Patents

Literature

353 results about "Retention agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A retention agent is a process chemical that improves the retention of a functional chemical in a substrate. The result is that totally less chemicals are used to get the same effect of the functional chemical and fewer chemicals go to waste.

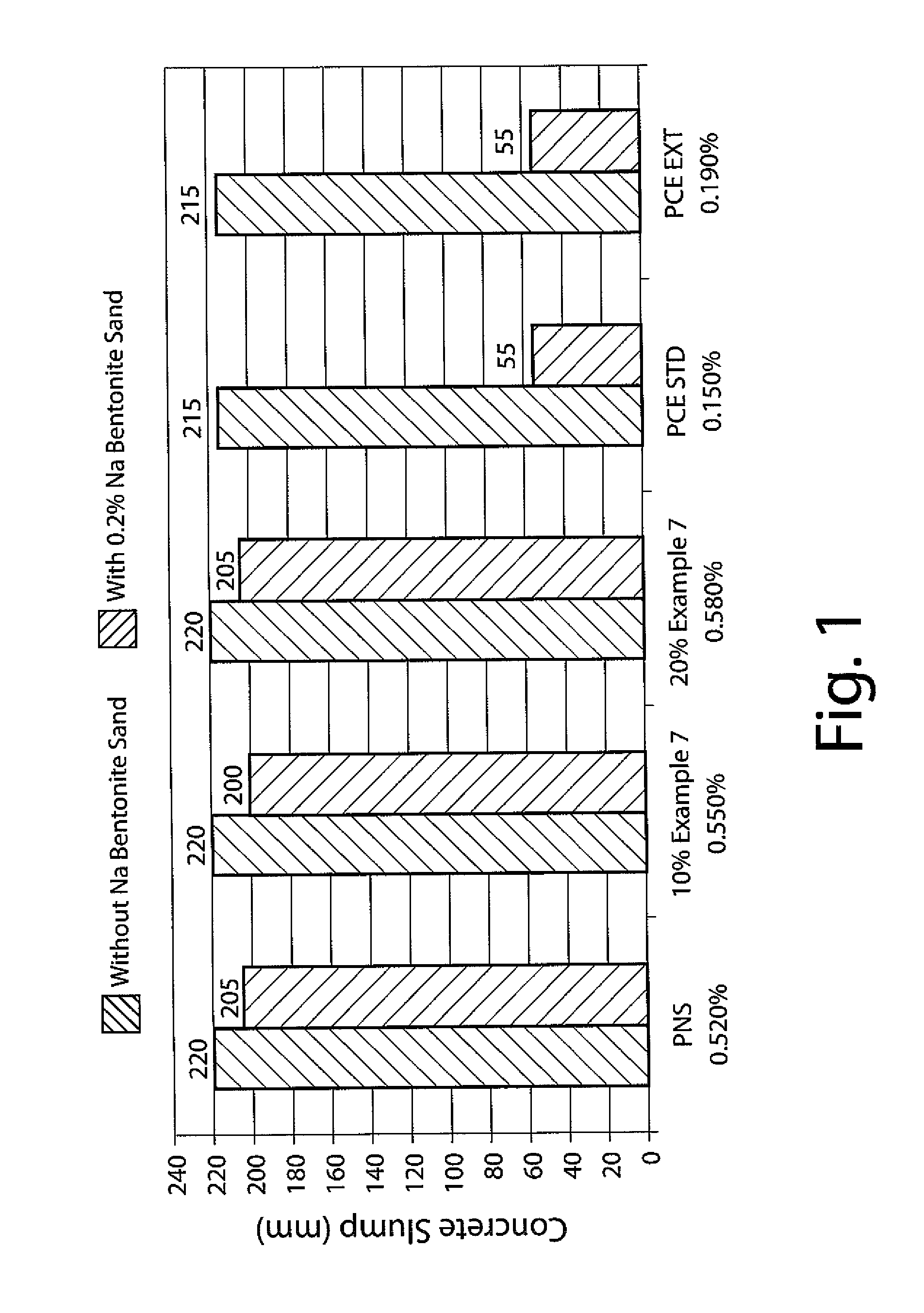

Slump Retaining and Dispersing Agent for Hydraulic Compositions

InactiveUS20130231415A1Avoid settingLow and no air entraining effectDrilling compositionLignosulfonatesSuperplasticizer

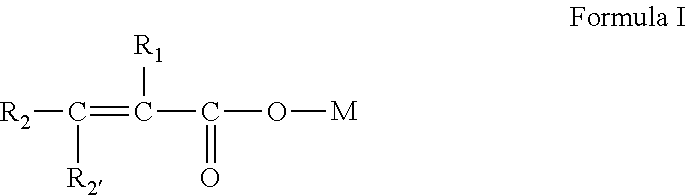

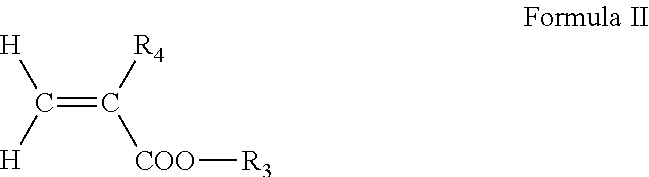

The invention relates to copolymers effective as slump retention agents for hydraulic compositions such as cement, mortar and concrete. The copolymers are formed by reacting monomers A, B and C, wherein monomer A is a compound of formula I, monomer B is a compound of formula II, and monomer C is a compound of formula III or IV as shown herein. The copolymers may be used alone or in combination with a water reducing agent or slump retaining agent, e.g. a superplasticizer such as PNS or PMS or a low range water reducer such as lignosulfonate. The copolymer includes a group that is hydrolyzable at elevated pH (e.g. around pH 12) typically present in hydraulic compositions, so that the group hydrolyzes when present in such compositions and forms a charged group that provides extended slump retention properties without introducing undesirable air-entraining characteristics.

Owner:RUETGERS POLYMERS LTD

Soft and durable tissue products containing a softening agent

InactiveUS20060137842A1Reduce hydrophobicityHigh retention rateNatural cellulose pulp/paperMechanical working/deformationCellulose fiberAcid anhydride

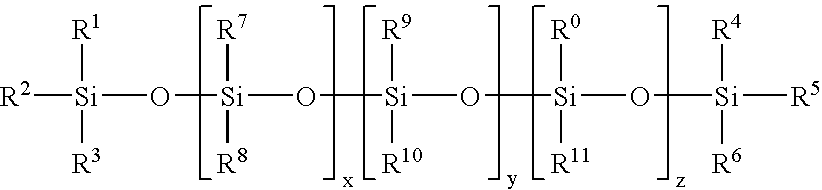

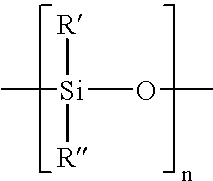

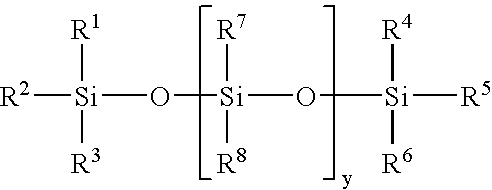

Fibrous products containing a durable softening agent are disclosed. The softening agent generally comprises a polysiloxane containing a plurality of first functional groups. In order to improve the wet retention of the softening agent on cellulosic fibers, the softening agent is reacted with a retention agent. The retention agent generally comprises a cationic polymer having a second functional group. In one embodiment, for instance, the softening agent contains epoxy groups or anhydride groups, while the retention agent contains amine groups. Products that may be made according to the present invention include tissue products, wipes and other absorbent articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Fibrous substrate containing fibers and nanofibrillar polysaccharide

A single-layer fibrous substrate comprising, by dry weight compared with the weight of the substrate:between 39.9 and 87.9% natural fibers refined to above 50° SR;between 12 and 60% nanofibrillar polysaccharide; andbetween 0.1 and 4% of at least one retention agent.

Owner:AHLSTROM MUNKSJO OYJ

High-cleanliness economical microemulsion metal cutting fluid

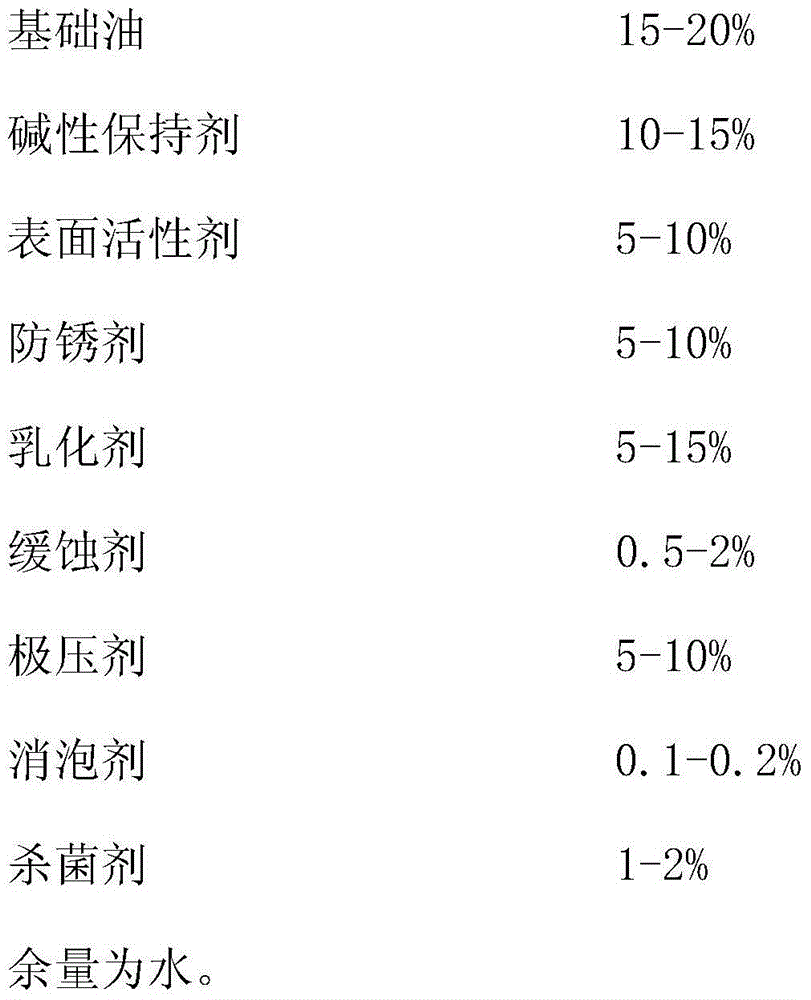

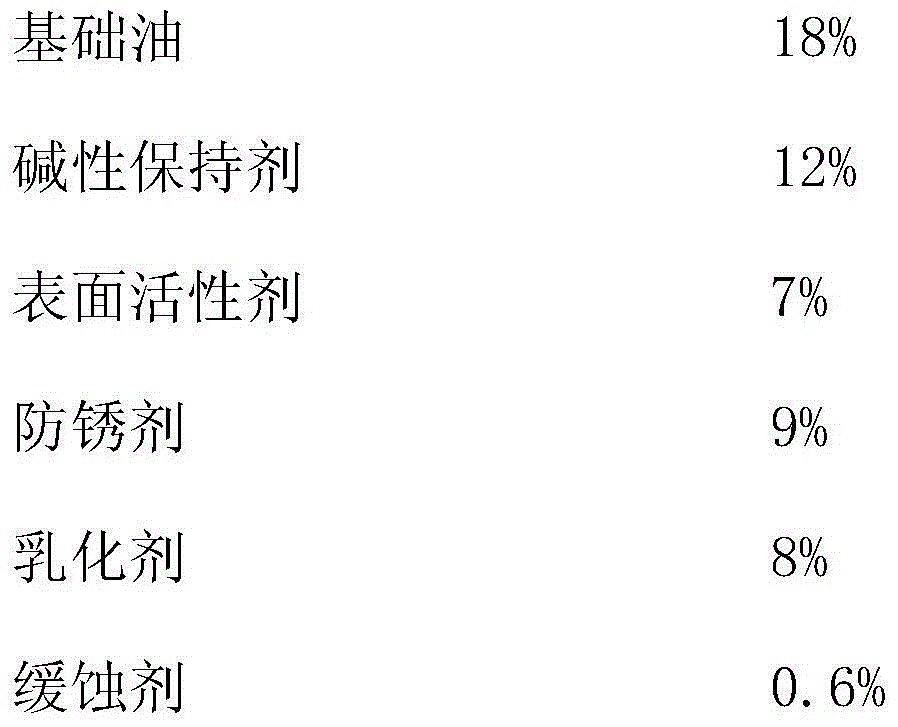

The invention relates to a cutting fluid used for metal processing and a preparation method thereof and in particular relates to a high-cleanliness economical microemulsion metal cutting fluid. The high-cleanliness economical microemulsion metal cutting fluid comprises the following raw material components in percentage by weight: 15-20% of base oil, 10-15% of alkaline retention agent, 5-10% of surfactant, 5-10% of antirust agent, 5-15% of emulsifying agent, 0.5-2% of corrosion inhibition agent, 5-10% of extreme pressure agent, 0.1-0.2% of defoaming agent, 1-2% of sterilizing agent and the balance of water. The preparation method of the high-cleanliness economical microemulsion metal cutting fluid comprises the following steps: adding the alkaline retention agent, the surfactant, the antirust agent, the emulsifying agent, the corrosion inhibition agent, the extreme pressure agent, the defoaming agent, the sterilizing agent, water and the like into base oil, and uniformly mixing and stirring. Compared with the prior art, the preparation method of the high-cleanliness economical microemulsion metal cutting fluid has the advantages that product quality and operating environment can be improved, processing efficiency is improved, durability of a cutter is enhanced, and cost for replenishing and managing cutting fluid is reduced, so that obvious economic benefit is obtained.

Owner:马思特(上海)化学有限公司

Method for improving performance of paper stock in retention and drainage aiding

InactiveCN101634120AImprove retentionGood filterabilityInorganic compound additionPaper-making machinesFiberSlurry

The invention provides a method for improving the performance of paper stock in retention and drainage aiding. The method comprises the following steps: firstly, dispersing plant fiber materials for papermaking in water, beating the plant fiber materials with the beating degree being controlled to 25 to 70 DEG SR (Schopper-Riegler); secondly, feeding the evenly mixed slurry into the approach flow system of a paper machine, and adding CPAM (cationic polyacrylamide) as retention agent before feeding the slurry into a fan pump of the approach flow system; then, adding electronegative bentonite before feeding the slurry into a pressure screen or a head box, and adding APAM (anionic polyacrylamide) before feeding the slurry into the head box; and finally, papermaking forming on the paper machine, drying and obtaining the qualified paper. By adding excessive CPAM to the paper machine, the invention allows the action between CPAM and bentonite to form fine particles, and the further combination with APAM to form floccules, thereby providing draining channels in good conditions and further improving the drainage capacity during the forming process of the paper stock.

Owner:SHAANXI UNIV OF SCI & TECH

Fruit retention agent as well as preparation method and use method of Feizixiao litchis

InactiveCN101692835ASolve the problem of slow drug effectEnhanced inhibitory effectBiocidePlant growth regulatorsBrassinolideP-chlorophenoxyacetic acid

The invention discloses a fruit retention agent as well as a preparation method and a use method of Feizixiao litchis. The fruit retention agent is prepared from amino acid, calcium acetate, borax, fulvic acid, p-chlorophenoxyacetic acid, gibberellin, forchlorfenuron and brassinolide. The fruit retention agent for the Feizixiao litchis is applied to the fruit retention of the Feizixiao litchis ten days after blossom falls in the mode of cluster spraying. The relative fertile fruit percentage of the fruit retention agent is 8.37 percent, which is improved by 37.70 percent compared with that of a contrast, and the weight of single fruit is not influenced. The fruit retention agent has low cost, simple preparation and simple and convenient operation and is easy of large-scale popularization. The fruit retention agent for the Feizixiao litchis is also suitable for the fruit retention of other varieties of litchis.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI

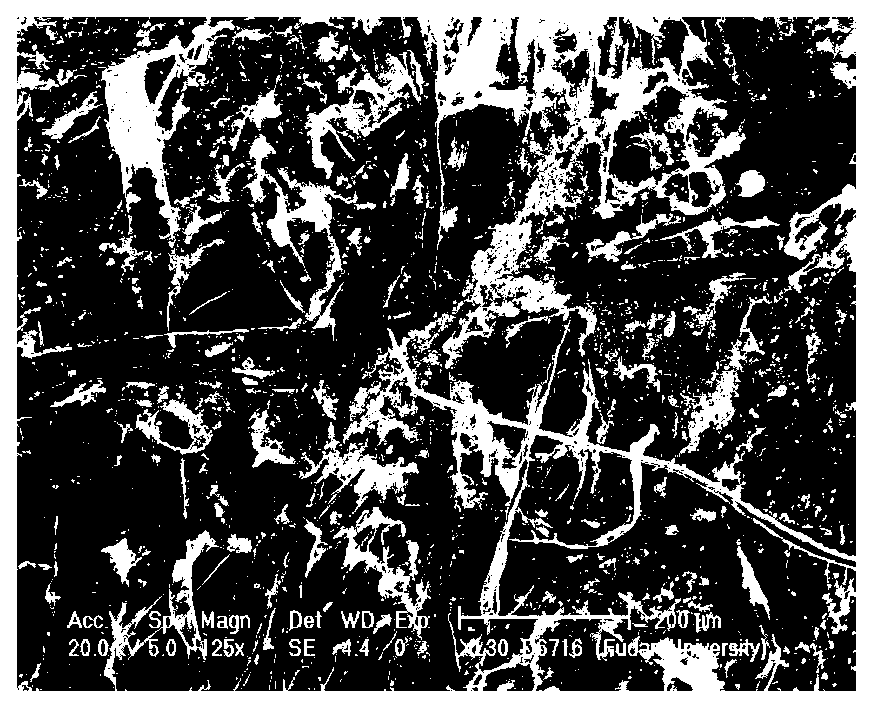

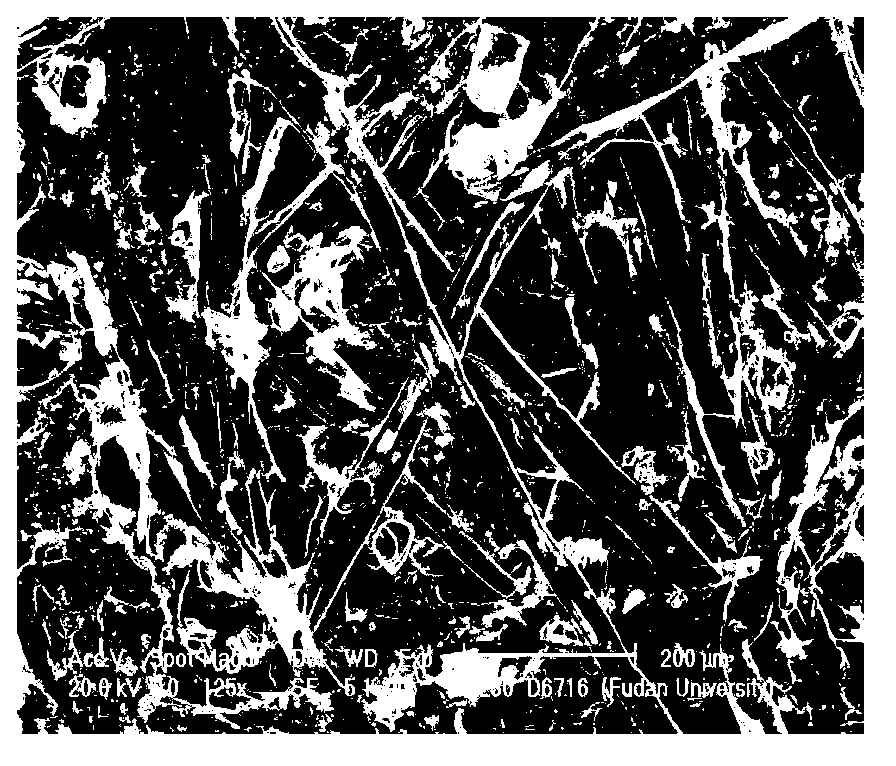

Short carbon nanotubes as adsorption and retention agents

InactiveUS20060051290A1Need be addressPowder deliveryMaterial nanotechnologyMonoclonal antibodyWater soluble

A method for delivering a radiotherapeutic agent to a target, comprises administering a composition comprising water-soluble nanotubes having an average length less than 50 nm and a radionuclide so as to expose the target to the composition. The nanotubes can be functionalized with a monoclonal antibody having an affinity for the target. The radionuclide can be contained in the nanotubes, which can be derivatized. The nanotubes can be loaded with I2 or 211AtI, another α-emitter, including but not limited to 211AtI, 225Ac, 212Bi, 213Bi, and combinations thereof. The nanotubes have an average length less than 40 nm, or an average length less than 30 nm.

Owner:RICE UNIV

Method for producing metallic high temperature transfer base paper

ActiveCN101255662AImprove high temperature resistanceHigh strengthNatural cellulose pulp/paperWax additionFiberExtremely good

The invention discloses the production method of a metal high temperature transfer printing base paper, including to use 50-70% blanching needle wood-pulp and 30-50% blanching broad-leaf wood-pulp to be the raw material, which is pulped by a pulper, then is added by beating with chemical auxiliary materials: 1-4% a wet strength agent, 1-3% a high temperature resistance agent, 1- 4% starch, 2-4% aluminum sulfate, 1.0-2.5% a rosin milk, 0.1-1.5% a remover, and 0.03 -0.1% a retention agent to make into a slurry; after making, the slurry is rewound to be the base paper when passing through a rewinder. The transfer printing base paper produced by the method has the advantages of extremely good high temperature resistance, being able to satisfy the request of the metal high temperature transfer printing, fine superficial smoothness, and full patterns, bright color and good transfer printing effect after printed. The intensity of the paper is very high, which can satisfy the need of the transfer printing, and the paper is crispness, is not coking and has good stripping paper effect after transfer printed on metal; the waste paper can be recycled to be used as secondary fiber, which saves resources and protects environment.

Owner:HUANGSHAN XINLONG SPECIALITY PAPER

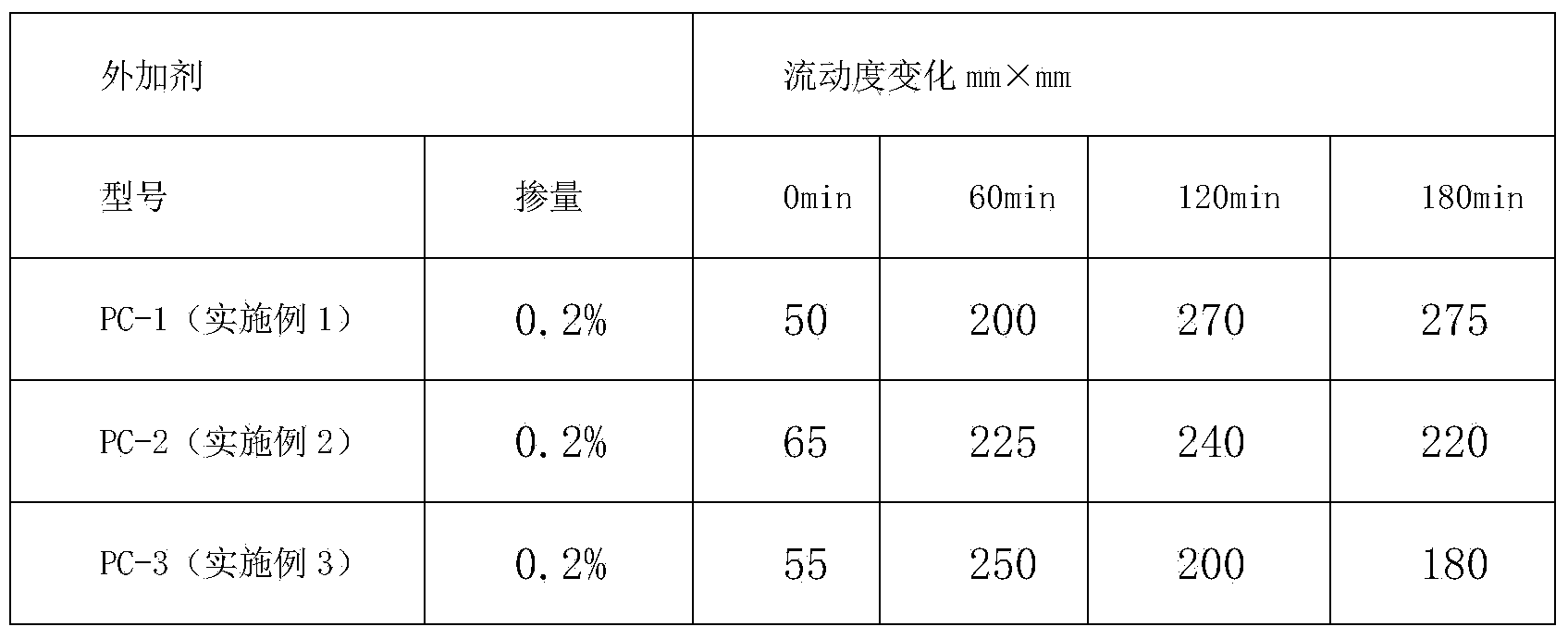

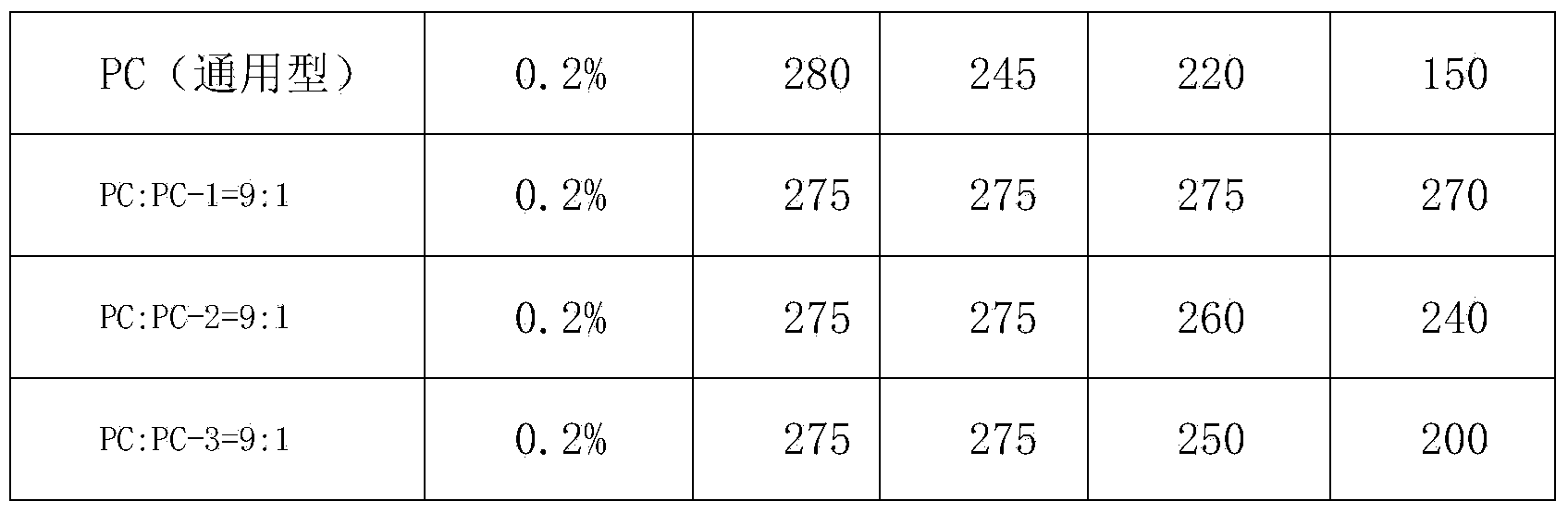

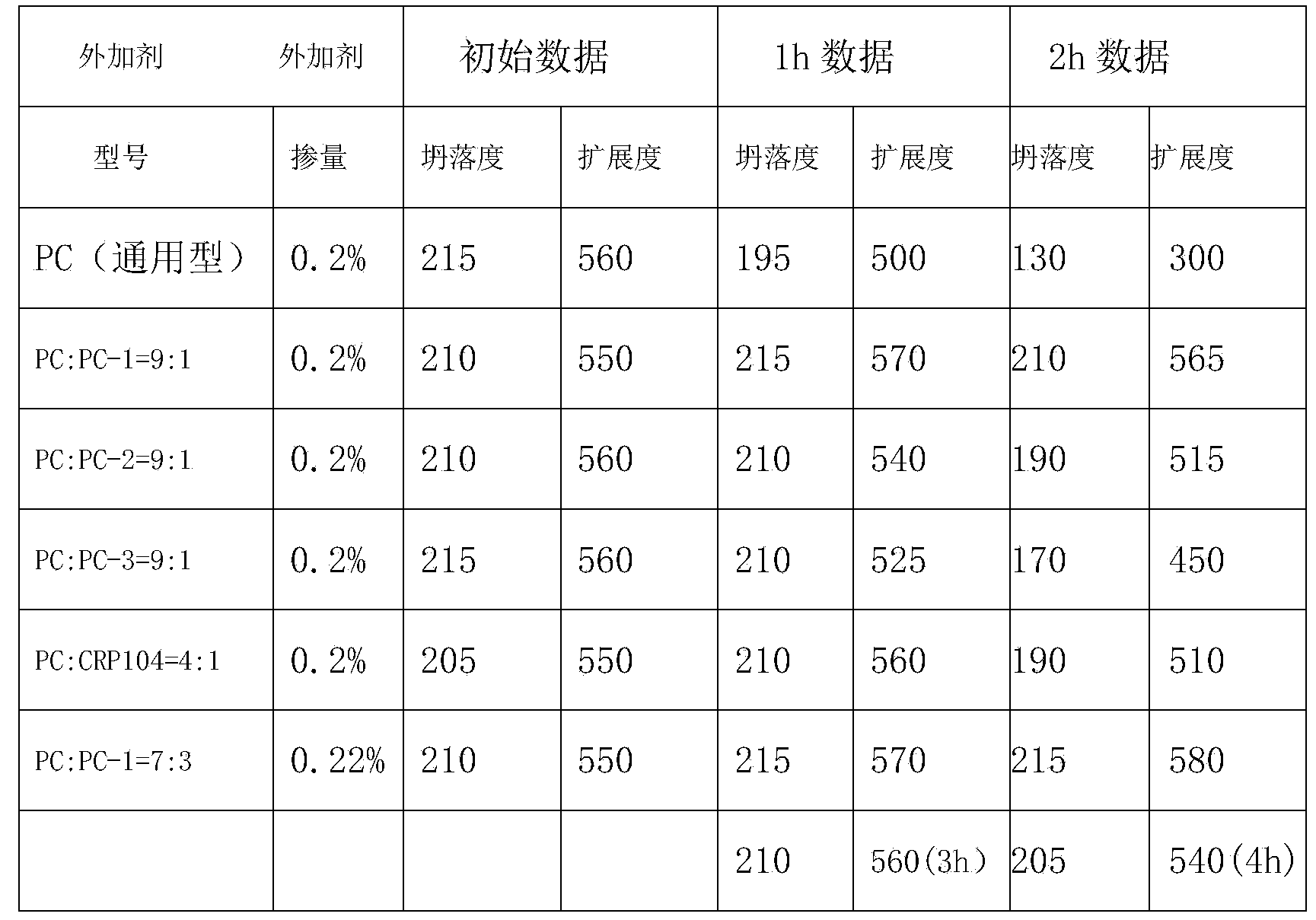

Super controlled release type polycarboxylate slump retention agent and preparation method thereof

The invention discloses a super controlled release type polycarboxylate slump retention agent and a preparation method thereof. The preparation method of the polycarboxylate slump retention agent comprises the following steps: carrying out free radical polymerization on a monomer A, namely polyoxyethylene ether (TPEG), a monomer B, namely maleic anhydride or polyethylene glycol maleic acid esters, a monomer C, namely acrylic acid, a monomer D, namely hydroxyalkyl acrylate or vinyl acetate, an initiator, a chain transfer agent and water, adding an alkaline liquor to neutralize the mixture, wherein a molar ratio of the monomer A to the monomer B to the monomer C to the monomer D is 1 to (1.0-2.5) to (1.0-2.5) to (2.0-4); the dosage of the initiator accounts for 1%-8% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D; the dosage of the chain transfer agent is 1%-3% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D. The super controlled release type polycarboxylate slump retention agent disclosed by the invention is in a liquid state, has solid content of 50%, and has performances of low alkaline content, a low water-reducing rate and excellent slump retention performance. Besides, the production process is simple, the reaction conditions are easy to control, and the environmental pollution is avoided.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

Method of increasing drainage in papermaking using colloidal borosilicates

InactiveUS6361652B2Additional componentPromote flocculationNatural cellulose pulp/paperSpecial paperColloidMaterials science

The invention comprises a borosilicate retention aid composition and a method for improving the production of paper by addition of the borosilicate. The borosilicate may be utilized in conjunction with a high molecular weight synthetic flocculant and / or starch, with or without the addition of a cationic coagulant. The borosilicate material is preferably a colloidal borosilicate. Methods for the preparation of the borosilicate material are disclosed.

Owner:ECOLAB USA INC

Hydrophobic finish compositions with extended flow time retention and building products made thereof

ActiveUS20160264461A1Improve water resistanceLow costConstruction materialSolid waste managementFiberBuilding product

Disclosed are hydrophobic finish compositions and cementitious articles made with the hydrophobic finish compositions. In some embodiments, the article is a waterproof gypsum panel surface reinforced with inorganic mineral fibers that face a flexible and hydrophobic cementitious finish possessing beneficial waterproofing properties. These waterproof gypsum panels have many uses, such as, tile backer board in wet or dry areas of buildings, exterior weather barrier panel for use as exterior sheathing, interior wall and ceiling, and roof cover board having water durability and low surface absorption. The flexible and hydrophobic cementitious finish can include fly ash, film-forming polymer, preferably silane compound (e.g., alkyl alkoxysilane), an extended flow time retention agent including either one or more carboxylic acids, salts of carboxylic acids, or mixtures thereof, and other optional additives. Preferably a pre-coated non-woven glass fiber mat is employed to provide the inorganic mineral fibers for the surface reinforcement.

Owner:UNITED STATES GYPSUM CO

Lubricating agent for superfine copper wire drawing

The invention discloses a lubricating agent for superfine copper wire drawing. The lubricating agent comprises the following components in parts by mass: 5-25 parts of lubrication base oil, 10-30 parts of an emulsifying agent, 1-5 parts of a surface active agent, 1-10 parts of an antirust agent, 1-5 parts of an extreme pressure antiwear additive, 1-5 parts of a thickening agent, 5-25 parts of an alkali retention agent, 1-5 parts of a bactericide, 0.1 part of a defoaming agent and 30-50 parts of water. The lubricating agent for superfine copper wire drawing has good oxidation resisting, cooling, cleaning, lubricating, rust preventing, hard water resisting and copper soap dispersing properties, and is particularly suitable for superfine copper wire drawing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Silver-loaded antibacterial paper and preparing method thereof

InactiveCN105780590AFast and good bactericidalFast and good bacteriostasisWater-repelling agents additionReinforcing agents additionPaper productionBleach

The invention discloses silver-loaded antibacterial paper.The silver-loaded antibacterial paper is prepared from a silver-loaded antibacterial agent, a softening agent, a dry strength agent, a wet strength agent, a drying agent, a retention agent, a sizing agent, an antibacterial agent, a dispersing agent and a decolorizer additive.The invention further discloses a preparing method of the silver-loaded antibacterial paper.The method comprises the following steps that pulping, pulp dispersing, pulp milling and pulp beating are carried out, the silver-loaded antibacterial agent is added into the pulp sizing agent, the sizing agent is conveyed, pulp is fed onto a net to be shaped and pressed into paper, pressing is carried out, and dry dehydration and paper forming are carried out.Compared with the prior art, the antibacterial paper and the antibacterial paper production method have the advantages that prebiotics and the antibacterial agent are used in the antibacterial paper in a combined mode, it is ensured that the antibacterial paper has the fast and good sterilization and bacteriostasis effects, can well restrain breeding and growth of microorganisms of the antibacterial paper, the damage to the quality of the antibacterial paper due to breeding of the microorganisms is avoided, and the quality of the antibacterial paper is ensured.

Owner:上海渊泉集币收藏品有限公司

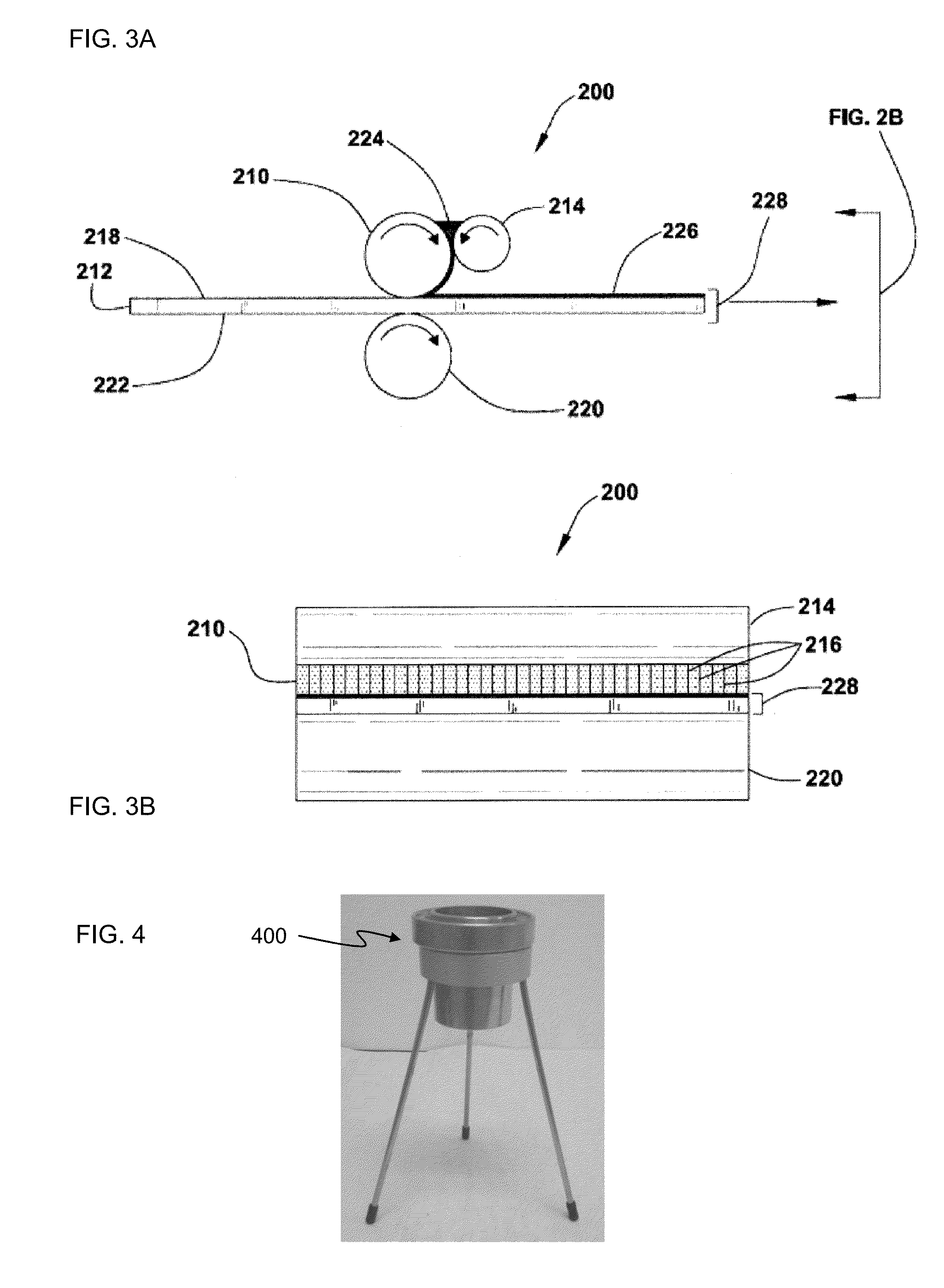

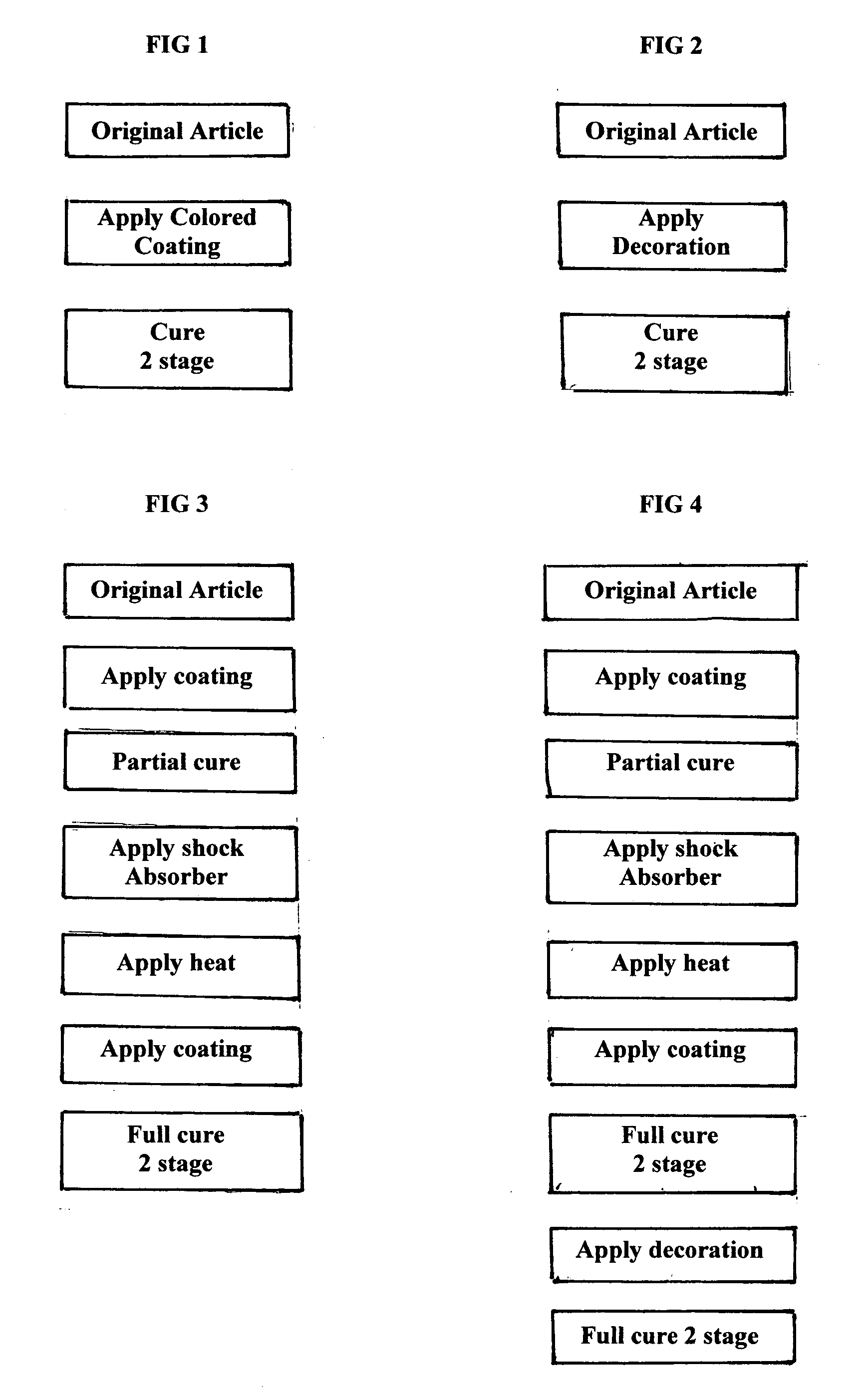

Decorative and protective system for wares

InactiveUS20110250405A1Good adhesion to glassImprove fracture resistanceLayered productsPretreated surfacesCross-linkProduction rate

A copolymer Tradenamed HexiLok is applied in the form of an ink as a decorative and protective outer covering to glassware and other tableware. It serves also as an adhesion coating to which a cross-linked ethylene acrylic acid copolymer is applied, to serve as a shock absorber and shard retention agent, in the event of breakage of the wares. The impact resistance of drinking glasses can be improved ten-fold with a 5 mil outer coating. The use of UV light as a curing agent in a 2-stage curing process, enables high production rates. The tough HexiLok ink serves to hermetically seal the decorated surface of the wares, enabling the use of non-FDA approved decorating agents.

Owner:SAWATSKY HANK

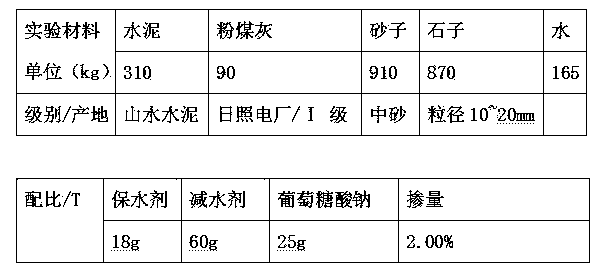

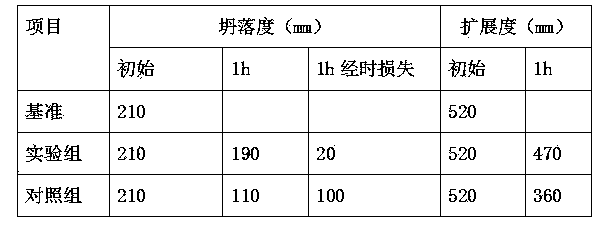

Polycarboxylic acid water retention agent, and preparation method and application thereof

InactiveCN104176969AThe reaction principle is reasonableSimple production processVitamin CPore distribution

The invention discloses a polycarboxylic acid water retention agent, and a preparation method and application thereof. The water retention agent is prepared from polyether, acrylic acid, vitamin C, mercaptopropionic acid, ammonium persulfate and hydrogen peroxide. The process mainly improves the pore distribution of the concrete against the participation of the water retention agent, thereby increasing the concrete compactness, keeping the internal water of the concrete and accelerating the later hydration effect of the cementing material. All the agents are sequentially mixed according to different functions and react under certain conditions. The formula is only against the water retention agent with local material characteristics. The product has the advantages of improved local material applicability of the additives, wider application range, favorable effect and obvious cost advantage.

Owner:RIZHAO POLYTECHNIC +1

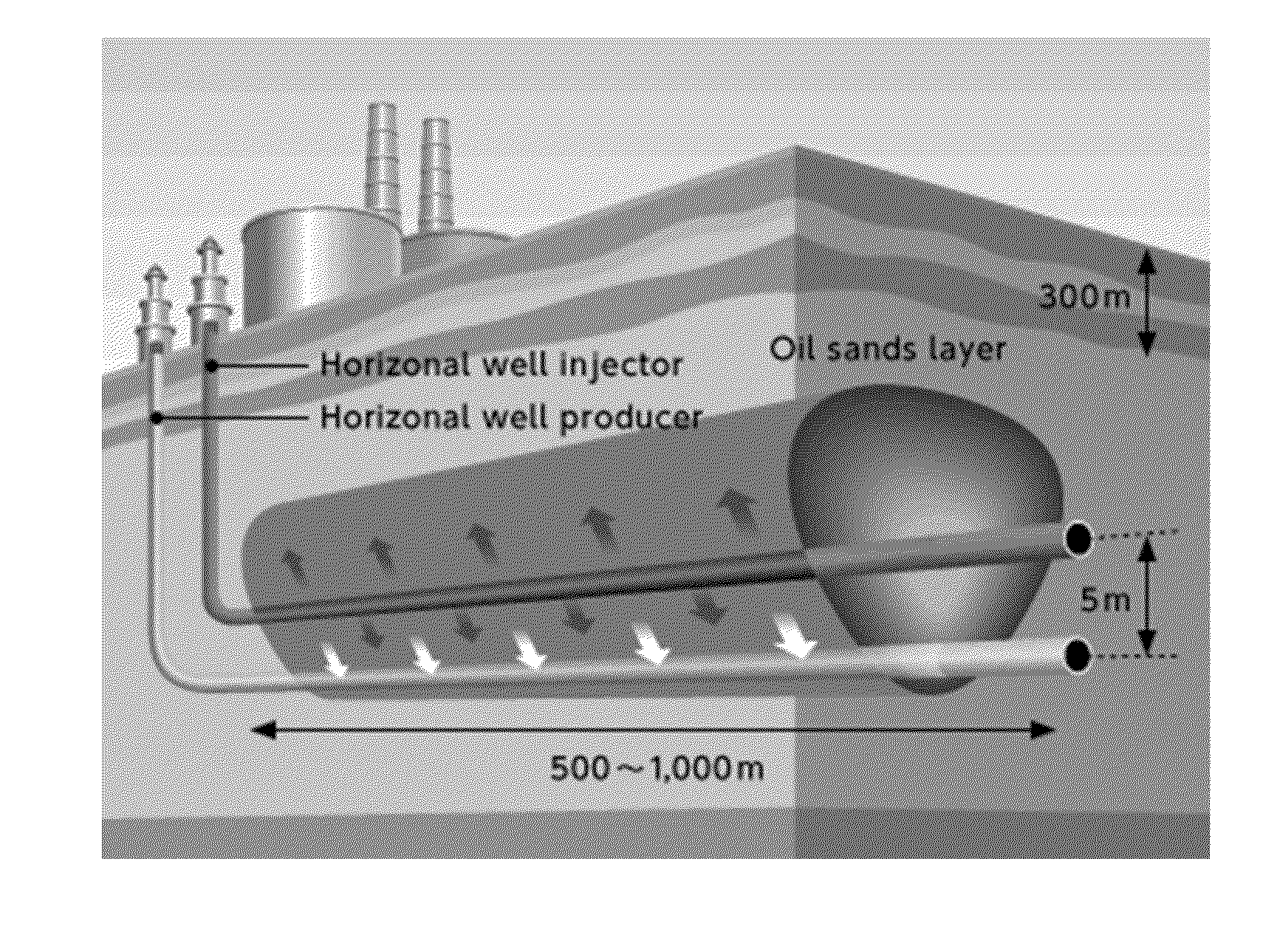

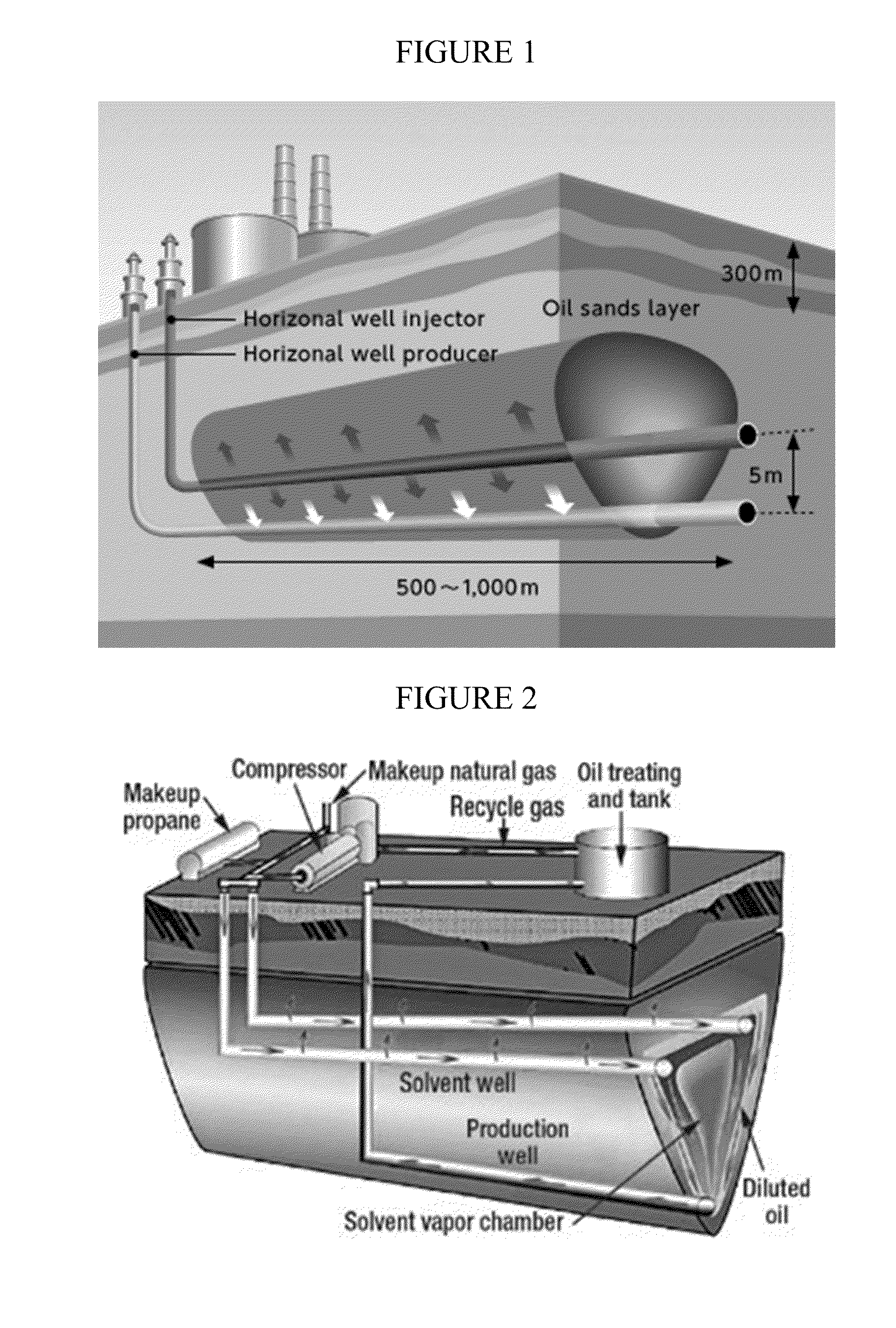

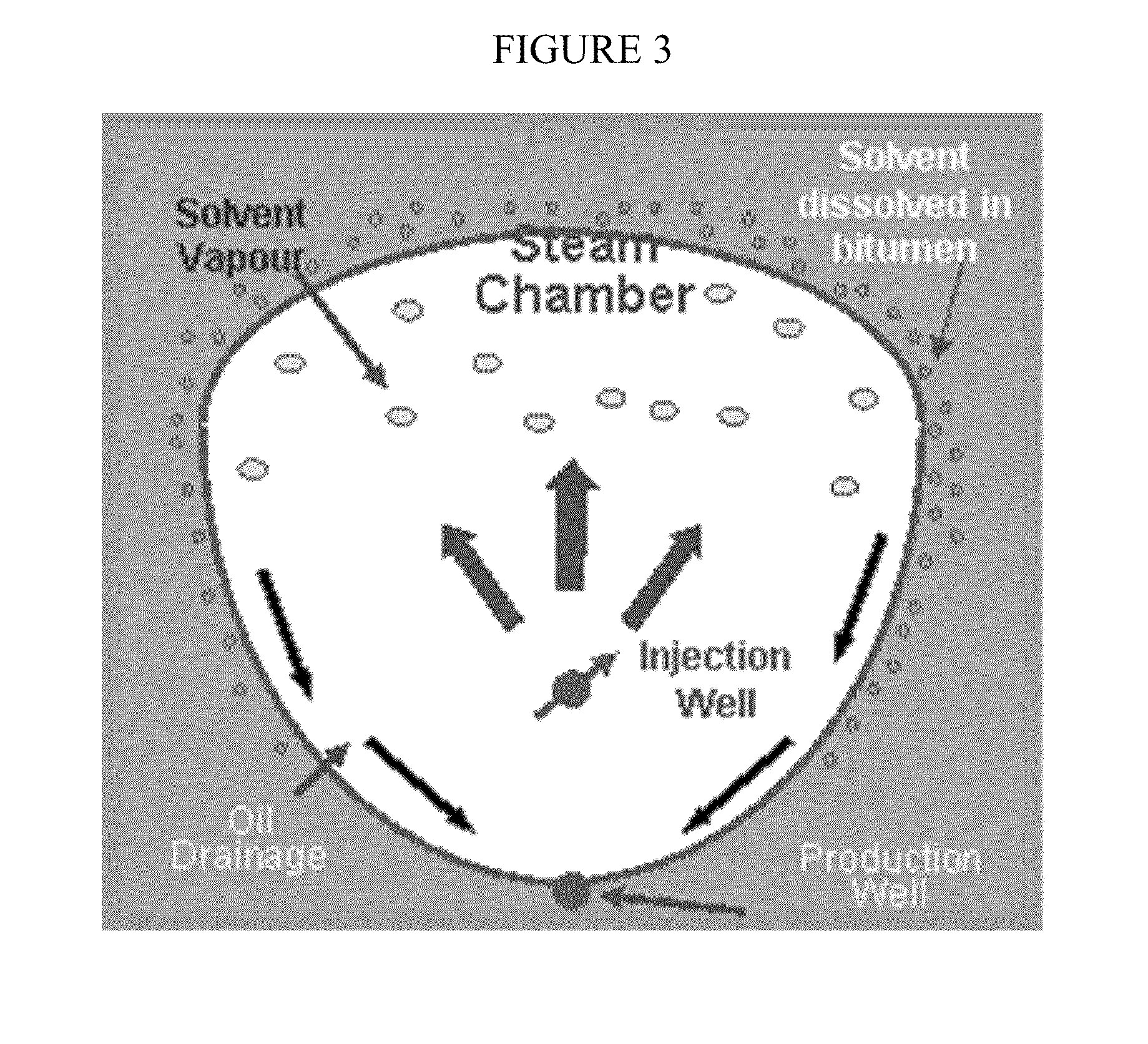

Anti-retention agent in steam-solvent oil recovery

ActiveUS20150198027A1Readily solubleAddition of solventFluid removalDrilling compositionColloidSolvent

The present invention relates to a method for reducing solvent retention in ES-SAGD process so as to increase process economics wherein an anti-retention agent is injected into the reservoir to decrease solvent retention in the reservoir. The anti-retention agent can be made pre-injection or can form in situ, and comprises an agent in which the solvent is readily soluble, such that the solvent partitions into the foam, colloidal dispersion, or gel, and out of the condensed water or steam, and away from the reservoir rock.

Owner:CONOCOPHILLIPS CO

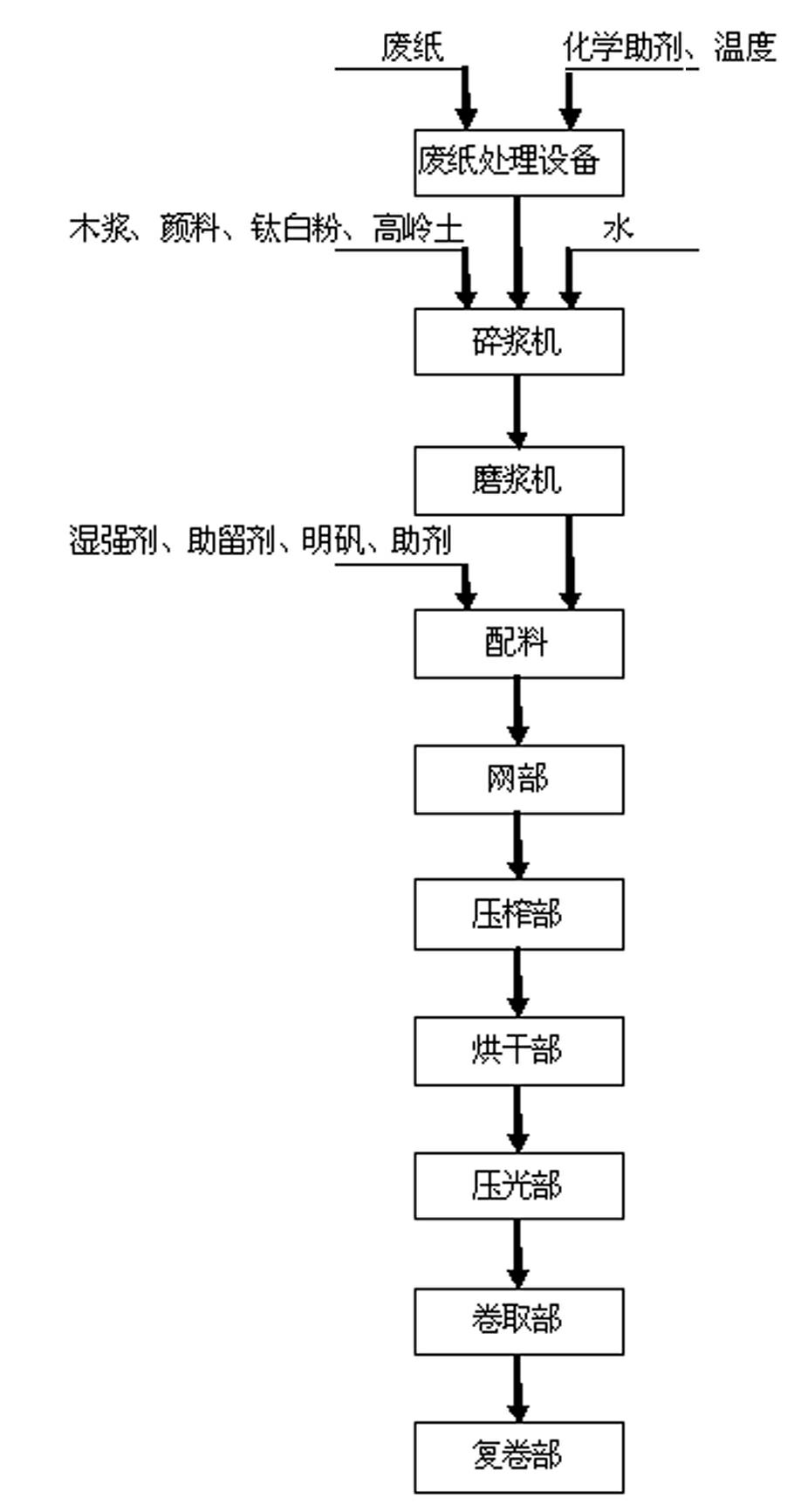

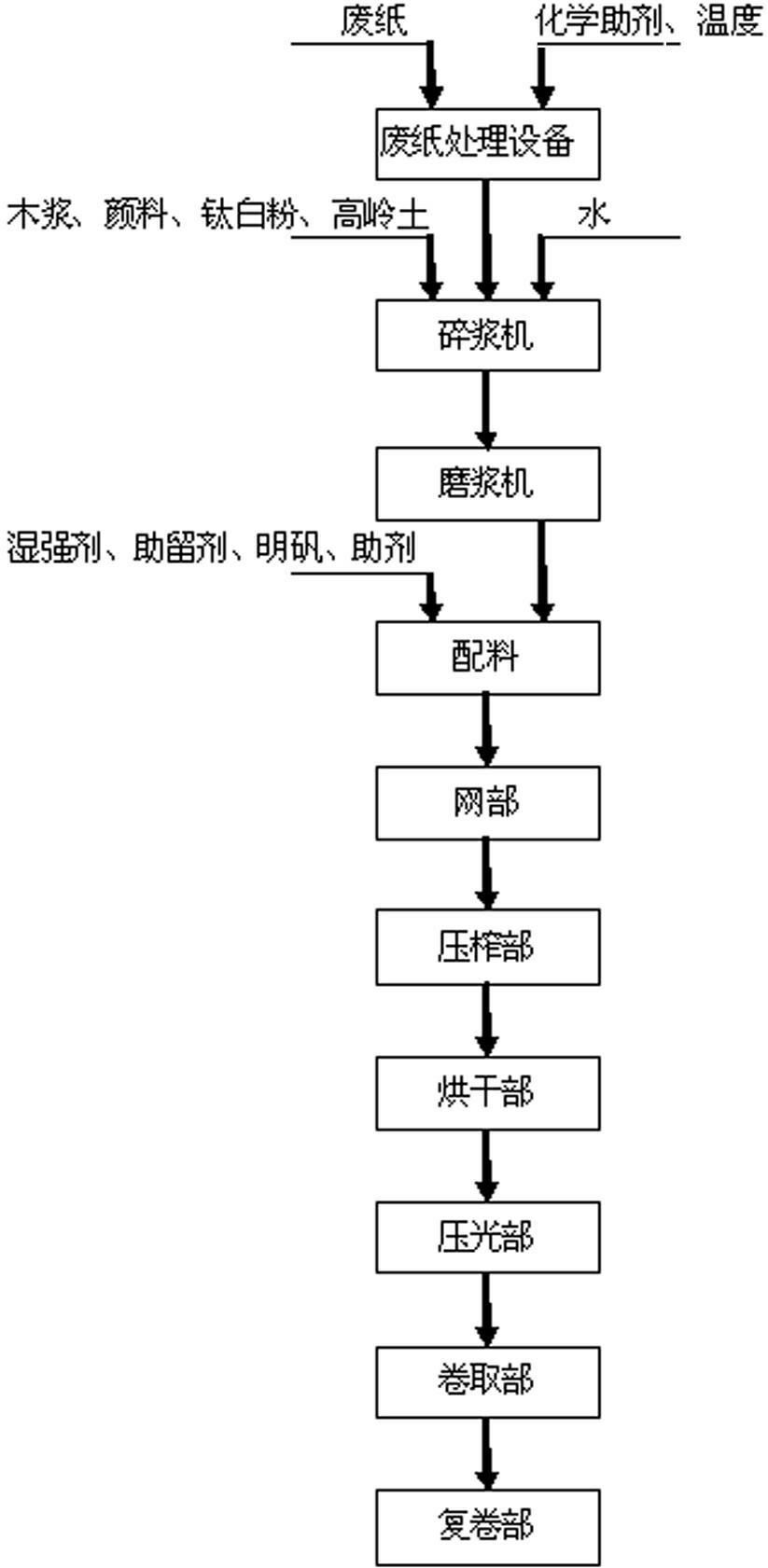

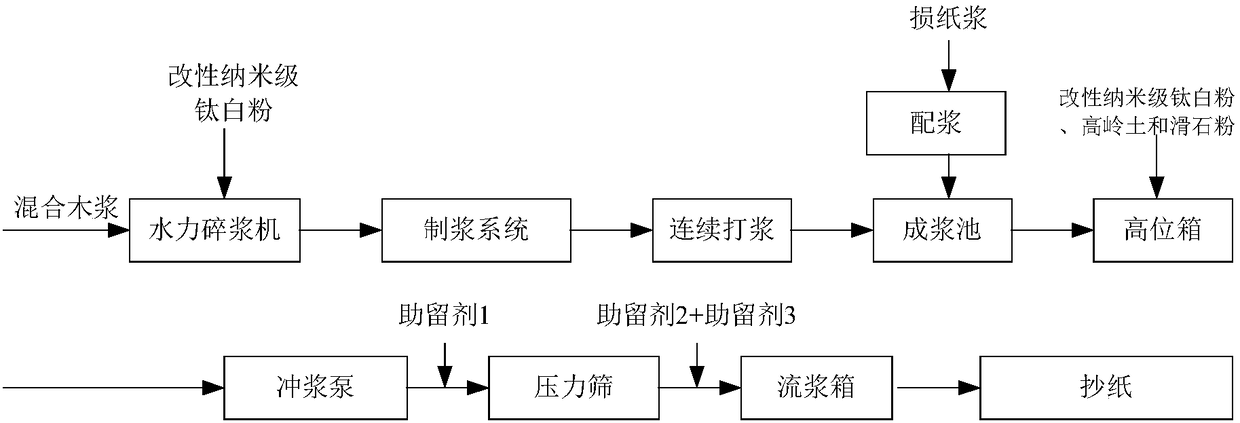

Process for producing printed decorative raw paper by using recycled waste paper

InactiveCN102174761AEmission reductionSolving Recycling ProblemsDefoamers additionPaper recyclingSocial benefitsPulp and paper industry

The invention relates to a process for producing printed decorative raw paper by using recycled waste paper. The process comprises the steps of waste paper treating, pulping, defibrinating, pulp preparing and papermaking, wherein the step of waste paper treating comprises the steps of mixing 80-90 wt% of waste paper and 10-20 wt% of chemical auxiliaries and then mixing with water at the temperature of 40-50 DEG C to prepare waste paper pulp with pH value being 8.0-9.0 and mass percent concentration being 6.0-8.0%; the step of pulping is characterized by mixing the waste paper pulp, wood pulp, kaolin, titanium dioxide, pigment and other raw materials with water to prepare pulp with a certain concentration; and the step of pulp preparing is characterized by adding a certain amount of a wet strength agent, a retention agent such as alum and an auxiliary to the defibrinated pulp to prepare pulp with a certain concentration. According to the invention, the treated waste paper and wood pulp are proportionally mixed to produce impregnated titanium oxide paper made from recycled waste paper; and all the quality indexes of the decorative raw paper can meet the requirements of the decorative raw paper; and the consumption and cost of the raw materials can be reduced and great economic and social benefits can be achieved.

Owner:杭州华旺新材料科技股份有限公司

Swollen starch-latex compositions for use in papermaking

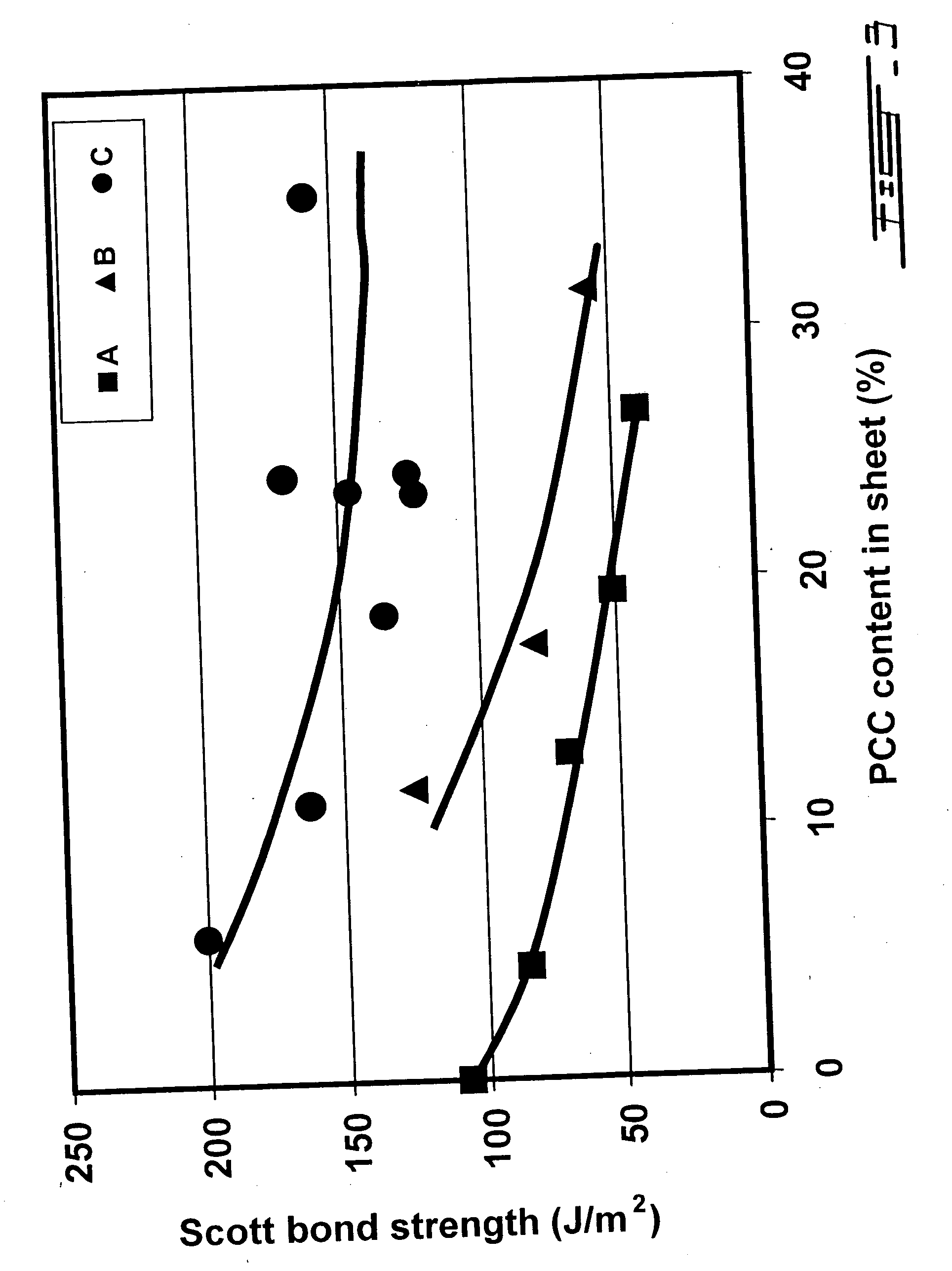

ActiveUS20050252629A1Improve filler retentionHigh retention rateNatural cellulose pulp/paperSpecial paperPapermakingPaperboard

A novel filler treatment comprising the preparation of swollen starch-latex compositions, prepared in the presence or absence of co-additives, and the addition of the said composition to a filler suspension, has been developed. Use of the treated filler during papermaking improves filler retention and produces filled papers where addition of the filler has only a minimal negative effect on strength properties. The swollen starch-latex compositions can be prepared in a batch or jet cooker, or by mixing with hot water under controlled conditions (i.e., temperature, pH, mixing, mixing time) in order to make the starch granules swell sufficiently to improve their properties as a filler additive but avoiding excess swelling leading to their rupture. The swollen starch-latex composition is then rapidly mixed with the filler slurry, preferably in a static mixer, and added to the papermaking furnish at a point prior to the headbox of the paper machine. The starch-latex composition can be used with wood-free or wood-containing furnishes. The treated filler is easily retained in the web during papermaking, improves drainage, and gives sheets having good formation. Sheets made with the treated fillers have higher bonding and tensile strengths than sheets produced using filler treated with either swollen starch alone or latex alone. Retention and drainage are further improved when conventional retention aid chemicals are added to the furnish containing the treated filler. The use of swollen starch-latex compositions could allow the papermaker to increase the filler content of the paper without sacrificing dry strength properties or increasing the amount, and hence the cost, of the retention aid added. The combination of swollen starch and latex could be used as furnish additives in the manufacture of both filled grades and grades that contain no filler such as sack papers and paperboard products.

Owner:FPINNOVATIONS INC

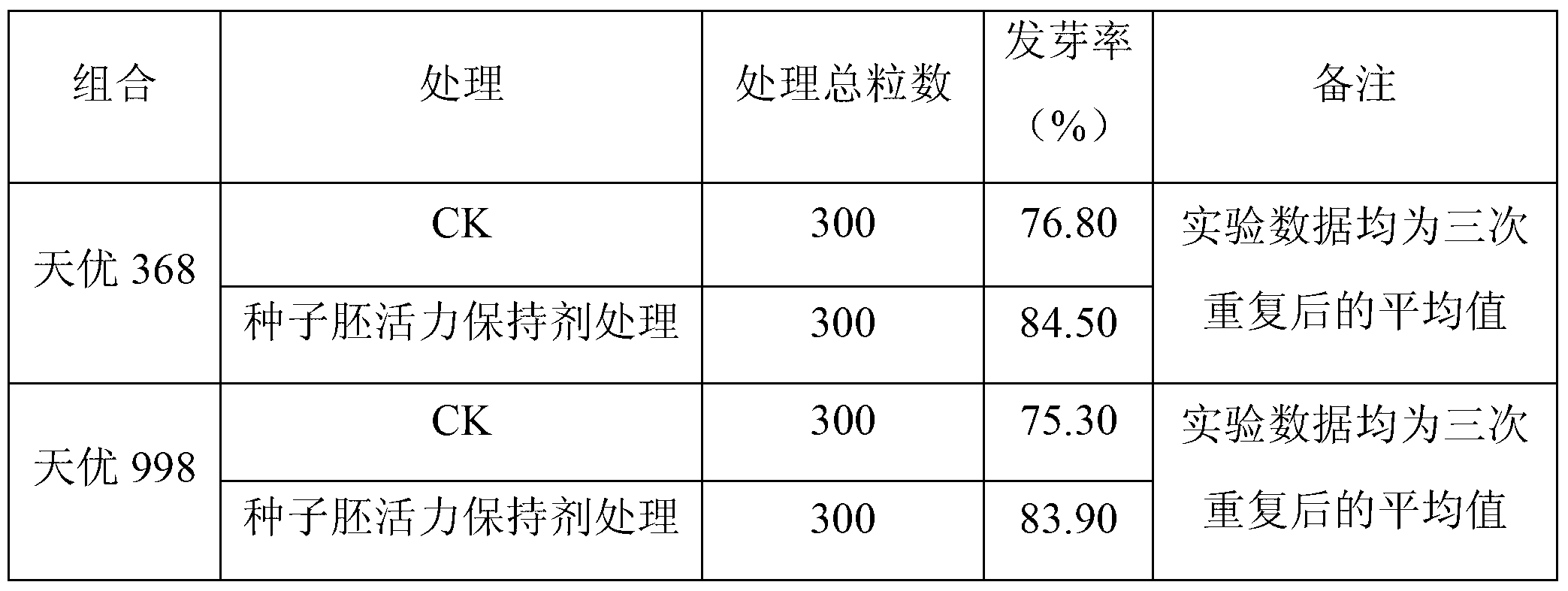

Natural plant extract rice seed embryo vigor retention agent as well as preparation method and application thereof

ActiveCN103250695AImprove the bactericidal effectReasonable formulaDead plant preservationYerba santa extractEmbryo

The invention belongs to the field of a rice seed embryo vigor retention technology, and discloses a natural plant extract rice seed embryo vigor retention agent as well as a preparation method and an application thereof. The rice seed embryo vigor retention agent comprises the following components by weight percent: 49.50-50.00% of a cany tea extract, 25.10-25.50% of a tea extract, 24.50-25.00% of a mulberry leaf extract, 0.15-0.20% of pericarpium citri reticulatae essential oil and 0.20-0.25% of clove essential oil. The natural plant extract rice seed embryo vigor retention agent is reasonable in formulation, fully utilizes the characteristics of all the components, and the components can be reasonably combined and matched, so that the comprehensive bactericidal effect can be achieved; the experiments proves that the natural plant extract rice seed embryo vigor retention agent is very obvious in the sterilizing effect on rice seeds, and effectively inhibits the adverse effect of microbial activities on the seed vigor; the natural plant extract rice seed embryo vigor retention agent achieves the aims of being safe, environment-friendly, practical and effective in the aspect of maintaining the seed vigor; and the natural plant extract rice seed embryo vigor retention agent is easy to process and prepare and convenient to use, and an ideal medicine is provided for maintaining the seed vigor and prolonging the storage period.

Owner:广州辰轩农业科技有限公司

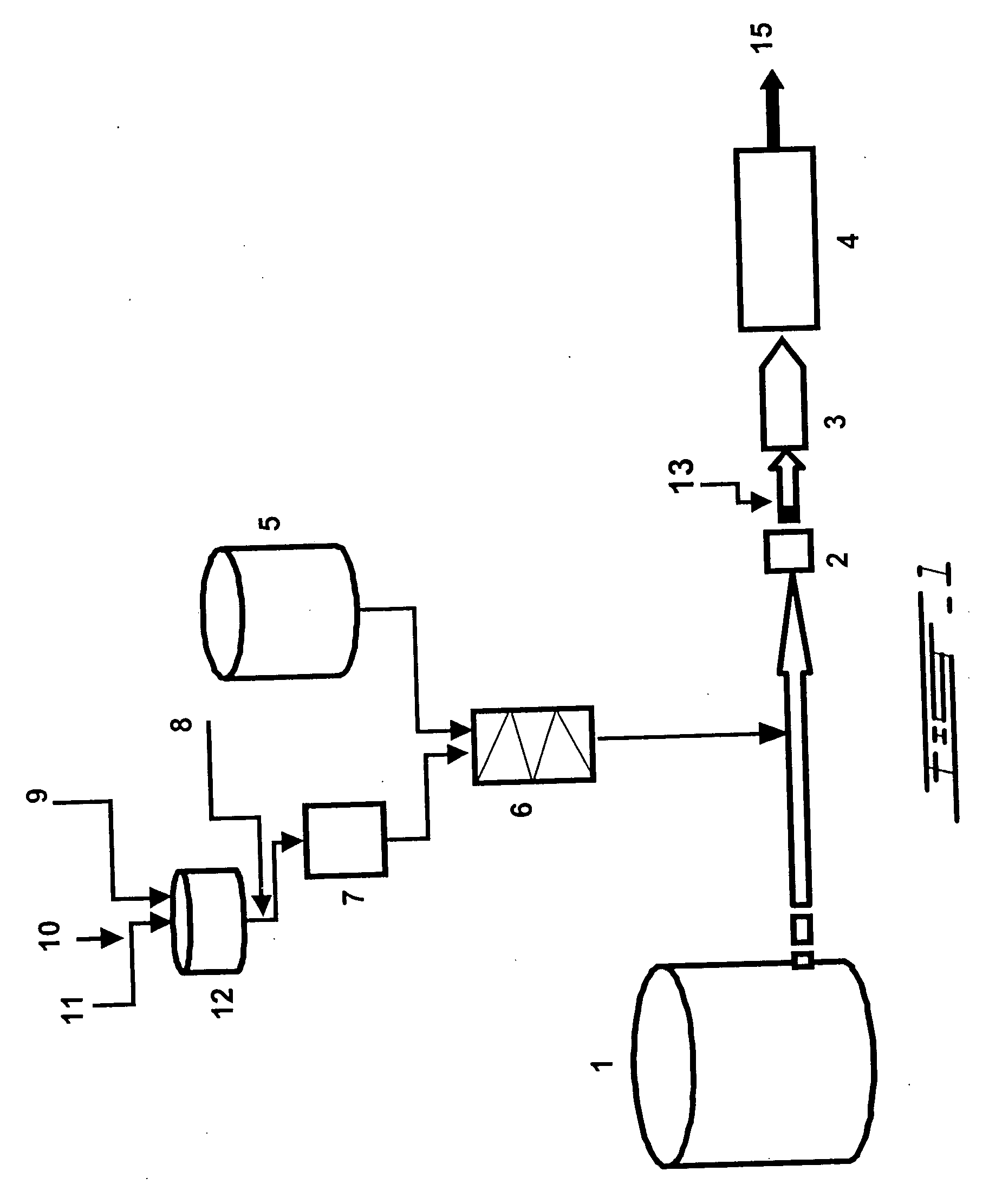

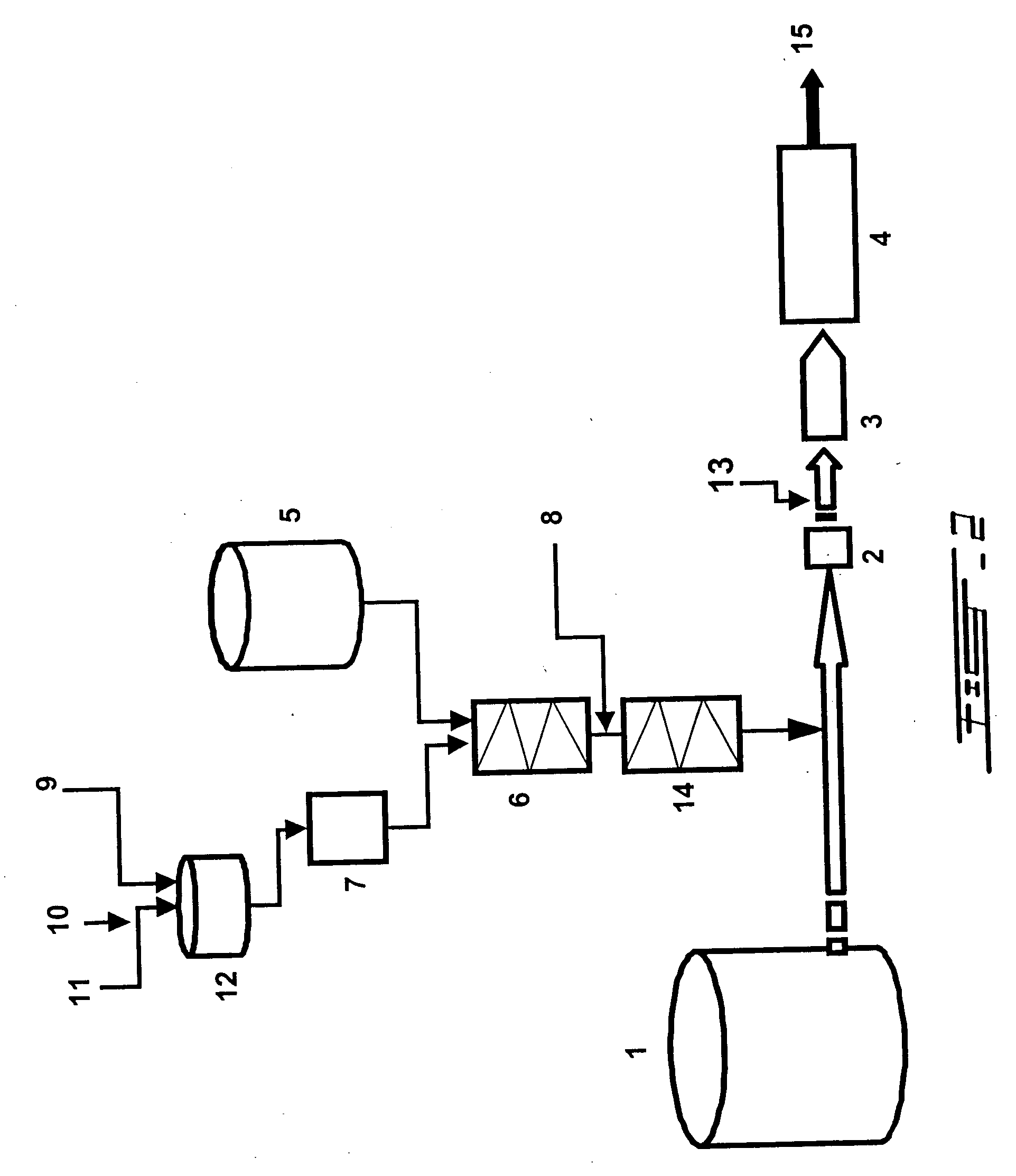

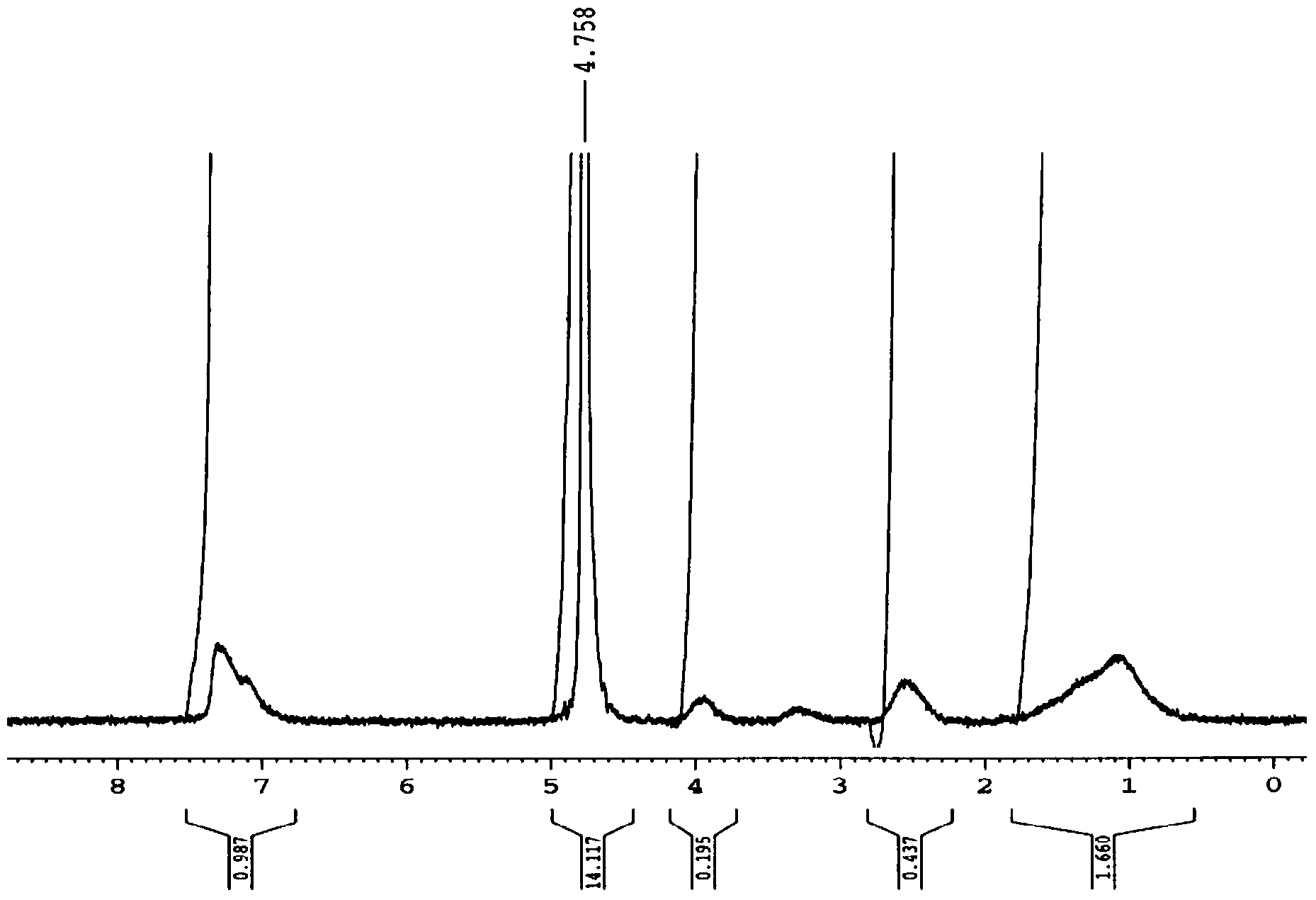

Preparation method and application of polymer retention filter aid containing phenylboronic acid functional group

ActiveCN103865060AImprove adsorption capacityIncrease productionRetention agents additionPhenylboronic acidFiber

The invention relates to a preparation method and application of a polymer retention filter aid containing a phenylboronic acid functional group and belongs to the technical field of papermaking. The preparation method is characterized by comprising the following steps of: mixing; carrying out coupling reaction; and separating to obtain the polymer retention filter aid containing the phenylboronic acid functional group. Compared with the existing general polymer retention filter aid, the retention filter aid applicable to the field of papermaking industry has the advantages that the retention effect is greatly improved, and the residual rate of fine filters and fillers in mother liquor can be greatly reduced under relatively small dosage; and with the use of the polymer retention filter aid, the load of papermaking wastewater treatment can also be effectively reduced.

Owner:LONGYOU COUNTY JINLONG PAPER

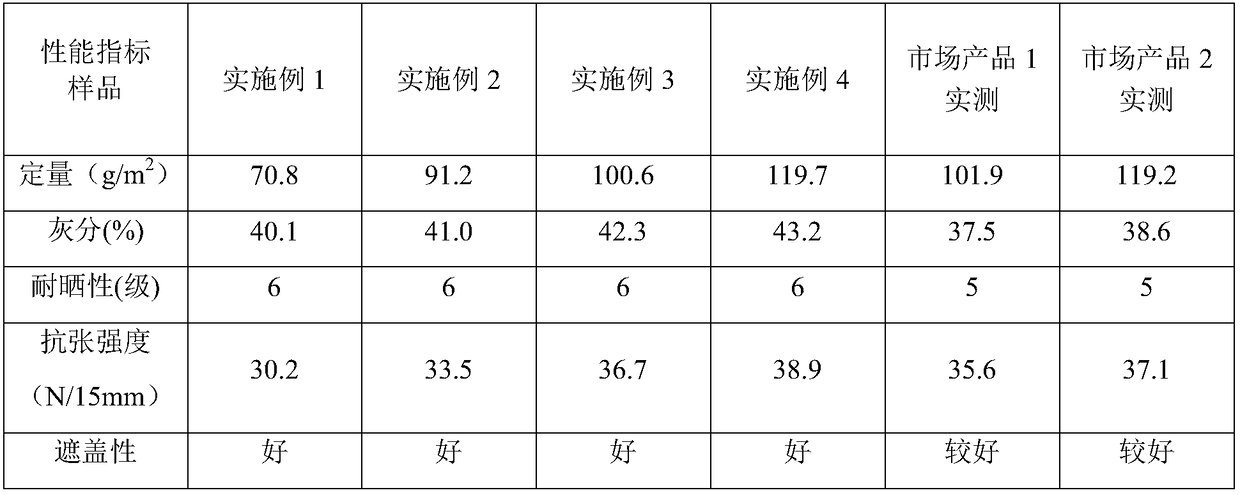

Special ecological board decoration base paper and preparation method thereof

ActiveCN108330720AImprove retentionEfficient mixingPulp beating methodsPaper recyclingSodium BentoniteSulfate

Owner:杭州华旺新材料科技股份有限公司

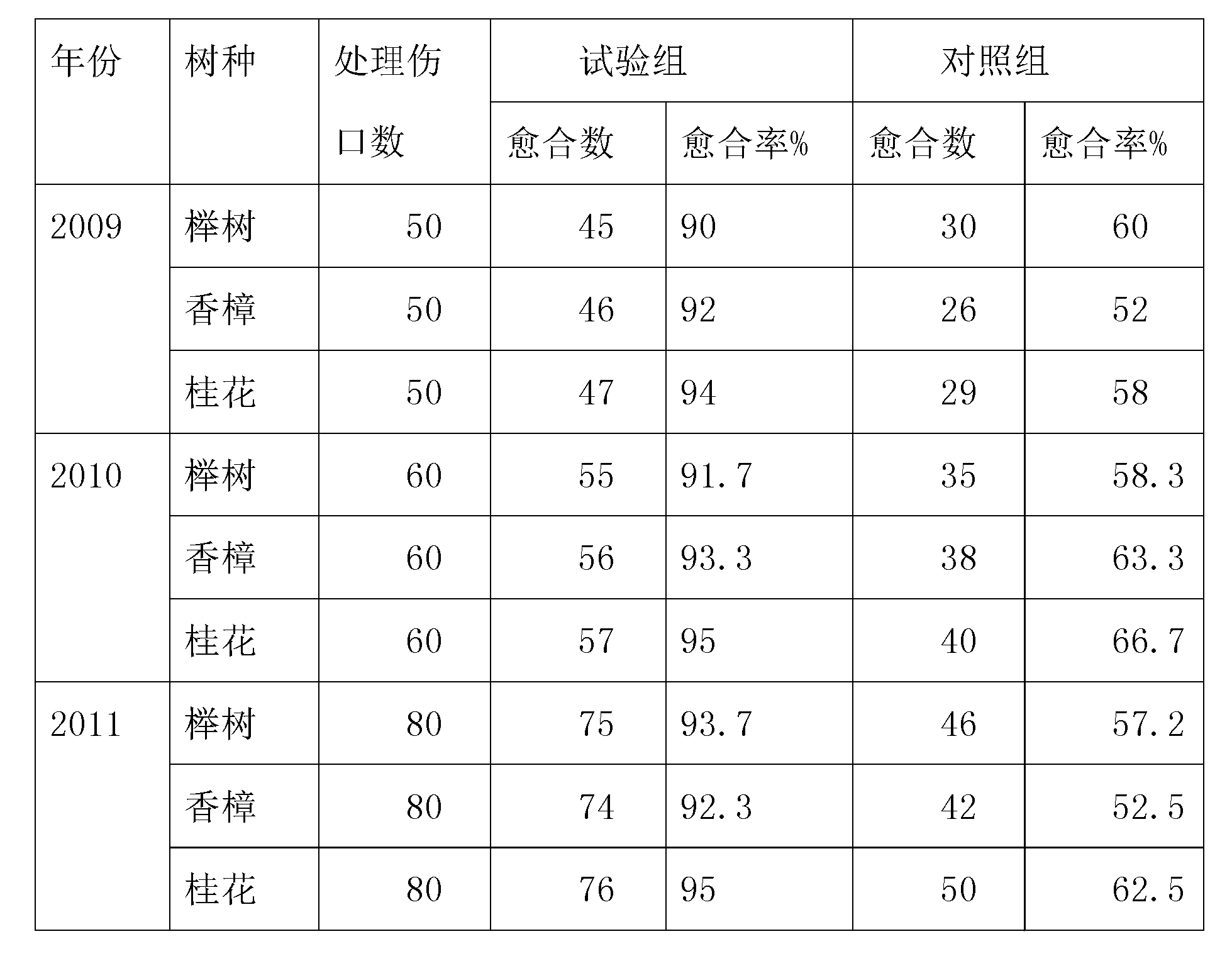

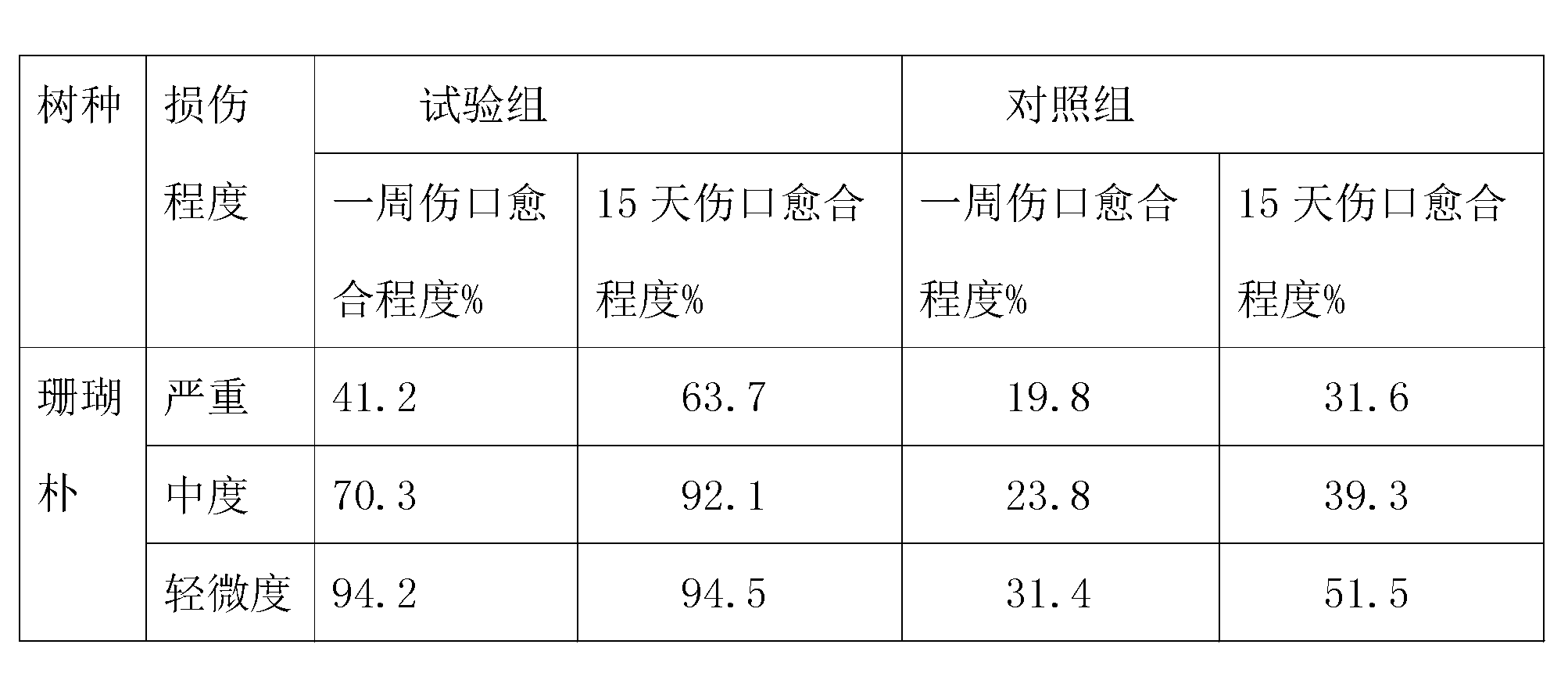

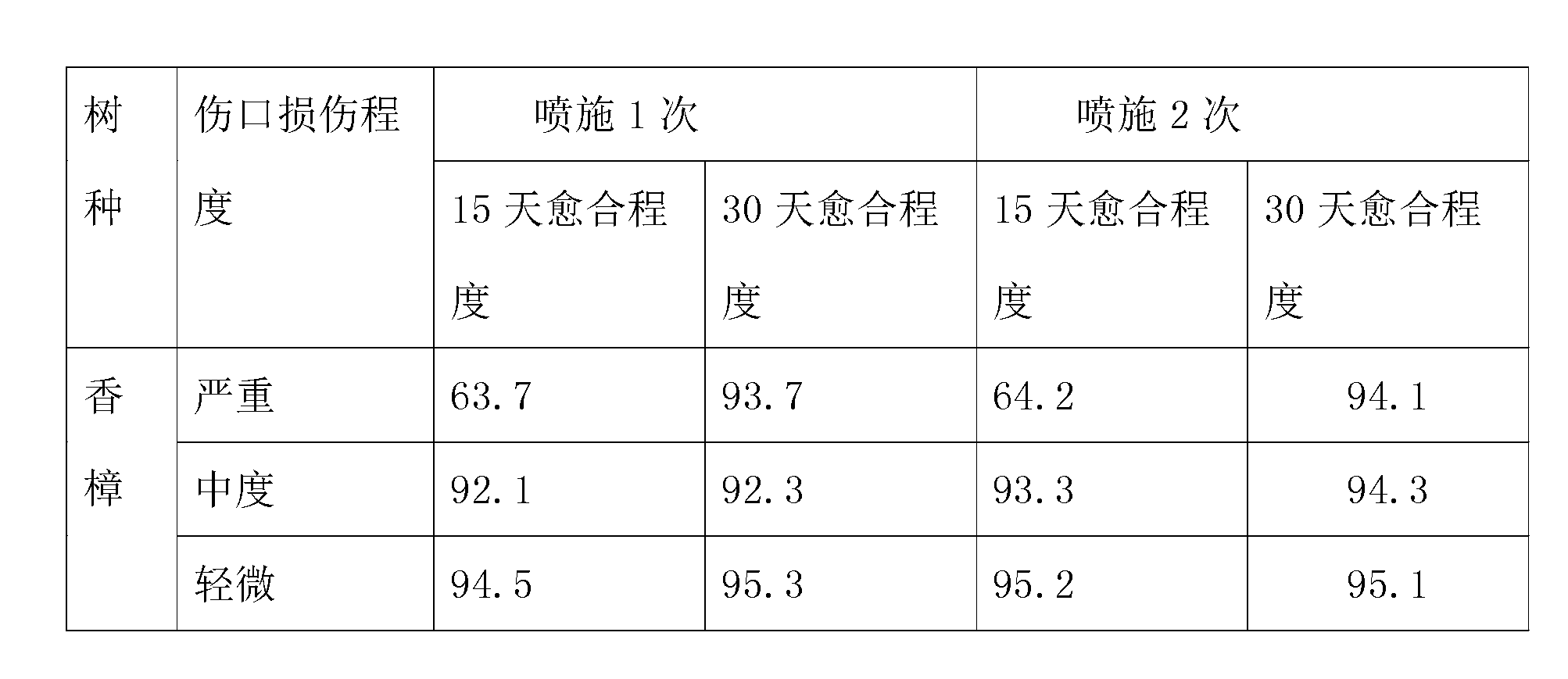

Wound restoration agent for damaged trees

ActiveCN103053615AQuick resultsSimple application processPlant growth regulatorsBiocideAdhesiveRetention agent

The invention relates to the field of protection and restoration of trees, and discloses a wound restoration and protection agent for damaged trees. The wound restoration and protection agent comprises the following components by weight portion: 10-30 portions of adhesive, 5-10 portions of bactericide, 10-20 portions of insecticide, 5 portions of wound healing agent and 20-30 portions of efficacy retention agent. The preparation method of the wound restoration and protection agent comprises the following steps: step1, respectively weighing the components according to the weight proportion, and uniformly mixing the insecticide, the bactericide and the wound healing agent; step2, adding the insecticide, the bactericide and the wound healing agent into the efficacy retention agent, and uniformly stirring; and step3, taking the adhesive, uniformly mixing the adhesive with the efficacy retention agent, and putting into a container. The wound restoration agent has a wide range of application, can be used for various damaged trees, quickly becomes effective, and has a simple application process.

Owner:杭州蓝天园林生态科技股份有限公司

Technique of manufacturing trifluoro acetic anhydride

InactiveCN101108797AWill not polluteProcess parameters are clear and completeCarboxylic acid anhydrides preparationAcetic anhydrideGas phase

A trifluoroacetic anhydride processing technique is provided, which utilizes the trifluoroacetic acid and the phosphorus pentoxide as raw materials. The material usage rate (weight) of the trifluoroacetic acid and the phosphorus pentoxide is 1 : 1.5 to 1 : 0.65 and the phosphorus pentoxide is added twice. The entire operation process is done in the fully sealed state, the high boiling substance (after cut) and the tail gas are treated and recycled after collecting the finished products; the condensing water and the cooling water are water from deep well and the byproduct phosphoric acid are all recycled. The invention prepares the trifluoroacetic anhydride applied in the highly efficient liquid chromatogram and the derivating agent of the gas chromatogram, the solvent, catalyst, the condensation dehydration agent and the retention agent of various synthetic reaction, which has complete, canonical and reasonable process and convenient operation, therefore is suitable for industrial production, can effectively improve the purity and the yield of the products, has no environment pollution and reduces the production cost.

Owner:申厚宝

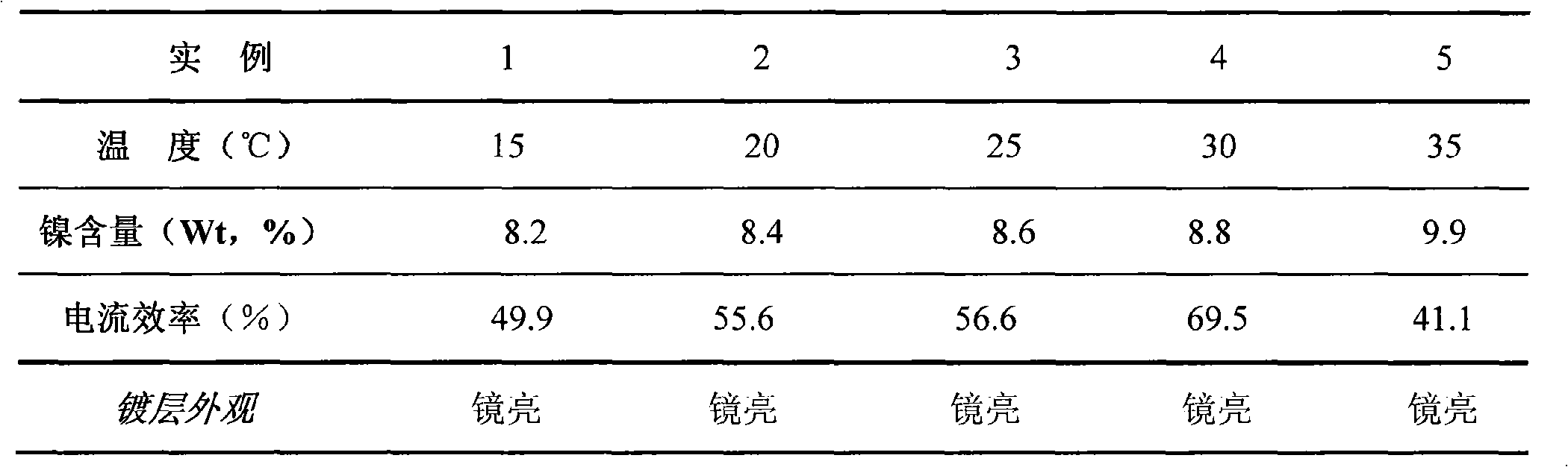

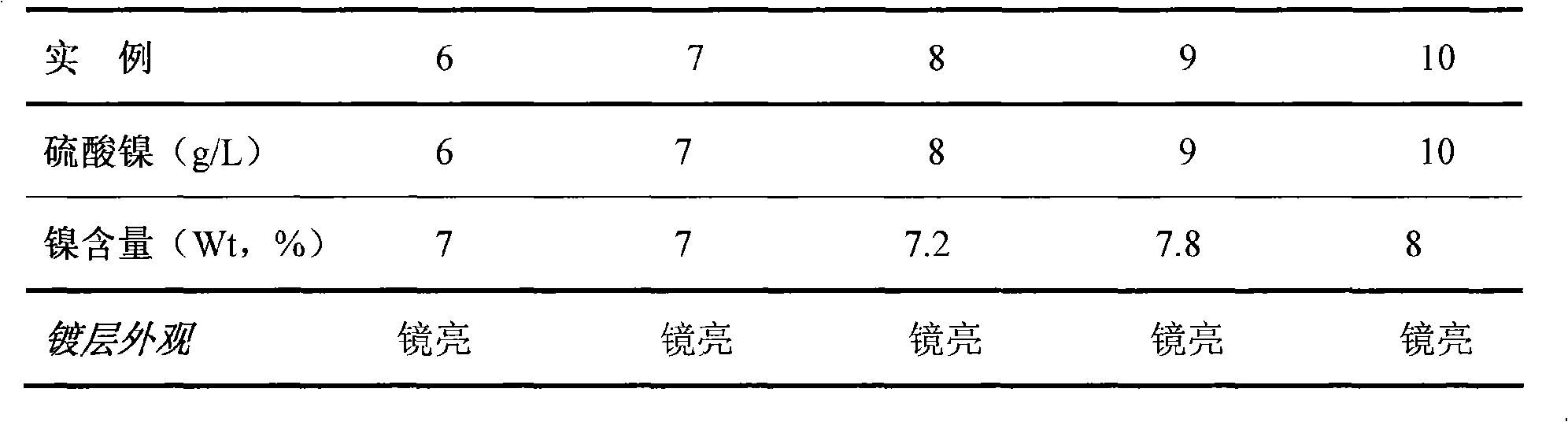

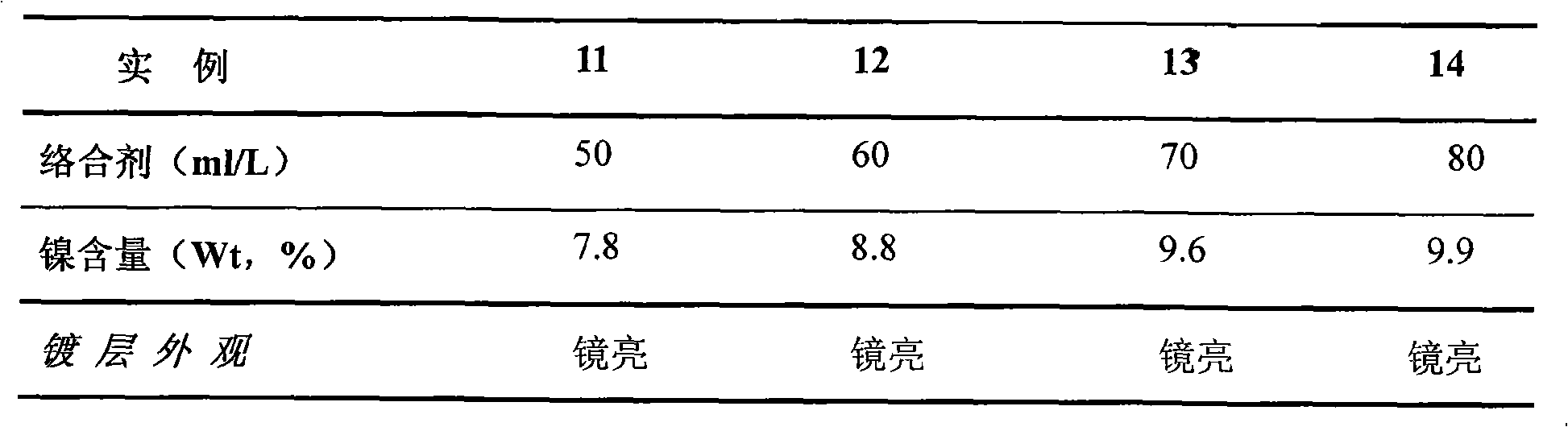

Plating process for low-nickel non-cyanogen alkalescent zinc-nickel alloy

The invention relates to a plating technology of alkaline zinc nickel alloy without cyanogen with low nickel content. The technology comprises the steps as follows: nickel retention agent is synthesized in the water medium through the reaction between divinyl triammonium and epoxy chloropropane in the temperature of 60 to 70 DEG C, wherein, the mol ratio between the divinyl triammonium and the epoxy chloropropane is 1:1; nickel composition is obtained after sufficient complexation between the nickel complexing agent and the nickel ions; the nickel composition is dissolved in alkaline zincate basic liquid, and then the mixed solution is mixed well; plating additive is added and then the mixed solution is mixed well; the plating is processed according to the plating technology demands. The plating technology has the beneficial effects that: the plating solution has excellent dispersive capacity; cladding alloying component is homogeneous in a wilder ampere density range; the thickness of a cladding layer is homogeneous; the equipment and the workpiece are corrupted slightly; the technology is steady, the operation is simple, and the cost is lower; a zinc plate or a nickel plate can be adopted as an anode; the plating technology has the advantages that the technology is stable, the dispersive capacity is good, the high temperature is endured and the nickel content is steady in the cladding layer, etc.; the industrial application is convenient.

Owner:杭州东方表面技术有限公司

Persimmon color retention agent and method for producing persimmon juice

InactiveCN105077202ADoes not affect nutritionDoes not affect flavorFood ingredient functionsFood preparationPectinaseFlavor

The invention relates to a persimmon color retention agent and a method for producing persimmon juice. The method comprises the following steps: cleaning persimmon fruits, and removing the peel and seed of the cleaned persimmon fruits for crushing; carrying out soaking with an aqueous solution I mixing cysteine, persimmon flavone, citric acid and NaCl; carrying out enzymolysis with an aqueous solution II mixing pectinase and tannase; carrying out natural clarification and filtration to obtain the persimmon juice. The method is simple, economical and practical; the impact of the whole process on the nutrition and flavor of persimmon is avoided; the persimmon juice can be prevented from browning, and the natural color and lustre (light red) of persimmon can be kept; the product stability and the juice yield are high.

Owner:HUANGGANG NORMAL UNIV

Super capacitor and preparation method thereof

ActiveCN106128788AAvoid churnEvenly dispersedHybrid capacitor electrodesHybrid/EDL manufactureFiberCapacitance

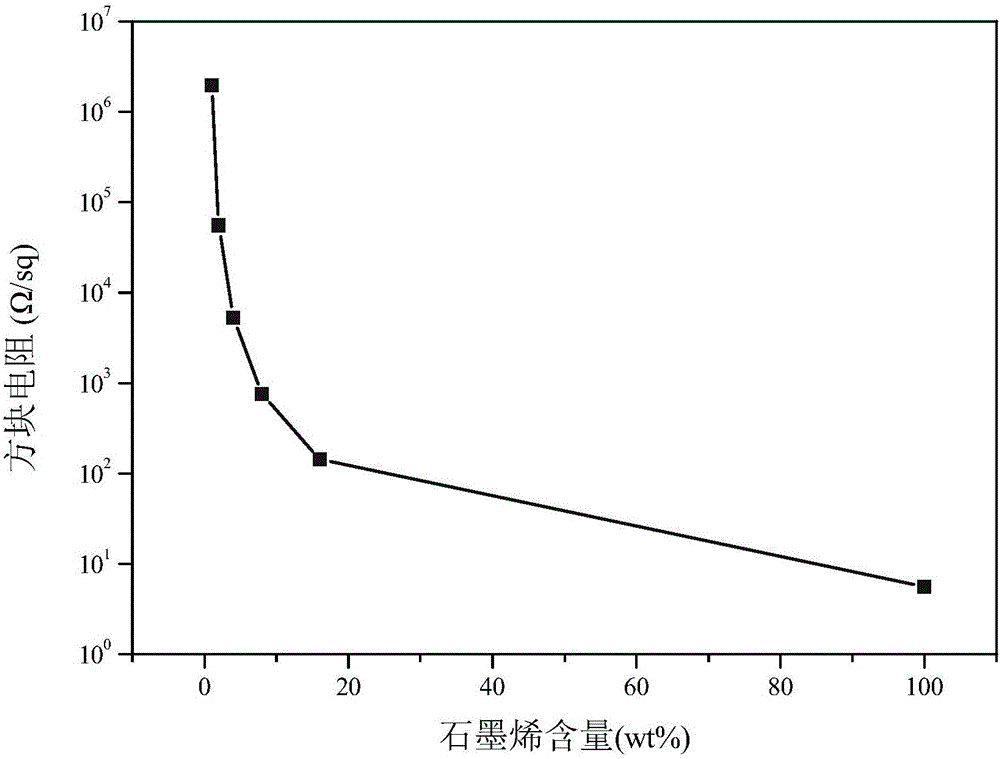

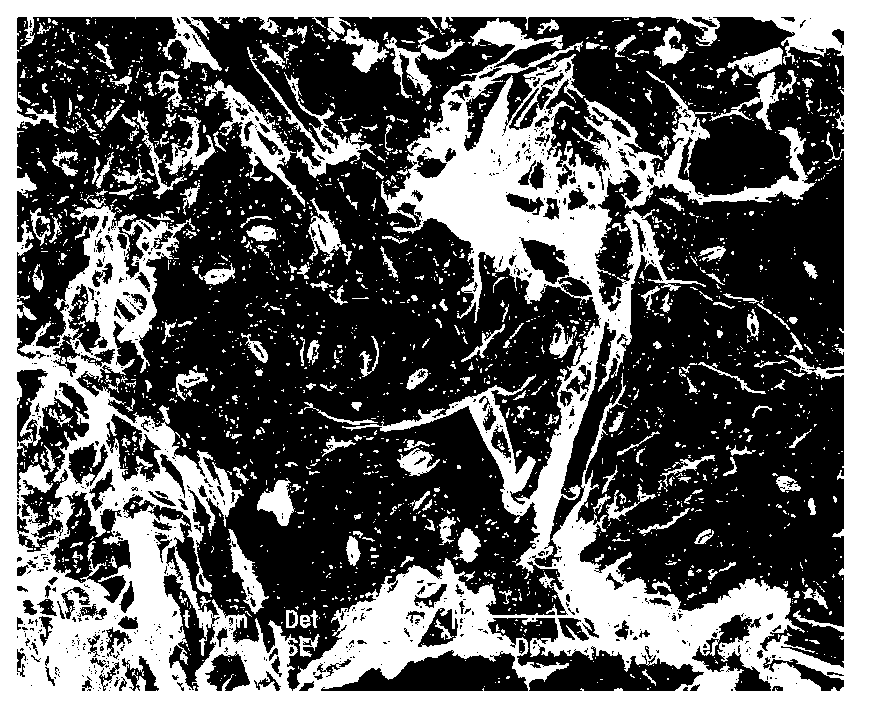

The invention belongs to the field of material science, and discloses a supercapacitor and a preparation method thereof, comprising the following steps: (1) adding a positively charged cationic retention aid aqueous solution into cellulose pulp and stirring to obtain a wrapped retention aid (2) mix the graphene oxide aqueous solution with the fiber mixed pulp wrapped with retention aid, and stir slowly to obtain graphene oxide cellulose mixed pulp; (3) mix the obtained mixed pulp manually Papermaking on the sheet machine, pressing and dehydrating to obtain graphene oxide / cellulose composite paper after drying; (4) adding a reducing agent to the obtained composite paper to reduce it into graphene / cellulose composite paper; (5) to the above-mentioned composite paper The paper is cut, attached to the current collector, electrolyte and separator are added for packaging and fixing, and assembled into a symmetrical supercapacitor. The preparation process of the invention is simple, and the prepared supercapacitor is light in weight and good in flexibility.

Owner:SOUTH CHINA UNIV OF TECH

Production process for reducing CO release amount of paper-making reconstituted tobacco and reconstituted tobacco

ActiveCN103005660AImprove physical structureIncrease ashTobacco preparationTobacco treatmentBiotechnologyProcess engineering

The invention relates to a production process for reducing the CO release amount of a paper-making reconstituted tobacco. The production process comprises the steps as follows: adding ground calcium carbonate (GCC) and a retention agent into tobacco slurry; carrying out sheet making to obtain a basic sheet of the reconstituted tobacco; coating a tobacco extraction solution onto the basic sheet; drying; and balancing water under the condition of constant temperature and humidity to obtain the reconstituted tobacco. According to the production process, by adding the GCC, the physical structure of the reconstituted tobacco can be improved, the retention rate of fillings can be increased, and the air permeability of the sheet can be improved, so that the CO release amount of the paper-making reconstituted tobacco can be greatly reduced, the content of tar and nicotine in smoke can be reduced at the same time, the ash content of the reconstituted tobacco can be increased, and the smoking quality can be also improved at the same time.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Green rice ball capable of keeping soft for long time without color change and preparation method thereof

InactiveCN104351640AOvercome blackening and hardeningNatural extract food ingredientsFood preparationColor changesGreen tea

The invention discloses a green rice ball capable of keeping soft for long time without color change and a preparation method thereof. The green rice ball comprises main materials and auxiliary materials, wherein the auxiliary materials contain additional function components; the function components comprise 0.15-3 parts of green-tea leaf and 0.05-1.5 parts of a color retention agent in parts by weight; the main materials contain the following components in parts by weight: 17.5-40 parts of glutinous rice flour and 5-8 parts of rice; and the auxiliary materials contain the following components in parts by weight: 1-10 parts of folium artemisiae argyi and 5-30 parts of drinking water. Therefore, the green rice ball and the preparation method have the advantage that the defect that the green rice ball easily becomes black and hard in the preparation process and later-period storage is overcome.

Owner:ZHEJIANG OCEAN UNIV

Method for raising color fastness and brilliance of plain-colored decorative base paper

The invention belongs to the field of a papermaking technology and specifically relates to a method for raising color fastness and brilliance of plain-colored decorative base paper. The method comprises the following steps: smashing softwood pulp and hardwood pulp into a pulp chest; selecting a pigment, diluting 10-15 times by adding water, filtering the pigment with a meshed of 100-200 meshes and putting the filtered pigment into a repulping tank, stirring for 5-10 min until the pigment is fully adhered to fiber; pumping stirred titanium dioxide into the repulping tank and stirring for 5-10 min, and grinding, wherein a fluffer and a double disc refiner are connected in series for grinding, the mode of cutting before defibering is adopted, and beating degree of grinding is 38-42 degrees SR; beating pulp into a filling tank for filling after grinding and successively filling PAE, a retention agent and an antifoaming agent; and finally adjusting concentration and pH value, and beating pulp into a machine chest to prepare for papermaking. By the method, use amount of the pigment is minimized, and production cost is reduced. Pigment cost accounts for a high proportion in dark plain-colored paper cost. Thus, the method is beneficial to cleaning of the meshed and coarse cotton cloth, and service life of the meshed and coarse cotton cloth is prolonged; the method is beneficial to treatment of sewage; and the processed plain-colored decorative base paper is bright in color and satisfies customers.

Owner:ZIBO OU MU SPECIAL PAPER

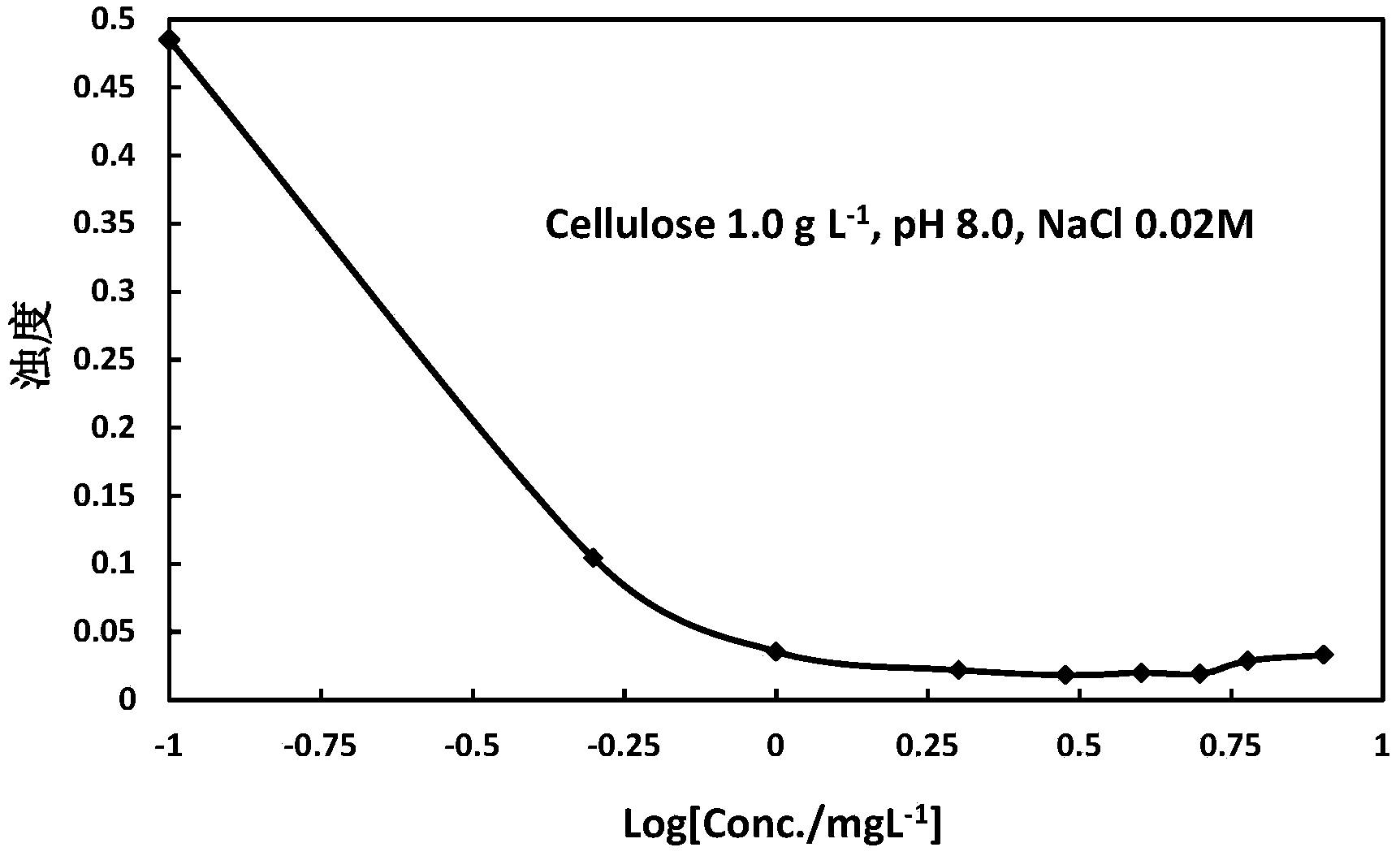

Low quantitative coating type food package raw paper, and preparation method thereof

The invention discloses a low quantitative coating type food package raw paper, and a preparation method thereof. The preparation method comprises following steps: firstly, cationic starch is added into a PCC suspension solution, uniform mixing is carried out, then gelatinization is carried out so as to form a partically-crosslinked gel substance, and normal temperature cooling and dispersion treatment are carried out so as to obtain a starch coated PCC filling material; bleached sulfate softwood pulp, and bleached sulfate hardwood pulp are subjected to mixing pulping, the starch coated PCC filling material, a wet strength agent, a sizing agent, and a retention agent are added, and concentration adjusting, slag removing, and sieving are carried out so as to obtain a slurry for wet loadingpaper making; the slurry is subjected to fourdrinier dehydration moulding and squeezing, and pre-drying; and at last, paper surface glue applying, soft calendaring, and rolling are carried out to obtain a finished product. According to the preparation method, no expensive titanium dioxide is adopted as a filling material, production cost is low, the retention rate of the filling material and finefiber is high, environment pollution caused by white water discharge is reduced, the obtained paper is uniform, full width tightness is constant, paper surfaces are flat and fine, surface strength andwet tensile strength are high, and water based coating quality requirements are satisfied.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com