Bismuth-telluride-based thermoelectric element and preparation method thereof

A bismuth telluride-based, thermoelectric element technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problems of high device cost, complicated process, high cost, etc., without special equipment , Low preparation cost and low interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

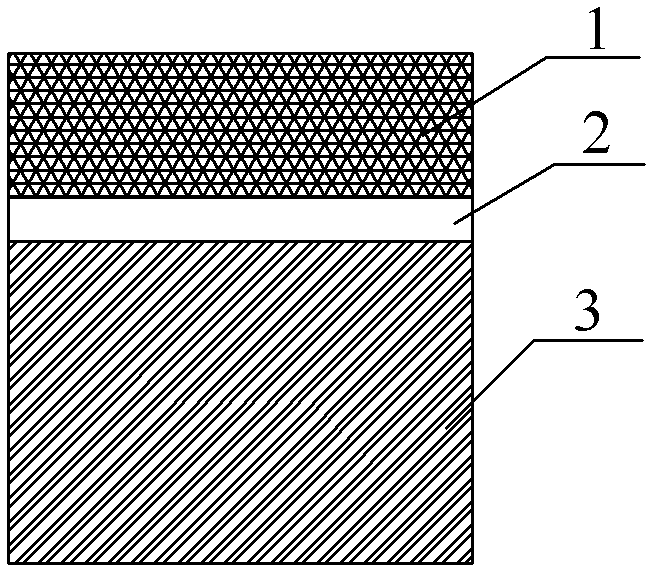

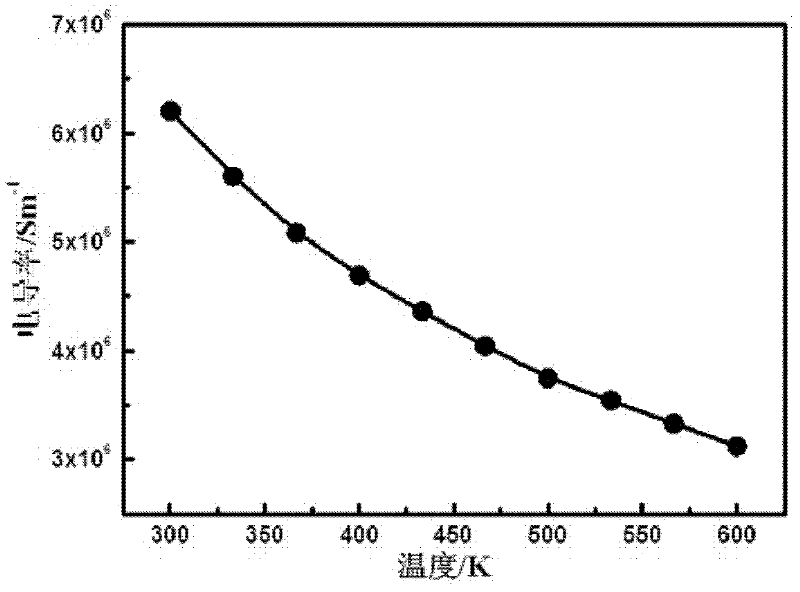

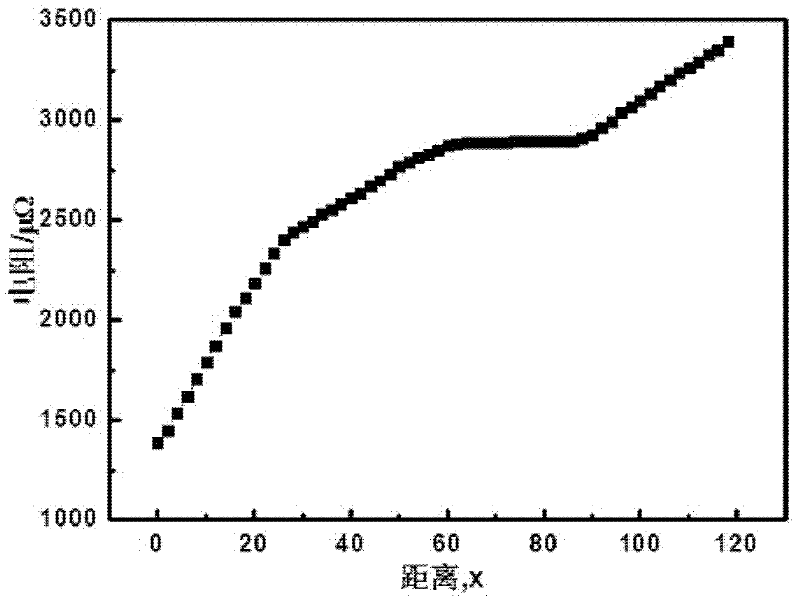

Embodiment 1

[0032] Weigh 4g of P-type bismuth telluride-based thermoelectric powder, 0.2g of metal antimony powder, and 0.1g of metal aluminum powder, and put them into a graphite mold with a diameter of 10mm in the order of bismuth telluride-based thermoelectric powder, antimony powder, and aluminum powder , and then carry out discharge plasma sintering under vacuum: the vacuum degree is 10Pa, the sintering pressure is 60MPa, the heating rate is 100°C / min, the sintering temperature is 420°C, and the holding time is 8min; finally, it is cooled to room temperature with the furnace, and the obtained solid solution ( solid solution, abbreviated as SS) is the bismuth telluride-based thermoelectric element described in the present invention: Al / Sb / Bi 2 Te 3 , whose structure is shown in the figure 1 As shown: it includes an electrode layer 1 , a barrier layer 2 and a bismuth telluride-based thermoelectric layer 3 , and the barrier layer 2 is located between the electrode layer 1 and the bismu...

Embodiment 2

[0039] Weigh 4g of N-type bismuth telluride-based thermoelectric powder, 0.2g of metal antimony powder, and 0.1g of metal aluminum powder, and put them into a graphite mold with a diameter of 10mm in the order of bismuth telluride-based thermoelectric powder, antimony powder, and aluminum powder , and then carry out discharge plasma sintering under vacuum: the vacuum degree is 10Pa, the sintering pressure is 40MPa, the heating rate is 100℃ / min, the sintering temperature is 440℃, and the holding time is 8min; finally, it is cooled to room temperature with the furnace, and the obtained solid solution is Bismuth telluride-based thermoelectric element according to the present invention: Al / Sb / Bi 2 Te 3 .

[0040] According to the analysis, the bismuth telluride-based thermoelectric element prepared in this example also has figure 1 The structure described in and Figure 2 to Figure 6 Features and performance shown.

Embodiment 3

[0042] Weigh 4g of P-type bismuth telluride-based thermoelectric powder, 0.2g of metal antimony powder, and 0.3g of metal copper powder, and put them into a graphite mold with a diameter of 10mm in the order of bismuth telluride-based thermoelectric powder, antimony powder, and copper powder. , and then carry out discharge plasma sintering under vacuum: the vacuum degree is 10Pa, the sintering pressure is 60MPa, the heating rate is 100℃ / min, the sintering temperature is 420℃, and the holding time is 8min; finally, it is cooled to room temperature with the furnace, and the obtained solid solution is Bismuth telluride-based thermoelectric element according to the present invention: Cu / Sb / Bi 2 Te 3 .

[0043] According to the analysis, the bismuth telluride-based thermoelectric element prepared in this example also has figure 1 The structure described in and Figure 2 to Figure 6 Features and performance shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com