Halogen-free flame retardant polypropylene material with low smoke release rate and preparation method thereof

A release rate, polypropylene technology, applied in the field of halogen-free flame retardant polypropylene material and its preparation, can solve the problems of not paying attention to smoke release, poor mechanical properties of flame retardant polypropylene materials, low flame retardant efficiency, etc. Encapsulation, low smoke release rate, and the effect of expanding the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

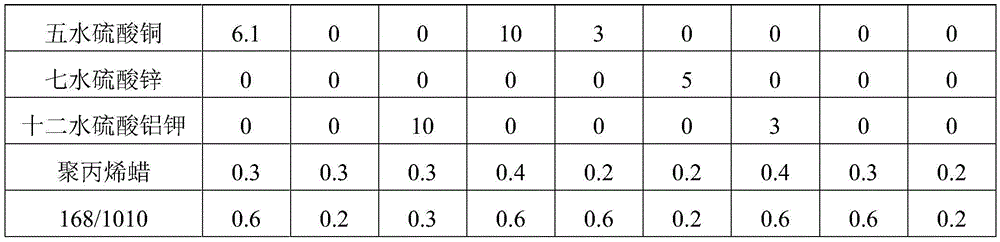

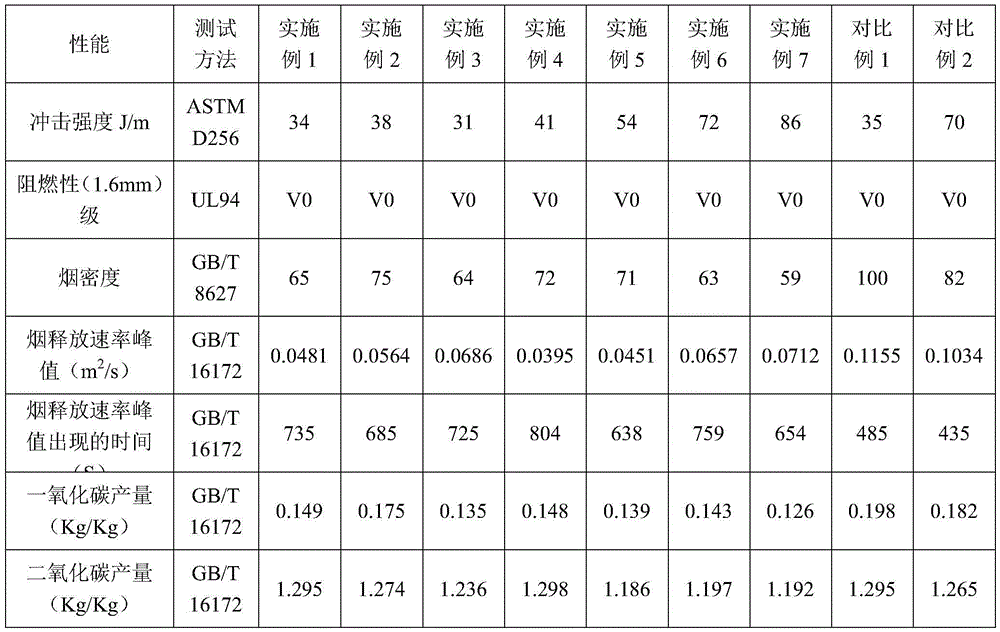

[0035] See Table 1 for the components and proportions of Examples 1-7 and Comparative Examples 1-2.

[0036] The polypropylenes used in Examples 1-7 and Comparative Examples 1-2 are copolymerized polypropylene K7926 and homopolypropylene S2040 produced by Shanghai Secco;

[0037] The halogen-free flame retardants adopted in Examples 1-7 and Comparative Examples 1-2 are ammonium polyphosphate (HT-208) produced by Wujiang Today Chemical Co., Ltd., melamine pyrophosphate produced by Shanghai Yijing Industrial Co., Ltd. and Jinan Aluminum hypophosphite produced by Jinquan Chemical Co., Ltd.;

[0038] The alkali-free long glass fiber 988A produced by the glass fiber Jushi Company used in Examples 1-7 and Comparative Examples 1-2.

[0039] The polyketone resin (PK) used in Examples 1-7 and Comparative Examples 1-2 is M230A produced by Korea Hyosung Corporation.

[0040] The nano-vermiculite used in Examples 1-7 and Comparative Examples 1-2 was produced by Lingshou County Tengda Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com