Polycarbonate and polyketone alloy and preparation method thereof

A polycarbonate and polyketone technology, applied in the field of polycarbonate polyketone alloy and its preparation, can solve the problems of stress cracking, rigid molecular chain, large steric hindrance, and difficult processing, and achieve good heat resistance and resistance. Solvent resistance, excellent physical and mechanical properties, and the effect of improving chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

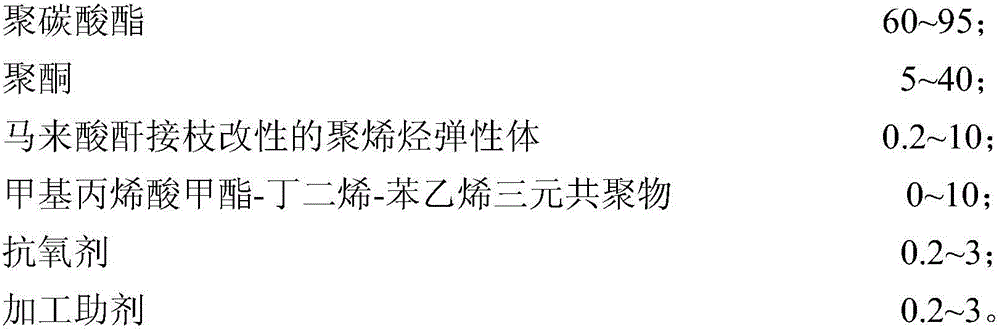

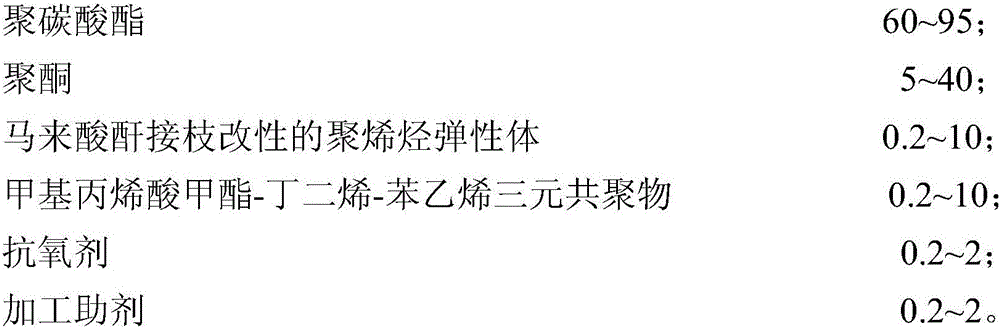

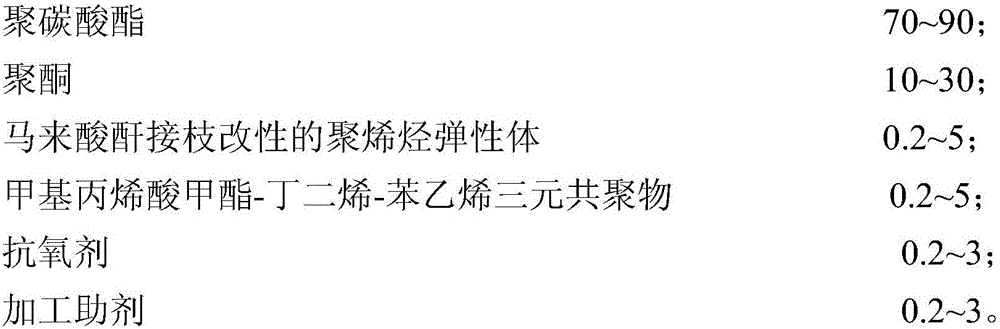

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 (as comparative example 1)

[0039] The specific ratio is: polycarbonate, 95; polyketone 5; compatibilizer A, 0.5; 1010, 0.2; 168, 0.2; silicone powder, 0.3. Dry PC and POK in an oven at 120°C for 8 hours, then put the dried PC and POK resin, compatibilizer A, antioxidant and processing aid into the stirring pot according to the ratio and fully disperse them evenly, and then pass through the twin-screw shear Cutting, mixing and granulation. In the preparation method, the processing temperatures of the twin-screw extruder from feeding to extrusion are 220°C in the first zone, 235°C in the second zone, 245°C in the third zone, 255°C in the fourth zone, and 265 in the fifth zone. ℃, 245℃ in the sixth zone, 235℃ in the seventh zone, 225℃ in the eighth zone, 220℃ in the ninth zone, and 265℃ in the die head.

Embodiment 2

[0041] The specific ratio is: polycarbonate, 90; polyketone 10; compatibilizer A, 0.8; compatibilizer B, 0.5; 1010, 0.2; 168, 0.2; silicone powder, 0.3. Dry PC and POK in an oven at 120°C for 8 hours, then put the dried PC and POK resins with compatibilizer A, compatibilizer B, antioxidant and processing aids into the stirring pot according to the ratio and fully disperse them evenly. After twin-screw shearing, mixing and granulation, in the preparation method, the processing temperature of the twin-screw is 220°C in the first zone, 235°C in the second zone, 245°C in the third zone, 255°C in the fourth zone, 265°C in the fifth zone, and 245°C in the sixth zone. ℃, 235℃ in the seventh zone, 225℃ in the eighth zone, 220℃ in the ninth zone, and 265℃ in the die head.

Embodiment 3

[0043]The specific ratio is: polycarbonate, 85; polyketone 15; compatibilizer A, 1; compatibilizer B, 0.5; 1010, 0.2; 168, 0.2; silicone powder, 0.3. Dry PC and POK in an oven at 120°C for 8 hours, then put the dried PC and POK resins with compatibilizer A, compatibilizer B, antioxidant and processing aids into the stirring pot according to the ratio and fully disperse them evenly. After twin-screw shearing, mixing and granulation, in the preparation method, the processing temperature of the twin-screw is 220°C in the first zone, 235°C in the second zone, 245°C in the third zone, 255°C in the fourth zone, 265°C in the fifth zone, and 245°C in the sixth zone. ℃, 235℃ in the seventh zone, 225℃ in the eighth zone, 220℃ in the ninth zone, and 265℃ in the die head.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com