Method for manufacturing patterned metal film based on poly-dopamine and product thereof

A technology for patterning metal and polydopamine films, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of long cycle and high cost, and achieve the effect of strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

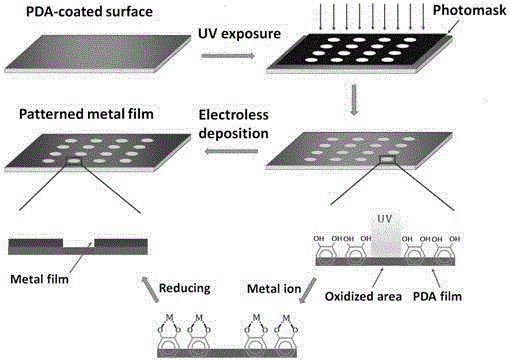

[0031] Embodiment 1, a method for preparing patterned metal thin film based on polydopamine

[0032] A method for preparing a patterned metal film based on polydopamine, comprising the steps of:

[0033] (1) Preparation of polydopamine film: immerse the clean substrate in a newly prepared dopamine solution with a pH of 8.5 and a concentration of 2 mg / mL to form a polydopamine film on the surface of the substrate, take it out, rinse it with water, and dry it with nitrogen gas to obtain The substrate of the polydopamine membrane;

[0034] (2) UV oxidation of polydopamine: a photomask is placed on the substrate of the polydopamine film attached to the gained step (1), and then the ultraviolet light intensity is 20mw / cm 2 Irradiated under the same conditions for 10 minutes, then washed with double distilled water, and dried with nitrogen to obtain the substrate of UV-oxidized polydopamine;

[0035] (3) Metal patterning: metal ions are deposited on the substrate of ultraviolet ox...

Embodiment 2

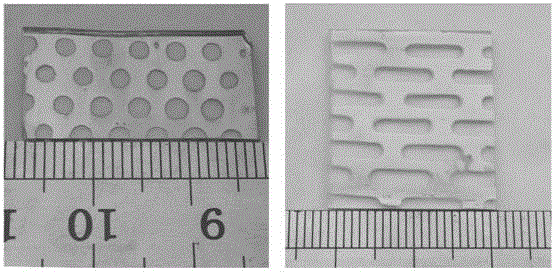

[0037] Embodiment 2, a kind of method for preparing patterned copper film based on polydopamine

[0038] Using polyester (poly(ethylene terephthalate)) as a substrate to prepare a patterned copper film, the specific steps are as follows:

[0039] (1) Preparation of polydopamine membrane: immerse clean polyester in a freshly prepared dopamine solution with a pH of 6 and a concentration of 0.1 mg / mL for 10 minutes. Repeat immersion 20 times, take out and rinse with water, then blow dry with nitrogen to obtain a substrate with a polydopamine film;

[0040] (2) Ultraviolet oxidation of polydopamine: a photomask is placed on the substrate of the polydopamine film attached to the gained step (1), and then the ultraviolet light intensity is 10mw / cm 2 Irradiated under the same conditions for 15 minutes, then washed with double distilled water, and dried with nitrogen to obtain the substrate of UV-oxidized polydopamine;

[0041] (3) Metal patterning: preparation containing 50mM EDTA,...

Embodiment 3

[0070] A method for preparing a patterned silver film based on polydopamine, comprising the steps of:

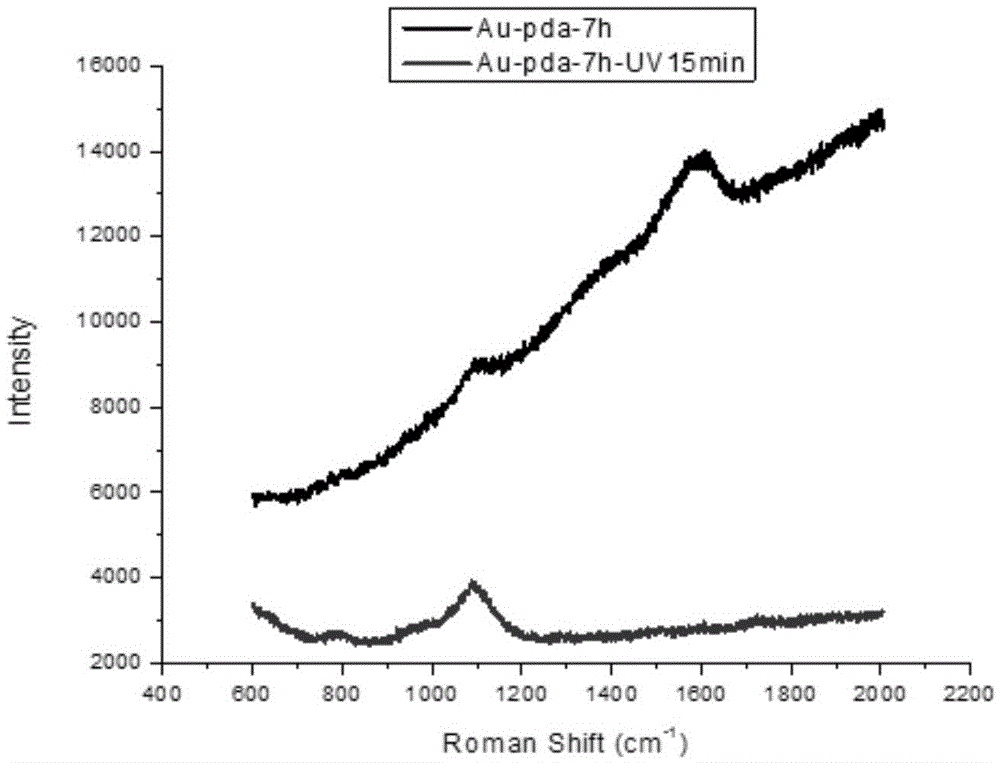

[0071] (1) Preparation of polydopamine membrane: immerse the clean glass slide in a newly prepared solution with a pH of 8.5 and a dopamine concentration of 2 mg / mL for 7 hours, take it out, rinse it with double distilled water, and dry it with nitrogen to obtain the attached film. Substrate with polydopamine membrane;

[0072] (2) UV oxidation of polydopamine: a photomask is placed on the substrate with polydopamine film, and the ultraviolet light intensity is 35mw / cm 2 Irradiated for 15 minutes under the same conditions, then washed with double distilled water, and dried with nitrogen;

[0073] (3) Metal patterning: Add ammonia water dropwise to the 10mM silver nitrate solution, the solution turns light brown, continue to add ammonia water until the solution becomes colorless, then add an equal volume of 3.33mM glucose solution to the system to oxidize the UV Insert the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com