Preprocessing method for lignocellulose raw material

A lignocellulose and pretreatment technology, applied in the field of agricultural and forestry biomass resource utilization, can solve the problems of high cost, waste of resources, and high price of cellulase, achieve high hydrolysis rate and recovery rate, speed up the industrialization process, and improve the The effect of development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

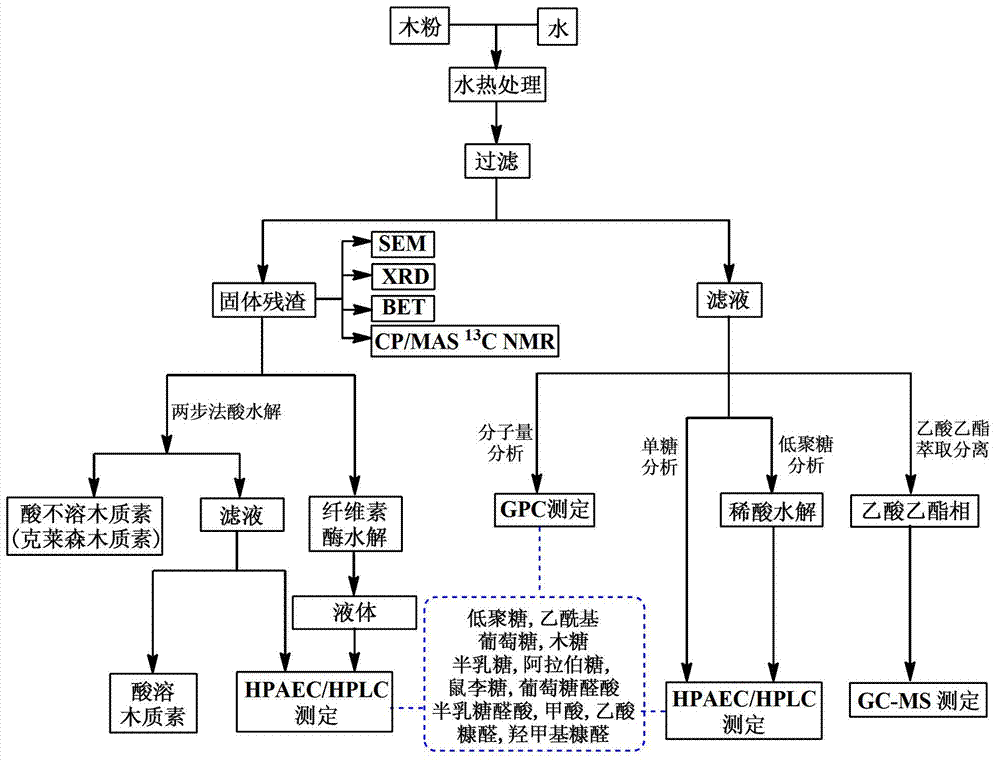

Method used

Image

Examples

Embodiment 1

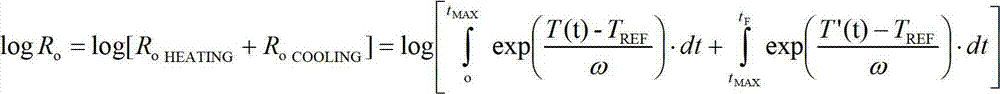

[0033] (1) Fully mix the lignocellulosic raw material (shrub red willow) crushed to 40-60 mesh with water at a mass ratio of 1:10, let it stand for 4 hours, then transfer the mixture to a high-pressure reactor, Under protection, the autoclave was heated from room temperature to 180°C, corresponding to an intensity factor of 2.40 and a pressure of 1.19MPa. After rising to the predetermined maximum temperature (180°C), immediately pass condensed water to quickly lower the reactor to room temperature.

[0034] (2) The product obtained in step (1) is subjected to solid-liquid separation to obtain a solid-phase product and a liquid-phase product: the solid product is washed with hot water, dried and stored, and the liquid-phase product is stored in a 4°C refrigerator for later use.

[0035] (3) The solid-phase product obtained in step (2) was hydrolyzed by cellulase for 96 hours, and the yield of cellulase hydrolysis measured by high-performance anion exchange chromatography (HPAEC...

Embodiment 2

[0038] (1) Fully mix the lignocellulosic raw material (shrub red willow) crushed to 40-60 mesh with water at a mass ratio of 1:10, let it stand for 4 hours, and then transfer the mixture to a high-pressure reactor. Under the protection of nitrogen, heat the autoclave from room temperature to 190°C, the corresponding intensity factor is 2.70, and the pressure is 1.34MPa. When it rises to the predetermined maximum temperature (190°C), immediately pass condensed water to quickly cool the autoclave to room temperature .

[0039] (2) The product obtained in step (1) is subjected to solid-liquid separation to obtain a solid-phase product and a liquid-phase product: the solid product is washed with hot water, dried and stored, and the liquid-phase product is stored in a 4°C refrigerator for later use.

[0040] (3) The solid-phase product obtained in step (2) was hydrolyzed by cellulase for 96 hours, and its cellulase hydrolysis rate was 47.3% based on glucose conversion determined by...

Embodiment 3

[0043] (1) Fully mix the lignocellulosic raw material (shrub red willow) crushed to 40-60 mesh with water at a mass ratio of 1:10, let it stand for 4 hours, then transfer the mixture to a high-pressure reactor, Under protection, the autoclave is heated from room temperature to 200°C, corresponding to an intensity factor of 2.98 and a pressure of 1.63MPa. After rising to the predetermined maximum temperature (200°C), immediately pass condensed water to quickly lower the reactor to room temperature.

[0044] (2) The product obtained in step (1) is subjected to solid-liquid separation to obtain a solid-phase product and a liquid-phase product: the solid product is washed with hot water, dried and stored, and the liquid-phase product is stored in a 4°C refrigerator for later use.

[0045] (3) The solid-phase product obtained in step (2) was hydrolyzed by cellulase for 96 hours, and the cellulase hydrolysis rate of glucose measured by HPAEC-PAD was 65.8%. And the specific surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com