Patents

Literature

128 results about "Newsprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Newsprint is a low-cost, non-archival paper consisting mainly of wood pulp and most commonly used to print newspapers and other publications and advertising material. Invented in 1844 by Charles Fenerty of Nova Scotia, Canada, it usually has an off white cast and distinctive feel. It is designed for use in printing presses that employ a long web of paper (web offset, letterpress and flexographic) rather than individual sheets of paper.

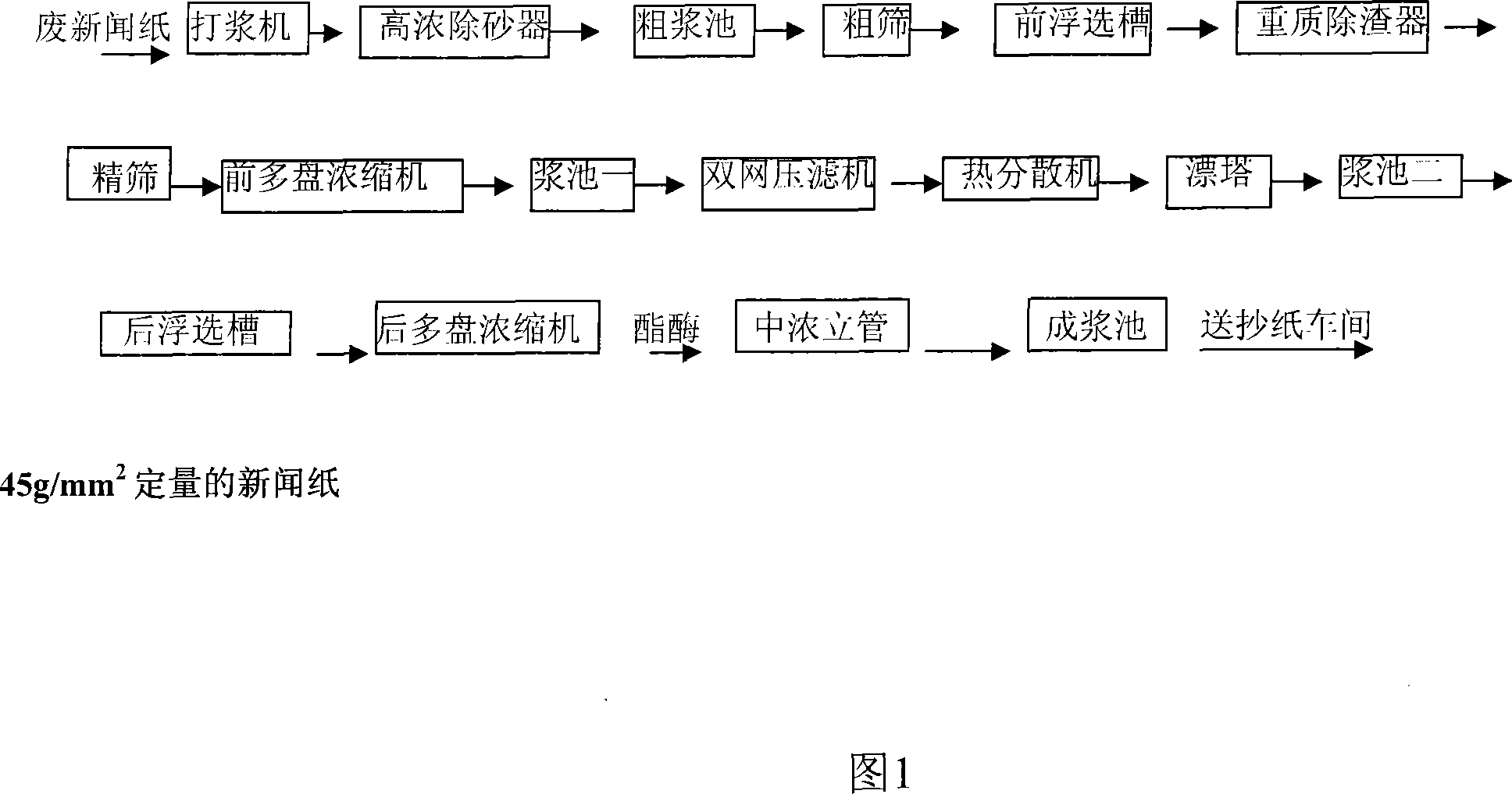

Method for controlling with 100aste newsprint paper deinked pulp esterase

InactiveCN101220567AReduce contentGuaranteed uptimePulp de-wateringPaper recyclingProcessing costPollution

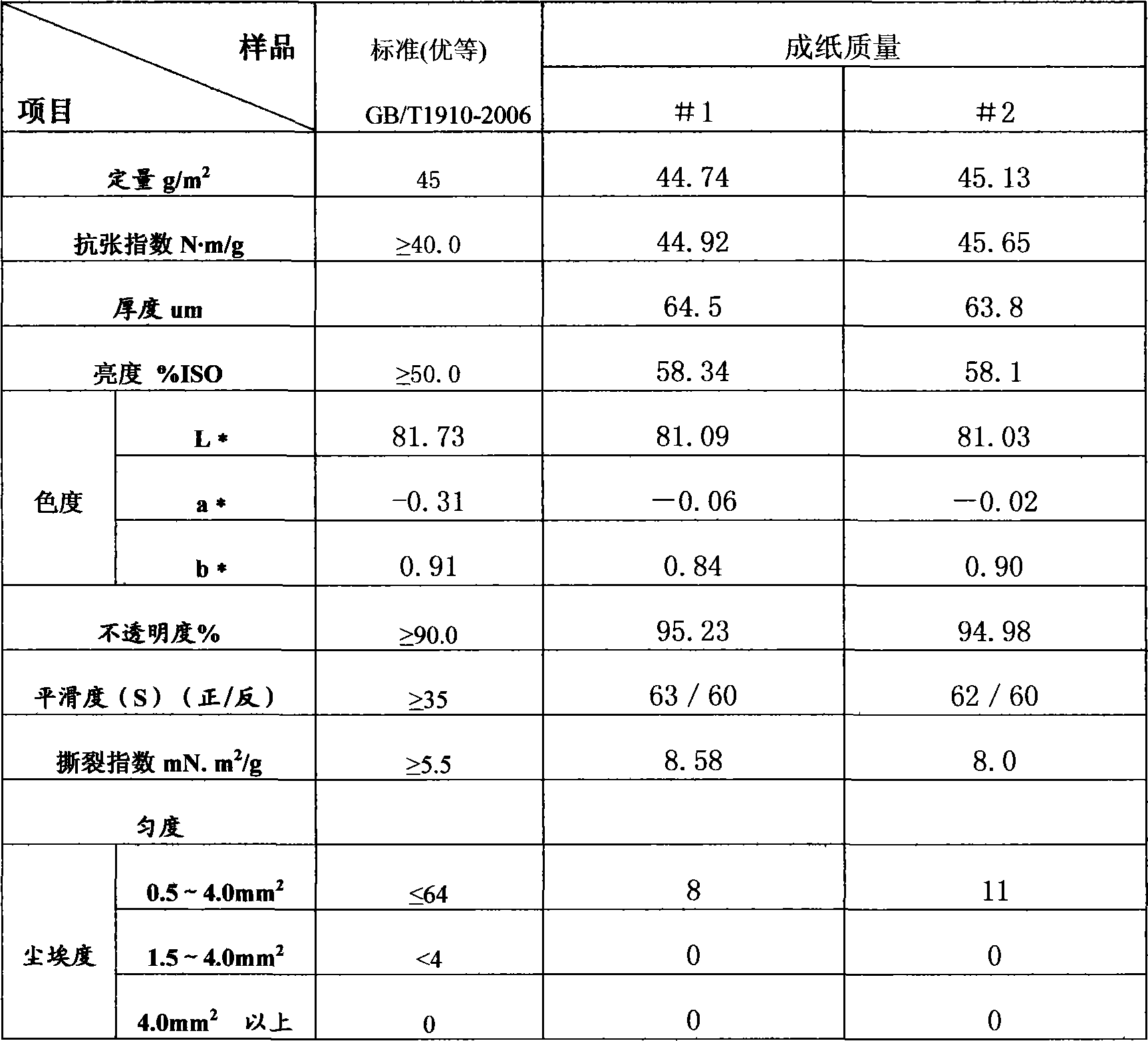

The invention discloses a method that uses esterase obtained by 100 percent deinking and desizing of wasted newspaper controls sticky which mainly aims at producing the low fixed amount newspaper by using the 100 percent deinking and desizing of the wasted newspaper, adopts Optimyze 525 esterase control sticky and produces the newspaper with 45g / mm<2> fixed amount. The invention has the advantages of reducing the dosage of the sticky in the paper pulp, leading the sticky removing rate to be about 20 percent to 40 percent, reinforcing the operating performance of a paper machine, and helping to improve the speed and the output of the paper machine; by adopting deinking and desizing of 100 percent wasted newspaper to make 45g / m<2> lowing amount offset newsprint, the obtained products have good quality, chemical pulp and groundwood pulp which are high in pollution and high consumption are eliminated, the manufactory cost of the pulp material and the processing cost of the water are reduced, and the discharged waste water and the pollutants are reduced.

Owner:GUANGDONG IND TECHN COLLEGE +1

Deinking Technique for news bogus paper through enzyme

InactiveCN1563567AImprove bleachabilityPaper recyclingChemical paints/ink removersDeinkingPulp and paper industry

A waste new print zyme deinking technology includes crushing the pulp, deinking, suspension selection, washing, bleaching among which, deinking agent, laccase, amboceptor are added into the pulped with waste newsprints and waster to be inlet with oxygen and the pulp concentration is controlled at 3%-18%, temperature 20-70deg.C pulping, keeping warmth.

Owner:QILU UNIV OF TECH

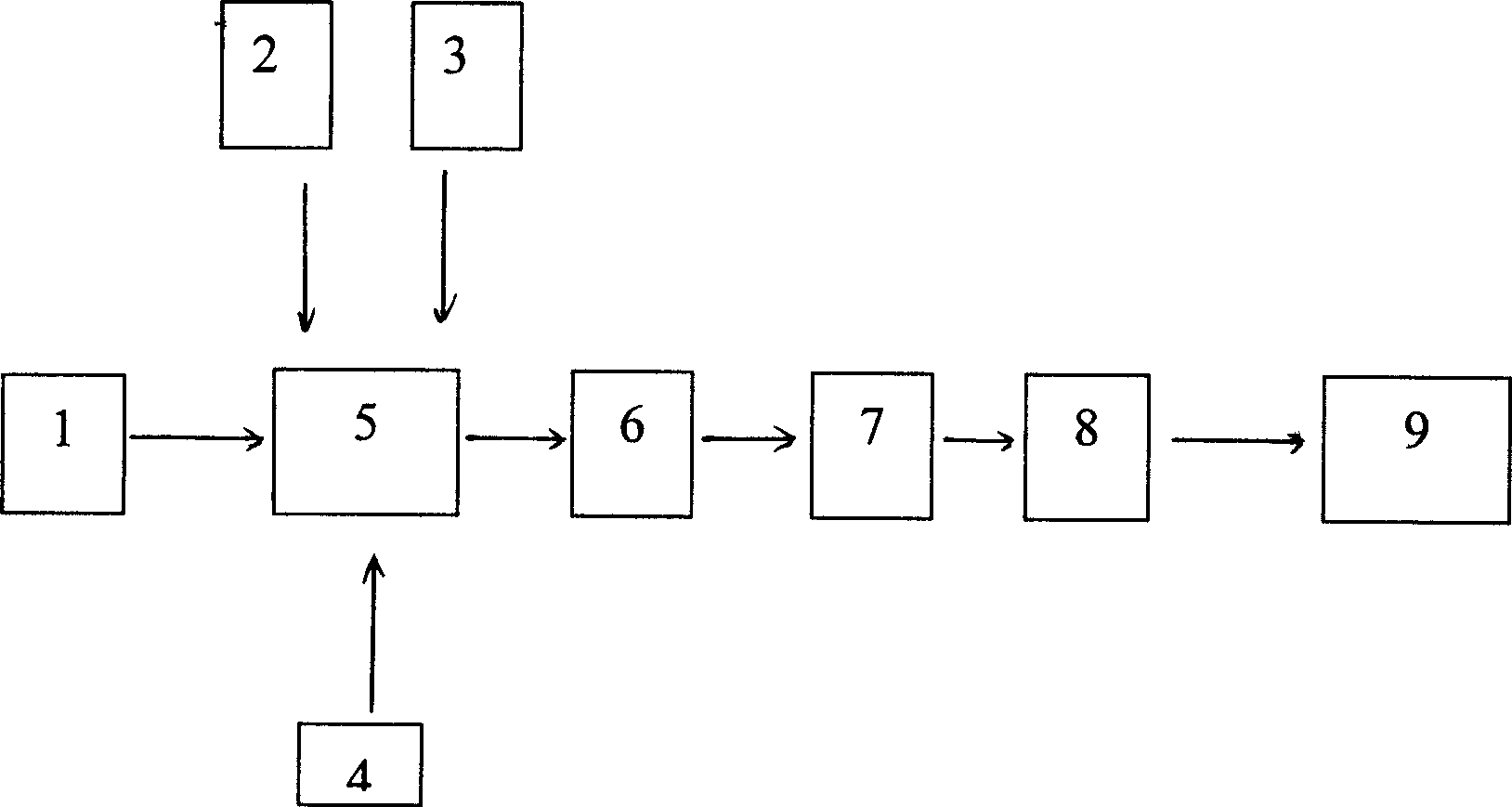

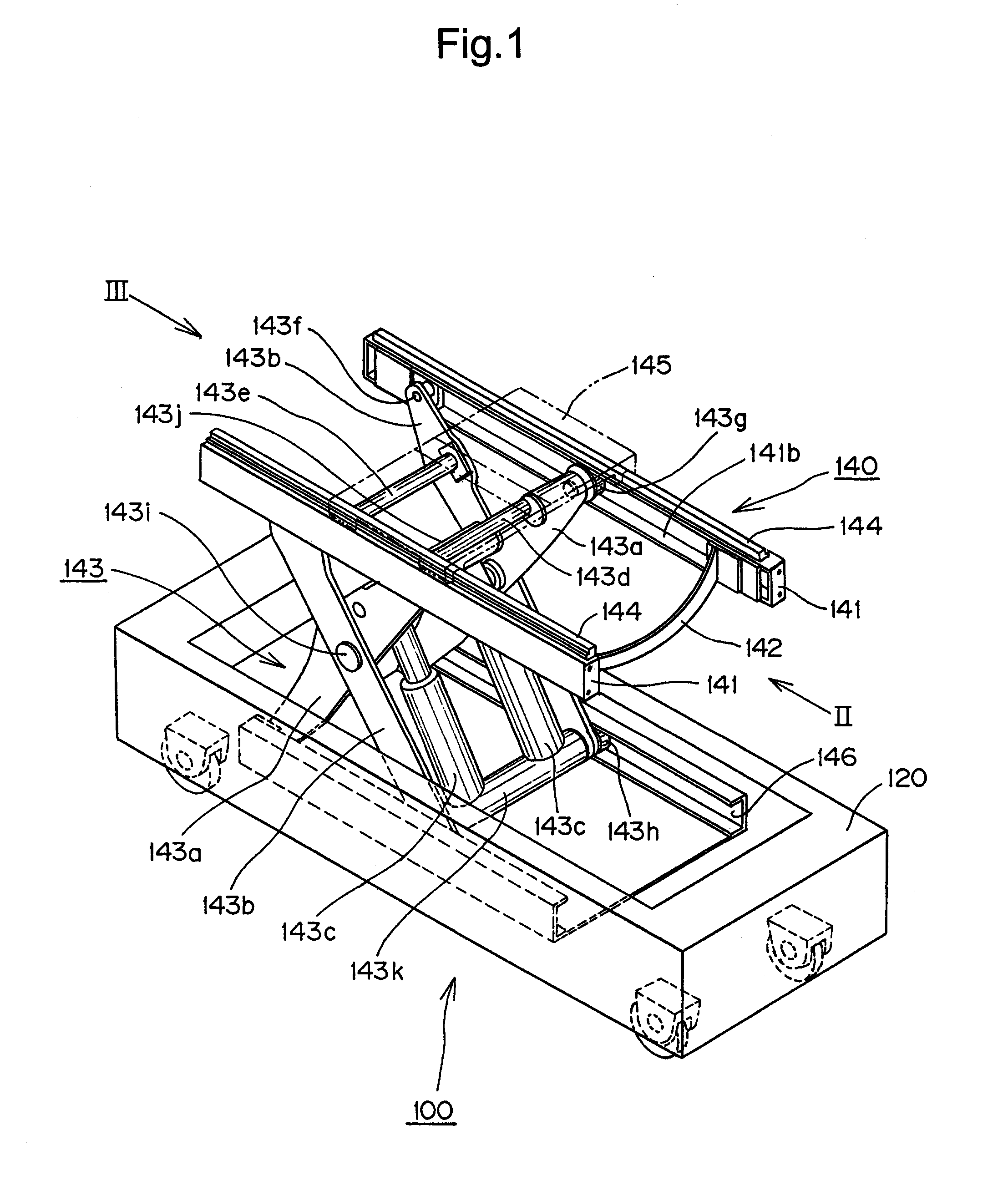

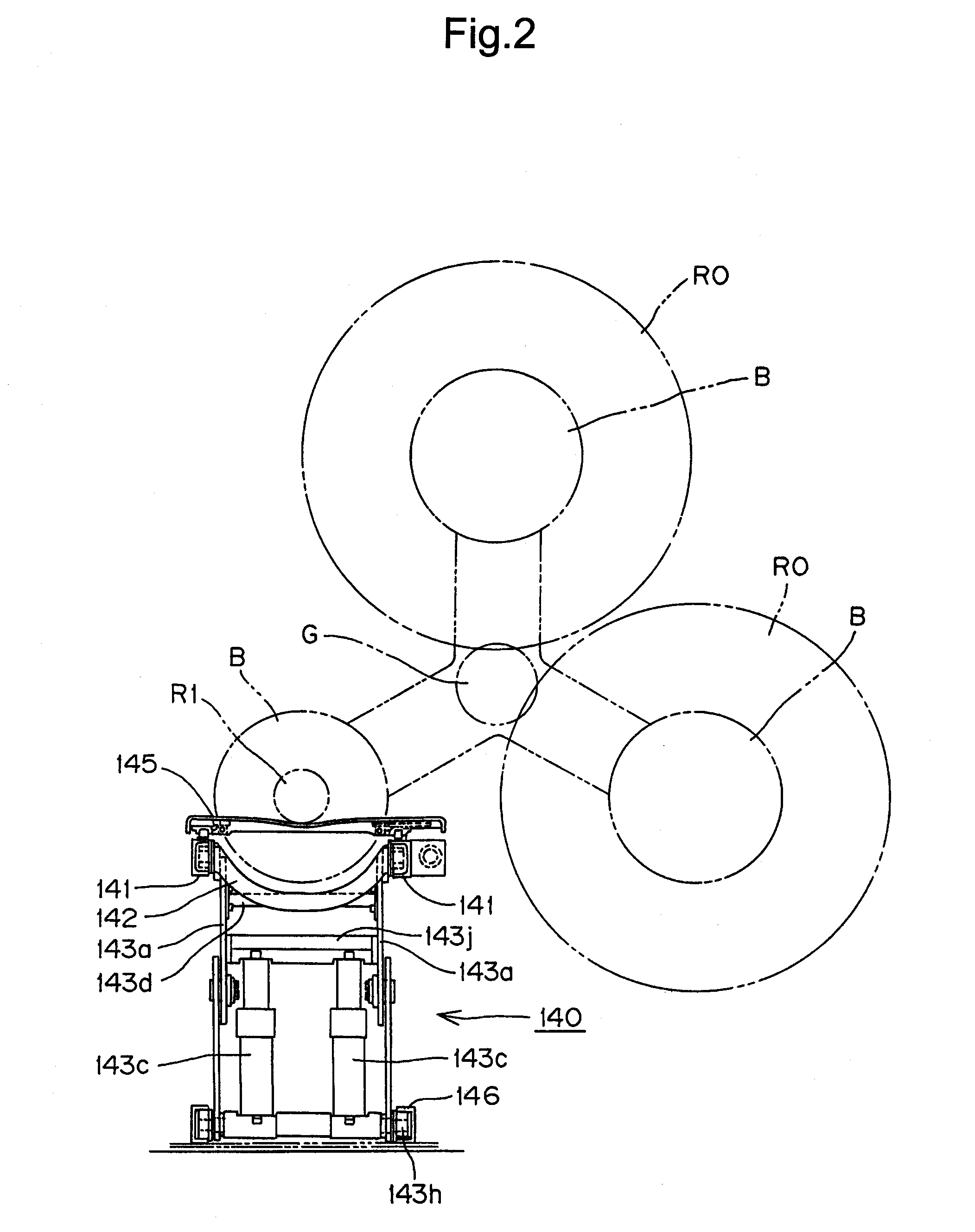

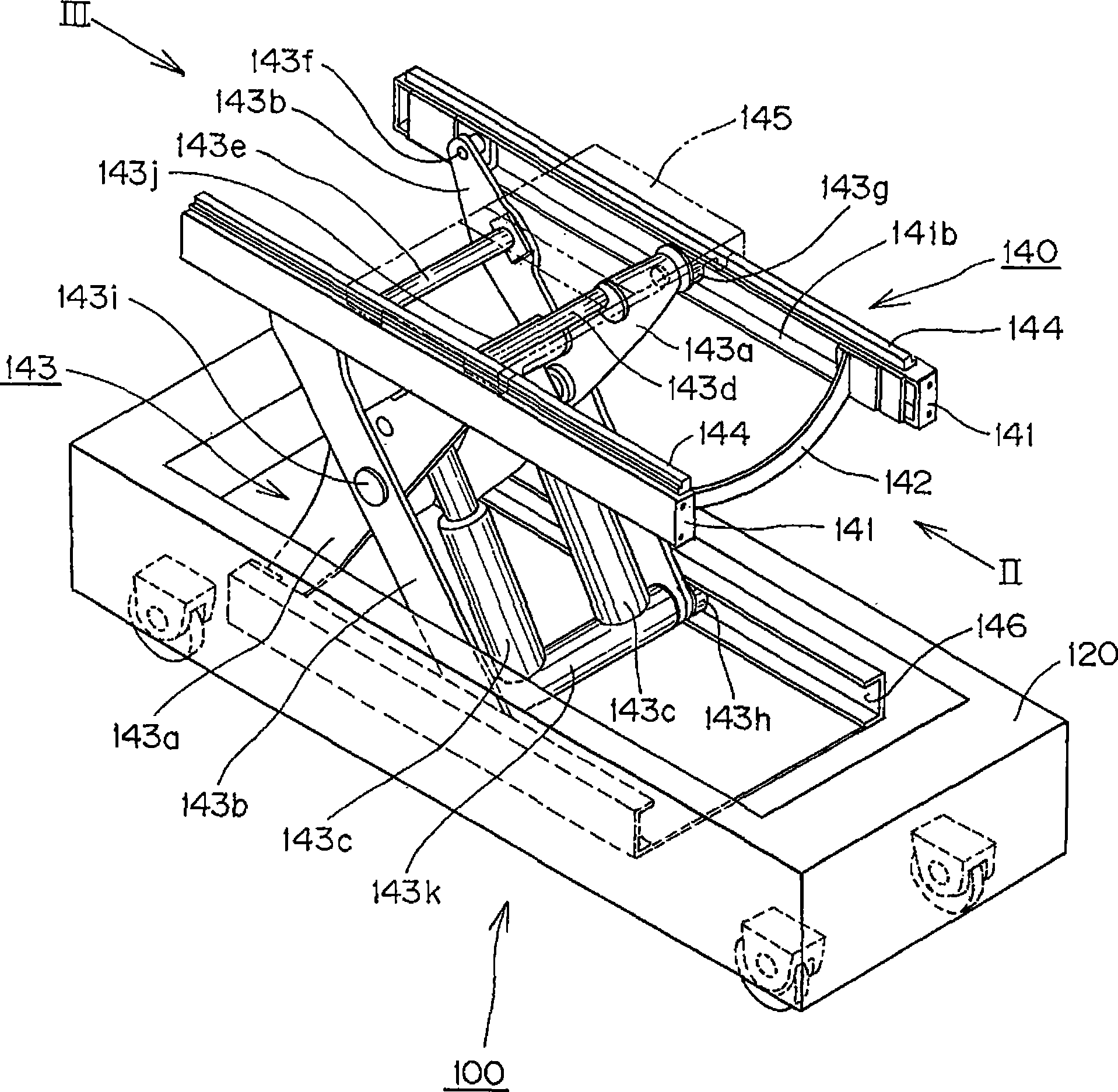

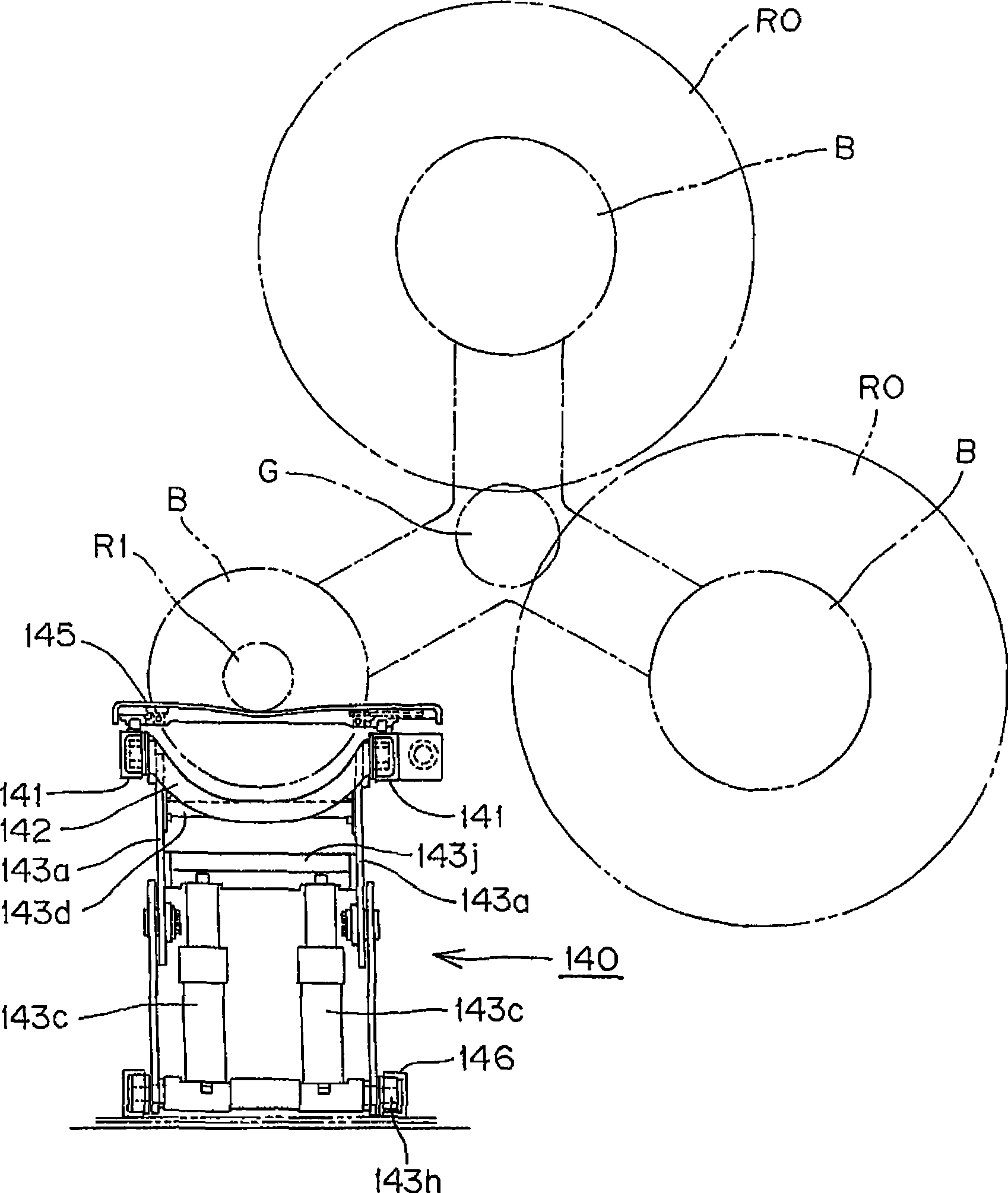

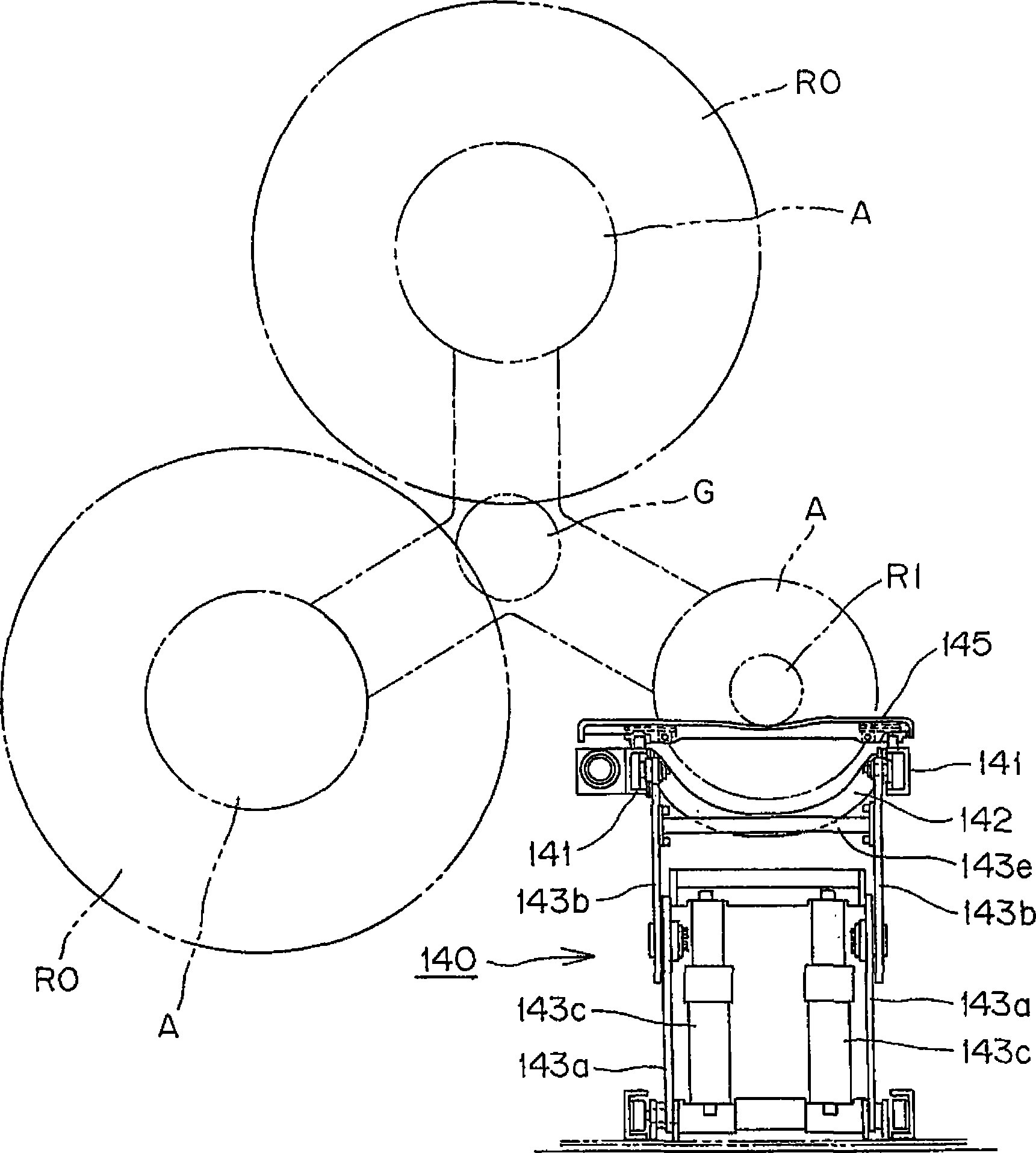

Automated guided vehicle for rolls of newsprint

InactiveUS20090104007A1Low beddingReduce weightControl devices for conveyorsLifting devicesVehicle frameRoad surface

An automated guided vehicle for loading and unloading a rotary press with various types and widths of rolls of newsprint or other paper irrespective of their diameters. The vehicle has a traveling carriage for automatically transporting a newsprint between a storage area and the setting area in a rotary press machine. It includes a hoisting / lower unit which hoists and lowers the newsprint in the vertical direction into and away from registering with the paper holding arms of the rotary press machine. The hoisting / lowering unit includes two hoisting / lowering frames parallel to a traveling road surface, and the central axis between the fixed and movable paper holding arms of the rotary press paper. The frames are kept spaced apart by an arc-shaped connecting member. Linear guides on upper surfaces of the two hoisting / lowering frames slidably support a moving table bridging over the linear guide 144 which supports the roll and permits the supported roll to be axially displaced into engagement with the support cones of the fixed holding arms.

Owner:UMEZAWA KENJI +1

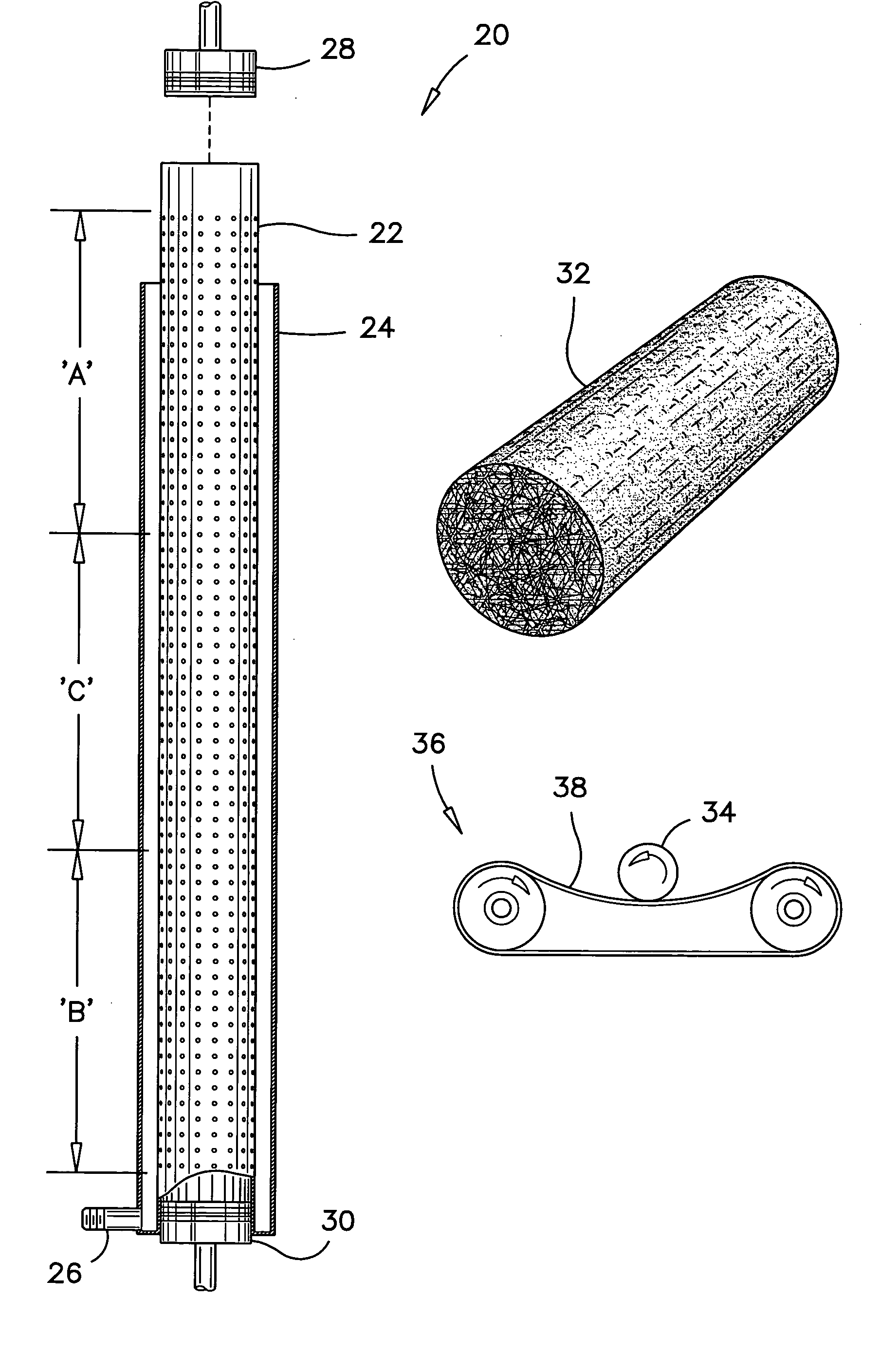

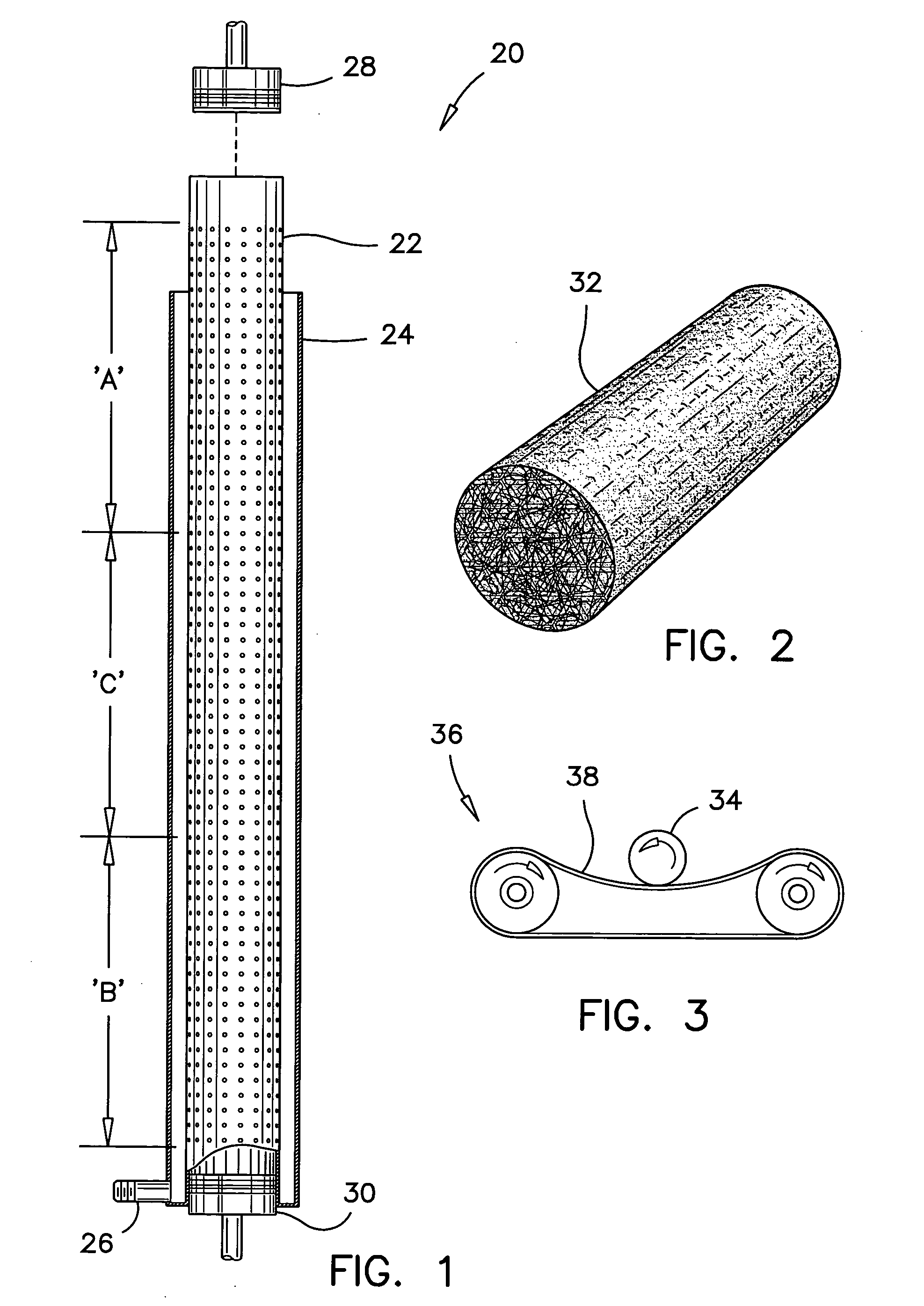

Fire log made of recycled materials and a method and an apparatus for manufacturing the same

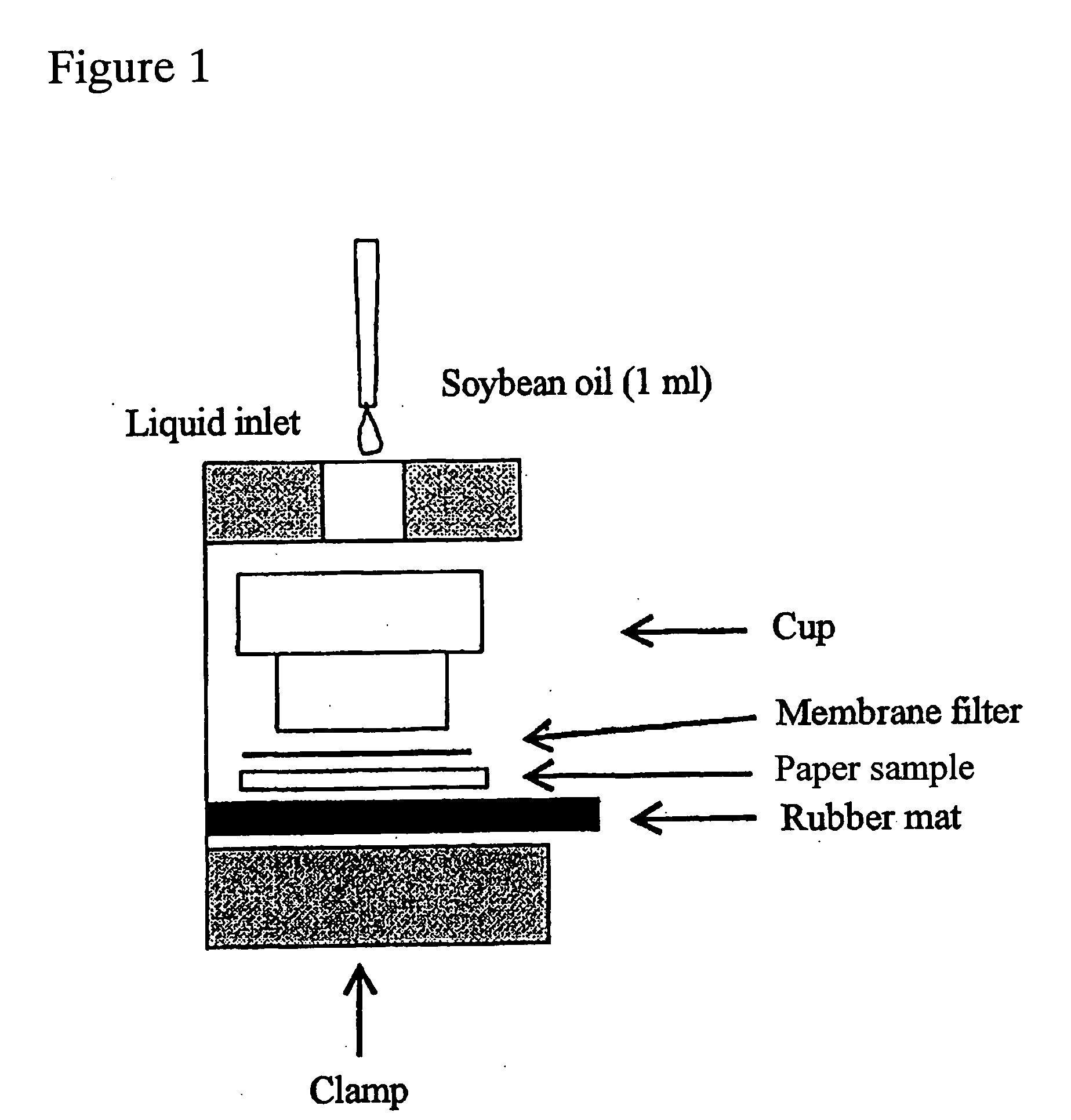

The fire log comprises an organic fibre base that is over-saturated with vegetable cooking oil. The vegetable oil is contained and sealed therein by a casing made of the vegetable wax. More specifically, the fire log is over saturated with 65%-75% by weight of vegetable oil. The vegetable oil is used vegetable cooking oil. The organic fibre base represents about between 20%-30% by weight and consists of compressed paper-based products such as cardboard, newsprint and recyclable paper. The vegetable wax casing represents about between 1-5% of its weight. In another aspect of the present invention, the organic fibre base is made of broken fibres and interstices, and the vegetable oil is infused therein while these fibres are dilated from their natural states. In yet another aspect, the organic fibre base is formed in a perforated cylinder whereby a bark-like appearance is imprinted on its surface.

Owner:BONNELL RICKARD CARLA +1

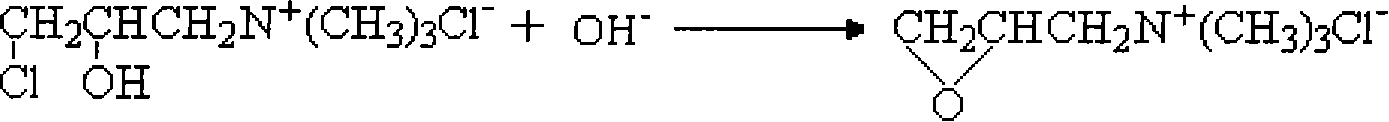

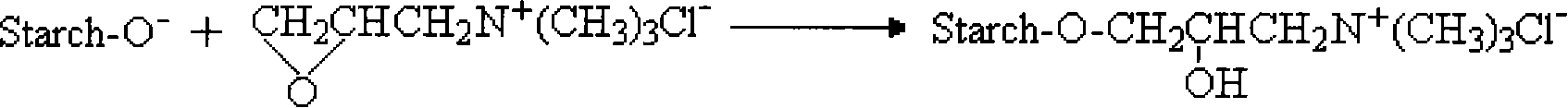

Method for synthesizing cationic starch

InactiveCN101177458AEtherification reaction time is shortenedReduce manufacturing costPotato starchNewsprint

The invention relates to a method for synthesizing cationic starch at low cost, wherein sweet potato starch or corn starch is mixed with water to obtain starch suspension, and then the sodium hydroxide with weight of 1.5% to 3.0 % relative to starch as well as the cationic etherifying agent 3-chlorine-2- hydroxypropyl trimethyl ammonium chloride are dripped; subsequently, reaction is conducted for 2 to 4 hours at 40 DEG C to 90DEG C, followed by neutralization by dilute hydrochloric acid solution to reach pH 6.5 to 7.0; finally, rinsing, dewatering, drying and preparing are conducted to substitute the cationic starch within the range from 0.02 to 0.04, which can reach the yield of no less than 99% with the use amount of cationic etherifying agent reduced by about 50% and the reaction duration shortened by 4 to 7 hours. The product has the advantages of dramatic stability of 3% paste liquid, no stratification within 100 hours, high transparency, improved strength and quality of the finished paper in production of regenerative newsprint.

Owner:SHANDONG TAIYANGZHIYE

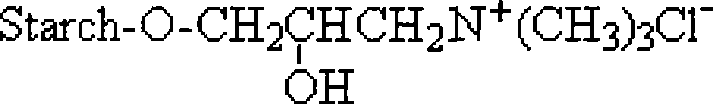

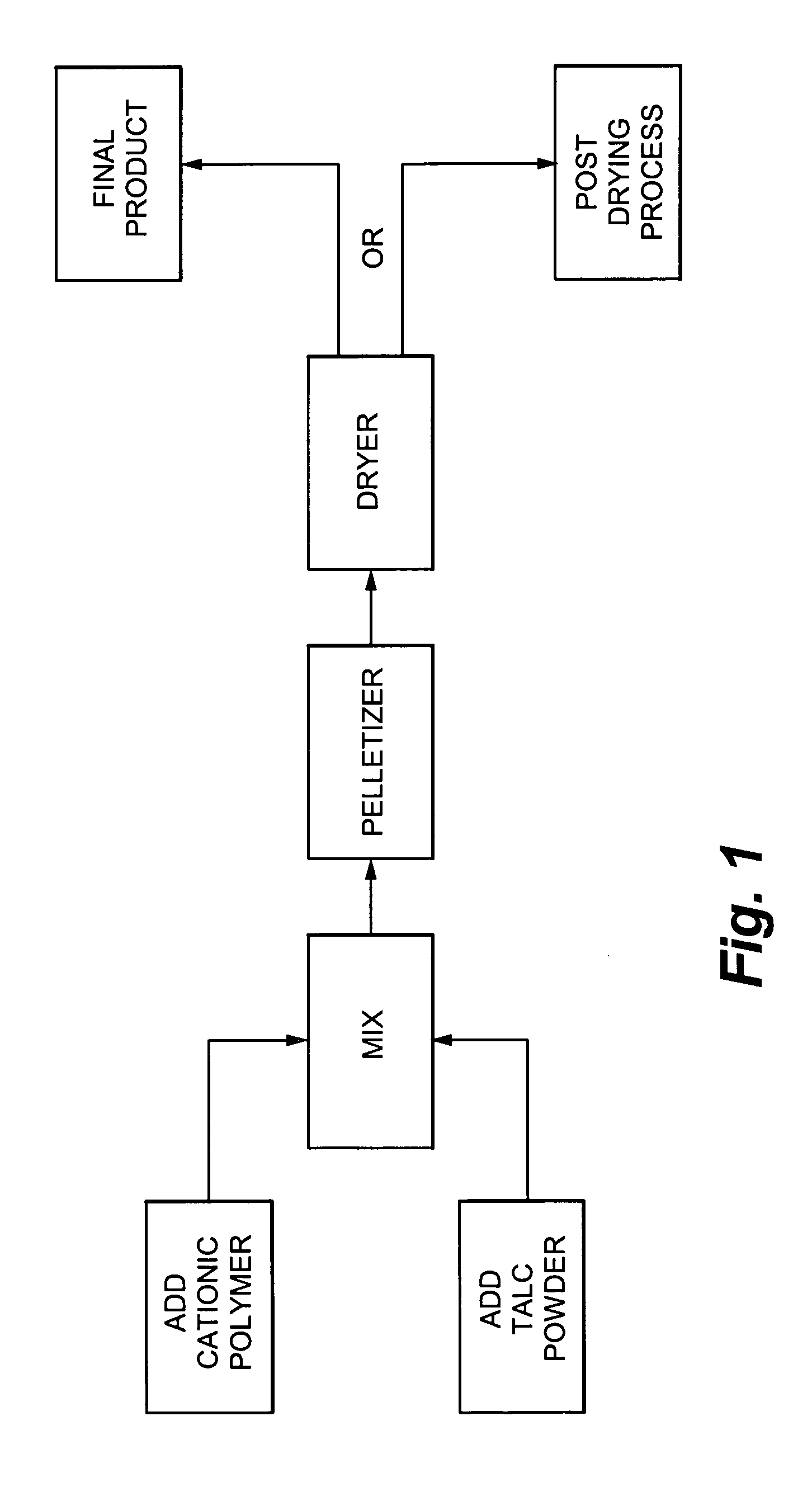

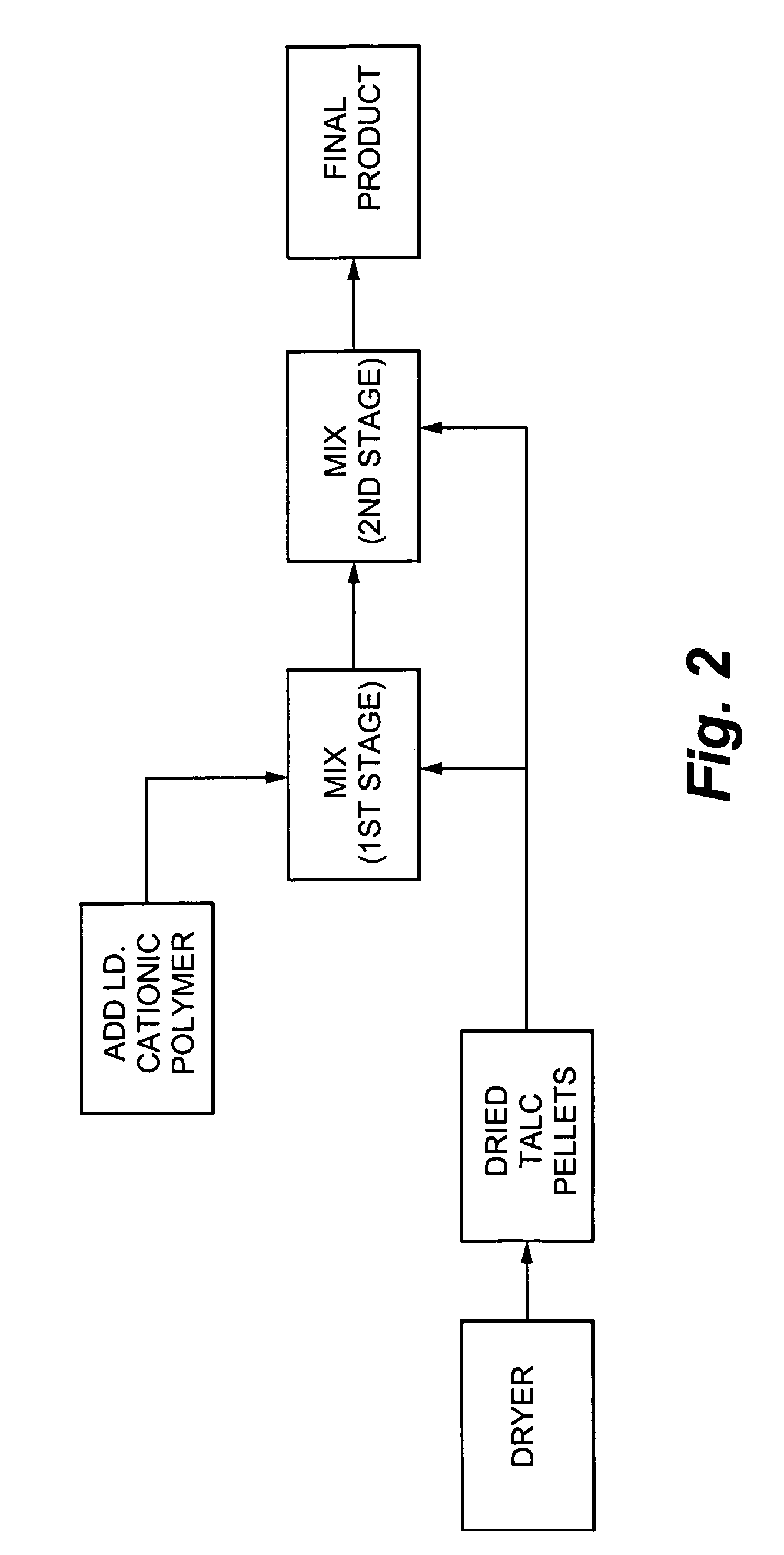

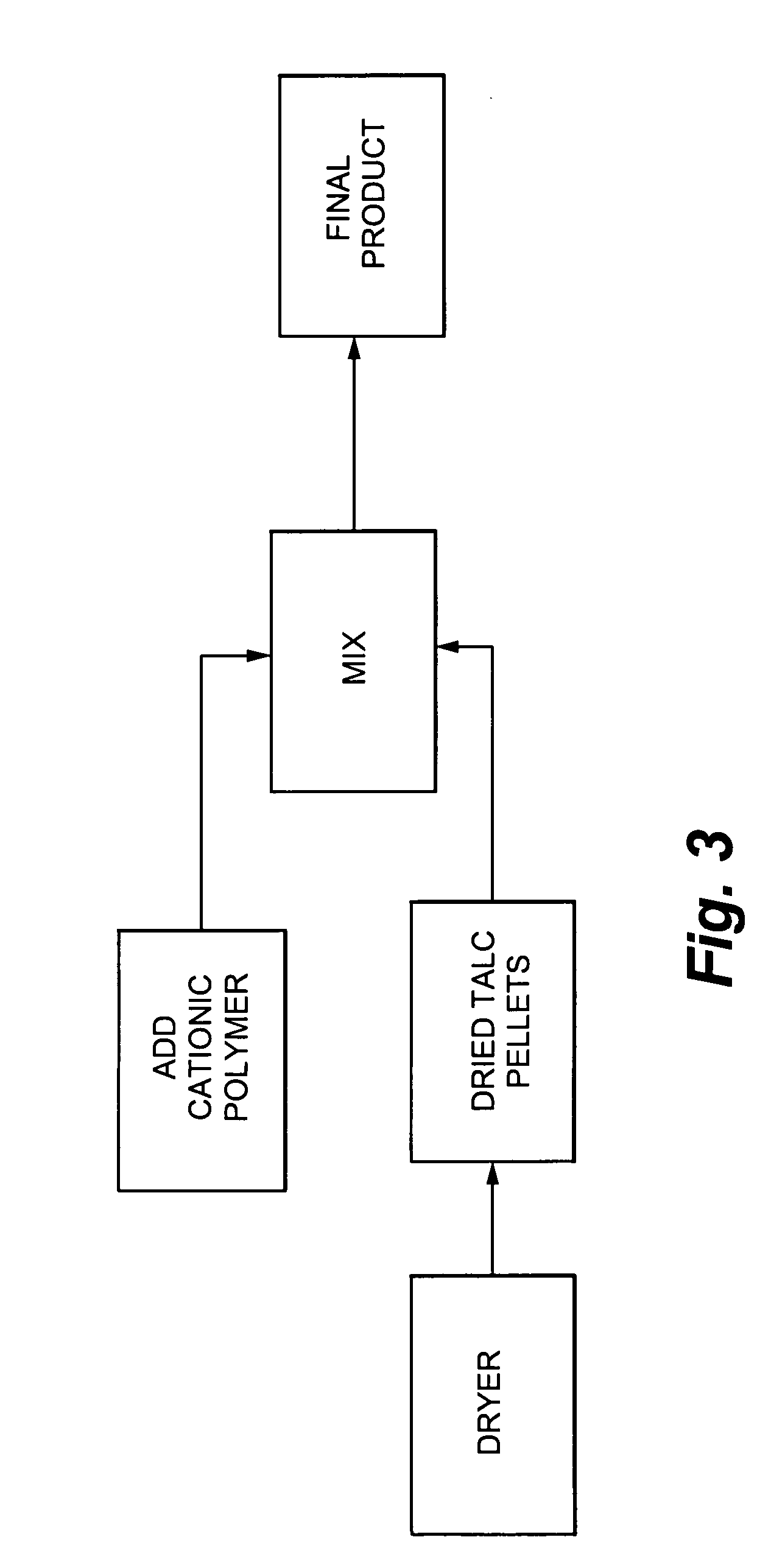

Additive and process for sticky control in recycled pulps

The present invention describes an additive which controls stickies formation and removes anionic trash from recycled old corrugated container furnish, old newsprint furnish, deinked pulp furnish, old magazine grade furnish, coated broke furnish, or thermomechanical pulp furnish. The present invention treats talc with either a tertiary or quaternary amine. The treated talc is then added to the pulp slurry and removes stickies by binding the stickies to the talc and neutralizes the anionic trash that may be present.The present invention also describes a method for modifying talc particles involving contacting a tertiary or quaternary amine with talc particles. The present invention further describes a talc created by the process of contacting a tertiary or quaternary amine with talc particles. The present invention additionally describes a paper product having a modified talc filler wherein the modified talc filler has been contacted with a tertiary or quaternary amine.

Owner:MAGRIS TALC USA INC

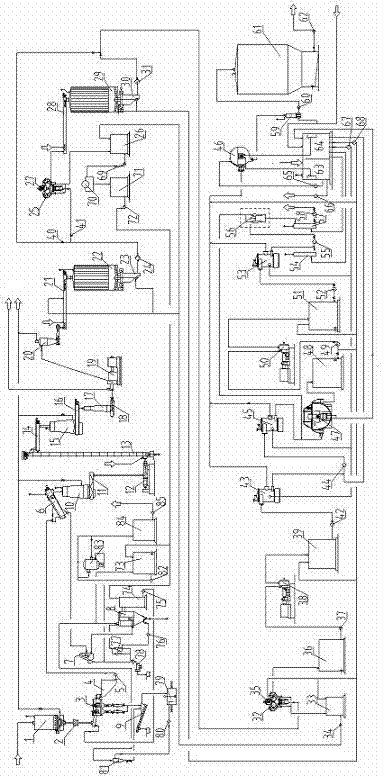

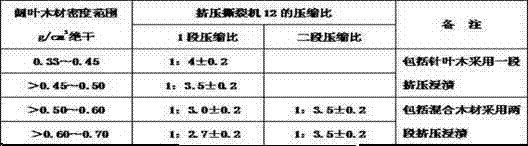

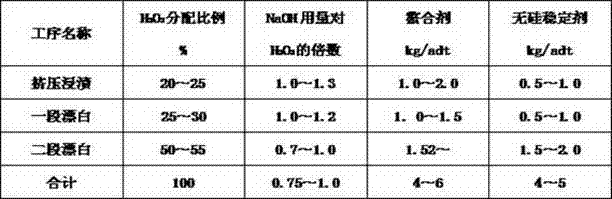

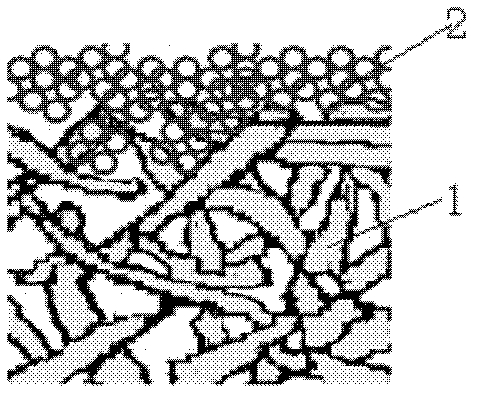

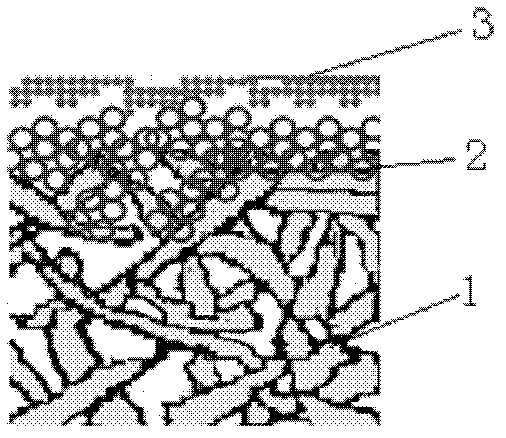

Chemi-mechanical pulp manufacturing technology

ActiveCN104711880AImprove purification qualityIncrease productivityPretreatment with water/steamWashing/displacing pulp-treating liquorsFiberManufacturing technology

The invention discloses a chemi-mechanical pulp manufacturing technology which includes the step of wood chip washing, the step of extruding and dipping, the step of pulp grinding, bleaching and pulp washing, the step of screening, purifying and regrinding of pulp residues, the step of pulp condensation and storage, the step of water circulating use and the step of chemical application and control. In the step of extruding and dipping, the extruding and dipping technology and an extruding and tearing device are used, heated and softened wood chips are evenly squashed in the texture direction, air in the wood chips and extracts affecting bleaching are discharged, it is ensured that the wood chips evenly absorb bleaching chemical liquid to be in a saturated state, fibers are promoted to be in the best moist and expanded state, and accordingly separation of the wood chips and fibrillation of the fibers are facilitated. The chemi-mechanical pulp manufacturing technology is wide in raw material application range and successfully combines the advantages that chemical pulp is high in strength and mechanical pulp is high in yield, produced bleached pulp can be used for newsprint, high-grade toilet paper, facial tissues, high-grade culture and printing paper, coating paper, light paper, white paper boards, food package paper and the like, and development prospects are wide.

Owner:WENRUI MACHINERY SHANDONG

Newsprint paper treated with cationic surface sizing agent

ActiveUS20060225854A1Decreased color registration errorSolve the lack of resistanceNatural cellulose pulp/paperSpecial paperEngineeringPolyacrylamide

Newsprint for offset printing having sufficient water absorption resistance to provide a clear printing image with less color registration problems upon offset printing is manufactured by coating base paper, to which aluminum sulfate (a 50% by weight Al2O3.14H2O product) is added at a ratio of less than 3.0% by weight upon paper making, with a surface treating agent mainly comprised of (A) a water-soluble macromolecular substance selected from starches, PVAs, polyacrylamides, and cellulose derivatives, (B) a copolymer obtained by the copolymerization of a styrene monomer and a cationic monomer, a water-soluble copolymer obtained by the copolymerization of a styrene monomer, a cationic monomer and a hydrophobic monomer, or a water-soluble copolymer obtained by treating one of these copolymers in which a tertiary amine-containing vinyl monomer is used as a cationic monomer, with a quaternizing agent.

Owner:HARIMA CHEM INC

Offset printing paper

InactiveUS6783847B1Excellent peelabilityNo paper breaksFilm/foil adhesivesDuplicating/marking methodsColloidal silicaChemical oxygen demand

To accommodate recent progress in printing technologies including conversion to offset printing, color printing, high-speed mass printing and automation of printing, by providing a coating layer containing an inorganic surface preparation agent mainly comprising silica sol and colloidal silica or a coating layer containing an inorganic surface preparation agent, to which an inorganic pigment, surface-sizing agent, inorganic salt and / or organic binder accordingly added in addition to silica sol or colloidal silica, offset paper serviceable for newsprint paper, which has improved qualities such as high whiteness, excellent water absorption resistance and ink acceptability, few adhesion troubles such as surface tack and curling caused by adhesion, and low chemical oxygen demand COD) load in wastewater when recycled, is provided.

Owner:NIPPON PAPER IND CO LTD

Automated guided vehicle for rolls of newsprint

InactiveCN101412490AReduce workloadAvoid interferenceControl devices for conveyorsLifting framesRolling paperAutomated guided vehicle

An object of the invention is to provide an automated guided vehicle, which can be adapted to various types of rolls of newsprint such as narrow, medium and wide, irrespective of their diameters and in which low bedding, weight lightening and energy saving are obtained. The invention solves the above-mentioned problems by providing an automated guided vehicle comprising a traveling carriage, which supports a newsprint roll and automatically transports the supported roll between a storage station and a setting area in a rotary press machine. A hoisting / lowering unit is mounted on the travelingcarriage, which hoists and lowers the supported roll of newsprint in a vertiacal direction and installs and callbacks the newsprint roll. The invention is characterized in that the hoisting / lowering unit includes two spaced-apart hoisting / lowering frames provided in parallel to a traveling road surface, hoisting / lowering means, which hoisting / lowering raises and lowers the hoisting / lowering frames, an arc-shaped connecting member, which keeps a spacing between the two hoisting / lowering frames to avoid interference with the winding paper holding arms, linear guides respectively formed on uppersurfaces of said two hoisting / lowering frames and a moving table, bridging over said linear guide, slides along the guides.

Owner:TSUBAKIMOTO CHAIN CO

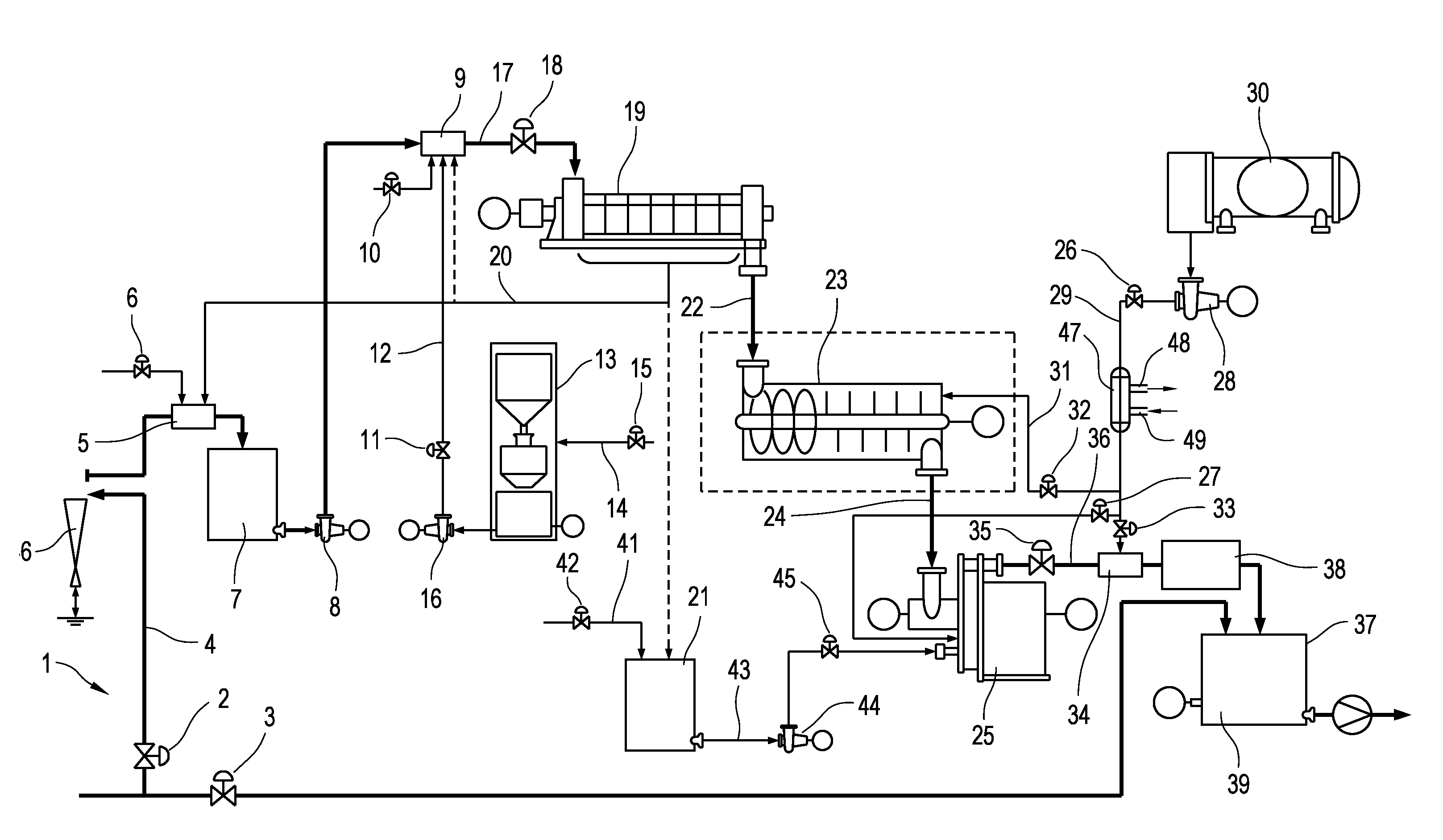

Method and apparatus of the prepartion of a fibrous stock suspension

InactiveUS20070119561A1For further processingAvoid darkeningSpecial paperPaper after-treatmentFiberEngineering

SC paper which is produced from a fibrous stock suspension containing fibers which are partially loaded with ash is characterized in that the ash content in the SC fiber web which was produced from the fibrous stock suspension is higher than 35%, preferably higher than 39%. Newsprint which is produced from a fibrous stock suspension containing fibers which are partially loaded with ash is characterized in that the ash content in the newsprint fiber web which was produced from the fibrous stock suspension is higher than 15%, preferably higher than 19%. Wood-free, uncoated paper which is produced from a fibrous stock suspension containing fibers which are partially loaded with ash is characterized in that the ash content of the wood-free, uncoated fiber web which was produced from the fibrous stock suspension is higher than 15%, preferably higher than 19%.

Owner:VOITH PATENT GMBH

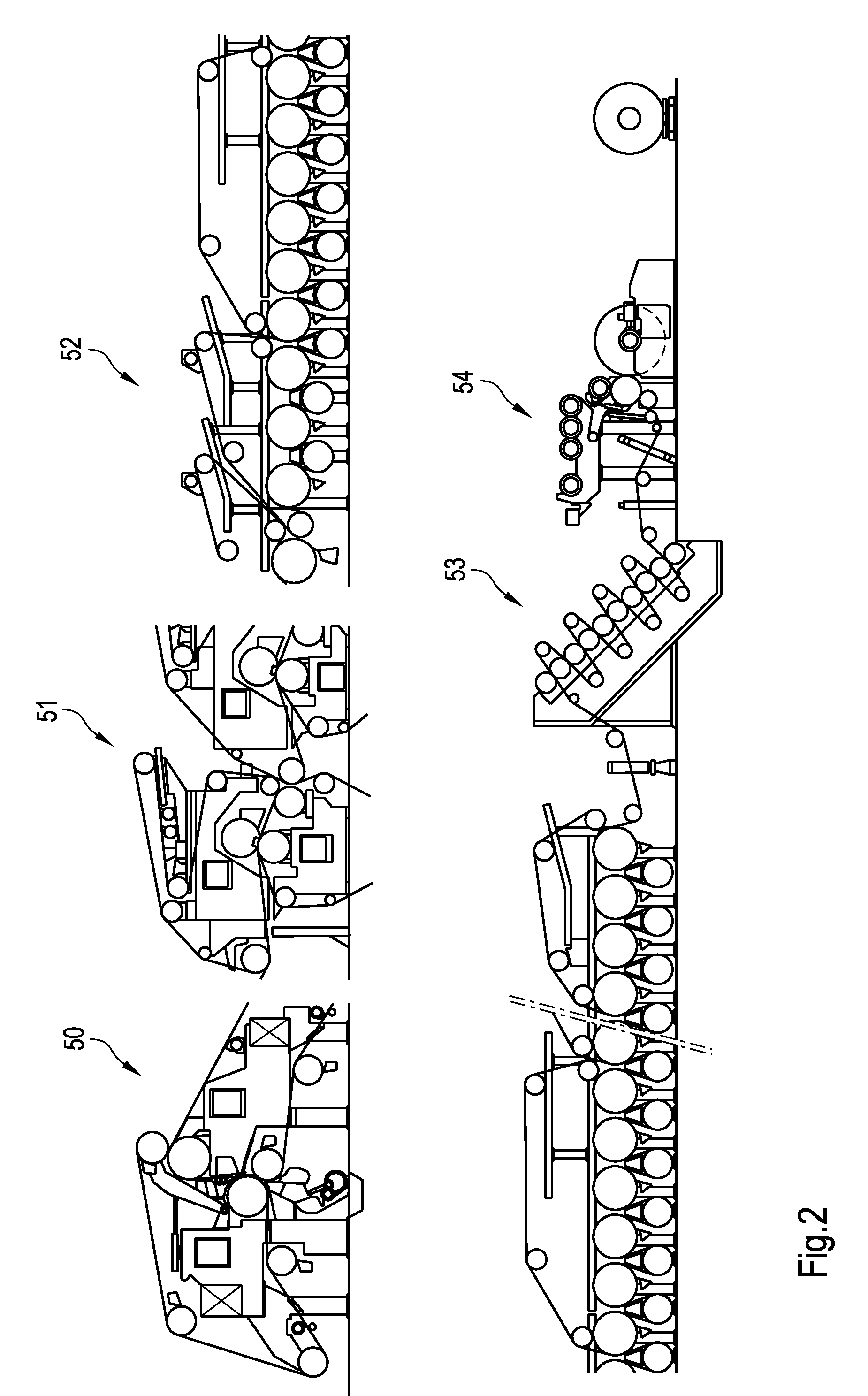

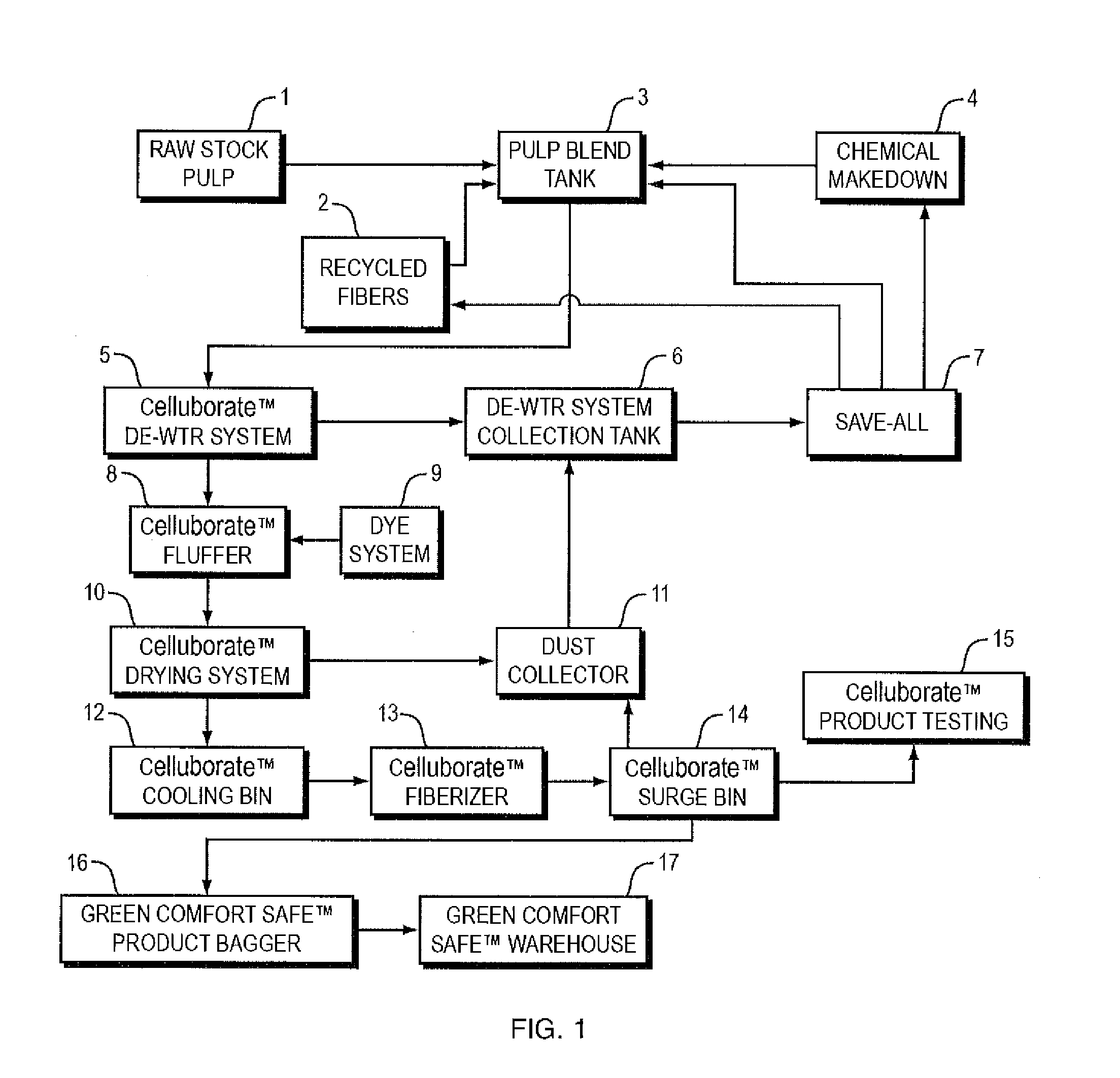

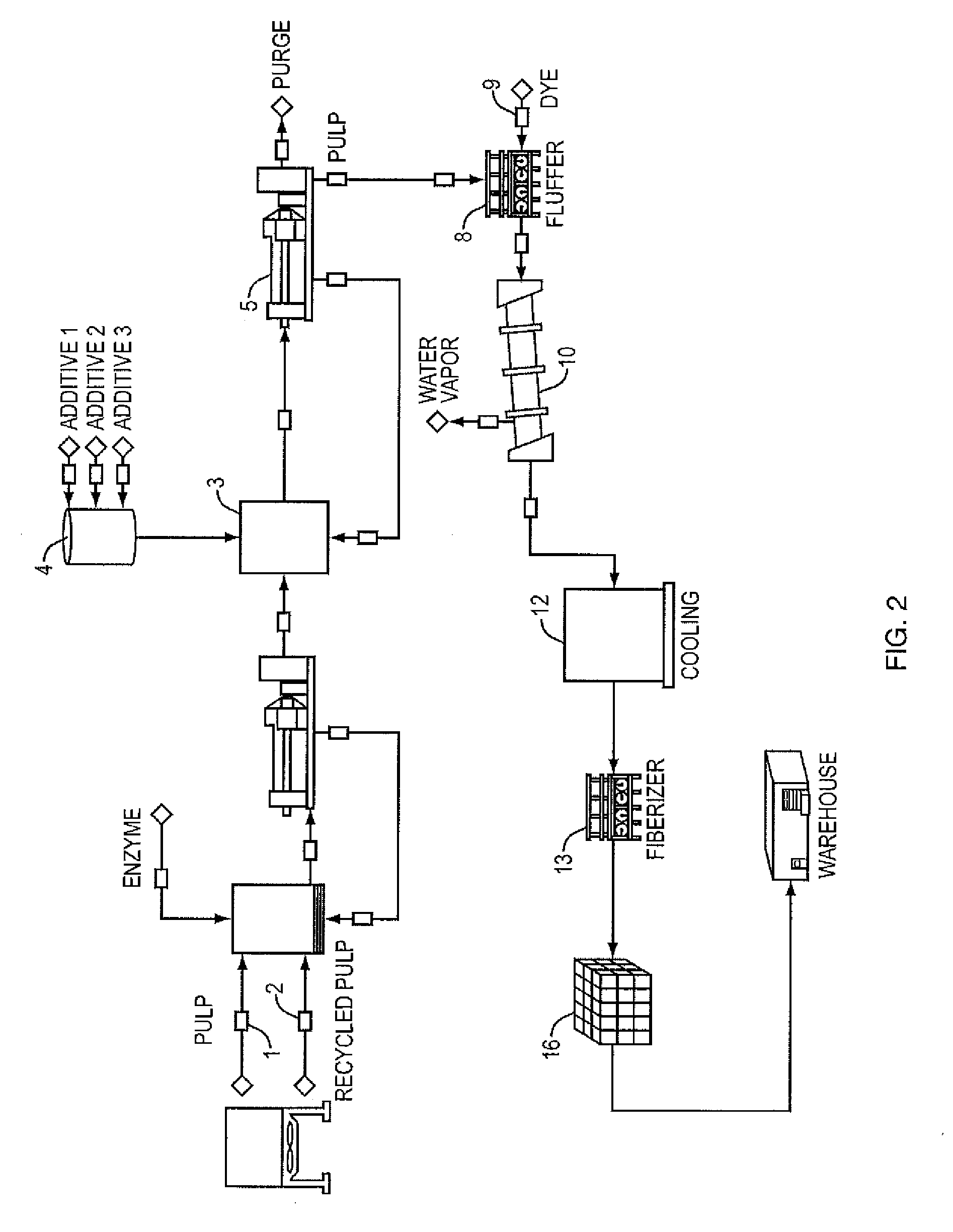

Method for Making Fire Retardant Materials and Related Products

InactiveUS20110095245A1Improves fire retardant application methodWide rangePaper recyclingIgnifugeants additionFiberChemical compound

A method for making fire retardant material including fire retardant cellulosic insulation. The method includes an arrangement for adding one or more feedstocks and a fire retardancy chemical compound to a common blend tank prior to feedstock drying. The one or more feedstocks may include at least one virgin pulp stock feed and at least one recycled material stock feed. The amount and type of both the virgin feedstock and the recycled material feedstock is selectable. Old newsprint (ONP) may be one type of recycled material feedstock. Another suitable type of recycled material feedstock is old corrugated containers (OCC). The method further includes retaining the fiber feedstock and the chemical compound together for enough time to ensure adherence or impregnations of enough of the chemical to the fibers after the drying process. Fluffing or fiberizing of the treated fibers may be accomplished under less severe conditions than ordinarily employed when making conventional cellulose insulation.

Owner:ULTRACELL INSULATION LLC +1

Neutral deinking method for waste newspaper

InactiveCN1763306AHigh whitenessReduce pollution loadFats/resins/pitch/waxes removal in pulpPaper recyclingInorganic saltsDeinking

The invention discloses a newsprint neutral voiding method in the pulping paper making technique domain with pulping, floating, scrubbing and bleaching procedure, which is characterized by the following: adapting flotation-scrubbing method without alkali; inputting 0.1 úÑ-2.0úÑ voiding agent, 1úÑ-6úÑ inorganic salt in the floating course; controlling the floating paste density between 2 and 18 percent, temperature between 20 and 70 deg.c, pre-impregnated time between 0 to 40 min, floating time between 10 and 60 min, insulating time between 0 and 40 min; The method improves the voiding efficiency and voiding paste whiteness by 16.6 percent as well as reduces the CoDcr in the neutral voiding waste-water by 190mg / l, which lessens the waste-water pollution load.

Owner:QILU UNIV OF TECH

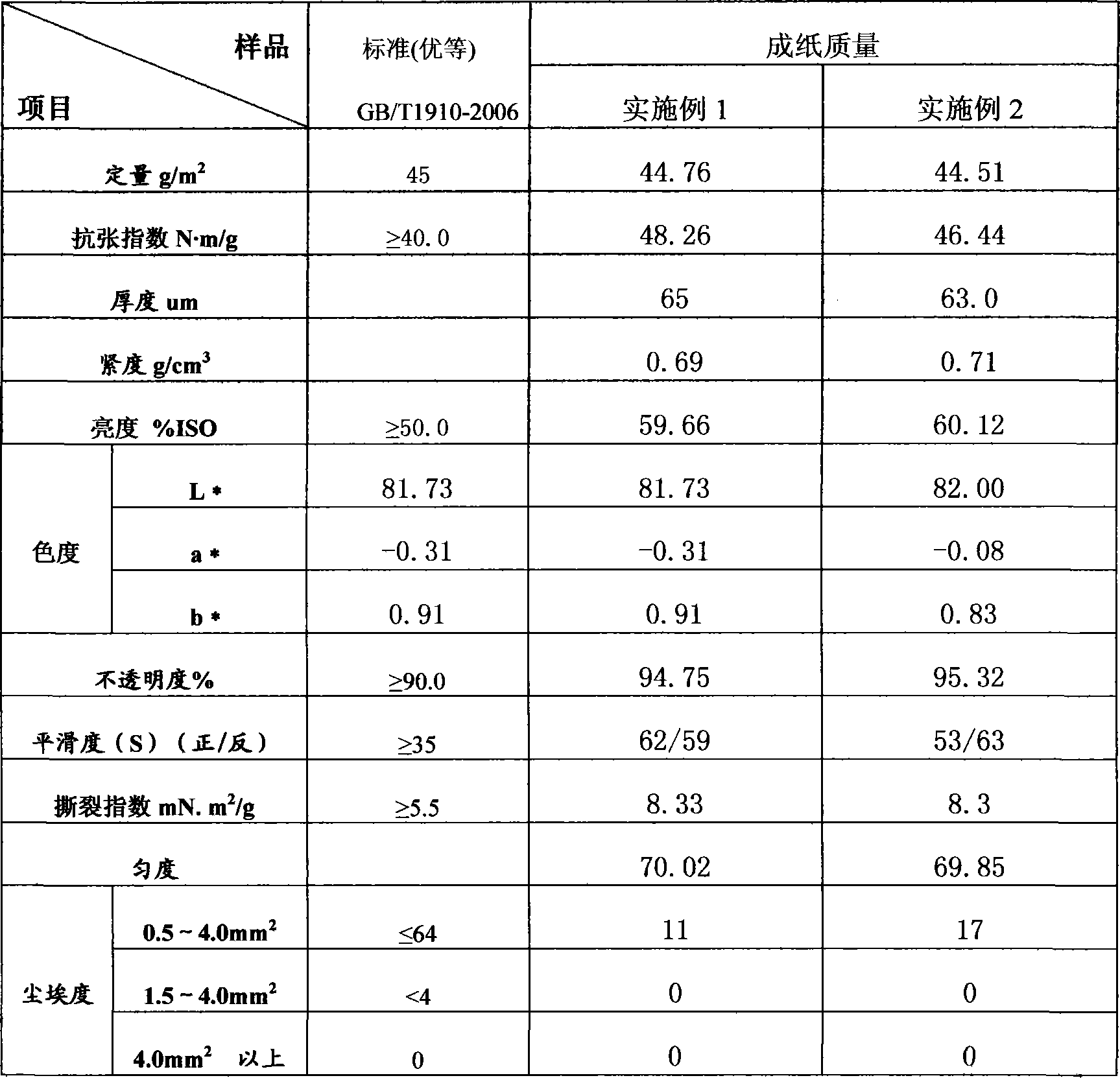

Surface glued newsprinting paper and manufacturing method thereof

The present invention discloses a surface-sized news-paper and its making method. It includes the following steps: using bleached sulfate needle wood pulp (BKP), beating, then mixing it with Italia poplar alkaline hydrogen peroxide hot-ground mechanical wood pulp (APMP) and bleached mechanical grindstone ground wood pulp (GP), according to mixing ratio blending them into mixed pulp, adding auxiliary material and making them into raw material pulp for making paper. The standard quantity of said news-paper is 45-49 g / sq.m, brightness (ISO) is 57-63%, opaqueness is greater than 91%, transverse tearing index is greater than 5.5mV, sq.m / g, surface strength is greater than 0.5 m / s, and breaking length longitudinal is greater than 4000 m.

Owner:YUEYANG FOREST & PAPER CO LTD

Lignocellulose material for road and method for making same

InactiveCN101096835AReduce manufacturing costImprove hydrophobicityIn situ pavingsTextile disintegration and recoveryCelluloseCardboard

The invention discloses a road wood fibre, which comprises the following steps: choosing waste newspaper as raw material; proceeding high concentration fluff; screening; deslagging; purifying slurry; stirring with mixed filling evenly; pasting; forming paper web; squeezing; drying with drying cylinder and infrared; proceeding flicking course; adding into caoline (talcum powder), active calcium carbonate filler and NaCl with dry method; getting the wood fiber product.

Owner:NANJING FORESTRY UNIV

Cationic Surface Sizing Agent and Newsprint Paper

InactiveUS20090068485A1Improve sizing effectImprove washabilityWater-repelling agents additionSynthetic resin layered productsMonomer compositionHydrophobe

It is an object to improve sizing performance and anti-plate-soiling property in offset printing, for example, in a cationic surface sizing agent to be used for coating base paper of newsprint paper, and as a means for solving the object, a cationic surface sizing agent is produced by quaternizing a copolymer having a weight average molecular weight ranging from 30,000 to 60,000 obtained by polymerizing (a) 20 to 40% by weight of a monomer containing tertiary amino group; (b) 10 to 80% by weight of a C4 to C18 alkyl ester of (meth) acrylic acid; and (c) 0 to 70% by weight of a styrene or derivative thereof, using an azoic polymerization initiator in the presence of a chain transfer agent. In this manner, it is possible to improve sizing performance without reducing the hydrophobic level of copolymer and to suppress sensitization of printing plate such as PS plate by specifying the monomer composition ratio, using an azoic polymerization initiator, and specifying molecular weight of the copolymer.

Owner:HARIMA CHEM INC +1

Ceiling tile base mat

Owner:USG INTERIORS INC

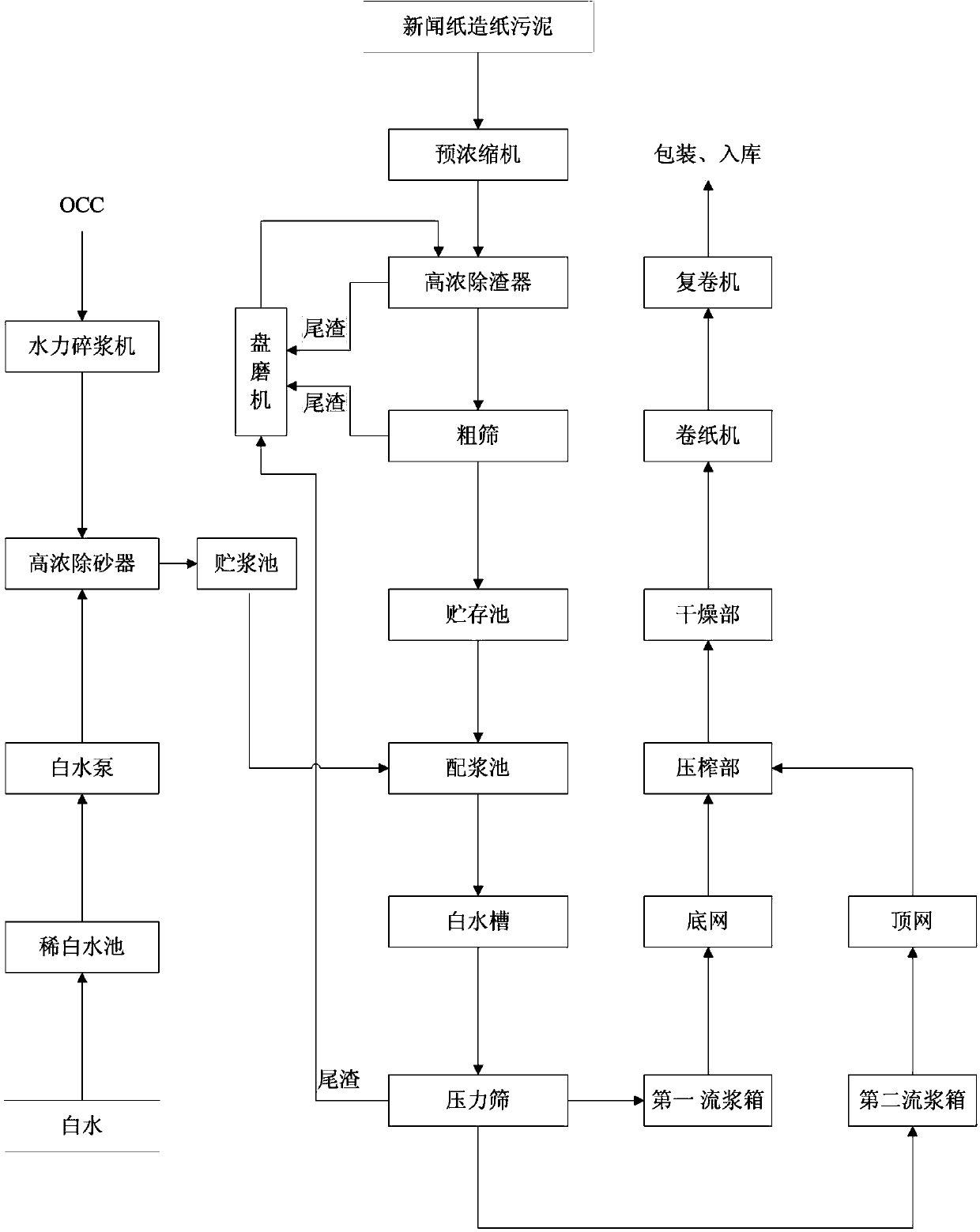

Method for producing environment-friendly regenerated bobbin body paper by using paper mill sludge of newsprint

ActiveCN103437238AAvoid pollutionLow costWaste product additionSecondary cellulose fibresBobbinPapermaking

The invention discloses a method for producing environment-friendly regenerated bobbin body paper by using paper mill sludge of newsprint, relating to the field of recycle of paper mill sludge of newsprint. According to the method provided by the invention, the environment-friendly regenerated bobbin body paper is prepared by the following steps: mixing treated paper mill sludge of newsprint with treated OCC pulp in a certain proportion; and manufacturing paper with pulp by white water in a newsprint papermaking process. According to the method provided by the invention, the environment-friendly regenerated bobbin body paper is produced by using paper mill sludge produced in the production process of newsprint, so that the production cost is lowered, the waste paper resources are saved, the water resources are recycled, and the environmental pollution is avoided.

Owner:GUANGDONG HUATAI PAPER IND

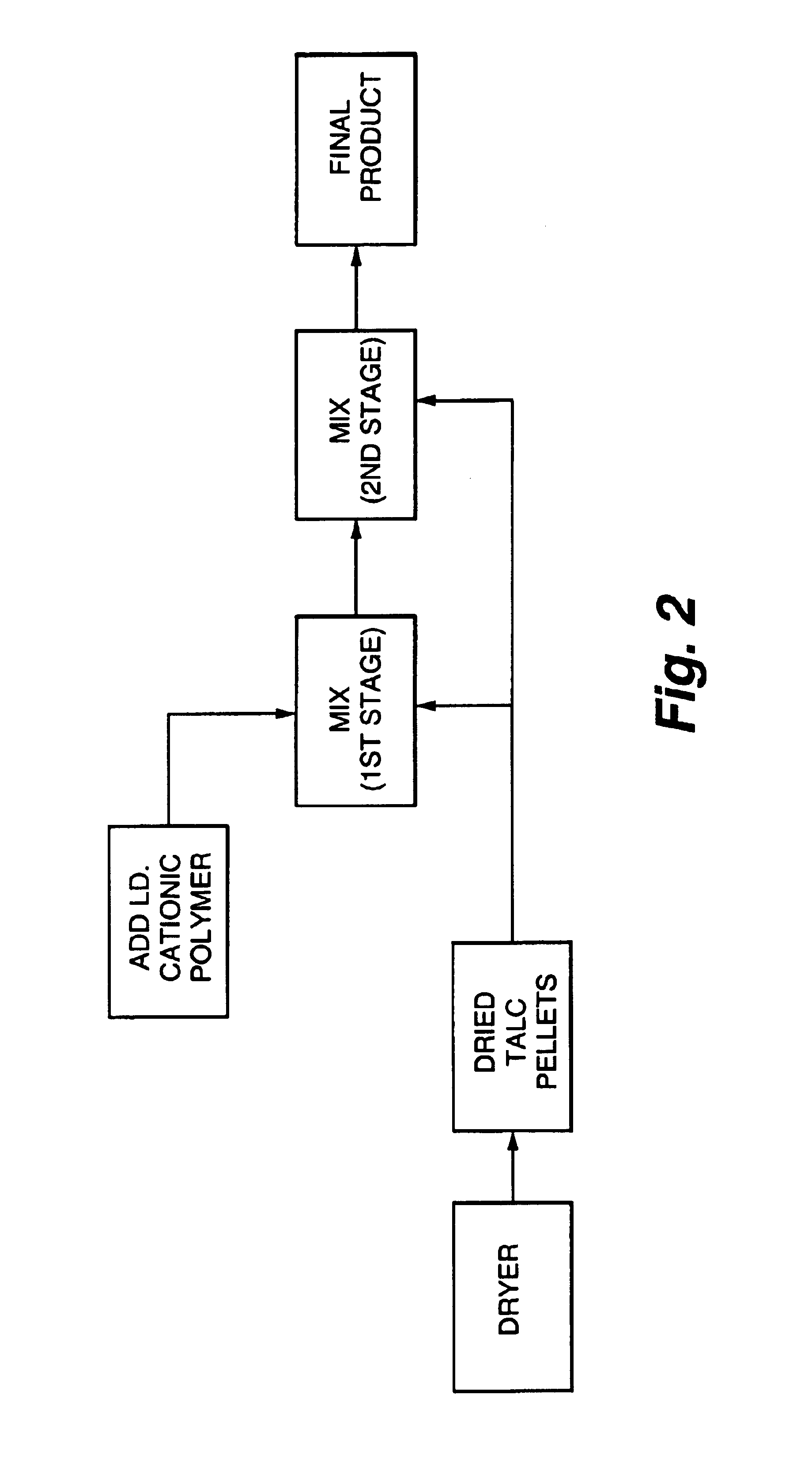

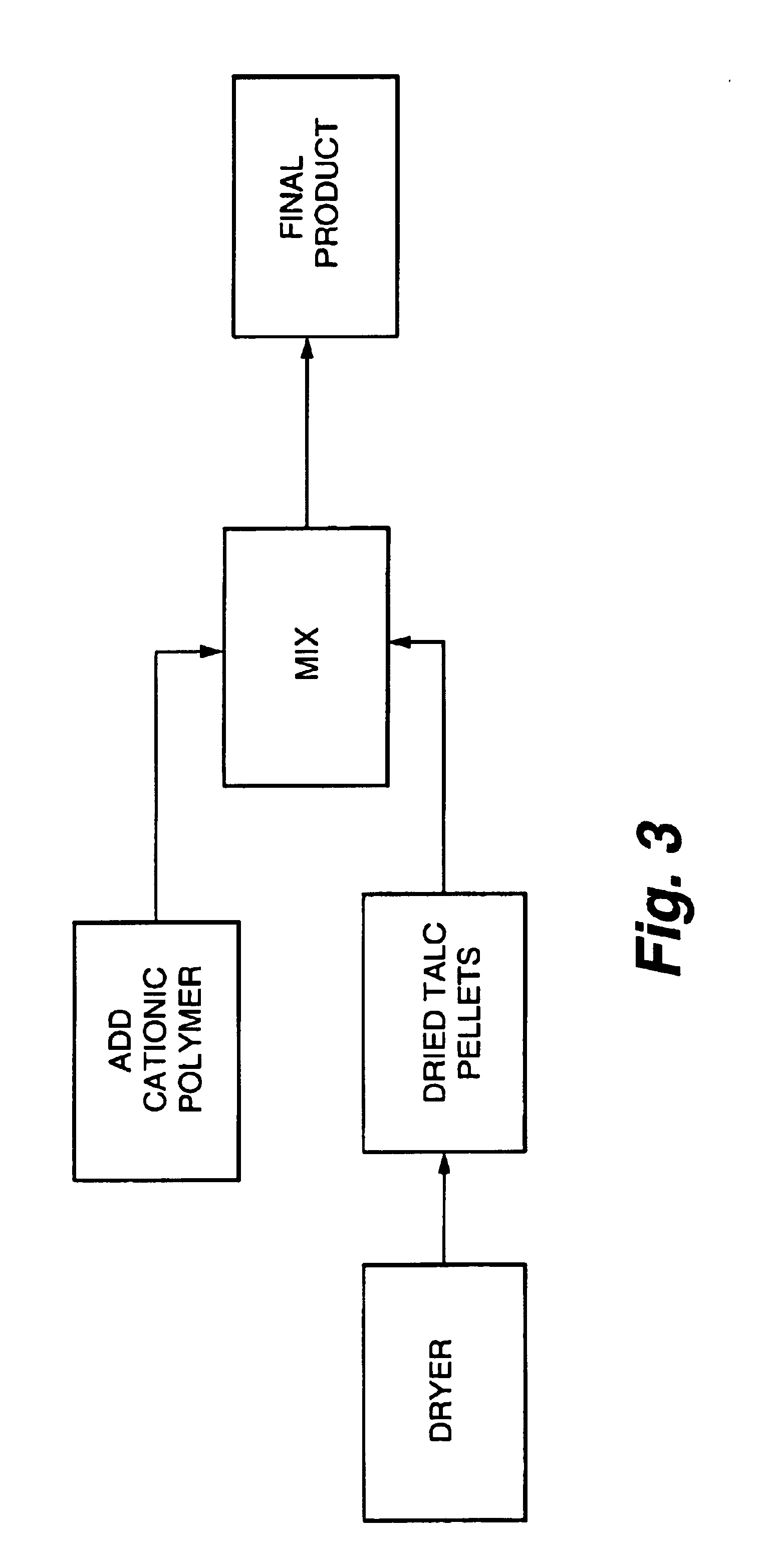

Additive and process for sticky control in recycled pulps

InactiveUS20060249050A1Pigmenting treatmentNatural cellulose pulp/paperPulp and paper industrySlurry

The present invention describes an additive which controls stickies formation and removes anionic trash from recycled old corrugated container furnish, old newsprint furnish, deinked pulp furnish, old magazine grade furnish, coated broke furnish, or thermomechanical pulp furnish. The present invention treats talc with either a tertiary or quaternary amine. The treated talc is then added to the pulp slurry and removes stickies by binding the stickies to the talc and neutralizes the anionic trash that may be present. The present invention also describes a method for modifying talc particles involving contacting a tertiary or quaternary amine with talc particles. The present invention further describes a talc created by the process of contacting a tertiary or quaternary amine with talc particles. The present invention additionally describes a paper product having a modified talc filler wherein the modified talc filler has been contacted with a tertiary or quaternary amine.

Owner:LUZENAC AMERICA

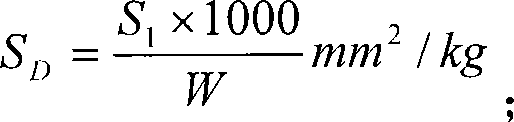

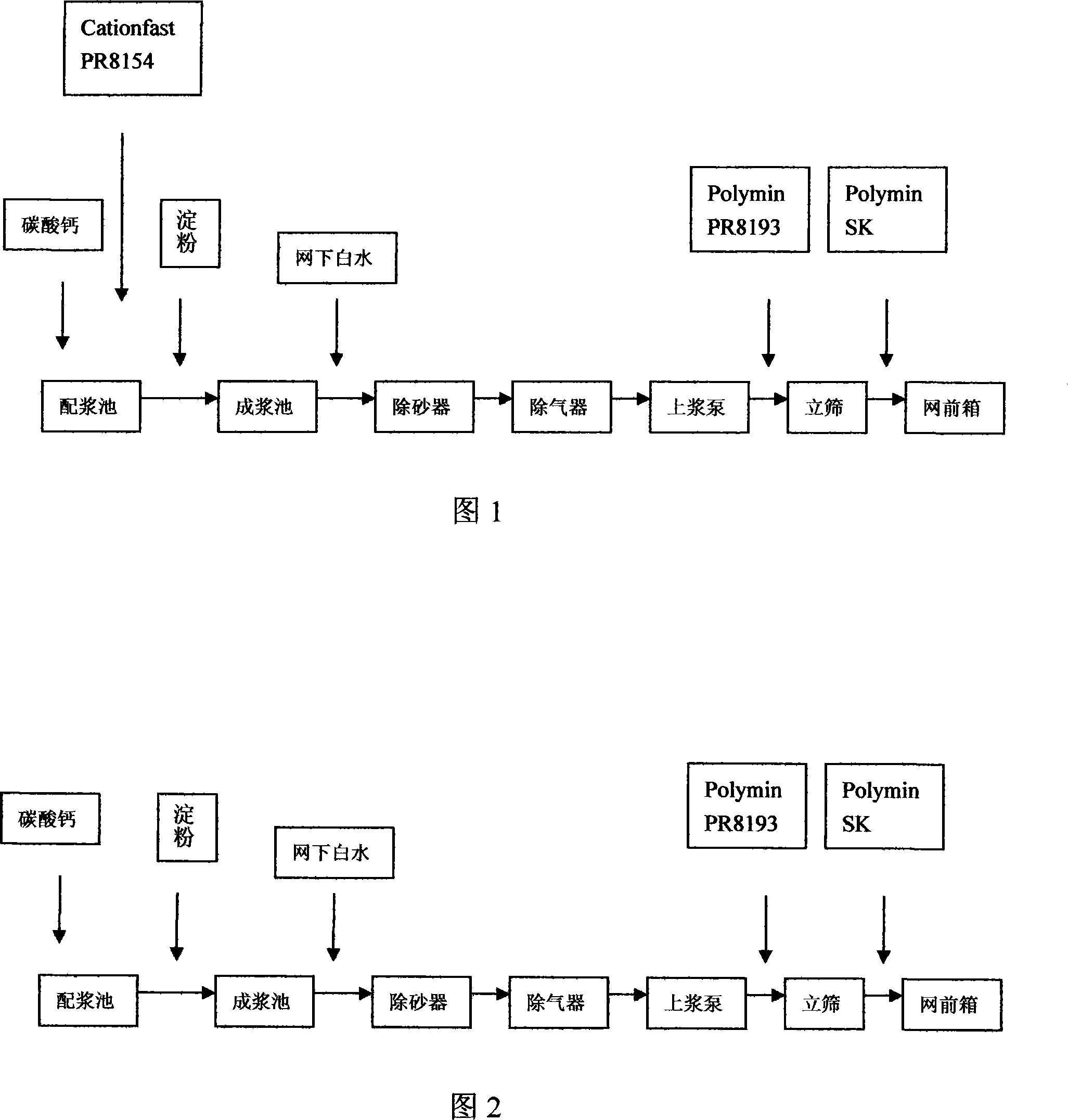

Method for producing low basis weight newsprint by 100 percent deinking waste pulp added with retention and drainage agent

InactiveCN101225615AImprove product qualityEmission reductionNon-fibrous pulp additionPaper recyclingFiberNewsprint

The invention discloses a preparation method for low basis weight newsprint by using 100% de-inking waste paper pulp added with retention and filter aid, which comprises a plurality of steps: add 100% de-inking waste paper pulp into a proportioning tank of a high-speed paper machine; then add calcium carbonate and fixing cation modified polyamines; add starch at the entrance of a machine chest; use tray water to flush the pulp at the outlet of the machine chest; control the wite pulp concentration at 1.0%; after desanding and deaerating, add the retention aid cation water soluble macromolecule polyacrylamide derivative at the outlet of a sizing pump and the inlet of a vertical screen; add filter aid polyethylenimine at the outlet of the vertical screen; the pulp is sent into a head box of the high-speed paper machine; thus, the low basis weight newsprint can be produced. The preparation method for low basis weight newsprint by using 100% de-inking waste paper pulp added with retention and filter aid has the advantages that by adopting 100% de-inking waste paper pulp, the preparation method saves fiber material for making paper on the basis of changing the material structure of the newsprint, greatly reducing the consumption of timber, water and electricity and the emission of pollutant, relieving the environmental pollution and lowering the production cost.

Owner:GUANGDONG IND TECHN COLLEGE +1

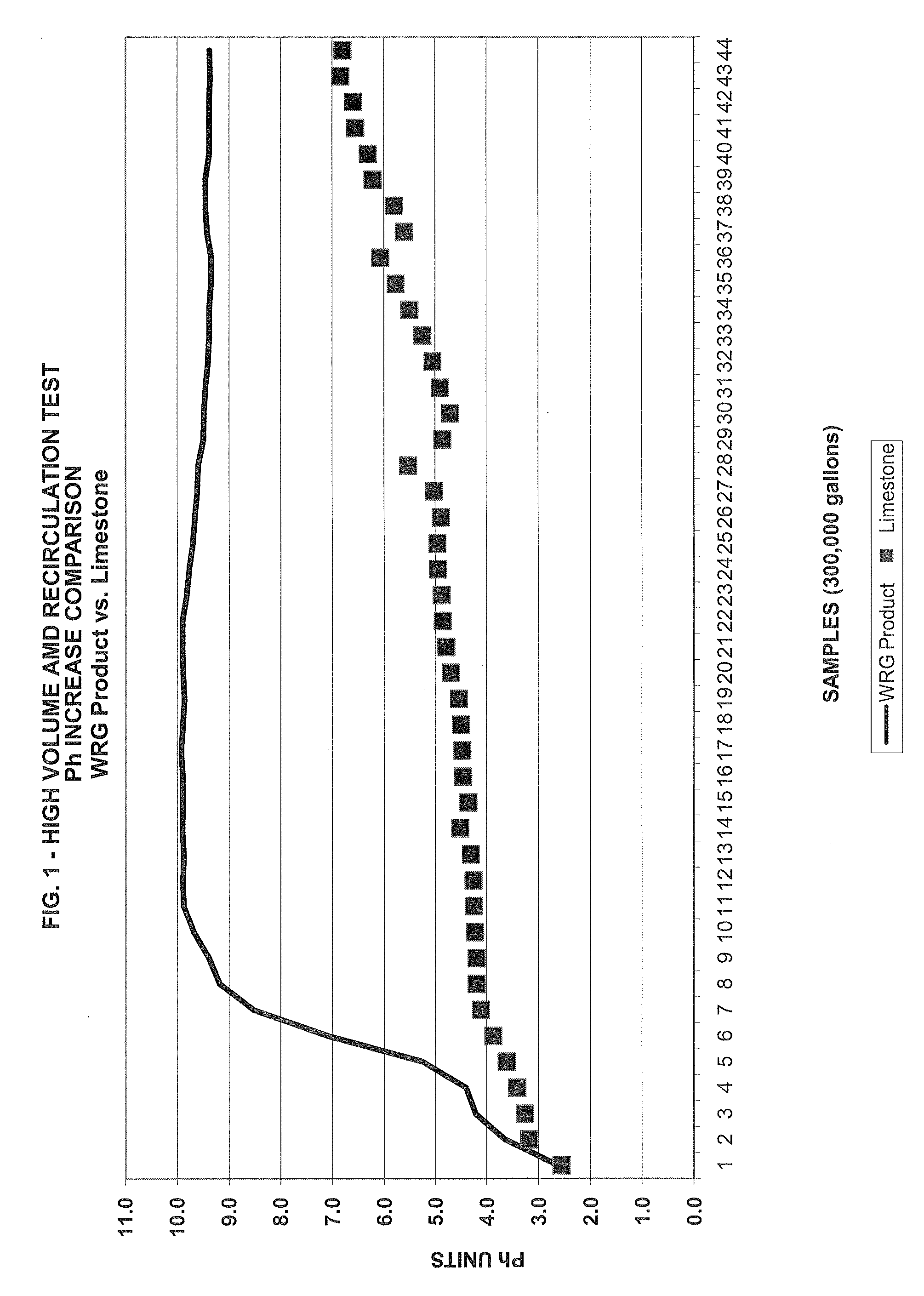

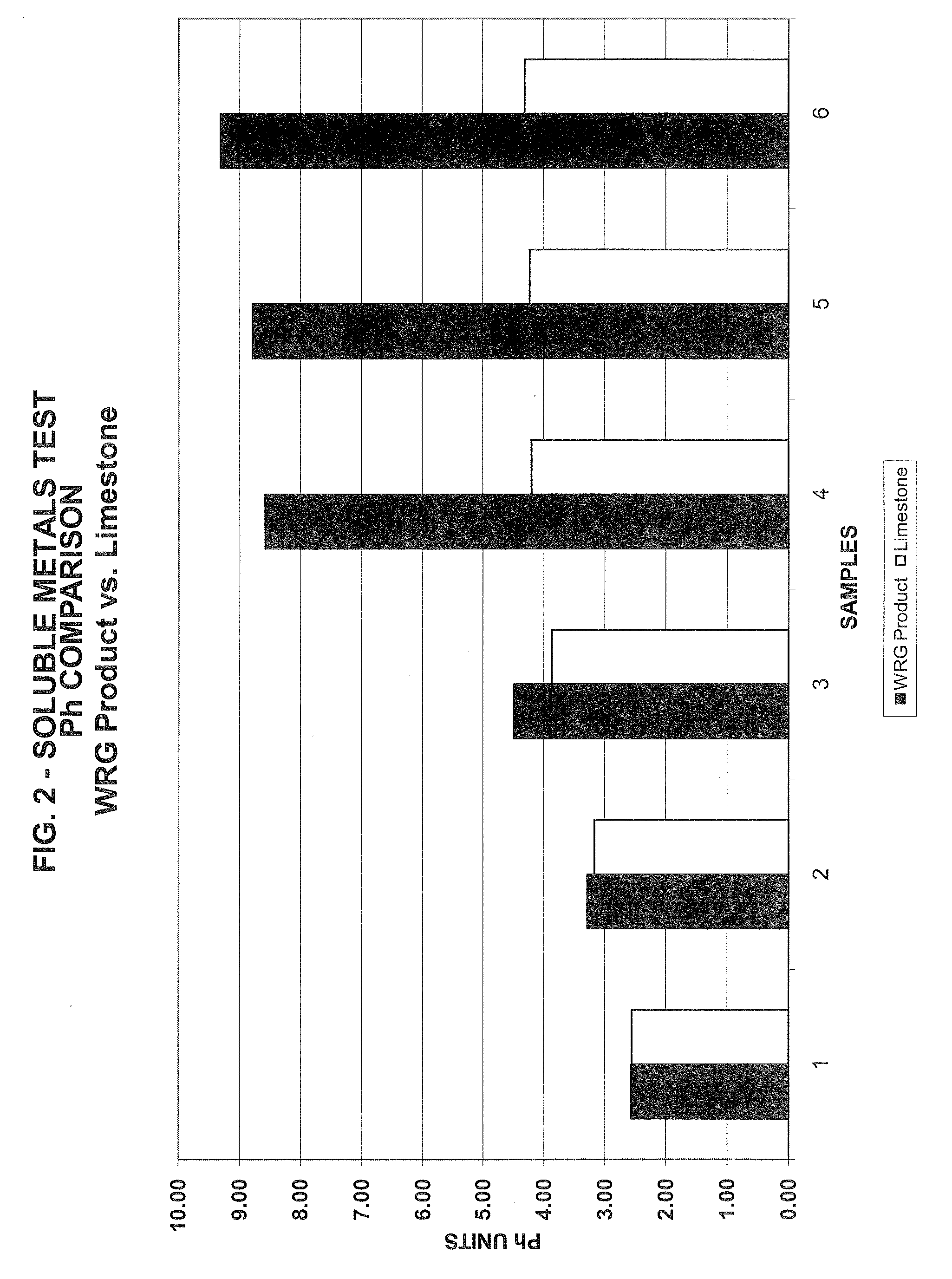

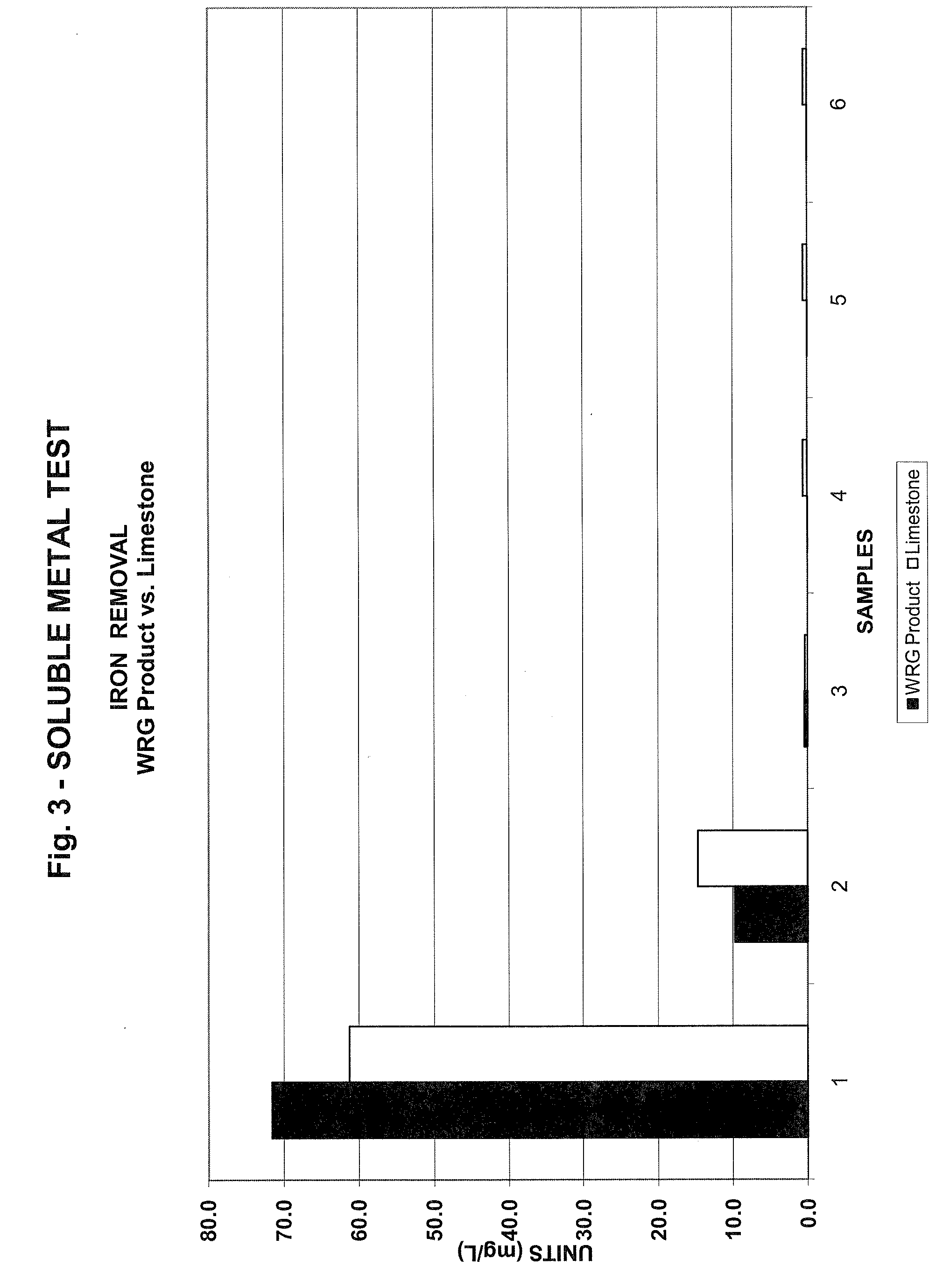

Agglomeration for the treatment of acid mine drainage

InactiveUS20090114606A1Minimize propertyLow costWaste water treatment from quariesNon-fibrous pulp additionFiltrationSlag

Provided is an agglomeration for neutralizing acid mine drainage which includes a neutralizer and binder component consisting of steel slag in an amount of 75% to 95% by weight of the agglomeration, a sodium carbonate selected from the group consisting of soda ash and pulp liquor in an amount of 0.5% to 25% of the agglomeration, and, optionally, a lime component selected from the group consisting of limestone sand and slag. Further included is a dissolution control and filtration component consisting of an organic material in an amount of 0.24% to 15% by weight of the agglomeration selected from the group consisting of recycled newsprint, sphagnum peat moss, and sawdust. Next is a dispersant and neutralizer component consisting of a surfactant in an amount of 0.01% to 0.075% by weight of the agglomeration. The agglomeration may further comprise an oxidation component such as calcium peroxide, potassium permanganate, and hydrogen peroxide.

Owner:WATERWAYS RESTORATION GROUP

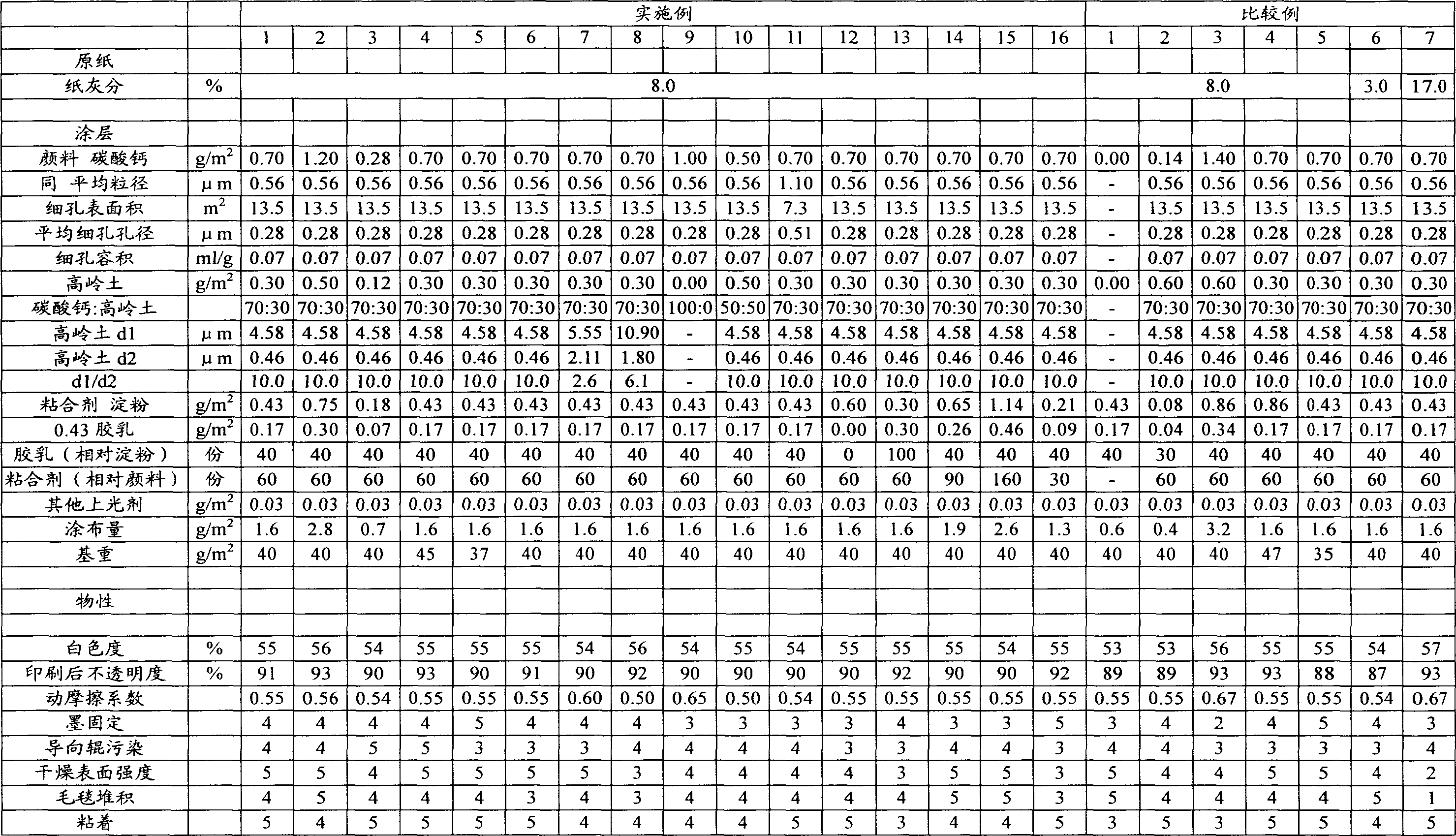

Newsprint for affset print

InactiveCN101092807AHigh opacityEasy to fixNon-fibrous pulp additionCoatings with pigmentsSolid componentPulp and paper industry

This invention provides a kind of news paper used in high speed cold offset point cycle printing and a news paper suitable for printing with environment protection printing ink, which forms a dye coating containing CaCO3 on the two sides of base paper to be converted to dry solid component and the total coating volume of the two sides is 0.5-3.0g / m2, whiteness is greater than or equal to 54% and ash is 5-15 mass%, non-transparency is greater than or equal to 90%, dynamic friction coefficient is 0.50-0.65, the basic weight is 37-45 / m2.

Owner:OJI PAPER CO LTD

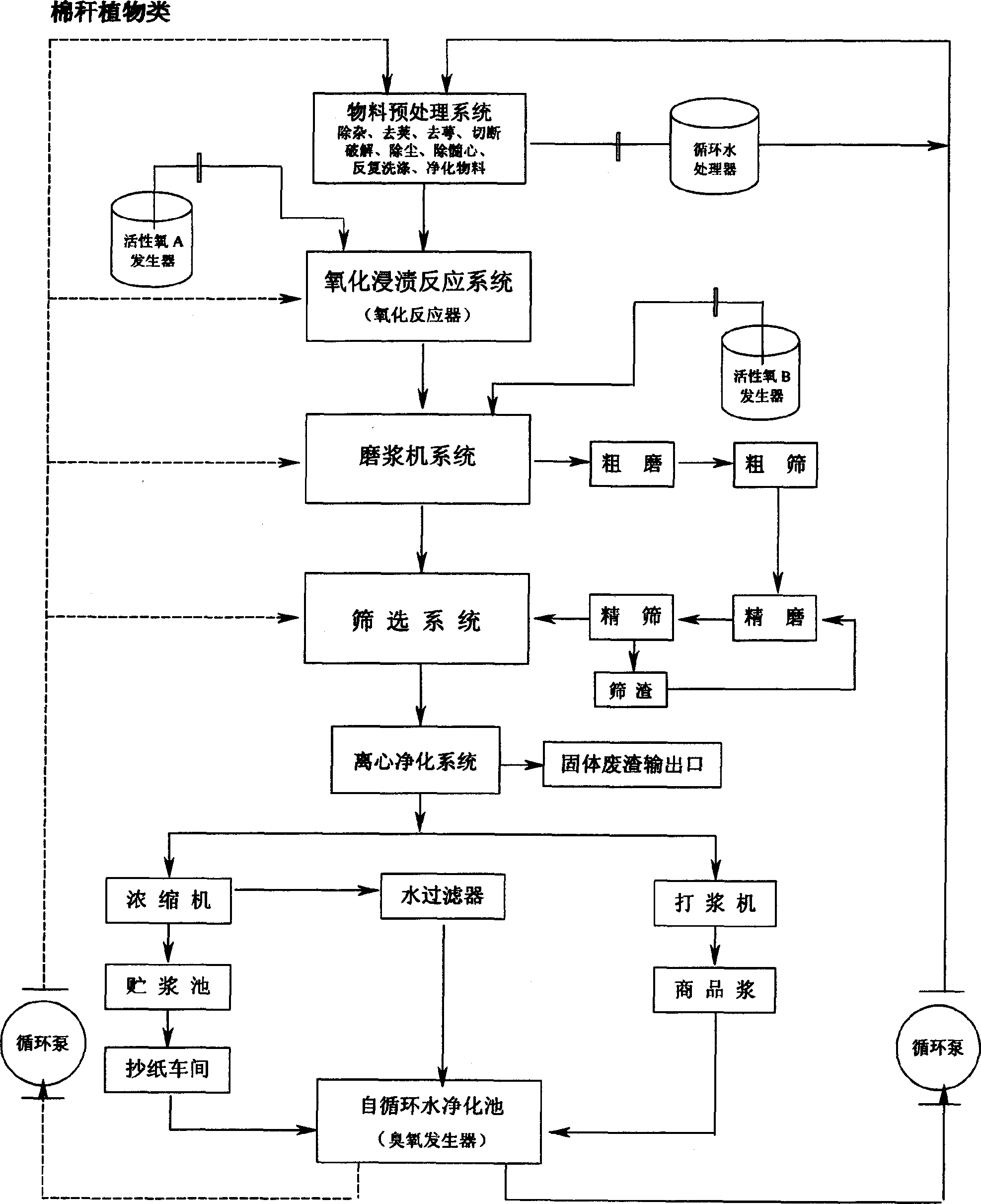

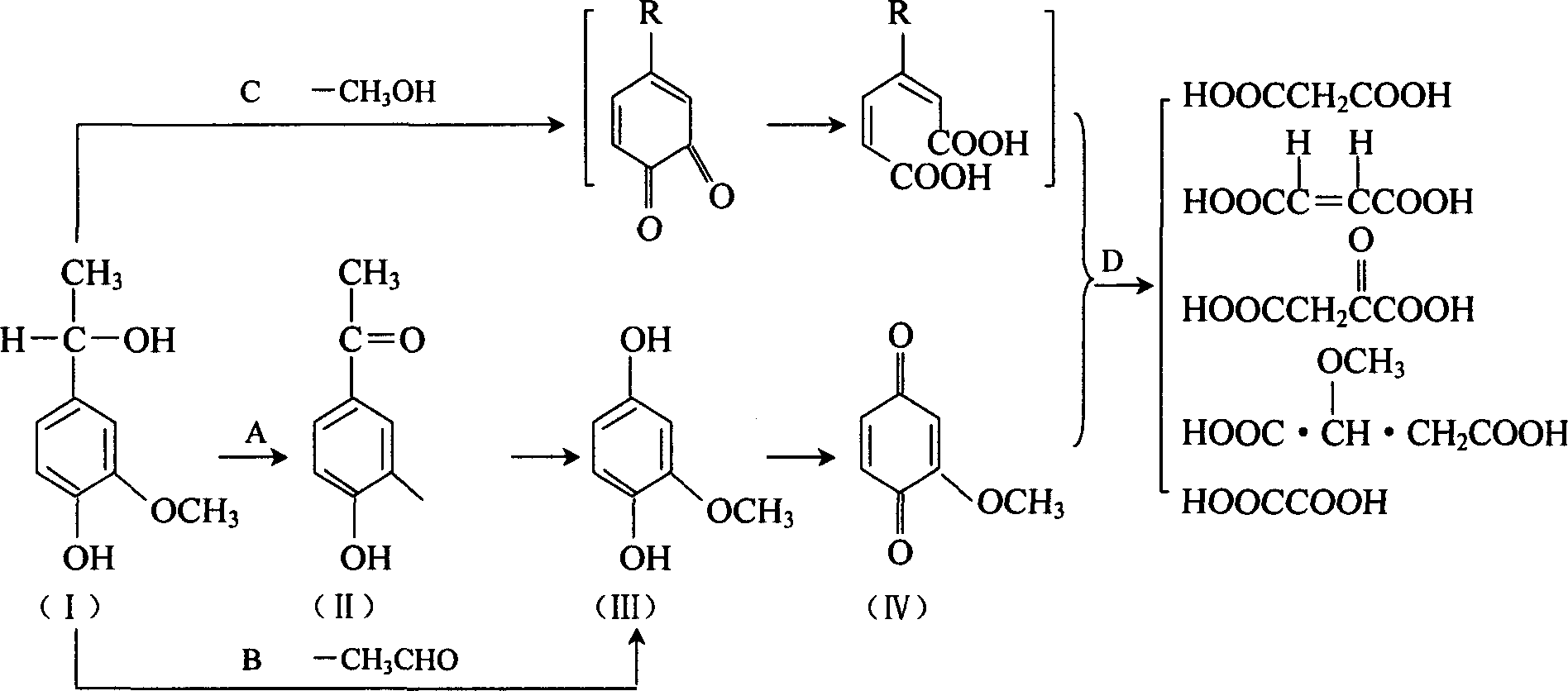

Oxidation method prepared whole-cotton stalk newspaper pulp and its preparation method

The invention discloses a full-cotton stalk news pulp and preparing method through full-sealing, non-polluting, self-circulating and zero-discharge oxidizing method, which is characterized by the following: utilizing electron reducing reaction in the ion reaction of oxygen molecular to produce free radical of active oxygen to transmit and separate lignin; making chromogenic gene change in the plant cell interlayer to obtain pulp. The invention changes chemical pulping technology without polluting acid, alkaline and anthraquinone, which saves boiling and bleaching procedures.

Owner:梅秀泉

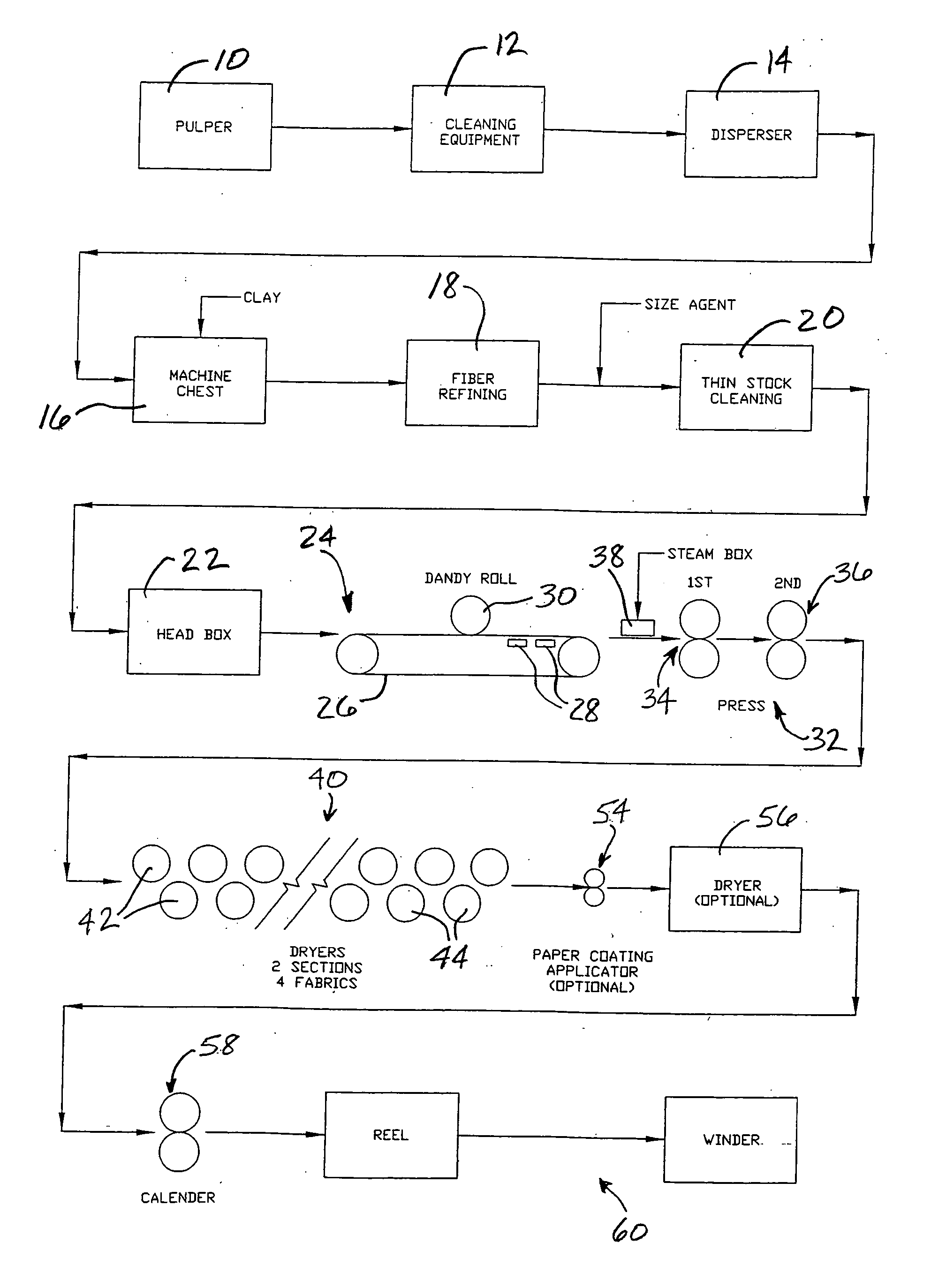

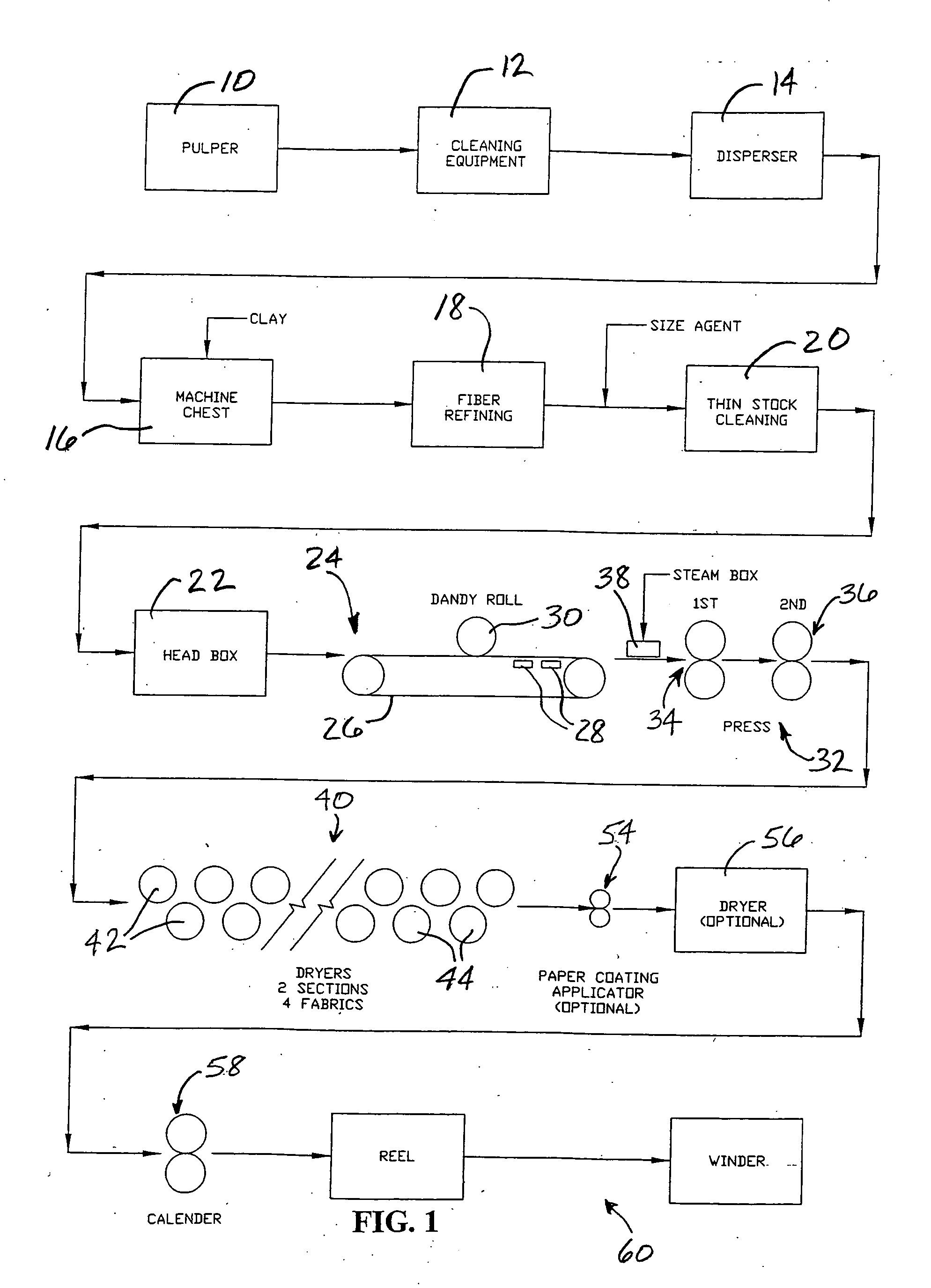

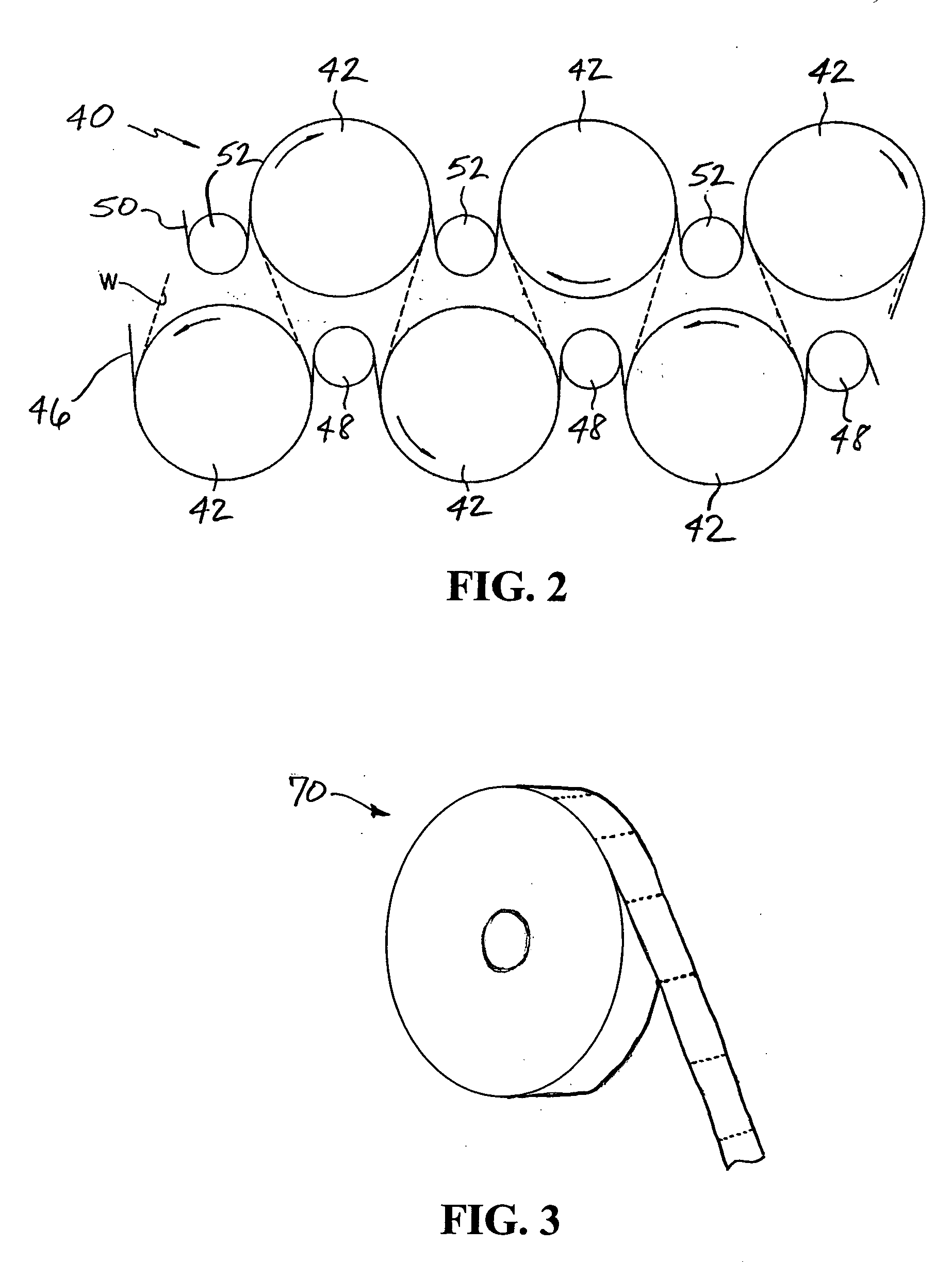

Recycled white ticket stock and method of making same

InactiveUS20050279472A1Increase stiffnessReduce dustSpecial paperPaper recyclingFiberSolid bleached board

A ticket stock and manufacturing process wherein a pulp is formulated from a blend of recycled furnishes, with added starch for enhancing sheet stiffness and reducing linting and dusting on cut edges of the stock, and clay or other opacifier for enhancing opacity of the stock. A preferred pulp comprises a blend of recycled solid bleached sulfate plate stock, recycled coated soft white, and recycled ground wood furnish such as newsprint or the like. In one embodiment, the blend comprises about 25-50 wt. % recycled solid bleached sulfate plate stock, about 25-50 wt. % recycled coated soft white, and about 15-25 wt. % recycled ground wood furnish. The furnish blend is repulped with minimal mechanical refining, is treated with steam injection for hydrating and softening the fibers, and is formed into a web that is pressed, dried, and soft calendered. The caliper of the resulting stock is about 7 to 9 points.

Owner:SONOCO DEV INC

Newsprint paper for offset printing

InactiveUS20060257635A1Suppresses show-throughReduces paper powder depositSpecial ornamental structuresPattern printingZeta potentialPulp and paper industry

Provide a newsprint paper for offset printing that offers good printing efficiency and print quality, wherein the paper, despite a high content of deinked pulp, notably suppresses show-through in offset printing and also reduces paper powder deposit on the blanket cylinders of the press. Adding a filler or fillers by more than 15 percent by weight but less than 40 percent by weight as ash relative to the paper weight notably suppresses show-through of a newsprint paper for offset printing. In particular, adding calcium carbonate with an average grain size of 0.5 to 5 μm and zeta potential of 0 mV or above by more than 15 percent by weight but less than 40 percent by weight as ash relative to the paper weight not only suppresses show-through further but also reduces the paper powder deposit on the blanket cylinders of the press.

Owner:NIPPON PAPER IND CO LTD

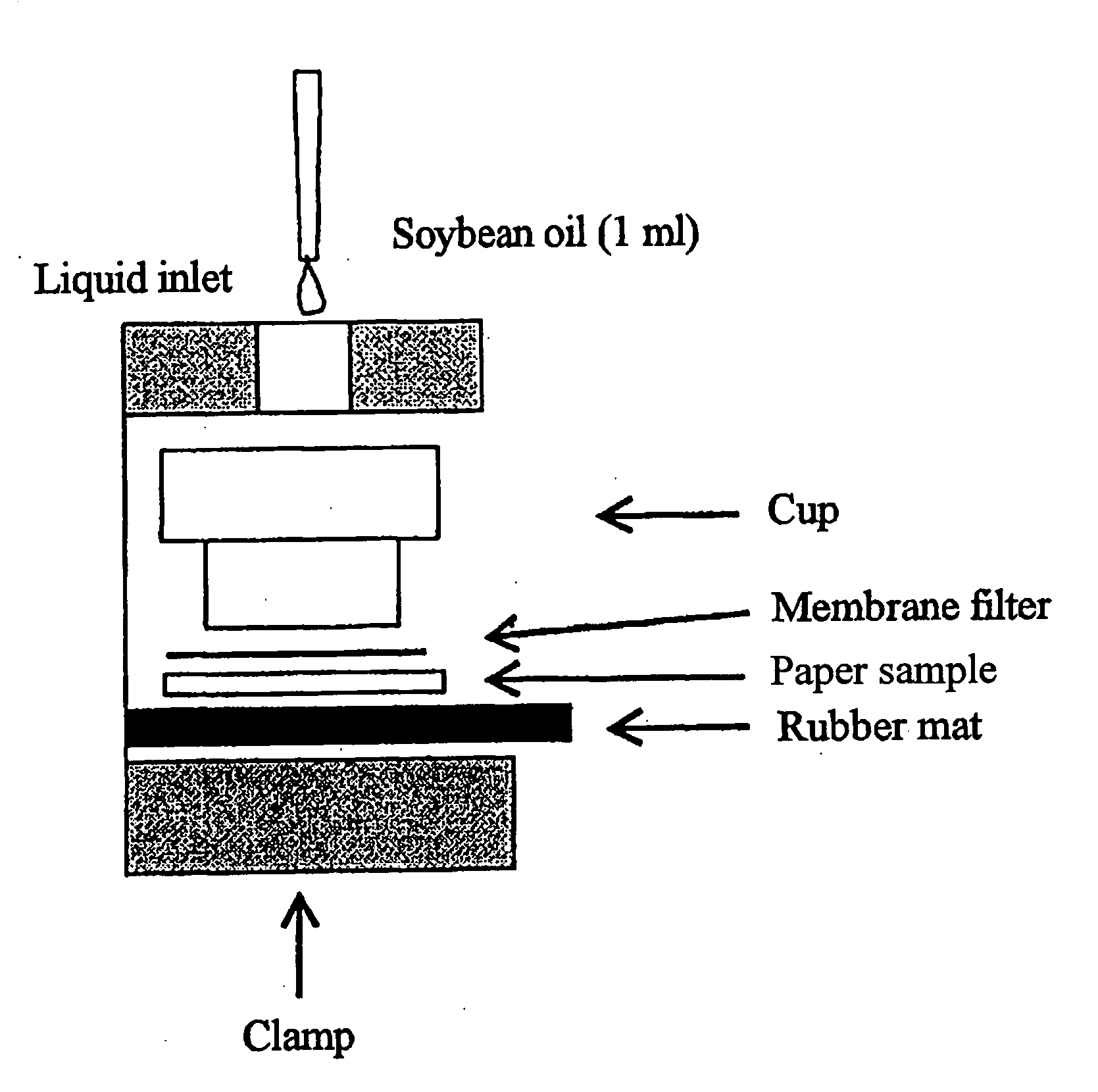

Coated Papers for Newsprint Inks and Processes for Preparing Them

InactiveUS20070240838A1Fast ink drying propertyPromote reproductionNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveCopper

The present invention aims to provide coated papers for newsprint inks having fast ink drying properties comparable to those of conventional newsprint papers, without stickiness, and having good reproduction and sharpness of printed images comparable to those of coated papers printed using penetration drying type inks; as well as processes for preparing them. Herein disclosed is a coated printing paper for newsprint inks comprising a coating layer containing a pigment and an adhesive on a base paper, characterized in that the coating layer on the base paper has a coat weight of 4.0 g / m2 or more per side and that the coated paper has an oil absorbency under pressure of 20 g / m2 or more and a Bekk smoothness of 75 seconds or less; as well as a process for preparing the paper.

Owner:NIPPON PAPER IND CO LTD

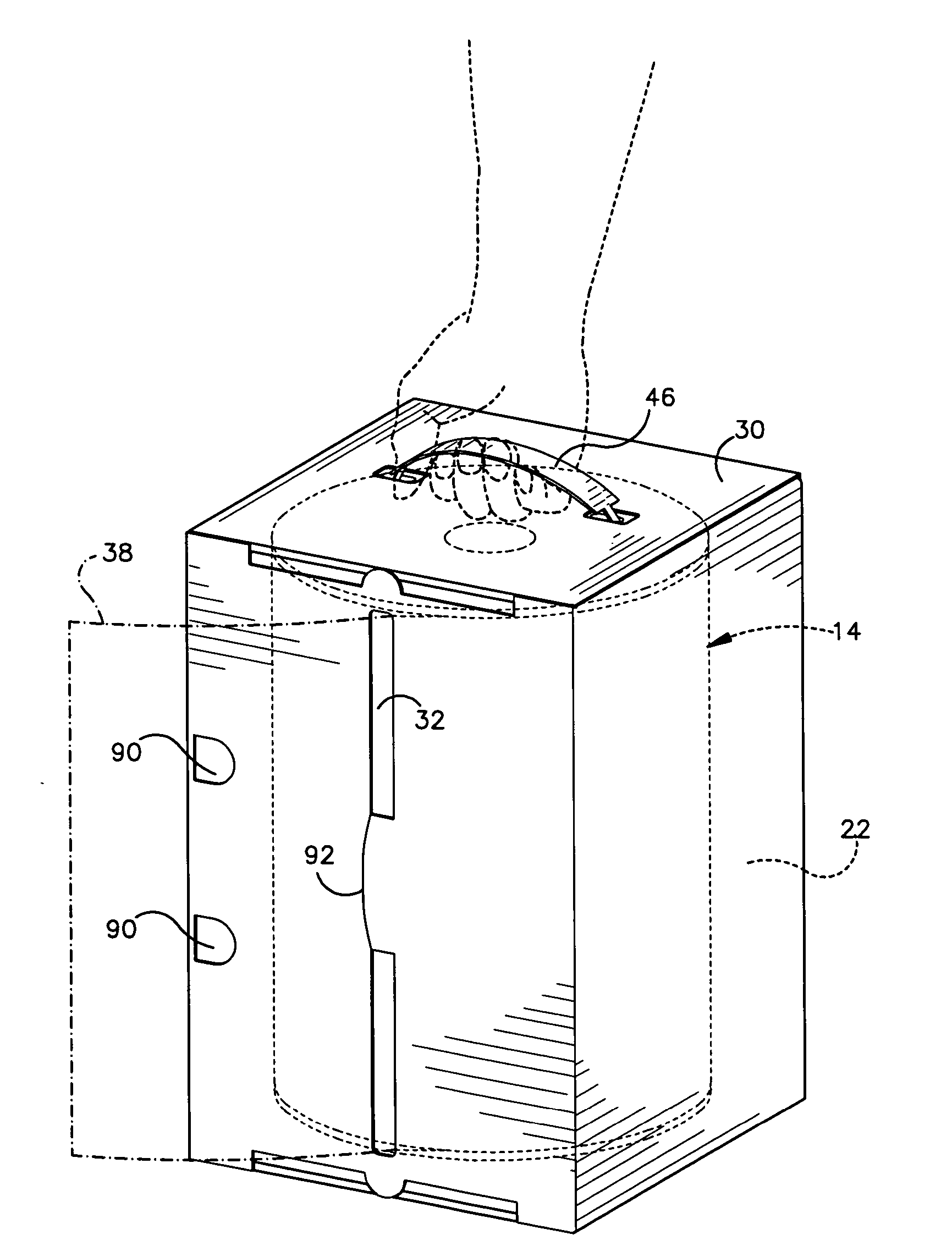

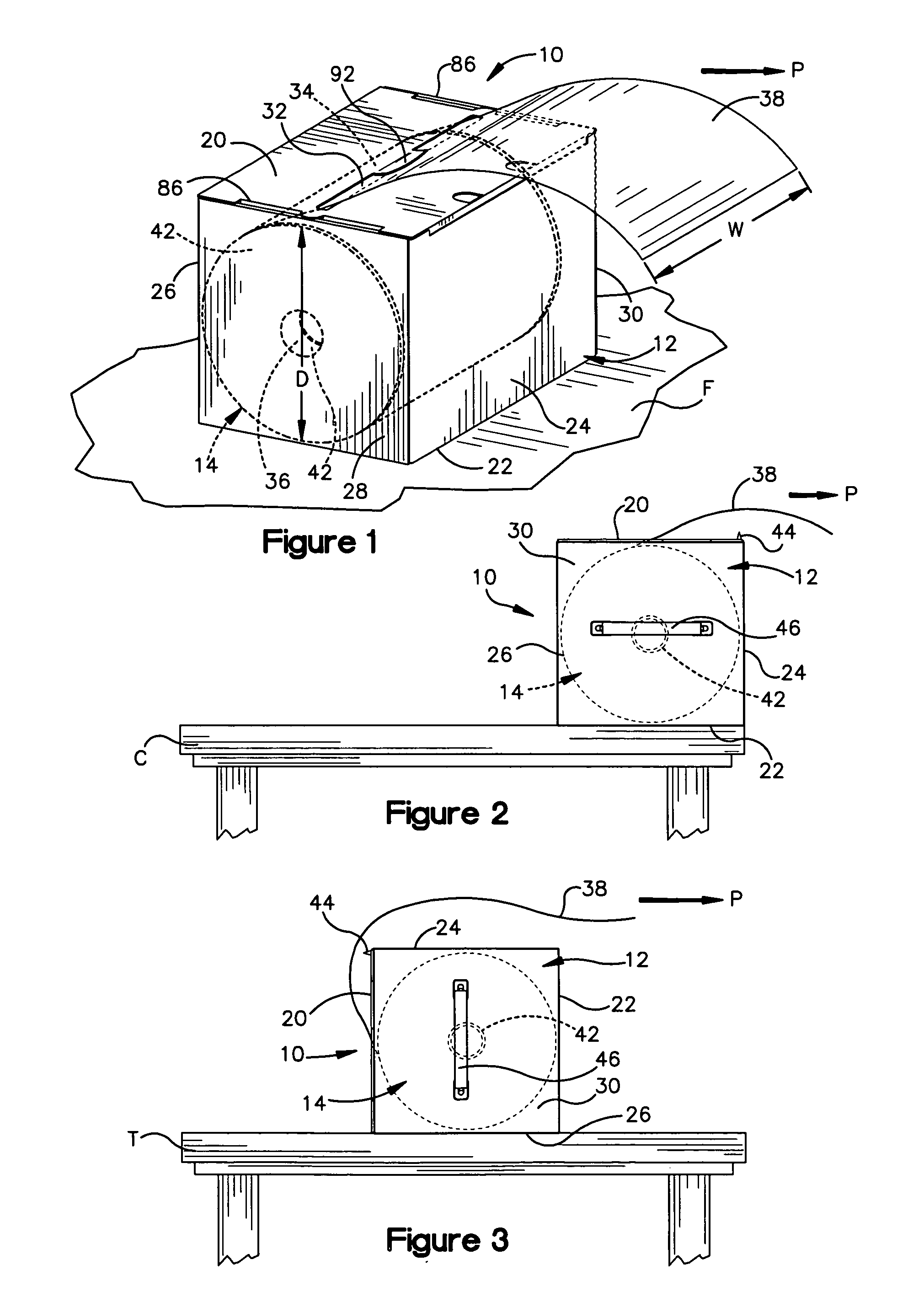

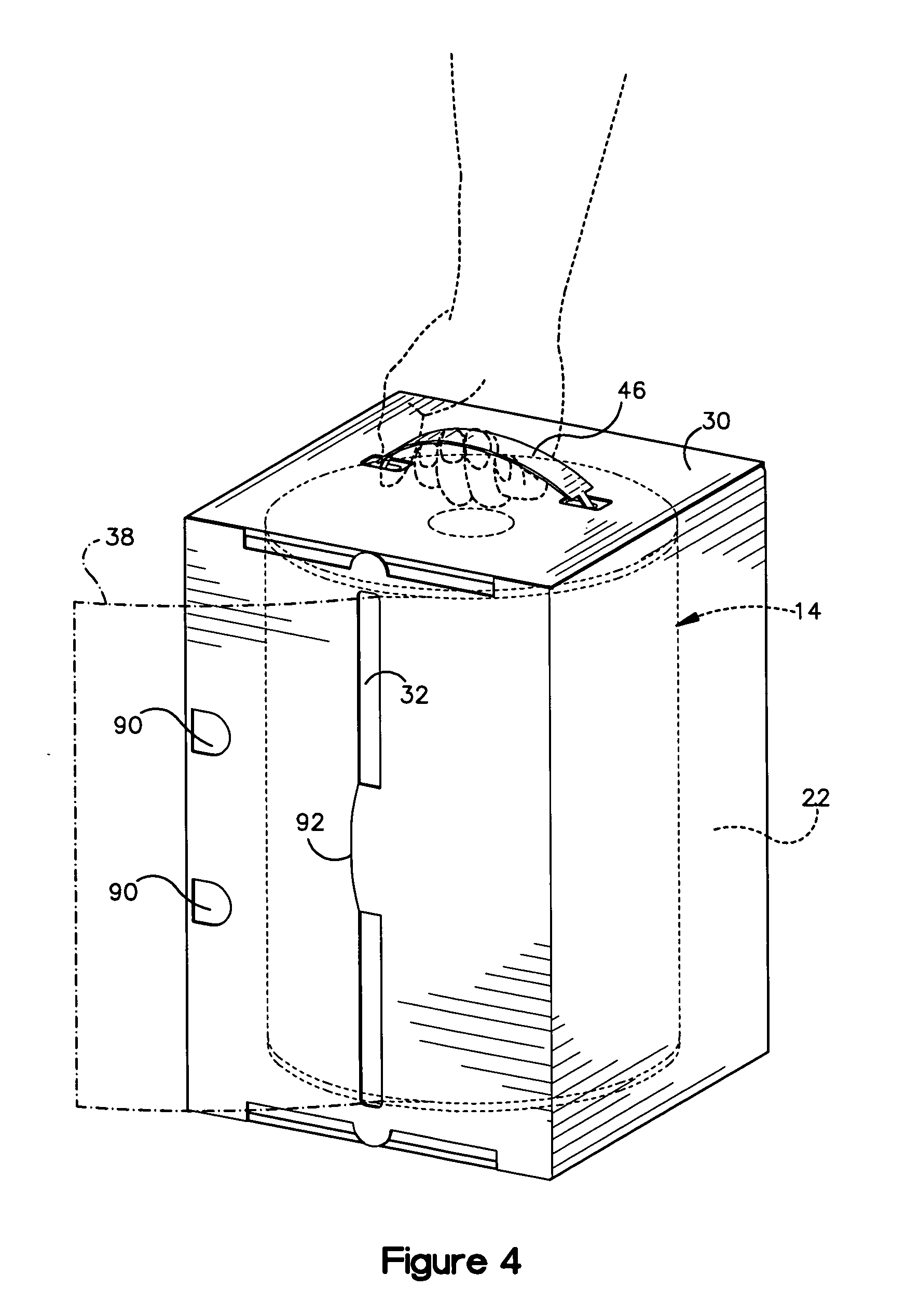

Newsprint dispensing device

InactiveUS20050139626A1Easy to provideEasy to transportMetal working apparatusRigid containersNewsprintPaper sheet

A dispensing device comprises a dispensing box, a roll of a sheet-like packaging material, and a cutting edge. The box includes a series of sides and a dispensing slot on one of these sides. The roll includes a leading portion which is inserted through the dispensing slot and pulled in a pulling direction (P). The cutting edge is positioned downstream of the dispensing slot relative to the pulling direction (P) whereby the packaging material can be dispensed in a desired length to suit the packaging needs of a particular item and then cut to this desired length by the cutting edge.

Owner:OWENS JOHN R

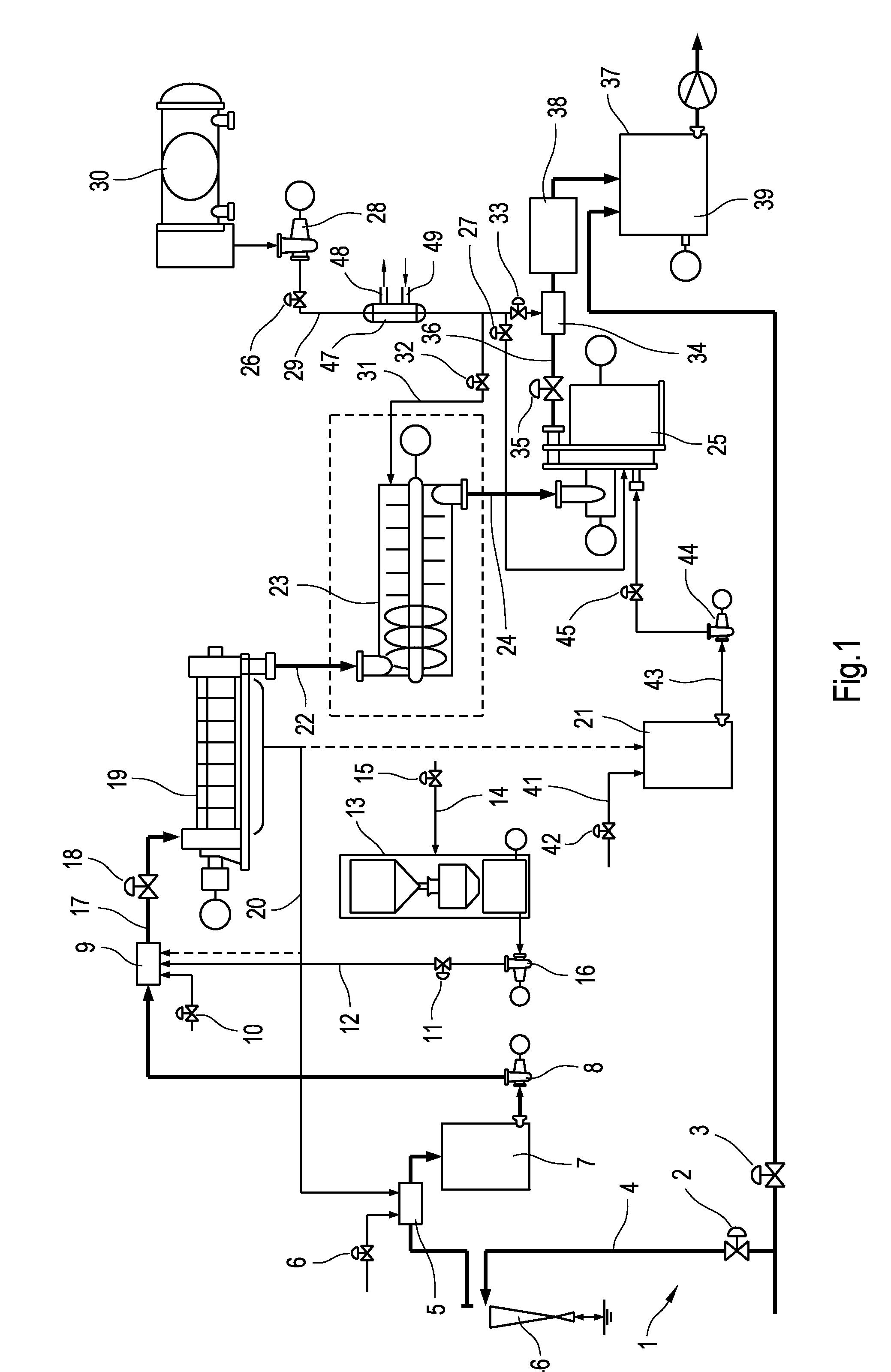

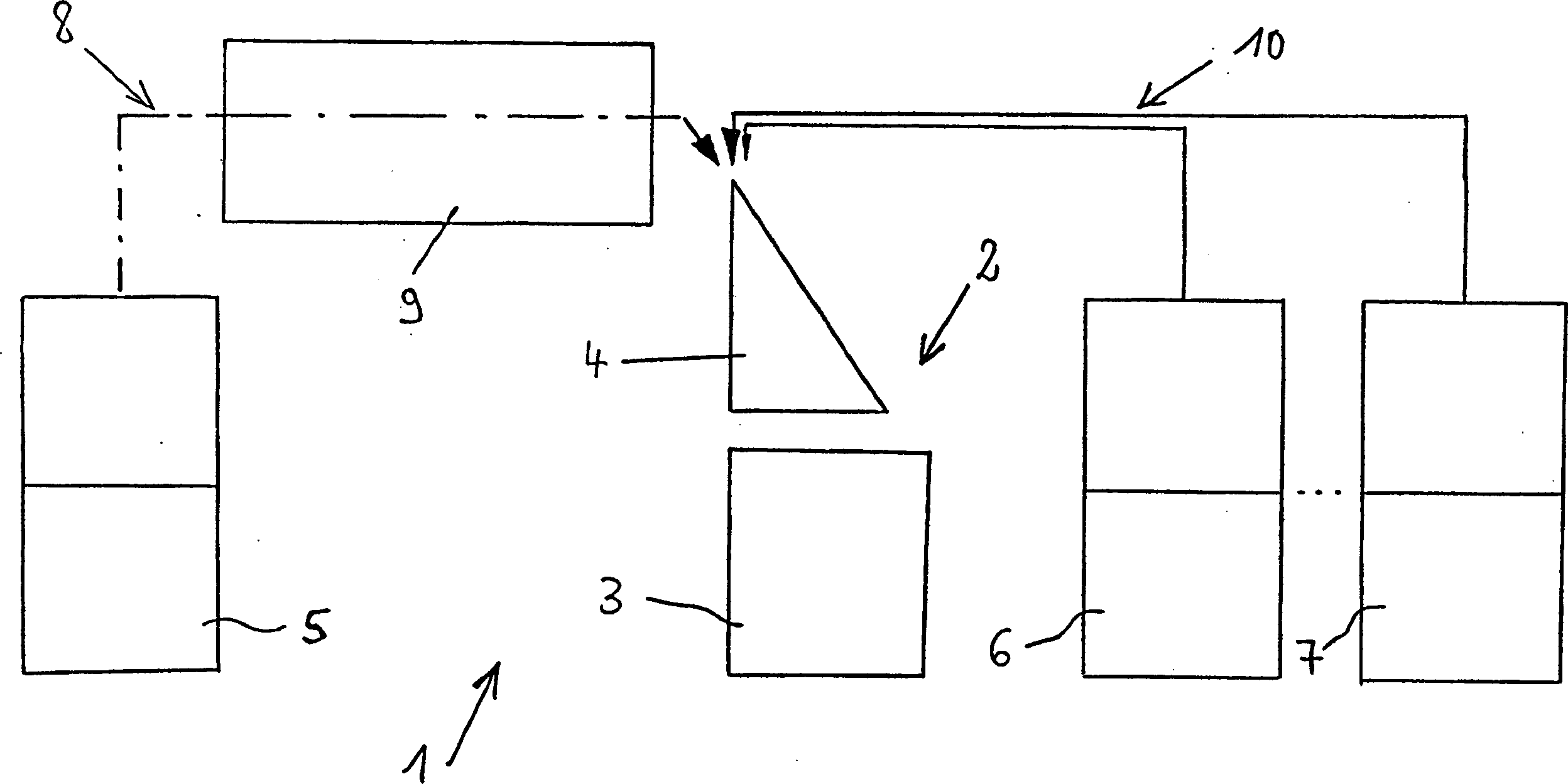

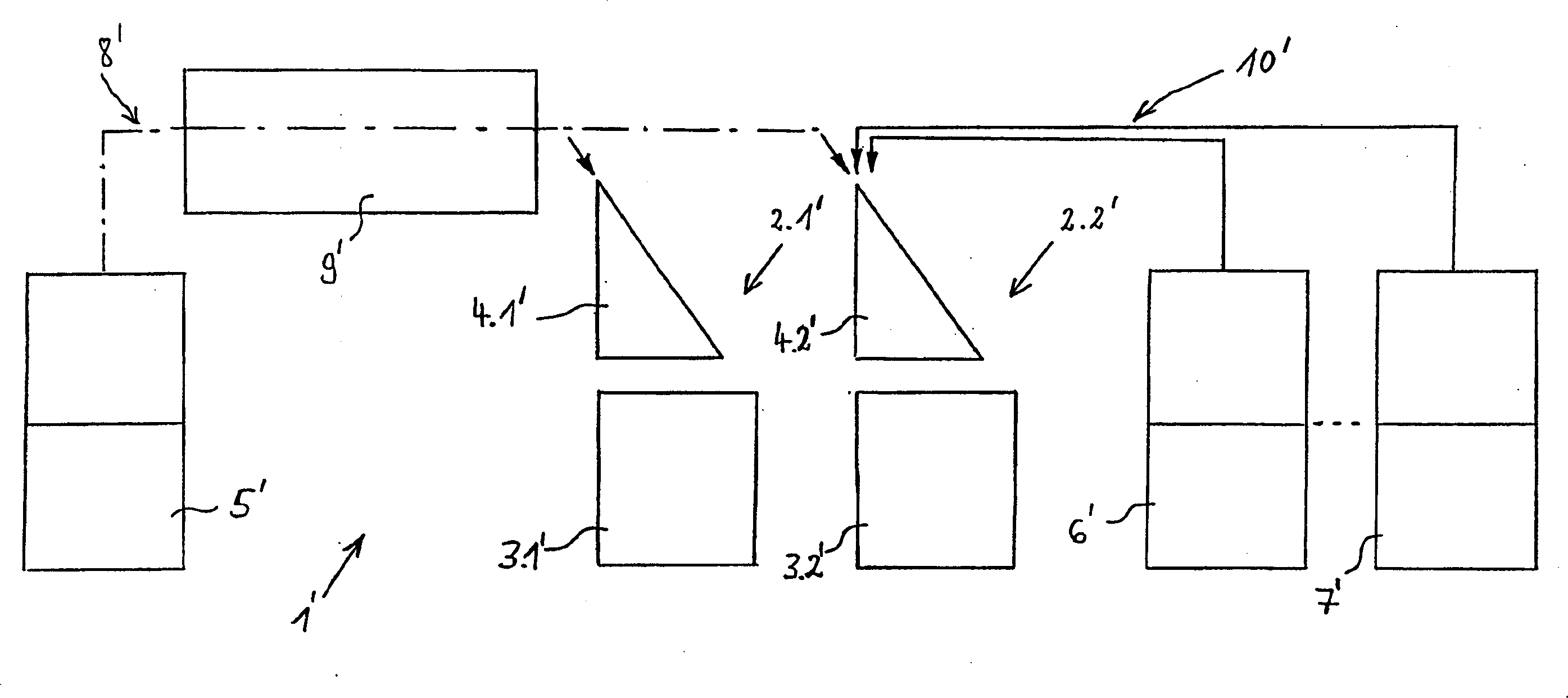

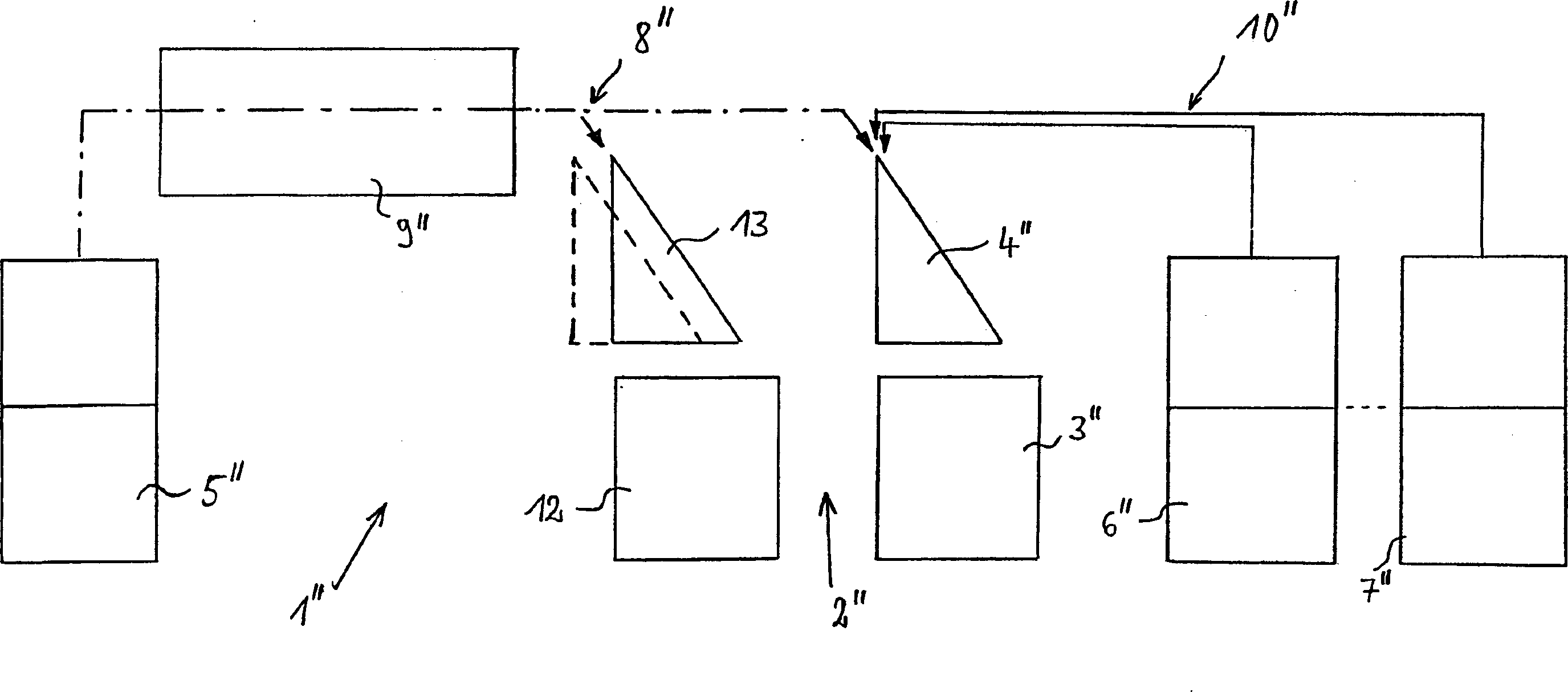

Folding sheets unit of rotary press used for union newspaper and selective commercial products production

InactiveCN1486843AExpand product rangeEfficient use ofFolding thin materialsRotary pressesPrinting pressMechanical engineering

The roller rotation printing machine enables sheets to be printed in both newsprint and commercial quality with printing units of the roller rotation printing machine. The folding unit consists of at least one newspaper folding mechanism and at least one illustration folding mechanism and the relevant printed sheets can be fed to the newspaper folding mechanism and to the illustration folding mechanism according to the required folding quality. The roller rotation printing machine (1) enables sheets to be printed in both newsprint and commercial quality with printing units (5-7) of the roller rotation printing machine. The folding unit (2) consists of at least one newspaper folding mechanism (3) and at least one illustration folding mechanism (12) and the relevant printed sheets can be fed to the newspaper folding mechanism and to the illustration folding mechanism according to the required folding quality.

Owner:MANROLANAD AG

Environmental-protection waste paper deinking method

InactiveCN105178084AQuality improvementHigh whitenessPaper recyclingWaste paper working-upDeinkingFiber

The invention discloses an environmental-protection waste paper deinking method; the method comprises the processes: preliminary cleaning, crushing enzyme treatment, ultrasonic enzyme treatment, flotation and washing. The environmental-protection waste paper deinking method provided by the invention can be applicable to deinking treatment of waste corrugated paper, waste newspaper, colored offset newsprint paper, waste books and magazine paper, office waste paper and laser and electrostatic duplicated paper, a used deinking agent is a bio-enzyme, the pH value of the entire treatment process is neutral, additional additives have no need for adjusting the pH value, the costs are saved, the quality of a waste paper pulp is improved, the difficulty of subsequent sewage treatment is reduced, produced wastewater can be recycled after simple treatment, resources are saved, the costs are reduced, and the environment is protected; a non-woven fabric is prepared from waste paper fibers, the price is low, and the costs are saved; and the waste paper after deinking has the advantages of less fiber loss, high whiteness, small dust degree, and good reutilization property.

Owner:HEFEI LONGFA PACKING CO LTD

Coating newsprint and making method thereof

InactiveCN102587193AEasy to manufactureReduced whiteness requirementsCoatings with pigmentsPaper/cardboardFiberRegenerating fibers

The invention provides coating newsprint and a making method thereof. The newsprint has the following specifications: the fixed weight is 45-49g / m<2>, whiteness is 59-63%, transverse tear index is larger than 5.5m N.m<2> / g, opaqueness is larger than 95%, surface strength is larger than 1.0m / s, average smoothness of the front side and the back side is larger than 60S, the smoothness difference of the front side and the back side is less than 20%, and the longitudinal breakage length is larger than 1500m. The making method of the coating newsprint comprises the following steps of: preparing 100% regenerated fiber deinked pulp completely made from No.8 waste paper and adding auxiliary materials including retention aid, dyes and cationic starch to obtain material pulp; distributing pulp by using a headbox, forming at a neat part, carrying out composite squeezing in a four-roller three-pressing region, primary drying, surface mineral pigment coating and finishing, post-drying, reeling by using reeling machine and external re-reeling. The making method is simple, the coat of coating newsprint per ton is reduced by 250-280 yuan; the surface whiteness of the product is greatly improved, the surface of the product is smooth and fine, the ink absorption rate of the product is moderate; the printability is improved; ink consumption during printing can be reduced 10-15wt%; the printed pictures have bright color and clear wire marks; and the made coating newsprint can meet printing requirements of common newspapers and periodicals and high-quality colored newspapers and periodicals.

Owner:WUHAN CHENMING HANYANG PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com