Method for producing low basis weight newsprint by 100 percent deinking waste pulp added with retention and drainage agent

A retention and drainage aid, low quantitative technology, applied in the direction of adding non-fibrous pulp, processing waste paper, paper, etc., can solve the problems of opacity, tensile index and tear index not meeting the quality standards, etc. Achieve the effect of shortening drying time, saving production costs and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

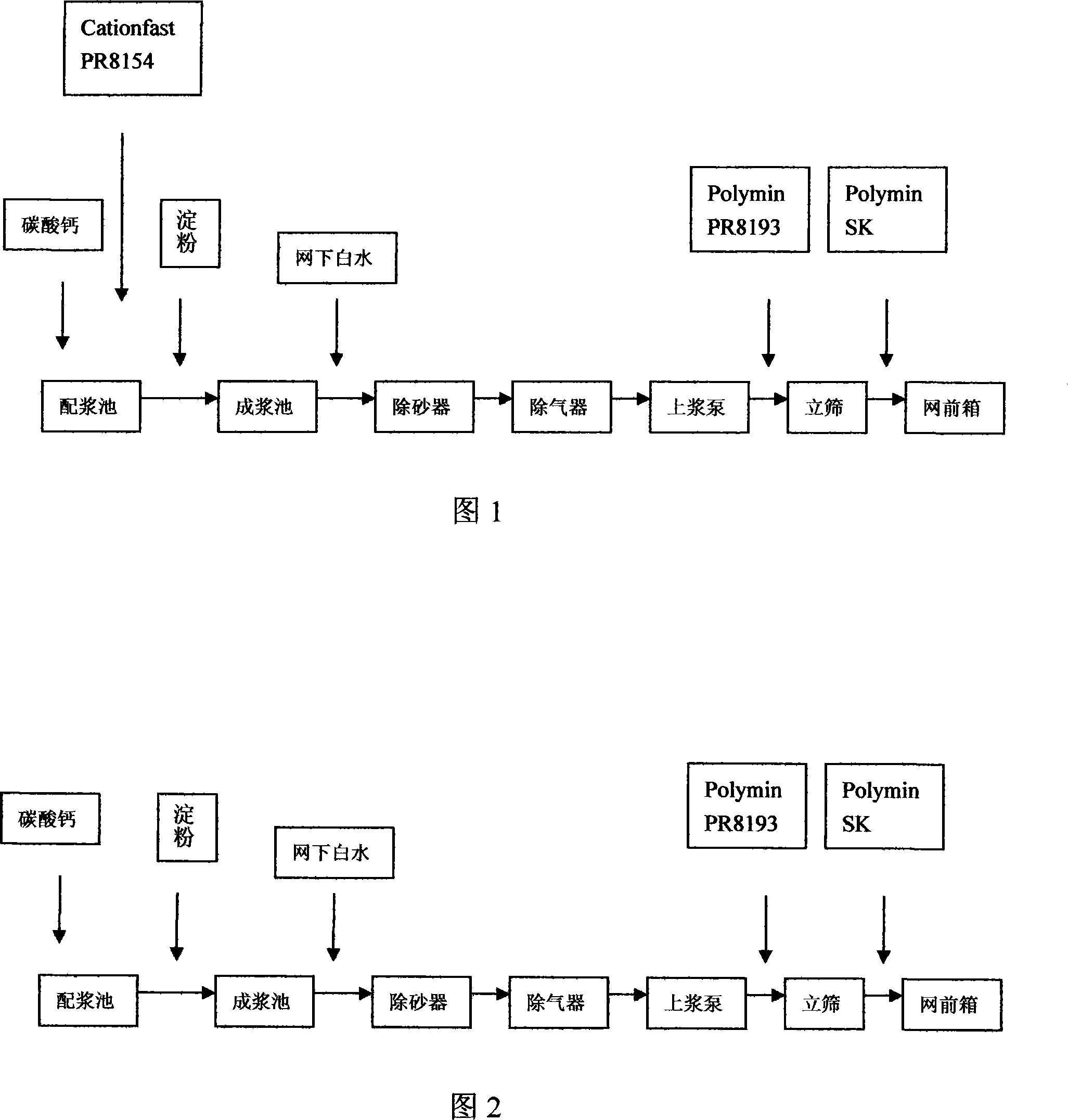

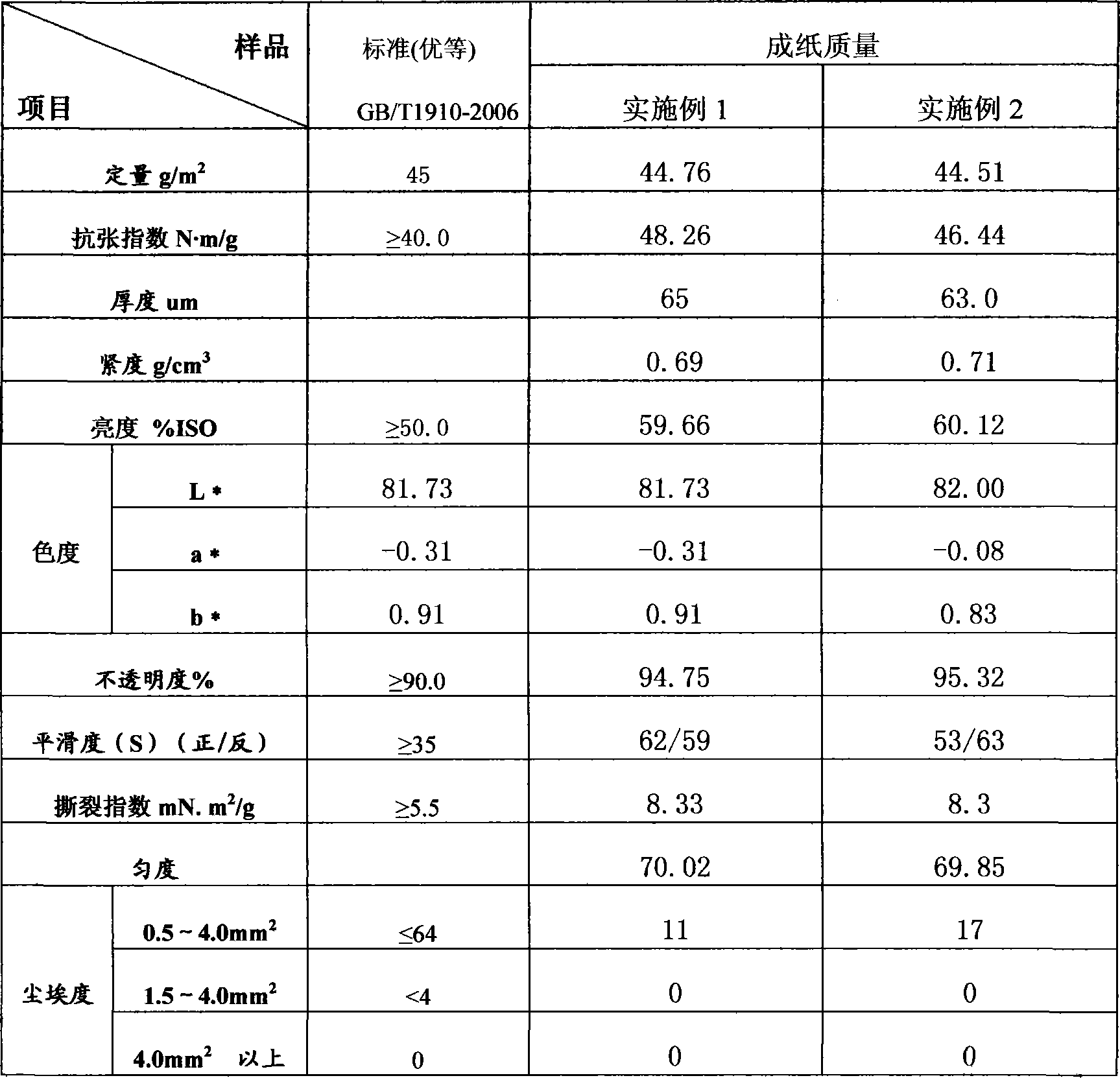

[0022] As shown in Figure 1, adopt 100% deinking waste paper pulp (DIP) to add the method for ternary retention and drainage aid to produce low quantitative newsprint, comprise the steps:

[0023] In the pulp supply system of the high-speed paper machine adopted by the present invention, that is, the Metso OptiConcept horizontal sandwich paper machine (5300mm in width, 4800mm in clean paper width, and 1400 m / min in vehicle speed), there are pulp mixing tank, pulp tank and sand remover , degasser, sizing pump, vertical sieve, and headbox; add 100% (mass percentage) of deinked waste paper pulp (DIP) to the stock tank, and then add 1.5% (for absolute dry pulp) The fixing agent Cationfast PR8154 (produced by German BASF company) of calcium carbonate and 400PPM, at the entrance of the pulping tank, add the starch of 6kg / t paper; 1.0%; After desandering by desander and degassing by degasser, add 200PPM retention aid Polymin PR8193 (produced by German BASF company) at the outlet of s...

Embodiment 2

[0029] As shown in Figure 1, adopt 100% deinking waste paper pulp (DIP) to add the method for ternary retention and drainage aid to produce low quantitative newsprint, comprise the steps:

[0030] In the 100% (mass percentage) deinking waste paper pulp (DIP) in the pulping tank of the high-speed paper machine, add 1% (to the absolute dry pulp) of calcium carbonate and 100PPM of the fixative cationic modified polyamine CationfastPR8154, in the pulping At the entrance of the pool, add 4kg / t of paper starch; at the exit of the pulping pool, use white water under the net to flush the pulp, and the concentration of the net pulp is controlled at 1.0%; Add 100PPM retention aid cationic water-soluble polymer polyacrylamide derivative Polymin PR8193 at the outlet of the vertical sieve and the inlet of the vertical sieve; add 400PPM filter aid polyethyleneimine Polymin SK at the outlet of the vertical sieve; the pulp is sent to the high-speed The headbox of the paper machine can produce...

Embodiment 3

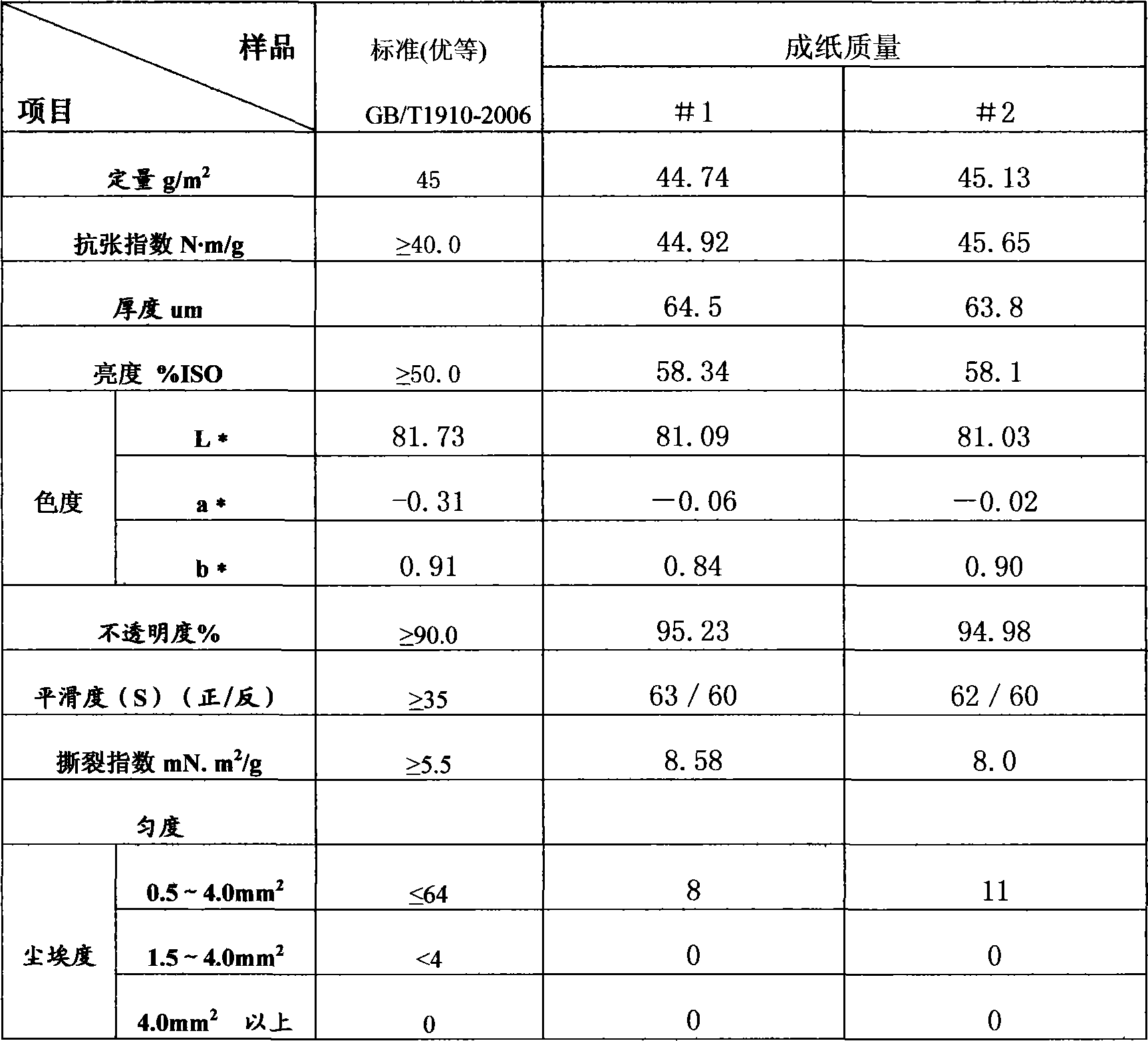

[0036] As shown in Figure 2, adopt 100% deinking waste paper pulp (DIP) to add the method for binary retention and drainage aid to produce low quantitative newsprint, comprise the steps:

[0037] Add 2% (relative to absolute dry pulp) calcium carbonate to 100% (mass percentage) deinked waste paper pulp (DIP) in the pulping tank of the high-speed paper machine, and add 8kg / t paper starch at the entrance of the pulping tank ; Use white water under the net to flush pulp at the outlet of the pulping tank, and the concentration of the net slurry is controlled at 1.0%; after desandering by the desander and degassing by the degasser, add 300PPM auxiliary Retention agent cationic water-soluble polymer polyacrylamide derivative Polymin PR8193; 800PPM filter aid polyethyleneimine Polymin SK is added at the outlet of the vertical sieve; the pulp is sent to the headbox of the high-speed paper machine, and can be produced 45g / m 2 Low basis weight newsprint. The quality indicators of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com