Patents

Literature

92 results about "Co release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

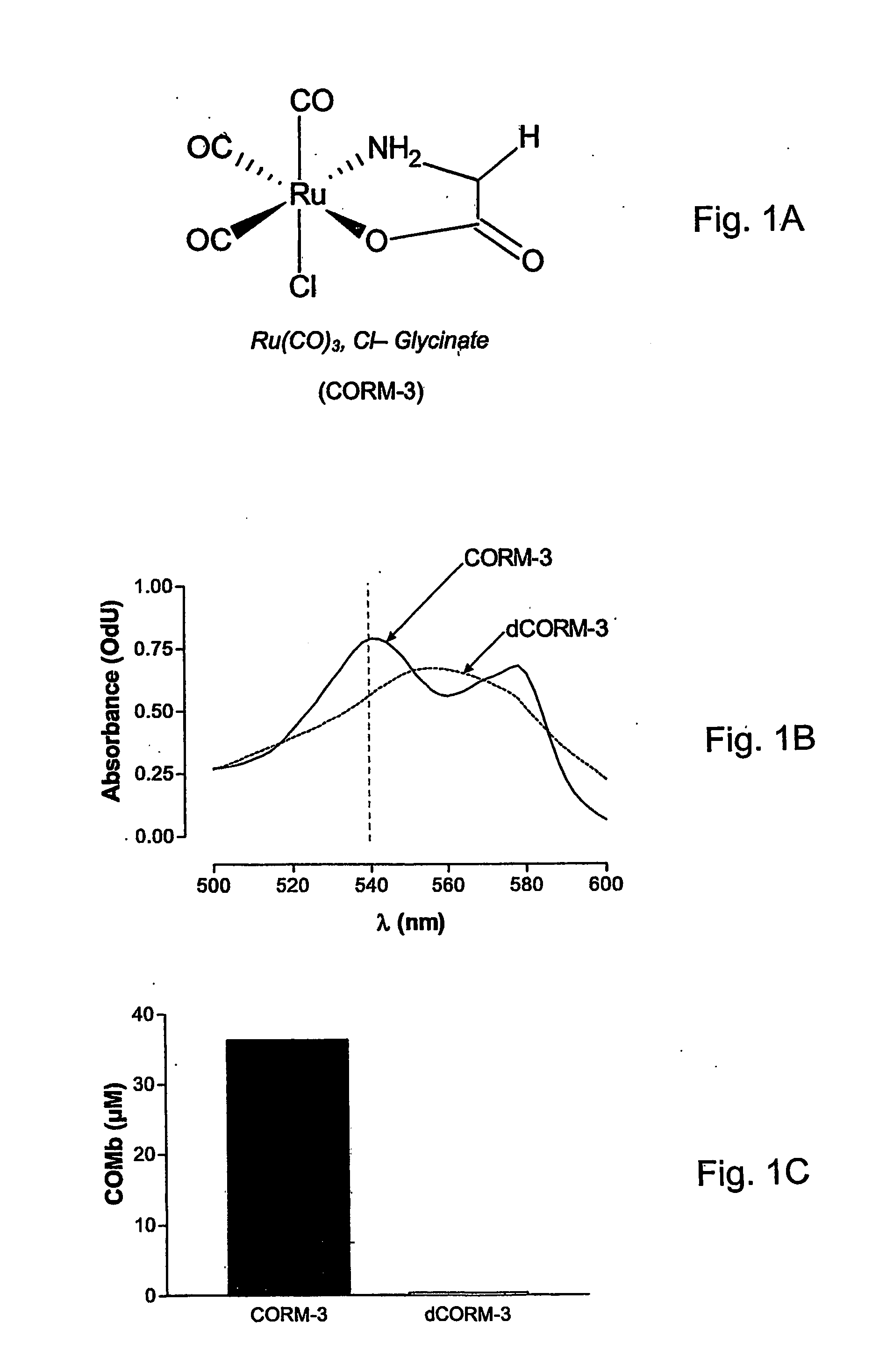

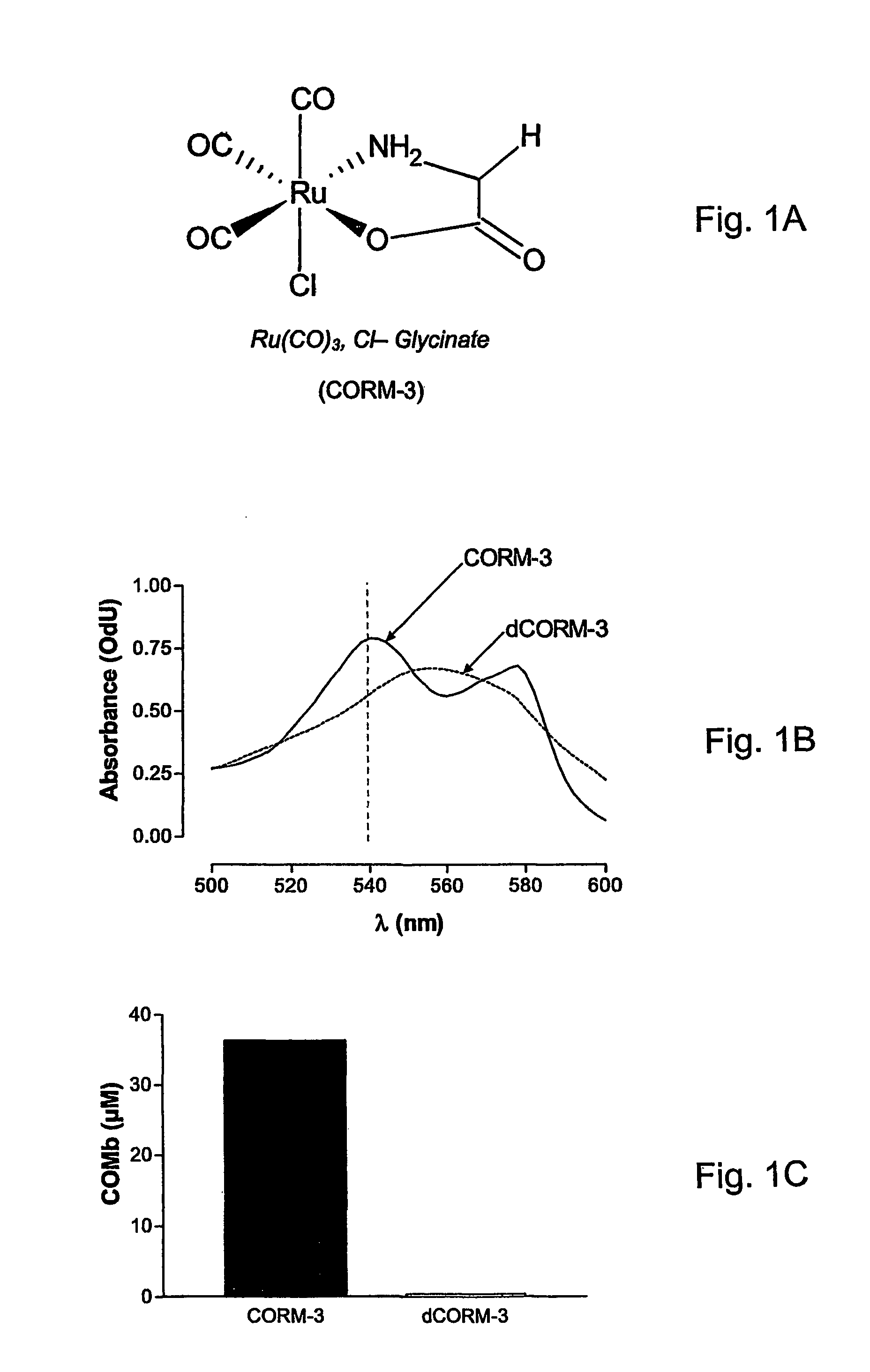

Therapeutic delivery of carbon monoxide

InactiveUS7045140B2Increase stimulationRegulate expressionOrganic active ingredientsPlatinum group organic compoundsSolubilityTransplant rejection

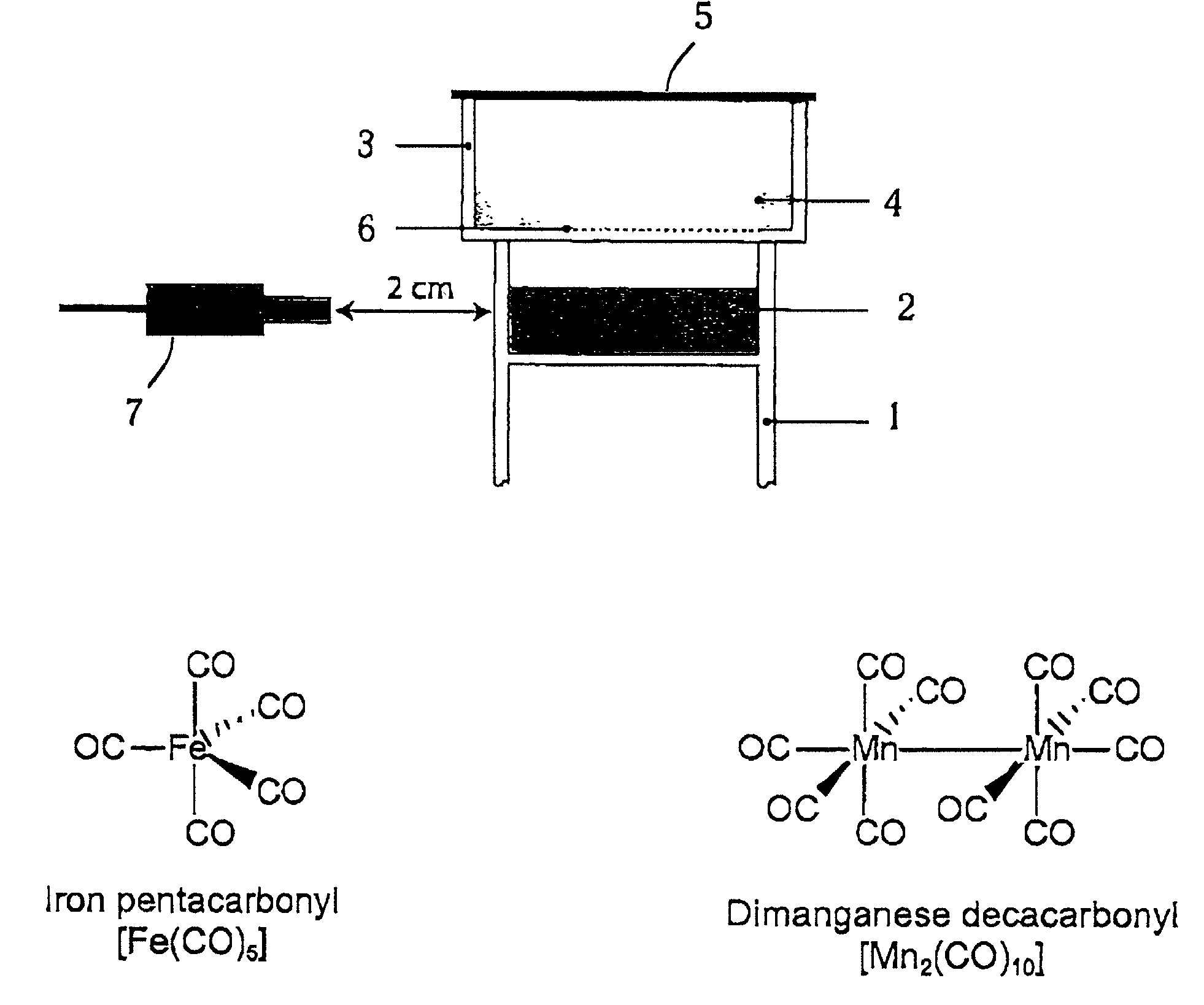

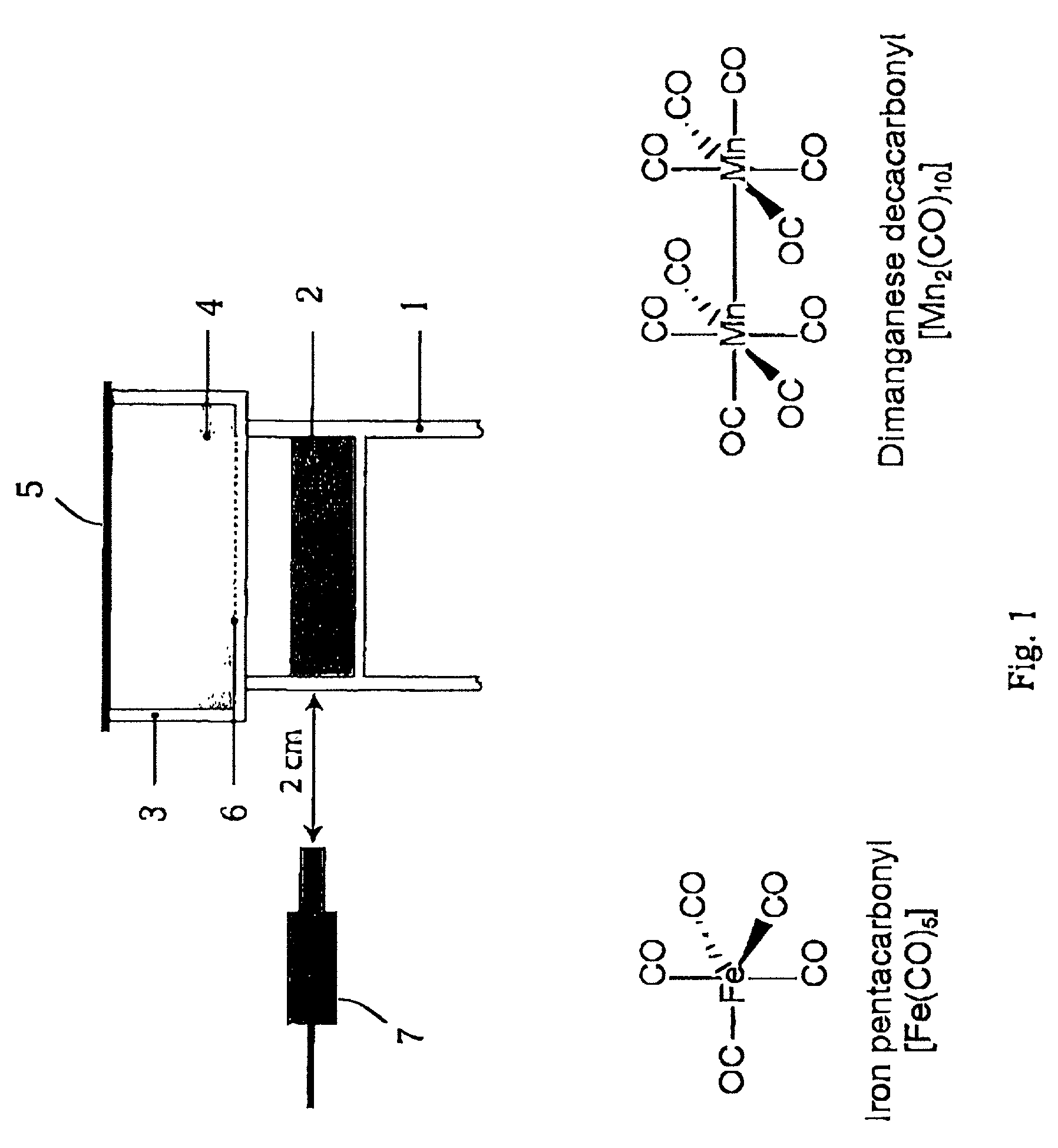

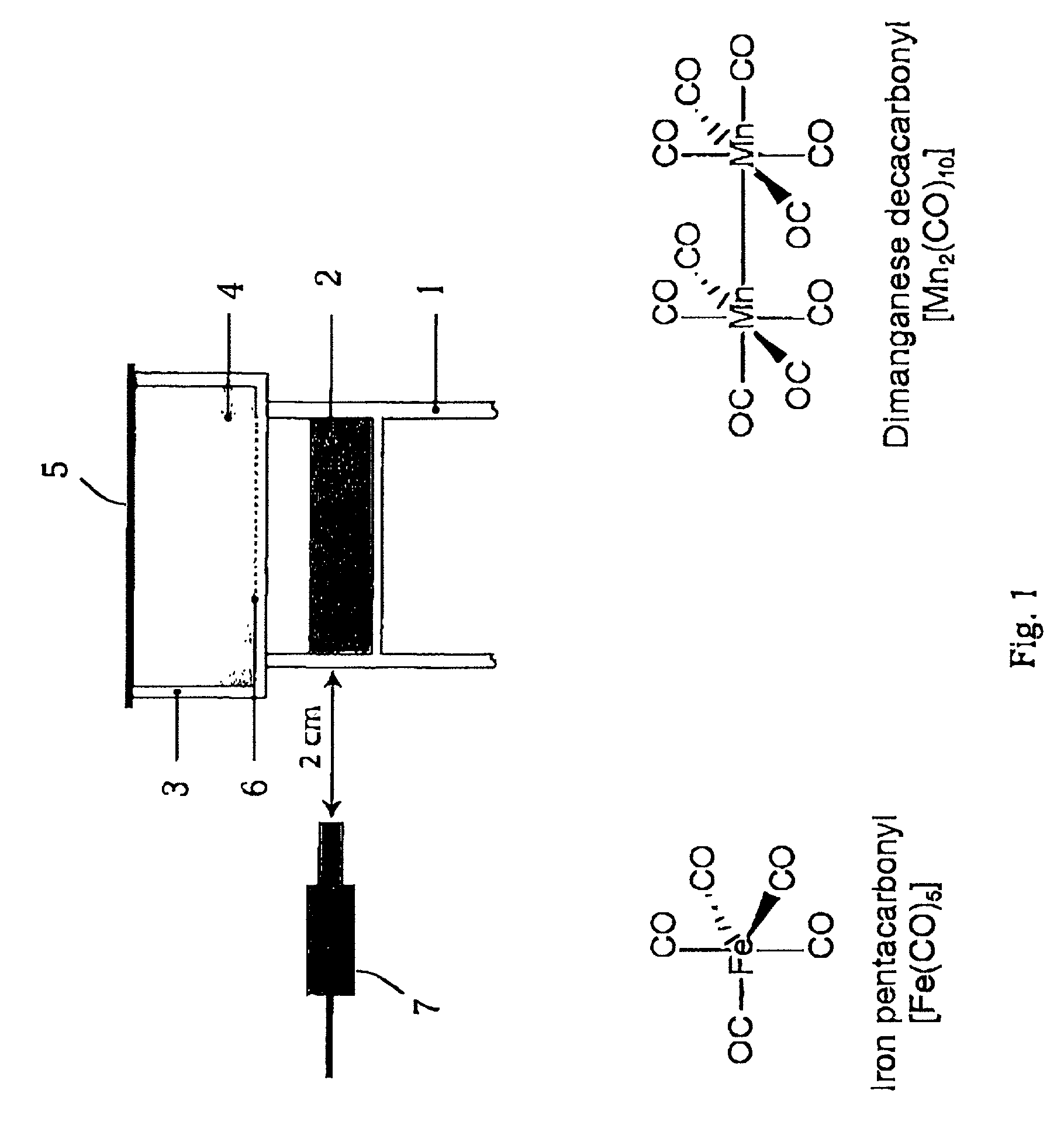

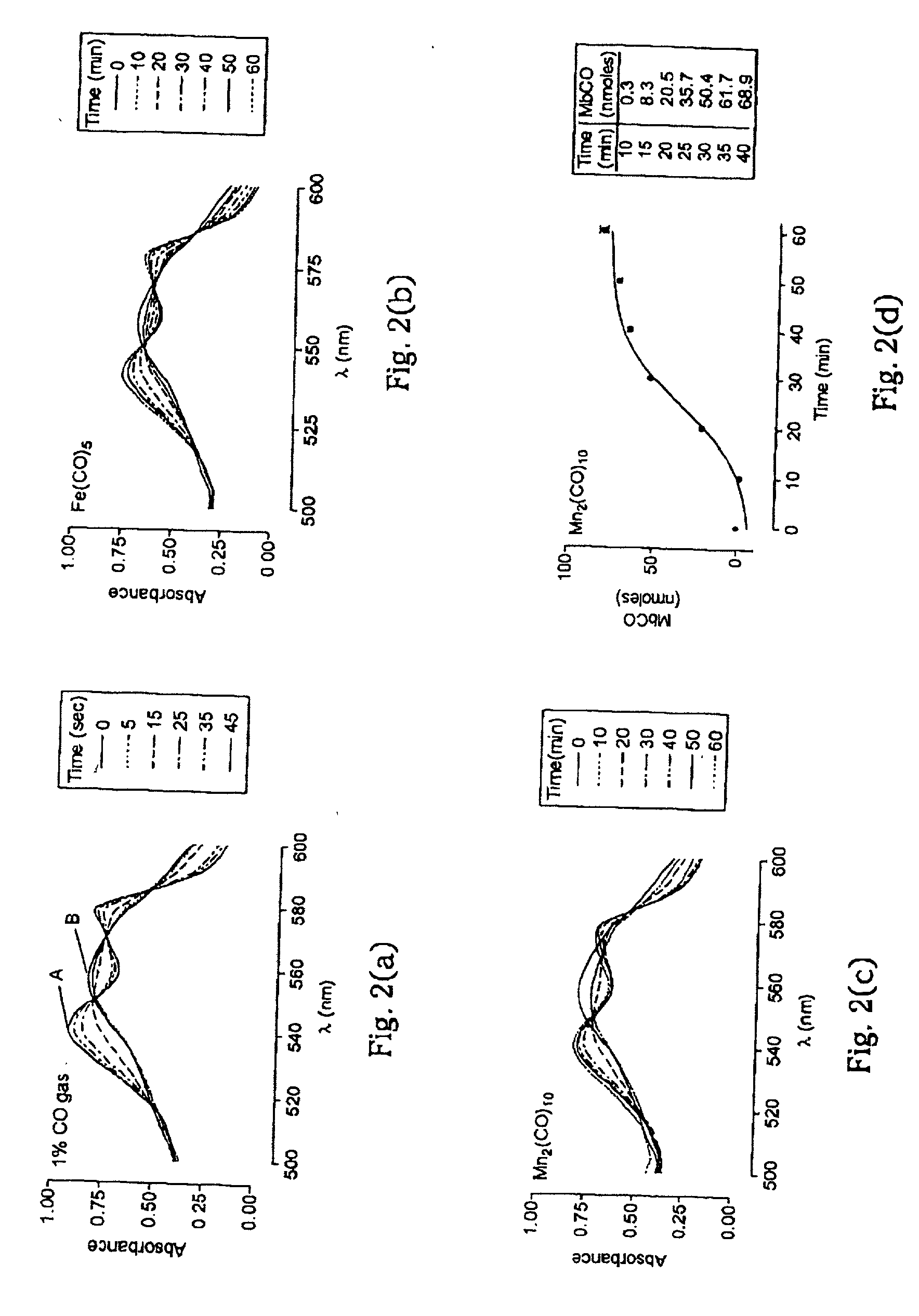

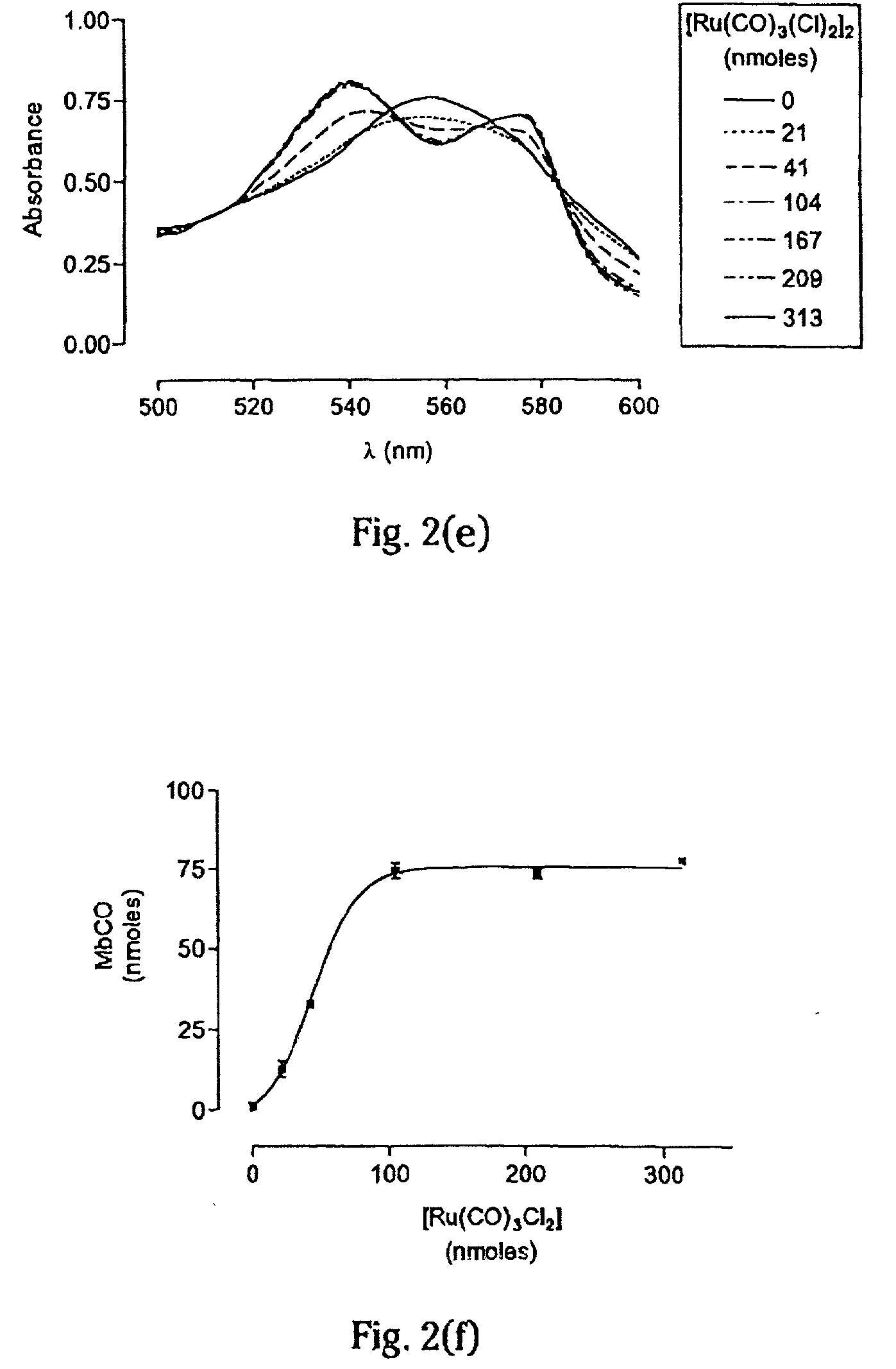

Metal carbonyls are used to deliver CO having biological activity, for example vasodilatation and inhibition of transplant rejection. The metal of the carbonyl is typically of groups 7 to 10, e.g. Fe and Ru. The carbonyl preferably has one or more ligands other than CO, such as amino acids, to modulate the CO release property and solubility.

Owner:HEMOCORM

Compositions and methods to improve the storage quality of packaged plants

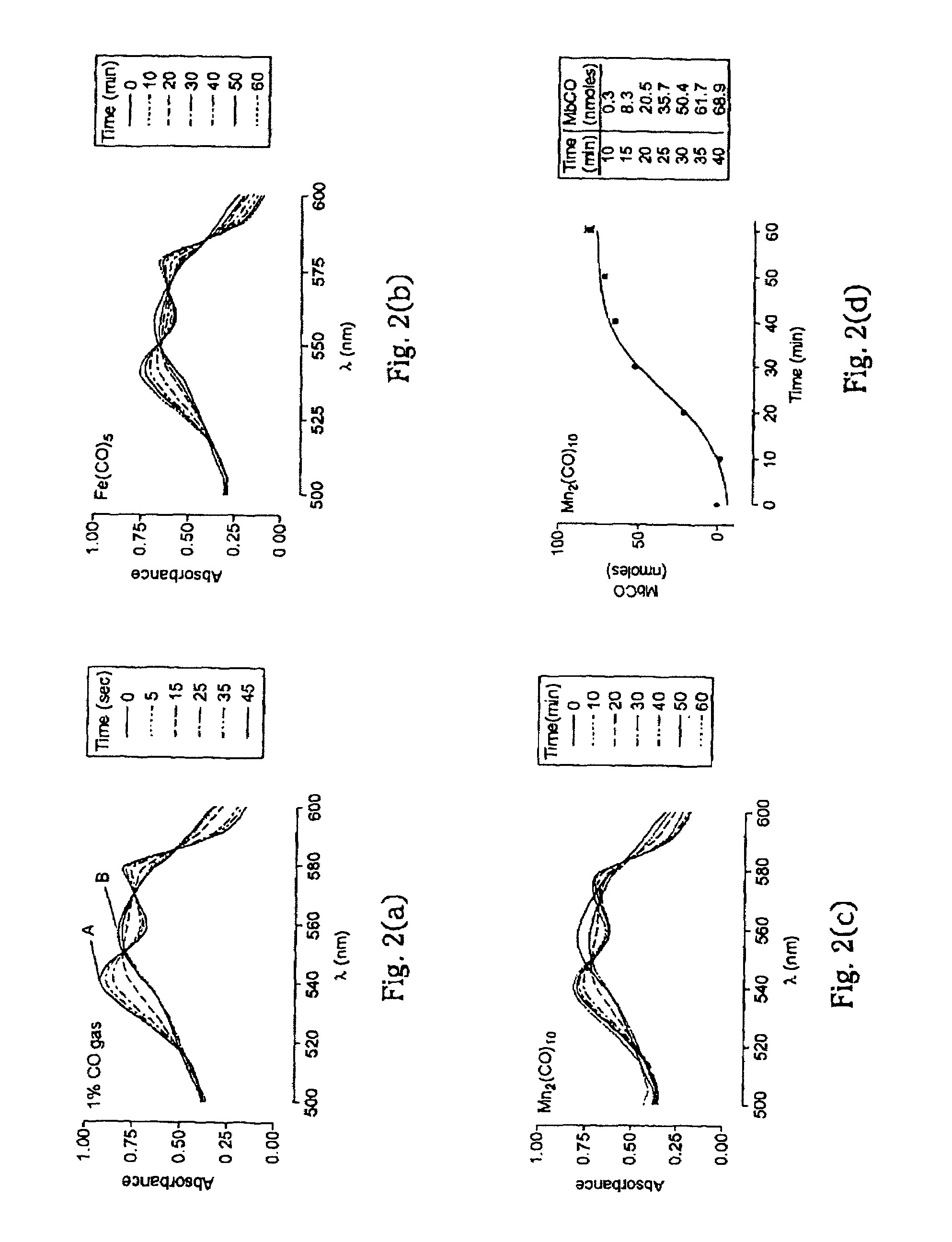

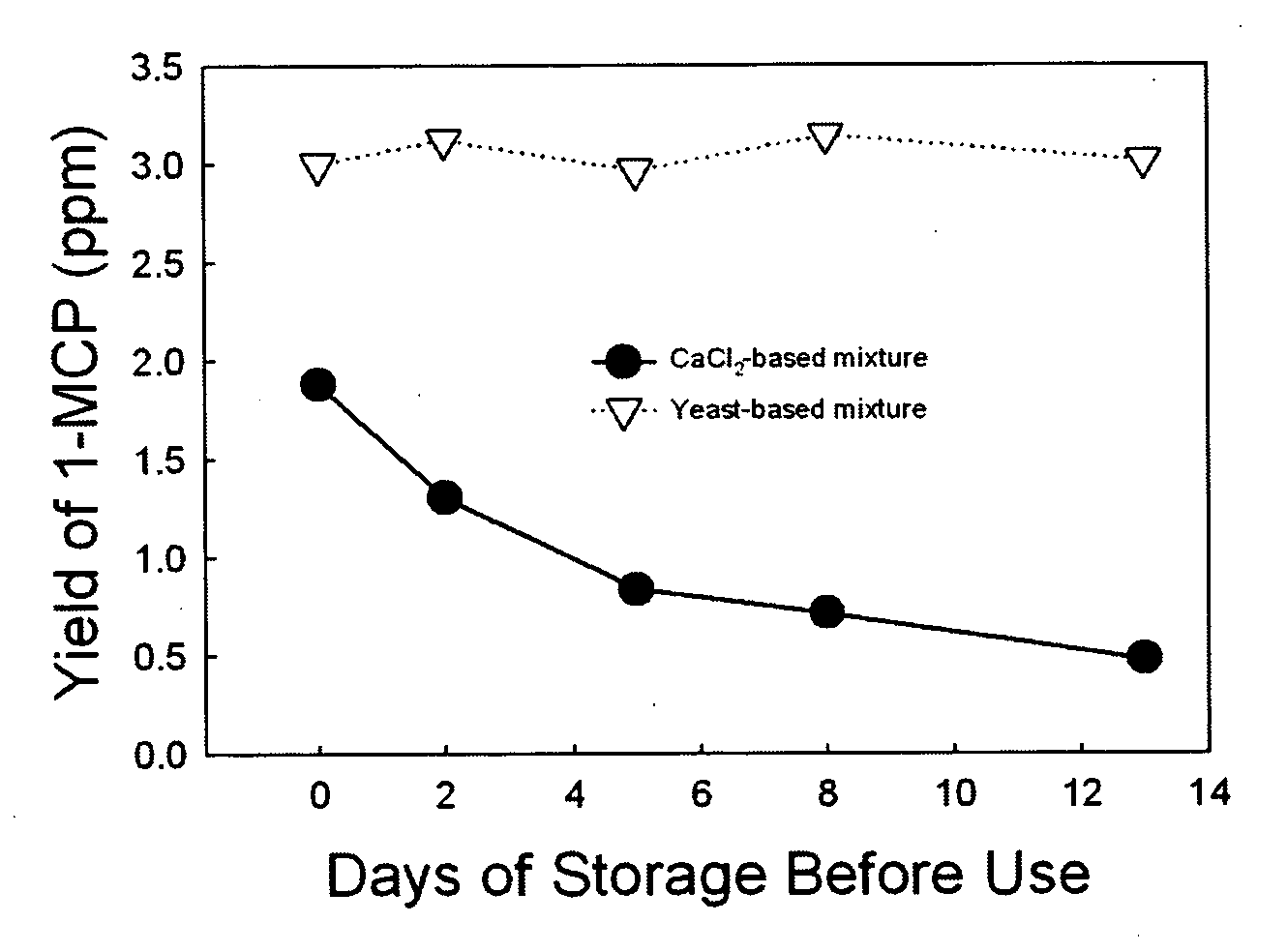

InactiveUS20060154822A1Increased shelf stabilityImprove publishing efficiencyBiocideDead animal preservationAlcoholCyclodextrin

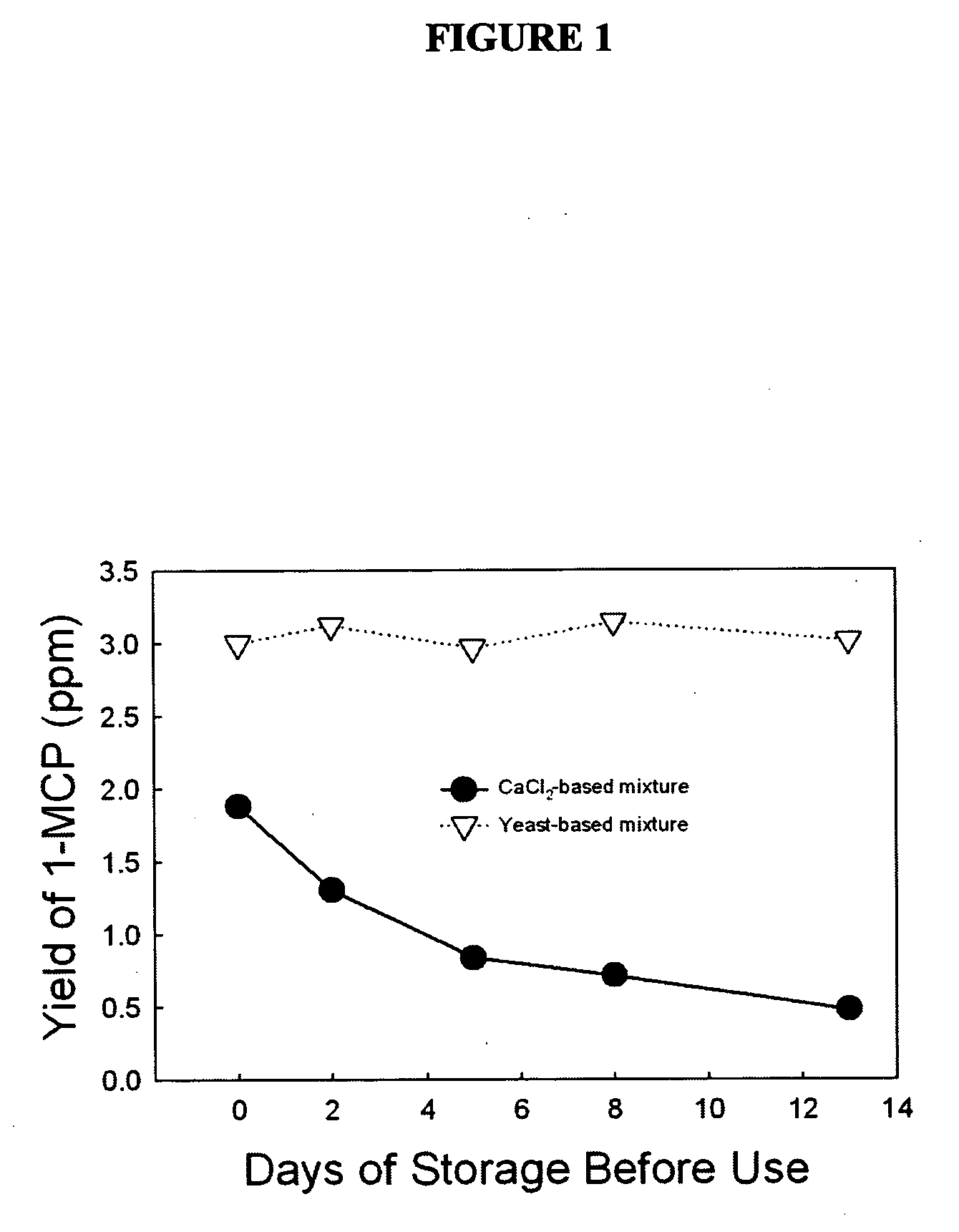

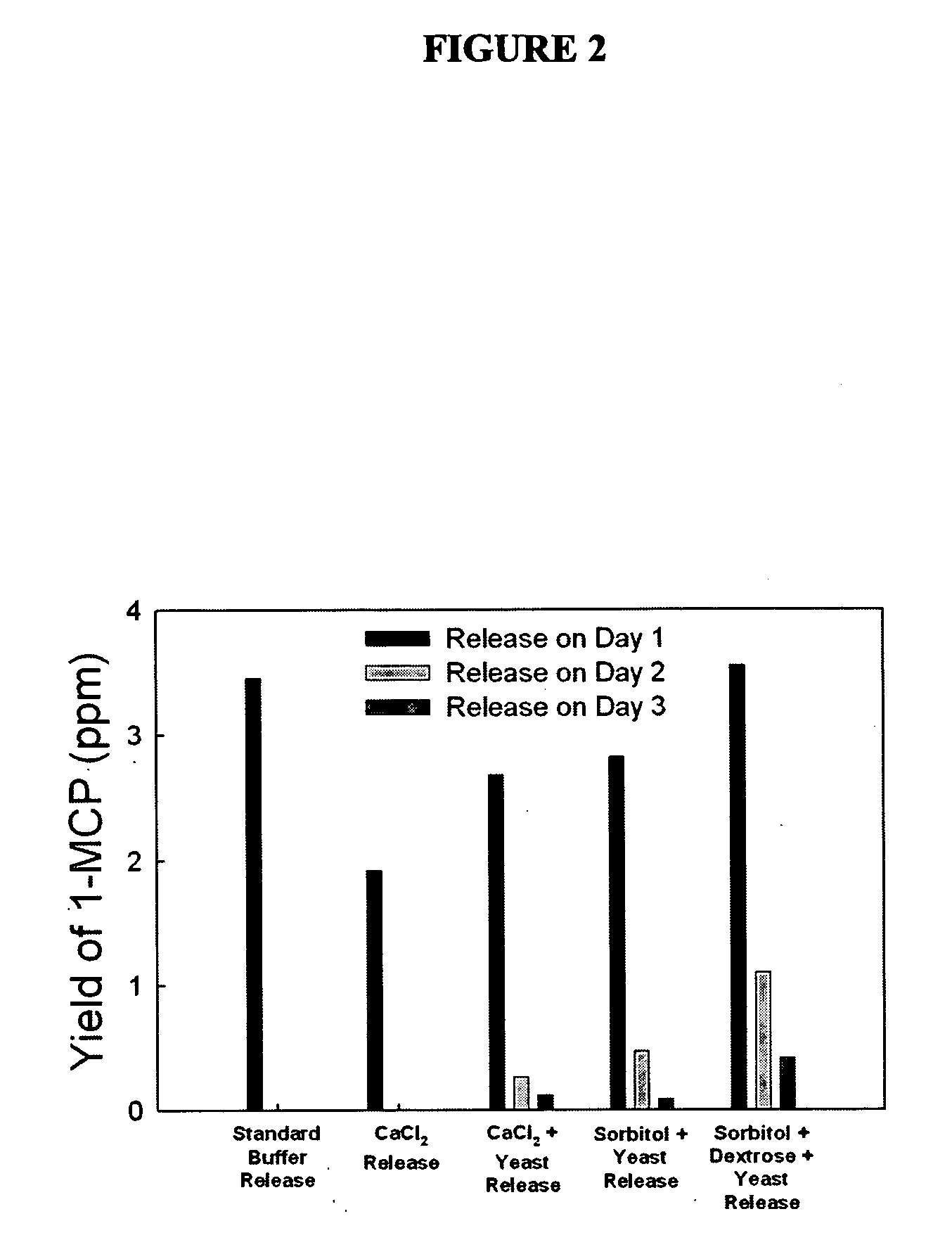

The present invention relates to a composition comprising a cyclopropene, for example 1-MCP, encapsulated in a cyclodextrin matrix, a hygroscopic compound, yeast and / or other enzymes involved in the production of alcohols and aldehydes from organic substrates, and, optionally an organic substrate for the enzymes. The composition of the present invention provides, under controlled conditions, the co-release of the cyclopropene, alcohols, aldehydes and carbon dioxide, which work together to improve the quality of plants during storage. Methods and commercial packages employing these compositions are also disclosed.

Owner:AGRI & AGRI FOOD

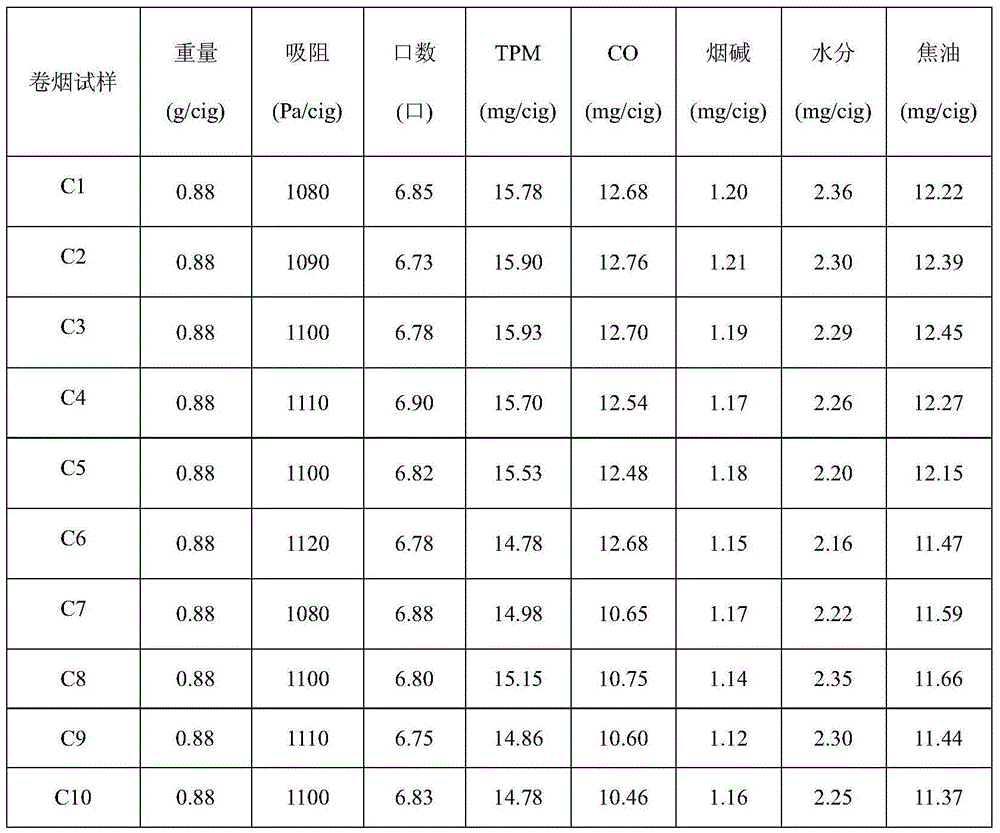

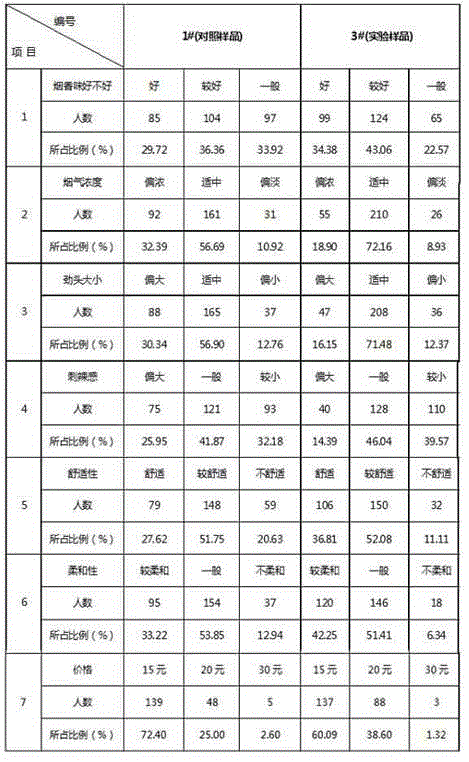

Method for improving cigarette soot whiteness

ActiveCN105725255AIncrease moisture contentUniform sizeTobacco preparationTobacco treatmentRolling paperPotassium

The invention provides a method for improving cigarette soot whiteness. Tobacco raw materials include mature tobacco with the potassium-chlorine ratio large than 4, and papermaking process reconstituted tobacco at least accounting for 5% of the tobacco raw materials. Finished product tobacco is obtained by conducting vacuum moisture regaining, loose moisture regaining, screening and casing, shredding, the leaf and tobacco temperature increase procedure before drying, the leaf and tobacco drying procedure, leaf and tobacco winnowing and perfuming. A collimator of the appropriate specification is selected to conduct cigarette rolling on finished product cut tobacco, and it is ensured that the density change rate of finished product tobacco distribution at the ends and in the middles of the cigarettes is smaller than 11.5%. By controlling the cigarette production process, finished product cut tobacco can have the appropriate moisture content, an appropriate filling value and appropriate elasticity, and the problem that the tobacco combustibility is poor is solved; by selecting cigarette rolling paper matched with cut tobacco and controlling relatively-low-weight cigarettes, combustion of smoked cut tobacco of cigarettes is more complete, the cigarette soot whiteness is obviously improved, and the tar release amount and the CO release amount are decreased.

Owner:CHINA TOBACCO HENAN IND

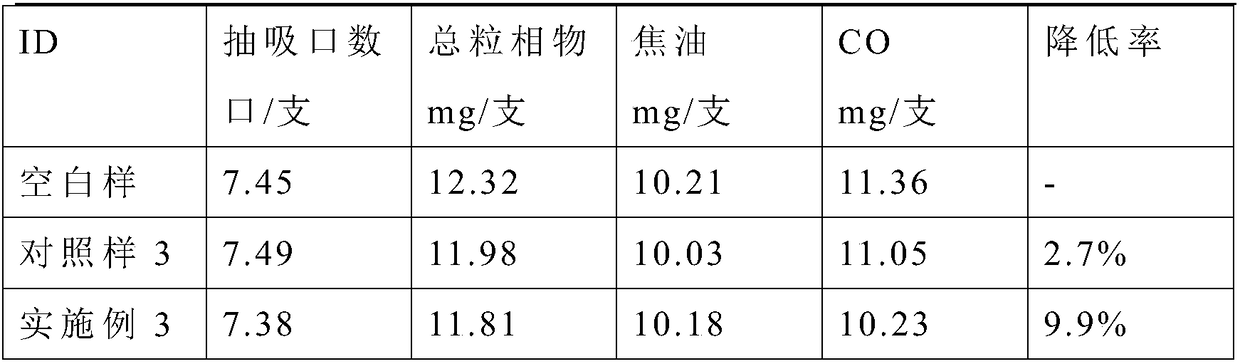

Catalyst for reducing CO release guantity in main flow smove of cigarette, its preparation method and application

InactiveCN1460548AReduce releaseReduce carbon monoxide emissionsTobacco smoke filtersDispersed particle separationNano sizeActive component

The general formula of the catalyst is Au(a) Pt(b) Pd(c) Ni(d) Co (e) Fe(f) Cu(g) Zn(h) Ti(i) O(j) / carrier, in which a is 0.05-3.0 wt%, b is 0.05-3.0 wt%, c is 0.05-3.0 wt%, d is 0.0-20.0 wt%, e is 0.0-45.0 wt%, f is 5.0-40.0 wt%, g is 3.0-30.0 wt%, h is 0.0-75.0 wt%, i is 0.0-70.0 wt% and j is the rest. The active components of the catalyst and adjuvant are distributed on the carrier in nano size. Said invention can be used in the cigarette, and can be used for reducing CO release amount in the main flow smoke by 20-45%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

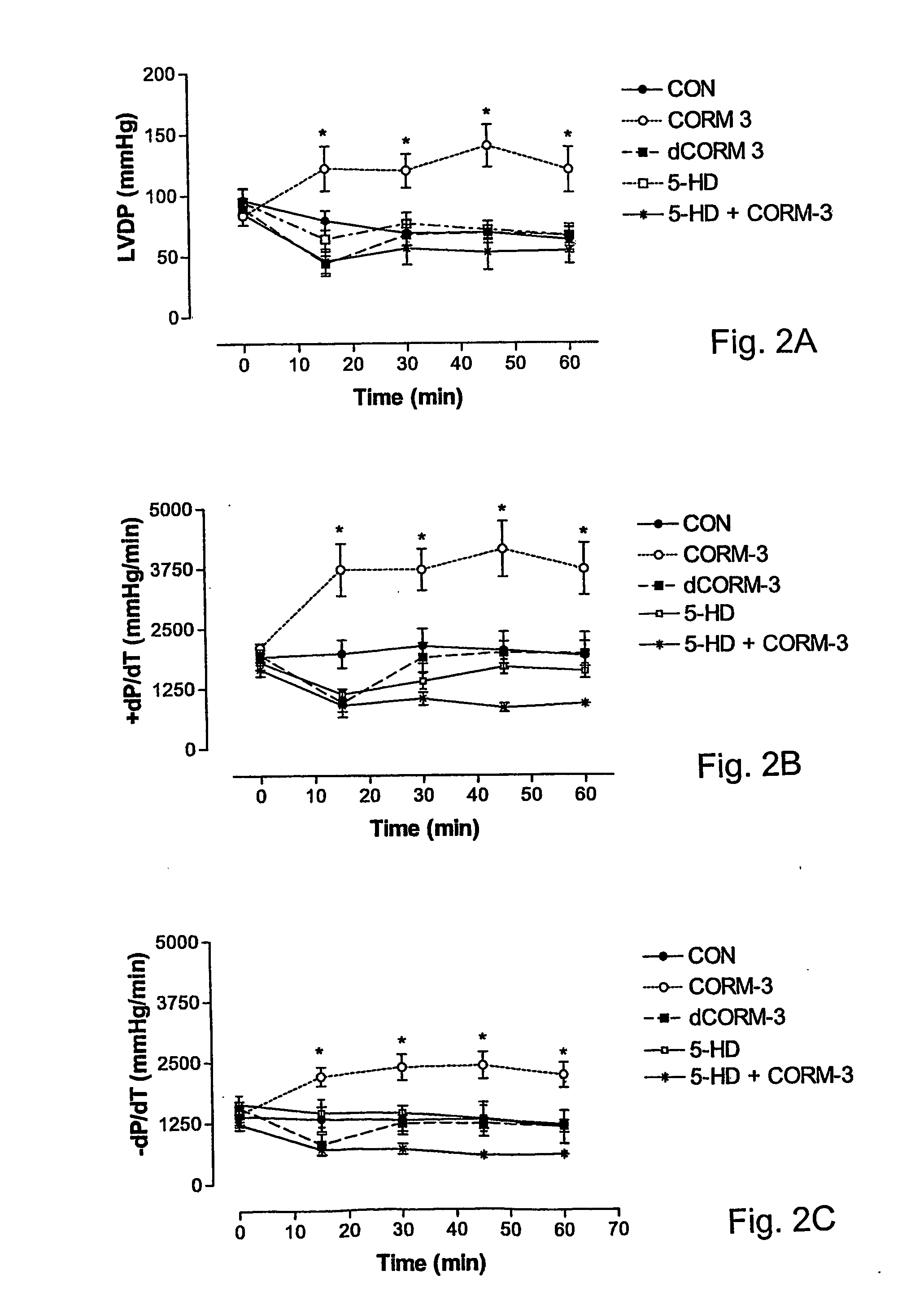

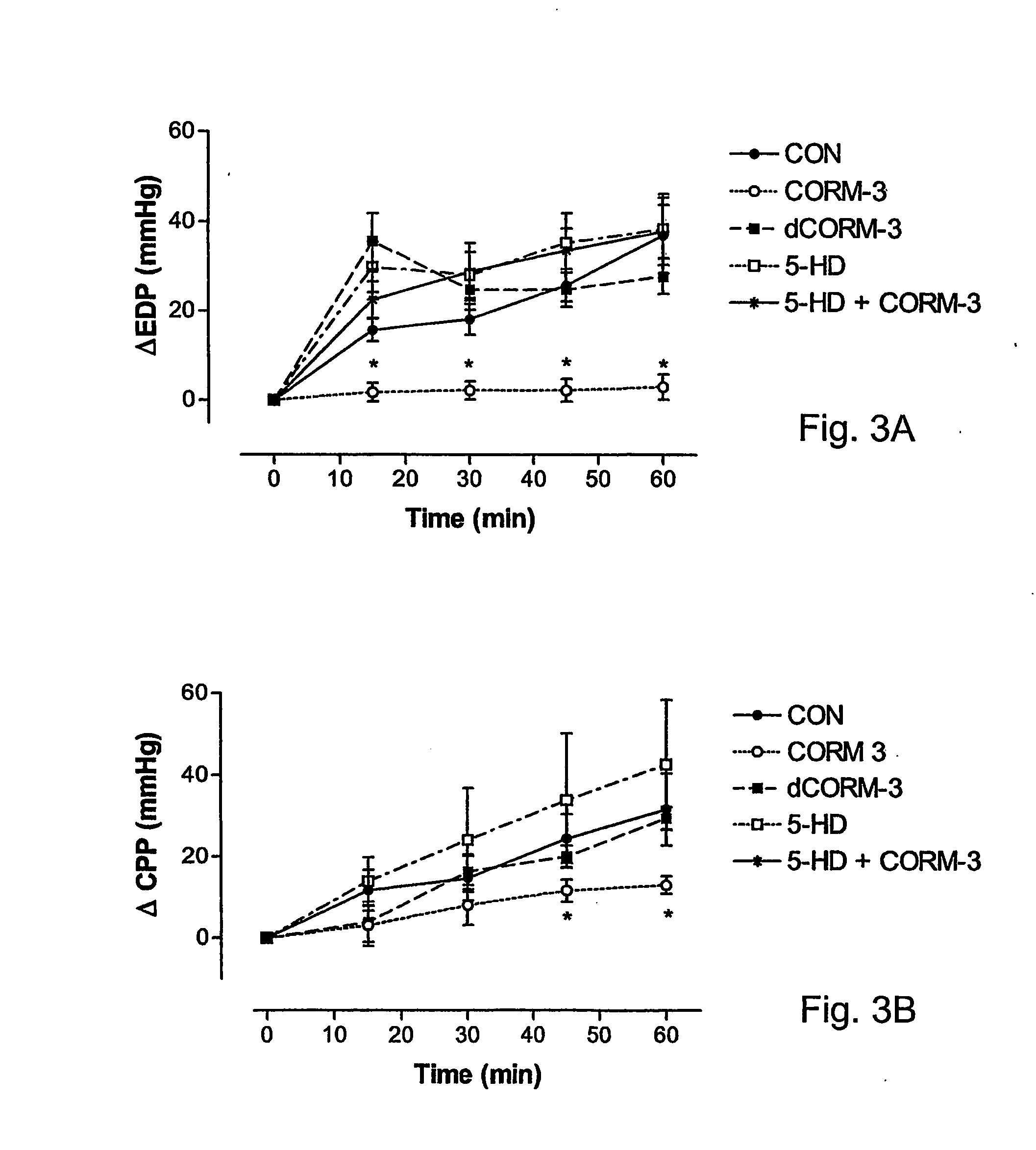

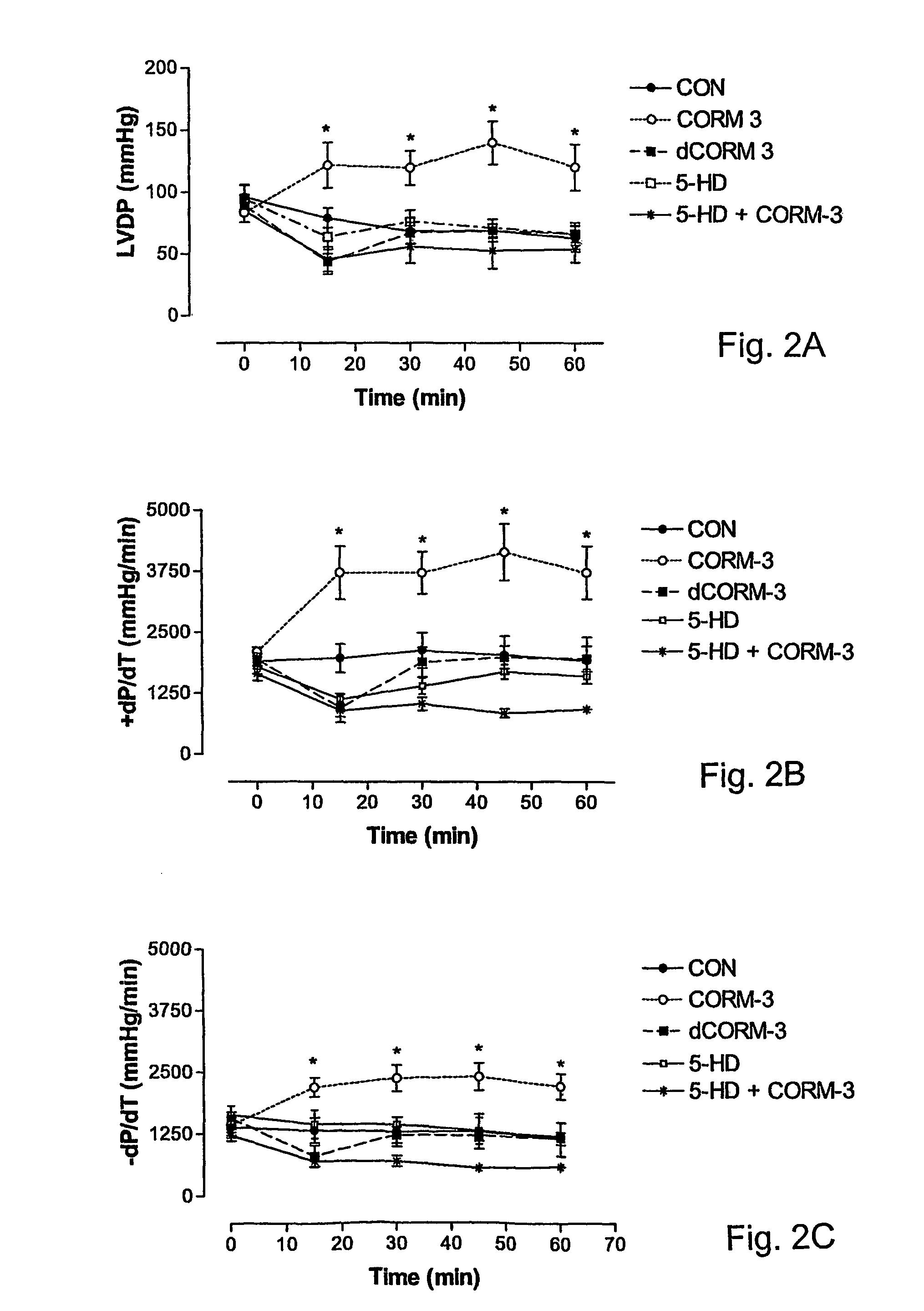

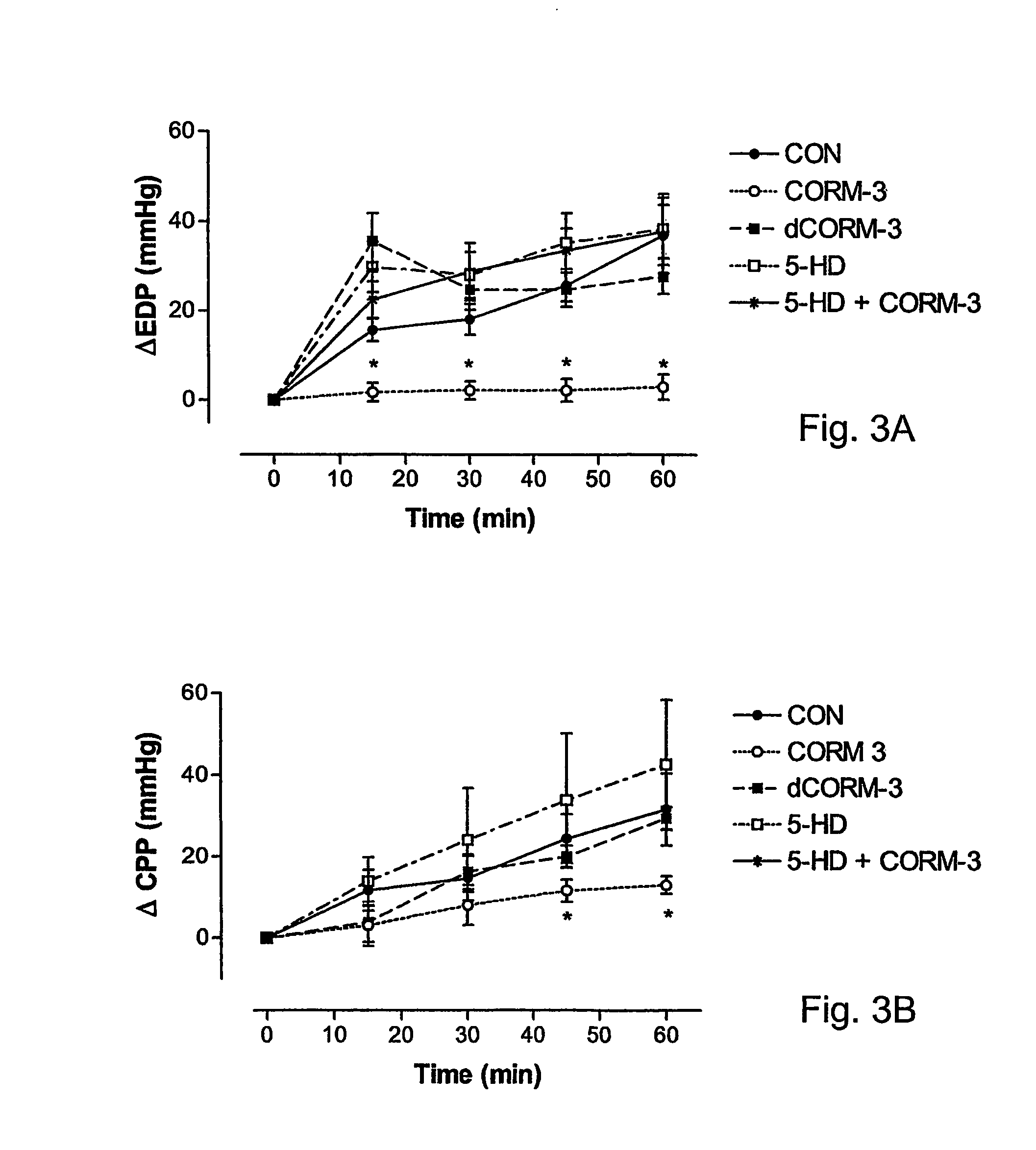

Therapeutic delivery of carbon monoxide to extracorporeal and isolated organs

ActiveUS20060127501A1Increase stimulationAlter and enhance biological effectBiocideHeavy metal active ingredientsSolubilityBlood flow

Metal carbonyls are used to deliver CO to organs to limit post-ischaemic damage. The organ may be extracorporeal, e.g. for use in a transplant, or may be an isolated organ inside or attached to the body but isolated from the blood flow. The carbonyl preferably has one or more other ligands other than CO, such as amino acids, to modulate the CO release property and solubility.

Owner:HEMOCORM

Therapeutic delivery of carbon monoxide

InactiveUS20060115542A1Increase stimulationRegulate expressionOrganic active ingredientsNervous disorderSolubilityTransplant rejection

Metal carbonyls are used to deliver CO having biological activity, for example vasodilatation and inhibition of transplant rejection. The metal of the carbonyl is typically of groups 7 to 10, e.g. Fe and Ru. The carbonyl preferably has one or more ligands other than CO, such as amino acids, to modulate the CO release property and solubility.

Owner:HEMOCORM

Production process for reducing CO release amount of paper-making reconstituted tobacco and reconstituted tobacco

ActiveCN103005660AImprove physical structureIncrease ashTobacco preparationTobacco treatmentBiotechnologyProcess engineering

The invention relates to a production process for reducing the CO release amount of a paper-making reconstituted tobacco. The production process comprises the steps as follows: adding ground calcium carbonate (GCC) and a retention agent into tobacco slurry; carrying out sheet making to obtain a basic sheet of the reconstituted tobacco; coating a tobacco extraction solution onto the basic sheet; drying; and balancing water under the condition of constant temperature and humidity to obtain the reconstituted tobacco. According to the production process, by adding the GCC, the physical structure of the reconstituted tobacco can be improved, the retention rate of fillings can be increased, and the air permeability of the sheet can be improved, so that the CO release amount of the paper-making reconstituted tobacco can be greatly reduced, the content of tar and nicotine in smoke can be reduced at the same time, the ash content of the reconstituted tobacco can be increased, and the smoking quality can be also improved at the same time.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

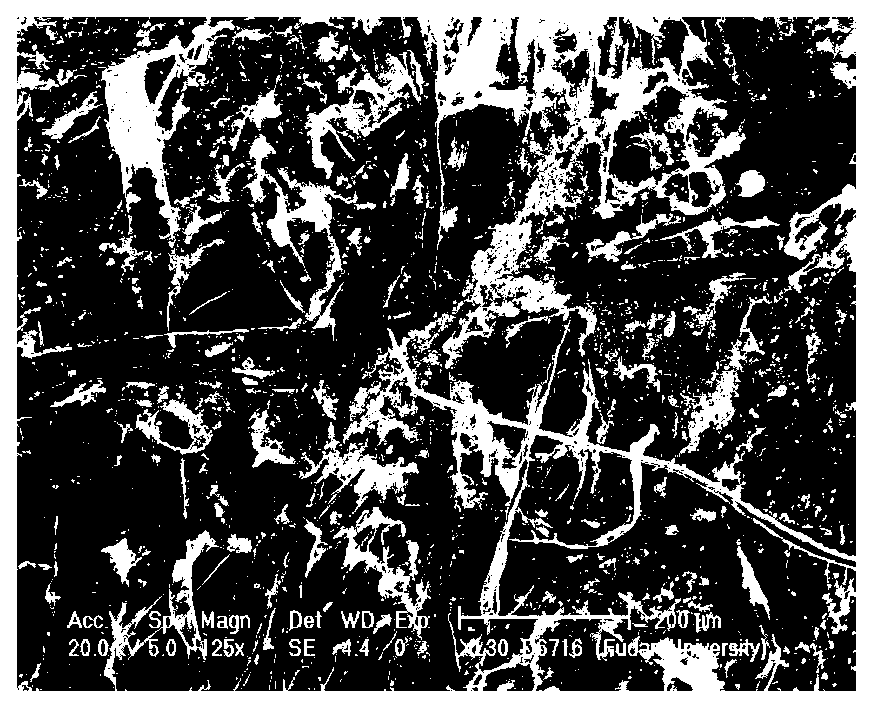

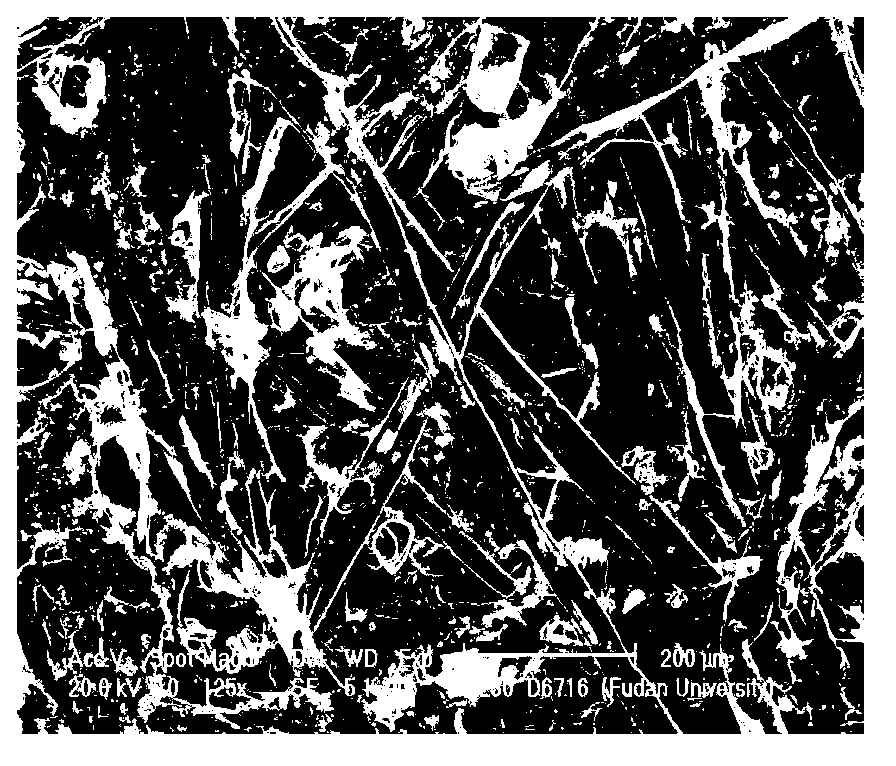

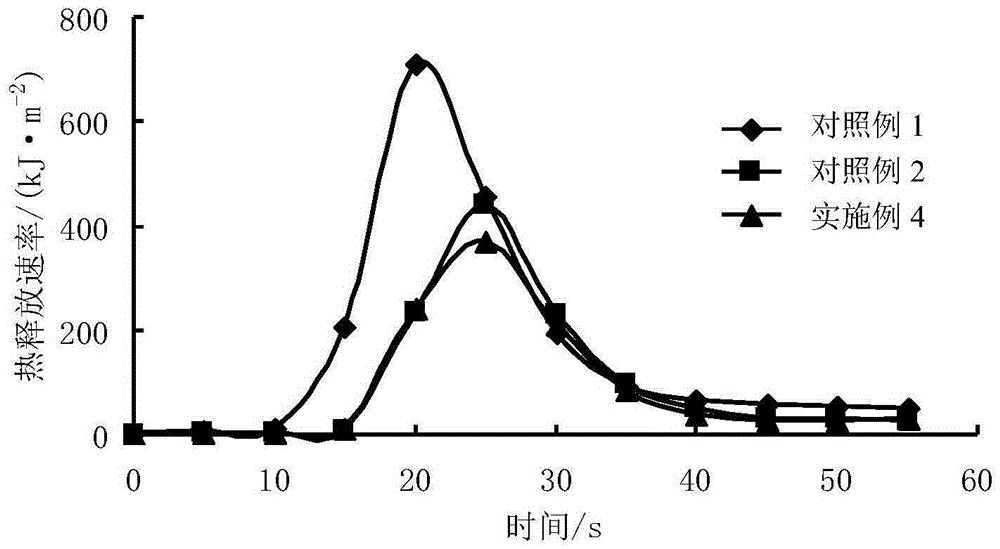

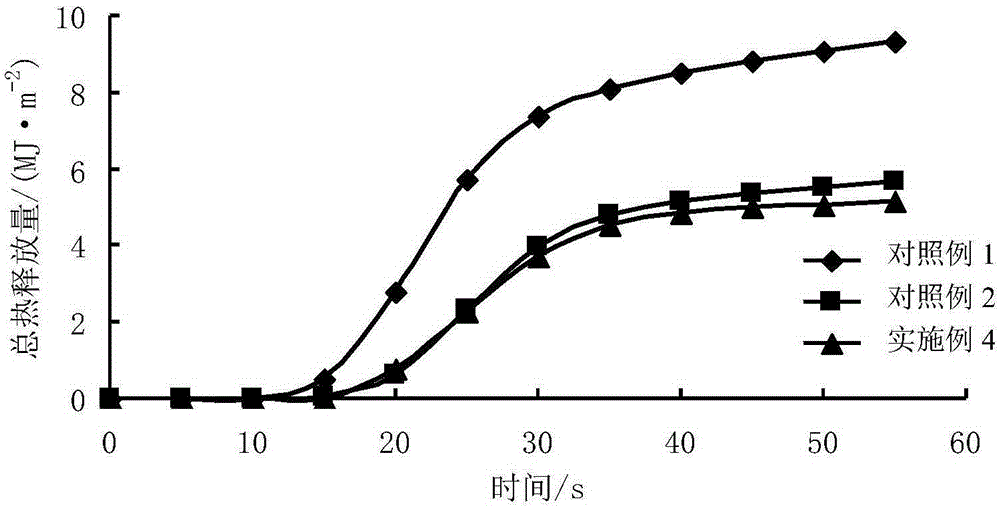

Flame-retardant wallpaper and preparation method thereof

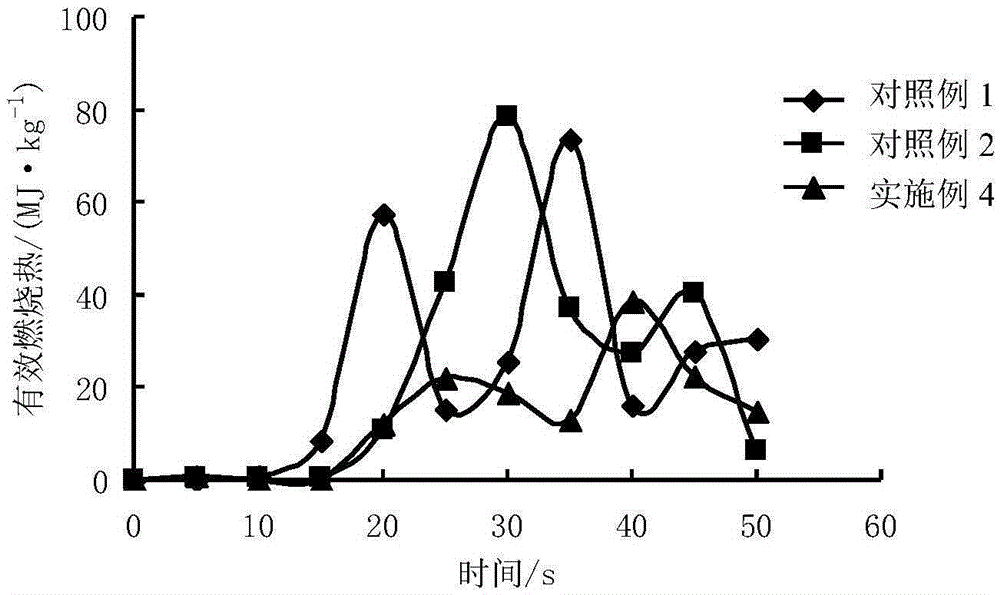

ActiveCN105297551AImprove flame retardant performanceTotal calories lowSpecial paperLaminationToxic gasFire risk

The invention discloses flame-retardant wallpaper as an indoor wall decoration material and a preparation method thereof. The preparation method for the flame-retardant wallpaper includes the following steps: after being immersed in a flame retardant solvent, a decorative veneer and a wallpaper substrate (backing paper) are ultrasonically immersed, so that a flame-retardant decorative veneer and a flame-retardant substrate are obtained; the flame-retardant decorative veneer is attached onto the surface of the flame-retardant substrate. The flame-retardant property of the wallpaper is good, the potential fire risk is low when the material burns, and the flame-retarding effect is remarkable; the smoke suppression effect is obvious, the amount of CO released from smoke is obviously reduced, toxic CO gas can be partially turned into non-toxic gas, and the wallpaper has a good effect of suppressing CO released at fire scenes. Moreover, since the adopted materials are natural materials, the wallpaper is safe to use.

Owner:沈阳领拓科技有限公司

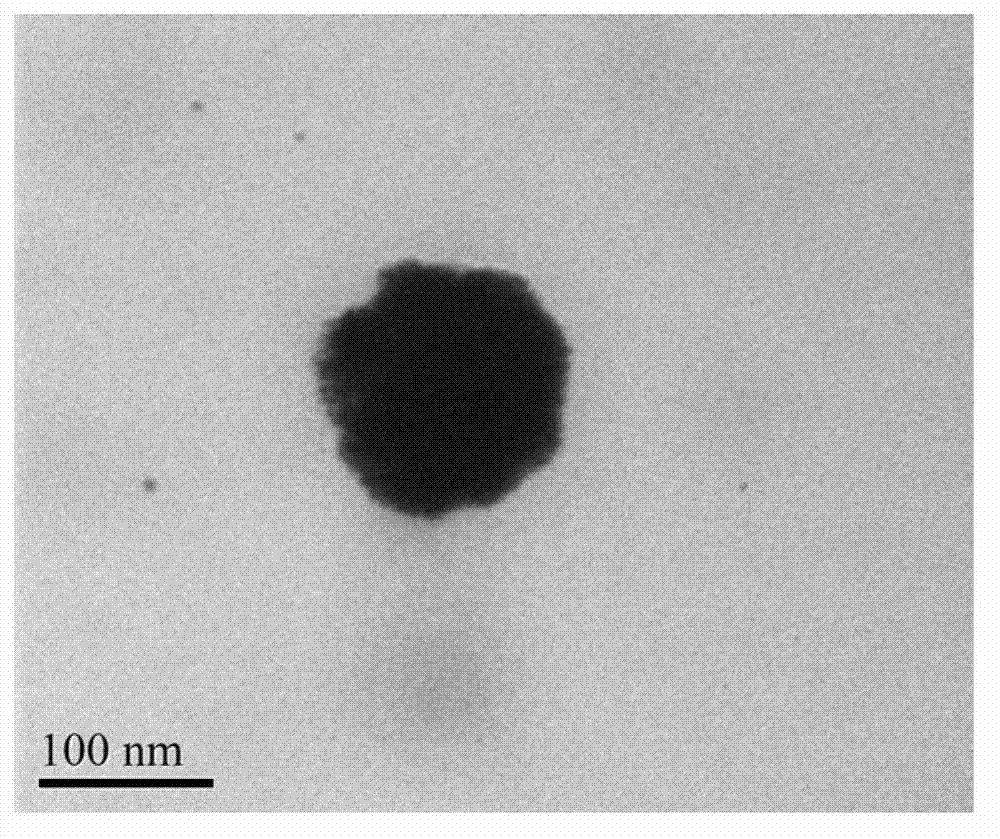

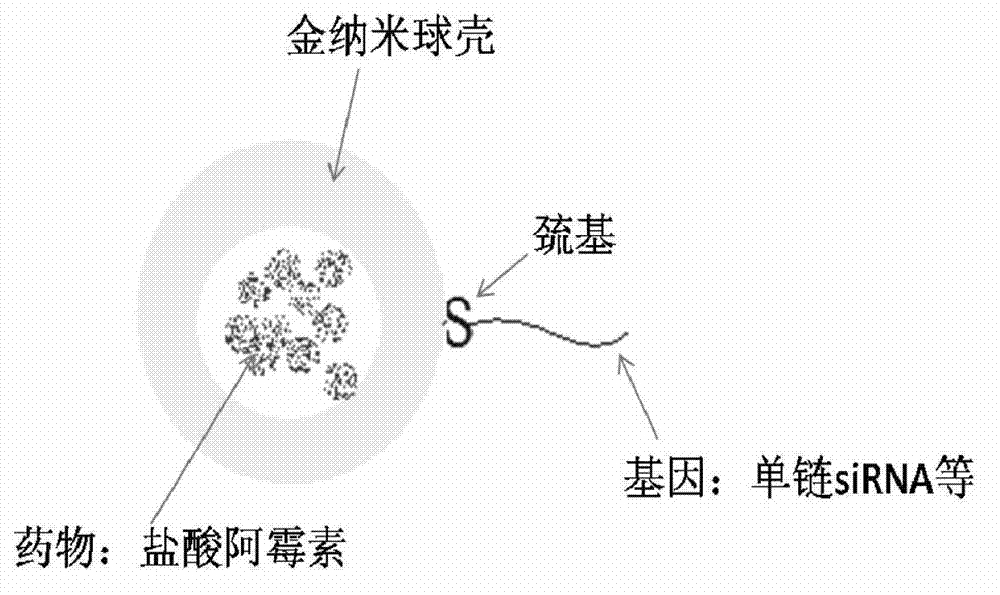

Gene drug co-carrier system using cation liposome to establish gold nano-spherical shell and preparation method

InactiveCN102805873AOrganic active ingredientsGenetic material ingredientsCarrier systemPhospholipid

The invention relates to a gene drug co-carrier system using cation liposome to establish a gold nano-spherical shell and a preparation method. The method comprises: using phosphatides such as DPPC, MPPC and DPPE-PEG and the derivatives thereof to form the cation liposome via membrane extrusion; carrying the hydrophilic drug hydrochloric acid adriacin into the liposome in the forming process; forming the drug-carried cation liposome; adding chlorauric acid solution into cation liposome solution; adsorbing on the surface of the cation liposome; adding ascorbic acid solution for reduction; forming the gold nano-spherical shell structure; reducing sulfhydryl out of the single chain of green fluorescent protein silent gene with a disulfide bond, grafting onto the surface of the gold nano-spherical shell; and forming the gene drug co-carrier system. The gold nano-spherical shell has low toxicity and unique optical properties. The gene drug co-carrier system using cation liposome to establish the gold nano-spherical shell can provide carrier for the co-treatment of drugs and genes, can select light to illuminate the gold nano-spherical shell, and utilize light-heat conversion property to realize the co-release of the drugs and genes.

Owner:TIANJIN UNIV

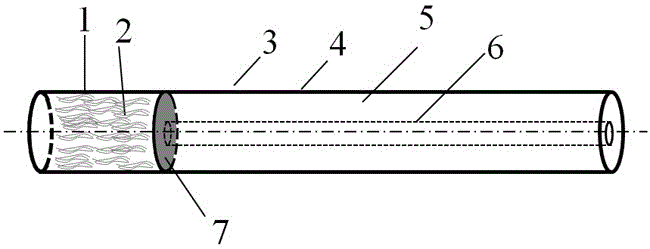

Cigarette with porous material

A cigarette with a porous material comprises a filter tip and a tobacco shred stick, and is characterized in that a hollow tube is axially arranged in the tobacco shred stick, and the porous material is arranged at a position where the hollow tube is connected with the filter tip. The structure of the cigarette is improved, and enough air is provided for combustion of tobacco shreds in a burning and smoking process of the cigarette to reduce CO gas generated by incomplete combustion of the tobacco shreds at high temperature. The original overall size of the cigarette is not changed, the CO release amount of the cigarette and smoking temperature of mainstream smoke can be reduced obviously on the premise of not changing the original smoking taste, and therefore, consumers can receive the cigarette.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Method for producing cigarette expansion cut tobacco with low tar content and low harm by using microbial fermentation

The invention discloses a method for producing cigarette expansion cut tobacco with low tar content and low harm by using microbial fermentation and particularly relates to a method for producing expansion cut tobacco with low tar content and low harm by using quick fermentation of discarded tobacco leaves by using safe good-grade microorganisms and then using a process for expanding cut leaves with CO2. The method specifically comprises the following steps: after the discarded tobacco leaves are threshed and redried or before the discarded tobacco leaves are produced into expansion cut leaves, inoculating one or more than two kinds of strains with different concentrations; after the discarded tobacco leaves are threshed and redried, carrying out microbial mild fermentation within the alcoholization period of one to two years; and before the discarded tobacco leaves are produced into expansion cut leaves, carrying out artificial quick fermentation for 24-72 hours and then intercepting the enzyme activity by adopting the process for expanding the cut leaves through a parameter-optimized CO2 method and using high temperature in the expansion process to obtain the expansion cut tobacco leaves with enhanced compatibility and reduced tar and CO release amount. According to the method, due to the utilization of the safe food-grade microorganisms and high-temperature enzyme activity interception in the expansion process, the expansion cut tobacco leaves obtained by production have the advantages of favorable tar and harm reducing effects, favorable repeatability and low cost; the operation process is simple and safe; and a cigarette formula is easily used.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

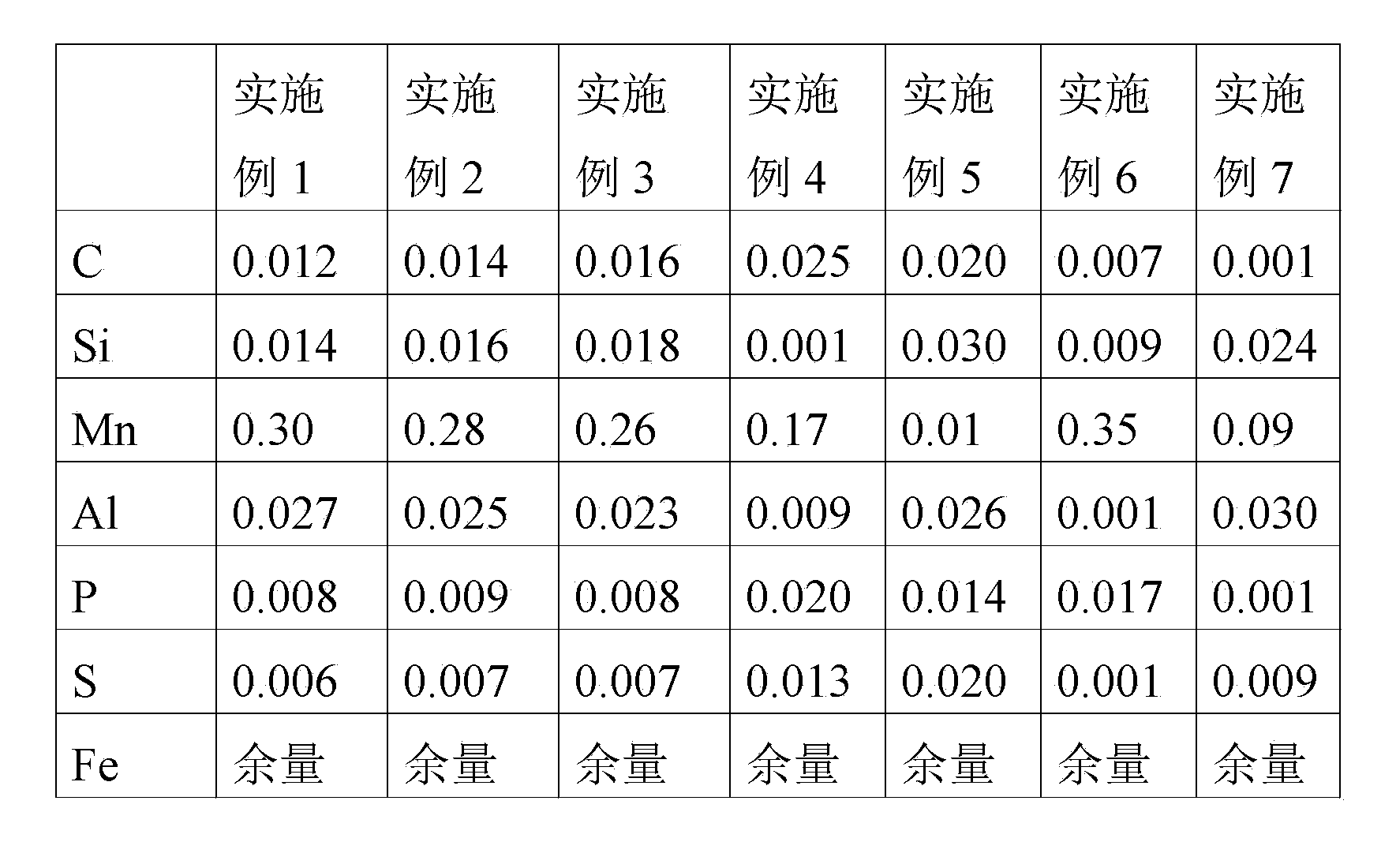

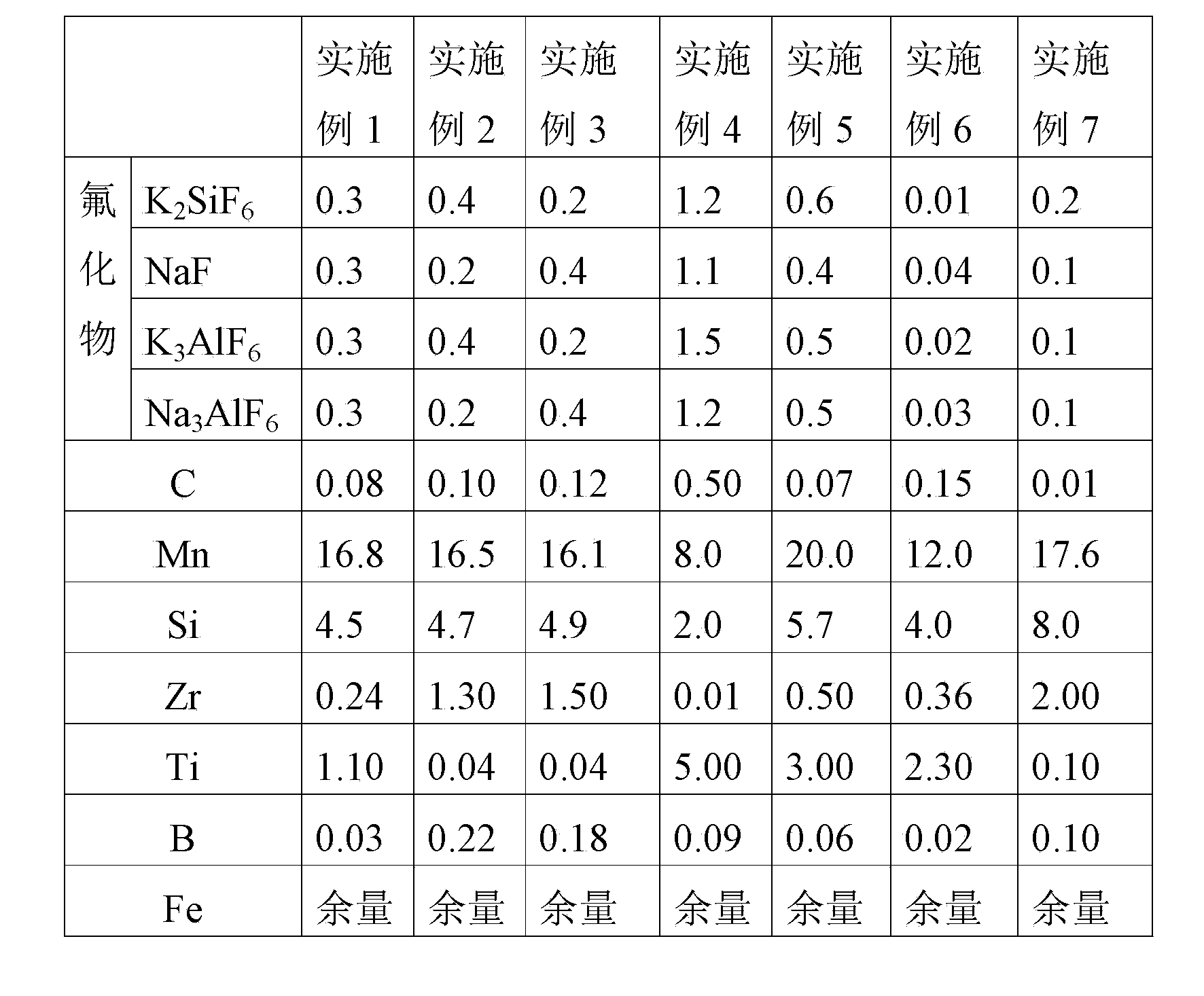

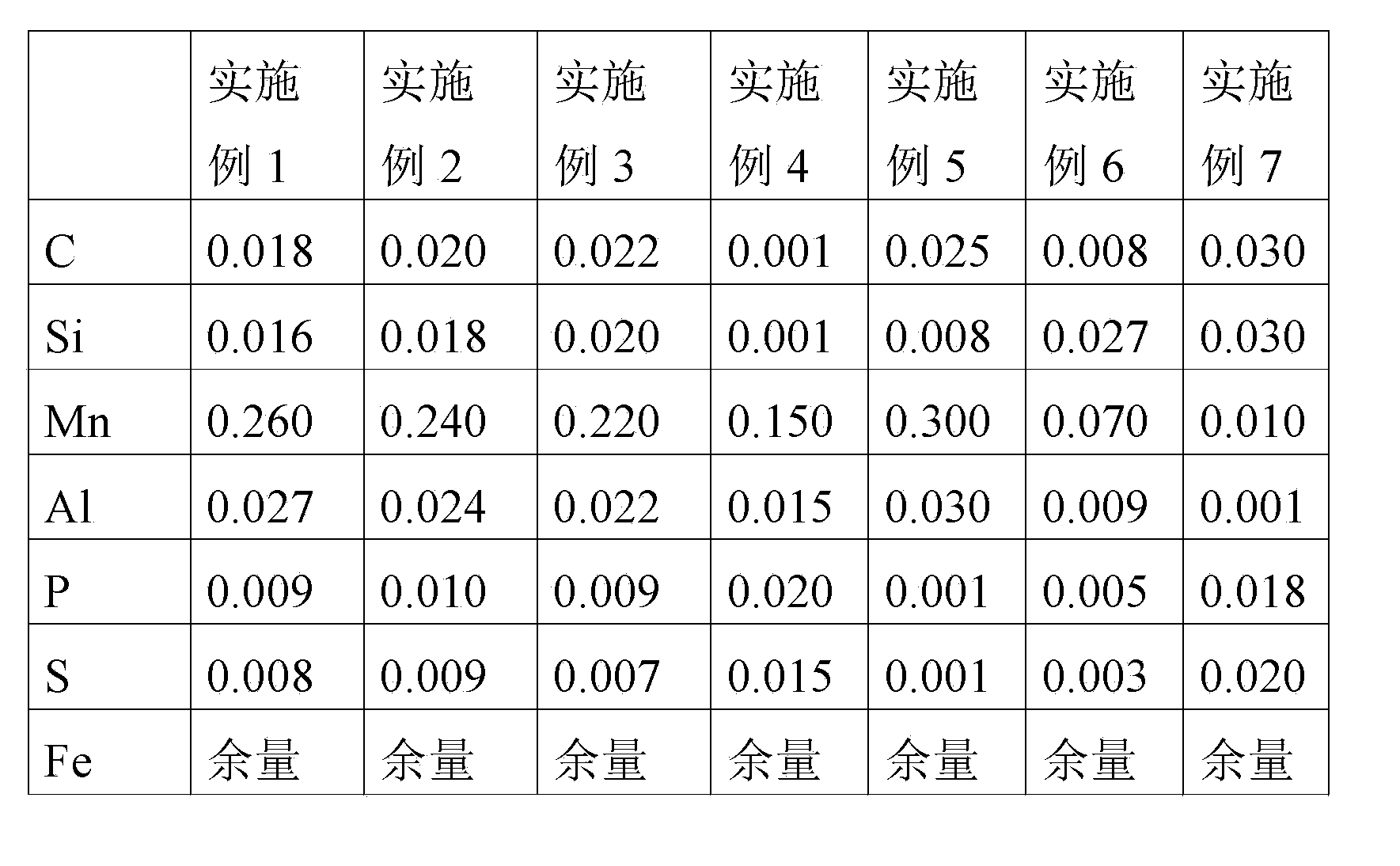

Series-connected double-wire type combined welding wire for CO2 gas shield high-speed flat fillet weld

ActiveCN103659043ASimple welding processDeposition speed is fastWelding/cutting media/materialsSoldering mediaSlagEngineering

The invention discloses a series-connected double-wire type combined welding wire for CO2 gas shield high-speed flat fillet weld. The series-connected double-wire type combined welding wire for the CO2 gas shield high-speed flat fillet weld comprises an antecedent electrode welding wire and a posterior electrode welding wire, the antecedent electrode welding wire and the posterior electrode welding wire are connected in series, the antecedent electrode welding wire is formed by a first steel-tape sheath and metal cored powder contained inside the first steel-tape sheath, the weight of the metal cored powder is 10-30% of the total weight of the antecedent electrode welding wire, the antecedent electrode welding wire is high in deposition rate, the quantity of generated slag is small in a welding process, and a small amount of added fluoride enables the electric arc to be more stable. The posterior electrode welding wire is formed by a second steel-tape sheath and welding flux powder contained inside the second steel-tape sheath, the weight of the welding flux powder is 10-30% of the total weight of the posterior electrode welding wire, the content of the diffusible hydrogen of deposited metal can be reduced to be lower than 5ml / 100g through the posterior electrode welding wire, and CO released by combustion of an undercoat can be reduced by Al and Mg in the welding process. A small amount of titanium and boron are added in both the metal cored powder and the welding flux powder, and the impact value of the deposited metal can be improved greatly. When welding is carried out at the welding speed higher than 1.5m / min, the combined welding wire is excellent in welding process, and good paint resistant performance can be obtained.

Owner:KUSN GINTUNE WELDING

Therapeutic delivery of carbon monoxide to extracorporeal and isolated organs

ActiveUS7989650B2Limiting ischaemic damageReduce ischaemic damageBiocideInorganic active ingredientsSolubilityCo release

Owner:HEMOCORM

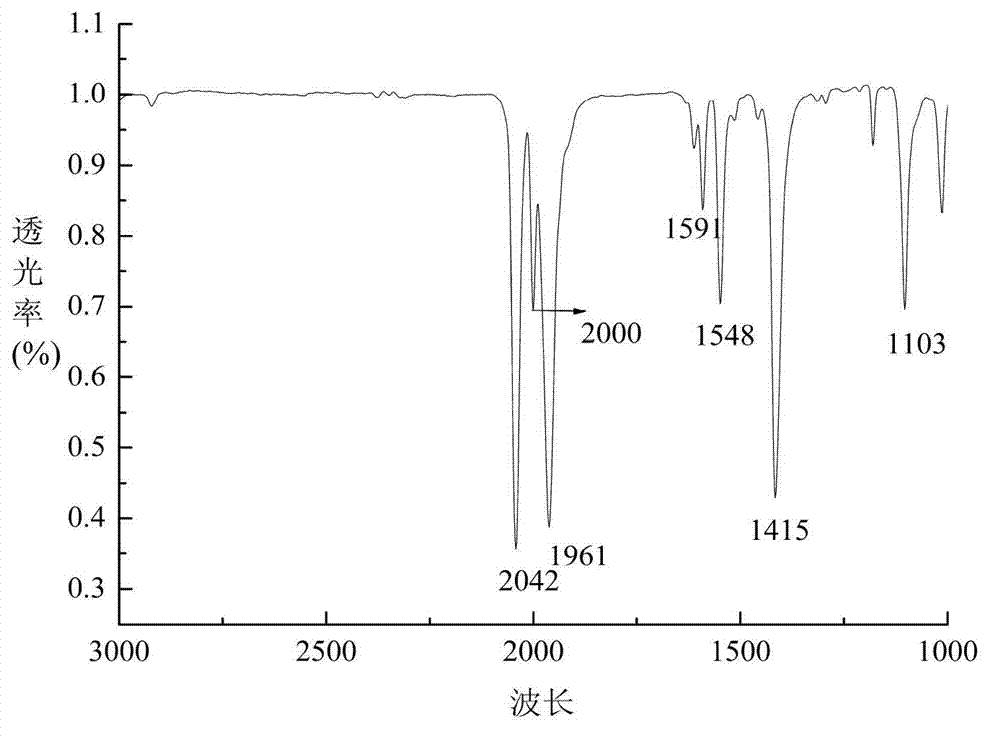

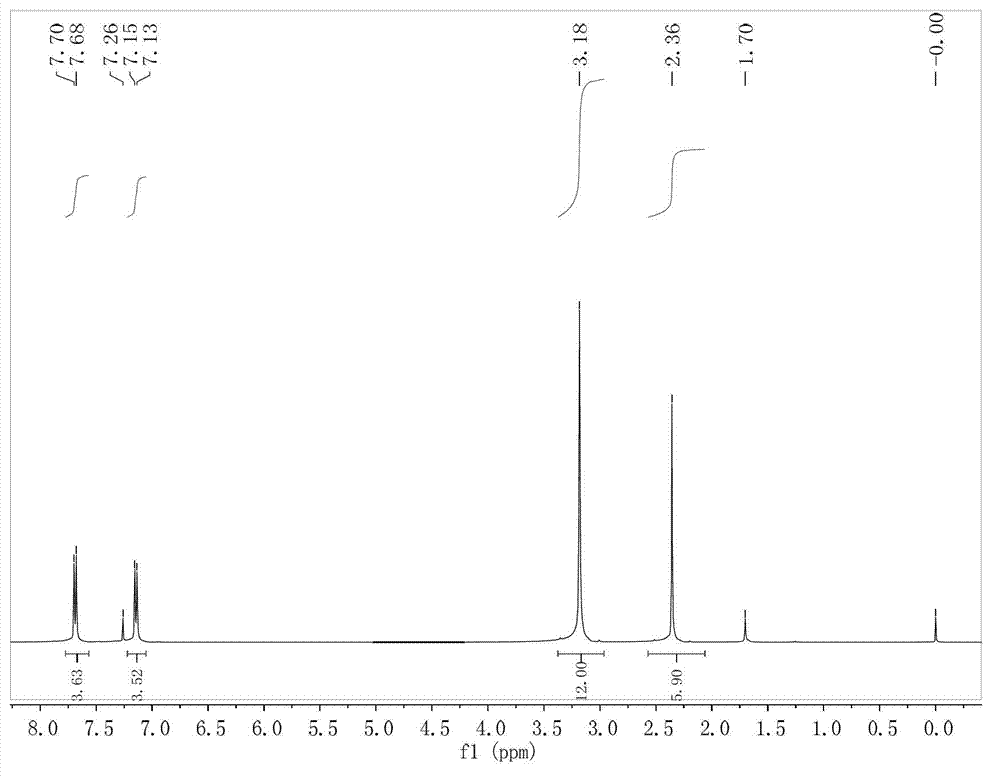

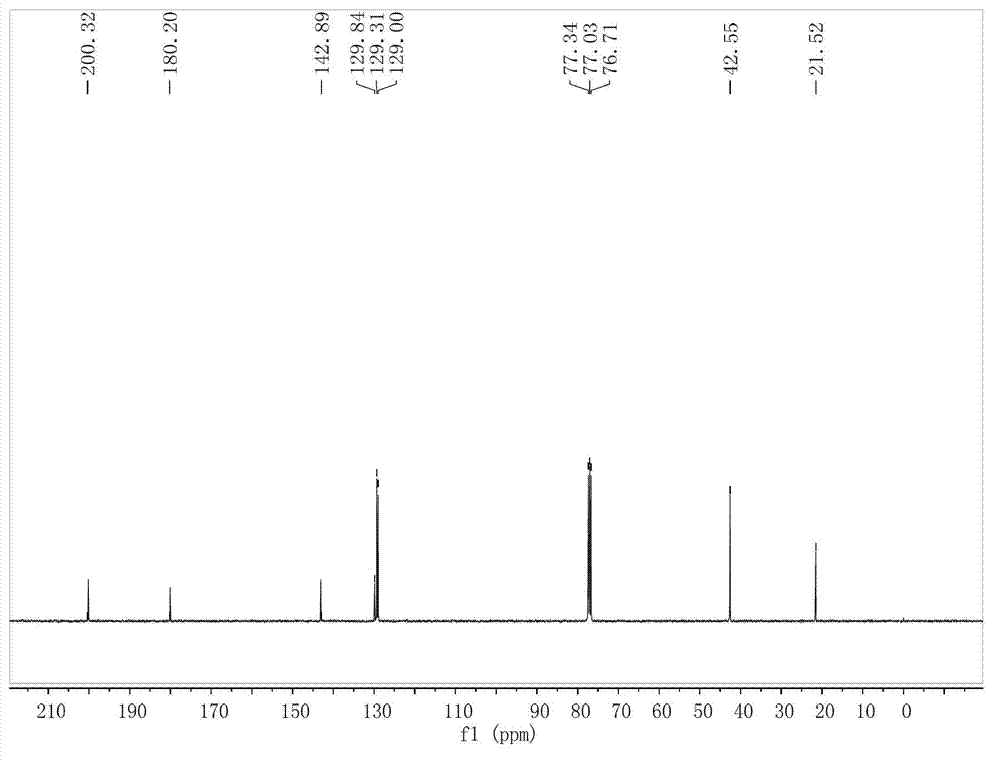

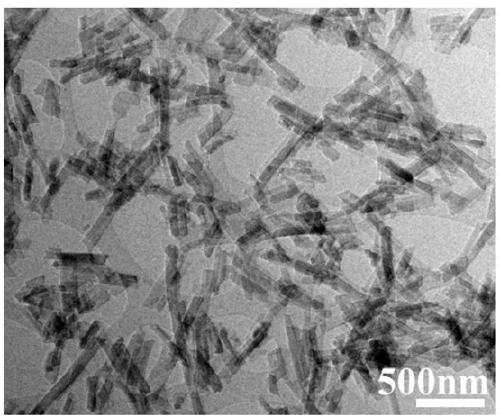

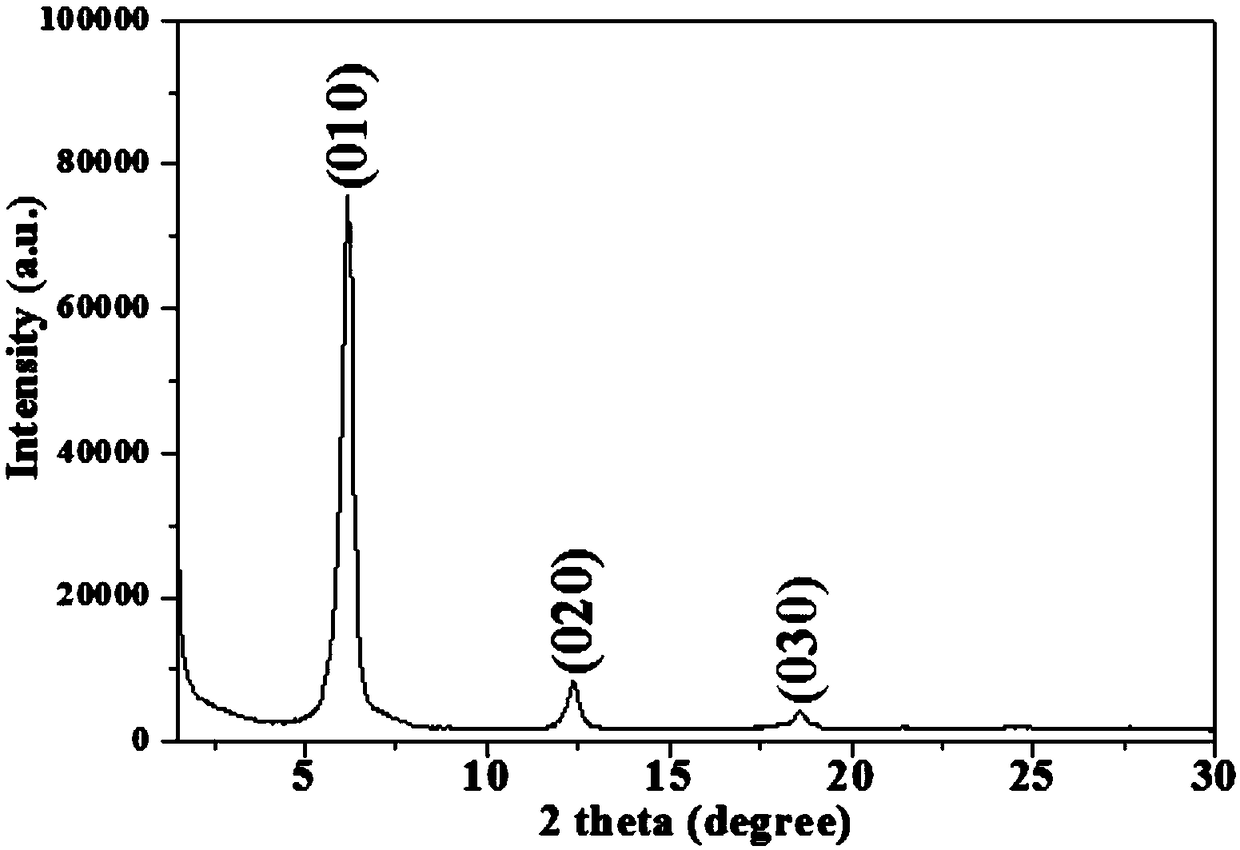

Saw horse carbonyl ruthenium compound and preparation method thereof

InactiveCN103087110AHigh bonding strengthGood water solubilitySugar derivativesGroup 8/9/10/18 element organic compoundsSolubilityRuthenium

The invention relates to a saw horse carbonyl ruthenium compound which is a carboxylic acid group and an axial 2 electronic ligand through connecting a bridging on a double-ruthenium tetracarbonyl saw horse skeleton structure, the bridged carboxylic acid group is coordinated with metal ruthenium through O, the bond strength of Ru-Co is improved by utilizing center metal Ru (I) with low price, the saw horse carbonyl ruthenium compound has good stability under physiological conditions and is beneficial to target release, CO release is controllable, and the water solubility of molecular and the CO release speed can be improved by changing bridging carboxylic acid group R1CO2 and the axial 2 electronic ligand, so that the saw horse carbonyl ruthenium compound can be functionalized efficiently and is easy to derive. The synthetic process is simpler and easy to obtain, and an efficient functionalization method for saw horse carbonyl ruthenium is provided.

Owner:SHAANXI NORMAL UNIV

Real-time hole forming cigarette paper and application of real-time hole forming cigarette paper in reducing CO and tar releasing amount of mainstream smoke

ActiveCN105019298AReduce CO releaseImprove applicabilityCigar manufactureInorganic compound additionCarbonizationPaper based

The invention discloses real-time hole forming cigarette paper based on metal organic frame (MOF) materials and application thereof. The real-time hole forming cigarette paper is mainly used for reducing the CO and tar releasing amount of mainstream smoke without producing negative effects on the smoking quality of a cigarette. The real-time hole forming cigarette paper is characterized in that the MOF materials are used in the cigarette paper producing process; in the cigarette paper burning process, the MOF materials can produce more microcellular structures after being heated and decomposed, the diffusion rate of the part, near a carbonization line, of the cigarette paper in the cigarette burning process is obviously increased, and the hole structure of the cigarette paper is changed. The CO and tar releasing amount of the mainstream smoke is reduced. By means of the cigarette paper, the CO releasing amount of the mainstream smoke can be reduced by 15 percent or more, and the tar releasing amount can be reduced by 4 percent to 8 percent. The cigarette paper is simple in preparing method, cost is low, and industrial production can be achieved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

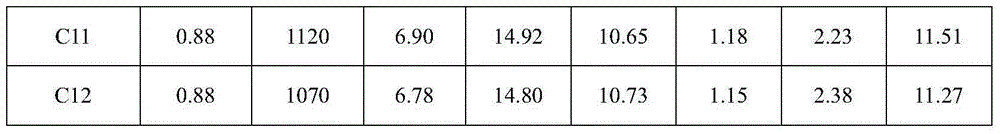

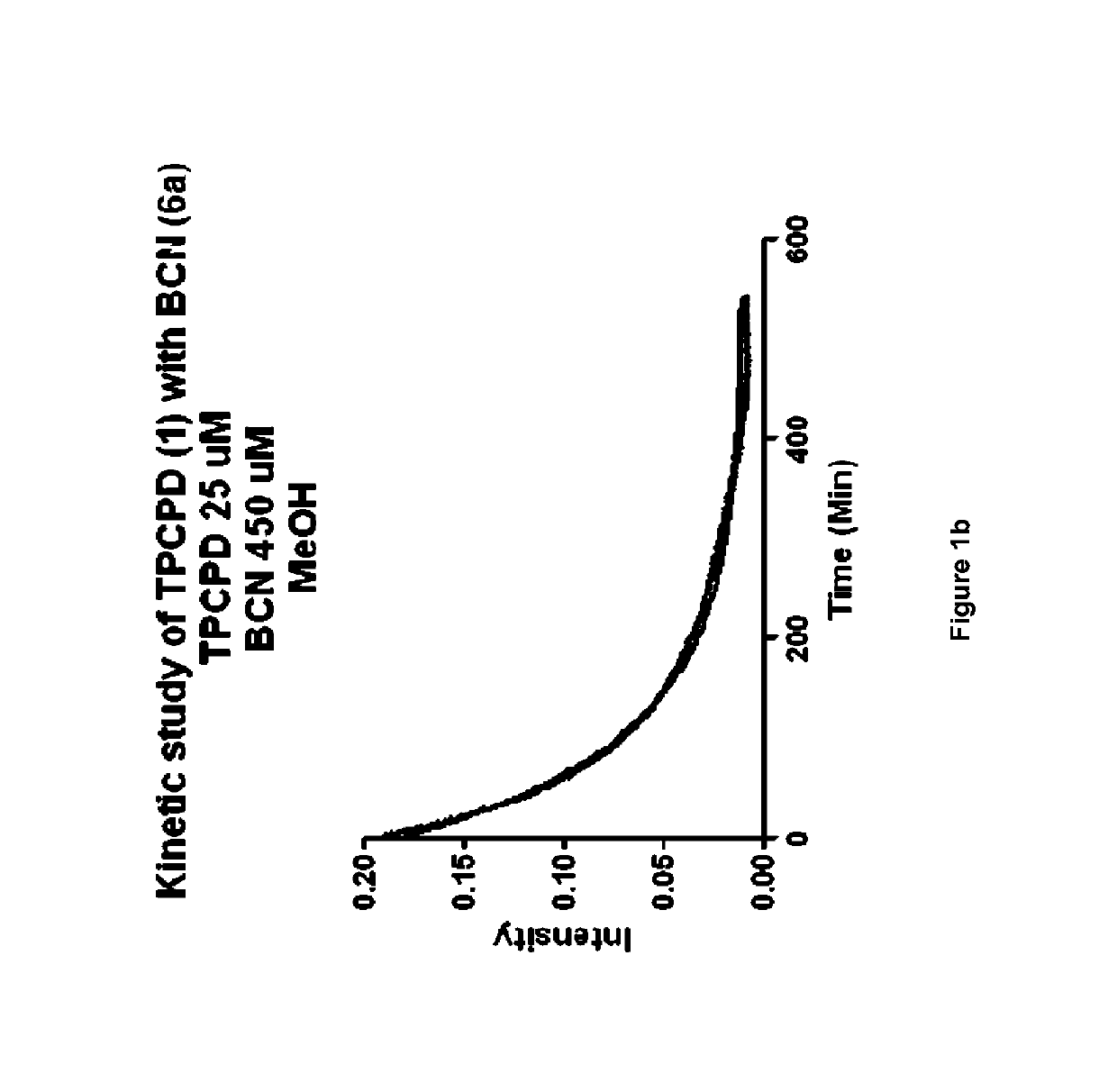

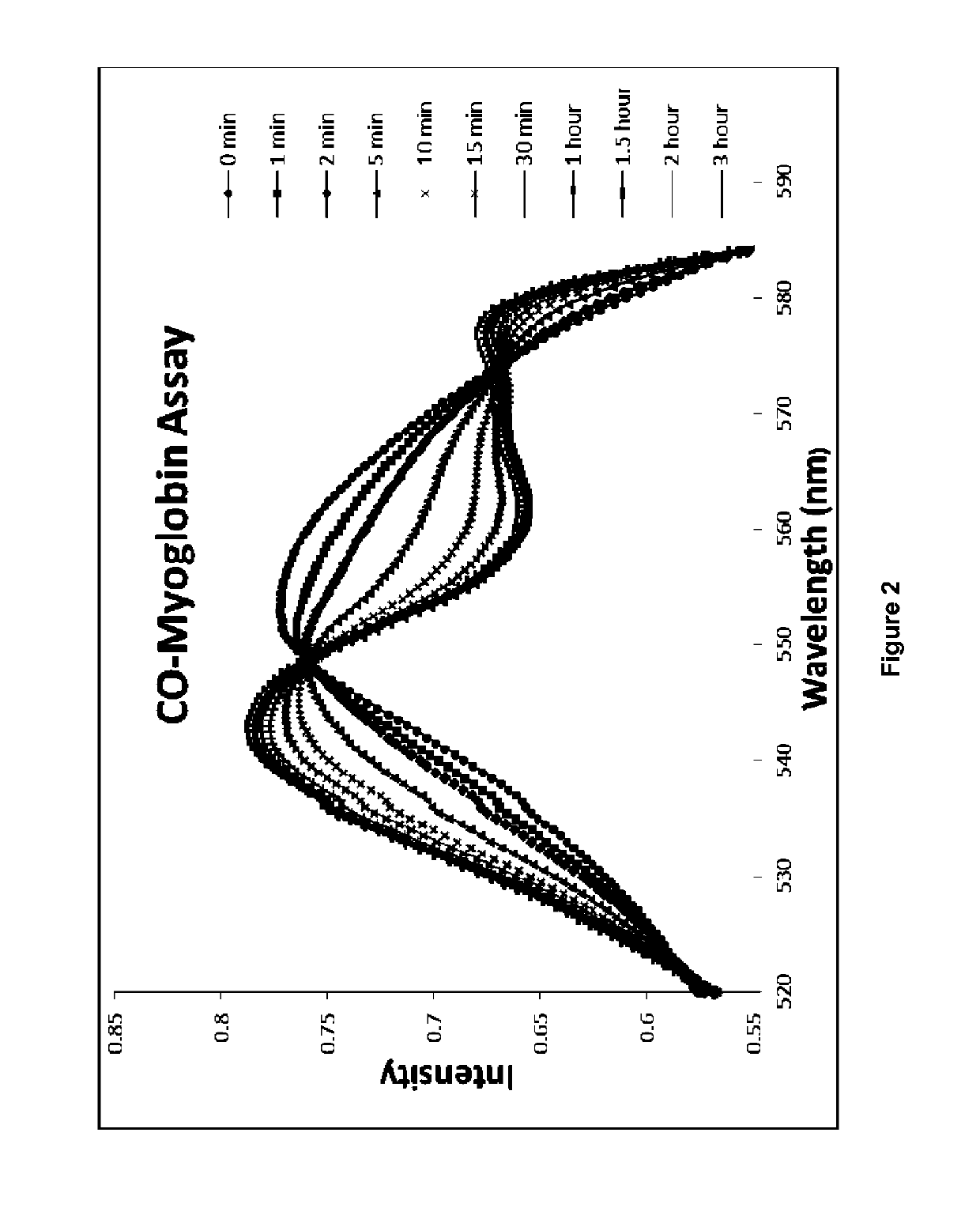

Carbon monoxide-releasing molecules for therapeutic applications and methods of making and using thereof

Carbon monoxide-releasing organic molecules are described herein. The molecules can be synthesized prior to administration (e.g., ex vivo) or formed in vivo. In those embodiments where the molecules are formed in vivo, reactants are administered under physiological conditions and undergo a cycloaddition reaction to form a product which releases carbon monoxide. In applying such reactions for therapeutic applications in vivo, the cycloaddition and CO release typically occur only under near-physiological or physiological conditions. For example, in some embodiments, the cycloaddition reaction and / or release of carbon monoxide occur at a temperature of about 37 C and pH of about 7.4. Pharmaceutical compositions and methods for release carbon monoxide are also described.

Owner:GEORGIA STATE UNIV RES FOUND INC

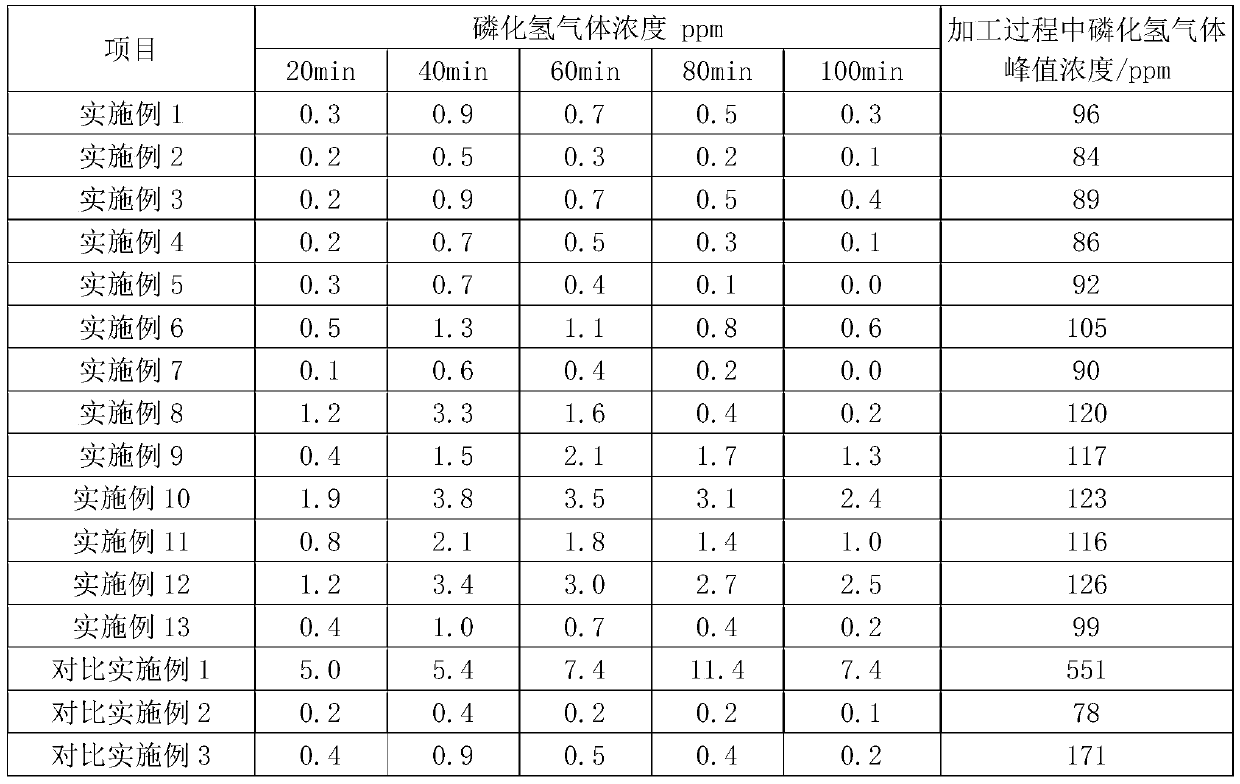

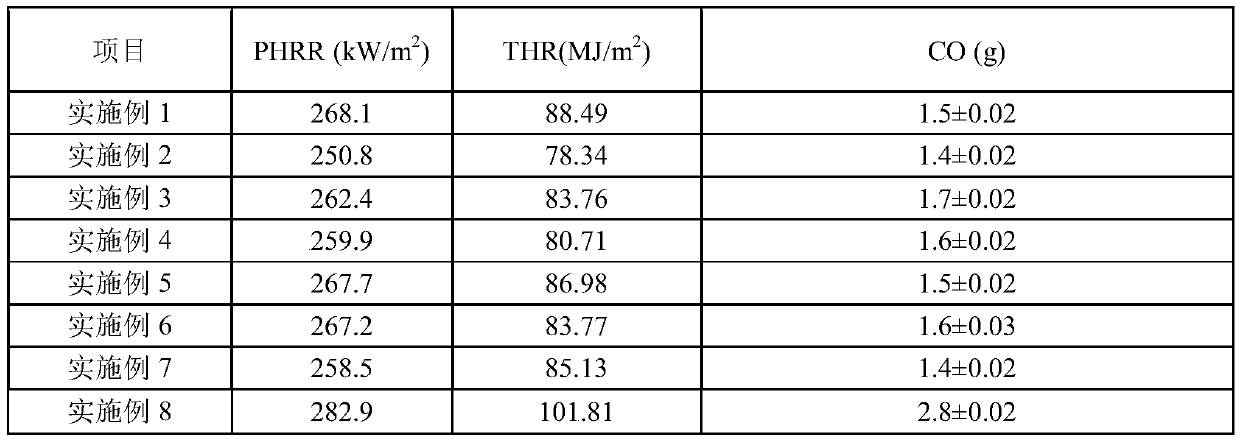

Aluminum hypophosphite composite halogen-free flame retardant as well as preparation and application thereof

The invention relates to an aluminum hypophosphite composite halogen-free flame retardant as well as preparation and application thereof, the flame retardant comprises the following raw materials: anorganic phosphorus-nitrogen flame retardant, MOFs and aluminum hypophosphite, the preparation method comprises the following steps: preparing three dispersions with different solid contents, mixing and drying to prepare the flame retardant, and the application of the flame retardant is flame retardant application in nylon materials. According to the invention, the organophosphorus-nitrogen flame retardant, MOFs and aluminum hypophosphite are utilized to prepare the aluminum hypophosphite composite halogen-free flame retardant; by adjusting the use amounts and proportions of the three components and fully exerting the synergistic effect of the three components, the prepared composite halogen-free flame retardant not only can reduce the use amount of aluminum hypophosphite and improve the flame retardant efficiency of aluminum hypophosphite, but also can inhibit and reduce the release of phosphine gas in the processing process and the product and reduce the harm of phosphine in the environment. According to the aluminum hypophosphite composite halogen-free flame retardant flame-retardant nylon prepared by the invention, the heat release rate of the nylon can be effectively reduced, the CO release amount is reduced, and the flame retardance of the flame-retardant nylon is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

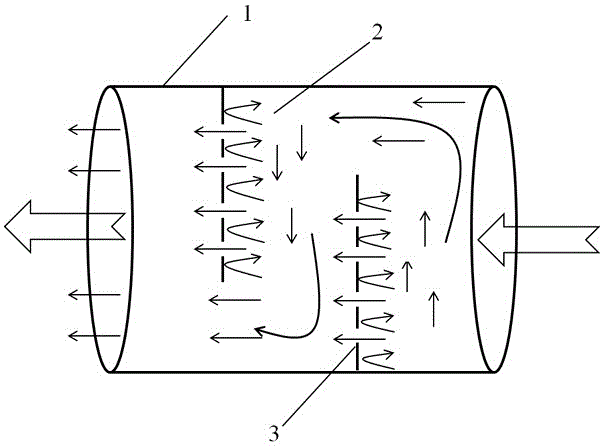

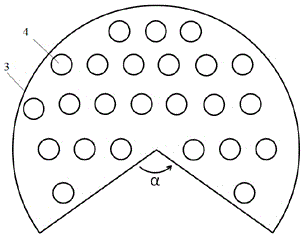

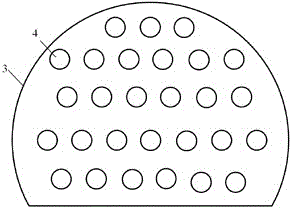

Cigarette with baffle plates in filter tip

The invention relates to a cigarette with baffle plates in a filter tip. The cigarette comprises a filter tip and a cut tobacco rod, and is characterized in that at least two baffle plates are arranged in the filter tip in a direction being vertical to the axial direction, and are in a flaky shape; the shape is a big half circle shape or a fan shape; a plurality of through holes are formed in each baffle plate. By improving the structure of the cigarette filter tip, in the cigarette combustion and smoking process, the porous baffle plates are used for simultaneously achieving the two effects of prolonging the circulation path of partial smoke gas in the filter tip and enhancing the smoke gas returning and mixing effect, so that the absorption performance of acetic acid fiber can be sufficiently and effectively achieved; further, the tar and CO release quantity in the main stream smoke gas can be reduced. The cigarette has the advantages that the original integral dimension of the filter tip and the cigarette smoking resistance are not changed; the acceptance by customers is convenient.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Co-releasing compounds & formulations thereof useful for inducing mitochondrial biogenesis and tissue repair

InactiveUS20160243151A1Promote repairPromote tissue growthDigestive systemDead animal preservationTissue repairCo release

Provided are pharmacological methods of inducing through a unified set of molecular mechanisms the maturation of stem cells, methods of promoting mitochondrial biogenesis in a cell and tissue, methods of reducing pluripotency in a stem cell, and methods of promoting differentiation of a stem cell. In particular, the invention relates to methods for promoting tissue growth and / or tissue repair and / or improving tissue survival, preventing and treating fibrotic lesions and disorders.

Owner:UNIV ZURICH +1

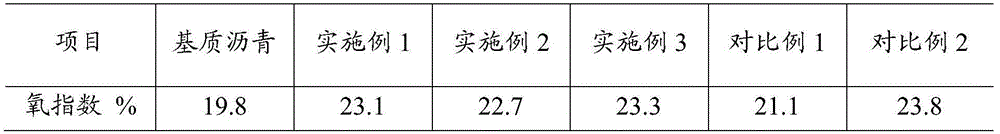

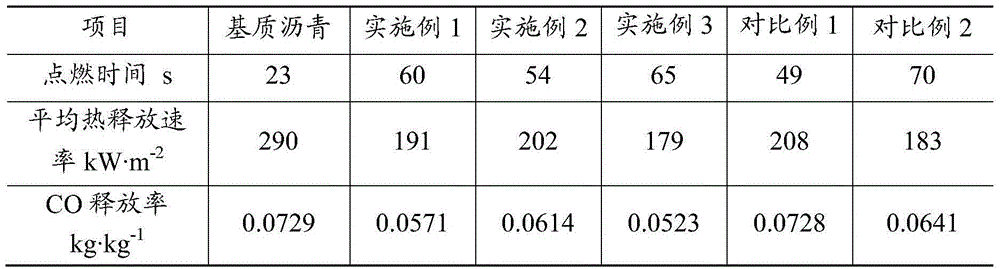

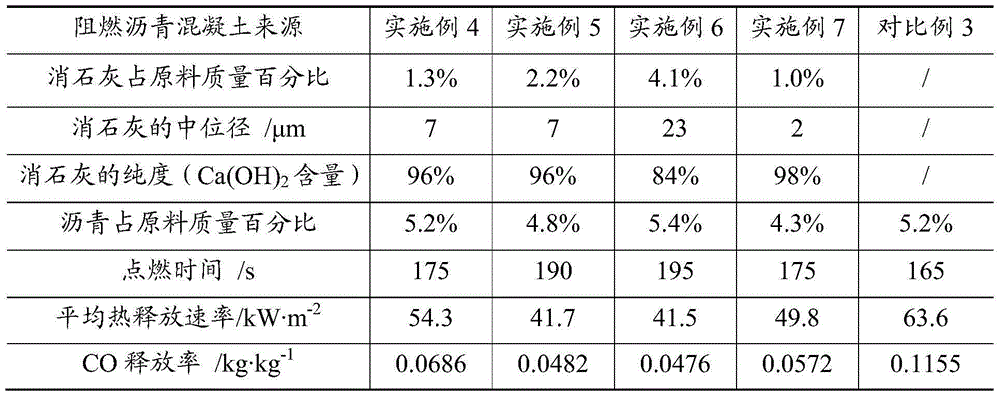

Flame retardant modified asphalt, flame retardant asphalt concrete and preparation method thereof, and application of slaked lime as flame retardant

ActiveCN104629389AOpen up new fields of applicationGood flame retardant and smoke suppression effectBuilding insulationsCo releaseFire retardant

The invention discloses flame retardant modified asphalt. The mass of added slaked lime is 25% to 80% of the mass of original unmodified asphalt. The invention also discloses a flame retardant asphalt concrete, which comprises the following raw materials by mass percent: 86% to 93% of aggregates, 3% to 6% of asphalt, 0.6% to 4.8% of slaked lime, and 3 % to 7% of limestone dust. The invention also discloses a preparation method of the flame retardant asphalt concrete. The preparation method comprises the following steps: heating the asphalt to 140 to 170 DEG C, and then adding the asphalt to 180 to 200 DEG C aggregates to be mixed for 85 to 95 seconds; simultaneously adding slaked lime and limestone dust to be mixed again for 85 to 95 seconds, and then molding to obtain the flame retardant asphalt concrete. The invention also discloses application of slaked lime as an asphalt flame retardant. When the slaked slime is used as the flame retardant of the flame retardant modified asphalt and the asphalt concrete, the oxygen index of the asphalt can be enhanced, the time to ignition of the asphalt is prolonged, and the combustion heat release rate and the CO release rate of the asphalt are reduced; the high and low temperature performance and the water stability of the asphalt concrete are improved, and the application value is good.

Owner:ZHEJIANG UNIV

Preparation method of papermaking-process reconstituted tobaccos capable of reducing content of CO in mainstream smoke

ActiveCN104013096AStrong adaptability of production processReduce carbon monoxideTobacco preparationAlcoholPapermaking

The invention relates to a preparation method of papermaking-process reconstituted tobaccos capable of reducing the content of CO in mainstream smoke. The CO release amount of papermaking-process reconstituted tobacco products produced at home and abroad is relatively high and basically the same as that of pure tobacco shreds, and even is greatly higher than that of the tobacco shreds. The preparation method comprises the following steps: soaking lalang grass rhizome in cold water, boiling, filtering to obtain a crude extract of lalang grass rhizome, soaking the crude extract in the cold water, and continuously repeating the step for three times to obtain a final crude extract of lalang grass rhizome; processing the final crude extract of lalang grass rhizome obtained in the step 1 by adopting an alcohol-water method to obtain a fine extract of lalang grass rhizome; mixing the fine extract of lalang grass rhizome, a tobacco flavoring module and tobacco raw material concentrated liquid according to a ratio of 2 : 1 : 12 to obtain coating liquid, and coating a papermaking substrate with the coating liquid to prepare the functional papermaking-process reconstituted tobaccos. The content of CO in the mainstream smoke of a cigarette containing the functional papermaking-process reconstituted tobaccos can be reduced to 1.0mg / cigarette.

Owner:CHINA TOBACCO SHAANXI IND

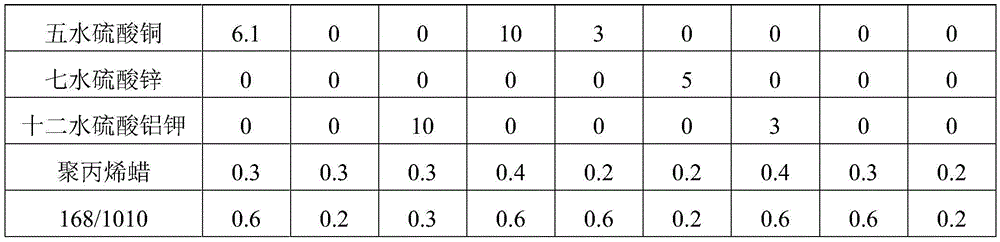

Halogen-free flame retardant polypropylene material with low smoke release rate and preparation method thereof

The invention relates to a halogen-free flame retardant polypropylene material with the low smoke release rate and belongs to the technical field of high molecular materials. The material is prepared from, by weight, 40-70% of polypropylene, 18-30% of halogen-free flame retardant, 0-30% of glass fiber, 3-15% of polyketone resin, 1-5% of nanometer vermiculite, 3-10% of crystalline hydrate, 0.2-0.6% of lubricating agent and 0.2-0.6% of antioxidant. The invention further provides a preparation method of the halogen-free flame retardant polypropylene material. The halogen-free flame retardant polypropylene material with the low smoke release rate has the advantages of being low in smoke release rate, smog release amount and CO release ratio and capable of being widely applied in various fields of communal facilities, decoration, electronic and electric components and the like with high requirements for inflaming retarding and smog release, and saving precious time for people escape.

Owner:上海日之升科技有限公司

Method for promoting carbon monoxide release of carbon monoxide-releasing molecules and preventing sedimentation

InactiveCN104814952AFacilitated releaseEfficient removalOrganic active ingredientsAntipyreticChemical compoundBiocompatibility Testing

The invention discloses a method for promoting carbon monoxide release of carbon monoxide-releasing molecules (CORM) and preventing sedimentation and belongs to the technical field of medical chemistry. The method particularly comprises the following steps: dissolving CO releasing molecules in dimethyl sulfoxide, and adding amino acid, or derivatives thereof, or medicine molecules and an EDTA water solution. After adding of EDTA, generation of CO is effectively promoted, and sedimentation in reaction can be quickly removed. The method has good university; compounds related to the reaction have excellent biocompatibility; and after release of CO, sedimentation can be quickly and effectively prevented, and the CO release time and rate can be easily controlled.

Owner:JIAXING UNIV

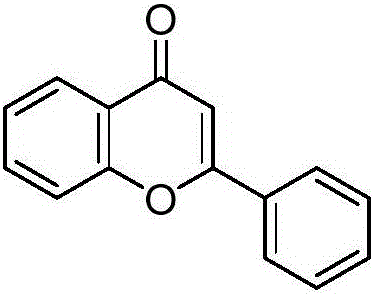

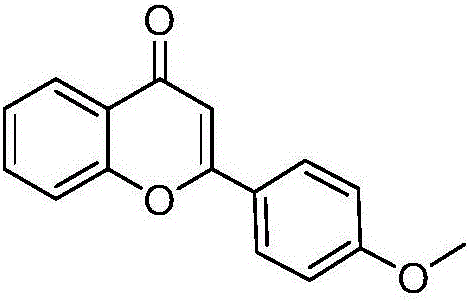

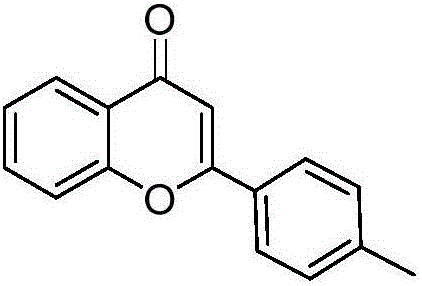

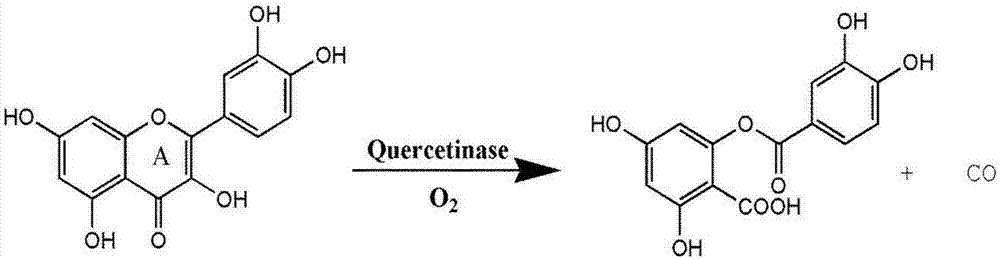

Method for preparing benzopyrone compound through adopting pentacarbonyl iron as CO release source

InactiveCN106632194ABroad biological activityExtensive medicinal valueOrganic chemistryNatural productBenzopyrone

The invention discloses a method for preparing a benzopyrone compound through adopting pentacarbonyl iron as a CO release source. The method comprises the step of subjecting a 2-iodophenol compound and terminal alkyne to a coupling reaction under mild conditions in a manner of taking palladium acetate as a catalyst, taking piperazine as a base and taking the pentacarbonyl iron as the CO release source, so as to produce the benzopyrone compound. According to the method, the operation is simple, the reaction conditions are mild, the consumption of the catalyst is low, the consumption of the CO release source is low, the toxicity is relatively low, the cost is relatively low, the substrate applicability is high, and the yield of target object is high, so that the method can be extensively applied to the preparation of a natural product, i.e., the benzopyrone compound.

Owner:SHAANXI NORMAL UNIV

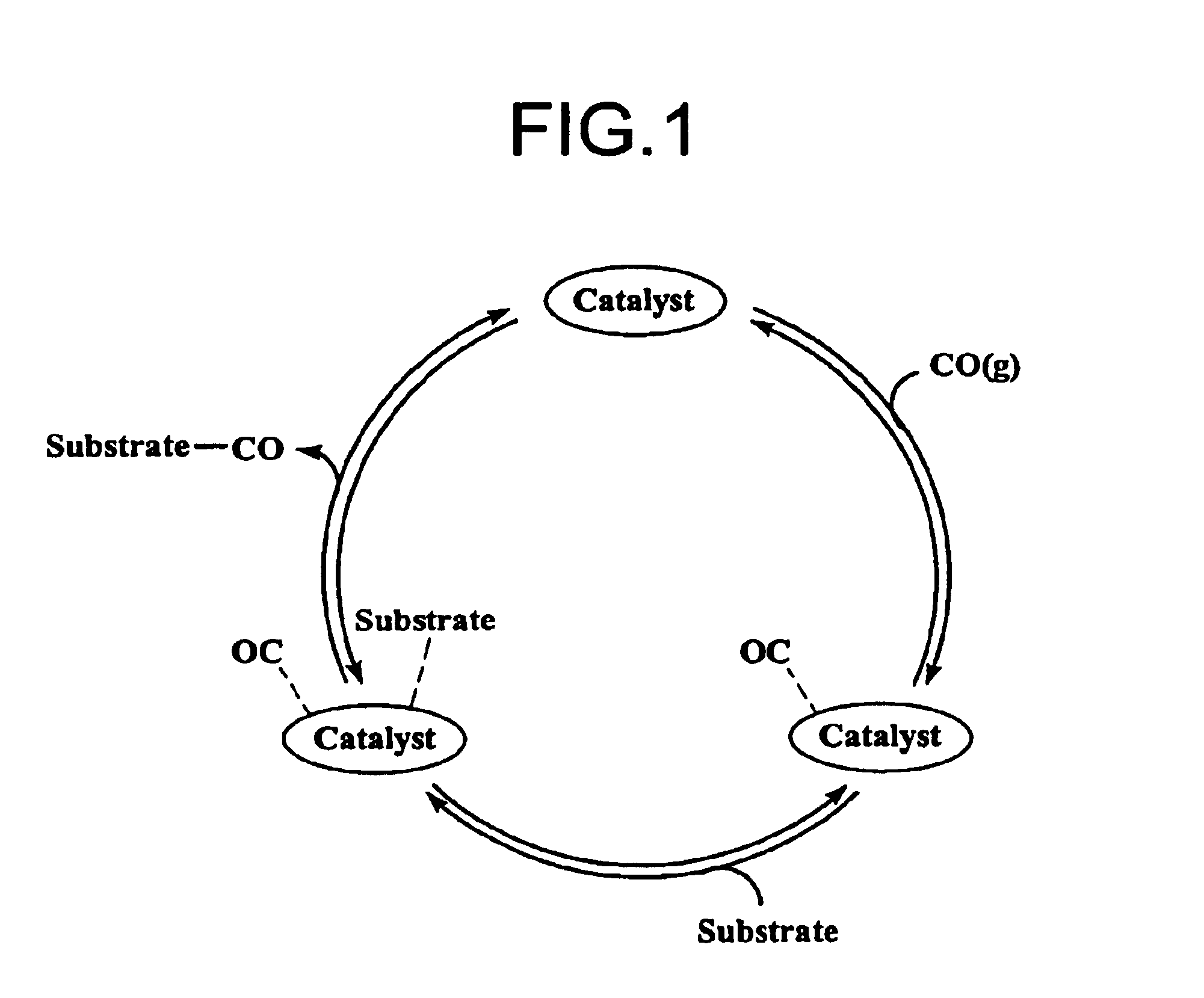

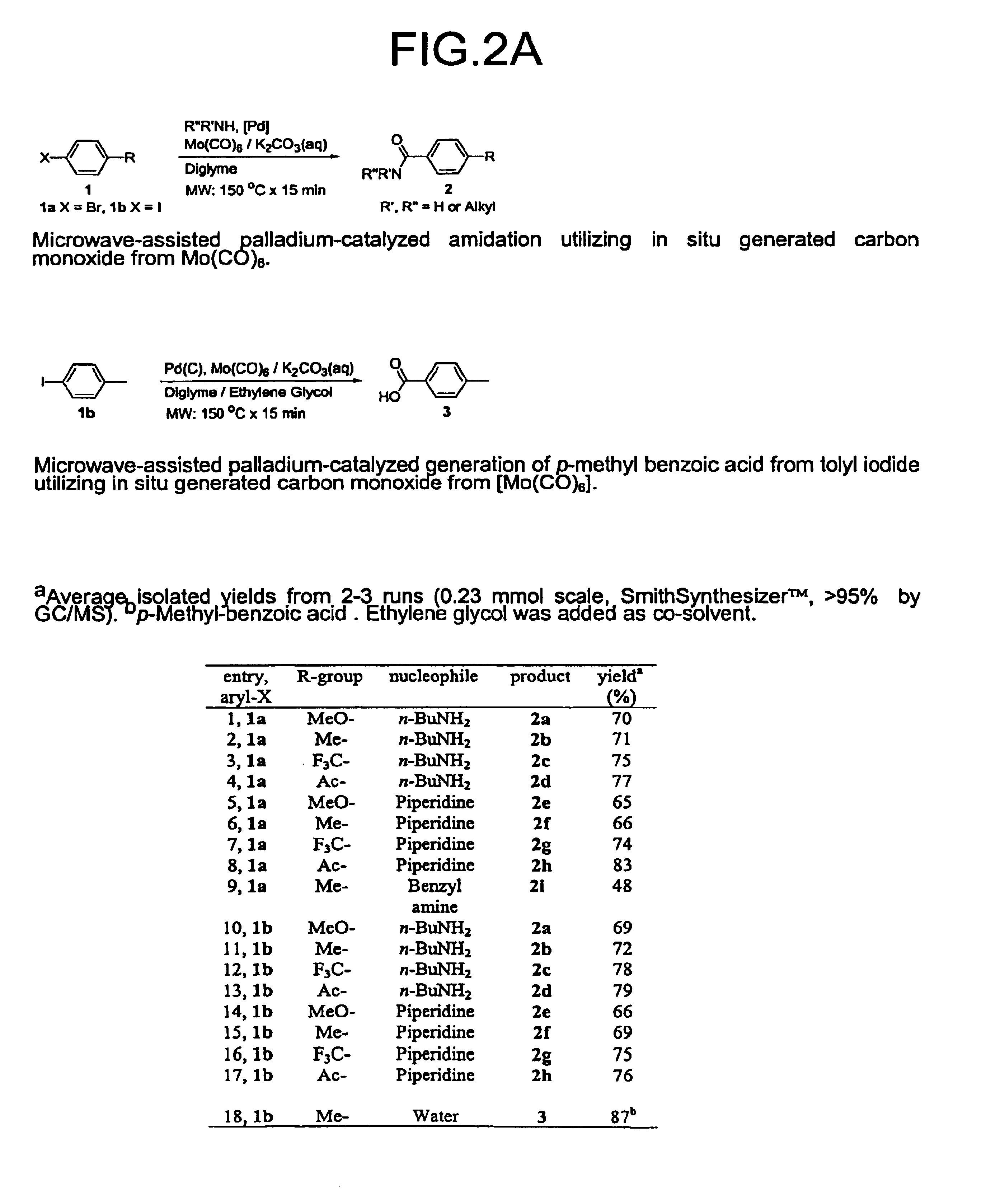

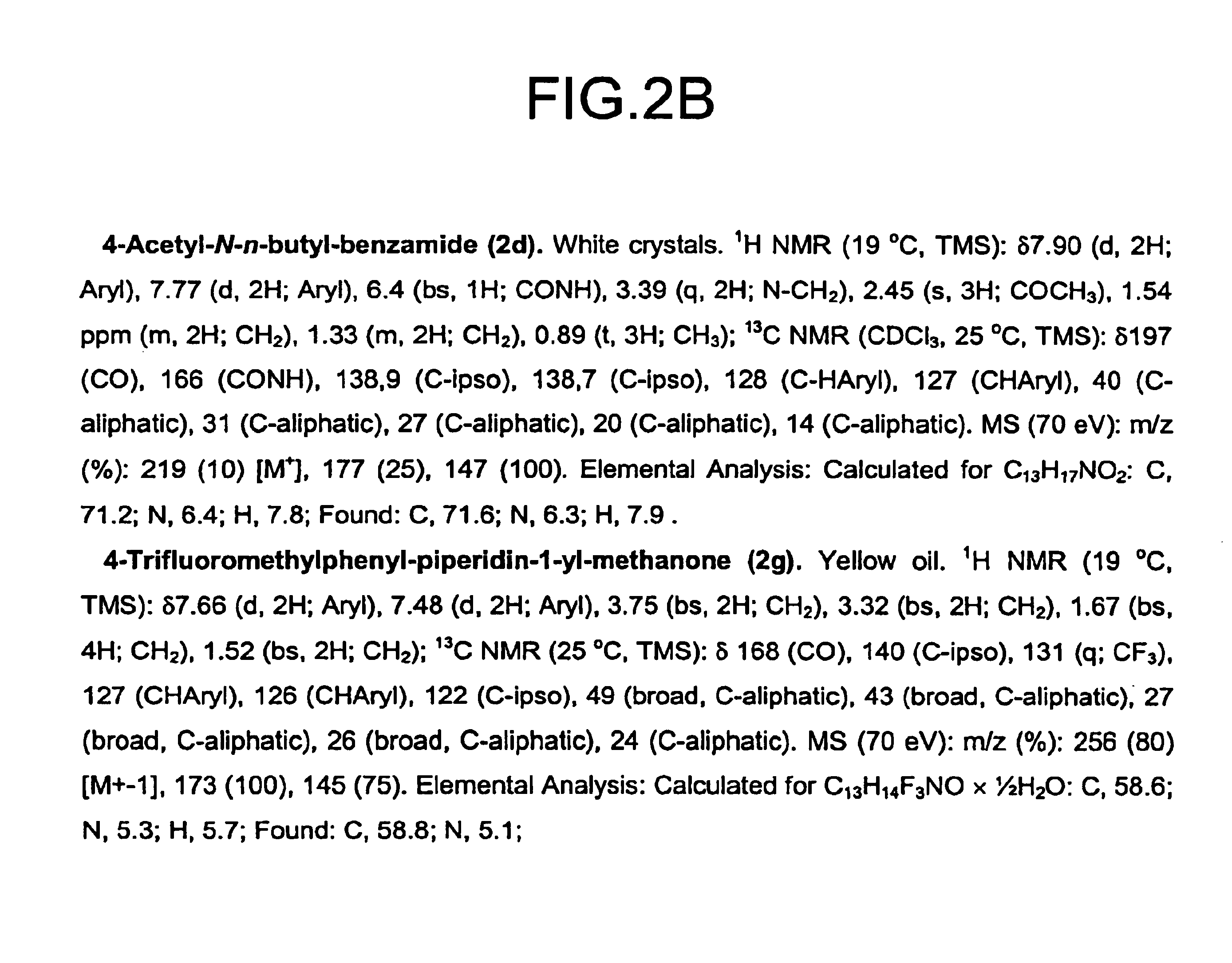

Organic reactions with CO generating materials

InactiveUS6958243B2Organic compound preparationCarboxylic acid amides preparationMetal catalystOrganic reaction

The present invention is drawn to a method of performing a one-pot organic reactions including carbon monoxide as reactant, without the use of an external CO gas source, wherein a reaction mixture containing a solid or liquid CO releasing compound, a non-metal substrate and a metal catalyst is exposed to an energy source to release carbon monoxide from the CO releasing compound and wherein carbon atoms of the released carbon monoxide form a bond with the non-metal substrate compound. The present invention is further drawn to a method of preparing chemical libraries and a kit for organic reactions.

Owner:BIOTAGE INC

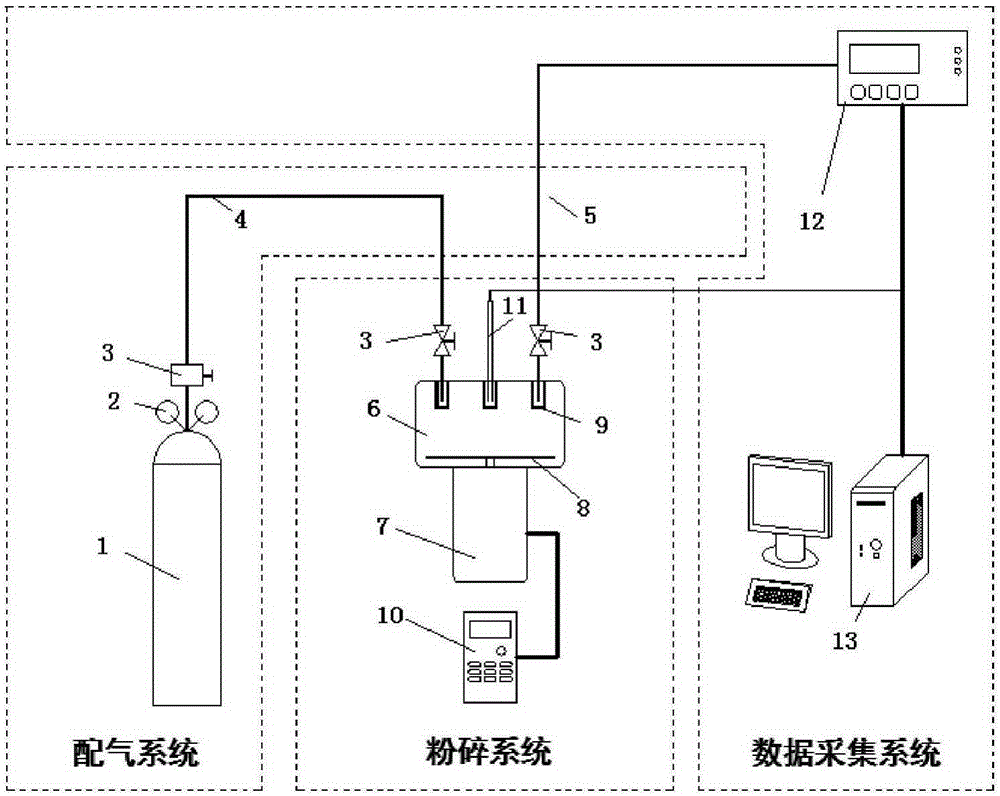

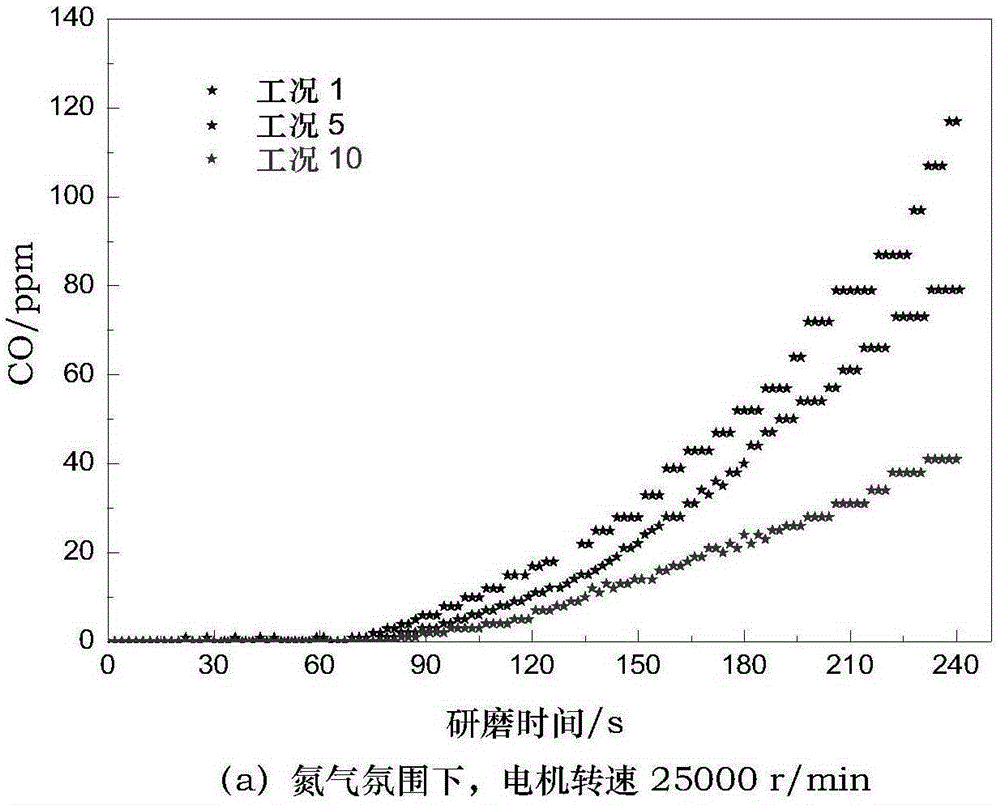

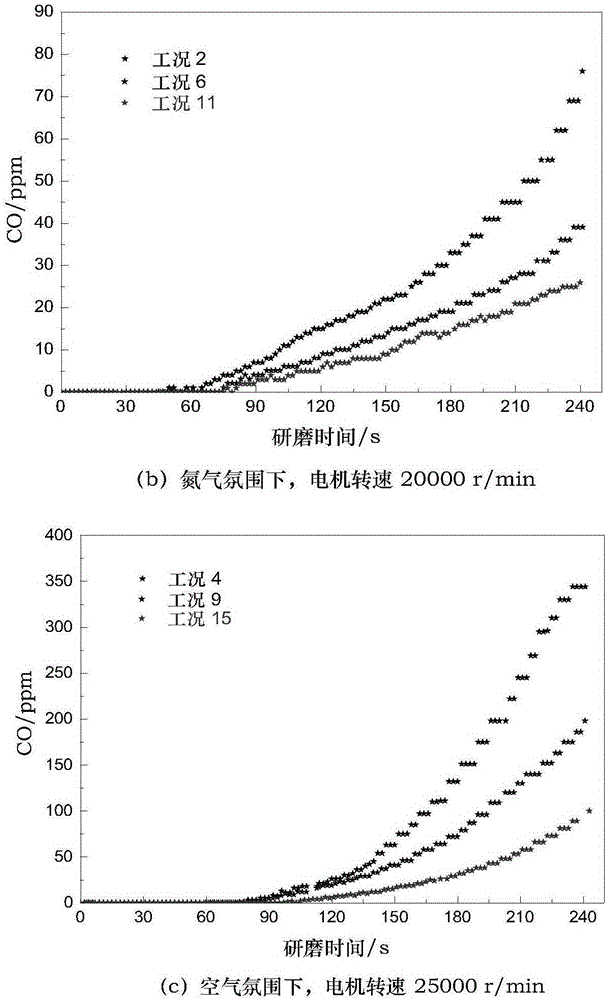

Device system for testing CO release and temperature change in coal incising process

ActiveCN105181165AExperimental conditions are easy to controlAssemble gradientComponent separationThermometers using electric/magnetic elementsData acquisitionDistribution system

The invention discloses a device system for testing CO release and temperature change in a coal incising process and relates to a test system for simulating the coal breaking. The device system comprises a coal incising simulation device and a data acquisition system, wherein the coal incising simulation device comprises a gas distribution system (gas, a pressure meter, a control valve and a gas pipeline), a smashing system (a pulverizer and a frequency converter); and the data acquisition device comprises a temperature measuring thermocouple, a gas chromatograph and a data analysis and collection computer. The gas distribution system is connected with a gas inlet end of the pulverizer, the gas chromatograph is connected with a gas outlet end of the pulverizer, the temperature measuring thermocouple is arranged inside a coal sample tank, and the gas chromatograph and the temperature measuring thermocouple are respectively connected to a computer. The device system can be used for effectively simulating and analyzing the temperature change and gas release condition when the coal structure is damaged during the process that the coal is incised by a coal mining machine. The system is simple and convenient to install and easy to operate, and experiment data have good measurability and operability.

Owner:HENAN POLYTECHNIC UNIV

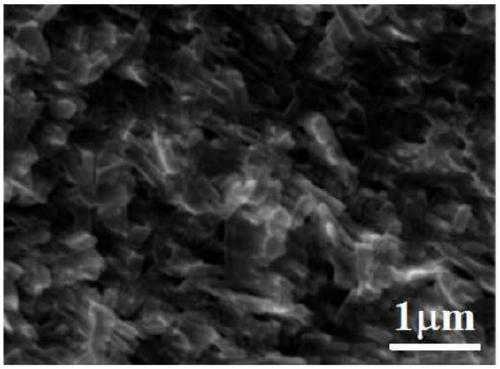

Preparation method of epoxy resin/iron phenyl phosphate composite

ActiveCN109486105AImprove flame retardant performanceHigh smoke suppression effectEpoxyHexamethylenetetramine

The invention belongs to the field of new materials and particularly discloses a preparation method of epoxy resin / iron phenyl phosphate composite. The preparation method includes: adding phenyl phosphoric acid, iron nitrate, polyvinylpyrrolidone and hexamethylenetetramine into a mixed solvent of ethanol, ethylene glycol and water to obtain FePP nanosheets; mixing the FePP nanosheets with epoxy resin L20, heating by oil bath, adding a curing agent, dissolving, vacuumizing to remove bubbles, and solidifying in staged manner to obtain epoxy resin / iron phenyl phosphate composite. Combustion performance results show that when the addition of the FePP nanosheets reaches 4% by weight, oxygen index increases to 35.1, reaching V-1 level (t1+t2 equals 15 s), heat release rate peak is 42.6% less than that of pure epoxy resin, and heat release total quantity decreases by about 26.3%; additionally, smoke release total quantity decreases by 32.8%, and CO release quantity decreases by 50.0%. The preparation method herein is simple and feasible, the epoxy resin / iron phenyl phosphate composite has excellent flame retardance and smoke-inhibiting efficiency and is applicable to flame-retardant protection for the matrix materials, such as foam, plastics, and rubber.

Owner:TECHSTORM MATERIAL TECH SHANGHAI CO LTD

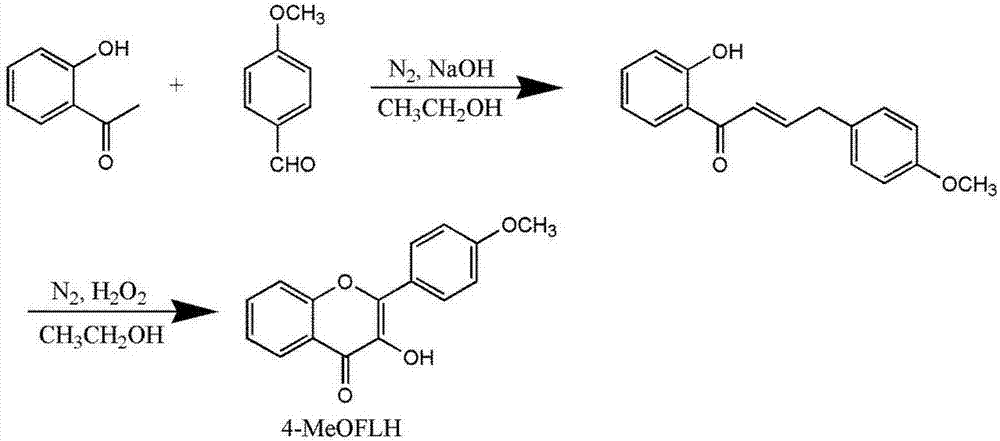

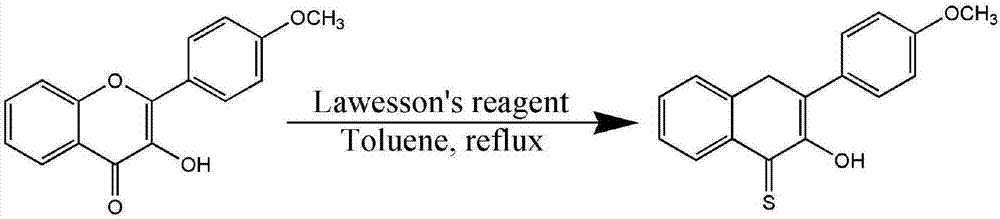

Light induced carbon monoxide release molecule and preparation method thereof

The invention discloses light induced carbon monoxide release molecules (photoCORMs) and a preparation method thereof. The photoCORMs is of modular design and is synthesized from a CO release unit, support ligand and metal zinc ions, wherein 4-MeOFLH or 4-MeOFLTH is adopted as a CO release unit; 6-Me2TPA is used as the support ligand; the CO release unit and the support ligand independently exist in photoCORMs. The preparation method of the photoCORMs comprises the following steps: (1) by taking methoxybenzaldehyde and 2-phenol acetophenone as initial raw materials, synthesizing 4-MeOFLH or 4-MeOFLTH; (2) by taking 2-(aminomethyl) pyridine as another initial raw material, synthesizing 6-Me2TPA; (3) enabling the CO release unit and the support ligand to react with metal zinc ions, thereby synthesizing photoCORMs. The light induced carbon monoxide release molecules have the beneficial effects that firstly photoCORMs is good in CO release property, and as a CO release medicine, is capable of greatly reducing side effects on bodies, and CO release can be induced through visible light; secondly, the molecule is definite in synthesis step, controllable in process and possible in batched production.

Owner:NORTHWEST UNIV(CN)

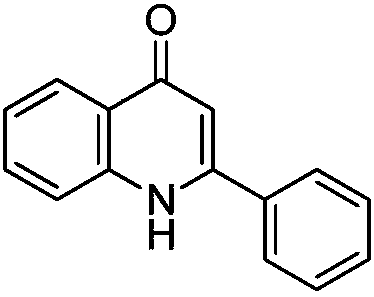

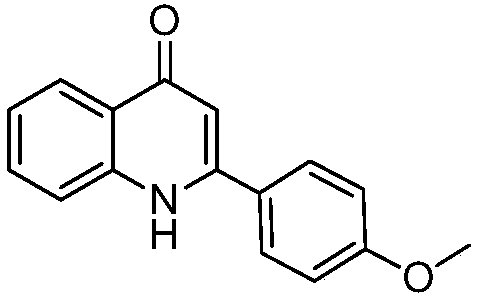

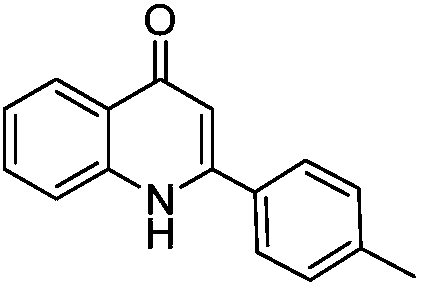

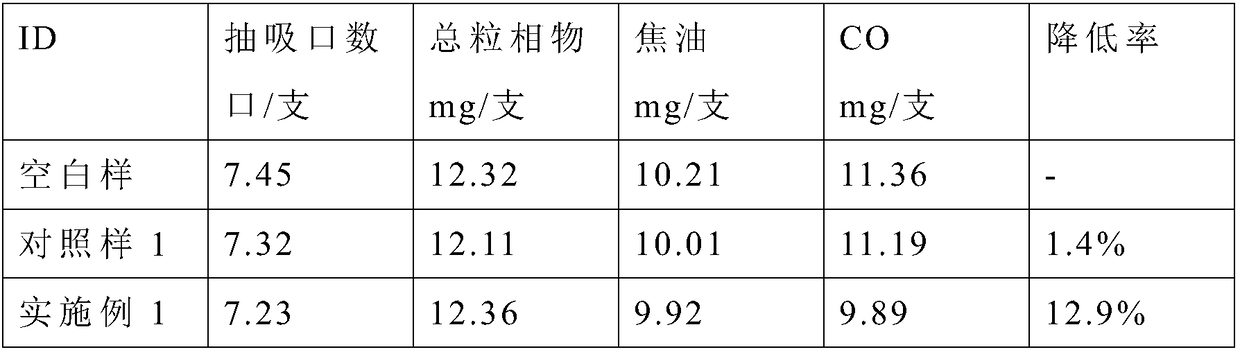

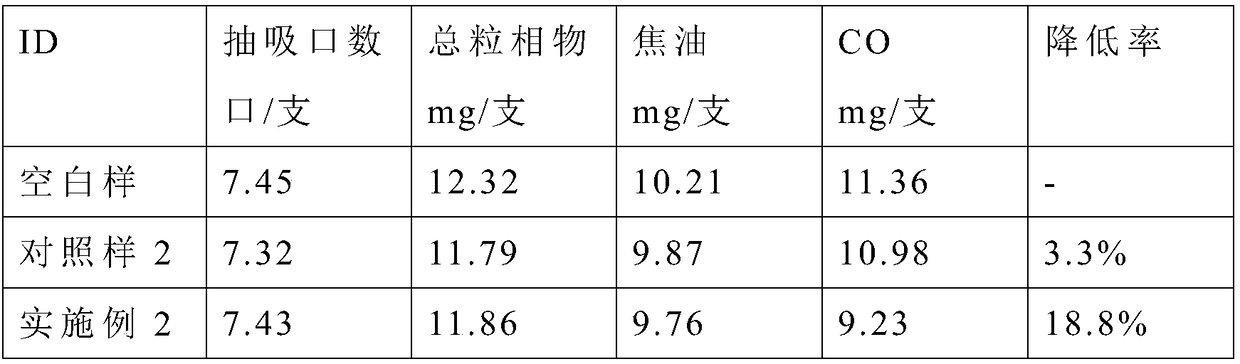

Method for preparing quinolones compound by using pentacarbonyl iron as CO release source

The invention discloses a method for preparing quinolones compound by using pentacarbonyl iron as a CO release source. In this method, iron pentacarbonyl is used as a CO release source, and palladiumacetate is used as a catalyst, potassium phosphate and piperazine are used as a base, and acetonitrile is used as a solvent to couple a 2-iodoaniline compound with a terminal alkyne under mild conditions to obtain the quinolones compound. The preparation method has the advantages of simple operation, mild reaction conditions, less catalyst use, less CO release source use, low toxicity, lower cost,wide substrate applicability, and high target compound yield, and the method can be widely used for the preparation of natural quinolones compound.

Owner:SHAANXI NORMAL UNIV

Modified active carbon additive for reducing CO release amount in flue gas and preparation method and application thereof

ActiveCN108523215AReduce CO releaseSmell has no obvious effectTobacco smoke filtersFiltrationCuprous salt

The invention relates to a modified active carbon additive for reducing CO release amount in flue gas and a preparation method and application thereof and belongs to the technical field of cigarette harm reduction. The method comprises the following steps: adding a polyvinyl pyrrolidone (PVP) compound into water, and performing stirring for dissolving the compound to obtain a PVP aqueous solution;adding a cuprous salt aqueous solution of which the concentration is 1wt%-10wt% to the PVP aqueous solution, adjusting the pH value to be 5.0 with acid, performing reaction at 45 DEG C until no precipitate is separated out, performing filtration, washing the filter residue with water to remove free metal ions, and performing drying to obtain a PVP-Cu(I) complex; and dissolving the PVP-Cu(I) complex in ethanol, adding active carbon, performing stirring at room temperature for 30 min, performing filtration, and drying the filter residue to obtain the modified active carbon additive. The modified active carbon additive provided by the invention is simple in preparation and low in cost; after the prepared product is added to a cigarette filter, the CO release amount in the flue gas can be obviously reduced; and furthermore, the product has no obvious influence on the smoking taste of cigarettes and has good application prospects.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com