Patents

Literature

1488results about "Binary selenium/tellurium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis of colloidal nanocrystals

InactiveUS6872249B2High crystallinityGood monodispersityFrom gel stateMaterial nanotechnologyPresent methodSulfur

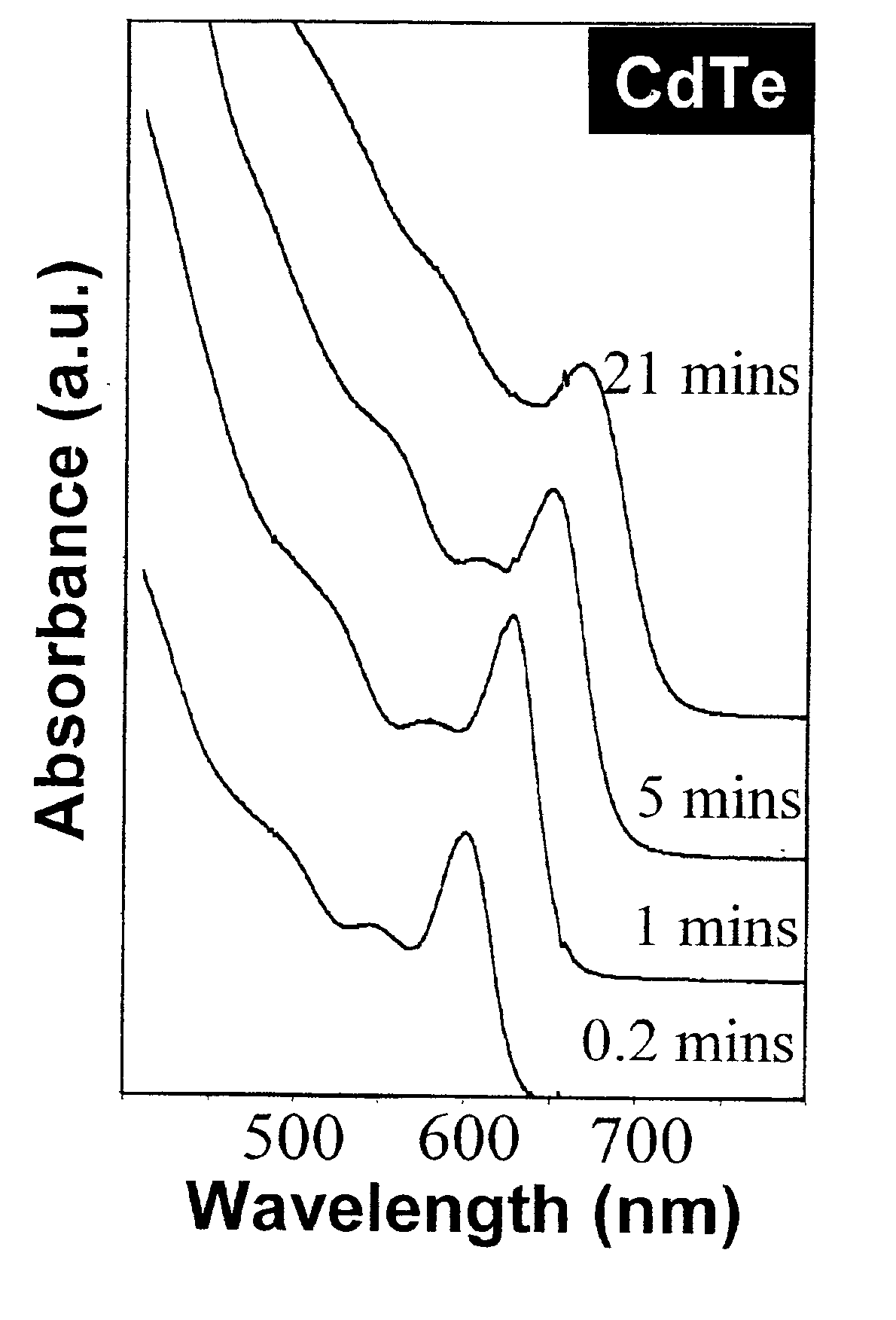

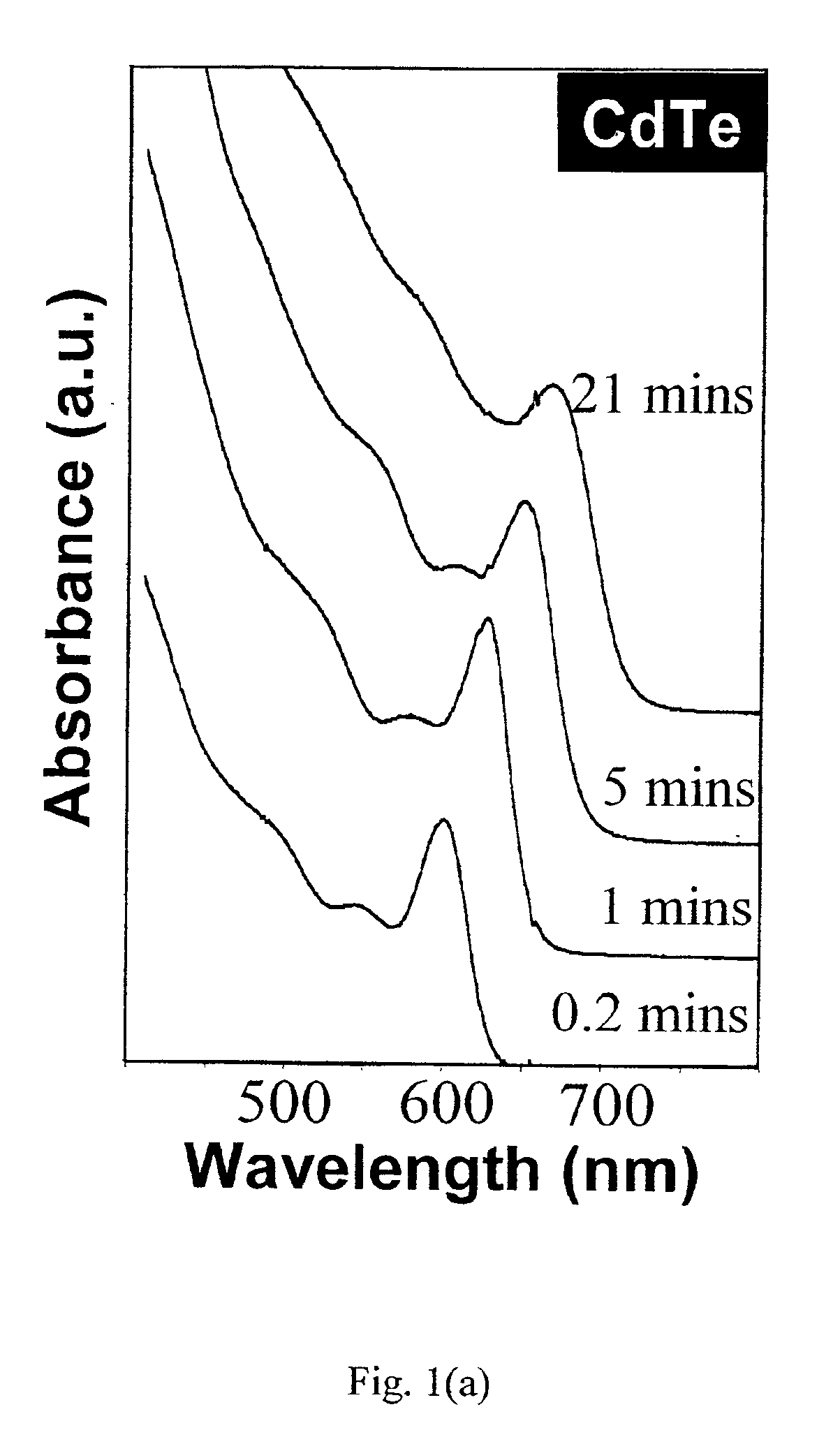

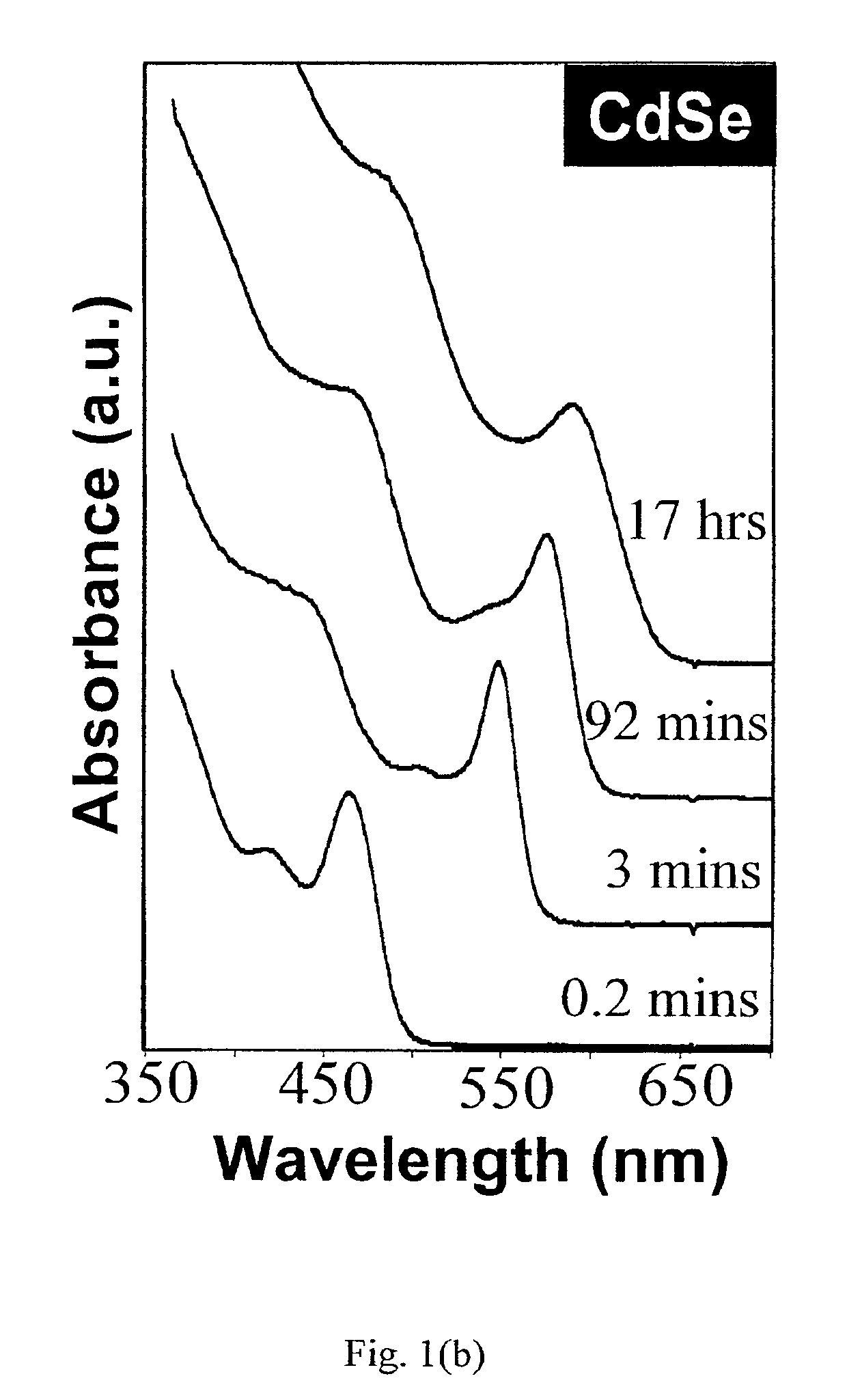

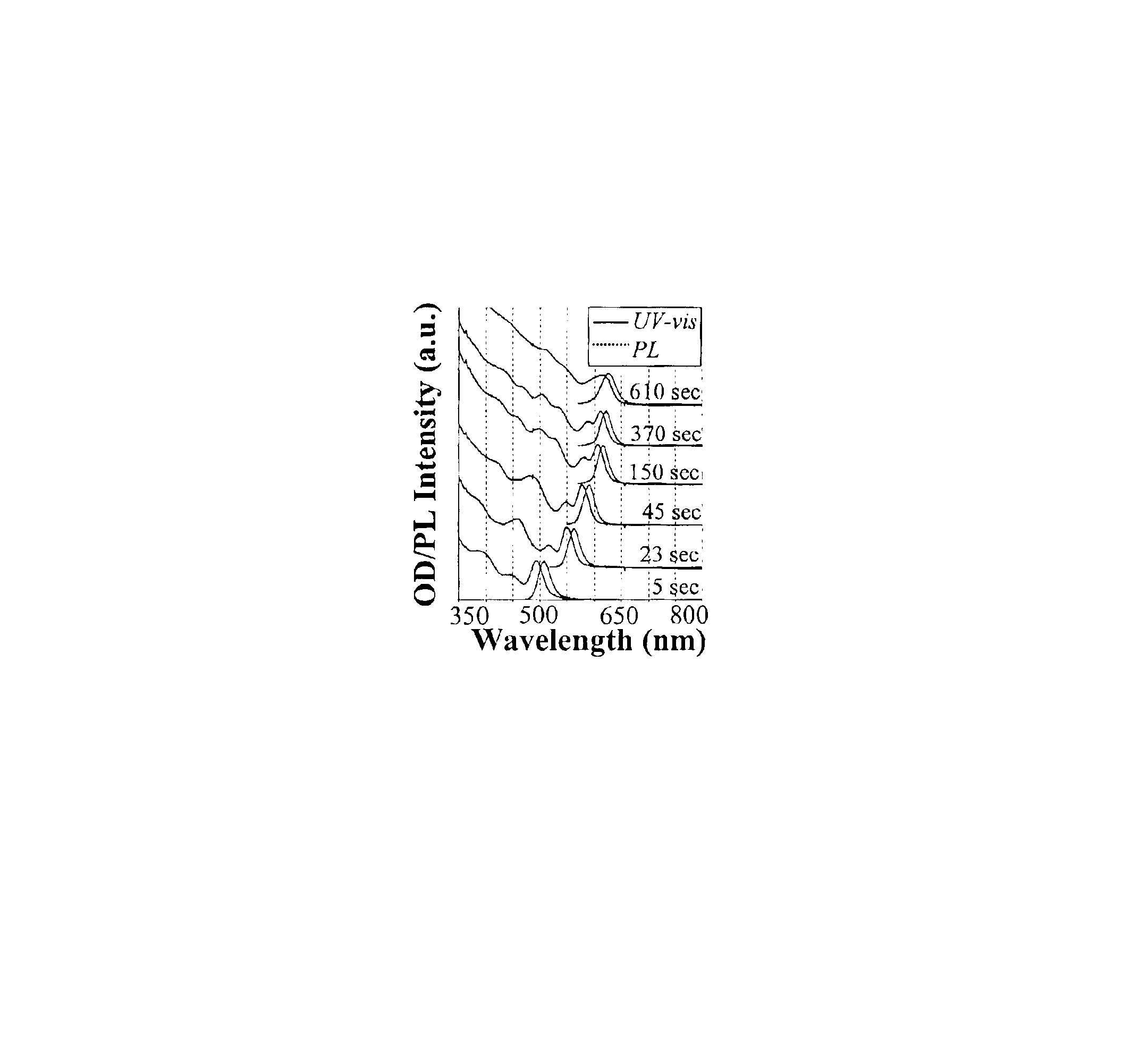

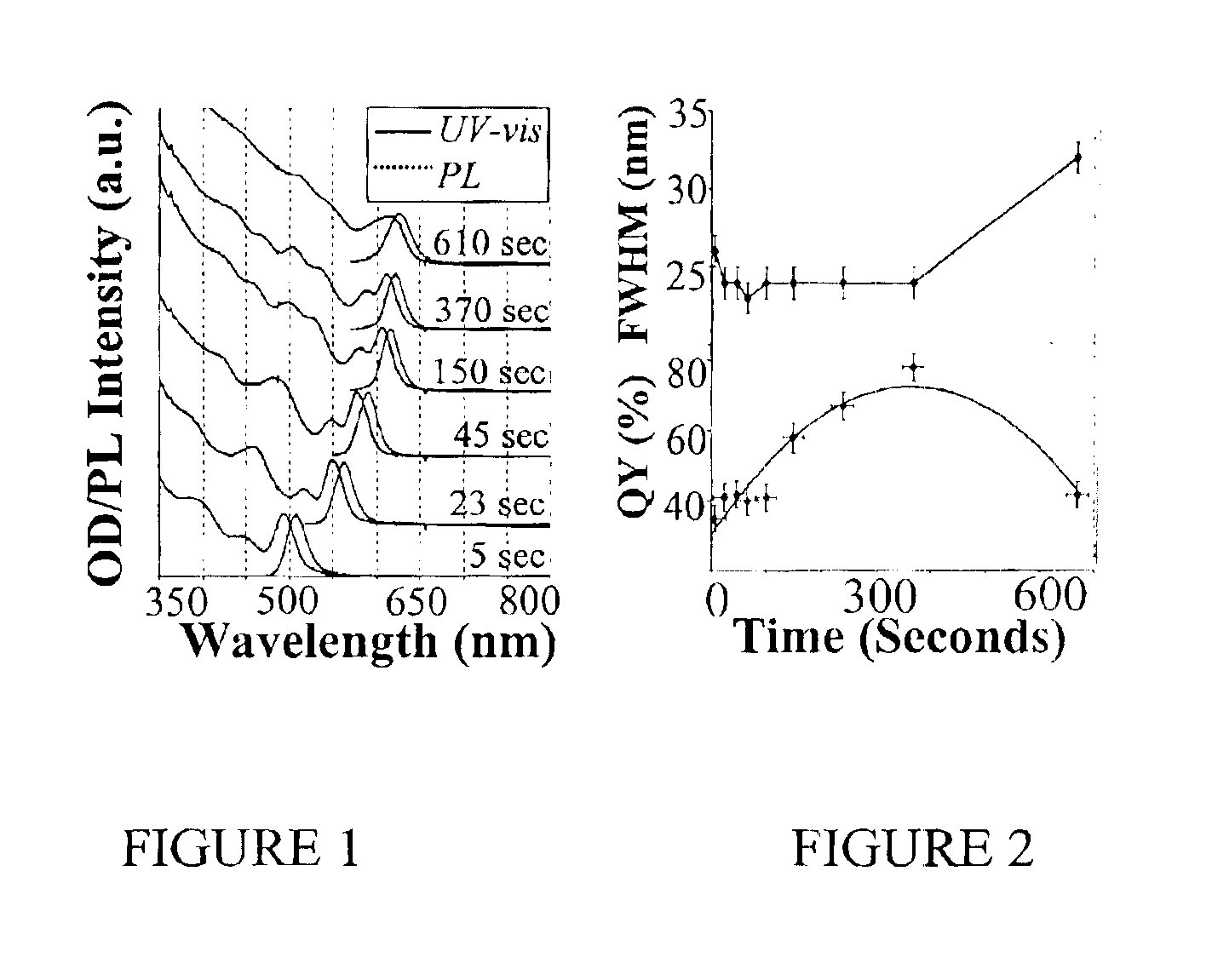

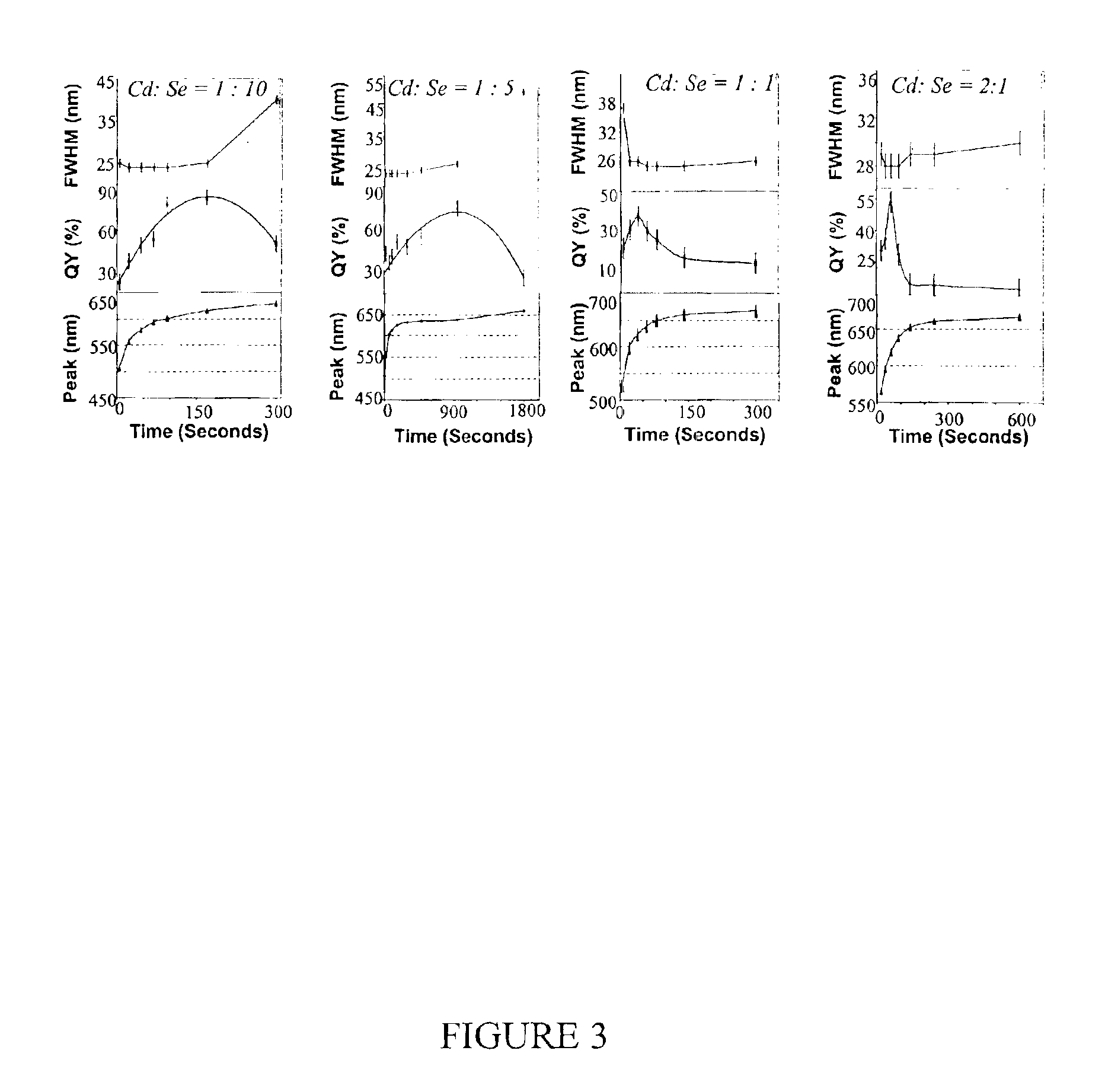

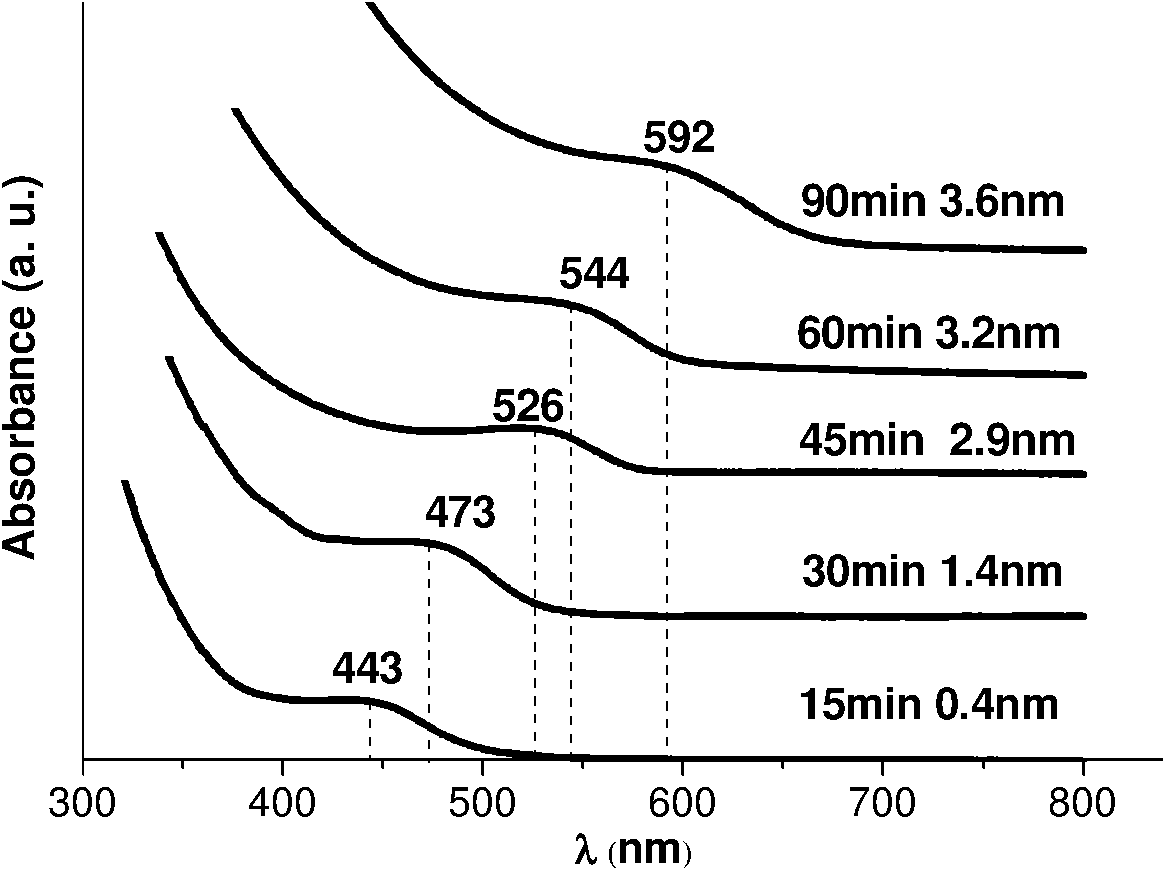

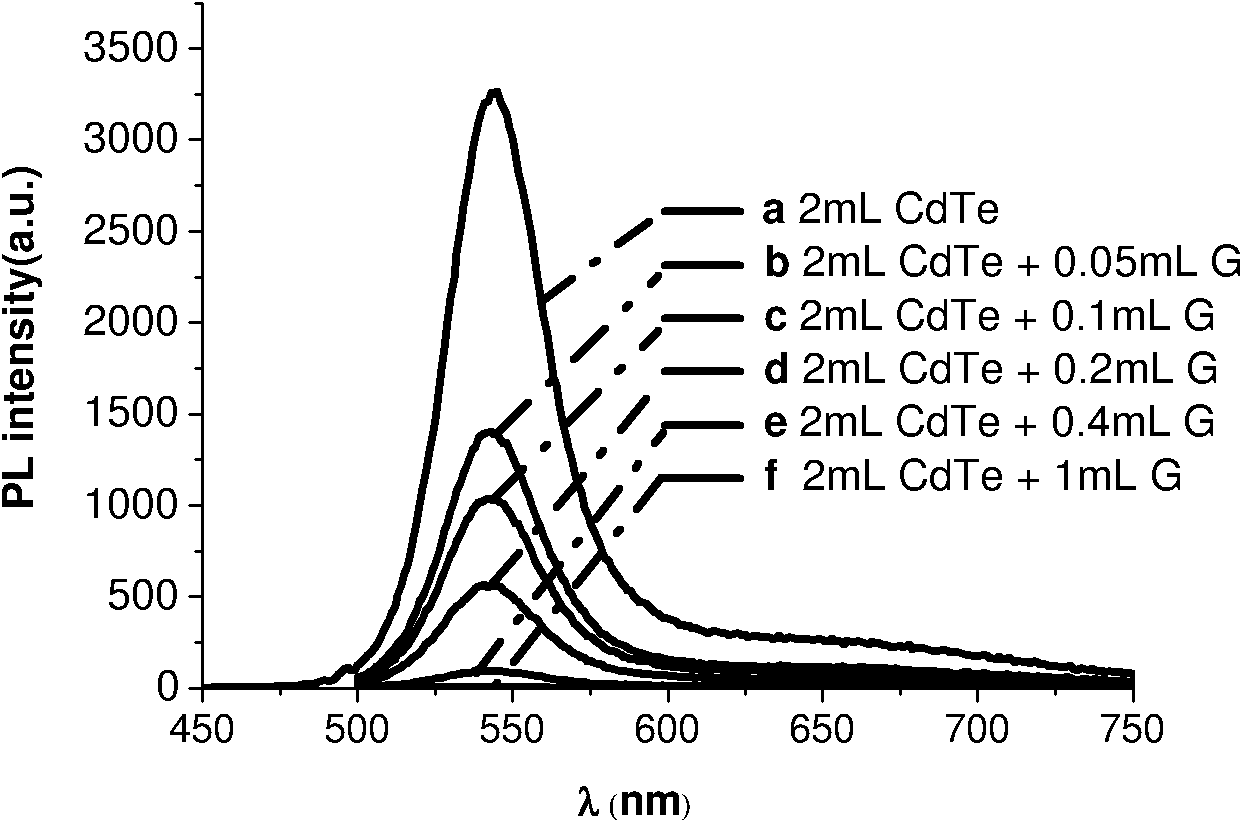

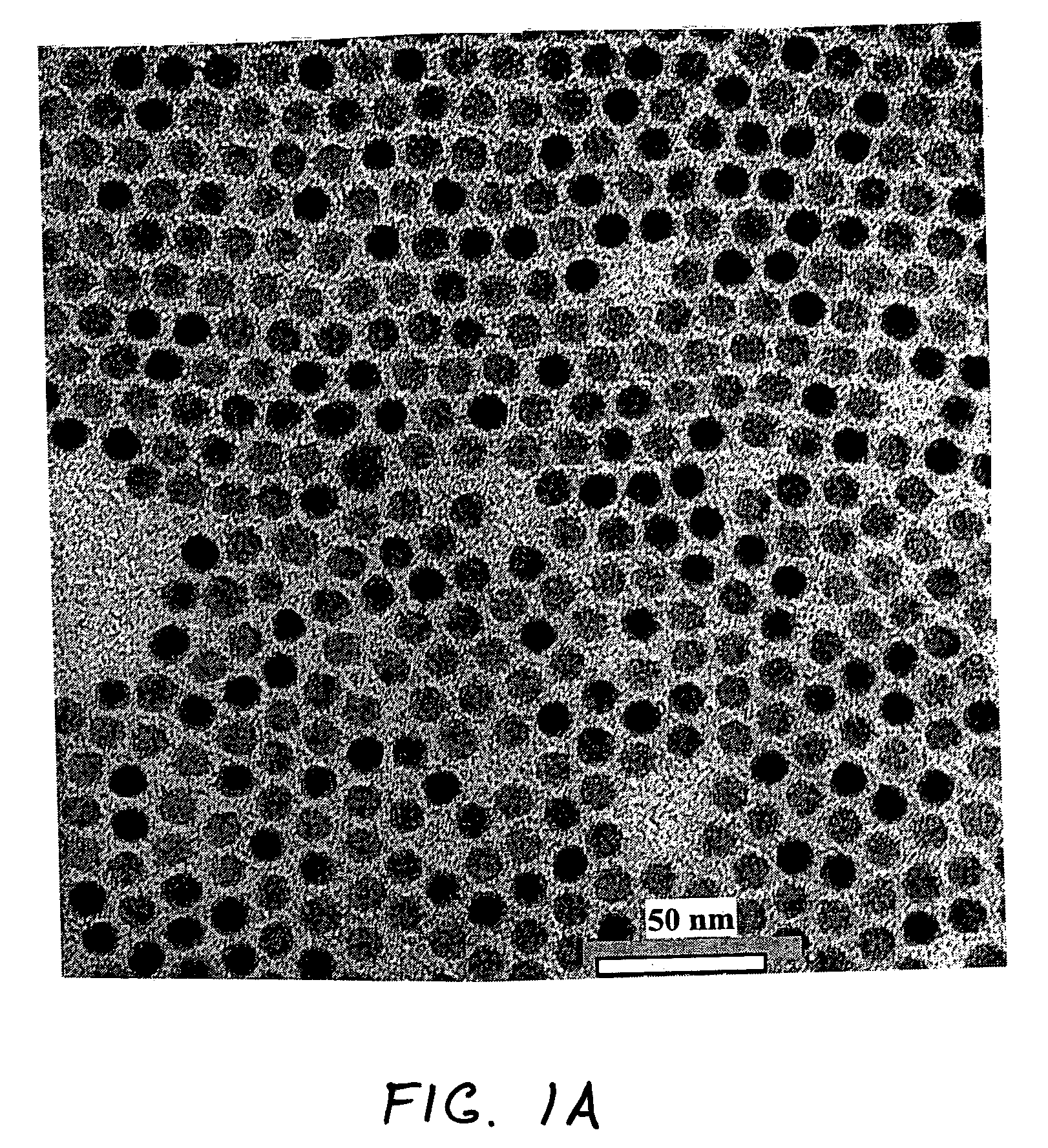

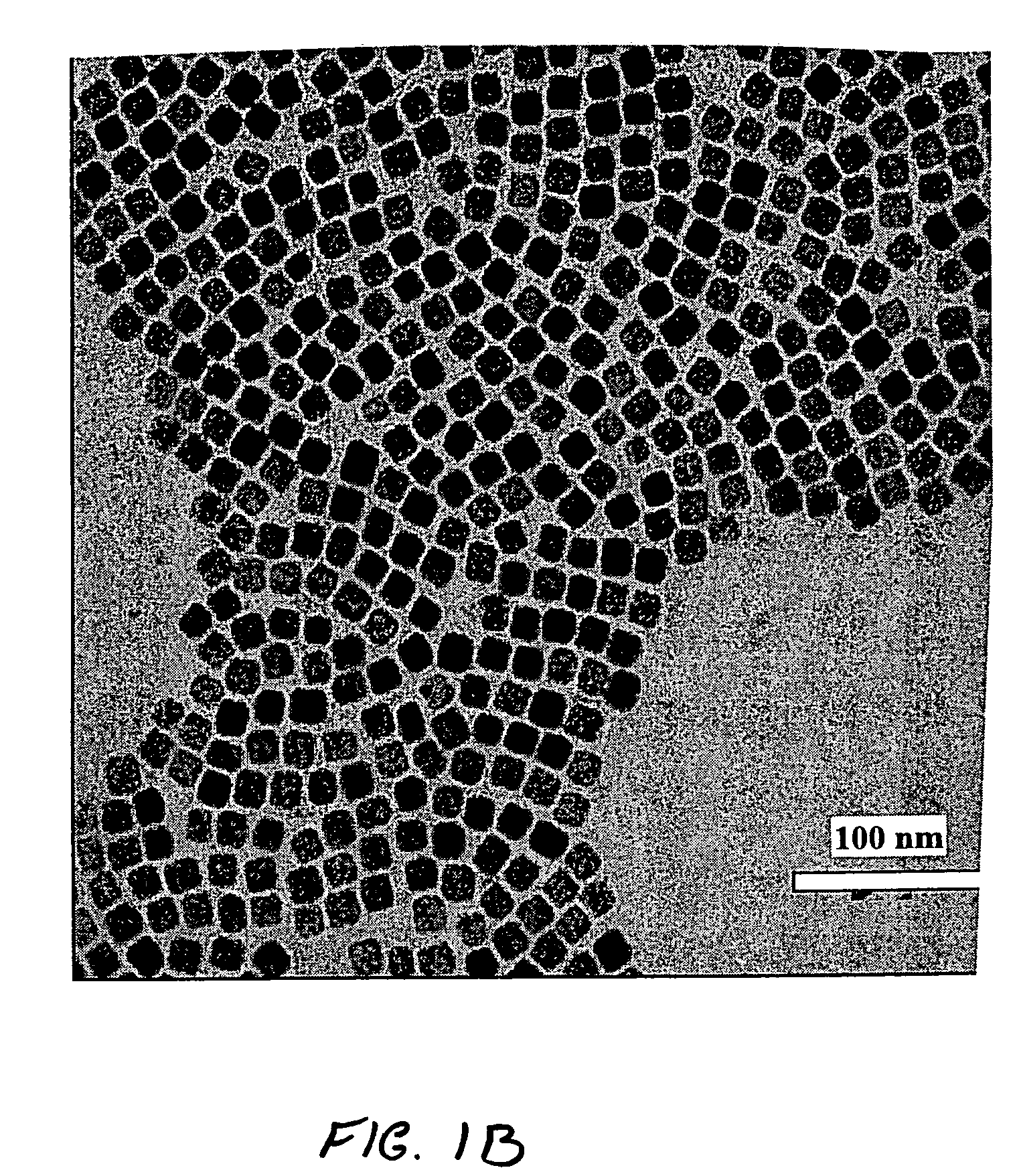

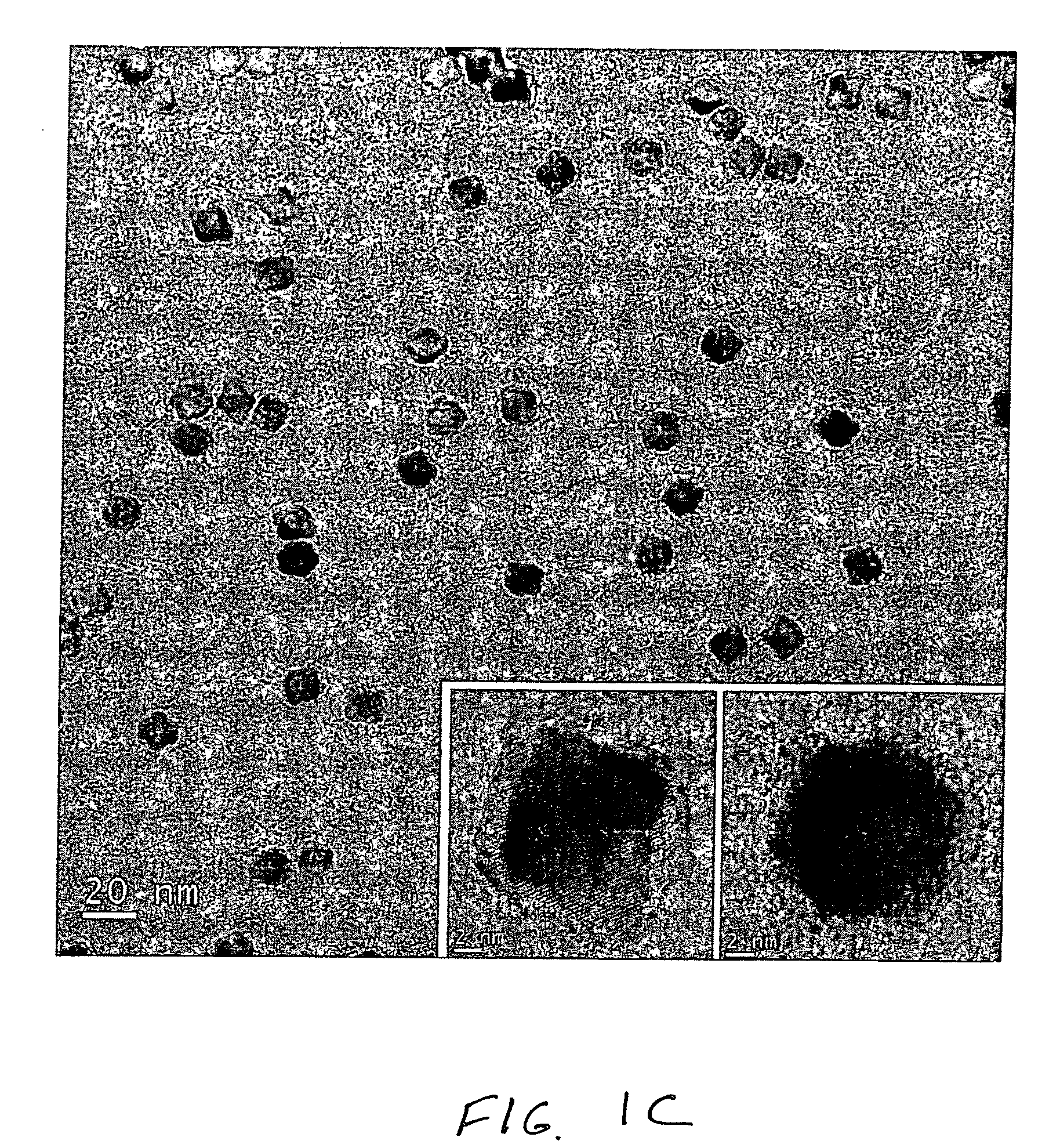

A method of synthesizing colloidal nanocrystals is disclosed using metal oxides or metal salts as a precursor. The metal oxides or metal salts are combined with a ligand and then heated in combination with a coordinating solvent. Upon heating, the metal oxides or salts are converted to stable soluble metal complexes. The metal complexes are formed by cationic species combining with the ligands and / or with the coordinating solvent. Finally, an elemental chalcogenic precursor, for example, Se, Te, or S, is introduced into the soluble metal complex to complete the formation of the nanocrystals at a controllable rate. High-quality CdSe, CdTe, and CdS nanocrystals are produced when CdO is used as the cadmium precursor. With the present method, the size, size distribution, and shape (dots or rods) of the resulting nanocrystals can be controlled during growth. For example, the resulting nanocrystals are nearly monodisperse without any size separation. Further, the method represents a major step towards a green chemistry approach for synthesizing high-quality semiconductor nanocrystals.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

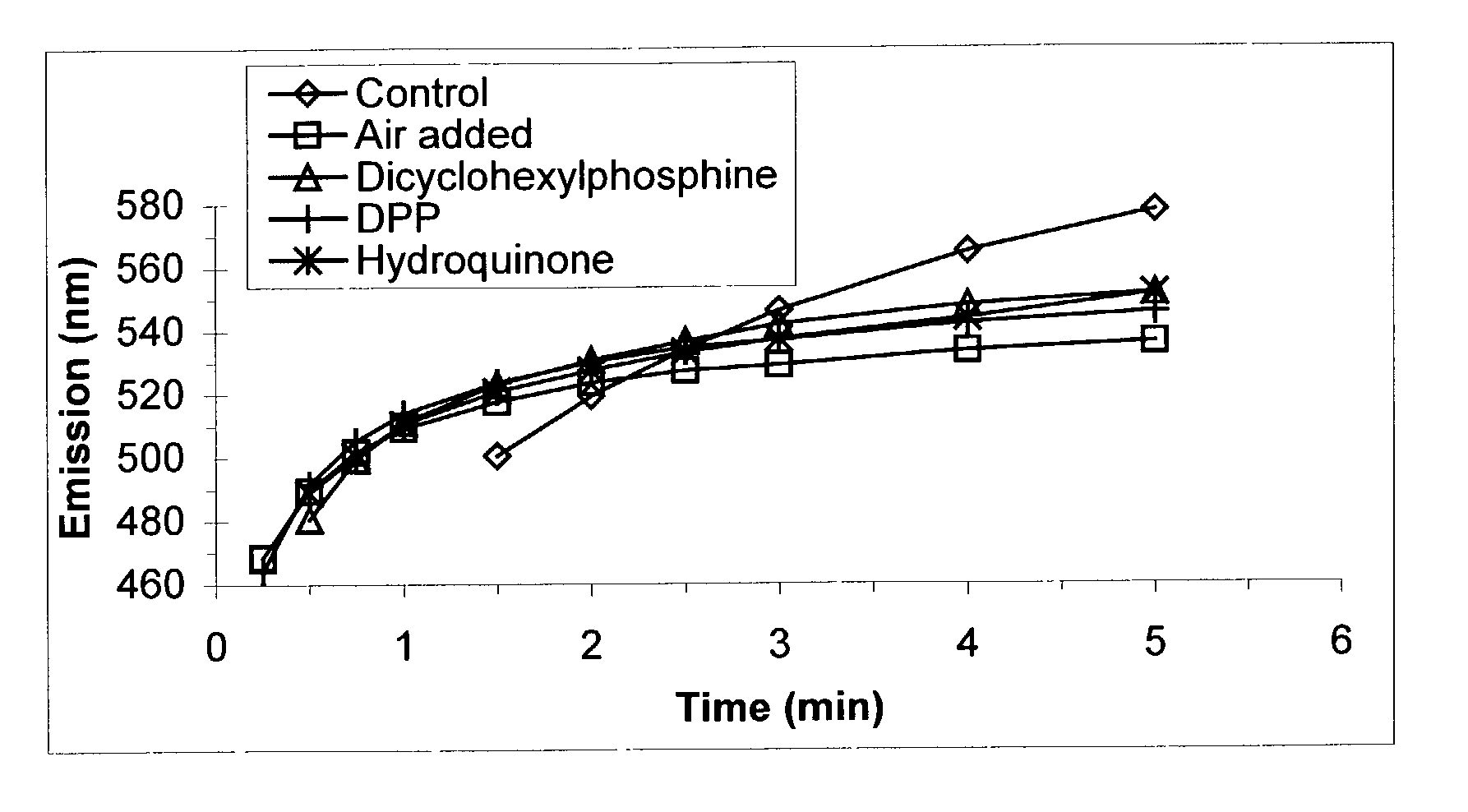

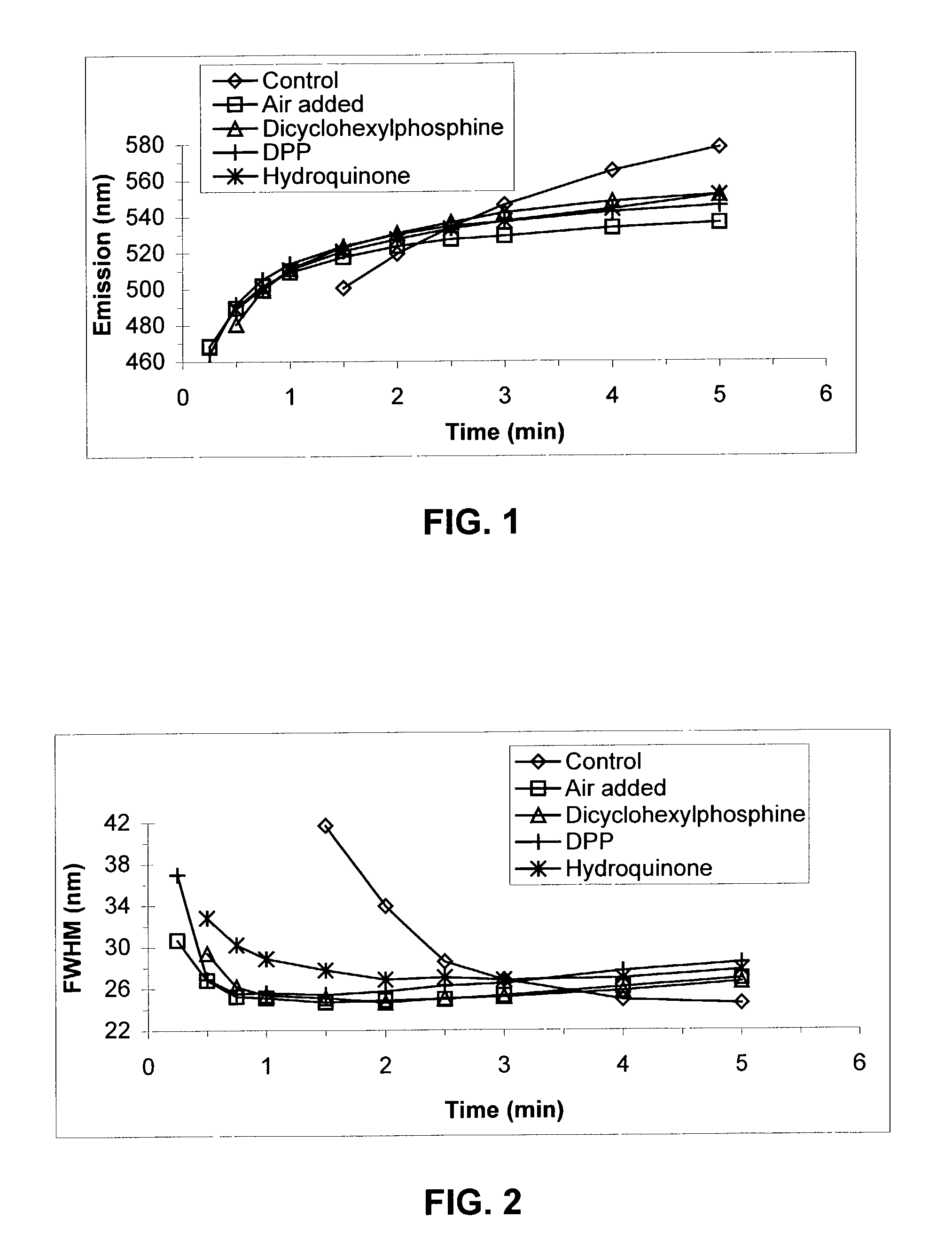

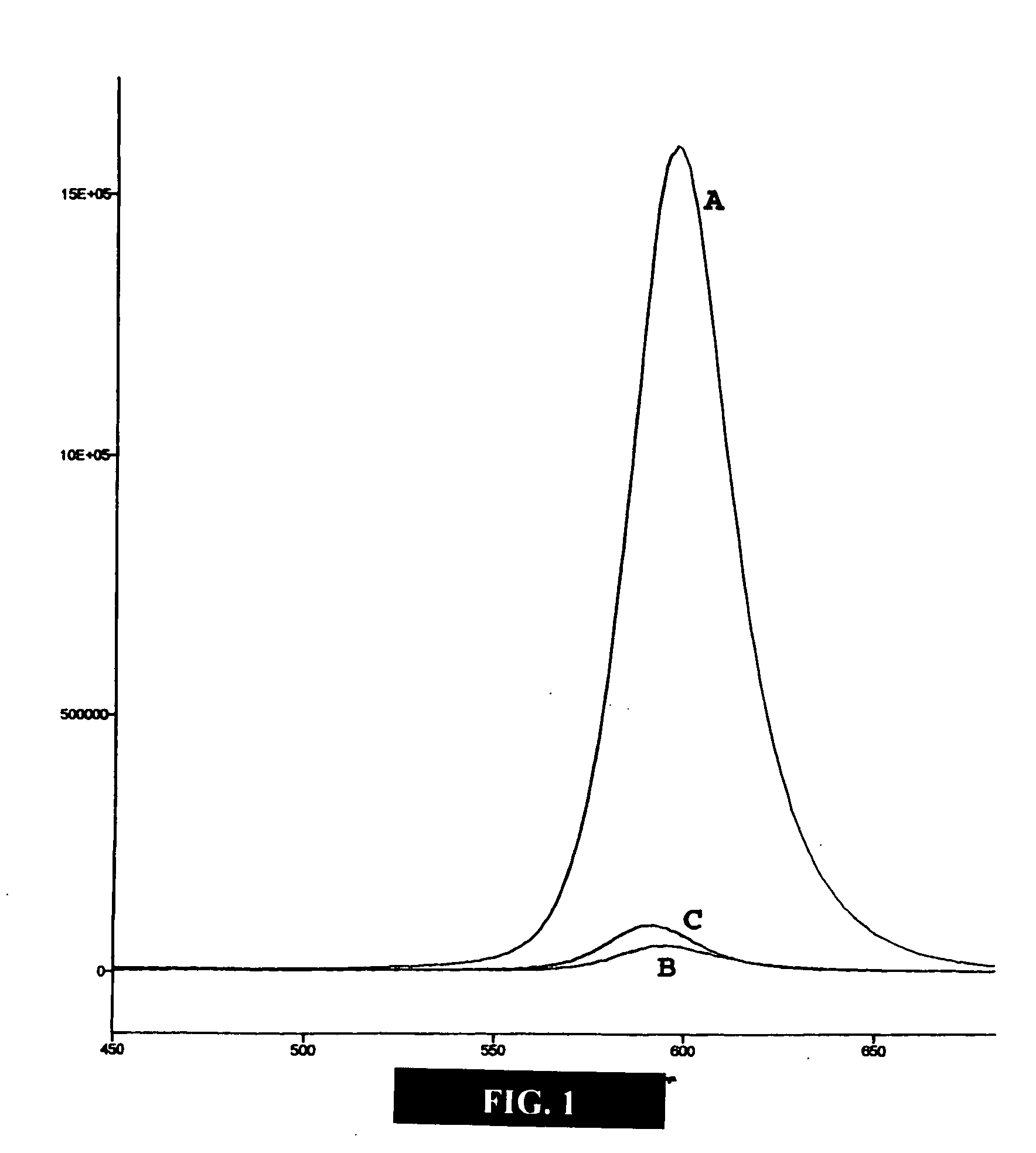

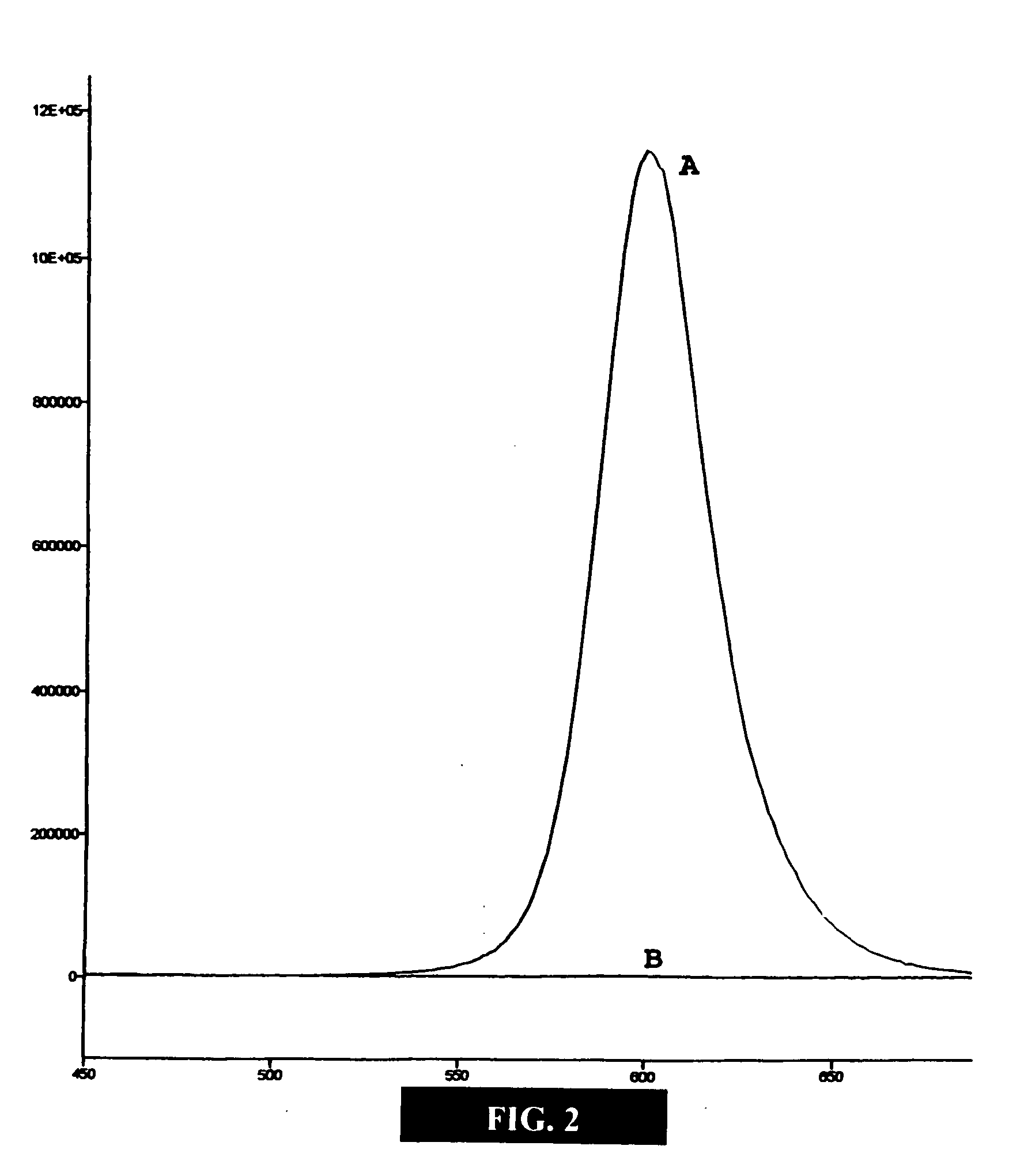

Colloidal nanocrystals with high photoluminescence quantum yields and methods of preparing the same

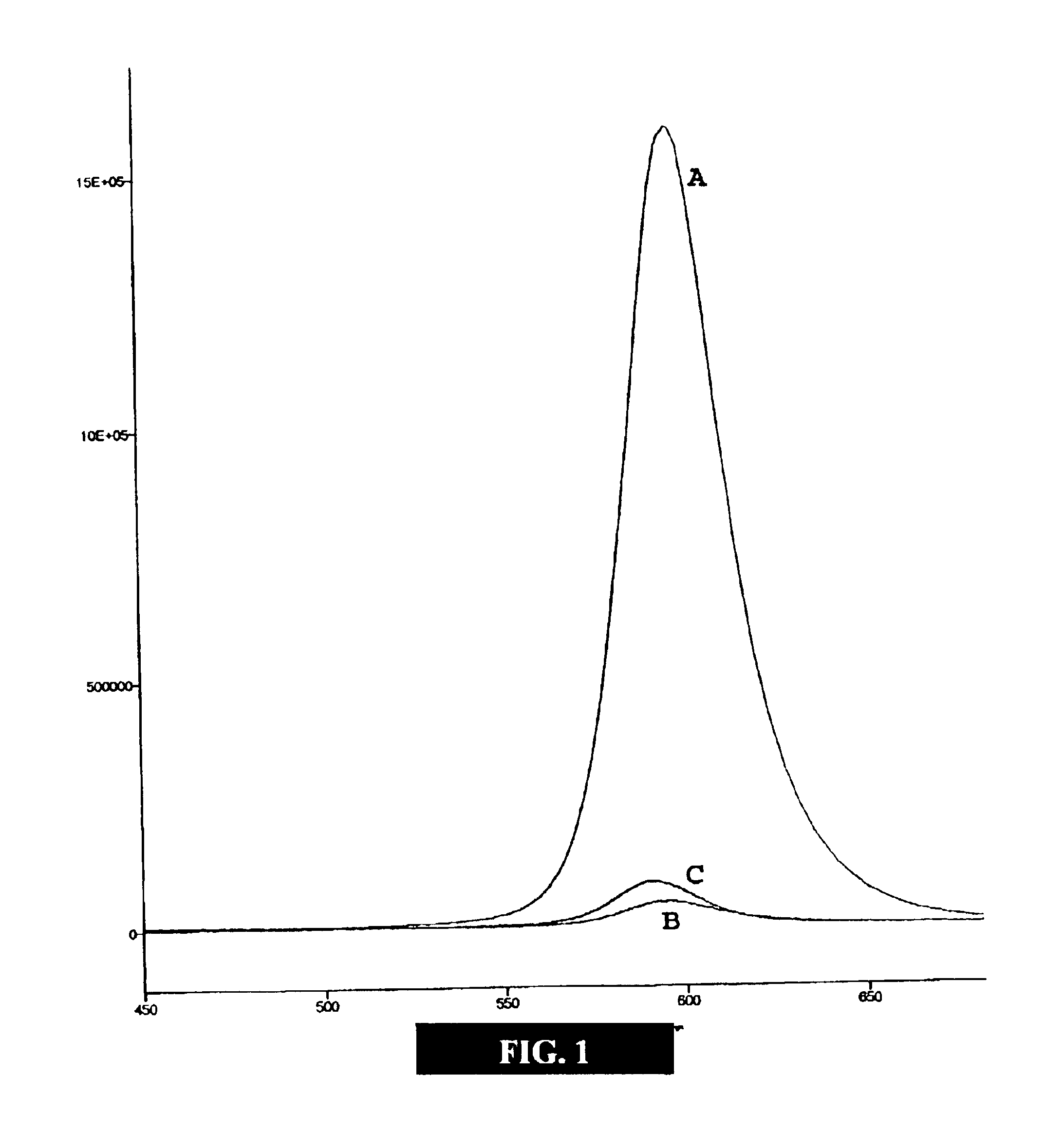

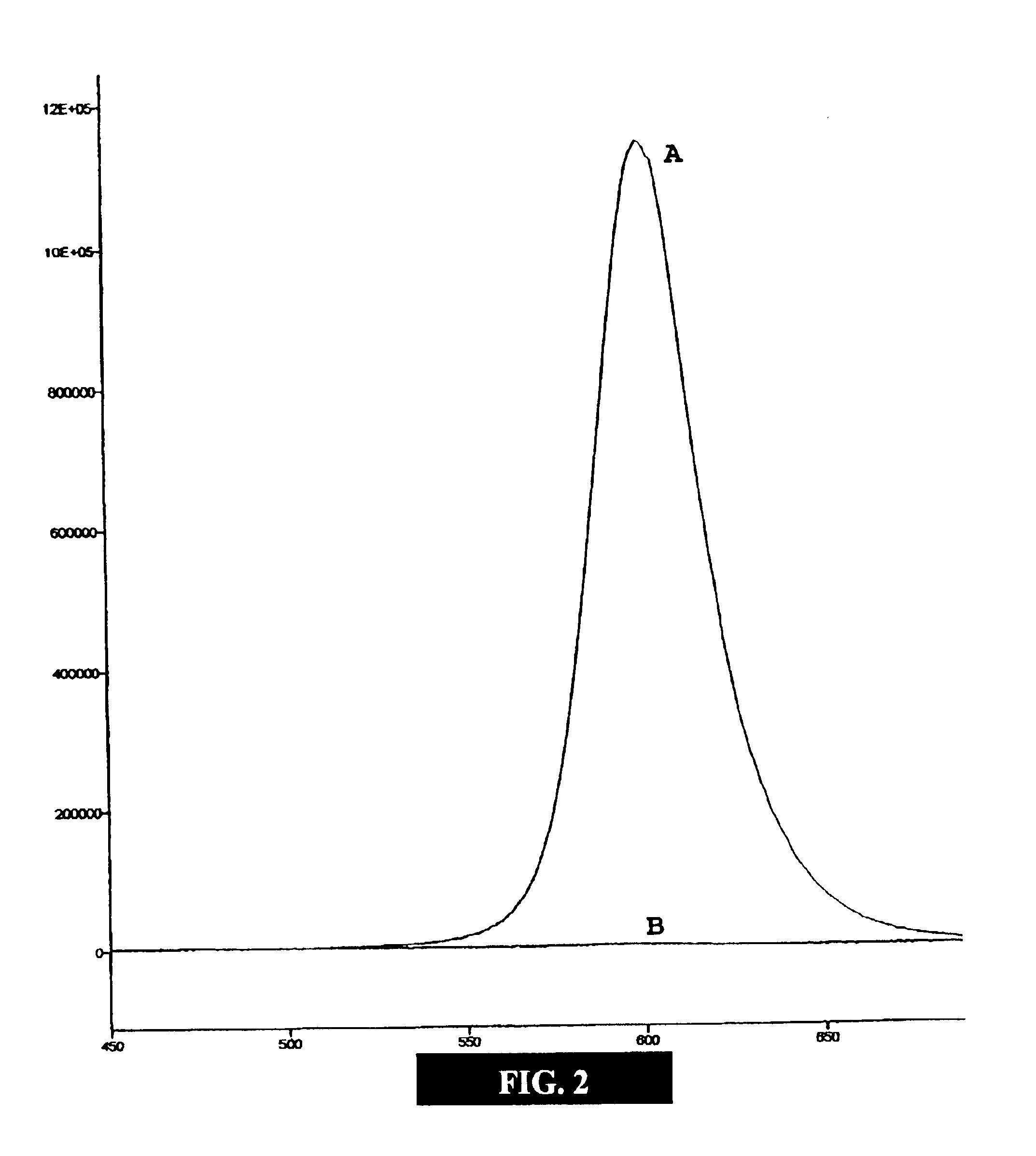

InactiveUS6869545B2Good monodispersityImprove launch performanceMaterial nanotechnologyNanoopticsQuantum yieldPhotoluminescence

The present invention provides new compositions containing colloidal nanocrystals with high photoluminescence quantum yields, new synthetic methods for the preparation of highly luminescent colloidal nanocrystals, as well as methods to control the photoluminescent properties of colloidal nanocrystals. The new synthetic methods disclosed herein allow photoemission brightness (quantum yield) to be correlated with certain adjustable nanocrystal growth parameters associated with a given synthetic scheme.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

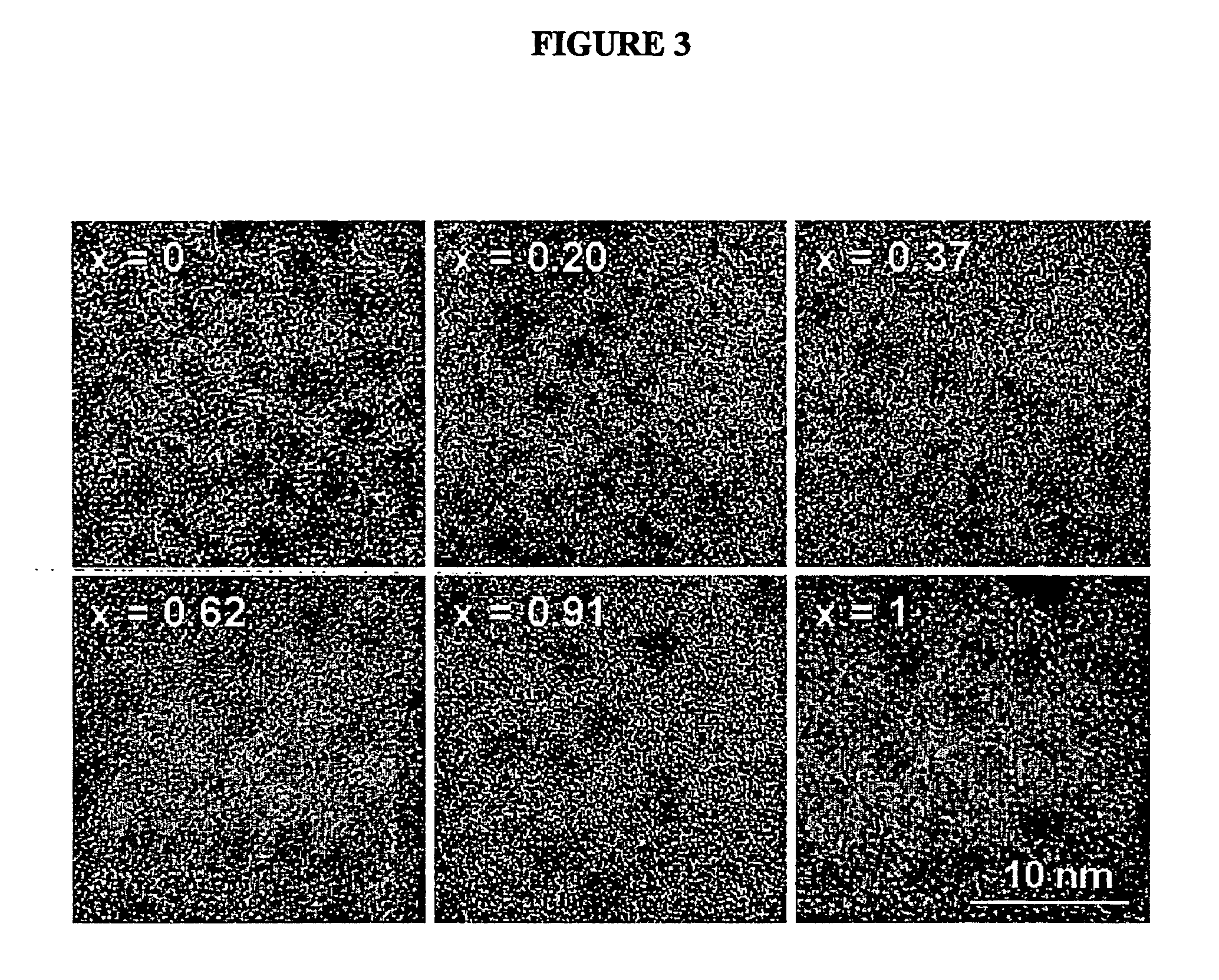

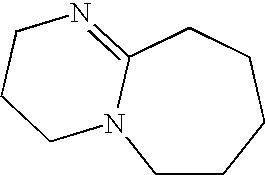

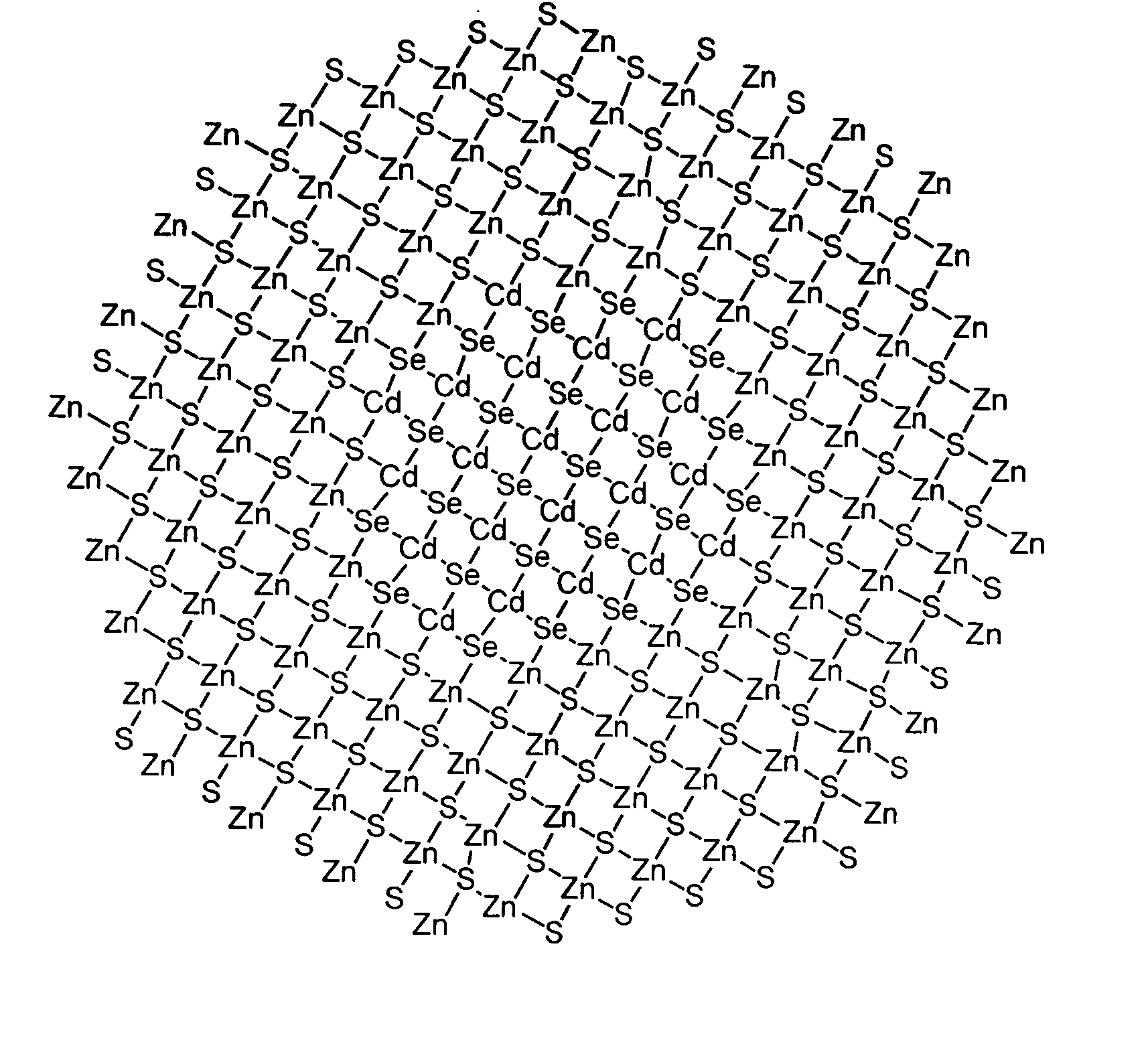

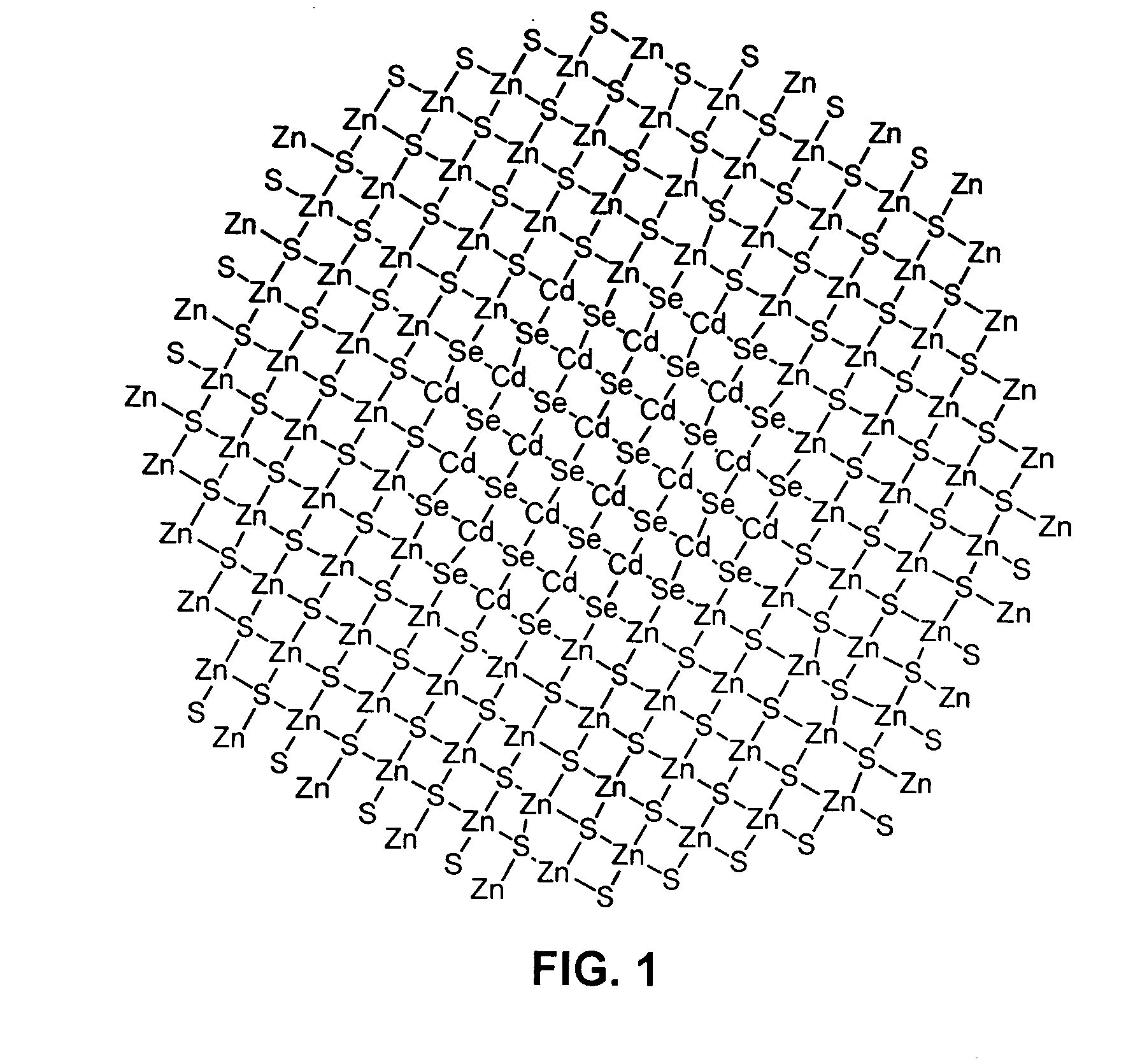

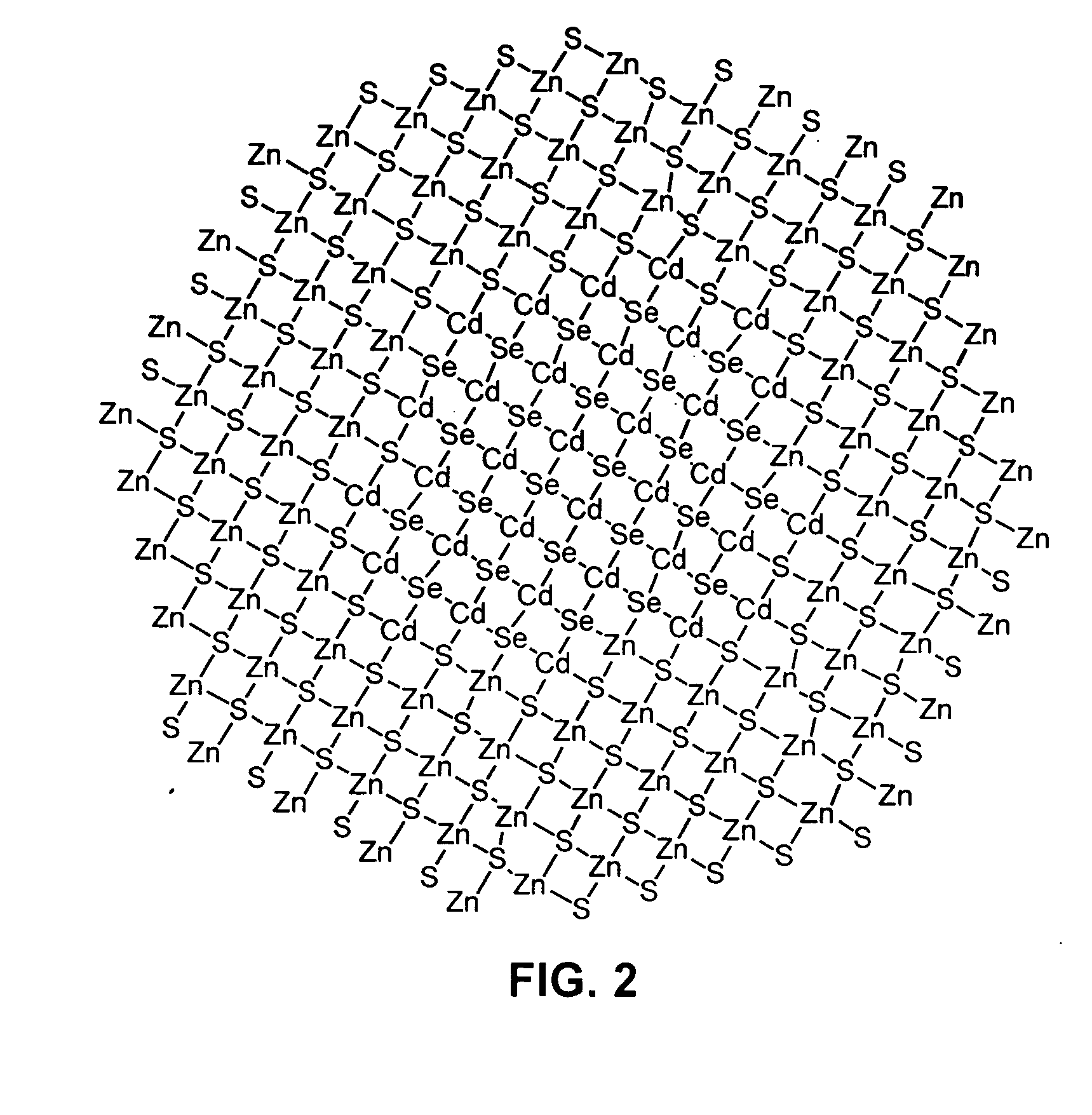

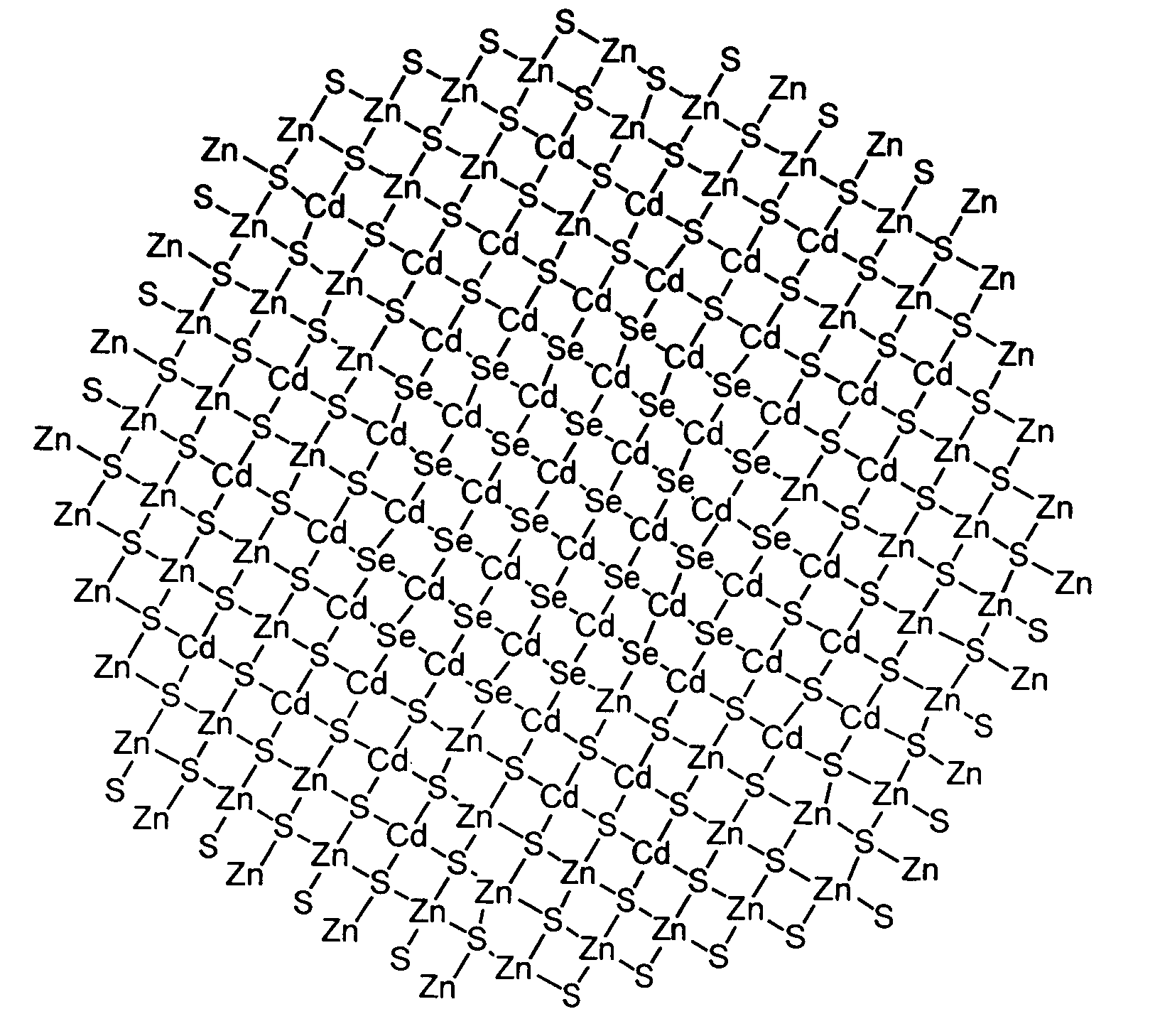

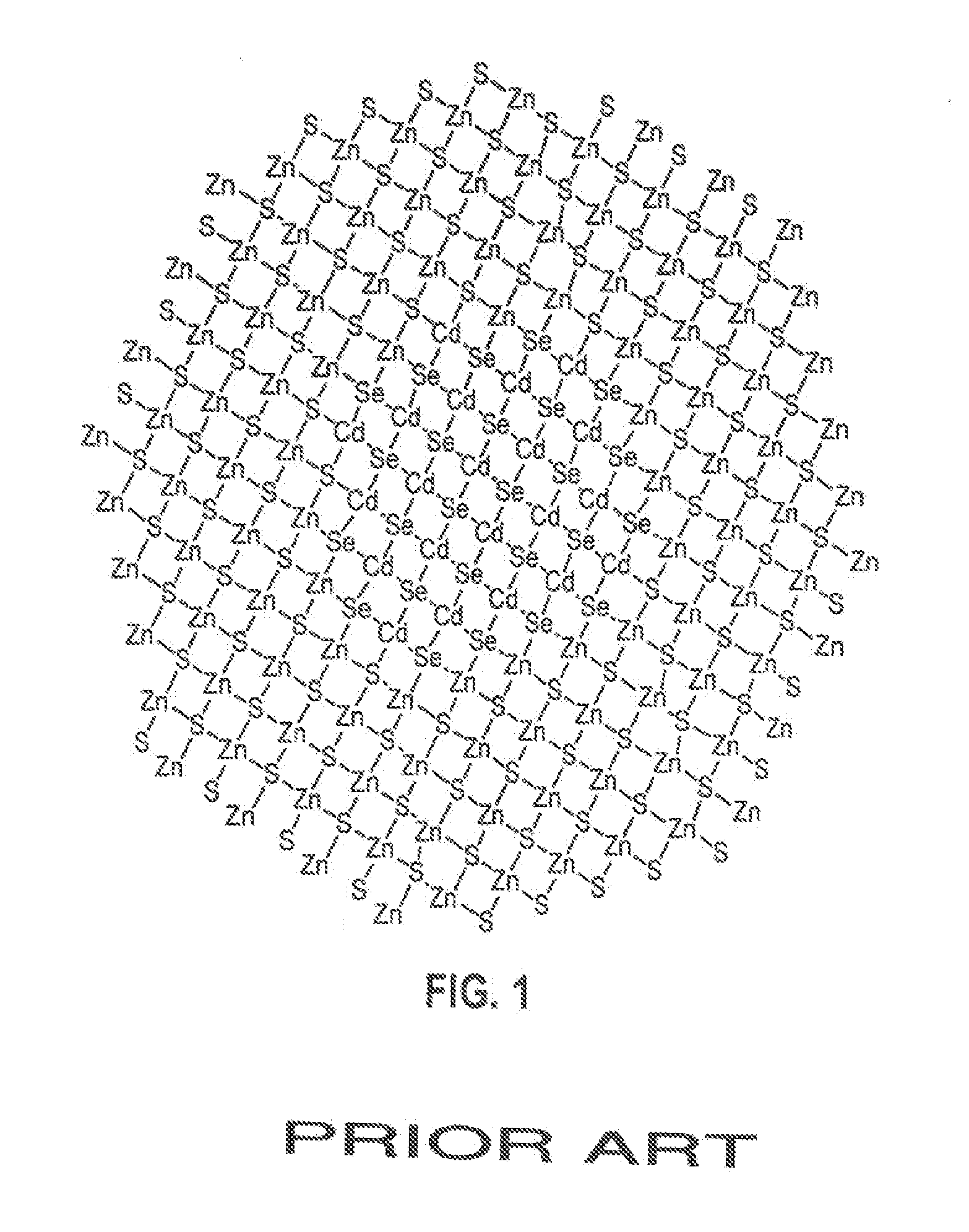

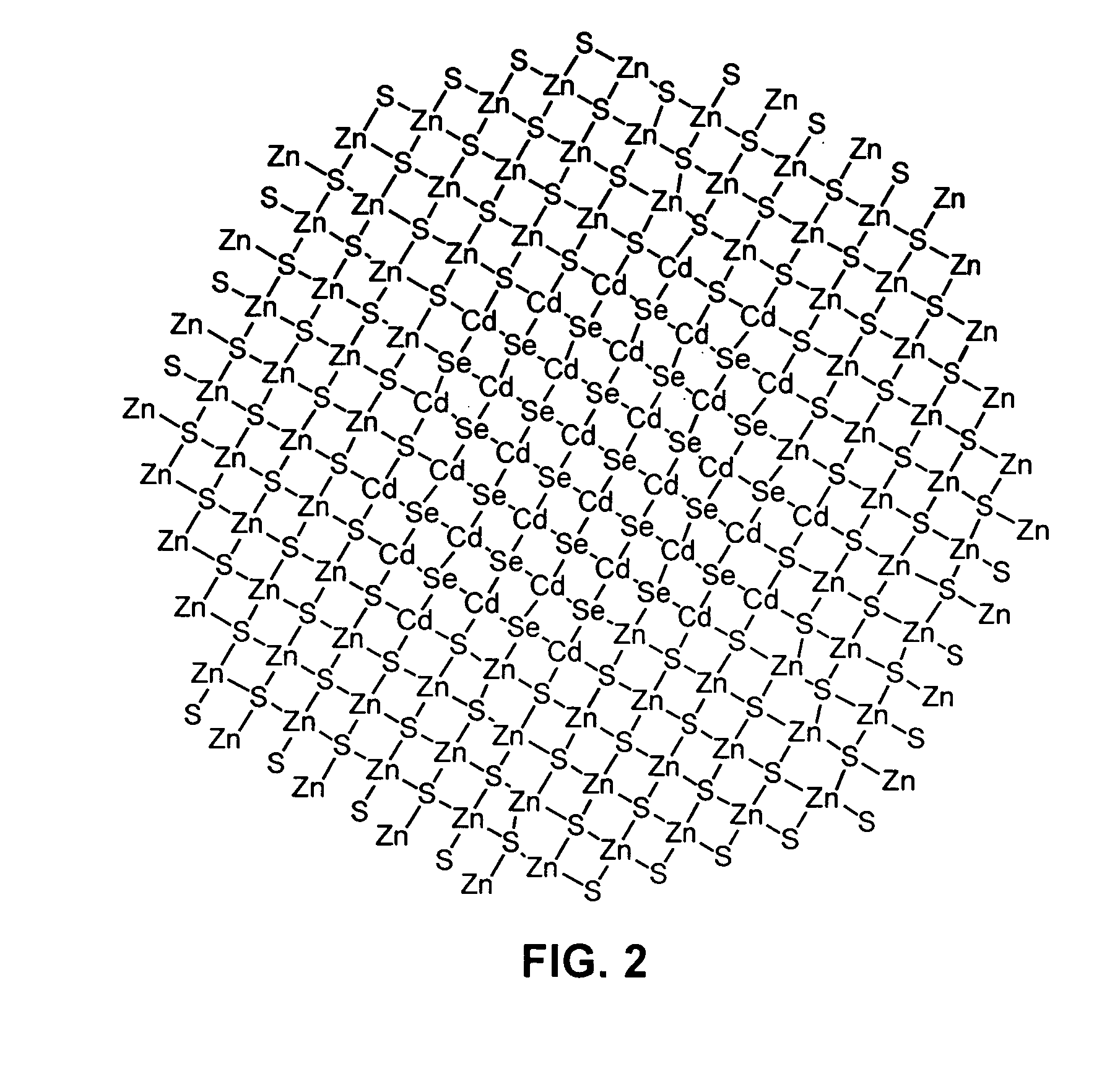

Alloyed semiconductor quantum dots and concentration-gradient alloyed quantum dots, series comprising the same and methods related thereto

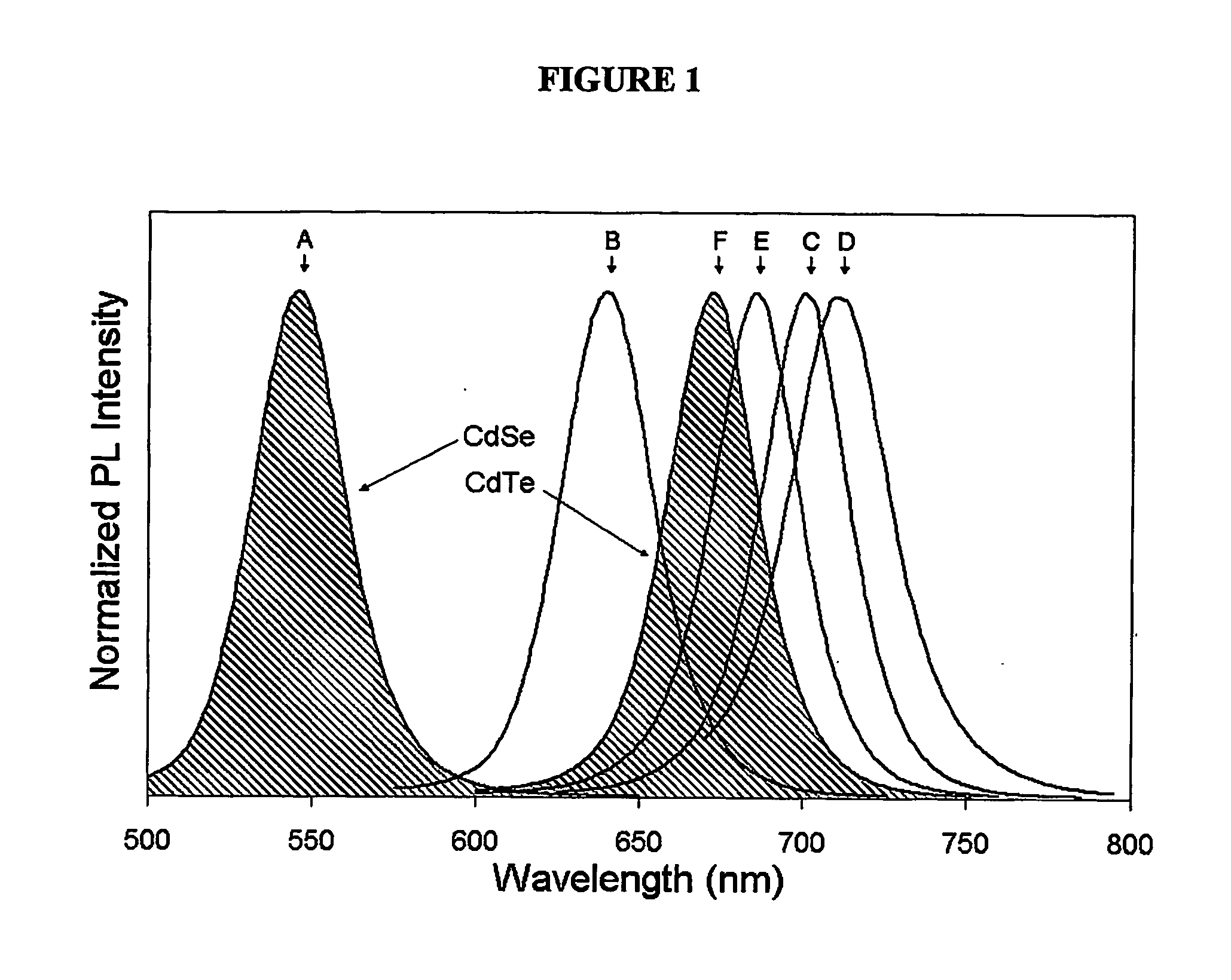

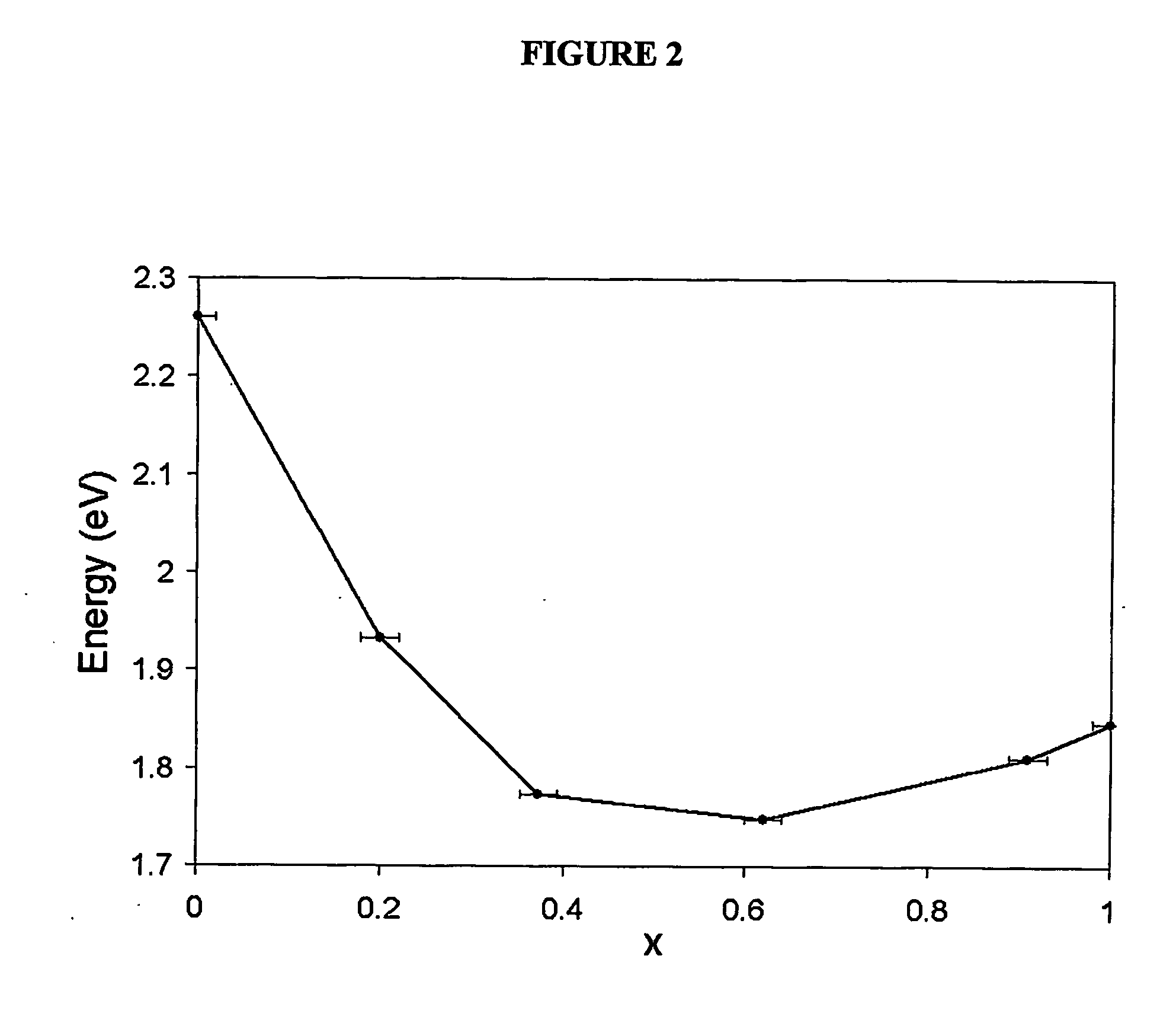

An alloyed semiconductor quantum dot comprising an alloy of at least two semiconductors, wherein the quantum dot has a homogeneous composition and is characterized by a band gap energy that is non-linearly related to the molar ratio of the at least two semiconductors; a series of alloyed semiconductor quantum dots related thereto; a concentration-gradient quantum dot comprising an alloy of a first semiconductor and a second semiconductor, wherein the concentration of the first semiconductor gradually increases from the core of the quantum dot to the surface of the quantum dot and the concentration of the second semiconductor gradually decreases from the core of the quantum dot to the surface of the quantum dot; a series of concentration-gradient quantum dots related thereto; in vitro and in vivo methods of use; and methods of producing the alloyed semiconductor and concentration-gradient quantum dots and the series of quantum dots related thereto.

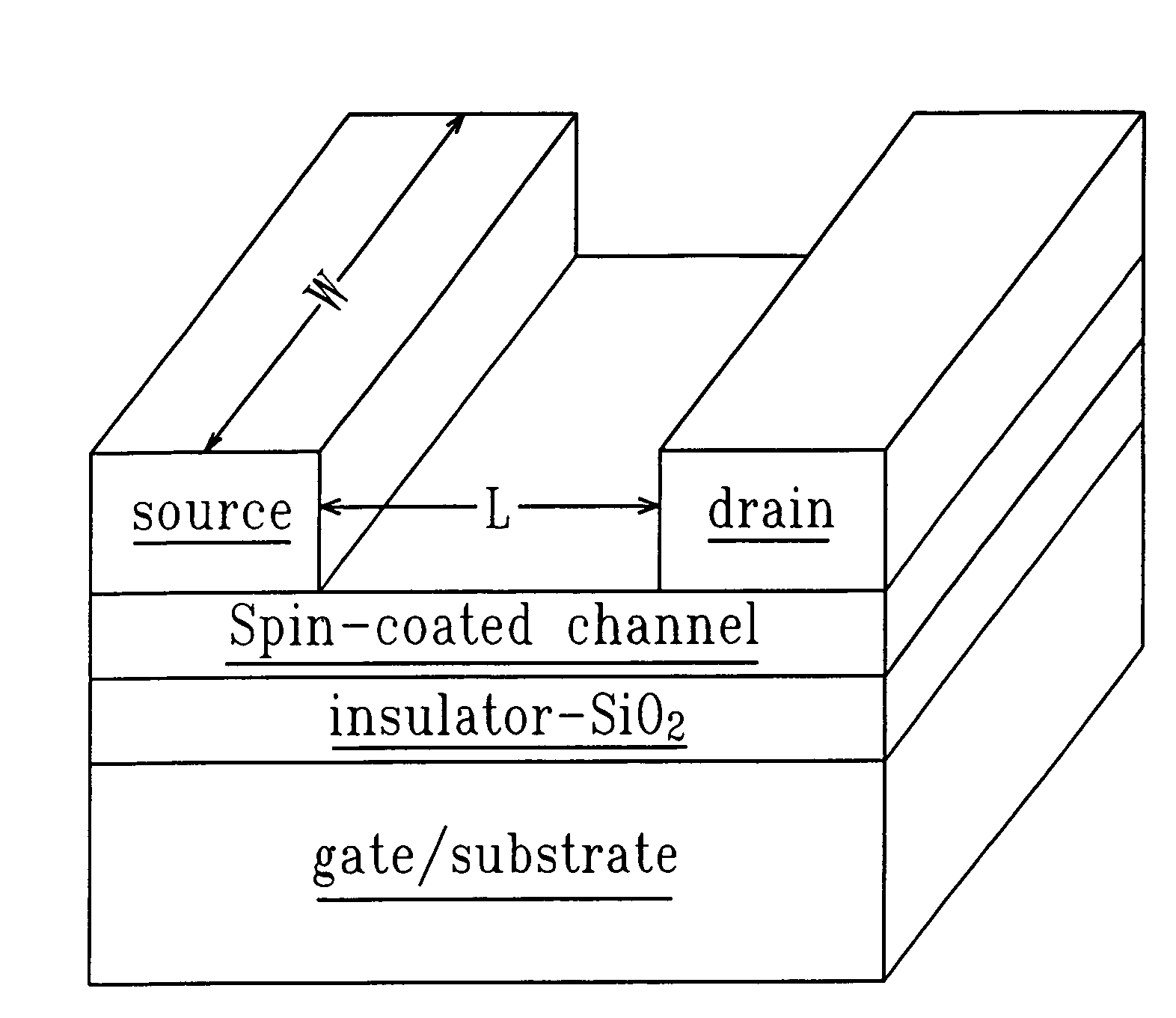

Solution-based deposition process for metal chalcogenides

A solution of a hydrazine-based precursor of a metal chalcogenide is prepared by adding an elemental metal and an elemental chalcogen to a hydrazine compound. The precursor solution can be used to form a film. The precursor solutions can be used in preparing field-effect transistors, photovoltaic devices and phase-change memory devices.

Owner:GLOBALFOUNDRIES U S INC

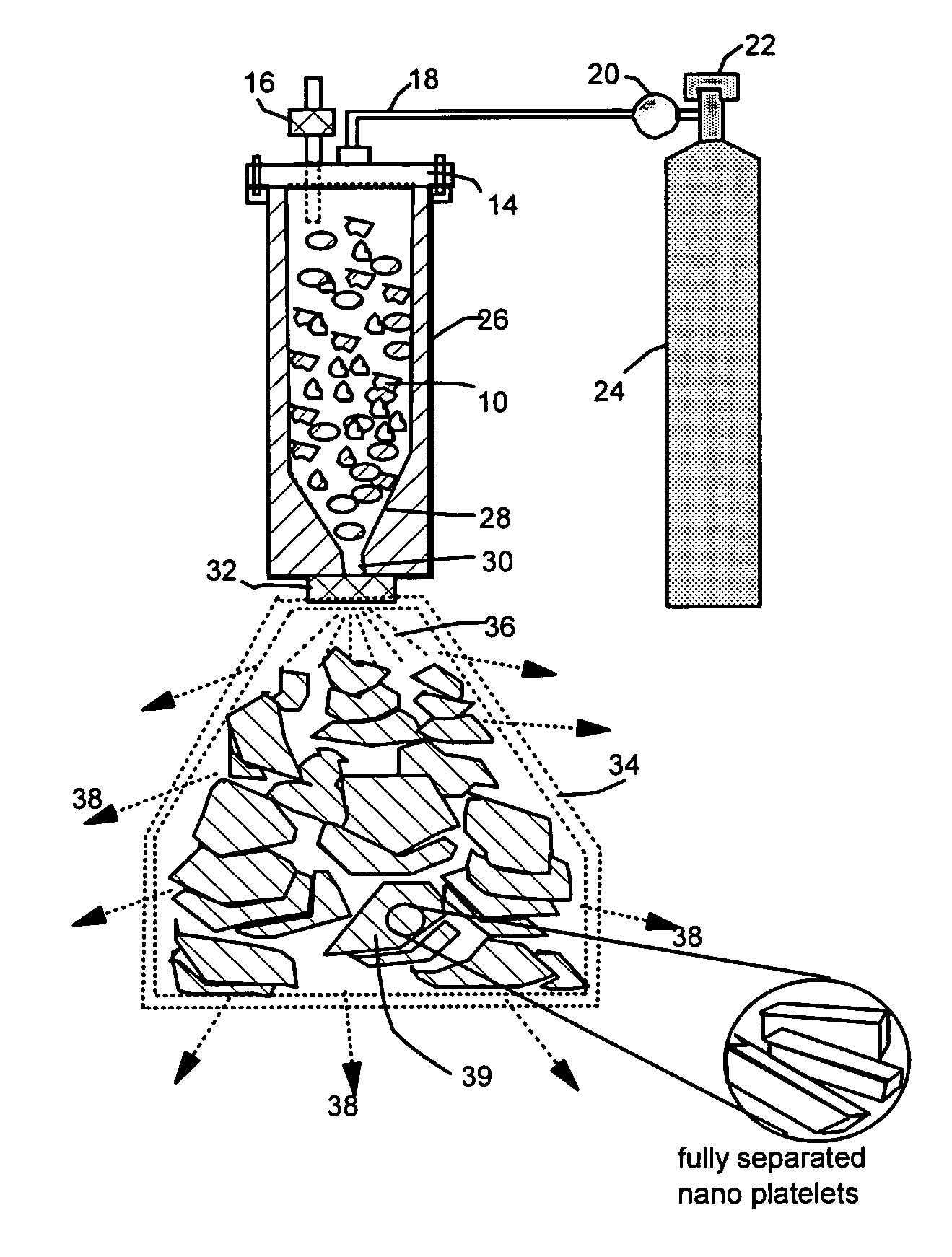

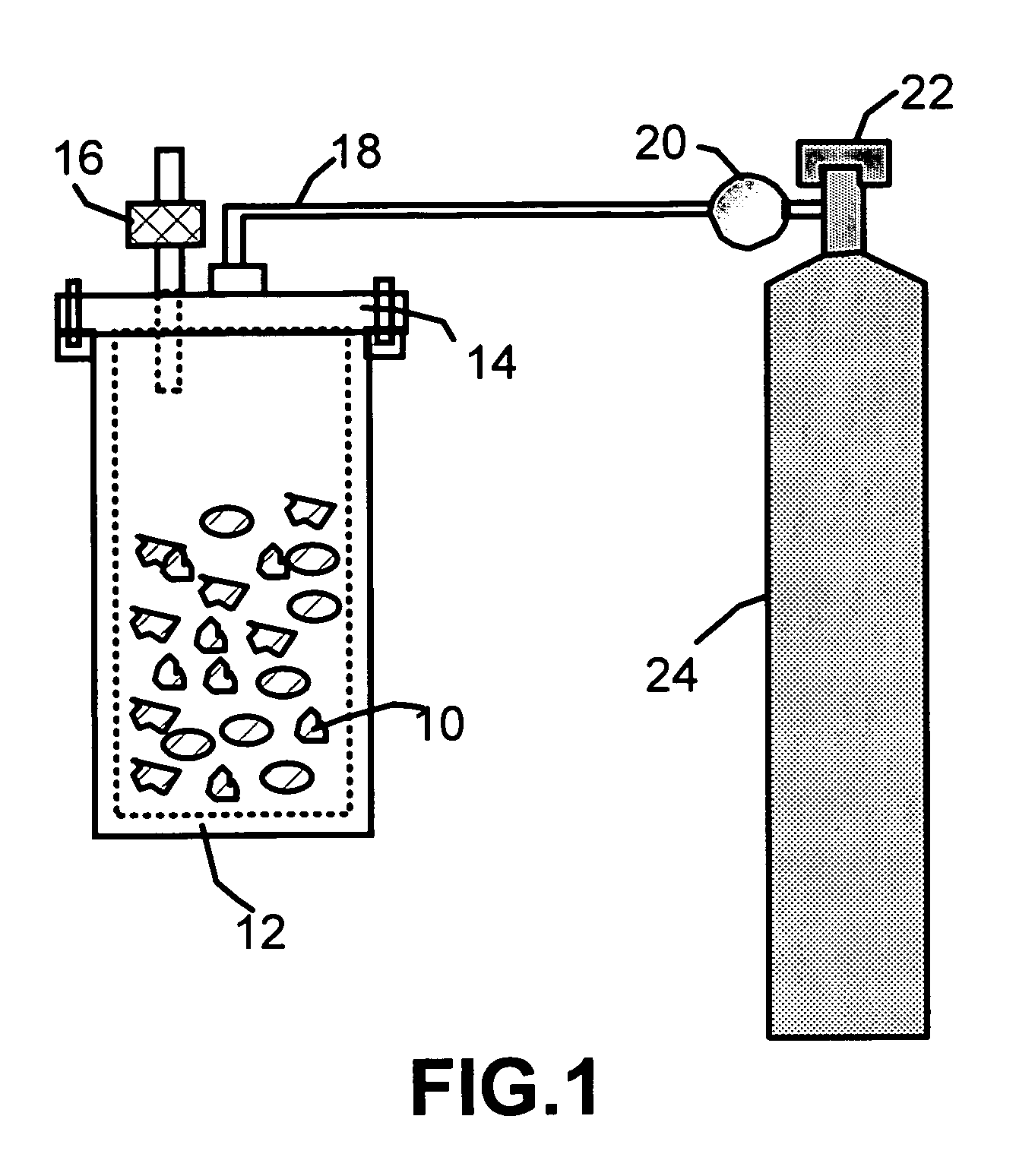

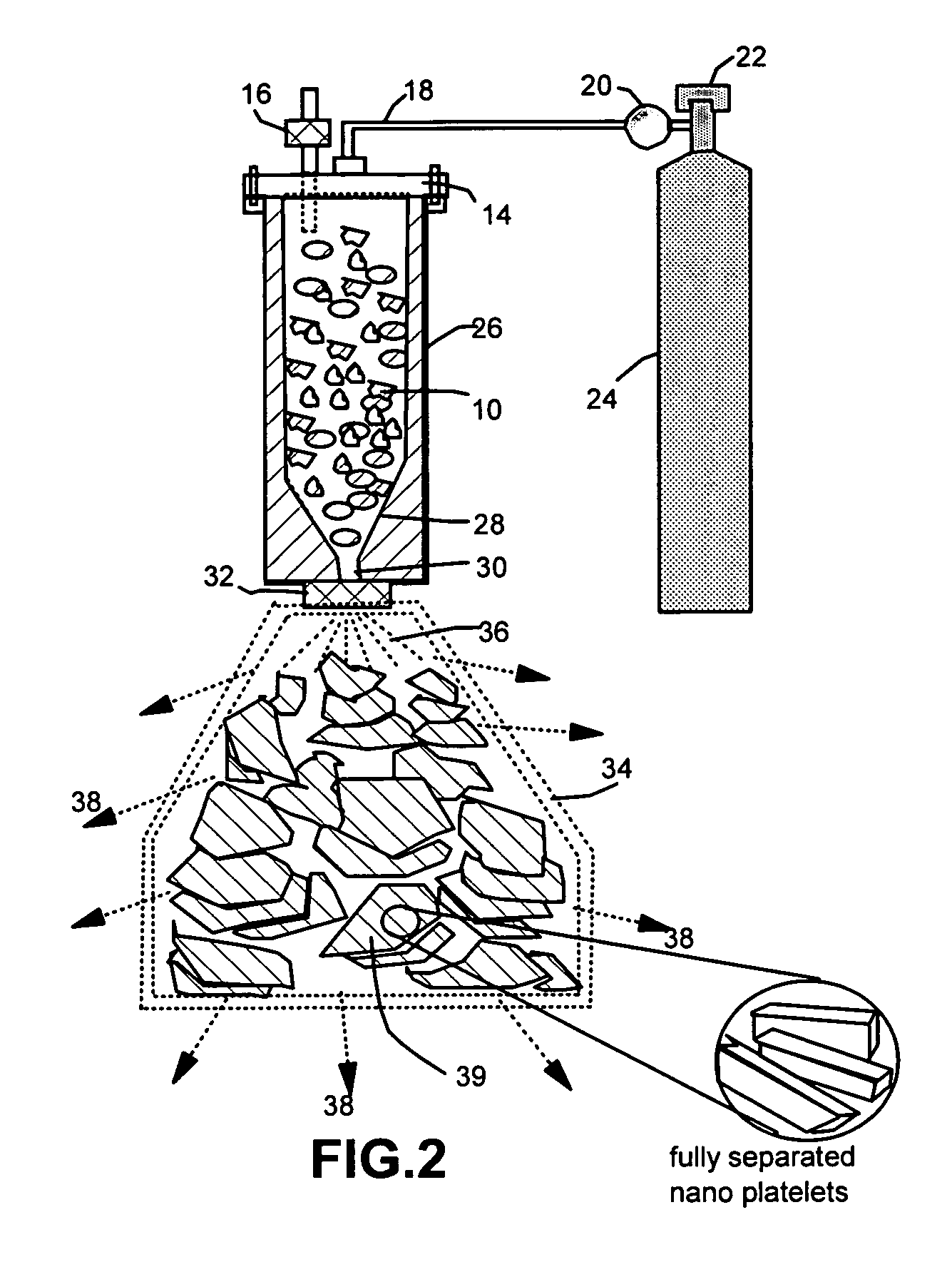

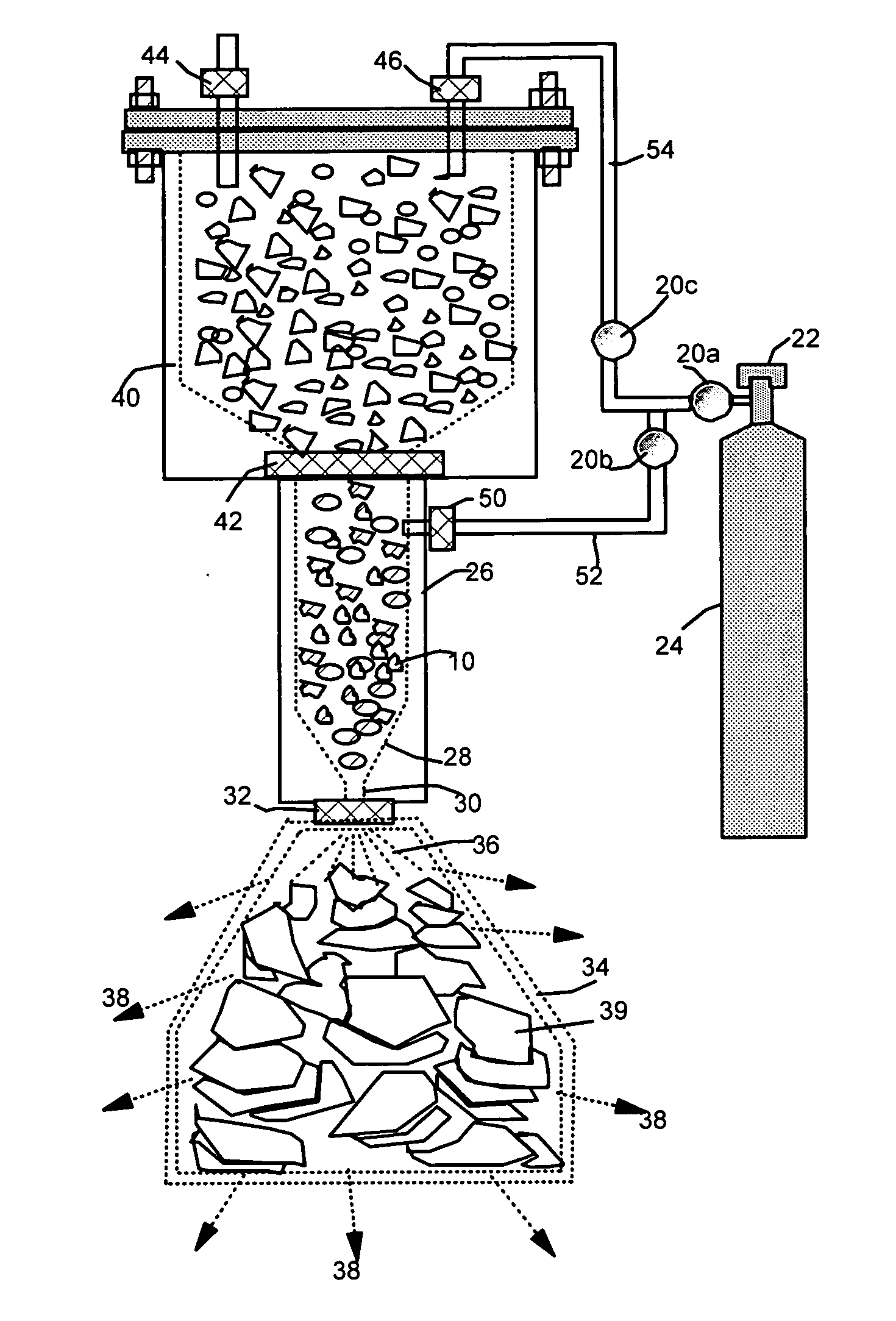

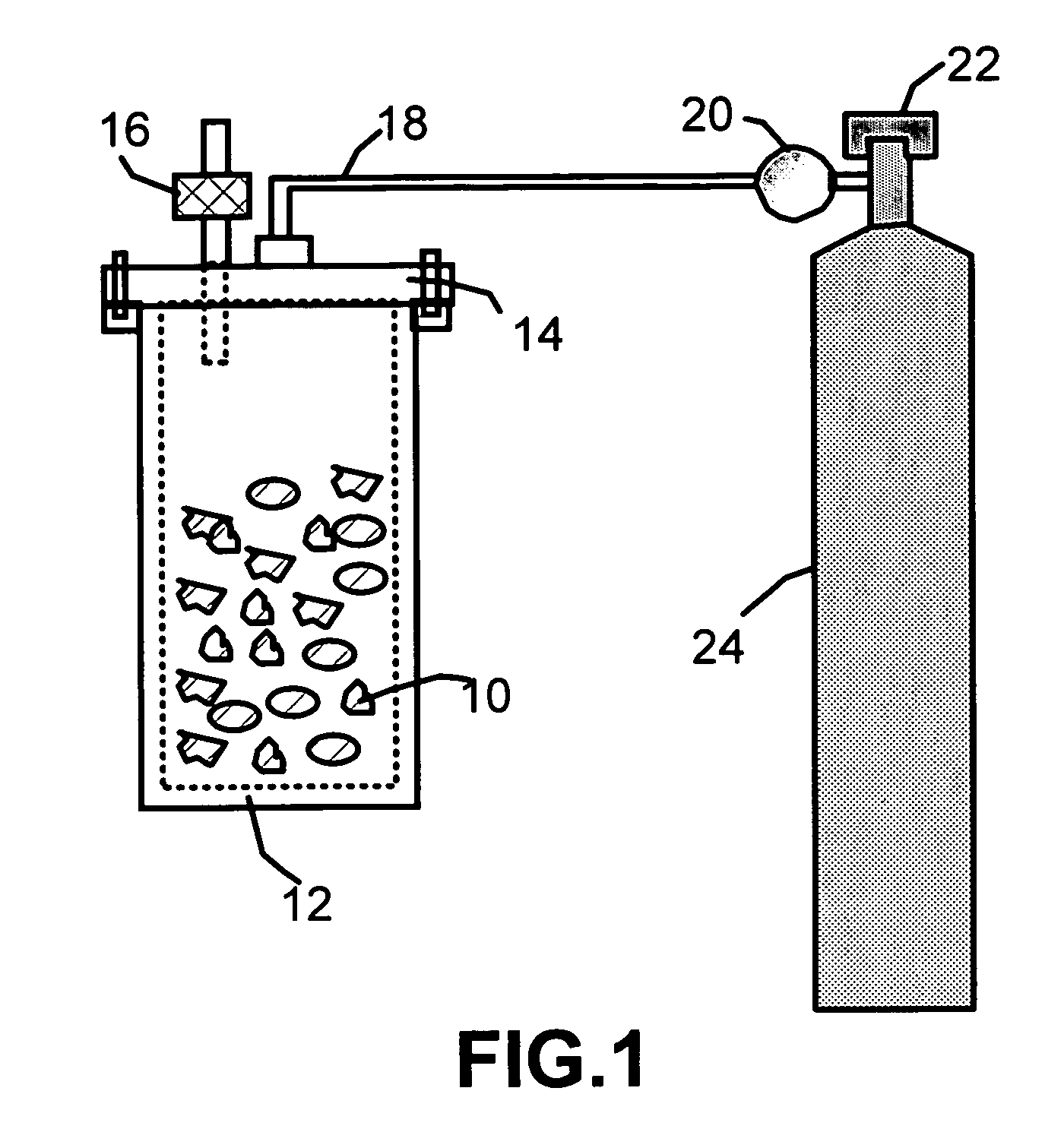

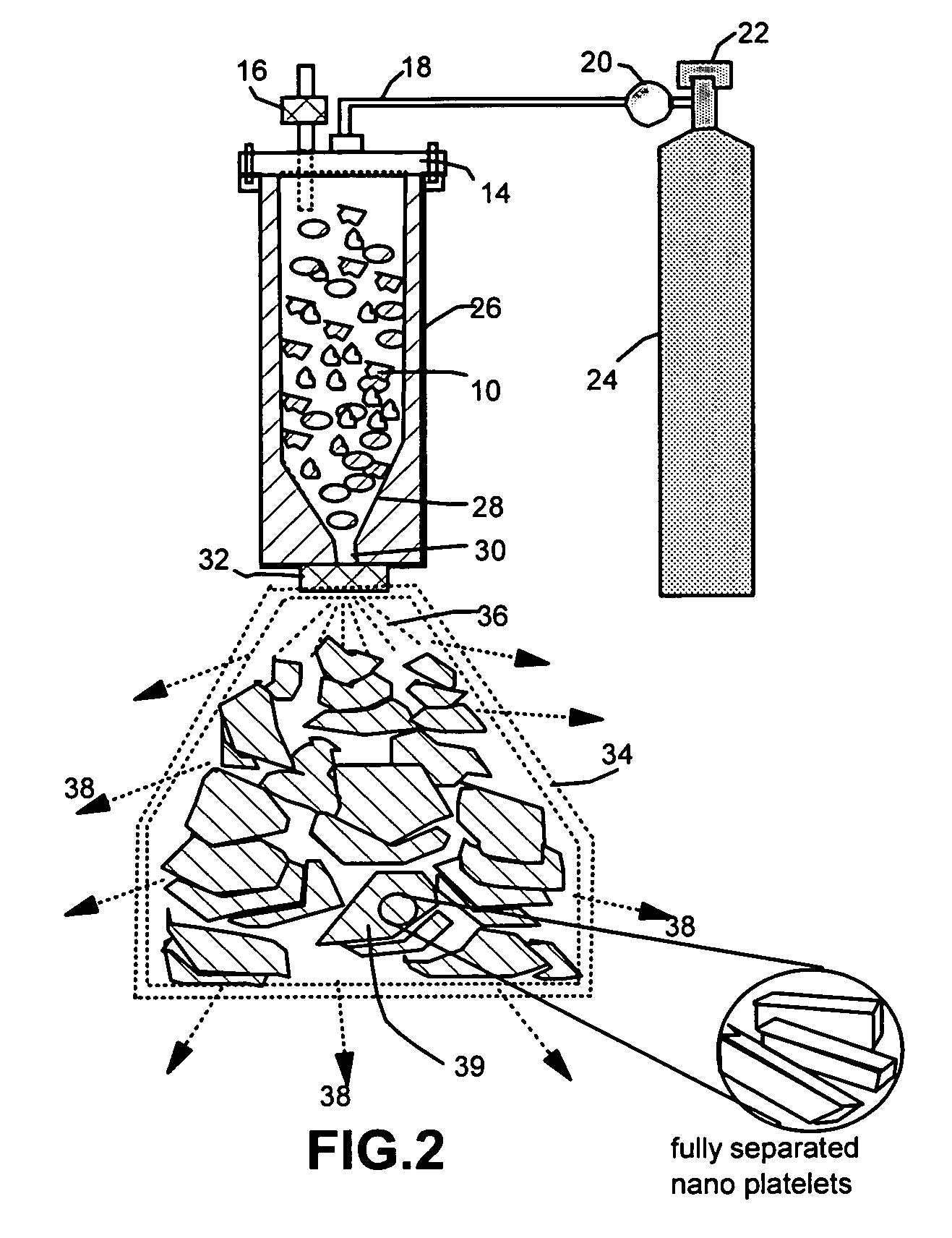

Mass production of nano-scaled platelets and products

ActiveUS7785492B1Reduce necessary intercalation timeSmall thicknessMaterial nanotechnologyGraphiteNoble gasGraphite

Disclosed is a process for exfoliating a layered material to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The process comprises: (a) charging a layered material to an intercalation chamber comprising a gaseous environment at a first temperature and a first pressure sufficient to cause gas species to penetrate into the interstitial space between layers of the layered material, forming a gas-intercalated layered material; and (b) operating a discharge valve to rapidly eject the gas-intercalated layered material through a nozzle into an exfoliation zone at a second pressure and a second temperature, allowing gas species residing in the interstitial space to exfoliate the layered material to produce the platelets. The gaseous environment preferably contains only environmentally benign gases that are reactive (e.g., oxygen) or non-reactive (e.g., noble gases) with the layered material. The process can additionally include dispersing the platelets in a matrix material to form a nanocomposite. The process also can include an additional process of re-compressing the nana-scaled platelets into a product such as a flexible graphite sheet.

Owner:GLOBAL GRAPHENE GRP INC

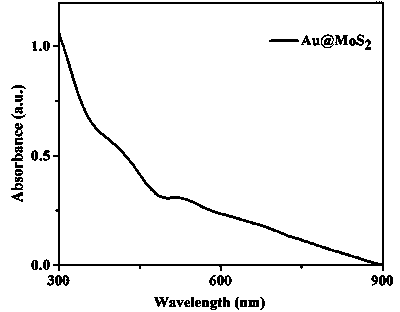

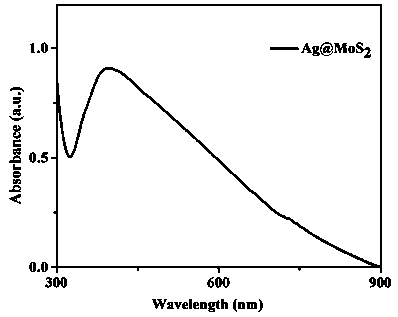

Method for preparing nanocomposite by using two-dimensional transition metal chalcogenide nanosheets and metal

InactiveCN103480856AOvercome limitationsEasy to operateMaterial nanotechnologySulfide/polysulfide preparationNanocompositeReducing agent

The invention relates to a method for preparing a nanocomposite by using two-dimensional transition metal chalcogenide nanosheets and metal, and belongs to the field of nanomaterial synthesis. The method mainly includes adding a reducing agent and a stabilizing agent into monolayer or multi-layer two-dimensional transition metal chalcogenide nanosheet aqueous dispersion obtained after chemical intercalation, then injecting a certain amount of metal salt solution, and preparing the metal nanocomposite based on monolayer or few-layer two-dimensional transition metal chalcogenide nanosheets on the conditions of ice bath, hydrothermal method, microwaves, ultrasound and the like. In the composite, metal nanoparticles can be evenly distributed on the surfaces of the nanosheets, and the obtained composite can be evenly dispersed in water, and can be used in the solution phase and further processed. Through compositing of the metal nanoparticles, photoelectric property of two-dimensional transition metal chalcogenide can be improved, and the nanocomposite has good application prospects in the fields of supercapacitors, fuel cells and biosensors based on surface enhanced Raman detection, and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method of semiconductor nanoparticle synthesis

InactiveUS7147712B2Stop growthMaterial nanotechnologyPolycrystalline material growthSemiconductor NanoparticlesOxygen

A method is described for the manufacture of semiconductor nanoparticles. Improved yields are obtained by use of a reducing agent or oxygen reaction promoter.

Owner:INVITROGEN

Synthesis of several metal selenides and tellurides as semiconductor material

InactiveCN1384047AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureSemiconductor/solid-state device manufacturingBinary selenium/tellurium compoundsSemiconductor materialsHydroxylamine

By using the soluble salt of transition metalz Zn, Cd, Pb, Mn, Co, Ni, Cu, Ag, Sb and Bi, selenious acid or its solutl salt, or antimonous acid or its soluble salt as raw material, and hydrazine hydrate, sodium borohydride, potassium borohydride, hydroxylamine or hydrazine sulfate as reductant, and through hydrothermal reduction reaction at 100-200 deg.c in a sealed container for 2 hr to 5 days, selenides or tellurides of the said metals as semiconductor material may be synthesized. Unlike available synthesis process, which needs high temperature, toxic feedstock and complex technological course, the present invention has the advantages of low-cost material, simple apparatus, easy control, good technological reproducibility, stable product quality, etc.

Owner:TSINGHUA UNIV

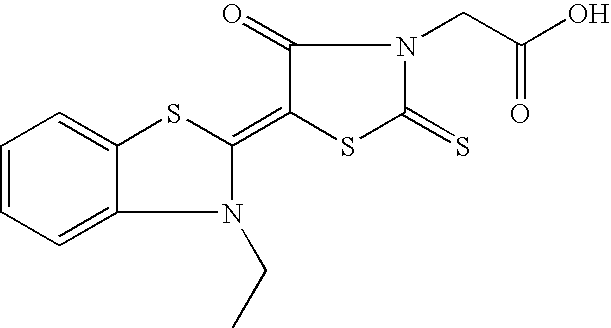

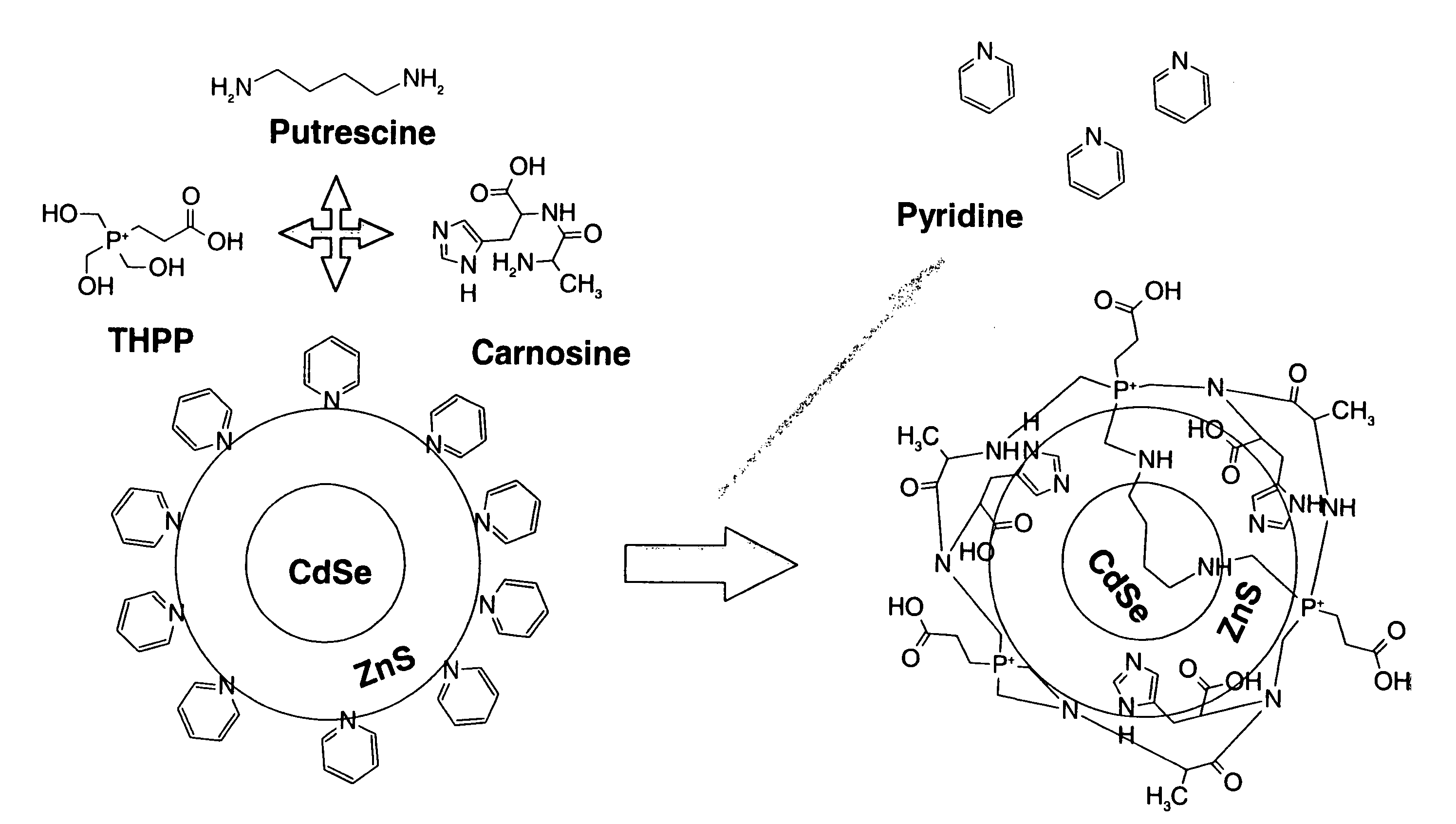

Nanocrystals

InactiveUS6955855B2High levelImprove the level ofIndividual molecule manipulationSynthetic resin layered productsCross-linkFluorescence

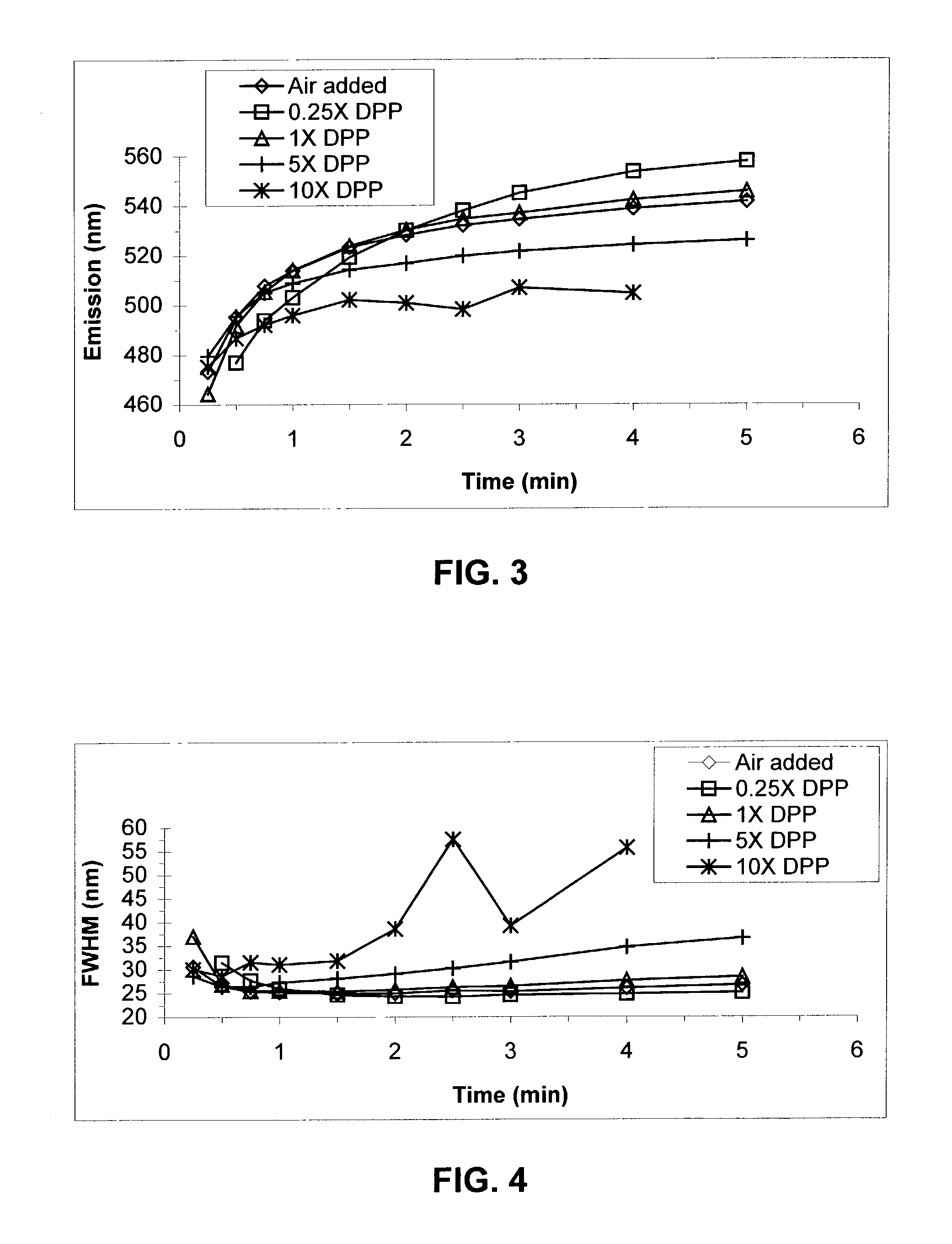

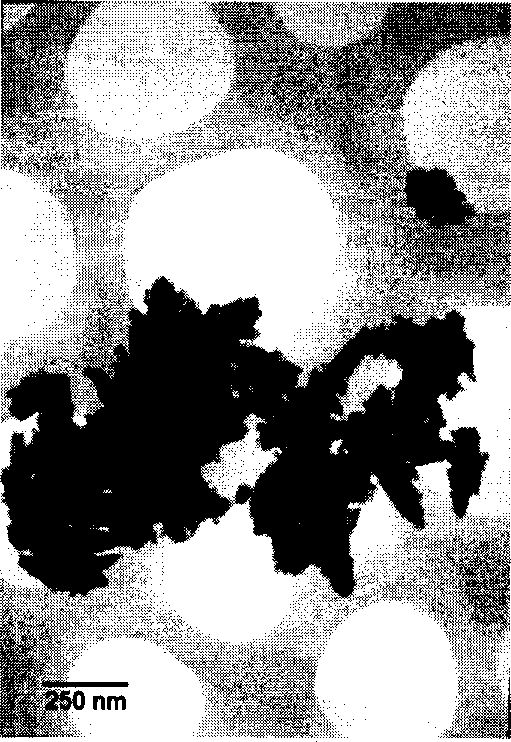

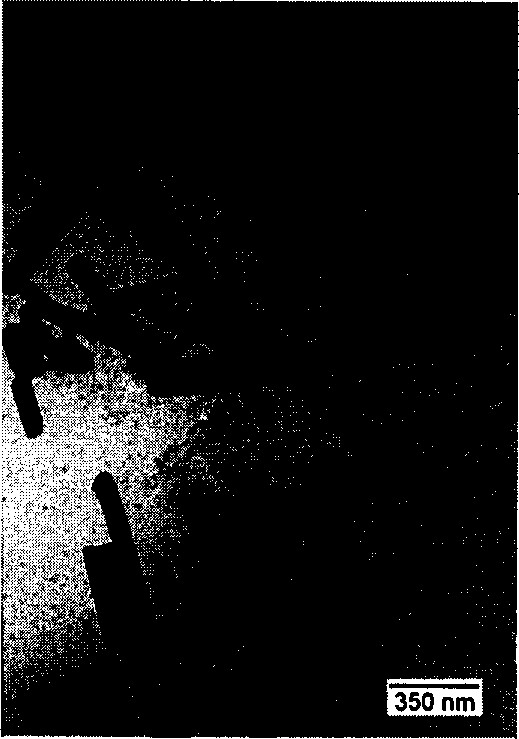

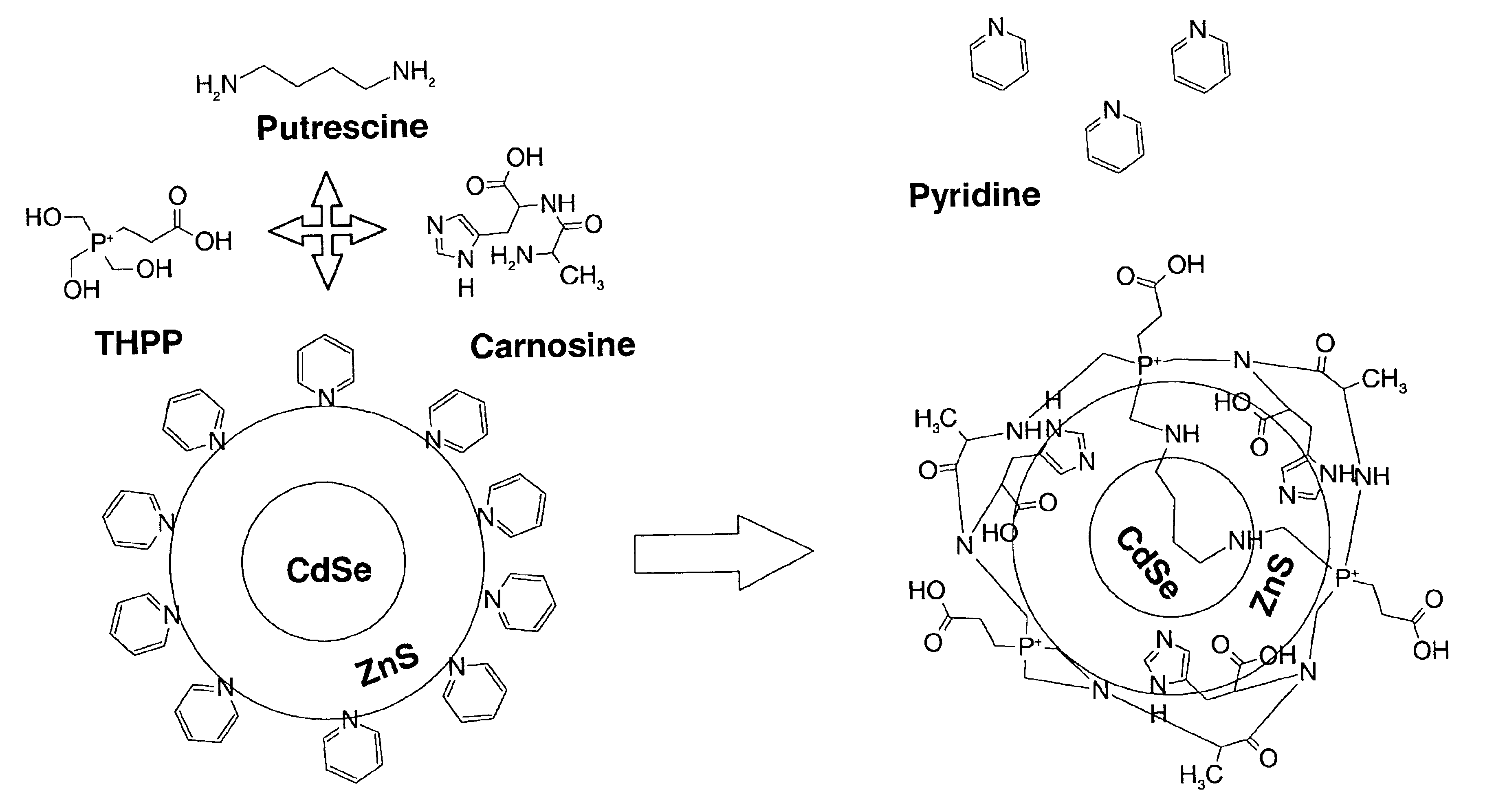

Provided herein are compositions of functionalized, fluorescent nanocrystals comprising fluorescent nanocrystals coated with an imidazole-containing compound; compositions of functionalized, fluorescent nanocrystals comprising fluorescent nanocrystals coated with an imidazole-containing compound and cross-linked with a phosphine cross-linking compound; compositions of functionalized fluorescent nanocrystals operably bound to molecular probe; a process of making functionalized, fluorescent nanocrystals; and a process of using functionalized, fluorescent nanocrystals in a detection system.

Owner:LIFE TECH CORP

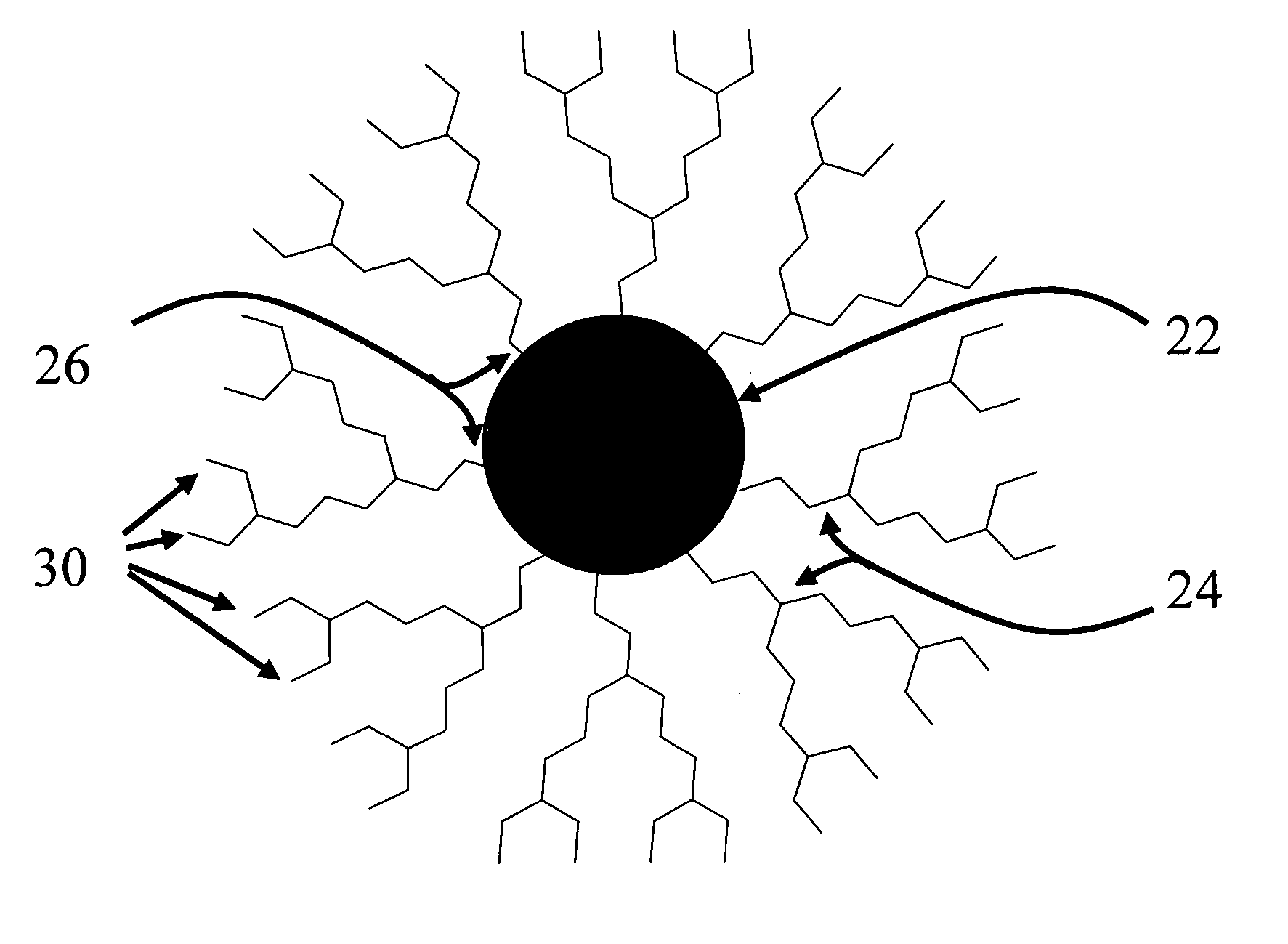

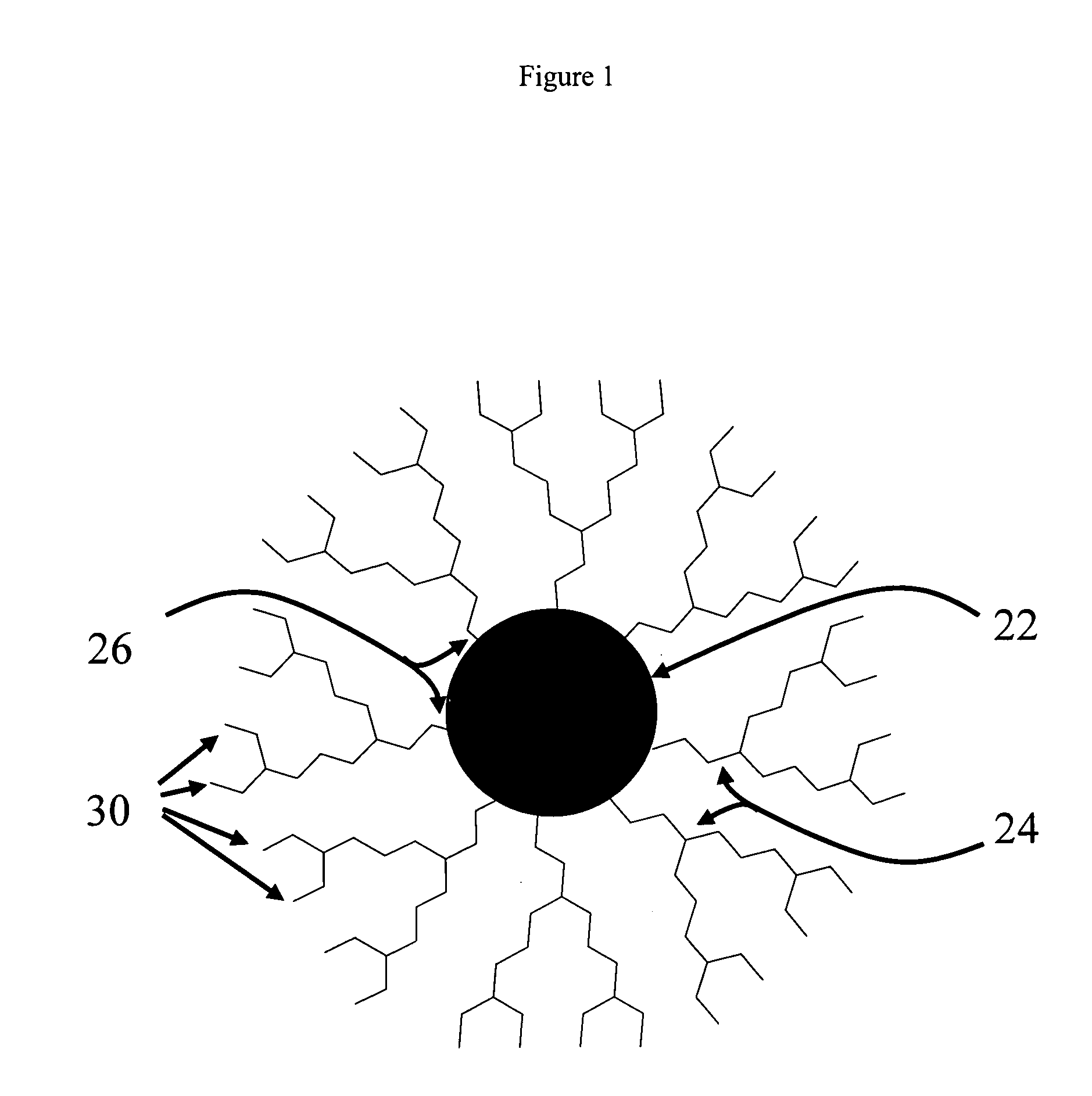

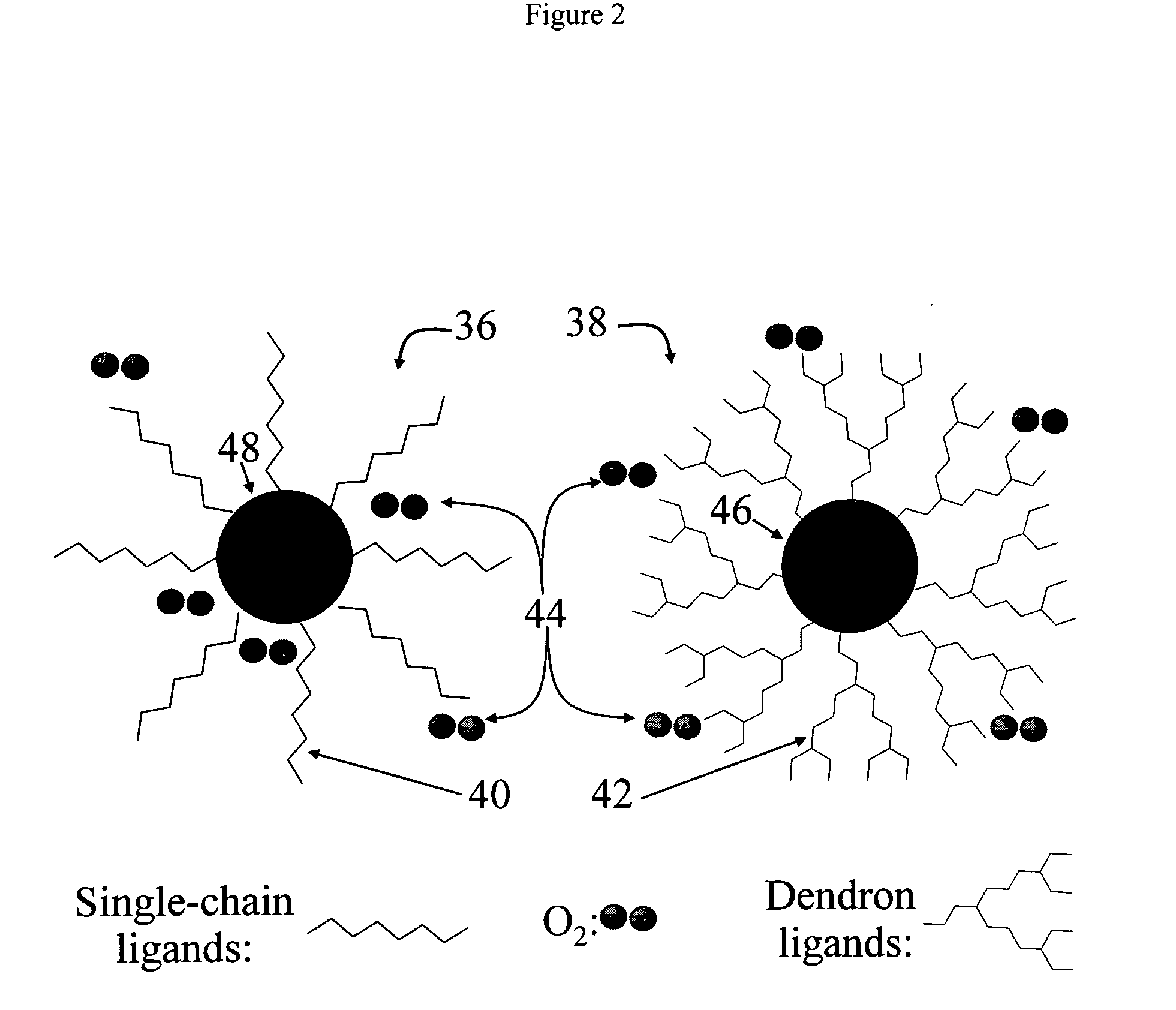

Synthesis of stable colloidal nanocrystals using organic dendrons

ActiveUS7153703B2Enhances protection against oxidationIncrease the number ofFrom gel statePolycrystalline material growthCross-linkNanoparticle

A method for stabilizing colloidal suspensions of nanocrystals or nanoparticles in a solvent or solid matrix is provided by coating the nanocrystals with bulky organic molecules, specifically dendrons. By coating nanocrystals with a dense organic dendron coat and further cross-linking the dendron ligands, oxidation of the nanocrystals and dissociation of the ligands are avoided. This invention allows nanocrystals to undergo rigorous purification and processing. It may regularly be applied to a variety of nanocrystals.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS +1

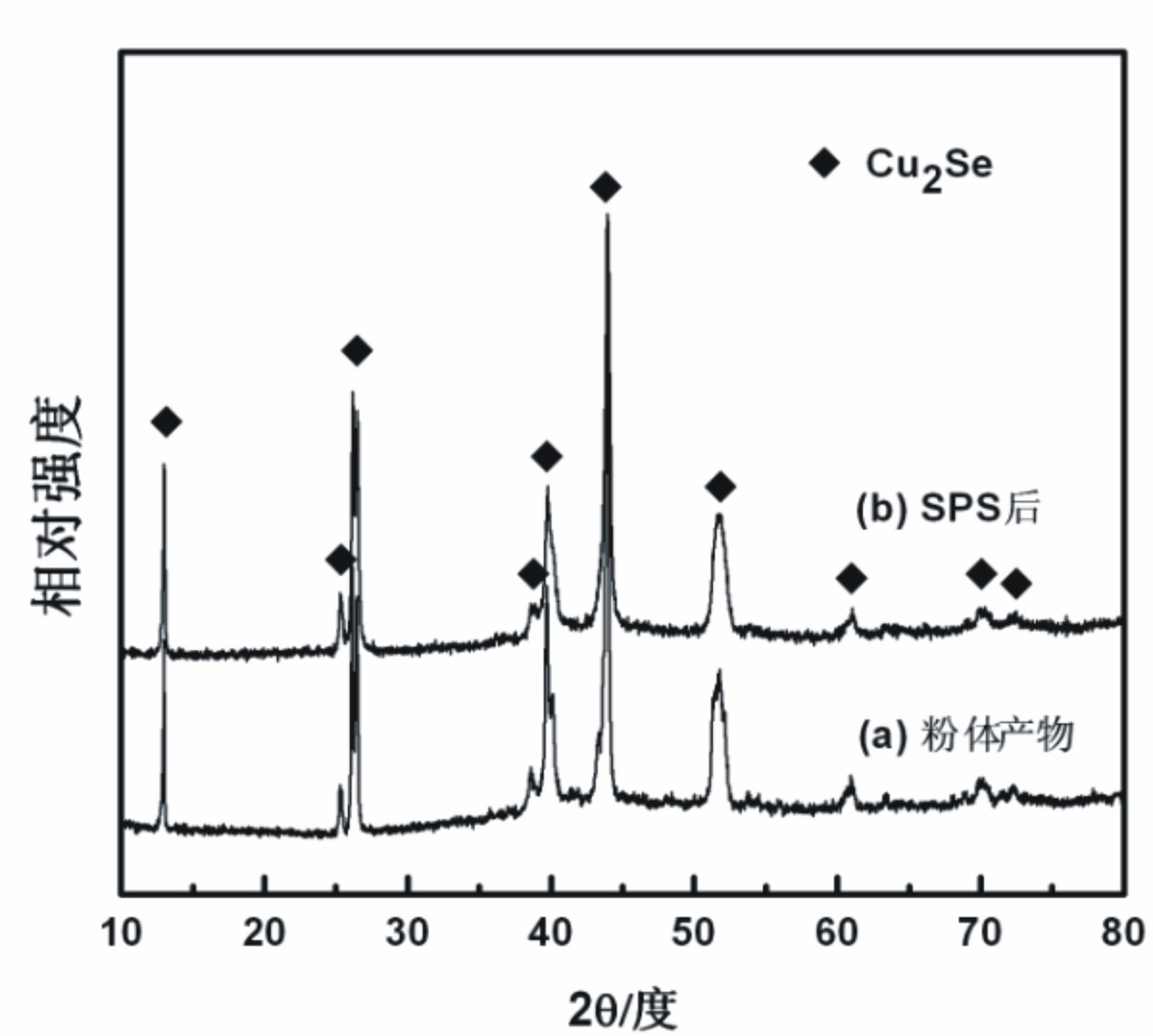

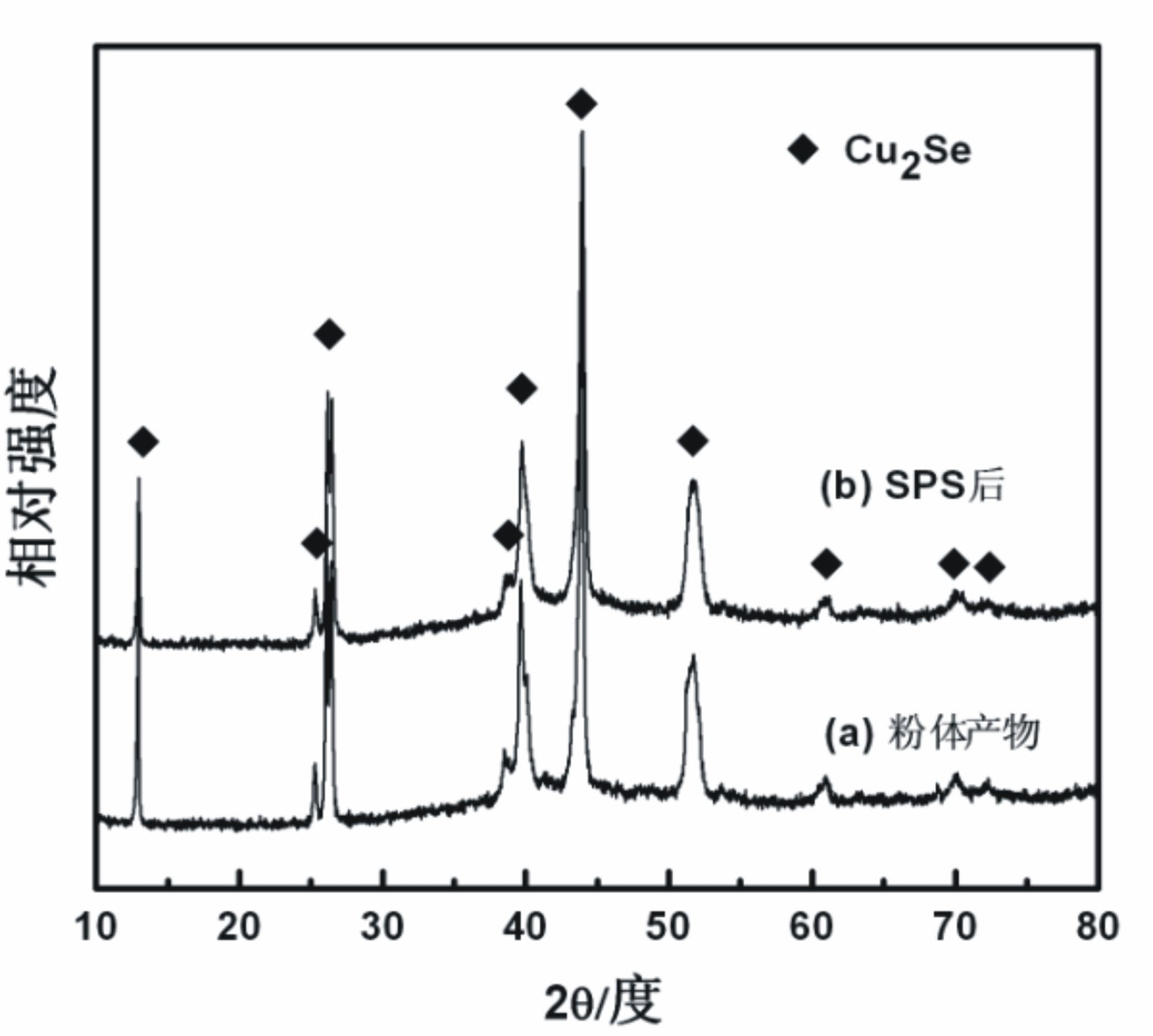

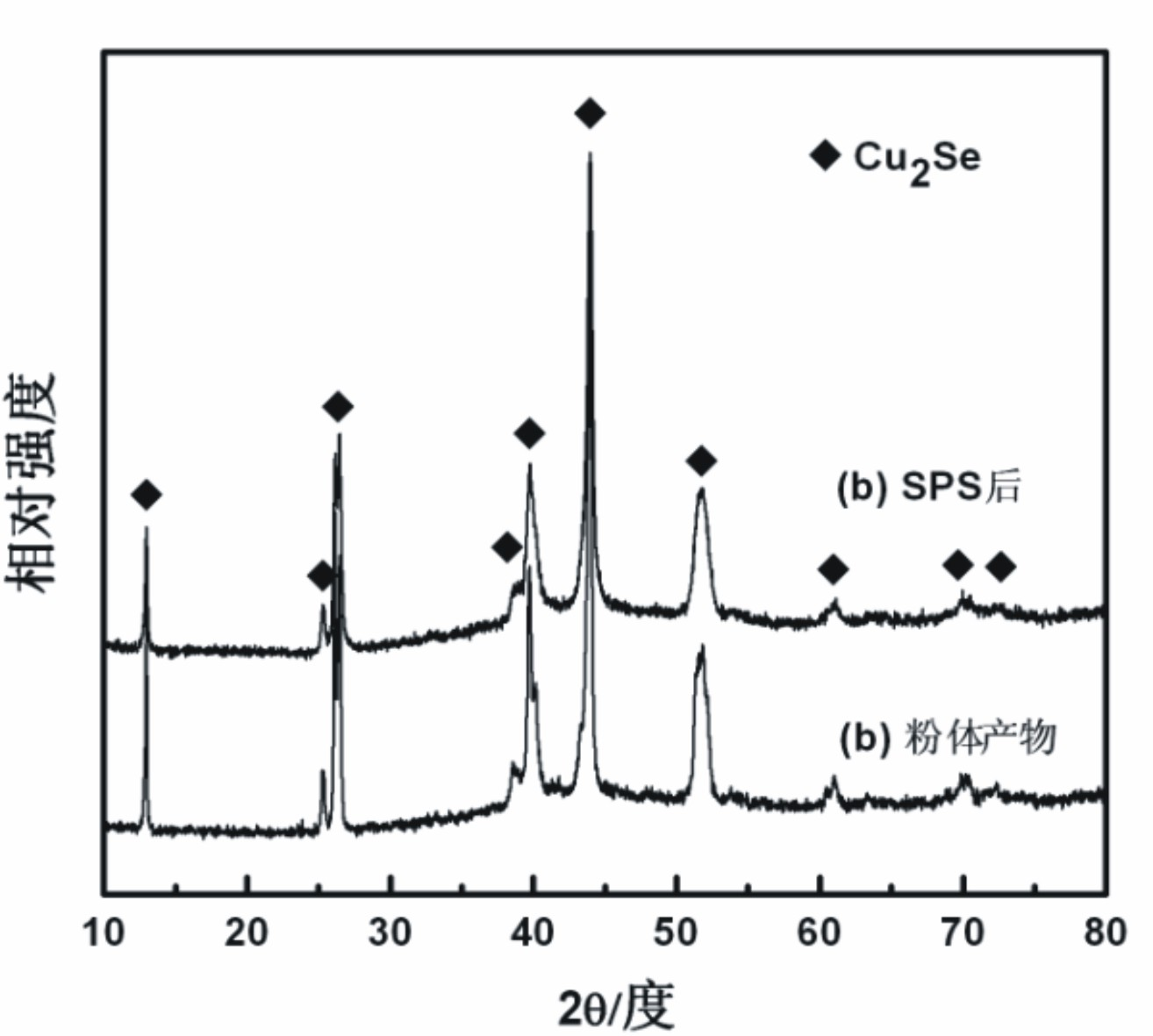

Method for preparing Cu2Se thermoelectric material by low-temperature solid-phase reaction

InactiveCN102674270ALow costControl compositionChemical industryBinary selenium/tellurium compoundsThermoelectric materialsMuffle furnace

The invention relates to a method for preparing a Cu2Se thermoelectric material. The method for preparing the Cu2Se thermoelectric material by the low-temperature solid-phase reaction is characterized by comprising the following step: 1) weighing Cu powder and Se powder according to the molar ratio of 2:1 and mixing the Cu powder and the Se powder uniformly to obtain mixed powder, wherein the Cu powder and the Se powder serve as raw materials; 2) pressing the mixed powder into a block body by using tablet press, placing the block body into a graphite crucible, vacuumizing, sealing into a quartz glass tube, placing into a muffle furnace, performing solid-phase reaction at the temperature of between 650 and 750 DEG C for 12 to 24 hours, and grinding the obtained product into powder; and 3) performing spark plasma sintering on the powder obtained in the step 2) to obtain a compact block body, namely the Cu2Se thermoelectric material. By the method, the raw materials have low cost; the reaction temperature is low; energy is saved; and the materials are fed according to the stoichiometric ratio of the Cu2Se, so the product composition can be controlled precisely; and the repeatability is high.

Owner:WUHAN UNIV OF TECH

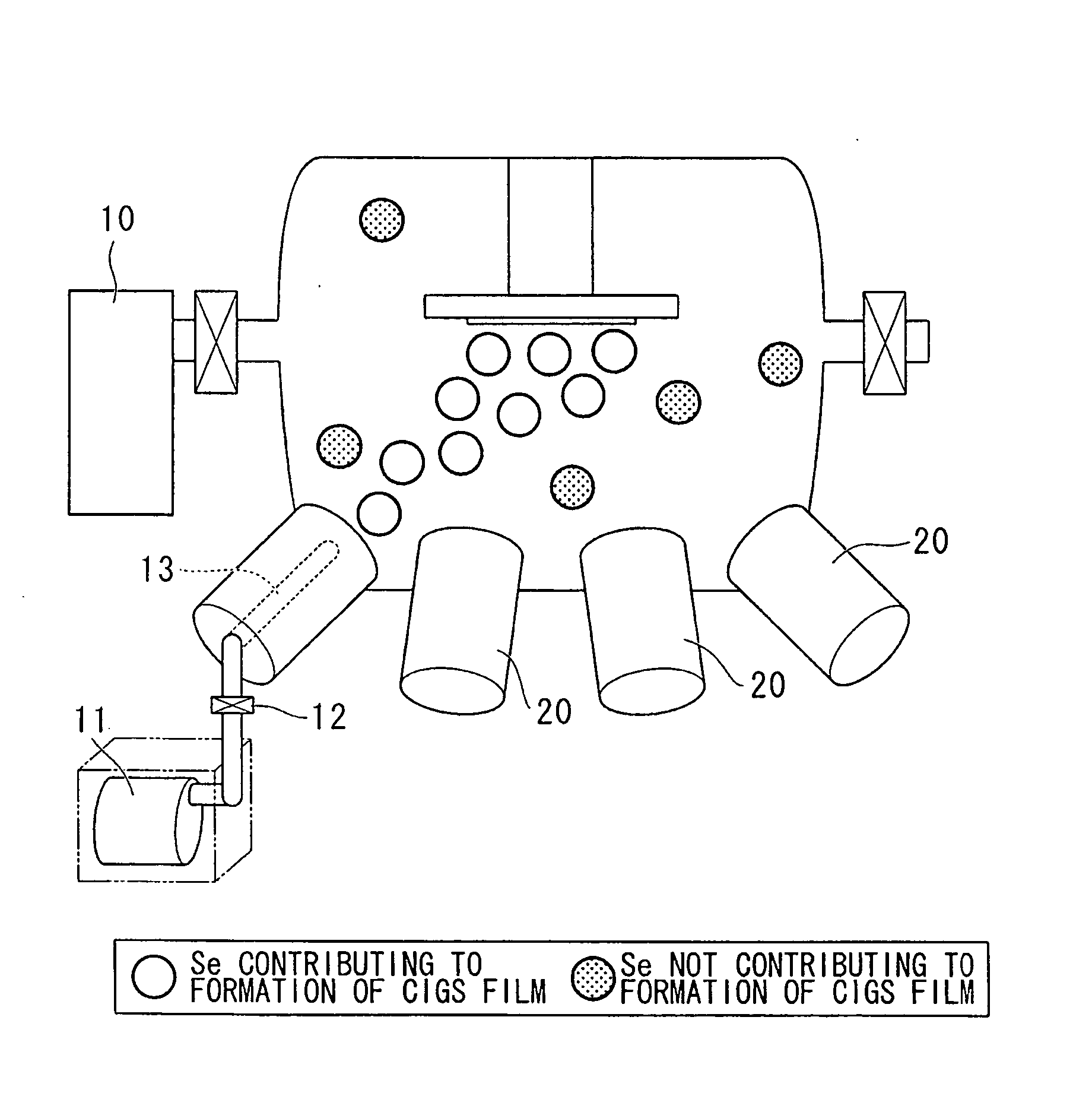

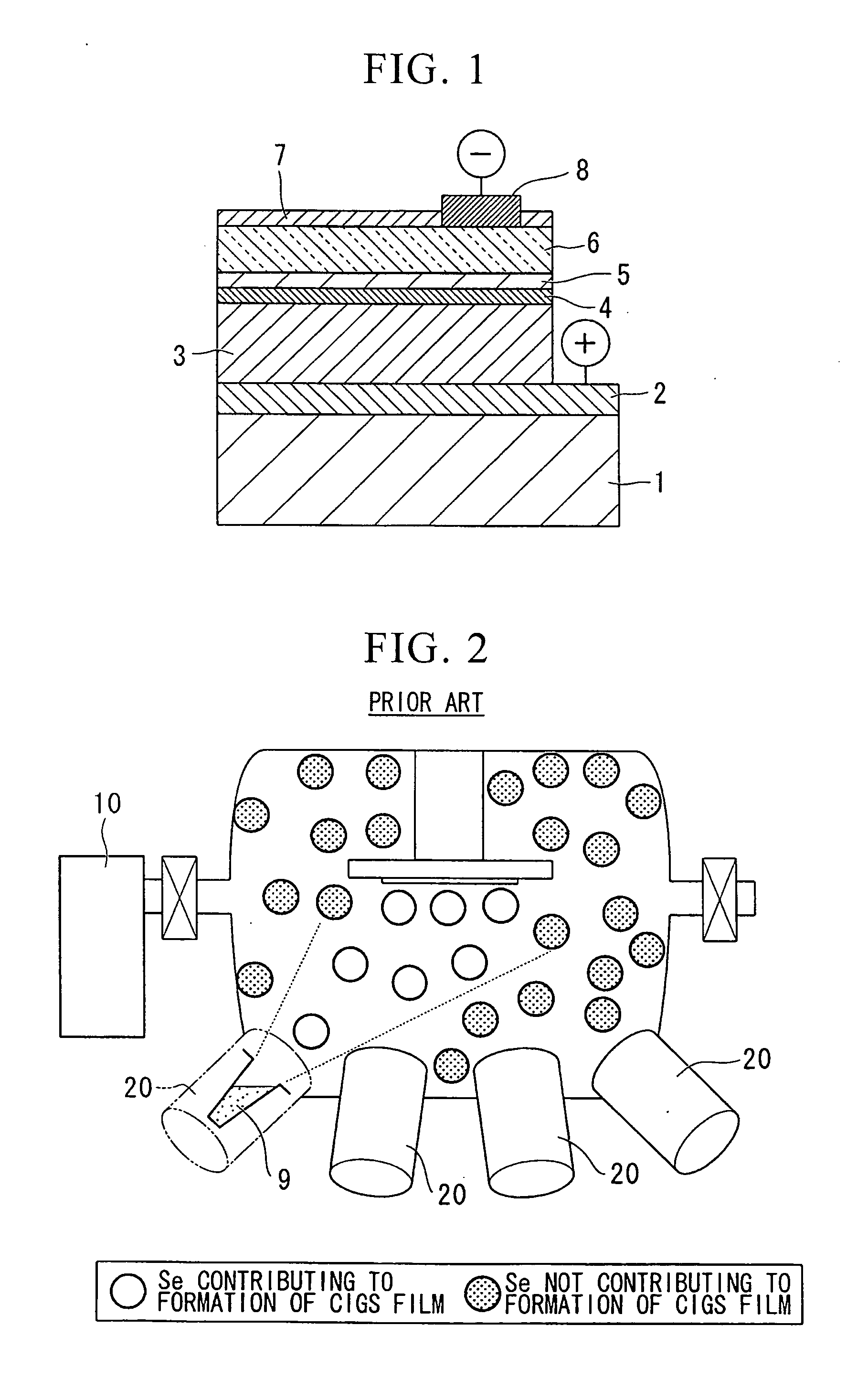

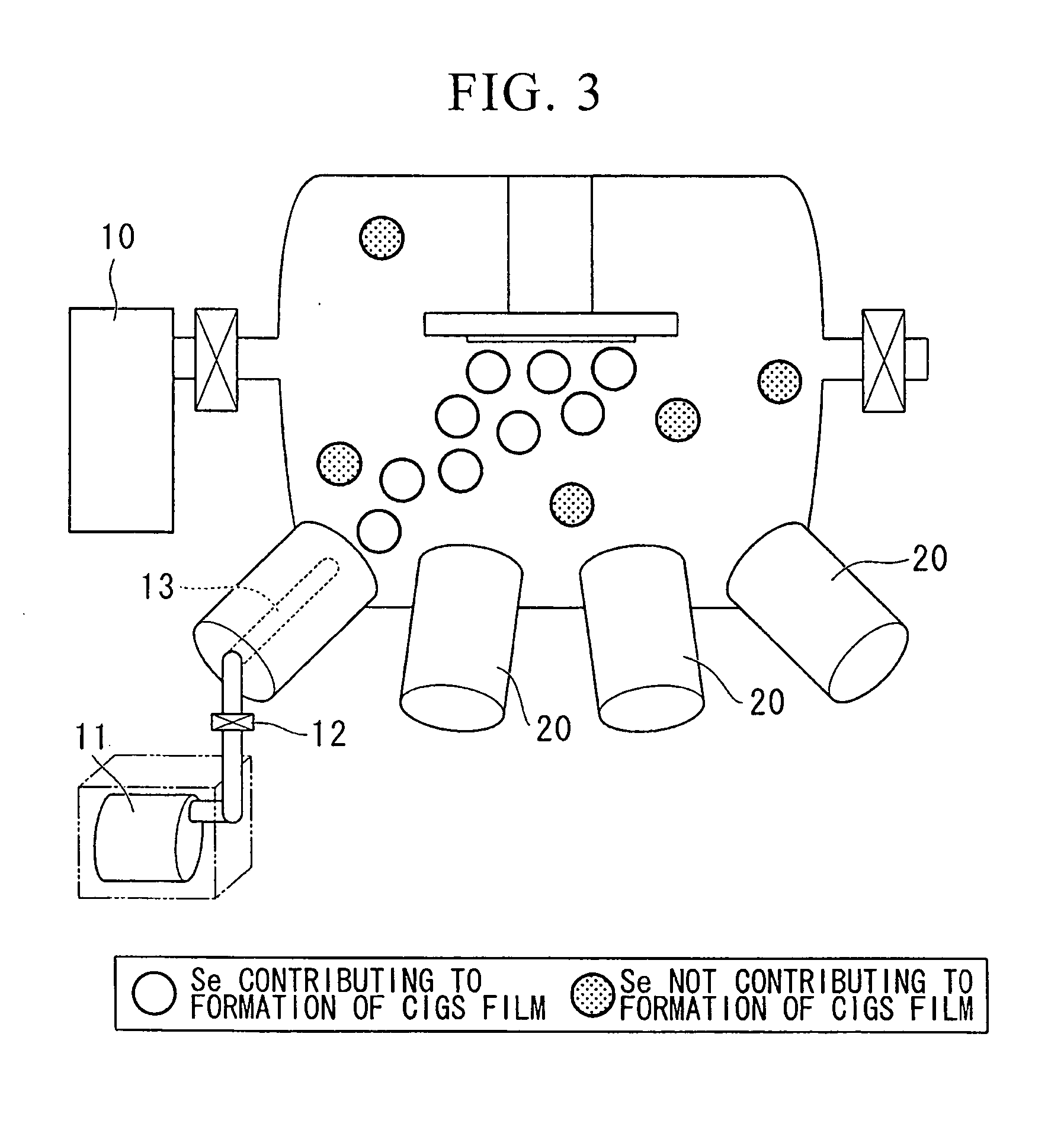

Method and apparatus for producing semiconductor films, photoelectric conversion devices and method for producing the devices

InactiveUS20080072962A1Prevent and suppress adhesionPhosphorus sulfur/selenium/tellurium compoundsFinal product manufacturePhotoelectric conversionGroup element

A method for producing a semiconductor film having a chalcopyrite structure including a Ib group element, a IIIb group element and a VIb group element including selenium, the method including cracking selenium with plasma to generate radical selenium, and using the radical selenium in the process of forming the semiconductor film.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Metal chalcogenide composite nano-particles and layers therewith

A metal chalcogenide composite nano-particle comprising a metal capable of forming p-type semiconducting chalcogenide nano-particles and a metal capable of forming n-type semiconducting chalcogenide nano-particles, wherein at least one of the metal chalcogenides has a band-gap between 1.0 and 2.9 eV and the concentration of the metal capable of forming p-type semiconducting chalcogenide nano-particles is at least 5 atomic percent of the metal and is less than 50 atomic percent of the metal; a dispersion thereof; a layer comprising the nano-particles; and a photovoltaic device comprising the layer.

Owner:AGFA GEVAERT AG

Luminescent nanoparticles and methods for their preparation

InactiveUS20060057382A1Guaranteed accuracyGood colorNanostructure manufacturePretreated surfacesGroup 12 elementNanoparticle

Methods for synthesizing luminescent nanoparticles and nanoparticles prepared by such methods are provided. The nanoparticles are prepared by a method in which an additive is included in the reaction mixture. The additive may be a Group 2 element, a Group 12 element, a Group 13 element, a Group 14 element, a Group 15 element, or a Group 16 element. In additions, a luminescent nanoparticle is provided that comprises a semiconductive core surrounded by an inorganic shell, an interfacial region and an additive present in the interfacial region or both the interfacial region and the shell.

Owner:INVITROGEN

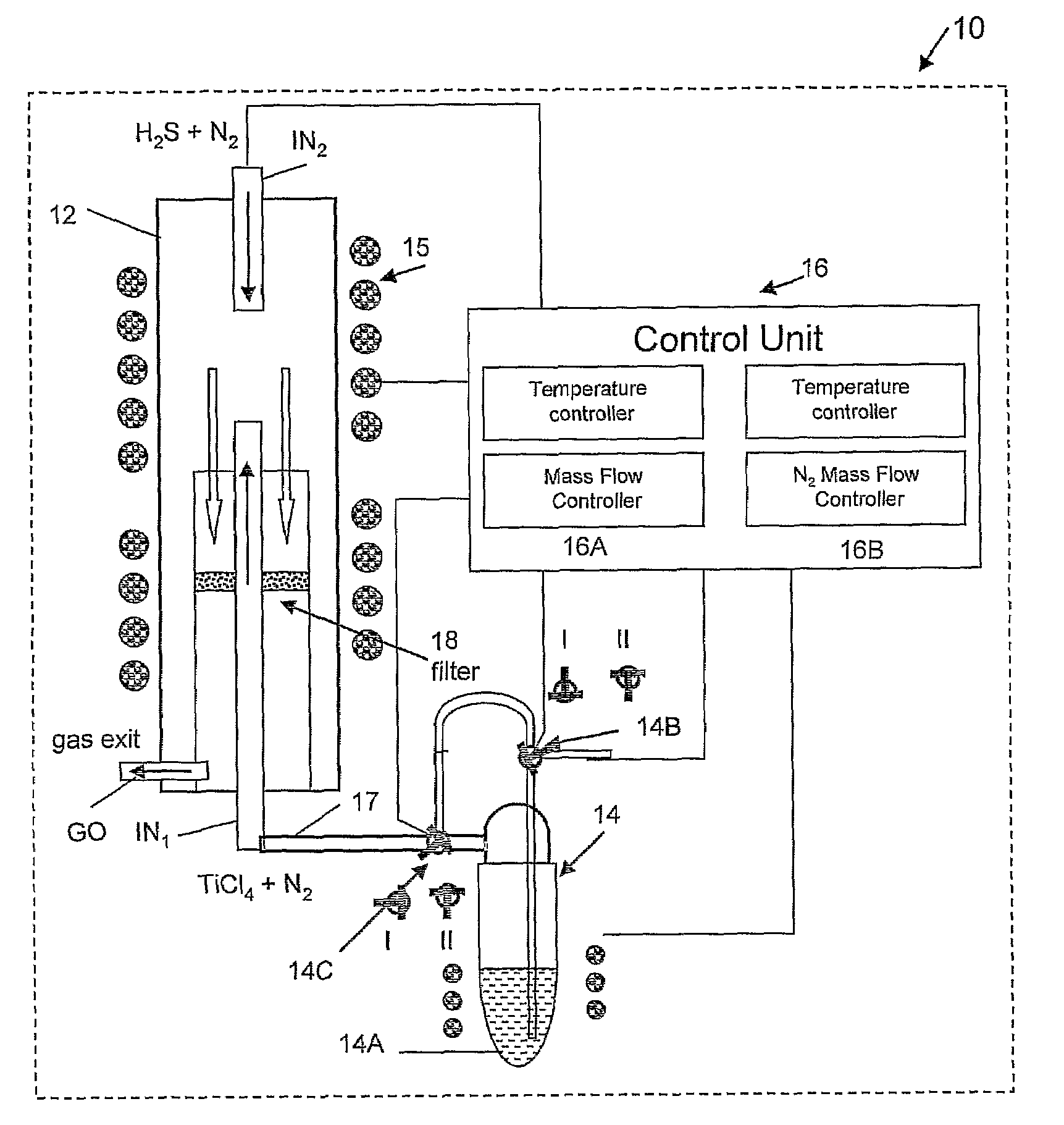

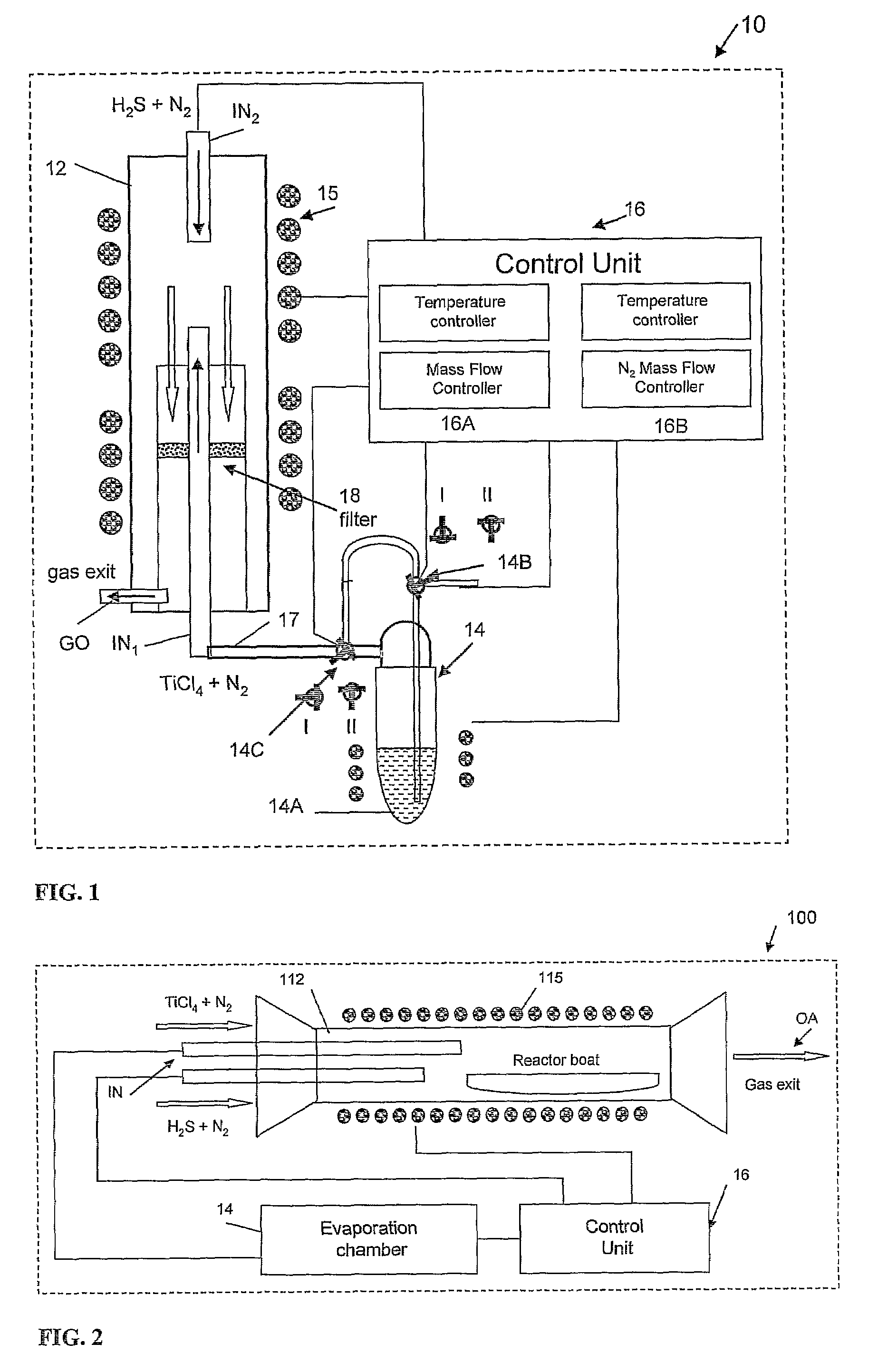

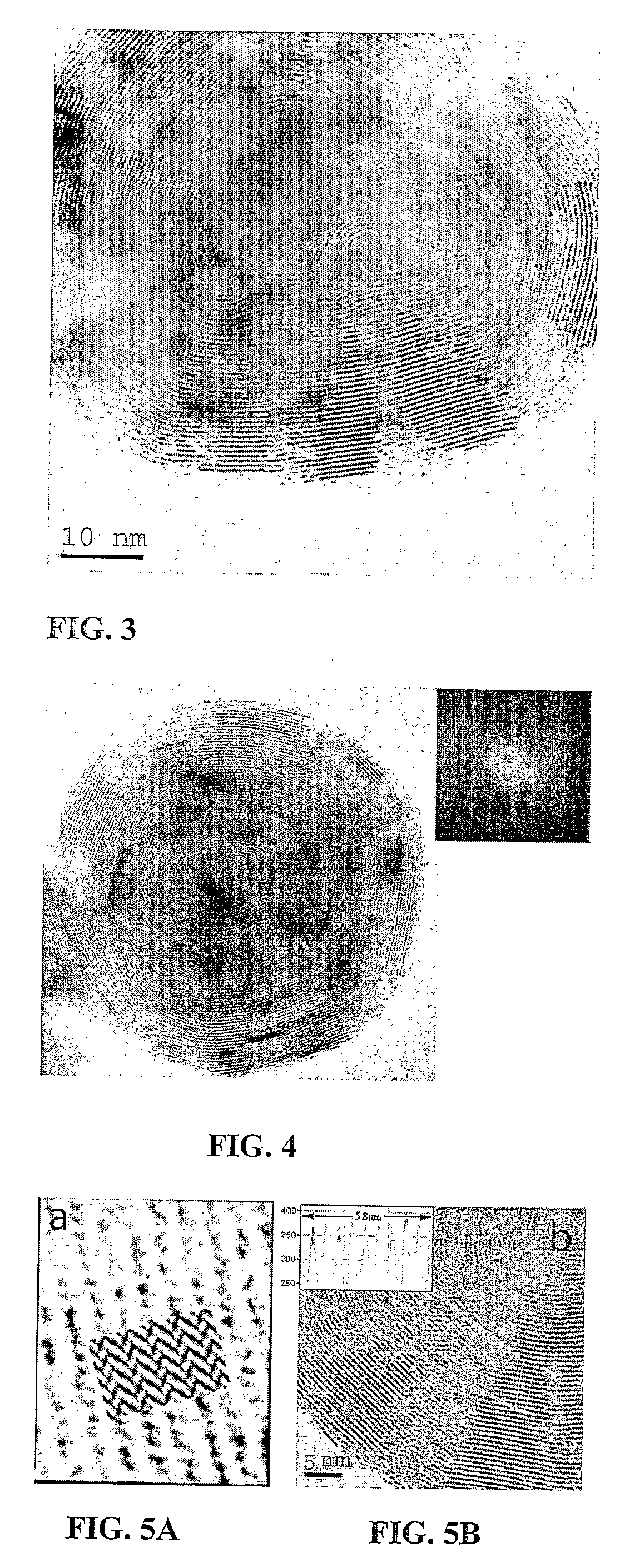

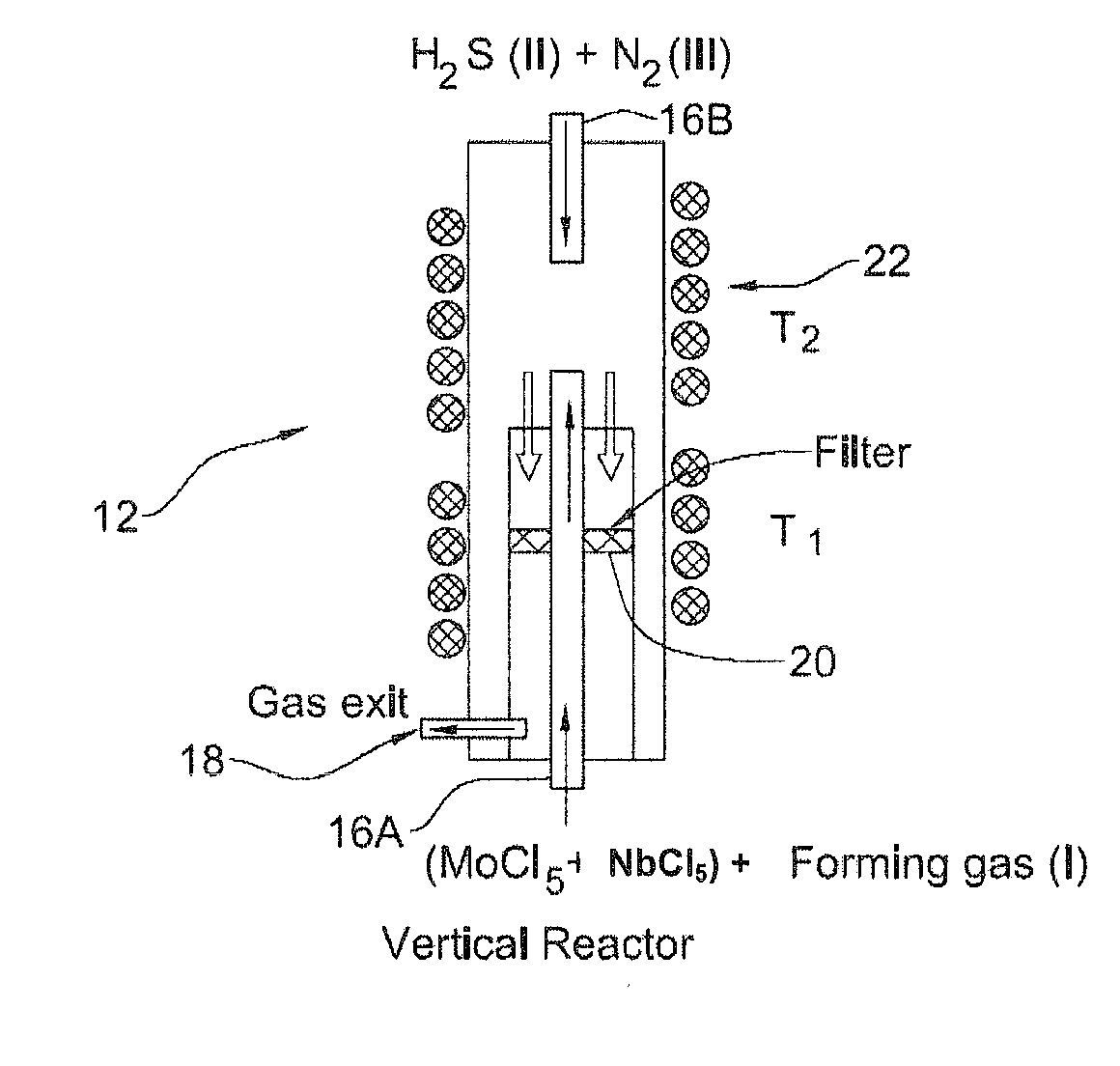

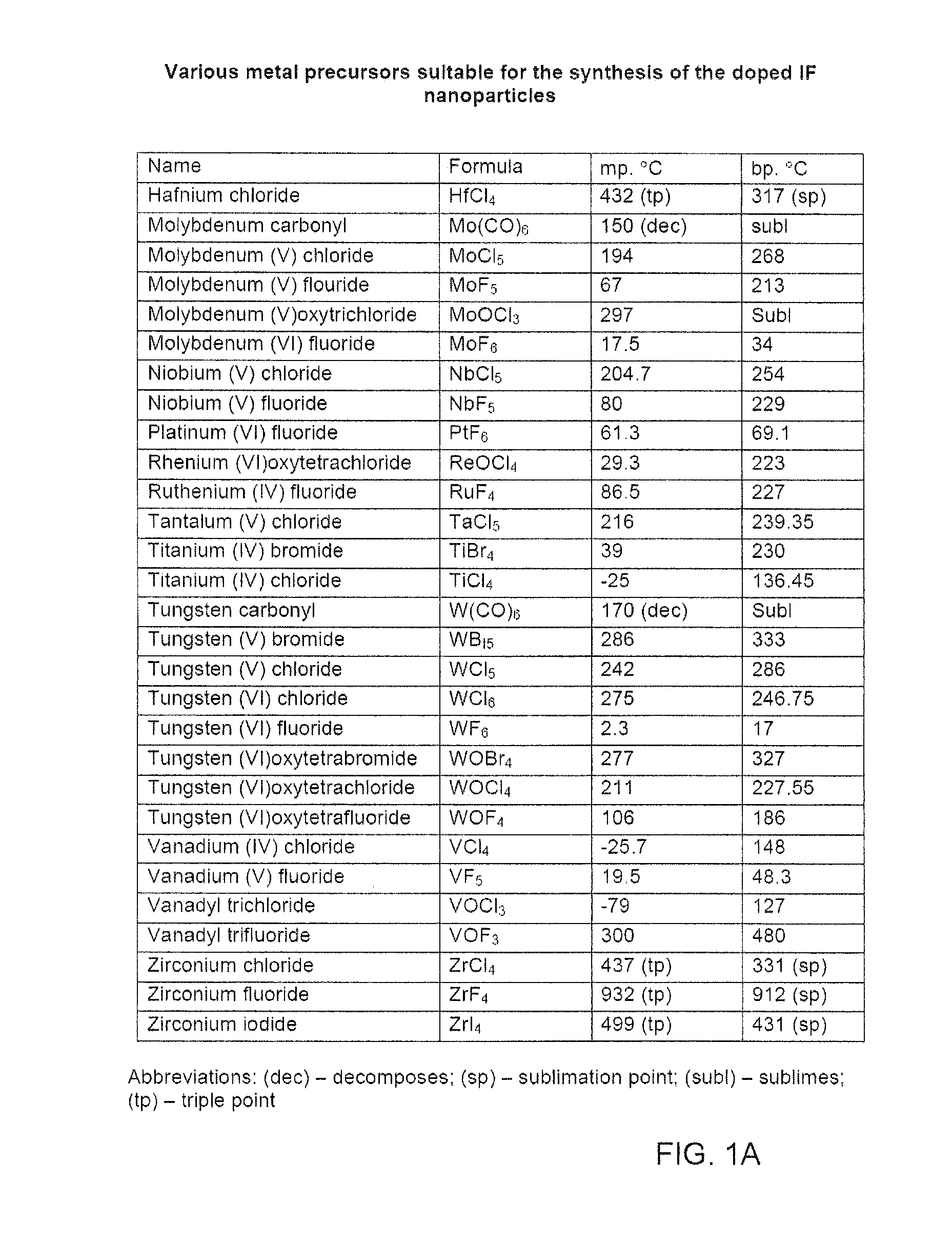

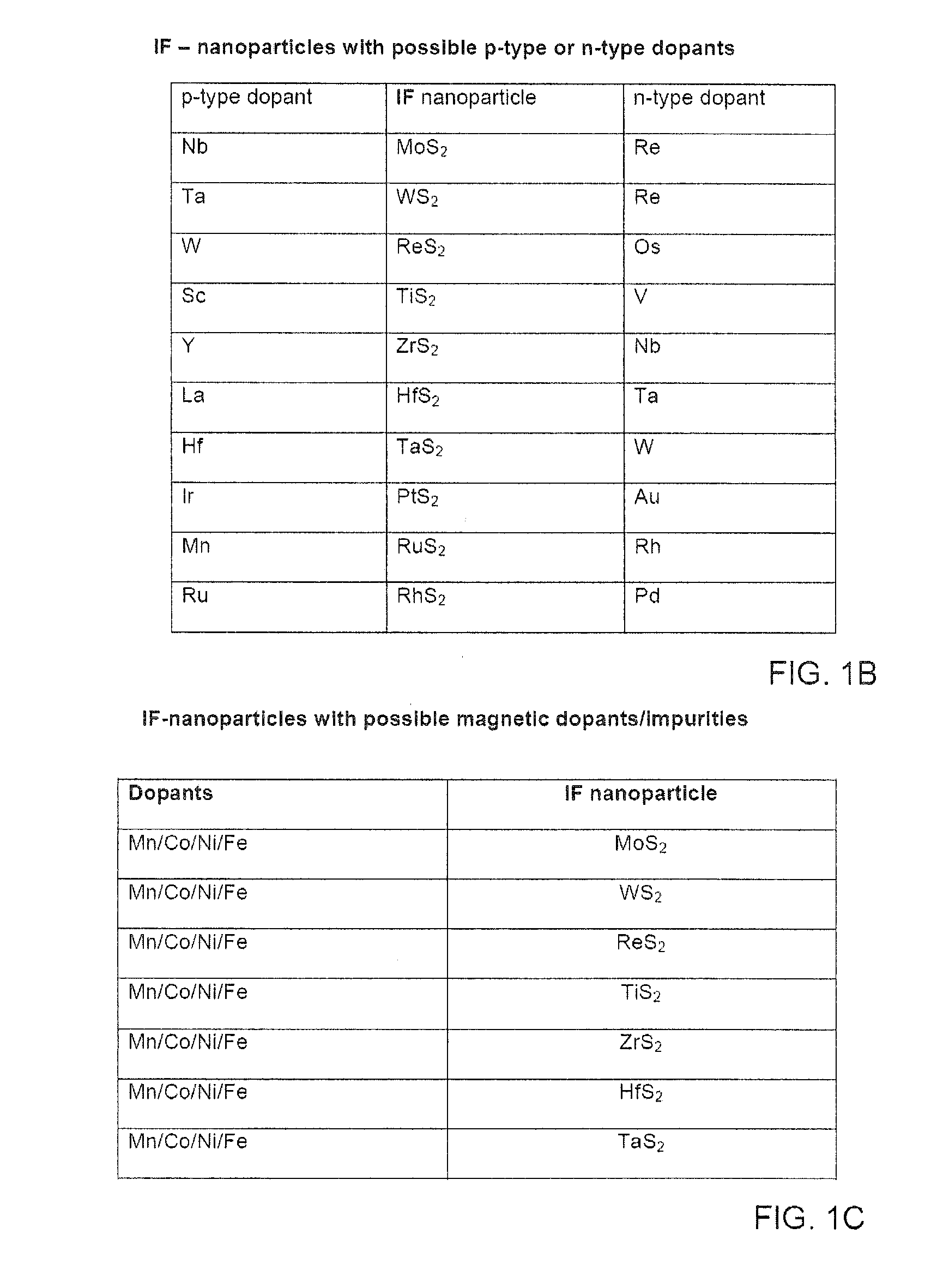

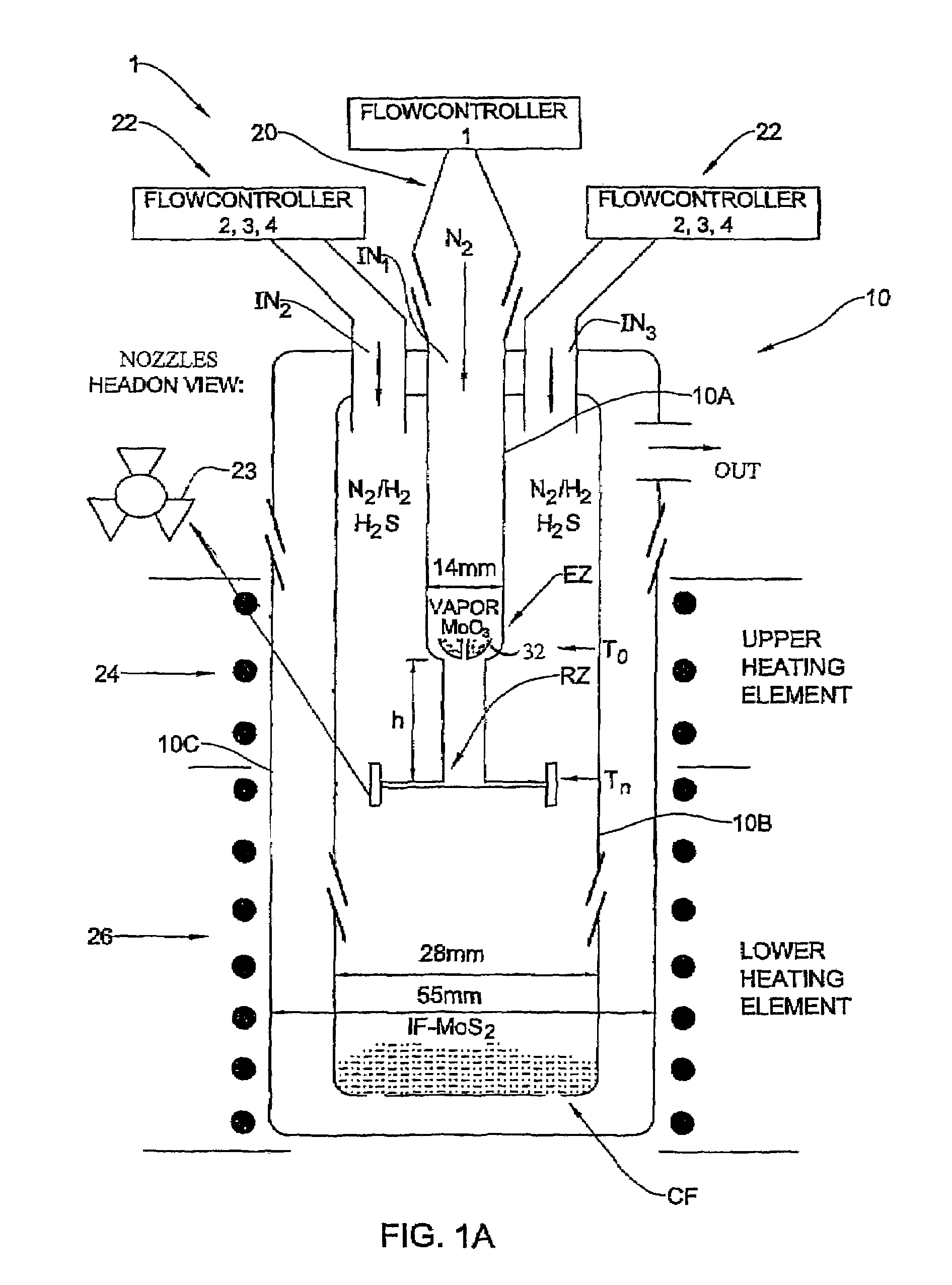

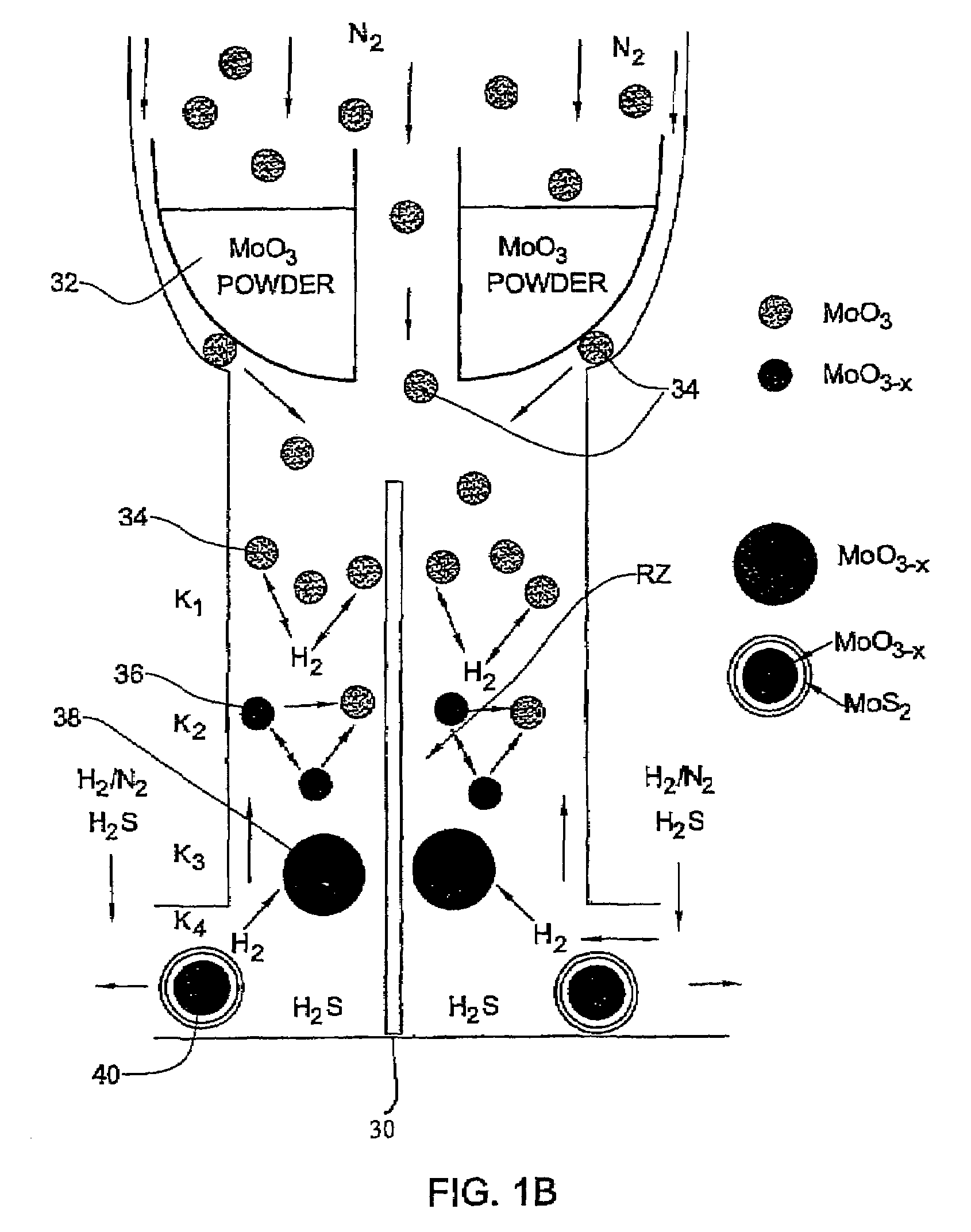

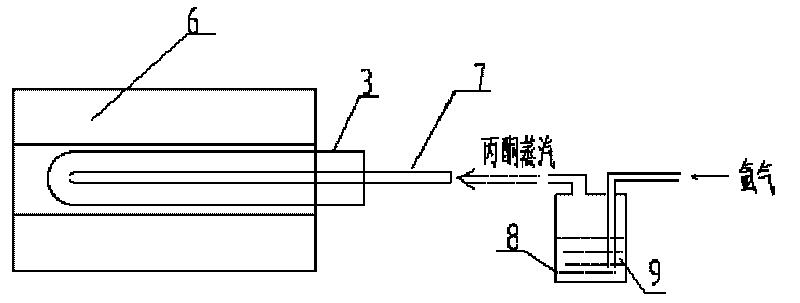

Process and apparatus for producing inorganic fullerene-like nanoparticles

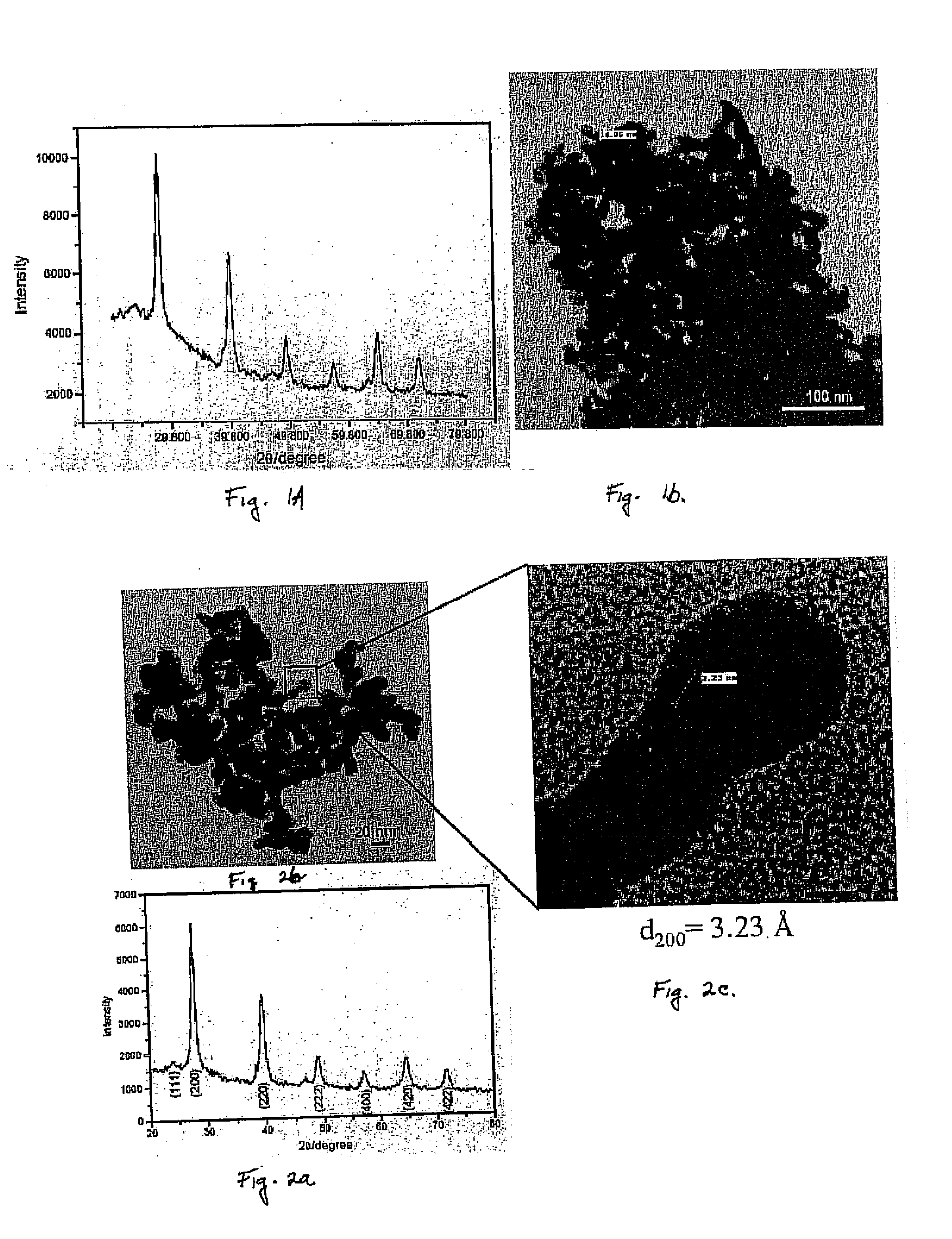

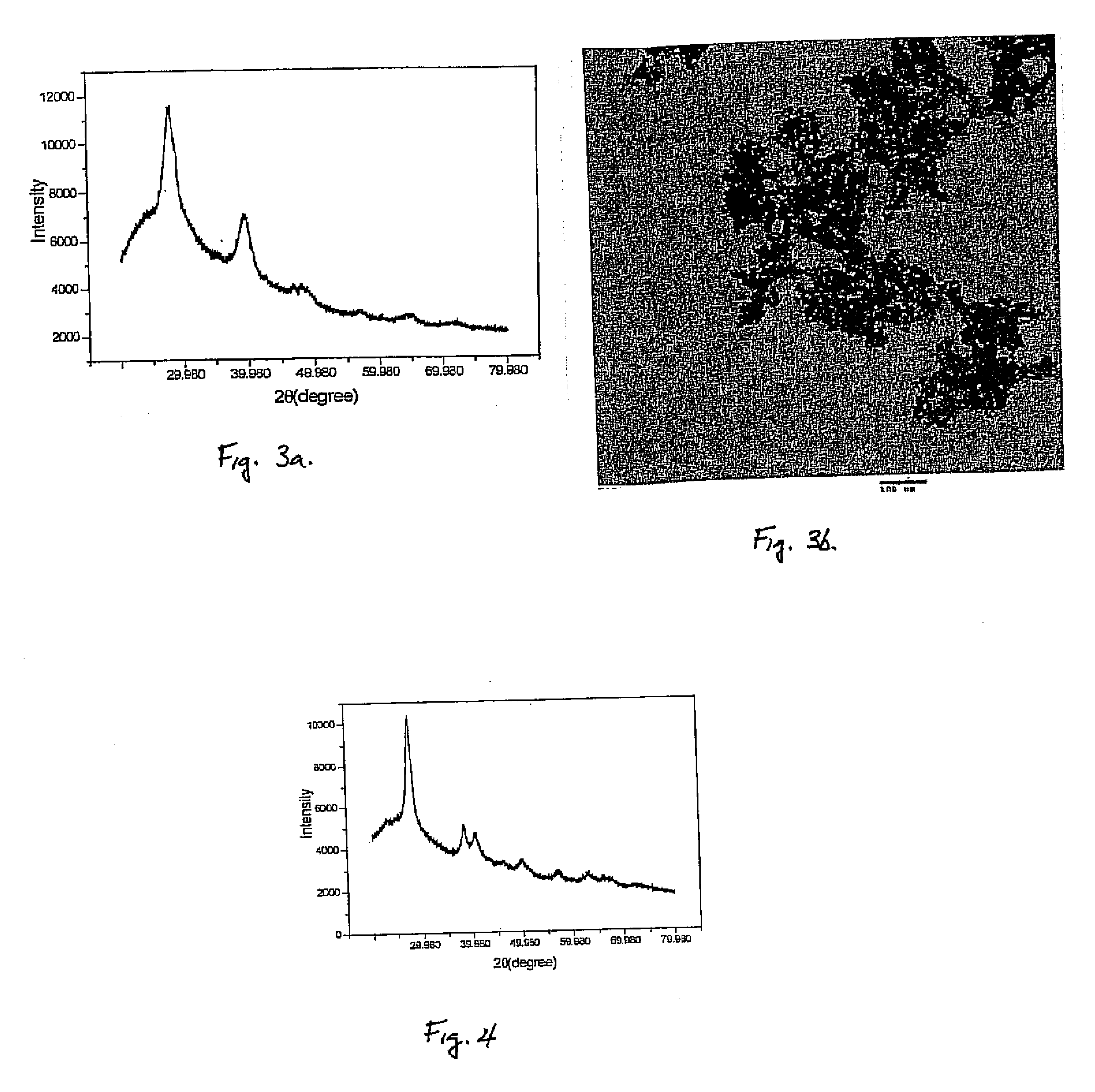

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

Mass production of nano-scaled platelets and products

ActiveUS20100222482A1Time necessarySmall thicknessMaterial nanotechnologyGraphiteNoble gasProduct gas

Owner:GLOBAL GRAPHENE GRP INC

Nanocrystals

InactiveUS20050112376A1Level of radiation can be quite highImprove the level ofNanosensorsCeramic layered productsCross-linkFluorescence

Provided herein are compositions of functionalized, fluorescent nanocrystals comprising fluorescent nanocrystals coated with an imidazole-containing compound; compositions of functionalized, fluorescent nanocrystals comprising fluorescent nanocrystals coated with an imidazole-containing compound and cross-linked with a phosphine cross-linking compound; compositions of functionalized fluorescent nanocrystals operably bound to molecular probe; a process of making functionalized, fluorescent nanocrystals; and a process of using functionalized, fluorescent nanocrystals in a detection system.

Owner:LIFE TECH CORP

Luminescent nanoparticles and methods for their preparation

InactiveUS7172791B2Good colorNarrow emission spectrumNanostructure manufacturePretreated surfacesGroup 12 elementNanoparticle

Methods for synthesizing luminescent nanoparticles and nanoparticles prepared by such methods are provided. The nanoparticles are prepared by a method in which an additive is included in the reaction mixture. The additive may be a Group 2 element, a Group 12 element, a Group 13 element, a Group 14 element, a Group 15 element, or a Group 16 element. In additions, a luminescent nanoparticle is provided that comprises a semiconductive core surrounded by an inorganic shell, an interfacial region and an additive present in the interfacial region or both the interfacial region and the shell.

Owner:INVITROGEN

Rapid synthesis of ternary, binary and multinary chalcogenide nanoparticles

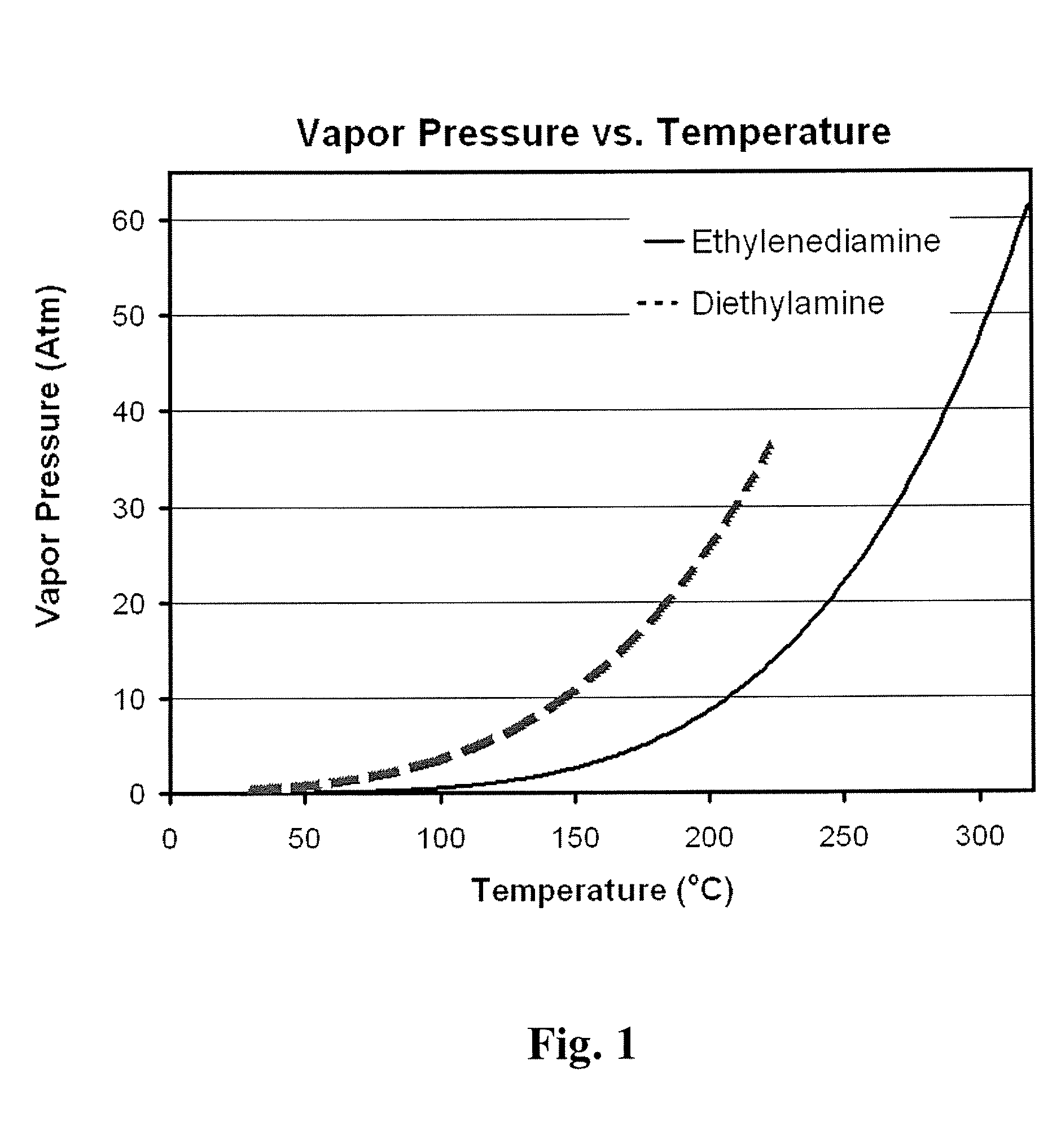

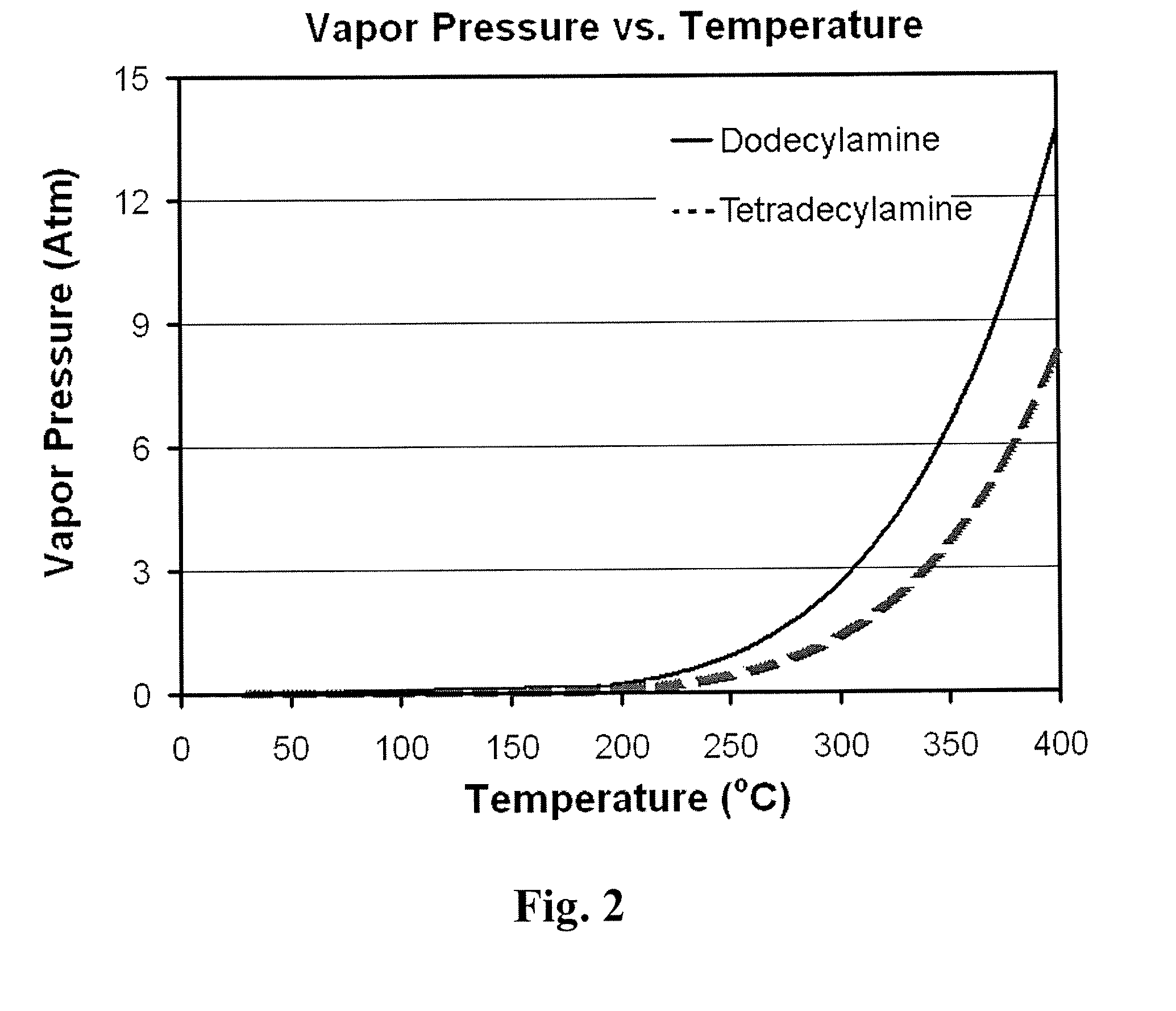

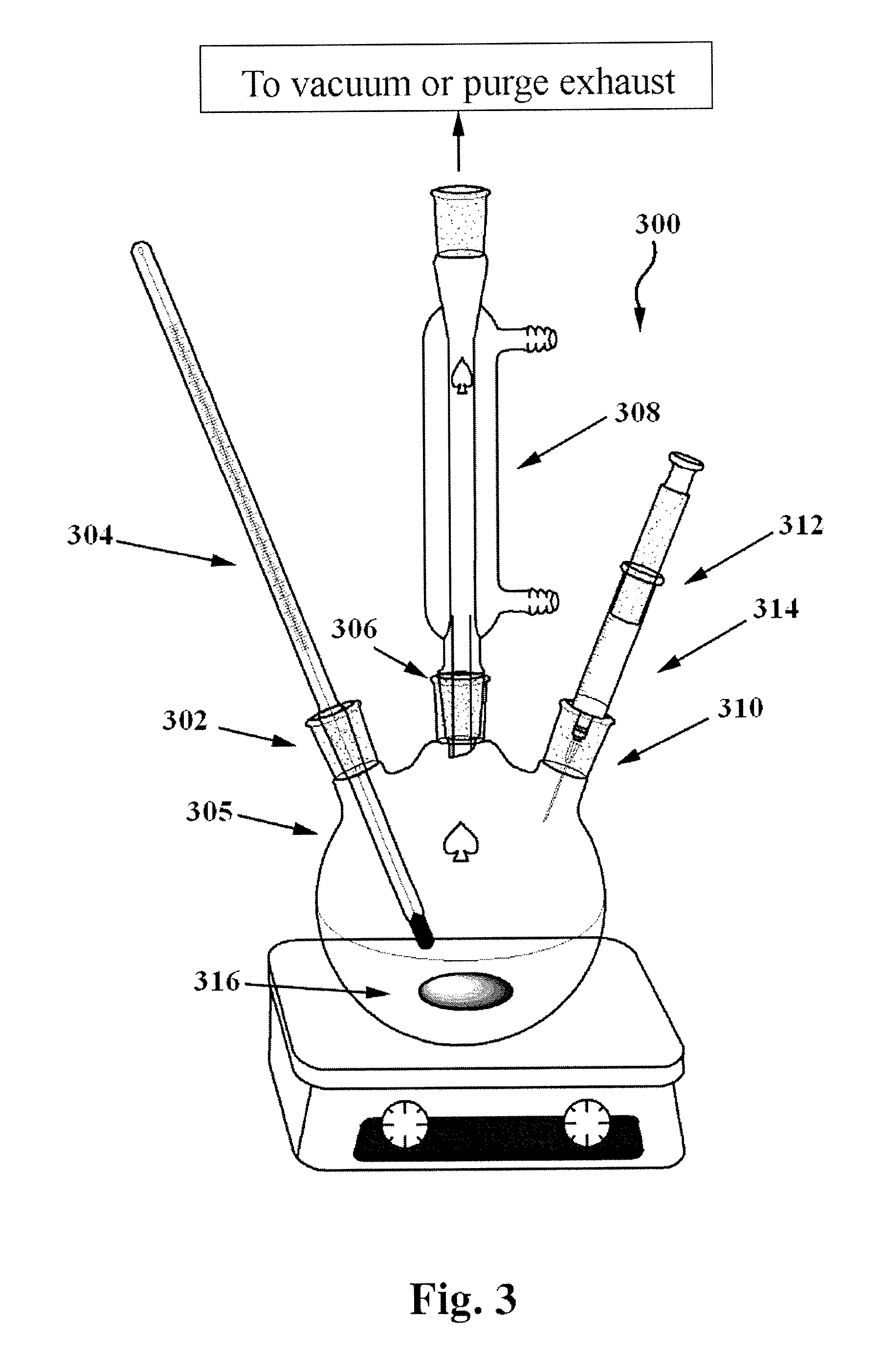

InactiveUS20100003187A1Rapid responseEasy to handleMaterial nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsOrganic solventSulfur

A method for synthesizing a chalcogenide nanoparticle is provided. The method comprises reacting a metal component with an elemental chalcogen precursor in the presence of an organic solvent. The chalcogenide nanoparticles include ternary, binary and / or multinary chalcogenide nanoparticles and the metal component comprises metal halides or elemental metal precursors. The alkylamine solvent has a normal boiling temperature of above about 220° C. and an average particle size of from about 5 nm to about 1000 nm.

Owner:PURDUE RES FOUND INC

Method for preparing graphene/semiconductor quantum dot composite material

InactiveCN101913600ASimple preparation processSimple manufacturing processBinary selenium/tellurium compoundsWater solubleSingle layer graphene

The invention discloses a method for preparing a graphene / semiconductor quantum dot composite material, which belongs to the technical field of inorganic nano materials and prepares the graphene / semiconductor quantum dot composite material by preparing solution of single-layer graphene and solution of quantum dots and uniformly mixing the solution of graphene and the solution of quantum dots. The surfaces of the quantum dots synthesized by using mercaptan acid as a stabilizer of the invention have carboxyls, while the surfaces of graphene slices prepared by a chemical oxidation reduction process have hydroxys; therefore, the carboxyls can be bonded with the hydroxys by covalent bonds to form the graphene / quantum dot composite material. As the graphene and the quantum dots mutual soluble in water, ligand disreplacement or modification is avoided. Thus, the preparation process is simplified greatly and the cost is lowered.

Owner:SHANGHAI JIAO TONG UNIV

Method for the preparation of IV-VI semiconductor nanoparticles

InactiveUS20060110313A1Controlled in sizeControl shapeMaterial nanotechnologyNitrogen compoundsOrganic solventQuantum dot

A high temperature (on the order of about 90° C. or above) non-aqueous synthetic procedure for the preparation of substantially monodisperse IV-VI semiconductor nanoparticles (quantum dots) is provided. The procedure includes first introducing a first precursor selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element into a reaction vessel that comprises at least an organic solvent to form a mixture. Next, the mixture is heated to a temperature of about 90° C. or above and thereafter a second precursor which is different from the first precursor and is selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element is added into the heated mixture. The reaction mixture is then mixed to initiate nucleation of IV-VI nanocrystals and the temperature of the reaction mixture is controlled to provide substantially monodispersed IV-VI nanoparticles having a diameter of about 20 nm or less.

Owner:GLOBALFOUNDRIES INC +1

Bi2Te3 thin-piece/graphene composite material, preparation method and applications thereof

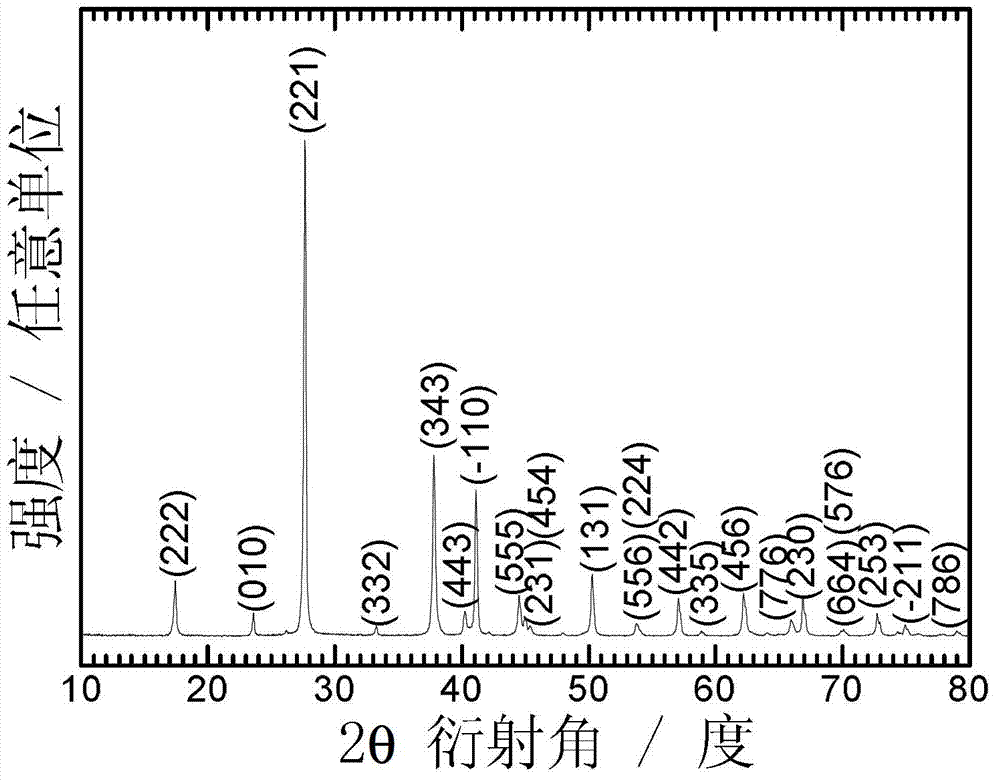

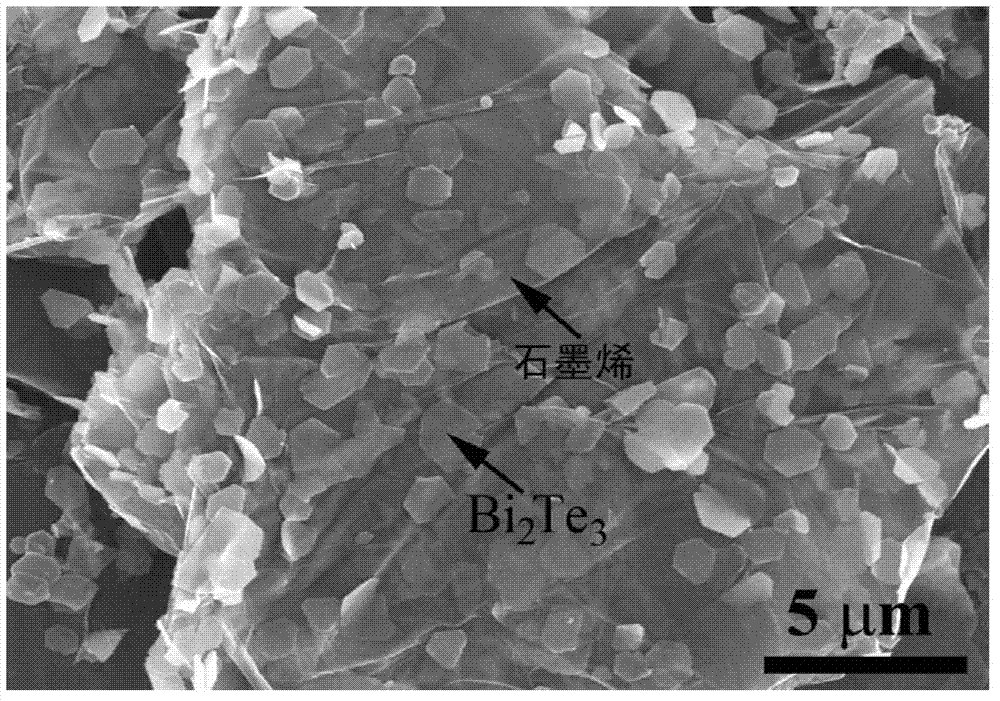

InactiveCN102760827AImprove thermoelectric performanceAvoid reunionGrapheneThermoelectric device junction materialsSolventCvd graphene

The invention discloses a Bi2Te3 thin-piece / graphene composite material. The Bi2Te3 thin-piece / graphene composite material consists of a micron-sized Bi2Te3 thin sheet and graphene. Due to the actions of dispersion, bearing and isolation of the graphene, the sintering of the micron-sized Bi2Te3 thin sheet in the heat-treatment process can be effectively prevented for maintaining effective scattering of the crystal boundary to phonons, and the great significance for improving the thermoelectric properties of the Bi2Te3 material is embodied. The composite material can be used as a thermoelectric material. The invention also discloses a preparation method of the composite material by a one-step hydrothermal method or a one-step solvothermal method, and has the advantages of simple process, low cost, short period and low energy consumption and the like.

Owner:ZHEJIANG UNIV

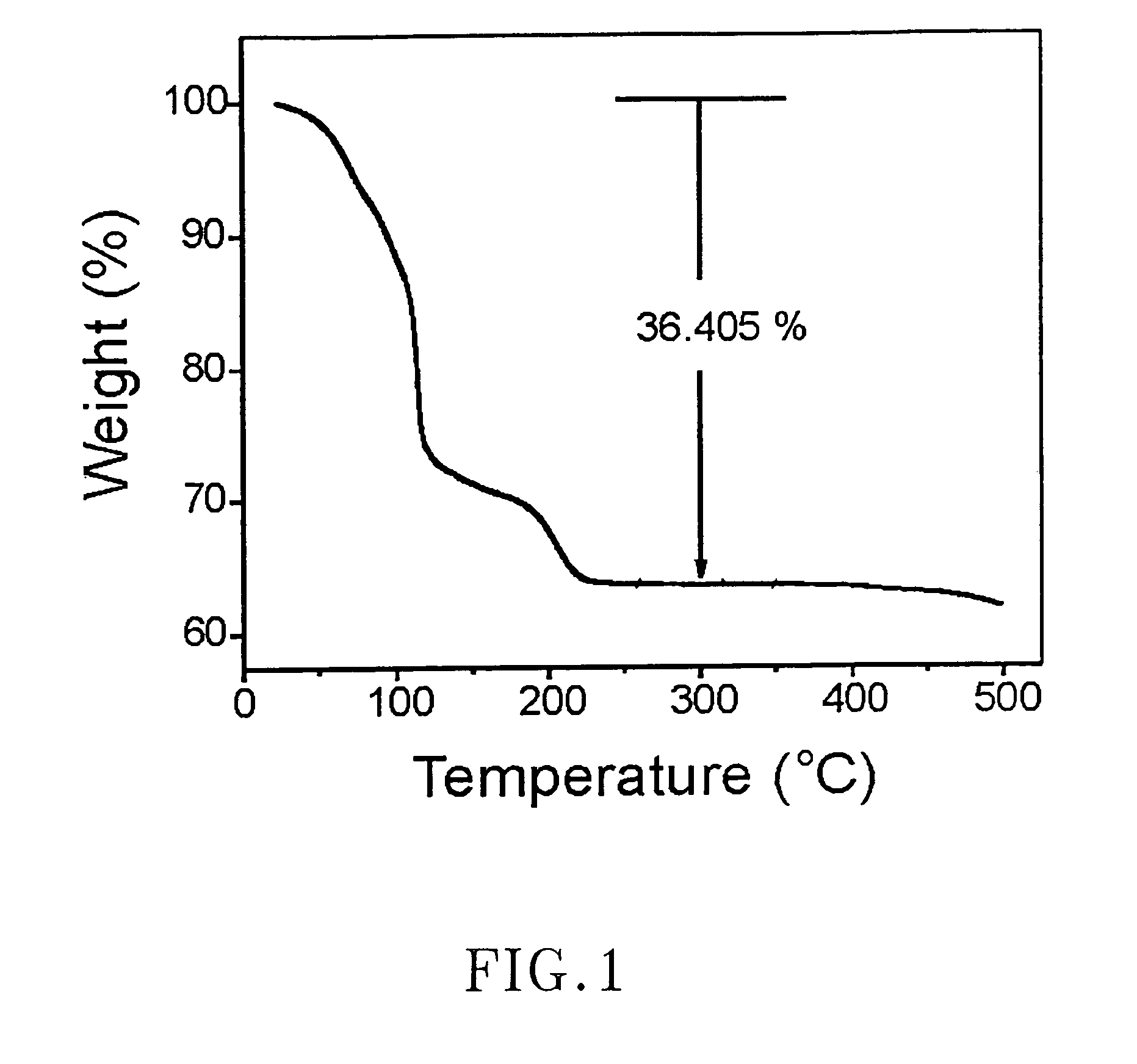

Metal telluride nanocrystals and synthesis thereof

InactiveUS20080112877A1Material nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsBismuth tellurideLead telluride

A process for synthesizing a metal telluride is provided that includes the dissolution of a metal precursor in a solvent containing a ligand to form a metal-ligand complex soluble in the solvent. The metal-ligand complex is then reacted with a telluride-containing reagent to form metal telluride domains having a mean linear dimension of from 2 to 40 nanometers. NaHTe represents a well-suited telluride reagent. A composition is provided that includes a plurality of metal telluride crystalline domains(PbTe)1-x-y(SnTe)x(Bi2Te3)y (I)having a mean linear dimension of from 2 to 40 nanometers inclusive where x is between 0 and 1 inclusive and y is between 0 and 1 inclusive with the proviso that x+y is less than or equal to 1. Each of the metal telluride crystalline domains has a surface passivated with a saccharide moiety or a polydentate carboxylate. A densified mass having a density of greater than 95% of the theoretical density includes a plurality of lead telluride, tin telluride, bismuth telluride, or a combination thereof of domains having a mean linear dimension of from 2 to 40 nanometers inclusive that have been subjected to hot isotactic pressing.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA +1

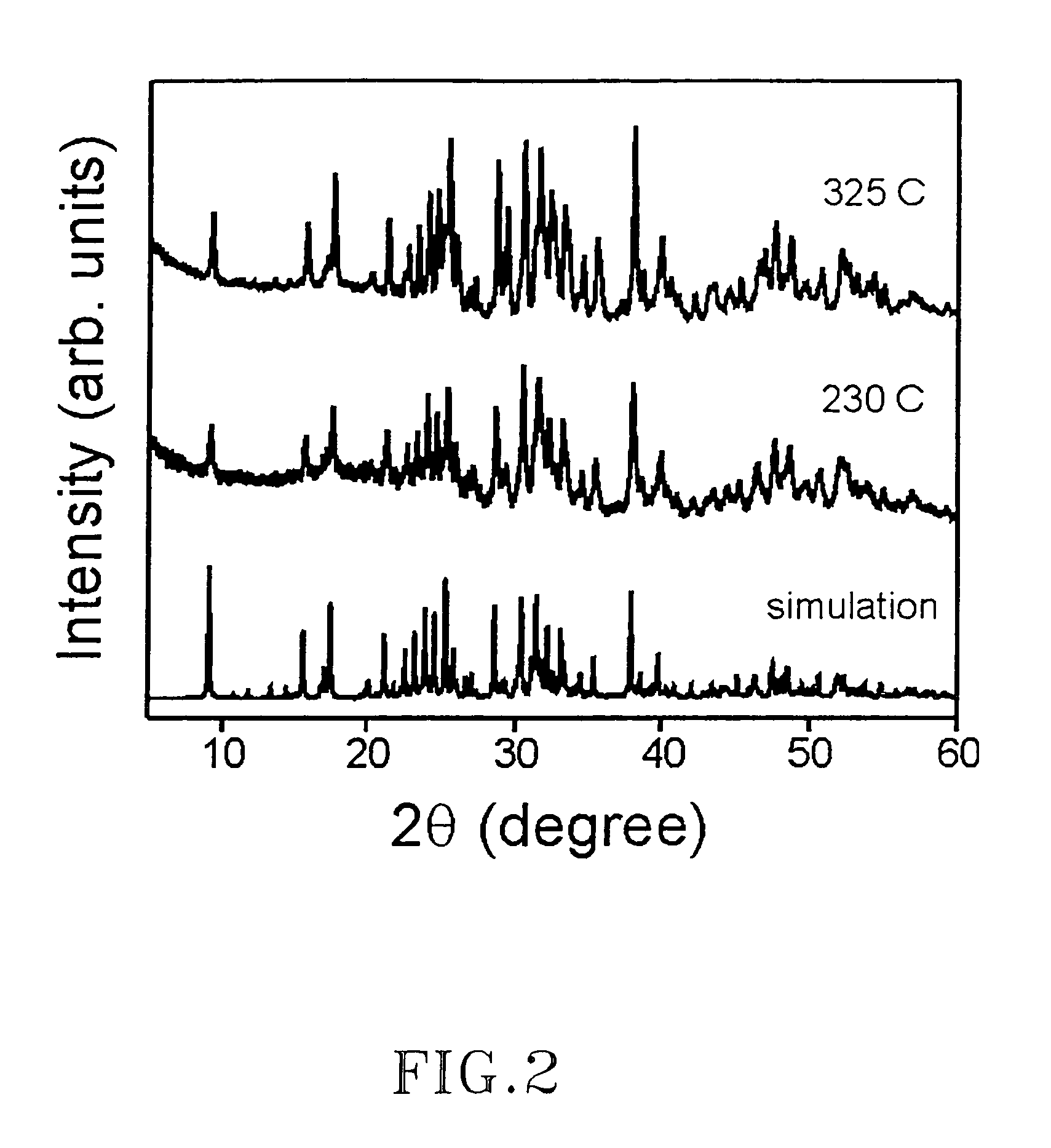

Fullerene-like nanostructures, their use and process for their production

ActiveUS20100227782A1Improve conductivityMaterial nanotechnologyConductive materialAlloyElectronic properties

A nanostructure, being either an Inorganic Fullerene-like (IF) nanostructure or an Inorganic Nanotube (INT), having the formula A1−x-Bx-chalcognide are described. A being a metal or transition metal or an alloy of metals and / or transition metals, B being a metal or transition metal B different from that of A and x being ≦0.3. A process for their manufacture and their use for modifying the electronic character of A-chalcognide are described.

Owner:YEDA RES & DEV CO LTD

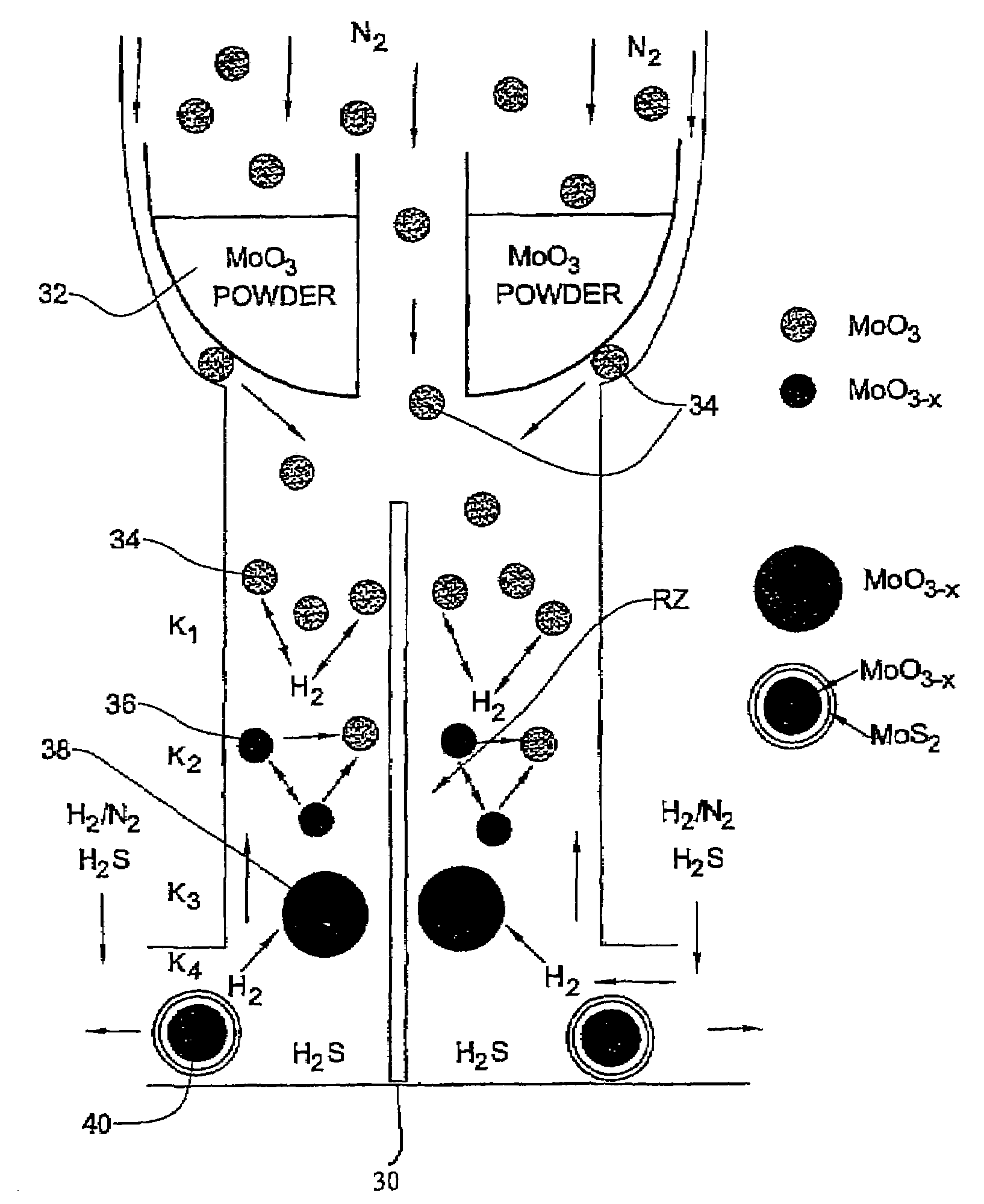

Method and apparatus for producing inorganic fullerene-like nanoparticles

InactiveUS7018606B2Easy to produceMaterial nanotechnologyNanostructure manufactureNanoparticleGas phase

A process and apparatus are presented for obtaining inorganic fullerene-like nanostructures. A metal oxide is evaporated at predetermined temperature conditions, and is swept towards a reacting zone, to which first and second gas phase reacting agents are concurrently swept. The evaporated metal oxide thus interacts with the first reacting agent and is converted into metal suboxide nanoparticles in the gas phase. The condensing metal suboxide nanoparticles interact with the second reacting agent in the gas phase resulting in substantially pure phase of the inorganic fullerene-like nanoparticles.

Owner:YEDA RES & DEV CO LTD

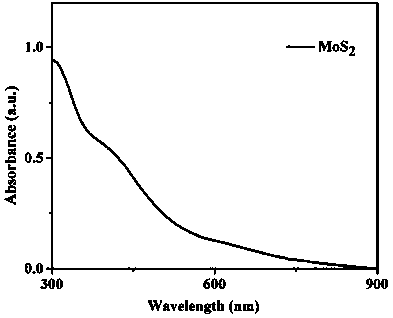

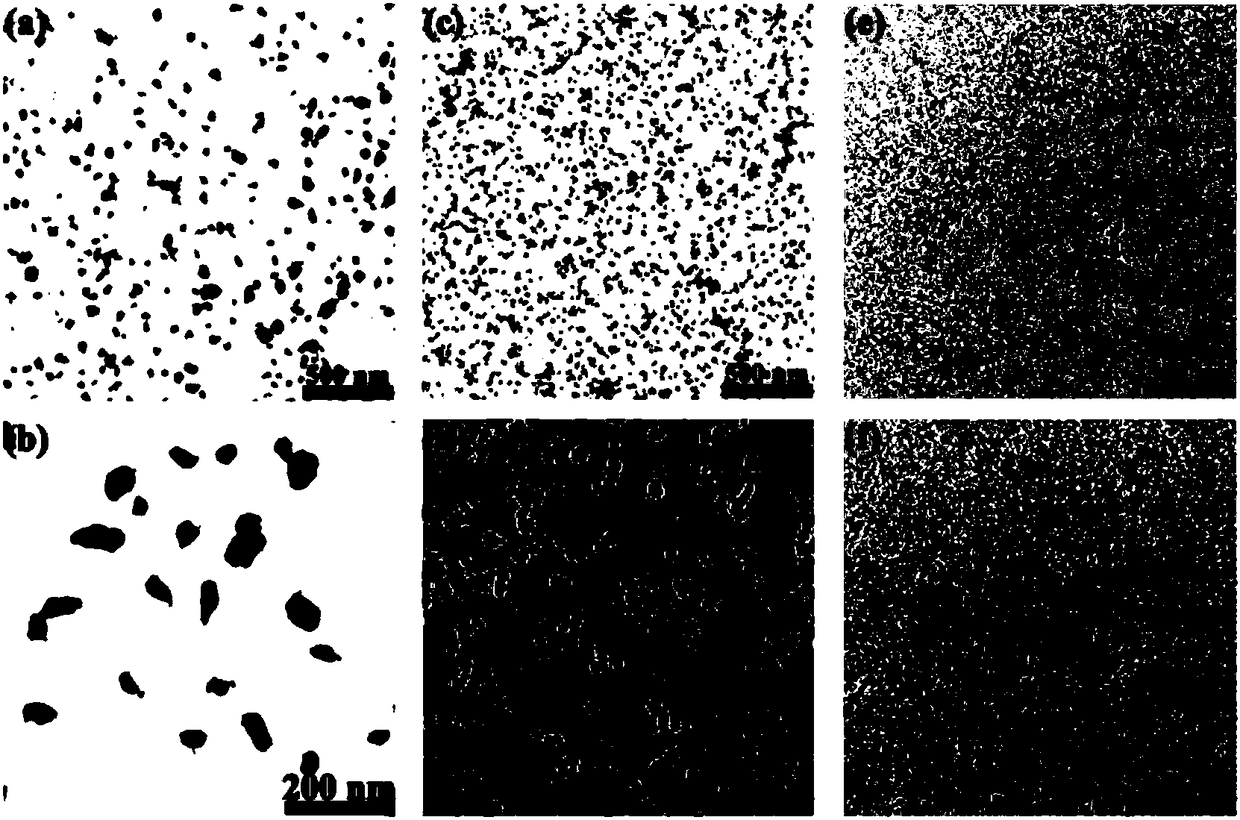

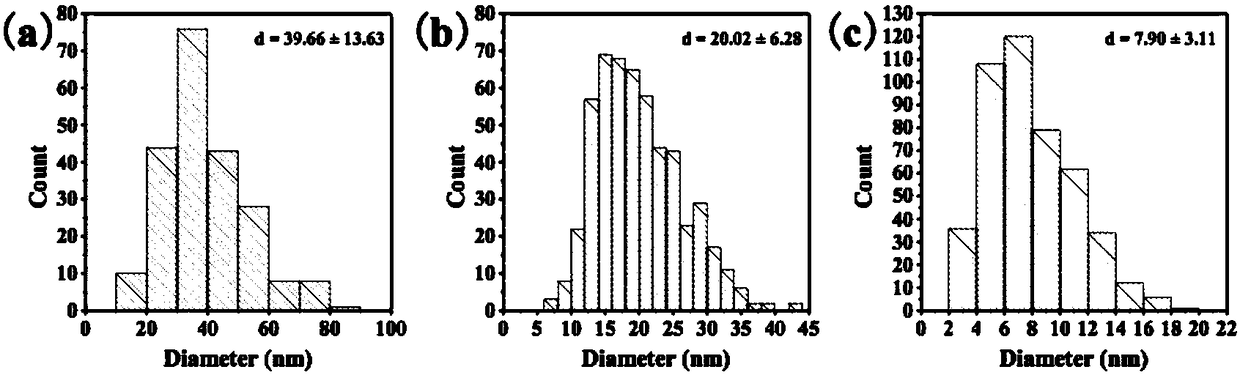

Preparation method of small-size transition metal chalcogenide two-dimensional nanosheet

ActiveCN108423642AHigh yieldAvoid reunionMaterial nanotechnologyMolybdenum sulfidesPolymer scienceGradient centrifugation

The invention relates to a preparation method of a small-size transition metal chalcogenide two-dimensional nanosheet. The method is characterized in that the powder of a block is treated as a raw material; a polymer is used as an additive, and polymer assistant ball milling is performed to obtain transition metal chalcogenide two-dimensional nanosheets with different sizes and different components. The method comprises three steps of weighing high polymers and polymer assistant ball milling prepared blocky powder; performing ball milling, separating, water adding, uniformly mixing and movingout; performing gradient centrifugation to obtain products with different sizes; purifying to remove excessive polymers. With the adoption of the method, the problems such as low yield, non-uniform appearance and complex processes of a current preparation method of a current small-size transition metal chalcogenide two-dimensional nanosheet can be solved; the method has the advantages of being high in yield, simple in processes, high in generality, easy to control processes,and the like; the prepared small-size transition metal chalcogenide two-dimensional nanosheet can be applied to differentfields, such as the fields of catalyzing, photoelectric and biomedicines.

Owner:NANJING UNIV OF POSTS & TELECOMM

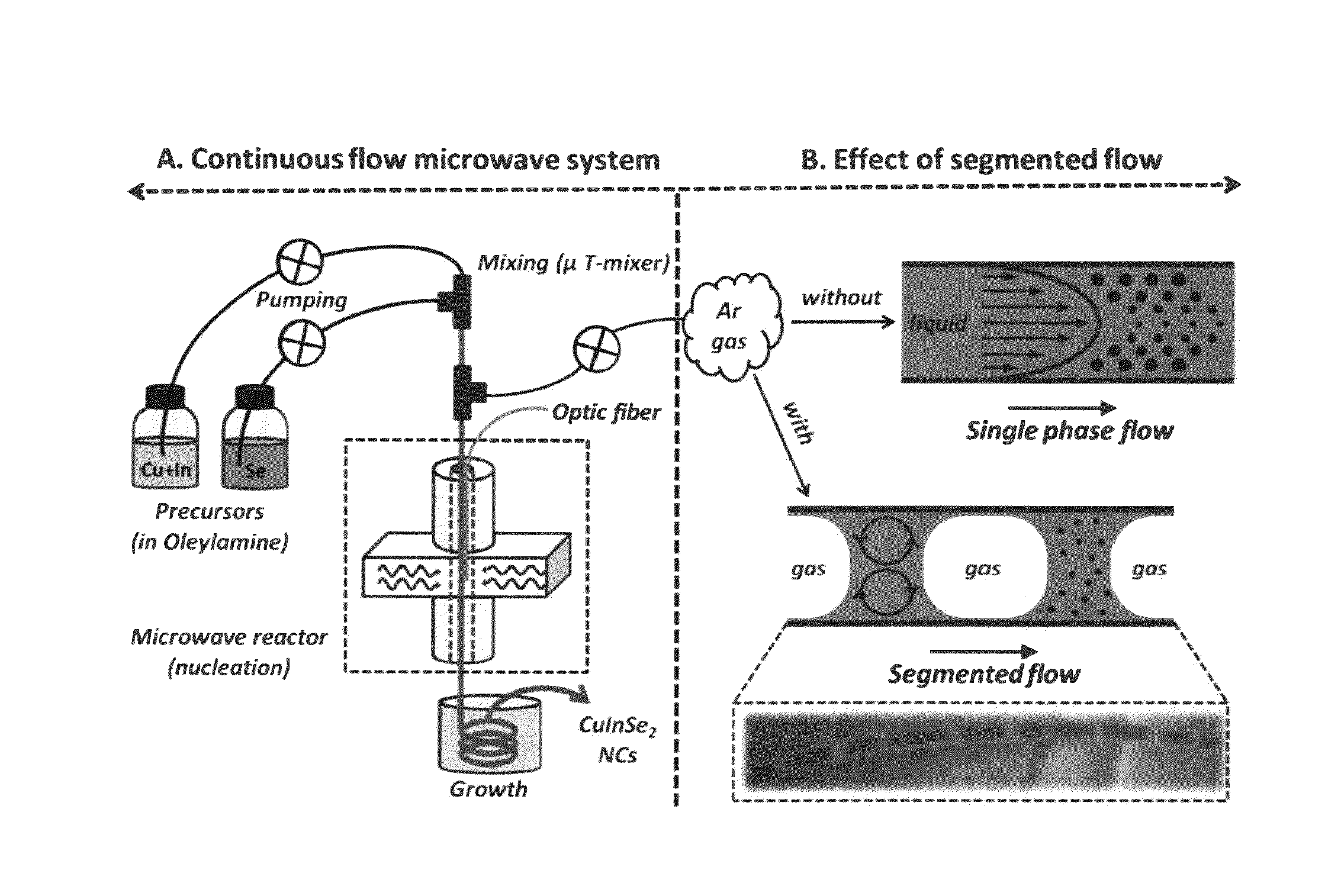

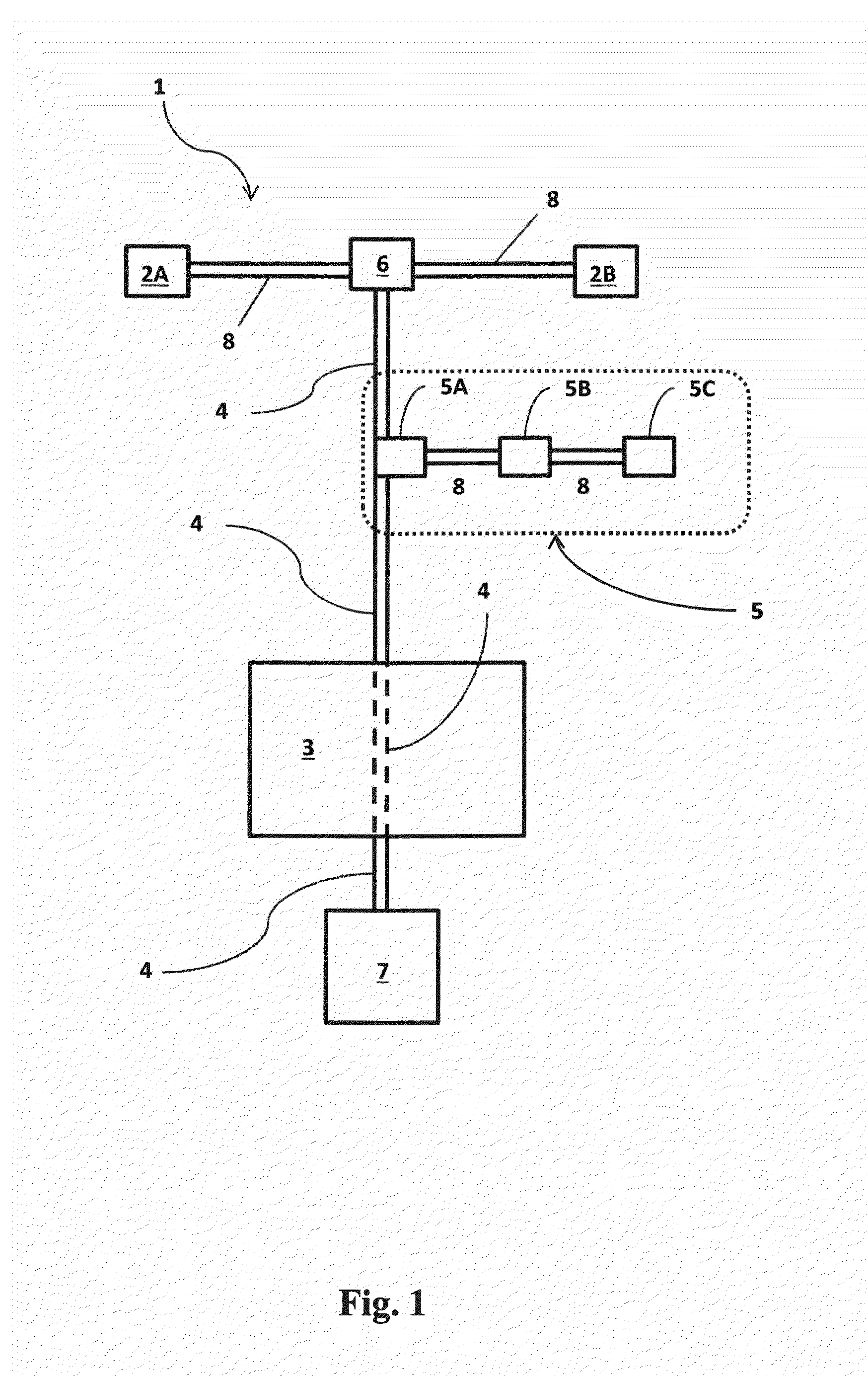

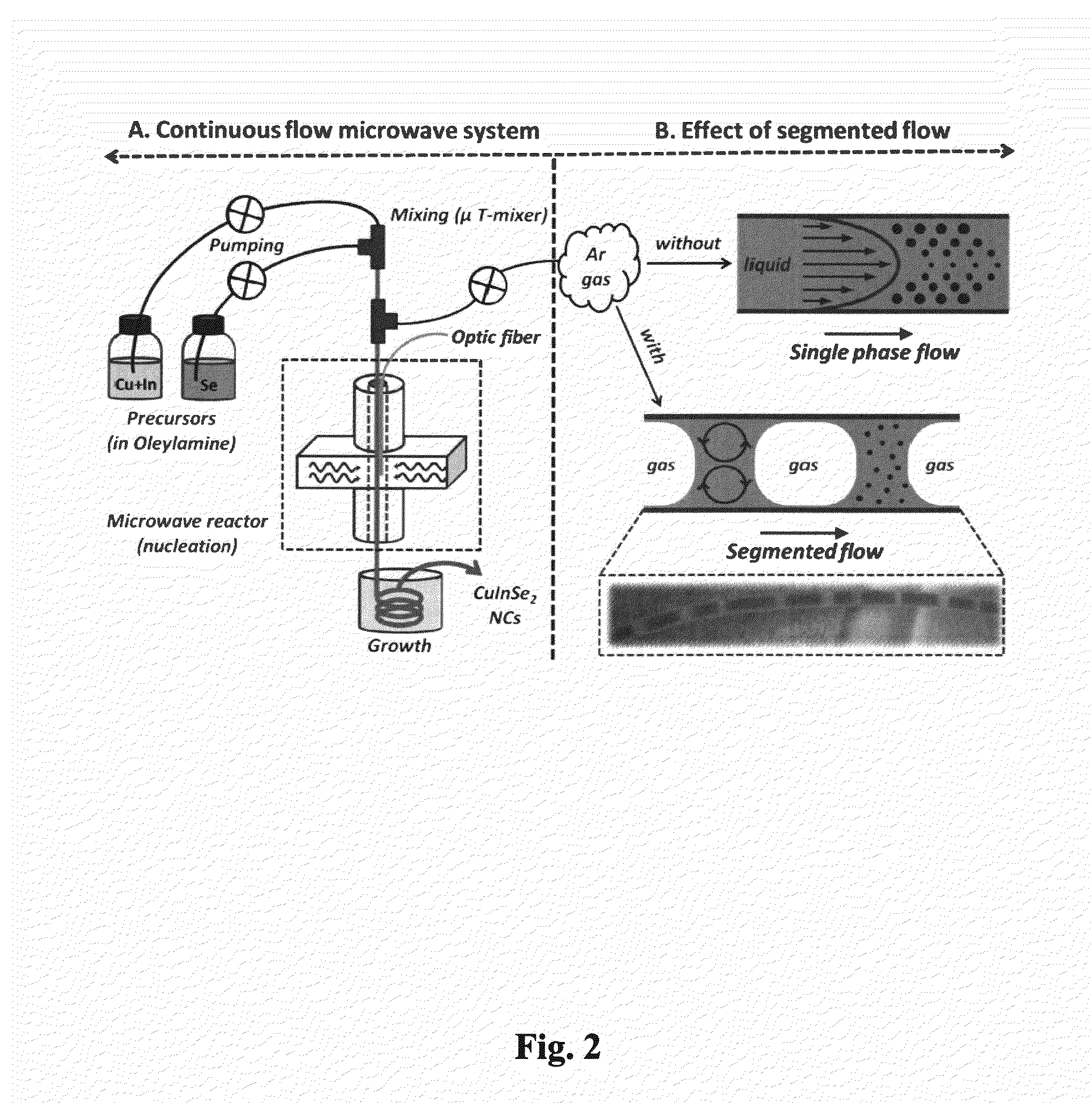

Continuous microwave-assisted segmented flow reactor for high-quality nanocrystal synthesis

ActiveUS20150182936A1Quality improvementTin compoundsPhosphorus sulfur/selenium/tellurium compoundsProcess engineeringContinuous flow

Systems and methods for synthesizing high-quality nanocrystals via segmented, continuous flow microwave-assisted reactor were developed.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

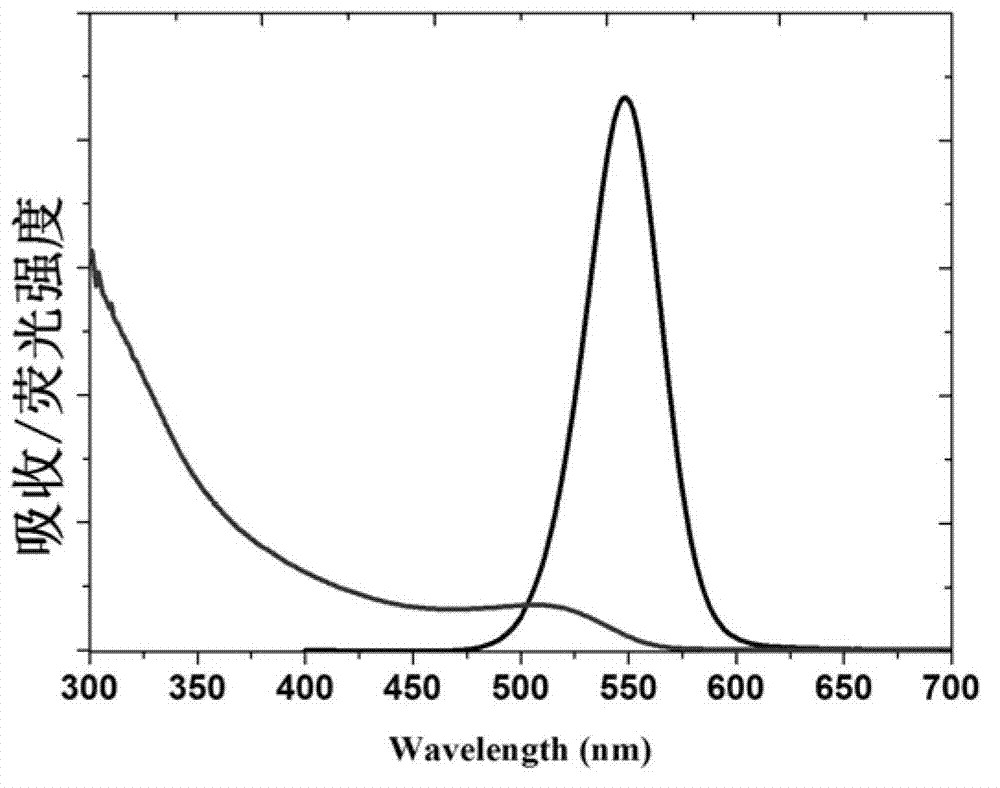

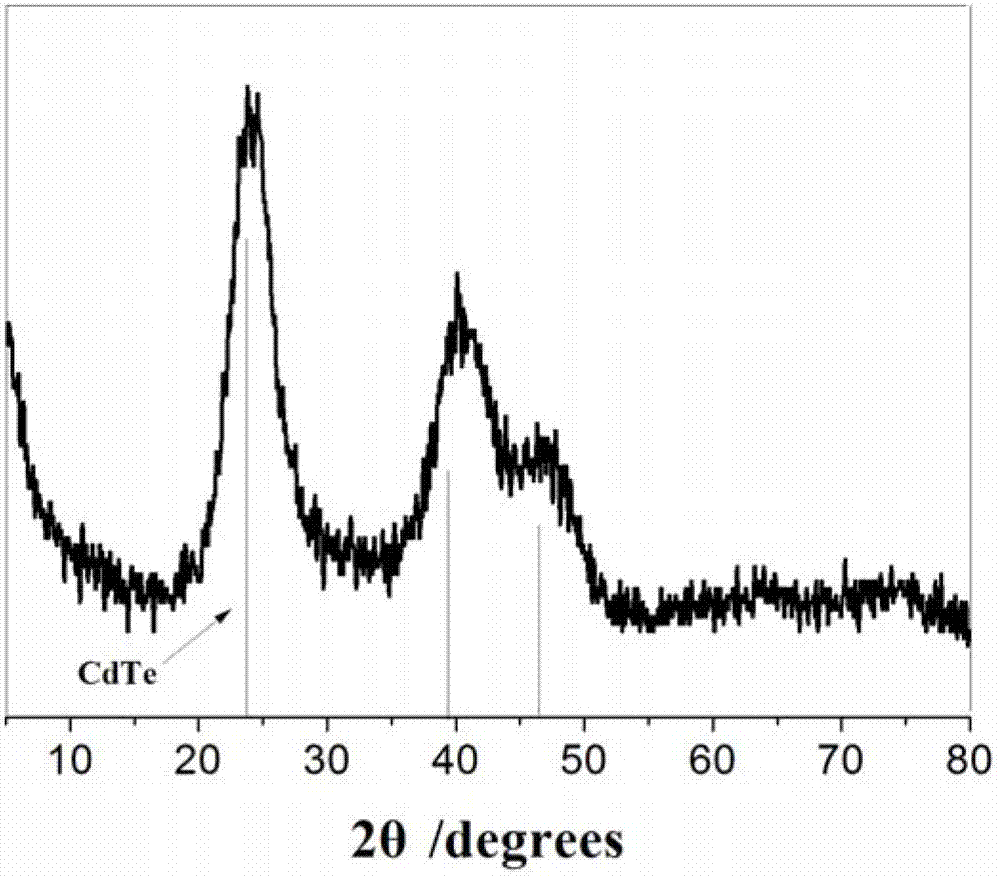

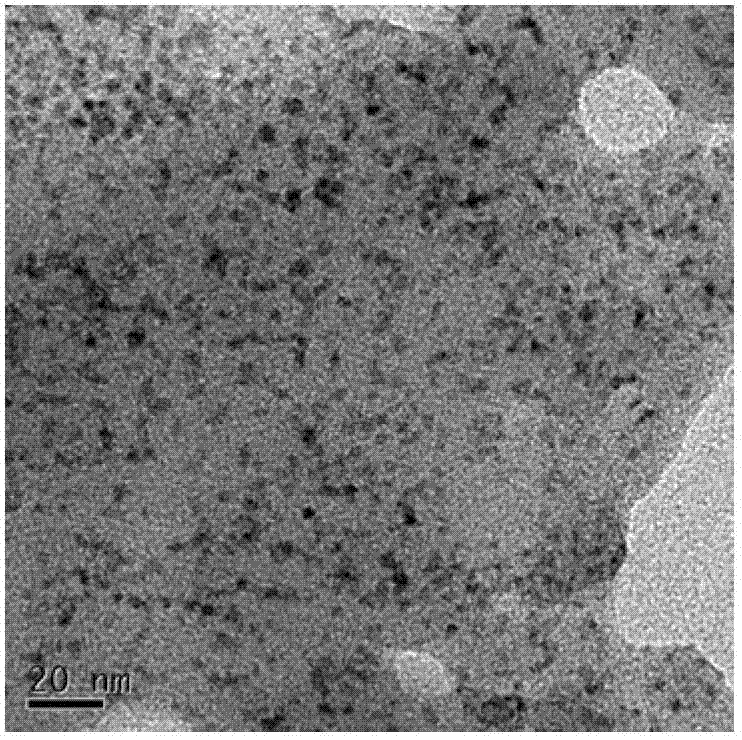

CdX quantum dot and preparation method thereof

InactiveCN102786037AGood water solubilityHigh quantum yieldLuminescent compositionsBinary selenium/tellurium compoundsQuantum yieldHydrazine compound

The present invention relates to a method for preparing a CdX (X= Se or Te) quantum dot nano material with high quantum yield in an aqueous phase by using simple operation conditions, and belongs to the field of nano material preparation. The preparation method does not require nitrogen as a protective gas, or a buffer solution, or a particular ligand, or a large amount of hydrazine hydrate as a reducing agent, or a special post-treatment. In the aqueous phase, a thiol compound is used as a ligand; cadmium salt and potassium tellurite (selenite) are selected respectively as a cadmium source and a tellurium (selenium) source; and sodium borohydride is used as a reducing agent. The water-soluble CdTe (CdSe) quantum dot with quantum yield up to 83% can be prepared from a one-pot reaction.

Owner:DALIAN UNIV OF TECH

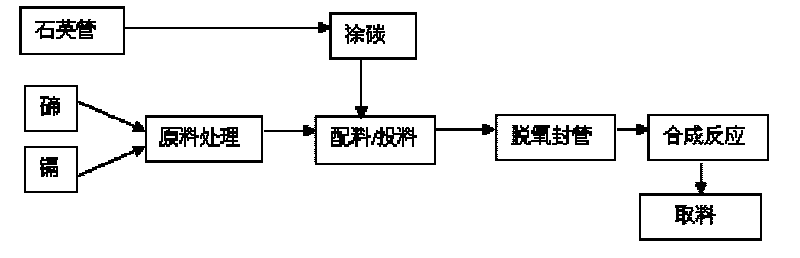

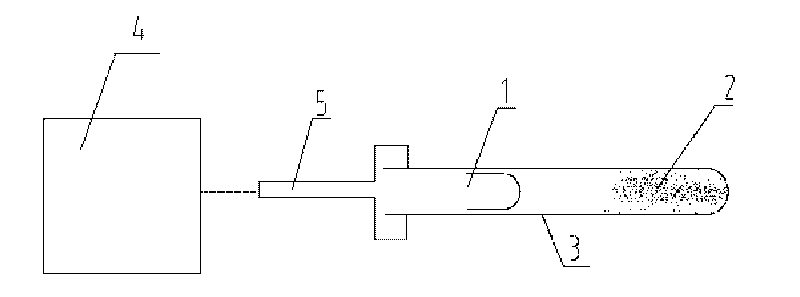

Method for preparing high-purity cadmium telluride

ActiveCN101734630AAvoid direct contactEvenly meltedBinary selenium/tellurium compoundsMolten stateMass ratio

The invention discloses a method for preparing high-purity cadmium telluride. The reaction process is carried out in a closed quartz tube with melting point above cadmium and tellurium and after carbon coating treatment, wherein the mass ratio of a 5N cadmium material to a 5N tellurium material is 1: 1.1-1.15. The method comprises the following steps: dividing the weighed tellurium material into N parts according to the charging times N, dividing the weighed cadmium material into N-1 parts, alternately adding each part of tellurium material and each part of cadmium material into the quartz tube and adding the tellurium material into the quartz tube firstly and lastly, removing oxygen after charging, sintering and sealing the tube by using a sealed bulb, and slowly performing high-temperature and high-pressure synthetic reaction. The method has the advantages that the contact area of the raw materials is larger in a molten state, the reaction speed is more sufficient compared with the solid raw material, the micro-sized crushing treatment for the raw materials is avoided, the shape requirement of the raw materials is relaxed, the preparation cost is greatly reduced, the purity of the raw material is ensured, the method is suitable for large-scale production, the synthetic conversion rate of the cadmium telluride can reach 98 to 99.5 percent, and the single-tube yield of 800 to 1,000 grams can be ensured by using the quartz tube with the inside diameter of 32 millimeters under the premise of safety.

Owner:中国东方电气集团有限公司

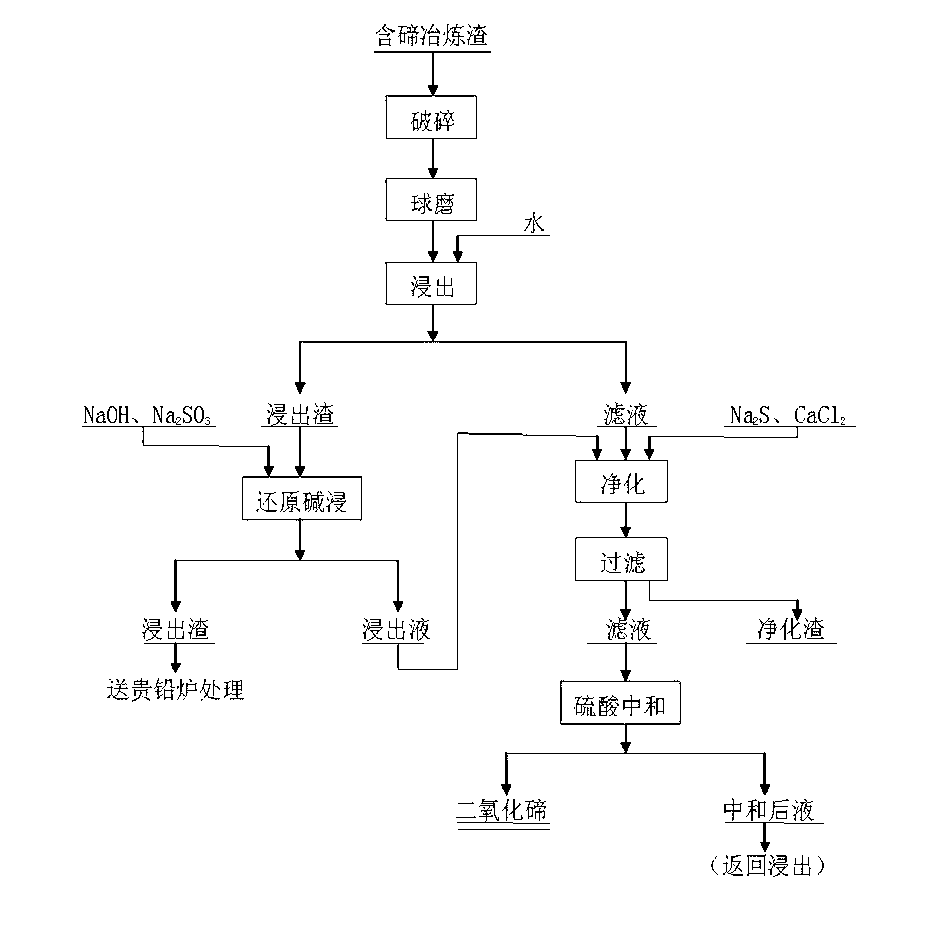

Technology for extracting tellurium dioxide from tellurium-containing smelting slag

ActiveCN102992280AImprove leaching rateReduce dosageWaste processingSolid waste disposalSlagMaterials science

The invention relates to a technology for extracting tellurium dioxide from tellurium-containing smelting slag. The technology comprises the following steps: ball-milling tellurium slag, leaching by water, carrying out reduction alkali leaching, vulcanizing, carrying out silicon removal purification, and neutralizing to precipitate tellurium. The method has the advantages of tellurium leaching rate improvement, reduction of the alkali application amount in the leaching operation, and production cost reduction. The method is characterized in that sodium hydrosulphite is adopted as a transition agent to transit insoluble high-valence tellurium to low-valence tellurium, so the leaching rate leaching rate is increased. The total tellurium leaching rate can reach above 90% under a suitable technological condition; and after recovering tellurium through neutralizing, the TeO2 grade of the smelting slag can reach above 50%, and the content of tellurium in the waste liquid obtained after the neutralizing is 0.1-0.3g / L. The method also has the advantages of further enrichment of copper, lead, bismuth, antimony and precious metals in the leaching slag, realization of the resource reuse, production cost reduction, and energy saving, and is of great importance to the resource recovery and the environmental protection.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com