Method for treating waste water containing vanadium and chromium

A chromium wastewater, chromium ion technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of strong temperature resistance and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

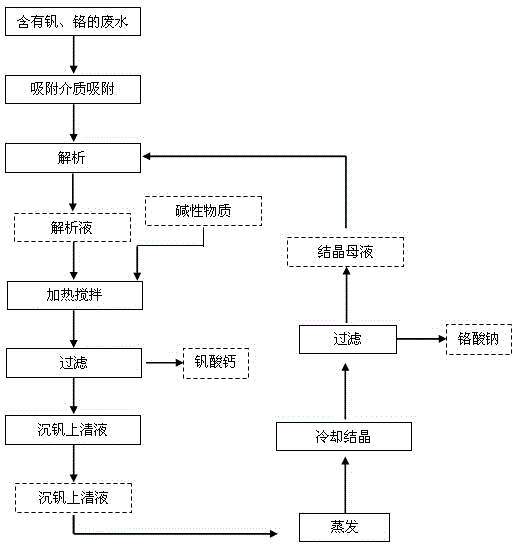

Image

Examples

Embodiment 1

[0028] Get 1L of vanadium-extracting wastewater from a certain iron and steel enterprise in Chengde, and process it as follows:

[0029] 1) Adsorption: Use strong base anion exchange resin D201 to adsorb vanadium and chromium ions in wastewater to obtain a strong base anion exchange resin containing vanadium and chromium ions;

[0030] 2) Analysis: At 20°C, add 3mol / L NaOH aqueous solution to the strong base anion exchange resin containing vanadium and chromium ions obtained in step 1) for analysis to obtain an analysis solution. After analysis, the adsorption medium can be reused;

[0031] 3) Precipitation of vanadium: Add alkaline substances to the analysis solution, the alkaline substance is calcium hydroxide slurry, the amount added is the amount of vanadium element substances in the analysis solution: the amount of calcium element substances in the alkaline substances = 0.8:1 , stirring and reacting, the temperature is 80°C, the reaction time is 1h, and after being unifor...

Embodiment 2

[0041] Get the vanadium extraction tail liquid 2L of a certain iron and steel enterprise in Chengde, process as follows:

[0042] 1) Adsorption: Use a strong base anion exchange resin to adsorb vanadium and chromium ions in wastewater to obtain a strong base anion exchange resin containing vanadium and chromium ions;

[0043] 2) Analysis: Add 5 mol / L NaOH aqueous solution to the strong base anion exchange resin containing vanadium and chromium ions obtained in step 1) at 40°C to obtain an analysis solution, and the adsorption medium can be reused after analysis;

[0044] 3) Precipitation of vanadium: Add alkaline substance to the analysis solution, the alkaline substance is calcium hydroxide powder, the amount added is the amount of vanadium element substance in the analysis solution: the amount of calcium element substance in the alkaline substance = 1:1, Stir the reaction, the temperature is 90°C, the reaction time is 2h, and filter after uniformity to obtain the calcium van...

Embodiment 3

[0054] Get the vanadium extraction tail liquid 2L of a certain iron and steel enterprise in Chengde, process as follows:

[0055] 1) Adsorption: Use strong base anion exchange fibers to adsorb vanadium and chromium ions in wastewater to obtain anion exchange fibers containing vanadium and chromium ions. The anion exchange fibers are polypropylene grafted with styrene and then grafted with quaternary amino groups the product obtained;

[0056] 2) Analysis: Add 4mol / L NaOH aqueous solution to the strong base anion exchange resin containing vanadium and chromium ions obtained in step 1) at 80°C to obtain an analysis solution, and the adsorption medium can be reused after analysis;

[0057] 3) Precipitation of vanadium: Add an alkaline substance to the analysis solution, the alkaline substance is calcium oxide, and the amount added is the amount of vanadium element substance in the analysis solution: the amount of calcium element substance in the alkaline substance = 1.1:1, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com