A method for the controllable preparation and patterning of two-dimensional transition metal dichalcogenide layers based on surface plasmon waves

A technology of surface plasmons, transition metals, metal selenides/tellurides, nanotechnology for materials and surface science, chemical instruments and methods, which can solve the needs of large-scale devices that are not always guaranteed, damage Degradation, time-consuming nanosheets and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a method for the controllable preparation and patterning of layers of two-dimensional transition metal dichalcogenides based on surface plasmon waves, comprising the following steps:

[0030] A laser with a wavelength of 670nm is used to irradiate the surface of a transition metal disulfide sample placed in an aqueous solution at the maximum incident angle of total internal reflection;

[0031] Controlling the output power of the laser for exciting surface plasmon waves to obtain a transition metal dichalcogenide with a controllable number of layers; the number of layers is 1, 2 or 3 layers;

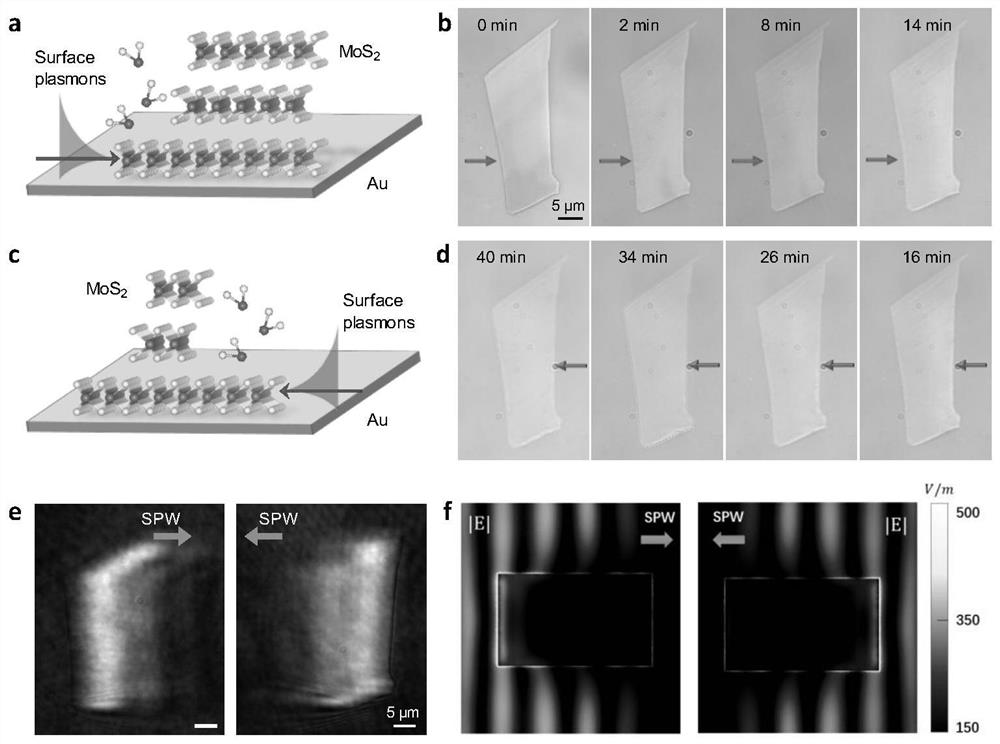

[0032] The propagation direction and etching time of the surface plasmon wave are adjusted to obtain patterned layered transition metal dichalcogenides.

[0033] The invention adopts the laser with the wavelength of 670nm to irradiate the surface of the transition metal disulfide sample placed in the aqueous solution at the maximum incident angle of ...

Embodiment 1

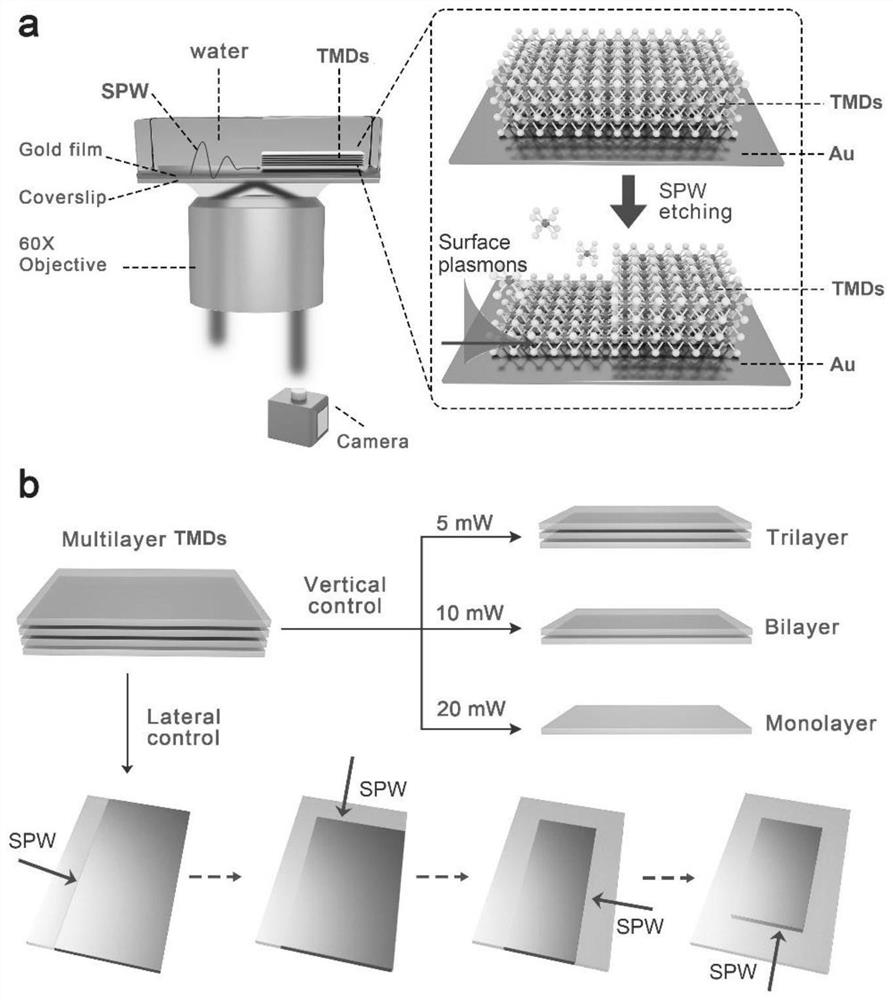

[0044] Example 1: Exciting Surface Plasmon Waves

[0045] Layer-number-controllable fabrication and patterning of 2D transition metal dichalcogenides is achieved in surface plasmon resonance microscopy, see figure 1 . On the basis of an inverted total internal reflection fluorescence microscope (Nikon Ti-E), a high numerical aperture oil immersion objective lens (60X, NA=1.49) was selected to construct a surface plasmon resonance microscope. Gold-plated chips were prepared by evaporating 2nm chrome as an adhesion layer on a BK-7 glass cover slip, and then evaporating 47nm gold layer. A laser diode (coherent OBIS, wavelength = 670nm, output power adjustable from 0.5 to 70mW) was used as the light source, and a polarizer was inserted in the optical path to generate p-polarized light to excite surface plasmon waves. The system includes a laser light source, a collimator, a polarizer, a condenser, a scanning galvanometer, a lens, an oil immersion objective, a gold-plated chip, a...

Embodiment 2

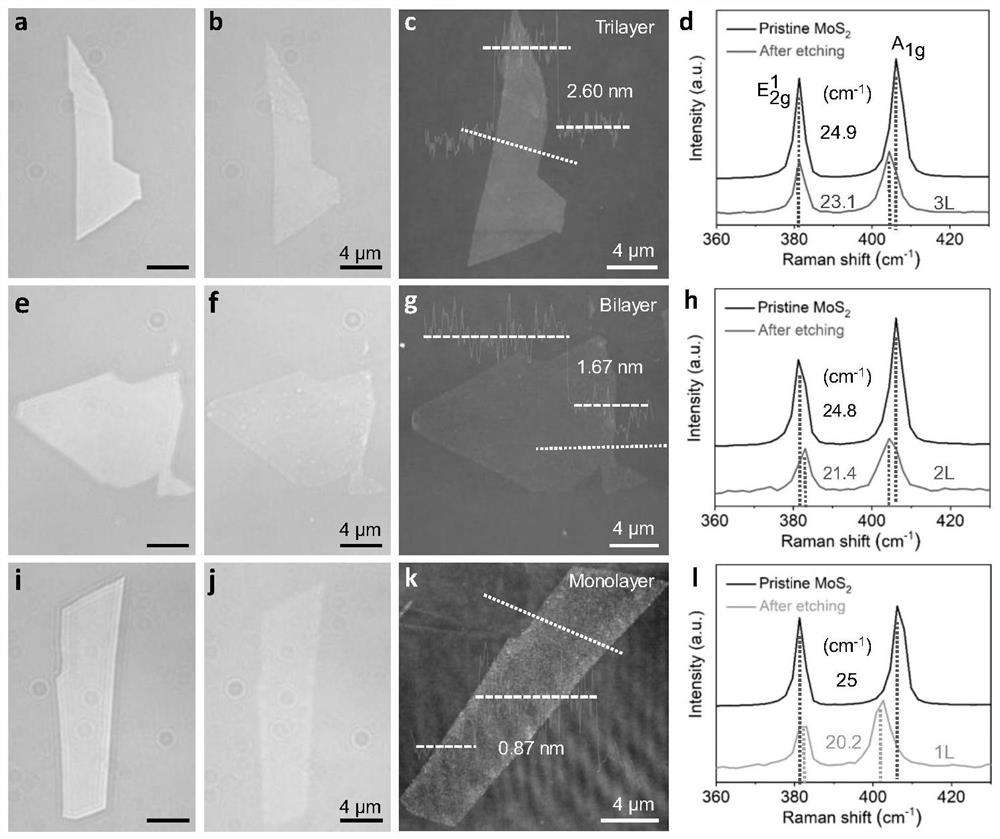

[0047] Example 2: Controllable preparation of molybdenum disulfide with adjustable layers

[0048] The etching rate of molybdenum disulfide nanosheets depends on the output power of the laser that excites surface plasmon waves, and the layer number control of molybdenum disulfide (such as single layer, double layer and triple layer) can be realized by directly adjusting the output power of the laser. figure 2 In a, e and i are the optical images of the molybdenum disulfide nanosheets that were initially exfoliated. When the output power of the laser is 5mW, 10mW and 20mW, the optical images of the molybdenum disulfide nanosheets after etching are recorded to obtain three-layer, double-layer layer and monolayer of molybdenum disulfide. figure 2 In b, f and j are the optical images of three-layer, two-layer and single-layer MoS2, respectively. The image and the corresponding height map of the atomic force microscopy experiment show that the thickness of the molybdenum disulfi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com