Composition of polyketone with high impact strength

一种组合物、聚酮的技术,应用在聚酮组合物领域,能够解决产品硬度降低等问题

Inactive Publication Date: 2012-10-24

HYUNDAI MOTOR CO LTD +2

View PDF4 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in order to achieve a considerable improvement in impact strength, the rubber content should be about 20% by weight or more at a temperature of -30°C or lower which significantly reduces the bending coefficient, resulting in a decrease in product hardness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0033] The following examples illustrate the invention without intending to limit it.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides a polyketone composition having about 40-90 wt % of polyketone, about 5-40 wt % of polyamide, and about 5-20 wt % of modified rubber. The composition of the present invention greatly improves the impact resistance of polyketone, which has increased heat resistance, chemical resistance, fuel permeation resistance, abrasion resistance or the like, and thus may be widely applied in various industrial fields, such as automotive parts including wheel covers, wheel caps, fuel filler necks, fuel tanks, fuel tubes, center fascias, door handles, roof rack covers, gear, junction boxes, connectors, seat backs or the like, electric / electronic parts, and household items, thereby providing durability of the parts and price competition.

Description

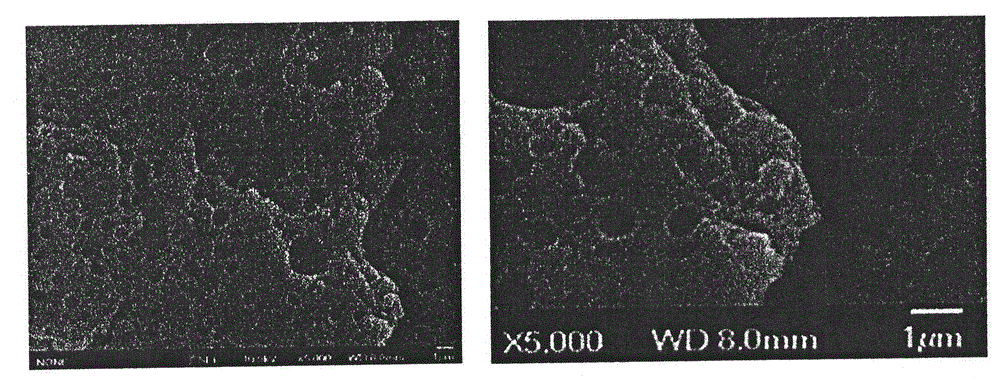

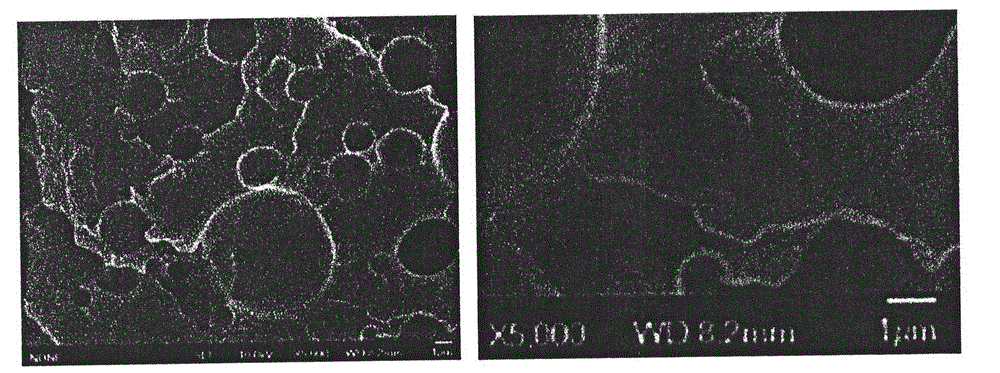

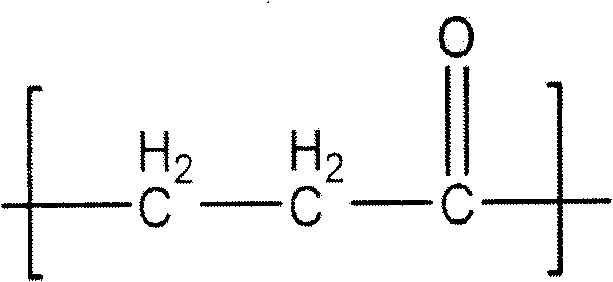

technical field [0001] The present invention relates to polyketone compositions having improved impact resistance. Background technique [0002] Polyketones (PK) are terpolymers obtained by the polymerization of carbon monoxide, ethylene and propylene monomers. Compared to other engineering plastics such as polyamide, polyester, polycarbonate, etc., the price of these raw materials is quite low, and the cost of their polymerization process is relatively low. Polyketones also have excellent resistance to heat, chemicals, fuel permeation and abrasion. Thus, it can be applied to various industrial fields because of its impact resistance. [0003] Polyketone can be blended with polyamide 6 (PA6) to improve its impact resistance, however as described in Korean Patent No. 10-2010-0065526, its impact resistance is less effective in dry state. On the contrary, as described in Journal of Applied Polymer Science, Vol.116 (2010), pp 3056-3069, in a wet state, its impact resistance p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L73/00C08L77/00C08L77/02C08L51/06C08L51/00

CPCC08L77/02C08L61/02C08L77/06C08L51/04C08L23/16C08L73/00C08L33/12C08L77/00C08L23/26C08L33/04

Inventor 李椿洙李珉熙朴凤铉李省勋金钟活尹圣均姜秉局

Owner HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com