Patents

Literature

361 results about "Bismuth telluride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth telluride (Bi₂Te₃) is a gray powder that is a compound of bismuth and tellurium also known as bismuth(III) telluride. It is a semiconductor, which, when alloyed with antimony or selenium, is an efficient thermoelectric material for refrigeration or portable power generation. Bi₂Te₃ is a topological insulator, and thus exhibits thickness-dependent physical properties.

Homogeneous thermoelectric nanocomposite using core-shell nanoparticles

ActiveUS20080087314A1Uniform and improved thermoelectricThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideSilicon dioxide

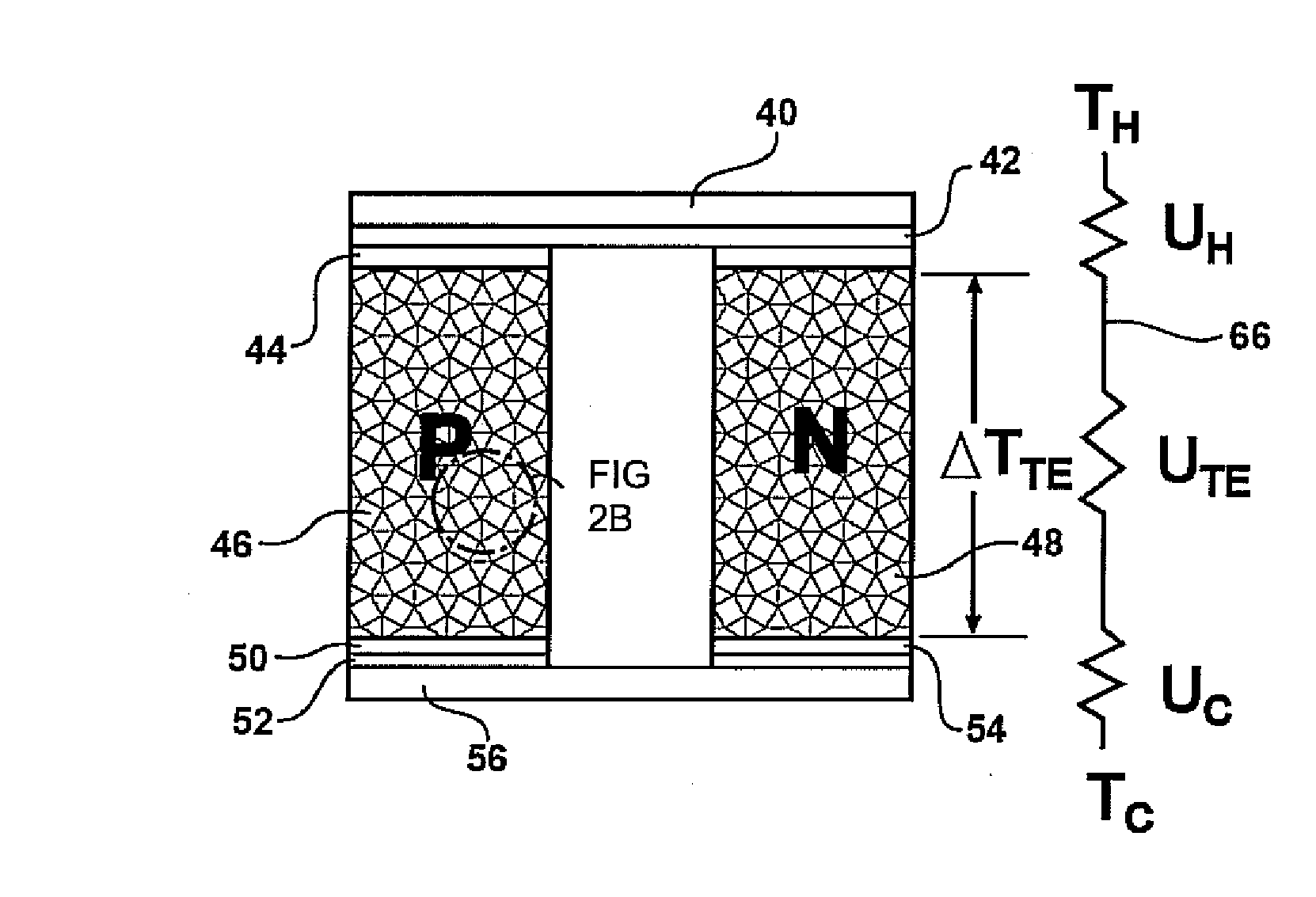

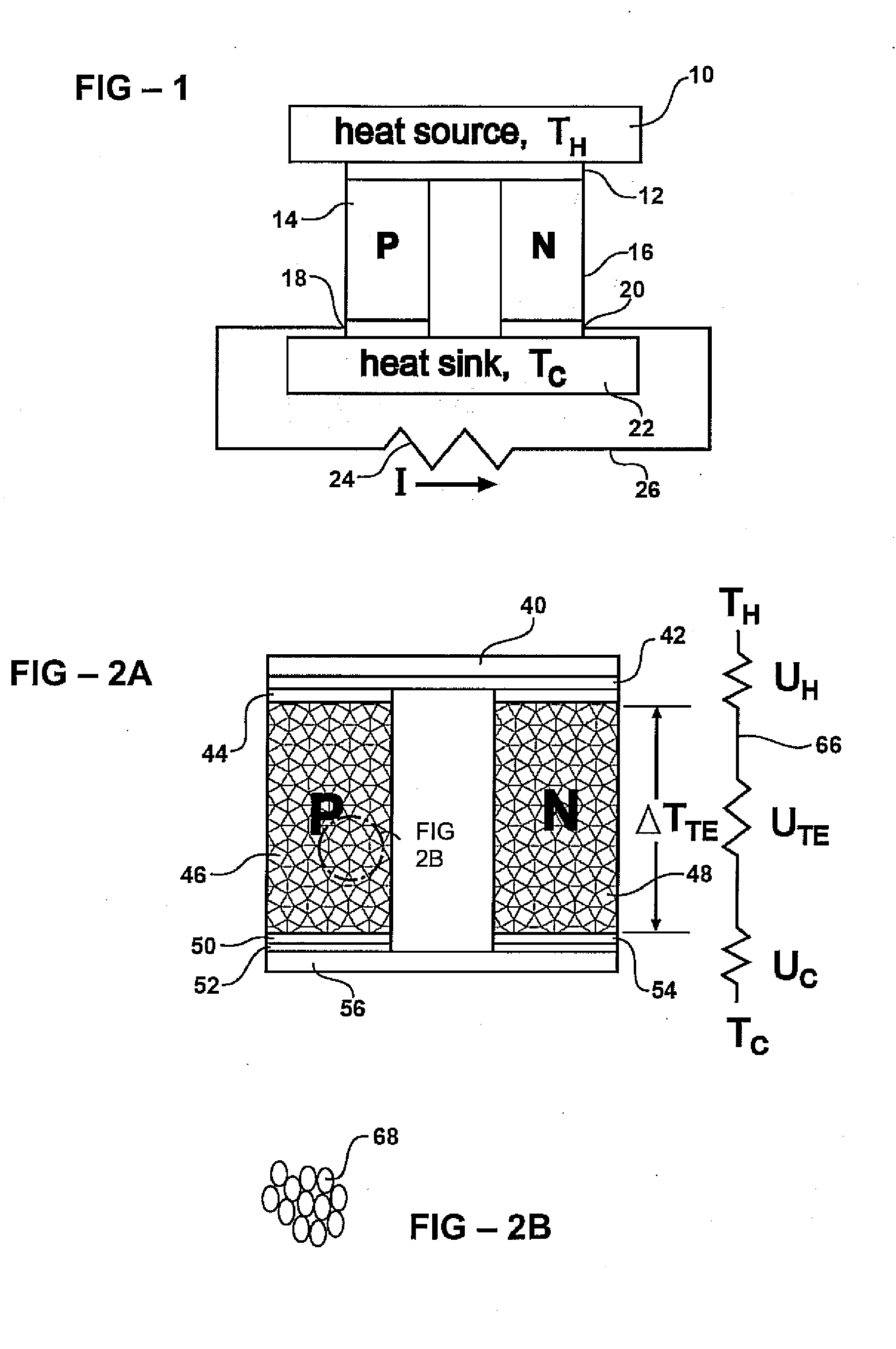

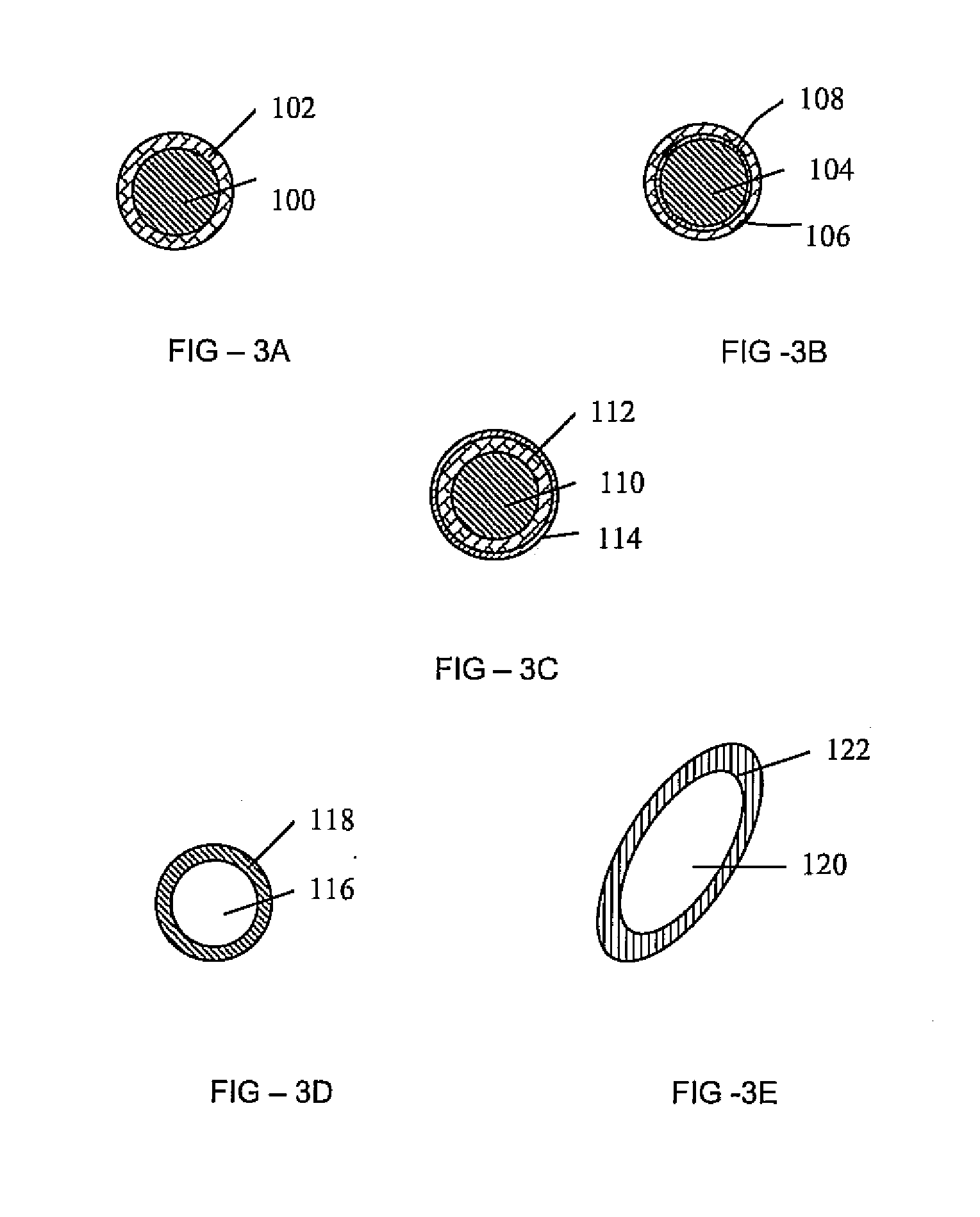

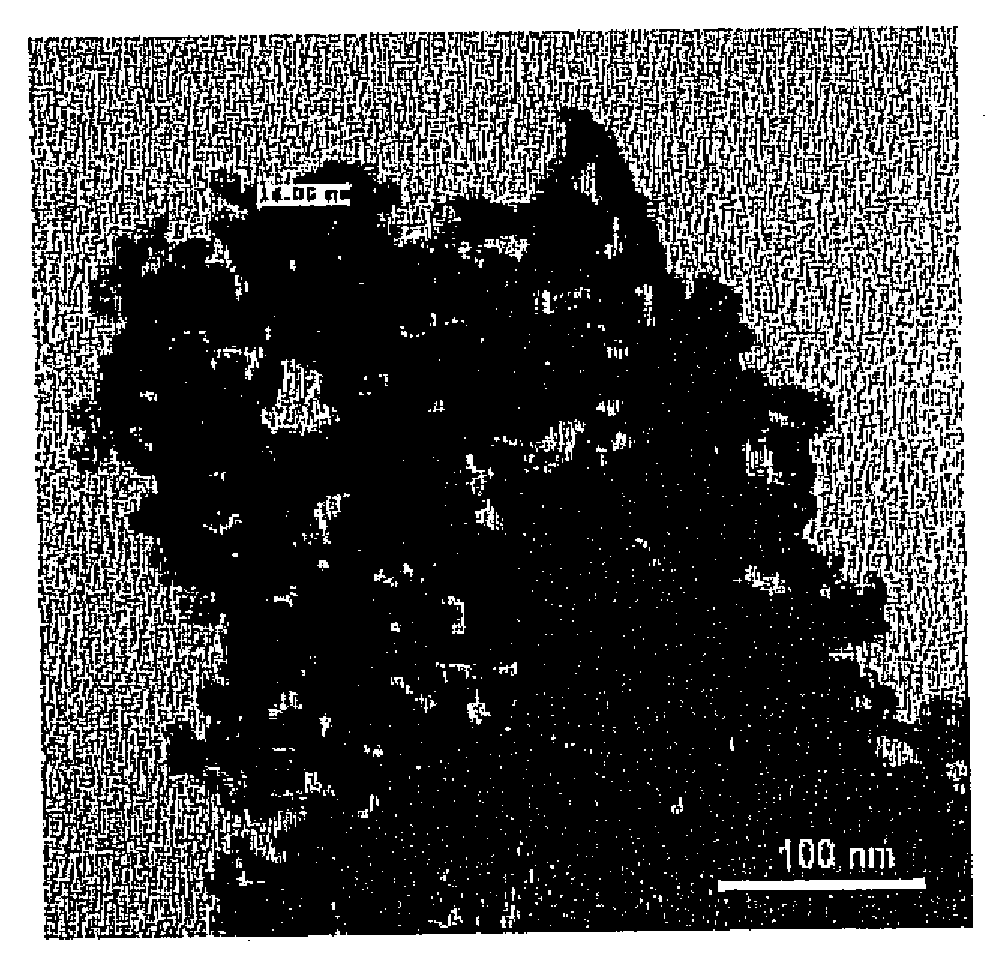

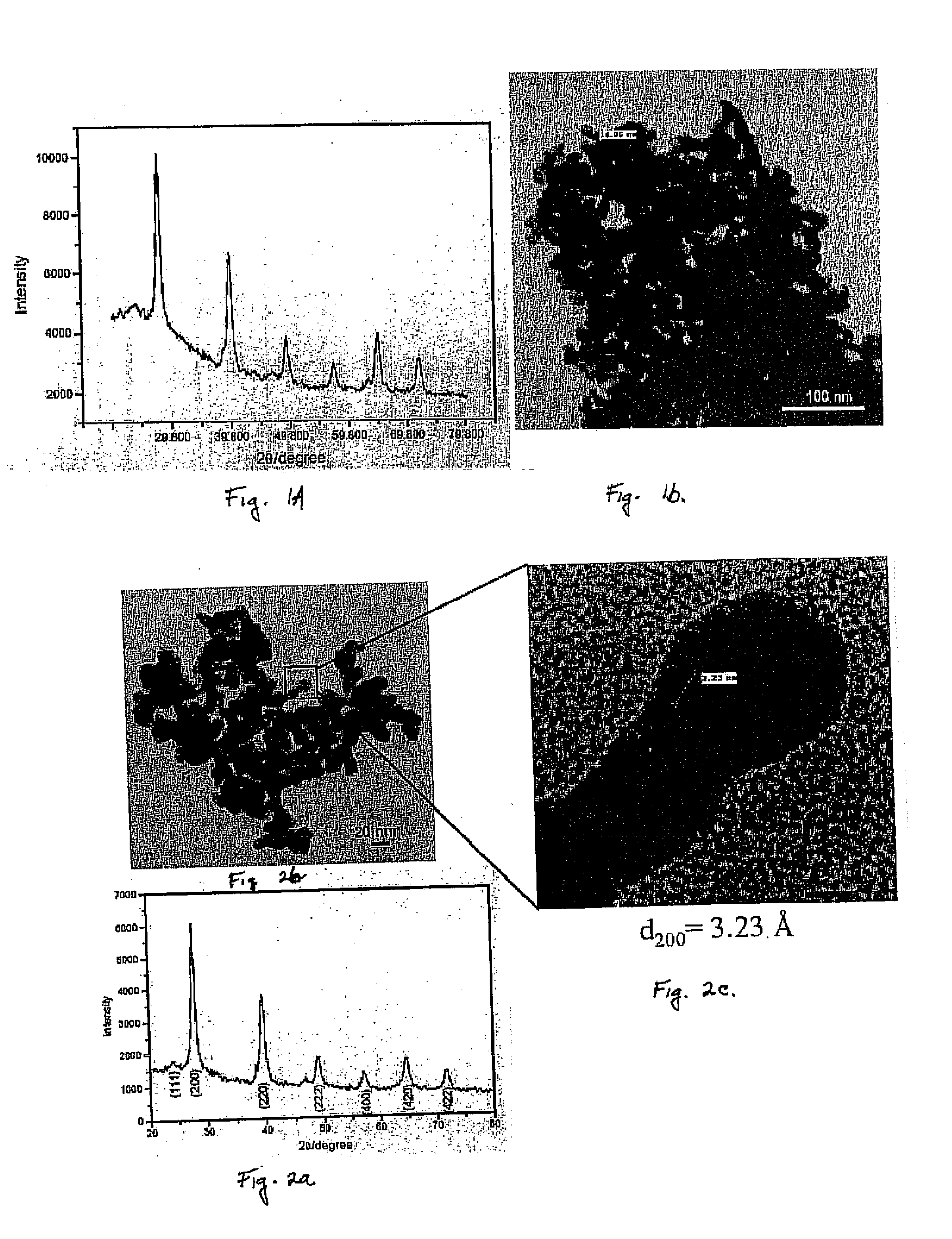

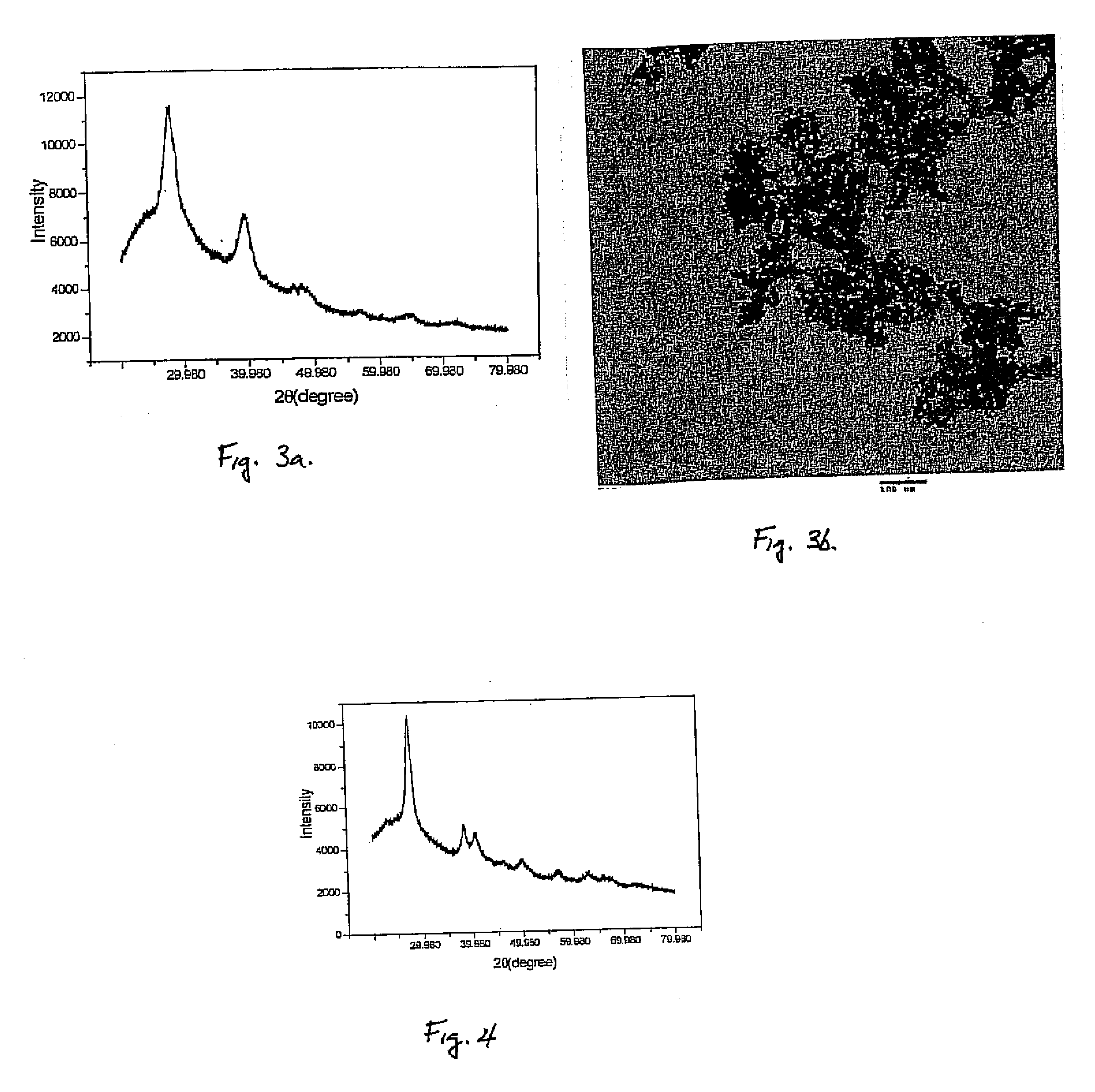

A thermoelectric material comprises core-shell particles having a core formed from a core material and a shell formed from a shell material. In representative examples, the shell material is a material showing an appreciable thermoelectric effect in bulk. The core material preferably has a lower thermal conductivity than the shell material. In representative examples, the core material is an inorganic oxide such as silica or alumina, and the shell material is a chalcogenide semiconductor such as a telluride, for example bismuth telluride. A thermoelectric material including such core-shell particles may have an improved thermoelectric figure of merit compared with a bulk sample of the shell material alone. Embodiments of the invention further include thermoelectric devices using such thermoelectric materials, and preparation techniques. The use of core-shell nanoparticles allows highly uniform nanocomposites to be formed, and embodiments of the invention also includes other materials and devices using core-shell particles.

Owner:TOYOTA MOTOR CO LTD +1

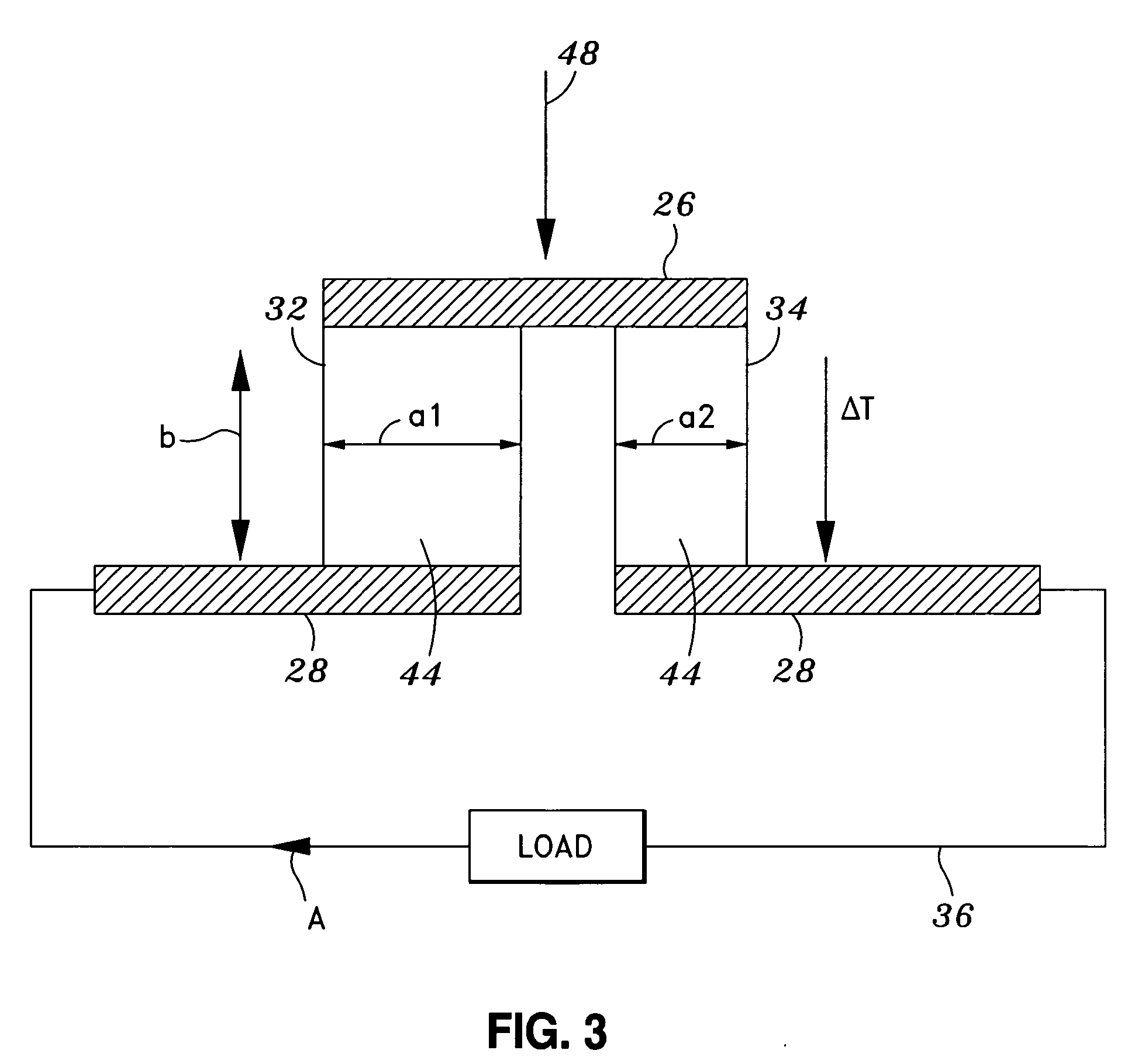

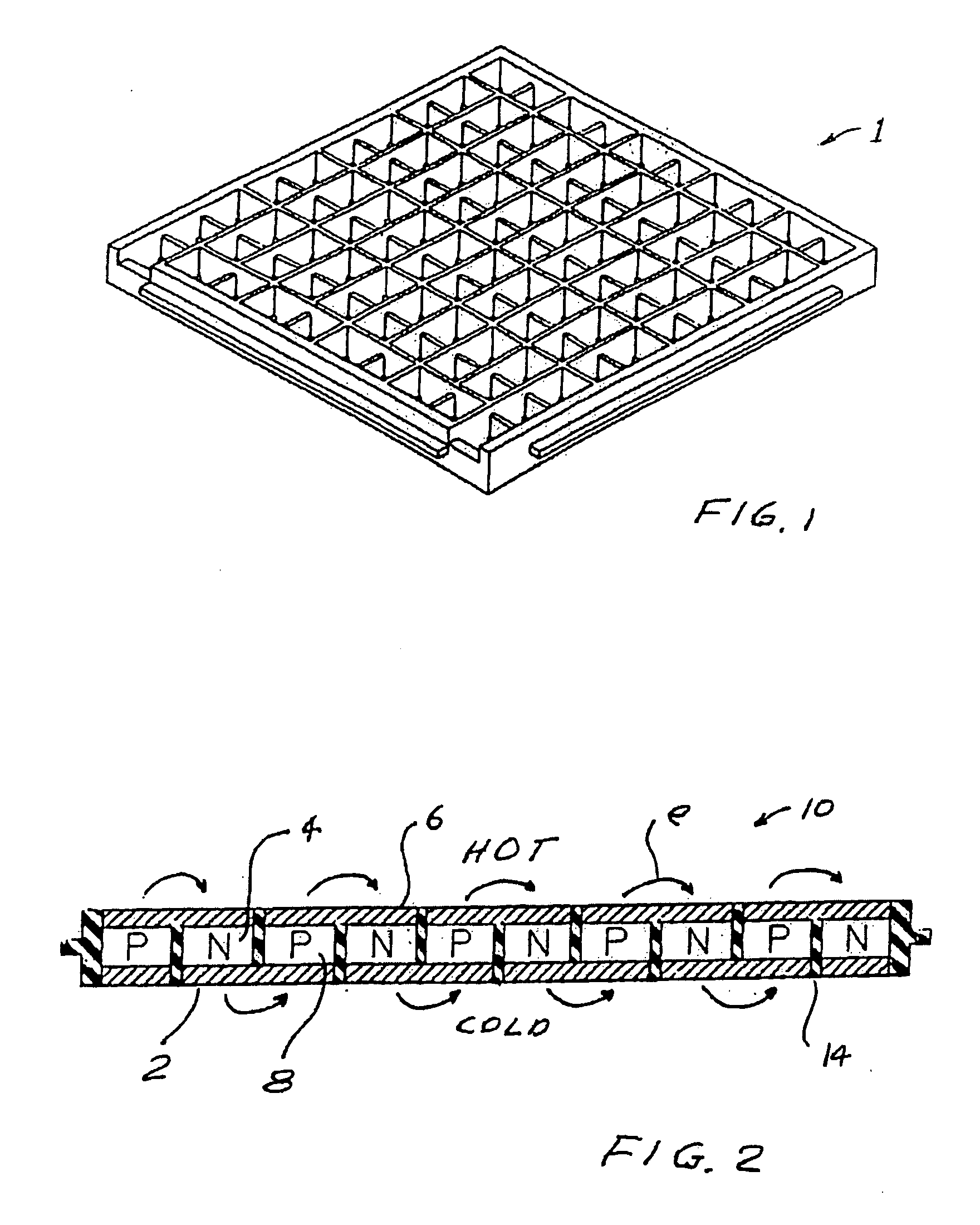

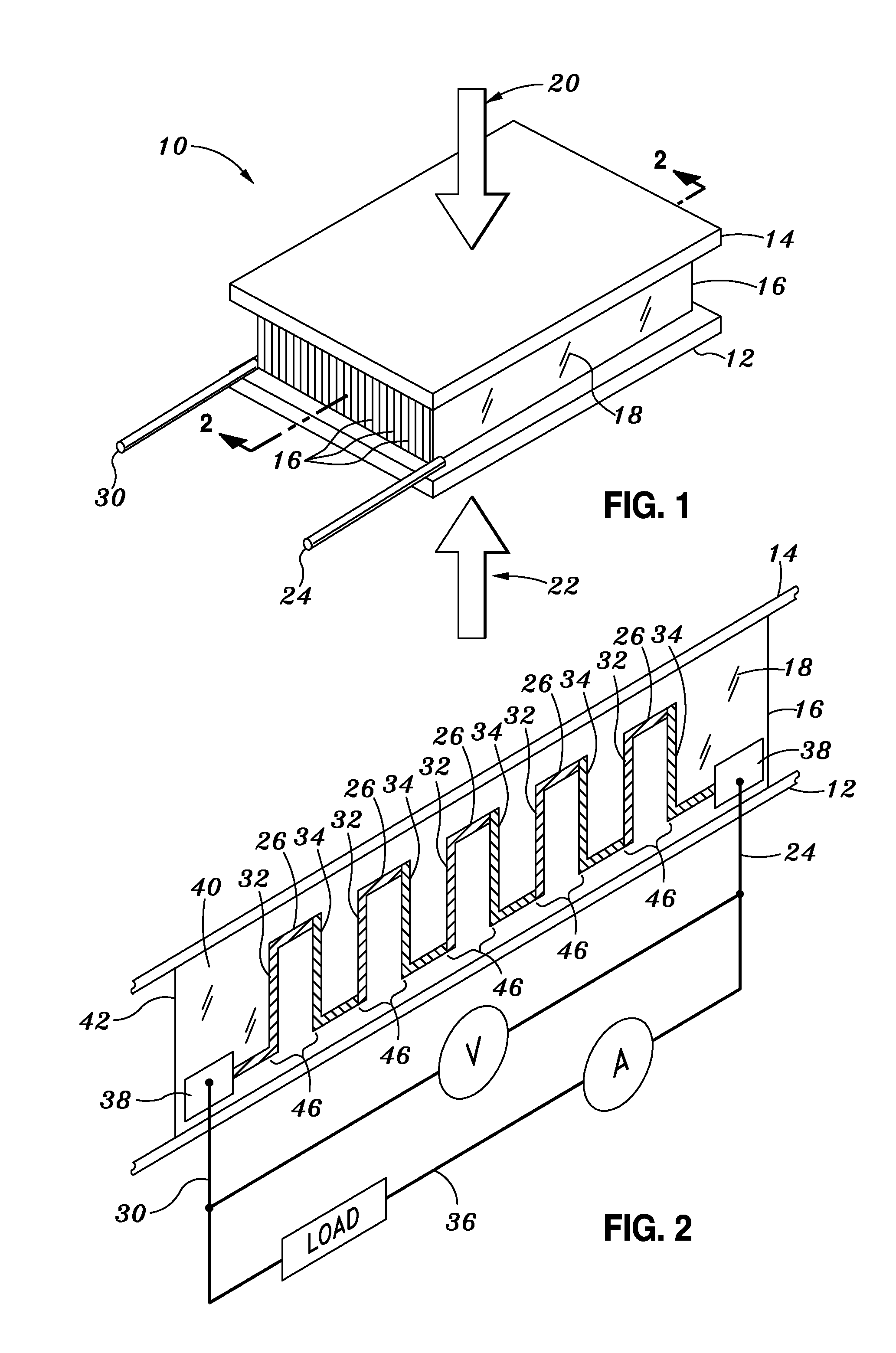

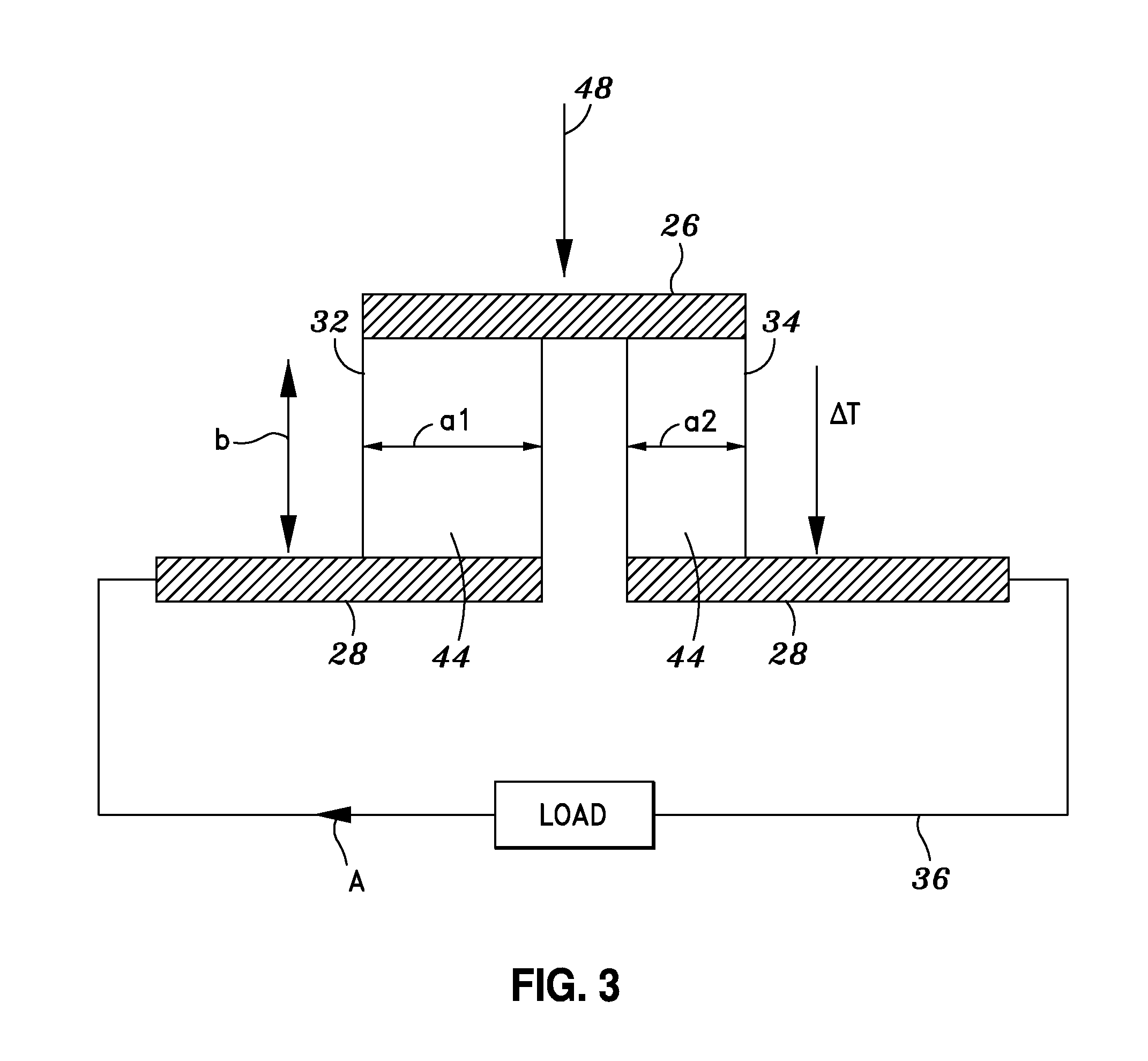

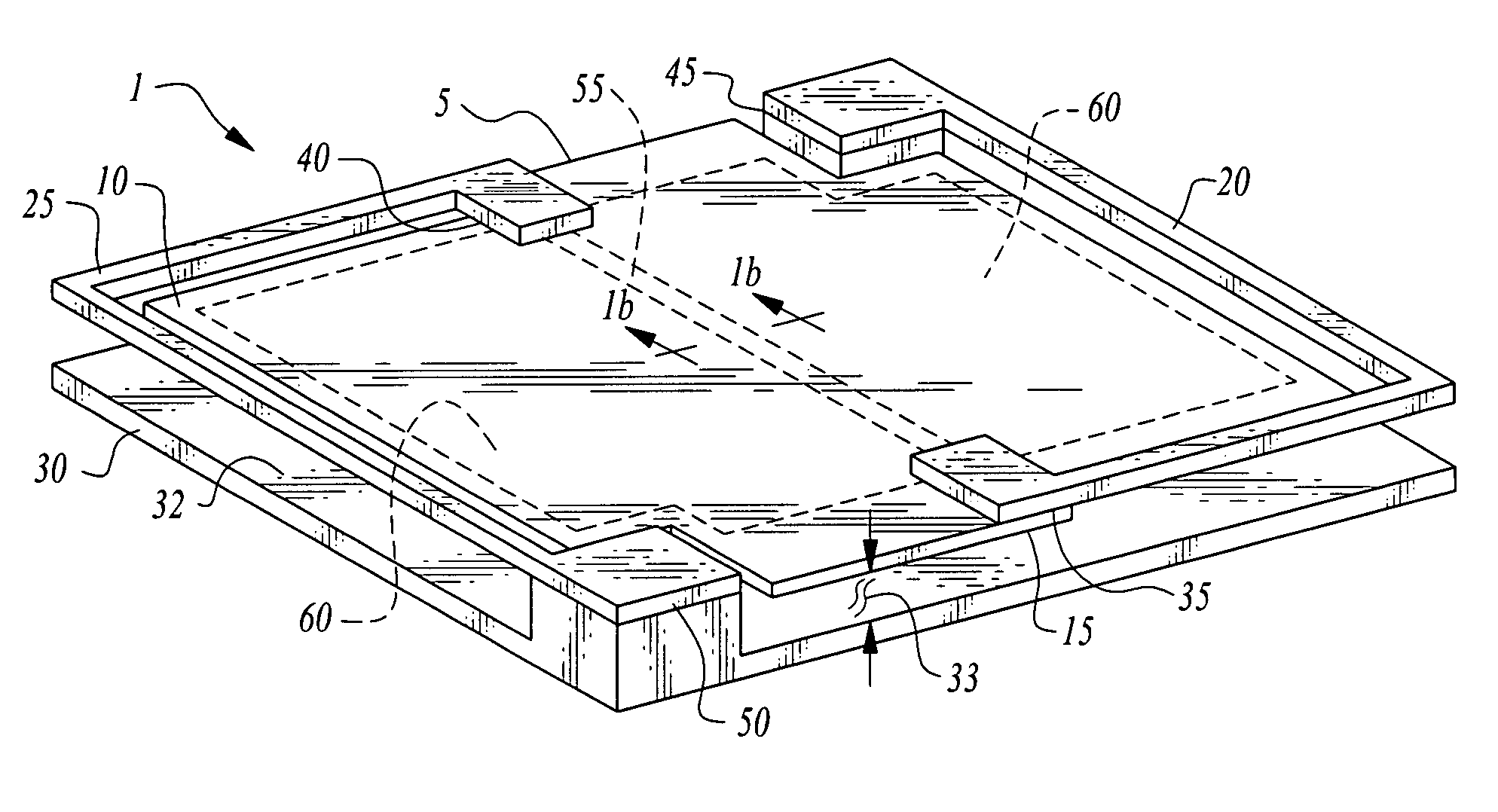

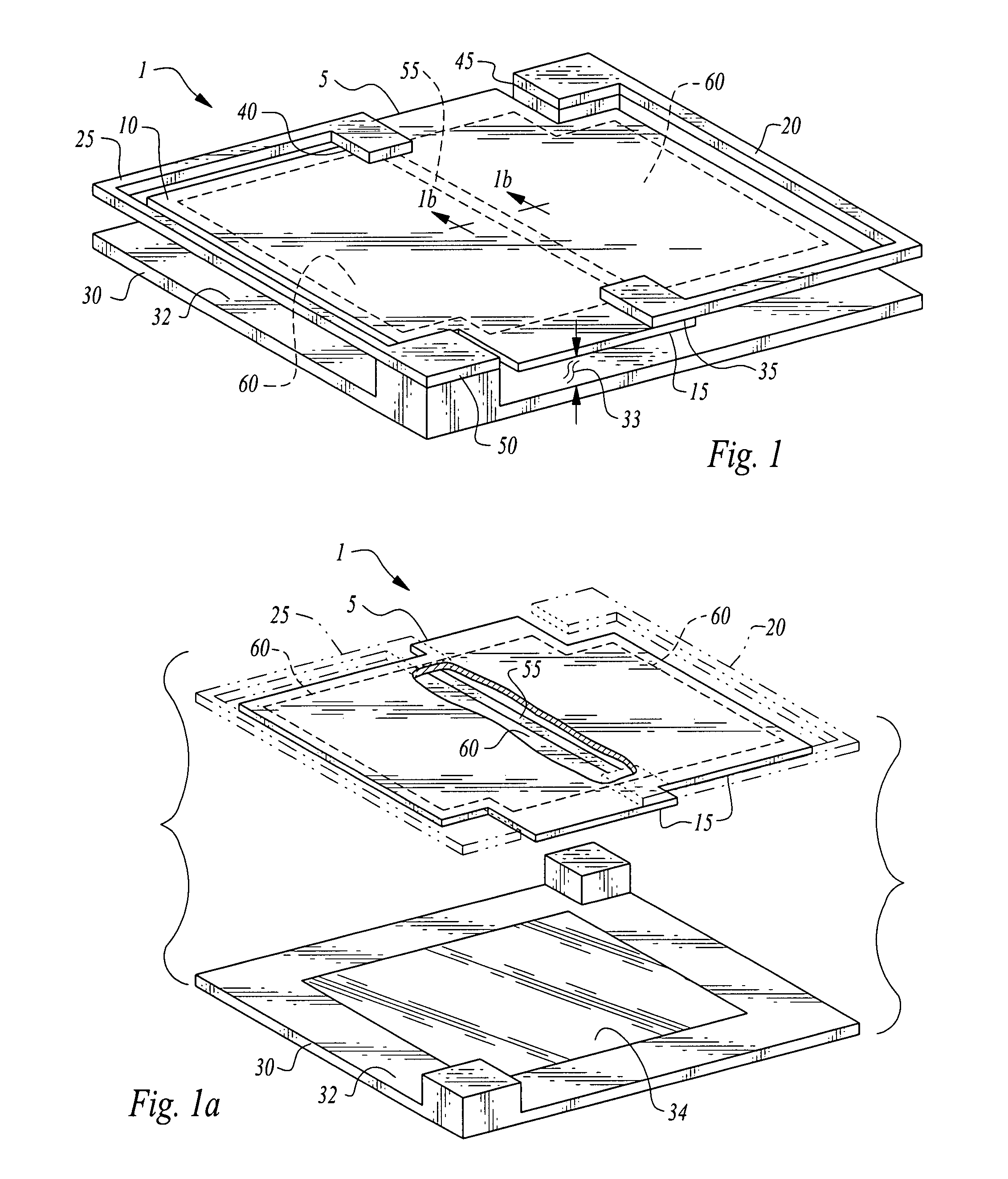

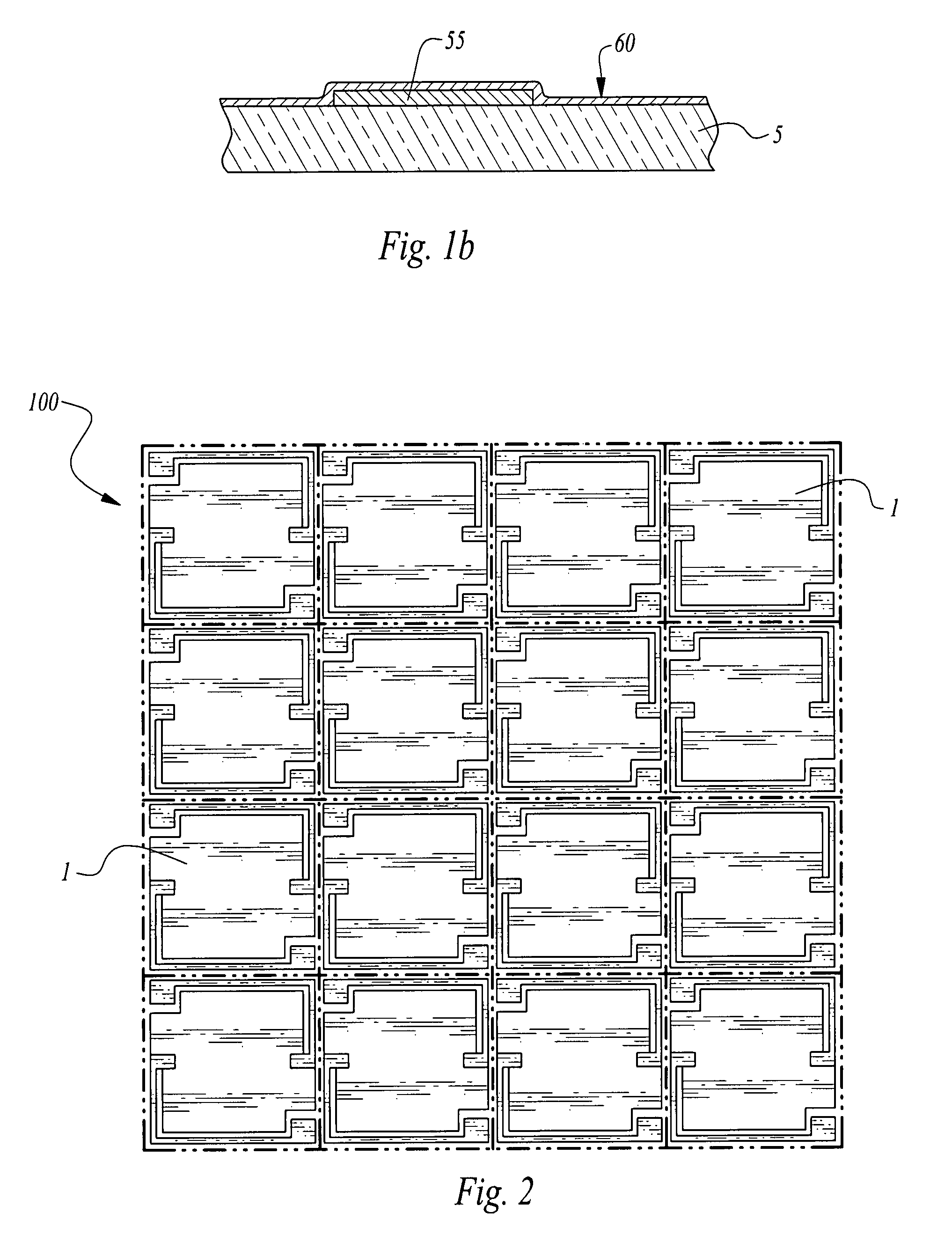

Low power thermoelectric generator

InactiveUS20060151021A1Improve thermoelectric performanceEnhance fabricationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideEngineering

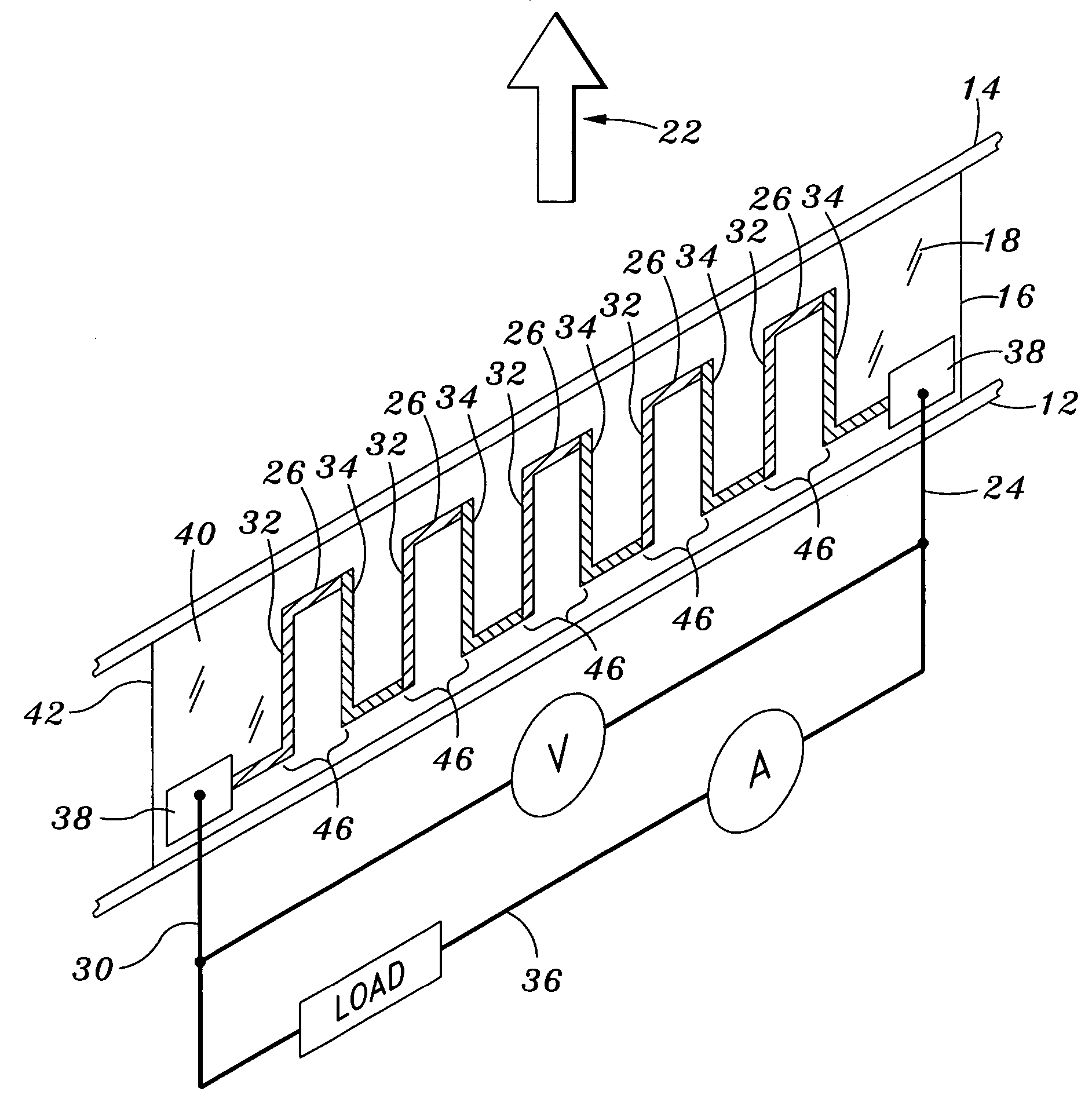

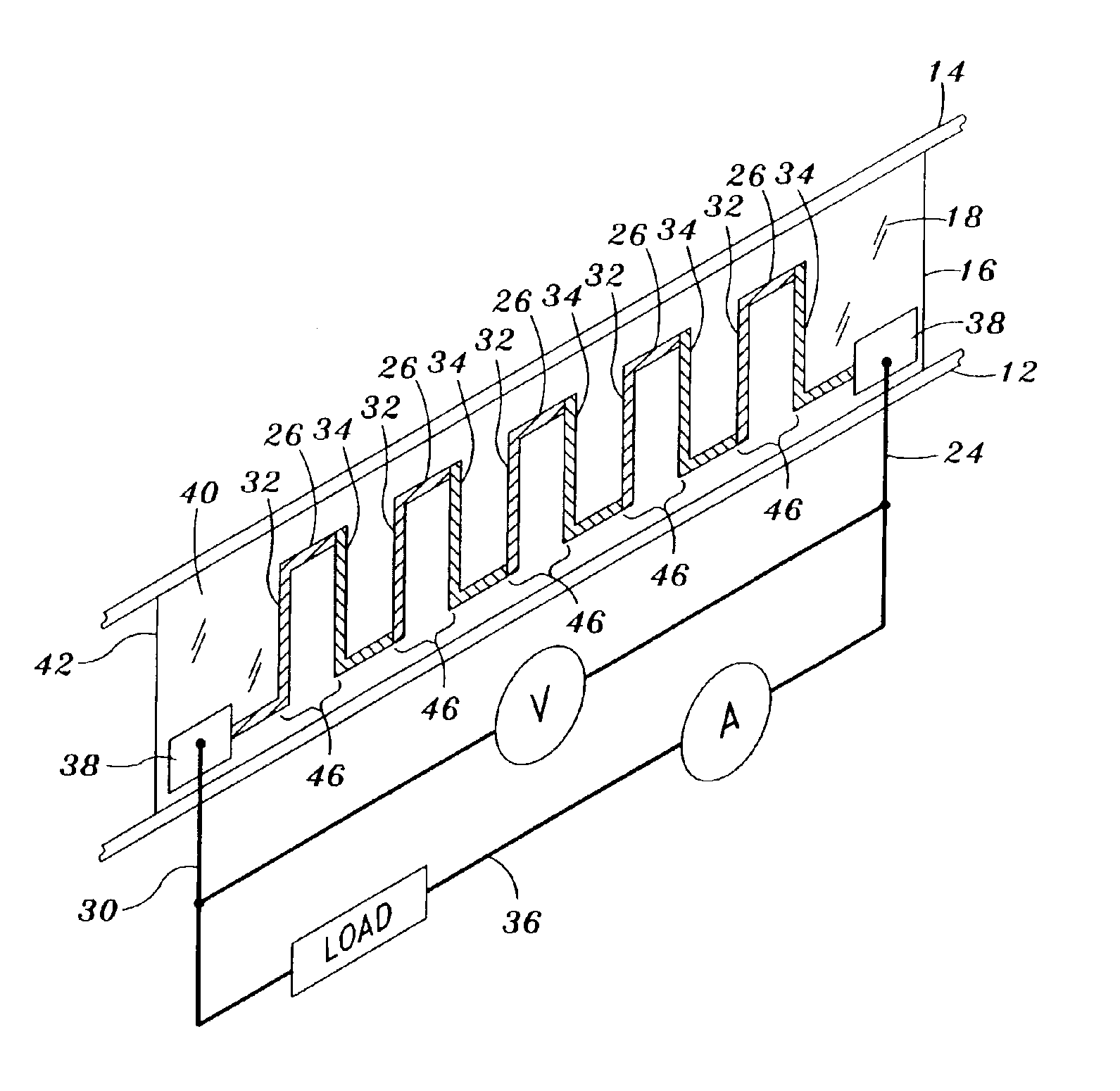

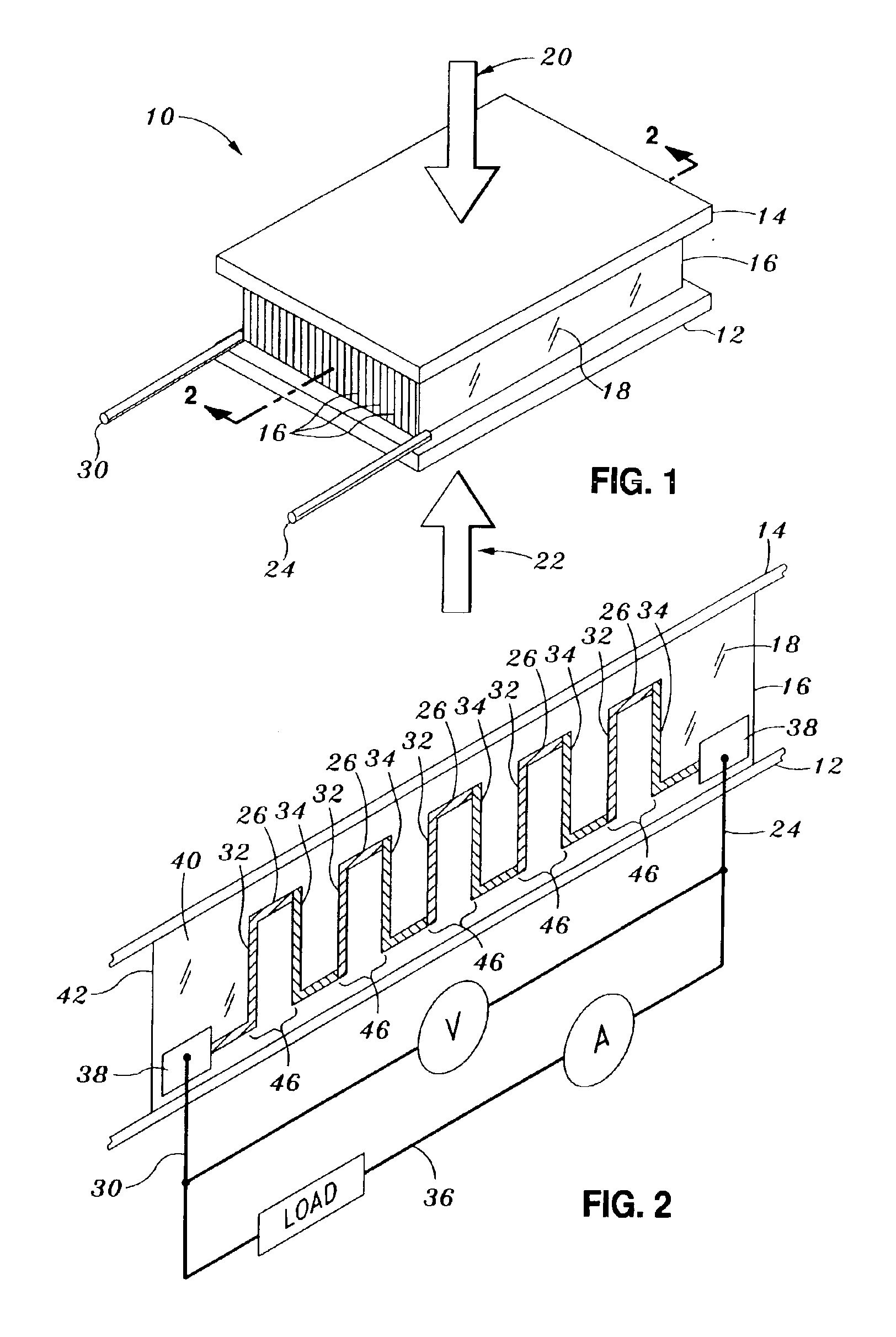

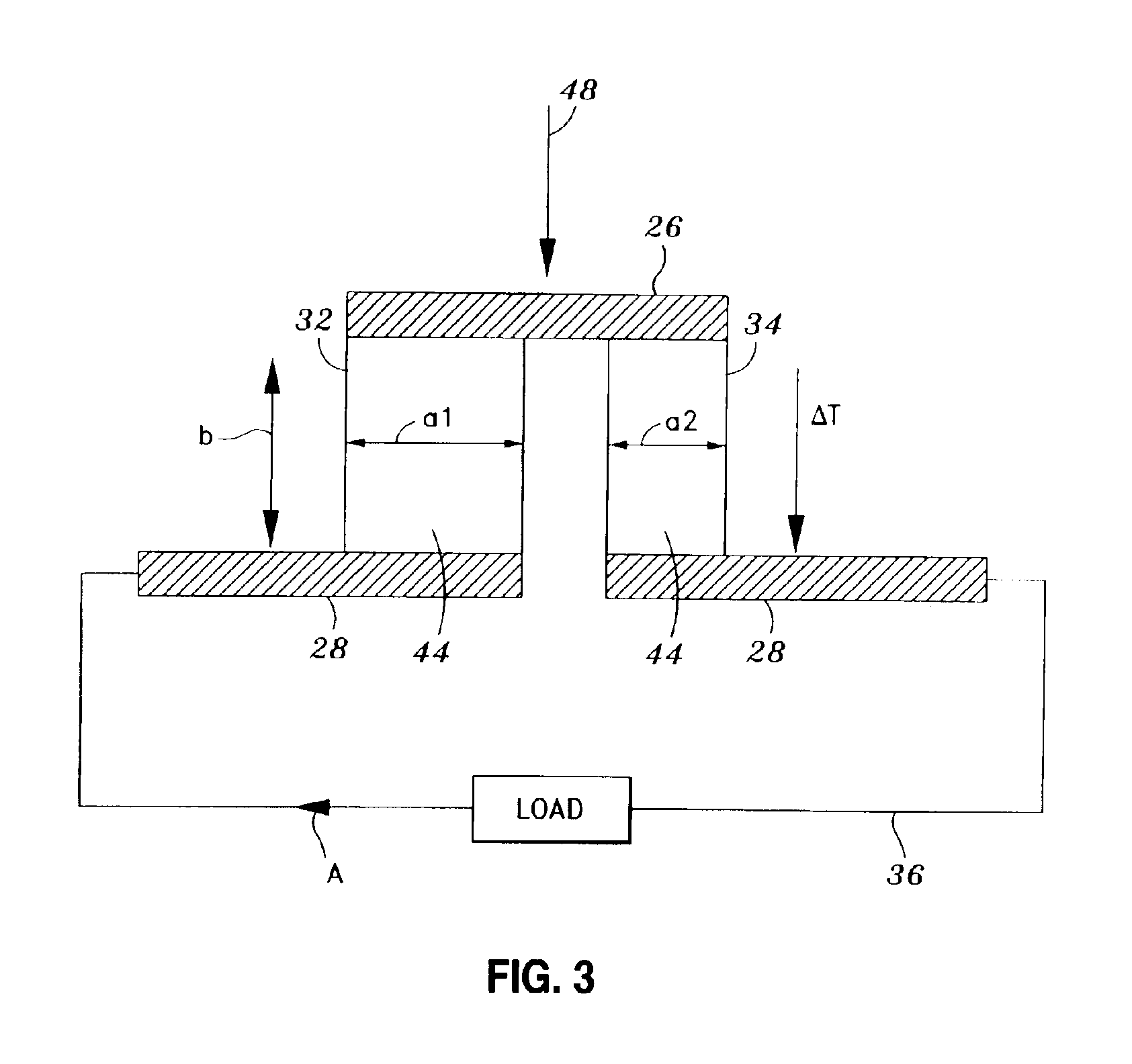

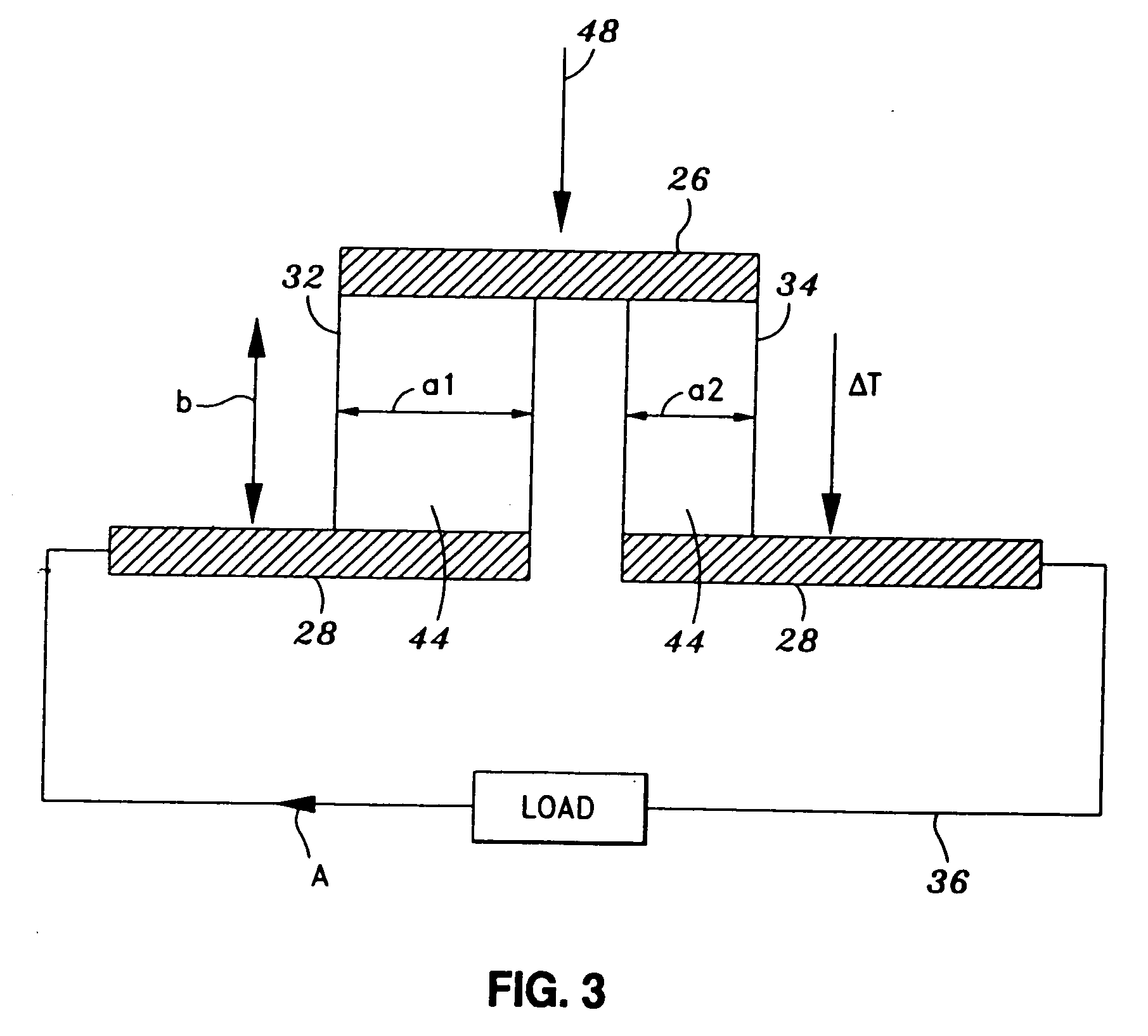

A thermoelectric generator has a top plate disposed in spaced relation above a bottom plate. A series of foil segments are electrically and mechanically connected end-to-end to generate a foil assembly that is spirally wound and in thermal contact with the bottom and top plates. Each foil segment comprises a substrate having a series of spaced alternating n-type and p-type thermoelectric legs disposed in parallel arrangement on the front substrate surface. Each of the n-type and p-type legs is formed of a bismuth telluride-based thermoelectric material having a thickness of about 10-100 microns, a width of about 10-100 microns and a length of about 100-500 microns. The alternating n-type and p-type thermoelectric legs are electrically connected in series and thermally connected in parallel such that a temperature differential between the bottom and top plates results in the generation of power.

Owner:DIGITAL ANGEL CORP

Large format thermoelectric infrared detector and method of fabrication

ActiveUS20100031992A1Promote absorptionSimple structureThermoelectric device with peltier/seeback effectSemiconductor/solid-state device manufacturingNano compositesBismuth telluride

The thermoelectric detector consists of an absorber structure supported by two electrically connected beams made of thermoelectric materials such as polysilicon, polysilicon / germanium, bismuth-telluride, skutterrides, superlattice structures, nano-composites and other materials. One end of the thermoelectric beam connects to the absorber structure; the other end connects to the substrate. Infrared radiation incident on the absorber heats up the absorber, resulting in a temperature gradient along the length of the thermoelectric legs, and generating an electrical voltage. The detector arrays are fabricated using micromachining process. The absorber structure is formed over a sacrificial material that is removed at the end of the processing, leaving the detector suspended and thermally isolated. The sacrificial processing method enables the production of small pixel thermoelectric detectors in large two-dimensional arrays with high sensitivity.

Owner:NYTELL SOFTWARE LLC

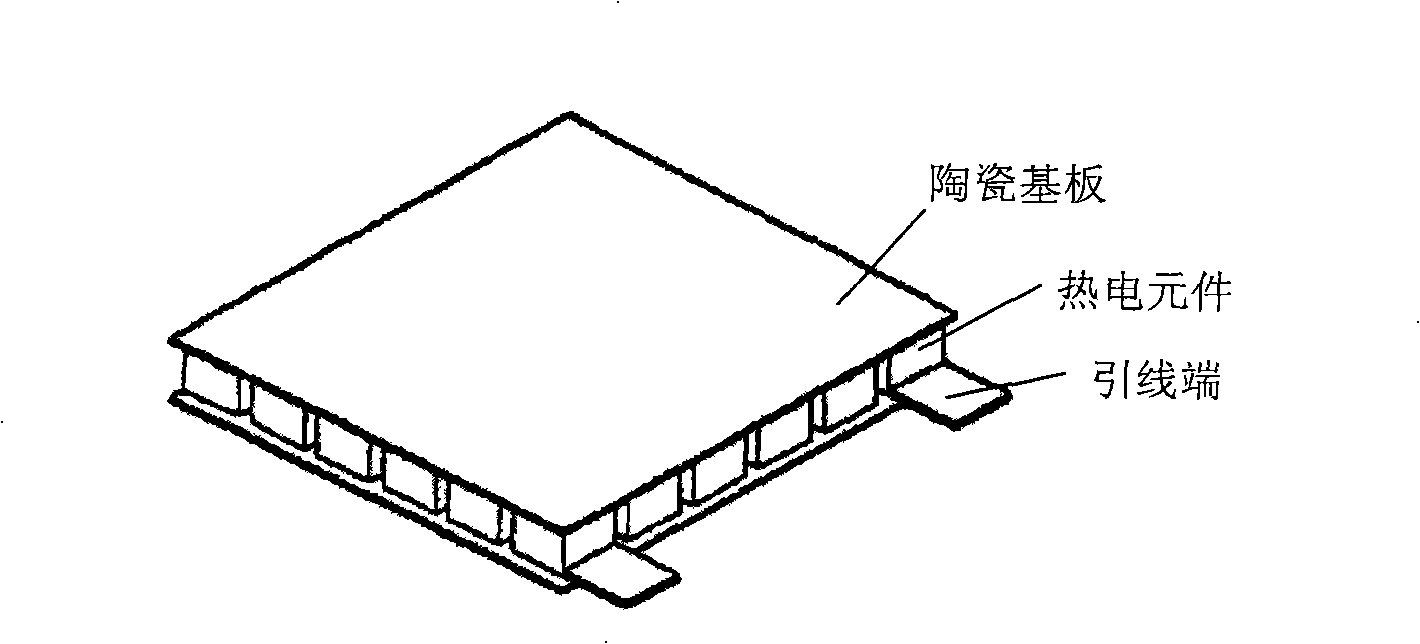

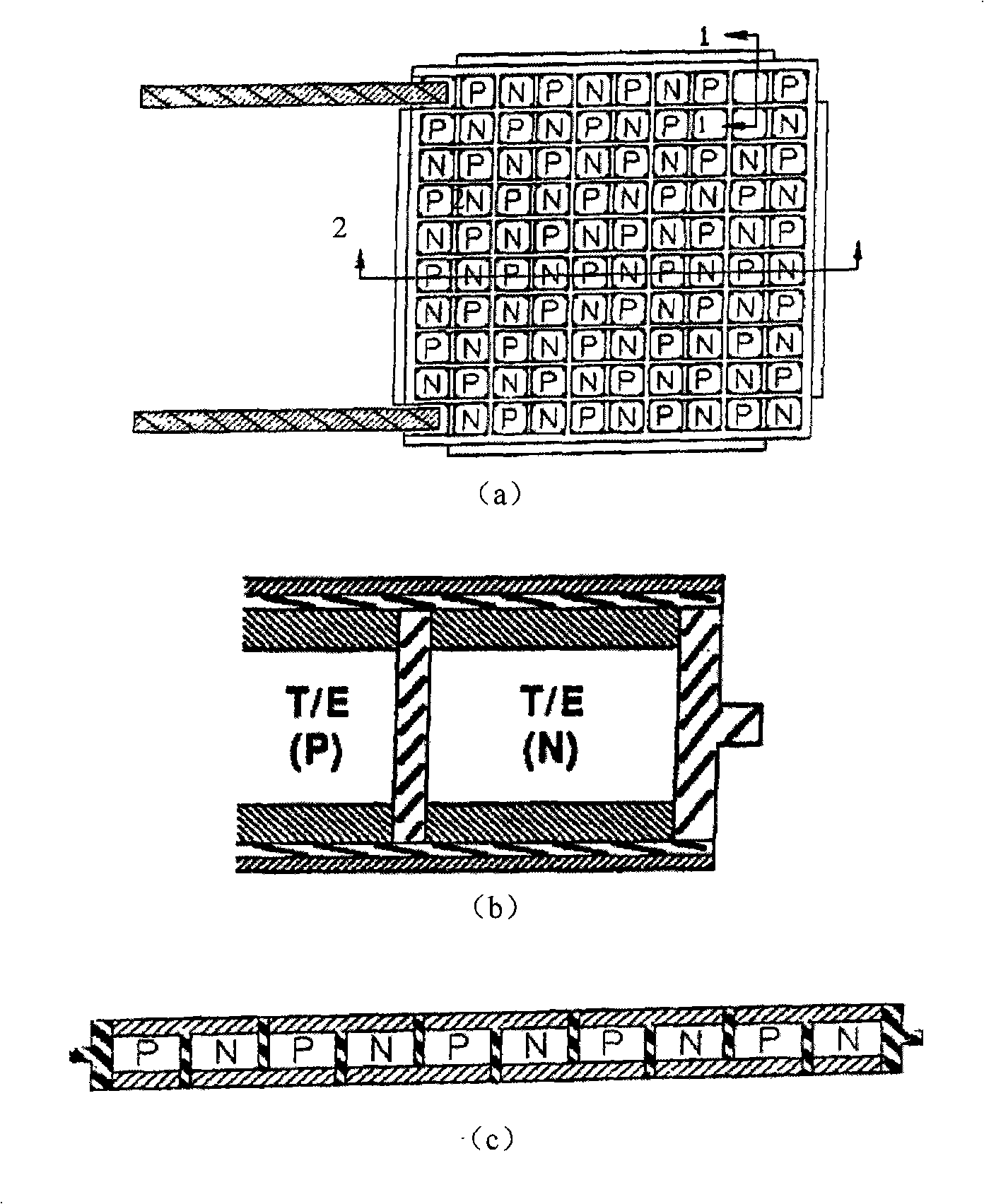

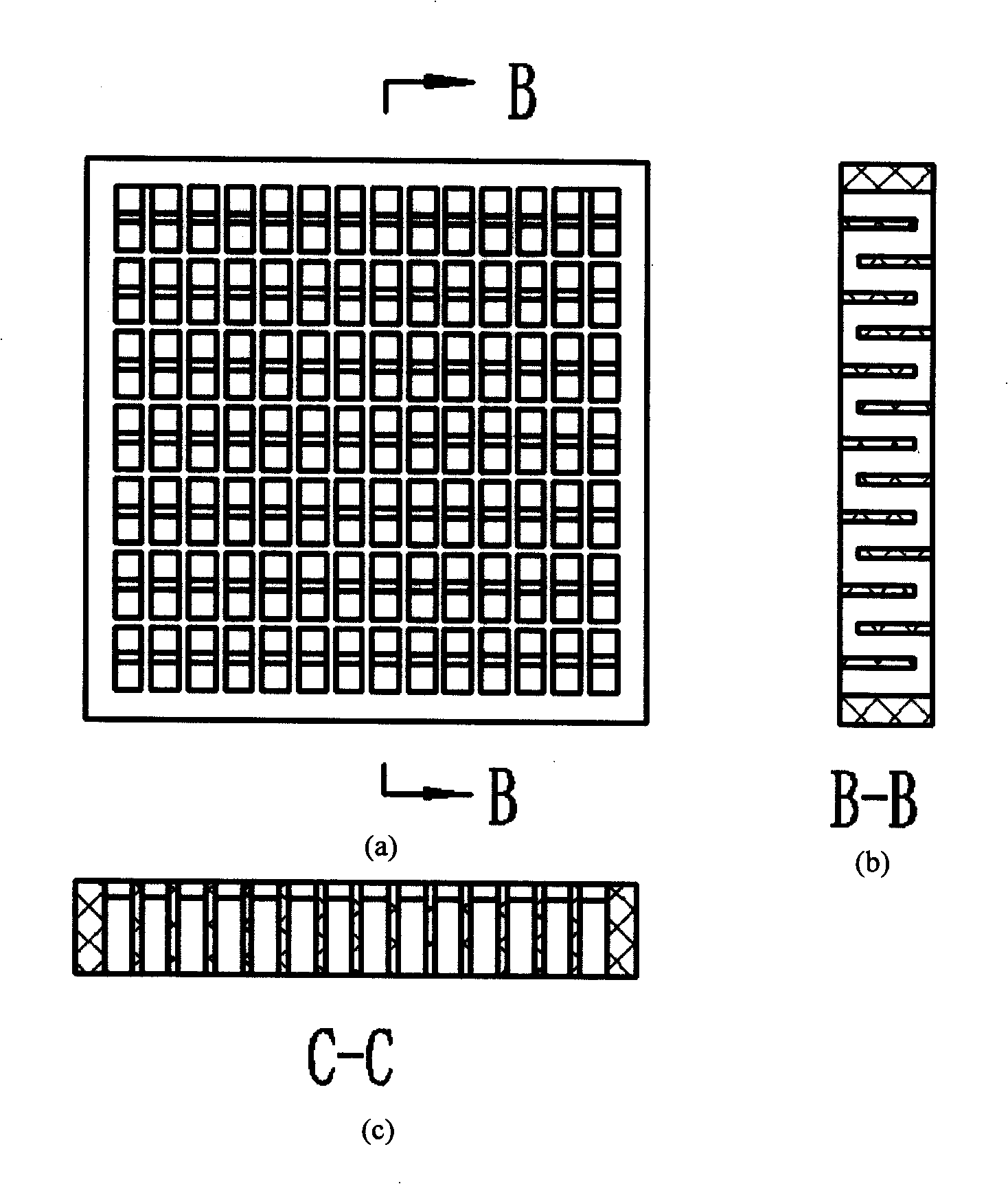

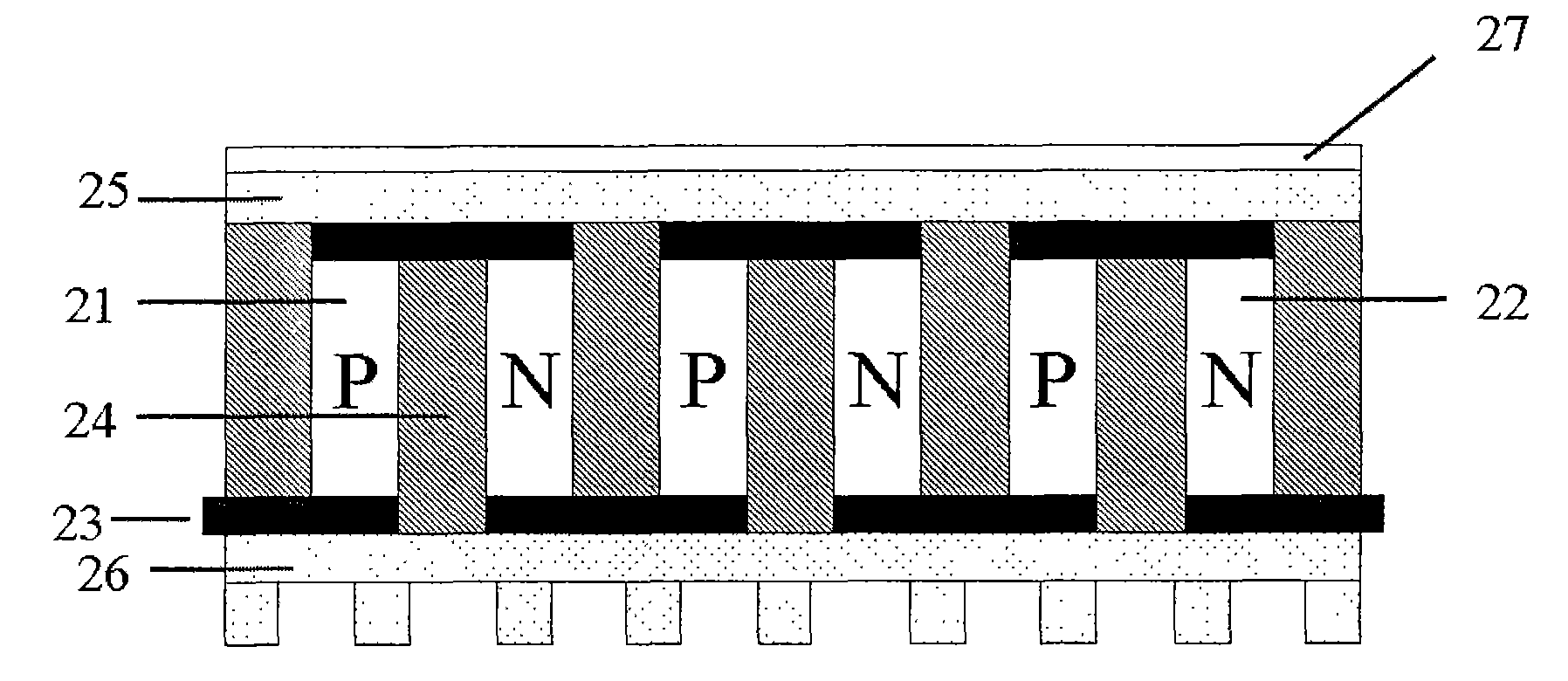

Bismuth-telluride-based thermoelectric electrification device and manufacturing method thereof

ActiveCN101409324AEliminate gapsAvoid restrictionsThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideSoldering

The invention relates to a bismuth telluride-based thermoelectric generating device and a manufacturing method thereof. The bismuth telluride-based thermoelectric generating device is characterized by consisting of a perforated bracing frame, P / N-type elements, a barrier layer, a soldering tin layer, a low-temperature terminal electrode, a ceramic substrate, a sealant, a high-temperature terminalspraying electrode and the ceramic substrate; the pattern of the low-temperature terminal electrode corresponds to holes of the perforated bracing frame. The manufacturing method comprises the steps of preparing the perforated bracing frame, preparing the elements, mounting the elements, soldering the cold terminal electrode with tin, spaying a hot terminal electrode, grinding the sprayed surfaceand the like; the perforated bracing frame is put on the ceramic substrate covered by the low-temperature terminal electrode, the low-temperature terminal electrode is arranged in a hole of the bracing frame, the bismuth telluride-based P / N-type elements are put in the holes of the bracing frame, the soldering tin layers of the elements contact with a tin layer on the low-temperature terminal electrode, the elements are soldered on the low-temperature terminal electrode by heating; the high-temperature terminal of the device is sprayed with aluminum or aluminum alloy and taken as the high-temperature terminal electrode, and the P / N-type elements are connected in series. The device and the method overcome the problem that the existing tin soldering devices are restricted by operating environment and temperature, and the rejection rate and the manufacturing cost are far less than these of plasma spraying devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Metal telluride nanocrystals and synthesis thereof

InactiveUS20080112877A1Material nanotechnologyPhosphorus sulfur/selenium/tellurium compoundsBismuth tellurideLead telluride

A process for synthesizing a metal telluride is provided that includes the dissolution of a metal precursor in a solvent containing a ligand to form a metal-ligand complex soluble in the solvent. The metal-ligand complex is then reacted with a telluride-containing reagent to form metal telluride domains having a mean linear dimension of from 2 to 40 nanometers. NaHTe represents a well-suited telluride reagent. A composition is provided that includes a plurality of metal telluride crystalline domains(PbTe)1-x-y(SnTe)x(Bi2Te3)y (I)having a mean linear dimension of from 2 to 40 nanometers inclusive where x is between 0 and 1 inclusive and y is between 0 and 1 inclusive with the proviso that x+y is less than or equal to 1. Each of the metal telluride crystalline domains has a surface passivated with a saccharide moiety or a polydentate carboxylate. A densified mass having a density of greater than 95% of the theoretical density includes a plurality of lead telluride, tin telluride, bismuth telluride, or a combination thereof of domains having a mean linear dimension of from 2 to 40 nanometers inclusive that have been subjected to hot isotactic pressing.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA +1

Low power thermoelectric generator

InactiveUS6958443B2Good repeatabilityThermoelectric device with peltier/seeback effectPhotovoltaicsBismuth tellurideThermal contact

Owner:DIGITAL ANGEL CORP

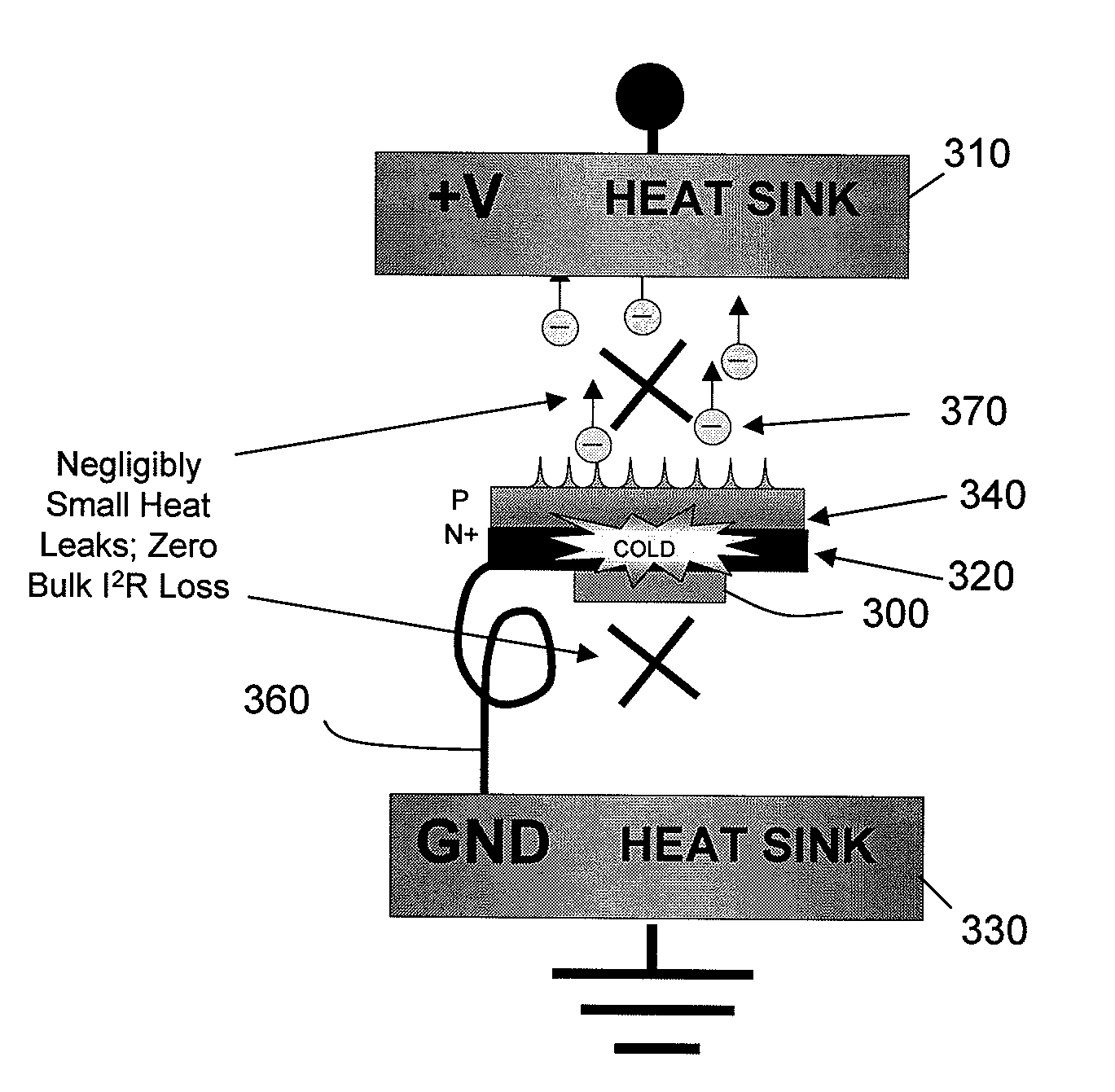

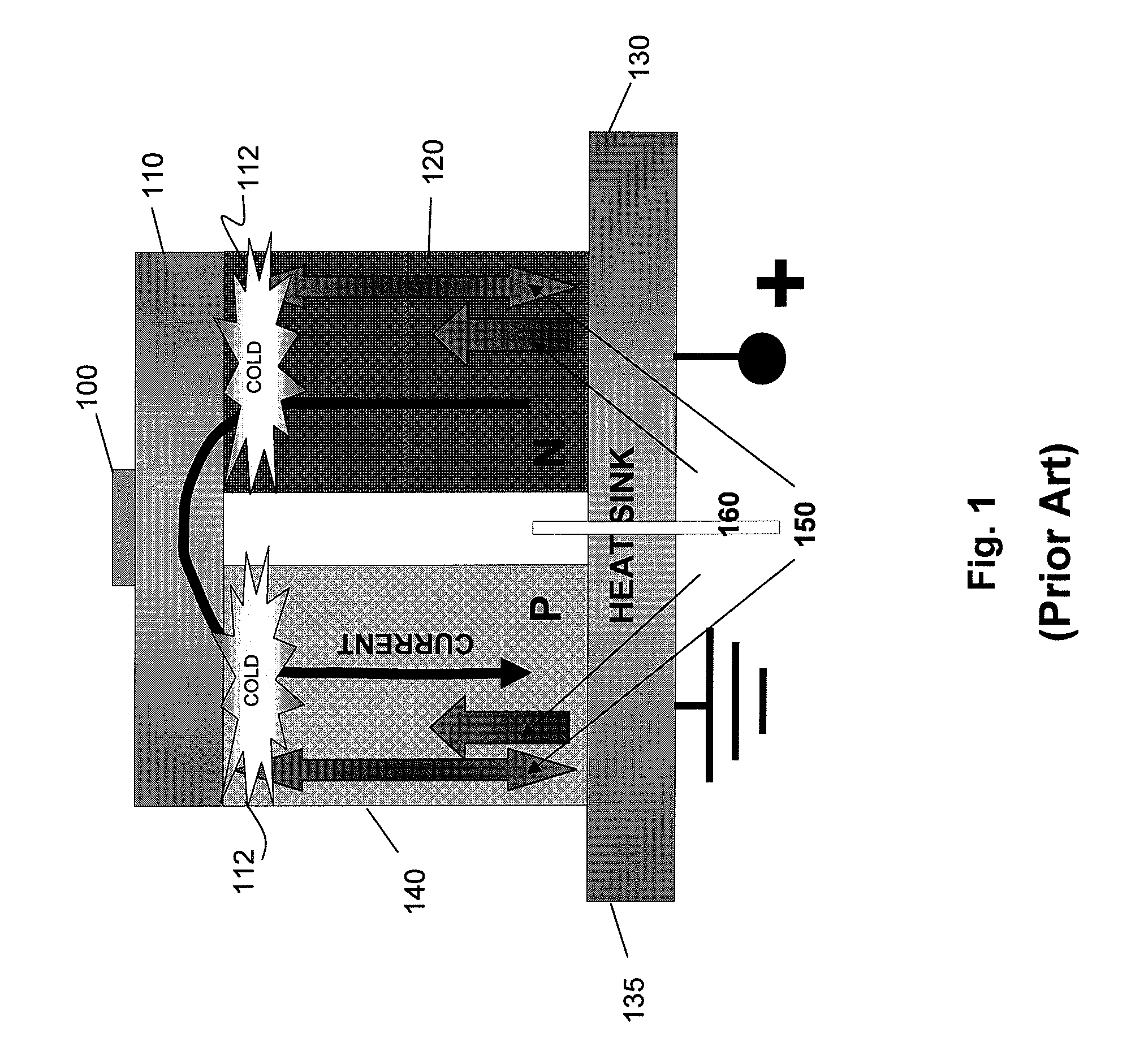

Method and Apparatus for Solid State Cooling System

ActiveUS20090194870A1Semiconductor/solid-state device detailsSolid-state devicesThermoelectric coolingSingle stage

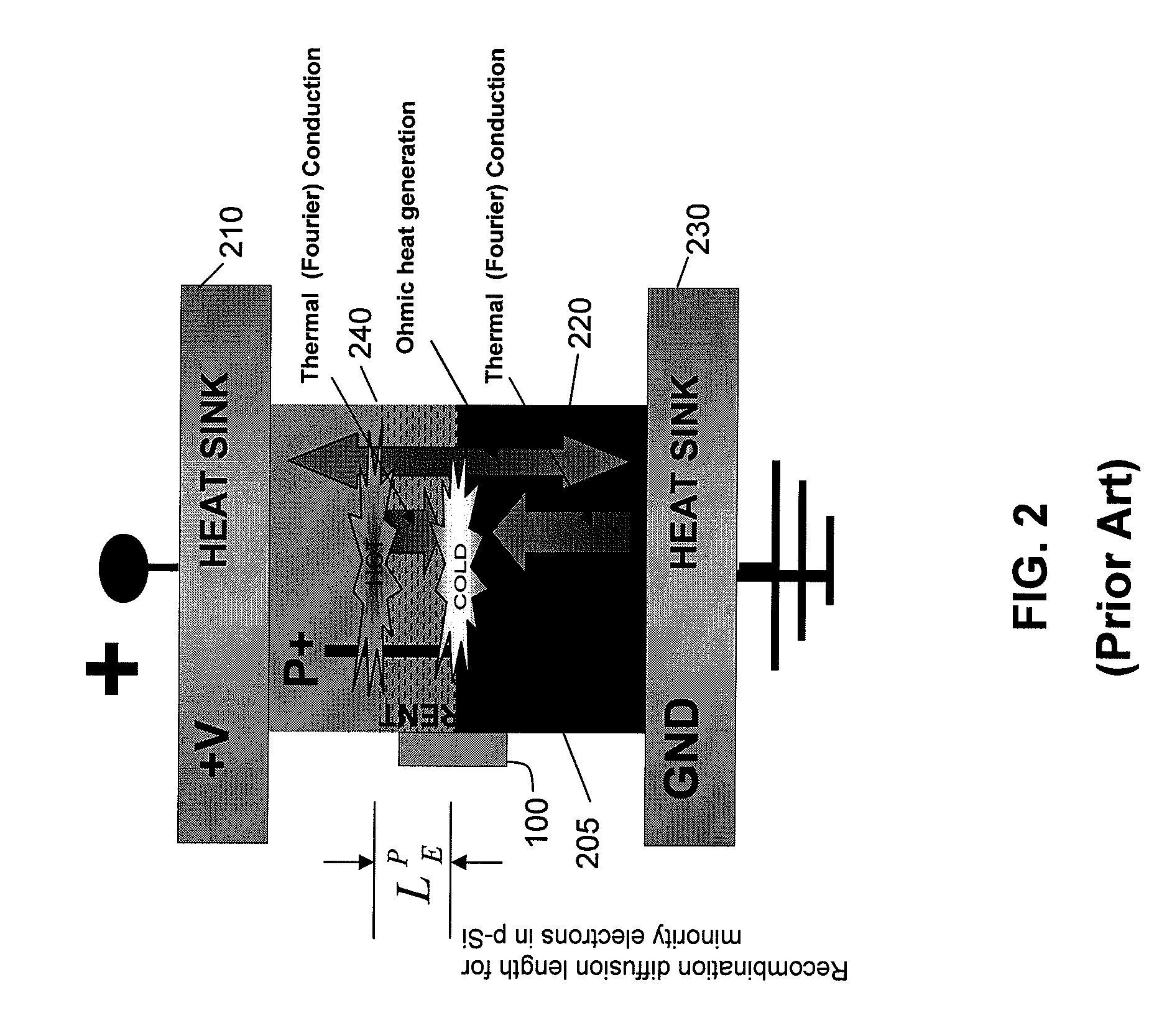

The disclosure relates to a Point Cooler based on a combination of principles, including large area, low current density PN junction cooling, and electron emission from heavily doped shallowly-depleted P tips. Using Junction Cooling rather than thermoelectric cooling enables an all silicon device to be made that favorably competes with the commercial thermoelectric cooling systems. Theoretical values of THOT / TCOLD of 6 or more (in contrast to about 1.5 for other solid state refrigerators) predict this single-stage solid state vacuum electronic cooler can approach 50K at light loading, significantly lower than conventional Bismuth Telluride based thermo electrics. The high Z values for PN junction cooling with wire connection and Tunnel heat extraction opens up solid state vibration-less form fit and function replacement cooling.

Owner:NORTHROP GRUMAN CORP

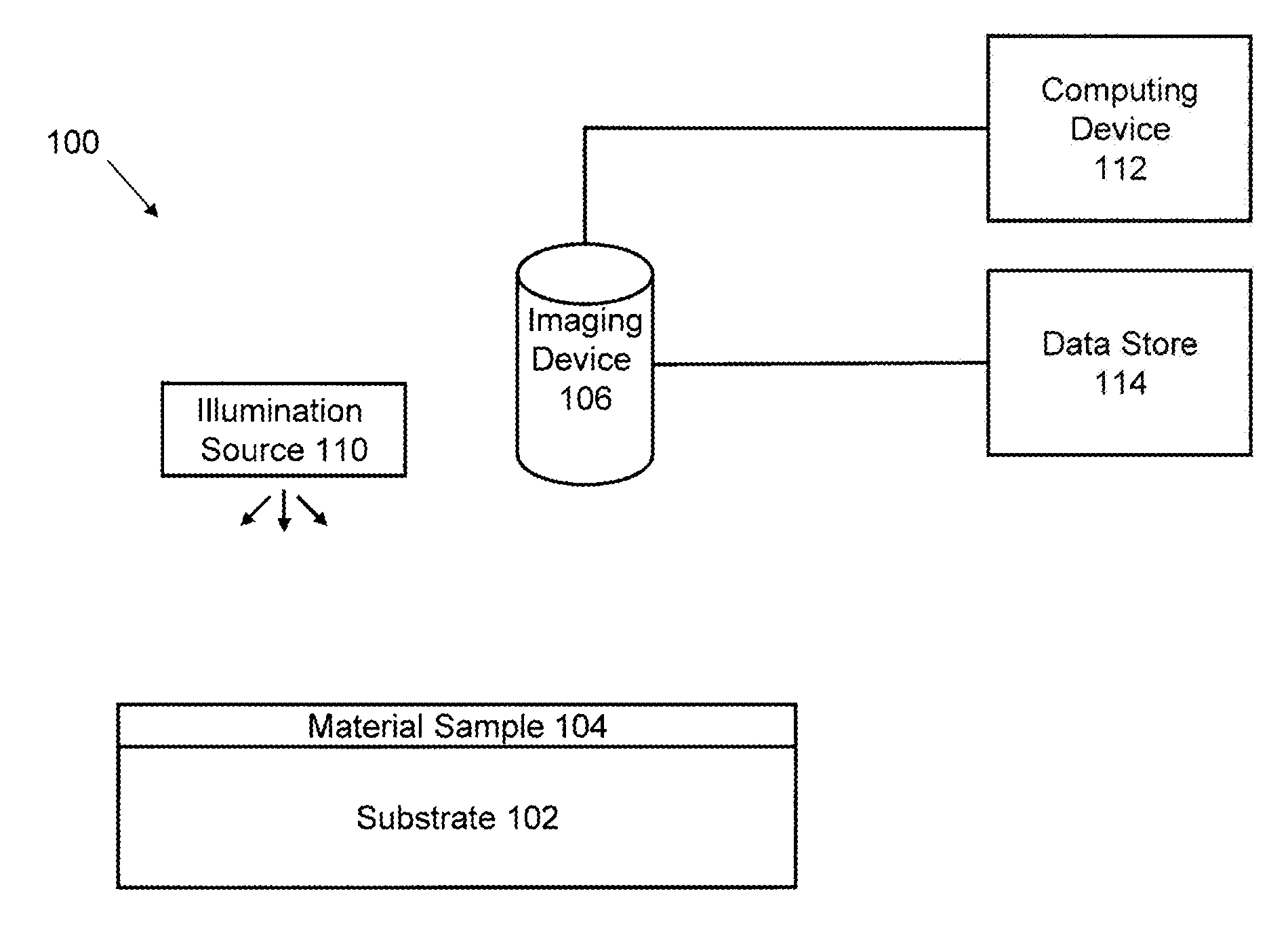

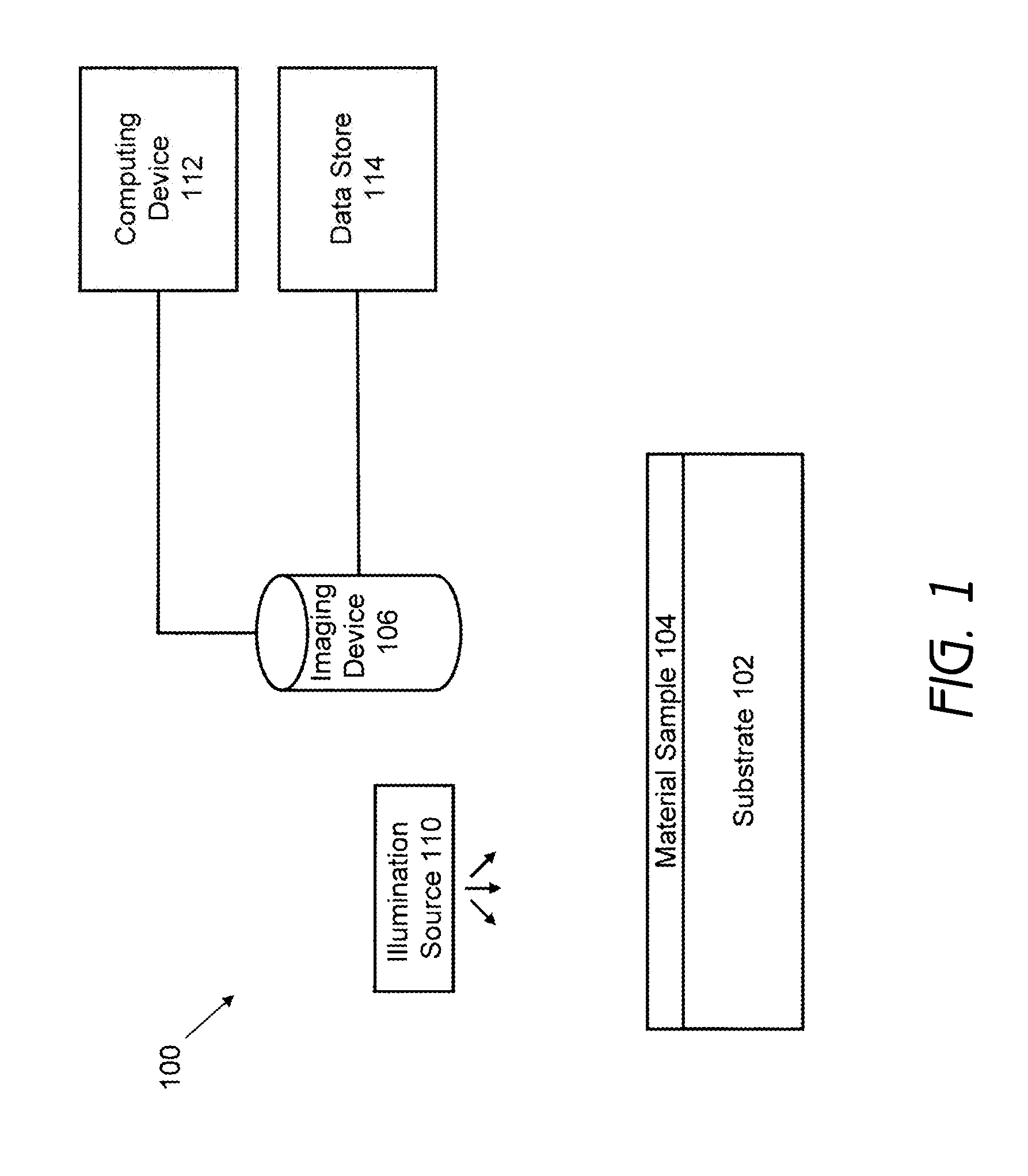

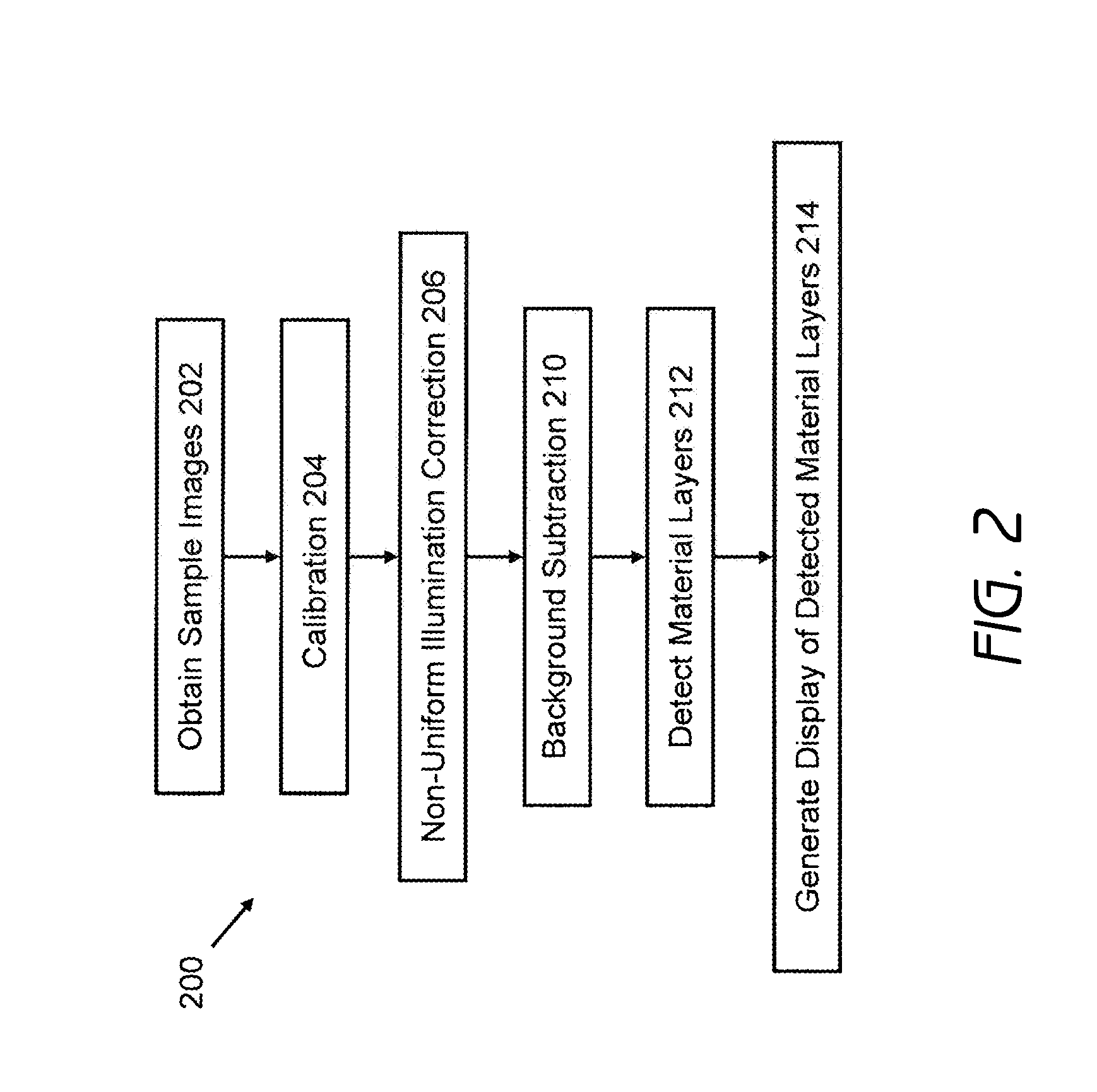

Systems and methods for material layer identification through image processing

A fast and fully automated approach for determining the number of atomic planes in layered material samples is provided. Examples of such materials may include graphene and bismuth telluride (Bi2Te3), and materials from the bismuth selenide (Bi2Se3) samples is provided. The disclosed procedure allows for in situ identification of the borders of the regions with the same number of atomic planes. The procedure is based on an image processing algorithm that employs micro-Raman calibration, light background subtraction, correction for lighting non-uniformity, and color and grayscale image processing on each pixel of a graphene image. The developed procedure may further provide a pseudo-color map that marks the single-layer and few-layer regions of the sample. Beneficially, embodiments of the developed procedure may be employed using various substrates and can be applied to materials that are mechanically exfoliated, chemically derived, or deposited on an industrial scale.

Owner:RGT UNIV OF CALIFORNIA

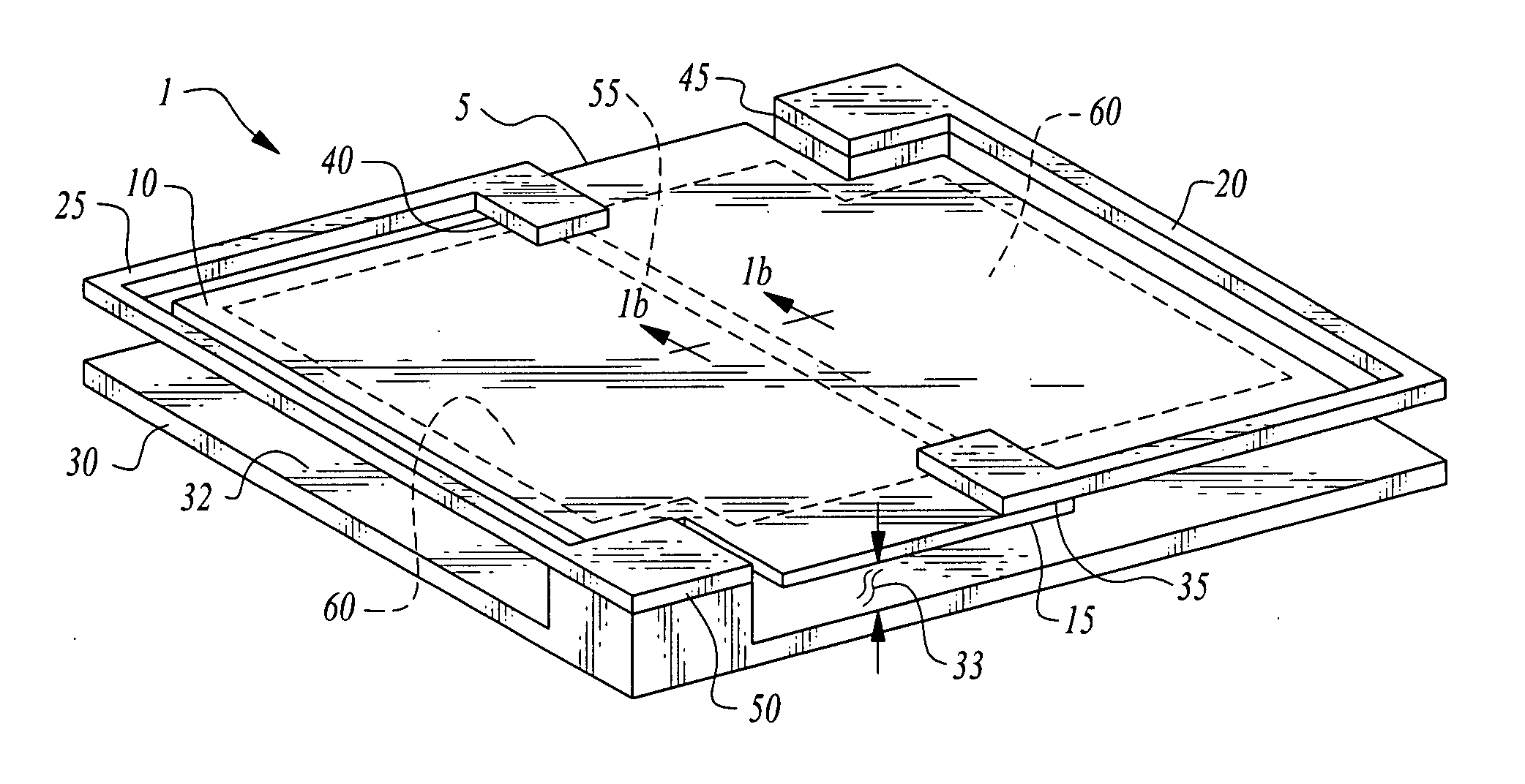

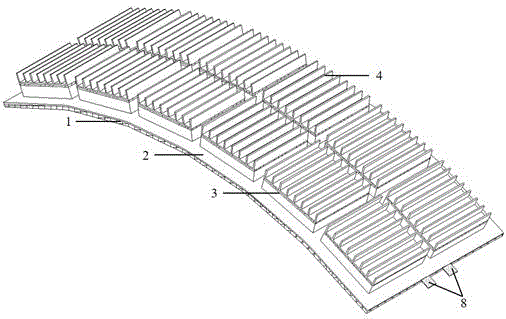

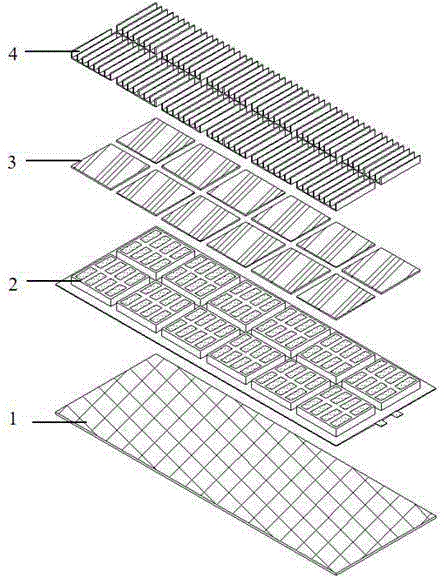

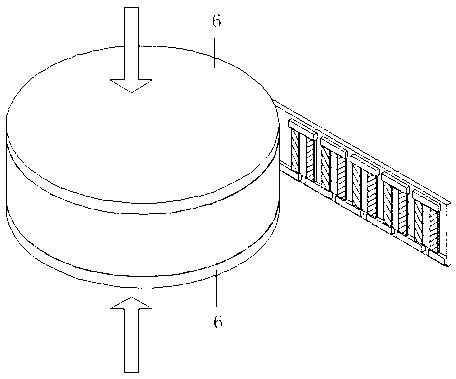

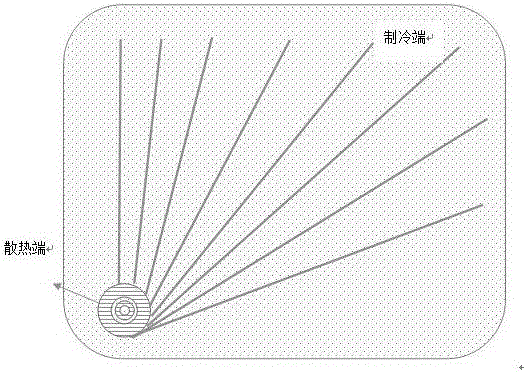

Wearable type flexible temperature-difference power generation structure with stretchable wire

InactiveCN105406769AAvoid breakingAvoid connectivityGenerators/motorsThermoelectric device detailsBismuth tellurideHeat transfer efficiency

The invention discloses a wearable type flexible temperature-difference power generation structure with a stretchable wire. The structure comprises a flexible thermal conductive silica gel cushion, a temperature-difference power generation layer, a thermal conductive patch and a metal cooling fin from the wearable surface to outside in sequence; the cold end plane and the hot end plane of the temperature-difference power generation layer are connected with the bottom surface of the thermal conductive patch and the upper surface of the flexible thermal conductive silica gel cushion respectively; and the upper surface of the thermal conductive patch is connected with the bottom surface of the metal cooling fin. When the wearable surface is adhered to non-planar human body skin, the stretchable wire and a polydimethylsiloxane package absorb deformation stress so as to avoid cracking of a bismuth telluride based thermoelectric arm with a poor mechanical performance and to avoid failure of electrode connection; the flexible thermal conductive silica gel cushion is packaged on one side of the hot end of the temperature-difference power generation layer, so that the tight contact with the skin of a user is ensured, and the heat transfer efficiency is improved; the cold end of each rigid temperature-difference power generation module is equipped with the independent thermal conductive patch and metal cooling fin, so that the structural thickness and quality are reduced and the temperature difference between the cold end and the hot end is increased; and in addition, the wearable type flexible temperature-difference power generation structure can be used for supplying power to wearable type medical apparatuses and has the value of popularization and application.

Owner:ZHEJIANG UNIV

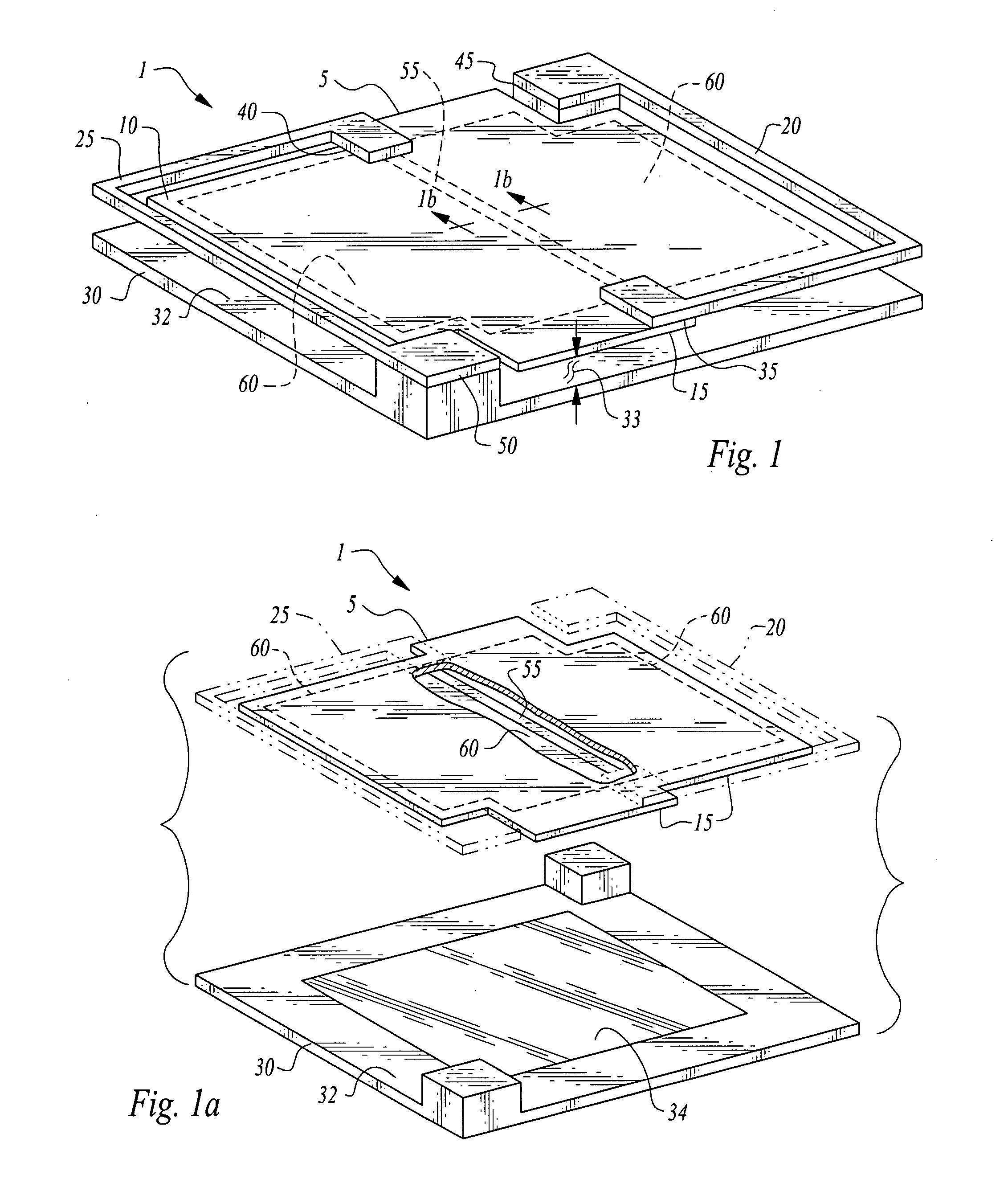

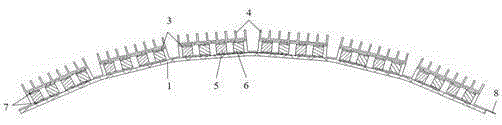

Flexible temperature differential power generation micro-unit structure

InactiveCN103178754AFlexibleAvoid failureGenerators/motorsThermoelectric devicesPolyimide substrateMicro devices

The invention discloses a flexible temperature differential power generation micro-unit structure. The flexible temperature differential power generation micro-unit structure is characterized in that a plurality of insulating hard films which are equidistantly distributed to form a layer are deposited on the upper surface of a polyimide substrate, a P-type film thermoelectric arm and an N-type film thermoelectric arm which are parallel to each other are respectively arranged on two upper sides of each insulating hard film, the length and the width of each P-type film thermoelectric arm are equal to those of each N-type film thermoelectric arm, one end of each P-type film thermoelectric arm is connected with one end of the corresponding N-type film thermoelectric arm by a conducting wire, the other end of each P-type film thermoelectric arm is connected with the other end of the adjacent front N-type film thermoelectric arm by a conducting wire, the other end of each N-type film thermoelectric arm is connected with the other end of the adjacent rear P-type film thermoelectric arm, and the same procedure is sequentially repeatedly carried out, so that the flexible temperature differential power generation micro-unit structure is formed. The flexible temperature differential power generation micro-unit structure has the advantages that the flexible temperature differential power generation micro-unit structure is flexible and can deform in multiple directions, the insulating hard films can prevent bismuth telluride thermoelectric materials with poor ductility from being broken when a temperature differential power generation unit structurally deforms, and failure is prevented; and the flexible temperature differential power generation micro-unit structure is mainly used for supplying power for implanted medical micro-devices, and has popularization and application value.

Owner:ZHEJIANG UNIV

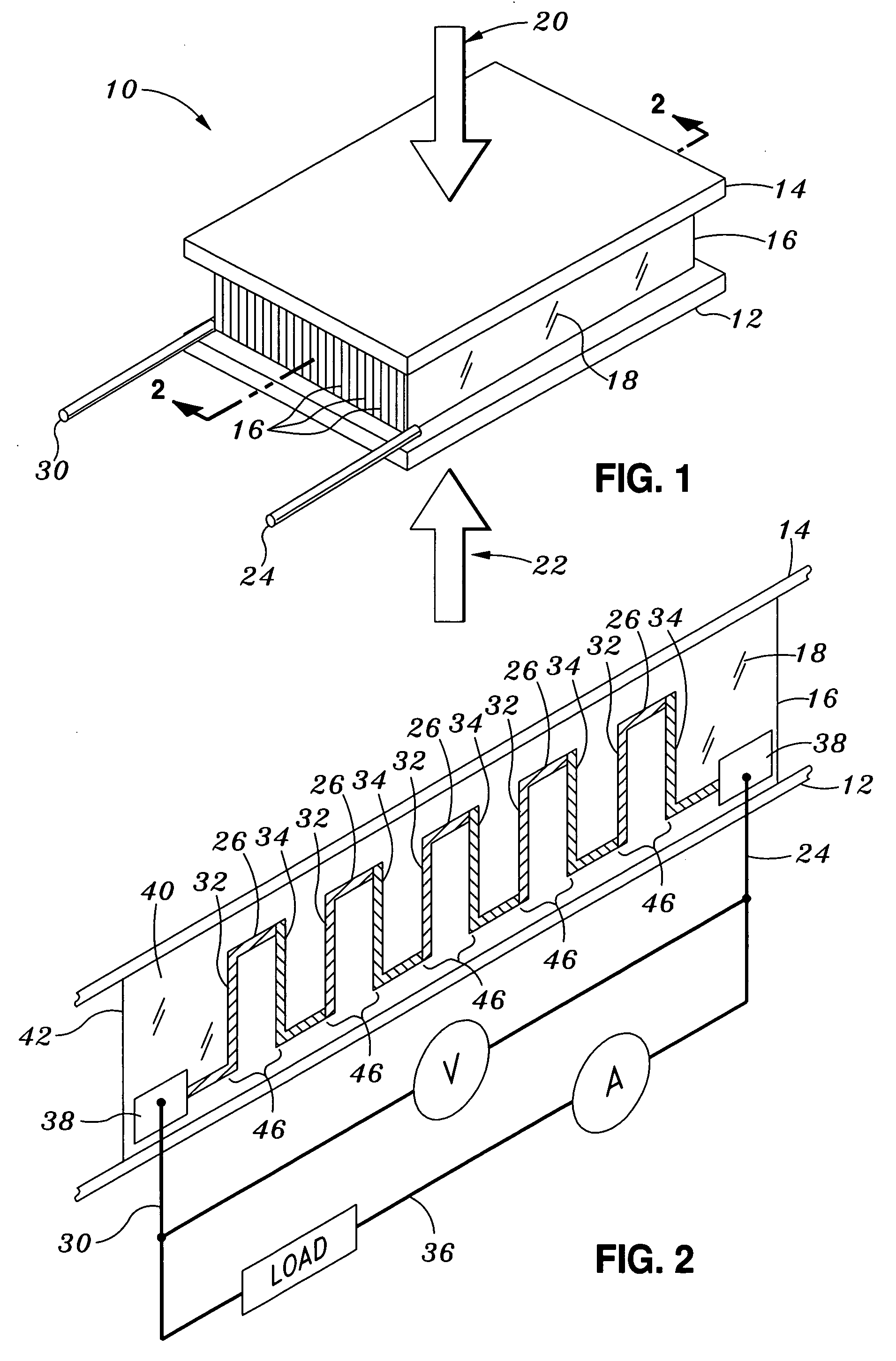

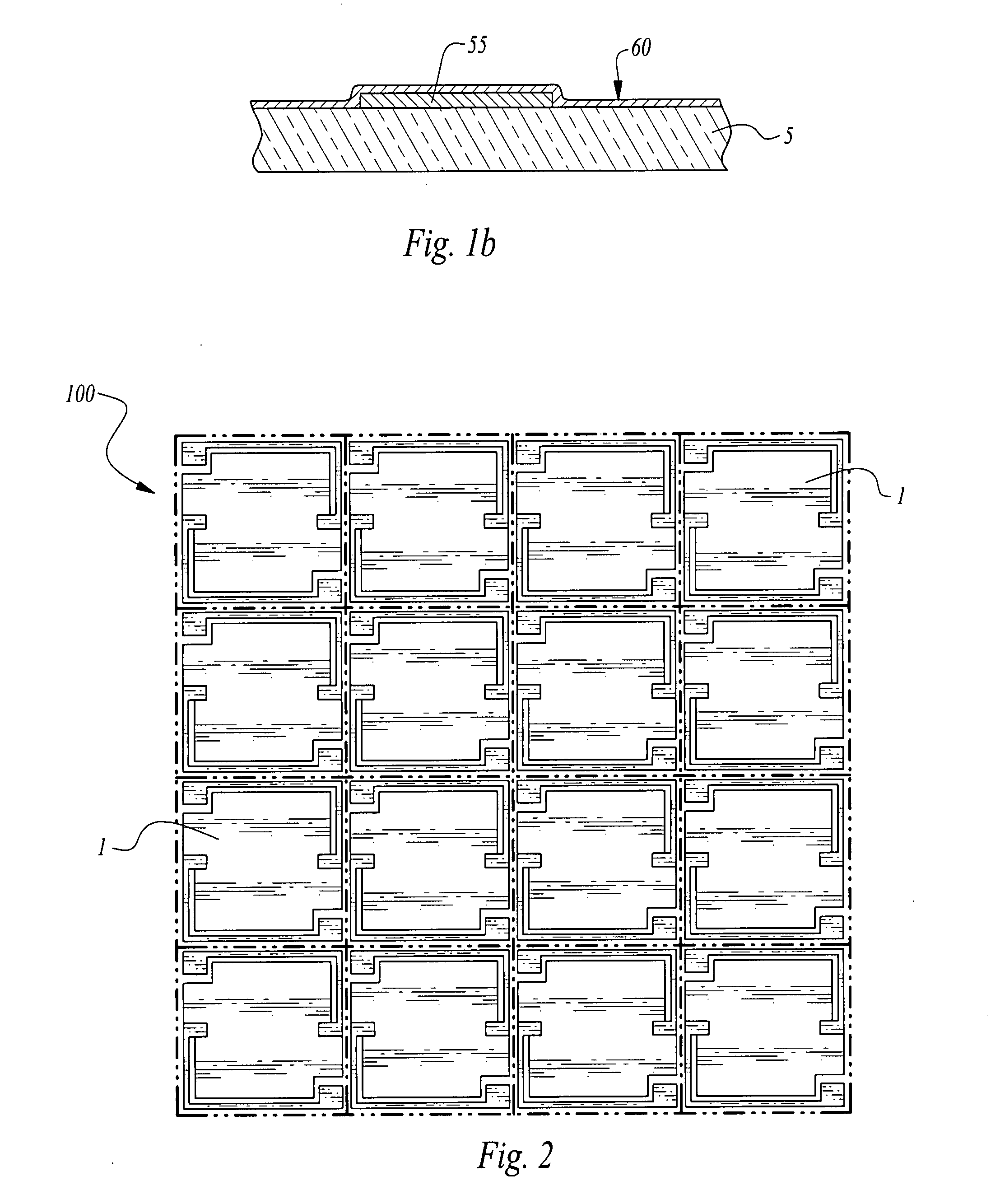

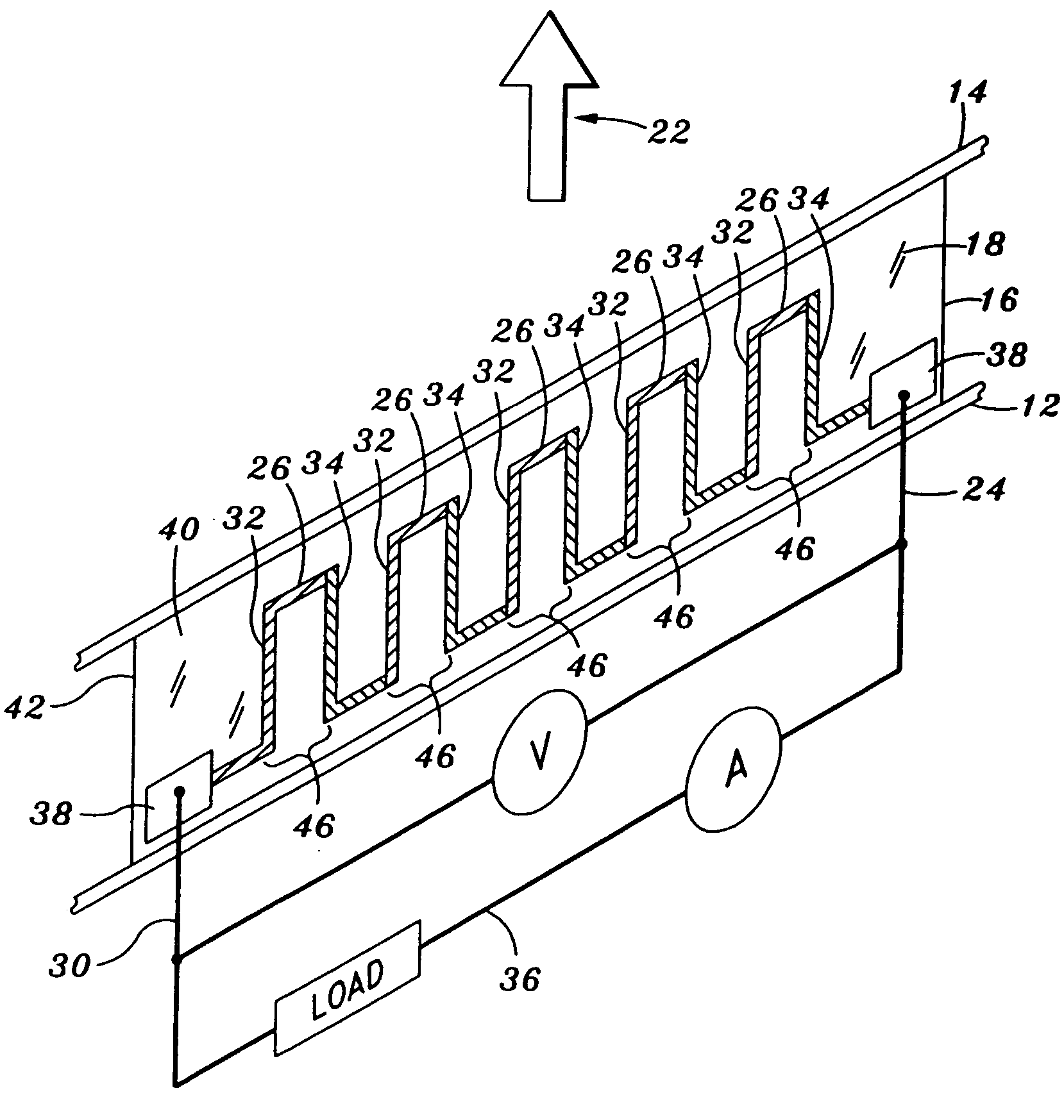

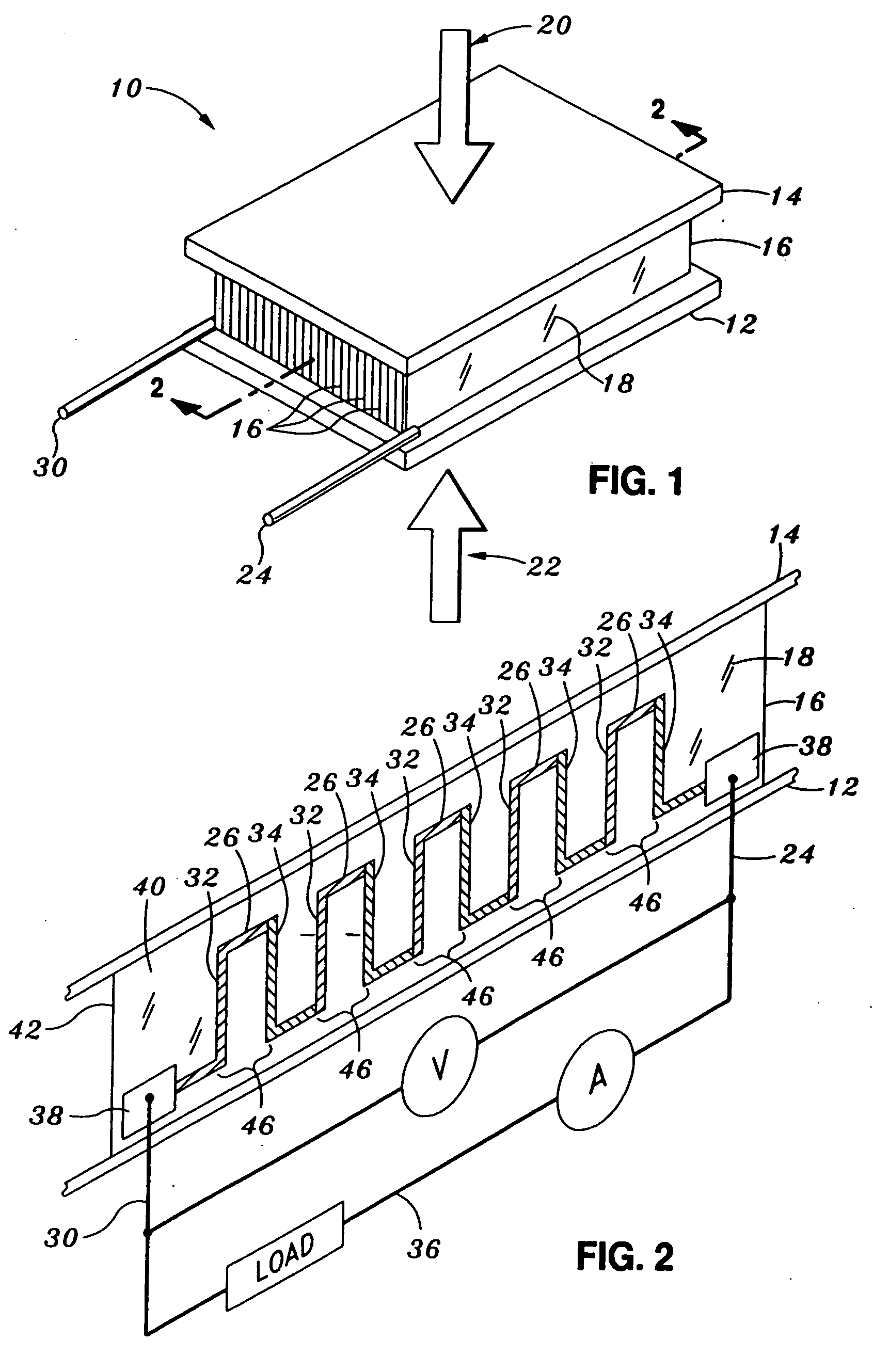

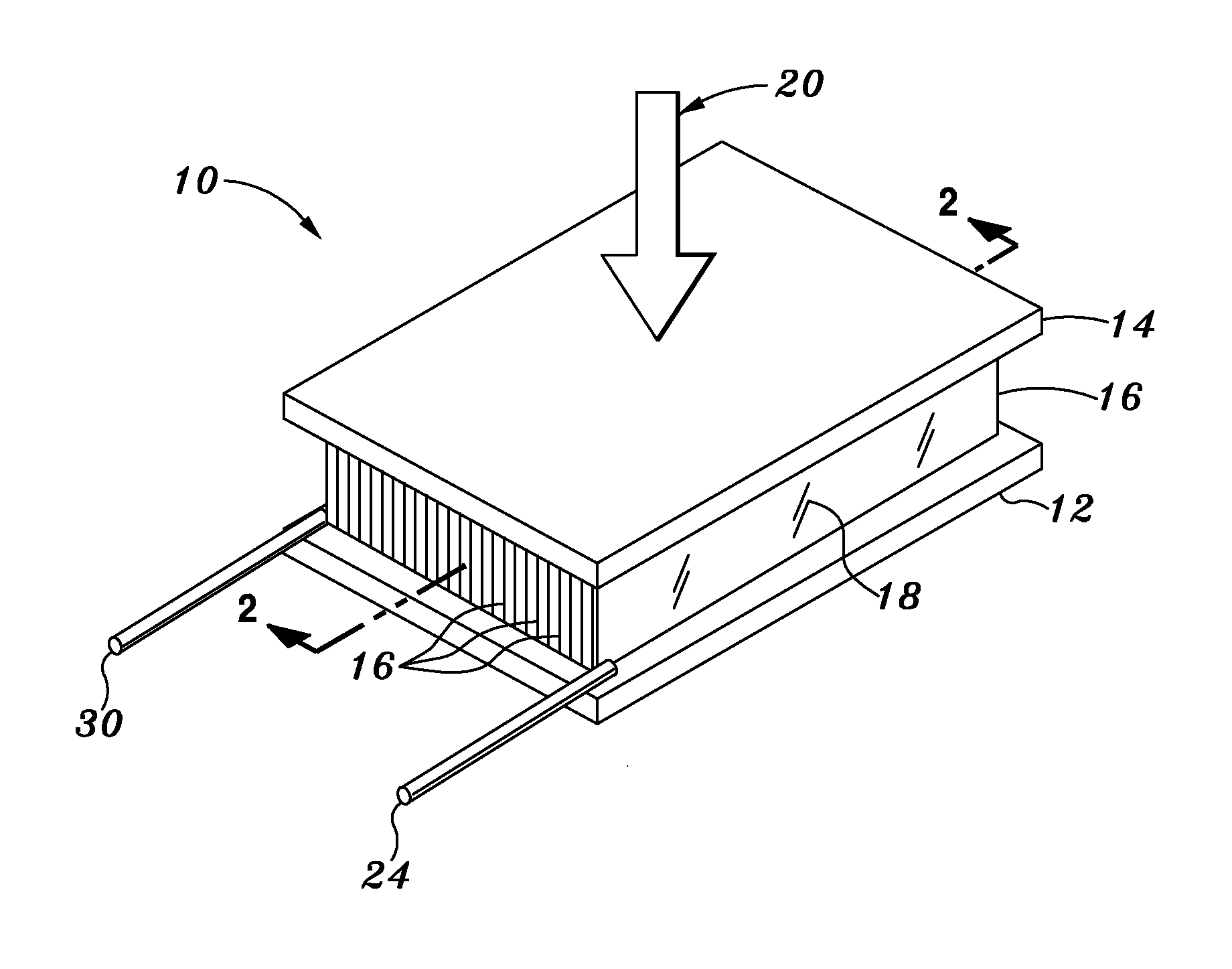

Low power thermoelectric generator

InactiveUS20050252543A1Good repeatabilityThermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsBismuth tellurideEngineering

Disclosed is a foil segment for a thermoelectric generator comprising a top plate disposed in spaced relation above a bottom plate. An array of the foil segments is perpendicularly disposed in side-by-side arrangement between and in thermal contact with the bottom and top plates. Each foil segment comprises a substrate having a thickness of about 7.5-50 microns, opposing front and back substrate surfaces and a series of spaced alternating n-type and p-type thermoelectric legs disposed in parallel arrangement on the front substrate surface. Each of the n-type and p-type legs is formed of a bismuth telluride-based thermoelectric material having a thickness of about 5-100 microns, a width of about 10-100 microns and a length of about 100-500 microns. The alternating n-type and p-type thermoelectric legs are electrically connected in series and thermally connected in parallel such that a temperature differential between the bottom and top plates results in the generation of power.

Owner:STARK INGO +1

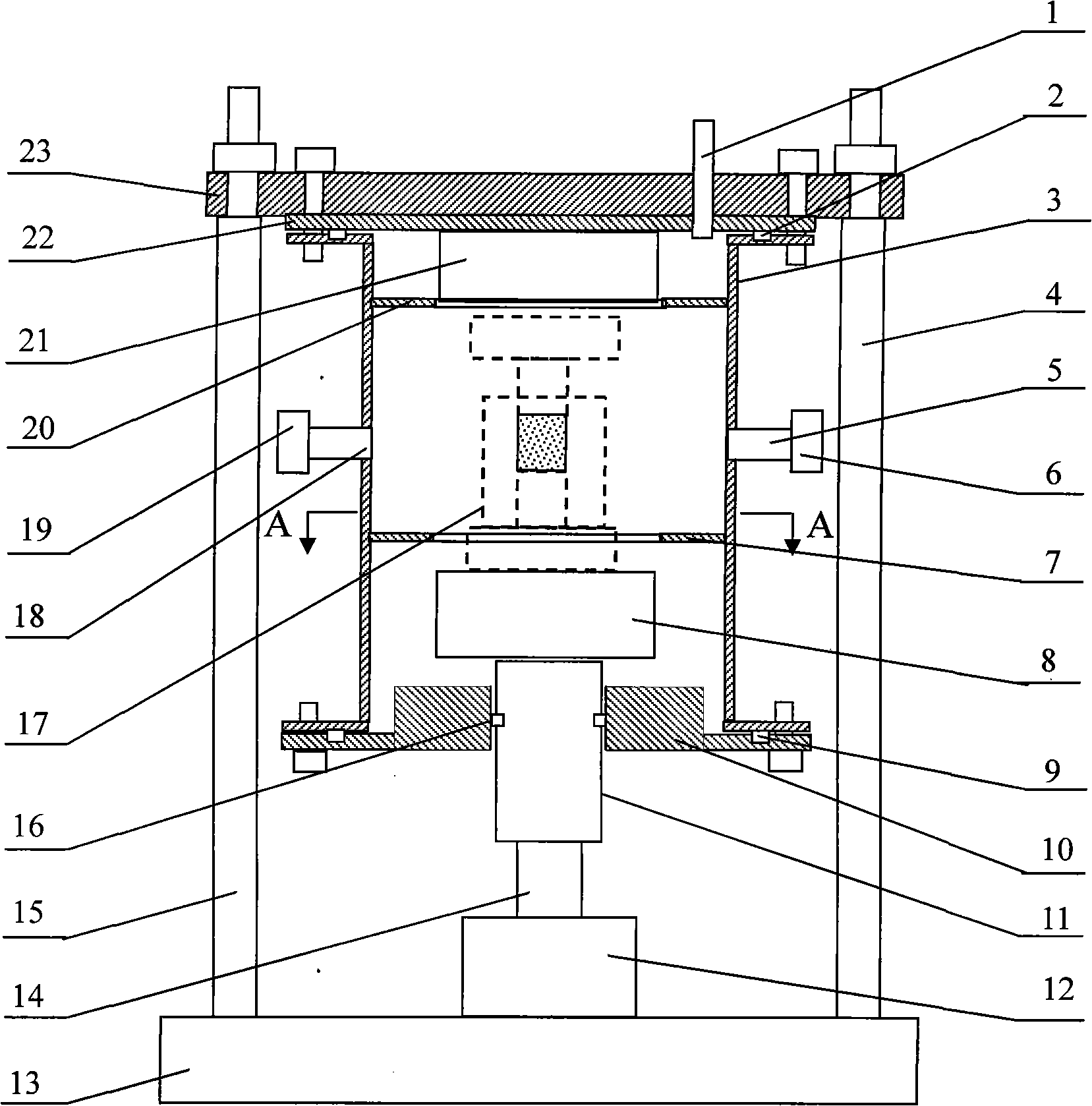

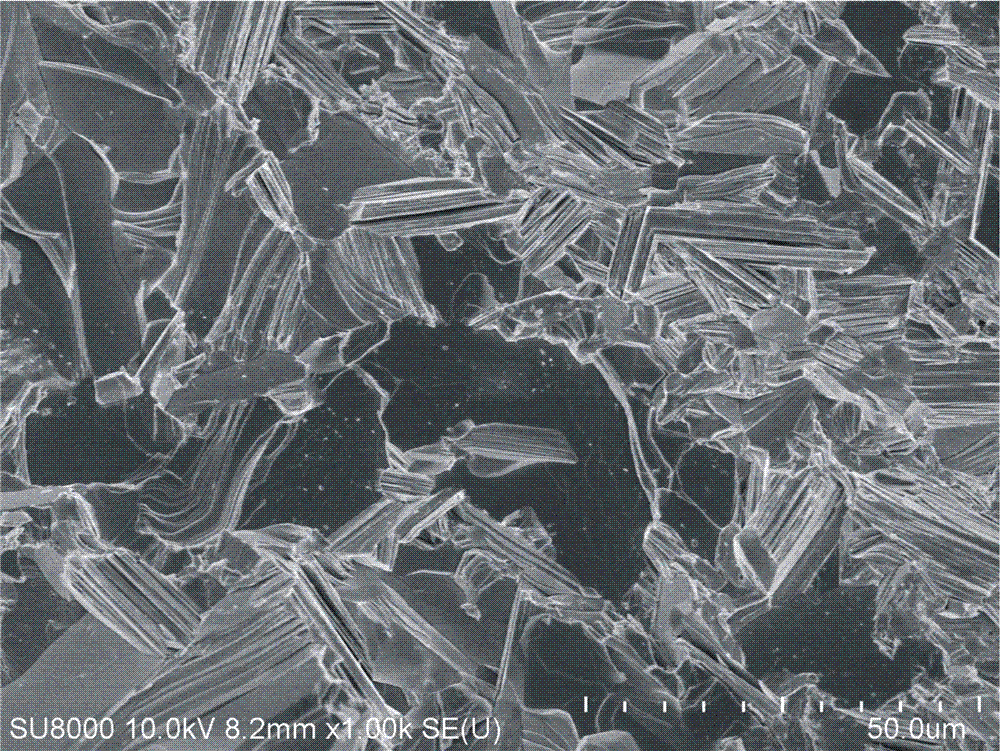

Preparation method of bismuth telluride based bulk nano crystalline thermoelectric material

InactiveCN101786162ASimple processLess investmentThermoelectric device manufacture/treatmentMicrowaveBismuth telluride

The invention relates to a bismuth telluride based bulk nano crystalline thermoelectric material and preparation method thereof. The technical scheme includes that: firstly simple substance powder with mass percent more than 99.99% is taken as raw material, burdening is carried out according to the chemical formula (SbxBi1-x)2Te3 or Bi2(SeyTe1-y)3, wherein x is more than or equal to 0.75 and less than or equal to 0.85, y is more than or equal to 0.04 and less than or equal to 0.06, mixing to be uniform is carried out, and then ball milling is carried out by a ball mill, thus obtaining bismuth telluride base alloy nano powder; secondly, the bismuth telluride base alloy obtained in the first step is loaded into a graphite mould or ceramic mould to be sintered in a micro wave irradiation pressure sintering device; temperature rises to 300-550 DEG C by heating under the condition that the pressure applied to the powder is 10-40MPa, and then heat preservation is carried out for 10-60min under the condition that the pressure applied to the powder is 30-60MPa, thus obtaining the bismuth telluride based bulk nano crystalline thermoelectric material. The invention has the characteristics of less investment, low production cost, simple technology and short period; and the obtained bismuth telluride based bulk nano crystalline thermoelectric material has high performance.

Owner:WUHAN UNIV OF SCI & TECH

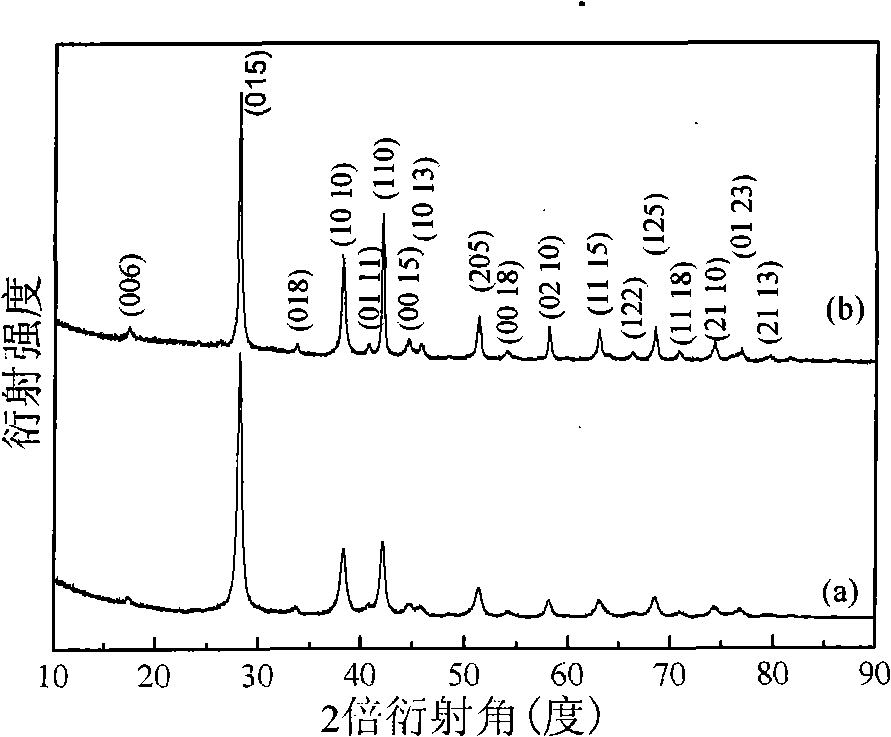

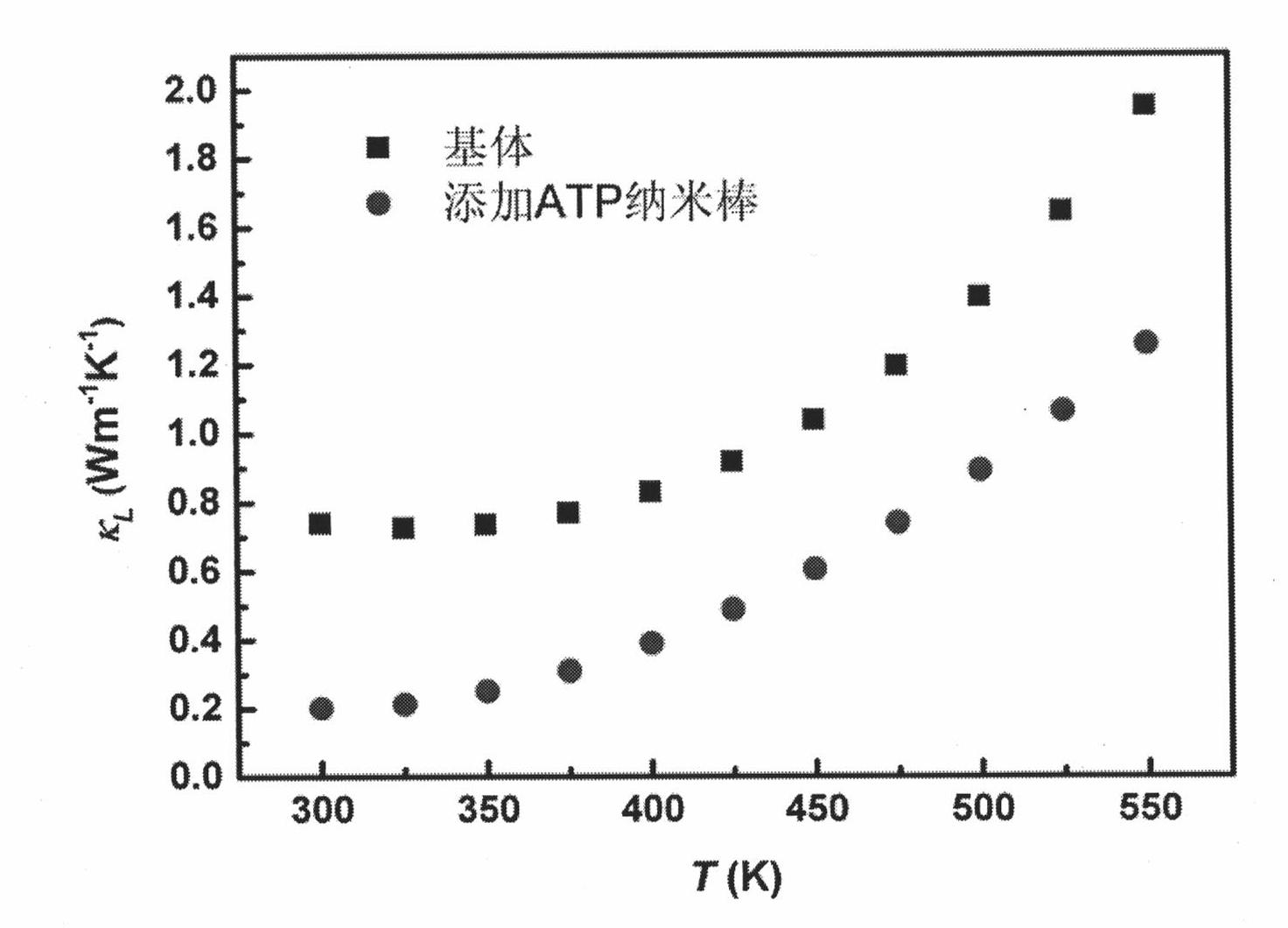

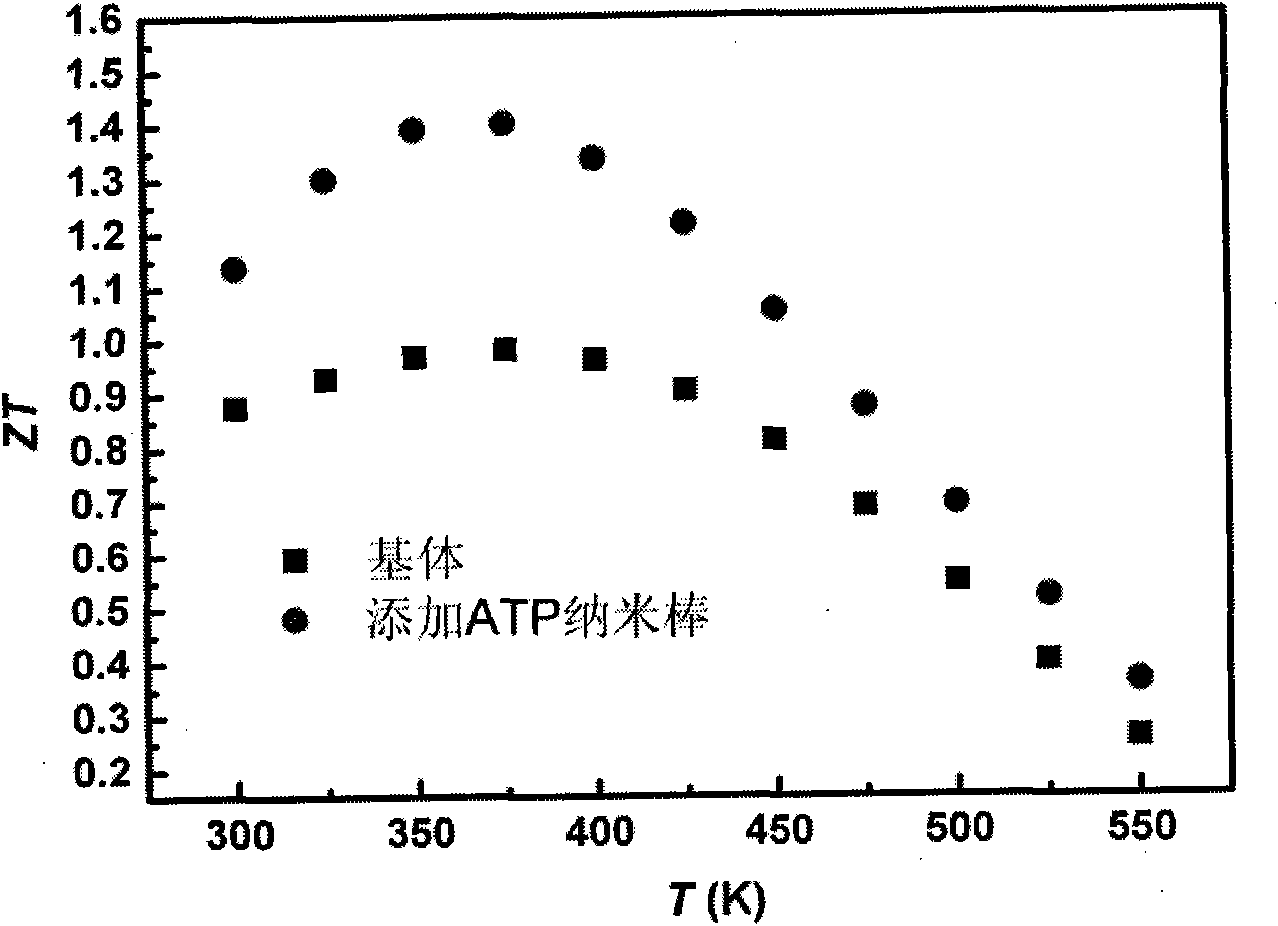

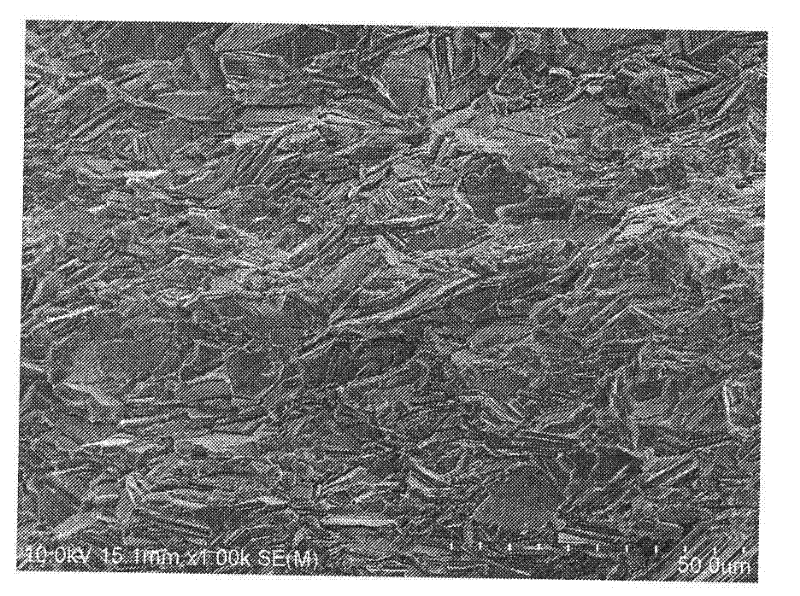

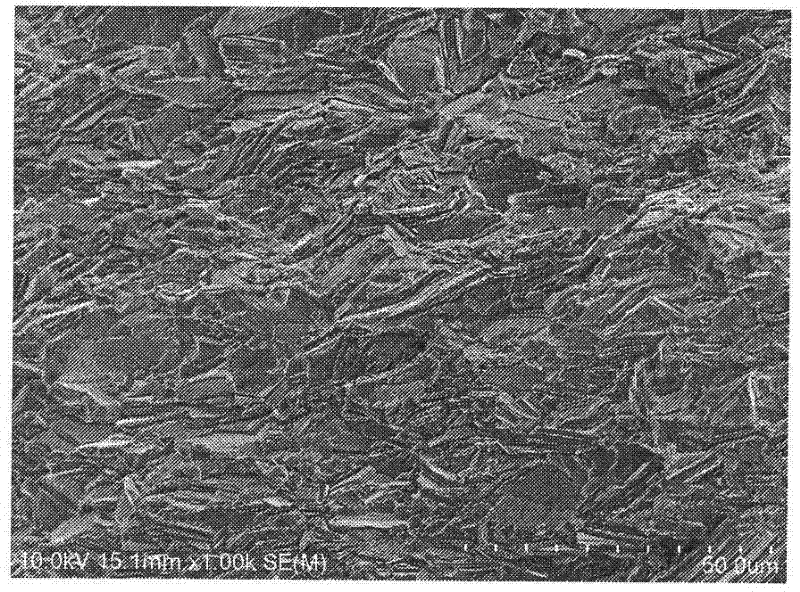

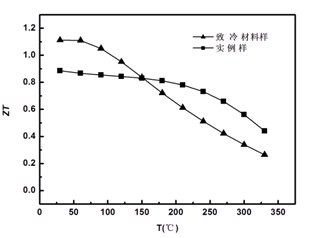

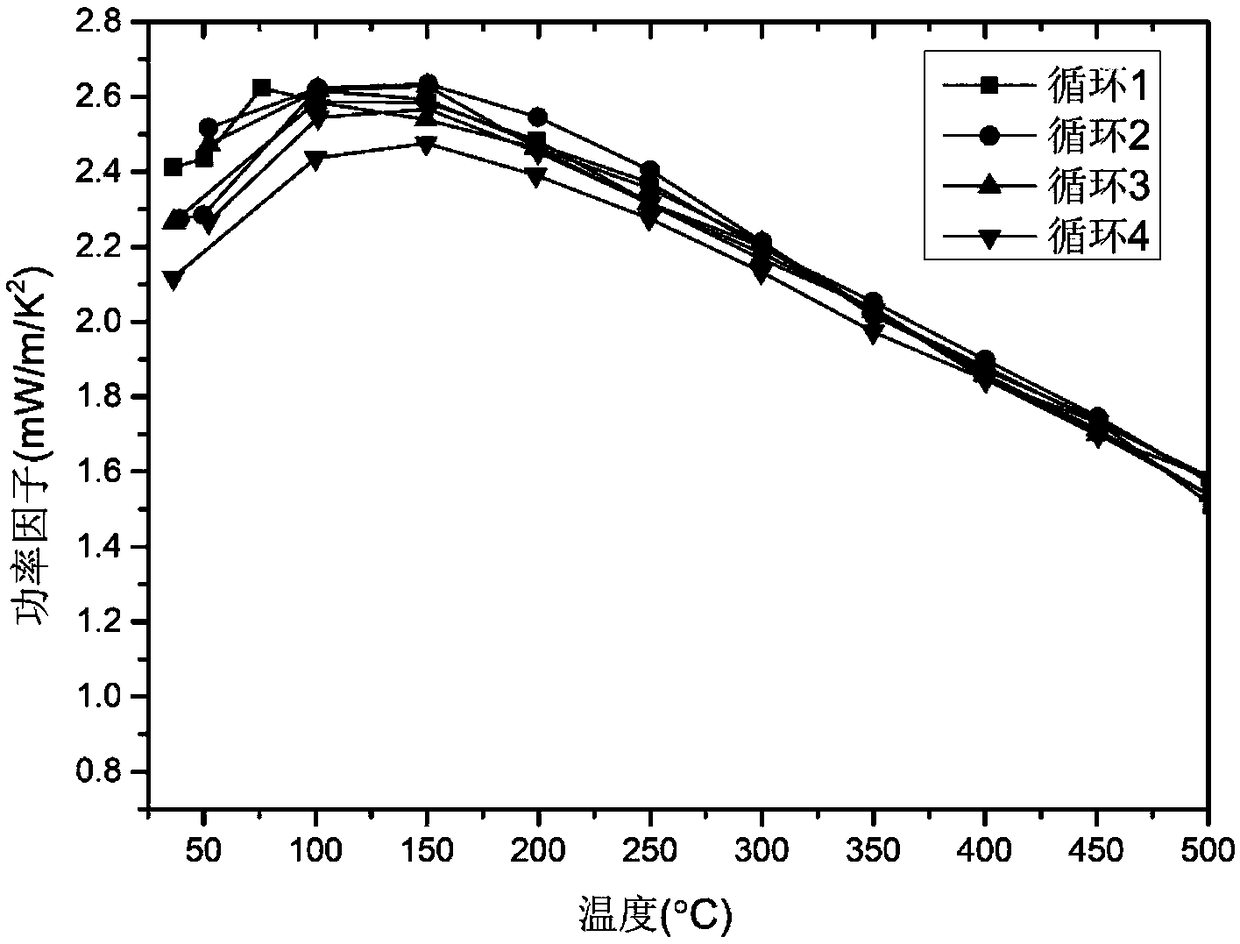

Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

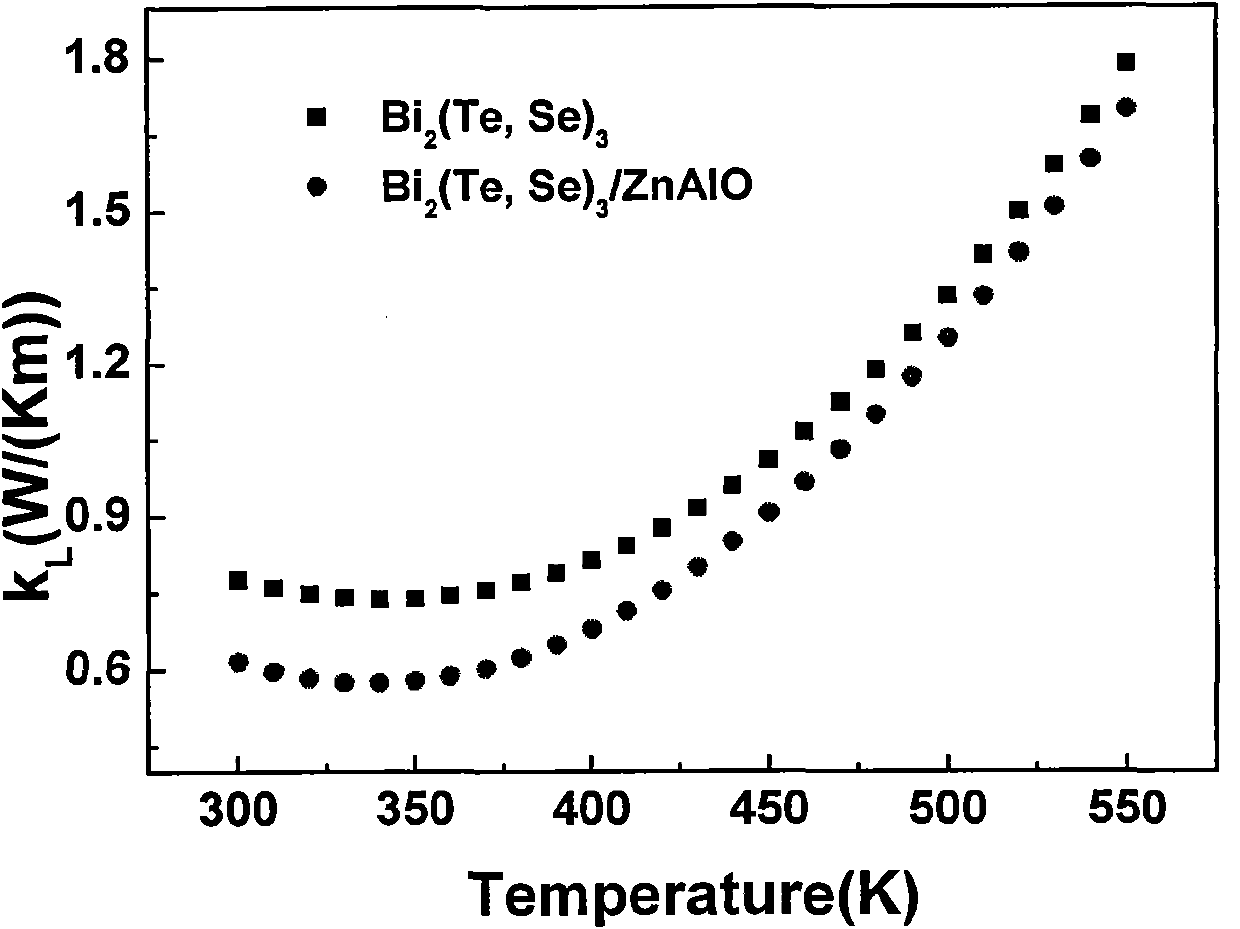

ActiveCN101994155ALower lattice thermal conductivityReduced lattice thermal conductivity κ

<sub>L</sub>Polycrystalline material growthBy zone-melting liquidsBismuth tellurideCarbon nanotube

The invention discloses a nanophase doped bismuth telluride-based thermoelectric material and a preparation method thereof. The bismuth telluride-based thermoelectric material is characterized in taking the bismuth telluride-based thermoelectric material containing a tellurium element, a bismuth element and a doped chemical element, as a matrix. The doped nanophase is a one-dimensional nanophase,and the weight of the one-dimensional nanophase accounts for 0.01-5 percent of the weight of the matrix. Attapulgite or a zinc oxide nanowire or a single-wall carbon nanotube or a multi-wall carbon nanotube is preferable to the one-dimensional nanophase. Compared with the prior art, in the bismuth telluride-based thermoelectric material, the lattice heat conductivity within the whole temperature zone range is reduced, thereby a ZT value is greatly improved and the thermoelectric performance of the bismuth telluride-based thermoelectric material is improved. The preparation method is simple and easy to implement, and compared with other methods of balling milling or liquid phase and the like, impurities are not easy to introduce in the preparation method so that the one-dimensional nanophase is evenly staggered and distributed in the matrix and the mechanical property of the material is effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

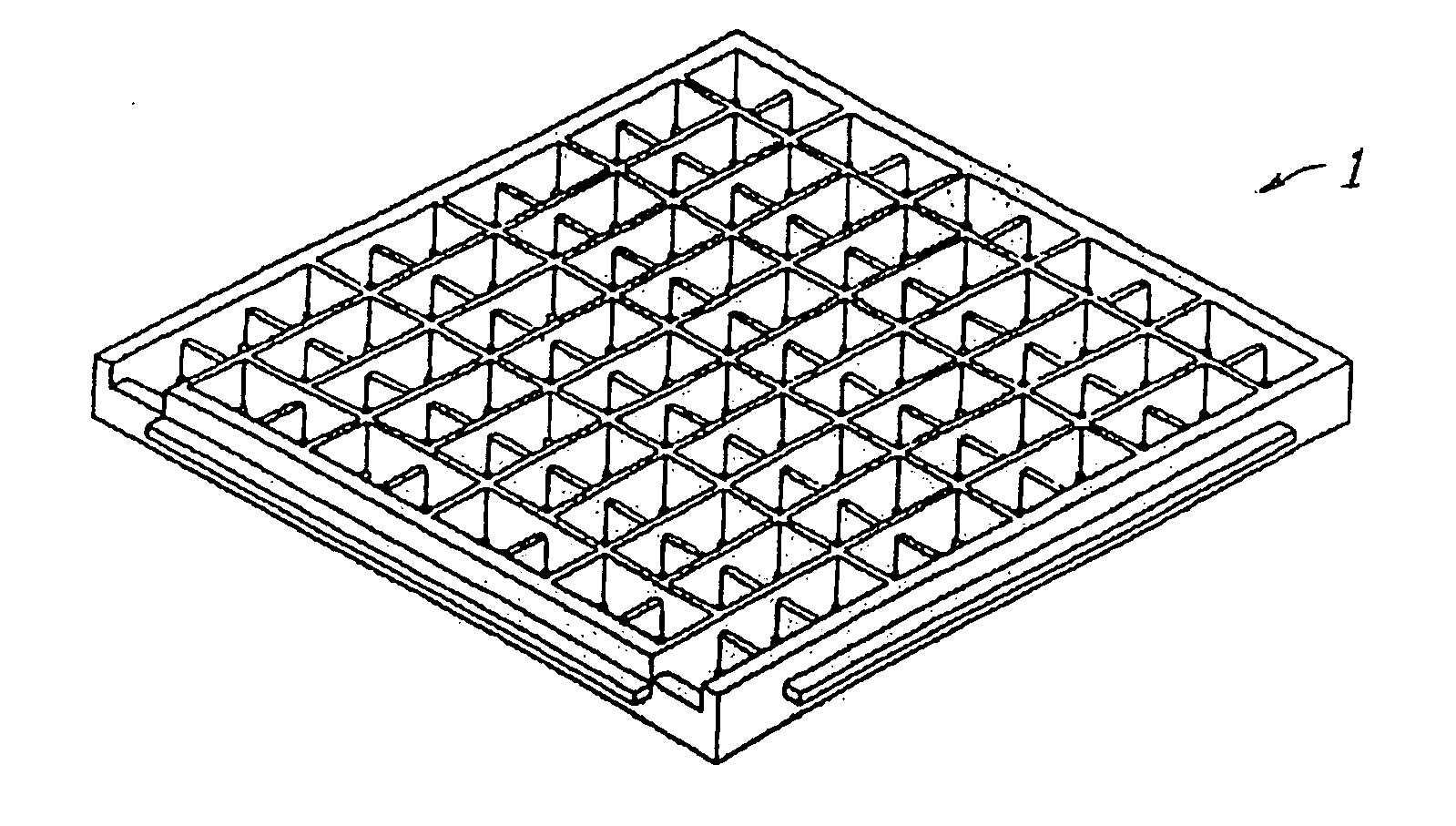

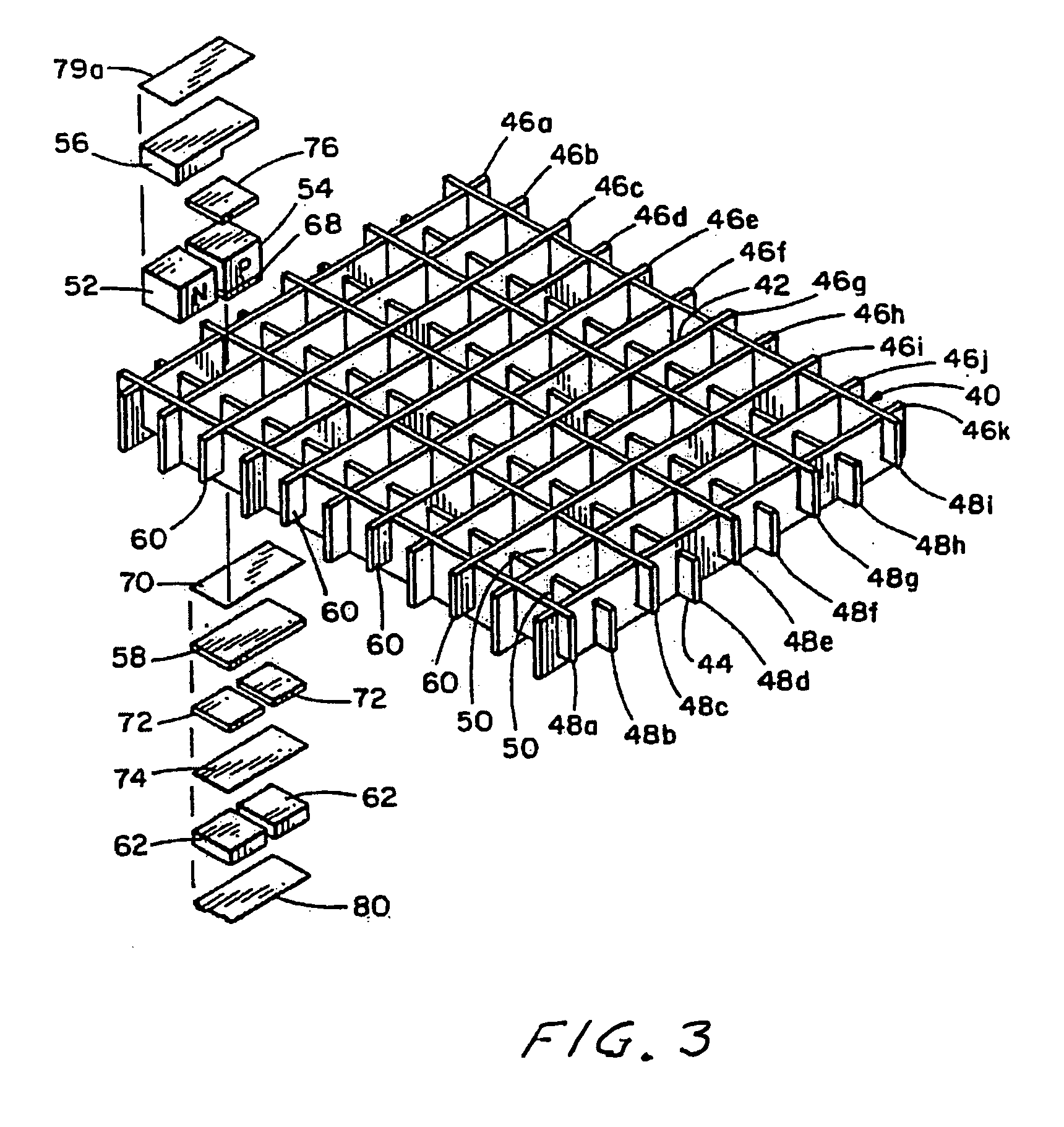

High temperature compact thermoelectric module with gapless eggcrate

InactiveUS20100024437A1Low thermal conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideLead telluride

A high-temperature thermoelectric module. The module includes a two part molded egg-crate for holding in place and providing insulation and electrical connections for a number of thermoelectric n-legs and p-legs. A first part of the egg-crate is comprised of a ceramic material capable of operation at temperatures in excess of 600° C. and a second part comprised of a thermoplastic material having very low thermal conductivity. In preferred embodiments the high temperature ceramic is zirconia and the thermoplastic material is DuPont Zenite. The thermoelectric legs are also comprised of high-temperature and low-temperature material. In preferred embodiments the high temperature thermoelectric material is lead telluride and the low temperature material is bismuth telluride. In preferred embodiments metal felt spacers are provided in each leg to maintain proper electrical contacts notwithstanding substantial temperature variations. Preferably the module is sealed in an inert gas filled insulating capsule.

Owner:HI Z TECH +1

Low power thermoelectric generator

InactiveUS20090025771A1Improve conductivityStrong mechanical connectionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideEngineering

A thermoelectric generator has a top plate disposed in spaced relation above a bottom plate. A series of foil segments are electrically and mechanically connected end-to-end to generate a foil assembly that is spirally wound and in thermal contact with the bottom and top plates. Each foil segment comprises a substrate having a series of spaced alternating n-type and p-type thermoelectric legs disposed in parallel arrangement on the front substrate surface. Each of the n-type and p-type legs is formed of a bismuth telluride-based thermoelectric material having a thickness of about 10-100 microns, a width of about 10-100 microns and a length of about 100-500 microns. The alternating n-type and p-type thermoelectric legs are electrically connected in series and thermally connected in parallel such that a temperature differential between the bottom and top plates results in the generation of power.

Owner:DIGITAL ANGEL CORP

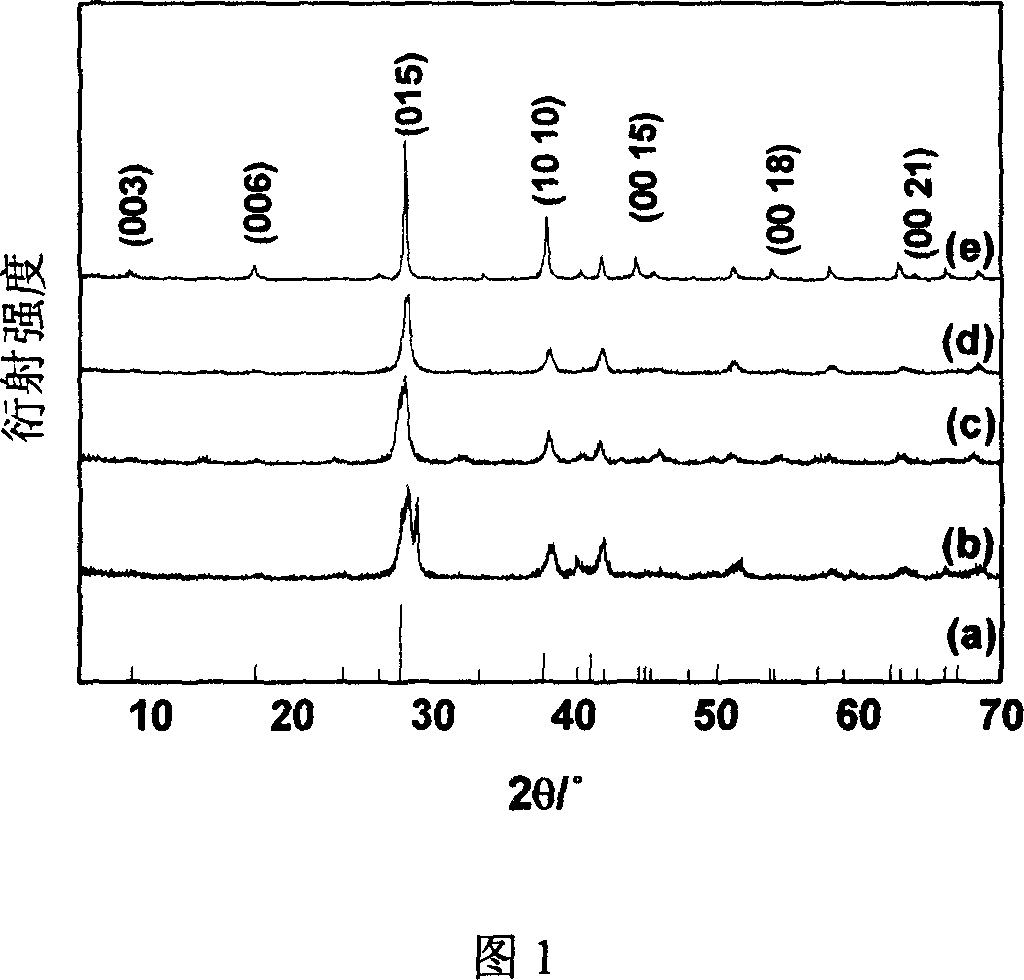

Process of preparing bismuth telluride-base thermoelectric material

InactiveCN1974079AIncrease profitImprove machinabilityThermoelectric device manufacture/treatmentIncreasing energy efficiencyBismuth tellurideZone melting

The present invention discloses process of preparing bismuth telluride-base thermoelectric material. By means of controlling the technological parameters in mechanical alloying and SPS process to maintain the powder material size within certain range, and the fast densification of SPS technology to avoid the growth of crystal grain in the sintered block material, the present invention lowers the heat conductivity of the material while maintaining the electric performance unchanged basically, so as to improve the thermoelectric performance and mechanical performance, raise the utilization rate of the prepared material and improve the stability and reliability of the corresponding thermoelectric device. The bismuth telluride-base thermoelectric material preparing process combining mechanical alloying and SPS technology of the present invention is superior to available zone melting growth process, which is slow and needs precise control.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

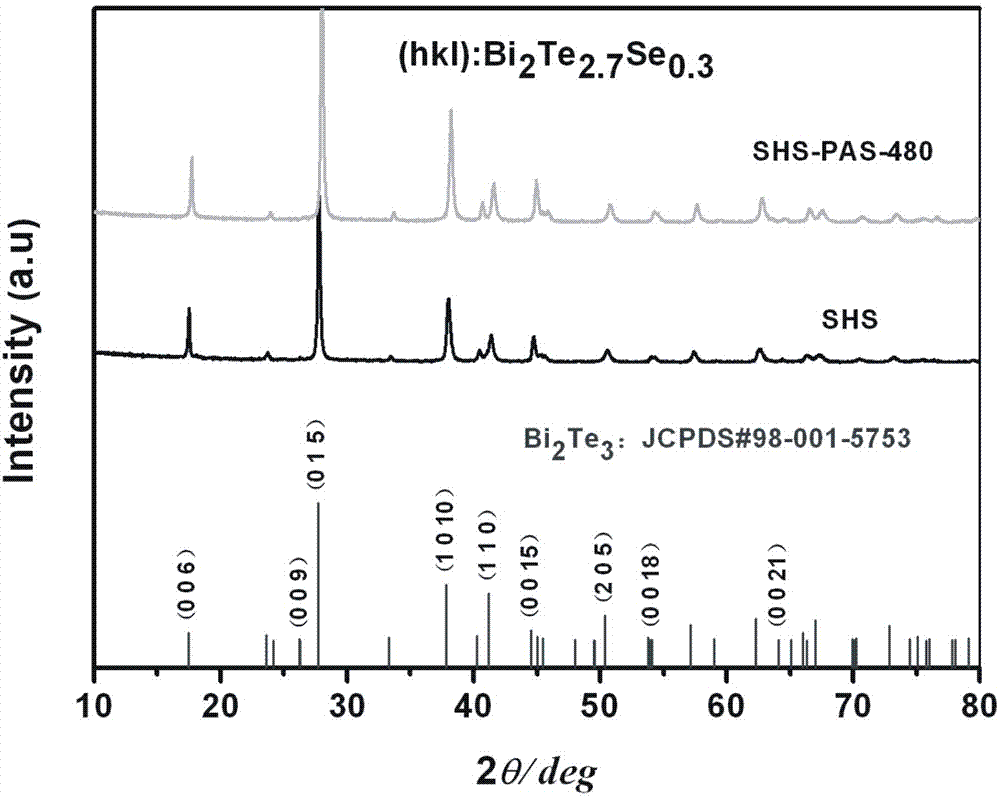

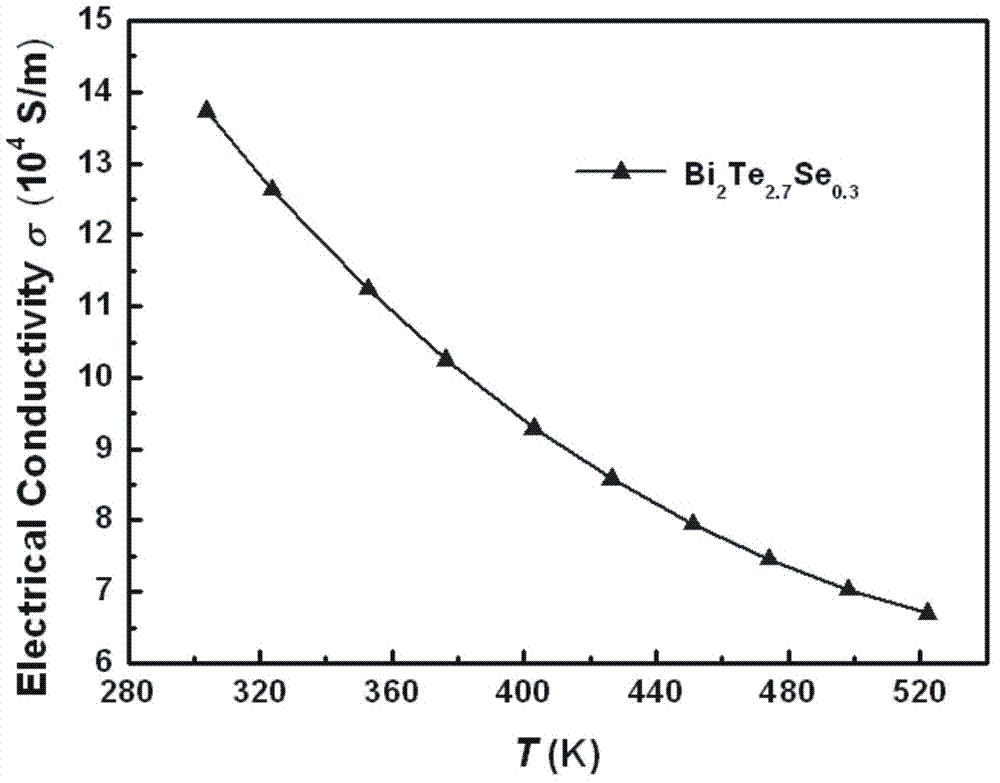

Method for fast manufacturing n-type bismuth telluride based high-performance thermoelectric materials

ActiveCN103928604AShort preparation timeSimple processThermoelectric device manufacture/treatmentThermoelectric device junction materialsMetallurgyBismuth telluride

The invention provides a method for fast manufacturing n-type bismuth telluride based high-performance thermoelectric materials. The method specifically comprises the steps that 1), Bi powder, Te powder and Se powder are weighed according to the stoichiometric ratio of all elements in Bi2Te3-xSex, 0=<x<=3, and the Bi powder, the Te powder and the Se powder are evenly mixed and pressed to be blocks; 2), a self-propagating reaction is generated on the blocks in the step 1), cooling is carried out after the reaction is completed, and a single-phase Bi2Te3-xSex compound is obtained; 3), the single-phase Bi2Te3-xSex compound obtained in the step 2) is ground to be powder, then plasma activation sintering is carried out, and the high-performance Bi2Te3-xSex thermoelectric materials are obtained. The technology with self-propagating combustion synthesis combined with plasma activation sintering is adopted, the n-type bismuth telluride block thermoelectric materials with the thermoelectric optimal value zT reaching 0.95 within 426 K are manufactured within 20 min, and the advantages of being short in manufacturing time, simple in technology, high in thermoelectric performance of the materials and the like are achieved.

Owner:武汉新赛尔科技有限公司

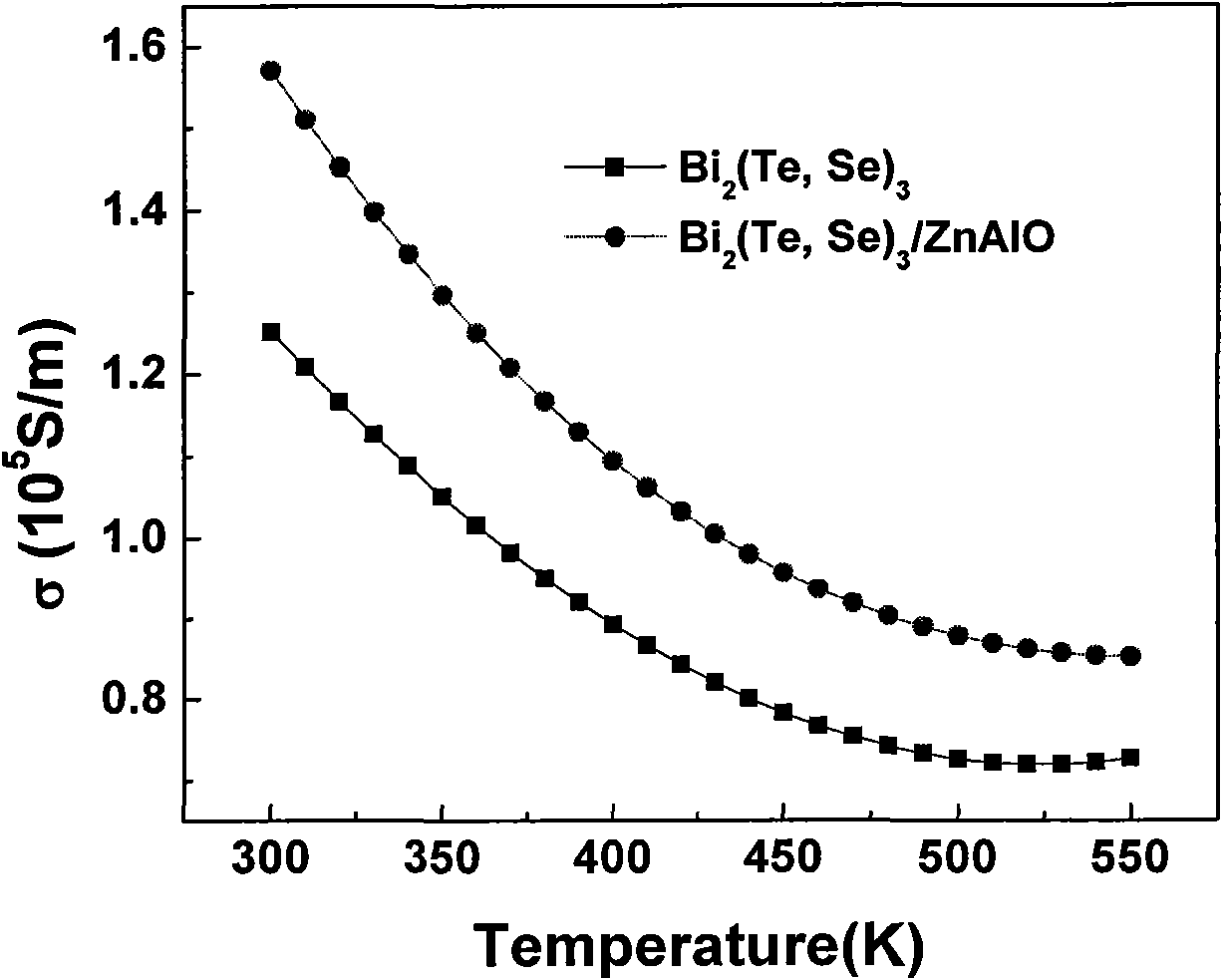

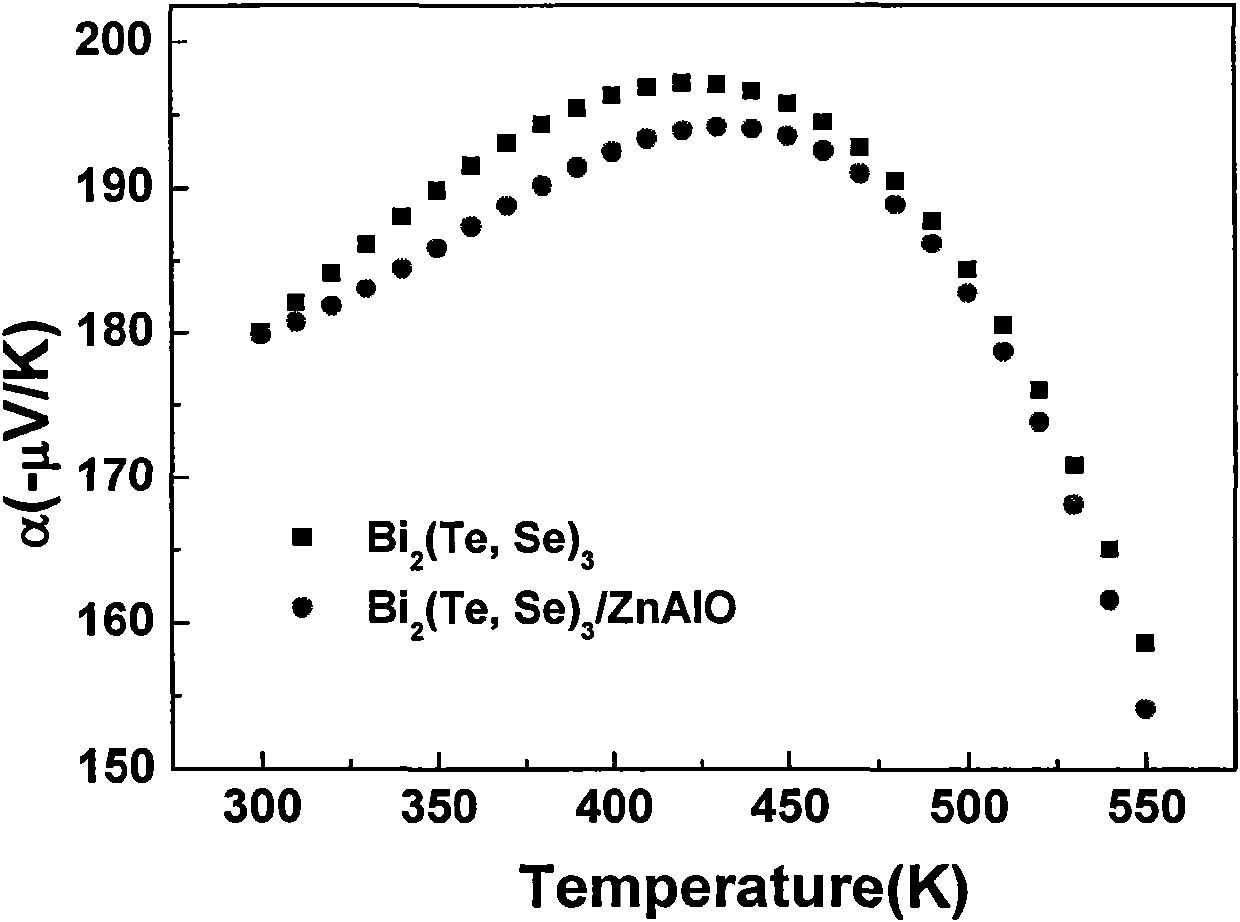

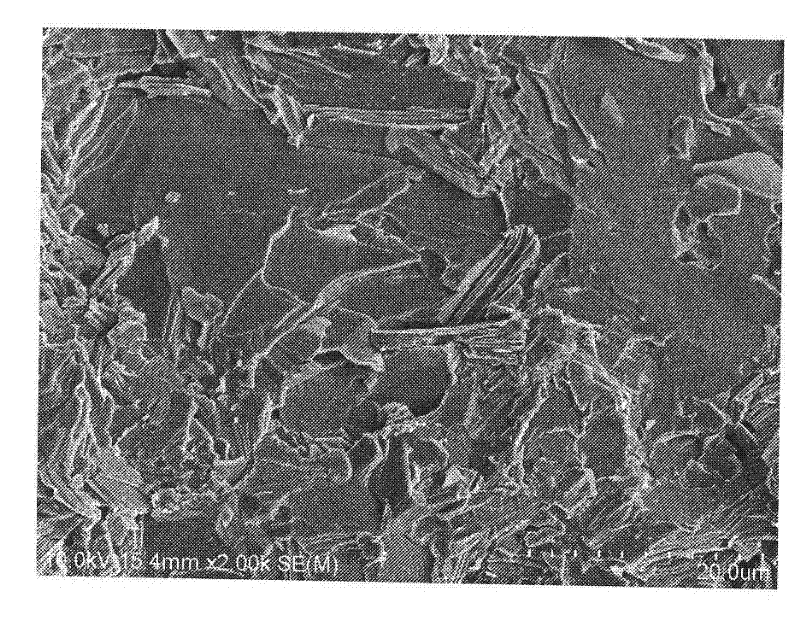

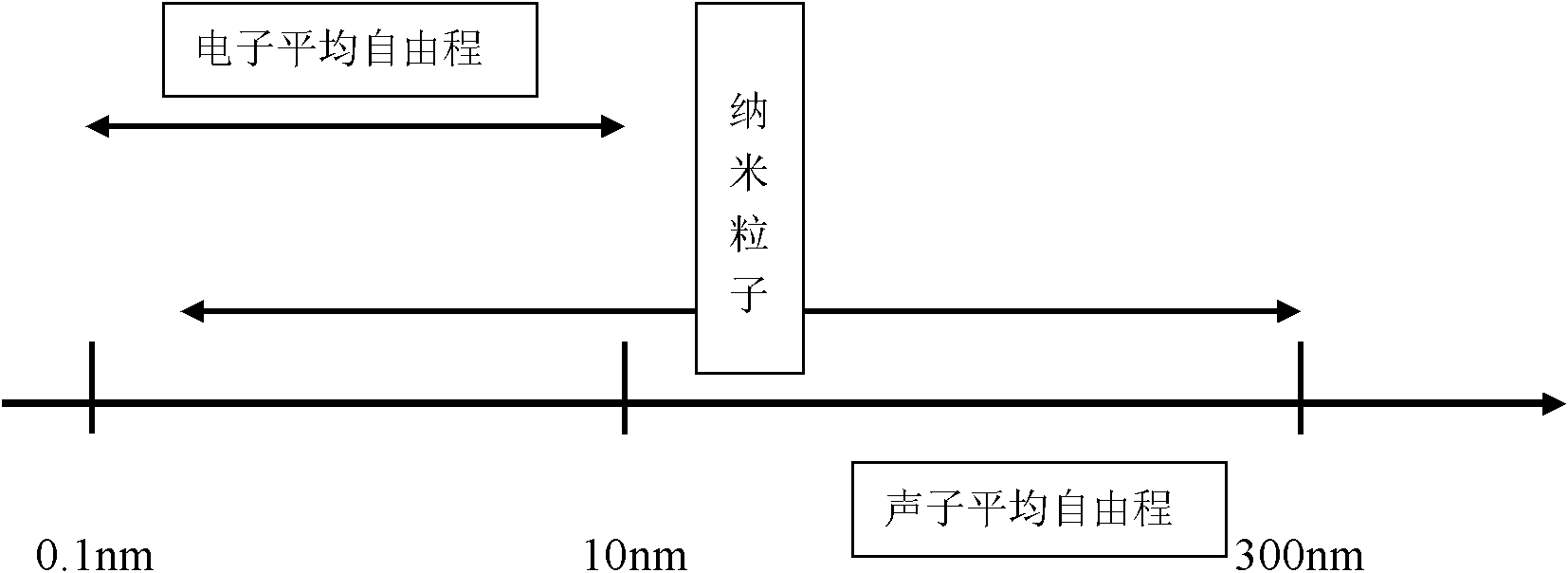

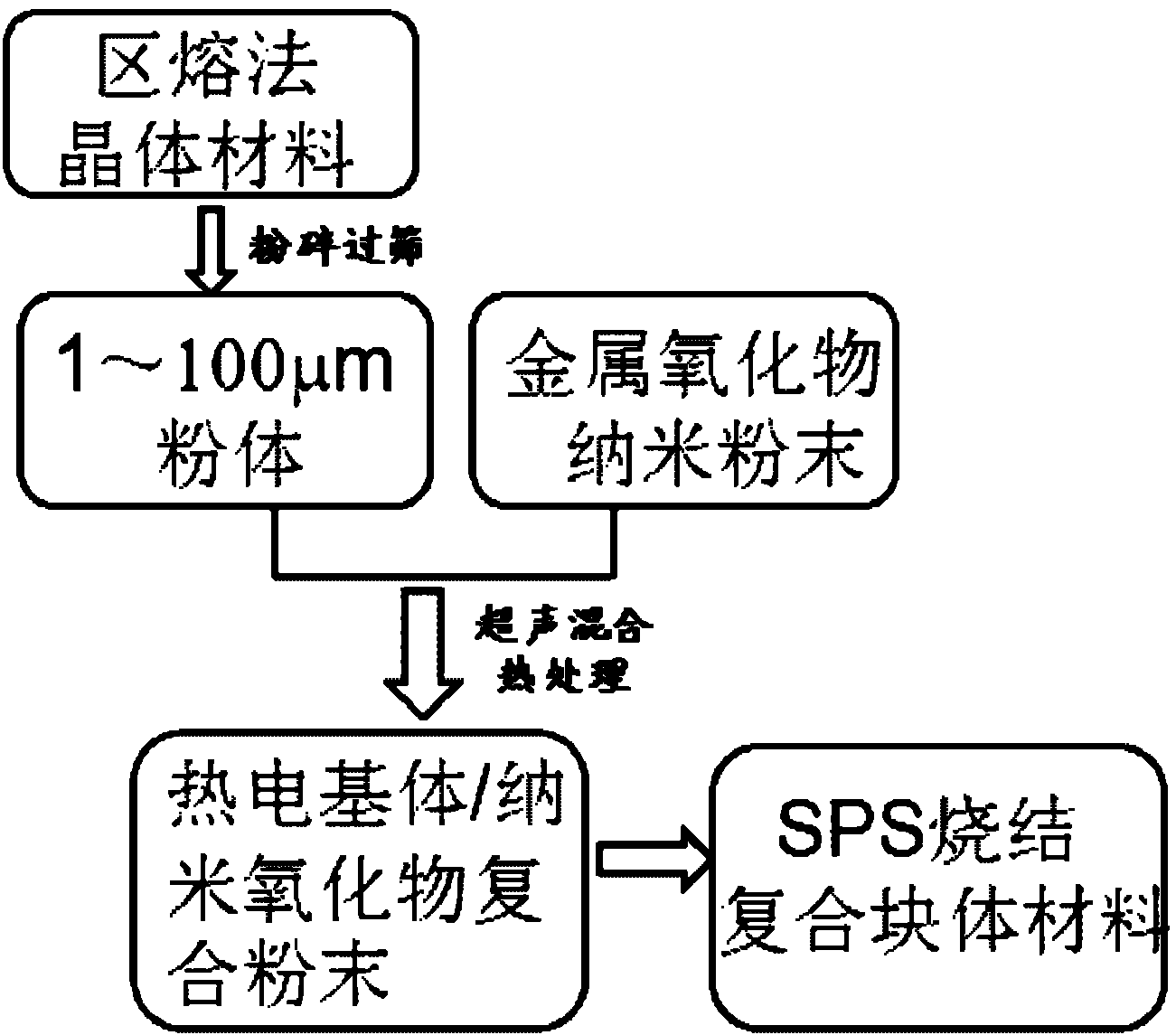

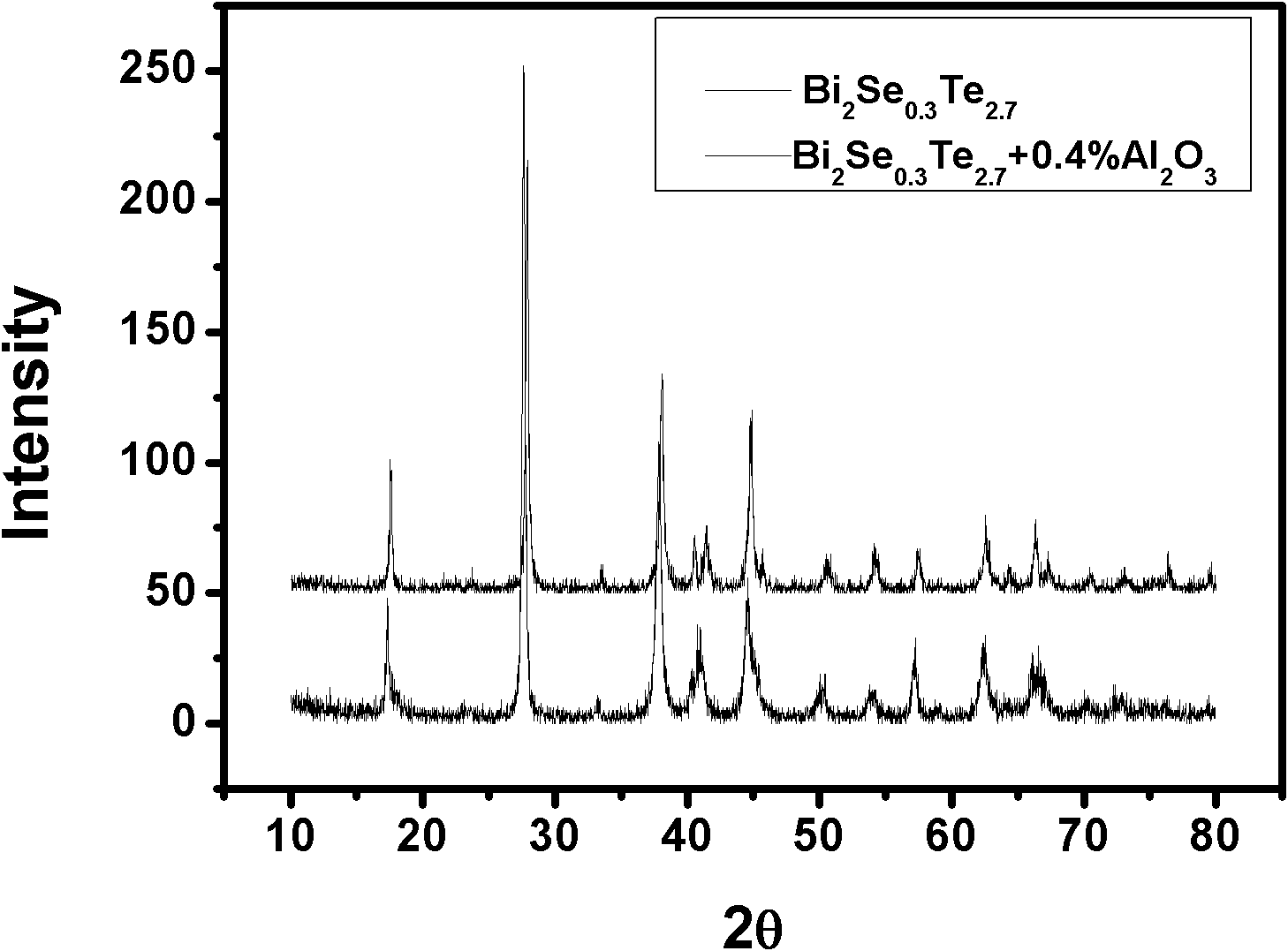

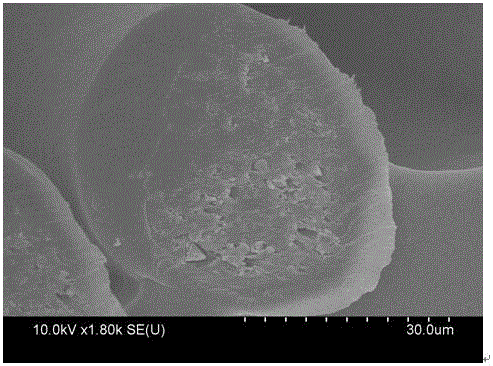

Nanoparticle composite bismuth telluride-based thermoelectric material and preparation method thereof

ActiveCN102024899ALower lattice thermal conductivityImprove thermoelectric figure of merit ZTThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention discloses a nanoparticle composite bismuth telluride-based thermoelectric material and a preparation method thereof. In the nanoparticle composite bismuth telluride-based thermoelectric material, a bismuth telluride thermoelectric material is used as a substrate, and nanoparticles are mixed in the substrate, wherein the nanoparticles are electrical-conduction oxide nanoparticles. Compared with the prior art, since the electrical-conduction oxide nanoparticles are used as a second phase and compounded with a bismuth telluride-based alloy substrate; on one hand, the electrical-conduction oxide nanoparticles can enhance the selective scattering to low-frequency phonons so that the crystal lattice heat conductivity of the bismuth telluride-based thermoelectric material can be effectively reduced, and on the other hand, the electrical-conduction oxide nanoparticles can improve the electrical conductivity of the material on the other hand, therefore, an integral regulation and control effect improves the thermoelectric figure of merit ZR of the bismuth telluride-based thermoelectric material so that the thermoelectric property of the bismuth telluride-based thermoelectric material is optimized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

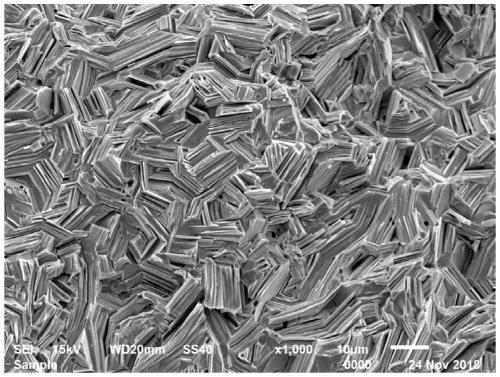

Sleeve forging and pressing preparation method of bismuth-telluride-base thermoelectric material

The invention relates to a sleeve forging and pressing preparation method of a bismuth-telluride-base thermoelectric material, which comprises the following steps: (1) material preparation: smelting raw materials to obtain a bismuth telluride base block material, pulverizing, grinding and screening to obtain powder; (2) sleeve filling: filling the powder into an aluminum sleeve, putting the aluminum sleeve in a cold-press die, and compacting the powder with a pressing machine to obtain a block blank; (3) presintering: heating to 300-580 DEG C, and keeping the temperature for 3 minutes to 1 hour; (4) forging and pressing: forging the bismuth telluride base block alloy thermoelectric material with the aluminum sleeve under the forging and pressing pressure of 20-900MPa until the die cavity is fully filled, and maintaining or not maintaining the pressure; and (5) sleeve removal: removing the aluminum sleeve to obtain the required bismuth telluride base block thermoelectric material. The invention has the following advantages: 1) the required equipment is simple; 2) the preparation technique is simple and practical; 3) the technique of sheathing an aluminum sleeve outside the sample is adopted to effectively avoid sample cracking which can possibly occur in the forging process; and 4) the prepared sample has high thermoelectric properties and favorable actual effect.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

High-performance thermoelectric composite material and preparation method thereof

ActiveCN102339946AImprove Seeback coefficientLow thermal conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsBismuth tellurideLattice thermal conductivity

The invention relates to a high-performance thermoelectric composite material and a preparation method thereof, belonging to the field of thermoelectric materials. The composite material consists of two phases. A first phase is n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3, and a second phase is nanometer powder of a metallic oxide. The nanometer powder of the metallic oxide accounts for 0.05-10% in terms of the total weight of the thermoelectric composite material. According to the preparation method provided by the invention, the n-type Bi2Te3-Bi2Se3 or p-type Bi2Te3-Sb2Te3 powder is ultrasonically mixed with the nanometer oxide, and discharge plasma sintering is carried out on the mixture to obtain a dense block material. Compared with the bismuth-telluride-based thermoelectric base material, under the condition that the electric conductivity of the thermoelectric base material is maintained to be unchanged basically in the invention, the high-performance thermoelectric composite material, provided by the invention, achieves the advantages of obviously reduced lattice heat conductivity and increased Seeback coefficient, and therefore the thermoelectric performance of the material can be greatly improved.

Owner:中科西卡思(苏州)科技发展有限公司

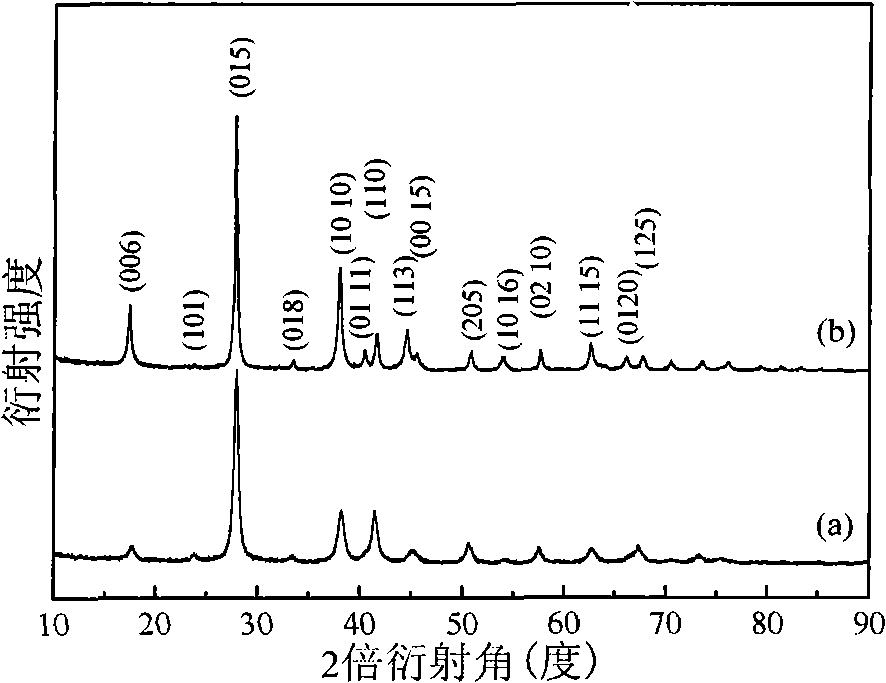

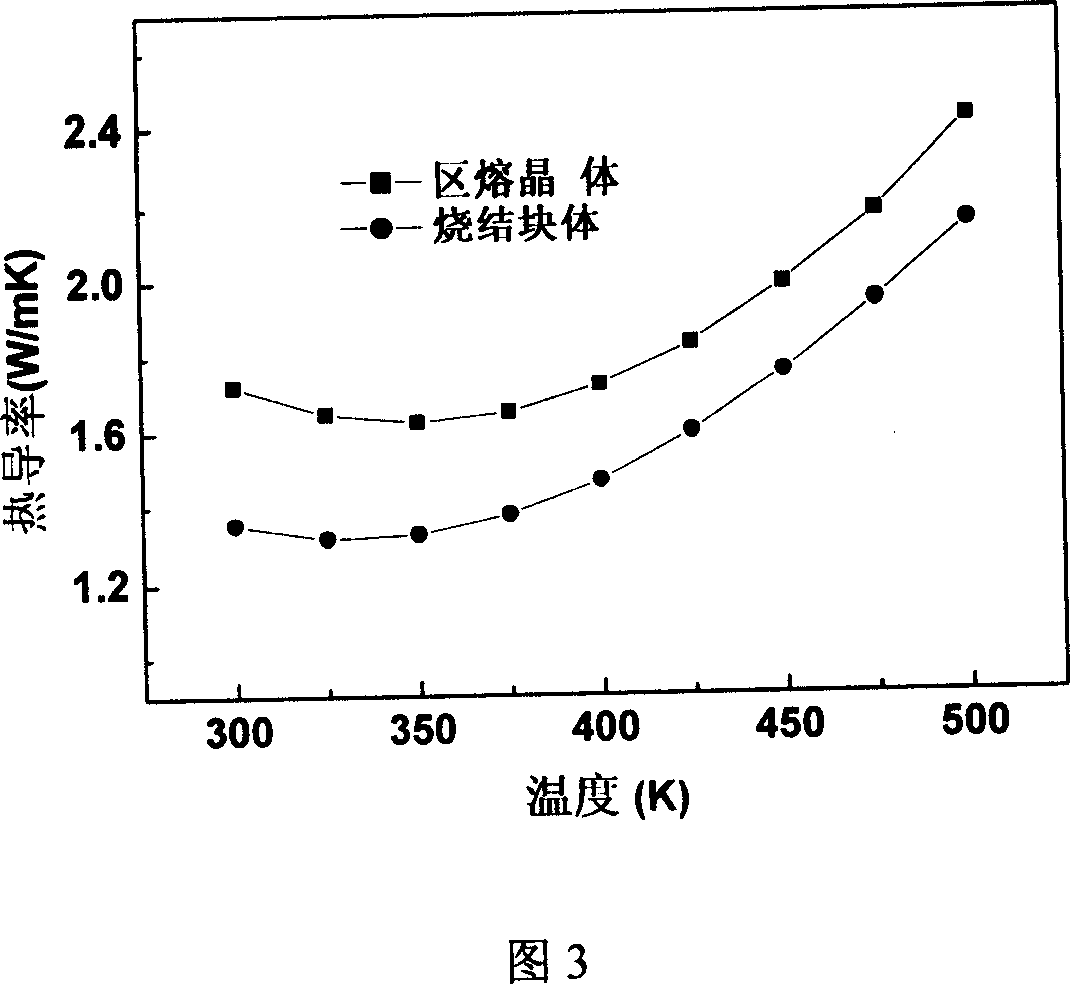

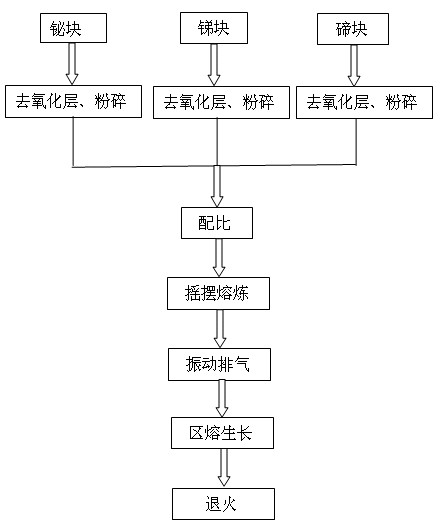

Method for preparing high-performance p-type bismuth telluride-based thermoelectric materials

ActiveCN102108554ACheap performanceRaw materials are cheap and easy to getPolycrystalline material growthBy zone-melting liquidsHigh volume manufacturingBismuth telluride

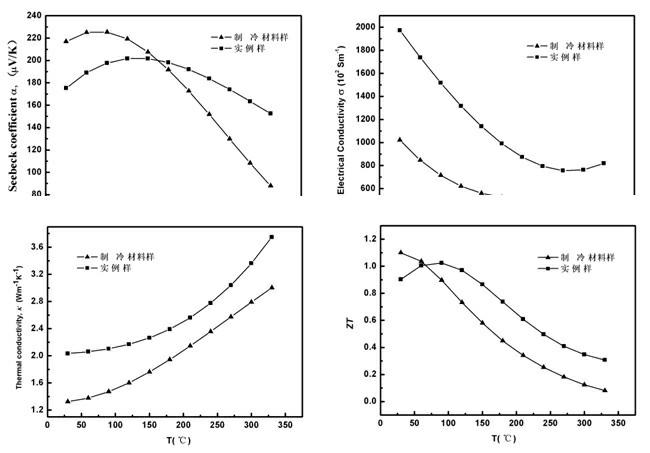

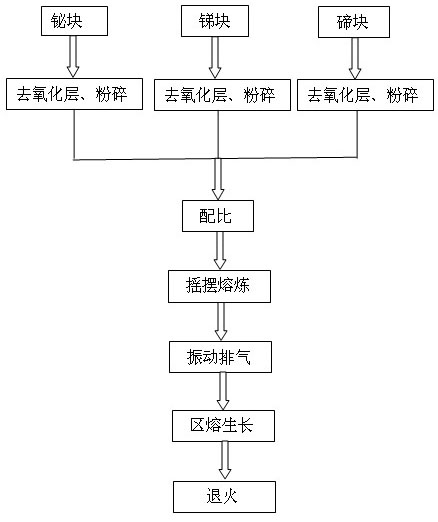

The invention discloses a method for preparing high-performance p-type bismuth telluride-based thermoelectric materials. High-purity tellurium blocks, bismuth blocks and stibium blocks which are industrially produced are used as raw materials, and the method comprises the following steps of: removing oxide layers, crushing, weighing in a certain ratio, and putting into a treated glass tube; and performing packaging, melting, zone-melting growth and annealing to obtain p-type bismuth telluride-based thermoelectric semiconductor crystal bars. At the temperature of between 30 and 300DEG C, the average ZT value is more than 0.75. The raw materials are cheap, readily available, nontoxic, and environment-friendly; and the equipment and process are simple, the energy consumption is low, the yield is high, and the method is suitable for large-scale industrial production.

Owner:江西纳米克热电电子股份有限公司

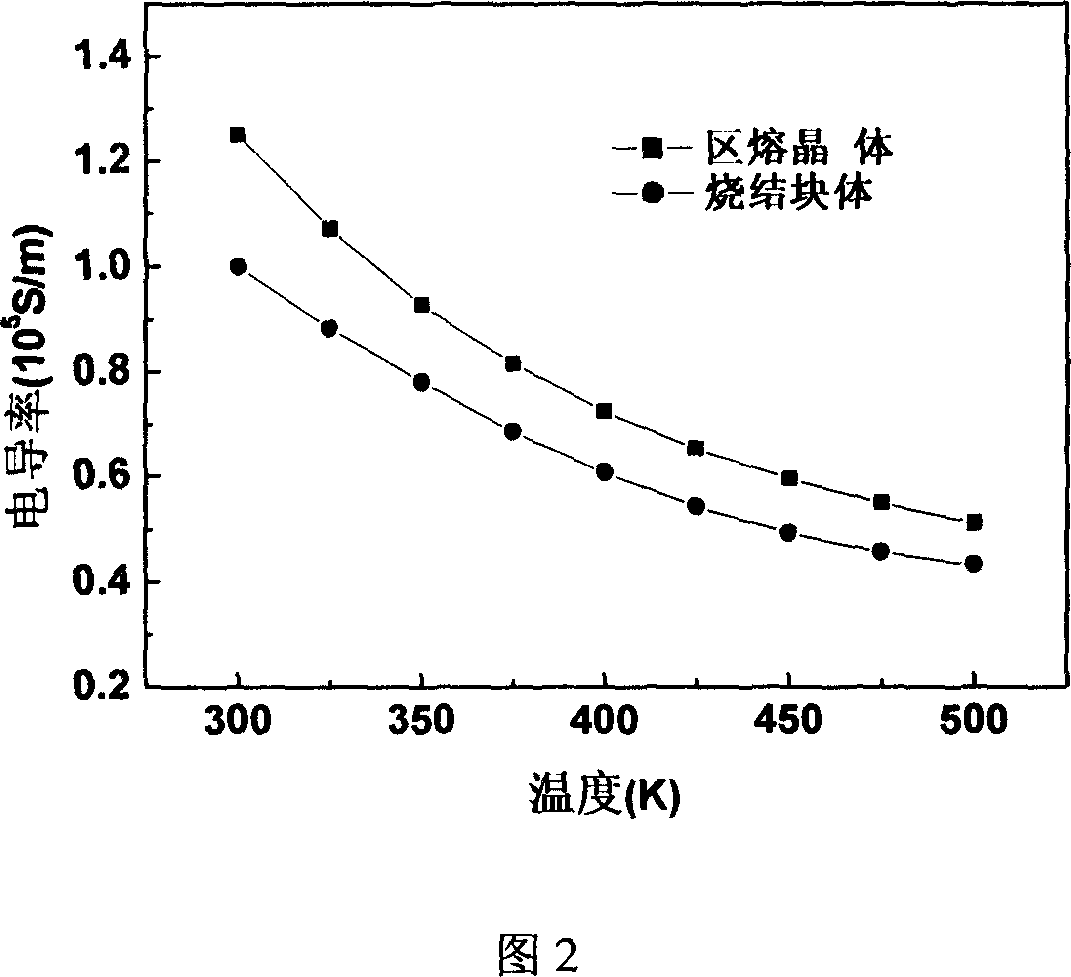

Preparation method for high-performance n-type bismuth telluride base thermoelectricity power generation material

ActiveCN102088058ACheap performanceRaw materials are cheap and easy to getThermoelectric device manufacture/treatmentDopantHigh volume manufacturing

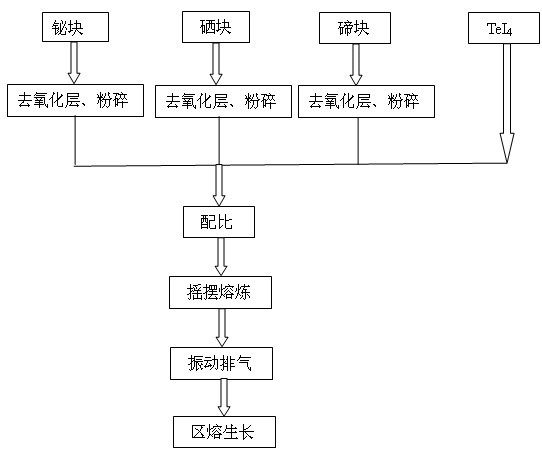

The invention discloses a preparation method for a high-performance n-type bismuth telluride base thermoelectricity power generation material. High-purity tellurium blocks, bismuth blocks and selenium blocks which are industrially produced on a large batch serve as raw materials; after the raw materials are subjected to oxide layer removal and smashing, a proper quantity of dopant is added; the mixture is put into a processed glass tube after being weighed at a certain ratio; and an n-type bismuth telluride base thermoelectricity semiconductor crystal bar is obtained by packaging, smelting and zone-melting growth. At the temperature of 30-300 DEG C, the average ZT value is 0.75, and the average power factor is 4.5*10<-3>W. m. K<-2>. The adopted raw materials are cheap and easy to get, have the advantages of no toxin, environment protection, simple equipment process, low energy consumption and large yield and can be industrially produced on a large scale.

Owner:江西纳米克热电电子股份有限公司

Large format thermoelectric infrared detector and method of fabrication

ActiveUS7755048B2Promote absorptionImprove energy absorptionThermoelectric device with peltier/seeback effectMaterial analysis by optical meansElectricityNano composites

The thermoelectric detector consists of an absorber structure supported by two electrically connected beams made of thermoelectric materials such as polysilicon, polysilicon / germanium, bismuth-telluride, skutterrides, superlattice structures, nano-composites and other materials. One end of the thermoelectric beam connects to the absorber structure; the other end connects to the substrate. Infrared radiation incident on the absorber heats up the absorber, resulting in a temperature gradient along the length of the thermoelectric legs, and generating an electrical voltage. The detector arrays are fabricated using micromachining process. The absorber structure is formed over a sacrificial material that is removed at the end of the processing, leaving the detector suspended and thermally isolated. The sacrificial processing method enables the production of small pixel thermoelectric detectors in large two-dimensional arrays with high sensitivity.

Owner:NYTELL SOFTWARE LLC

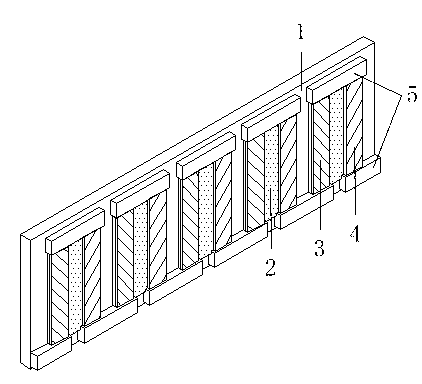

Bismuth-telluride-based thermoelectric element and preparation method thereof

InactiveCN102412366AImprove bindingReliable and goodThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentBismuth tellurideAlloy

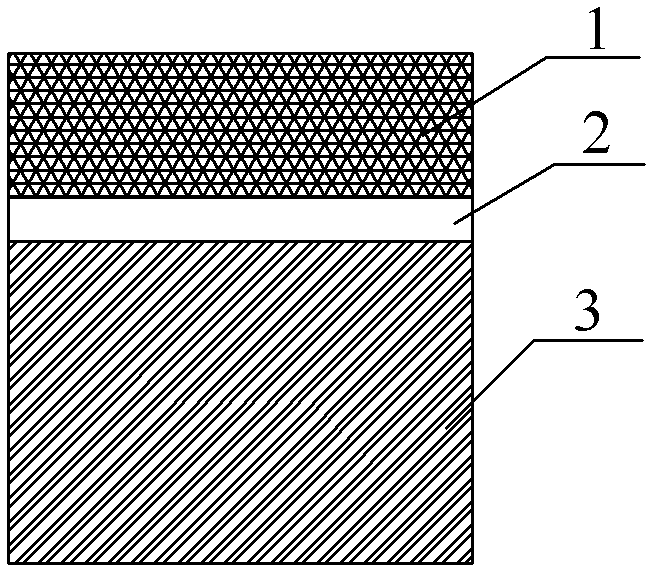

The invention discloses a bismuth-telluride-based thermoelectric element and a preparation method thereof. The bismuth-telluride-based thermoelectric element comprises an electrode layer, a blocking layer and a bismuth-telluride-based thermoelectric layer, wherein the blocking layer is positioned between the electrode layer and the bismuth-telluride-based thermoelectric layer; and the blocking layer is made of metallic bismuth or alloy of the metallic bismuth and other metal. The preparation method of the bismuth-telluride-based thermoelectric element comprises the following steps of: respectively weighing a bismuth-telluride-based thermoelectric layer material, a blocking layer material and an electrode layer material; putting the bismuth-telluride-based thermoelectric layer material, the blocking layer material and the electrode layer material into a graphite mold in sequence according to the sequence of the bismuth-telluride-based thermoelectric layer material, the blocking layer material and the electrode layer material; and carrying out hot-pressing sintering in vacuum. In the bismuth-telluride-based thermoelectric element provided by the invention, the combination among all interfaces is good, no cracks and obvious diffusion phenomenon at the interfaces exist, the interface resistance is low and the long-time heat fatigue test can be born. In addition, the preparation method disclosed by the invention has the advantages of simple process, good reliability, low manufacturing cost, no need for special equipment and suitability for on-scale production and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

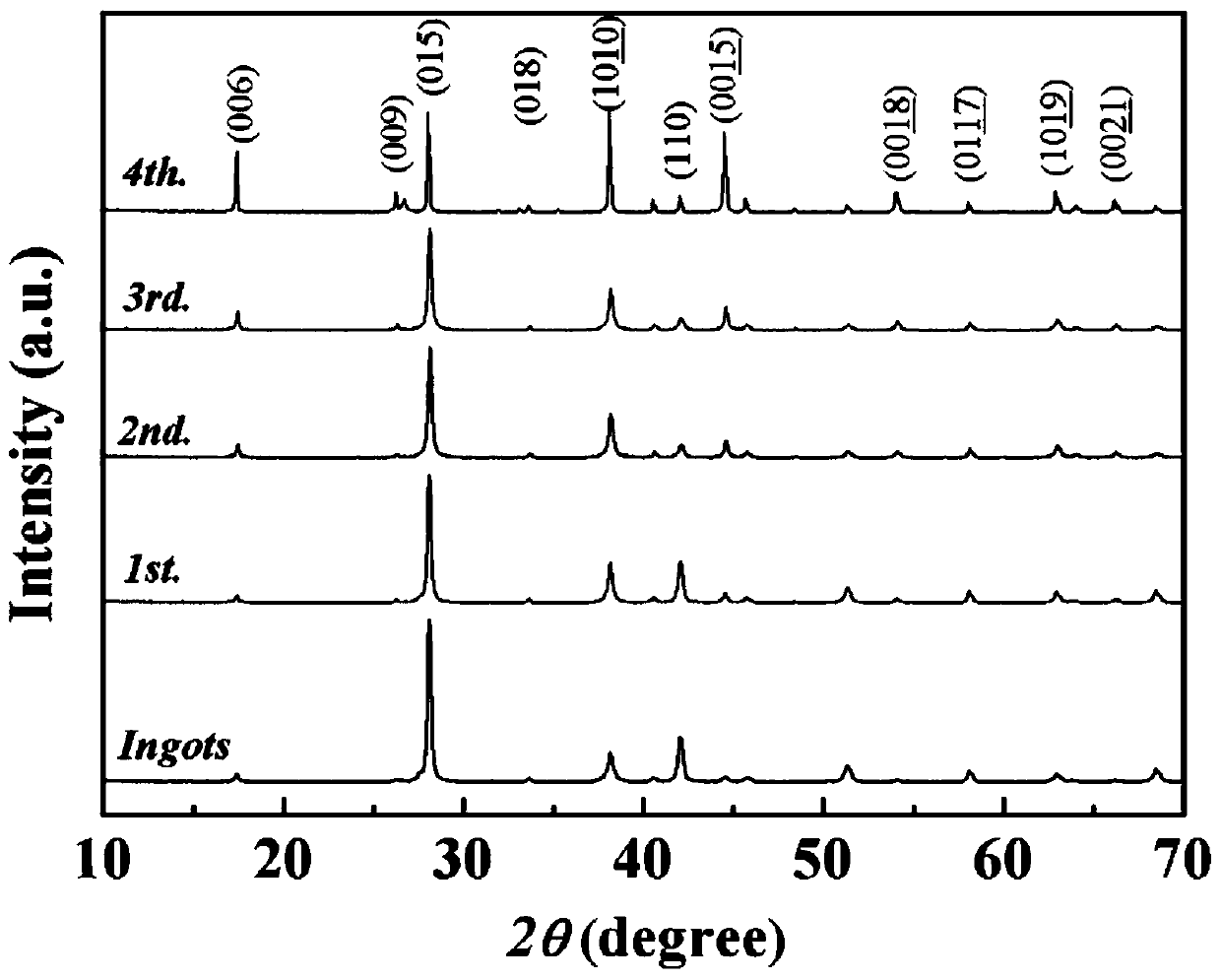

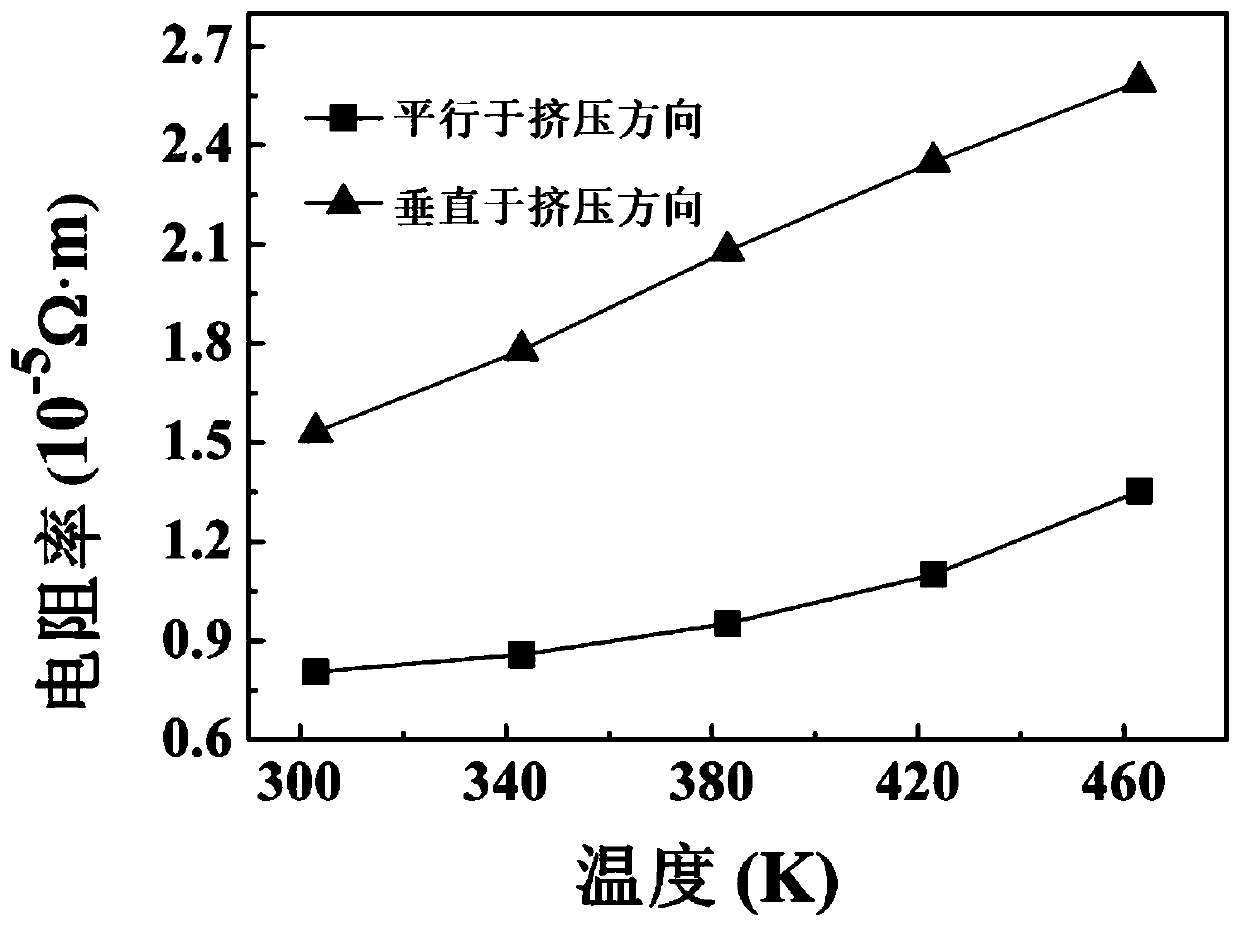

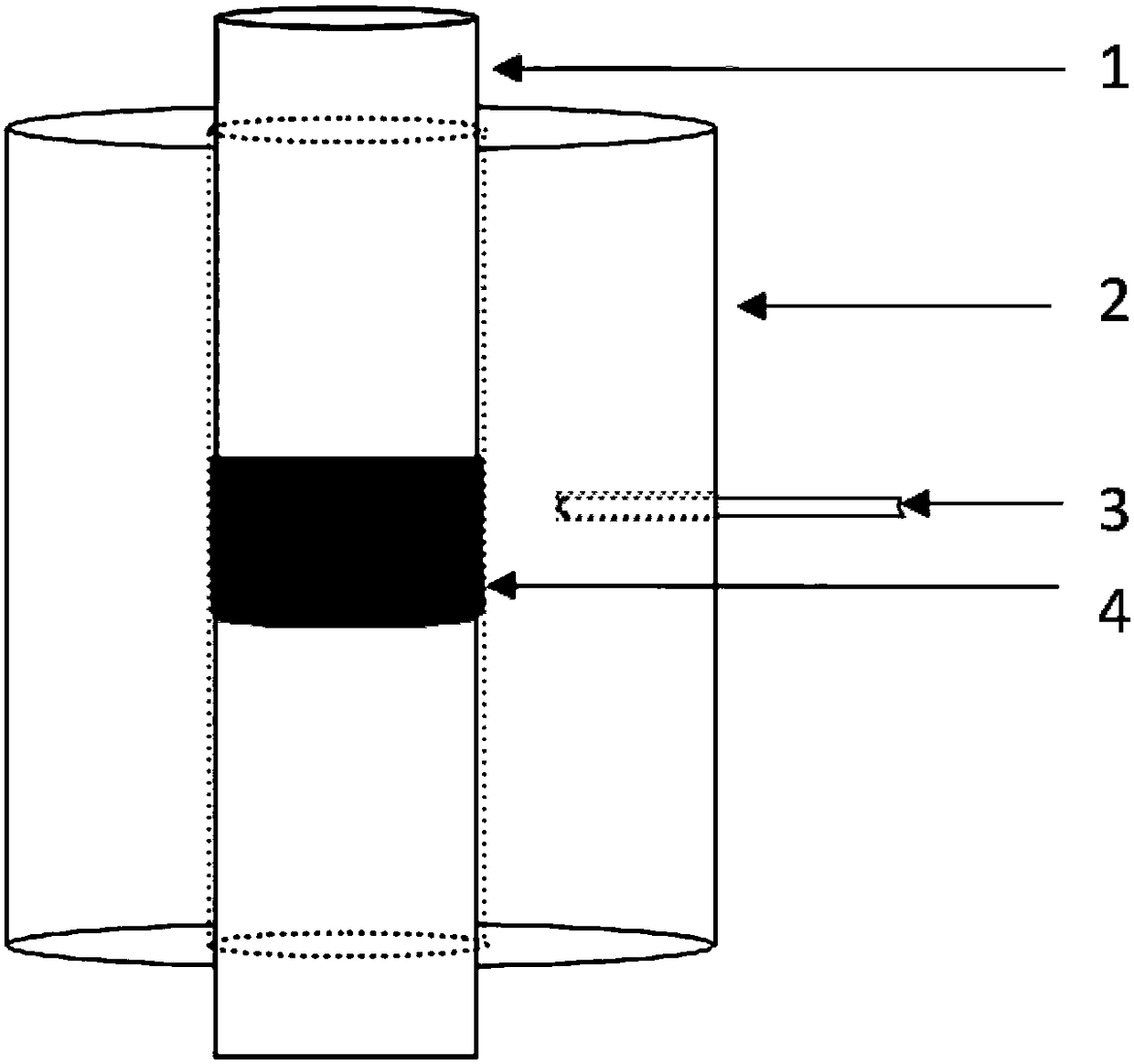

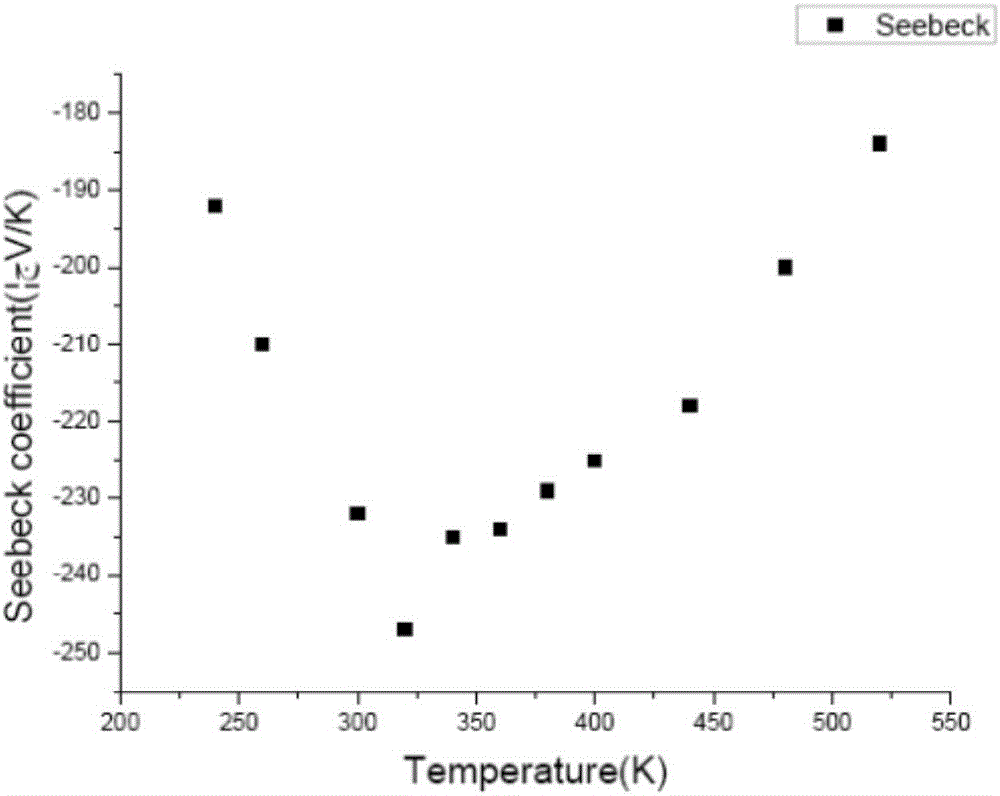

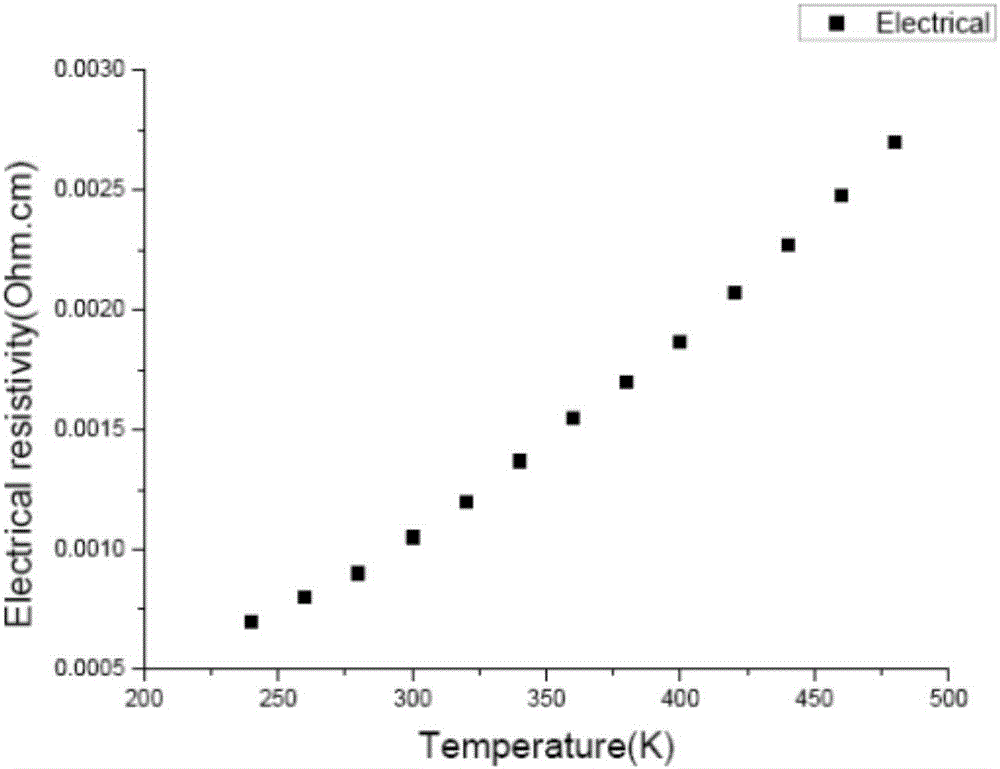

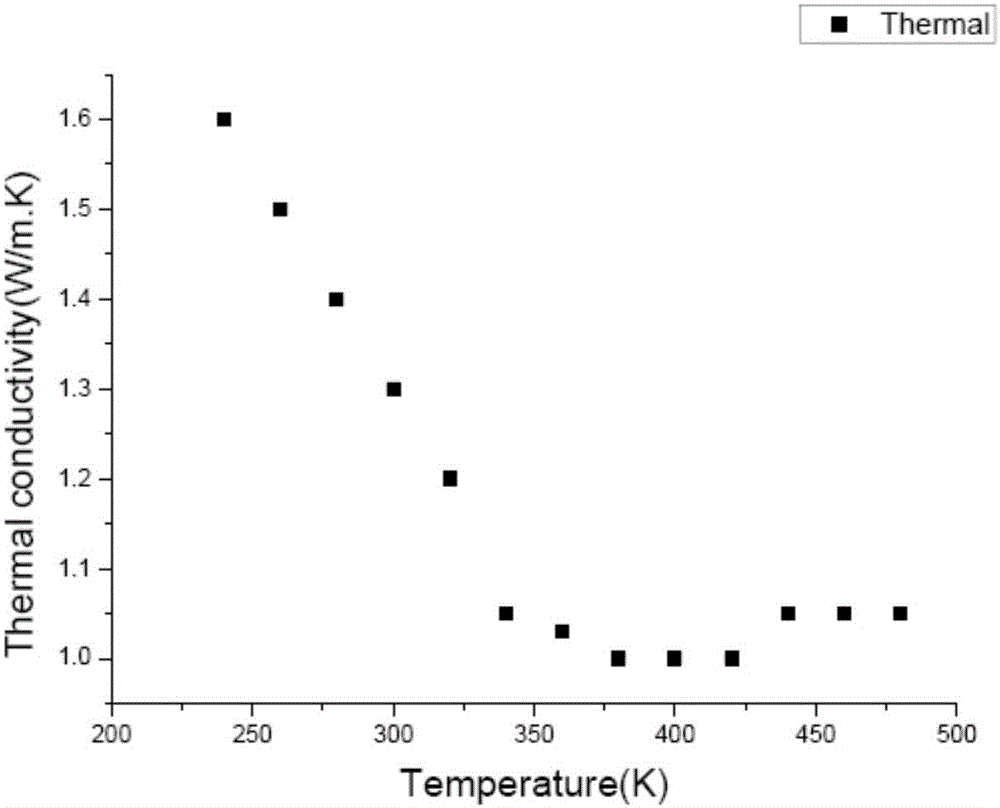

Preparation method of preferentially oriented n-type bismuth telluride-based polycrystalline bulk thermoelectric material

ActiveCN110002412AImprove performanceGood repeatabilityMetal selenides/telluridesBismuth tellurideHearth

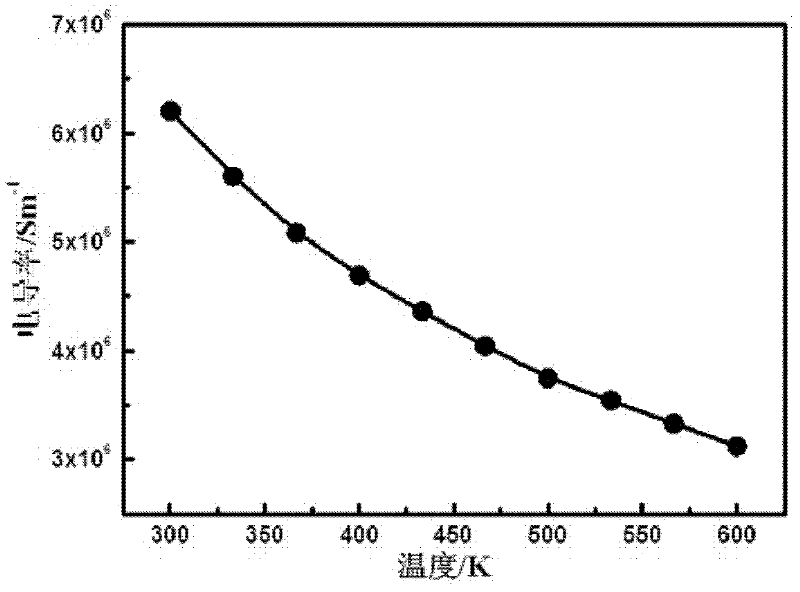

The invention provides a preparation method of a preferentially oriented n-type bismuth telluride-based polycrystalline bulk thermoelectric material, comprising the following steps: using Bi, Te and Se elemental powders as raw materials, weighing the ingredients according to Bi2Te3-xSex stoichiometric ratio, placing the above raw materials into a quartz glass tube or a high borosilicate glass tubeand vacuum-sealing, putting the sealed quartz glass tube or the high borosilicate glass tube into a rocking furnace and fully smelting, rotating a hearth of the rocking furnace to a vertical positionafter the smelting, and cooling to prepare an n-type bismuth telluride-based alloy ingot; cutting the prepared n-type bismuth telluride-based alloy ingot into blocks, and placing the blocks into an equal channel angular extrusion die and sintering and extruding in a hot-pressed sintering furnace so as to obtain the preferentially oriented n-type bismuth telluride-based polycrystalline bulk thermoelectric material. The prepared n-type bismuth telluride-based polycrystalline bulk thermoelectric material has low resistivity, high Seebeck coefficient, low thermal conductivity and high dimensionless thermoelectric figure of merit.

Owner:湖北赛格瑞新能源科技有限公司

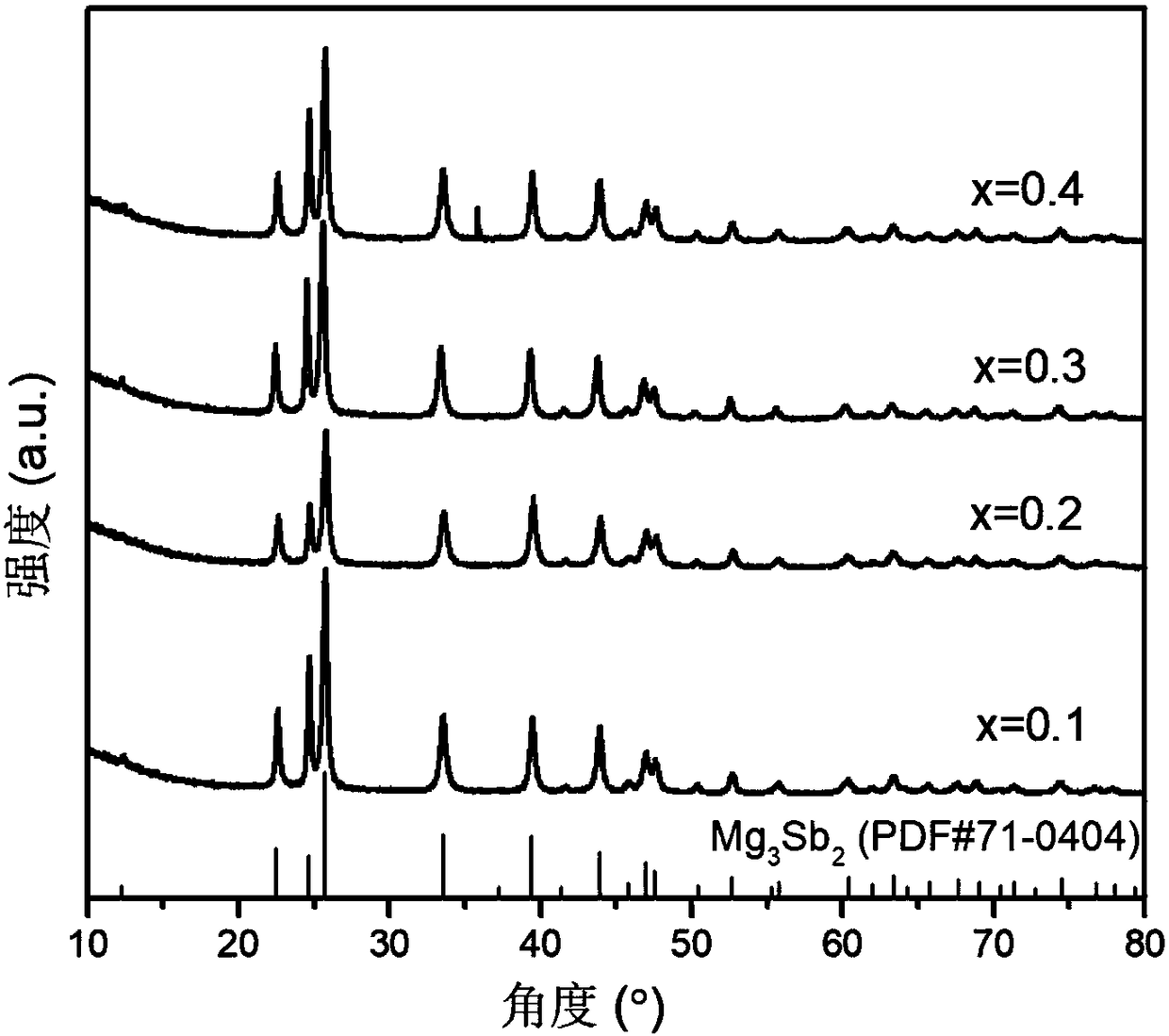

n-type Mg-Sb based room temperature thermoelectric material and preparation method thereof

ActiveCN108531795ARoom temperature thermoelectric figure of meritLarge reservesThermoelectric device manufacture/treatmentThermoelectric device junction materialsArgon atmosphereBismuth telluride

The invention provides a n- type Mg-Sb based room temperature thermoelectric material. A chemical general formula of the material is Mg3+DeltaMnxSb2-y-zBiyAz, wherein A represents oxygen family elements such as S, Se or Te, Delta is greater than or equal to -0.2 and is less than or equal to 0.3, x, y and z represent atomic ratios, x is 0.001-0.4, y is 0-1.0 and z is 0-0.2. The preparation method comprises the steps of selecting single elements with purity greater than or equal to 99% as raw materials according to the chemical general formula, proportioning and weighing the raw materials separately in an argon atmosphere, then putting the raw materials in a ball milling machine, adding stainless steel balls into the ball milling machine, and obtaining powder after the ball milling machine rotates at high speed; weighing the powder separately and then putting the powder in a graphite mold, then putting the mold in a high-temperature furnace, vacuumizing, sintering when the total air pressure is less than 4Pa, then cooling to room temperature after the sintering is ended. The thermoelectric material provided by the invention has higher room temperature thermoelectric figure of merit and better mechanical performance than traditional n-type bismuth telluride, and is low-cost; and the preparation method is easy to operate, is lower in cost, and has high controllability and repeatability.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

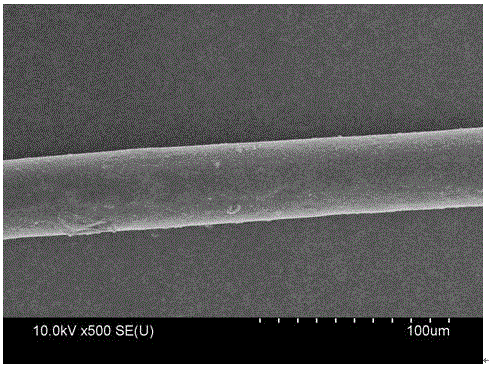

Polymer sheath-core composite fiber with thermoelectric effect as well as preparation method and application thereof

ActiveCN106637489ARealize the cooling effectRealize functionFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyethylene terephthalate glycol

The invention discloses a polymer sheath-core composite fiber with a thermoelectric effect as well as a preparation method and application thereof. The polymer sheath-core composite fiber is composed of a polymer sheath layer and a thermoelectric master batch material core layer, wherein the mass ratio of the sheath layer to the core layer ranges from (2 to 1) to (1 to 2); the polymer sheath layer is prepared from one of polypropylene, polyamide 6, polyamide 66 and polyethylene terephthalate resin; the thermoelectric master batch material core layer is composed of ternary components including carbon nanotubes / graphene, bismuth telluride and resin. According to the polymer sheath-core composite fiber disclosed by the invention, the graphene, the bismuth telluride and the macromolecule resin are used as raw materials, and are subjected to methods including melting and commixing, solid-phase force shearing and the like, so that uniform dispersion of a graphene and bismuth telluride compound phase is realized in one step. After thermoelectric master batches are prepared, a melting compounded spinning technology is adopted to prepare a sheath-core composite thermoelectric fiber material. The fiber material has an important application prospect in the field of thermoelectric conversion. The polymer sheath-core composite fiber can be made into a thermoelectric refrigerating device which is arranged in a fabric and clothes; the temperature can be adjusted and the temperature is comfortable and adjustable.

Owner:TIANJIN POLYTECHNIC UNIV

Bismuth telluride based N type thermoelectric material and preparation method thereof

ActiveCN106571422ALow purity requirementHigh densityThermoelectric device manufacture/treatmentThermoelectric device junction materialsSingle substanceSynthesis methods

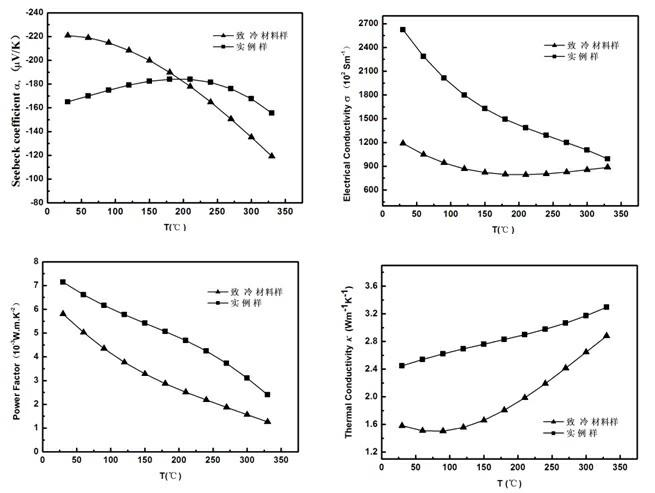

The invention discloses a preparation method of a bismuth telluride based N type thermoelectric material Bi2(Te<1-x>Se<x>)3. A melt mixing step and a zone melting step are used for synthesis. The synthesis method comprises that single-substance raw materials can be selected and weighed according to a chemical formula Bi2(Te<1-x>Se<x>)3 in which x is greater than or equivalent to 0.02 and lower than or equivalent to 0.1, metal antimony (Sb) in the weight percentage of 0.01% to 0.03% and nonmetal iodine (I) in the weight percentage of 0.03% to 0.06% are added on the basis of the weight obtained by weighing, and the purities of all the single-substance raw materials are greater than 4N; the materials are filled into a quartz tube whose bottom is relatively flat by sintering to implement vacuum-pumped tube sealing, and then filled into a rocking furnace of resistance heating, and the quartz tube is placed in a vertical position and then sintered by melt mixing synthesis. The quartz tube is cooled naturally to the room temperature after sintering, and then removed and placed in a melting furnace in a vertical zone for pulse zone melting. The bismuth telluride based N type thermoelectric material and the preparation method thereof have the advantages that the preparation method is simple, a high-density body material of a monocrystalline similar structure and including a few of inlaid nanometer crystal grains can be obtained, via measurement, the ZT value of the thermoelectric material Bi2(Te<1-x>Se<x>)3 can reach 1.33 during 340K, and the material can be applied to fields including waste heat recovery and space exploration.

Owner:SUZHOU UNIV OF SCI & TECH +1

Processing method for improving performance of N-type bismuth telluride base powder sinter block thermoelectric material

ActiveCN104409623AImprove thermoelectric performanceIncreased ZT valueThermoelectric device manufacture/treatmentLow speedThermal insulation

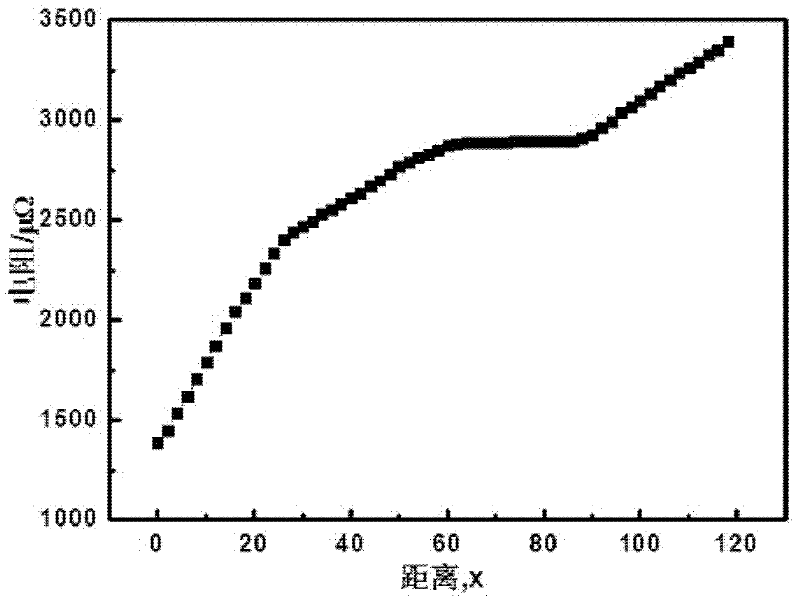

The invention discloses a processing method for improving the performance of an N-type bismuth telluride base powder sinter block thermoelectric material. The method comprises the steps of placing an N-type bismuth telluride base block formed by thermal pressing in a mold, performing low-speed thermal deformation at 500-550 DEG C and under a pressure condition, controlling a change rate of the block in a height direction to be 0.2-3mm / min for 1-10min, then removing the pressure, performing thermal insulation for 2-60min, and repeating the procedure for at least one time. According to the processing method for improving the performance of the N-type bismuth telluride base sinter block thermoelectric material, the thermoelectric performance of the N-type bismuth telluride base material is greatly improved by using a repeated low-speed thermal deformation induction technology, and an optimal value can reach 1.2 which is the reported maximum value of an N-type material in the world at present.

Owner:浙江电联矿业科技发展有限公司

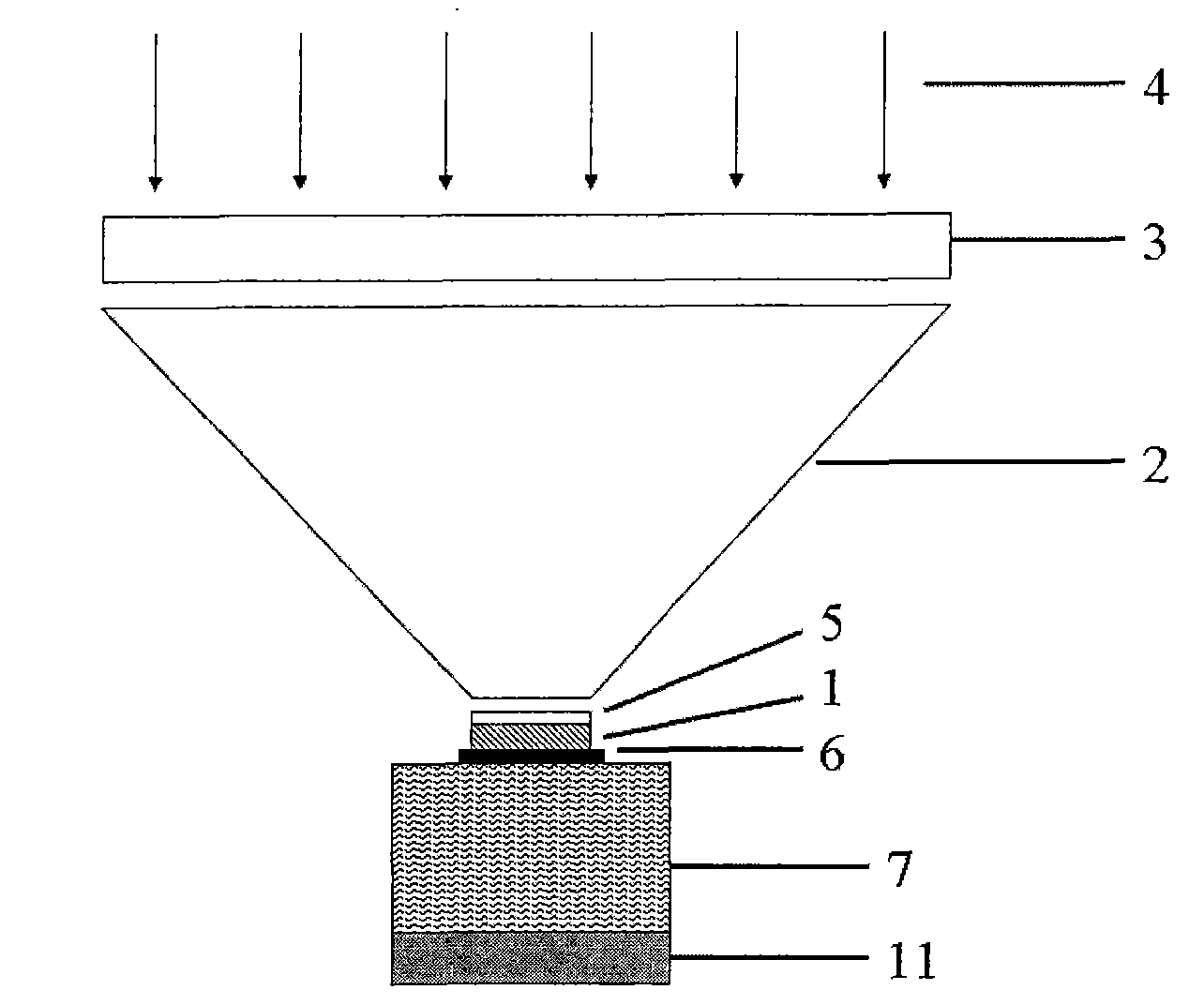

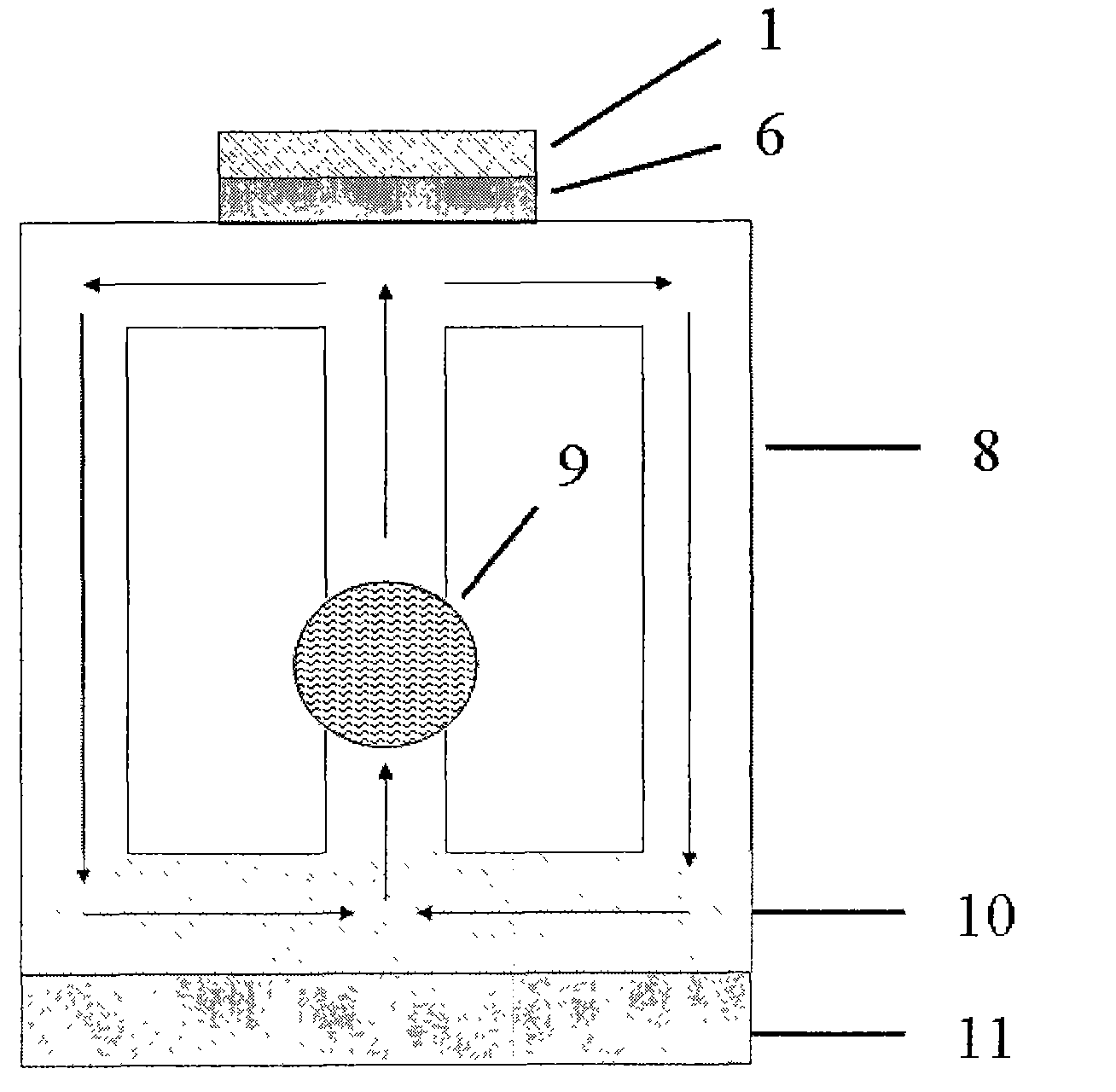

Light-concentrating photovoltaic-temperature difference power-generating integrated device

ActiveCN102104346AImprove efficiencyLow running costPV power plantsPhotovoltaic energy generationBismuth tellurideSilicon solar cell

The invention belongs to a light-concentrating photovoltaic-temperature difference power-generating integrated device, and comprises a light-concentrating battery component, a liquid cooling device, a thermal collecting device, and a bismuth telluride-based thermoelectric generator. The light-concentrating photovoltaic-temperature difference power-generating integrated device is characterized in that: the light-concentrating battery component consists of a monocrystalline silicon solar battery and a columnar light-concentrating lens on the upper part of the monocrystalline silicon solar battery; the bottom of the monocrystalline silicon solar battery is bonded on a ceramic substrate by a heat conductive silicon chip; the ceramic substrate is connected with the liquid cooling device, and the liquid cooling device consists of a circulatory cooling passage, a water pump and a radiator. One side of the circulatory cooling passage is connected with the ceramic substrate at the bottom of the monocrystalline silicon solar battery, and the other side is connected with the radiator; the circulatory cooling passage is connected with the water pump; a top ceramic chip of the thermoelectric generator is bonded on the radiator of the liquid cooling device by adhering to a heat conductive silicon chip. The invention has the advantages that the waste heat generated by the monocrystalline silicon solar battery during the light-concentrating photovoltaic power generation can be recycled, therefore the efficiency of the overall light-concentrating photovoltaic power generation is improved substantially.

Owner:GCL SYST INTEGRATION TECH +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com