Patents

Literature

724 results about "Paper mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

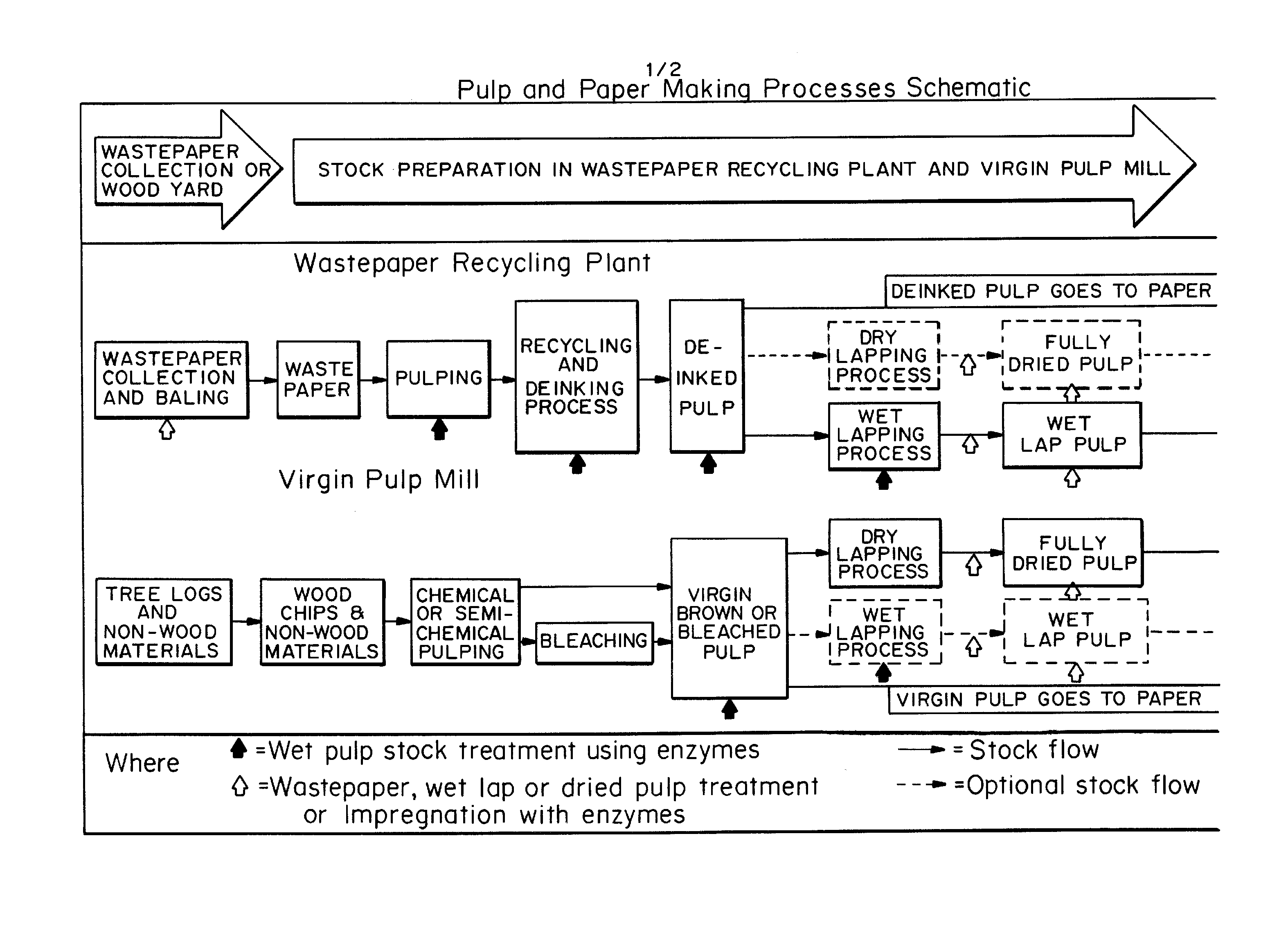

A paper mill is a factory devoted to making paper from vegetable fibres such as wood pulp, old rags and other ingredients. Prior to the invention and adoption of the Fourdrinier machine and other types of paper machine that use an endless belt, all paper in a paper mill was made by hand, one sheet at a time, by specialized laborers.

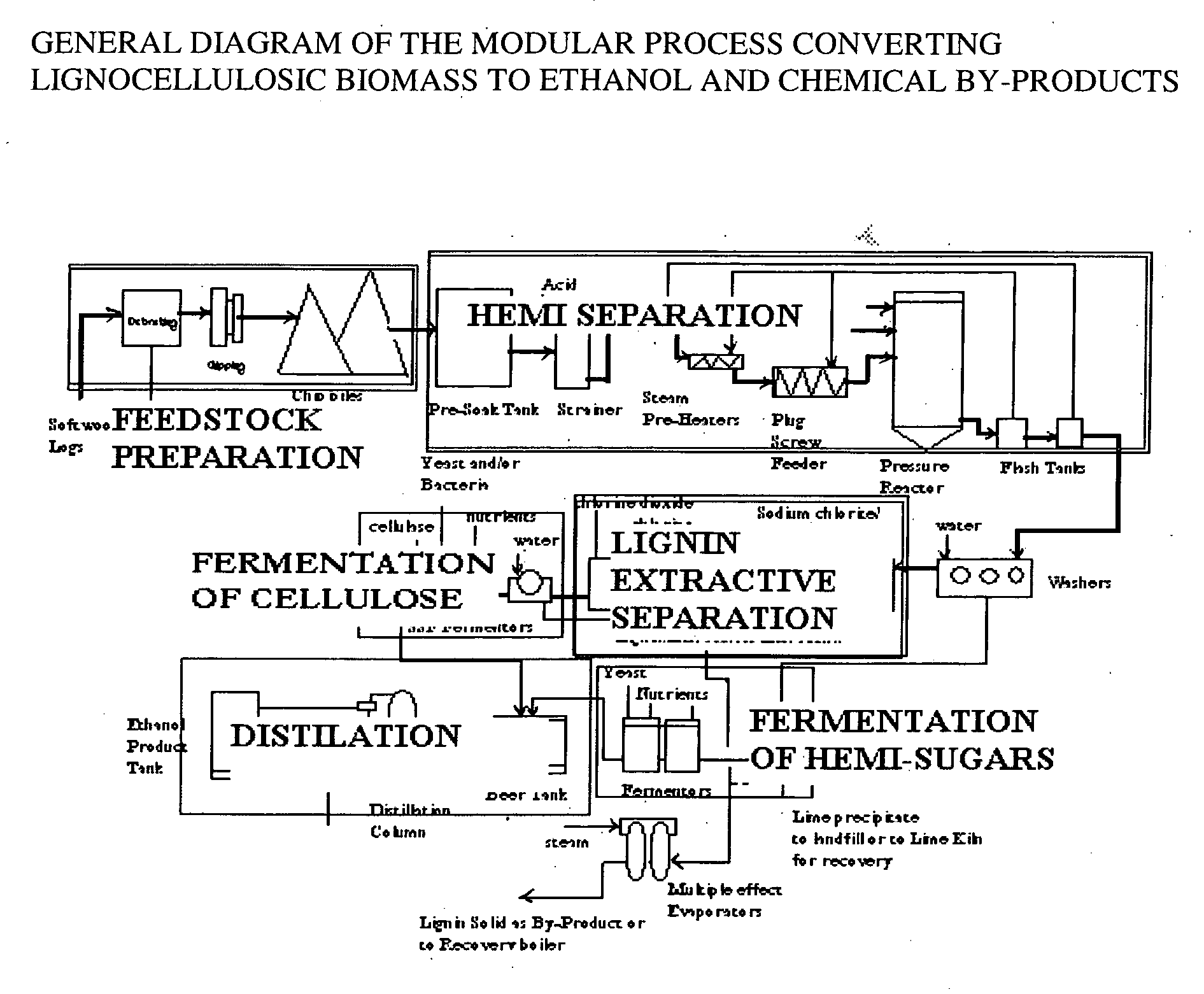

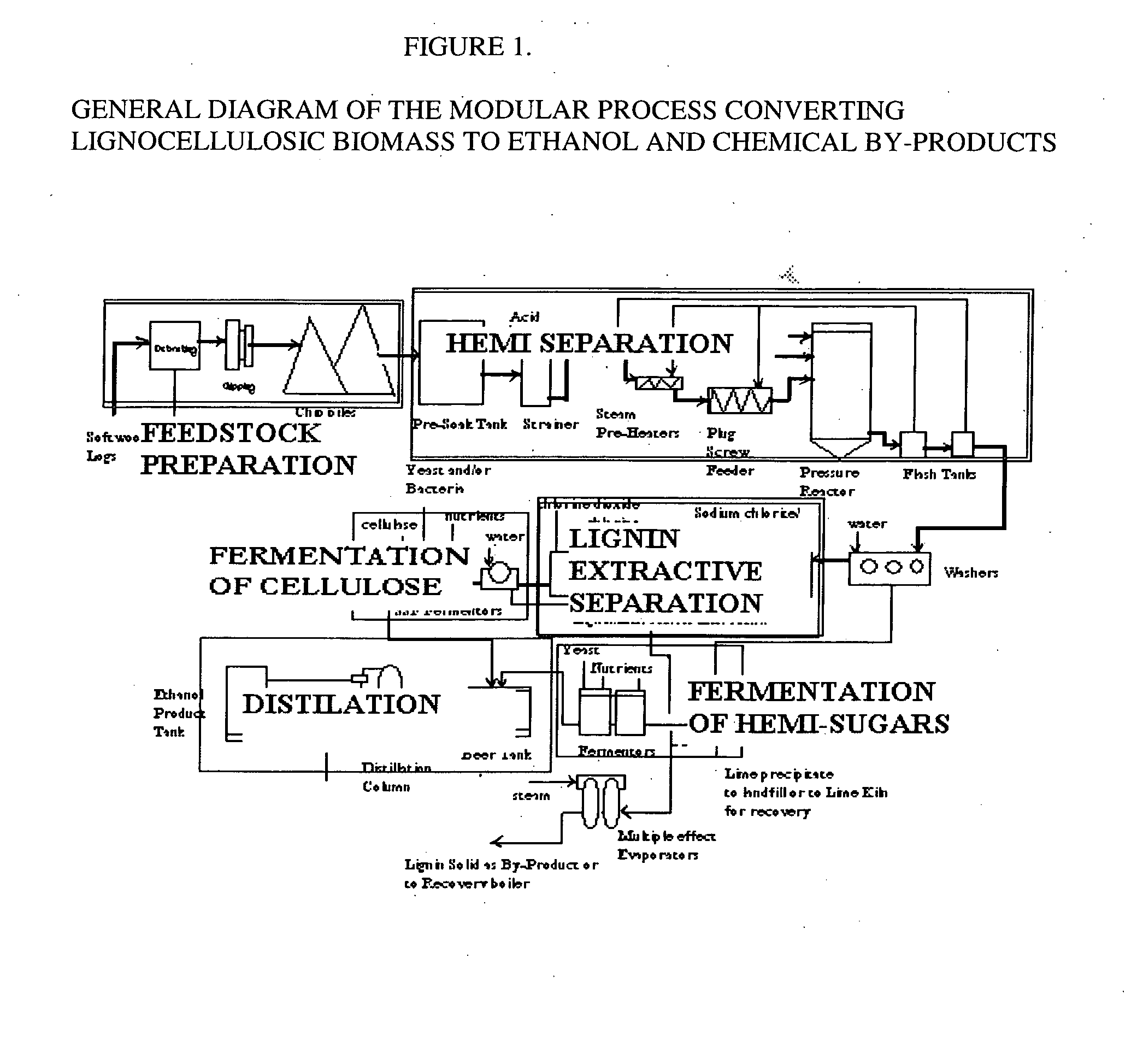

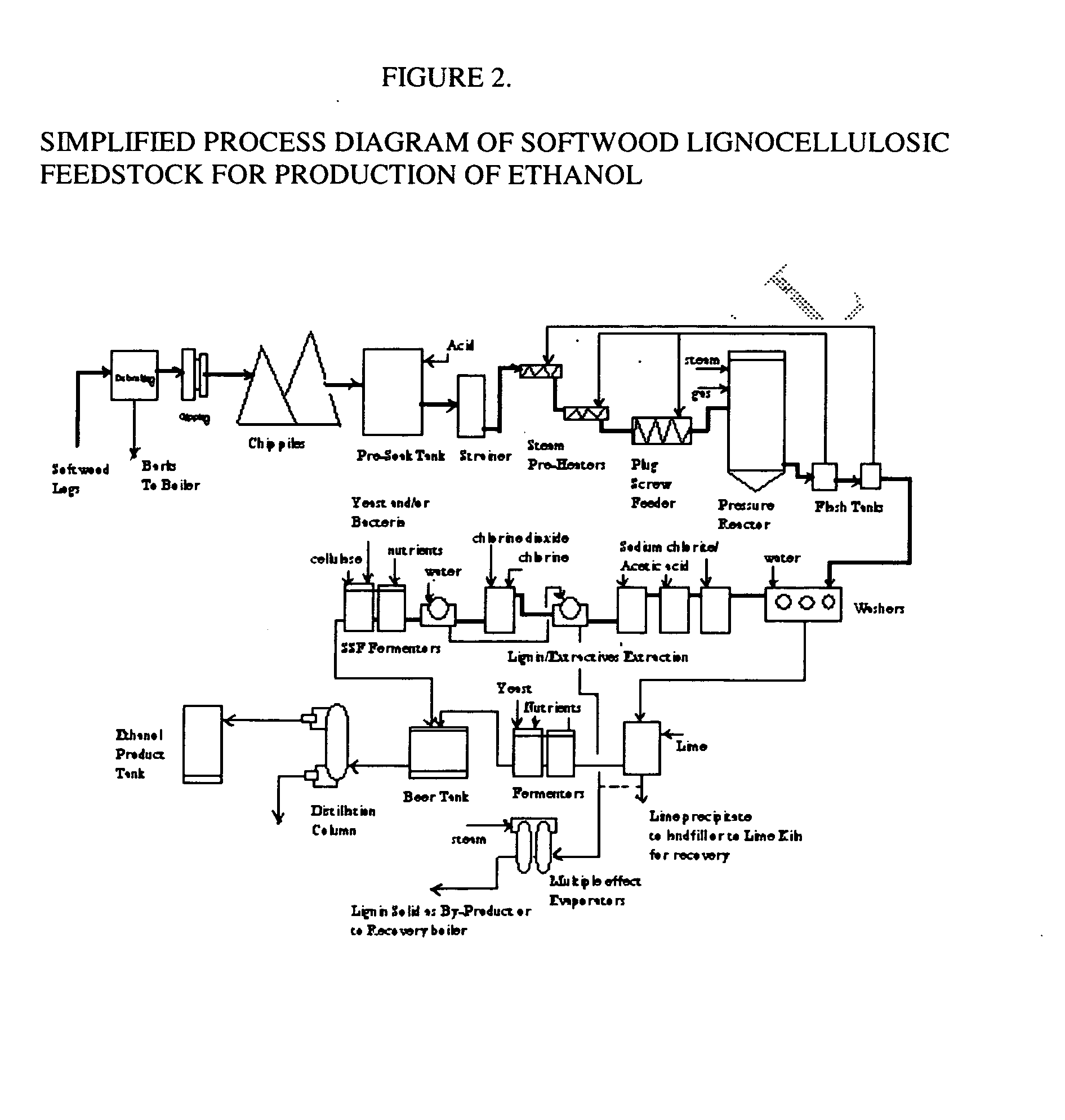

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

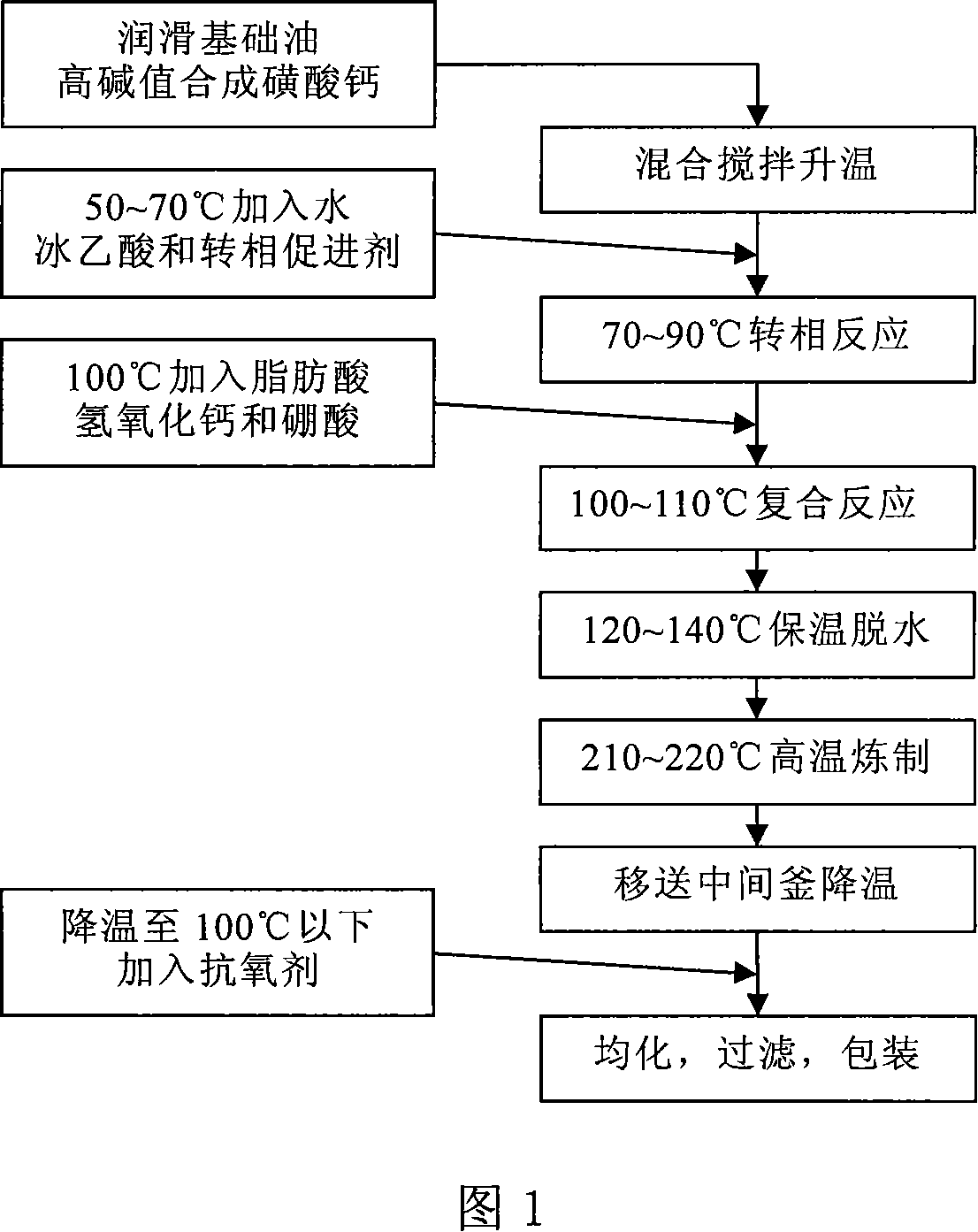

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

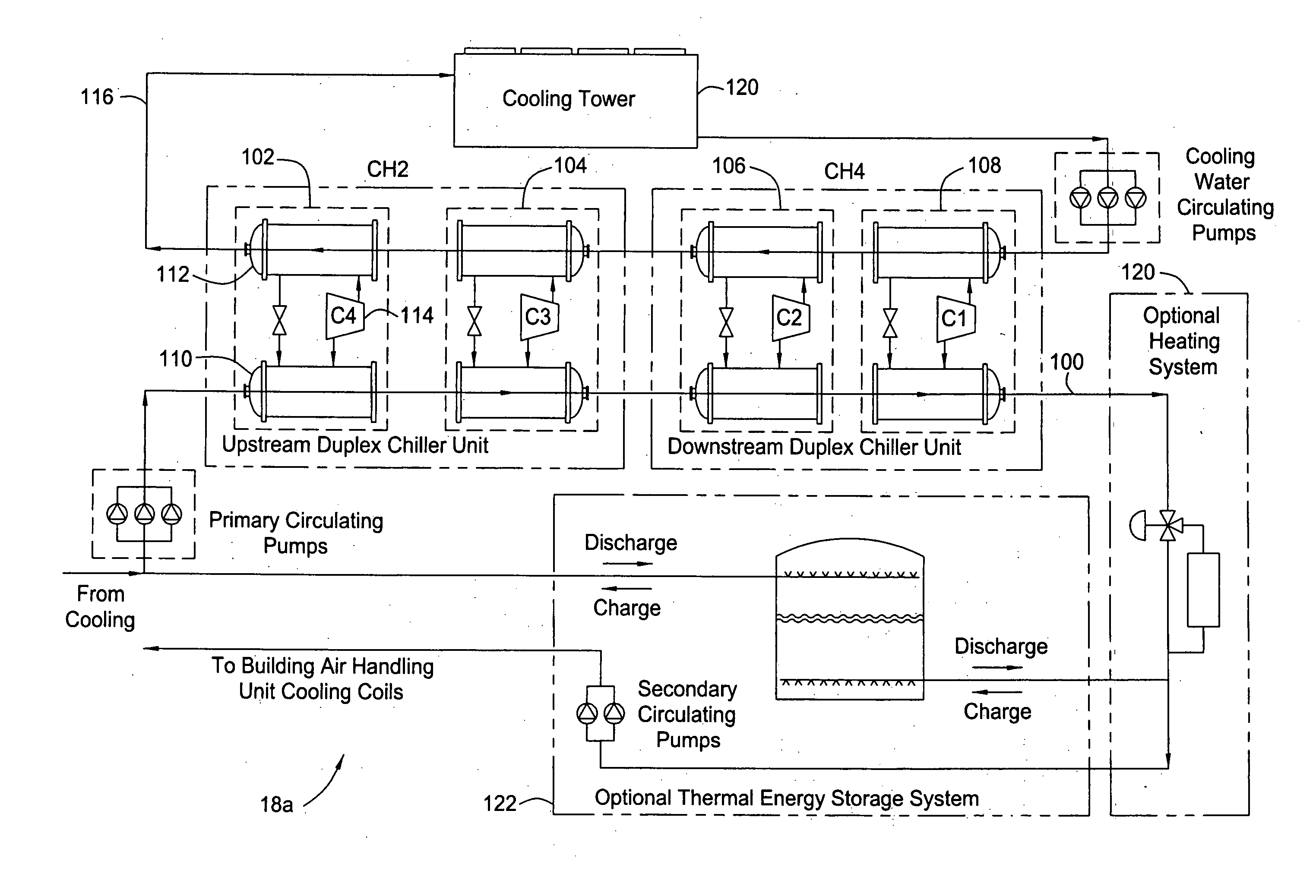

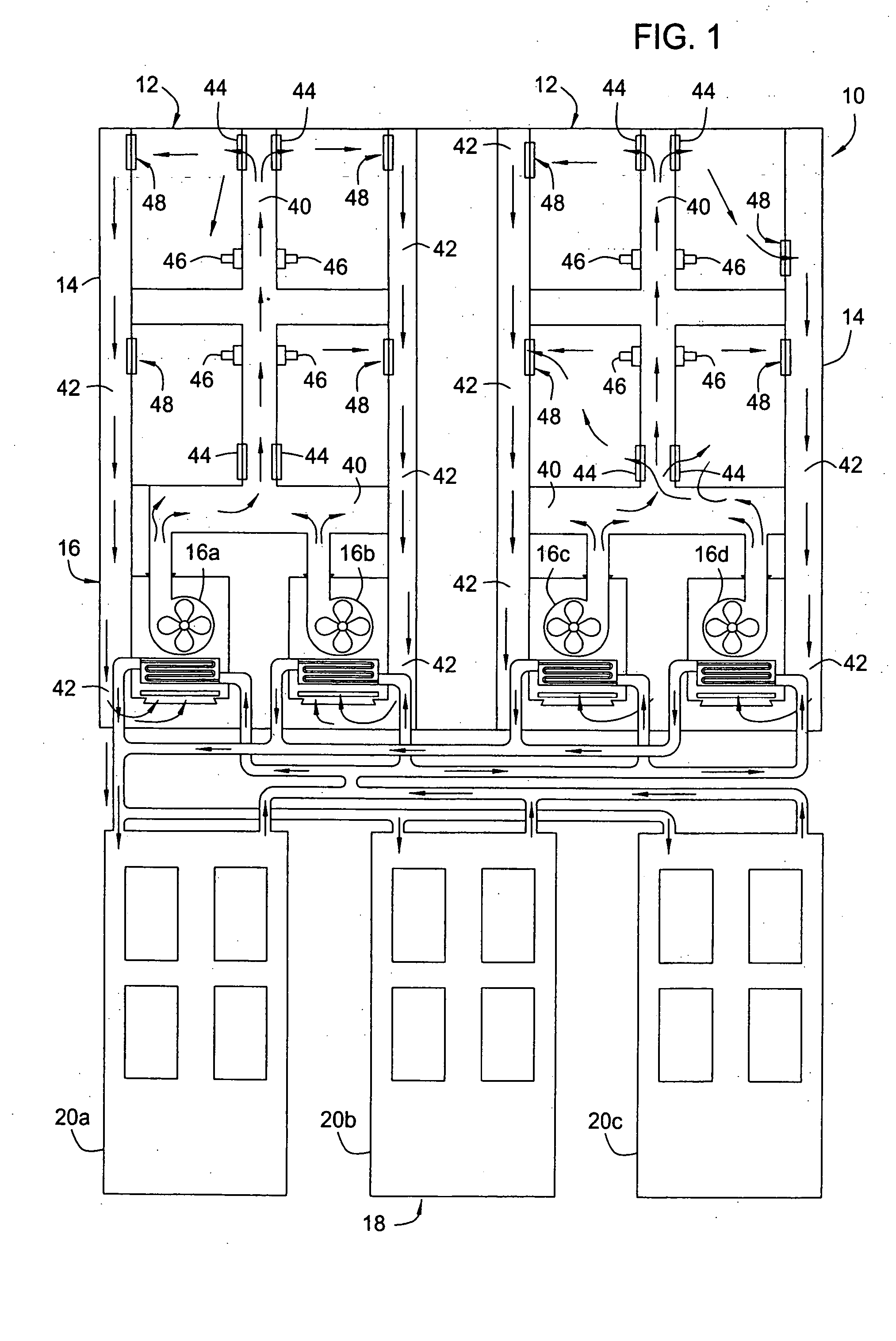

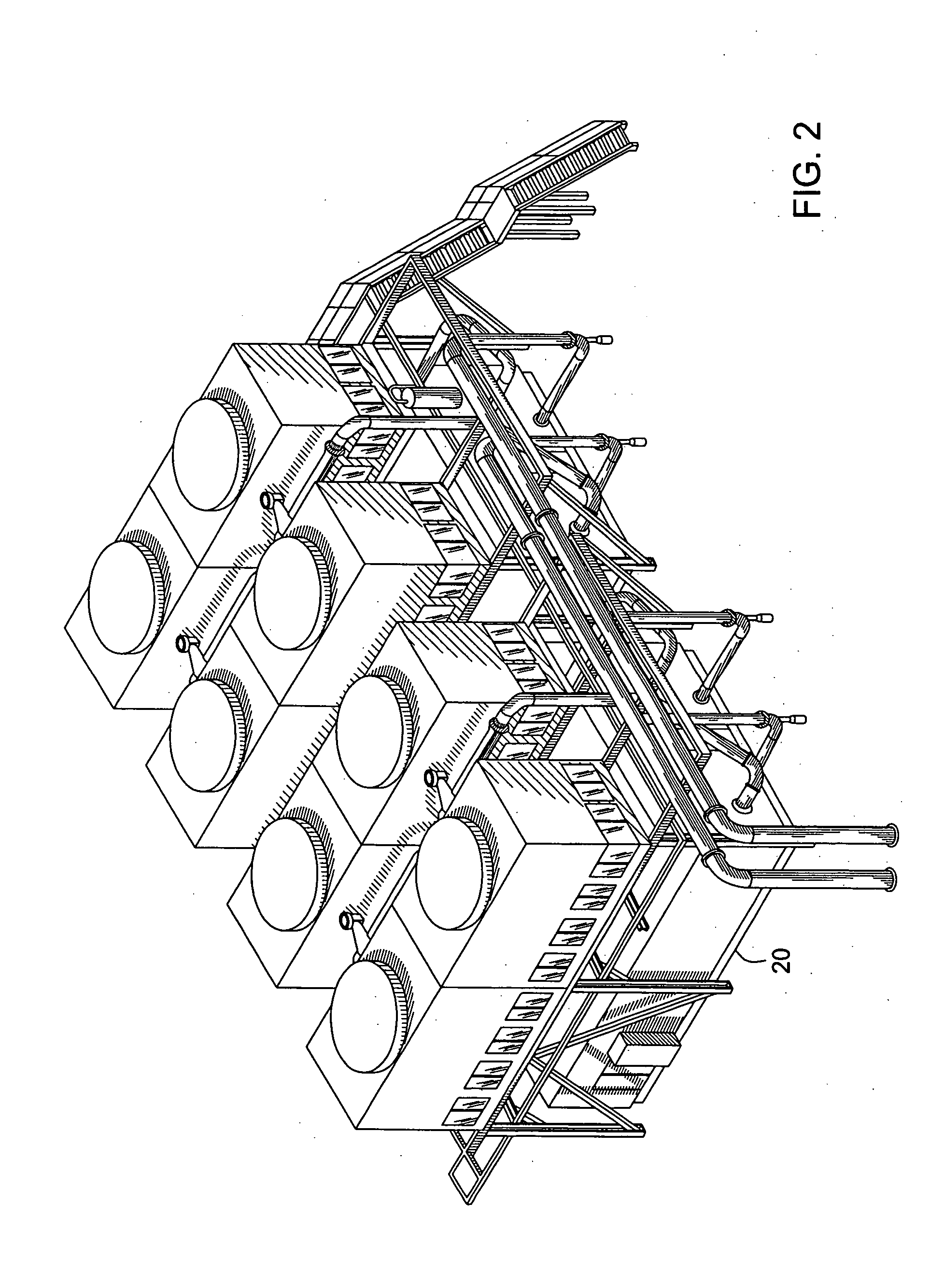

Packaged chilling systems for building air conditioning and process cooling

InactiveUS20050103032A1Domestic cooling apparatusClimate change adaptationChilled waterHandling system

Disclosed is a packaged chilling system for providing chilled water to an air conditioning system for a building that includes: a duct system; an air handling system; and a water chilling system; wherein: the duct system is in operable communication with a building that has a plurality of rooms, at least one of the rooms having a sensor for detecting the room air temperature in the room, the duct system comprising at least one supply duct for directing low temperature air from the air handling system to the building and at least one return duct for directing high temperature air from the building to the air handling system; the air handling system includes a plurality of air handling units, each air handling unit comprising an air inlet for receiving high temperature air from the building, a cooling coil that includes at least one conduit through which chilled water flows, the cooling coil having multiple passes and positioned for heat transfer contact with the high temperature air, and a fan for increasing the velocity of air in the air handling unit; the water chilling system is installed at a location proximate the building, and is operably connected to the air handling system; and the water chilling system includes a moveable support structure comprising a support base on which a plurality of water chilling system components are affixed, the components including at least one water chiller for lowering the temperature of water from a high temperature to a low temperature. This packaged chilling system may also be used to provide chilled water to industrial processes such as chemical plants, automotive plants, textile mills, paper mills, computer cooling, and factory air-conditioning.

Owner:TAS LTD

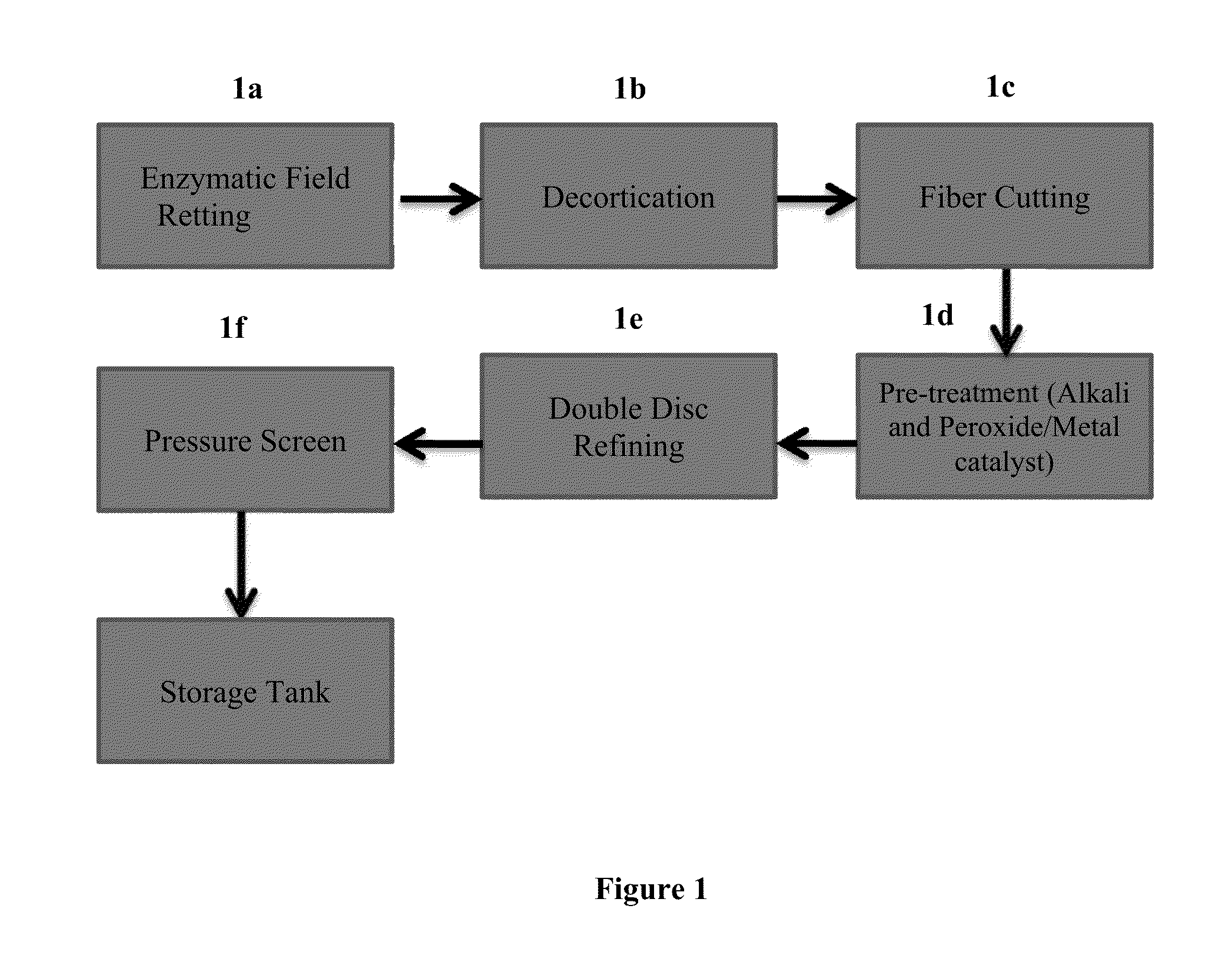

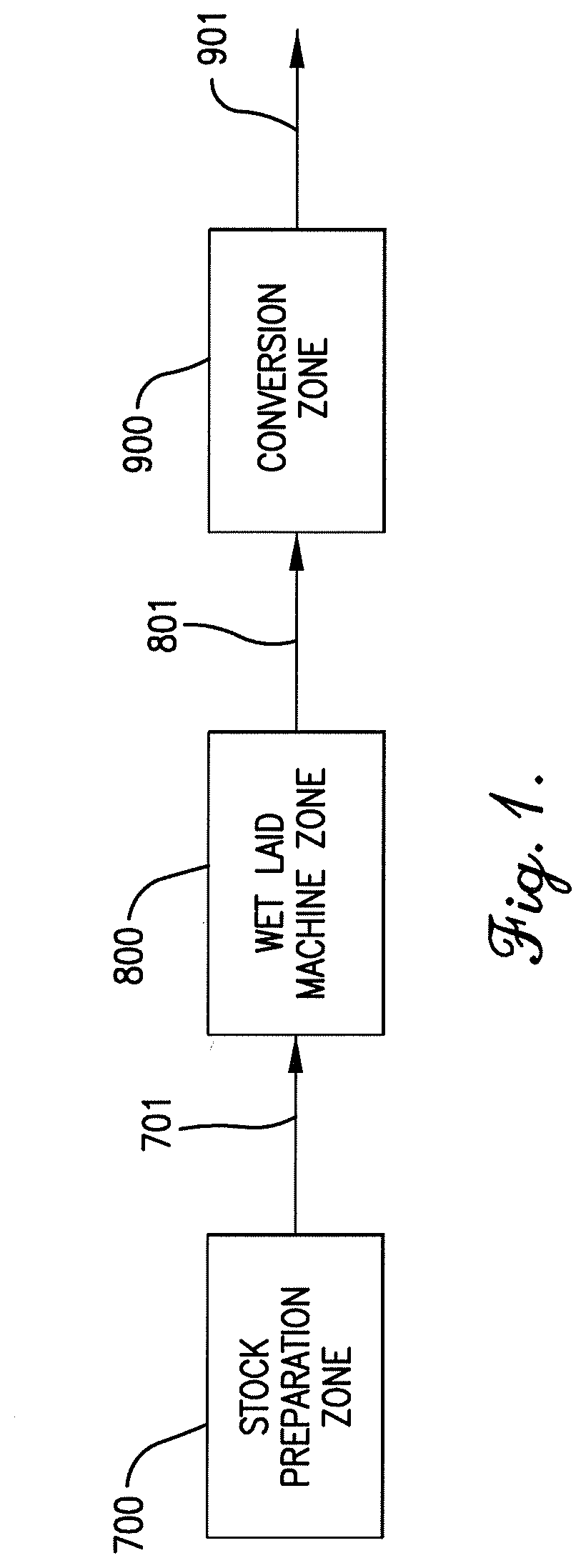

Cannabis fiber, absorbent cellulosic structures containing cannabis fiber and methods of making the same

ActiveUS20160130762A1Reduce manufacturing costLose weightNon-fibrous pulp additionPaper after-treatmentCelluloseBleach

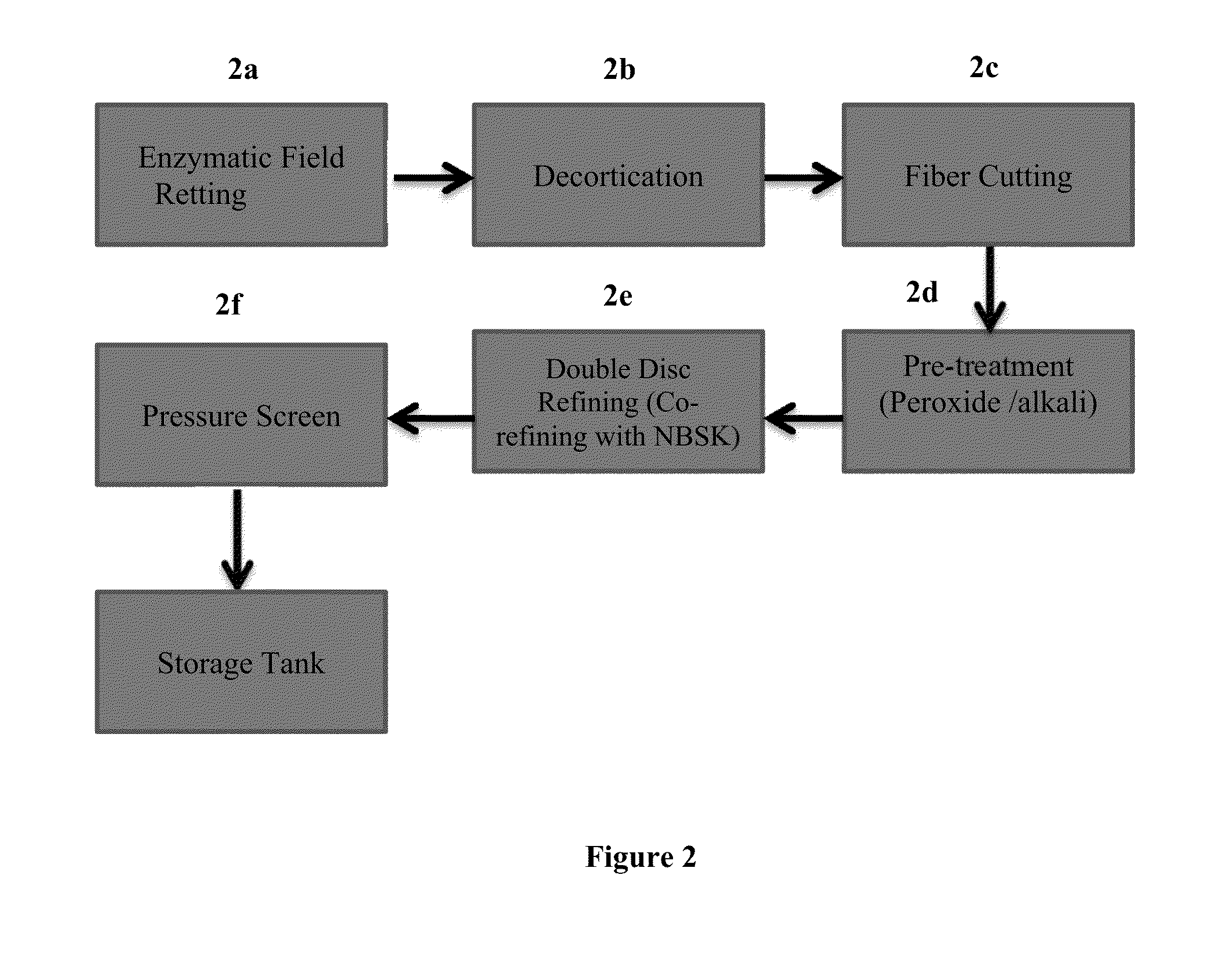

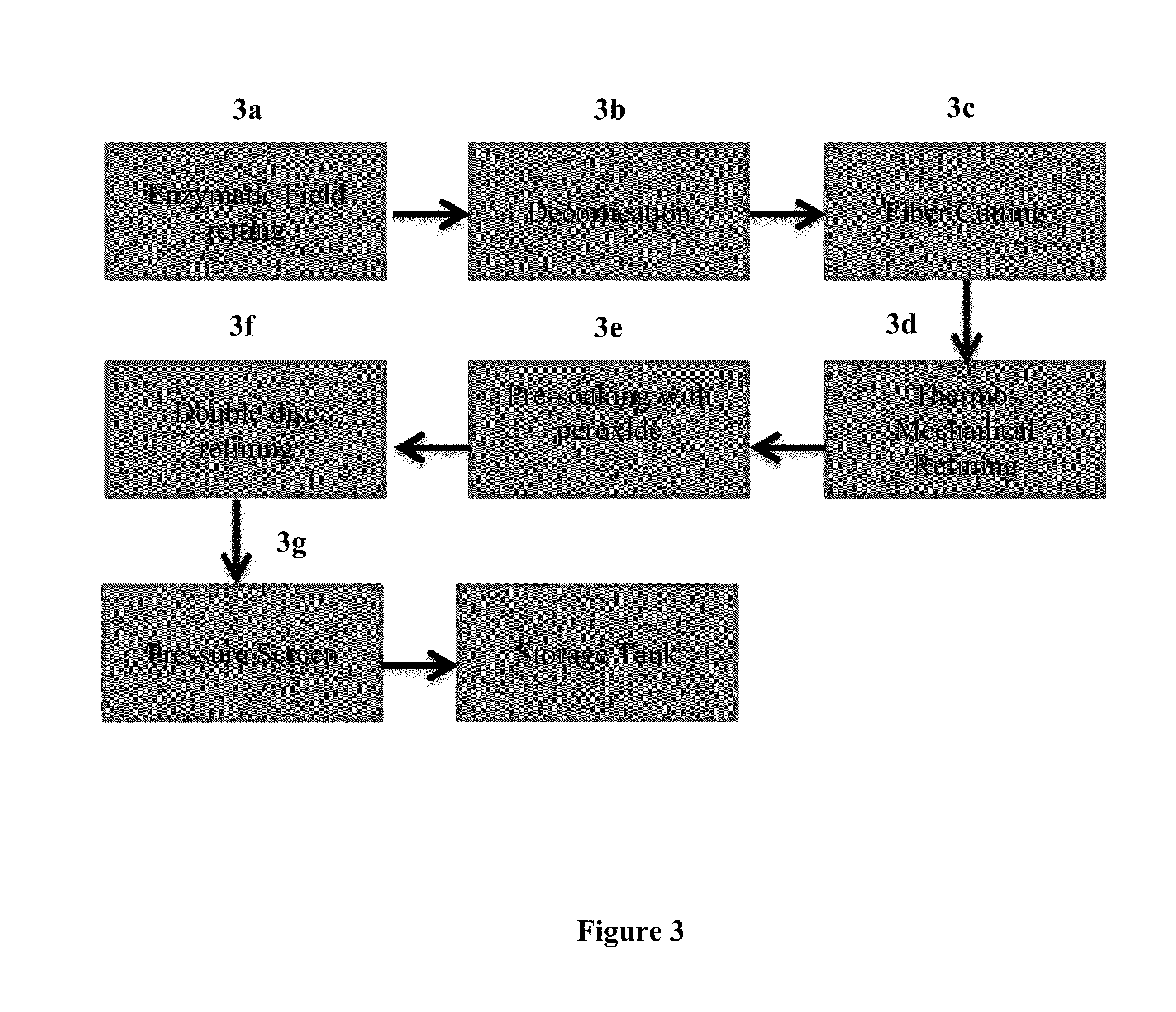

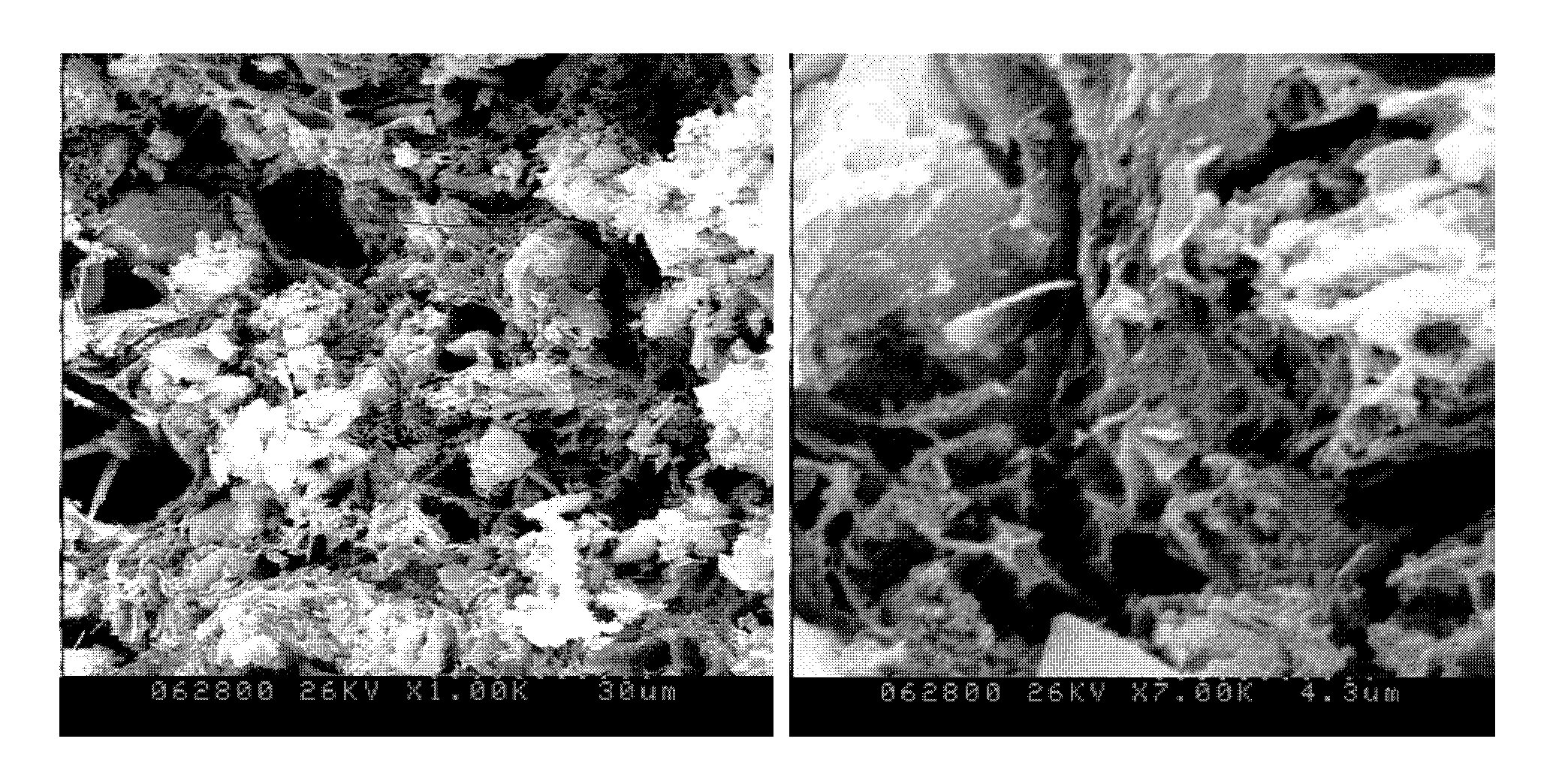

A method to prepare, pulp, and bleach cannabis bast and hurd fibers to allow for the fiber to be incorporated into absorbent cellulosic structures on a wet-laid paper machine while keeping the pectin within the fibers. The wet laid paper machine can use the ATMOS, NTT, ETAD, TAD, or UCTAD method to produce the absorbent cellulosic structure. Absorbent cellulosic structures are produced with the cannabis bast and hurd fibers or with the bast fibers alone with the hurd fibers being combined with paper mill sludge or dust to form a fuel pellet.

Owner:FIRST QUALITY TISSUE

Methods for wastewater treatment

InactiveUS6132630ALow cost of treatmentOptimize present wastewater treatment plantWater/sewage treatment by centrifugal separationWater contaminantsFuel oilOil and natural gas

A method has been invented for separating components of a wastewater stream, the stream containing water, oil (e.g. heavy oil and / or light oil), undesirable organic material (solid and / or liquid), and contaminating solids, the method including feeding a wastewater stream to a first pre-treatment unit producing a first pretreated stream, feeding the first pretreated stream to a first centrifuge for centrifugal separation, producing a first liquid centrifuged stream, and a second liquid stream, and feeding the first liquid centrifuged stream to a second centrifuge producing a resultant centrifuged stream of recoverable oil and a water phase centrifuged stream which can be treated further or fed back to a source for re-use. The source may be a facility from the group including refineries, chemical plants, paper mill plants, and oil and gas processing facilities.

Owner:TUBOSCOPE VETCO INT +1

Granular activated carbon filler for paper mill sludge and preparation method thereof

InactiveCN102205964AWell-developed pore structureHigh strengthOther chemical processesSolid waste disposalSodium BentoniteFluidized bed

The invention relates to a granular activated carbon filler for paper mill sludge and a preparation method thereof. The preparation method comprises the following steps: mixing 70-90 parts by weight of anhydrated paper mill sludge and 10-30 parts by weight of bentonite, performing granulation in a granulator, drying at room temperature, performing carbonization of the raw balls at a low temperature, modifying the carbonized material balls with hydrochloric acid, and activating the balls in an activation furnace. The sludge granular activated carbon filler prepared by the invention has the characteristics of large specific surface area, developed pores, high intensity, and the like. Fillers sintered at different process conditions can be respectively used as reactor fillers for sewage treatment, biological aerated filters, fluidized beds, and the like, have wide application range and low cost.

Owner:SHANDONG UNIV

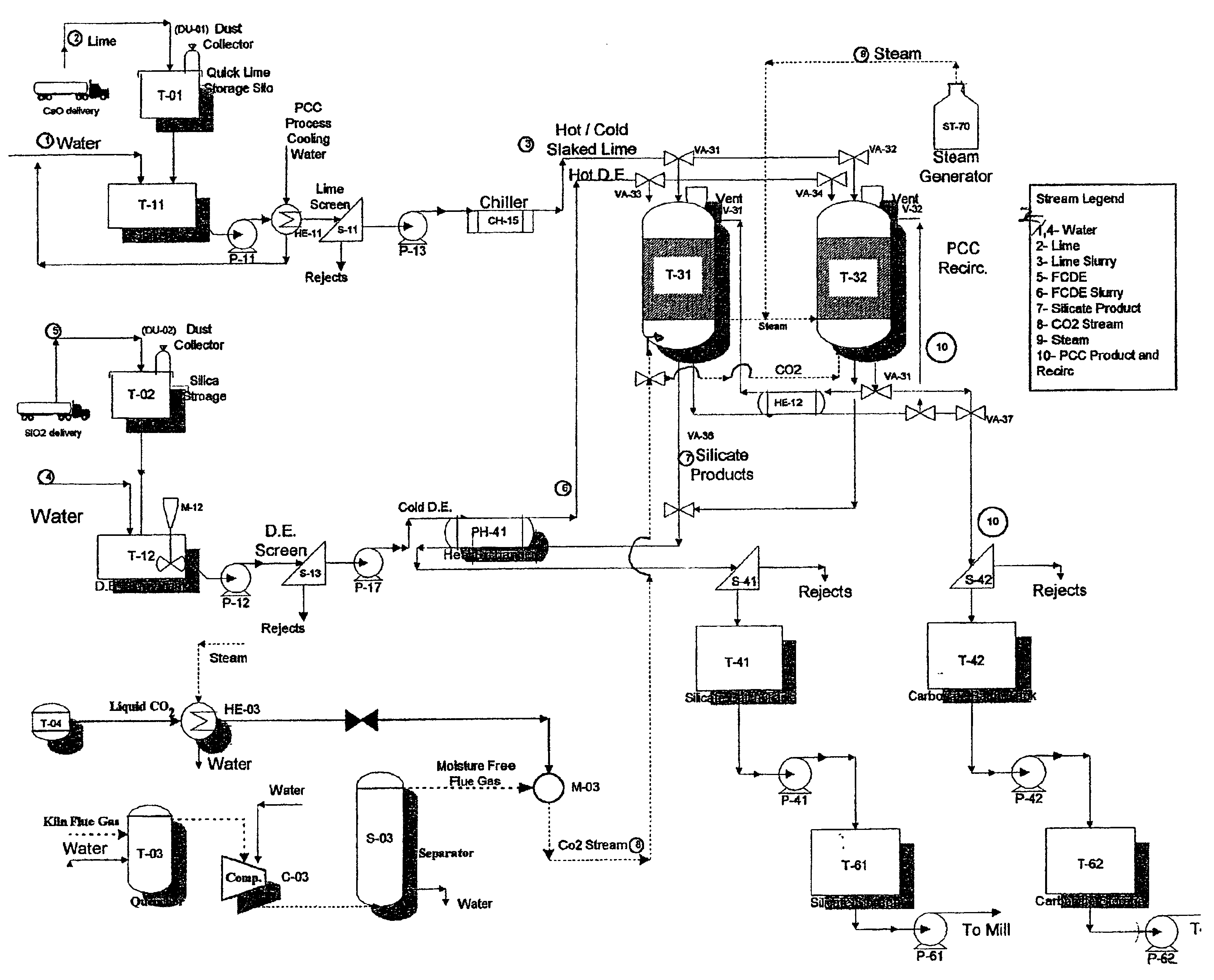

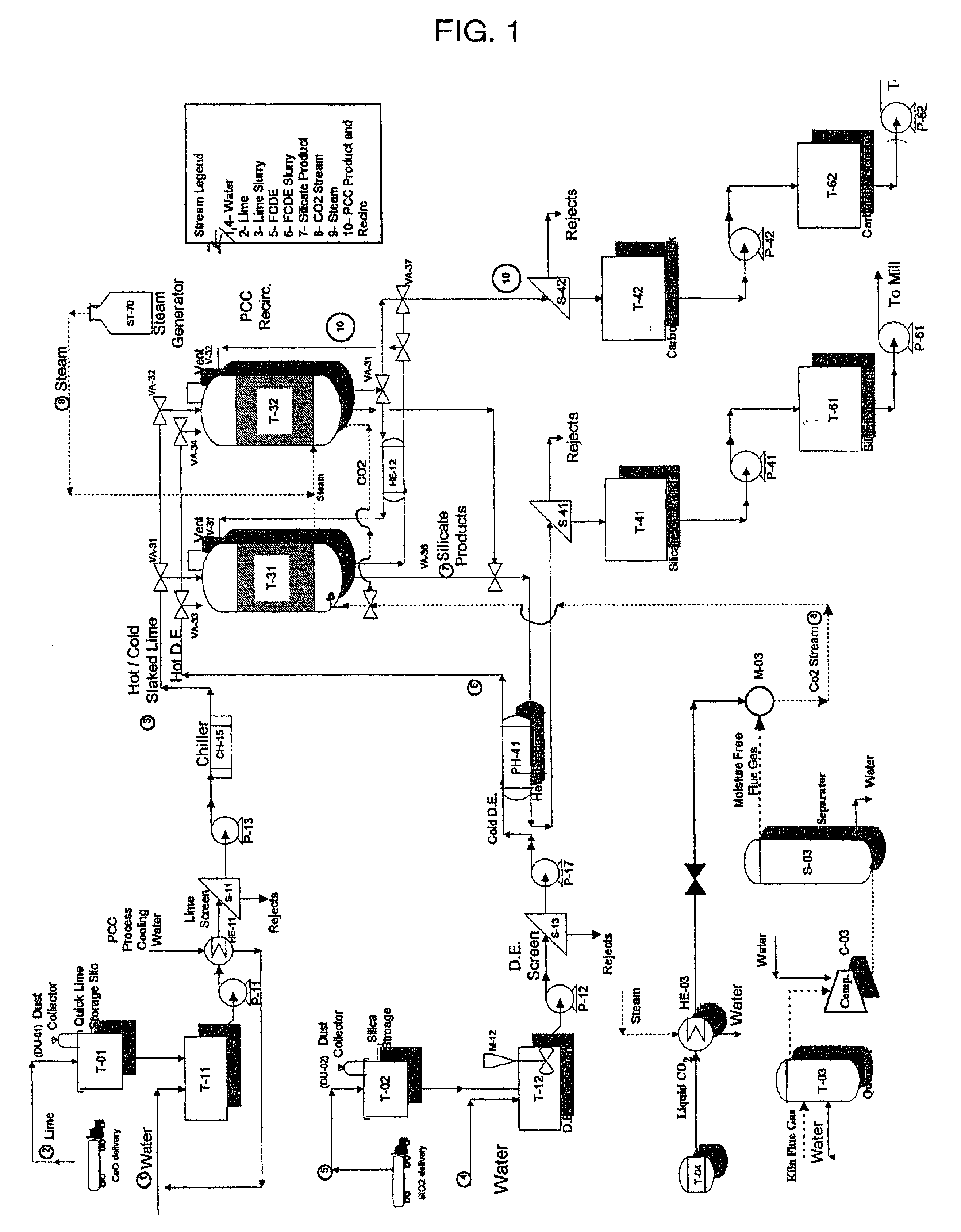

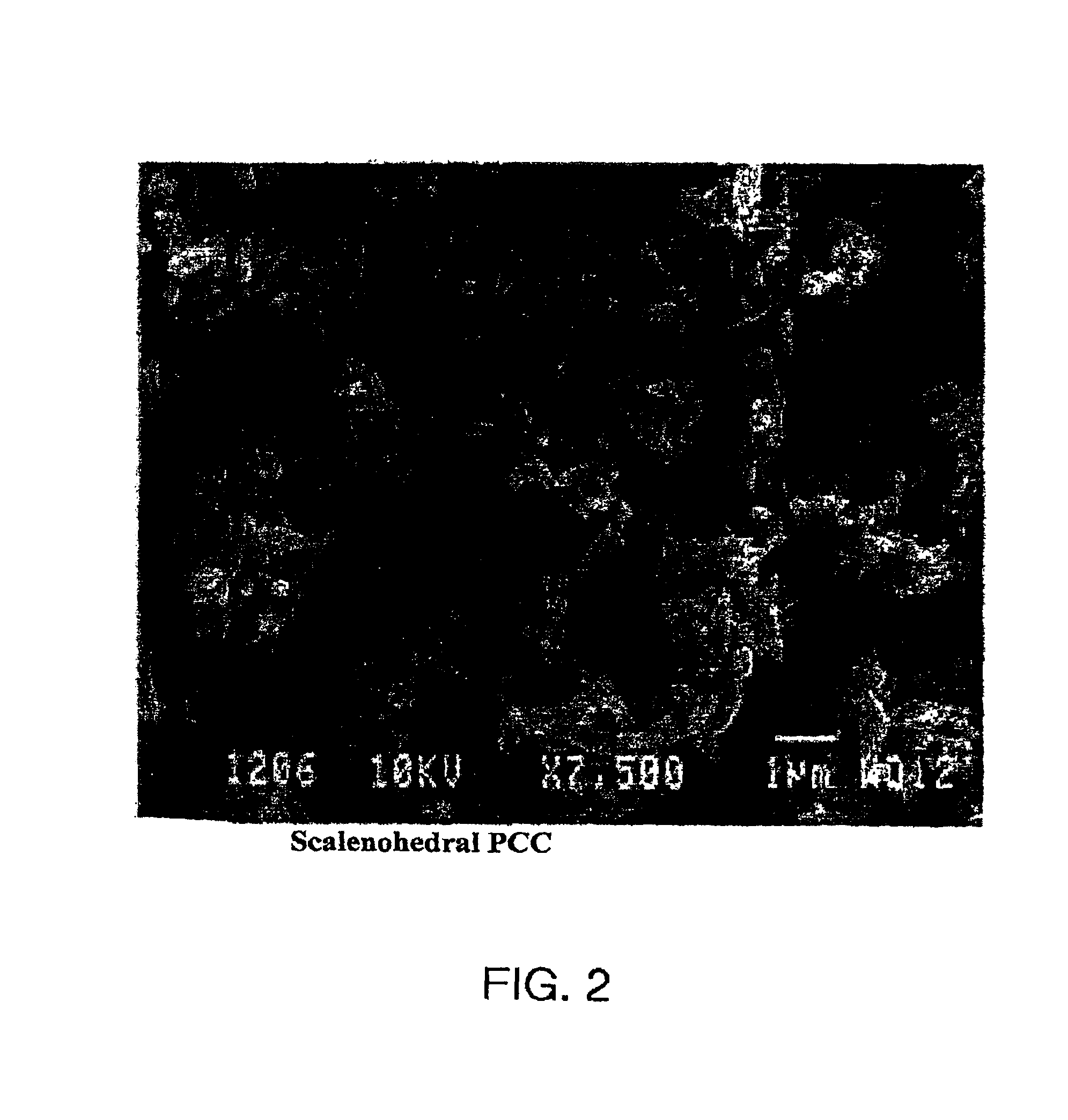

Method and apparatus for production of precipitated calcium carbonate and silicate compounds in common process equipment

InactiveUS7048900B2Increase brightnessHigh opacityCalcium/strontium/barium carbonatesPulp liquors combustionCalcium silicateProcess equipment

A method and apparatus for the production of calcium carbonate and calcium silicate in common superatmospheric reactors. Multiple reactors can be provided for switching production between reactors, and advantageously utilizing process waste heat. On site production of both PCC and Calcium Silicate Hydrates is thus achieved in a paper mill.

Owner:PACIFIC NANO PROD

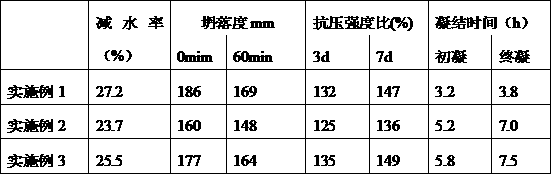

Alkali-activated high-performance water reducer and preparation method thereof

ActiveCN103011662AHigh water reduction rateEnhancement effect is goodBlack liquorProcess engineering

The invention discloses an alkali-activated high-performance water reducer and a preparation method thereof. The alkali-activated high-performance water reducer comprises a composite alkali-activator, a composite water reducer, black liquor of a paper mill, a composite retarder, a composite air entraining agent, a composite thickener, a composite regulator and the balance of water. The preparation method for the alkali-activated high-performance water reducer comprises the following steps of: adding the components and water to a reaction kettle in sequence; and mixing and carrying out a reaction on the components and the water under the room-temperature environment to obtain the finished product. The alkali-activated high-performance water reducer disclosed by the invention can activate the cementitious activity of the mixed materials such as slag, coal ash, gangue and the like, has excellent adaptability to different cements and highly doped concrete, and can greatly reduce the adding amount of cement clinker. The alkali-activated high-performance water reducer has the characteristics of a high water-reducing agent, good peaceability, a remarkable reinforcing effect, a good collapse preventing effect, adjustable setting time and the like. Moreover, the external additive has a simple production process, no pollution, low energy consumption and low cost, can solve an environmental pollution problem of the black liquor of the paper mill, and has good practicability.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Integrated Process for Producing Diesel Fuel from Biological Material and Products, Uses and Equipment Relating to Said Process

InactiveUS20100317903A1Quality improvementMaximize utilizationRefining to change hydrocarbon structural skeletonCombustible gas catalytic treatmentCelluloseHydrocotyle bowlesioides

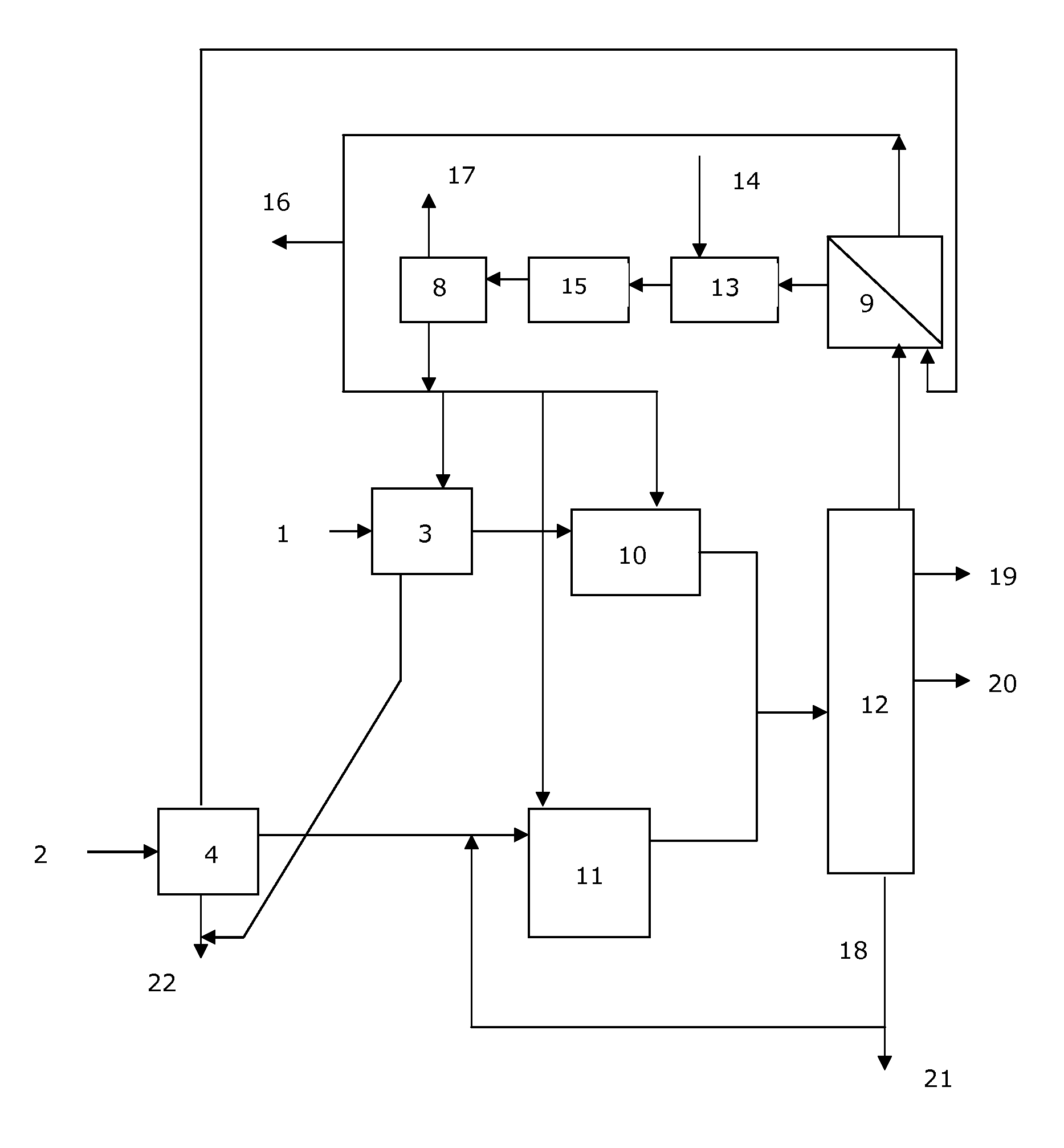

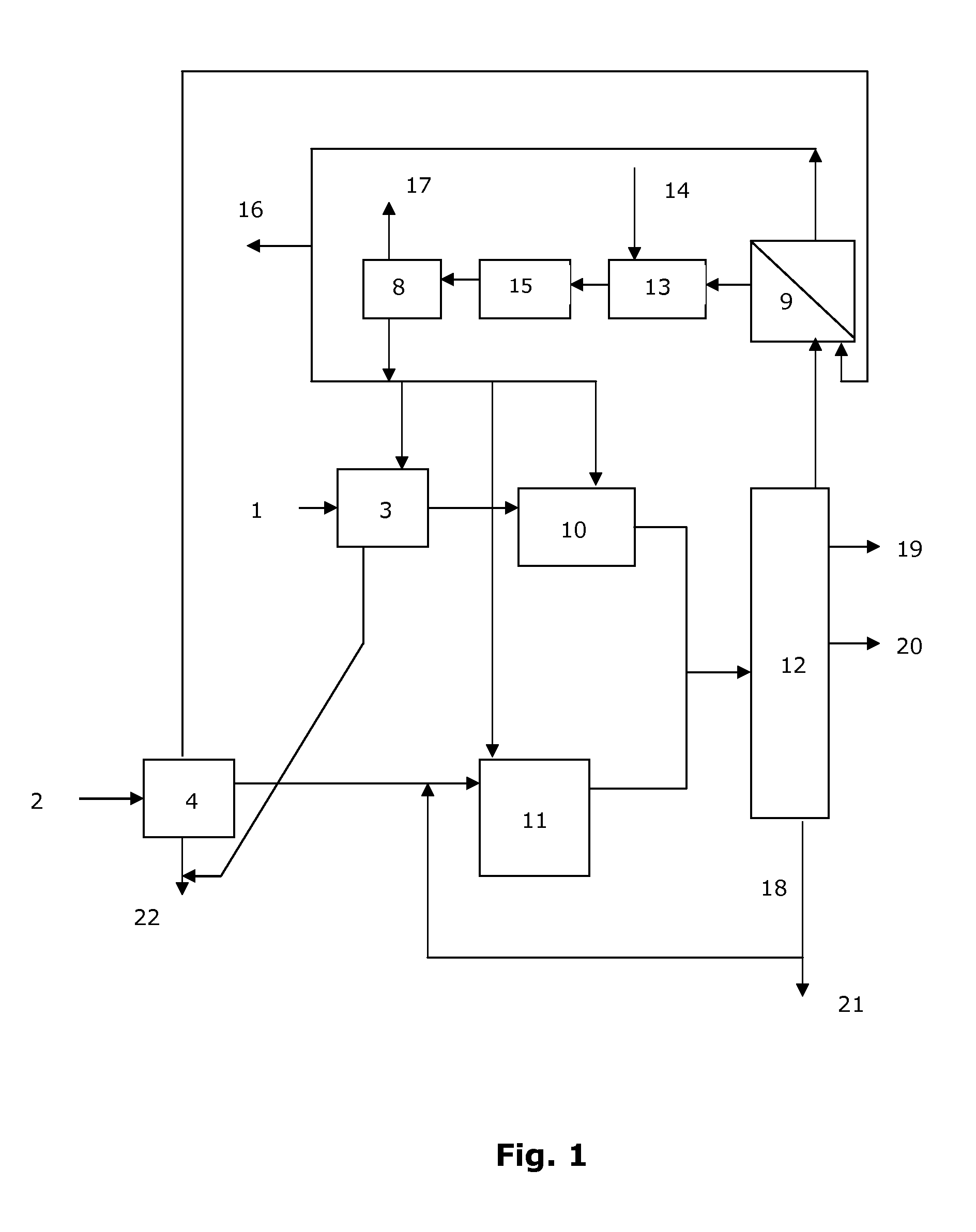

The present invention relates to an integrated process for producing diesel fuel or fuel additive from biological material by producing paraffins by a Fischer-Tropsch reaction on one hand and by a catalytic hydrodeoxygenation of bio oils and fats on the other hand. The two hydrocarbon streams are combined and distilled together. The invention also relates to the use of lignocellulosic material, such as by-products of the wood-processing industry for producing diesel fuel and to a method for narrowing the chain length distribution of Fischer-Tropsch derived diesel fuel. The invention provides a high-quality middle distillate fraction from various biological sources and most preferably from by-products of the wood-processing industry. The invention also relates to equipment for producing fuel form biological material, which comprises a hydrodeoxygenation reactor (3) for hydrocarbons, a cracking / isomerization reactor (11) for FT paraffins and a separation unit (12) for the combined hydrocarbons. Hydrogen is separated from light fractions in a separation unit (9) and reformed in the process. The equipment is advantageously integrated with a pulp and paper mill, which provides biological material and receives waste and energy.

Owner:UPM-KYMMENE OYJ

Cationization modification method for nano-crystalline cellulose and preparation method of high-strength cigarette paper

ActiveCN102180979ALess investmentHigh strengthReinforcing agents additionPaper/cardboardFiberReaction temperature

The invention belongs to the field of production of special paper, and in particular relates to a cationization modification method of nano-crystalline cellulose and a method for preparing high-strength cigarette paper from the modified nano-crystalline cellulose. Specific to the characteristic of high specific surface area of nano-crystalline cellulose, KOH and a method for adding an etherification reaction accelerant are adopted, the reaction temperature is lowered below 50 DEG C, cationization modification is performed on the nano-crystalline cellulose, and the modified nano-crystalline cellulose has the characteristics of retention and enhancement, so that the modified nano-crystalline cellulose has a wider application prospect; in the method for preparing cigarette paper, softwood pulp is not used, and higher natural air permeability and higher bonding strength of a product are ensured under the condition of reducing broadleaf wood fiber devillicate and fibrillation, so that energy consumption in the production process of paper, in particular in the pulping process, is remarkably lowered, equipment investment of a paper mill is reduced, high-strength cigarette paper is manufactured, the page quality is improved, higher strength and air permeability of the product are achieved, and the requirements on energy conservation and emission reduction are met.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Modified phosphogypsum and its preparation

The present invention discloses a modified phosphogypsum and its preparation process. Its main weight composition is formed from 10-30% of additive (one, two or three kinds of aluminium sulfate slag, alum stone, plant ash, bentonite, slag, dickite, waste liquor and waste residue of paper mill and soda plant, white mud and sepiolite) and 70-90% of phosphogypsum. The phosphogypsum and additive are mixed together, and stacked at a certain temp. so as to obtain the modified phosphogypsum. If said modified phosphogypsum is closed-heated at 30-100 deg.C for 8-48 hr., and formed, dried and can be made into the cement retarded, and if the modified phosphogypsum closed-heated for 8-24 hr, is calcined at 600-900 deg.C, and can be made into cement reinforcing agent.

Owner:孙国庆 +1

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20170328006A1Increasing pulp drainage and strength propertyQuality improvementMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Owner:ENZYMATIC DEINKING TECH LLC

Process for generating a hydrocarbon feedstock from lignin

ActiveUS20090218061A1Increase energy contentMachine wet endLiquid carbonaceous fuelsBlack liquorBiofuel

The present invention discloses processes for generating a hydrocarbon feedstock for biofuels synthesis from lignin via hydroprocessing. Embodiments of the present invention can occur in a refinery setting or in a paper mill setting. Embodiments of the present invention can utilize the separated lignin or the entire black liquor solution.

Owner:CHEVROU USA INC

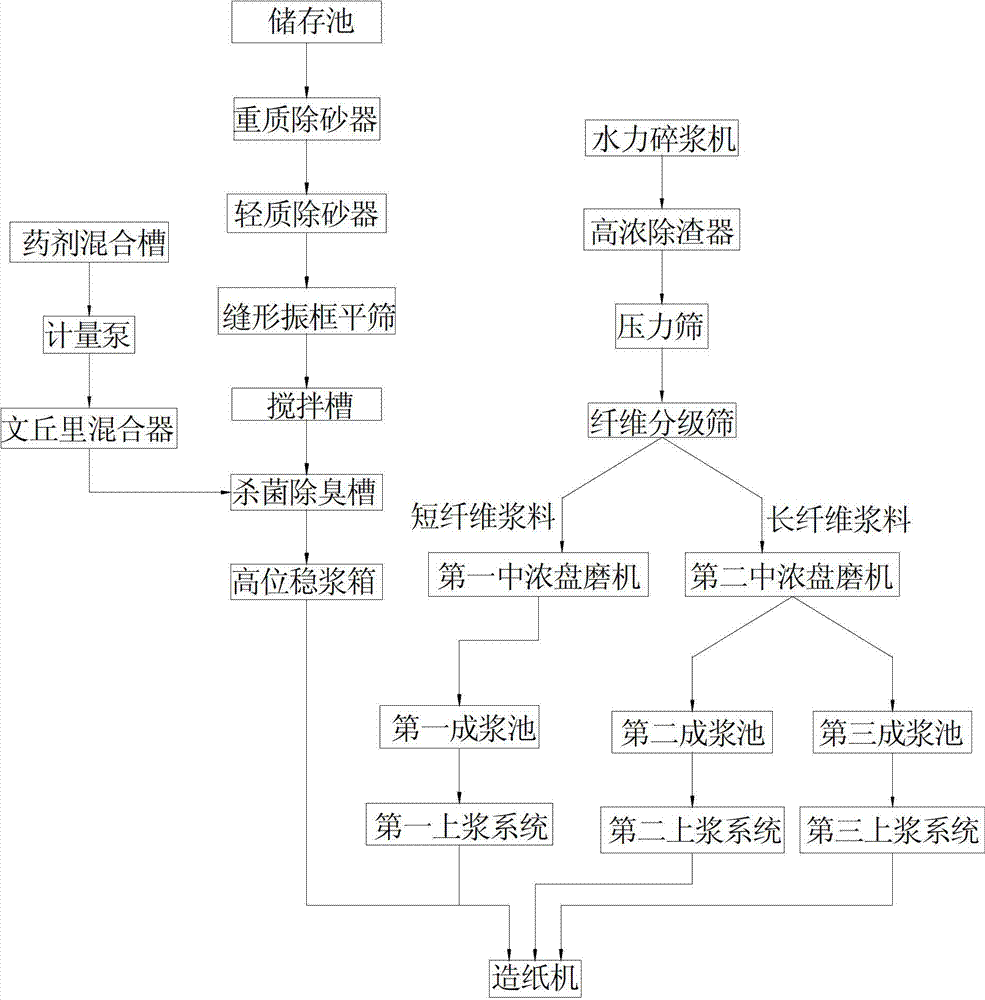

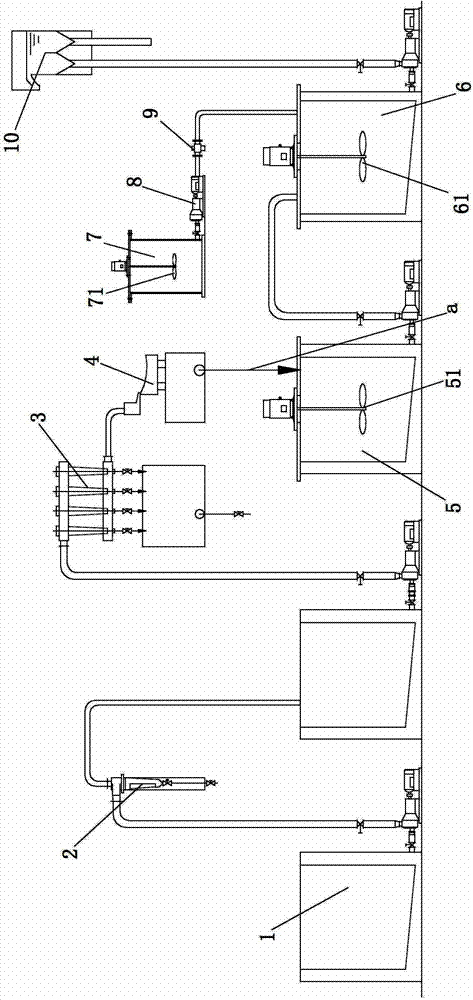

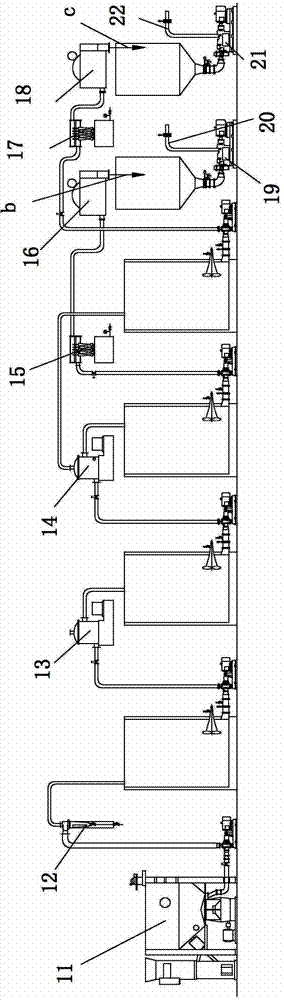

Device and method for producing cardboard paper by utilizing paper mill sludge and waste paper

InactiveCN103088695AReduce wasteReduce secondary pollutionPaper recyclingPaper/cardboardCardboardPulp and paper industry

The invention discloses a device and a method for producing cardboard paper by utilizing paper mill sludge and waste paper. According to the invention, impurity removal, sterilization, deodorization and the like are carried out on the paper mill sludge so that the paper mill sludge becomes paper pulp capable of being used for paper making, and then the paper pulp is combined with sizing agent prepared from the waste paper to produce the cardboard paper. According to the device and the method, the utilization value of the paper mill sludge is improved, and secondary pollution of paper making sludge to the environment is avoided; and simultaneously, the problem of timber resource shortage is solved, and the production cost of producing the cardboard paper is further reduced.

Owner:SOUTH CHINA UNIV OF TECH

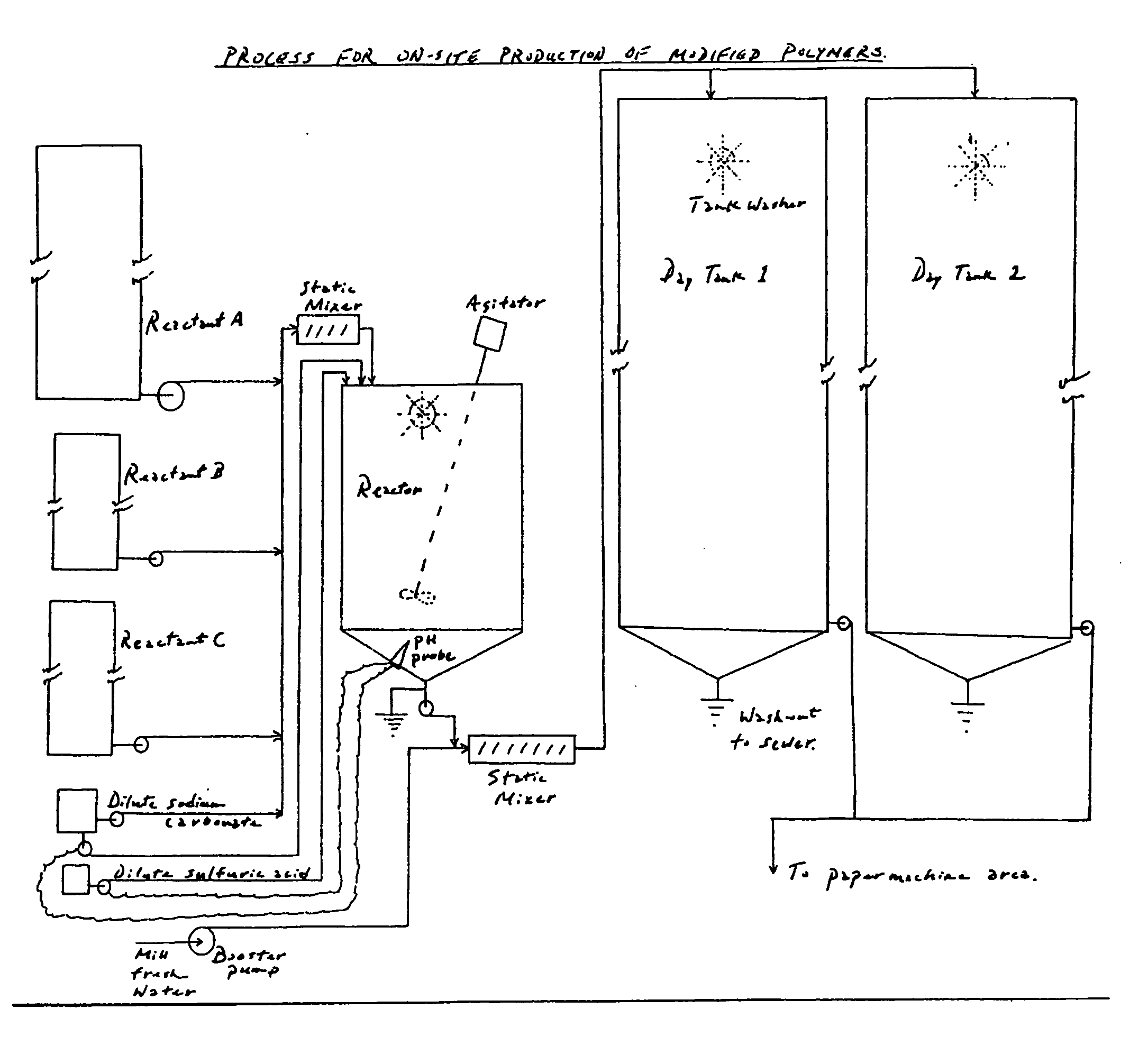

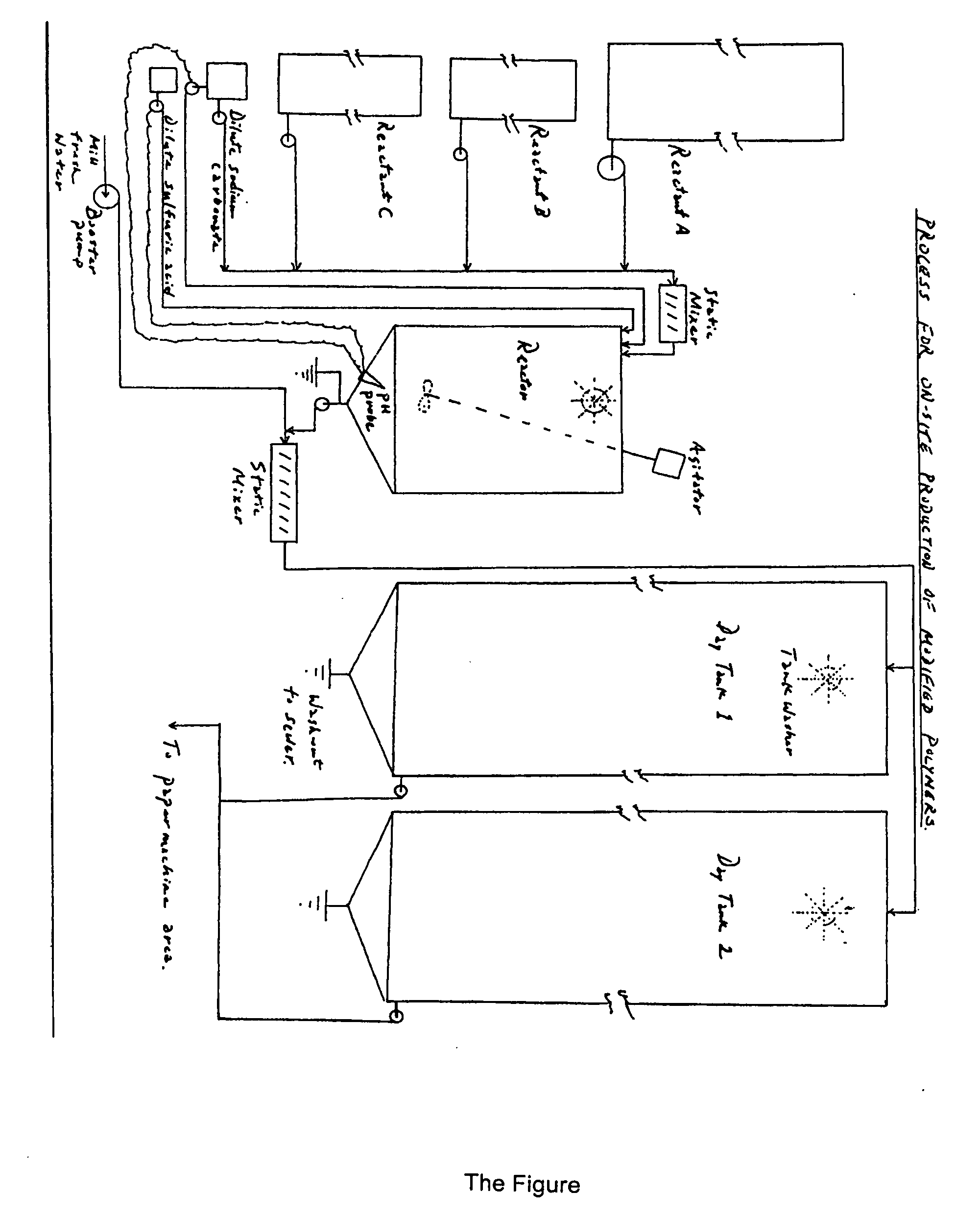

Process for improving dry strength and drainage of paper and paperboard

InactiveUS20060162886A1Good drainageImprove dry strengthNatural cellulose pulp/paperSpecial paperCellulosePaperboard

A process is provided of providing glyoxylated polymer additives to a paper making process which brings about improvements in drainage properties of a cellulosic pulp material along with the ability to increase the dry strength of a resulting paper product. The process uses concentrated glyoxal to generate a working solution of a glyoxylated polymer additive which can be generated on site in a paper mill and used within a 24 to 48 hour interval. The ability to glyoxylate polymers in a working solution concentration provides for a more active additive and which can be supplied in a more economical fashion than conventional glyoxylated polymers.

Owner:PARADIGM CHEM & CONSULTING

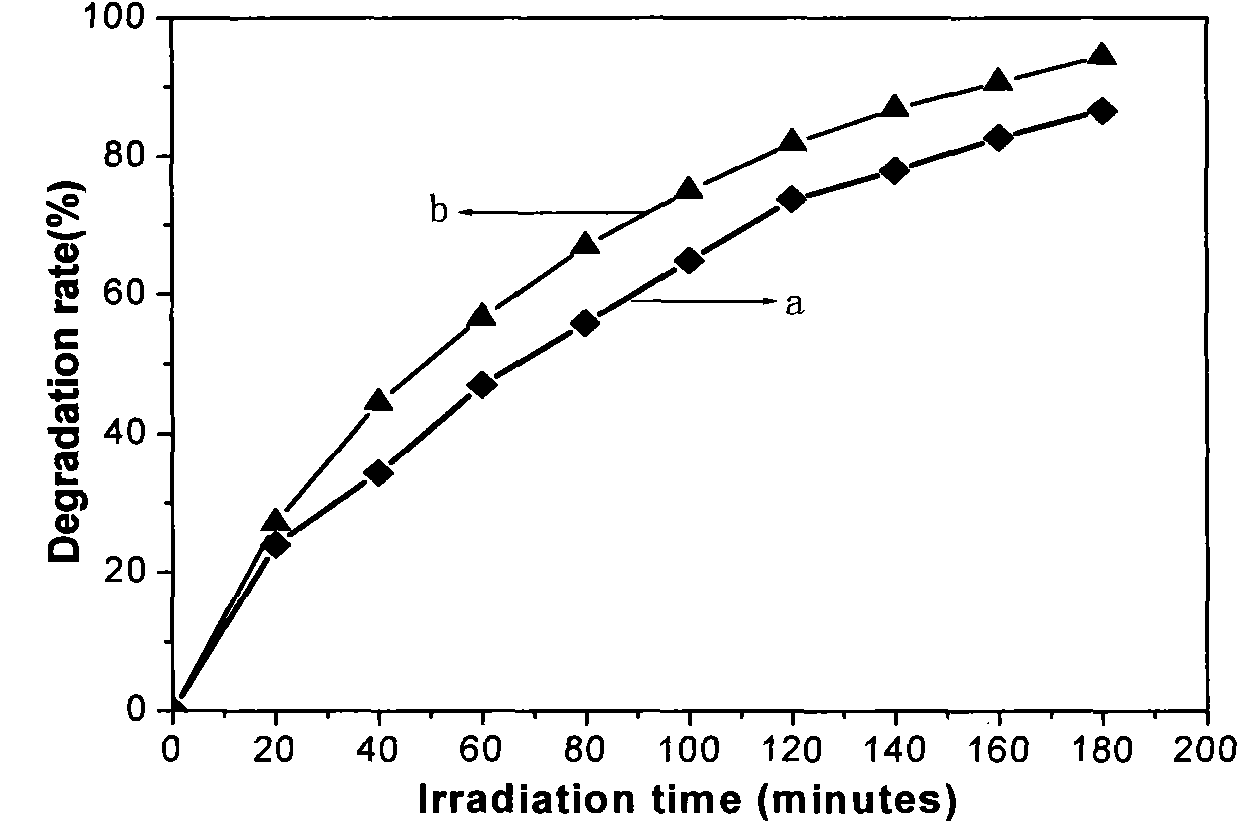

Method for treating industrial waste water by means of photoelectrocatalysis

InactiveCN101798126ANo physical transferHigh selectivityWater/sewage treatment by irradiationWater contaminantsOptical radiationTio2 nanotube

The invention provides a method for treating industrial waste water by means of chemical oxidation or chemical deoxidation in photoelectrocatalysis, belonging to the field of environmental protection. The method comprises the following steps of: taking a titanium positive electrode oxidation method-prepared high-ordered titanium-based TiO2 nanotube array thin film as an optical positive electrode or an optical negative electrode; taking high-purity black lead as an electrode; and degrading organic matter or heavy metal ion of the industrial waste water into H2O and CO2, low valent metal ion or metal simple substance under the conditions of the connection of an external circuit and the optical radiation. The invention has the advantages that: the adopted catalytic agent optical positive electrode is the high-ordered array thin film which is self assembled by anodic oxidation and is perpendicular to the bottom of the titanium base, thereby not only overcoming the defects of the existing powder body loading thin film optical positive electrode such as bad bond, easy falling and gradually-attenuated catalysis efficiency, but also being capable of directly using the sunlight by doping the modifying property to the array thin film, and being an advanced technology for treating single waste water (dye such as paper mill organic waste water, printing and dyeing mill organic waste water, or heavy metal ion such as electroplate factory chromium-containing waste water) or complex waste water with energy saving, high efficiency, high selectivity, cleaning and low cost.

Owner:SICHUAN UNIV

Wastewater treatment compositions

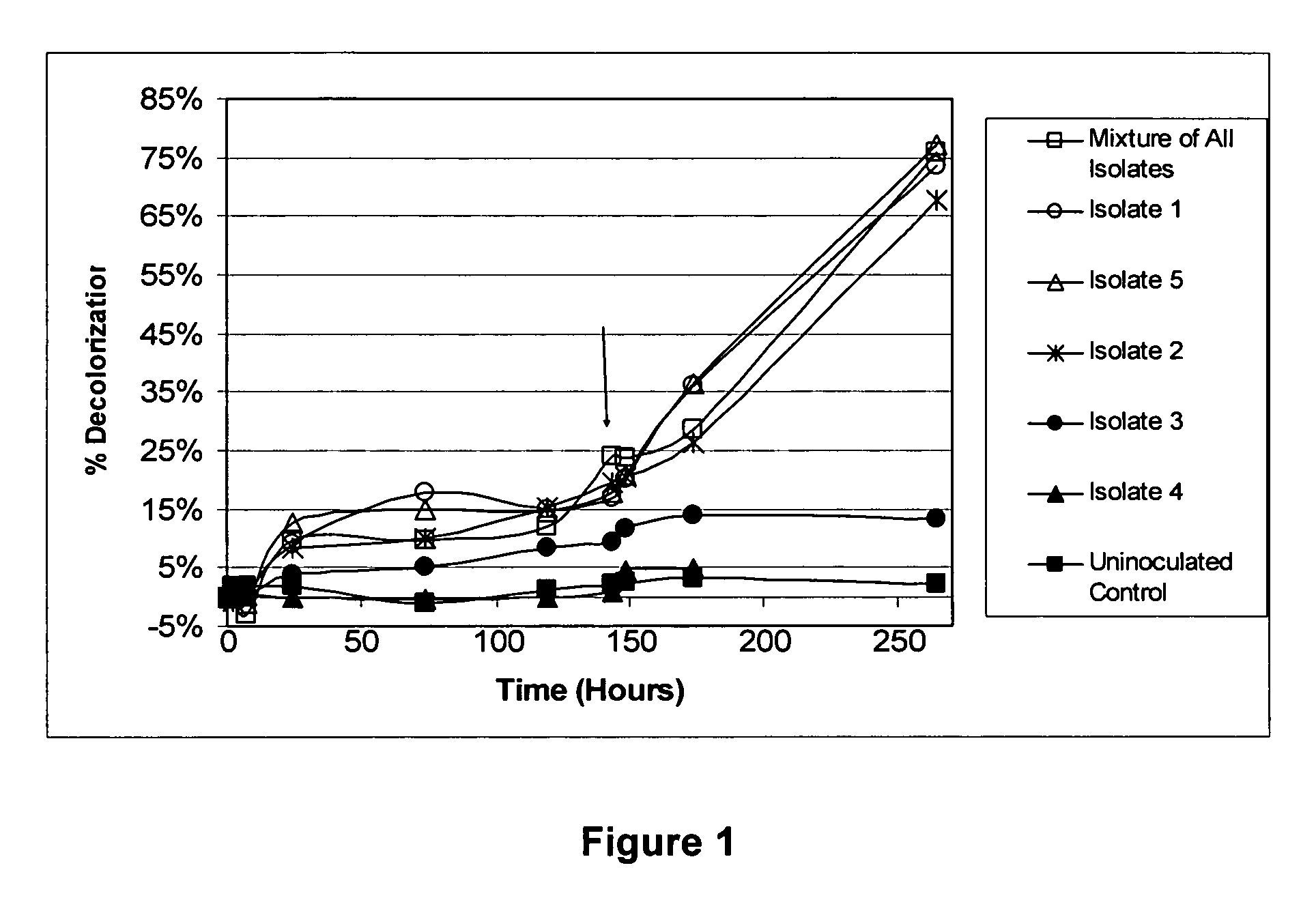

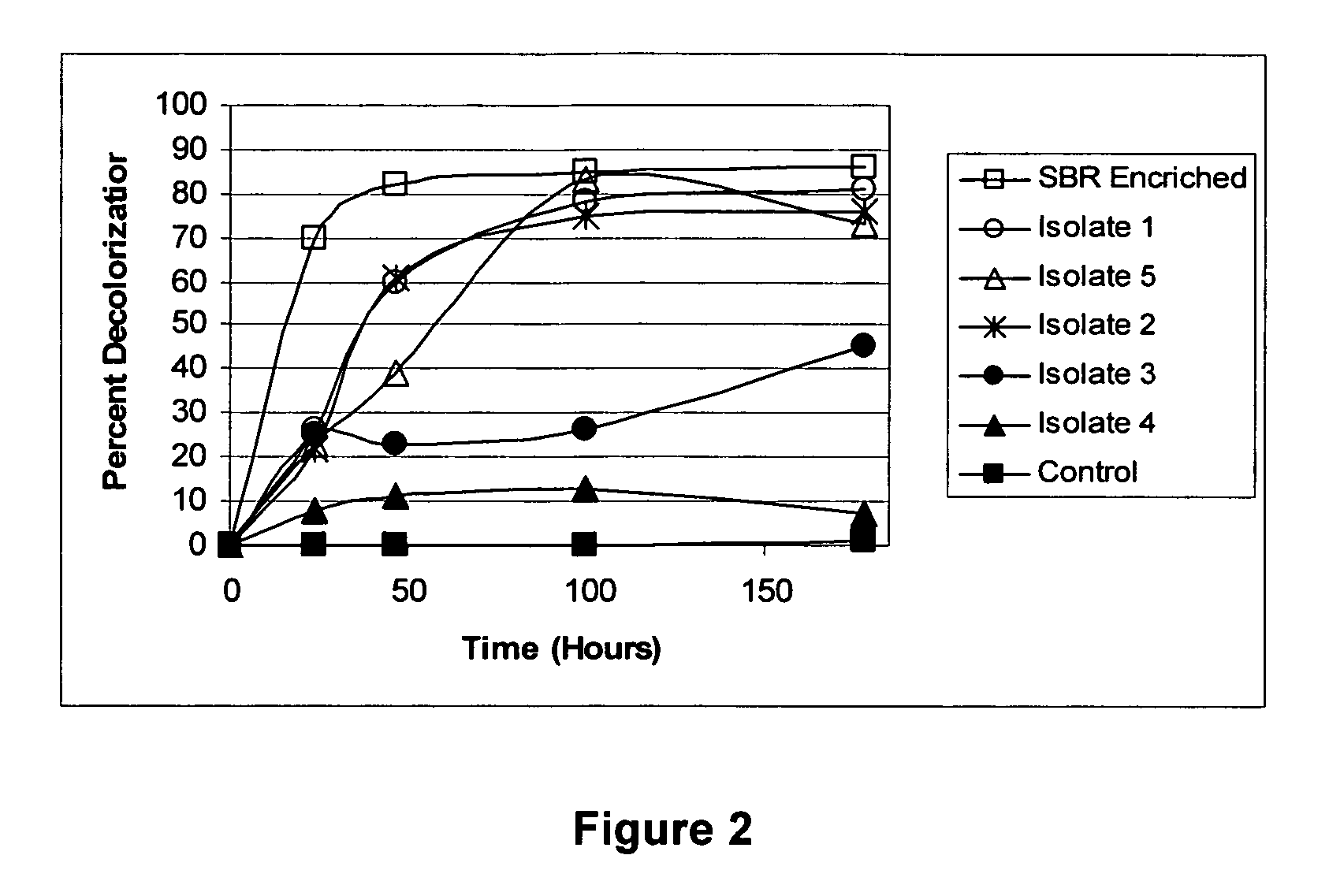

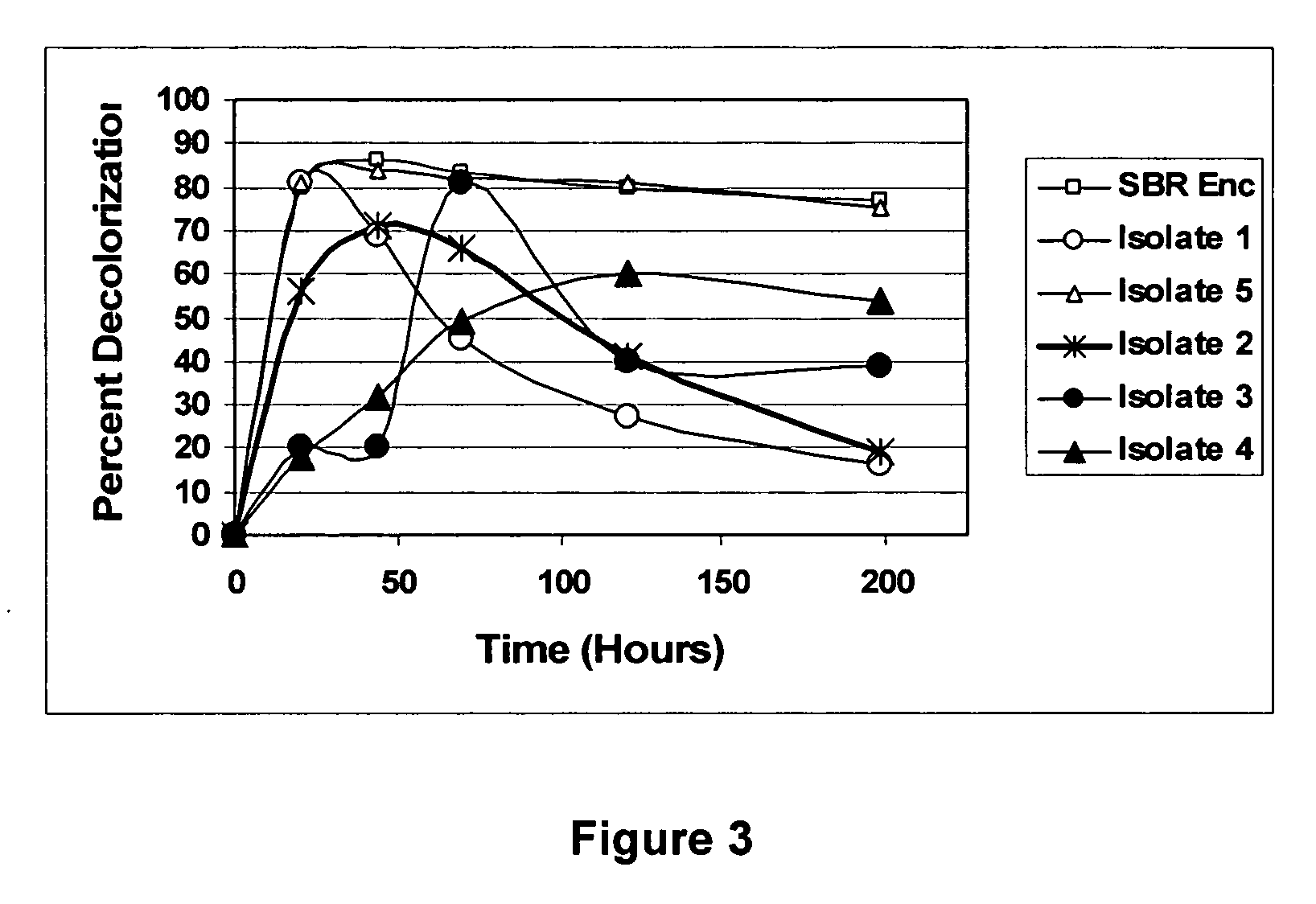

InactiveUS20060194303A1Remove and reduce colorReduce CODWater treatment compoundsWater contaminantsMicroorganismPaper mill

The present invention relates to a wastewater treatment composition and a process of decolorizing pulp and paper mill wastewater and, more specifically, to a process for treating wastewater effluent from a pulp or paper mill with a microorganism whereby color bodies in the pulp and paper wastewater are thereby removed and the wastewater is decolorized.

Owner:NOVOZYMES BIOLOGICALS +1

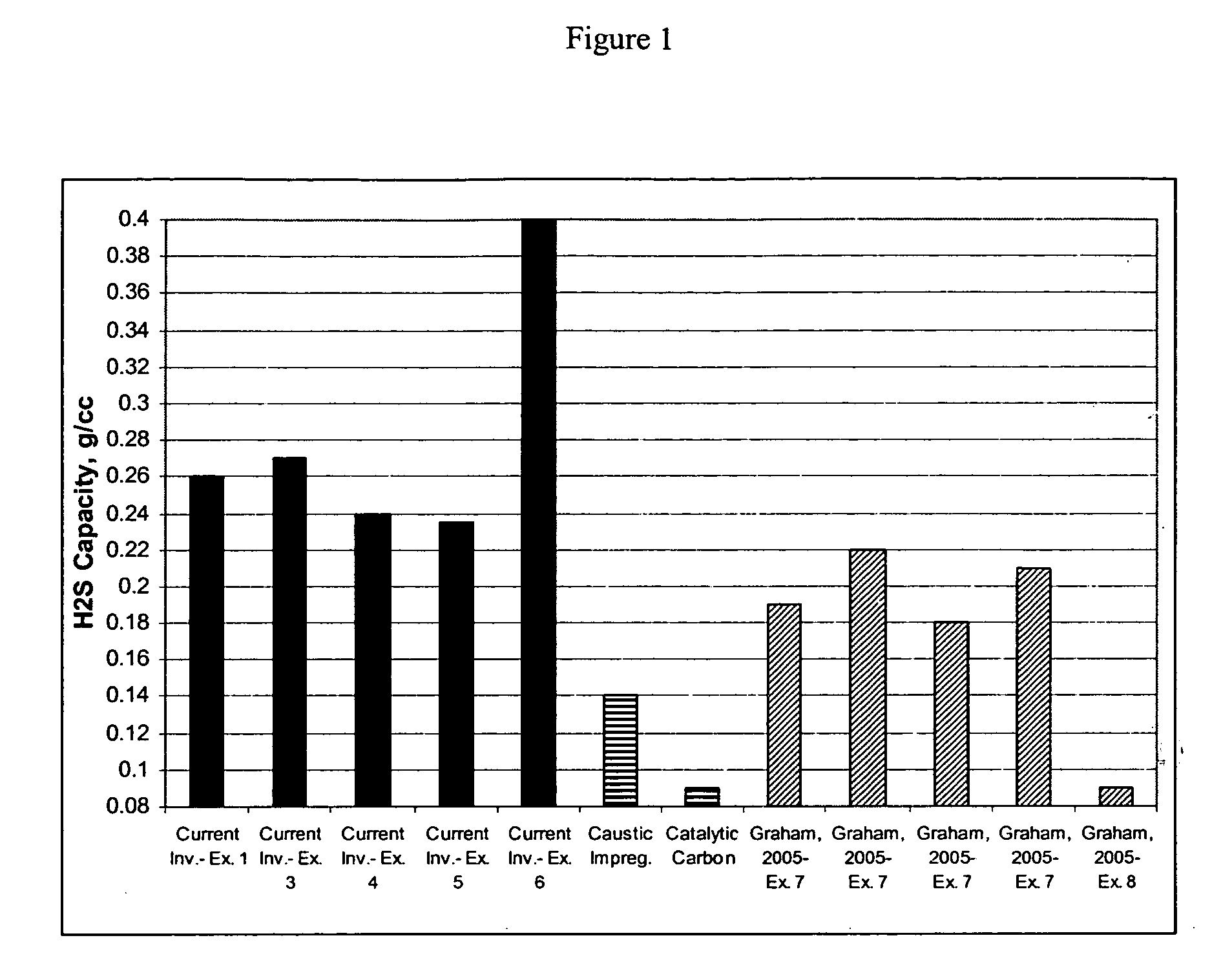

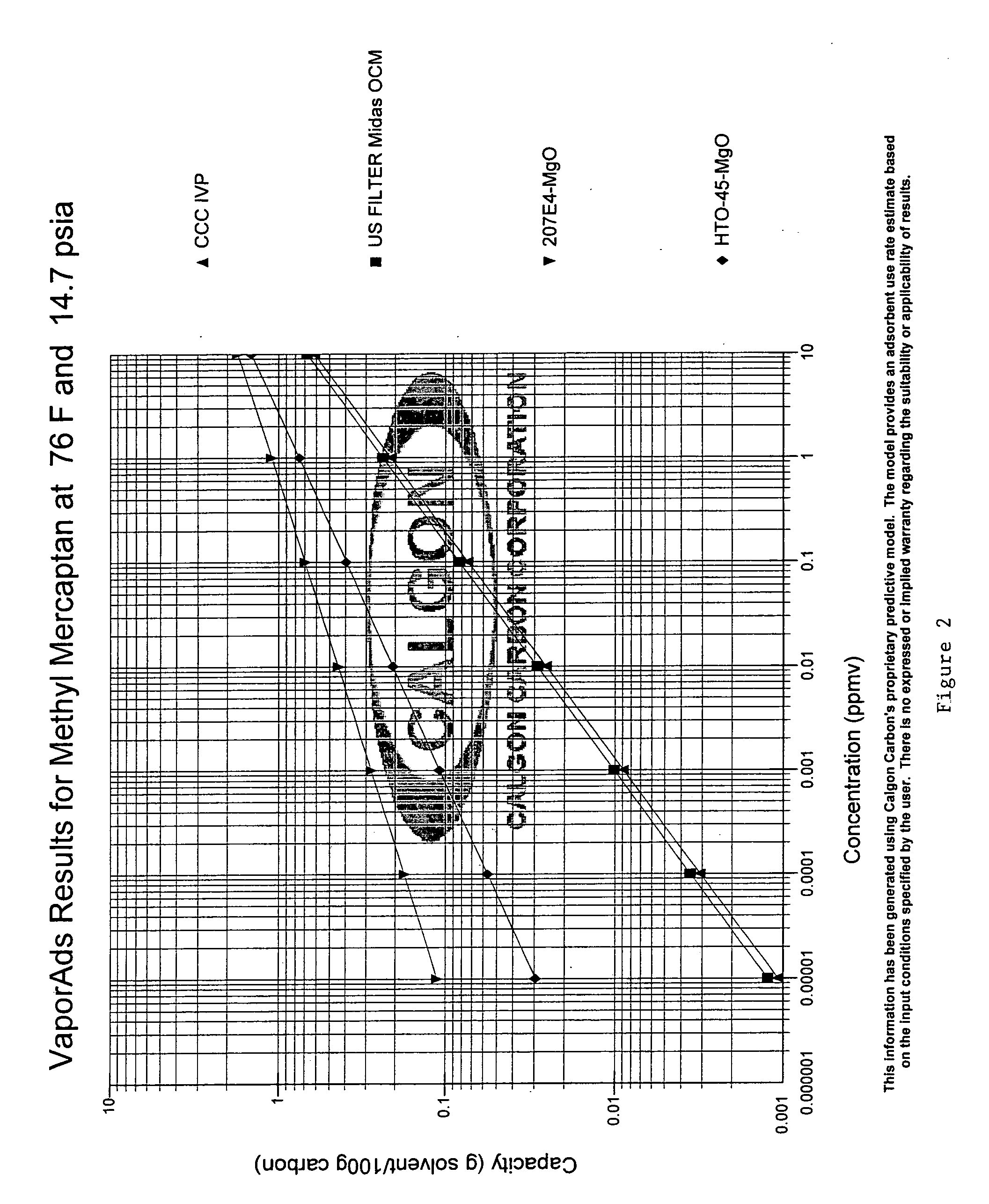

Adsorbents for removing H2S, other odor causing compounds, and acid gases from gas streams and methods for producing and using these adsorbents

Adsorbents for removing H2S, other odor-causing compounds, and other acid gases from gas streams, as well as methods for manufacturing and using adsorbents, are provided. Adsorbents comprise a porous media in which at least one metal oxide is primarily distributed on or over the surface of the pores of the media. In an example, the porous media is activated carbon and the metal oxide is magnesium oxide. The adsorbents of the present invention are particularly useful for removing odor caused by hydrogen sulfide and organic sulfinur compounds that are common at municipal waste treatment plants, paper mills and industrial plants.

Owner:CALGON CARBON

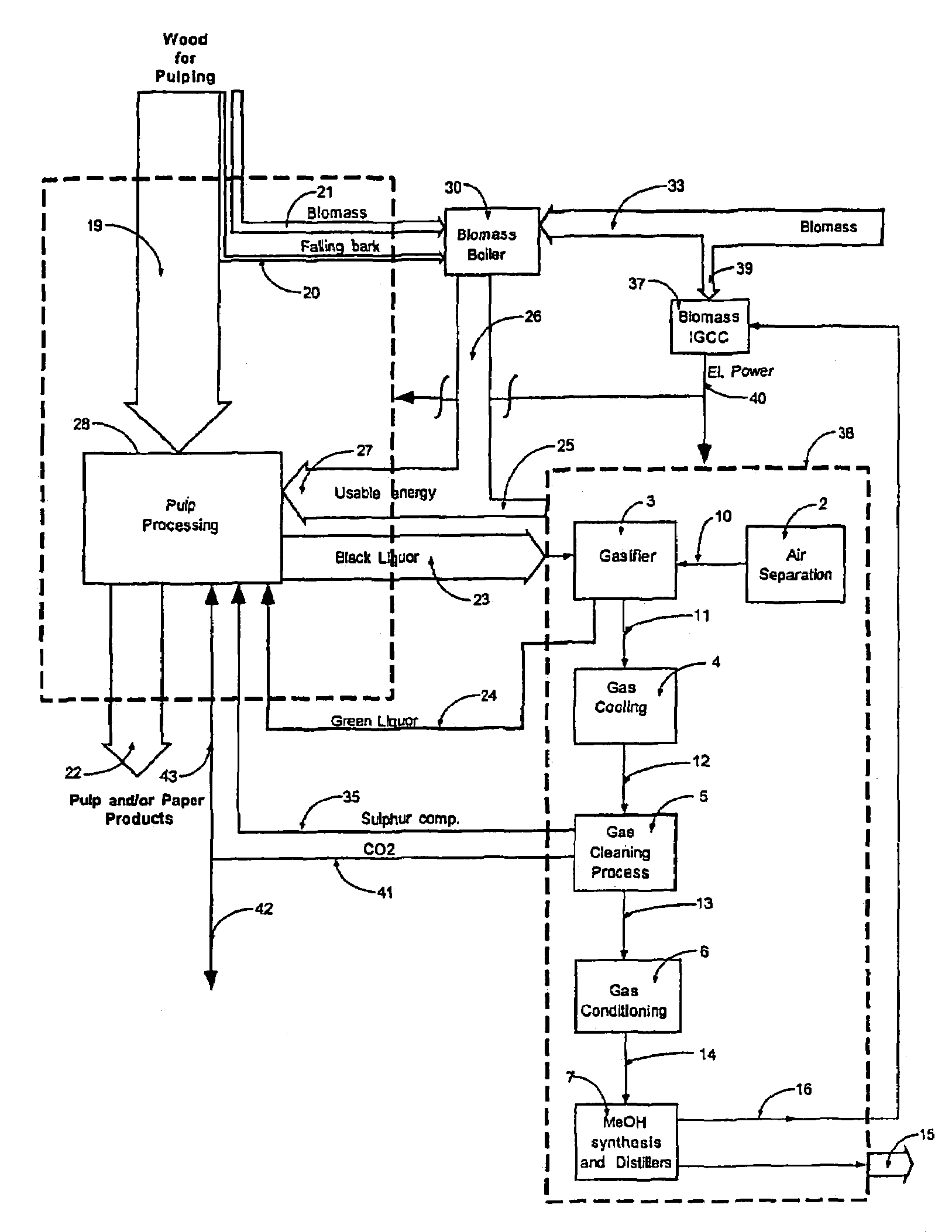

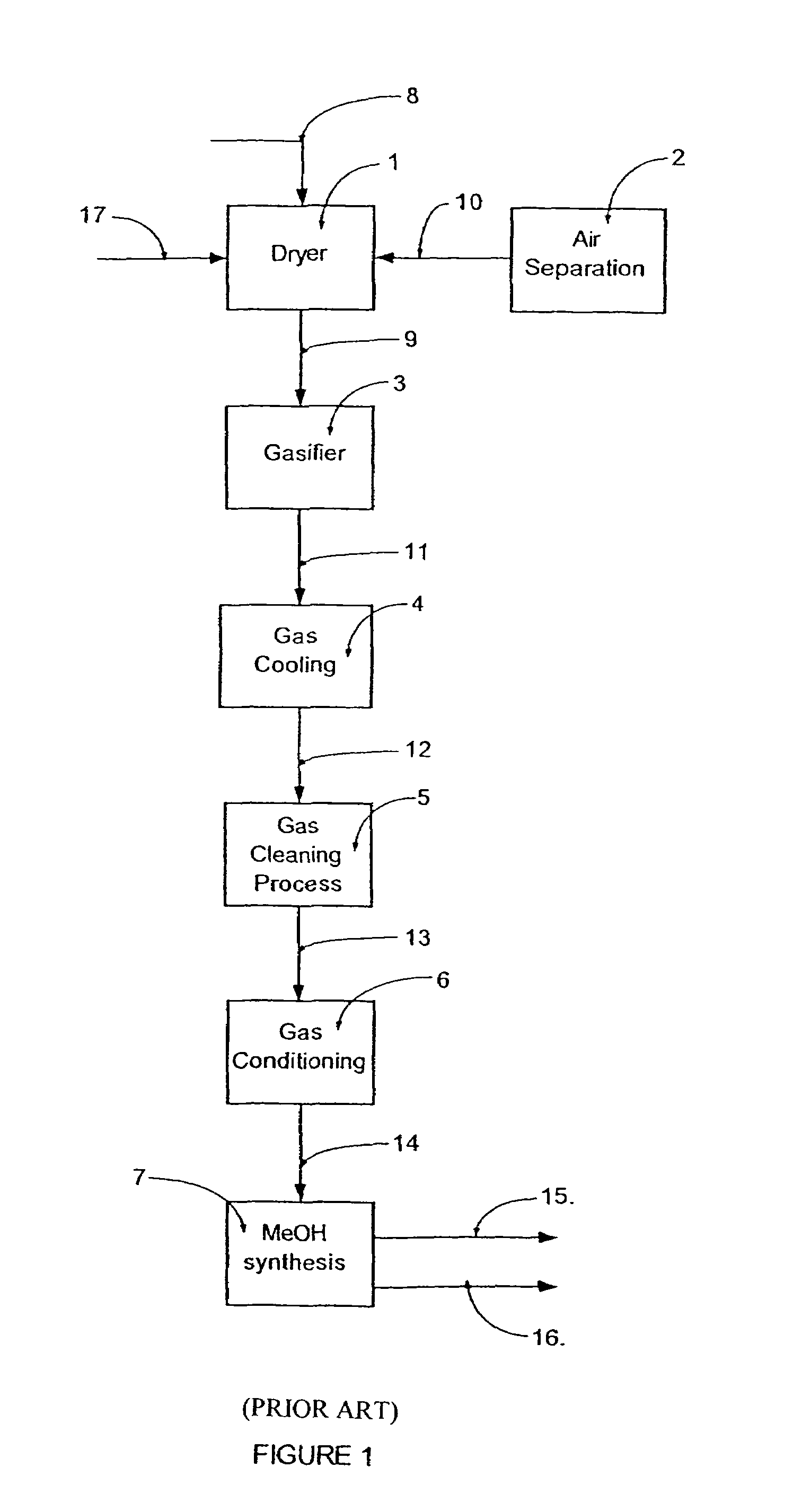

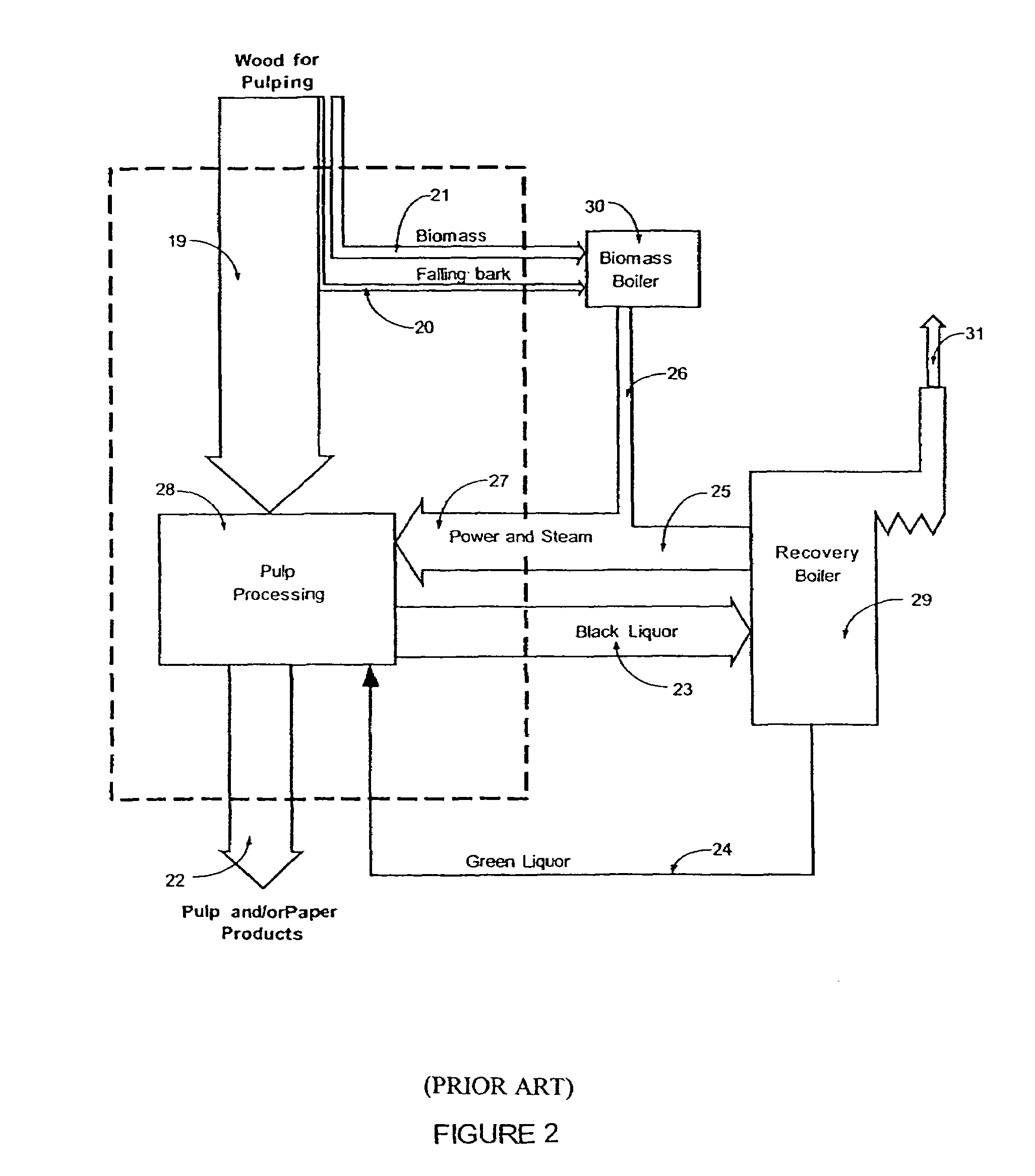

Process for production of synthesis gas in combination with the maintenance of the energy balance for a pulp mill

InactiveUS7294225B2Simpler andImprove energy savingPulp liquors combustionHydrocarbon from carbon oxidesEnergy balancingCombustion

A process (44) for the production of pulp and paper (28), recycling of cooking chemicals (3, 29), combustion of biomass (30, 37) and generation of heat and electric energy (27, 40) comprising a pulp and paper mill (28), in that the part of the process which is recycling cooking chemicals is adjusted from combustion (29) to gasification (3) to generate synthesis gas (14); and that biomass is added (33, 39) in an amount sufficient for compensating of the decrease in heat and electricity generation as a consequence of the generation of synthesis gas (14).

Owner:CHEMREC AB

Method for preparing active carbon from pulping paper mill sludge

The invention relates to a method for preparing active carbon by sludge in a pulp and paper mill. The method comprises the following steps: after being dried, crushed and screened, the sludge is impregnated and dried with the solution of zinc chloride, sulphuric acid or phosphoric acid; later the treated sludge is put into a pyrolysis furnace and activated for 10 to 90min under anoxic condition when the temperature is increased to 400 to 700 DEG C, with the heating rate of 10 to 40 DEG C per min; and when the activated product is cooled, through the impregnation of HCl and / or NaOH solution, the rinse and dry of distilled water, the active carbon is obtained. The method has simple process flow, low energy consumption, less pollution, low cost, wider mesopore and micropore distribution as well as larger pore volume of the active carbon, shows good adsorption property in the aspect of sewage treatment, and provides an optional new channel for the resource utilization of the sludge in the pulp and paper mill.

Owner:GUANGXI UNIV

Process for generating a hydrocarbon feedstock from lignin

The present invention discloses processes for generating a hydrocarbon feedstock for biofuels synthesis from lignin via hydroprocessing. Embodiments of the present invention can occur in a refinery setting or in a paper mill setting. Embodiments of the present invention can utilize the separated lignin or the entire black liquor solution.

Owner:CHEVROU USA INC

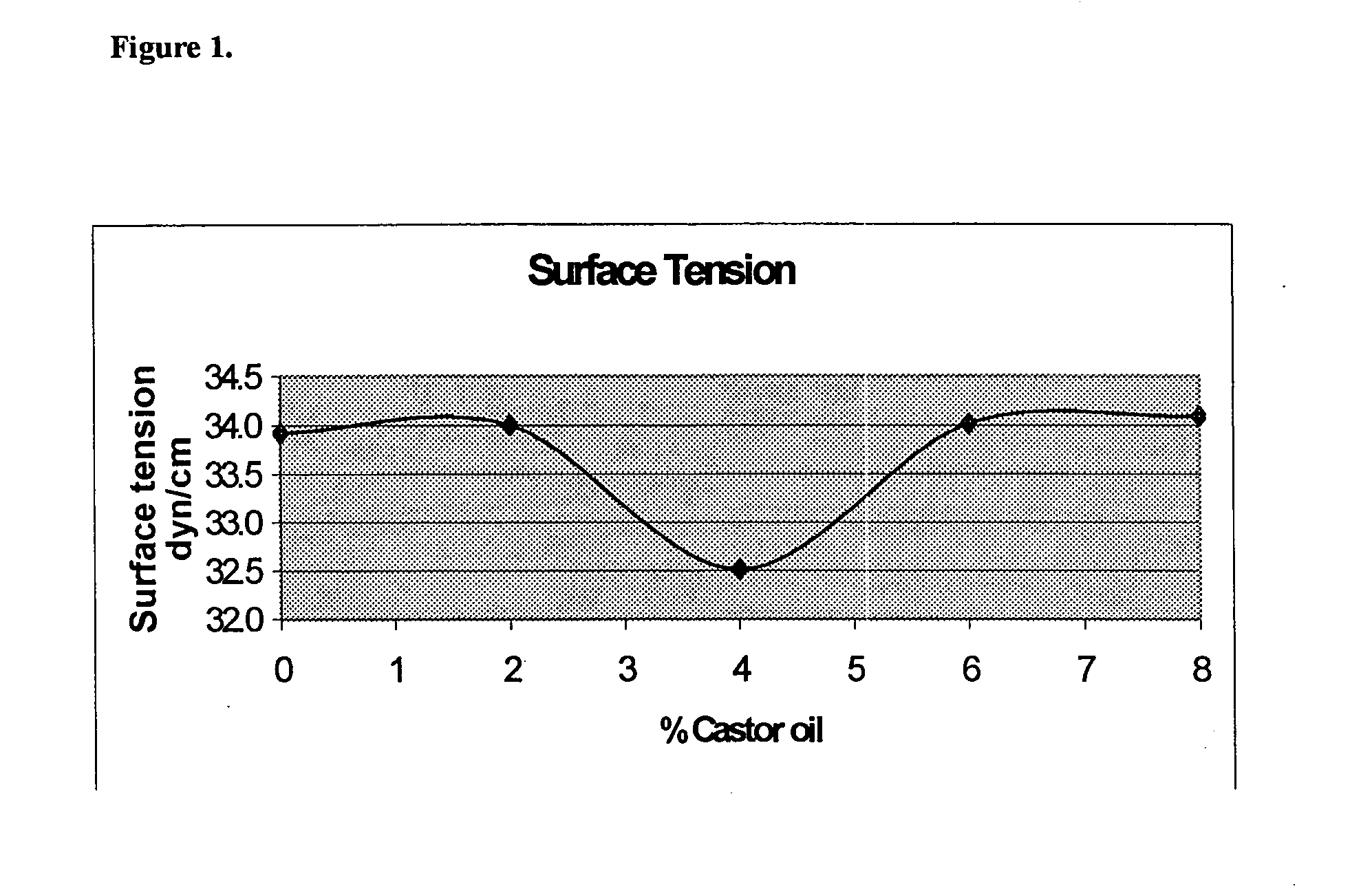

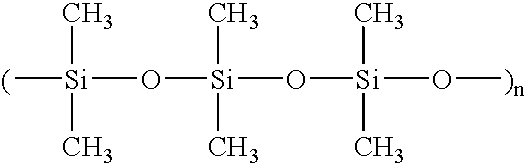

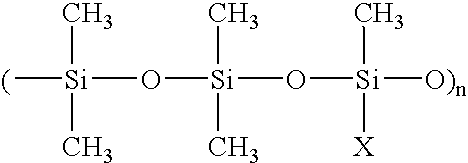

Defoamer emulsion compositions for pulp mill applications

InactiveUS20060128816A1Reduce usageLow costNatural cellulose pulp/paperDefoamers additionPulp millHydrophobic silica

An oil-in-water emulsion useful as a defoamer for pulp and paper mill applications is described. The defoamer has an oil blend (of a triglyceride oil or a mixture of triglyceride oils and silicone), a stabilizing agent (to make the oil blend stable in the emulsion), hydrophobic silica particles, surfactants, dispersants, and other components. The emulsion is usable directly at low concentrations to control foam.

Owner:SOLENIS TECH CAYMAN

Composite cat litter granule containing entrapped small size silica gel particles

InactiveUS6895896B1Improved odor controlEasy to controlAnimal housingOther apparatusPrillFilling materials

The present invention is directed to enhancing the odor control of a manufactured composite cat litter granule by including as a component thereof and entrapped therein an effective odor controlling amount of small size silica gel particles. The manufactured granule preferably includes a clay component but may rather include any number of absorbent filler materials such as paper mill sludge, recycled paper, corn cob renderings, rice or peanut hulls, or other organic plant materials, so long as the materials can be agglomerated into a cat litter granules and entrap small size silica gel particles.

Owner:BLOOMER LARRY D

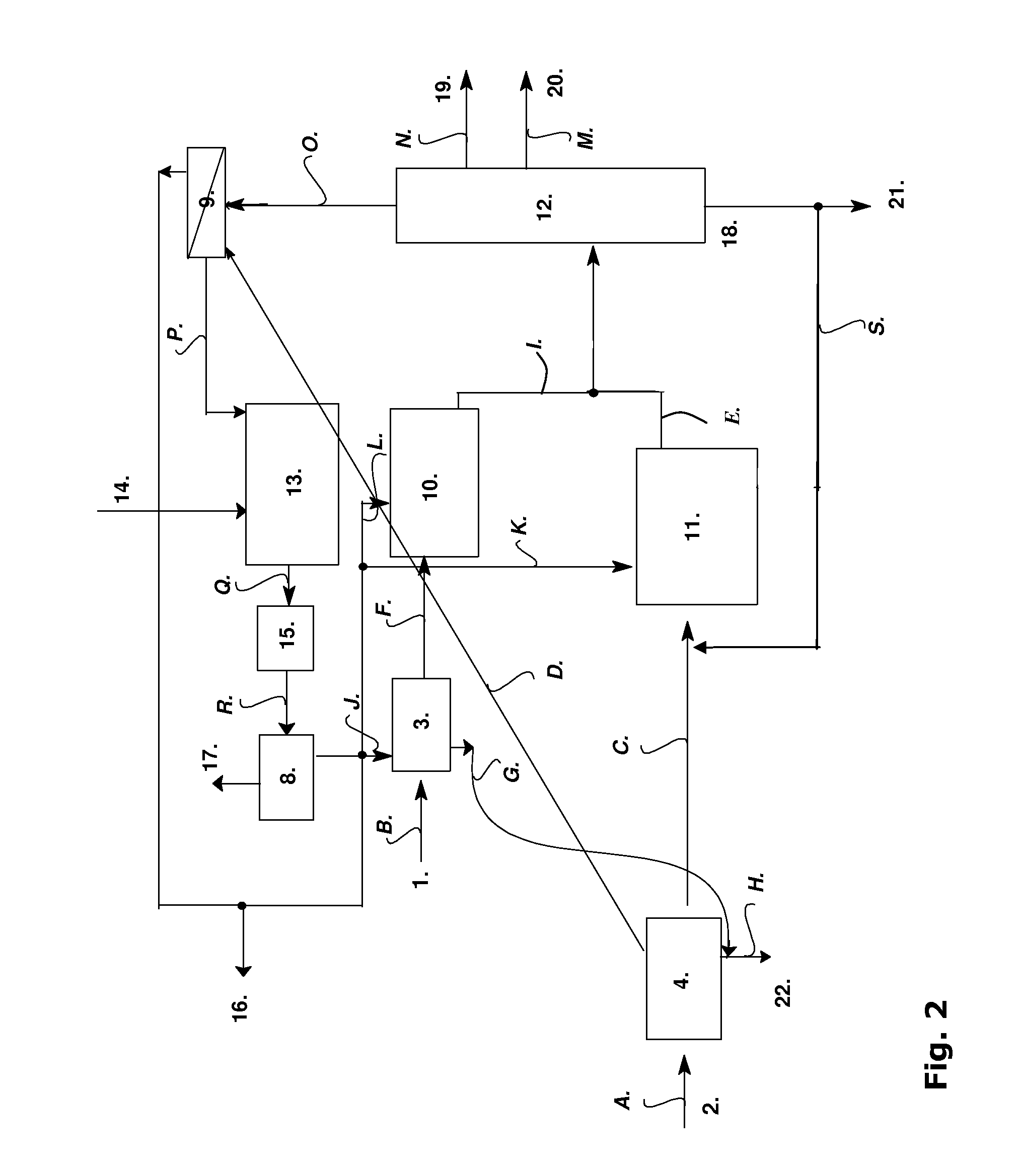

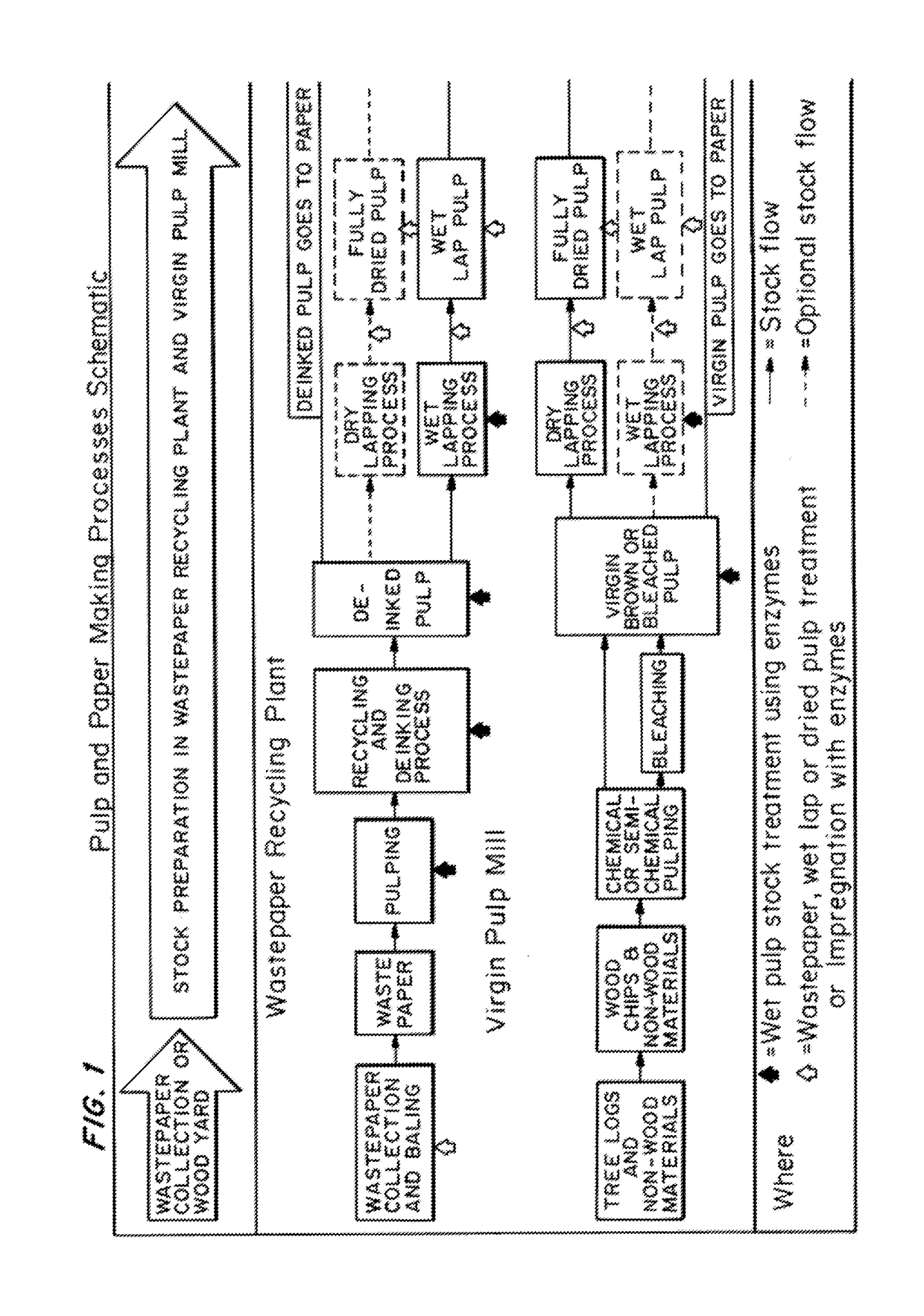

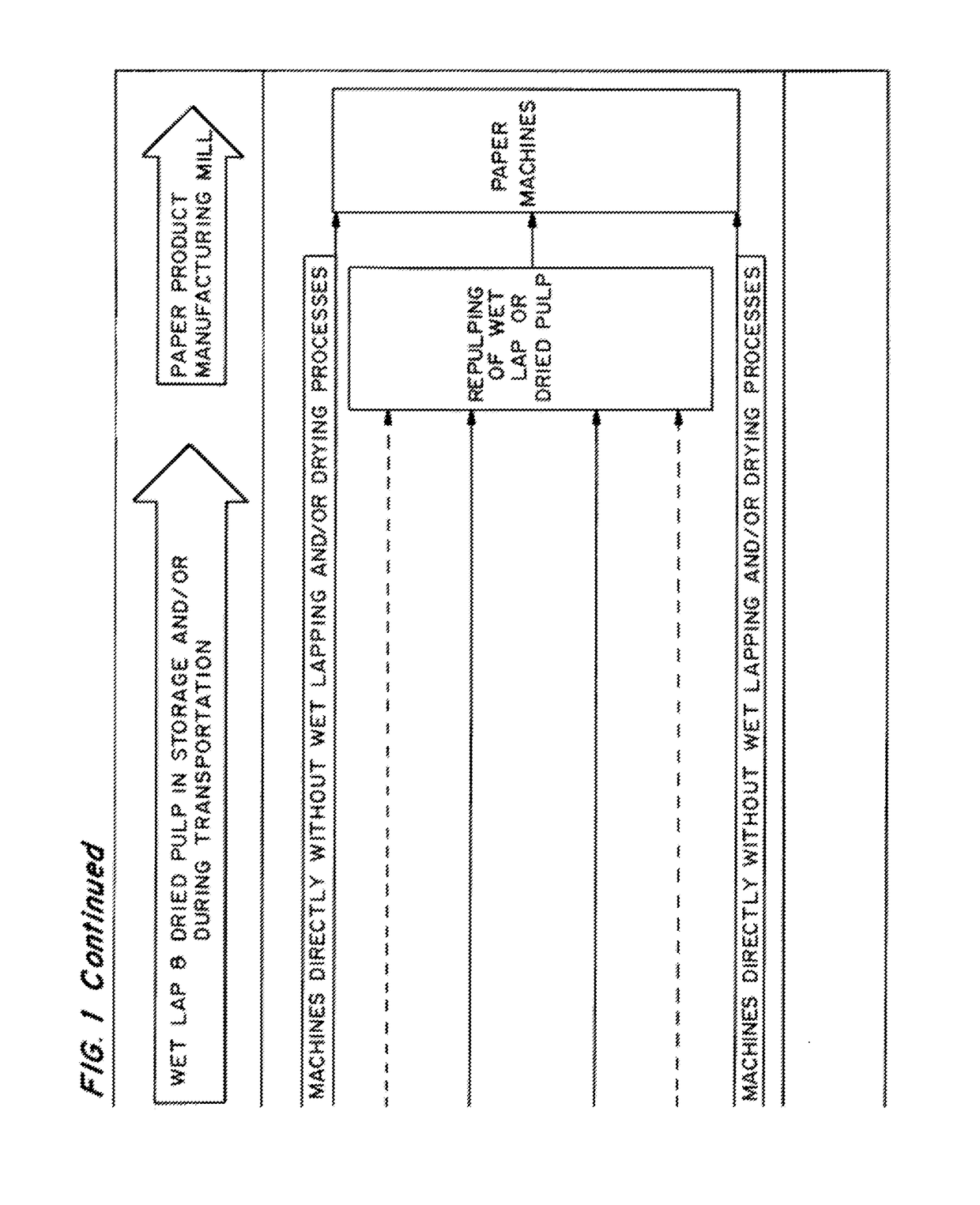

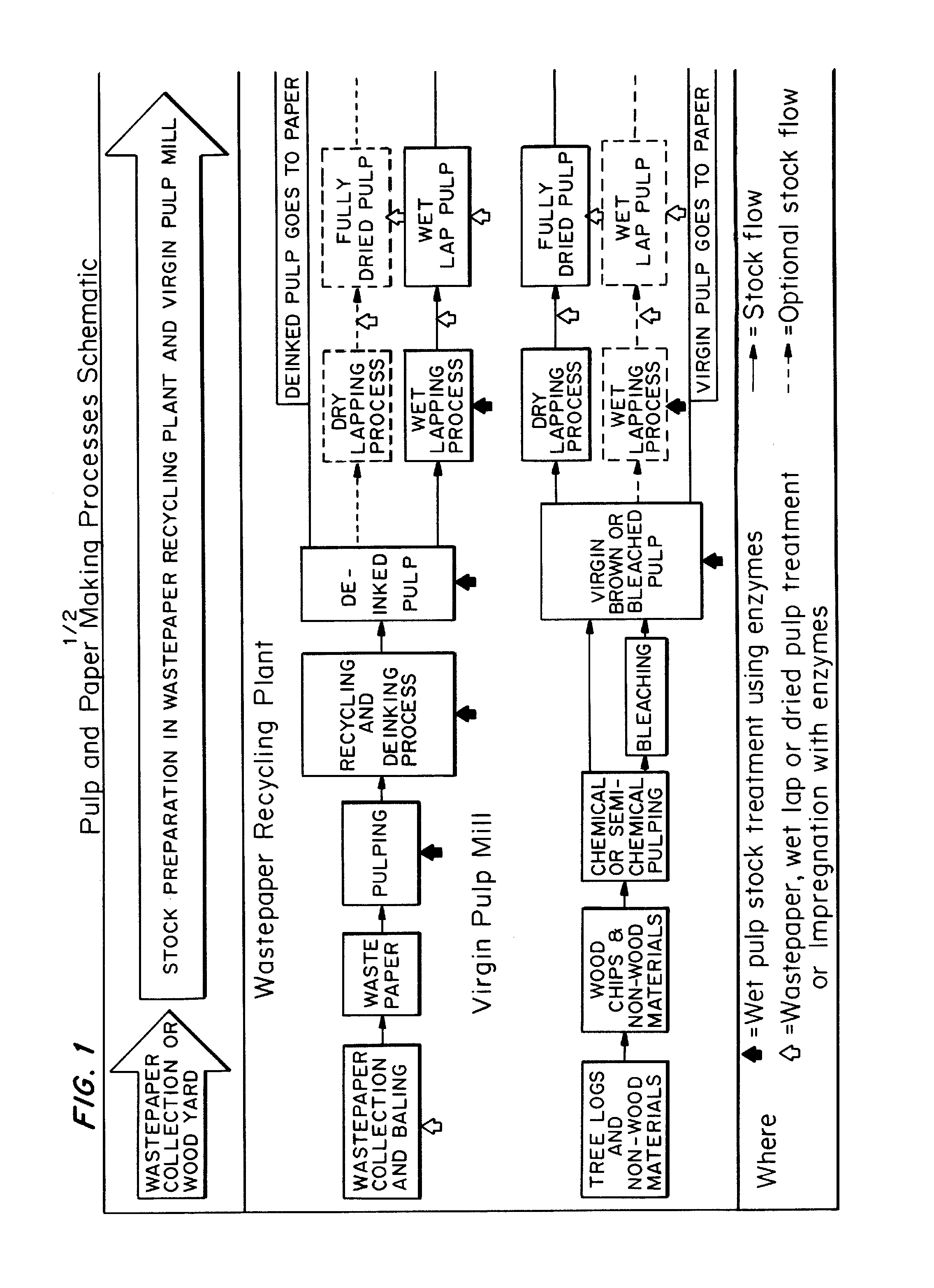

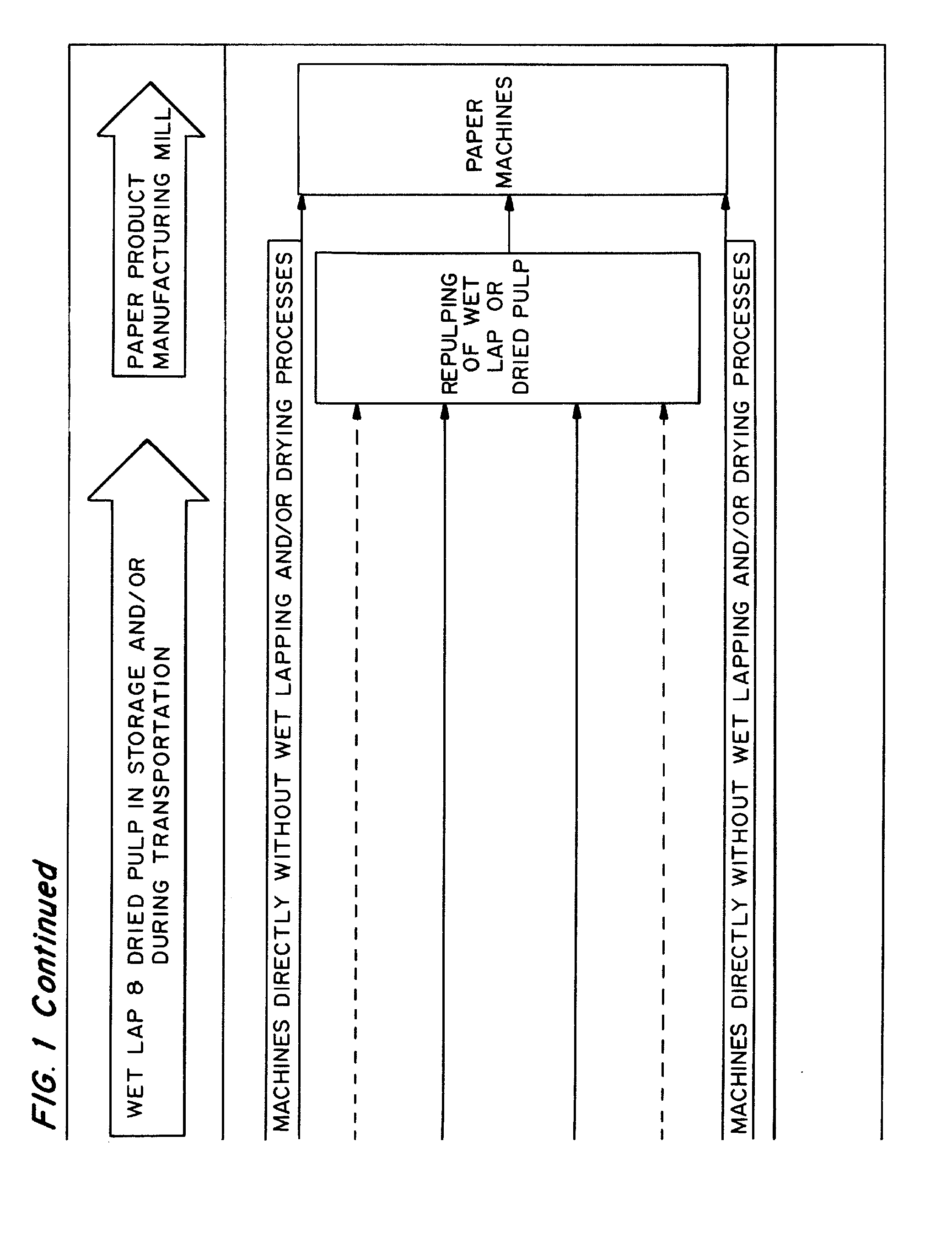

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20130146239A1Increasing pulp drainageImprove strength propertiesMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Methods for reducing the effects of wetlapping, drying, and hornification of pulp fibers and consequently increasing the pulp drainage and strength properties in the final product (i.e., paper) are provided. The method which has been developed creates a “value-added” product by the wastepaper supplier or at the pulp and / or deinking (recycled paper) mill—a wastepaper load / bale, wet pulp stock or wet lap, or dried pulp treated with or impregnated with enzymes that enhance the quality of the pulp or paper product when it is repulped and processed at the paper mill.

Owner:ENZYMATIC DEINKING TECH LLC

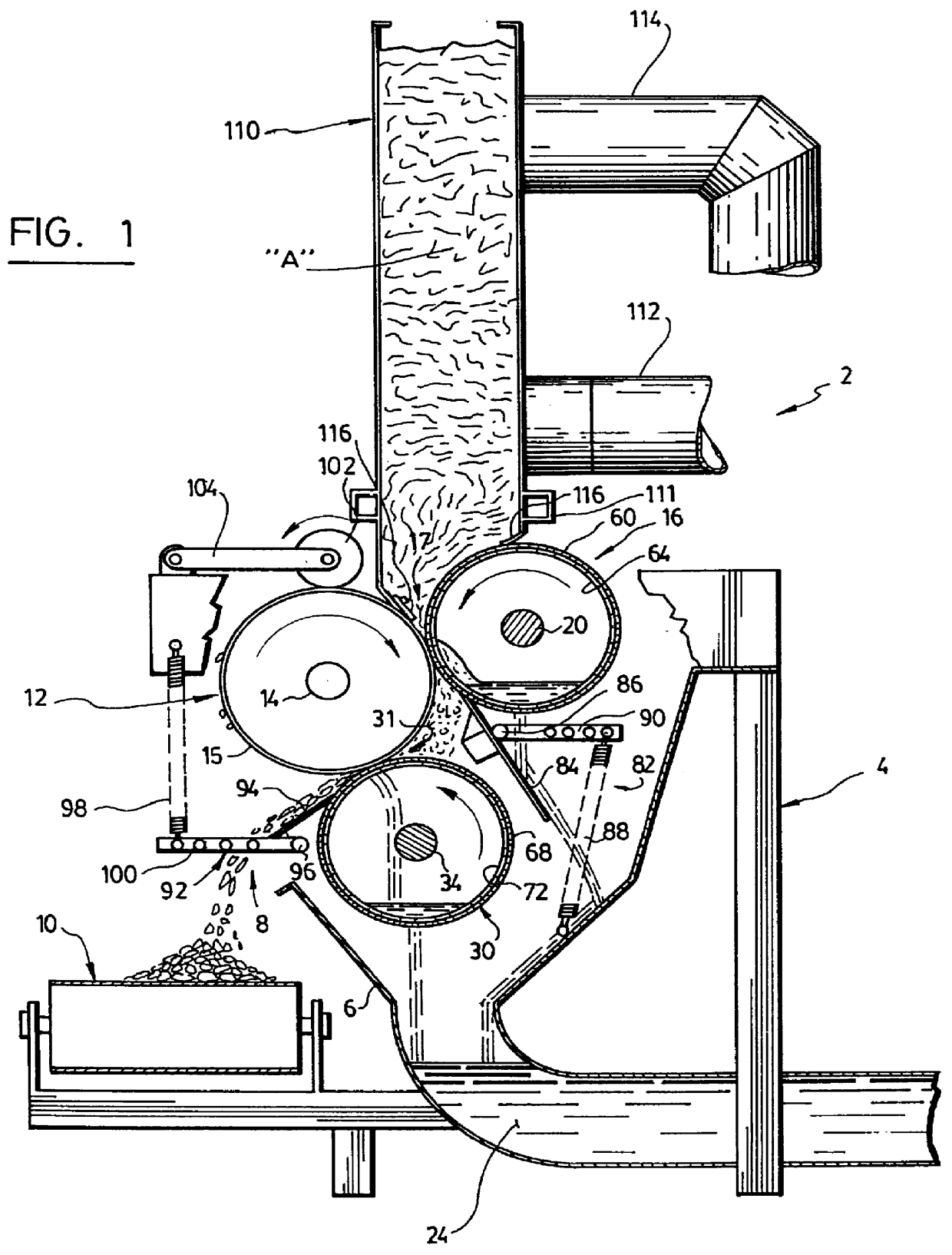

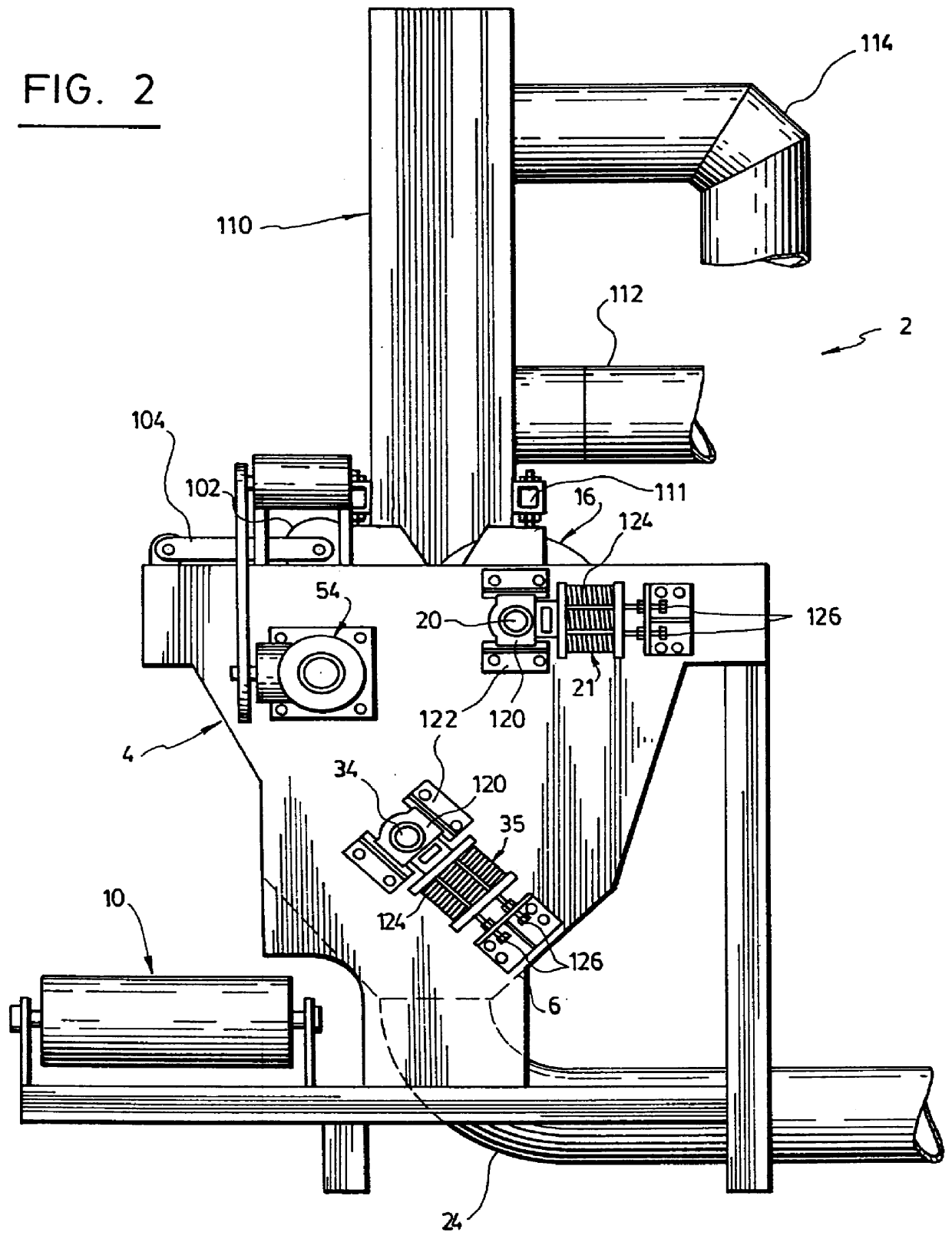

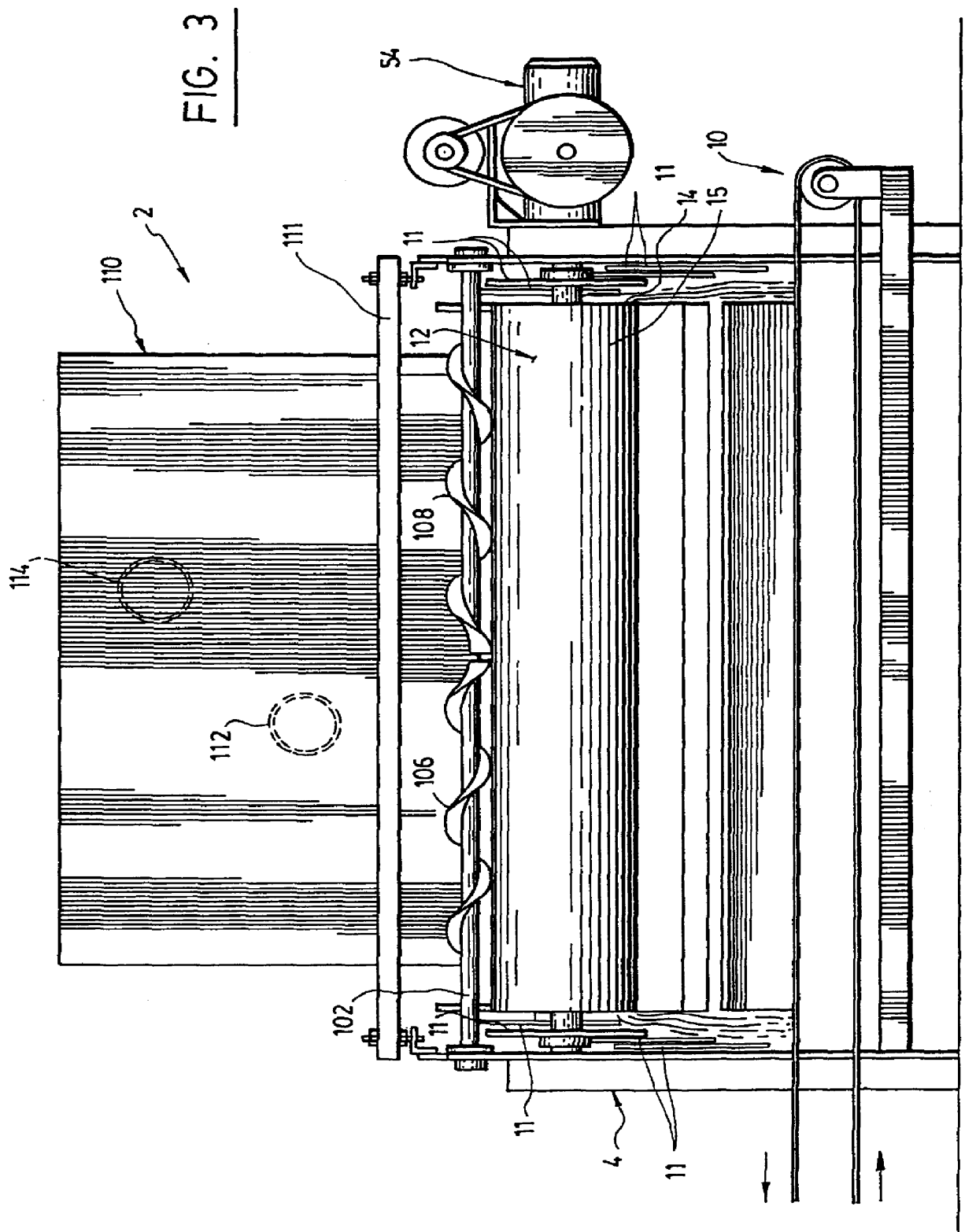

Drum press extractor

InactiveUS6044980AAvoid damage and deformationReduces rewatering of the fibers once separatedMembrane filtersPressesFiberSlurry

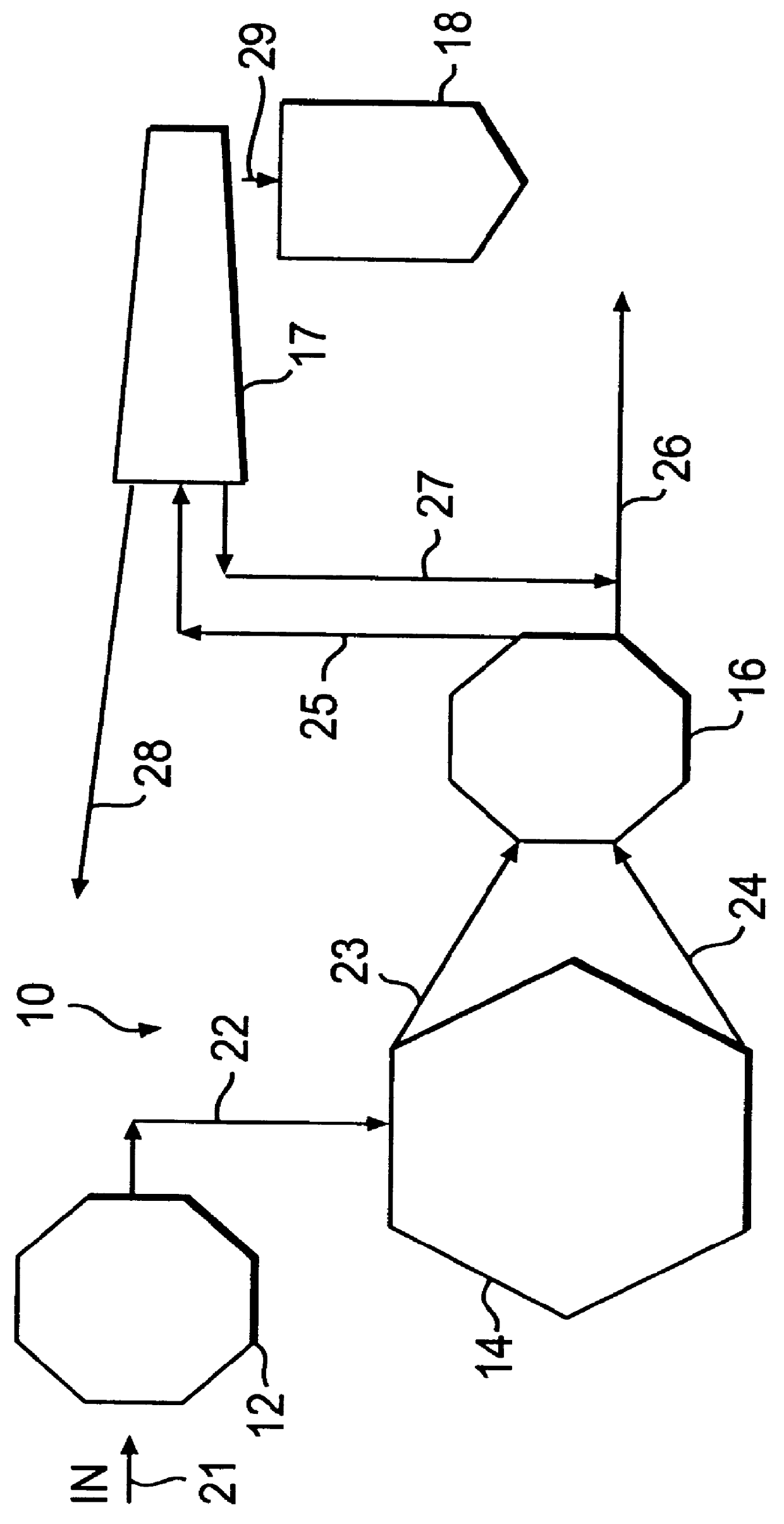

An apparatus for extracting liquids from a slurry formed of liquids and fibers, like diluted manure or paper mills residue. The apparatus has a rotatable drum covered with a resilient layer. The apparatus also has two draining rolls which are pressed against the drum so that the slurry passing in between is squeezed. Each roll has a hollow cylindrical shell with a uniform distribution of openings. Each roll also has a perforated filter screen fixed to is. The screen has perforations evenly distributed so that only some perforations lie over the openings in the shell. The perforations are smaller in size than the openings. The apparatus also has a pair of wipers in order to wipe the fibers out of the draining rolls and guide the liquids collected in the shells towards a liquids outlet. A reservoir can be mounted above the drum and upper draining roll for receiving the slurry, storing it to build-up a constant pressure, and supplying it in a continuous manner. An endless screw can also be mounted on top of the drum to scrape the fibers that may remain attached.

Owner:J HOULE & FILS

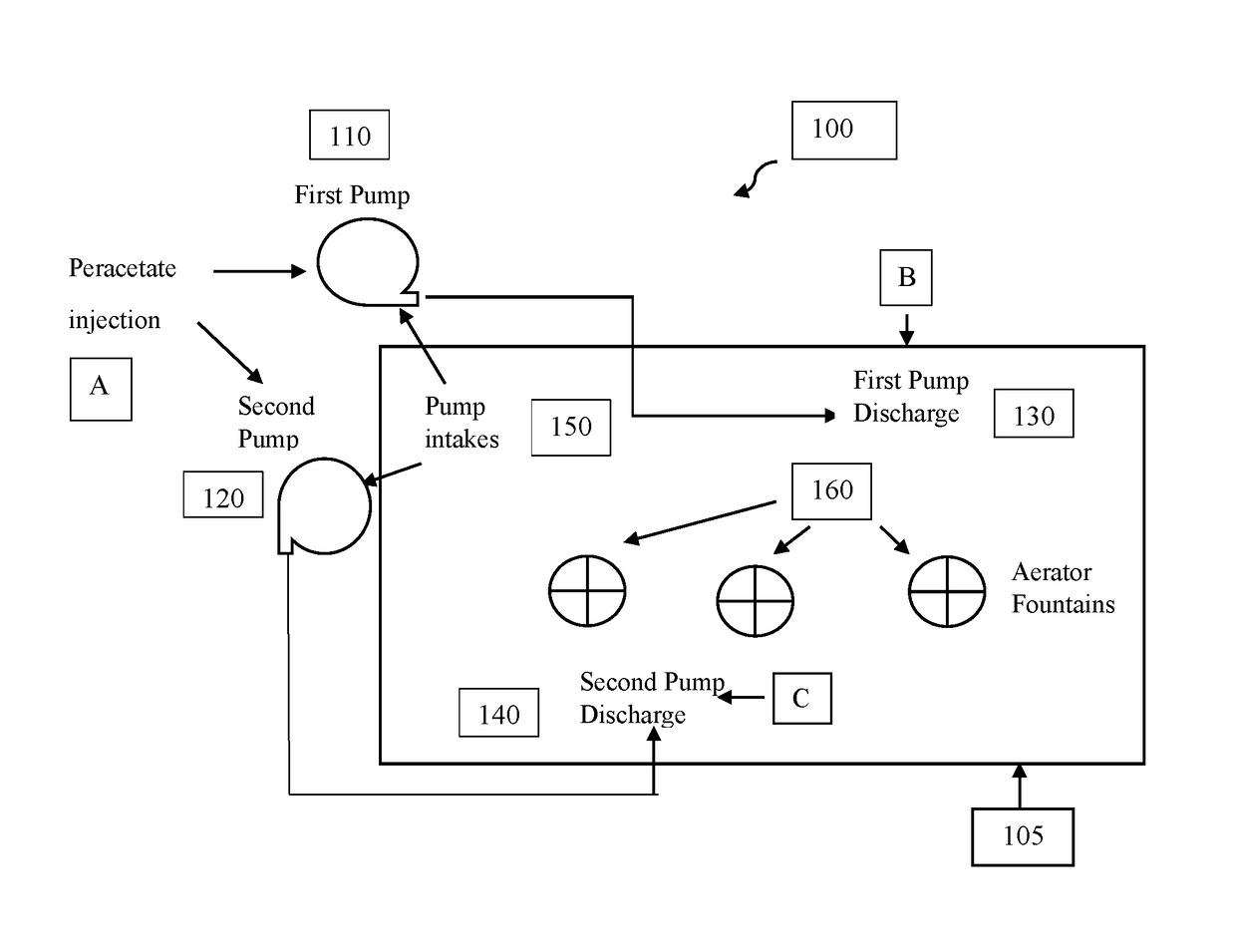

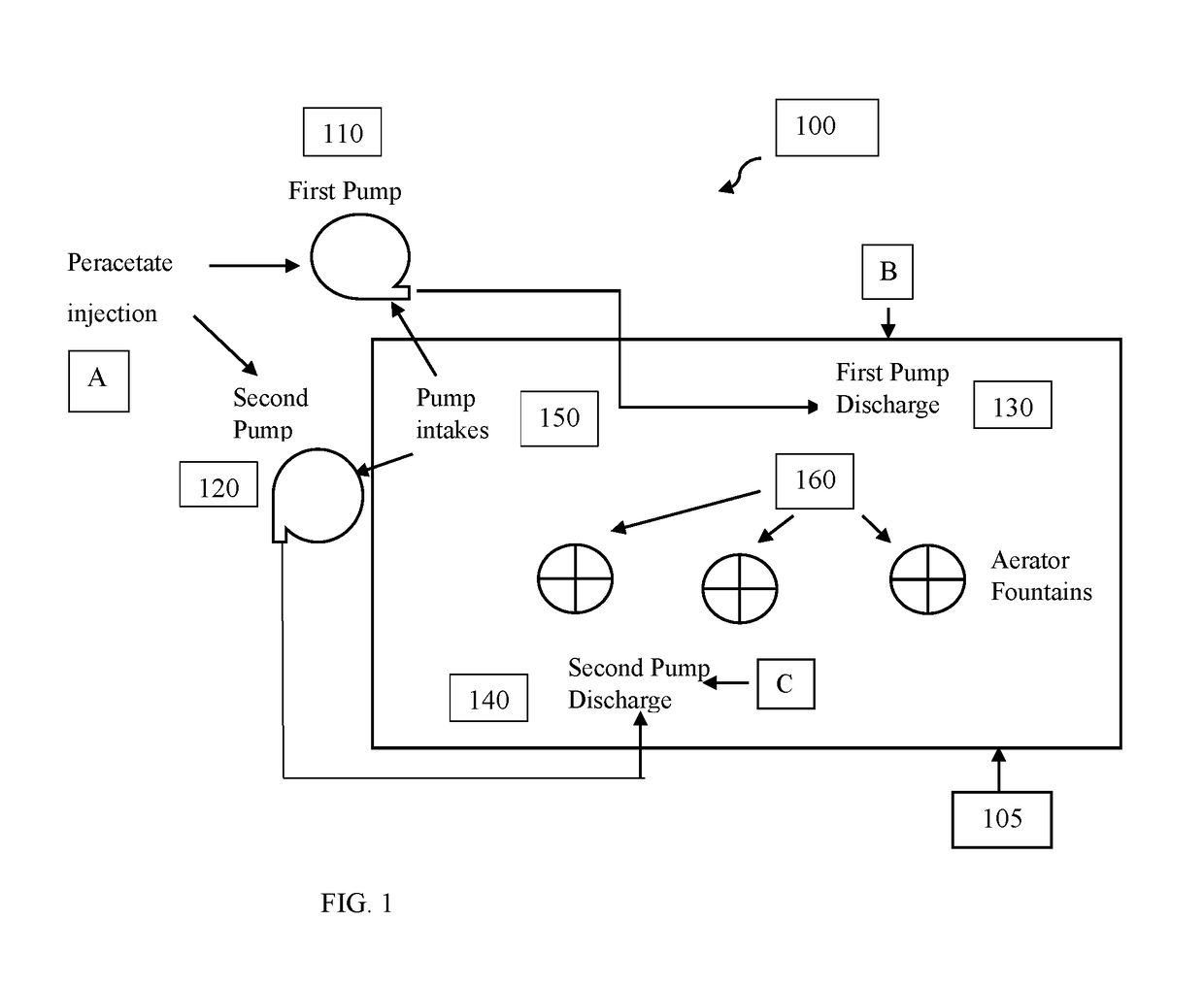

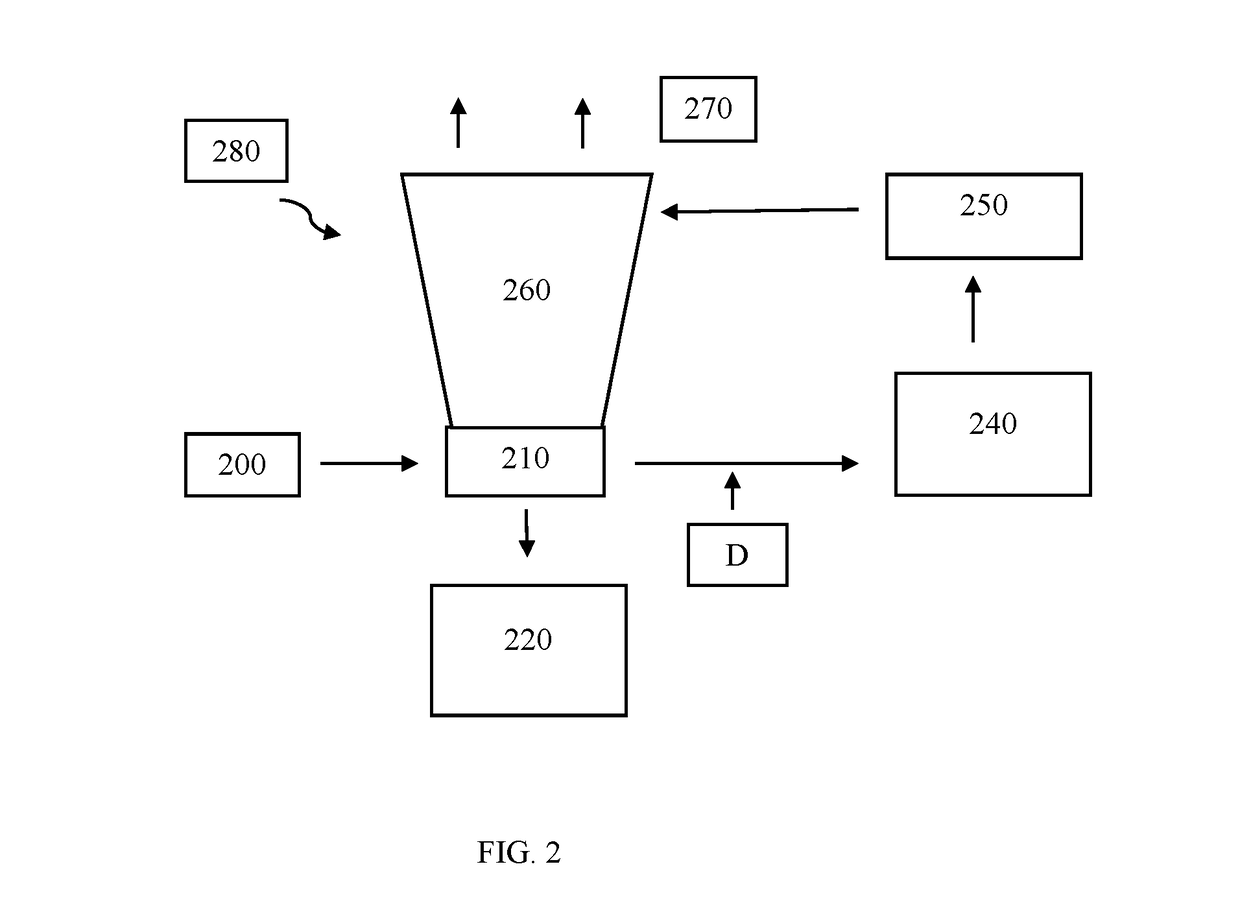

Methods of microbial control

ActiveUS20170158537A1Reduce microbial loadEasy to separateCellulosic pulp after-treatmentWater/sewage treatment using germicide/oligodynamic-processAcetic acidEnvironmental engineering

In some embodiments, a method may include reducing the microbial load in contaminated water of water recycle loops. These water recycling loops may include pulp and paper mills, cooling towers and water loops, evaporation ponds, feedstock processing systems and / or non-potable water systems. The methods may include providing a peracetate oxidant solution. The peracetate solution may include peracetate anions and a peracid. In some embodiments, the peracetate solution may include a pH from about pH 10 to about pH 12. In some embodiments, the peracetate solution has a molar ratio of peracetate anions to peracid ranging from about 60:1 to about 6000:1. In some embodiments, the peracetate solution has a molar ratio of peracetate to hydrogen peroxide of greater than about 16:1. The peracetate solution may provide bleaching, sanitizing and / or disinfection of contaminated water and surfaces. The peracetate oxidant solution may provide enhanced separation of microbes from contaminated water.

Owner:CLEAN CHEM

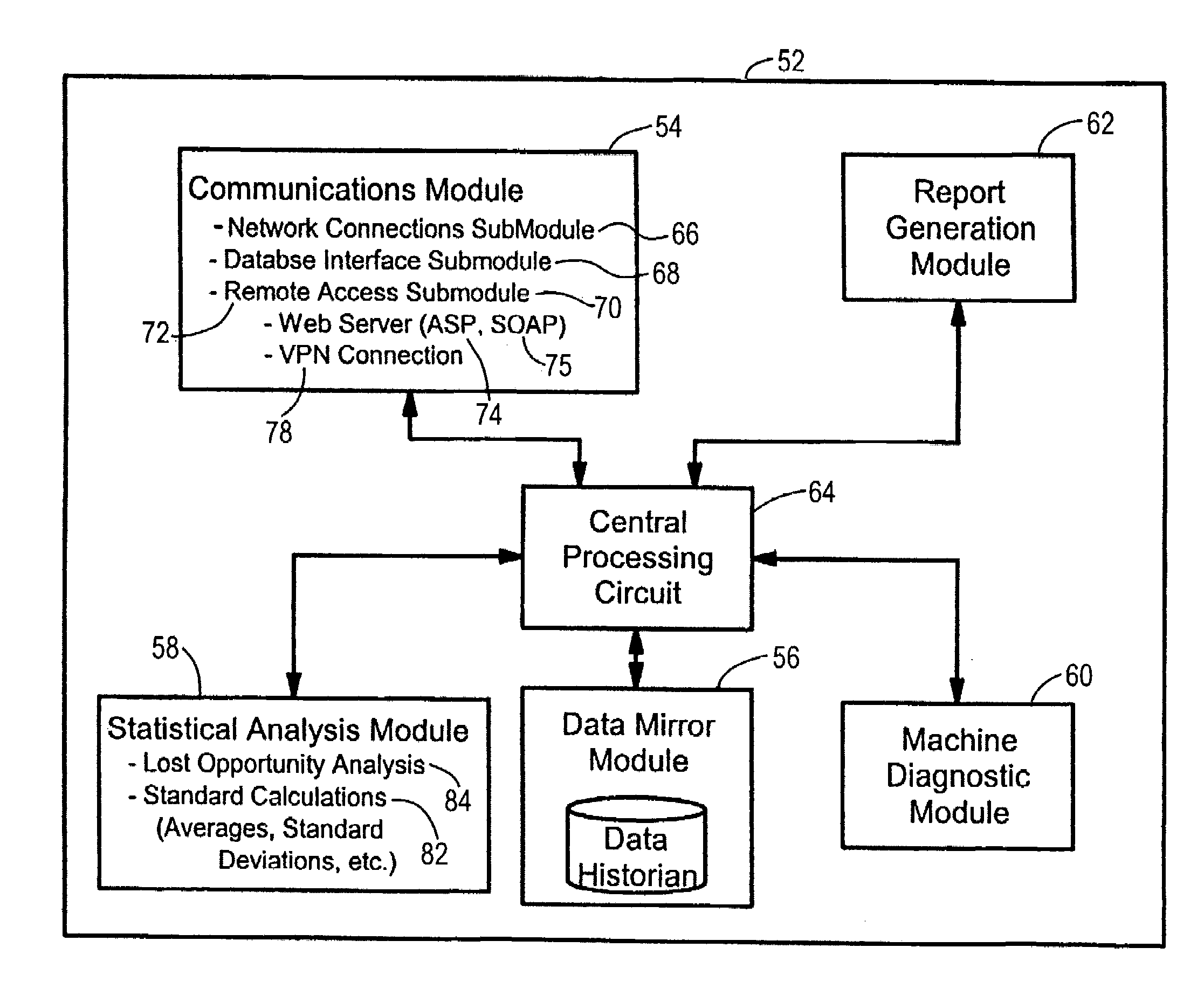

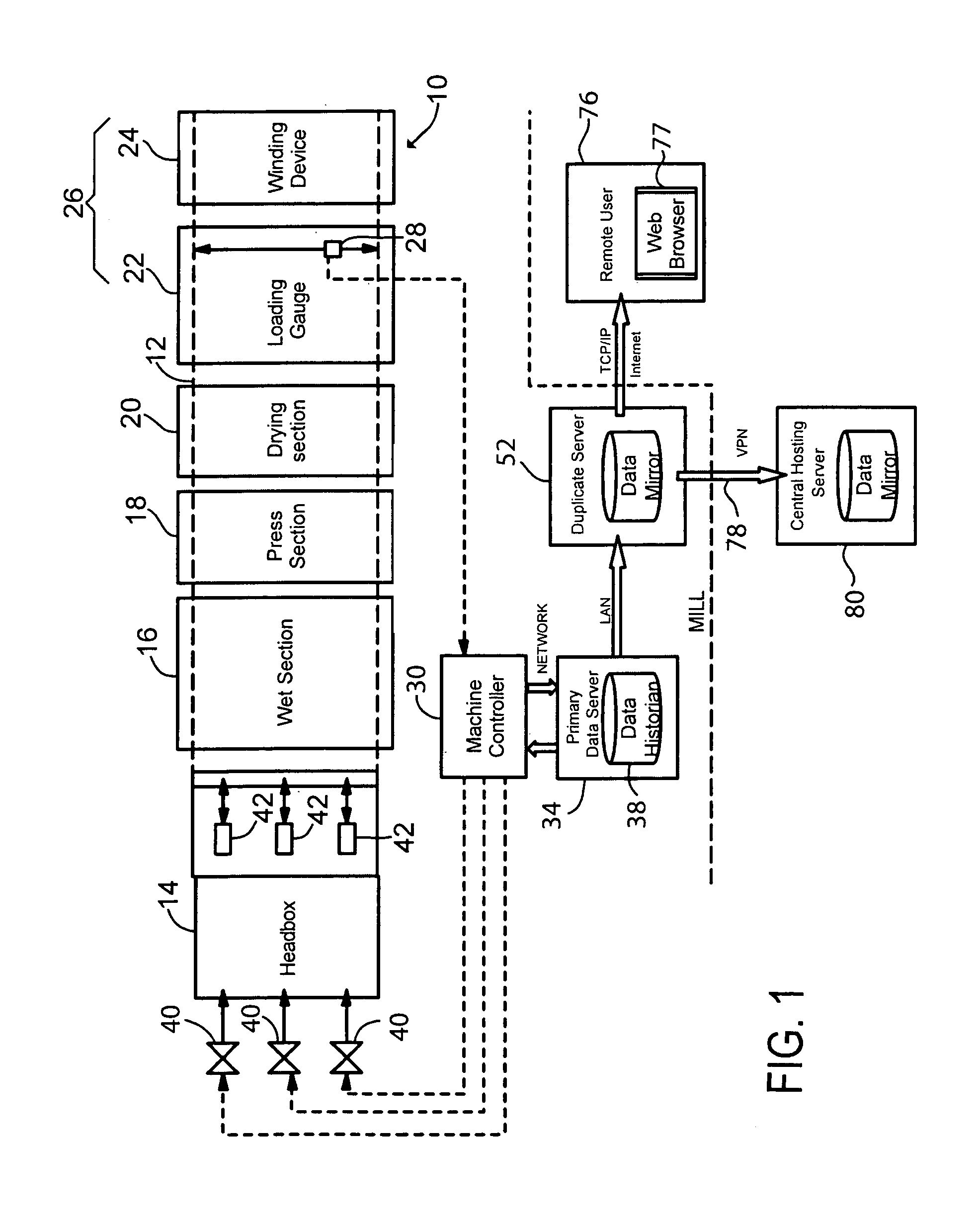

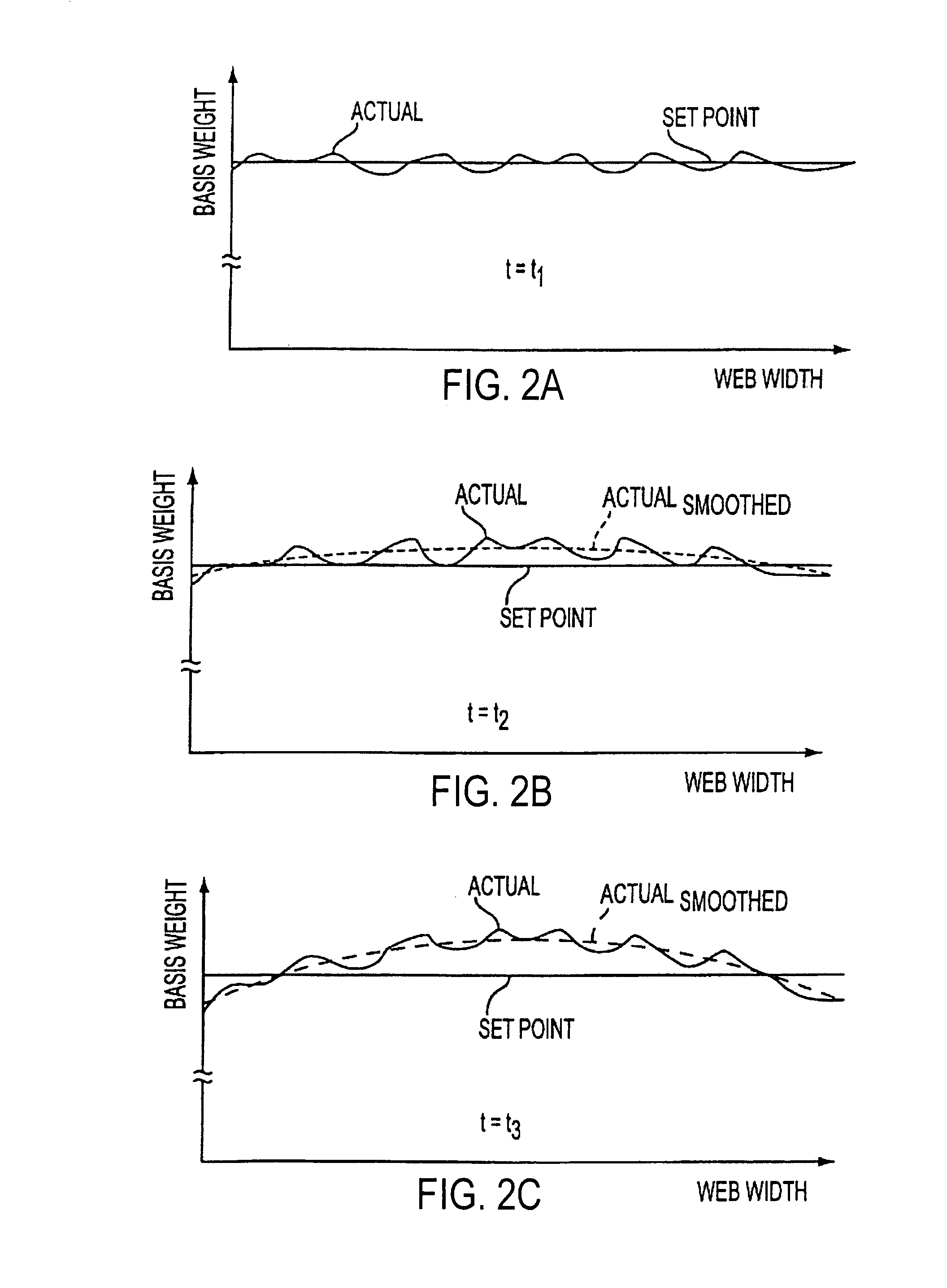

Method and system for assessing pulp and paper mill performance

A system and method is provided for analyzing data obtained during manufacture of a web of paper or paperboard on a machine. The system comprises a computer including a database module, a statistical analysis module, and a processor for executing the modules. The database module contains measurements of quality parameters obtained from the web during manufacture. The statistical analysis module is executed by the processor to analyze the measurement data and estimate a target shift in at least one quality parameter that could be made if the controllable variations were removed. The target shift can be transformed into an economic amount (i.e., dollar value) by the statistical analysis module to assist the mill operator with making well informed, economic based decisions. The system further includes a diagnostic module capable of automatically identifying machine parameters that correlate to quality parameters that caused the web to fall outside the desired quality specifications.

Owner:VOITH PAPTER

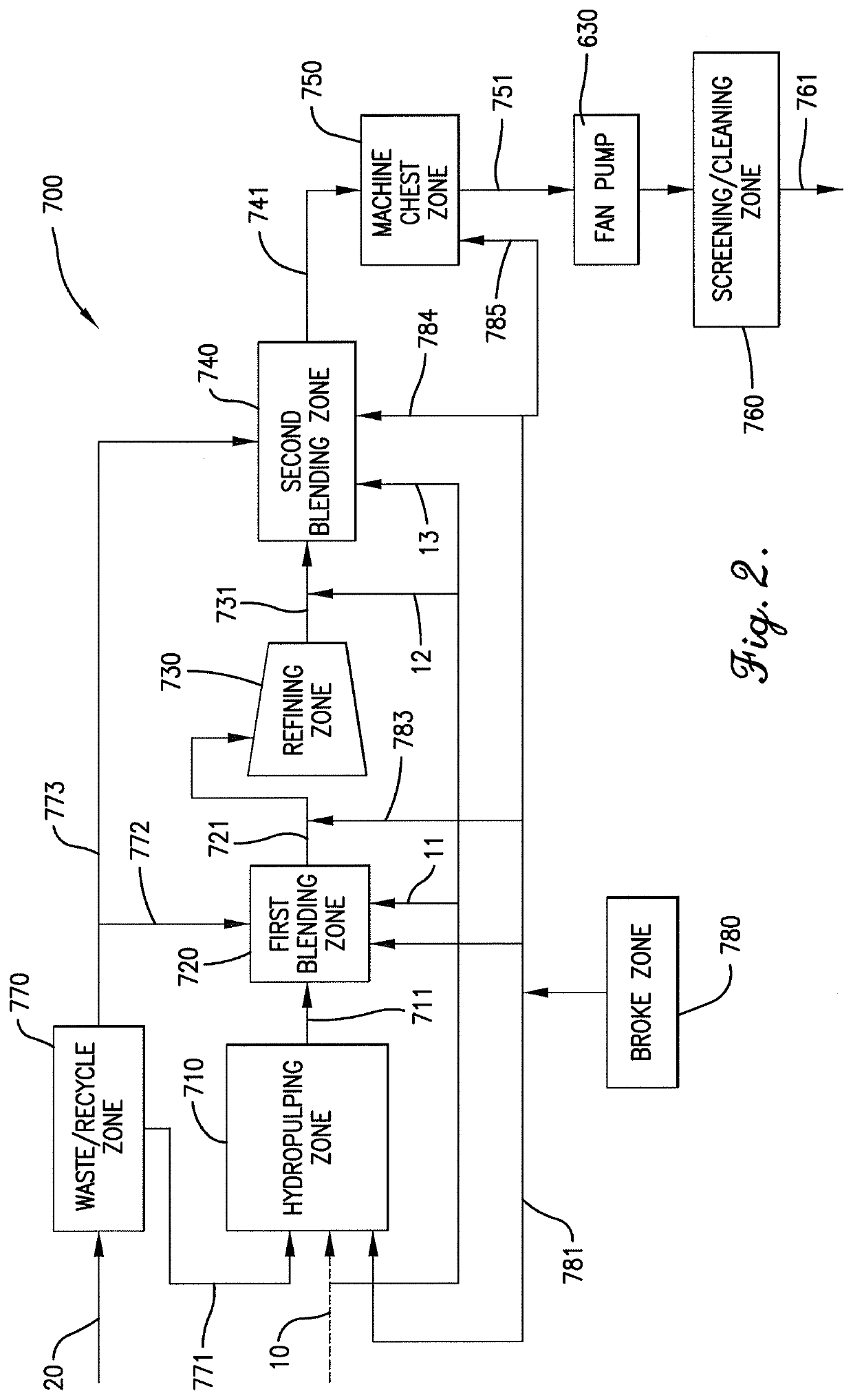

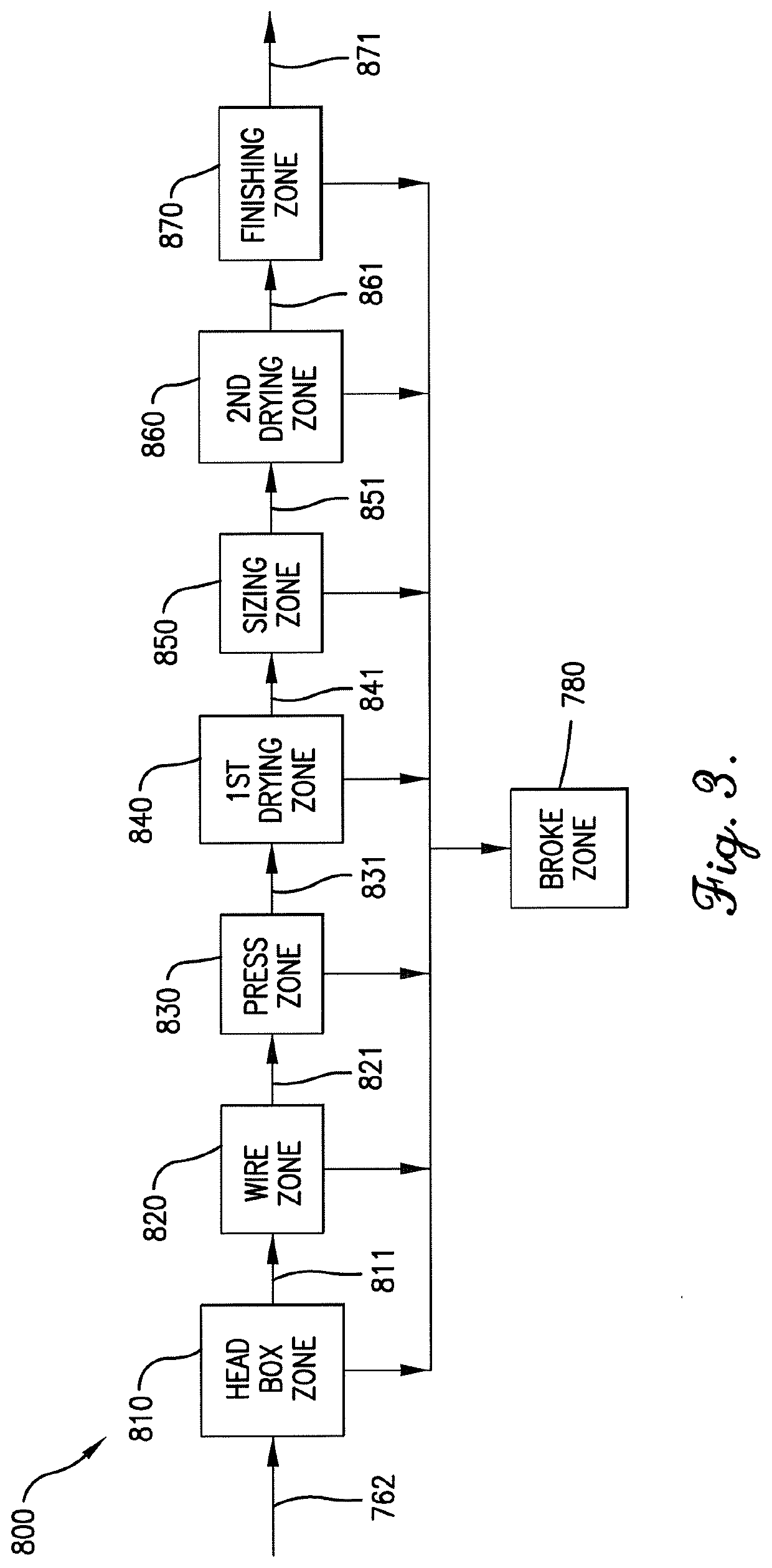

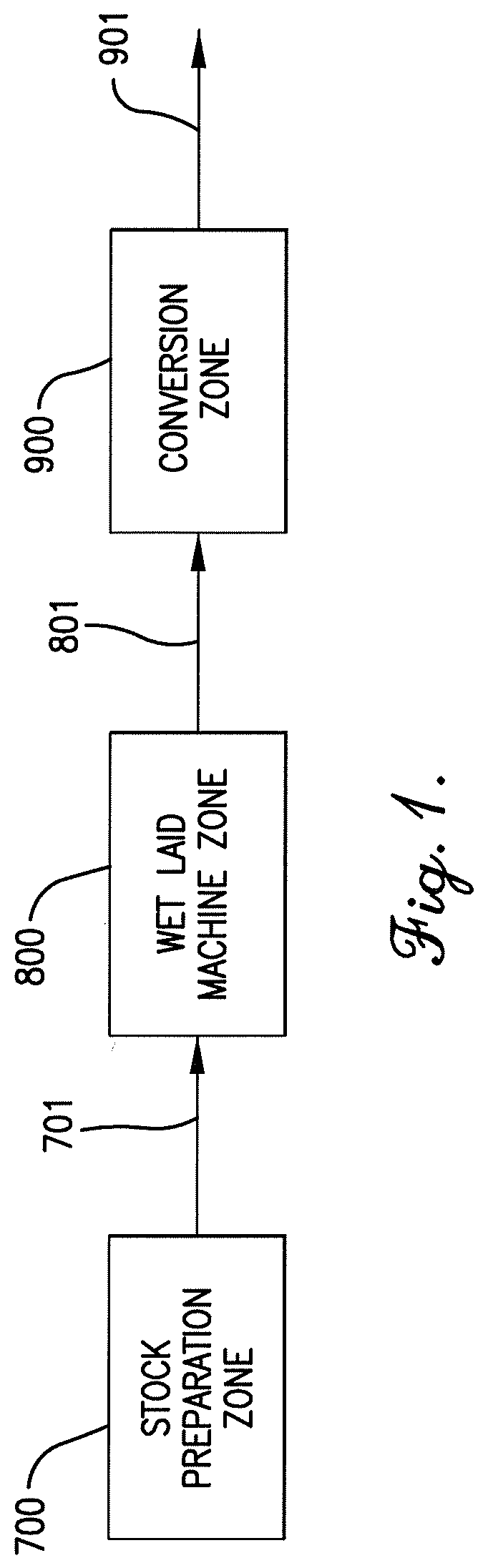

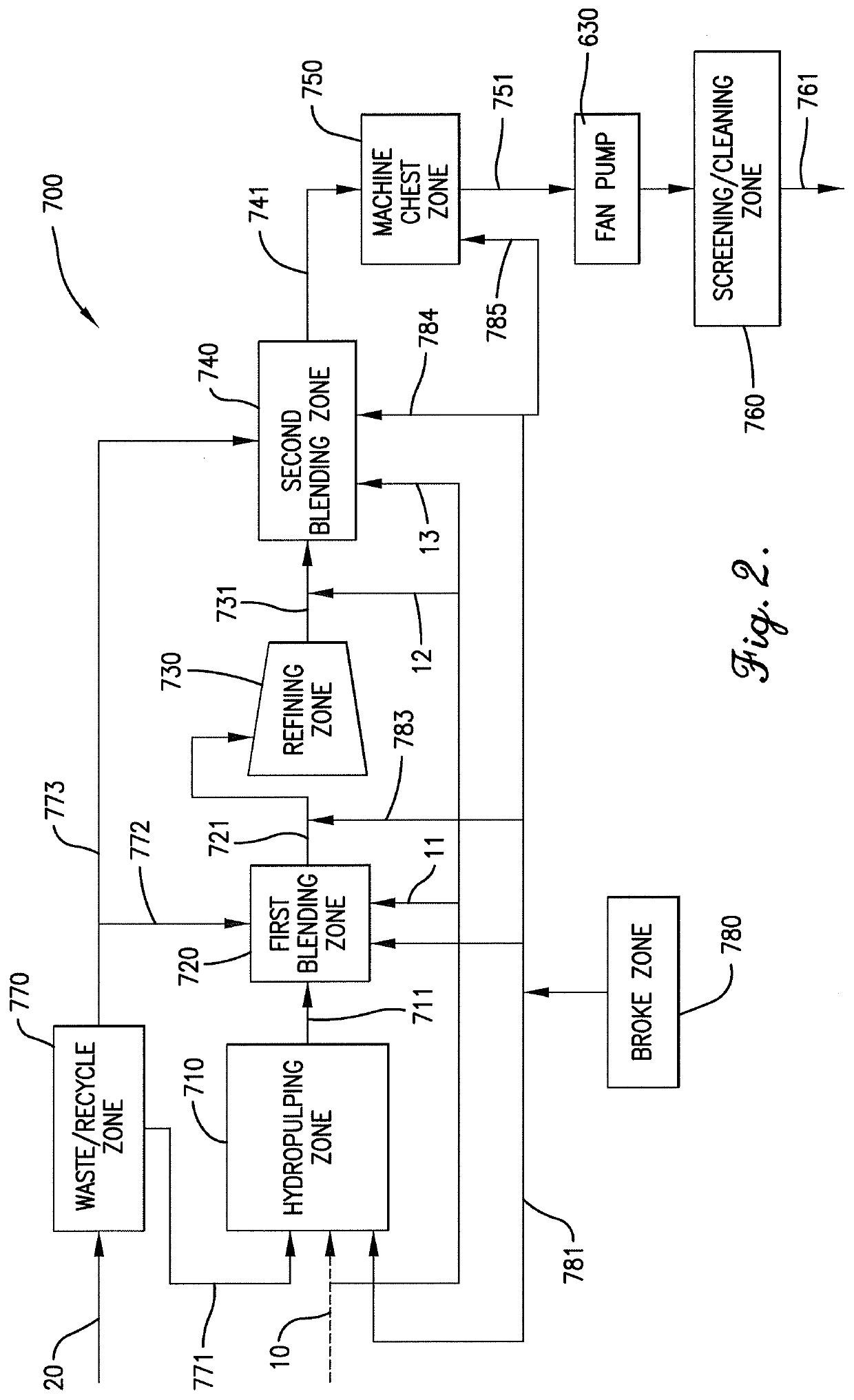

Addition of cellulose esters to a paper mill without substantial modifications

ActiveUS20200063342A1Reduce consistencyLow variabilityMachine wet endPaper/cardboardPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many the desired benefits. This invention also relates to a process to produce a wet laid article in a paper mill, said process comprising adding cellulose ester staple fiber to a hydropulper zone, and / or to a refining zone, and / or after the refining zone wherein said paper mill process is not substantially modified to allow for said adding of said cellulose ester

Owner:EASTMAN CHEM CO

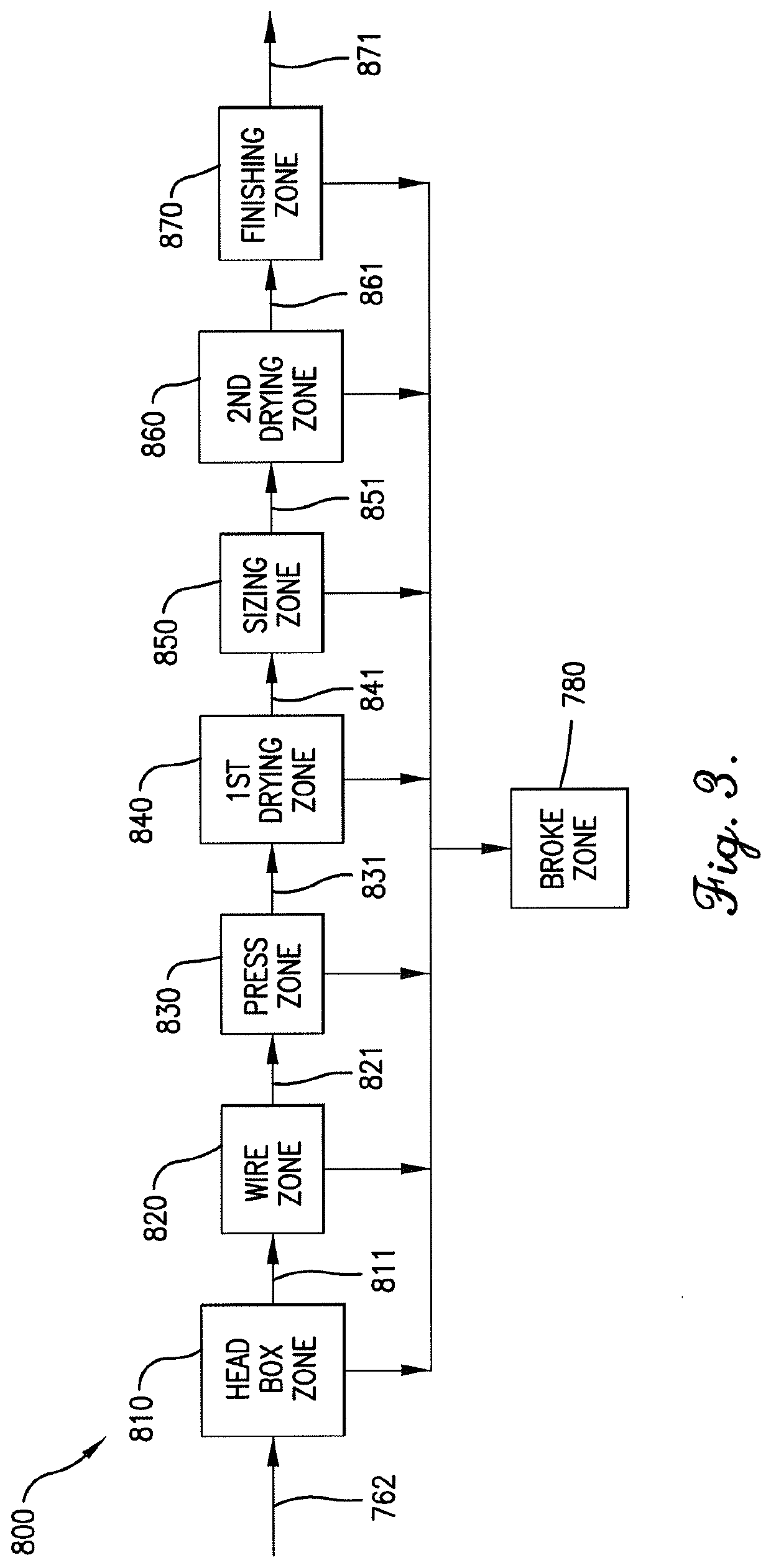

Water removal between wire and wet press of a paper mill process

ActiveUS20200063345A1High removal rateReduce consistencyPulp de-wateringPaper/cardboardPolymer scienceCellulose acetate

The present invention provides compositions comprising cellulose fibers and cellulose ester fibers and wet laid articles made from the compositions, as well as wet laid processes to produce these compositions. More specifically, the present invention provided compositions comprising cellulose fibers and cellulose acetate fibers and wet laid articles made from these compositions as well as wet laid processes to produce these compositions. The present invention also relates to developing a composition, process, wet laid product, or articles exhibiting any one of many desired benefits.

Owner:EASTMAN CHEM CO

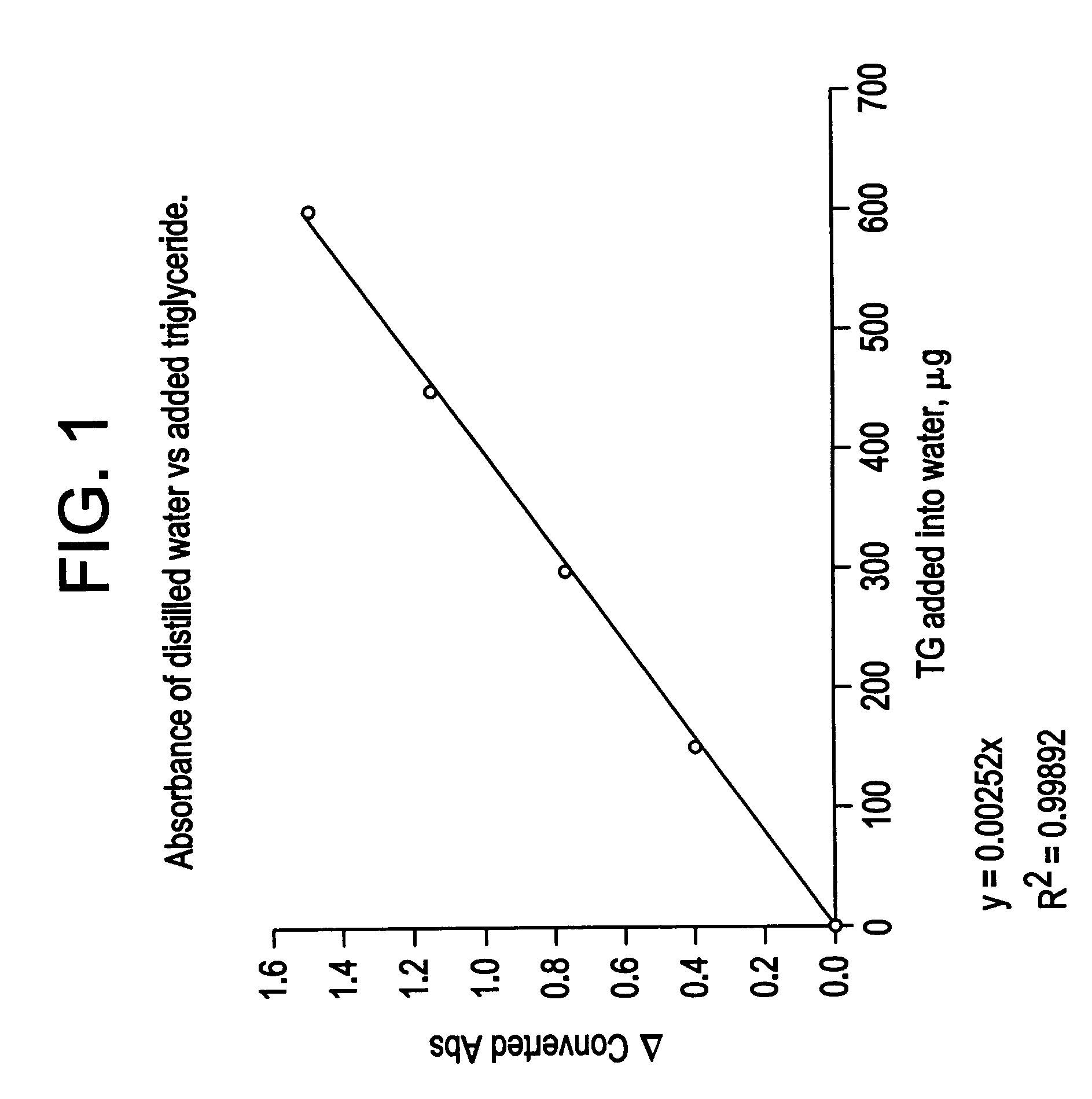

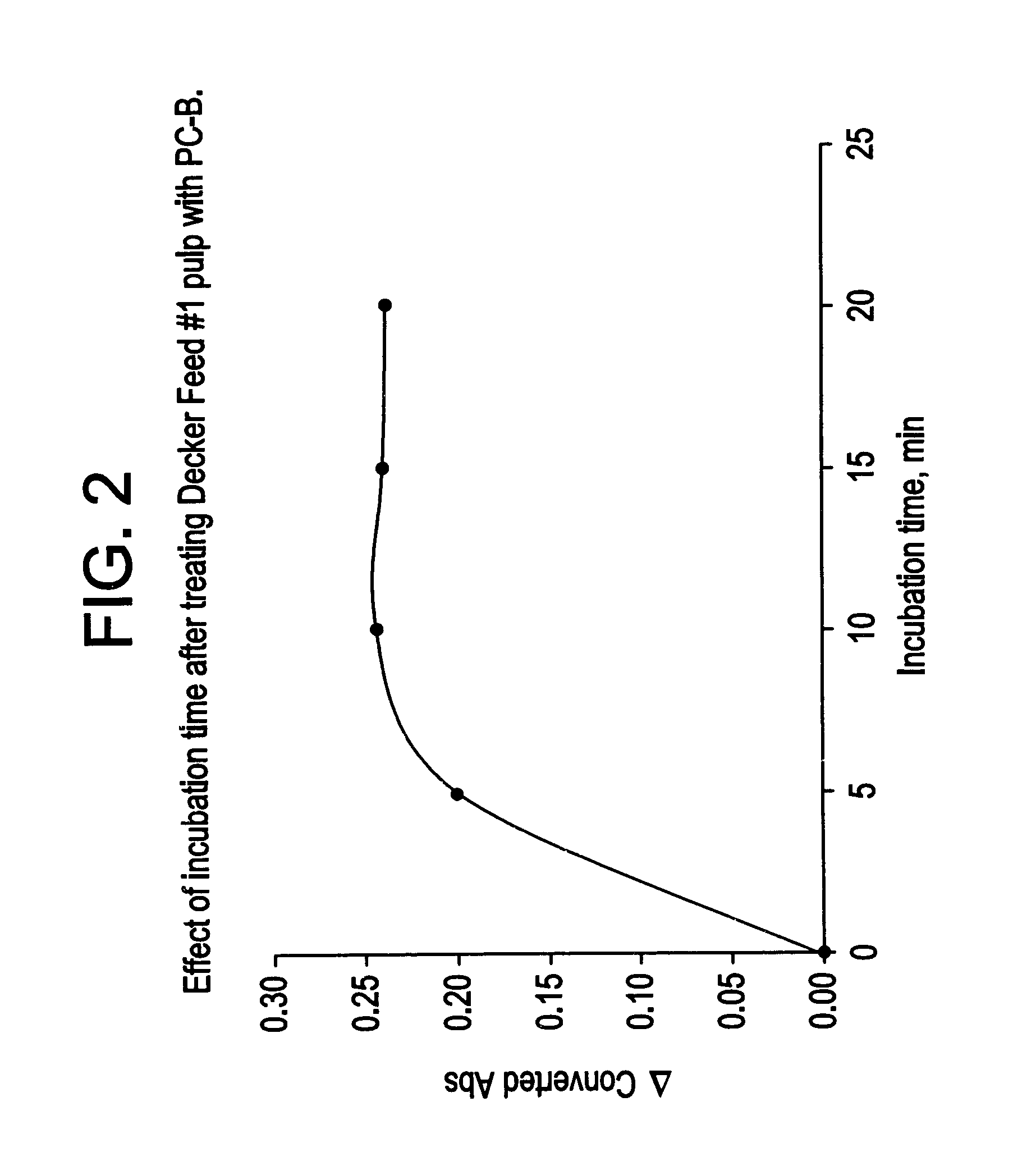

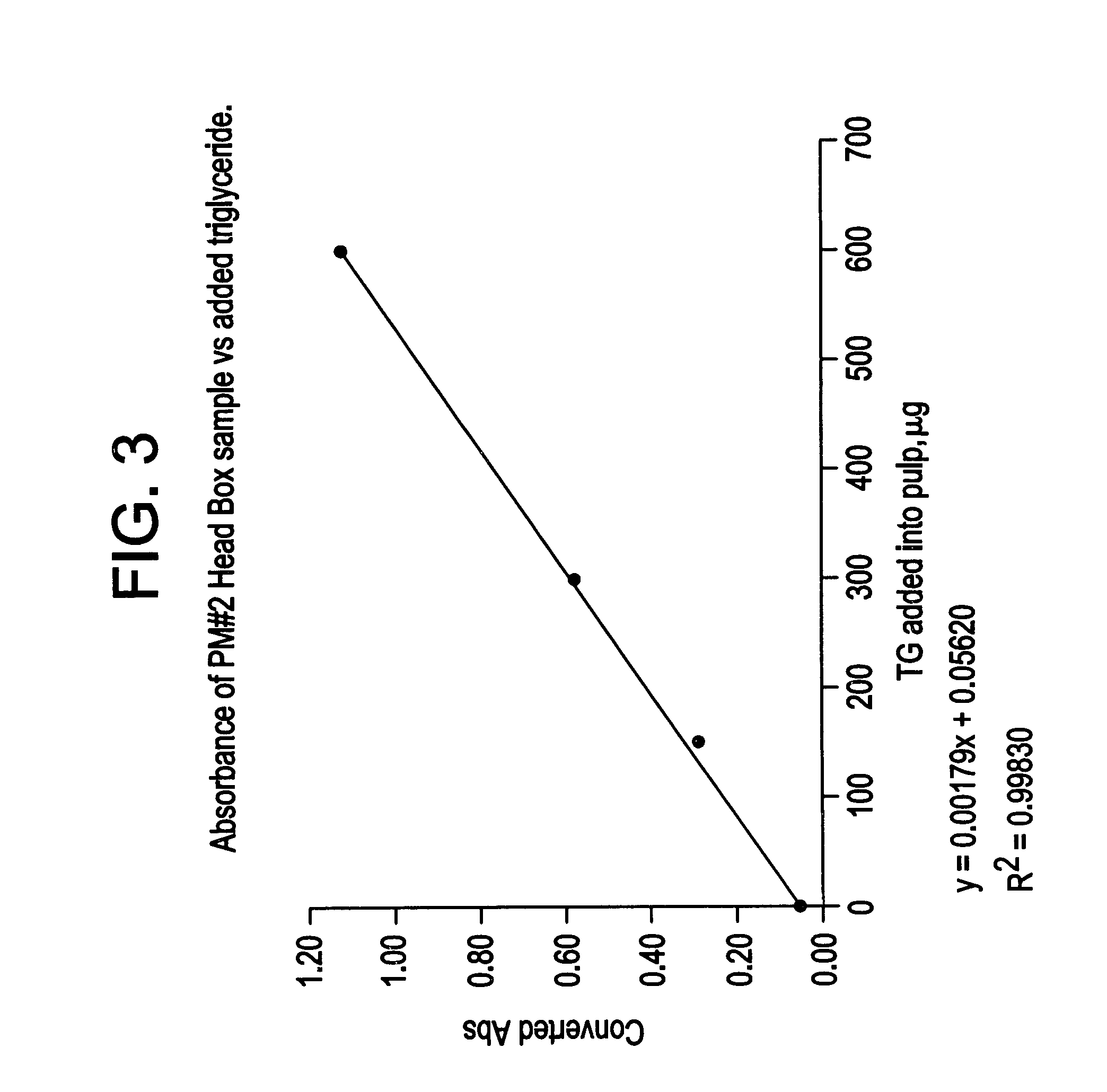

Rapid triglyceride assay for use in pulp pitch control

Enzymatic methods are provided for determining the surface triglycerides content in a sample of wood pulp. The methods preferably comprise reacting triglycerides which are present on the surface of the wood pulp fibers in the sample in the presence of a lipase to form glycerol and fatty acids, and then determining the difference between the amount of free glycerol present in the sample and the amount of glycerol formed from said triglycerides. The method is useful as a quick, portable, accurate, and low cost assay for assessing the amount of triglycerides present at various sample points in pulp and paper mills, which advantageously serves as a diagnostic tool for use in controlling the undesirable deposition of pitch during the papermaking process.

Owner:ENZYMATIC DEINKING TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com