Patents

Literature

308 results about "Deinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deinking is the industrial process of removing printing ink from paperfibers of recycled paper to make deinked pulp. The key in the deinking process is the ability to detach ink from the fibers. This is achieved by a combination of mechanical action and chemical means. In Europe the most common process is froth flotation deinking.

Method for enzymatic deinking of waste papers, the waste papers so treated and the treating composition

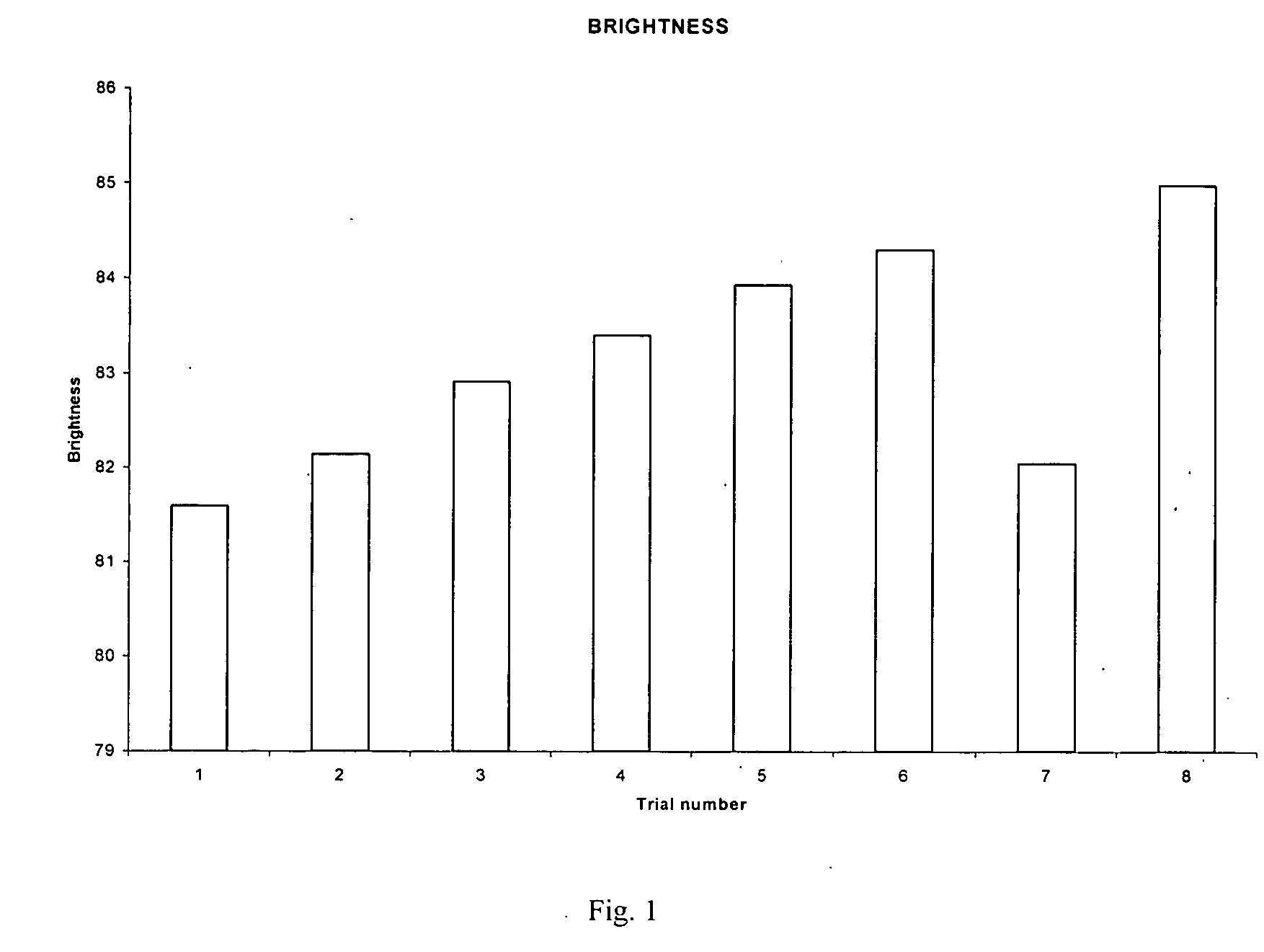

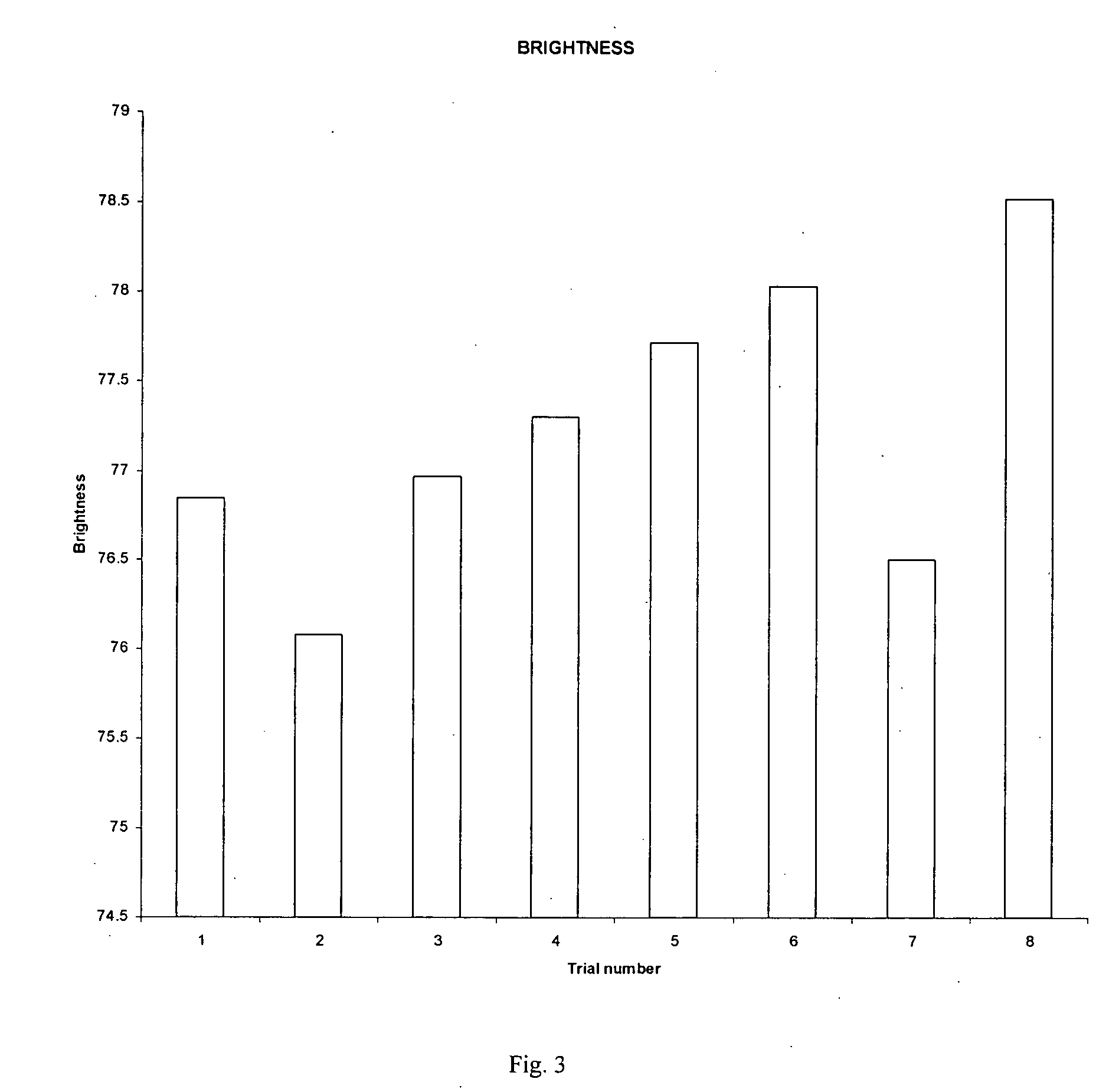

ActiveUS20060102299A1Prolonged actionIncrease brightnessPaper recyclingCellulose treatment using microorganisms/enzymesDeinkingPaper sheet

The present invention relates to a deinking composition and a method of deinking wastepaper by using a mixture of enzymes that act on constituents of all three waste paper components involved in ink retention on final pulp. The first component represents substrates located on the surface and in the internal waste paper structure. The second component represents substrates located in the interface between paper and ink, usually formed by coatings or size-press (starch containing or not) applied layers. The third component represents substrates located in the ink and / or toner compounds. This method provides improved performance in relation to conventional methods, or current deinking with enzymes, which acts on a limited number of substrates involved in ink retention on final pulp.

Owner:TRI TEX

Use of modified inorganic particles in deinking

InactiveUS20070158039A1Improves ink collection efficiencyQuality improvementPaper recyclingWaste paper working-upDeinkingInorganic particle

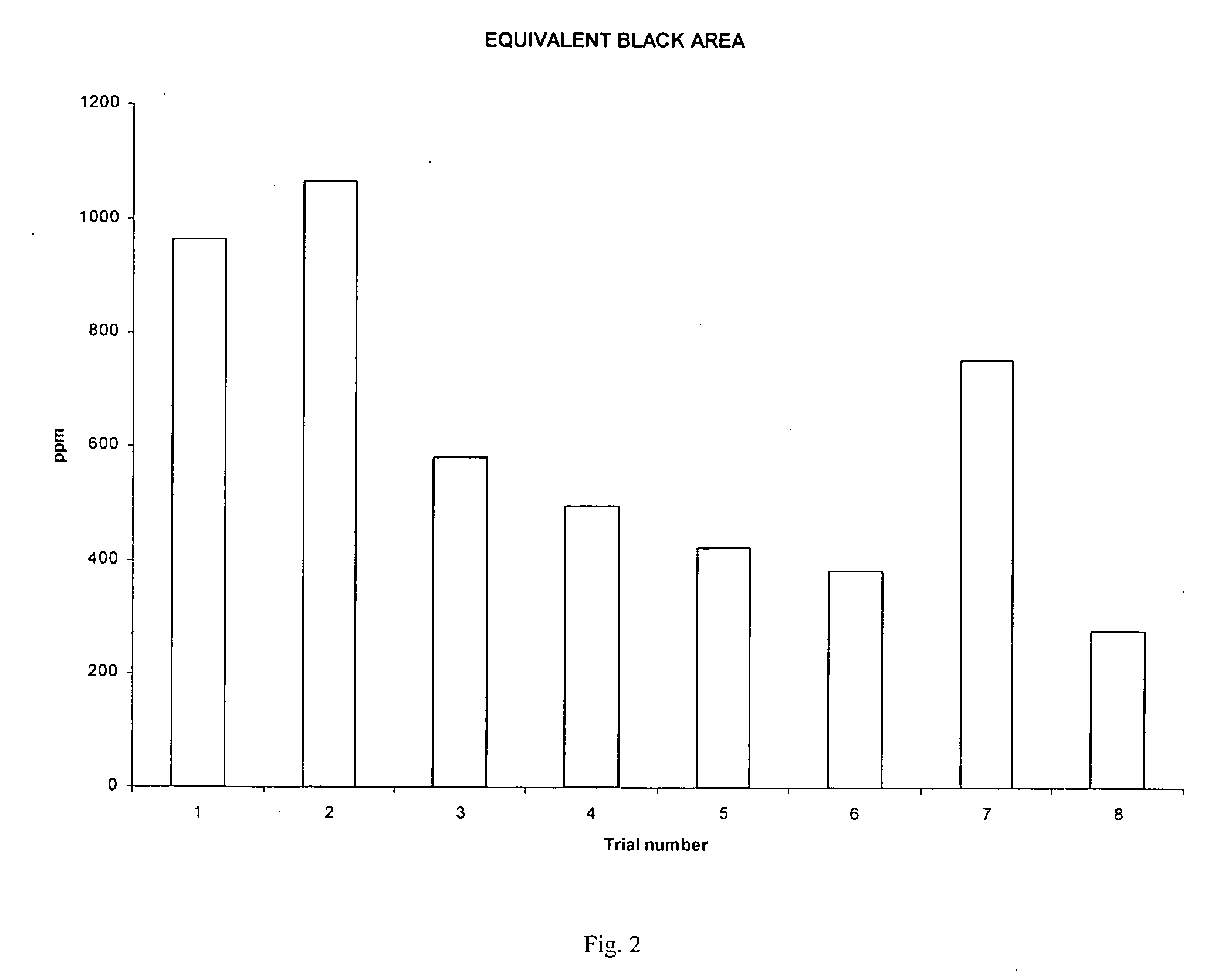

The present invention provides methods for deinking printed waste paper—particularly methods that use a deinking composition that includes a hydrophobically-modified inorganic particle (“MIP”) to improve ink collection efficiency under traditional alkaline, reduced alkali, and true neutral deinking conditions. Deinking compositions are provided that include a hydrophobically-MIP substrate, a nonionic surfactant, and a fatty acid, or mixtures thereof. The improved ink collection of the present invention can result in deinked pulp of high quality and / or yields that has excellent brightness and effective residual ink concentrations (“ERIC”) values.

Owner:KEMIRA CHEM

Process for recycling and preparing coated white board paper by using waste paper

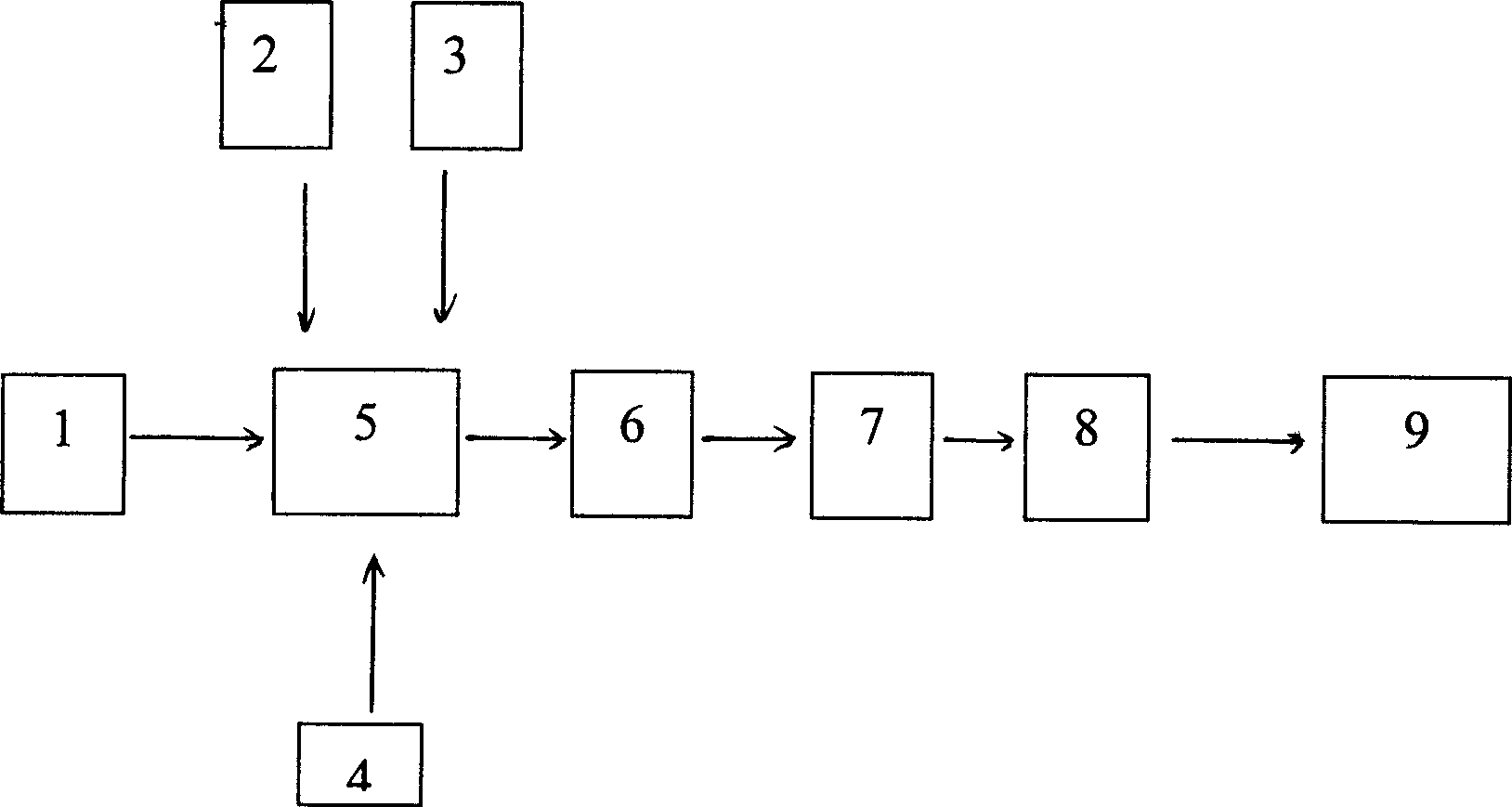

The embodiment of the invention discloses a process for recycling and preparing coated white board paper by using waste paper. The process comprises the following steps of: taking waste paper, repulping, screening, deinking, deslagging, washing and concentrating, whitening, storing in a pulp pool and making paper, wherein the step of repulping comprises the steps of dispersing the waste paper into a fiber suspension liquid, heating the fiber suspension liquid to be at 40-55 DEG C, adding a cellulose liquid and rotating for 20-35minutes so as to conduct primary deinking; the step of deinking comprises a step of further deinking by using an ultrasonic generator; the step of whitening comprises steps of oxidation and reduction whitening; the step of making paper comprises the steps of respectively feeding the whitening pulp into a surface layer, a core layer and a base layer of a paper machine conveying system, respectively making the pulp into three layers by using a paper machine according to the ratio of 38-78wt%, 15-35wt% and 12-30wt%, and subsequently conducting composite paper making so as to manufacture a raw paper board. According to the process, no raw wood pulp is used, so that the resource is saved, the environment is protected, the production cost is lowered, and moreover the produced white board paper is good in whiteness, high in strength and applicable to requirements of high-quality package and decoration.

Owner:GUANGDONG SONGYANG RECYCLE RESOURCES

Deinking Technique for news bogus paper through enzyme

InactiveCN1563567AImprove bleachabilityPaper recyclingChemical paints/ink removersDeinkingPulp and paper industry

A waste new print zyme deinking technology includes crushing the pulp, deinking, suspension selection, washing, bleaching among which, deinking agent, laccase, amboceptor are added into the pulped with waste newsprints and waster to be inlet with oxygen and the pulp concentration is controlled at 3%-18%, temperature 20-70deg.C pulping, keeping warmth.

Owner:QILU UNIV OF TECH

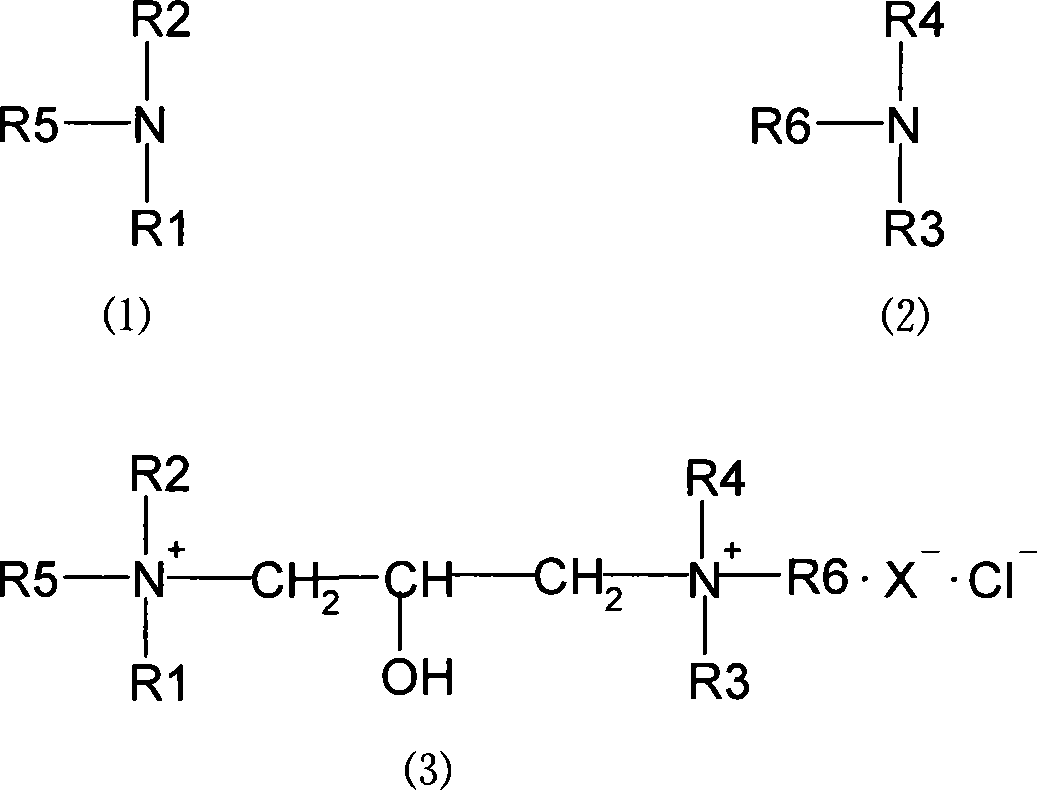

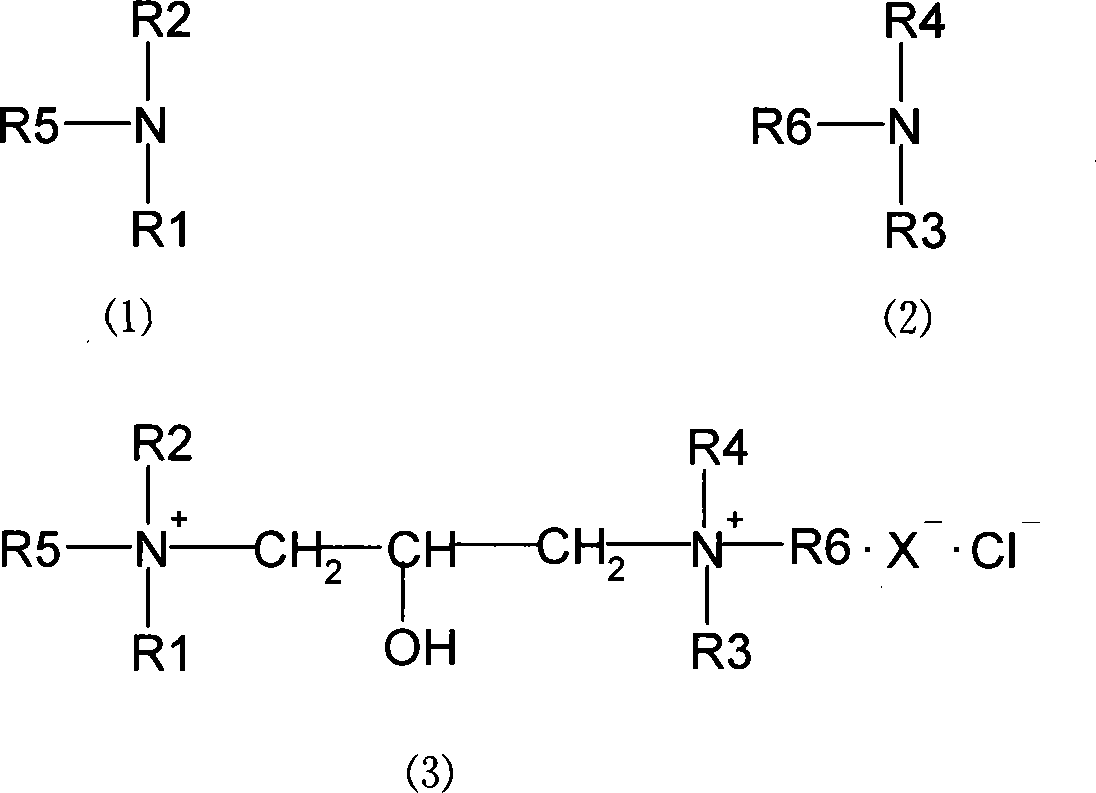

Method for preparing hydroxypropyl diquaternary ammonium salt

InactiveCN101168511AWide range of usesImprove performanceOrganic compound preparationTransportation and packagingWater basedFiber

The invention discloses a preparation method of hydroxy propyl bisquaternary ammonium salt, and the preparation method has the advantages that the process is simple, and the process is green and environment-protective. The invention comprises the following steps: under the required air atmosphere, the HX water solution in the formula (1) is poured into a reaction vessel, the control temperature is 15 DEG C to 60 DEG C, chloroepoxy propane is dropped into the reaction vessel, after the reaction, the substance in the formula (2) is added at one time or in several times, or dropped continuously, the temperature rises to 40 DEG C to 120 DEG C, after the sufficient reaction, the target product of hydroxy propyl bisquaternary ammonium salt can be obtained, and the structure of the target product is expressed with the formula (3). The product can be extensively applied in the preparation of sterilization and algae extermination, metal anticorrosion, fabric dyeing and finishing, asphalt emulsification, waste paper deinking, fiber dispersion and electropositive ion monomer containing repellency water base.

Owner:JIANGSU FEIXIANG CHEM

Environmentally friendly waste paper deinking method

ActiveCN102517949AAvoid negative effectsHigh whitenessPaper recyclingWaste paper working-upDeinkingActive agent

The invention discloses an environmentally friendly waste paper deinking method, which comprises the steps of: A. adding waste paper and water into a pulper, and simultaneously adding a biological enzyme which accounts for at least 0.01% of the weight of the waste paper, sodium hydroxide which accounts for at least 0.05% of the weight of the waste paper, and tall oil which accounts for at least 0.01% of the weight of the waste paper, controlling the pulping time at a minimum of 15min and the pulping temperature at a minimum of 35DEG C, thus obtaining a pulping slurry of a certain concentration; B. adding the pulping slurry into a flotation tank which has a ventilation volume of at least 25L / h and a pressure of at least 0.3MPa, and diluting the pulping slurry, with the flotation time maintained for at least 10 min; C. further diluting the pulping slurry and carrying out washing. The method of the invention uses tall oil and a biological enzyme for synergistic removal of ink from waste paper, and avoids the adverse effects of a surfactant on equipment and environments. Compared with waste paper deinking methods employing surfactants, the method provided in the invention produces a deinking slurry with substantially increased whiteness up to over 53%ISO, generates less dust, and make paper performance improved, thus boosting the progress of papermaking technologies.

Owner:ANHUI LEVEKING BIOTECH CO LTD

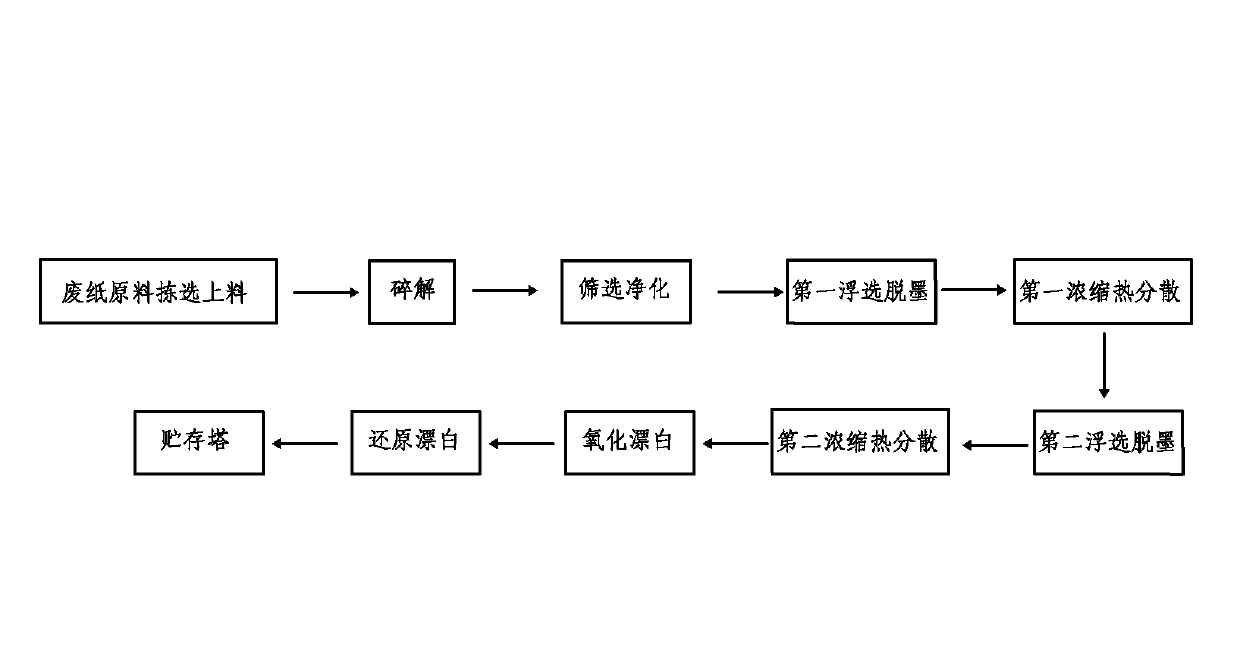

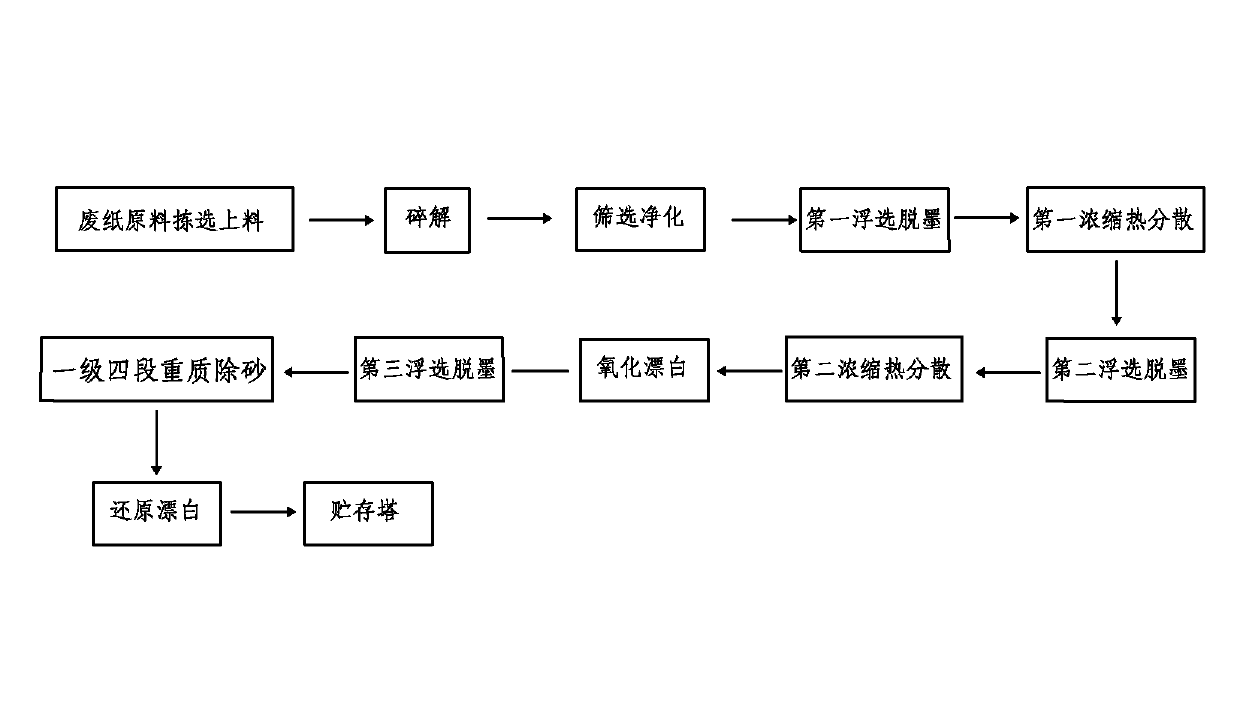

Process for preparing recovered pulp with high whiteness and high cleanliness

InactiveCN102677515ALow costHigh whitenessCellulosic pulp after-treatmentPaper recyclingDeinkingProduction line

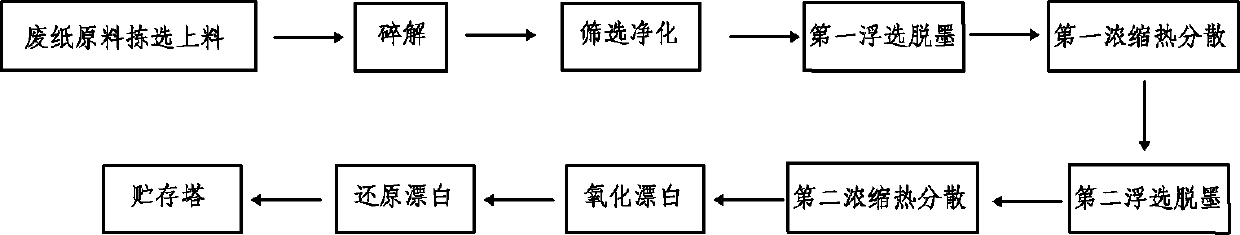

The invention relates to the technical field of papermaking raw material processing, in particular to a process for preparing recovered pulp with high whiteness and high cleanliness in a papermaking industry. The process comprises the following steps of: selecting and feeding of waste paper raw materials; disintegration; screening purification; first flotation deinking; first concentrated heat dispersion; second flotation deinking; second concentrated heat dispersion; oxidation bleaching; reduction bleaching; and storage in a storage tower. According to the process, 20-30 percent of high-quality office waste paper and 70-80 percent of other low-quality waste paper raw materials are matched, so that the cost of the waste paper raw materials is effectively reduced, and the corporate profit is increased. An advanced rotary drum pulper, a pulping machine and a production line of office waste paper screening purification, flotation deinking, concentrated heat dispersion and pulp bleaching are introduced, and the recovered pulp is prepared through the efficient use of chemicals and an effective production control process. The whiteness of the recovered secondary pulp achieves 90 percent ISO, and the cleanliness is high. The whiteness and the cleanliness of finished culture paper are increased.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Method for producing environment-friendly electrostatic copying paper

InactiveCN101691701AReduce usageReduce pollutionWater-repelling agents additionPaper recyclingDeinkingEnergy consumption

The invention relates to the technical field of paper making, and provides a method for producing environment-friendly electrostatic copying paper. The method comprises the following steps: using 10 to 20 percent of bleached chemical softwood pulp, 20 to 40 percent of bleached chemical hardwood pulp, 10 to 20 percent of BCTMP pulp and 30 to 50 percent of waste paper deinking pulp as paper pulp raw materials; adding chemical accessories and dyes into a pulp compounding pool; using corn starch and a starch modifier as surface treatment agents; making the compounded pulp into paper through a fourdrinier with a glue blender; and then further processing through finishing equipment to obtain the paper. Due to the adoption of the high-ash high-whiteness waste paper deinking pulp, the method for producing the environment-friendly electrostatic copying paper can effectively reduce the consumption of raw wood pulp and chemical raw materials, and is favorable for reducing the energy consumption, lightening the environmental pollution and saving the cost.

Owner:福建省晋江优兰发纸业有限公司

Pulping equipment and pulping method for cow card paper

ActiveCN102493263AFix appearance problemsReduce manufacturing costPaper recyclingWaste paper working-upDeinkingFibre treatment

The invention relates to the technical field of cow card paper manufacture, in particular to pulping equipment and a pulping method for cow card paper. The pulping equipment comprises a pulper, rough sizing equipment, a grading sieve, long fiber treating equipment and short fiber treating equipment, wherein the long fiber treating equipment comprises fine sizing equipment, a heat dispersion deinking machine and a dise mill; and the short fiber treating equipment comprises a low-concentration desander, a light slag remover and another heat dispersion deinking machine. The pulping method comprises the following steps: a, pretreating wastepaper; b, sorting long fiber and short fiber; c, treating long fiber; and d, treating short fiber. Wherein, long fiber pulp stock is used for making the bottom layer of the cow card paper; 100 percent of the sandwich layer of the cow card paper and 30 to 50 percent of the surface layer of the cow card paper are short fiber pulp stock; and the surface layer contains 50 to 70 percent of wood pulp. The invention radically solves the appearance problems of paraffin points and black spots in the cow card paper, and reduces the production cost of the cow card paper.

Owner:东莞理文造纸厂有限公司

Deinking agent for display window glass

The invention discloses a deinking agent for display window glass. The deinking agent is prepared from 30-70% of water, 5-20% of inorganic base, 0.5-8% of inorganic corrosion inhibitors, 7.5-16% of organic corrosion inhibitors, 5-20% of solvent and 5-20% of penetrant, and 7-22% of mixtures composed of alkyl alcohol ether polycarboxylate, alkyl polyoxyethylene phosphate and coco glucoside are added. In the heating application process, the deinking agent is capable of preventing a solution from being layered all the time, stable in performance and long in service life; due to the fact that the corrosion inhibitors are added, in the application process of the glass deinking agent, little corrosion is caused to a glass base plate, it is not easy to scratch the window glass, and the yield rate of the panel display window glass obtained after the deinking is raised; meanwhile, the deinking agent is great in penetrability, moderate in alkalinity and high in ink removal speed.

Owner:湖南利尔电子材料有限公司

Clean wastepaper deinking production method

The invention discloses a clean wastepaper deinking method comprising the steps that: A, wastepaper and water are added into a pulping machine; lipase with a weight of at least 0.01% of that of the wastepaper, sodium hydroxide with a weight of at least 0.05% of that of the wastepaper, and a surfactant with a weight of at least 0.01% of that of the wastepaper are added; a crushing time is at least 15min, and a crushing temperature is at least 35 DEG C, such that a pulp with a certain concentration is obtained; B, the pulp is added into a flotation cell, and is diluted, wherein an aeration volume of the floatation cell is at least 25L / h, a pressure is at least 0.3MPa, and a floatation time is at least 10min; and C, the pulp is further diluted and is washed by using a copper mesh.

Owner:ANHUI LEVEKING BIOTECH CO LTD

Clean production method of plant fiber product

InactiveCN103523945ARealize cleaner productionReduce processing costsMultistage water/sewage treatmentWaste water treatment from plant processingSludgeSugar industry

The invention discloses a clean production method of a plant fiber product, relating to the regeneration treatment on the black liquid generated by the deinking or degreasing or / and delignification in a production process of the plant fiber product or / and the implementation of interception-type recycling of the black liquid containing sodium ions, relating to the circulating water treatment and application in a production process in the field of different sub-products of the field of plant fiber products, relating to the treatment and utilization of the sludge obtained in black liquid regeneration and circulating water treatment processes, and relating to the blending treatment and utilization of drain water, wherein the plant fiber at least comprises any one of cotton and fibrilia crops, crop straw including any one of cotton straw, rice straw, wheat straw, reed, corn straw and the like, weed including any one of carex meyeriana, solidago decurrens and the like, broadleaf wood and the like including any one of poplar and eucalyptus, bagasse discarded by the sugar industry and any one of waste paper and old cotton or the combination of more than one waste plant fiber product and the like.

Owner:上海橡本永拓环保科技发展有限公司 +4

Method for improving removal effect of ink in waste paper pulp

InactiveCN101725069AGood removal effectGood deinking effectPaper recyclingPaper/cardboardDeinkingFiber

The invention discloses a method for improving a removal effect of ink in waste paper pulp. The method comprises the steps of: breaking waste paper, and diluting obtained pulp; then relative to the absolute dry mass of the paper pulp, adding 0.0025 to 0.5 percent of nonionic deinking agent into the pulp; at the same time, adding an anionic dispersant with a dispersion effect, wherein the consumption of the anionic dispersant is 0.001 to 0.3 percent of the absolute dry mass of the paper pulp; and floating at the temperature of between 40 and 50 DEG C after the mixture is stirred uniformly to remove the ink in the waste paper pulp, wherein the anionic dispersant is anionic polyacrylamide, or is one of polyacrylate and polymethacrylate. The method adopts the cheaper dispersant to compound the deinking agent with higher cost for floatation, which promotes deinking effect, and also solves the problems of cost increase caused by overhigh consumption of the deinking agent and the decrease of economic benefit caused by excessive fiber loss.

Owner:SOUTH CHINA UNIV OF TECH

Environmental protection waste paper deinking method

InactiveCN105256632ABest reaction enzyme activityIncrease enzyme activityPaper recyclingWaste paper working-upDeinkingSlurry

The invention relates to a deinking method, and provides an environmental protection waste paper deinking method. The method The method comprises the following processing steps: firstly, waste paper is crushed; secondly, coarse screening is carried out; thirdly, fine screening is carried out; fourthly, the slurry after fine screening processing is sent to a floating groove, a deinking agent is added, the deinking agent is composed of the following ingredients, by weight, 5-15 parts of fatty alcohol polyoxyethylene ether, 5-15 parts of aliphatic acid polyoxyethylene ether and 70-90 parts of neutral biological enzymes, the weight ratio of the deinking agent to the slurry is 5-10:90-95, and after the deinking agent is added, rotation is carried out for 15-20min at a rotating speed of 200-300r / min at a temperature of 30-40 DEG C; fifthly, the slurry after flotation is washed further.

Owner:福建省晋江优兰发纸业有限公司

Neutral deinking method for waste newspaper

InactiveCN1763306AHigh whitenessReduce pollution loadFats/resins/pitch/waxes removal in pulpPaper recyclingInorganic saltsDeinking

The invention discloses a newsprint neutral voiding method in the pulping paper making technique domain with pulping, floating, scrubbing and bleaching procedure, which is characterized by the following: adapting flotation-scrubbing method without alkali; inputting 0.1 úÑ-2.0úÑ voiding agent, 1úÑ-6úÑ inorganic salt in the floating course; controlling the floating paste density between 2 and 18 percent, temperature between 20 and 70 deg.c, pre-impregnated time between 0 to 40 min, floating time between 10 and 60 min, insulating time between 0 and 40 min; The method improves the voiding efficiency and voiding paste whiteness by 16.6 percent as well as reduces the CoDcr in the neutral voiding waste-water by 190mg / l, which lessens the waste-water pollution load.

Owner:QILU UNIV OF TECH

Method of deinking waste paper using cellulase without lowering paper strength and method of evaluating the same

InactiveUS7297224B2Reduce usageGood correlationCellulosic pulp after-treatmentPaper recyclingDeinkingPulp and paper industry

A deinking method using a cellulase which enables the load upon the environment to be reduced; and an evaluation method whereby a cellulase effective in deinking and the effective addition level of the cellulase can be appropriately determined.By proposing pulp-swelling activity (PSA) that elevates the water-retention value of pulp after pulp is reacted with cellulase, it becomes possible to select an enzyme that is effective in cellulase-deinking treatment without lowering the paper strength and to determine the effective enzyme dosage. Namely, a method of deinking waste paper is provided wherein the selection of an effective cellulase and the optimization of the enzyme dosage with the use of PSA as an indication make it possible to minimize the cellulase addition level and lessen the amount of the deinking agent.

Owner:MEIJI SEIKA KAISHA LTD

Waste paper deinking agent

ActiveCN101928485AEasy to produceReduce pollutionFats/resins/pitch/waxes removal in pulpChemical paints/ink removersDeinkingEconomic benefits

The invention relates to a waste paper deinking agent, which consists of surfactant, polyoxyethylene ether substance, penetrating agent, fatty acid sodium salt, caustic soda, sodium silicate, water and the like. All chemicals forming the waste paper deinking agent are common chemical products, and are easily purchased in a market. The components are innocuous and can be naturally degraded, namely the waste paper deinking agent meets the requirement of the current environment-friendly policy and has good environment friendliness. Meanwhile, a preparation process for the waste paper deinking agent is simple, easy in operation and good in finished product stability, can be applied to the deinking process of multiple waste papers and has ideal deinking effect; and the waste paper deinking agent is convenient to transport and store and is quickly dissolved in the deinking production process, namely the waste paper deinking agent has good economic benefit. Therefore, the waste paper deinking agent has remarkable environmental benefit and economic benefit.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Environment-friendly type production method of water transfer printing body paper

ActiveCN104452383AQuality improvementFulfil requirementsWater-repelling agents additionPaper recyclingDeinkingPulp and paper industry

Owner:DEZHOU HUABEI PULP & PAPER

Neutral deinking agent and preparation method thereof

ActiveCN103881467AHigh practical valueOvercoming the problem of low deinking efficiencyChemical paints/ink removersDeinkingInorganic salts

The invention relates to a neutral deinking agent and a preparation method thereof. The neutral deinking agent comprises the following components by weight: 10-20 parts of lauryl sulfate, 10-20 parts of polyoxyethylene alkyl ether, 10-20 parts of a rosin based surfactant, 10-15 parts of fatty acid salt, 1-5 parts of sodium lignosulfonate, 1-5 parts of inorganic mineral soil and 1-2 parts of an inorganic salt, wherein the lauryl sulfate, the polyoxyethylene alkyl ether, the rosin based surfactant and the fatty acid salt are main agents, and the sodium lignosulfonate, the inorganic mineral soil and the inorganic salt are auxiliary agents. The neutral deinking agent is high in deinking efficiency, deinked pulp is high in whiteness and less in ink residues, and the neutral deinking agent has the advantages of being low in production cost, easy in biodegradability and the like, and is suitable for all kinds of waste paper deinking.

Owner:朱勇强

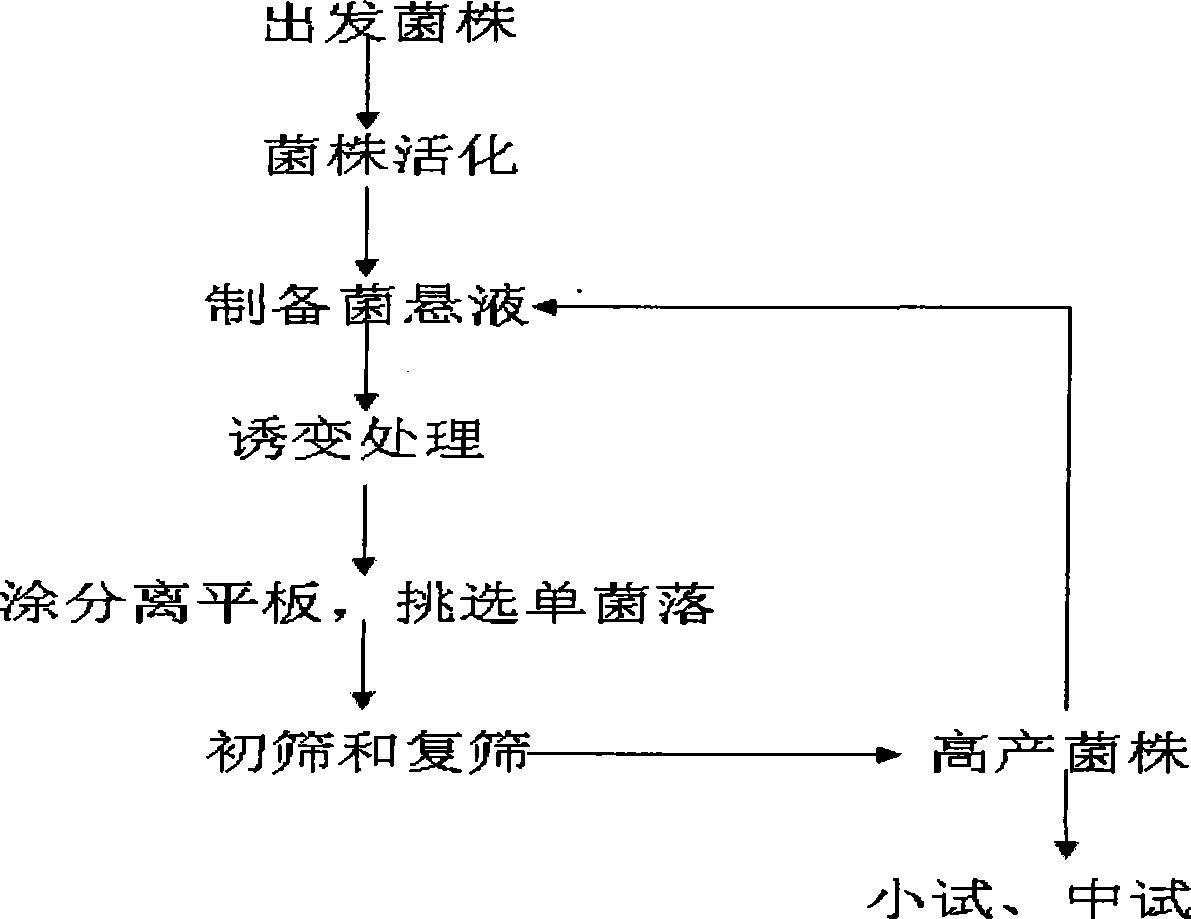

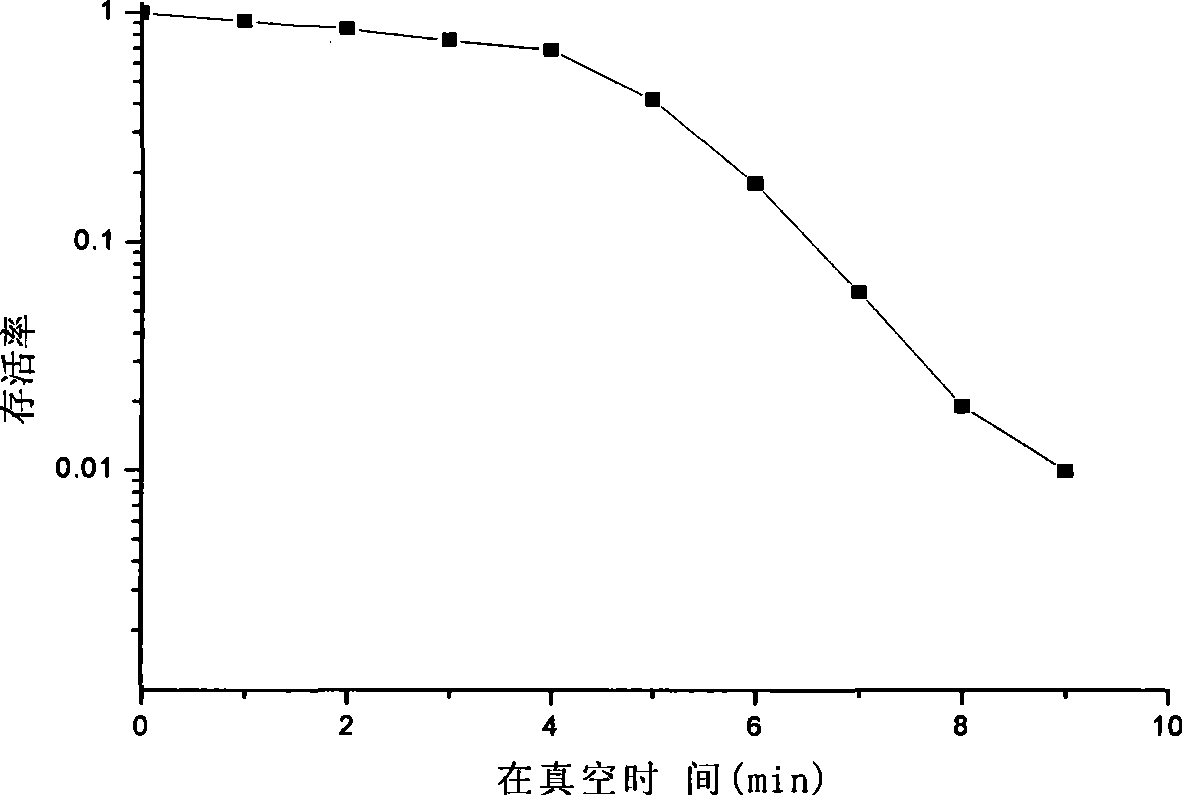

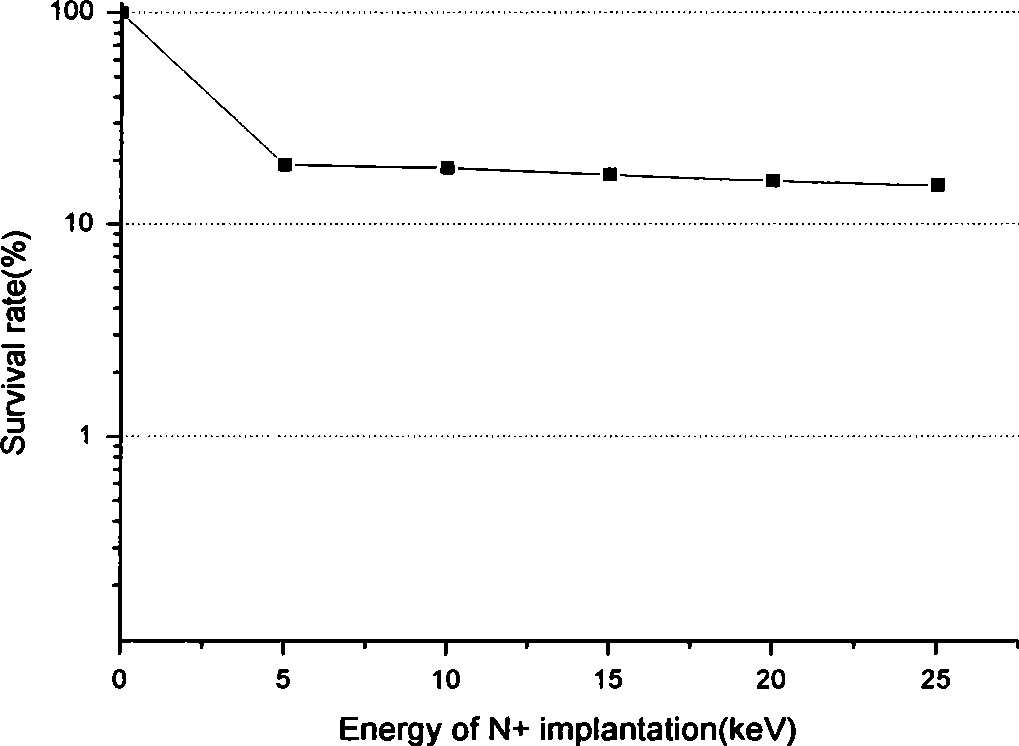

White rot fungi, breeding method and use thereof

InactiveCN101469312AStable enzyme productionShort cycleFungiMutant preparationFiberAutomatic control

The invention relates to Trametes Versicolor YS-L613 and a breeding method and application thereof. The Trametes Versicolor YS-L613 is prepared by the method through mutation breeding. The breeding method is to take Trametes Versicolor as a starting strain, adopt composite mutation breeding technology which combines UV, 60 CO, ultraviolet rays, nitrosoguanidine, ion implantation and microwave treatment, and breed the YS-L613 strain for high-yield production of laccase. The invention performs breeding operation through physiochemical treatment methods such as ion implantation, the ultraviolet rays and mutagen, finally obtains the YS-L613 strain for high-yield production of the laccase, and adopts experimental automatic control technology, strain fermentation control technology and strain extraction technology to develop laccase products. As proved by experiments of the laccase in pulp bleaching, fiber modification and pulp deinking, utilization of the laccase in the paper-making industry can improve the quality of paper, reduce environmental pollution and save the cost.

Owner:HENAN YANGSHAO BIOCHEM ENG

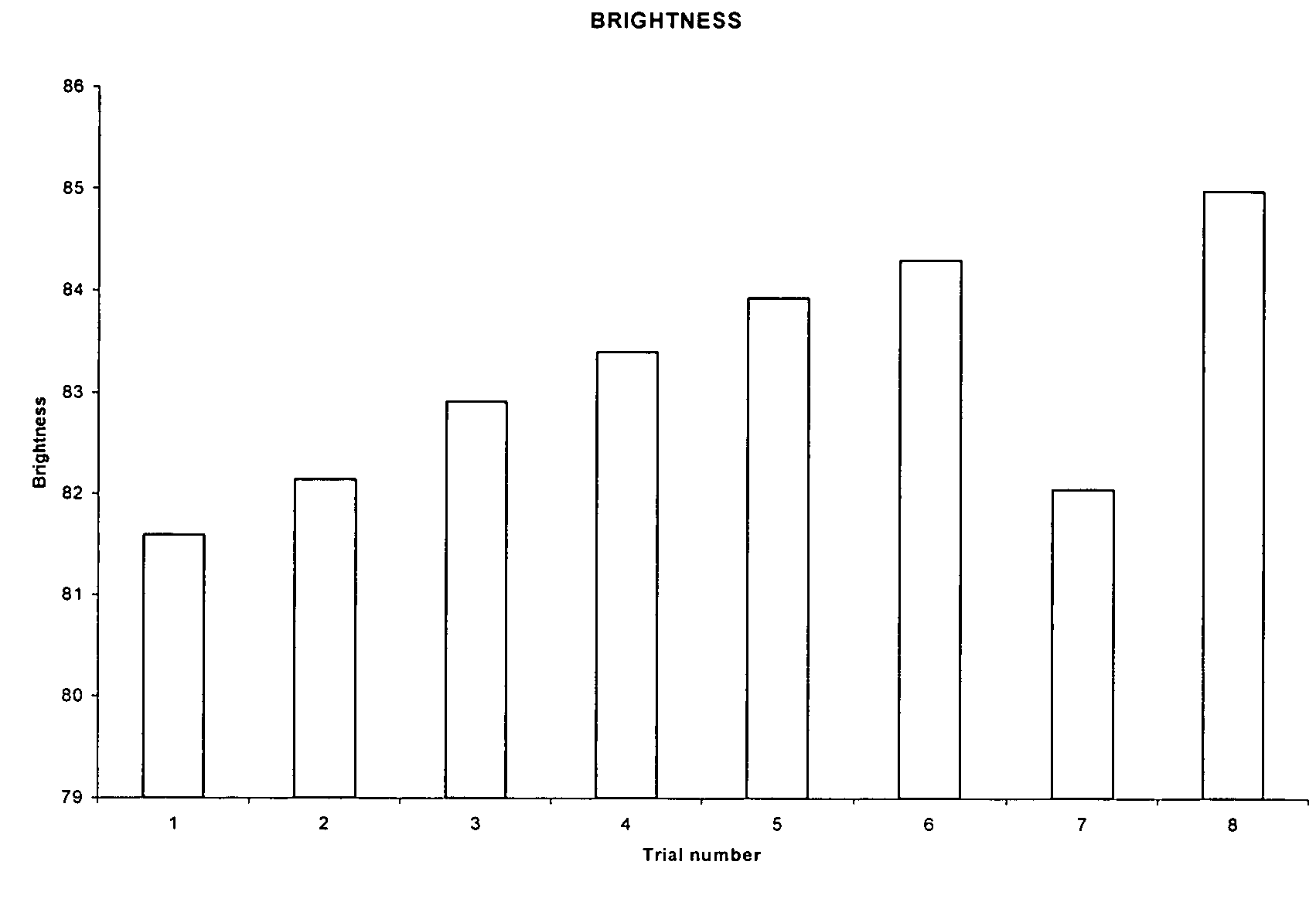

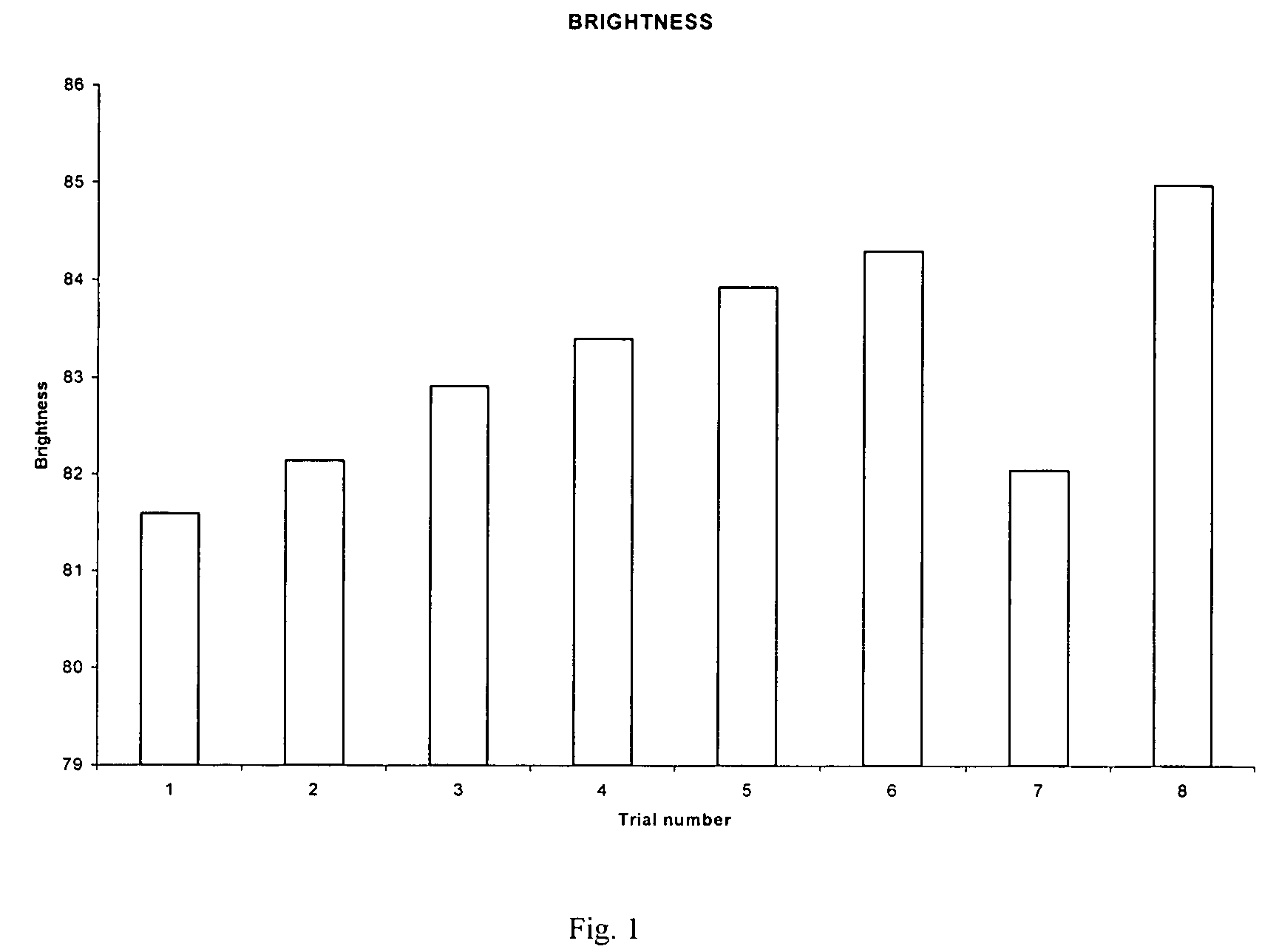

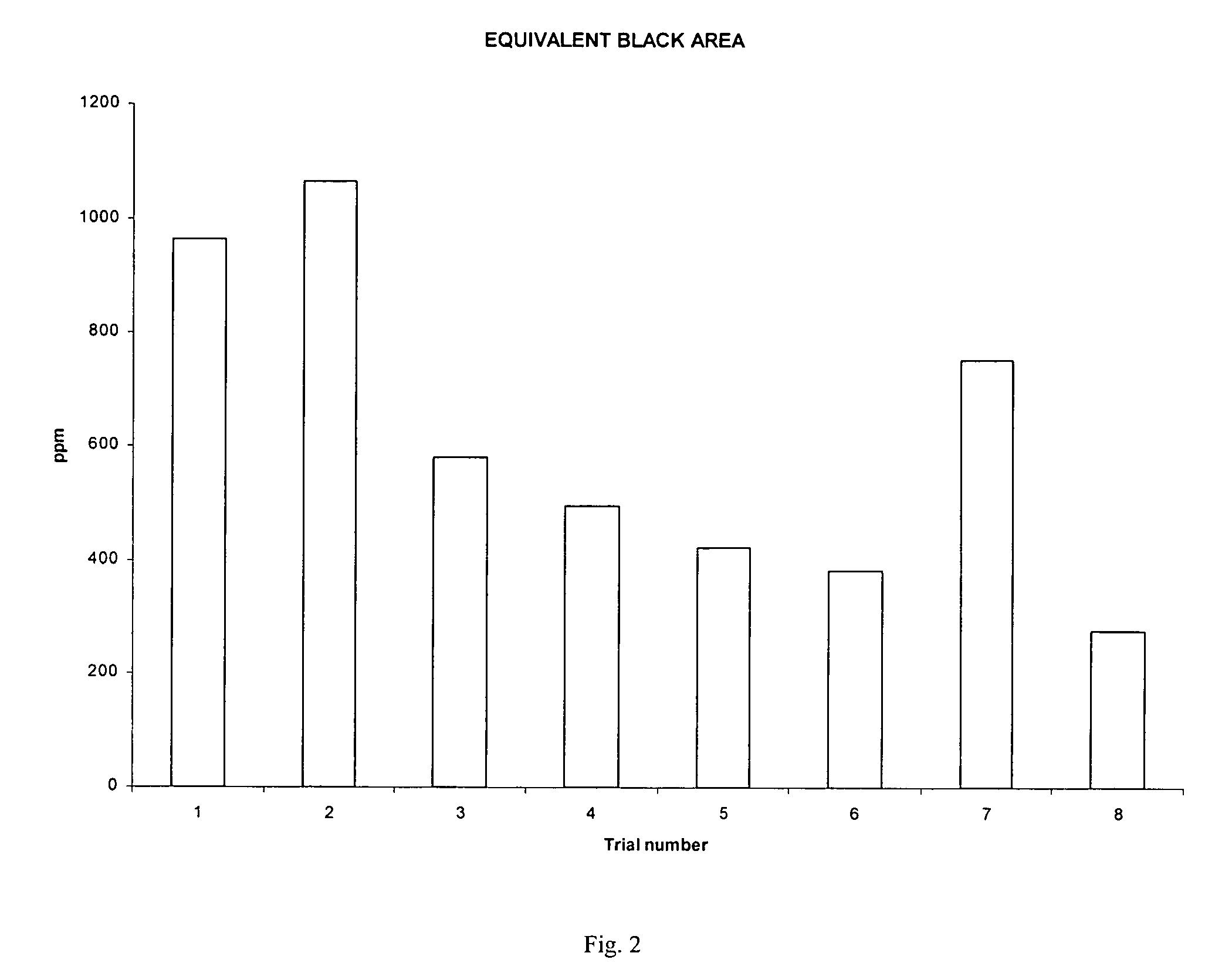

Use of Modified Inorganic Particles in Deinking

InactiveUS20090165967A1Improves ink collection efficiencyQuality improvementPaper recyclingWaste paper working-upDeinkingInorganic particle

The present invention provides methods for deinking printed waste paper—particularly methods that use a deinking composition that includes a hydrophobically-modified inorganic particle (“MIP”) to improve ink collection efficiency under traditional alkaline, reduced alkali, and true neutral deinking conditions. Deinking compositions are provided that include a hydrophobically-MIP substrate, a nonionic surfactant and a fatty acid, or mixtures thereof. The improved ink collection of the present invention can result in deinked pulp of high quality and / or yields that has excellent brightness and effective residual ink concentrations (“ERIC”) values.

Owner:KEMIRA CHEM +1

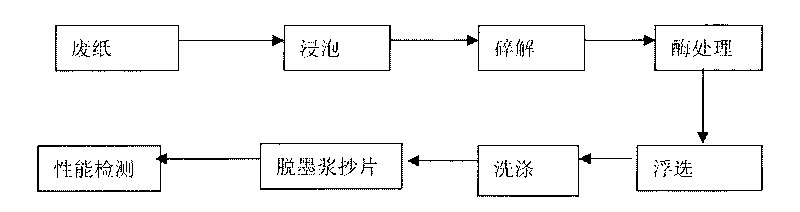

Deinking method of waste paper alkaline enzyme

InactiveCN101691699ASave the bleaching processLow costFats/resins/pitch/waxes removal in pulpPaper recyclingPectinaseDeinking

The invention discloses a deinking method of waste paper alkaline enzyme, comprising the following steps: carrying out soaking, disintegration, enzyme processing and washing on the waste paper to obtain the processed pulp; adding surface active agent when soaking at a usage amount of 0.10%-2.00%wt, wherein the enzyme processing is carried out under the conditions that the pH is 6-11, the temperature is 45-75 DEG C, and xylanase 30-150 mu / g of oven dry stock, pectinase 40-100 mu / g of oven dry stock and amylase 50-120 mu / g of oven dry stock are adopted to process the disintegrated waste paper for 10-30min. Cellulase can also be added in the enzyme processing procedure with an added quantity of 100 mu / g of oven dry stock. The processing effect is better if enzyme activator, such as sodium chloride is added in the enzyme processing procedure; and the alkaline enzyme can be bathed and used in a matching manner with a plurality of surface active agent, even with compounds with certain oxidation functions; and the process of waste paper deinking technology can be shortened and the bleaching process in deinking by the conventional enzyme method can be left out.

Owner:南京川平科技开发有限公司

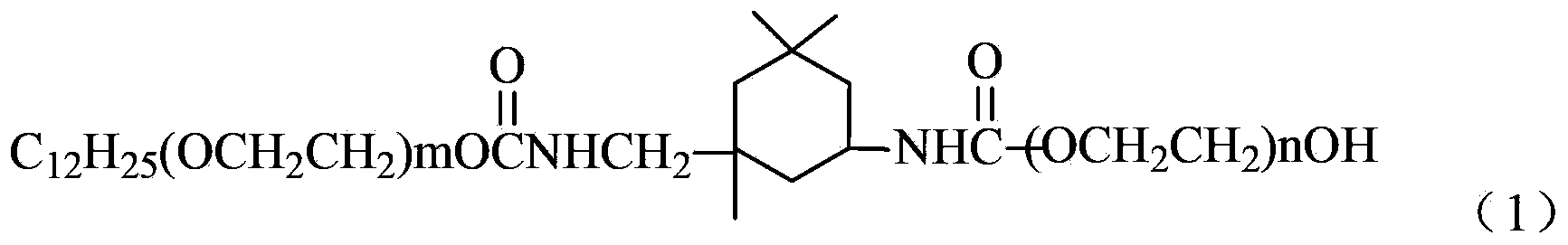

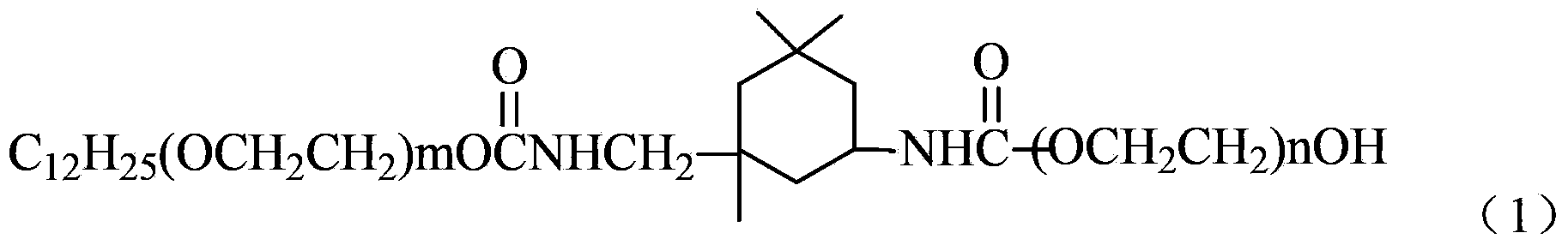

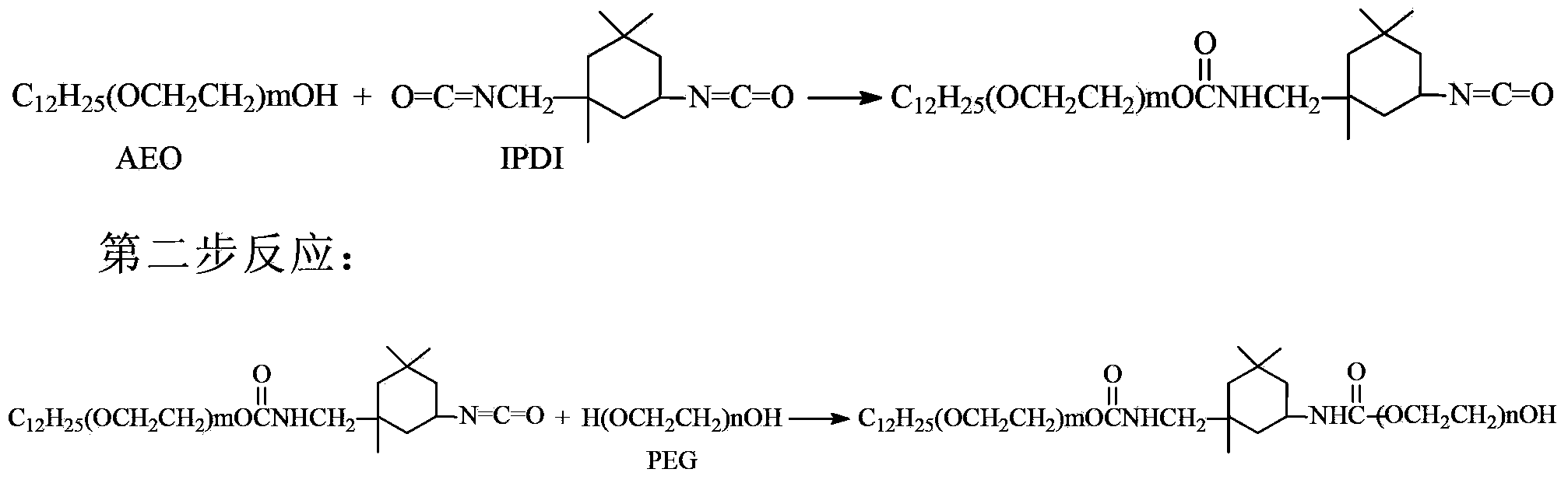

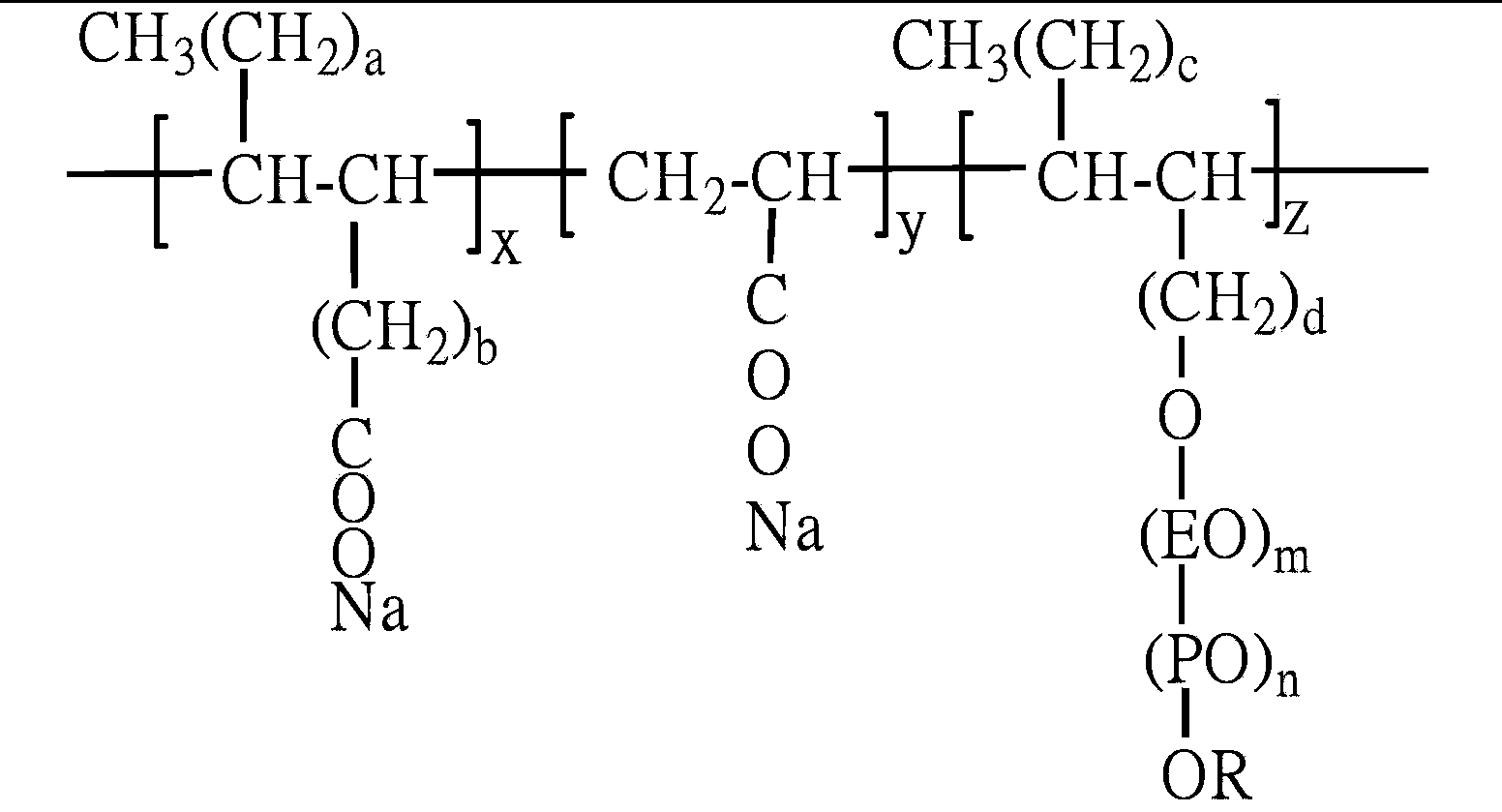

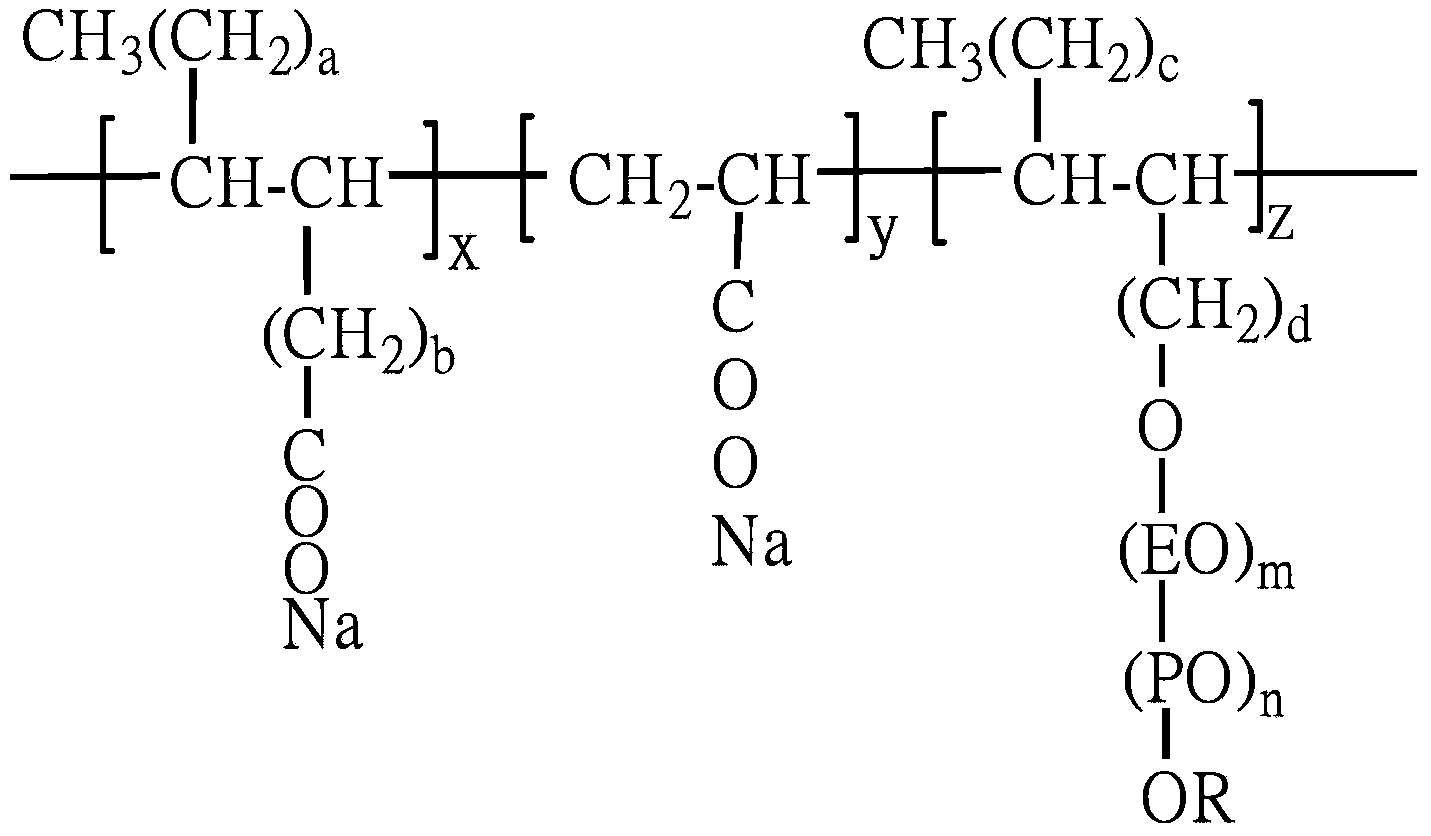

AIP (Aluminum Isopropoxide) type nonionic surfactant as well as preparation method and application thereof

InactiveCN103360860AMolecular chain lengthGood dispersionOrganic chemistryChemical paints/ink removersDeinkingPolyethylene glycol

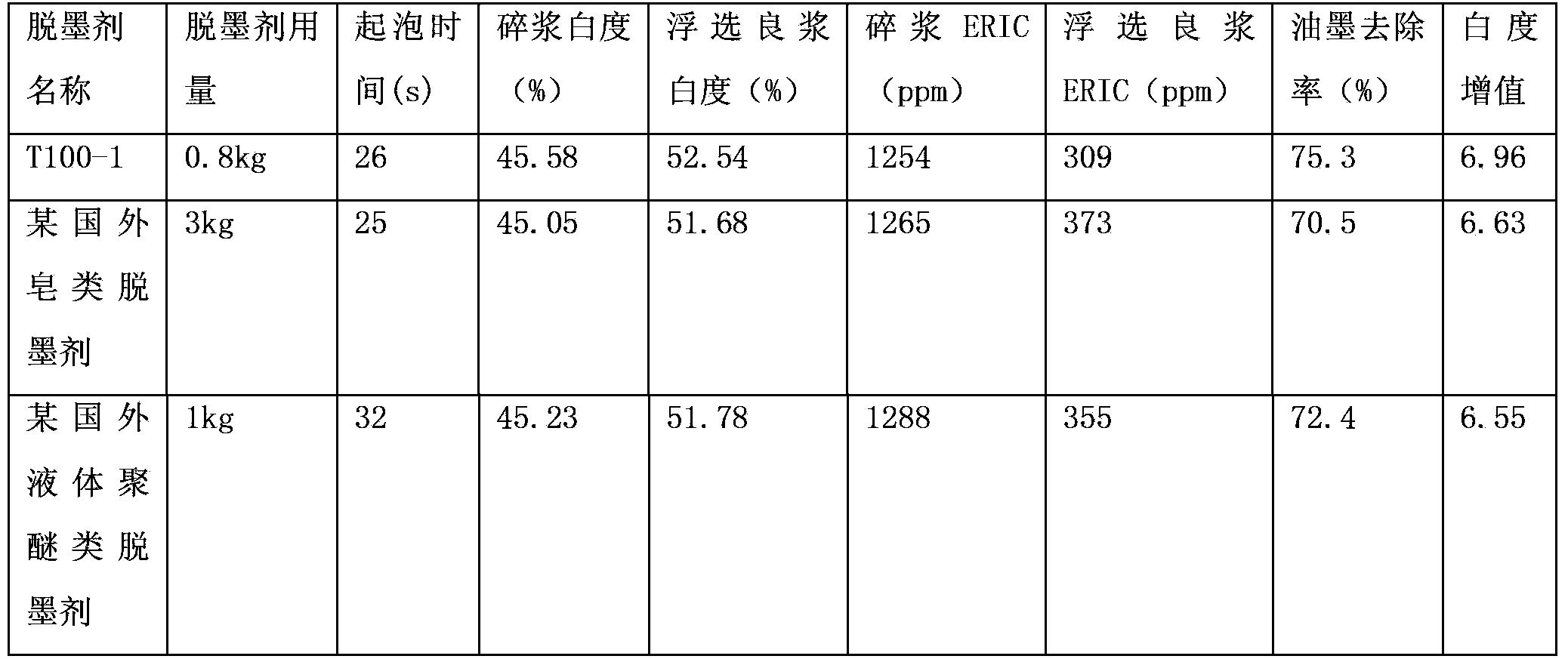

The invention provides an AIP (Aluminum Isopropoxide) type nonionic surfactant as well as a preparation method and application thereof. The chemical structural formula of the AIP type nonionic surfactant is as shown in the specification. The preparation method comprises the following steps of: adding IPDI (Isophorone Diisocyanate) into a reactor, heating to 50-70 DEG C while stirring, dropwise adding AEO (Fatty Alcohol Polyoxyethylene Ether) into the reactor while stirring, and then, continuing to stir and preserve the heat to react for 60-90min; and then, adding PEG (Polyethylene Glycol) into the reactor while stirring, and continuing to react at the temperature of 60-90 DEG C for 90-120min to obtain the AIP type nonionic surfactant. The preparation method has the advantages of simple preparation process and easiness for obtaining raw materials and controlling the reaction. Compared with a micromolecular surfactant sold on the market, the AIP type nonionic surfactant provided by the invention is longer in molecular chain, stronger in dispersing, collecting and washing capabilities for printing ink, capable of being independently used as a deinking agent for waste paper deinking or being used as a deinking agent for waste paper deinking after being compounded, good in deinking effect, high in whiteness of regenerated paper sheets, small in residual ink amount and favorable in application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Method for enzymatic deinking of waste papers, the waste papers so treated and the treating composition

ActiveUS7282113B2Prolonged actionIncrease brightnessPaper recyclingCellulose treatment using microorganisms/enzymesDeinkingPaper sheet

The present invention relates to a deinking composition and a method of deinking wastepaper by using a mixture of enzymes that act on constituents of all three waste paper components involved in ink retention on final pulp. The first component represents substrates located on the surface and in the internal waste paper structure. The second component represents substrates located in the interface between paper and ink, usually formed by coatings or size-press (starch containing or not) applied layers. The third component represents substrates located in the ink and / or toner compounds. This method provides improved performance in relation to conventional methods, or current deinking with enzymes, which acts on a limited number of substrates involved in ink retention on final pulp.

Owner:TRI TEX

Environment-friendly type deinking agent for mixing waste paper

InactiveCN101381534ALow freezing pointGood deinking effectChemical paints/ink removersDeinkingPhenyl Ethers

The invention relates to a deinking agent, in particular to an environment-friendly mixed waste paper deinking agent. The prior waste paper deinking agent can only deink one class of waste paper in general. The invention provides the environment-friendly mixed waste paper deinking agent with wider application range, which is characterized in that the weight percentage of every component is: 5 to 10 percent of polyoxyethylene nonyl phenyl ether, 25 to 30 percent of fatty alcohol polyoxyethylene ether sodium sulfide, 5 to 10 percent of fatty alcohol polyoxyethylene ether, 10 to 20 percent of sulfonic acid, 4 to 10 percent of ethanol and the balance being water. Compared with the prior deinking agent, the deinking agent of the invention has the advantages of wide application range, good deinking effect and the like, and is few in components and simple in method.

Owner:HANGZHOU KAIBO CHEM IND

Paper-making environmentally-friendly mineral deinking agent

InactiveCN102120901ABiodegradable withNo secondary pollutionChemical paints/ink removersWater basedStearic acid

The invention provides a paper-making environmentally-friendly mineral deinking agent. In the conventional anion and non-ion compound deinking agent and mineral material and surfactant compound deinking agent, waste gas and waste water are easy to produce in the production process of the deinking agent; and the product is difficult to biodegrade in the using process under the alkaline deinking condition. The paper-making environmentally-friendly mineral deinking agent comprises the following raw materials in percentage by mass: 5 to 35 percent of anion surfactant, 5 to 25 percent of stearic acid, 10 to 40 percent of silicate inorganic mineral soil, 5 to 20 percent of biodegradable nonionic surfactant, 0.5 to 5 percent of emulsifying agent, 0.01 to 2 percent of polyether type surfactant and 0.5 to 2 percent of inorganic salt electrolyte. By the paper-making environmentally-friendly mineral deinking agent, the effects of removing oily ink, water-based ink and sticky substances by using the deinking agent are improved obviously; the selected components have environmental friendliness and biodegradability and do not have toxicity to a human body and an environment; and secondary pollution is avoided.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Bureau wastepaper composite deinking agent and preparing method thereof

InactiveCN101012344AReduce dosageLow costChemical paints/ink removersStearic acidOleic Acid Triglyceride

The invention discloses a MOW void agent and making method in the void agent technical domain, which comprises the following steps: allocating raw material with 2-5% stearic acid, 10-20% oleic acid, 1-5% acrylic acid, 1-4% maleic anhydride, 3-5% alkyl aliphatic polyoxyethylene ester, 1-2% dodecanol, 2-3% tween, 3-4% sodium benzosulfonate alkyl and water; adding each component into thermostatic autoclave at 75-80 deg.c sequently; stirring at 130-150r / min for 45-60 min; blending evenly; adjusting pH value to 9-10 through NaOH; loading in the barrel; stewing; cooling naturally to indoor temperature; obtaining the product.

Owner:QILU UNIV OF TECH

Office waste paper recycling method

InactiveCN103696311ABreak through dependenceDepends on nonePaper recyclingWaste paper working-upChemical productsWaste treatment

The invention discloses an office waste paper recycling method.Qualified office paper is recycled by disintegrating, pulping, deinking, bleaching, pressing, drying and cutting. Compared with the prior art, the office waste paper recycling method adopts the bio-enzyme preprocessing technology to break through the dependency of the traditional paper making on chemical products, decreases the application of chemical reagents through the bio-enzyme and ultrasonic-wave synergic deinking technology, adopts the treatable hydrogen peroxide-ozone mixed bleaching technology to achieve the advantages of no pollution, environmental friendliness and reduced difficulty of the waste water treatment, improves the utilization rate of office copy waste papers and the recycling rate of the waste papers, reduces the cost of the office papers, saves water and energy, protects the environment, can integrate and automate all step treatment devices, and is convenient to promote and apply.

Owner:HENAN POLYTECHNIC UNIV

Low-foaming liquid polyether waste paper deinking agent and synthetic method thereof

ActiveCN103396697AImprove permeabilityThe size is easy to controlPaper recyclingChemical paints/ink removersPotassium hydroxideSolvent

The invention relates to a papermaking auxiliary agent, and more specifically relates to a low-foaming liquid polyether waste paper deinking agent and a synthetic method thereof. The low-foaming liquid polyether waste paper deinking agent is capable of completely replacing sodium soaps, and a main compound of the low-foaming liquid polyether waste paper deinking agent is a special polyether. The synthetic method comprises following steps: (1) adding an unsaturated fatty alcohol which is used as an initiator into a reaction vessel, adding potassium hydroxide which is used as a catalyst for reaction, removing water until weight ratio of water is less than 0.3%, and adding oxirane and epoxypropane separately so as to obtain unsaturated enol-polyether; (2) adding an unsaturated long-chain fatty acid, toluene solvent and a catalyst into the reaction vessel, heating to 60 to 80 DEG C, at the same time dropwise adding a mixed solution of the product obtained in step (1), acrylic acid and toluene, then heating the mixture to 70 to 85 DEG C, and keeping the temperature for 1.5 to 4h so as to obtain a product; and (3) mixing and reacting the product obtained in step (2), propylene glycol block polyether, fatty alcohol-polyoxyethylene ether-7 or fatty alcohol-polyoxyethylene ether-9, and water so as to obtain the special polyether.

Owner:威尔(福建)生物有限公司

High-pulp-yield deinking method

ActiveCN106223097AHigh strengthHigh yieldPaper recyclingCellulose treatment using microorganisms/enzymesDeinkingUltraviolet radiation

The invention discloses a high-pulp-yield deinking method, and belongs to the technical field of pulp deinking. Waste paper containing ink is prepared into a pulp liquid, and the pulp fluid is subjected to ultraviolet radiation and is then stirred and soaked with a complex enzyme to obtain a mixed liquid; wheat straw powder, anthracite powder, starch and the like are stirred, pressed to be formed, and calcined together to prepare carbonized particles; the carbonized particles, the mixed liquid and fatty alcohol-polyoxyethylene ether are stirred and then subjected to flotation, the obtained floated pulp is diluted and filtered, and a filtrate is finally heated, concentrated and diluted to complete deinking, so that a deinked pulp is obtained. The operation process is simple and convenient, the deinking efficiency is effectively improved, the addition of the complex enzyme reduces the degradation and loss of a pulp fiber in the deinking process, the strength of the deinked pulp is high, the yield is high, in addition, the carbonized particle is further deinked, the environment pollution is not caused because no deinking agent is used, few glue matters are produced, and the method has an extensive application prospect.

Owner:KOMPASS TECH INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com