Synthetic method of chabasite

A synthesis method and chabazite technology are applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of no application prospect, environmental pollution, low crystallinity, etc., and achieve the effect of broad application prospect and simple implementation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

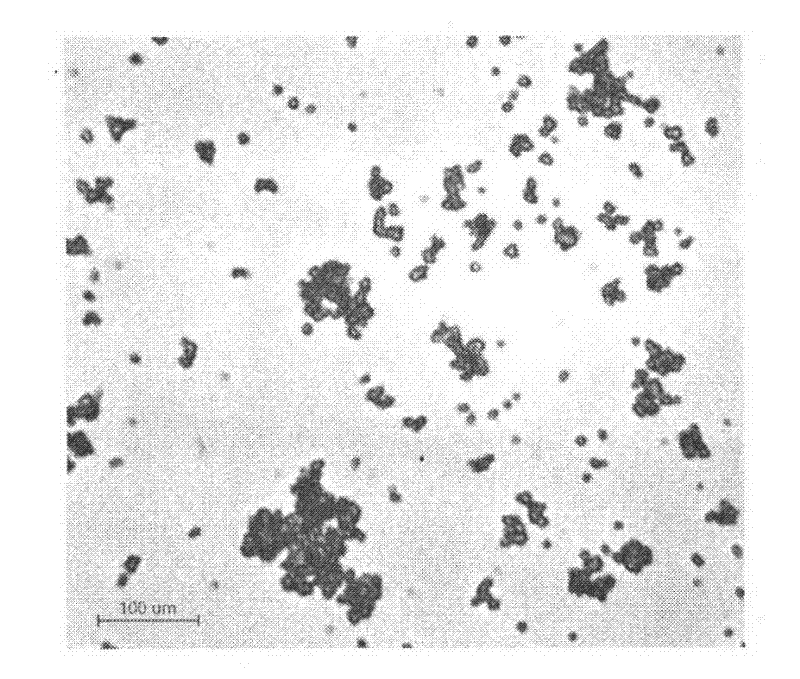

Image

Examples

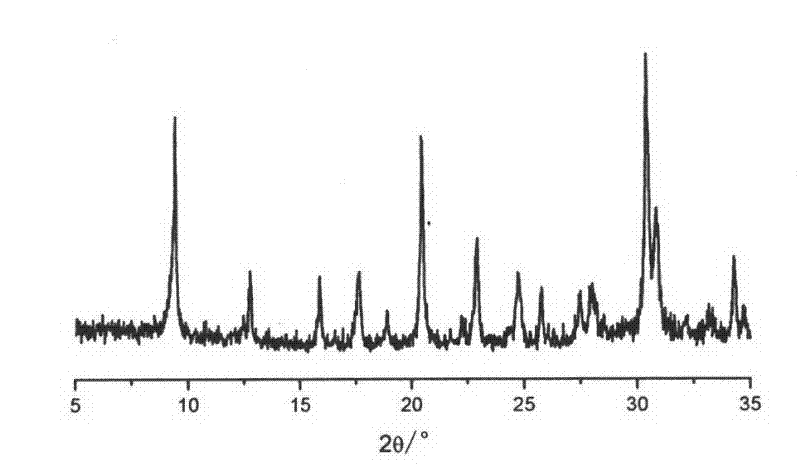

Embodiment 1

[0016] At room temperature, take 0.120 g of aluminum foil, add 0.68 ml of 13 mol / L potassium hydroxide solution, stir and mix well, add 0.693 g of thin layer chromatography silica gel, then add 9.32 ml of water, continue to stir, and finally add 0.069 G seed crystals and stir for half an hour. Transfer to a 20ml stainless steel reactor containing polytetrafluoroethylene, under autogenous pressure, crystallize at 150 degrees Celsius for 2 days. After quenching, washing, filtering, and natural drying, the original molecular sieve powder is obtained.

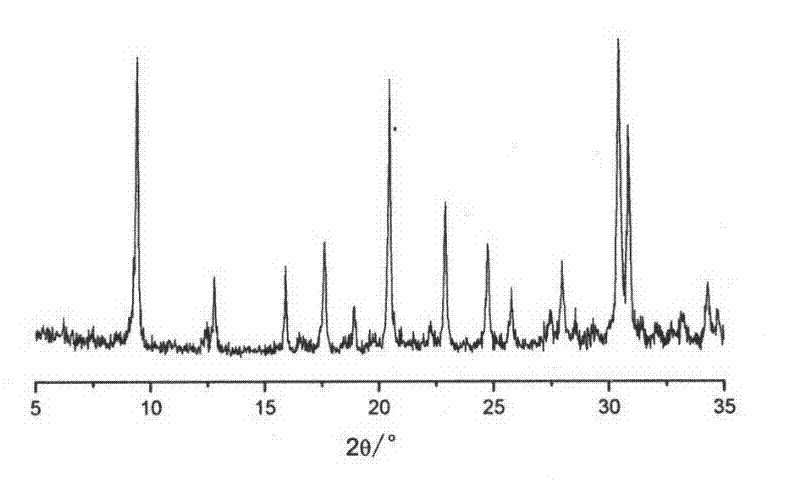

Embodiment 2

[0018] At room temperature, take 0.120 g of aluminum foil, add 0.68 ml of 13 mol / L potassium hydroxide solution, stir and mix well, add 0.693 g of white carbon black, then add 9.32 ml of water, continue to stir, and finally add 0.173 g of crystal Seed and stir for half an hour. Transfer to a 20ml stainless steel reactor containing polytetrafluoroethylene and crystallize at 85 degrees Celsius for 6 days under autogenous pressure. After quenching, washing, filtering, and natural drying, the original molecular sieve powder is obtained.

Embodiment 3

[0020] At room temperature, take 0.062 g of aluminum foil, add 3.47 ml of 10 mol / L potassium hydroxide solution, stir and mix well, add 2.222 g of white carbon black, then add 6.53 ml of water, continue to stir, and finally add 0.111 g of crystal Seed and stir for half an hour. Transfer to a 20ml stainless steel reactor containing polytetrafluoroethylene and crystallize at 110 degrees Celsius for 3 days under autogenous pressure. After quenching, washing, filtering, and natural drying, the original molecular sieve powder is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com