Application of heat-resistant porous diaphragm to lithium ion battery

A technology of lithium-ion batteries and porous diaphragms, which is applied to battery components, circuits, electrical components, etc., can solve the problems of battery micro-short circuit, large diaphragm pore size, self-discharge, etc., and achieve improved adsorption rate, high porosity, and easy Magnified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

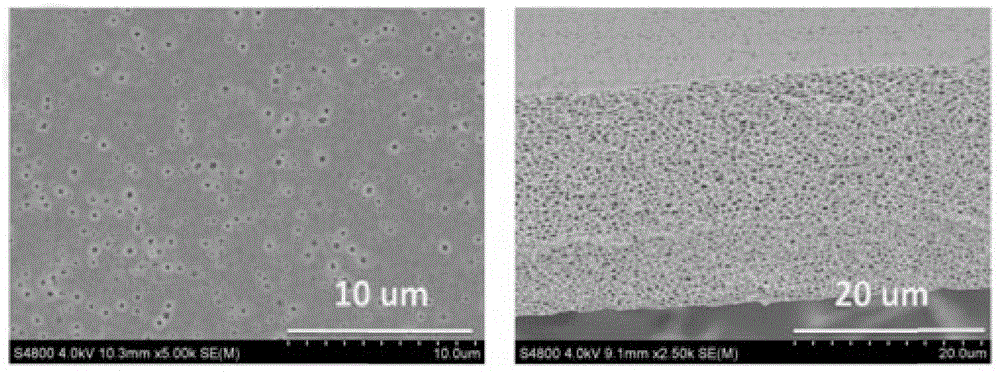

[0029] 10 g of polyetherimide was dissolved in 40 ml of nitrogen methylpyrrolidone to form a polymer solution. Spread the solution on a glass plate (scratch thickness 80um), and then put the glass plate in a constant temperature and humidity box with a temperature of 50° C. and a humidity of 100% for 5 minutes to obtain a porous diaphragm. The cross-sectional structure of the film was analyzed by scanning electron microscopy ( figure 1 ), the membrane cross-section is a highly symmetrical sponge-like structure. Lithium-ion coin cells were assembled for testing, wherein the assembly of the lithium-ion coin cells was carried out in an argon-filled glove box. Using LiFePO4 as the positive electrode material and lithium sheet as the negative electrode, the TC-E269 electrolyte provided by Guangzhou Tinci and the prepared separator were used to assemble a half-cell for testing. The cycle test is carried out between 2.5-4.2V, and the battery is charged and discharged at a rate of ...

Embodiment 2

[0034] Others are the same as embodiment 1, polyetherimide is changed into polyimide.

Embodiment 3

[0036] Others are the same as in Example 1, except that polyetherimide is changed to polyethersulfone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com