Patents

Literature

623 results about "Polyketone" patented technology

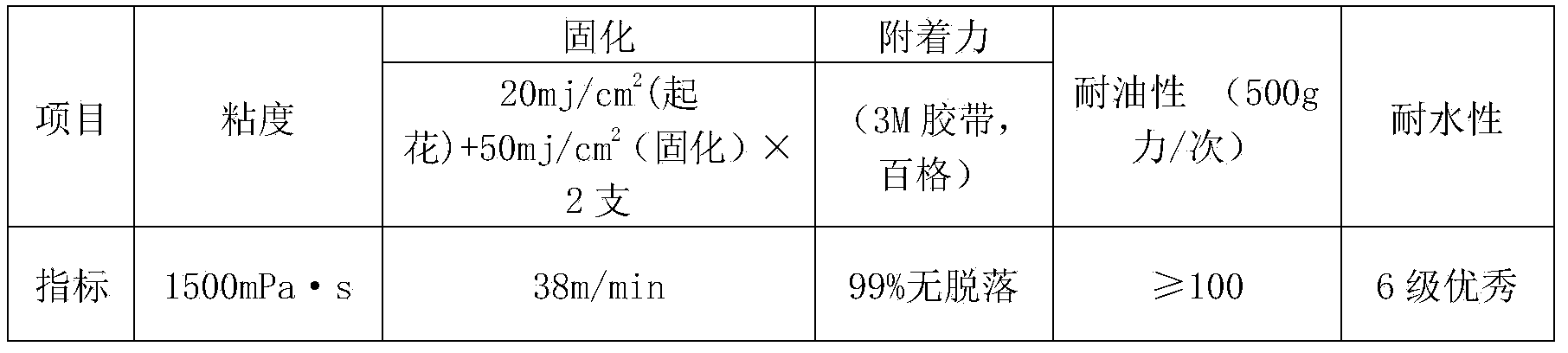

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

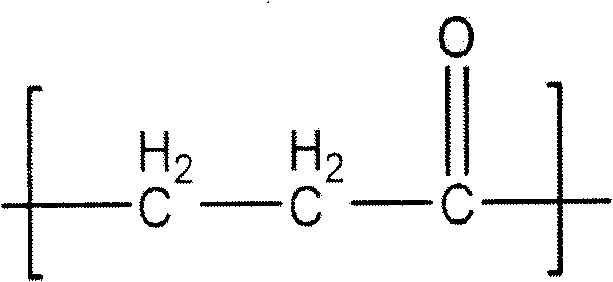

Polyketones are a family of high-performance thermoplastic polymers. The polar ketone groups in the polymer backbone of these materials gives rise to a strong attraction between polymer chains, which increases the material's melting point (255 °C for copolymer (carbon monoxide ethylene), 220 °C for terpolymer (carbon monoxide, ethylene, propylene). Trade names include Carilon, Karilon, Akrotek, and Schulaketon. Such materials also tend to resist solvents and have good mechanical properties. Unlike many other engineering plastics, aliphatic polyketones such as Shell Chemicals' Carilon are relatively easy to synthesize and can be derived from inexpensive monomers. Carilon is made with a palladium(II) catalyst from ethylene and carbon monoxide. A small fraction of the ethylene is generally replaced with propylene to reduce the melting point somewhat. Shell Chemical commercially launched Carilon thermoplastic polymer in the U.S.in 1996, but discontinued it in 2000. SRI International offers Carilon thermoplastic polymers. Hyosung announced that they would launch production in 2015

Polyketone Plasticizers

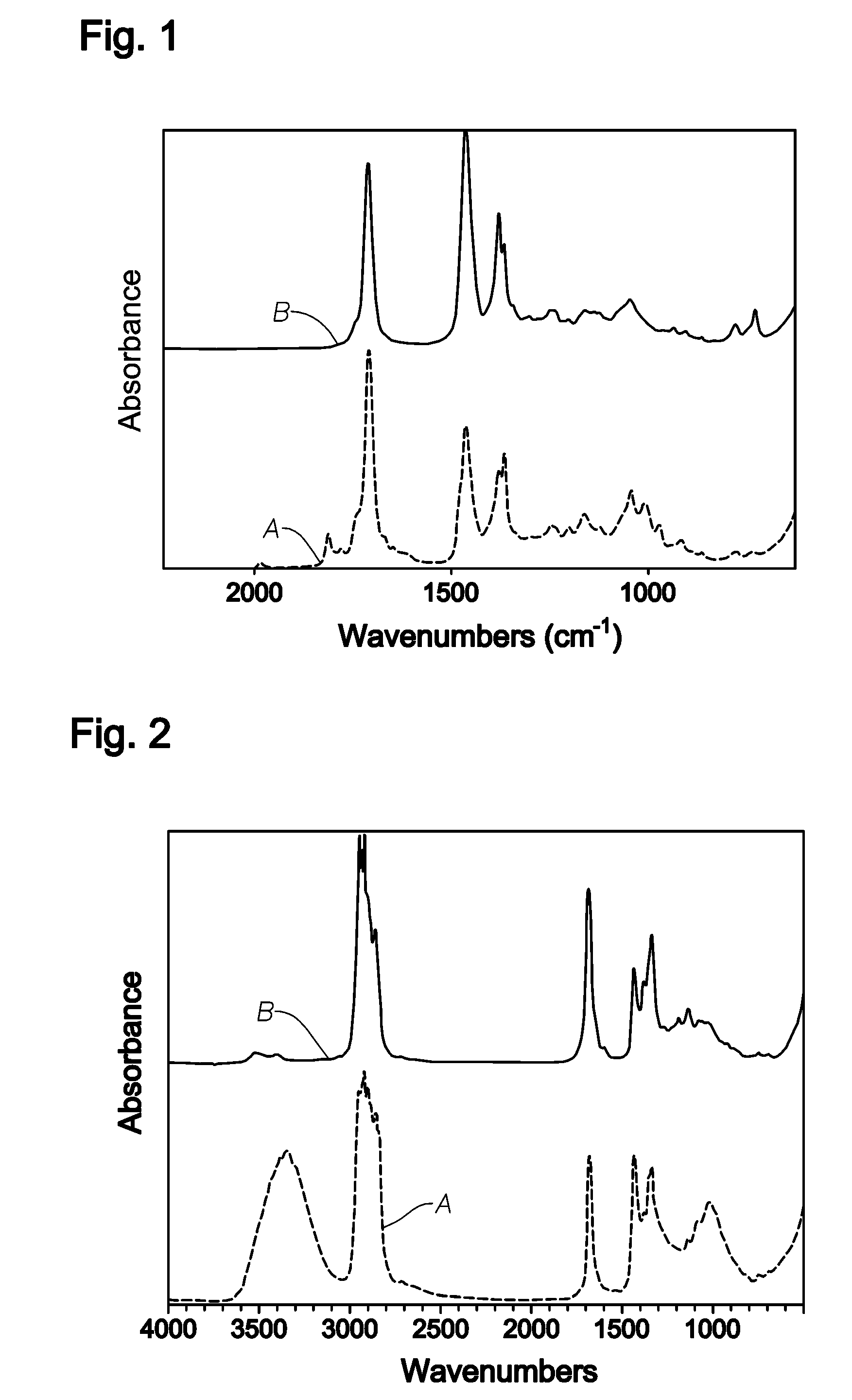

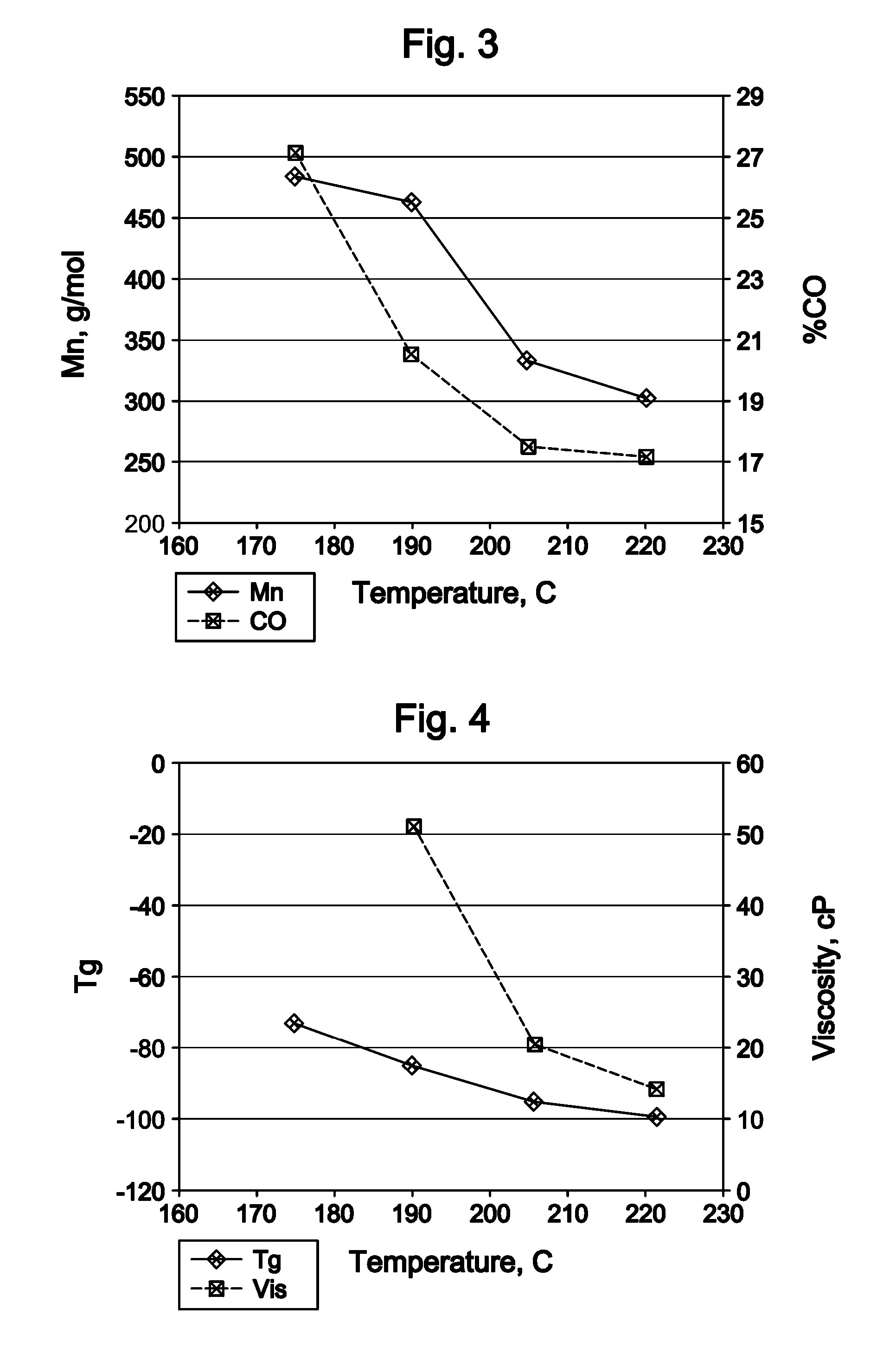

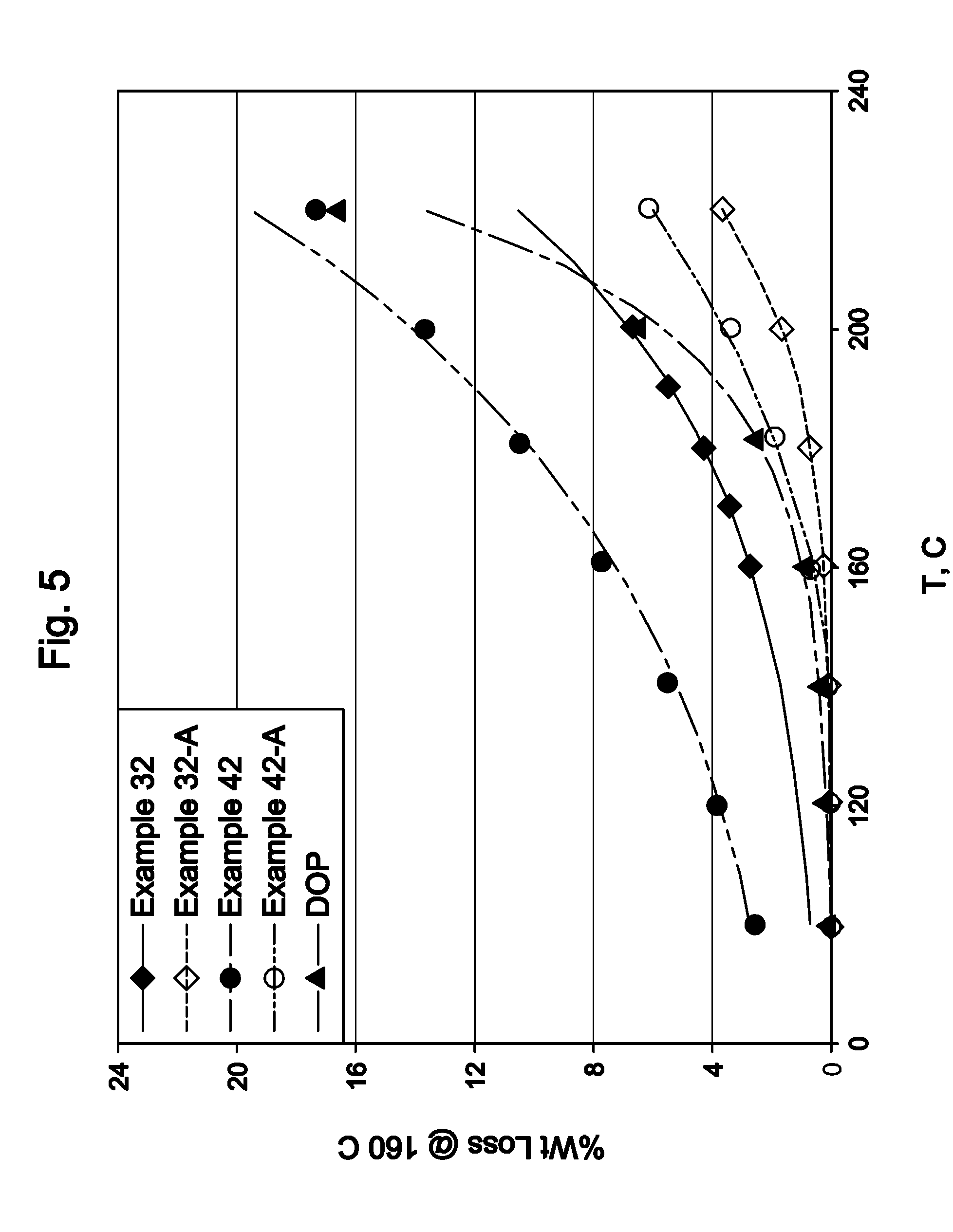

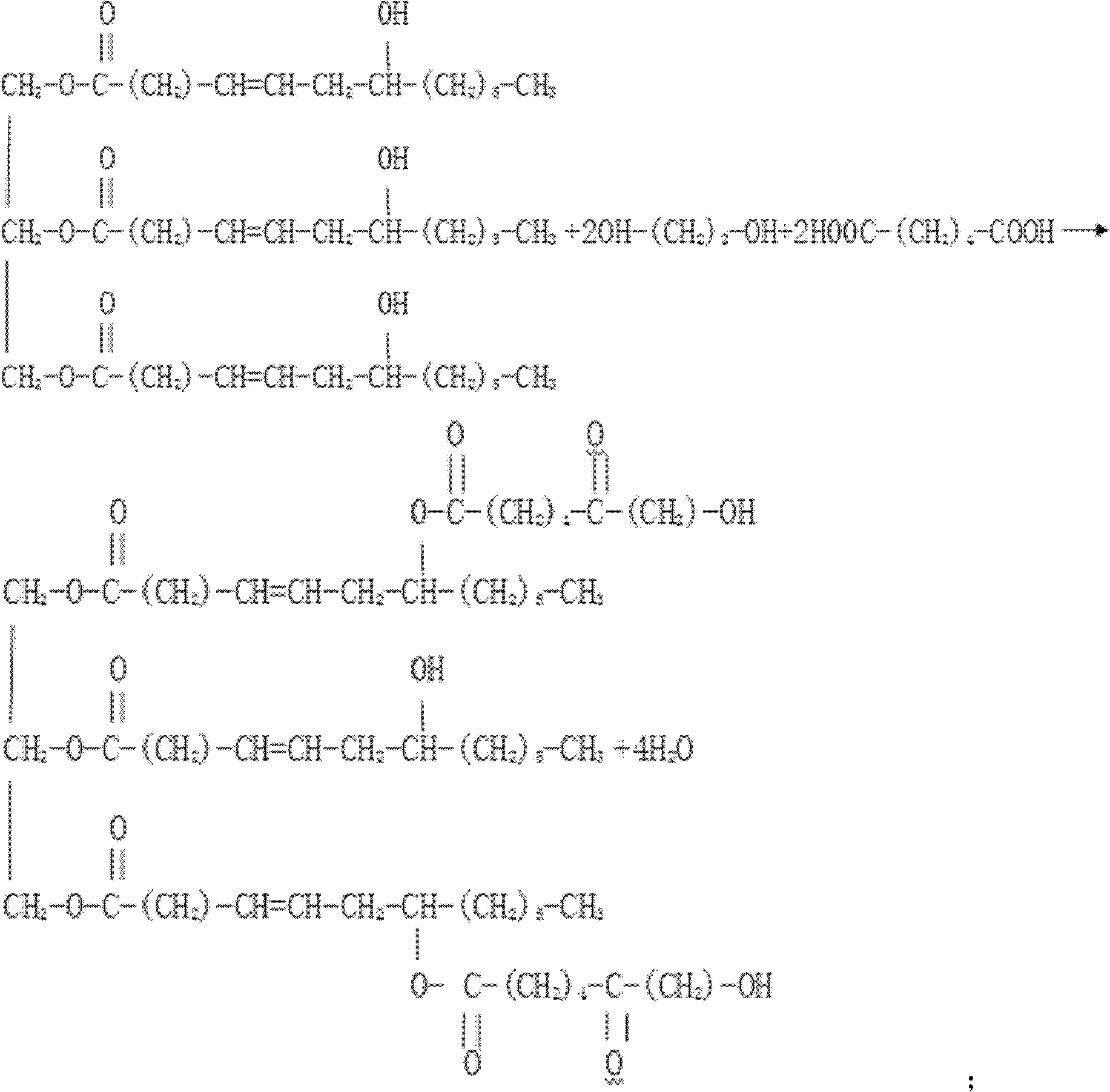

InactiveUS20080242895A1Remove colorEasy to separateOrganic compound preparationCarbonyl compound preparation by oxidationPolymer sciencePlasticizer

The invention relates to polyketone compounds and the at least partially hydrogenated products thereof, the use of said polyketone compounds and / or the at least partially hydrogenated products thereof as plasticizers, processes of making polyketone compounds and the at least partially hydrogenated products thereof, compositions comprising the polyketone compounds and / or the at least partially hydrogenated products thereof, and to articles formed from products of the invention.

Owner:EXXONMOBIL CHEM PAT INC

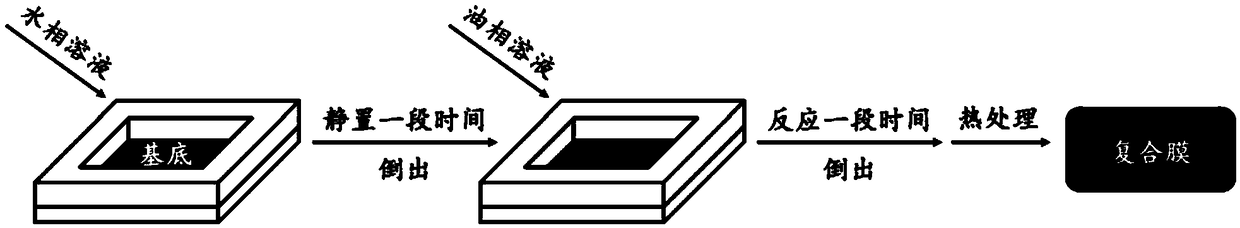

Method for preparing high-throughput covalent organic framework nano-filtration membrane on basis of interfacial polymerization

ActiveCN108889139AGood chemical stabilityHigh permeation fluxSemi-permeable membranesFiltration membraneBinding force

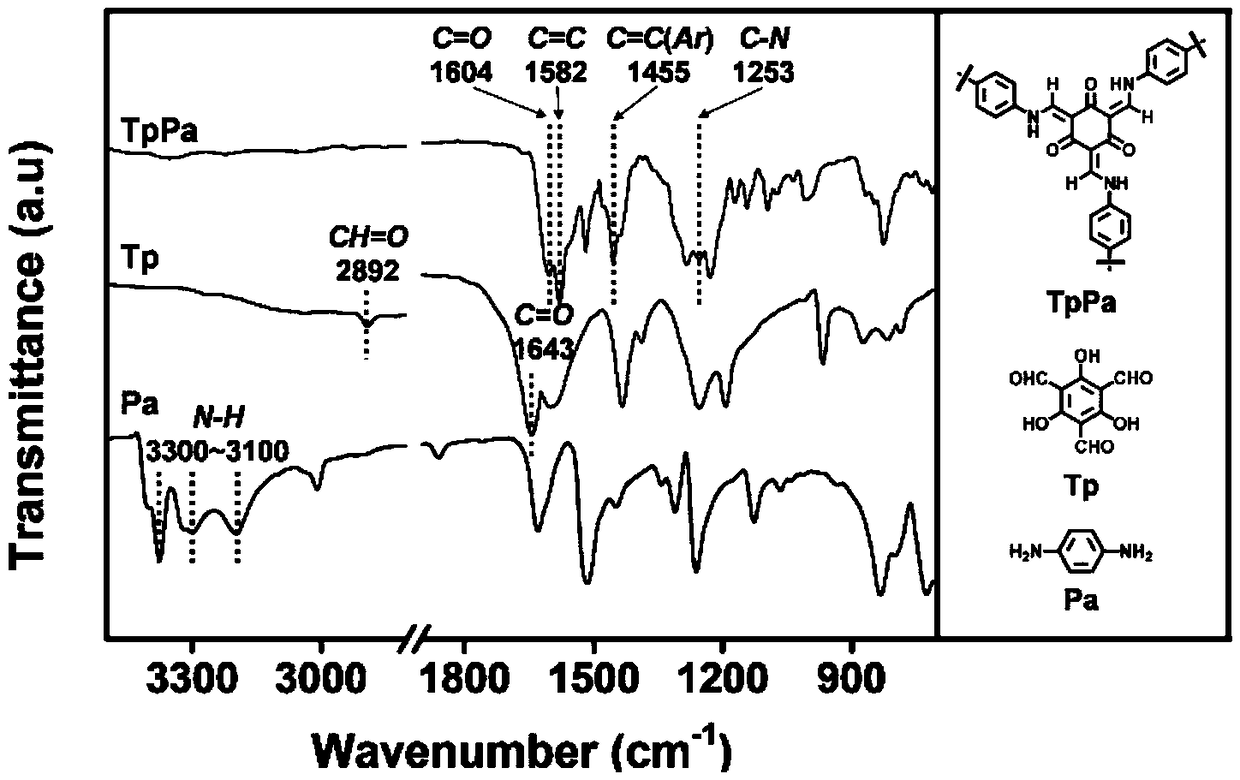

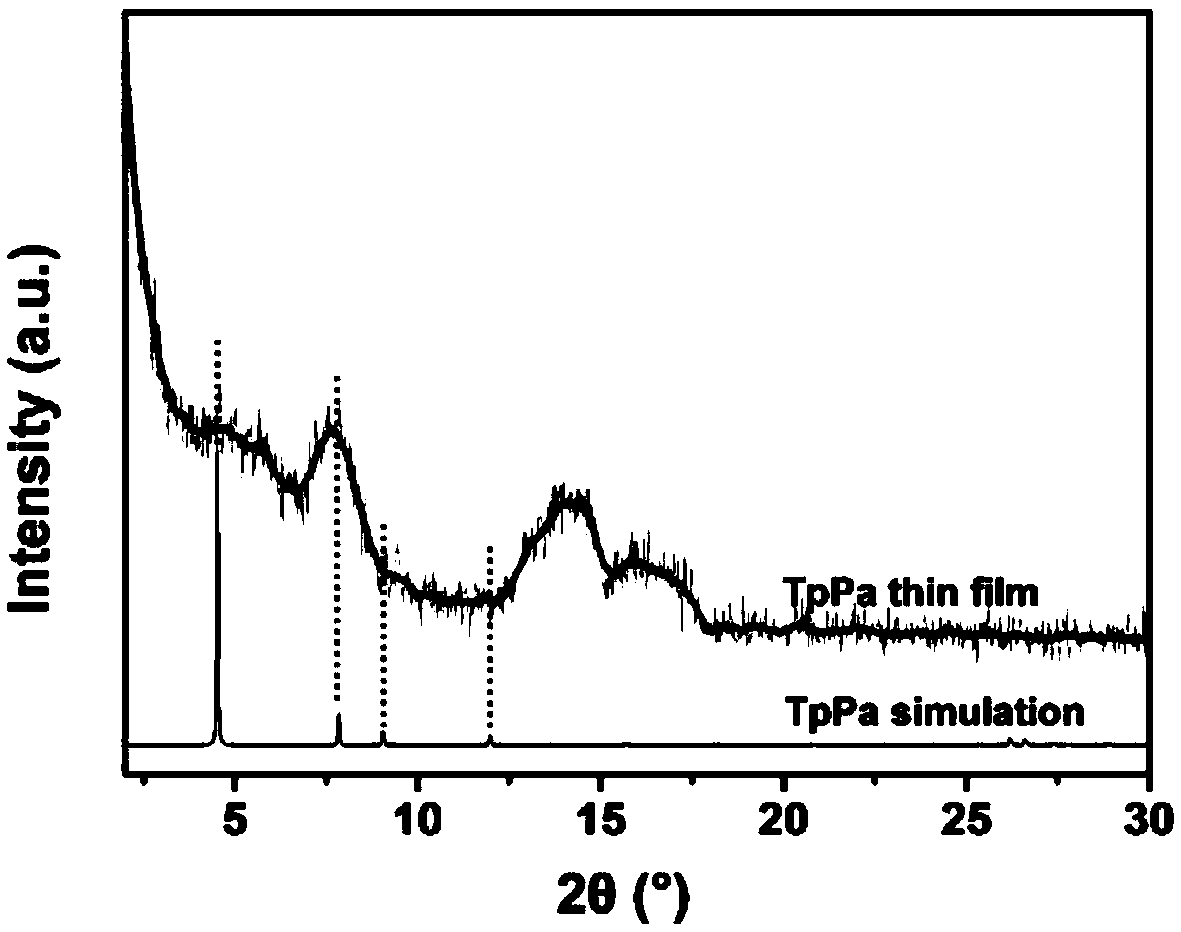

The invention provides a method for effectively preparing a high-throughput covalent organic framework (COFs) nano-filtration membrane on the basis of interfacial polymerization. The method comprisesthe following steps: sequentially applying an aqueous phase solution dissolved with polyamine monomers and an organic phase solution dissolved with polyaldehyde / polyketones monomers to the surface ofa porous carrier to carry out interfacial polymerization; diffusing the polyamine monomers in the aqueous phase solution saturated porous carrier to a water / oil interface to carry out schiff base reaction with polyaldehyde / polyketones in an organic phase, and gradually forming a covalent organic framework separating layer on the surface of the porous carrier by a conformal growth manner; and thencarrying out heat treatment on a composite membrane consisting of the separating layer and the porous carrier to enhance the binding force of the covalent organic framework separating layer and the porous carrier, and promoting crystallization and conversion of the covalent organic framework. The method not only is simple and convenient to operate and short in technological process, but also is well compatible with an existing process, thus, continuous product becomes possible, and the prepared composite membrane has high flux.

Owner:NANJING UNIV OF TECH

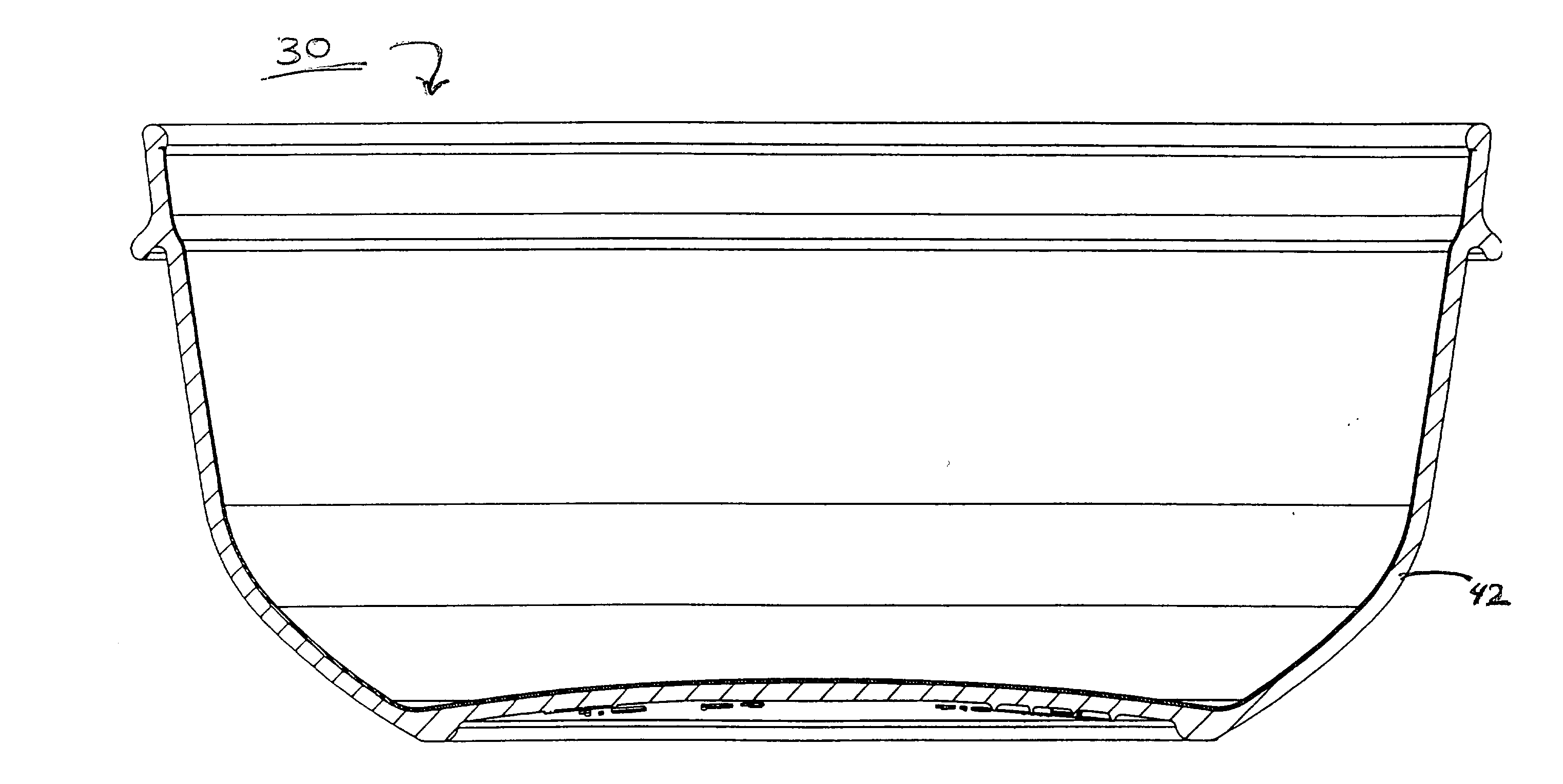

Multi-layer plastic articles and methods of making the same

A three-dimensional, multi-layer plastic product that is resistant to damage caused by environmental factors such as heat, chemicals, desiccants, oxygen, and / or weather is disclosed. The multi-layer product includes an engineering resin layer affixed to a commodity resin layer. The engineering resin layer of the multi-layer film may be directly fused to the commodity resin or post-consumer regrind layer. Alternatively, the engineering resin layer may be tied to the commodity resin or post-consumer regrind layer through the use of one or more adhesive and / or tie layers. The commodity resin layer may be manufactured from an economical polymer material such as a polypropylene, polyethylene, polystyrene or post-consumer regrind. Suitable engineering resins may be any of a variety of suitable materials such as a polysulphone, polymethylpentene, polyester, polycarbonate, polyetherimide, nylon, polyarylate, polyphenylenesulphide, polyphenylene oxide, polyethersulphone, aromatic polyketone, liquid crystal polymer, and mixtures thereof, for example, a method for manufacturing a three-dimensional multi-layer plastic product is also disclosed which includes the steps of providing an extruded or laminated sheet comprising an engineering resin layer, thermoforming a three-dimensional shell from the sheet, and injection molding a commodity resin layer onto the thermoformed shell.

Owner:RUBBERMAID

Alcohol-soluble aqueous composite plastic ink for gravure and making method thereof

ActiveCN1970655AGood alcohol solubilityGood solvent releaseInksOther printing apparatusSolubilityPropionate

The invention discloses a gravure alcohol aquosity composite plastic ink, which comprises the following parts: polybasic allyl propionate copolymerized resin, polyketone resin, dye, dispersant, adhesion accelerating and chelant and alcohol. The invention makes ink possess excellent alcohol solubility and solvent releasing property, which improves ink fluidity and adhesion effectively.

Owner:CHENGDU XINJIN TUOZHAN PRINTING INK

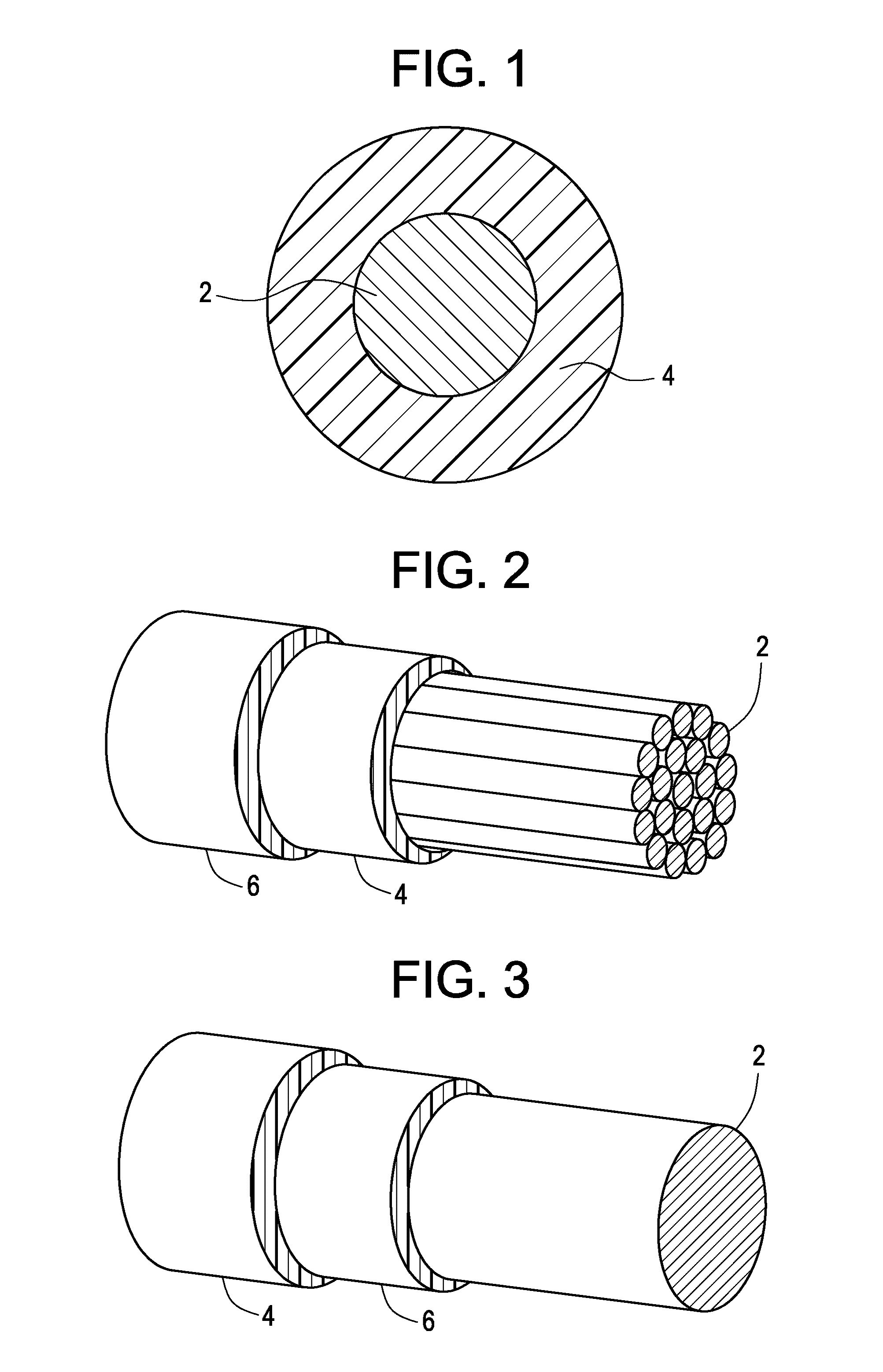

Flame retardant polymer compositions

InactiveUS6025422AReduce the amount requiredIncrease resistancePlastic/resin/waxes insulatorsSynthetic resin layered productsPolymer sciencePolyketone

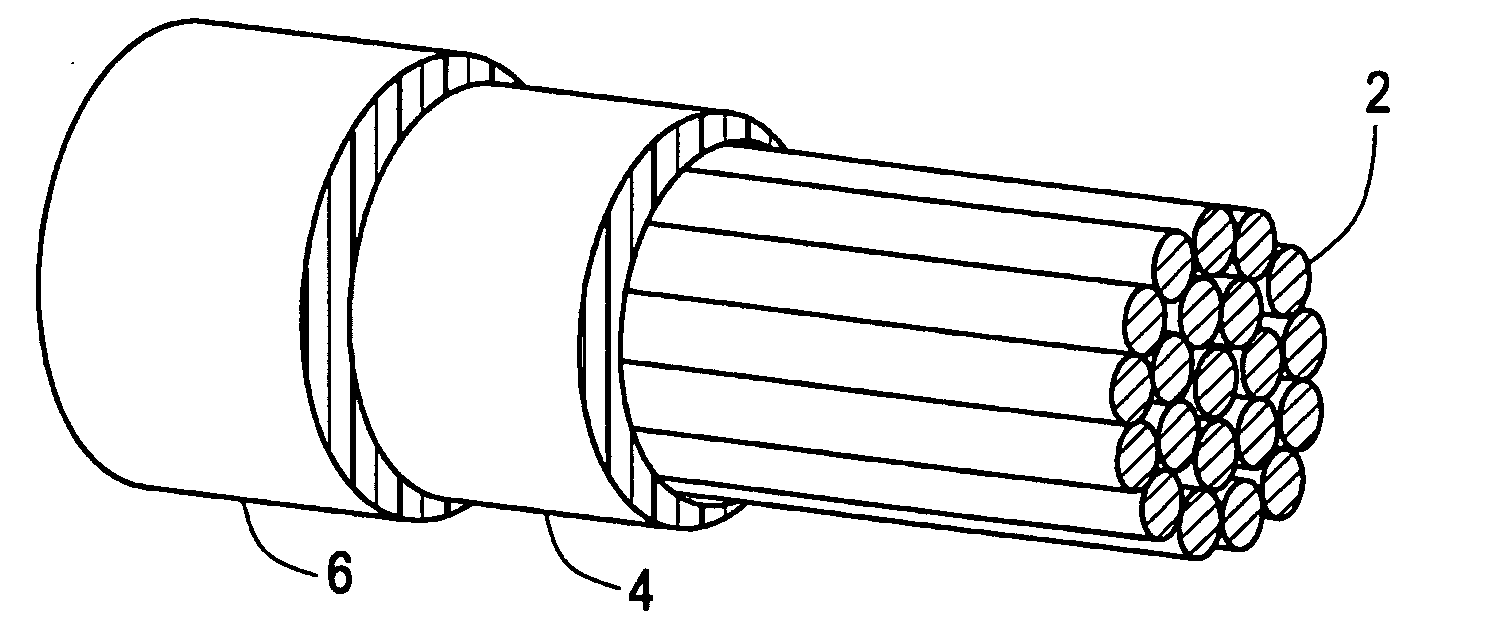

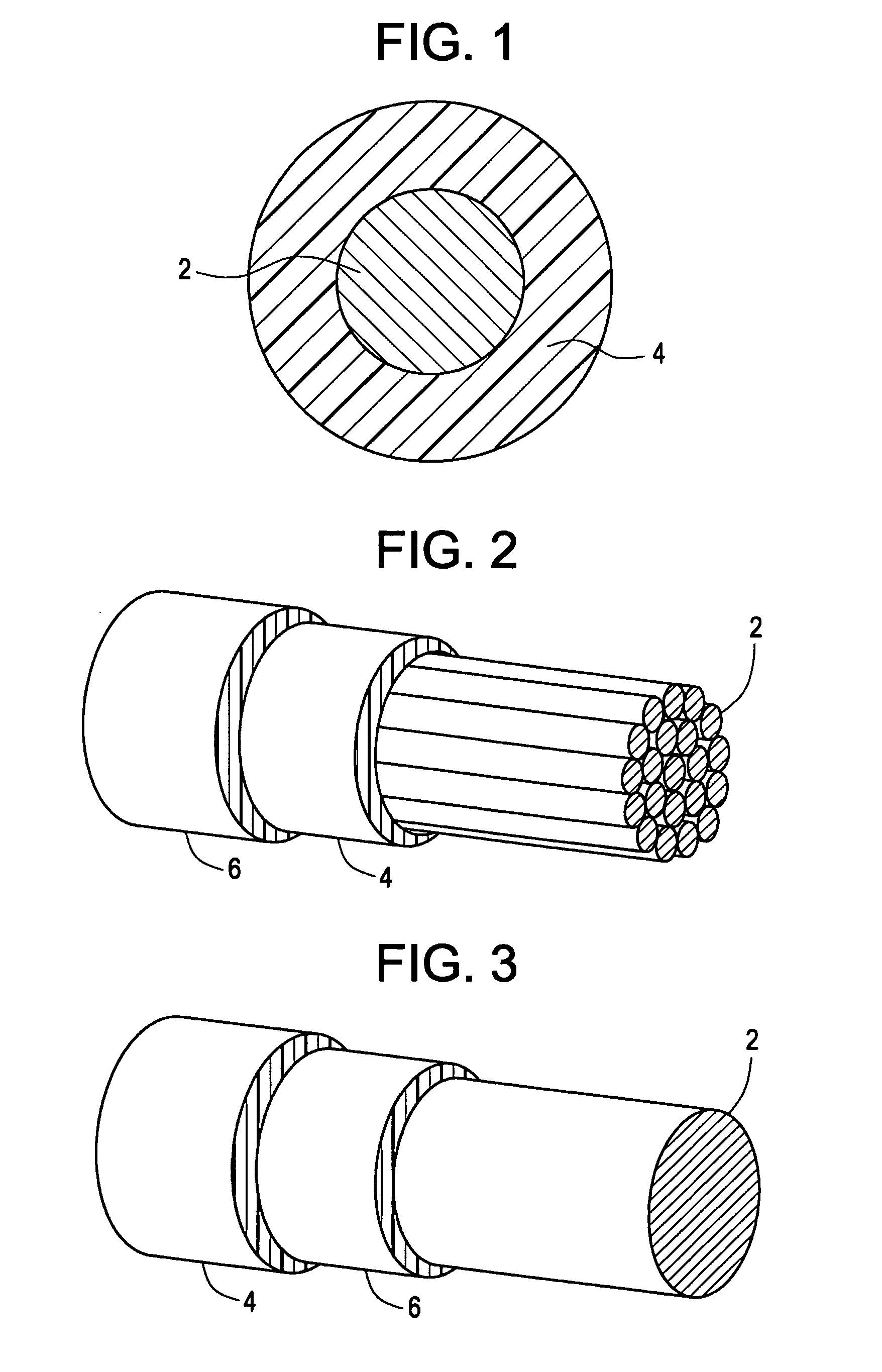

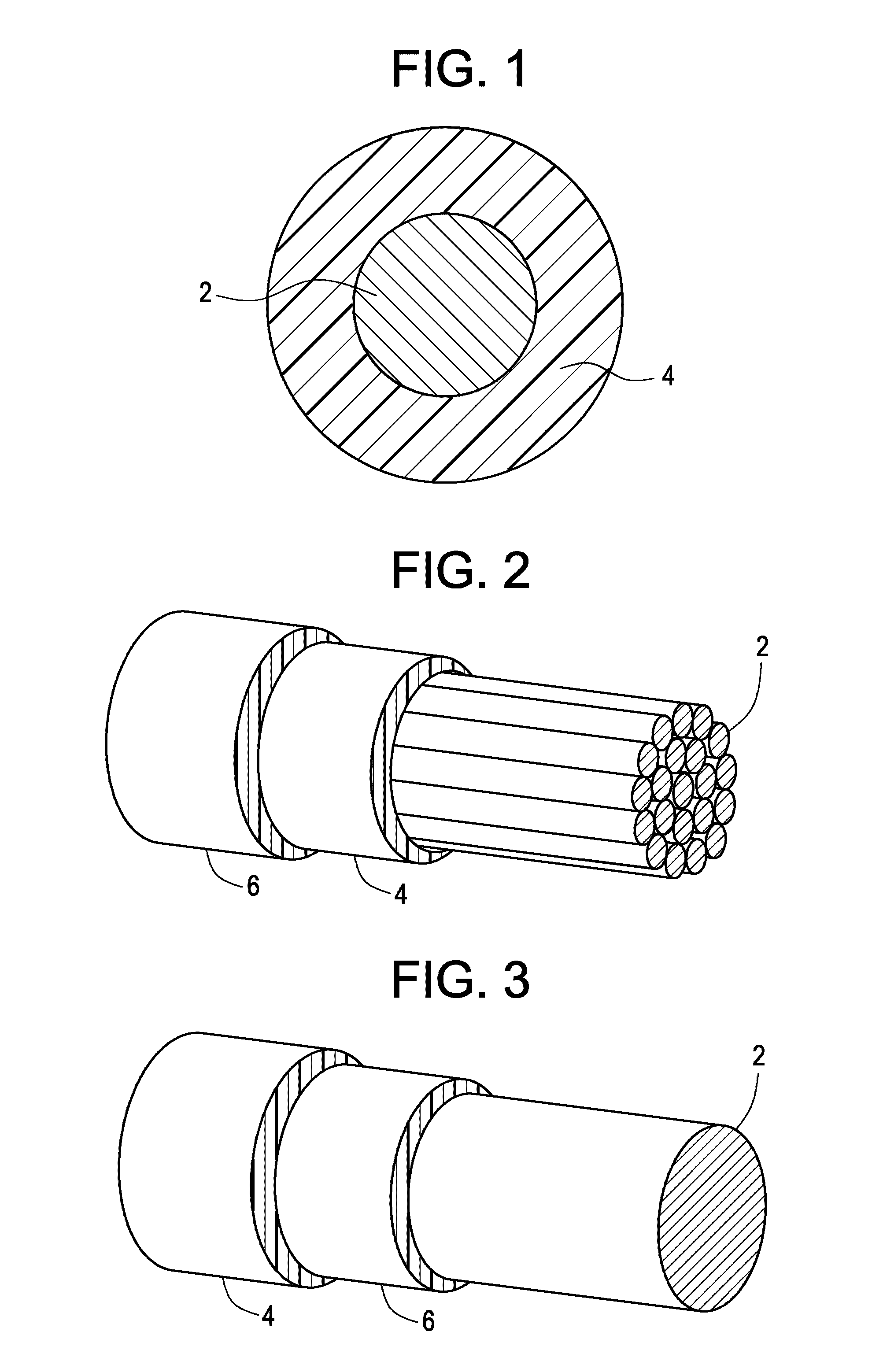

A composition that includes a hydrated inorganic filler and a polymer blend is disclosed. The polymer blend includes a polymerization or copolymerization product of one or more ethylenically unsaturated monomers. In addition, the polymer blend includes an aliphatic polyketone. The incorporation of aliphatic polyketone with polyethylene based polymers or copolymers results in dramatic improvements in both drip resistance and char strength; moreover, the composition of the present invention can use reduced amounts of hydrated inorganic filler relative to conventional polyethylene based compositions. This reduction in the amount of hydrated filler is expected to lead to improvements in physical properties and extrudability not otherwise possible. These properties make the compositions of the present invention particularly useful as an outer layer for electrical wires, optical fibers, or cables containing at least one wire, optical fiber, or both.

Owner:CORNING OPTICAL COMM LLC

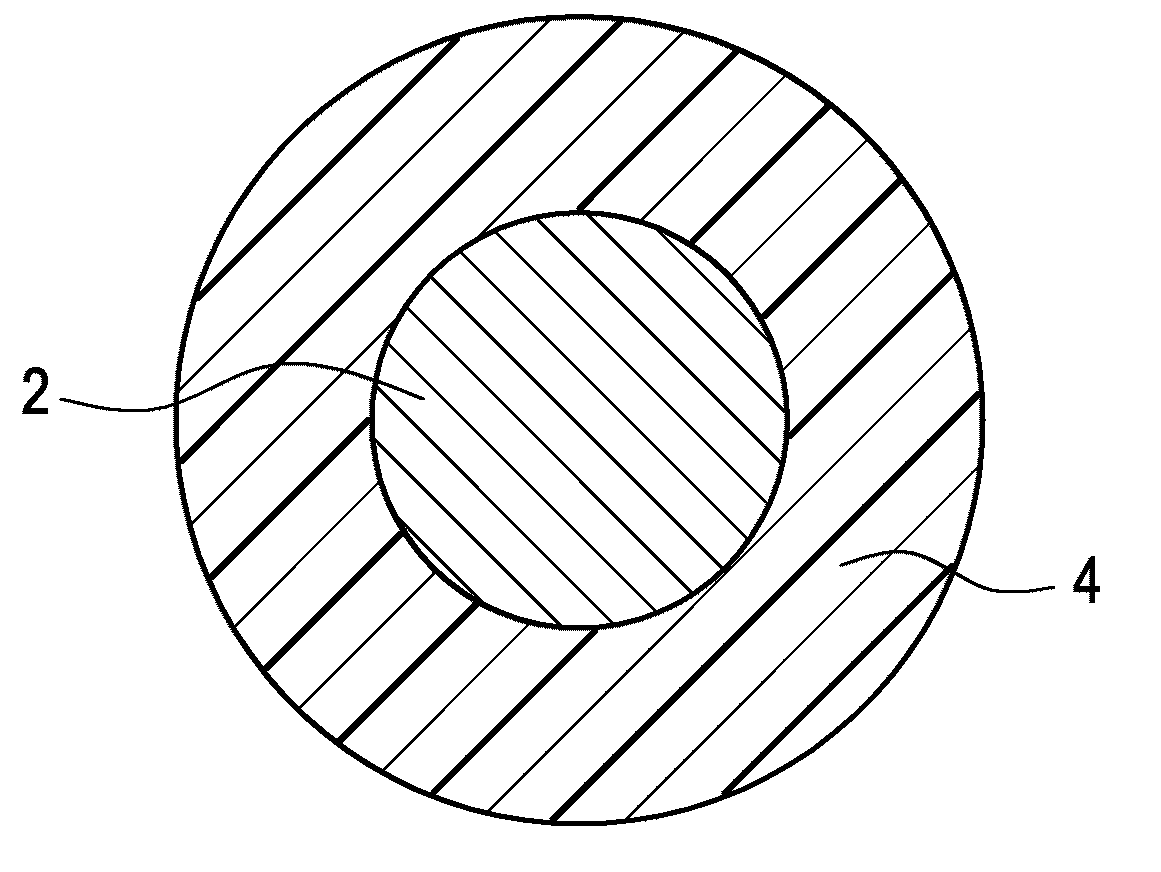

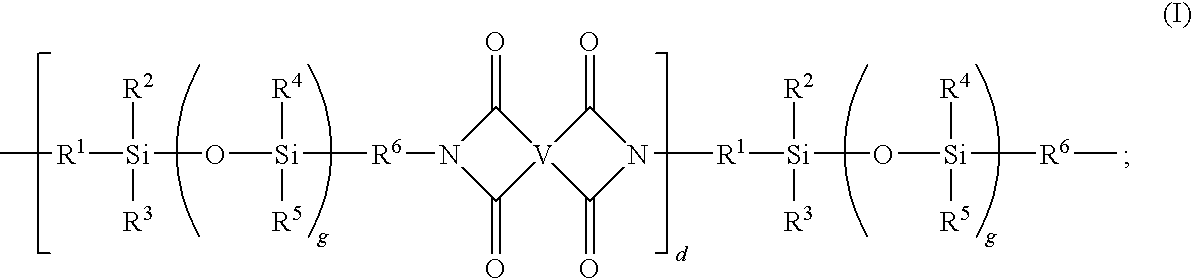

Electrical wire comprising an aromatic polyketone and polysiloxane/polyimide block copolymer composition

ActiveUS20100147548A1High-temperature performance featureImprove ductilityPlastic/resin/waxes insulatorsInsulating conductors/cablesElectrical conductorPolyketone

An electrical wire comprising a conductor and a covering disposed over the conductor. The covering comprises a thermoplastic composition. The thermoplastic composition comprises a blend of an aromatic polyketone and a polysiloxane / polyimide block copolymer. The composition can further comprise one or more additives.

Owner:SHPP GLOBAL TECH BV

Aromatic polyketone and polysiloxane/polyimide block copolymer composition

A composition comprises a blend of an aromatic polyketone and a polysiloxane / polyimide block copolymer. The composition can further comprise one or more additives.

Owner:SHPP GLOBAL TECH BV

Electrical wire comprising an aromatic polyketone and polysiloxane/polyimide block copolymer composition

InactiveUS8013251B2Plastic/resin/waxes insulatorsInsulating conductors/cablesElectrical conductorPolyketone

An electrical wire comprising a conductor and a covering disposed over the conductor. The covering comprises a thermoplastic composition. The thermoplastic composition comprises a blend of an aromatic polyketone and a polysiloxane / polyimide block copolymer. The composition can further comprise one or more additives.

Owner:SHPP GLOBAL TECH BV

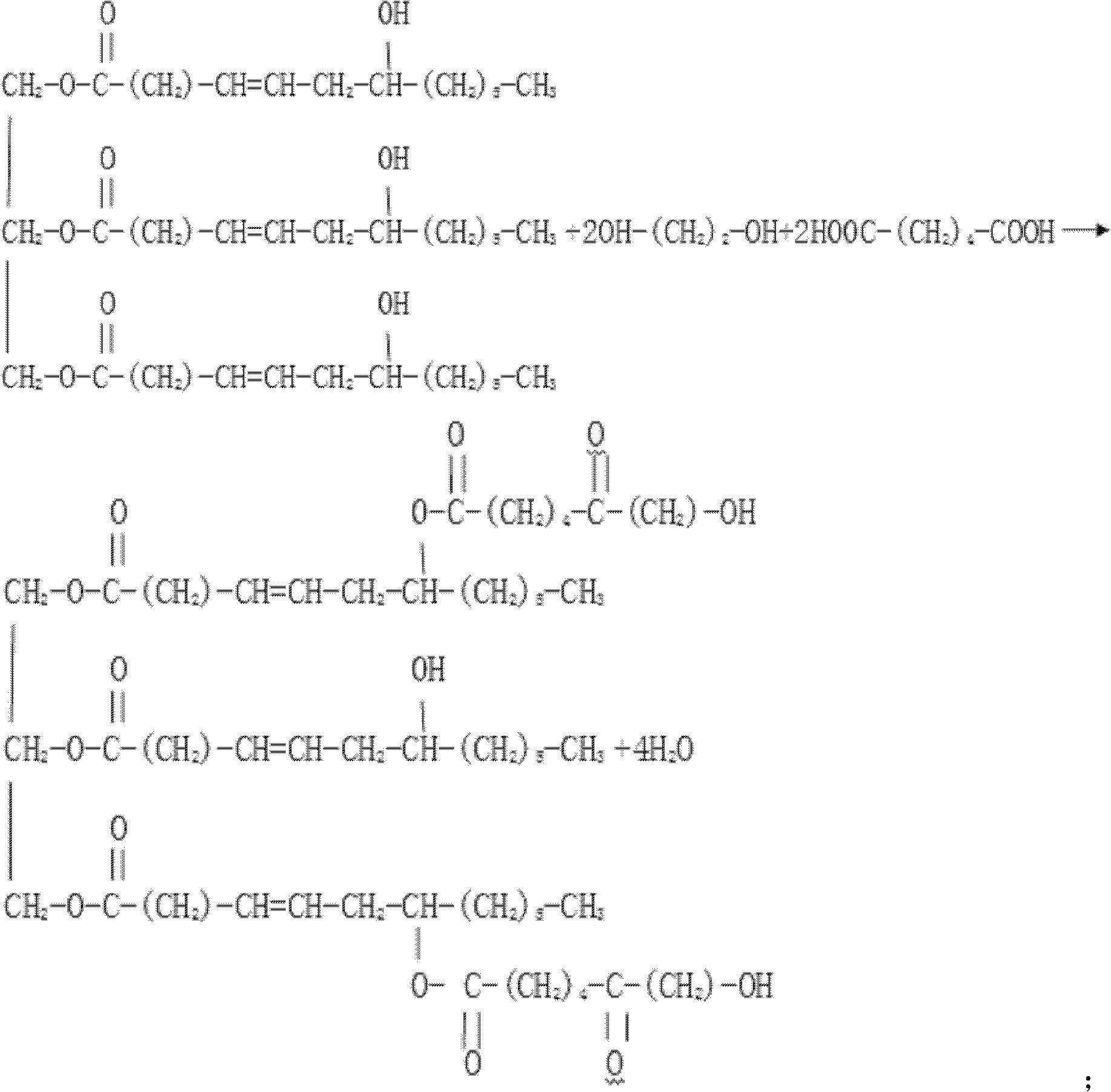

Modified polyurethane resin and benzene-free and ketone-free composite plastic ink containing same, as well as preparation methods thereof

The invention relates to benzene-free and ketone-free composite plastic ink which comprises 25-35 parts of modified polyurethane resin, 5-10 parts of matching resin (polyketone resin), 0.5-1 part of dispersant, 7-15 parts of pigment, 2-4 parts of adhesion promoter, 0.1-0.3 part of wax powder, 10-15 parts of ethanol, 20-30 parts of acetic ether and 10-20 parts of isopropyl alcohol, wherein the matching resin is L-872 polyketone resin, the contents of the ethanol, the isopropyl alcohol and the acetic ether are all above 99%, the content of benzene and ketone substances is below 0.01%, the dispersant is TM-950, the adhesion promoter is a titanate coupling agent HY-201, and the wax powder is polyethylene wax. The benzene-free and ketone-free composite plastic ink takes the isopropyl alcohol, the acetic ether and the ethanol as diluents without the assistance of the benzene and ketone substances for dissolving. The benzene-free and ketone-free composite plastic ink has no harm to operators, society and environment from preparation and production to printing and use and has excellent safe and healthy property.

Owner:新东方油墨有限公司

Thermoplastic polymer propellant compositions

Owner:CESARONI ANTHONY JOSEPH

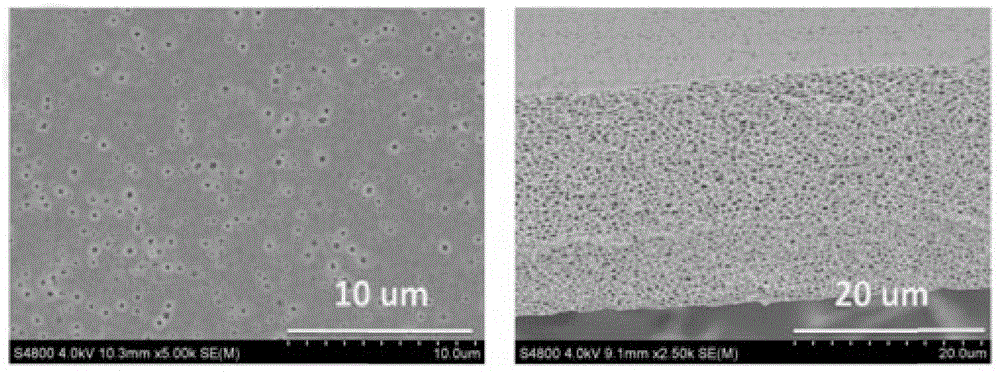

Porous material and its preparation method

The invention discloses a porous material and its preparation method. The method comprises the following steps of: uniformly mixing a base material and polyaldehyde or polyketones in a solvent, then adding polyamine for a reaction, forming a film after the reaction, and immersing and washing in an acid to obtain the porous material. The method can be used to prepare different porous materials, and simultaneously pore size distribution from nanometer to micron order is controllable. The preparation method provided by the invention has advantages of simple method and process, high preparation efficiency and good universality, is green and environmentally friendly, and is beneficial to large-scale production. In addition, raw materials can be recovered and repeatedly used.

Owner:INST OF CHEM CHINESE ACAD OF SCI

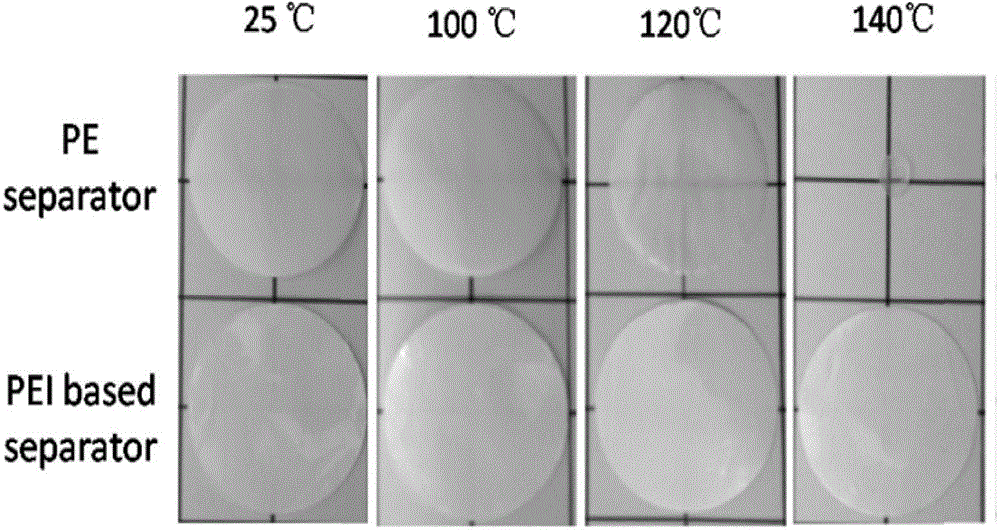

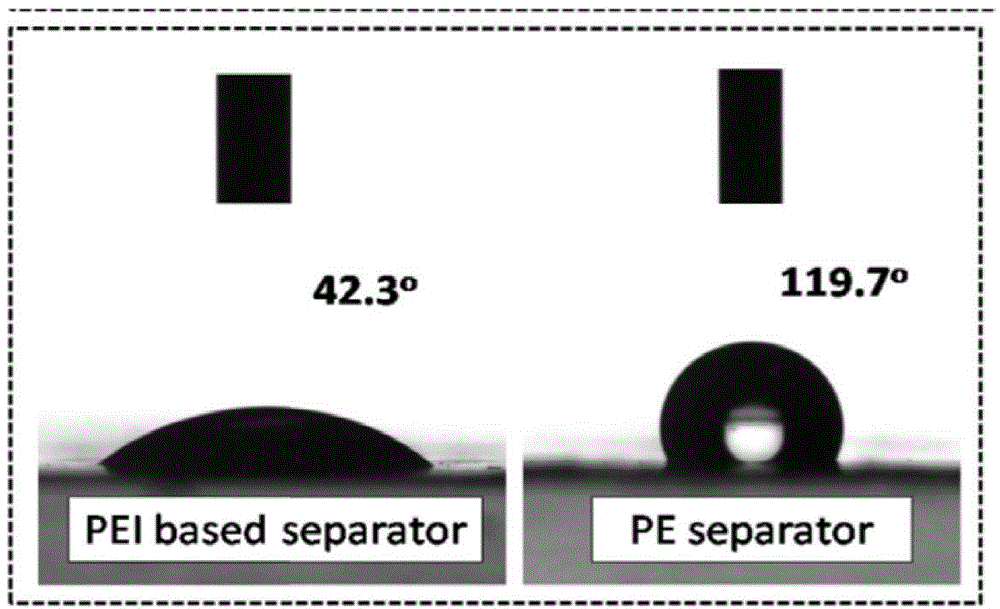

Application of heat-resistant porous diaphragm to lithium ion battery

ActiveCN105304847AHigh Separator PorosityHigh adsorption rateCell seperators/membranes/diaphragms/spacersPolyetherimideLithium-ion battery

The invention relates to application of a heat-resistant porous diaphragm to a lithium ion battery. The porous diaphragm is prepared from one or more than two of heat-resistant high-molecular polymers such as polysulfone, polyketone, polyimide, polybenzimidazole and polyetherimide; the pore diameter of the porous diaphragm is 5-500 nm, and the porosity rate is 30-70%. The porous diaphragm is high in porosity rate, the pore structure of porous diaphragm is easy to regulate, and obtained pores have a certain degree of curvature, so that when the porous diaphragm is applied to the lithium ion battery, micro short circuit and self-discharge phenomena can be effectively avoided, and meanwhile, higher electrolyte affinity and cycling stability are realized. A preparation method for the diaphragm is simple, environment-friendly, and easy to popularize; the porous diaphragm has a relatively good application prospect in the field of lithium ion batteries.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

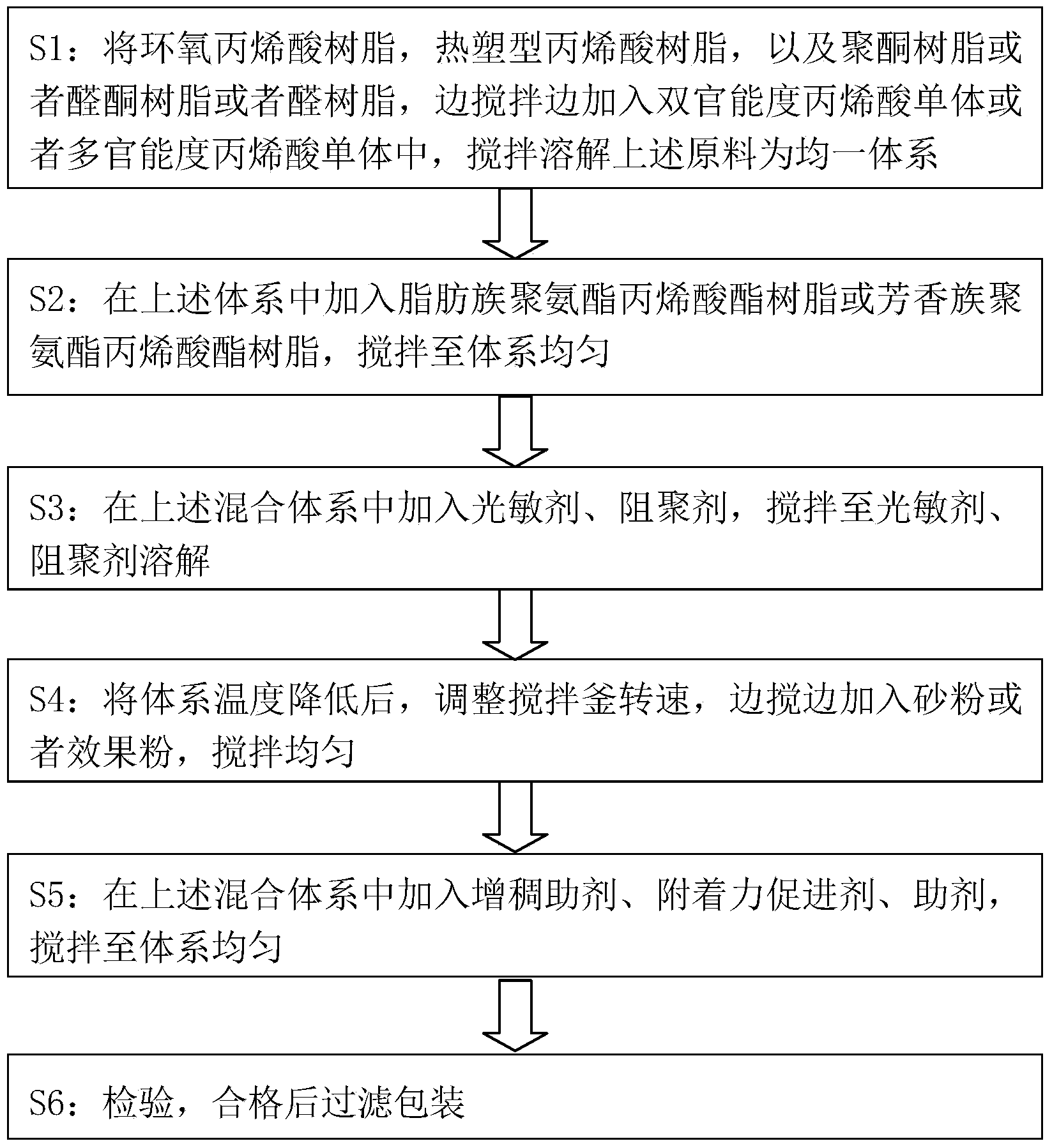

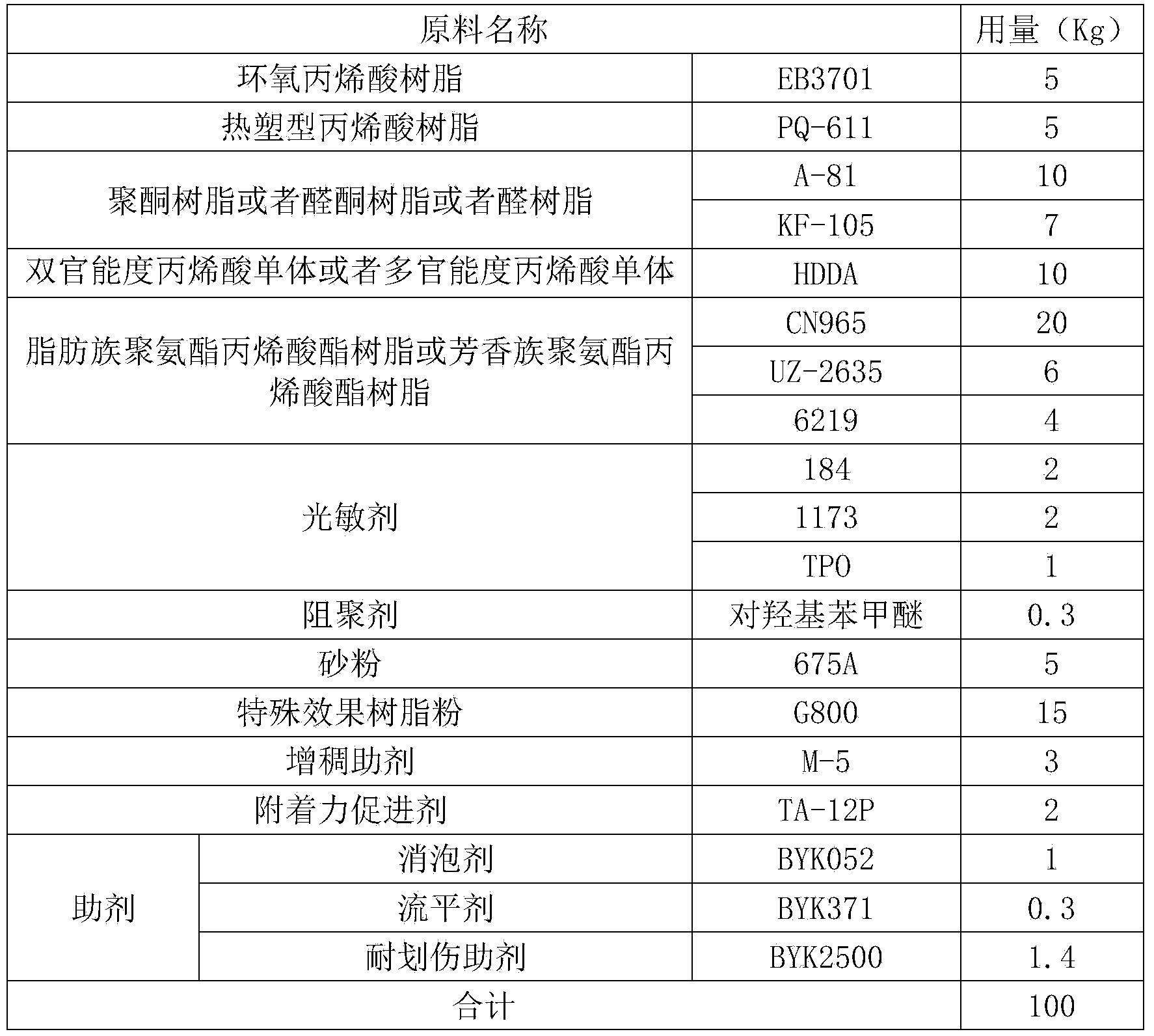

Waterproof UV snowflake printing ink and preparation method thereof

The invention provides waterproof UV snowflake printing ink and a preparation method thereof. The printing ink comprises the following components in percentage by weight: 20-35% of aliphatic polyurethane acrylate resin or aromatic polyurethane acrylate resin, 0-25% of epoxy acrylate resin, 0-20% of thermoplastic acrylic resin, 5-25% of polyketone resin or keto-aldehyde resin or urea formaldehyde, 10-45% of bifunctional acrylic monomer or polyfunctional acrylic monomer, 5-20% of sand powder or effect powder, 0-5% of bodying agent, 0-5% of adhesion promoter, 3-5% of photoinitiator, 0.1-2% of polymerization inhibitor and 0.2-5% of auxiliaries. The invention further provides a method for preparing the printing ink by adopting the formula. The waterproof UV snowflake printing ink prepared by the formula and the preparation method of the invention still keeps excellent adhesive force on the surface of wet paper printing stock and is very easy to operate and promote.

Owner:王景泉

Composition of polyketone with high impact strength

The present invention provides a polyketone composition having about 40-90 wt % of polyketone, about 5-40 wt % of polyamide, and about 5-20 wt % of modified rubber. The composition of the present invention greatly improves the impact resistance of polyketone, which has increased heat resistance, chemical resistance, fuel permeation resistance, abrasion resistance or the like, and thus may be widely applied in various industrial fields, such as automotive parts including wheel covers, wheel caps, fuel filler necks, fuel tanks, fuel tubes, center fascias, door handles, roof rack covers, gear, junction boxes, connectors, seat backs or the like, electric / electronic parts, and household items, thereby providing durability of the parts and price competition.

Owner:HYUNDAI MOTOR CO LTD +2

Transfer printing ink for polypropylene plastics, and preparation method and application thereof

ActiveCN102408782AHigh color densityColloidal properties are stableInksOther printing apparatusPolymer scienceAcrylic resin

The invention discloses a transfer printing ink for polypropylene plastics, and a preparation method and application thereof. The transfer printing ink for polypropylene plastics is composed of the following components: 15-35% chlorinated polypropylene resin, 20-30% thermoplastic acrylic resin, 5-15% polyketone resin, 1-2% stuffing, 4-20% pigment, 5-10% auxiliaries, and 20-40% solvent. The transfer printing ink is high in drying speed and stable, high in color concentration and stable in colloid properties; the transfer printing ink has good effects if being applied to direct transfer printing on the surface of the polypropylene plastics without pre-treatment; besides, the transfer printing ink is good in continuous printability, free of wire drawing, convenient for cleaning, clear in printed patterns, good in third dimension and excellent in adhesion.

Owner:CHINA PAINT MFG CO SHENZHEN

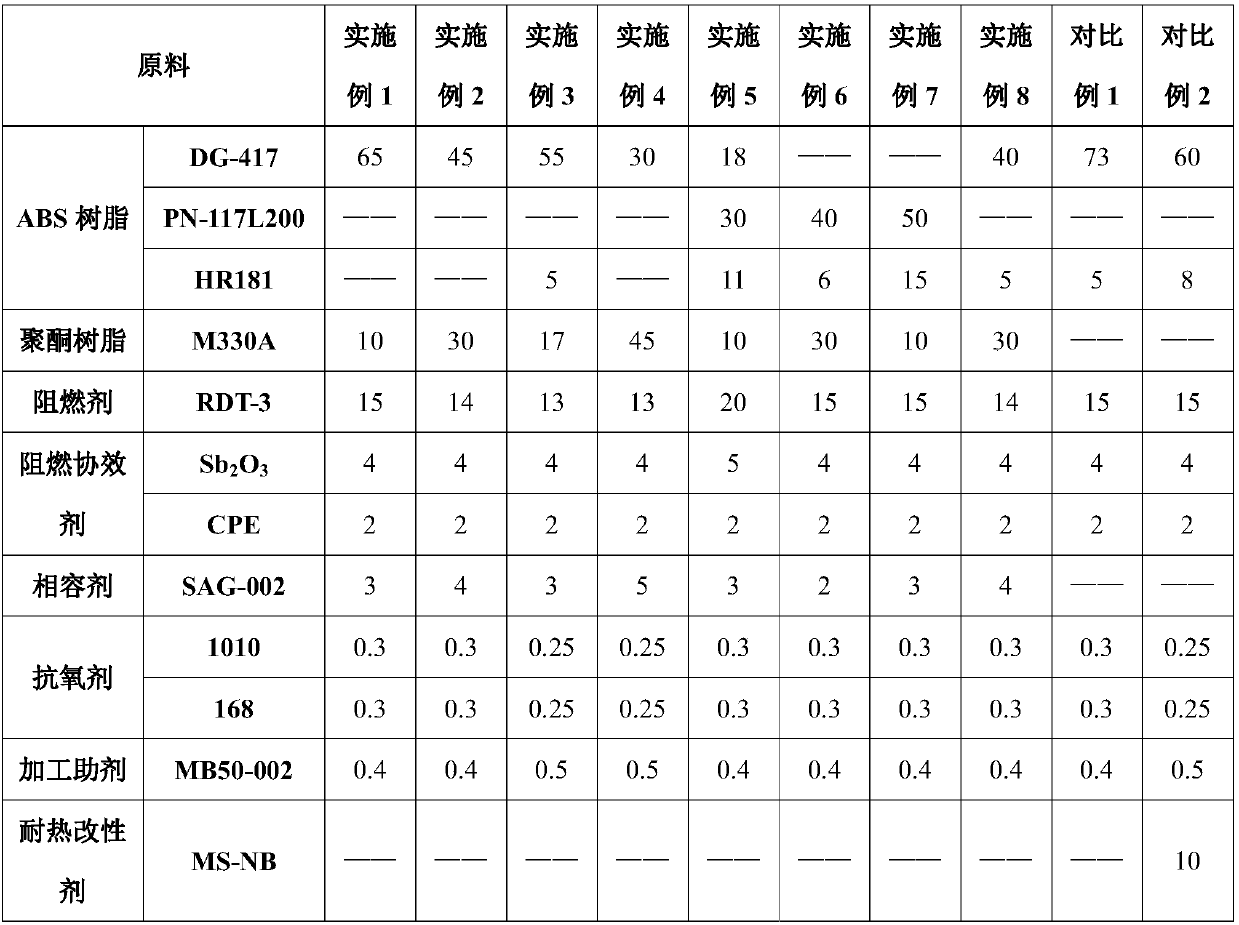

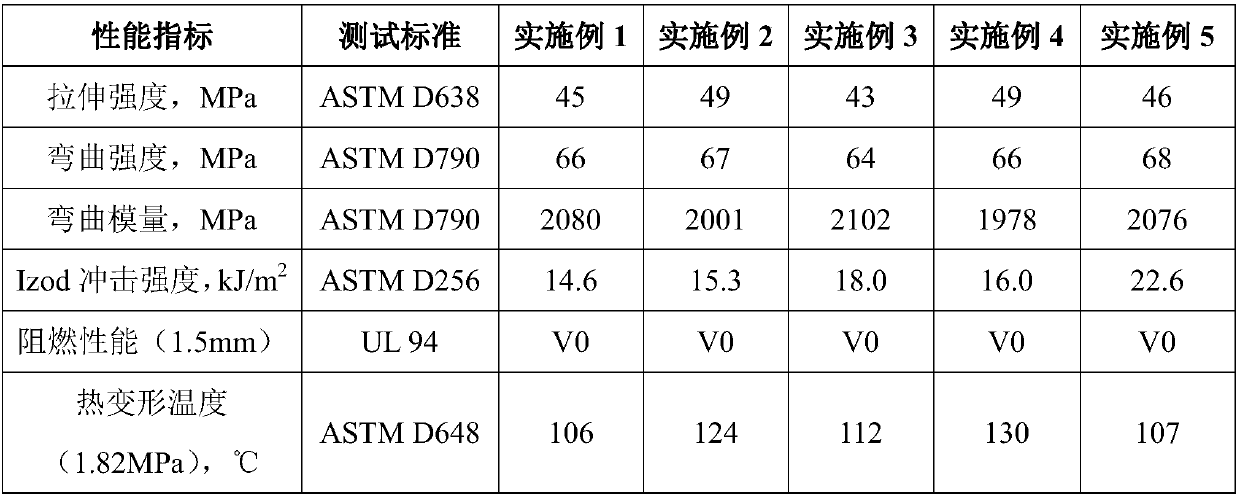

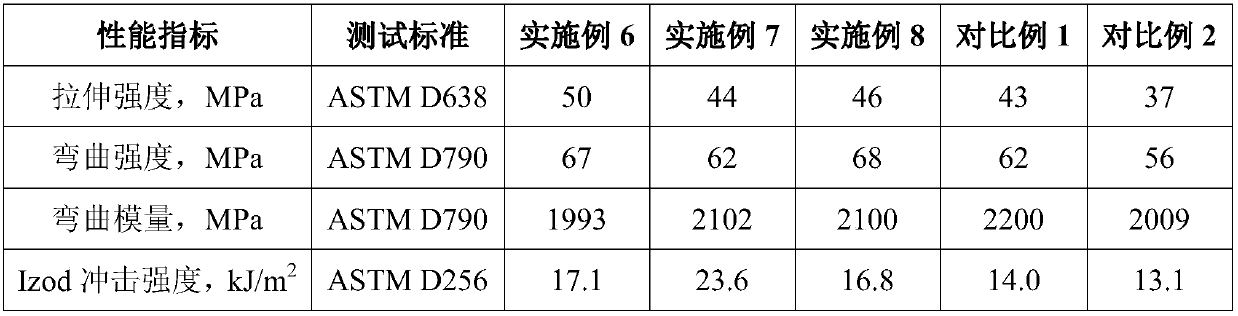

Flame-retarding ABS/POK alloy and its preparation method

InactiveCN107903567AImprove heat resistanceImprove mechanical propertiesHeat deflection temperatureAntioxidant

The invention discloses a flame-retarding ABS / POK alloy and its preparation method. The flame-retarding ABS / POK alloy is prepared from, by mass, 30-65 parts of ABS resin, 10-45 parts of polyketone resin, 13-25 parts of flame retardant, 3-8 parts of flame retardant synergist, 2-5 parts of compatilizer, 0.3-1 part of antioxidant, and 0.3-1 part of processing aid. The preparation method includes steps of 1), raw material drying and blending; 2), extrusion, cooling, prilling and drying of raw materials through a dual-screw extruder. The flame-retarding ABS / POK alloy is excellent in heat resistance, and the highest thermal deformation temperature is up to 130 DEG C; the flame-retarding ABS / POK alloy has very good physical performance, flame retarding performance and processing performance; therefore, the application scale of the ABS material is greatly widened, and the preparation technique is simple and convenient to large-scale production.

Owner:GUANGDONG JUSHI CHEM CO LTD

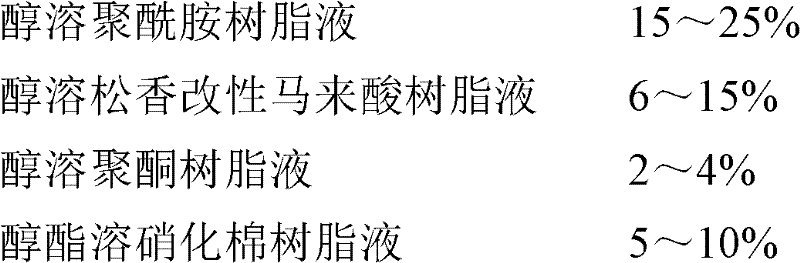

Alcohol-soluble polyamide gravure plastic surface printing ink

The invention relates to the technical field of printing ink, particularly discloses alcohol-soluble polyamide gravure plastic surface printing ink. The alcohol-soluble polyamide gravure plastic surface printing ink is prepared by mixing the following component by weight: 15-25% of an alcohol-soluble polyamide resin solution, 6-15% of an alcohol-soluble rosin-modified maleic acid resin solution, 2-4% of an alcohol-soluble polyketone resin solution, 5-10% of an alcohol ester-soluble nitro-cotton resin solution, 0.5-1% of wax powder, 9-30% of pigment, 30-40% of anhydrous ethanol, and 0.5-1% of an anti-settling agent. The surface printing ink disclosed by the invention adopts the alcohol-soluble polyamide resin as the main resin, and the alcohol-soluble rosin-modified maleic acid resin and the alcohol-soluble polyketone resin as the auxiliary resins, these three resins all adopt ethanol as a solvent for dissolution, and when the alcohol-soluble polyamide gravure plastic surface printing ink is prepared, ethanol is also used as a solvent system, so that benzene solvent is basically eliminated, and the problems that the benzene solvent system surface printing ink in the prior rat pollutes the environment and is harmful for human bodies and the like are solved.

Owner:河南伊特尔新材料科技有限公司

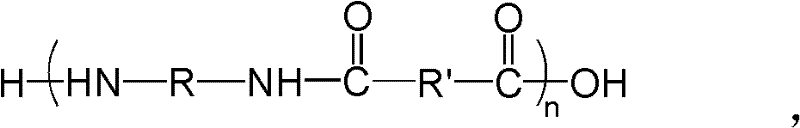

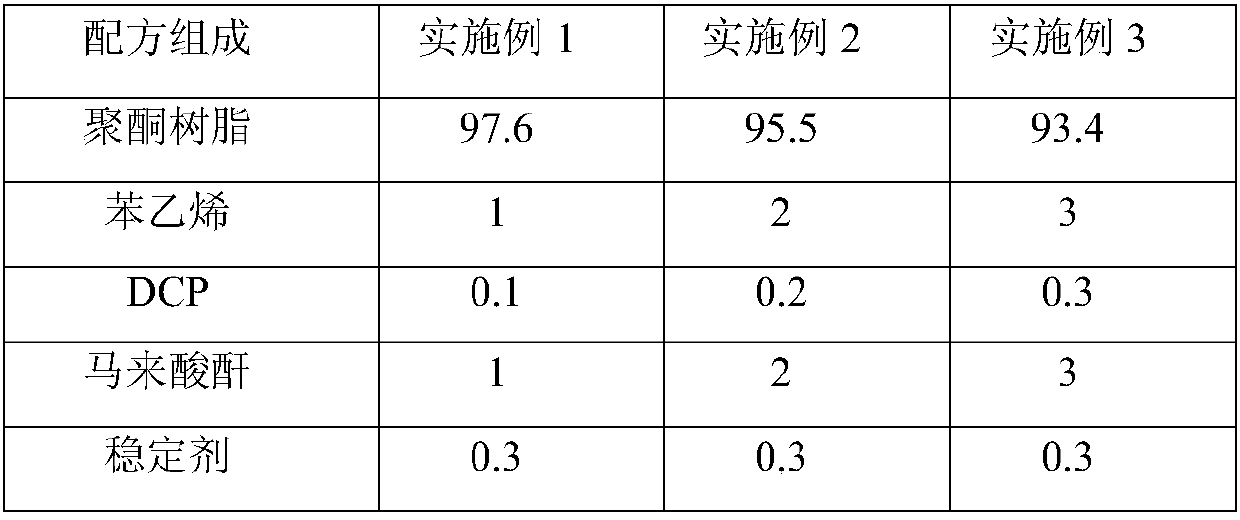

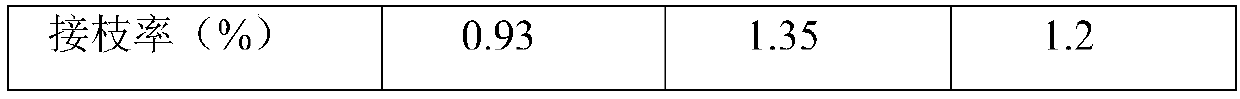

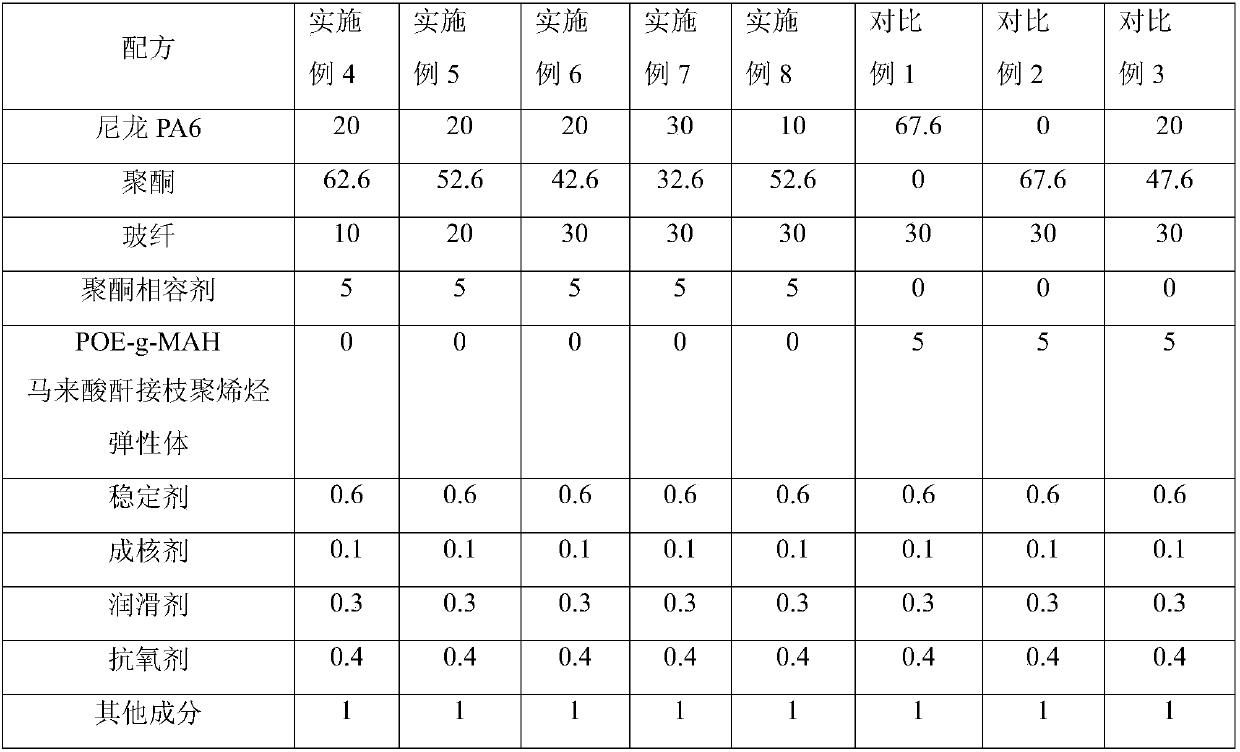

Nylon/polyketone alloy material and preparation method thereof

InactiveCN107652658AImprove thermal stabilityGood compatibility and dispersionGlass fiberAntioxidant

The invention discloses a nylon / polyketone alloy material and a preparation method thereof. The nylon / polyketone alloy material comprises, by weight, 10-50 parts of nylon resin, 40-80 parts of polyketone resin, 10-30 parts of glass fibers, 0.1-0.2 part of initiator, 1-3 parts of maleic anhydride, 2-6 parts of comonomer, 0.2-1 part of antioxidant, 0.2-0.8 part of stabilizer, 0.3-0.6 part of lubricant and 0.1-0.5 part of nucleating agent. The nylon / polyketone alloy material improves the performance of nylon materials and thermal stability of polyketone materials, can substitute for glass fiber reinforced nylon, reinforced PPS and POM and is applied to extremely harsh environments.

Owner:安徽科高新材料有限公司

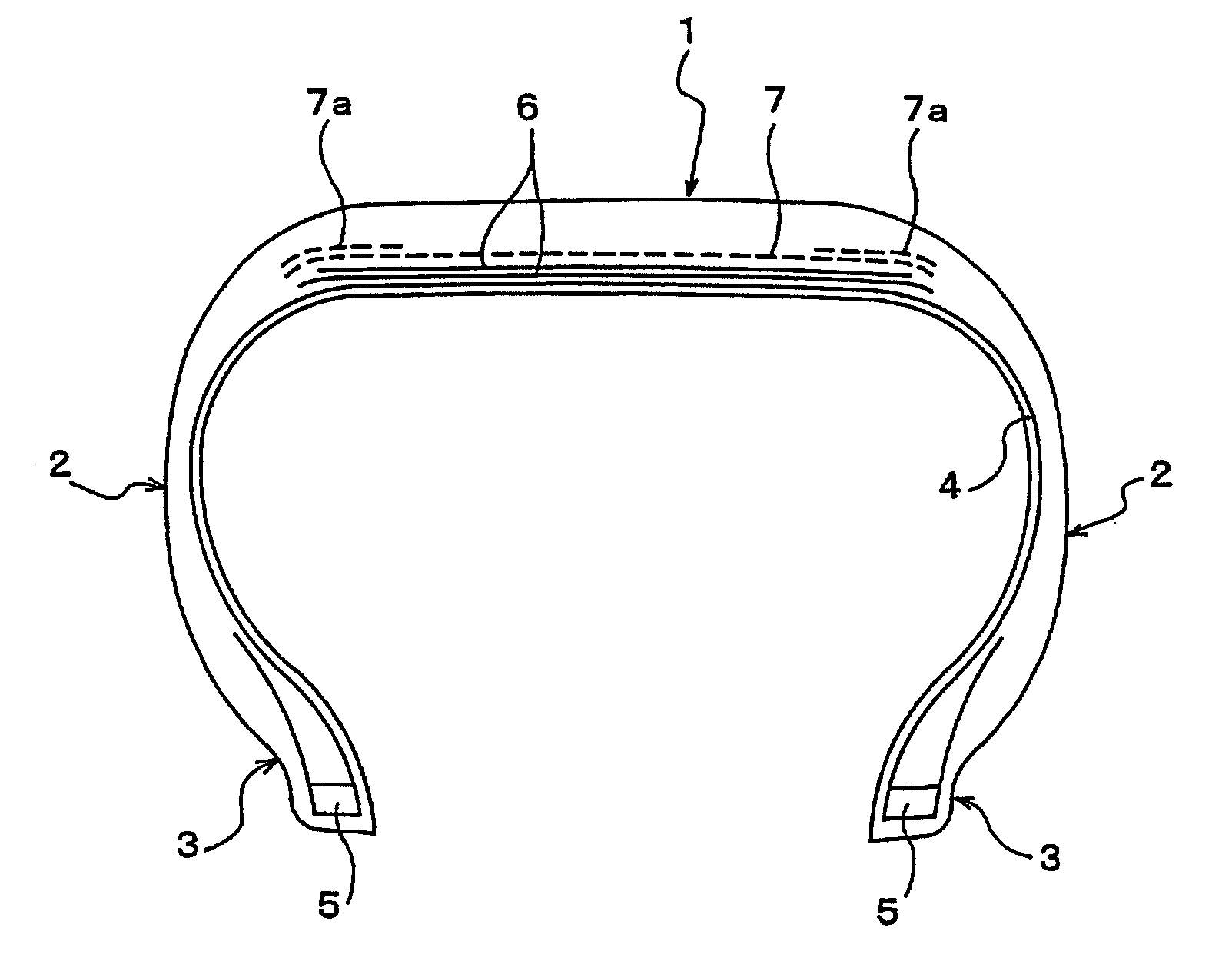

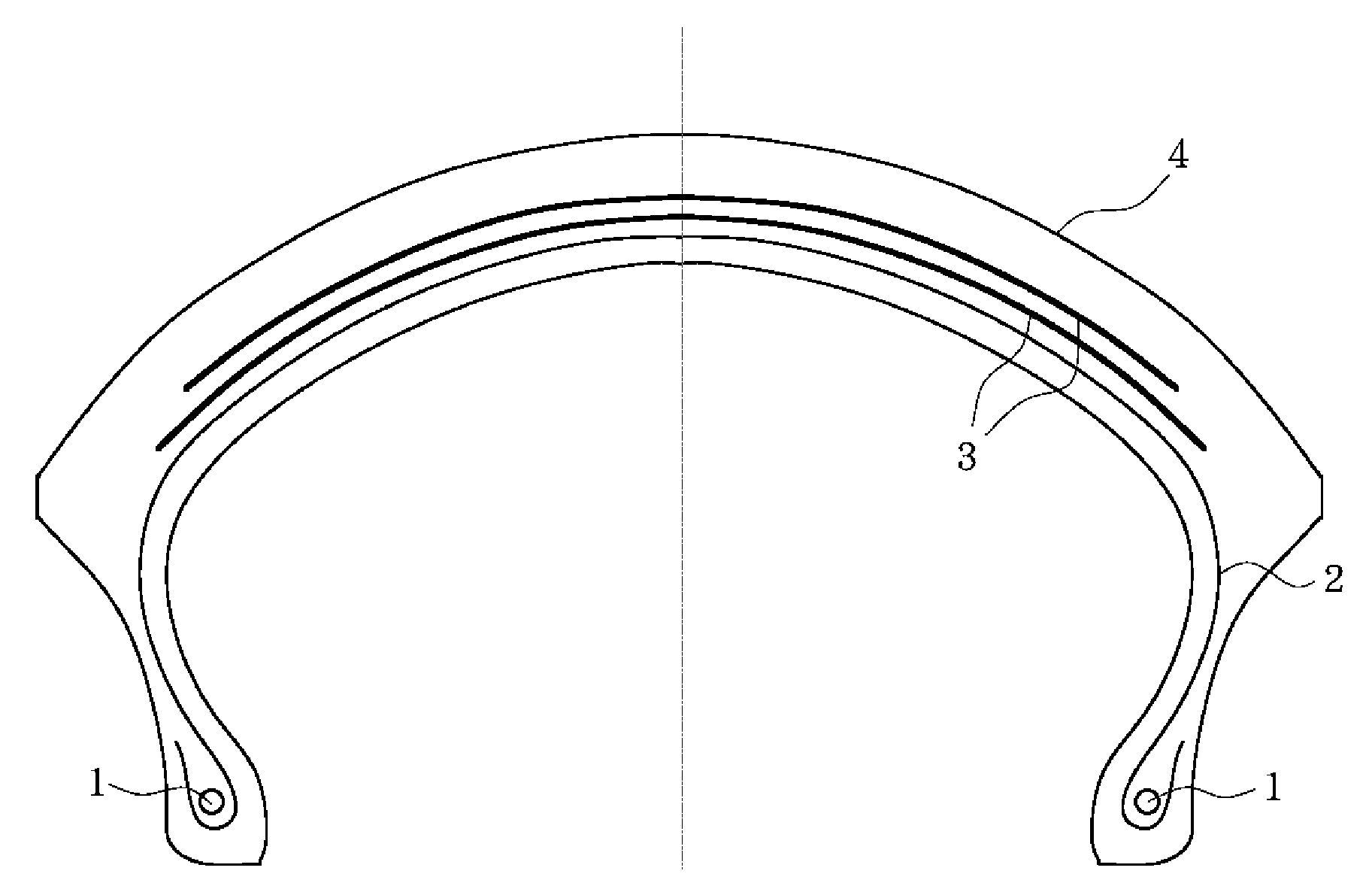

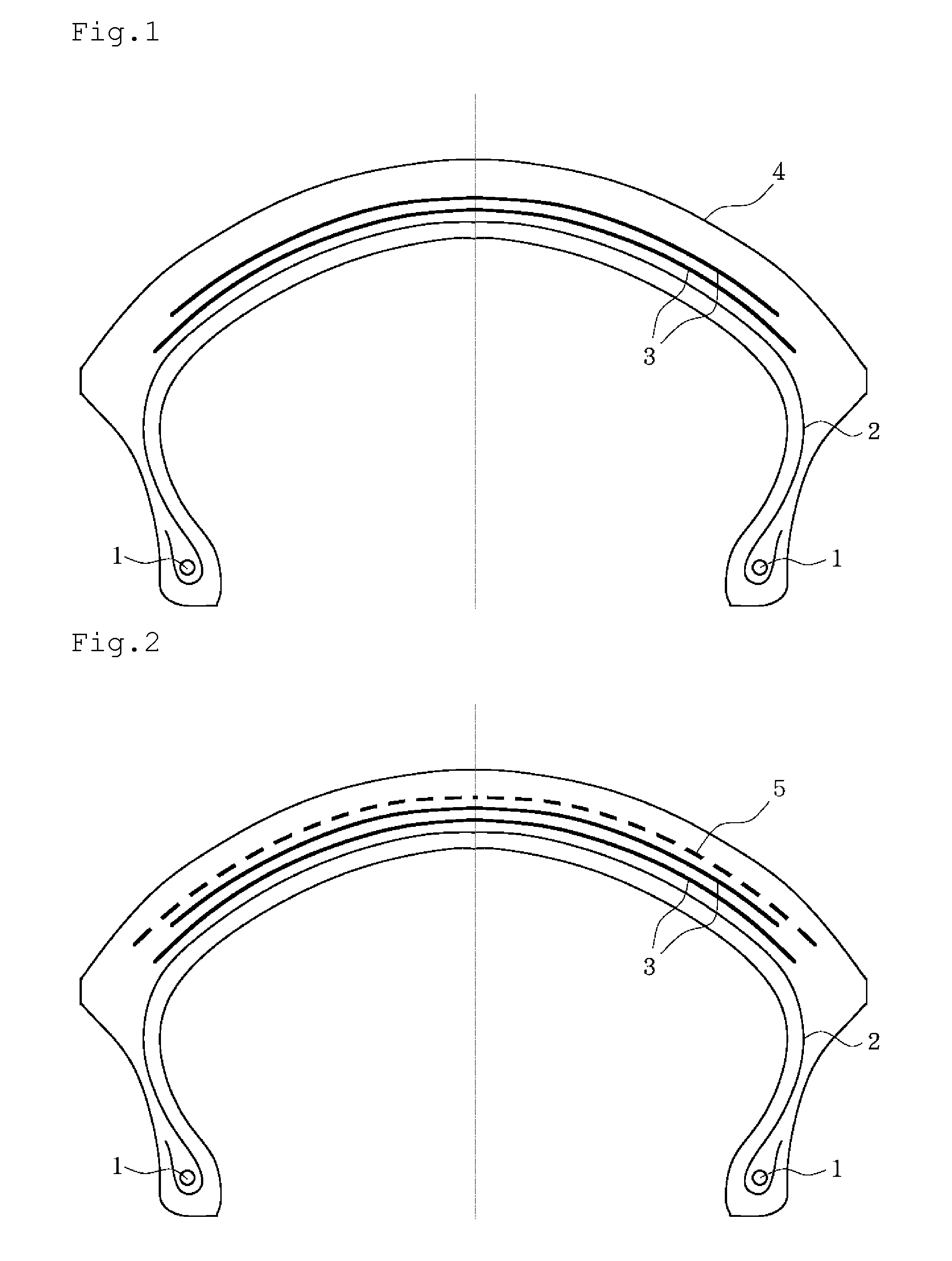

Pneumatic tire

InactiveUS20100276051A1Improve drivabilityReduce weightPneumatic tyre reinforcementsWheelsFiberDry heat

This invention relates to a pneumatic tire with an improved driveability and a reduced weight as well as a maintained traveling durability, and particularly a pneumatic tire having a high post cure inflation pressure, and being best suited as a pneumatic tire for a light truck with a high air pressure. In the pneumatic tire, twisted cords formed of a polyketone fiber represented by the following formula (a), and having a thermal shrinkage stress value, at a dry heat temperature of 150° C., of not less than 0.19 cN / dtex are used as cords for forming a carcass layer:—(CH2—CH2—CO)n-(R—CO—)m- formula (a);where the relationship between n and m is represented by the following formula (b), and R represents an alkylene group having 3 or more carbon atoms:1.05≧(n+m) / n≧1.00 formula (b).

Owner:YOKOHAMA RUBBER CO LTD

Degradable BOPP packing film and manufacturing method thereof

The invention discloses a degradable BOPP packing film and a manufacturing method thereof; the packing film is formed by co-extrusion of three layers of materials, namely surface-layer materials, core-layer materials and inner-layer materials, wherein the surface-layer materials and the inner-layer materials are formed by blending the following components by weight percent: 90-93 percent of random copolymer polypropylene modified raw materials, 4-7 percent of smoothing agents and 2-4 percent of antisticking agents; and the core layer is formed by copolymerization of the following components by weight percentage: 90-93 percent of homopolymer polypropylenes, 4-7 percent of binary polyketone polymers and 2-4 percent of anti-static agents. The manufacturing method thereof comprises the preparation of random copolymer polypropylene modified raw materials, the preparation of surface-layer materials and inner-layer materials, the preparation of core-layer materials, chilling and dual-axis two-way stretching, thus obtaining the degradable BOPP packing film. The packing film can meet the performance requirements of small commodity packages such as cigarettes, food, beverages, stationery and the like, and can simultaneously complete the degradation in a shorter time, thereby realizing the harmless automatic treatment of two-way stretching polypropylene films and the protection of environment.

Owner:QINGDAO ENER PACKAGING TECH +1

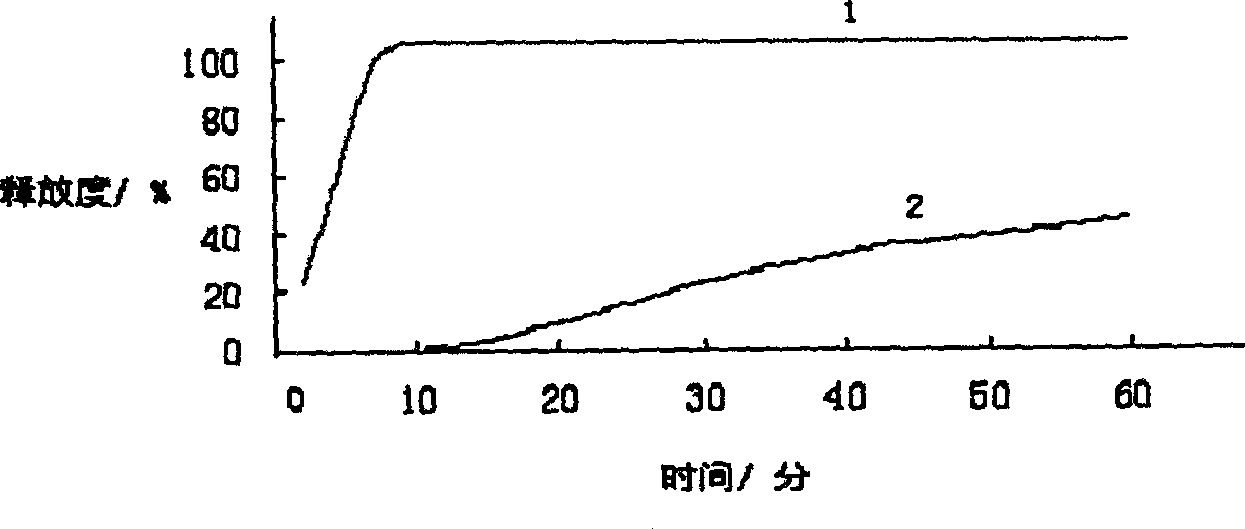

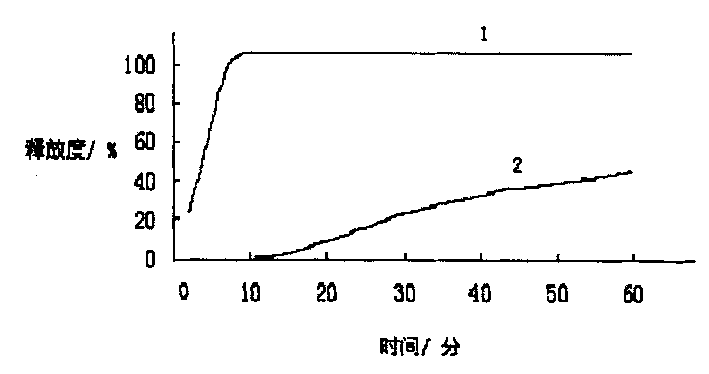

Hiliezdum fast-release tablet and preparing method thereof

InactiveCN1454600AGreat tasteHigh strengthOrganic active ingredientsNervous disorderCross-linkCellulose

The invention is a kind of quick-released tablet of shenshuai fruit elements and the manufacturing method. The tablet contains 10-30 % shenshuai fruit element extraction material, 2-5 % sputtering agent, 1.5-3%, the other is filter. The sputtering agent is cross-linked sodium cellulose glycolate, sodium carboxy methyl starch or the compound of them. The additive includes lubricant, flow aid, deodorizing agent. The filler is the compound of alditol and cellulose. The method used polyketone as adhesive, used alcohol or the fixed liquid of alcohol and water as humectant. The sputtering agent uses inner adding method or outer adding method, wet process to produce particles. The character of the invention lies in fast dilution, the medicine can be dissolved entirely in then minutes, it needn't sugar-coat, the troche has good taste, it has no obvious bitterness.

Owner:TSINGHUA UNIV

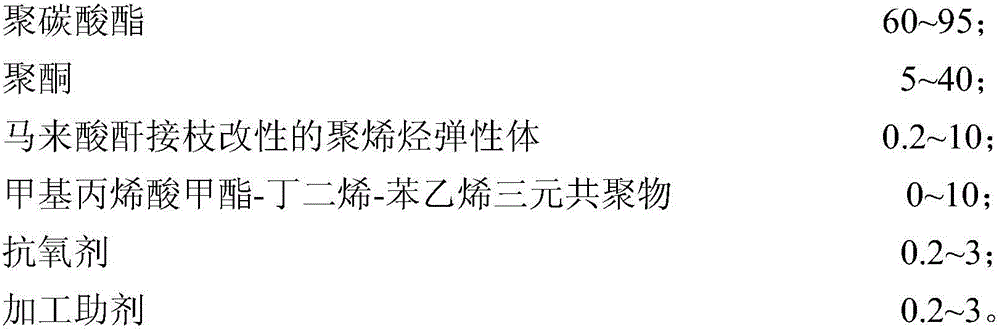

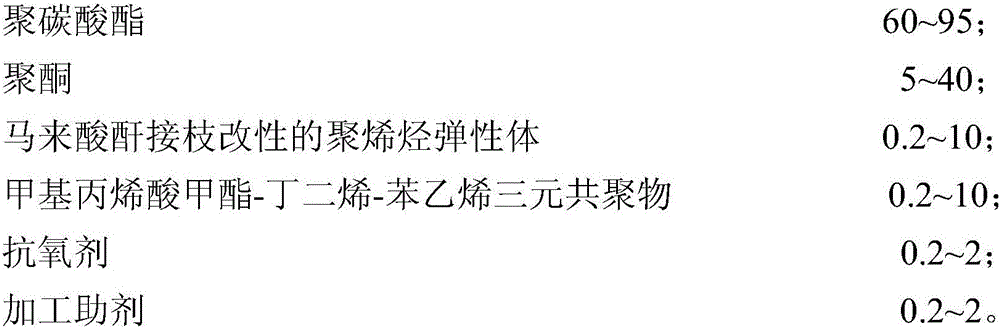

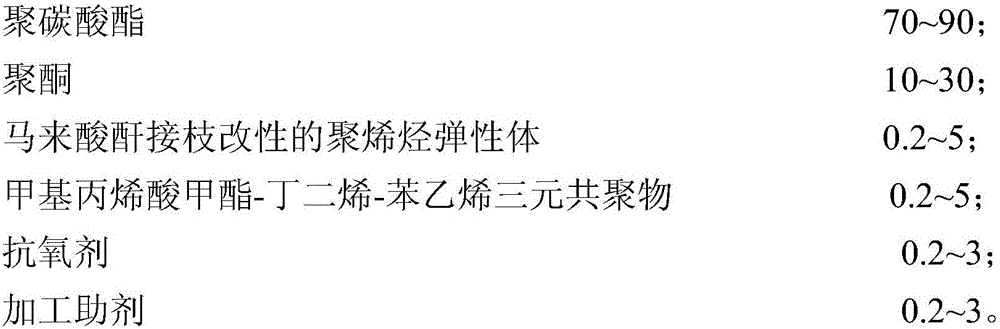

Polycarbonate and polyketone alloy and preparation method thereof

The invention discloses a polycarbonate and polyketone alloy and a preparation method thereof. The polycarbonate and polyketone alloy is prepared from the following ingredients in parts by weight: 60 to 95 parts of polycarbonate, 5 to 40 parts of polyketone, 0.2 to 10 parts of maleic anhydride graft modification polyolefin elastomers, 0 to 10 parts of methyl methacrylate-butadiene-styrene terpolymers, 0.2 to 3 parts of antioxidants and 0.2 to 3 parts of processing agents. The alloy material has the advantages that the defect of poor solvent-resistant performance of the polycarbonate is effectively overcome; and meanwhile, the alloy material has good heat-resistant performance and mechanical property. The polycarbonate, the polyketone, the maleic anhydride graft modification polyolefin elastomers, the methyl methacrylate-butadiene-styrene terpolymers, the antioxidants and the processing agent are fed and are uniformly mixed; the mixture is fed into a double-screw extruder; and a product is obtained through melt extrusion granulation. The production can be performed by using the existing production equipment; the operation is simple; and the industrial production is easy.

Owner:CGN JUNER NEW MATERIALS +1

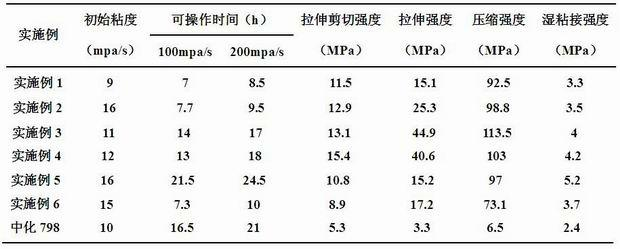

Pneumatic tire for motorcycle

InactiveUS20090266462A1Improve driving stabilityReduce weightPneumatic tyre reinforcementsYarnGround contactFiber

A pneumatic tire for a motorcycle, wherein the tire is optimized in the ground contact shape and the ground contact pressure distribution during high-speed running to achieve excellent driving stability, is provided. Furthermore, a pneumatic tire for a motorcycle, wherein the tire is optimized in the ground contact shape and the ground contact pressure distribution during high-speed running to realize excellent gripping force to stabilize the behavior of the tire near its cornering limit and excellent cornering ability, is provided.Provided is a pneumatic tire for a motorcycle, which employs a multifilament-twist polyketone fiber cord, as a reinforcing material, having a total dtex value of 1000 to 20000 dtex per cord and satisfying the relationships represented by the following Expressions (I) and (II):σ≧−0.01E+1.2 (I)σ≧0.02 (II)(wherein, E is an elastic modulus (cN / dtex) at 25° C. under a load of 49 N, and σ is a heat shrinkage stress (cN / dtex) at 177° C.).

Owner:BRIDGESTONE CORP

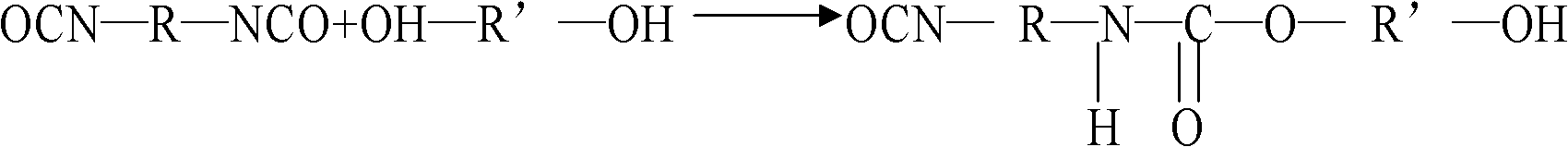

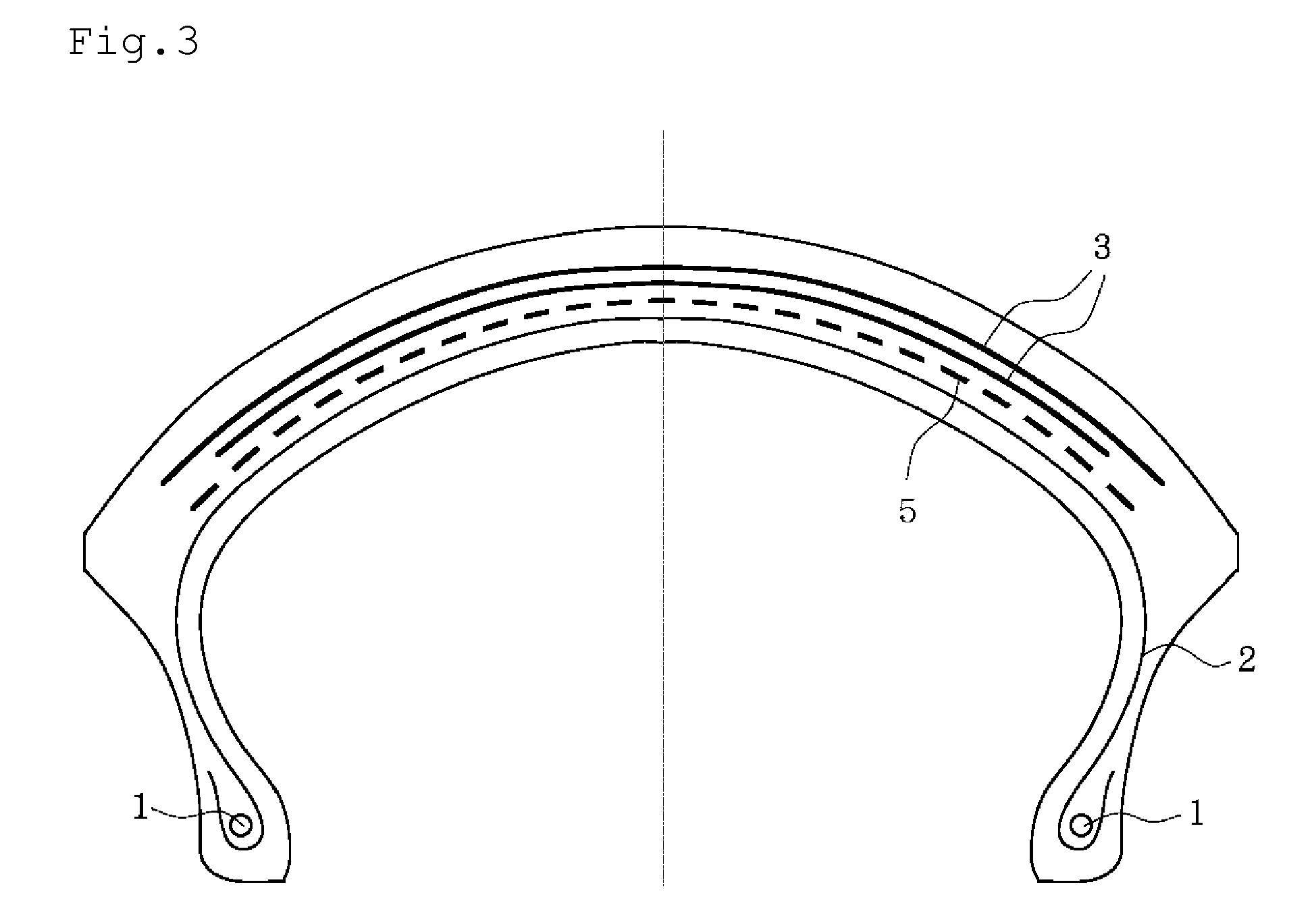

Performance-controllable epoxy-polyketone grouting material as well as preparation method and application thereof

ActiveCN102585441ACuring time controllableControllable operational timeProtective foundationBuilding repairsPolymer sciencePtru catalyst

The invention discloses a performance controllable epoxy-polyketone grouting material as well as a preparation method and application thereof. The epoxy-polyketone grouting material mainly comprises components A and B, wherein the component A comprises epoxy resin, s reactive solvent and sm interface modifier; and the component B comprises sn amine curing agent, a curing regulator, a curing accelerant and a catalyst. The reactive solvent forms polyketone resin under the actions of the catalyst and the like and further forms an interpenetrating network structure together with epoxy, so the mechanical property, the permeability, the operable time and the like of the grouting material are controllable; and the grouting material has low initial viscosity, strong spreading property on various rock, soil and concrete interfaces, good permeability and operable time controllability, quick later mechanical strength enhancement and high grouting body mechanical strength, and can be used for filling concrete cracks and repairing rock defects, can be used for strengthening foundation reinforcement and water and permeation prevention of large projects and buildings such as roads, bridges, ports and the like.

Owner:SOUTH CHINA UNIV OF TECH

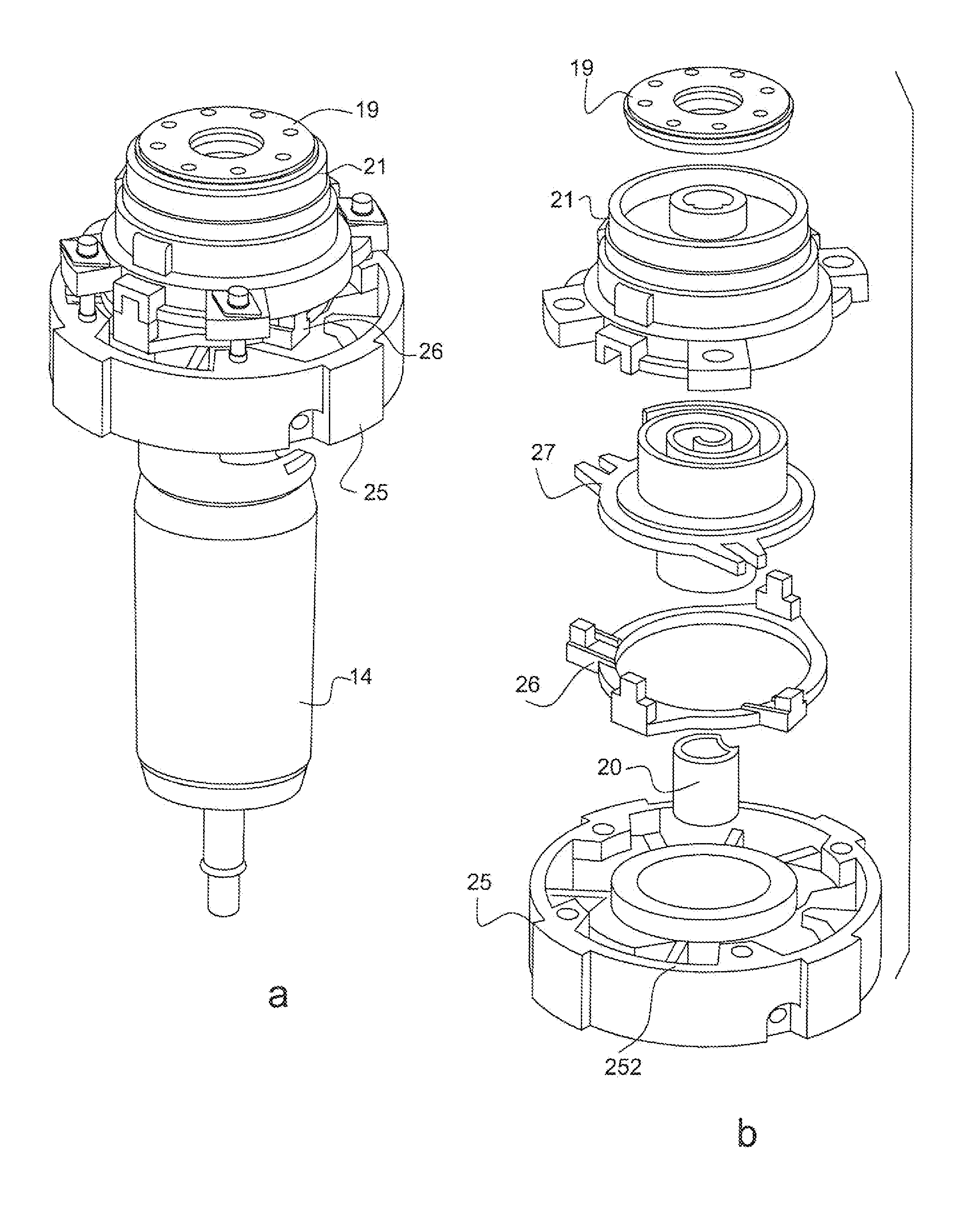

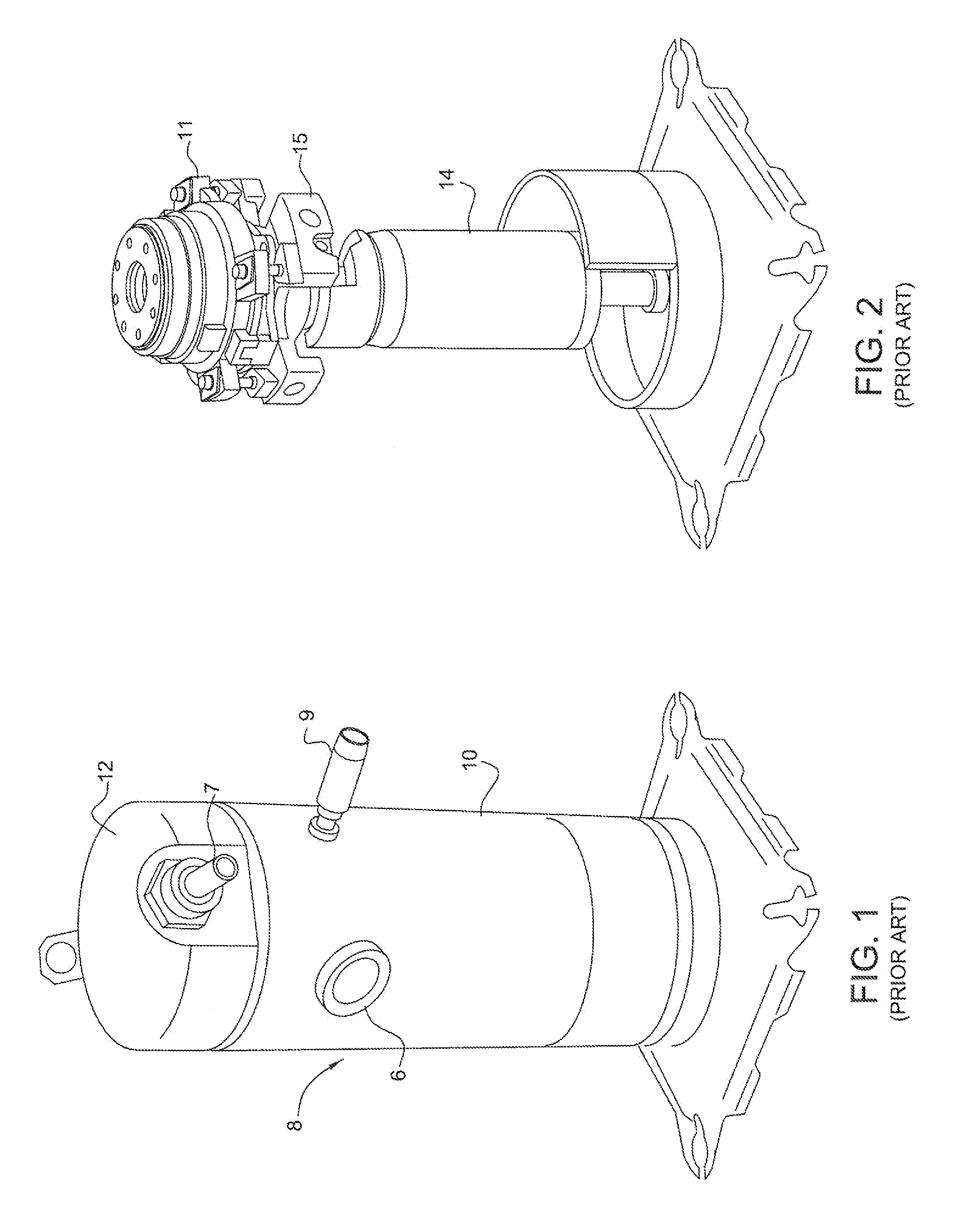

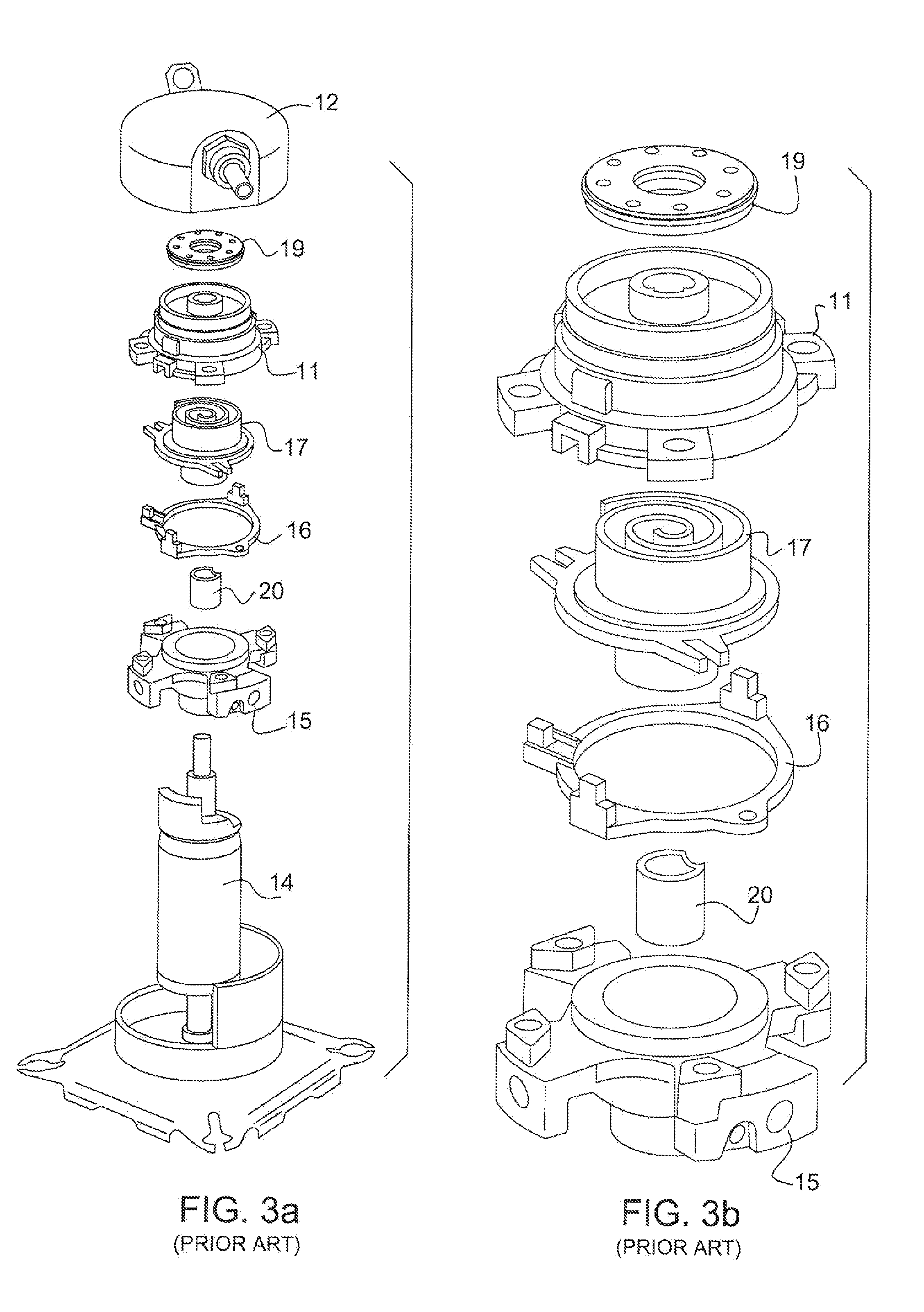

Compressors including polymeric components

ActiveUS20140010679A1Light weightEasy to makeRotary/oscillating piston combinations for elastic fluidsAdditive manufacturing apparatusMetal coatingPolyketone

Improvements in compressor manufacture are achieved by utilizing polymeric components which retain at least 90% of their dimensions after being exposed to a mixture of refrigerants and / or lubricants for 30 days at 60° C. Polymeric materials include (i) polyetherimides, (ii) polyphenylene sulfides, (iii) polyketones, (iv) polysulfones, (v) liquid crystal polymers, and (vi) combinations thereof. Metal coatings on the polymers are the preferred embodiments for housings.

Owner:SHPP GLOBAL TECH BV

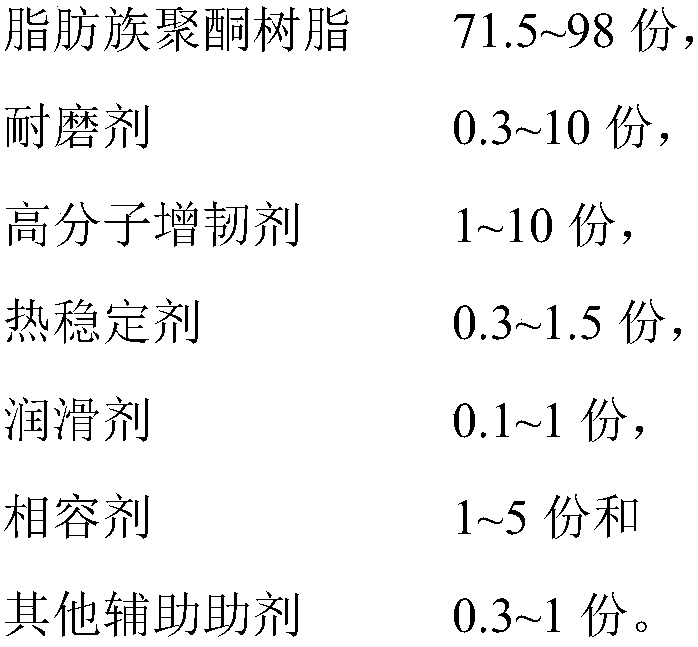

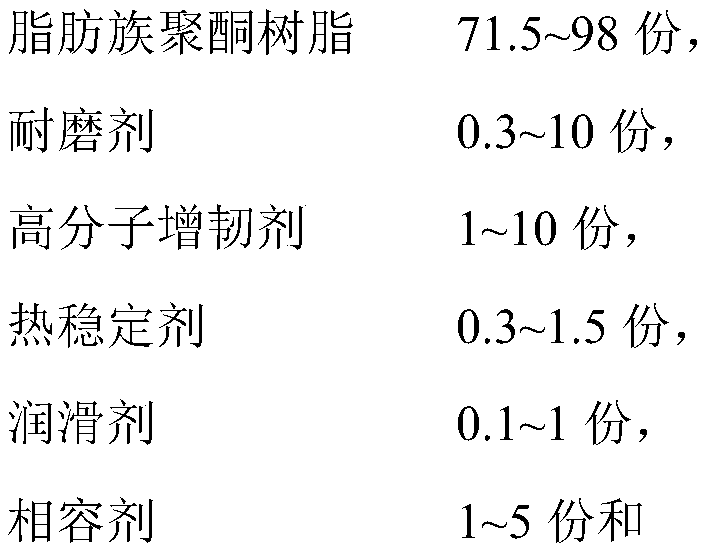

Polyketone composition applied to supporting and sliding elements in architectural engineering and preparation method thereof

InactiveCN107739501AGood self-lubricating performanceImprove carrying capacityHigh loadMechanical property

The invention discloses a polyketone composition applied to supporting and sliding elements in architectural engineering. The polyketone composition is prepared from the following raw material components in parts by mass: 71.5-98 parts of aliphatic polyketone resin, 0.3-10 parts of abrasion-resistant agents, 1-10 parts of polymer toughening agents, 0.3-1.5 parts of heat stabilizers, 0.1-1 part oflubricants, 1-5 parts of compatilizers and 0.3-1 part of other auxiliary additives. The polyketone composition applied to supporting and sliding elements in architectural engineering has excellent mechanical property, heat resistance, chemical resistance, low-temperature property and self-lubrication property, particularly has low friction coefficient, high abrasion resistance and high compressivestrength, and is applicable to conditions with higher load and wider use of temperature. Through combination of the formula of the polyketone composition, compared with the existing polyketone material extrusion molding scheme, a plate extruding scheme and a compression molding scheme which are used as two new product preparation processes are provided; the problem that the extrusion pelletizing-injection molding scheme is incapable of molding large-sized products and thick products is solved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Graphene dispersion slurry and organic and inorganic general priming paint modified by graphene dispersion slurry

ActiveCN105400375AAvoid reunionDifficult to disperseAnti-corrosive paintsEpoxy resin coatingsChemical industryPolyketone

The present invention provides graphene dispersion slurry and organic and inorganic general priming paint modified by the graphene dispersion slurry, and relates to the technical field of chemical industry. First, the graphene dispersion slurry with a good dispersion effect is prepared, the graphene dispersion slurry comprises graphene powder, an ultra-dispersing agent, a silane coupling agent, a multi-functional additive, polyketone resin, hydrated magnesium silicate and a solvent, wherein the mass ration of graphene powder to ultra-dispersing agent to silane coupling agent to multi-functional additive to polyketone resin to hydrated magnesium silicate to solvent is 8-10: 5-10:3-5:1-3:7-12:0.5-1: 75.5-59. The graphene dispersion slurry is used for modifying the organic and inorganic general priming paint, so that paint films of the organic and inorganic general priming paint have self-repairing function, and have good salt spray resistance, and in addition, the priming paint production cost can be reduced, and corrosion resistance and mechanical properties of the priming paint can be improved.

Owner:深圳市深赛尔股份有限公司

Ultraviolet radiation curing gravure freezing-point ink and preparation method thereof

The invention relates to an ultraviolet radiation curing gravure freezing-point ink and a preparation method thereof. The ink comprises the following raw materials in parts by weight of: 15-25 parts of unsaturated acrylate resin, 15-25 parts of polyketone resin, 25-35 parts of acrylate monomer, 1-2 parts of matt powders, 5-8 parts of wax powders, 2-8 parts of inorganic filler, 0.4-0.8 parts of antifoaming agents, 0.6-1.0 part of wetting and leveling agents, 5-10 parts of photoinitiators, and 5-10 parts of promoters. The preparation method of the ultraviolet radiation curing gravure freezing-point ink comprises a step of pre-preparing resin liquid and a step of mixing, dispersing and tempering. The invention provides the ultraviolet radiation curing gravure freezing-point ink, which has the advantages of environmental friendless, no toxicity, no pollution, no emission of harmless gas, rapid printing speed and high production efficiency.

Owner:东莞智源彩印有限公司

High-impact halogen-free flame-retardant POK/PA (polyketone/polyamide) alloy material

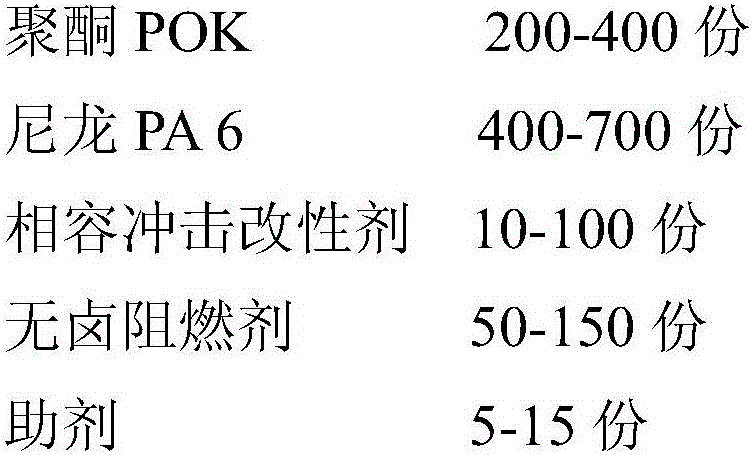

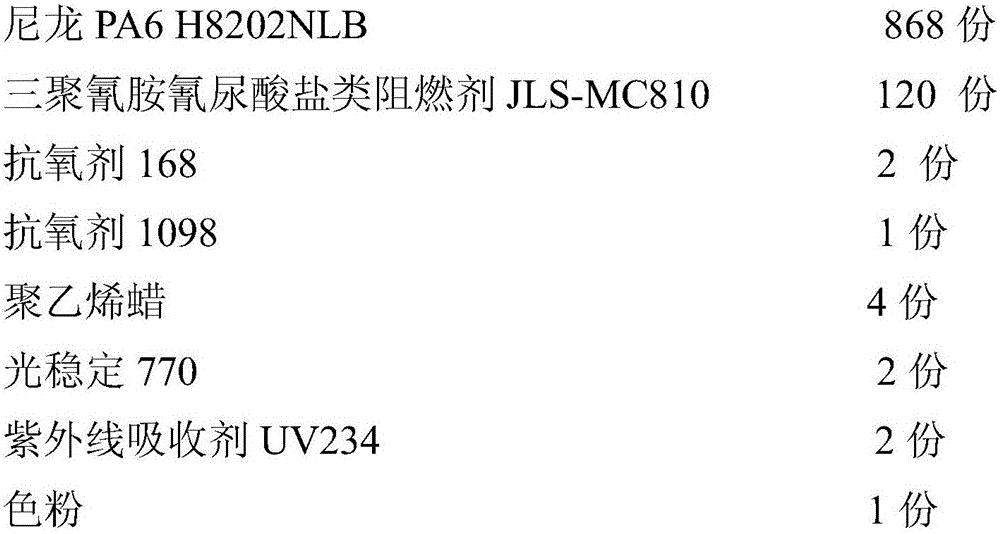

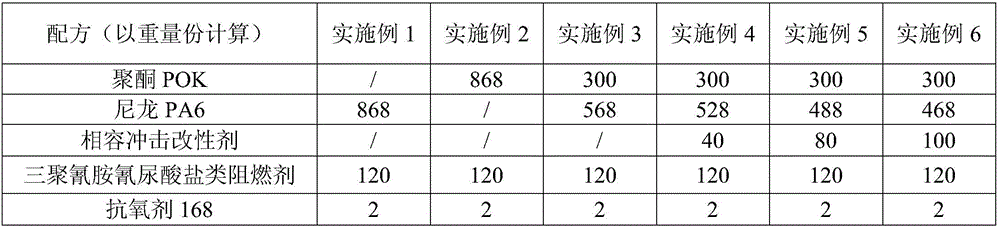

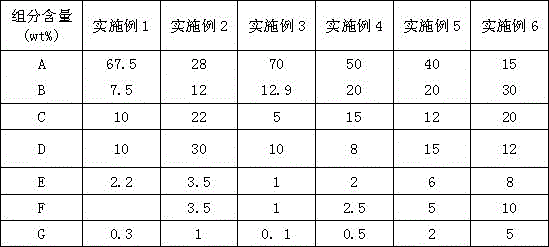

The invention relates to the field of high-polymer materials, and particularly relates to a high-impact halogen-free flame-retardant POK / PA (polyketone / polyamide) alloy material. The alloy material is composed of the following components in parts by weight: 200-400 parts of POK, 400-700 parts of PA6, 10-100 parts of compatibility and impact modifier, 50-150 parts of halogen-free flame retardant and 5-15 parts of aid. The high-impact halogen-free flame-retardant POK / PA alloy material has favorable high-impact properties (up to 250 J / M at 23 DEG C and up to 150 J / M at -30 DEG C); the halogen-free flame retardancy can reach V-0; the abrasion coefficient of the material is better than that of the simple flame-retardant PA6, and is up to 6.9 mm<3> / kg / km; and the heat-deformation temperature of the material is higher than that of the simple flame-retardant PA6, and is up to 190 DEG C.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Glass fiber enhanced polyamide composition and preparation method and application thereof

The invention relates to a composition of a macromolecular compound, in particular to a glass fiber enhanced polyamide composition and a preparation method and application thereof. The glass fiber enhanced polyamide composition is prepared from polyamide 6 or polyamide 66, low-melting-point polyamide, aliphatic polyketone, alkali-free chopped glass fibers and POE-grafted maleic anhydride. By the adoption of unique formula design and a two-step extrusion process, the glass fiber enhanced polyamide composition with low melting point, high wear resistance, low floating fiber content and high size stability is prepared, and can be widely applied to the fields of automobiles, engineering structural members, electronic and electrical products and the like which have high appearance requirement and relatively high requirements on rigidity and toughness balance, wear resistance and size stability.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com