A drug screening method with high precision and high reproducibility

An accurate and repeatable technology, applied in biochemical equipment and methods, microbial determination/inspection, etc., can solve the problems of high cost of raw materials, difficulty in preparing arrays of electrospun fibers, and difficulty in electrospun fibers, to ensure accuracy. and repeatability, large market practical value, simple implementation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

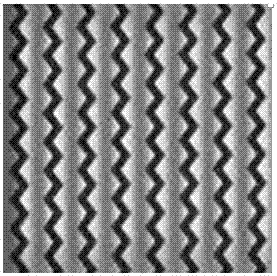

[0039] 1) Preparation of patterned fiber electrospinning receiving plate: First, coat a positive photoresist on an insulating glass sheet, then cover a layer of photomask, and use a photolithography machine to etch; Deposit a layer of metallic silver on the glass sheet, the shape of the deposited metallic silver is a broken line, and the width of the pattern is 80 μm; finally, the remaining positive photoresist is washed away;

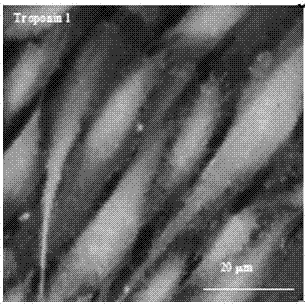

[0040] 2) Preparation of patterned electrospun fibers: Dissolve medical polymers in organic solvents, use the resultant in step 1) as an electrospinning receiving plate, and prepare patterned electrospun fibers by electrospinning technology; control the diameter of the obtained fibers to 400nm;

[0041] The medical polymer is polylactic acid, and the organic solvent is acetone;

[0042]3) Place SU-8 on the silicon wafer, remove the rest of SU-8 using photolithography technology, and keep the SU-8 cuboid with a width of 100 μm and a height of 70 μm as ...

Embodiment 2

[0046] 1) Preparation of patterned fiber electrospinning receiving plate: First, coat a positive photoresist on an insulating glass sheet, then cover a layer of photomask, and use a photolithography machine to etch; Deposit a layer of metallic silver on the glass sheet, the shape of the deposited metallic silver is in the shape of a broken line, and the pattern width is 40 μm; finally, the remaining positive photosensitive glue is washed away;

[0047] 2) Preparation of patterned electrospun fibers: Dissolve medical polymers in organic solvents, use the resultant in step 1) as an electrospinning receiving plate, and prepare patterned electrospun fibers by electrospinning technology; control the diameter of the obtained fibers to 300nm;

[0048] The medical polymer is polycaprolactone, and the organic solvent is acetone and dimethylformamide (9:1v / v);

[0049] 3) Place SU-8 on the silicon wafer, remove the rest of SU-8 using photolithography technology, and keep the SU-8 cuboi...

Embodiment 3

[0053] 1) Preparation of patterned fiber electrospinning receiving plate: First, coat a positive photoresist on an insulating glass sheet, then cover a layer of photomask, and use a photolithography machine to etch; Deposit a layer of metallic silver on the glass sheet, the shape of the deposited metallic silver is a zigzag shape, and the pattern width is 20 μm; finally, the remaining positive photosensitive adhesive is washed away;

[0054] 2) Preparation of patterned electrospun fibers: Dissolve medical polymers in organic solvents, use the resultant in step 1) as an electrospinning receiving plate, and prepare patterned electrospun fibers by electrospinning technology; control the diameter of the obtained fibers to 200nm;

[0055] The medical high molecular polymer is polyurethane, and the organic solvent is acetone;

[0056] 3) Place SU-8 on the silicon wafer, remove the rest of SU-8 using photolithography technology, and keep the SU-8 cuboid with a width of 40 μm and a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com