Method for preparing magnetic biochar

A biochar and magnetic technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of small specific surface area pore size, unsustainable biochar adsorption capacity, and difficult to recycle, etc., to achieve application prospects broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

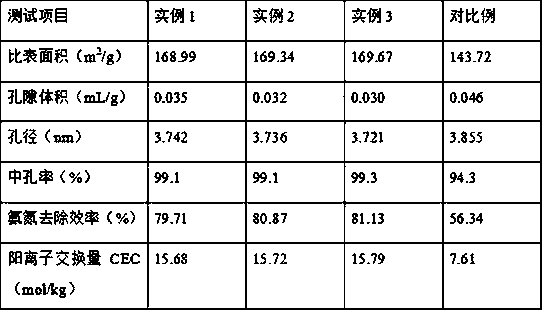

Examples

example 1

[0026]Add 20g of ferric chloride hexahydrate into a beaker containing 150mL of ethylene glycol, stir until ferric chloride hexahydrate dissolves, add 30mL of sodium acetate solution with a mass fraction of 30% and 5g of polyethylene glycol into the beaker, and continue mixing Stir for 40 minutes to obtain a viscous liquid; transfer the viscous liquid to a hydrothermal reaction kettle, seal the hydrothermal reaction kettle, place the hydrothermal reaction kettle in an oven with a set temperature of 190°C, react for 8 hours, and put the magnet into the water In the thermal reaction kettle, the black powder is separated by adsorption, and the black powder is washed with absolute ethanol and deionized water for 4 times, and the washed black powder is placed in a vacuum drying oven with a set temperature of 60°C for drying. 6h, ferroferric oxide magnetic nanopowder was obtained; 10g of ferroferric oxide magnetic nanopowder was dispersed in 200mL of hydrochloric acid with a mass frac...

example 2

[0028] Add 23g of ferric chloride hexahydrate into a beaker containing 165mL of ethylene glycol, stir until ferric chloride hexahydrate dissolves, add 35mL of sodium acetate solution with a mass fraction of 30% and 5g of polyethylene glycol into the beaker, and continue mixing Stir for 45 minutes to obtain a viscous liquid; transfer the viscous liquid to a hydrothermal reaction kettle, seal the hydrothermal reaction kettle, place the hydrothermal reaction kettle in an oven with a set temperature of 195°C, react for 9 hours, and put the magnet into the water In the thermal reaction kettle, the black powder is separated by adsorption, and the black powder is washed with absolute ethanol and deionized water for 4 times, and the washed black powder is placed in a vacuum drying oven with a set temperature of 70°C for drying. 6h, obtain ferroferric oxide magnetic nanopowder; get 13g ferroferric oxide magnetic nanopowder and disperse in 275mL hydrochloric acid that mass fraction is 15...

example 3

[0030] Add 25g of ferric chloride hexahydrate into a beaker containing 180mL of ethylene glycol, stir until ferric chloride hexahydrate dissolves, add 40mL of 30% sodium acetate solution and 6g of polyethylene glycol into the beaker, and continue mixing Stir for 50 minutes to obtain a viscous liquid; transfer the viscous liquid to a hydrothermal reaction kettle, seal the hydrothermal reaction kettle, place the hydrothermal reaction kettle in an oven with a set temperature of 200°C, react for 10 hours, and put the magnet into the water In the thermal reaction kettle, the black powder is separated by adsorption, and the black powder is washed with absolute ethanol and deionized water for 5 times, and the washed black powder is placed in a vacuum drying oven with a set temperature of 80°C for drying. 7h, obtain ferroferric oxide magnetic nanopowder; Get 15g of ferroferric oxide magnetic nanopowder and disperse in 250mL hydrochloric acid that mass fraction is 15%, obtain suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com