Process for preparing recovered pulp with high whiteness and high cleanliness

A technology with high cleanliness and preparation technology, which is applied in the field of papermaking raw material processing, and can solve the problems of dusty impurities and low pulp whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

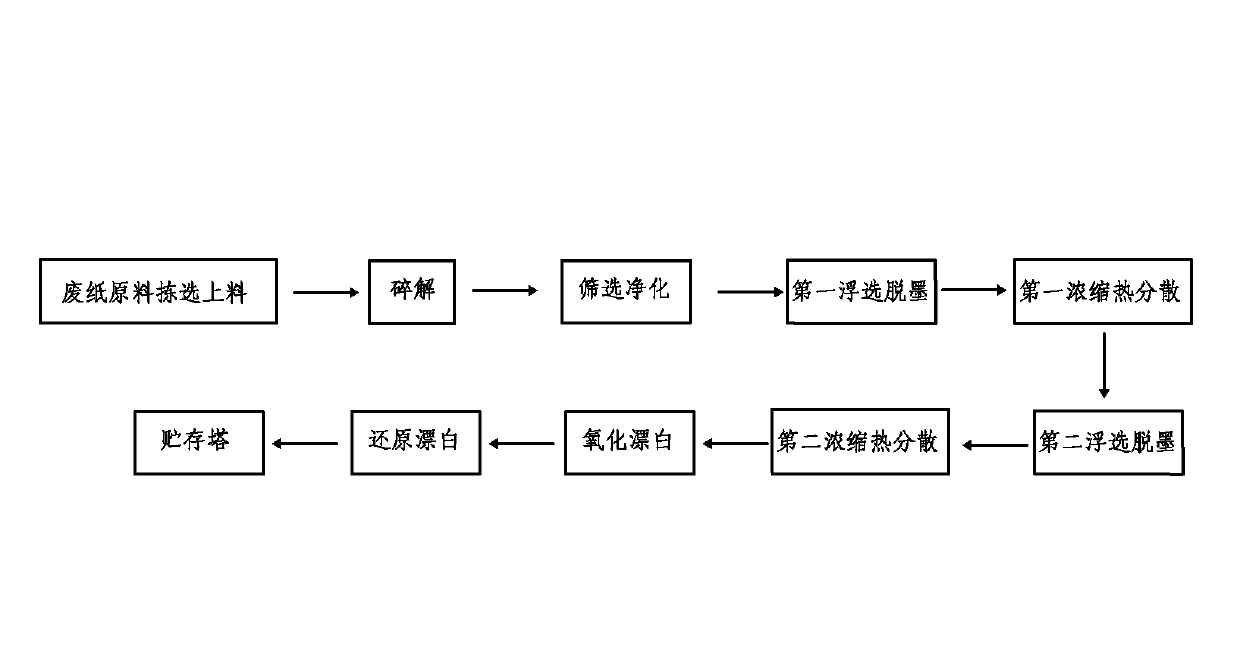

Embodiment 1

[0051] The preparation process of a high-whiteness and high-cleanliness recycled pulp in this embodiment includes the following process steps: A. Waste paper raw material selection and feeding: the mass ratio of each waste paper raw material is US waste 37#: Japanese waste 5#: U.S. waste 10#: U.S. waste 8# is 20%: 40%: 30%: 10%, and it is put on the chain conveyor, and the waste paper raw materials are evenly put into the drum pulper after being processed by the bulk bag machine and the leveling roller; B , Disintegration: Add 0.4% NaOH, 0.6% NaOH to the disintegration area in the front section of the drum pulper 2 Sio 2 , 0.2% industrial soap and 0.03% H 2 o 2 , and then add white water at 70°C, so that the concentration of the disintegration zone is 20%, the temperature is 50°C, and the pH value is 9, and the waste paper raw material is gently pulped to obtain a slurry; C. Screening and purification: the slurry is firstly used Two-stage high-concentration slag remover for...

Embodiment 2

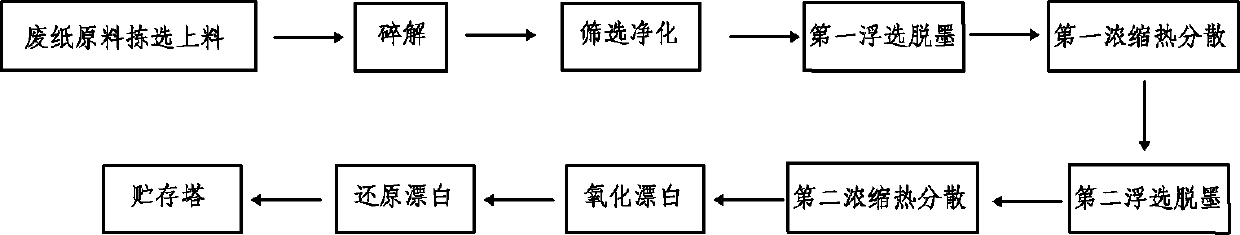

[0053]The preparation process of a high-whiteness and high-cleanliness recycled pulp in this embodiment includes the following process steps: A. Waste paper raw material selection and feeding: the mass ratio of each waste paper raw material is US waste 37#: Japanese waste 5#: U.S. waste 10#: U.S. waste 8# is 25%: 35%: 25%: 15%, and it is put on the chain conveyor, and the waste paper raw materials are evenly put into the drum pulper after being processed by the bulk bag machine and the leveling roller; B , Disintegration: add 0.5% NaOH, 0.65% NaOH to the disintegration area in the front section of the drum pulper 2 Sio 2 , 0.25% industrial soap and 0.05% H 2 o 2 , and then add white water at 75°C, so that the concentration of the disintegration zone is 21%, the temperature is 55°C, and the pH value is 10, and the waste paper raw material is gently pulped to obtain a slurry; C. Screening and purification: the slurry is firstly used Two-stage high-concentration slag remover f...

Embodiment 3

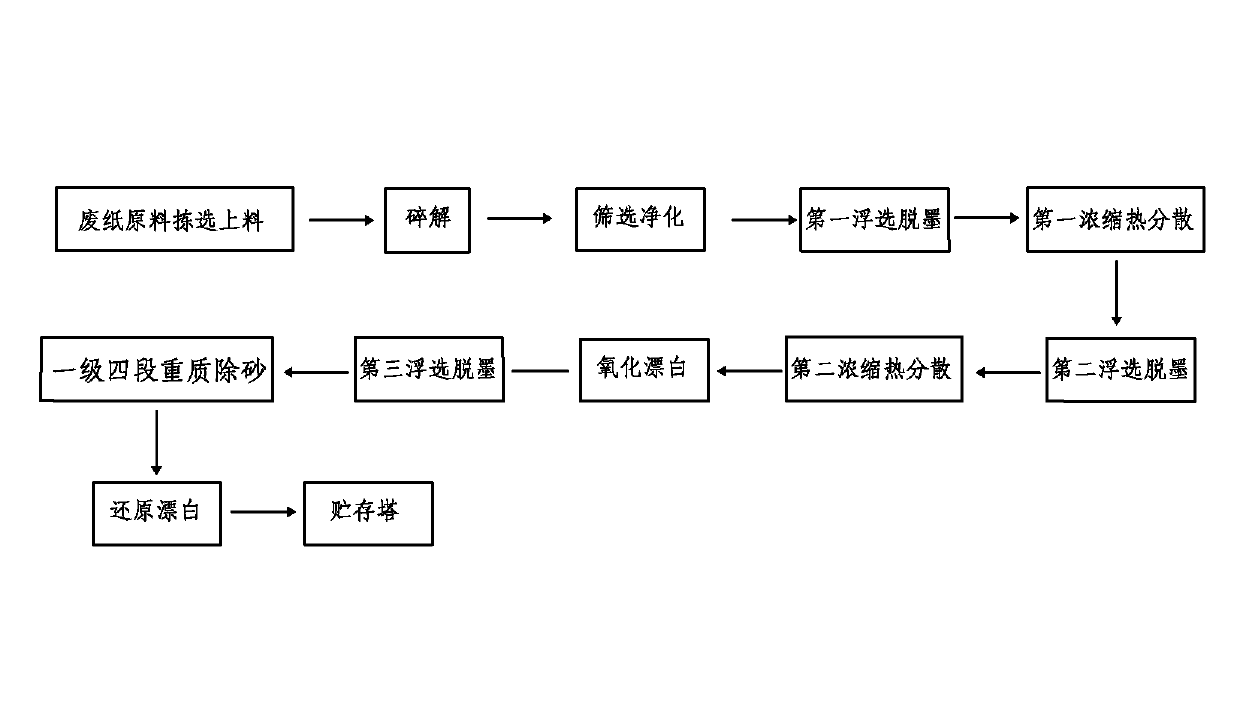

[0055] The preparation process of a high-whiteness and high-cleanliness recycled pulp in this embodiment includes the following process steps: A. Waste paper raw material selection and feeding: the mass ratio of each waste paper raw material is US waste 37#: Japanese waste 5#: U.S. waste 10#: U.S. waste 8# is 30%: 30%: 20%: 20%, and it is put on the chain conveyor, and the waste paper raw materials are evenly put into the drum pulper after being processed by the bulk bag machine and the leveling roller; B , Disintegration: add 6% NaOH, 0.7% Na 2 Sio 2 , 0.3% industrial soap and 0.06% H 2 o 2 , and then add white water at 80°C, so that the concentration of the disintegration zone is 22%, the temperature is 60°C, and the pH value is 10.5, and the waste paper raw material is gently pulped to obtain a slurry; C. Screening and purification: the slurry is firstly used Two-stage high-concentration slag remover for impurity removal, and then through a first-stage two-stage coarse s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com