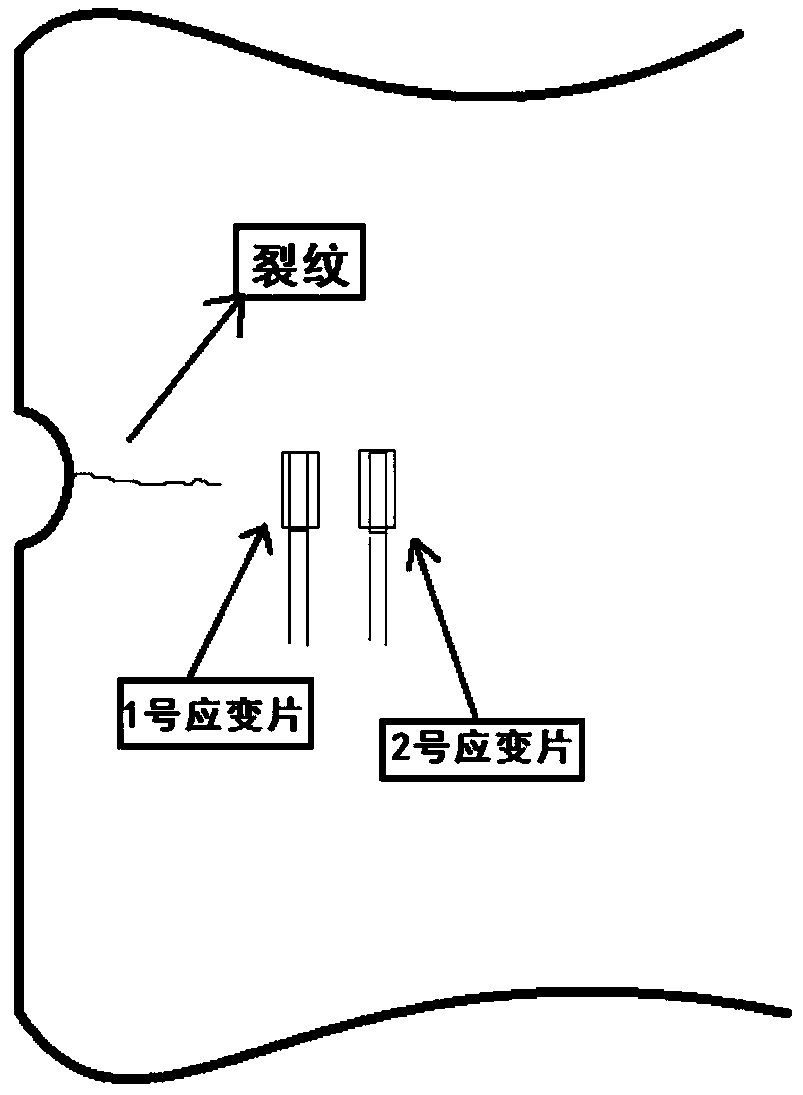

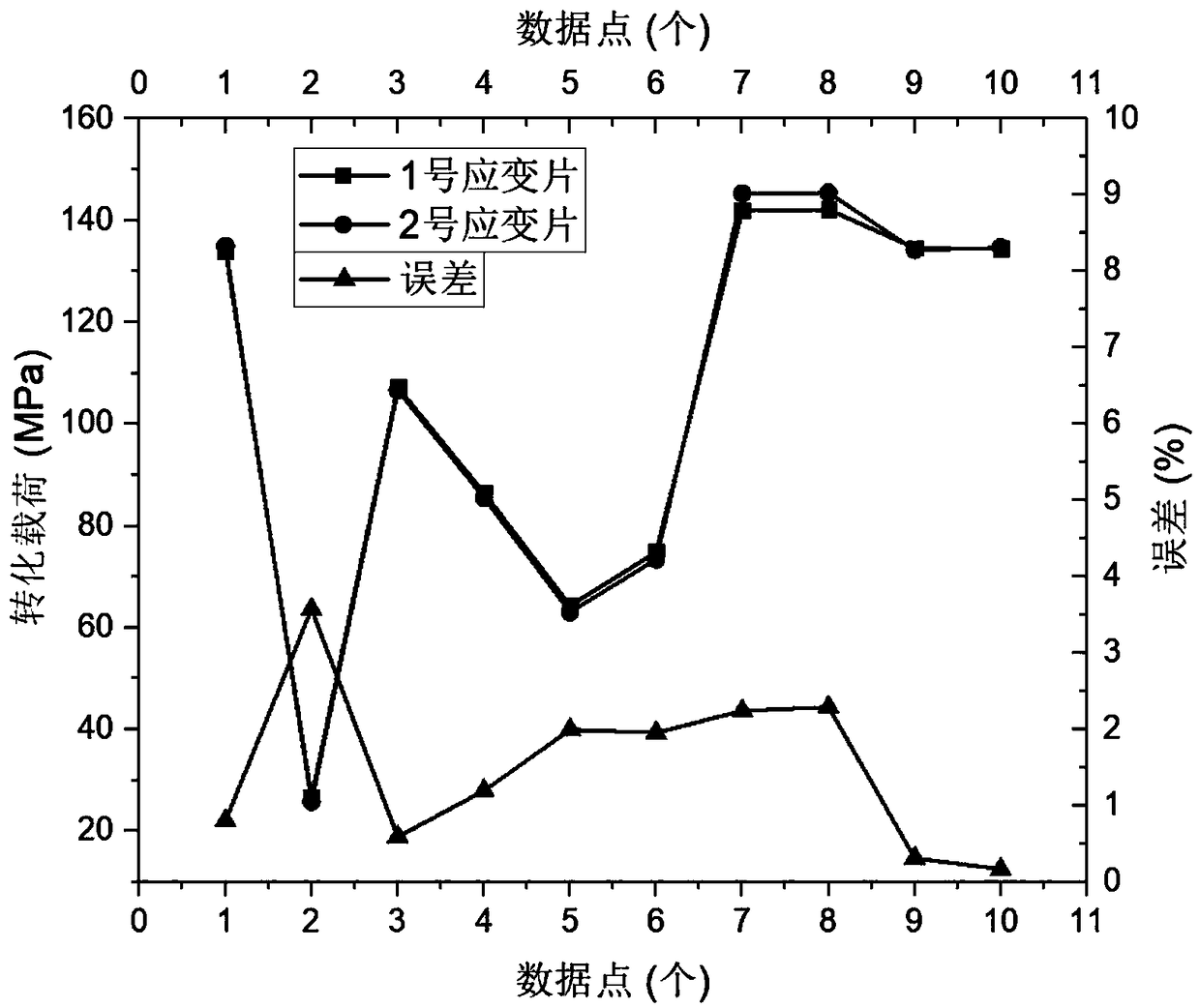

Simulation part load conversion method based on local actually measured strain at crack tip of actual structural part of airplane

ActiveCN108982205ALoad accuratelyThe load is accurately obtainedRailway vehicle testingStrength propertiesStress intensity factorEngineering

The invention discloses a simulation part load conversion method based on local actually measured strain at a crack tip of an actual structural part of an airplane and relates to the field of fatiguelife test. The method comprises the following steps: (1) measuring crack length and adhering a strain gauge; (2) converting the measured strain into local strain; (3) calculating a strain strength factor by employing the local strain; (4) calculating nominal strain through the strain strength factor and judging whether a calculating result is accurate or not; and (5) solving a load of the test simulation part by employing the calculated nominal strain. The conversion result shows that the method can convert the load of the actual structural part with the crack into the load of the test simulation part accurately and quickly.

Owner:BEIJING UNIV OF TECH +1

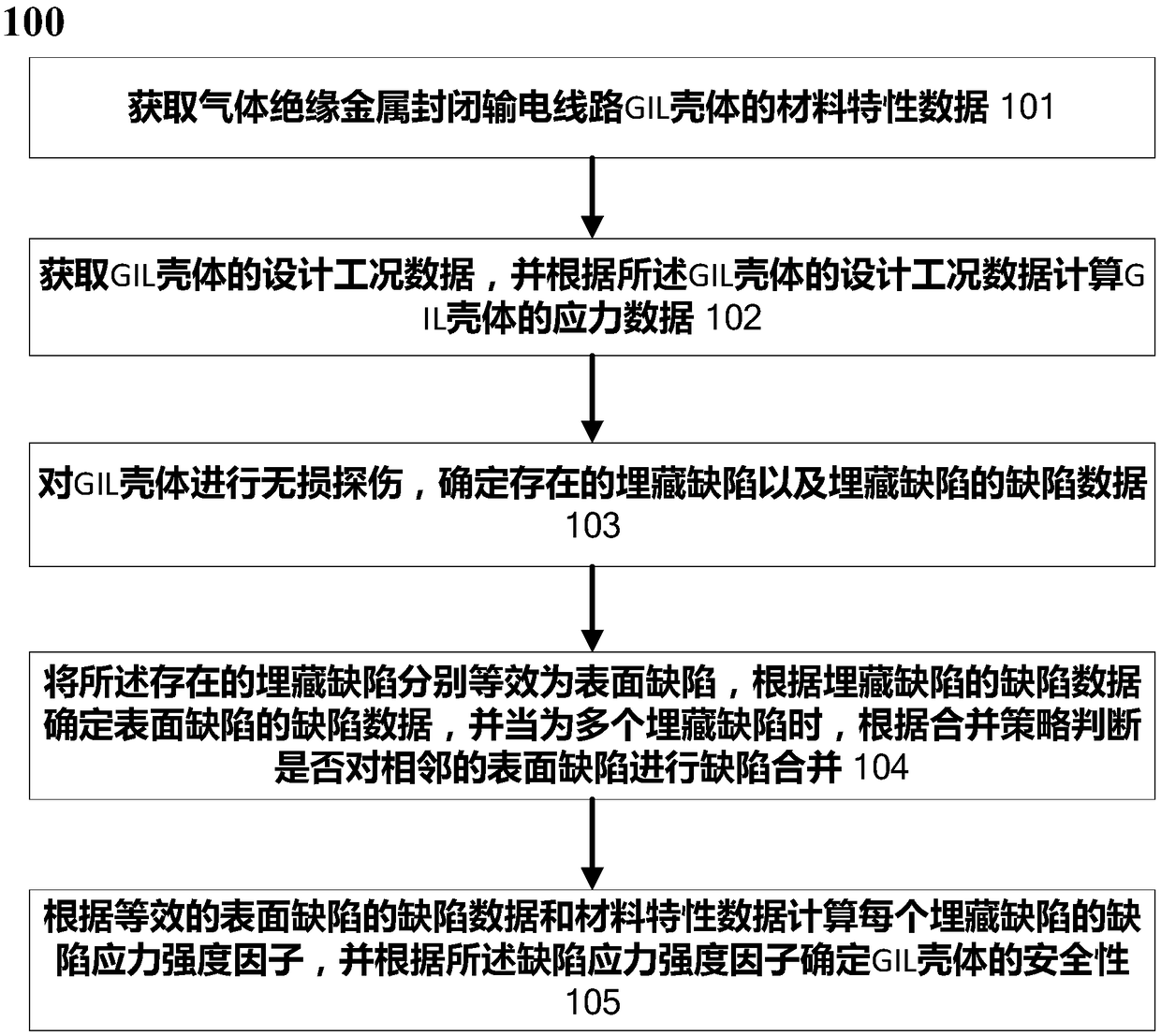

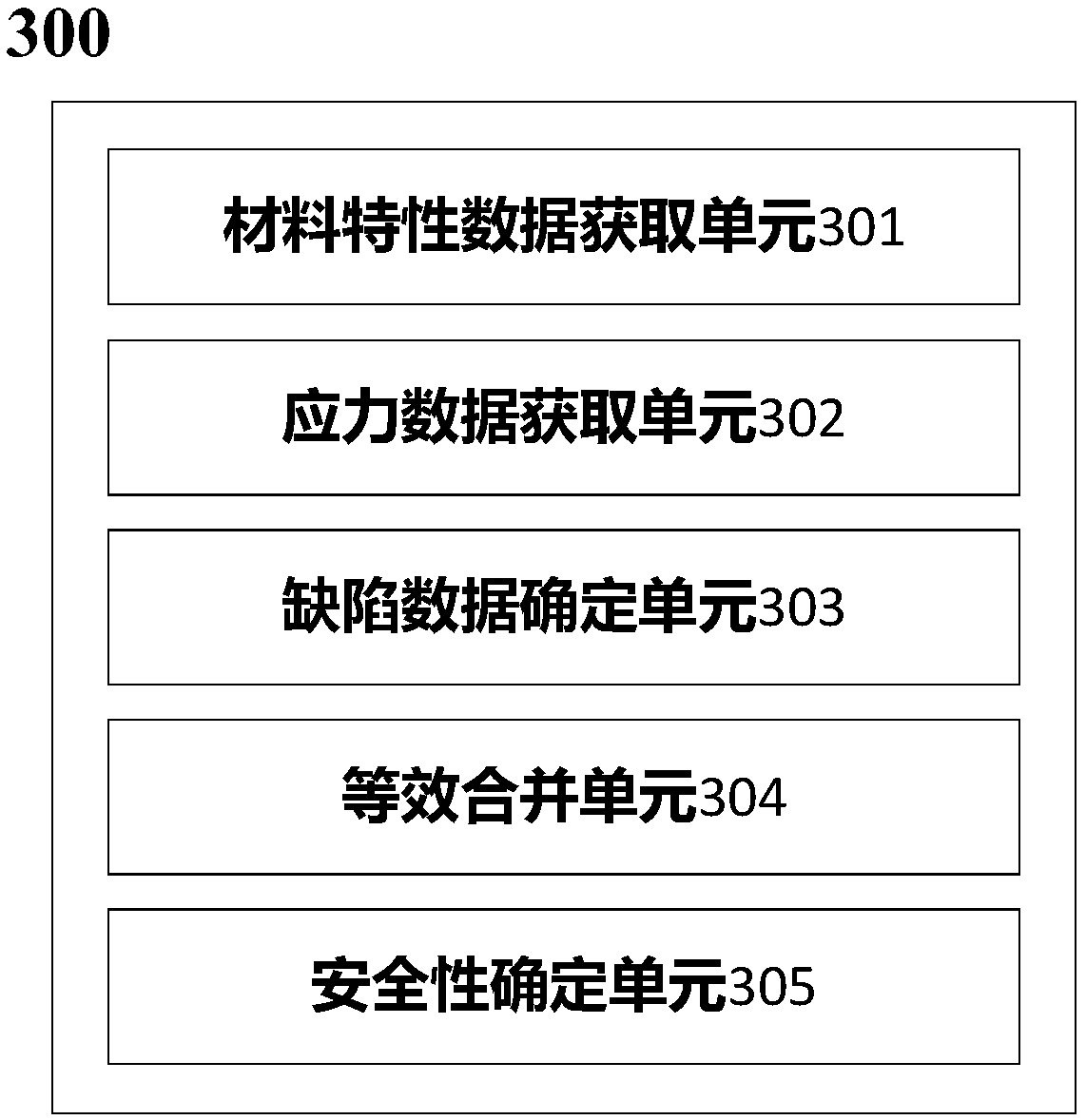

Method for determining safety of GIL shell containing buried defects and system thereof

ActiveCN108956930AImprove securityHigh precisionTesting metalsNon destructiveStress intensity factor

The invention relates to a method for determining safety of a GIL shell containing buried defects, comprising the following steps: acquiring material characteristic data of a gas insulated metal enclosed transmission line GIL shell; acquiring design condition data of the GIL shell, and calculating stress data of the GIL shell; performing non-destructive testing on the GIL shell to determine existing buried defects and defect data of the buried defects; equalizing the existing buried defects to surface defects respectively, determining defect data of the surface effects according to the defectdata of the buried defects, and judging whether to combine the defects of the adjacent surface defects according to a merge strategy when there are multiple buried defects; and calculating defect stress intensity factor of each buried defect, and determining safety of the GIL shell according to the defect stress intensity factor. The accuracy of evaluation of safety and remaining life of the GIL shell containing the buried defects can be improved. The method is convenient for practical application of engineering personnel. The maintenance cost is lowered, and the technical support is providedfor the inspection and maintenance of the extra-high voltage GIL shell.

Owner:CHINA ELECTRIC POWER RES INST +2

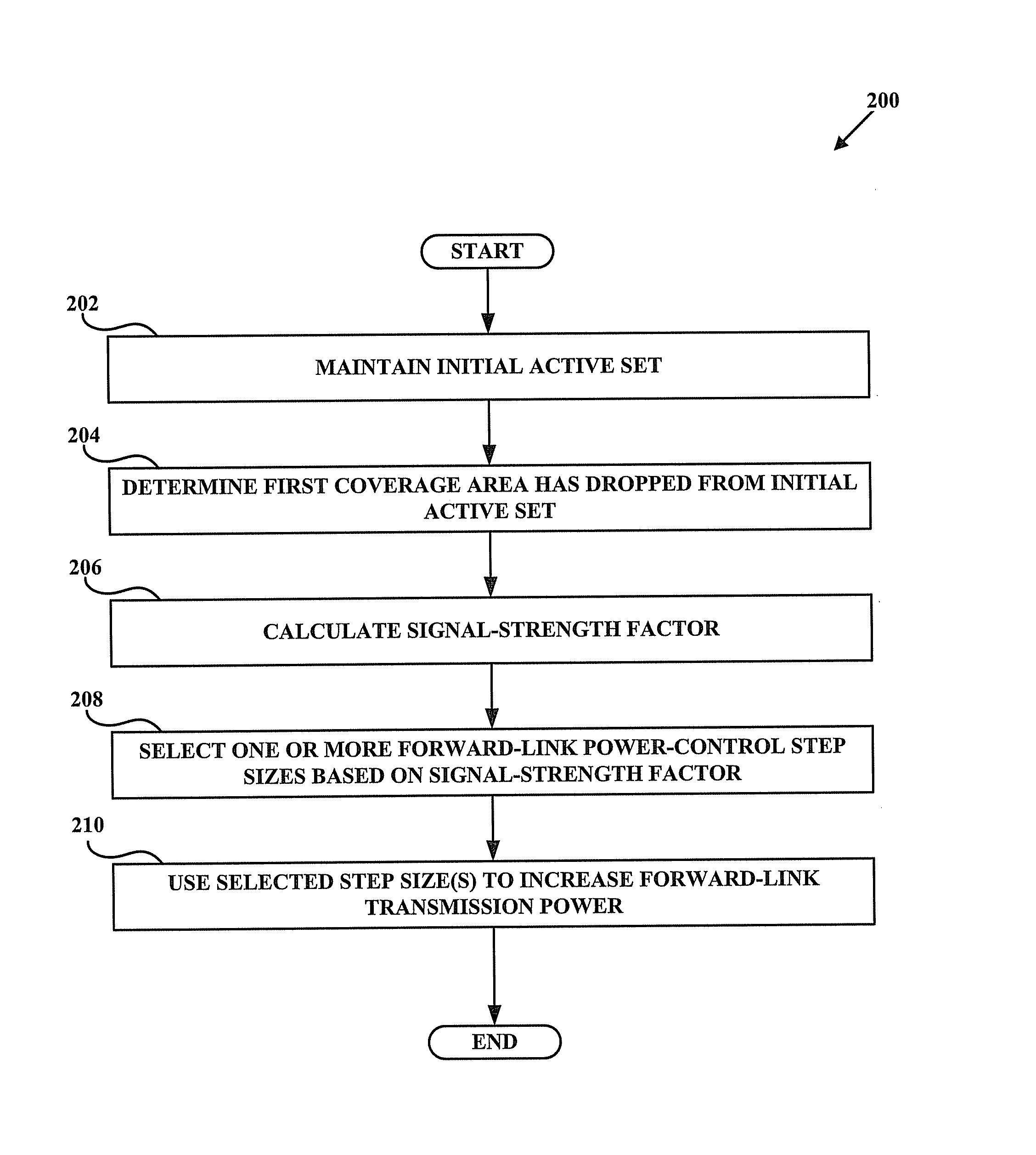

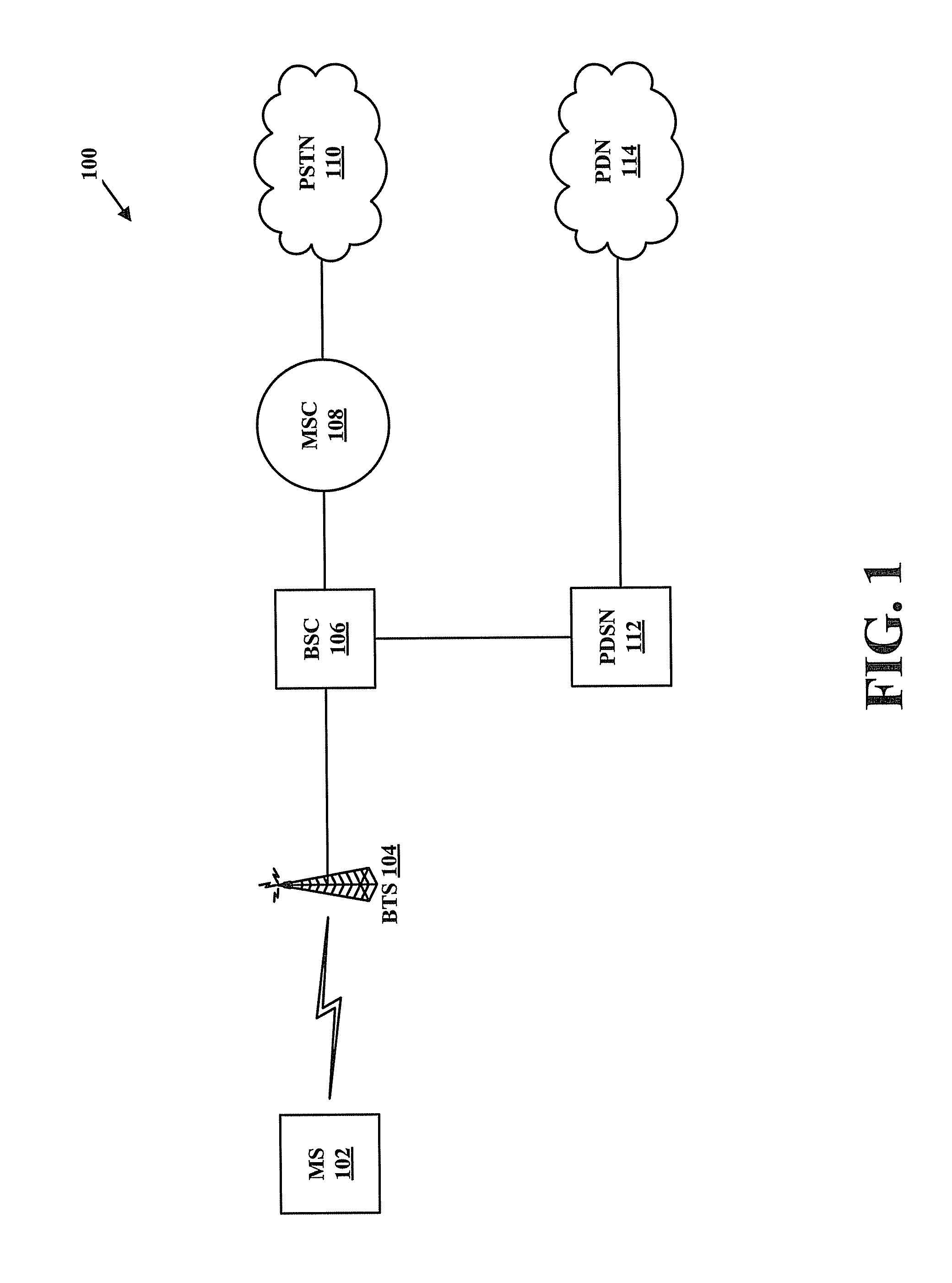

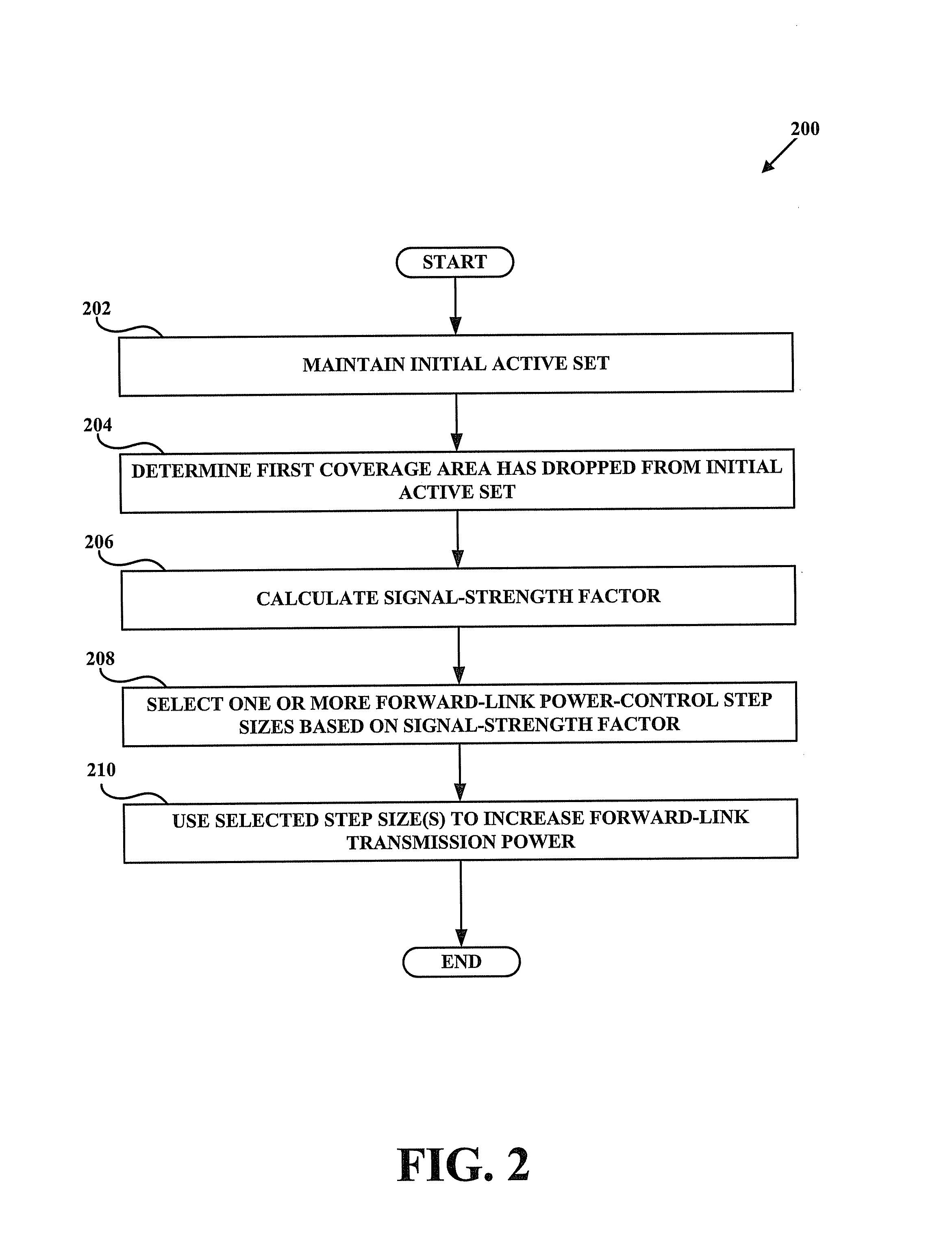

Selecting a power-control step size based on relative signal strength among signals in an active set

Methods and apparatus are provided for adjusting a forward-link power-control step size. An initial active set of coverage areas for a mobile station is maintained within which a first coverage area in the initial active set has a signal strength that is stronger than that of each of the other coverage areas in the initial active set. The first coverage area is determined to have dropped from the initial active set, resulting in a modified active set. In response, a signal-strength factor is calculated based on (a) a last non-zero signal-strength measurement of the first coverage area and (b) a second value. One or more forward-link power-control step sizes is selected based on at least the calculated factor. The one or more selected step sizes is used to increase the forward-link transmission power of at least one coverage area in the modified active set.

Owner:SPRINT SPECTRUM LLC

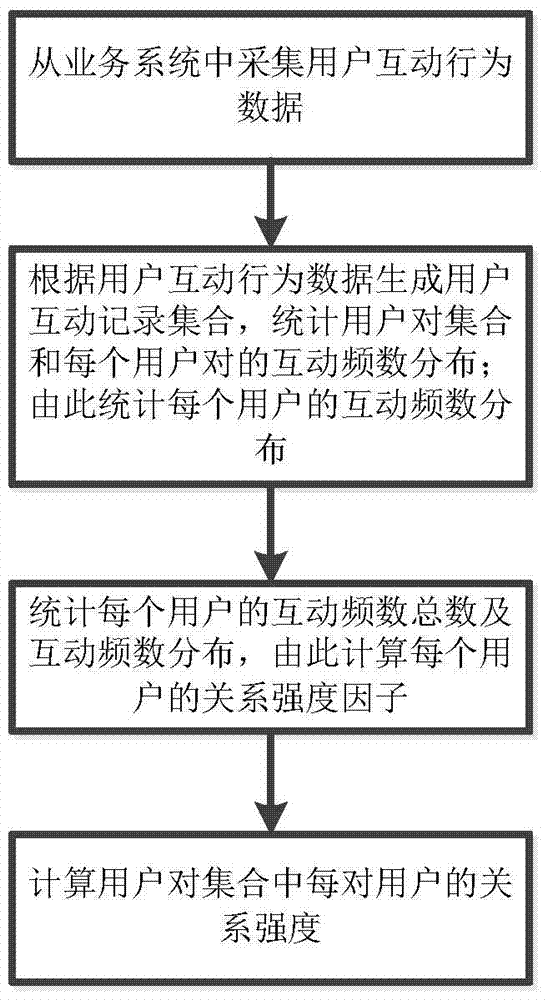

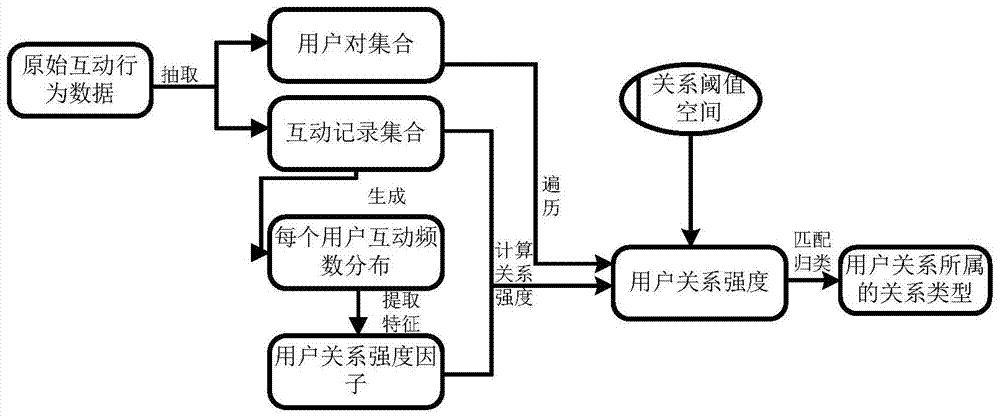

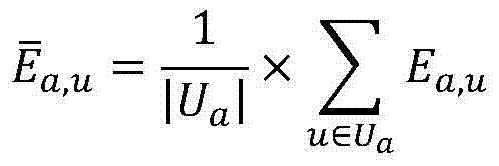

Calculation method for social network user relationship based on statistical characteristics

InactiveCN106959953ARelationship embodimentData processing applicationsRelational databasesHuman–computer interactionSocial web

The invention provides a calculation method for a social network user relationship based on statistical characteristics. The method comprises the steps that (1) user interaction behavior data is collected from a business system; (2) a user interaction record set is generated according to the user interaction behavior data, statistics is performed on interaction frequency distribution of a user pair set and each user pair, and accordingly statistics is performed on interaction frequency distribution of each user; (3) statistics is performed on total interaction frequency and interaction frequency distribution of each user, and relationship strength factors of each user are calculated; and (4) the relationship strength of each user pair in the user pair set is calculated. According to the method, the statistical characteristics of user interactions are utilized to quantize the user relationship, the quantized value can accurately and objectively reflect the relationship between users, and accordingly the type of the user relationship is judged.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

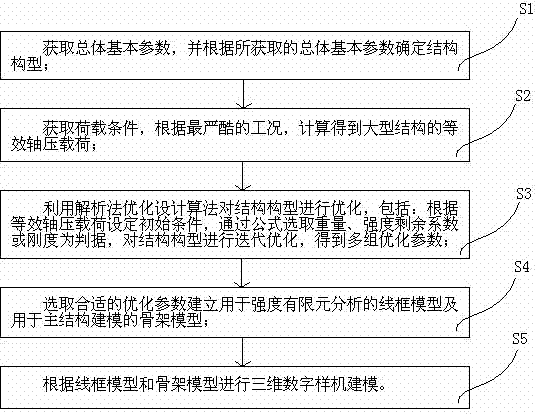

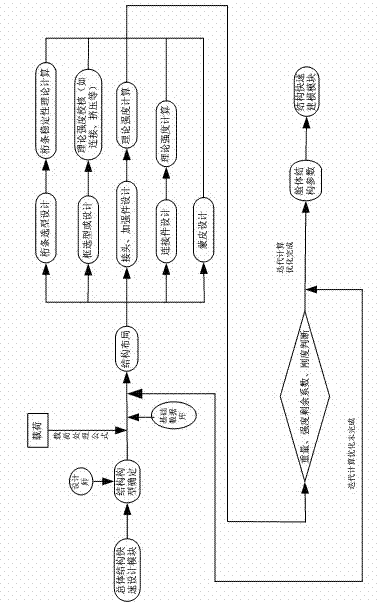

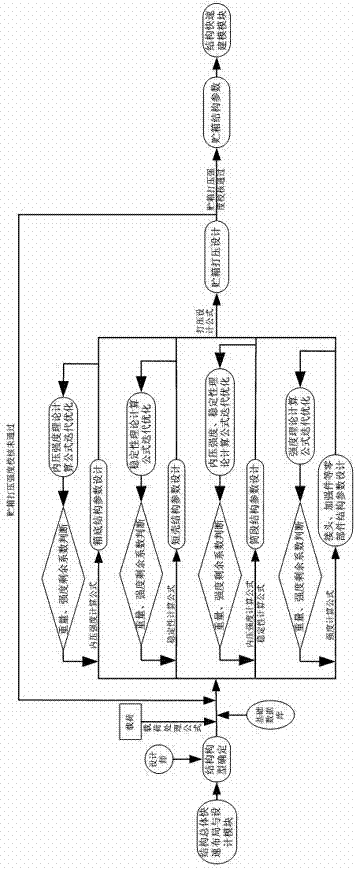

Quick design optimization method for large structure

InactiveCN103870634AImprove the efficiency of structural designSpecial data processing applicationsElement analysisUltimate tensile strength

The invention discloses a quick design optimization method for a large structure. The quick design optimization method comprises the following steps of 1, acquiring overall basic parameters and determining structure configuration according to the acquired overall basic parameters; 2, acquiring a loading condition, and calculating an equivalent axial load of the large structure according to the most harsh working condition; 3, optimizing the structure configuration by using an analytic method optimization design algorithm, namely setting an initial condition according to the equivalent axial load, selecting weight, a remaining strength factor or rigidity as a criterion through a formula, and performing iterative optimization on the structure configuration to obtain a plurality of groups of optimal parameters; 4, selecting proper optimal parameters to establish a wireframe model used for strength finite element analysis and a skeleton model for main structure modeling; 5, performing three-dimensional digital prototype modeling according to the wireframe model and the skeleton model.

Owner:SHANGHAI AEROSPACE SYST ENG INST

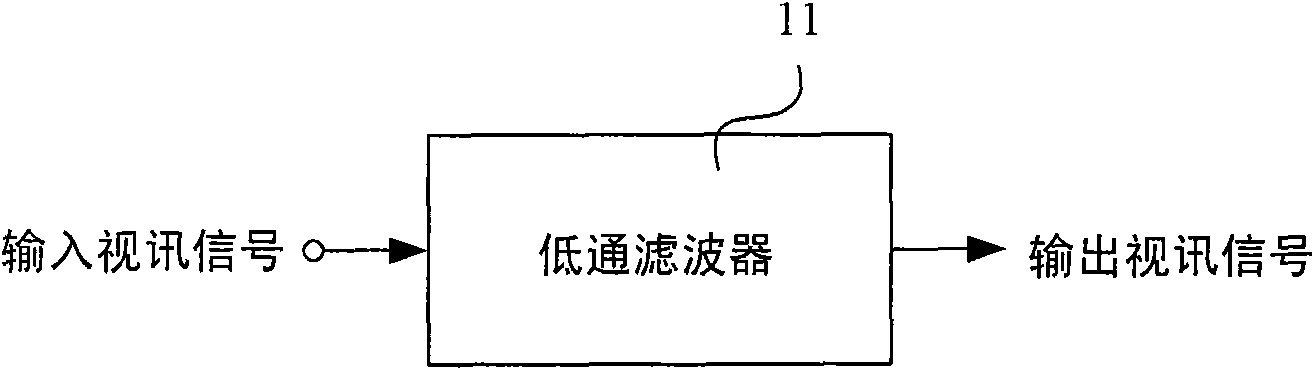

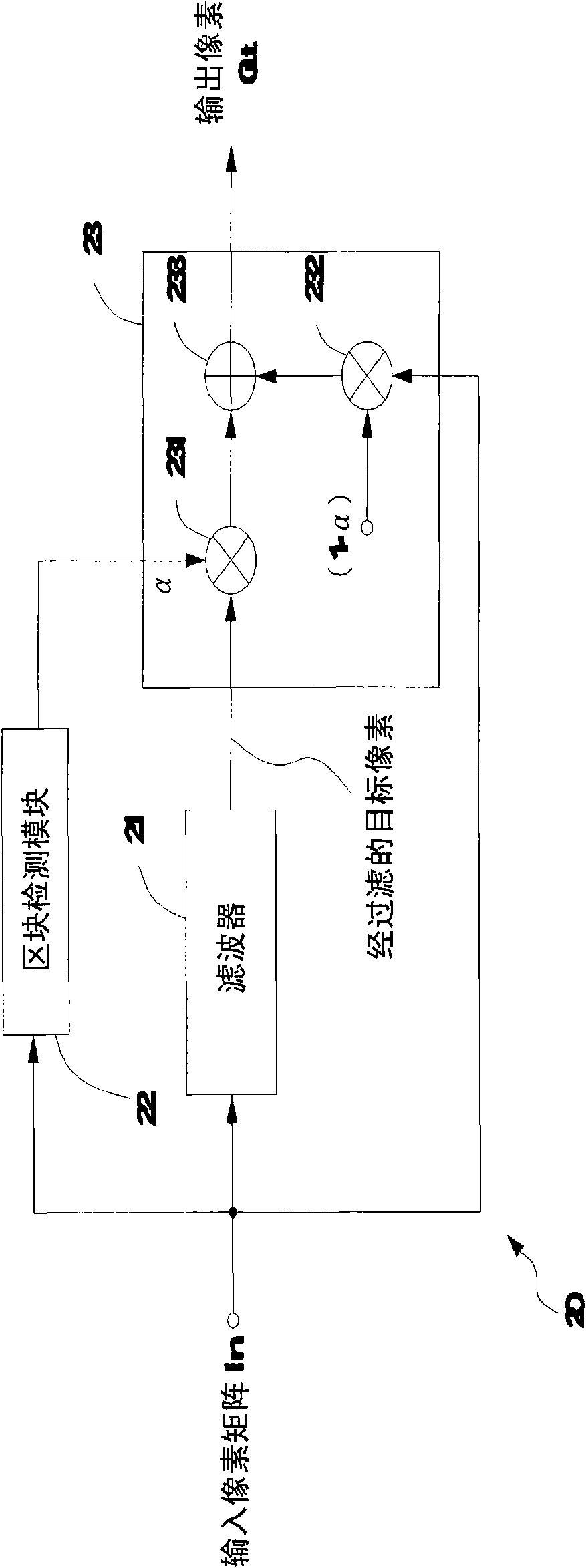

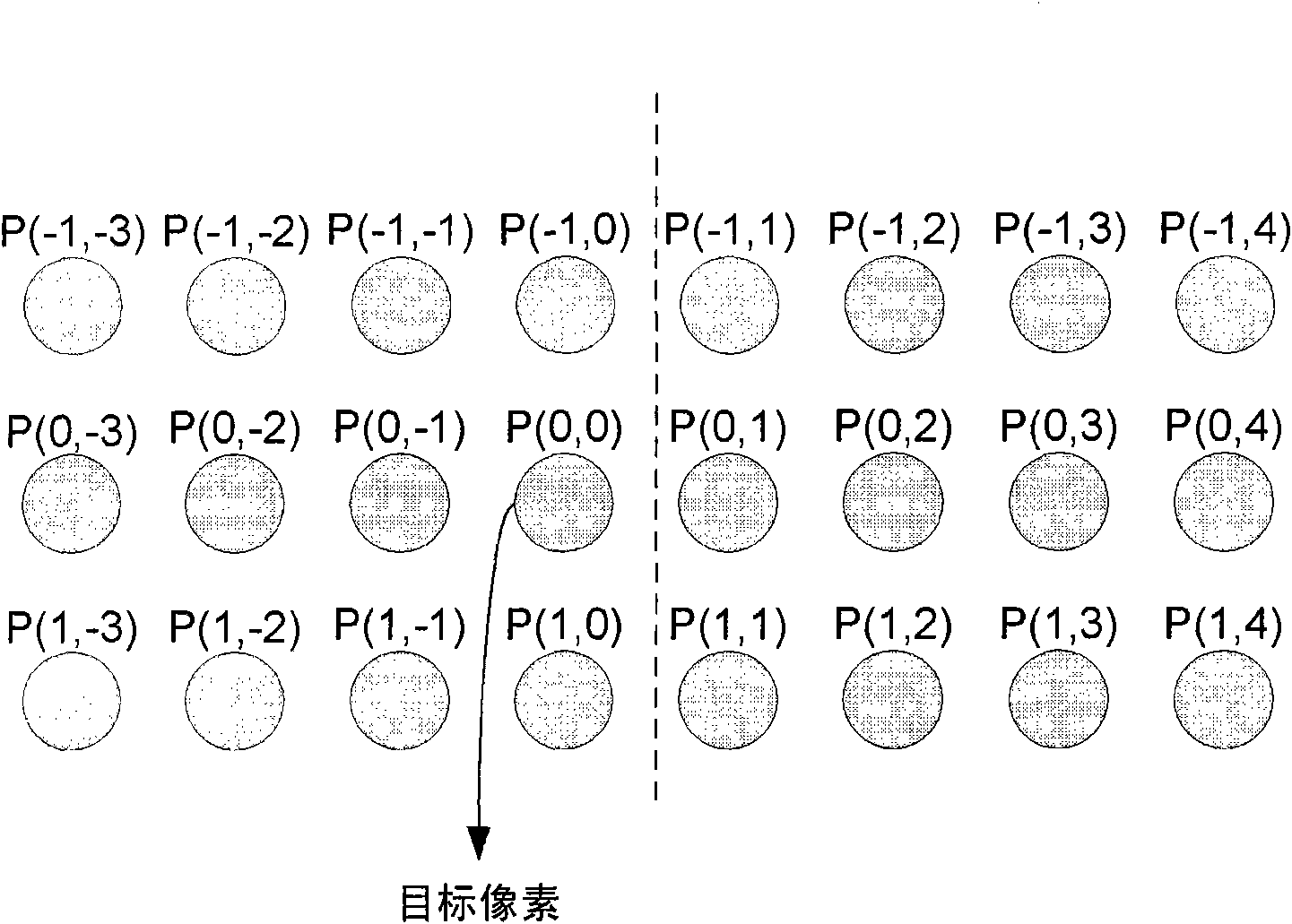

Block removing device and method

InactiveCN101964907ATelevision systemsDigital video signal modificationComputer visionUltimate tensile strength

The invention relates to a block removing device and a method. The block removing device comprises a filter, a block detecting module and a mixing unit, wherein the filter is used for receiving a target pixel in a pixel matrix to generate a filtered target pixel; the block detecting module is used for generating a block removing strength factor according to the pixel matrix; and the mixing unit is used for receiving the target pixels and the filtered target pixel and mixing the target pixels and the filtered target pixel to generate an output pixel according to the block removing strength factor.

Owner:MSTAR SOFTWARE R&D (SHENZHEN) LTD +1

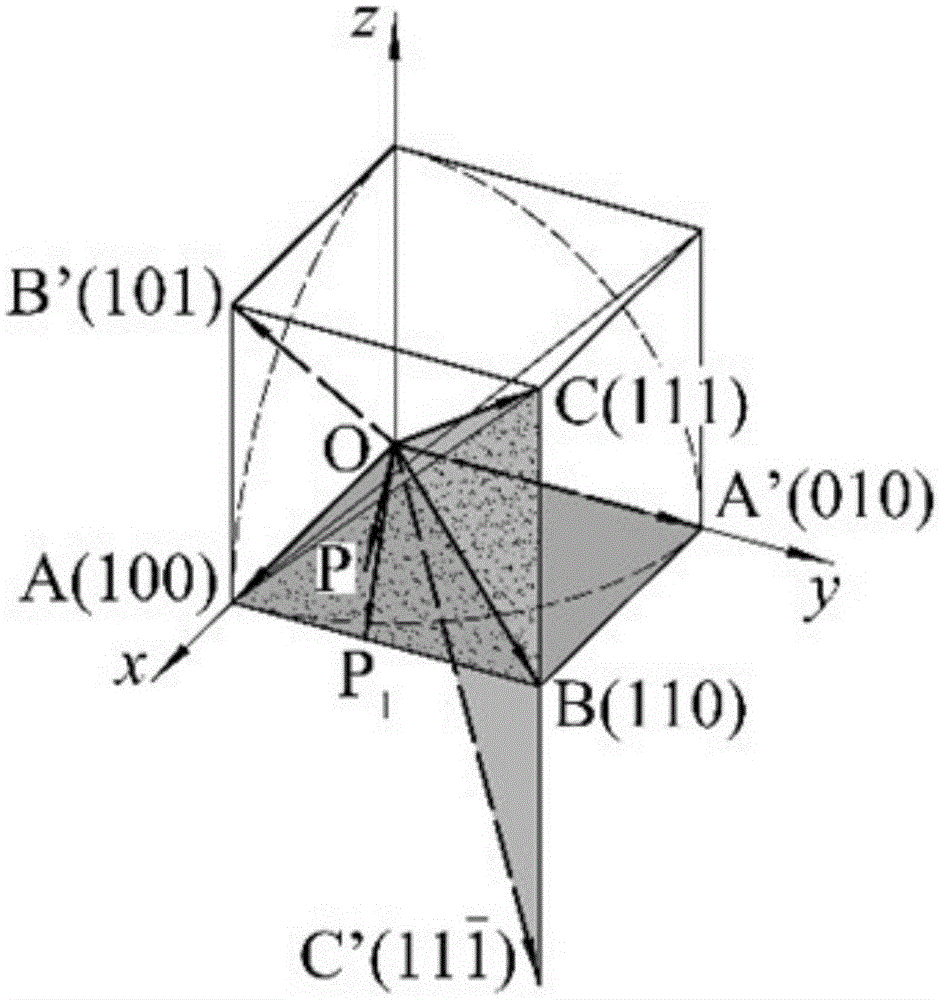

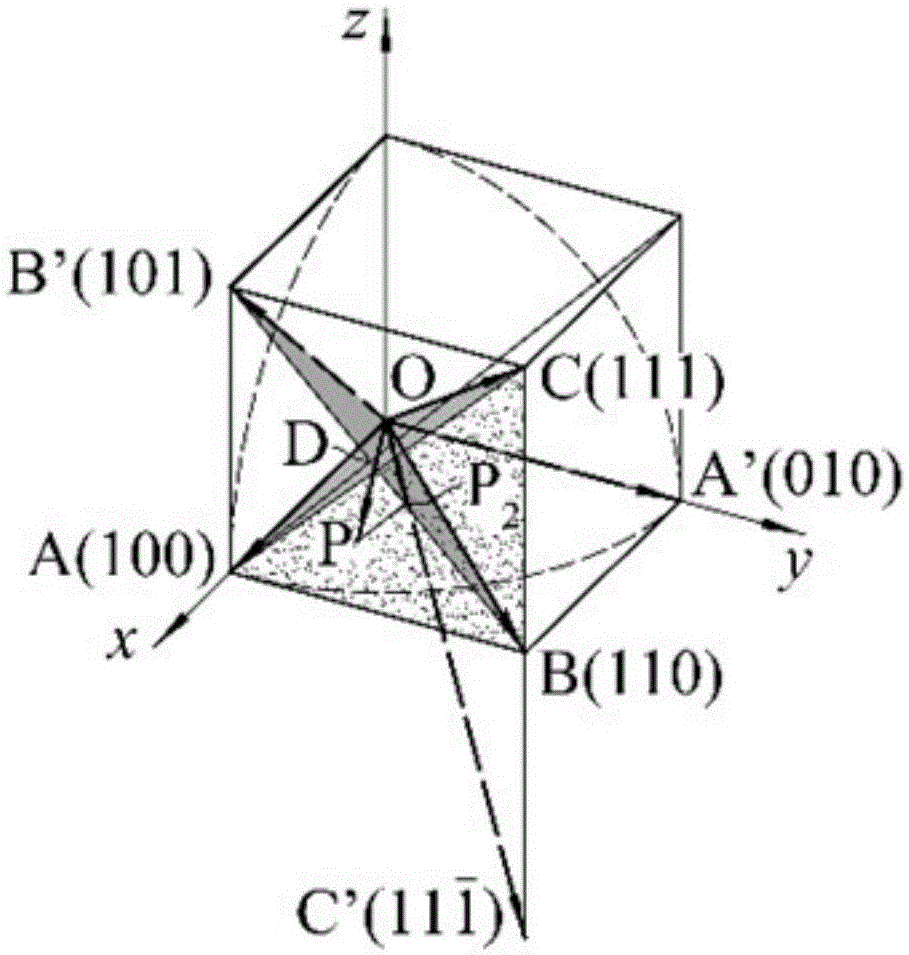

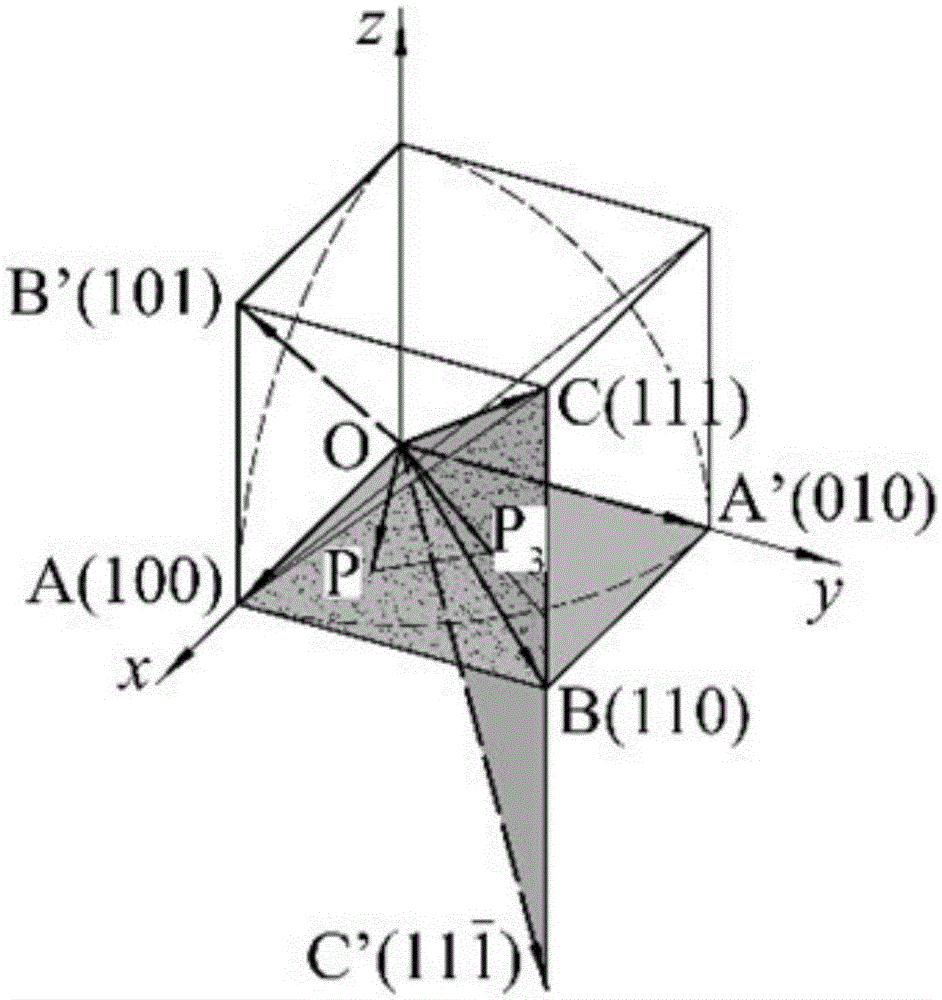

Diamond Berkovich indenter design method based on strength factors

ActiveCN105158097AHigh nanometer hardness measurement accuracyImprove wear resistanceInvestigating material hardnessMicro nanoManufacturing technology

A diamond Berkovich indenter design method based on strength factors comprises steps as follows: I, the dynamic microscopic tensile strength of three side surfaces of a diamond Berkovich indenter is assumed as weighed stacking of characters of three typical crystal plane families (100)(110)(111), and dynamic microscopic strength of any crystal plane and any crystal orientation of a diamond crystal is derived; II, the diamond Berkovich indenter with different crystal plane combinations is designed, and the dynamic microscopic tensile strength of each side surface is calculated; III, calculation and evaluation methods of the grinding strength factor and the anti-wear strength factor are put forward, and differences of radiuses of blunt rounds obtained by grinding an edge and a point of the indenter and the wear resistance of the indenter in the use process are quantitatively evaluated according to the grinding strength factors and the wear strength factors, obtained through comparison and calculation, of the edge and the point of the diamond Berkovich indenter. The diamond Berkovich indenter design method has important significance in breaking through technological monopoly of foreign countries, improving the measurement precision of the micro-nano scale mechanical property of a material and promoting development of manufacturing techniques of domestic high-precision diamond Berkovich indenters.

Owner:HARBIN INST OF TECH

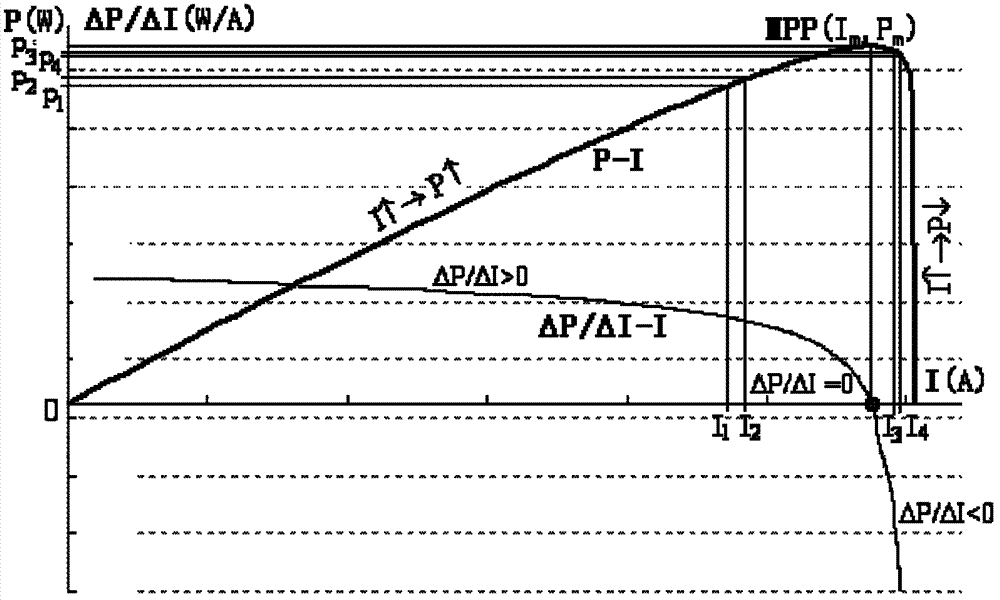

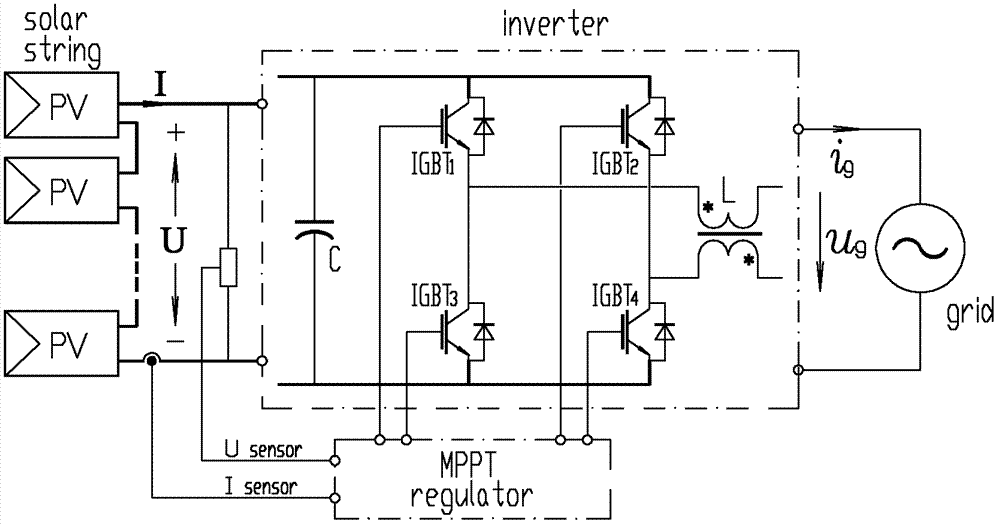

Self-regulation tracking method for tracking maximum power point of photovoltaic inverter

InactiveCN102904474AHigh precisionGood dynamic responseAc-dc conversionPhotovoltaic energy generationAlternating currentMaximum power point tracking

The invention discloses a self-regulation tracking method used for a tracking maximum power point of a photovoltaic inverter. The self-regulation tracking method is characterized in that a P-I variable rate dP / dI is utilized as a regulated variable to construct an inversion current regulation setting control law general expression, the inversion current regulation setting control law adopts a function concrete form variance time domain expression that Io[k]=Io[k-1]+delta Io[k], wherein k is the ordinal number of an alternating current sine wave period or the ordinal number of a pulse width modulation period, and Io is a set current; and delta P is output power differentiation or variation of a photovoltaic cell or an assembly bunch of discrete time, delta I is output power differentiation or variation of the photovoltaic cell or an assembly bunch of discrete time, and lambda k is a strength factor of a variable rate feedback action. The self-regulation tracking method provided by the invention can be used for tracking the maximum power point of the high performance photovoltaic inverter which performs adjustment according to a completely natural law, and the tracking property of the maximum power point is further improved because of a P-I variable rate asymmetry characteristic.

Owner:上海伊阿宋文化科技有限公司 +1

Method and device for three-point bending mechanical property test of small-sized sheet sample

InactiveCN100359317CResearch binding strengthAvoid conducting electricityMaterial strength using steady bending forcesControl mannerEngineering

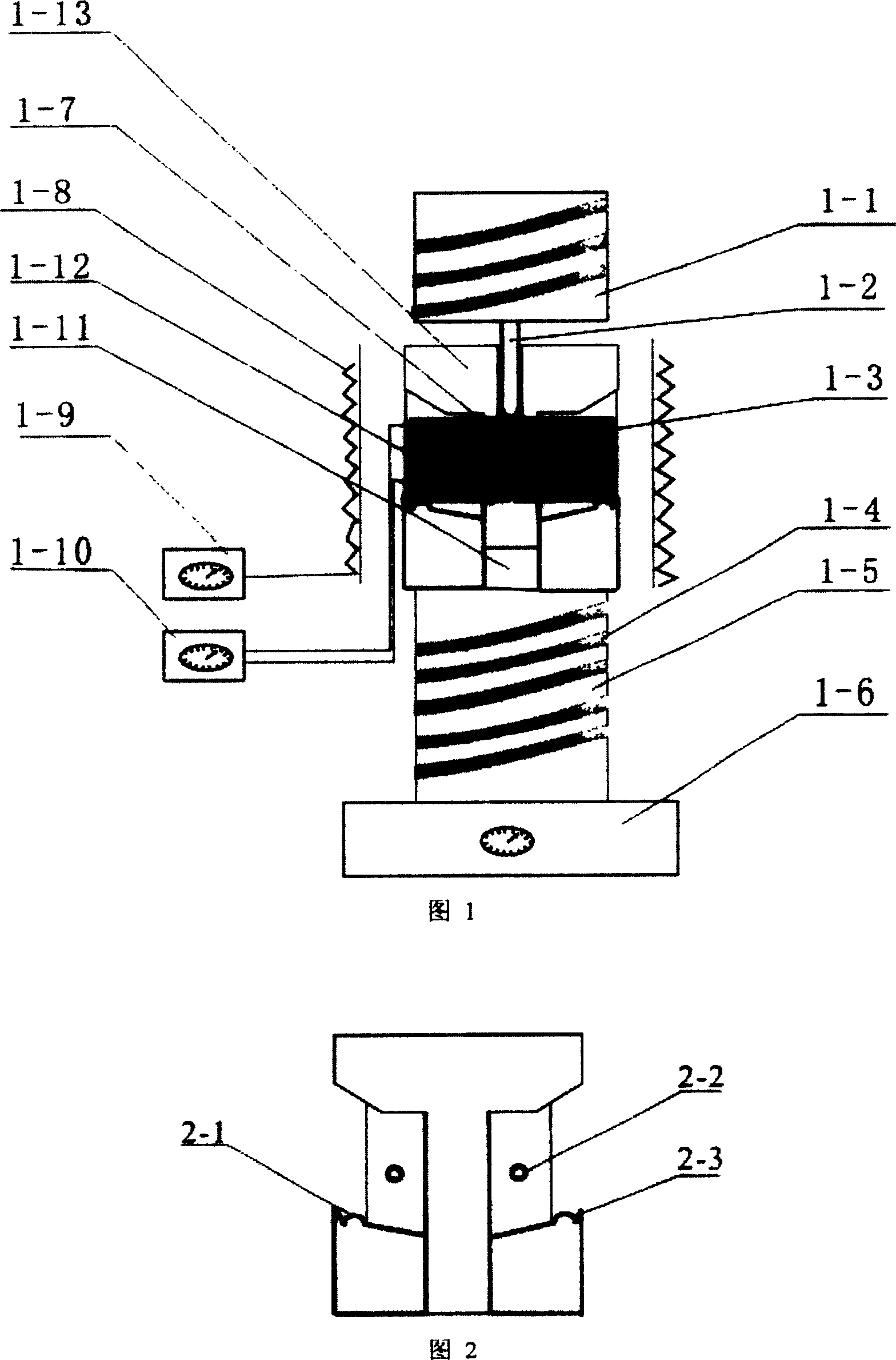

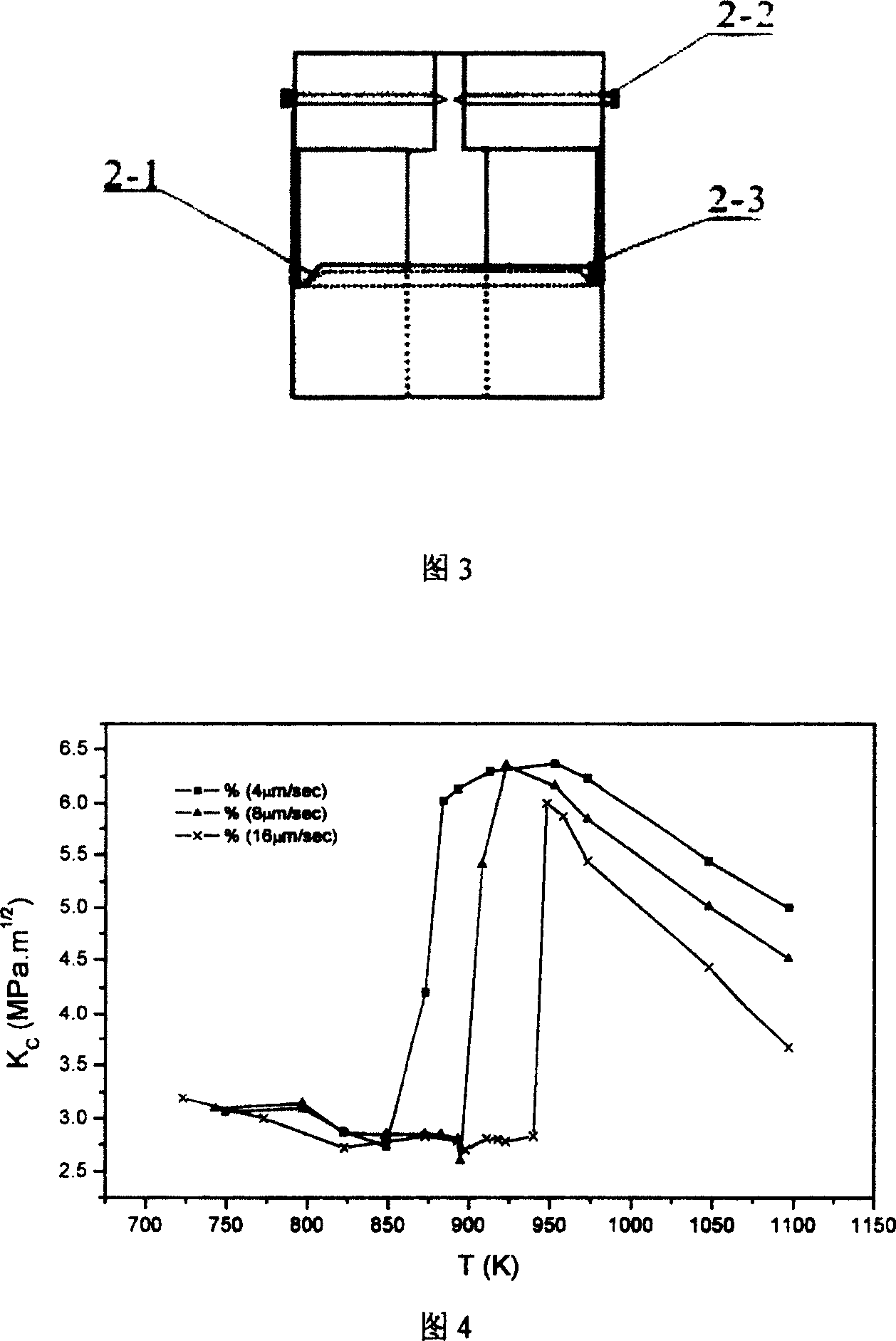

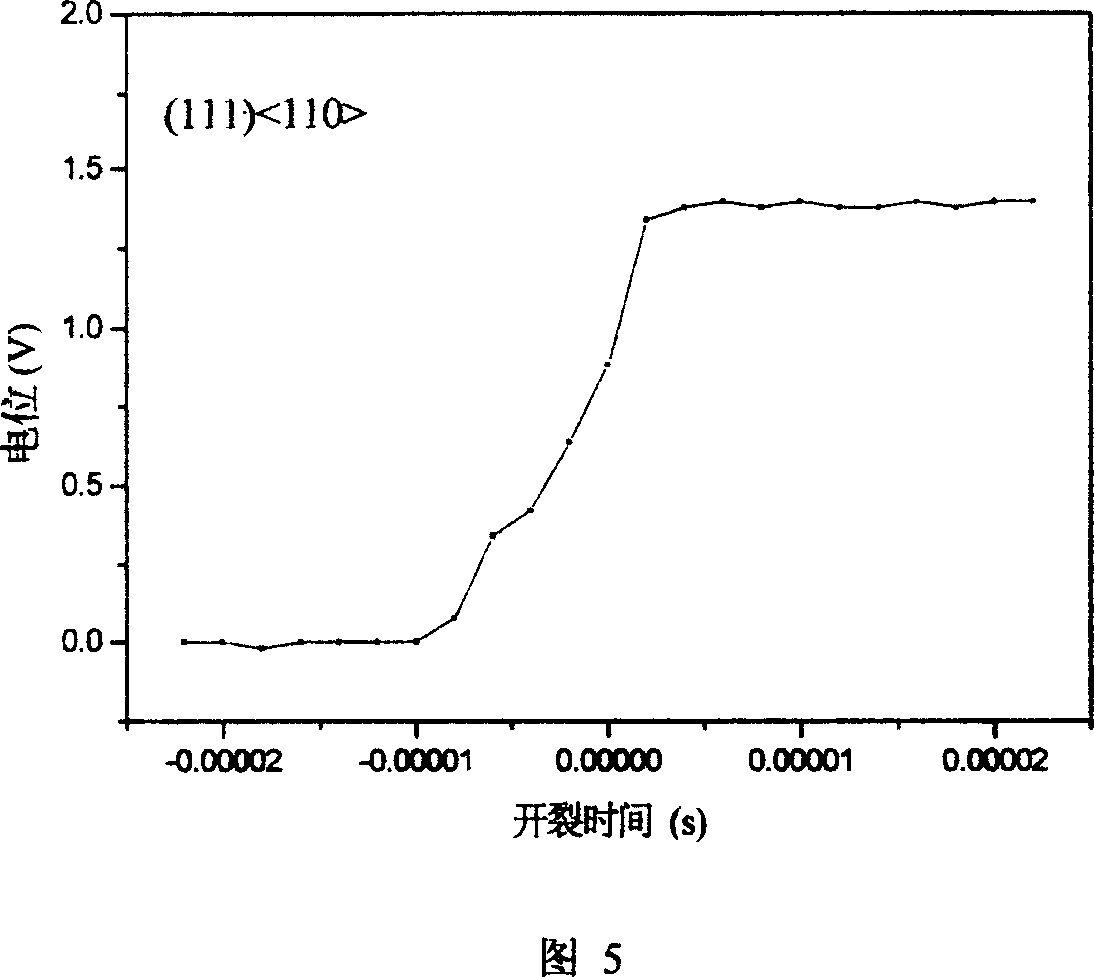

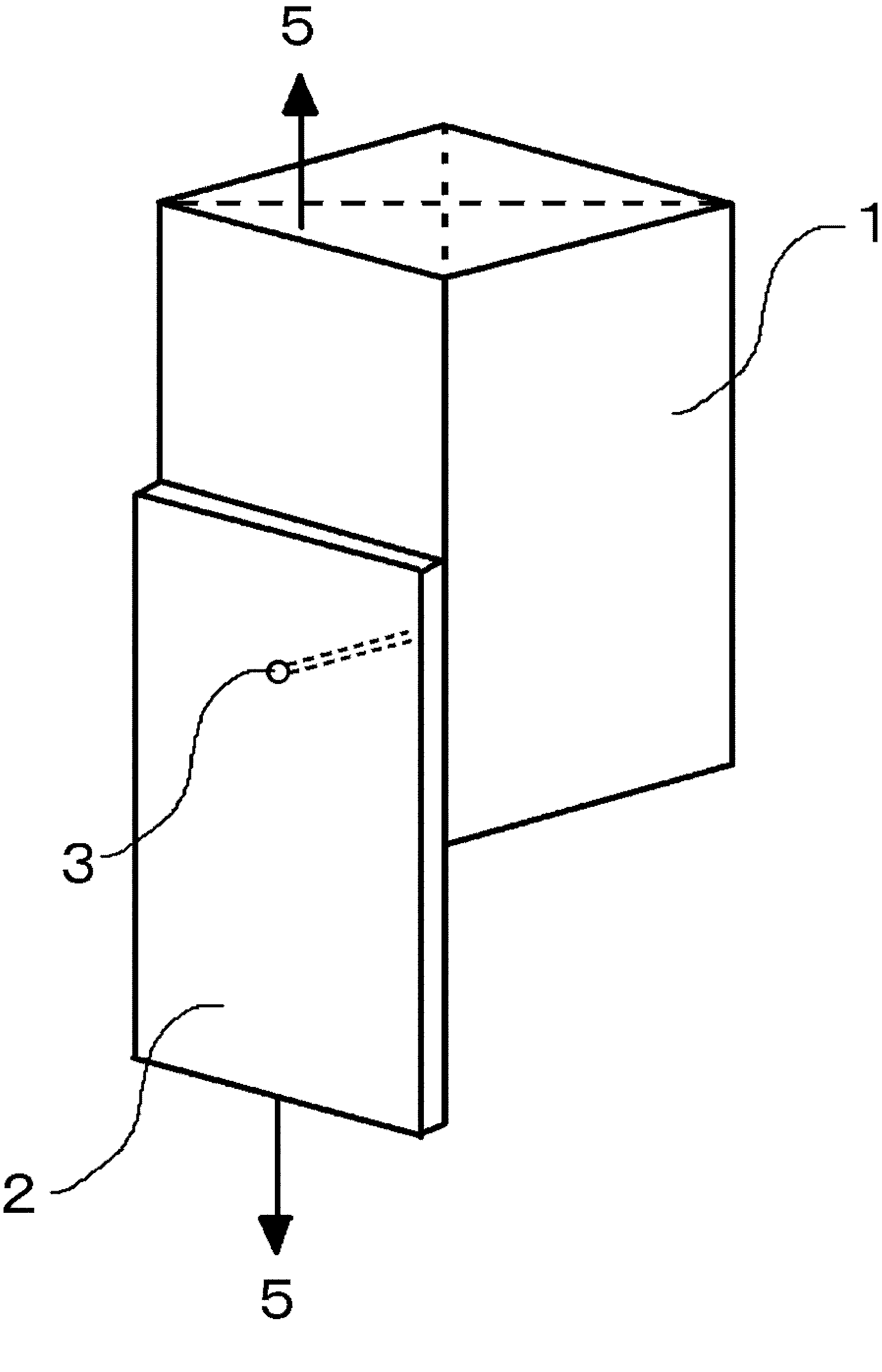

The invention relates to a method for testing the curvature physical property at three points of small sheet sample, wherein said method comprises: arranging preformed sheet sample with micro cracked surface deposit on the sample table; using force control method, to contact the compress head with the upper surface of sample; entering into testing conditions, to avoid high load at contact moment; connecting two electrodes of said sheet sample with voltage collecting system, and increasing load stepped, recording the maximum load, and detecting the voltage change at the crack moment of said micro crack, and converting the voltage and time data into the relationship between speed and time. Said device is formed by three-point curvature sample table, sample table support system, cooling system, heating system, loading system, and testing system. The invention can directly mount small sheet sample on the tester, to process three-point curvature test and process critical stress strength factor test of preformed micro cracked sample.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

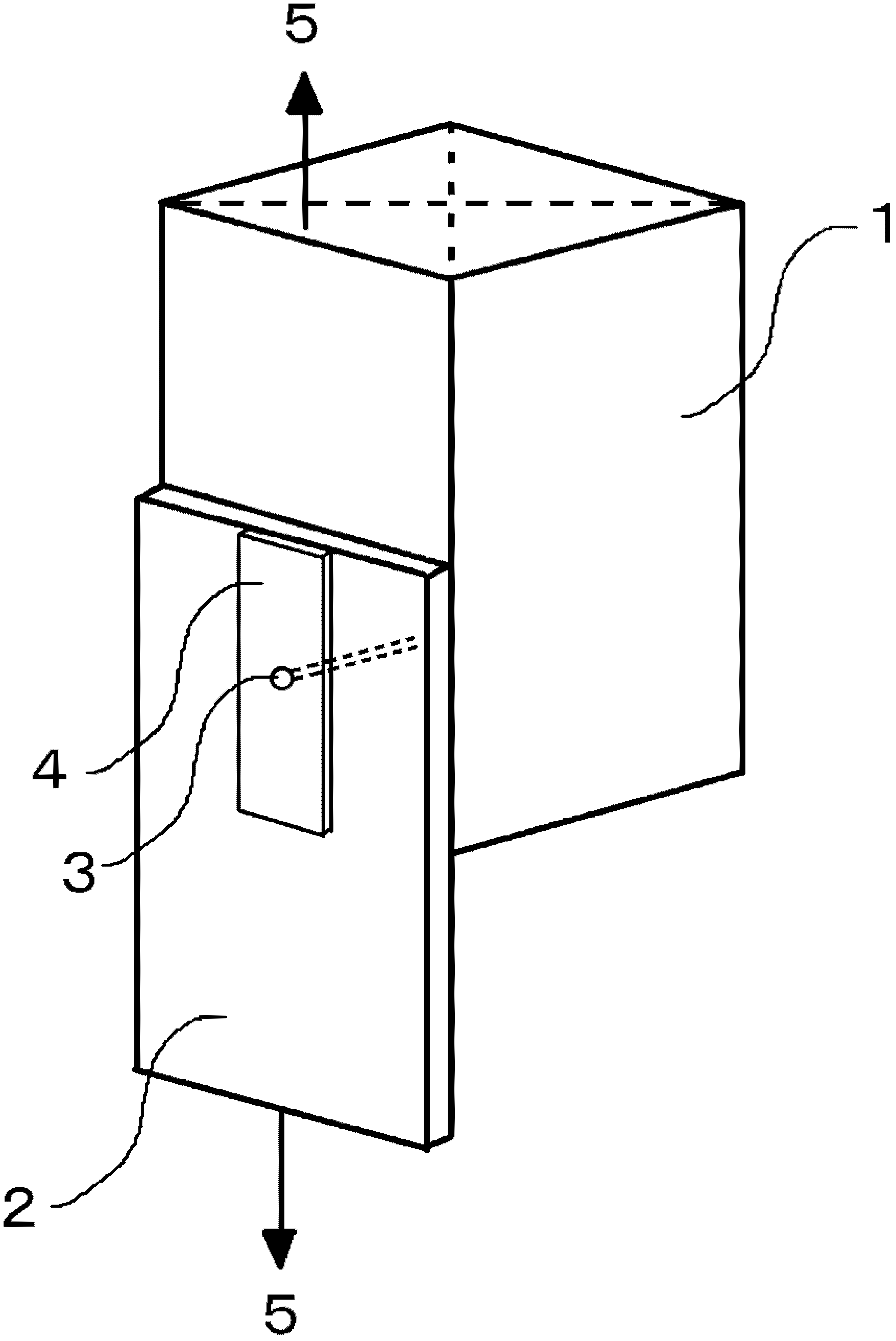

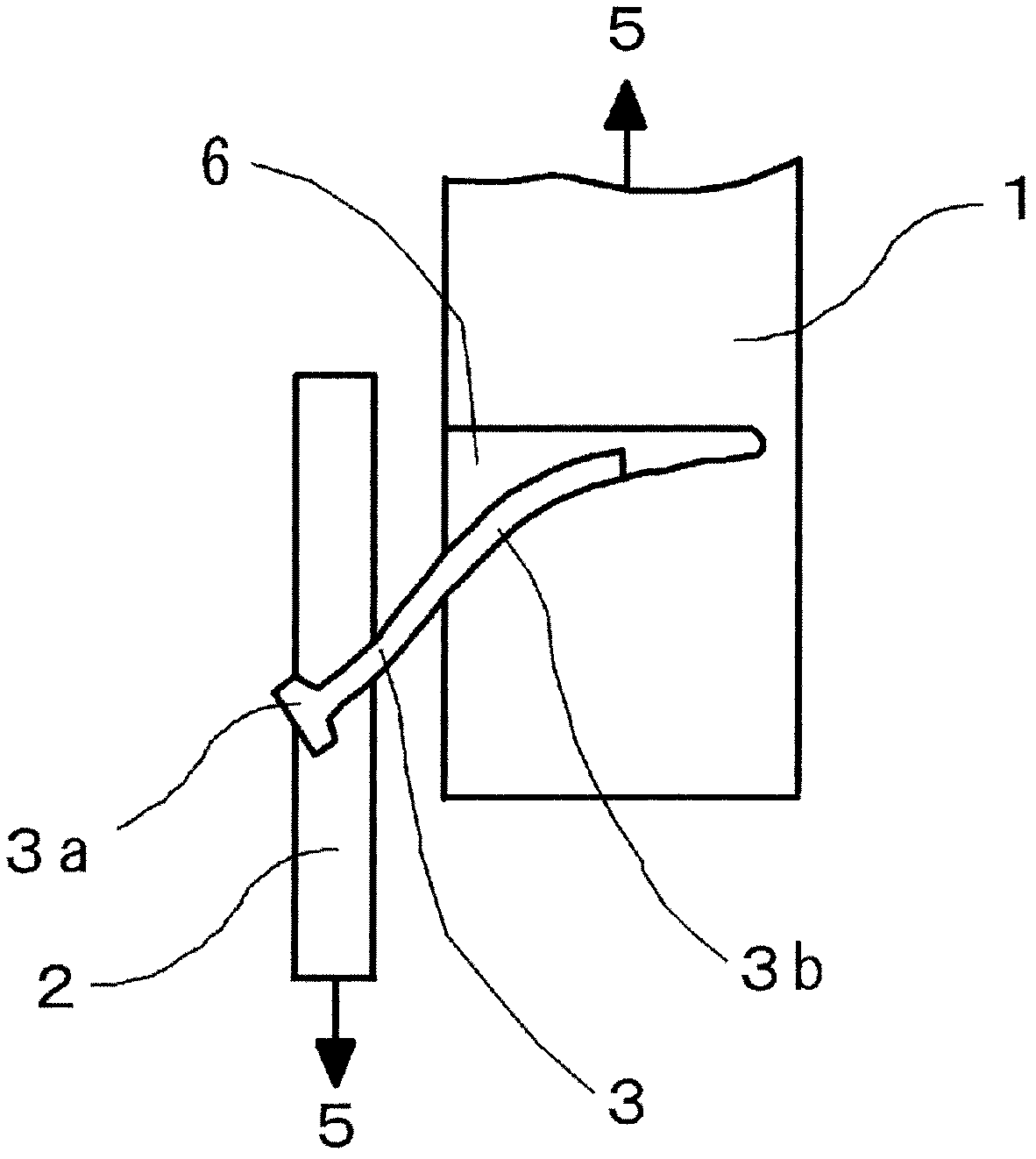

Installation structure of base of exterior wall

InactiveCN102691359AHigh wall strength multiplierIncrease freedomWallsBuilding repairsStructural engineeringDegrees of freedom

In external renovation of a wooden framework house in which a bearing face material is used as an exterior wall base member, is capable of partly increasing the wall strength factor, thereby providing a high degree of freedom of seismic design and, furthermore, facilitating installation of an exterior material such as ceramic siding after seismic reinforcement. A reinforcement member for preventing punching shear is interposed. Between a bearing face material of a wall that is required to have a high wall strength factor by a seismic design and a nailhead of a nail for fixing the bearing face material to a structural member.

Owner:NICHIHA CORP

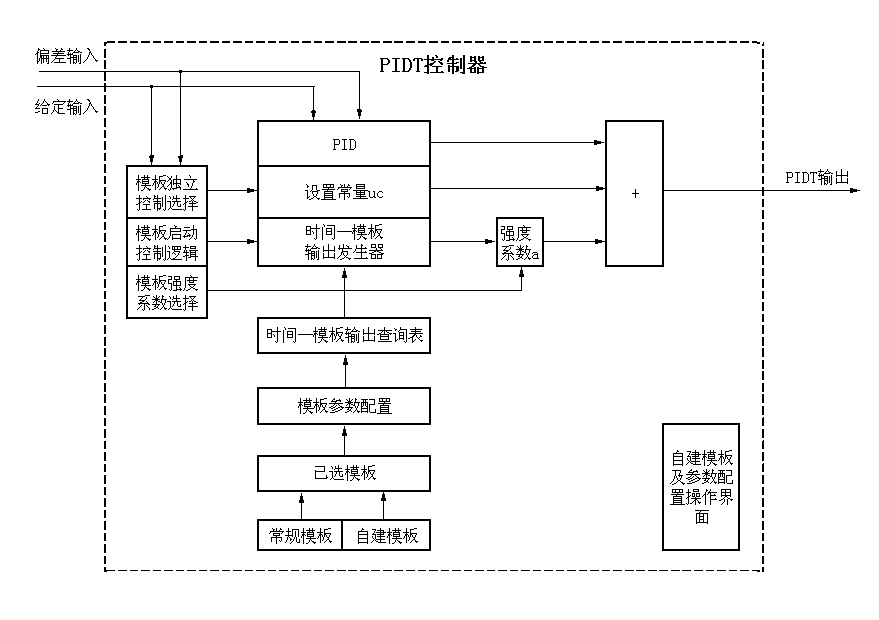

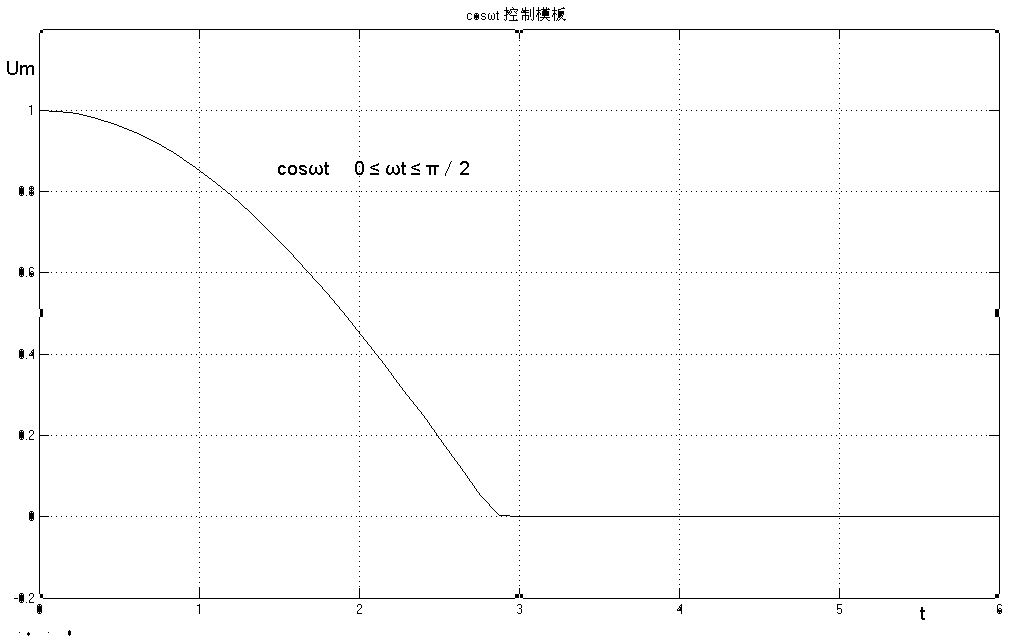

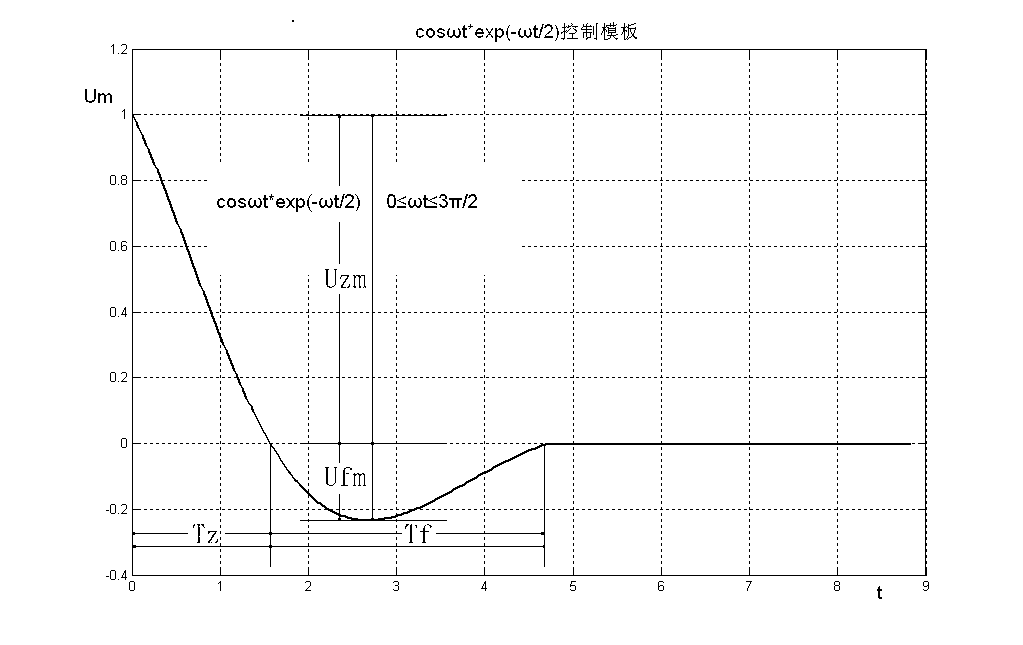

PIDT (proportion integration differentiation template) control technology and method with optional control template

InactiveCN102736514ASimple structureImprove performanceControllers with particular characteristicsProportion integration differentiationControl system

The invention discloses a PIDT (proportion integration differentiation template) control technology and method with an optional control template. The PIDT control technology comprises PID (proportion integration differentiation) control and template control. By the template control, the dynamic response performance of a system is improved. In the process of the PID control, a set of control parameters are difficult to adapt to a starting process when a large deviation occurs, and to a work process when a small deviation occurs at the same time, because the contradiction between a response speed and a overshoot quantity exists. The main method of the PIDT control technology comprises the following steps of: in the process of controlling the system to start (the deviation is relatively large), using the template (T) to independently control or using the PID and the template (T) to jointly control, wherein the controlled quantity of the template is determined by the selected template and the template control strength factor; in the process of working, when the deviation is small, using the PID control, when the deviation is more than a certain value, invoking the template control; and when the deviations are different, selecting different template control coefficients, wherein the action time of the template control at every time is limited. In the PIDT controller with the optional control template, not only a built control template is for use, but also the template can be individually built according to the control rule.

Owner:杜飞明 +1

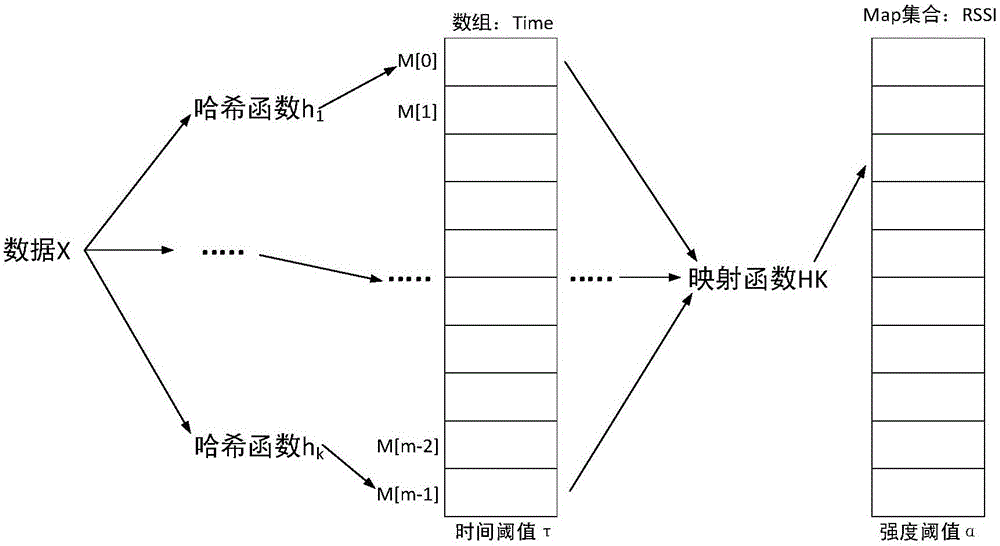

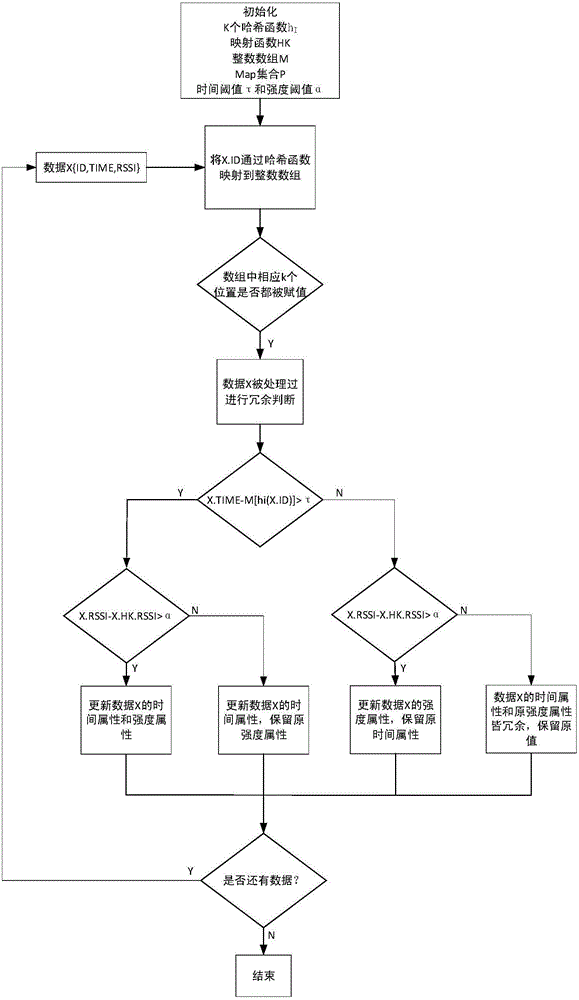

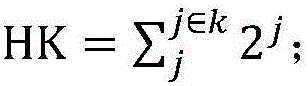

R-TBF-based RFID redundant data cleaning strategy

ActiveCN106844561ARestore authenticityEfficient use ofSpecial data processing applicationsHash functionArray data structure

The invention discloses an R-TBF-based RFID redundant data cleaning strategy. Firstly, a filter is initialized, wherein an integer array M used for storing data time attributes, a Hash function, a mapping function, a Map set P, a time threshold tau and an intensity threshold alpha are included; then, the redundancy of current data X is judged, and according to the {ID, TIME, RSSI} format transmission and cleaning rule, redundant data cleaning is conducted; finally, processing of the current data X is completed. According to the R-TBF-based RFID redundant data cleaning strategy, the two constraints, namely the time factor and the strength factor, are taken into consideration so as to conduct corresponding cleaning on the data, through primary timestamp cleaning and secondary intensity value cleaning, the cleaning effect is improved, the data quality is improved, the data authenticity is restored to the largest extent, and a strong guarantee is provided for the effective utilization of subsequent data.

Owner:重庆大学溧阳智慧城市研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com