Patents

Literature

638results about How to "Reduce interface resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

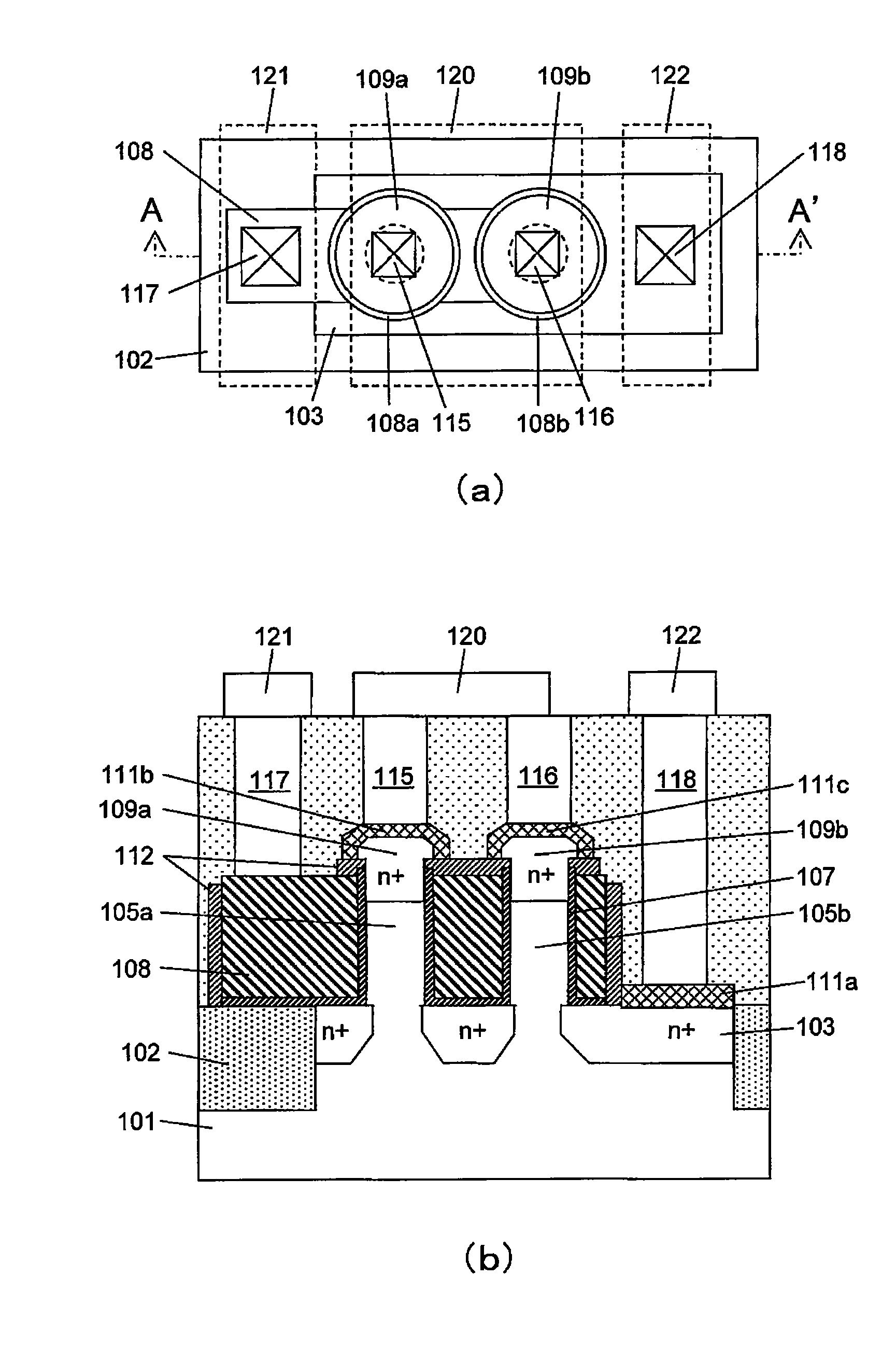

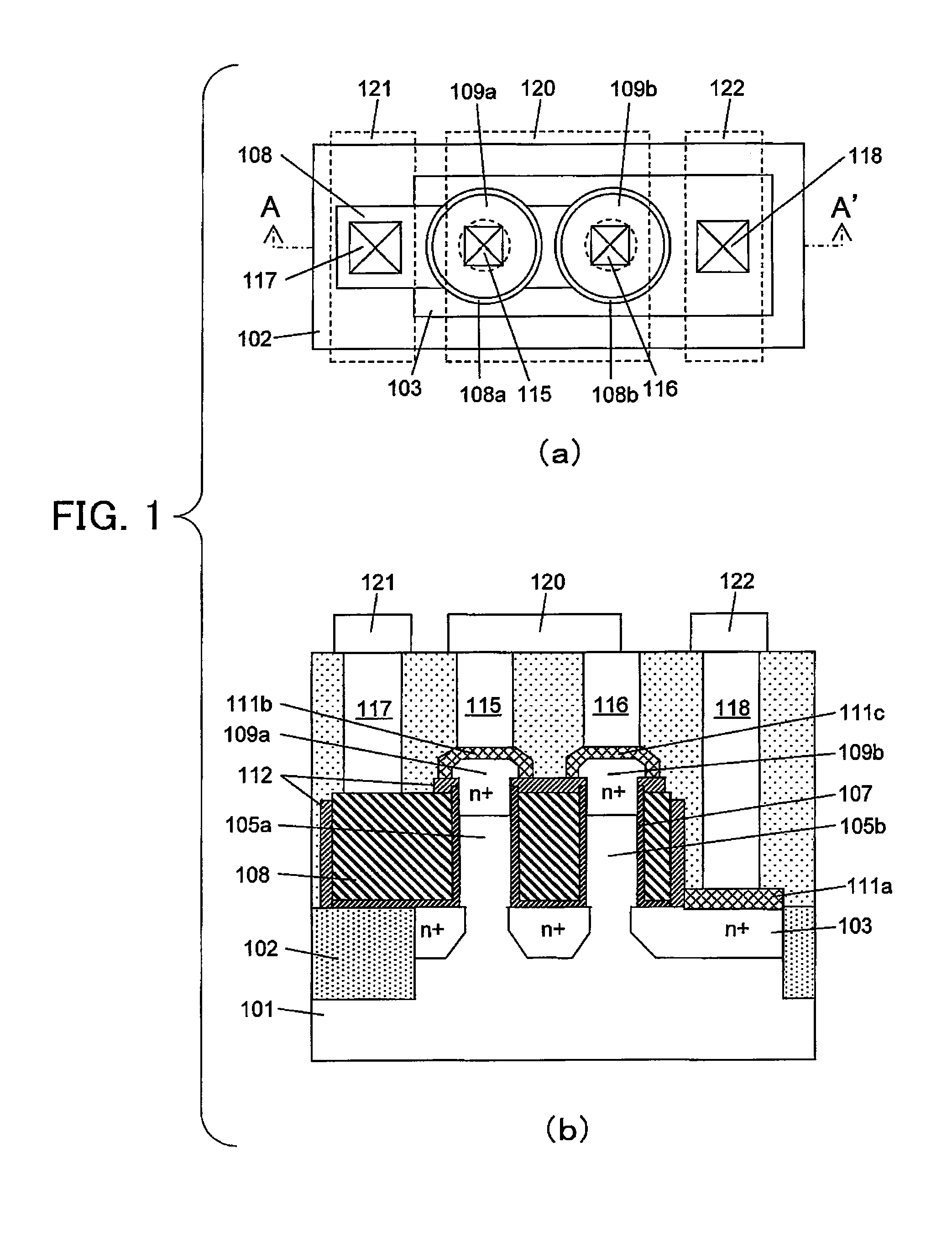

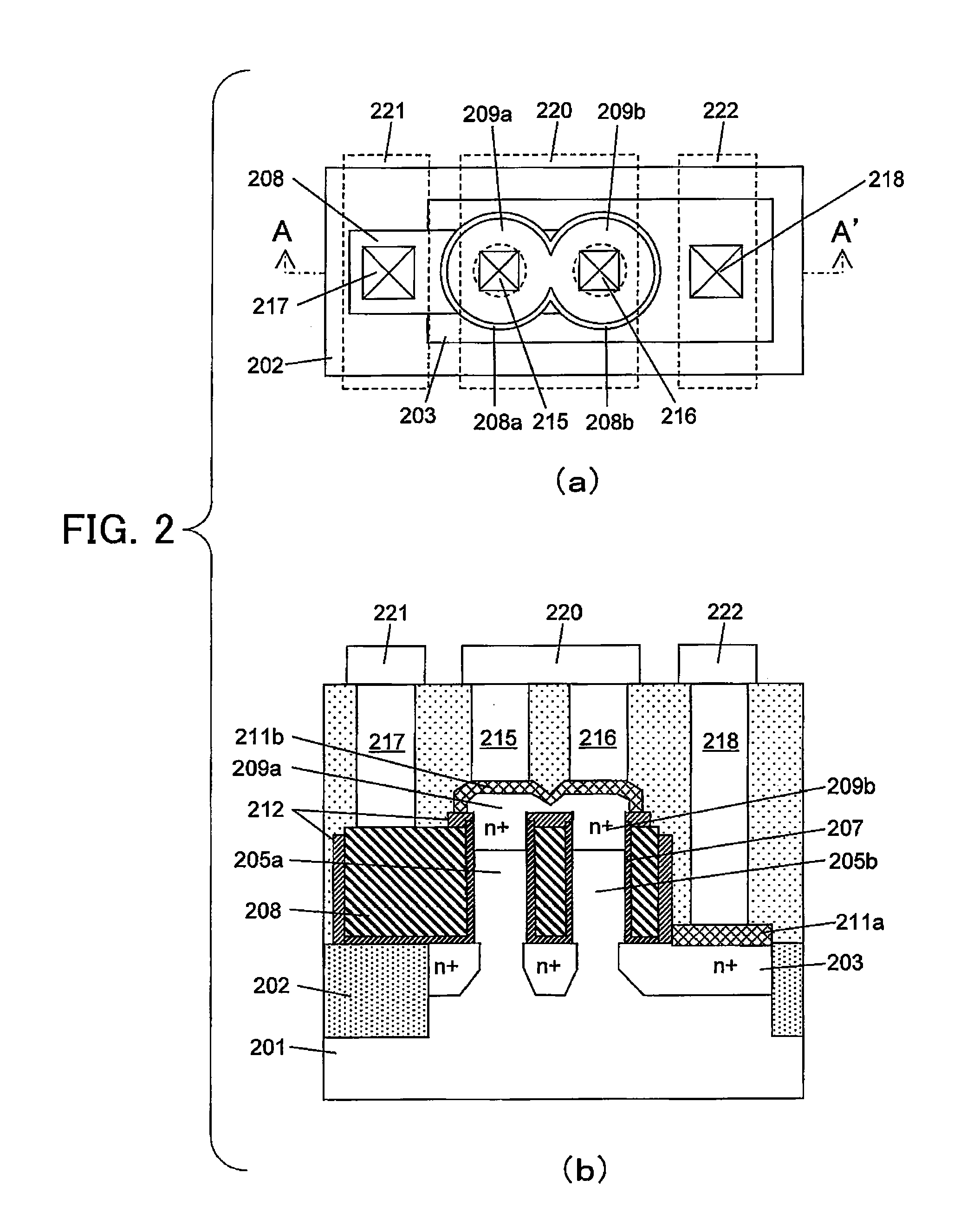

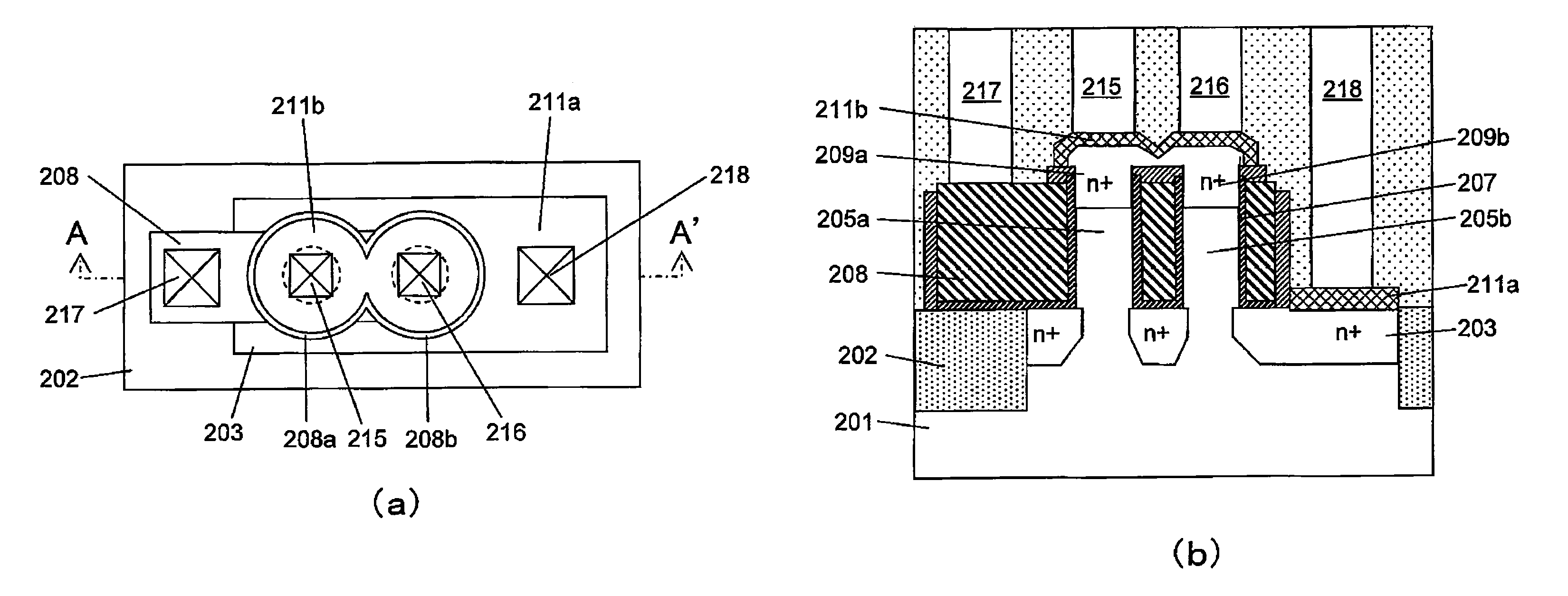

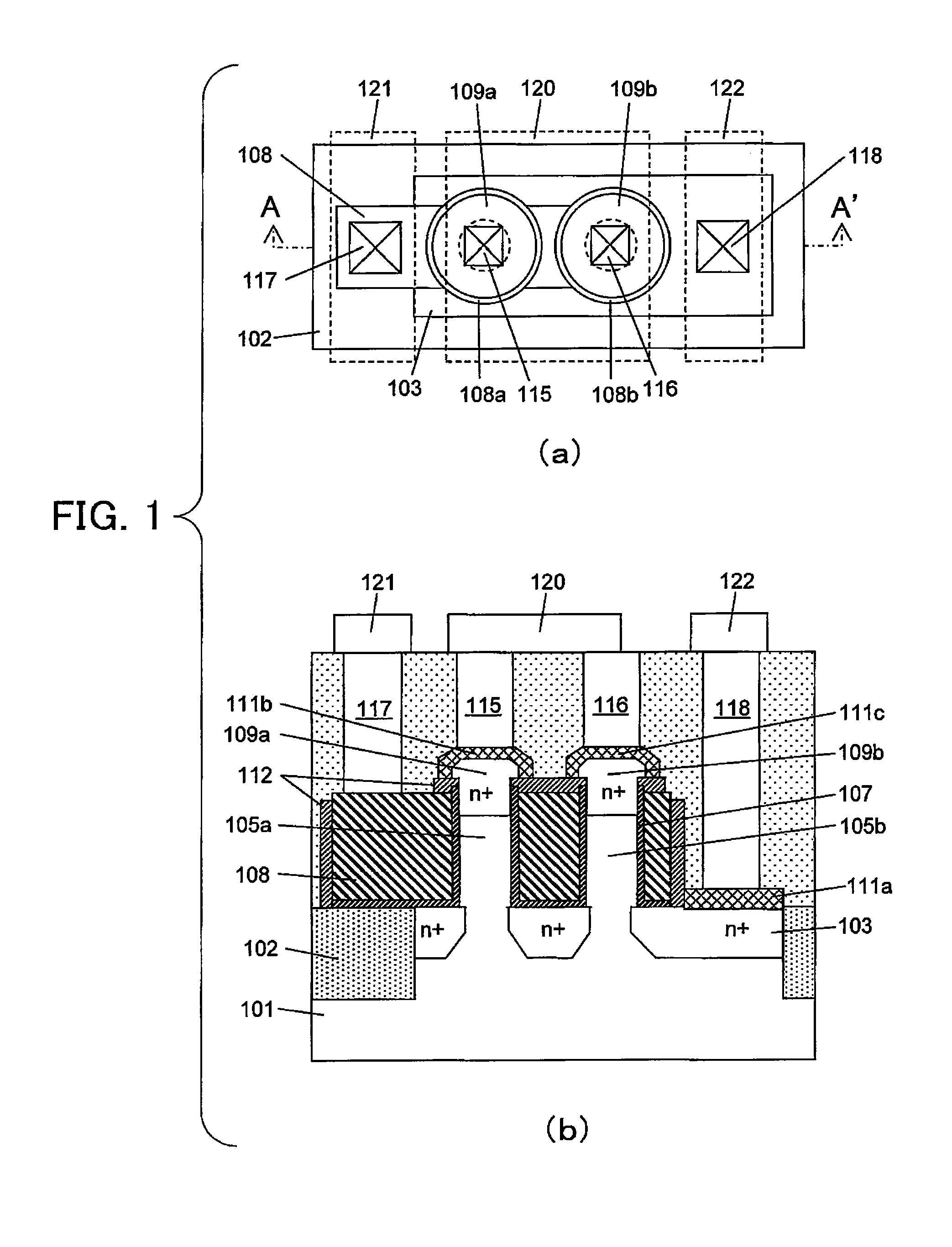

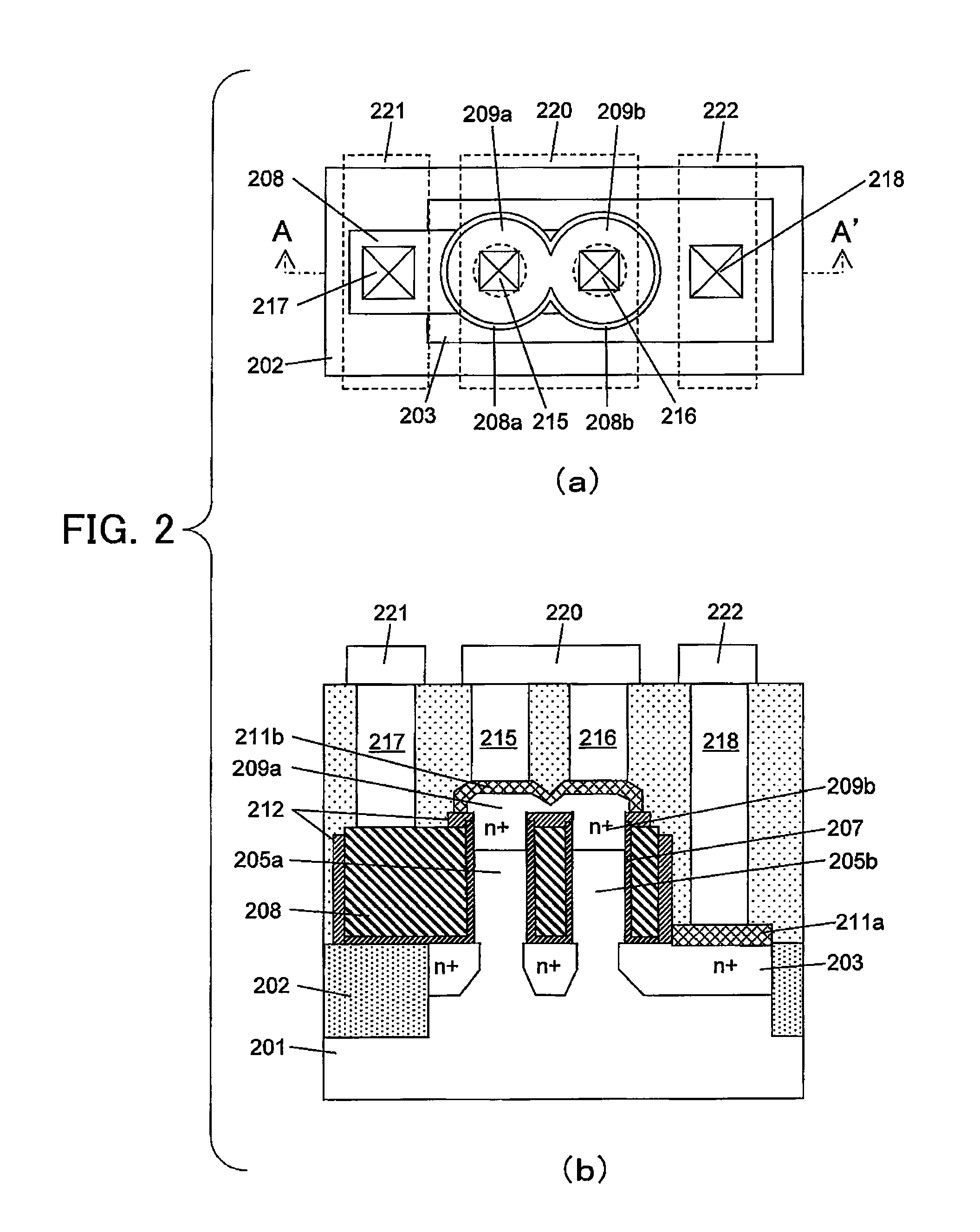

Semiconductor device including a mos transistor and production method therefor

ActiveUS20100270611A1Reduce narrow width effectReduce interface resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

It is intended to provide a semiconductor device including a MOS transistor, comprising: a semiconductor pillar; a bottom doped region formed in contact with a lower part of the semiconductor pillar; a first gate formed around a sidewall of the semiconductor pillar through a first dielectric film therebetween; and a top doped region formed so as to at least partially overlap a top surface of the semiconductor pillar, wherein the top doped region has a top surface having an area greater than that of the top surface of the semiconductor pillar.

Owner:UNISANTIS ELECTRONICS SINGAPORE PTE LTD

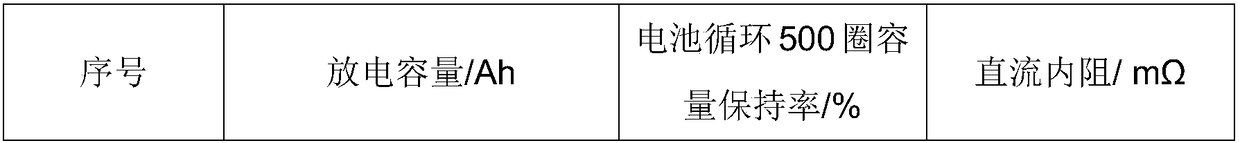

Manufacturing method of all solid state power lithium ion battery

ActiveCN108232318AReduce interface resistanceImprove securitySolid electrolytesFinal product manufactureHigh energyAdhesive

The invention discloses a manufacturing method of an all solid state power lithium ion battery. The manufacturing method comprises the steps of dissolving an anode active material, a conductive agent,an adhesive and a polymer electrolyte in a solvent, so as to prepare an anode sizing agent, applying the anode sizing agent to an anode current collector, performing thermal treatment and rolling treatment so as to obtain an anode piece; then dissolving a cathode material, a conductive agent, an adhesive and a polymer electrolyte in a solvent, so as to prepare a cathode sizing agent, applying thecathode sizing agent to a cathode current collector, and performing thermal treatment and rolling treatment so as to obtain a cathode piece; dissolving a polymer electrolyte, a filler and lithium salt in a solvent, so as to prepare an electrolyte solution; applying the electrolyte solution to the surface of the anode piece or the cathode piece, and performing thermal treatment to obtain an anodepiece or a cathode piece with an electrolyte layer; and finally, assembling the anode piece and the cathode piece in a winding or superposing manner, so as to prepare the all solid state lithium ion battery. The all solid state lithium battery prepared by the method has the advantages of lower interface resistance, higher energy density, high security and the like.

Owner:SHAANXI COAL & CHEM TECH INST

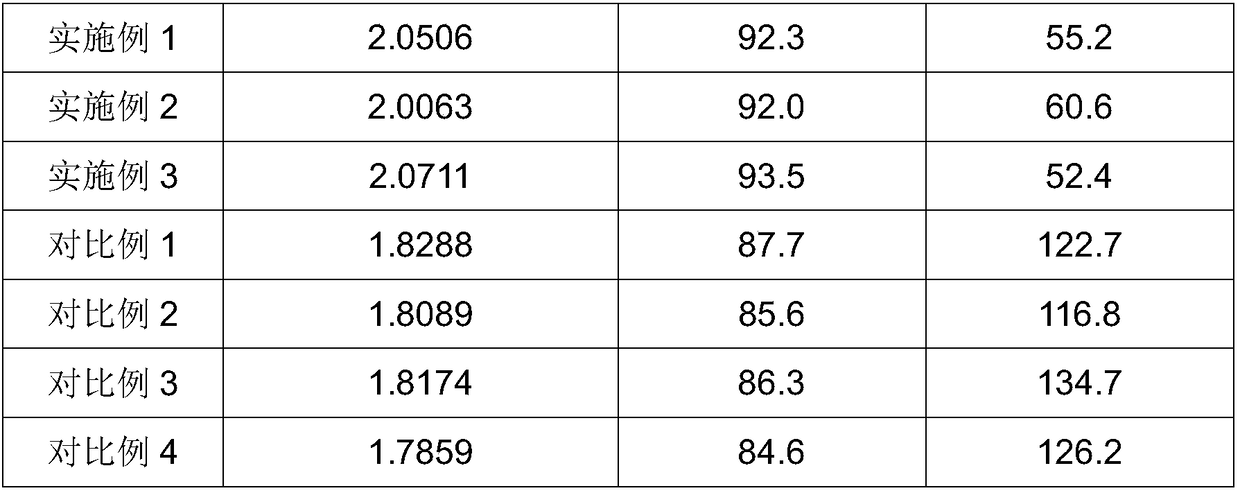

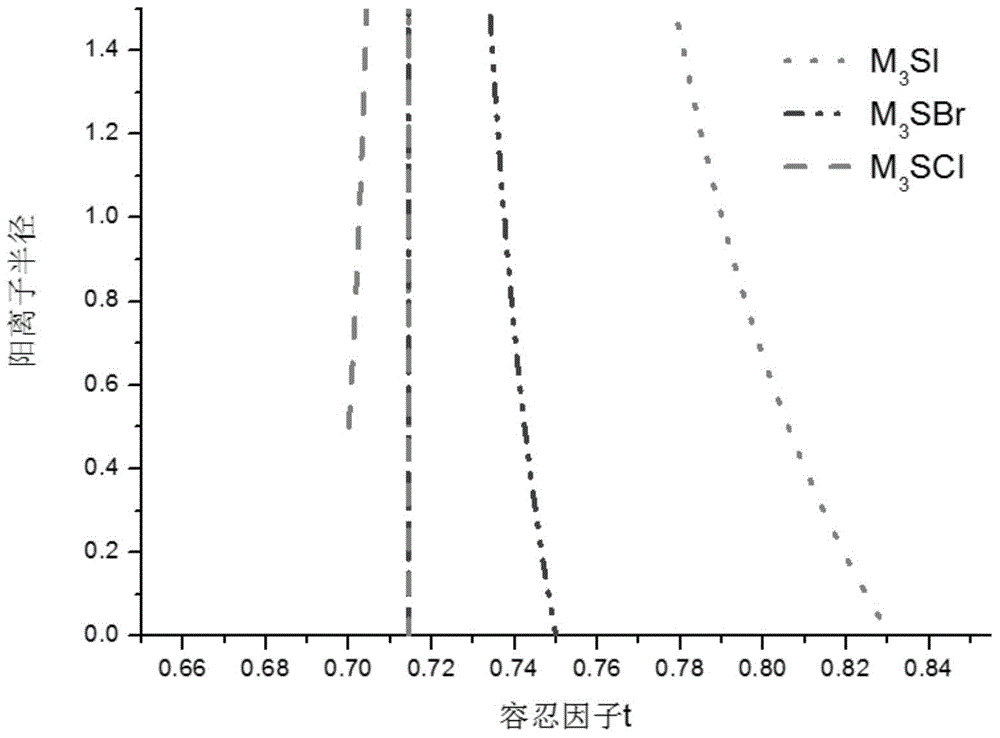

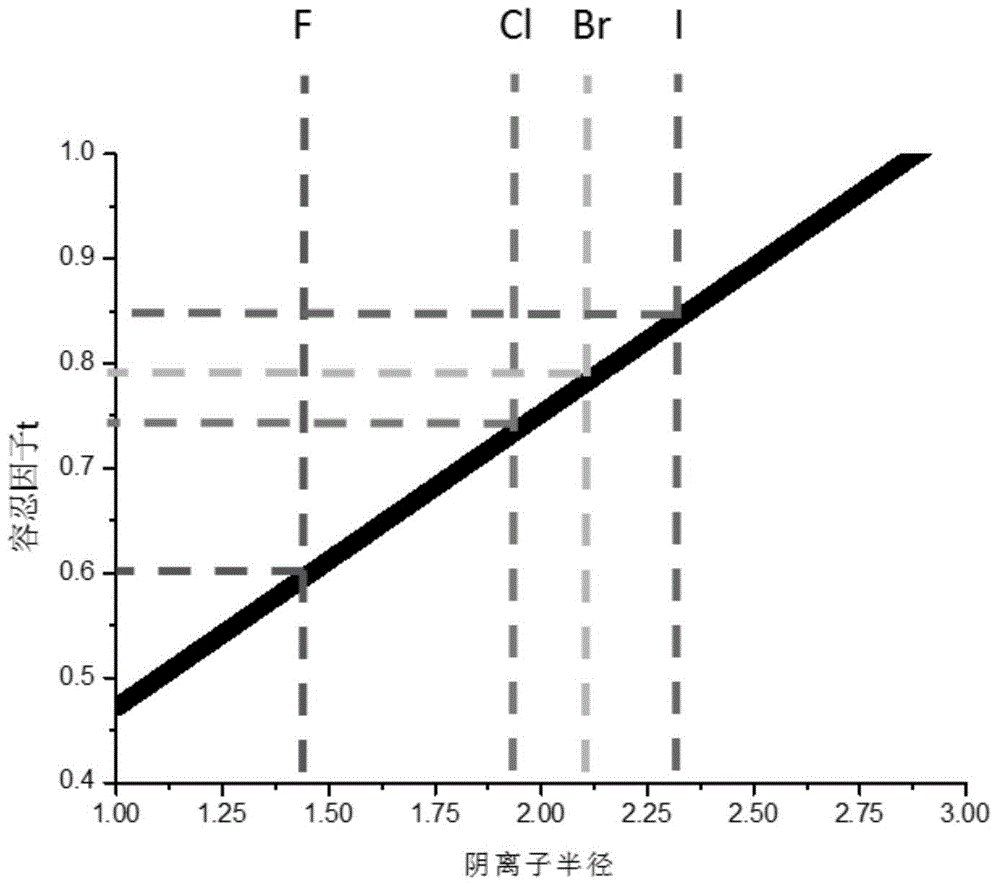

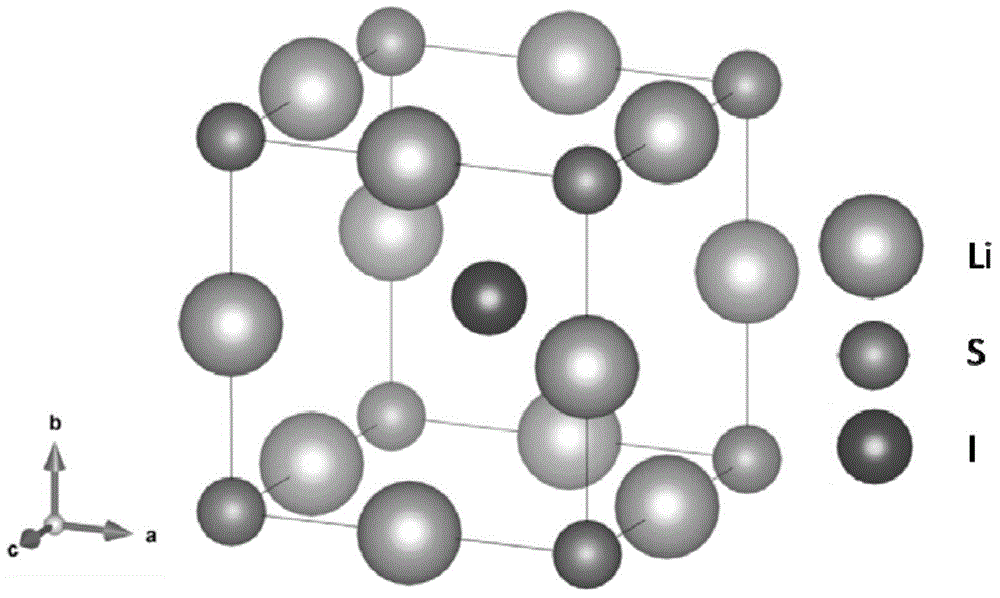

Lithium-enriched anti-perovskite sulfides, solid electrolyte material containing lithium-enriched anti-perovskite sulfides and application of solid electrolyte material

ActiveCN104466239AIncrease the carrier concentrationIncrease charge and discharge rateSecondary cellsElectrolytesWorking temperatureOperating temperature range

The invention discloses lithium-enriched anti-perovskite sulfides and a solid electrolyte material. The general formula of the lithium-enriched anti-perovskite sulfides is (LimMn)3-xS1-y(XaYb)1-z, wherein m is more than 0 and less than or equal to 1, n is more than or equal to 0 and less than to 0.5, (m+n) is less than or equal to 1, a is more than 0 and less than or equal to 1, b is more than or equal to 0 and less than 1, (a+b) is less than or equal to 1, x is more than or equal to 0 and less than or equal to 0.5, y is more than or equal to 0 and less than or equal to 0.5, z is more than or equal to 0 and less than or equal to 0.5 and x=2y+z; M is H, Na, K, Rb, Mg, Ca, Sr, Ba, Y, La, Ti, Zr, Zn, B, Al, Ga, In, C, Si, Ge, P, S or Se; and X is Fe, Cl, Br or I, and Y is a negative ion. The solid electrolyte material has high ion conductivity and thermal stability and a wide working temperature range, and can be applied to lithium ion batteries, rechargeable metal lithium batteries, lithium liquid flow batteries or lithium ion capacitors.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

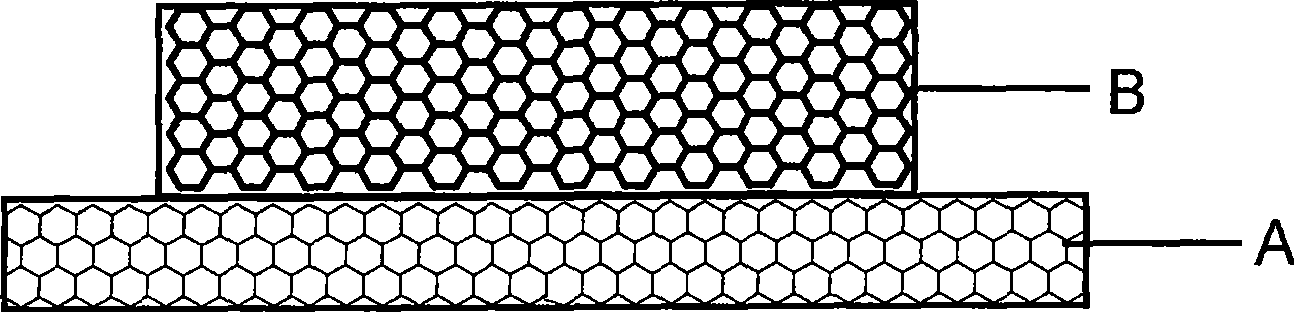

Carbon nano tube film-based solar energy battery and its preparing method

ActiveCN1996620AEasy to prepareImprove conversion efficiencyFinal product manufactureNanoinformaticsElectricityFilm base

This invention relates to solar energy battery of carbon nanometer tube film and its process method in solar battery and nanometer material application technique field, which comprises the following technique: adopting carbon nanometer tube film as photo electricity conversion materials with carbon nanometer film as upper electrode; the film is set with transparent conductive film as conversion materials; the film is used as upper electrode.

Owner:TSINGHUA UNIV

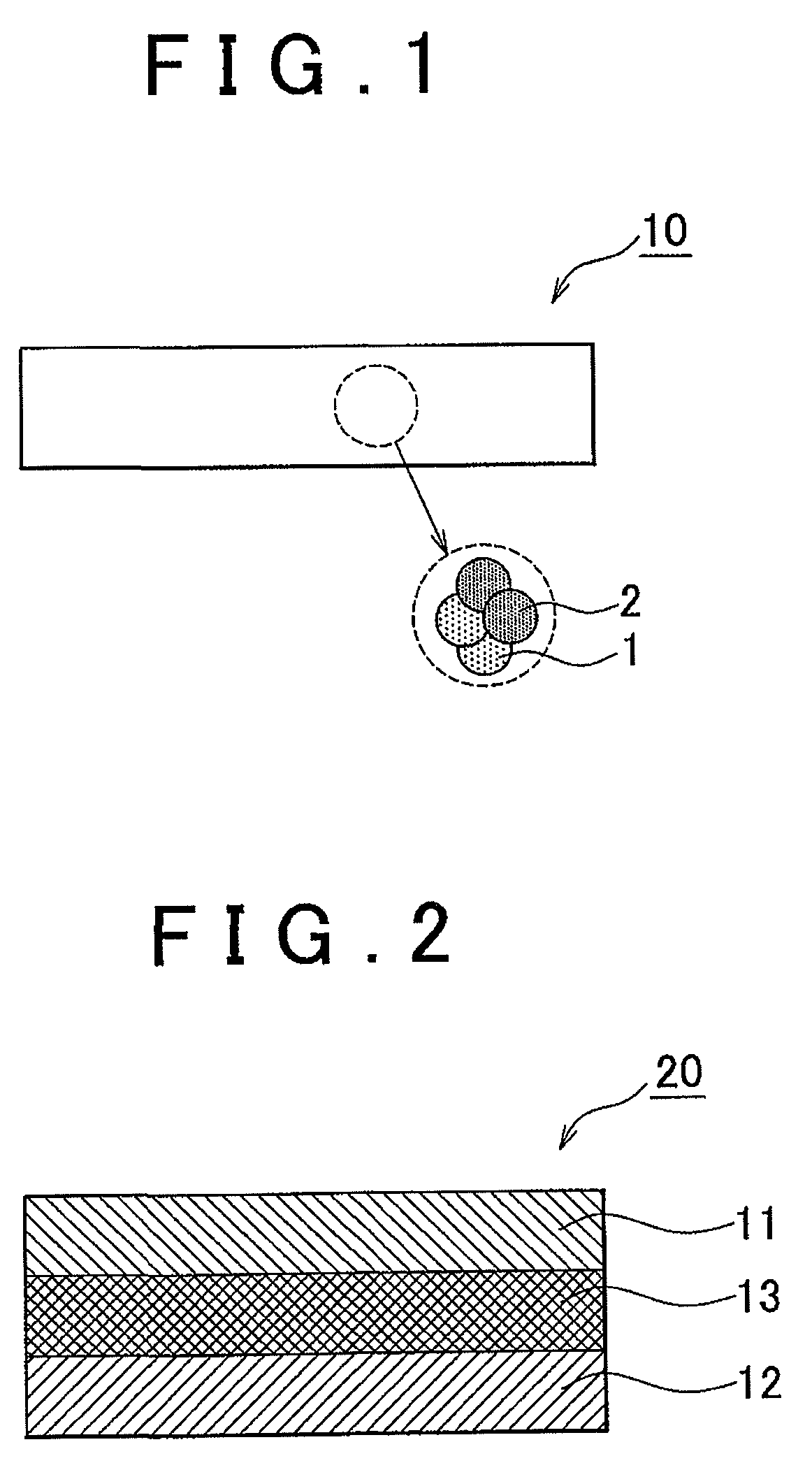

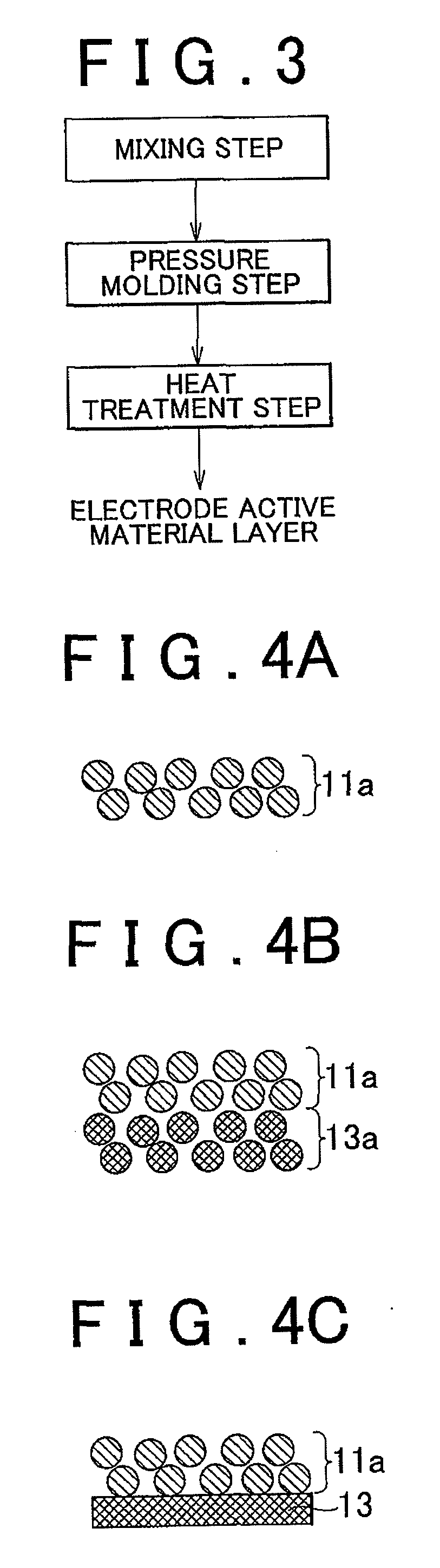

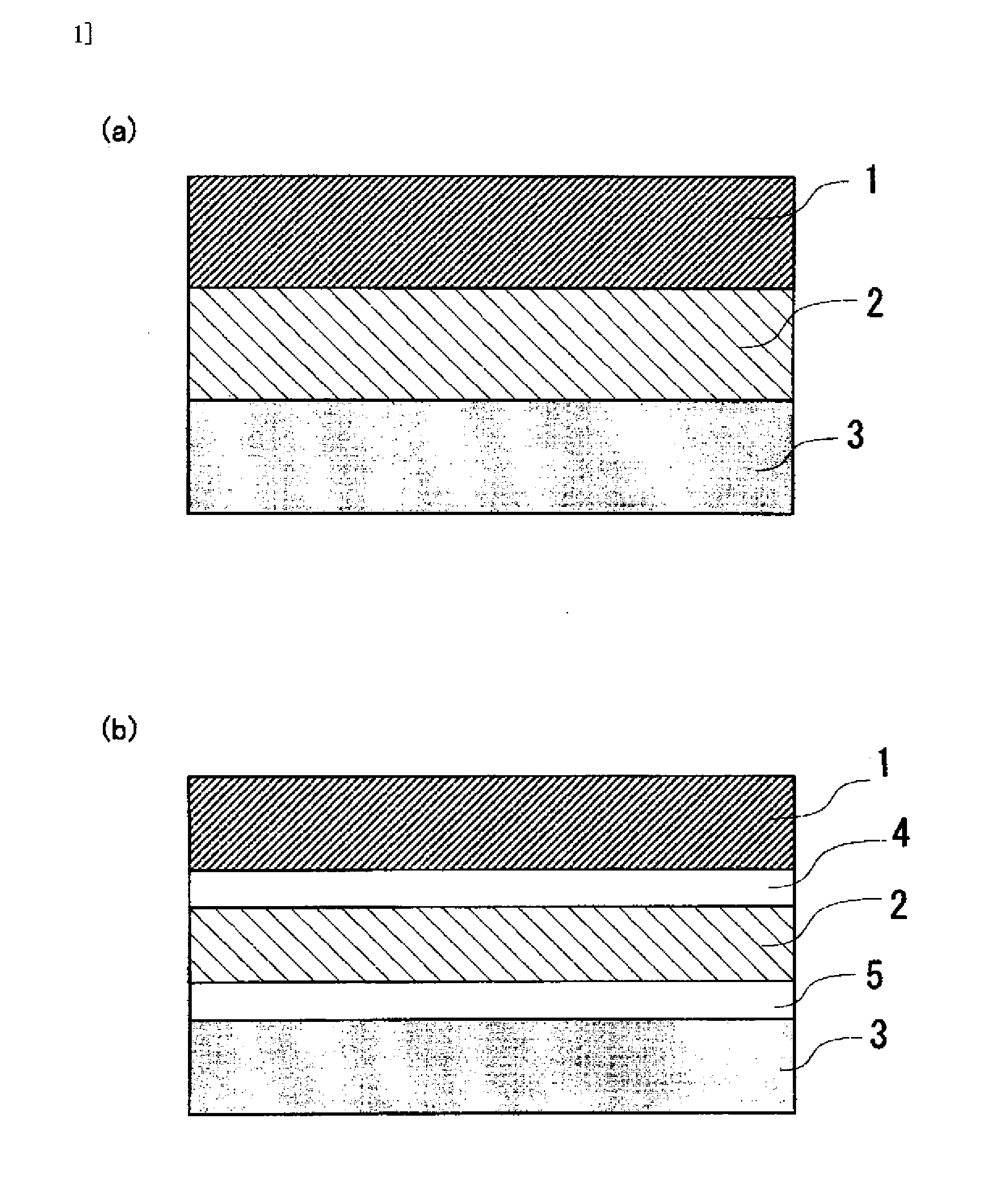

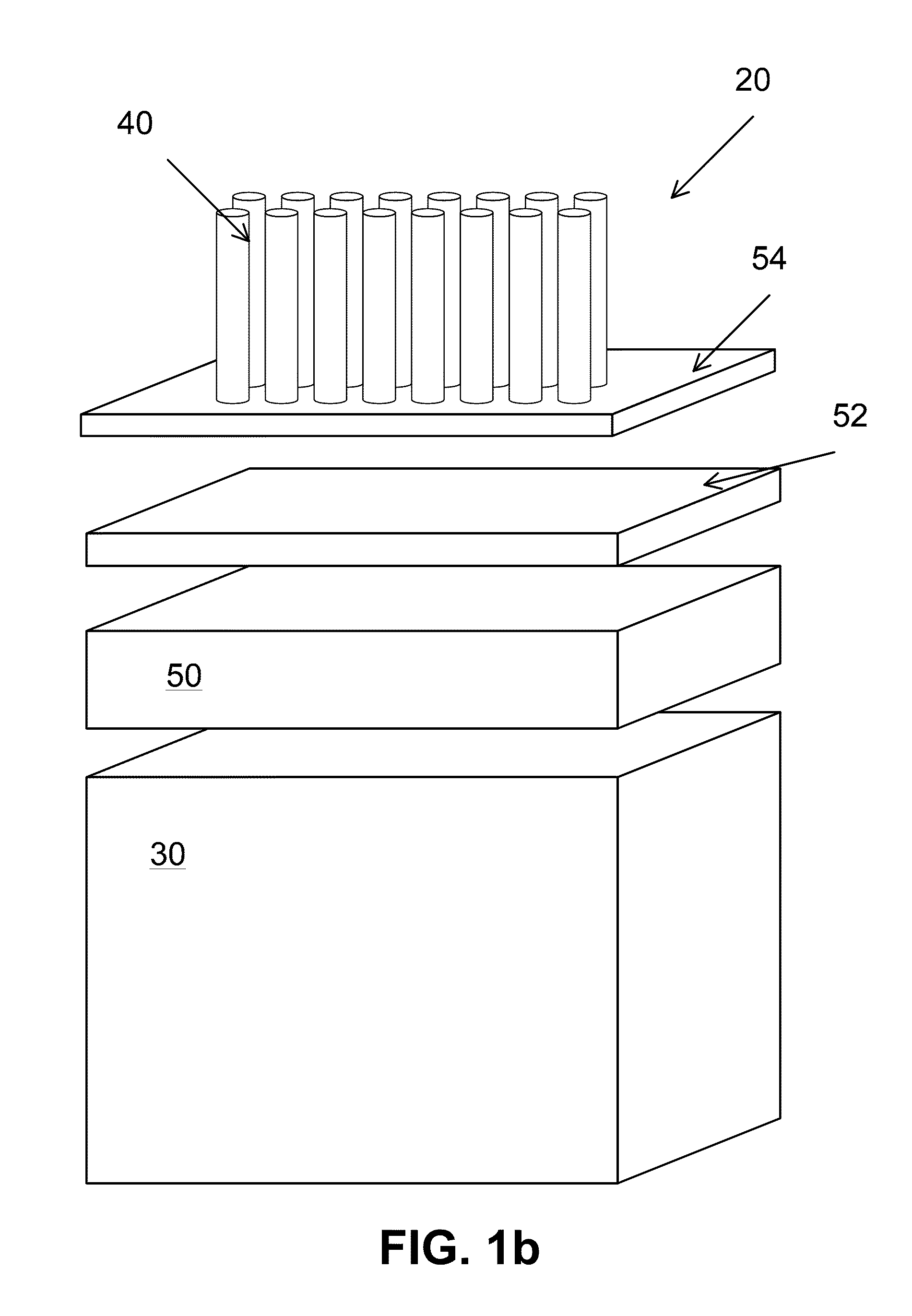

Electrode active material layer, all solid state battery, manufacturing method for electrode active material layer, and manufacturing method for all solid state battery

InactiveUS20110065007A1Reduce interface resistanceSuppress generationSolid electrolytesSolid electrolyte cellsAll solid stateSolid state electrolyte

Owner:TOYOTA JIDOSHA KK

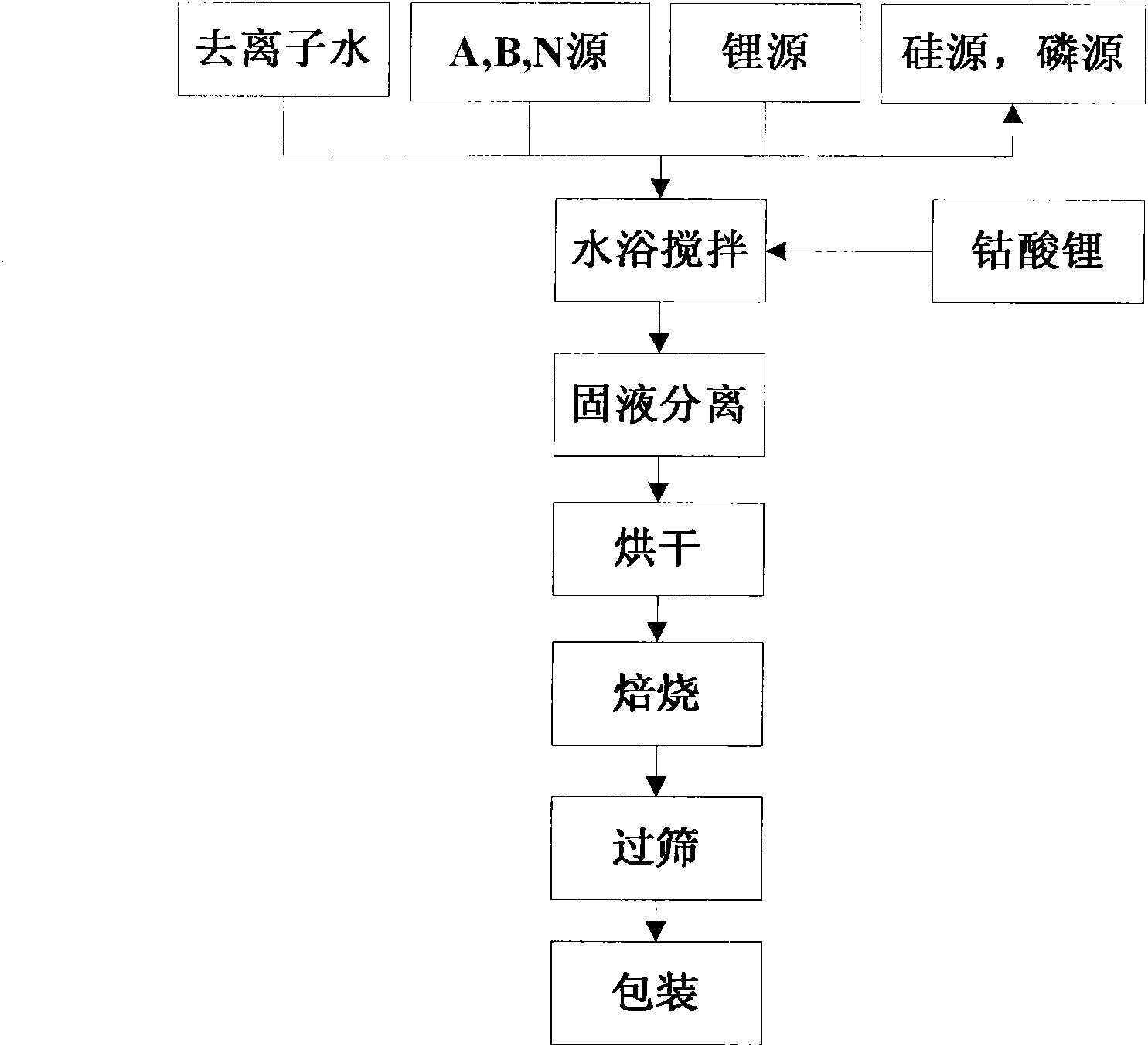

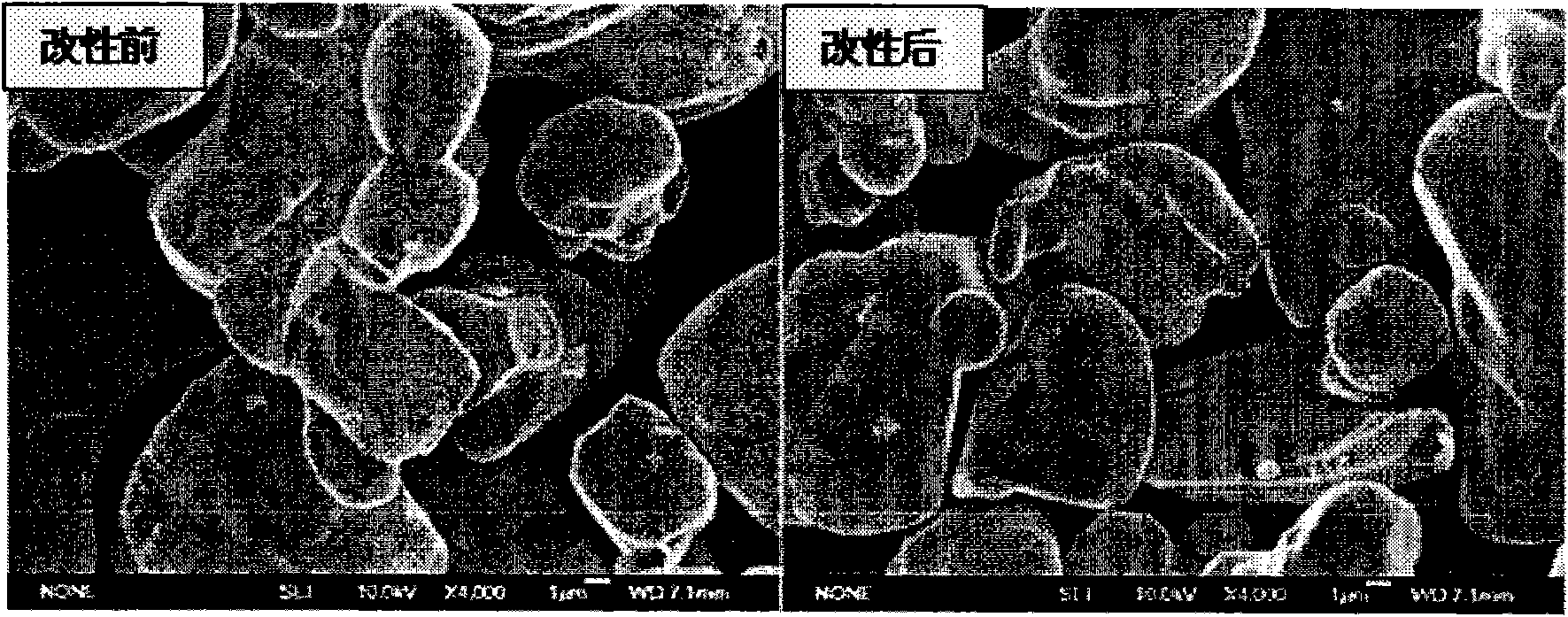

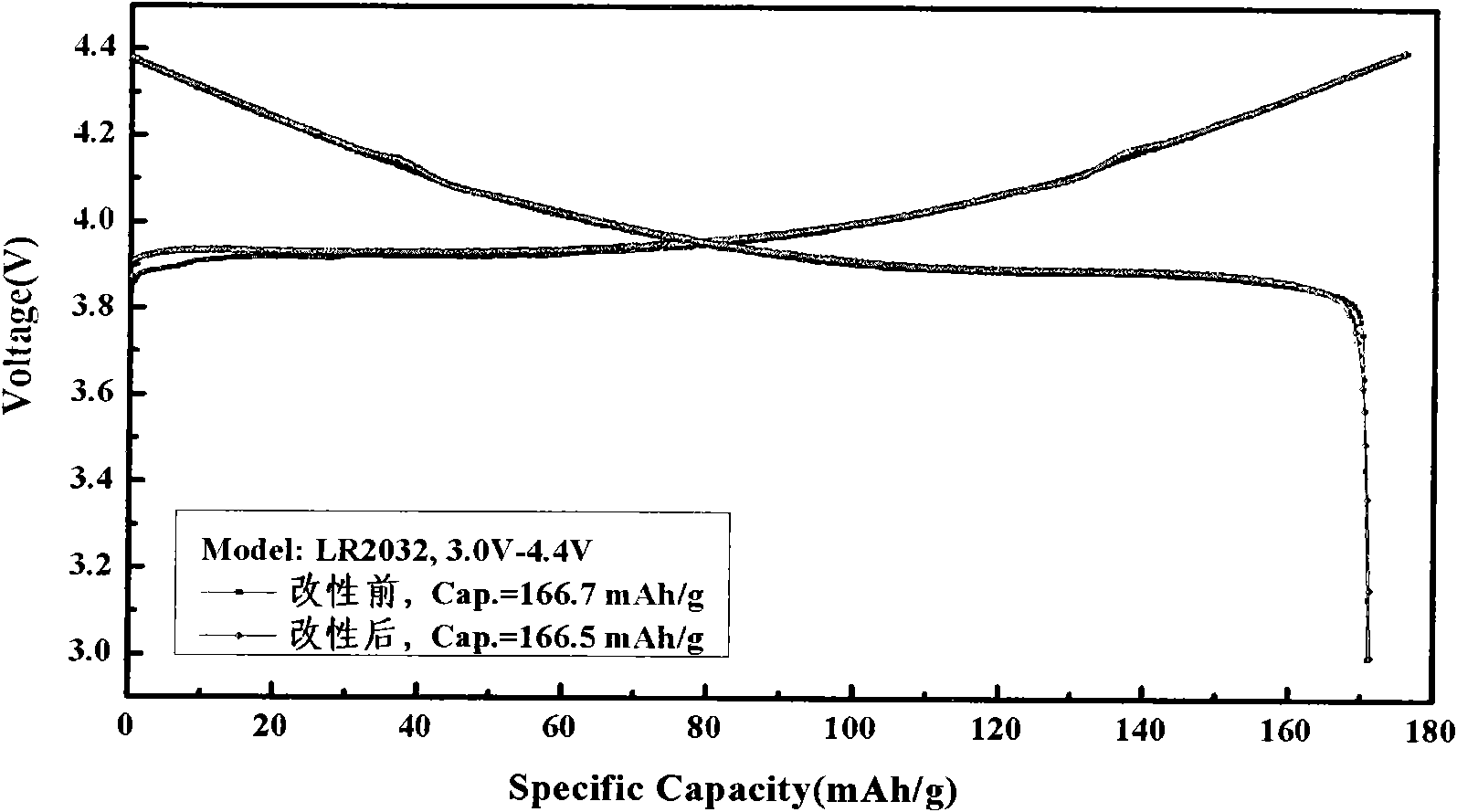

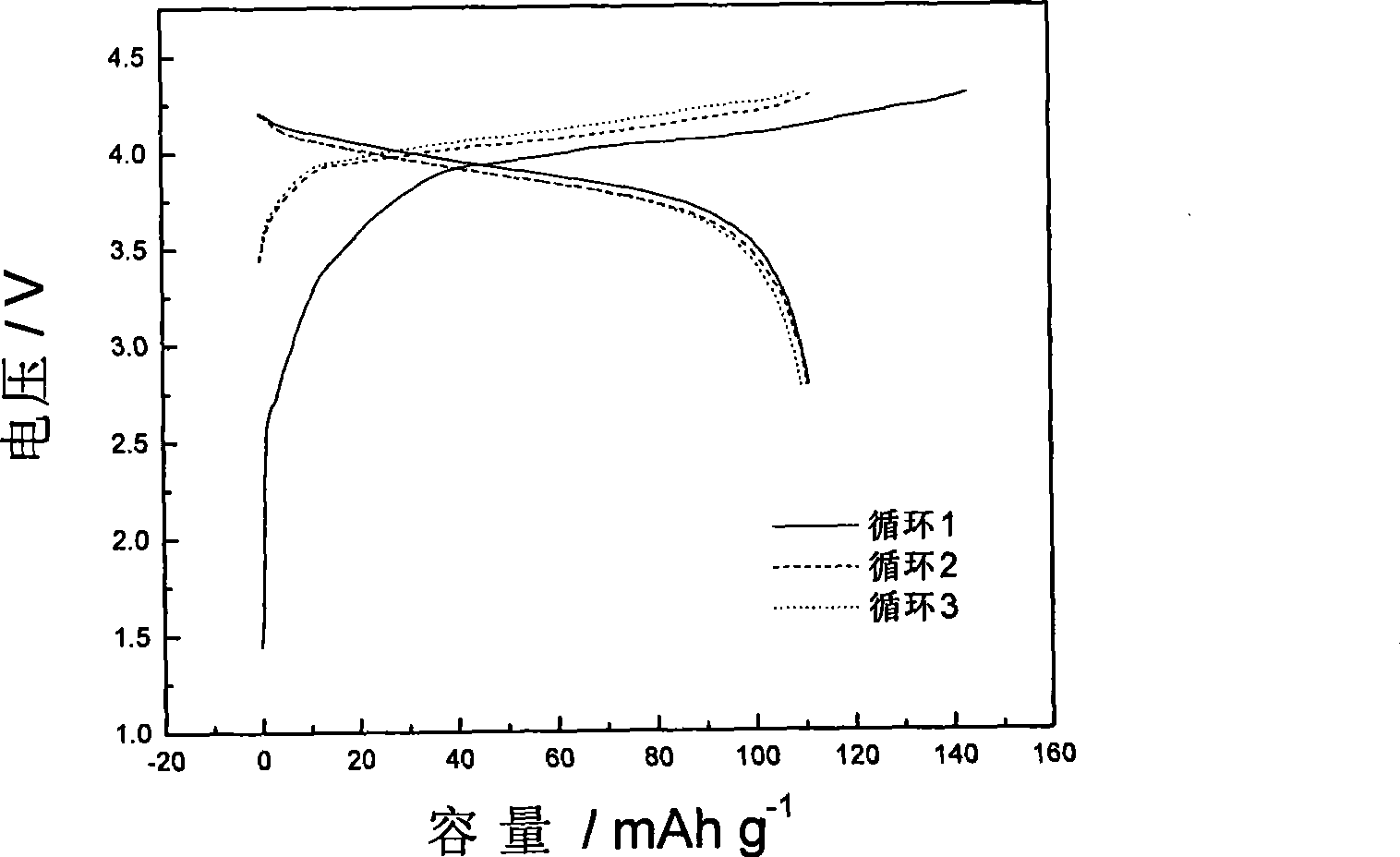

Fast ion conductor modified lithium ion battery cathode material lithium cobalt oxide with fast ion conductor and preparation method

InactiveCN101969110AIncrease capacityAvoid direct contactCell electrodesElectrical conductorPhosphate

The invention discloses a fast ion conductor modified lithium ion battery anode material lithium cobalt oxide comprising lithium cobalt oxide and a lithium fast ion conductor layer coating the outer surface of the lithium cobalt oxide. The lithium fast ion conductor layer comprises the components of Li1+x+yAxB2-xSiyP3-yO12-eN, wherein A is one or more than one of Al, Sc, La, Cr, Fe, Tl, Eu and In, B is one or more than one of Ti, Zr and Hf, N is one or more than one of Li2O, MgO and Y2O3, and x, y and e are all not less than 0 and not more than 2. The preparation method of the fast ion conductor modified lithium ion battery anode material lithium cobalt oxide comprises the following steps of: evenly mixing A, B an N sources, lithium salt, a silicon source, a phosphorus source and a lithium ion battery anode material to be modified, carrying out the processes of drying, roasting, crushing, screening and the like to prepare the lithium ion battery anode material coated with a phosphate system on the surface. The modified anode material lithium cobalt oxide not only can work under a higher voltage and greatly improve the battery capacity, but also greatly improves the cycle performance, the multiplying power performance, the overcharging performance and the safety performance thereof.

Owner:TIANJIN B&M SCI & TECH

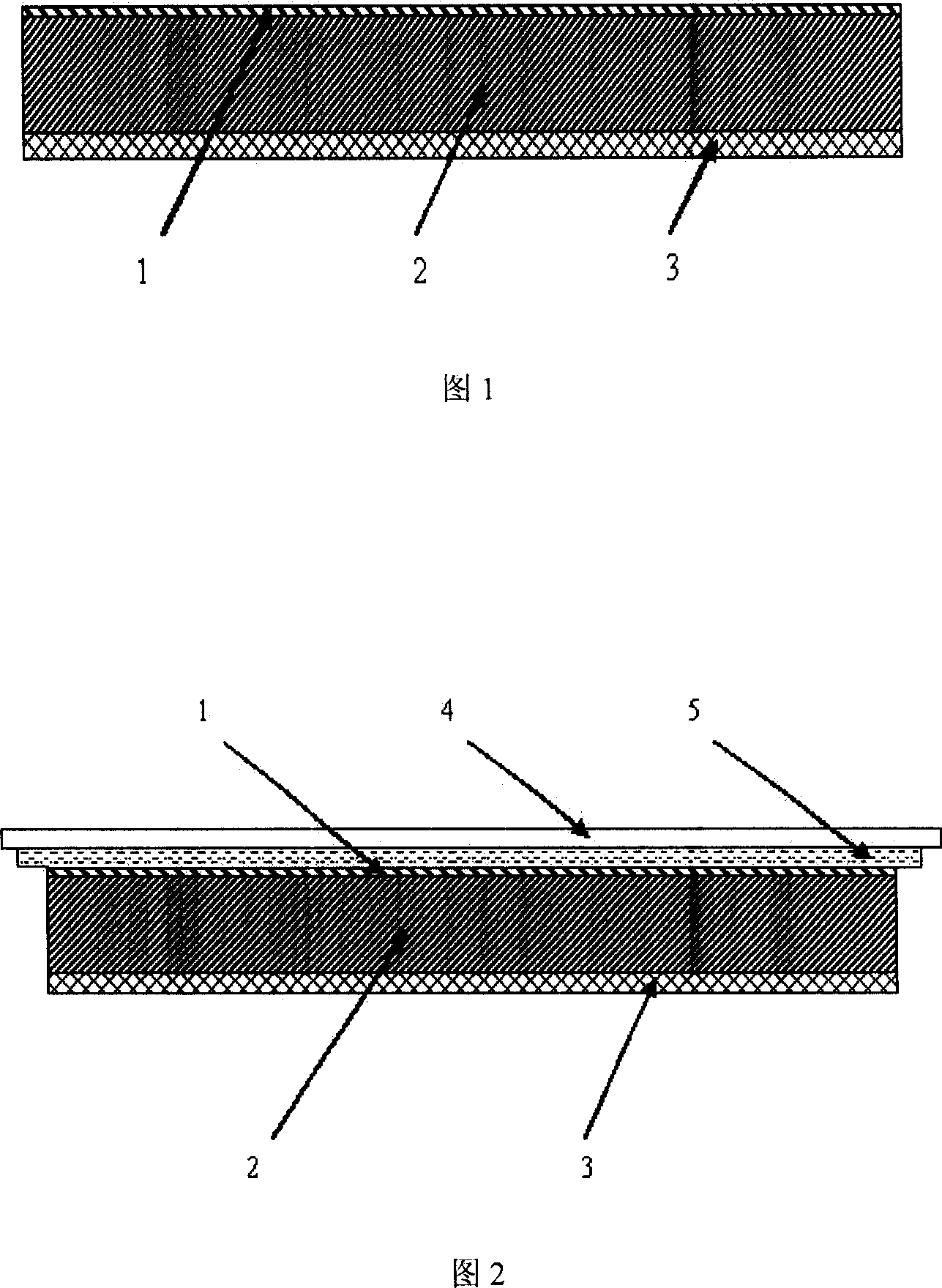

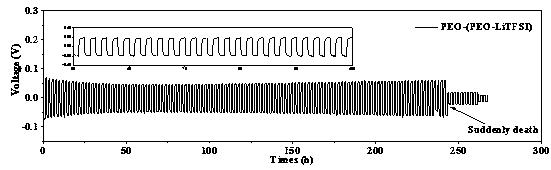

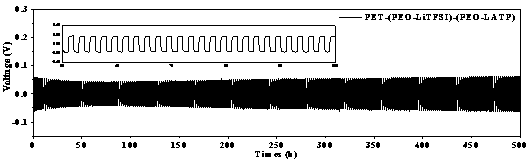

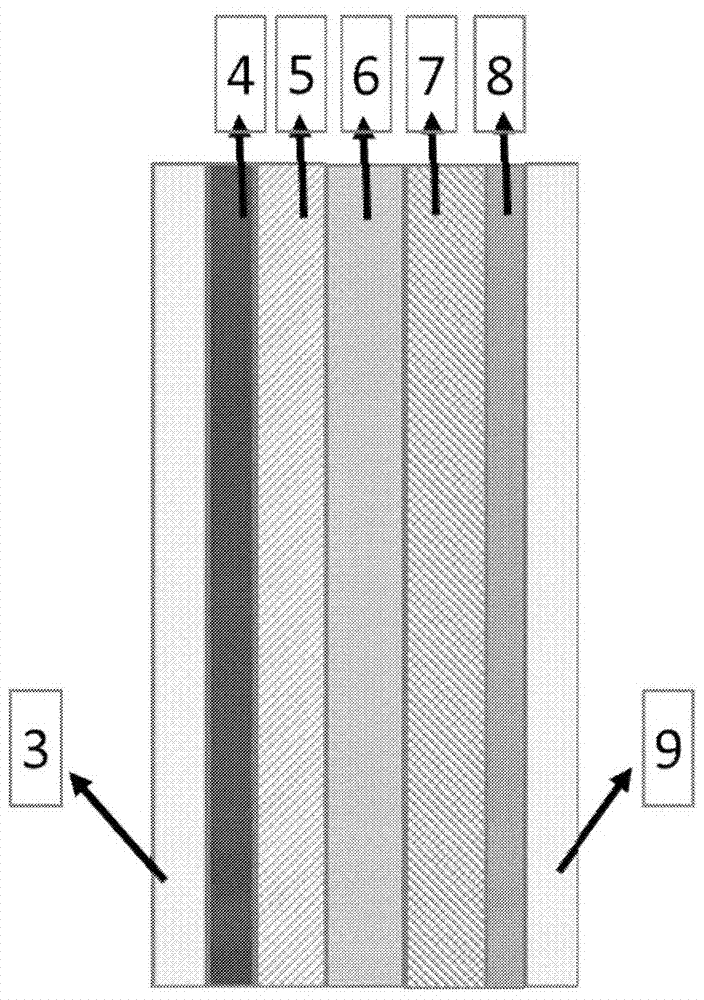

Inorganic-organic nano composite solid electrolyte membrane and preparation method and application thereof

ActiveCN109638349AImprove compatibilityEasy transferSolid electrolytesFinal product manufactureSolid state electrolyteHigh energy

The present invention discloses an inorganic-organic nano composite solid electrolyte membrane and a preparation method and application thereof. The composite solid electrolyte is a novel inorganic-organic nanocomposite combining the respective advantages of inorganic ceramic solid electrolyte and organic polymer electrolyte and is composed of a negative electrode protective layer, a support layerand a positive electrode interface layer. The support layer plays a supporting role, and the main component of the negative electrode protective layer is the inorganic solid electrolyte with good mechanical properties, which can effectively inhibit the growth of lithium dendrite; and the positive electrode interface layer is mainly composed of organic polymer electrolyte with good flexibility, ensures good contact with active materials and provides a continuous ion transport channel. In the present invention, the composite solid electrolyte with good interface compatibility is prepared by coating on both sides of the support layer, and the process is simple and efficient. The composite solid electrolyte can effectively inhibit dendritic crystal and reduces interface resistance so that a solid lithium metal battery has higher energy density and longer cycle life.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Composite microporous film, and production method and use thereof

ActiveCN1882436AGood adhesionHigh mechanical strengthSemi-permeable membranesFinal product manufactureDebyePolyolefin

Disclosed is a composite microporous film which is obtained by applying a liquid mixture containing (a) a fluororesin which can be gelated, (b) a good solvent therefor and (c) a poor solvent therefor having a dipole moment of not more than 1.8 Debye to at least one surface of a polyolefin microporous film and drying it, thereby forming a coating layer composed of a porous body of the fluororesin on the surface. The composite microporous film has columnar through holes in the coating layer, and has an excellent balance among permeability, adhesion to electrodes, mechanical strength, thermal shrinkage resistance, shutdown characteristics and meltdown characteristics.

Owner:TORAY IND INC

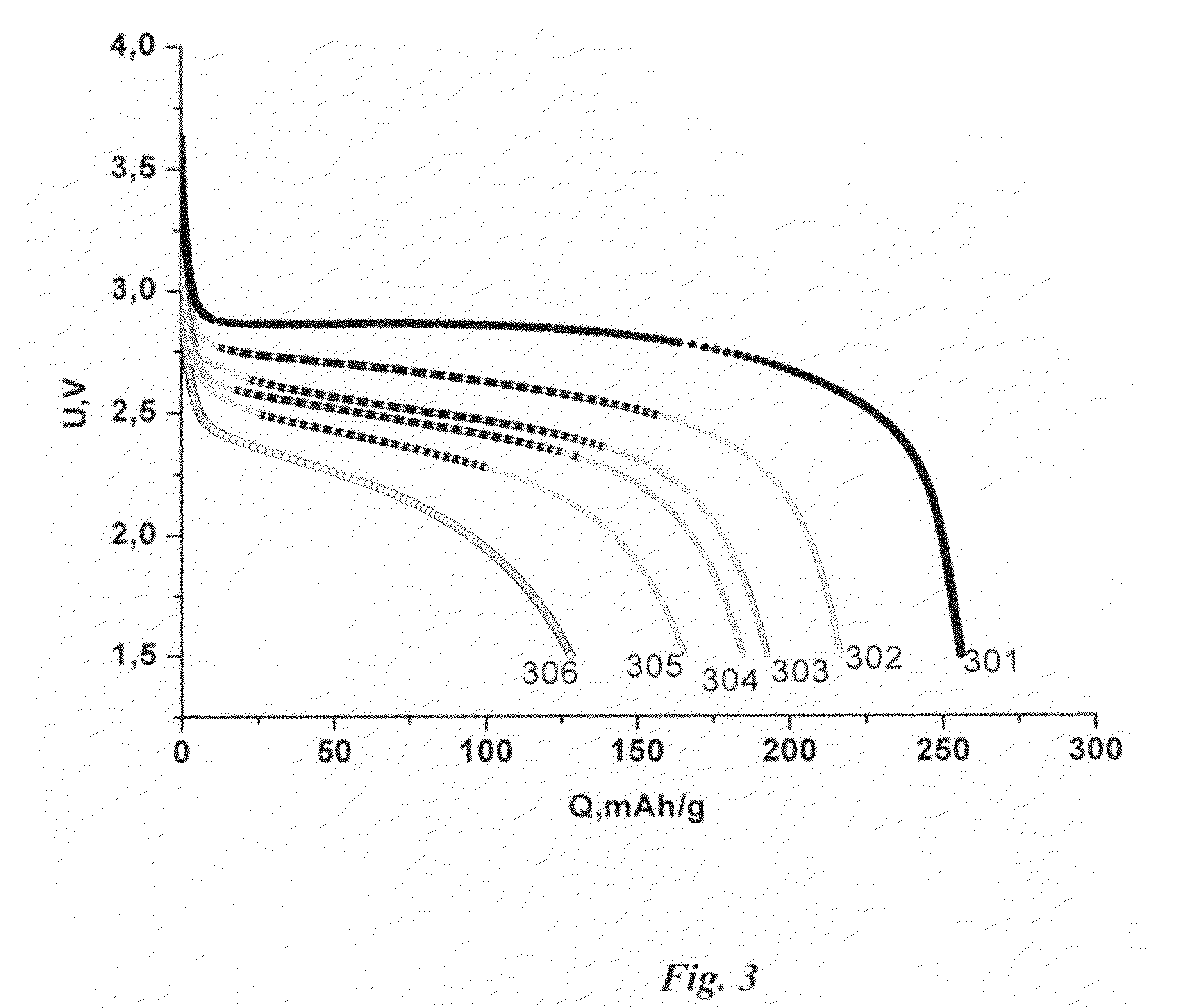

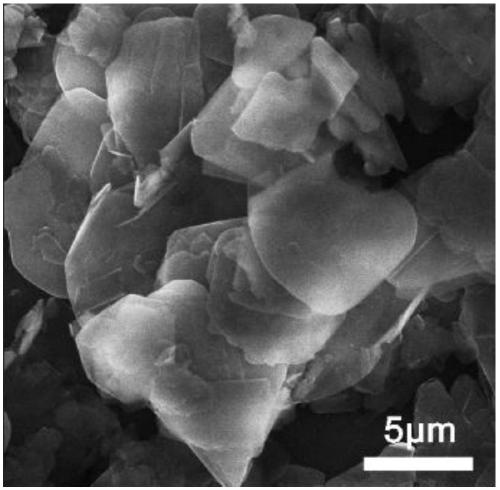

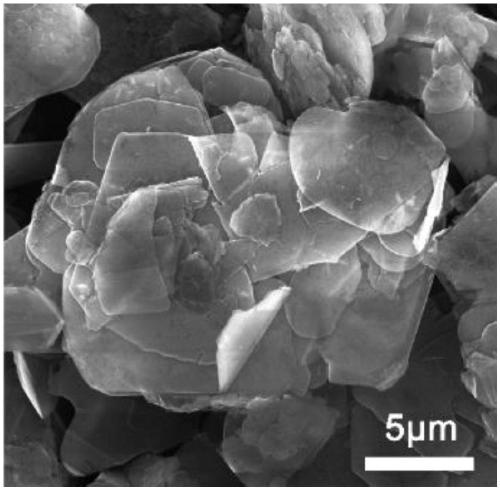

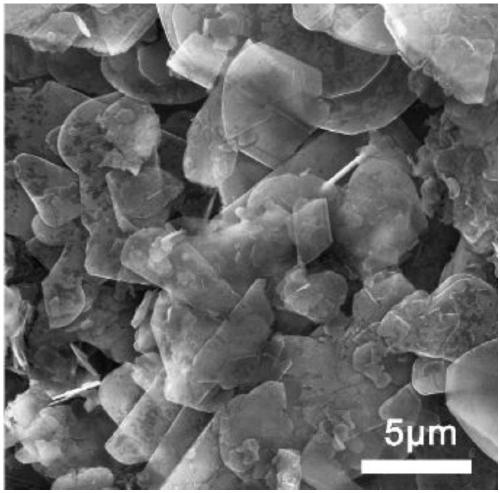

Electrode for lithium primary and secondary (rechargeable) batteries and the method of its production

InactiveUS20090117461A1Improve efficiencyWide operating temperature rangeElectrolytic capacitorsNon-aqueous electrolyte cellsElectrical resistance and conductanceLithium

The present invention relates to a method for production of electrodes for Li-primary and Li-ion batteries based of using two types of binder. The first binder is soluble in organic solvent and second binder is insoluble in organic solvent during the process of slurry preparation. Combination of the slurry composition and conditions of the electrode temperature treatment decrease the cathode production complexity, improve electrochemical characteristics of the electrode, increase adhesion properties and flexibility of coating, and reduce the interface resistance between the current collector and electrode mass.

Owner:ENERIZE CORP

Preparation method of BN/epoxy resin heat conductive insulation composite material

The invention provides a preparation method of a BN / epoxy resin heat conductive insulation composite material and belongs to the field of preparation of heat conductive insulation composite materials.The method includes: firstly, performing annealing pretreatment to BN powder and then surface modification with a silane coupling agent; then according to certain ratio, filling an epoxy resin matrixwith the modified hexagonal BN micropowder and the modified cubic BN micropowder. The method is simple process, wherein by adding the BN in different appearances, dimensions and phase structures, effective heat conduction channels are formed to finally improve the heat conductivity of the epoxy resin. After modification, the interface combination between the HBN and the resin is strong, wherein the sheet-like HBN and bulk CBN are overlapped in the epoxy resin to form excellent heat conductive network, thus effectively reducing interfacial thermo-resistance. The composite material is beneficial to quick transmission of heat, improves heat conductivity of the epoxy resin, has excellent insulation performance, and is improved in mechanical property.

Owner:JILIN UNIV

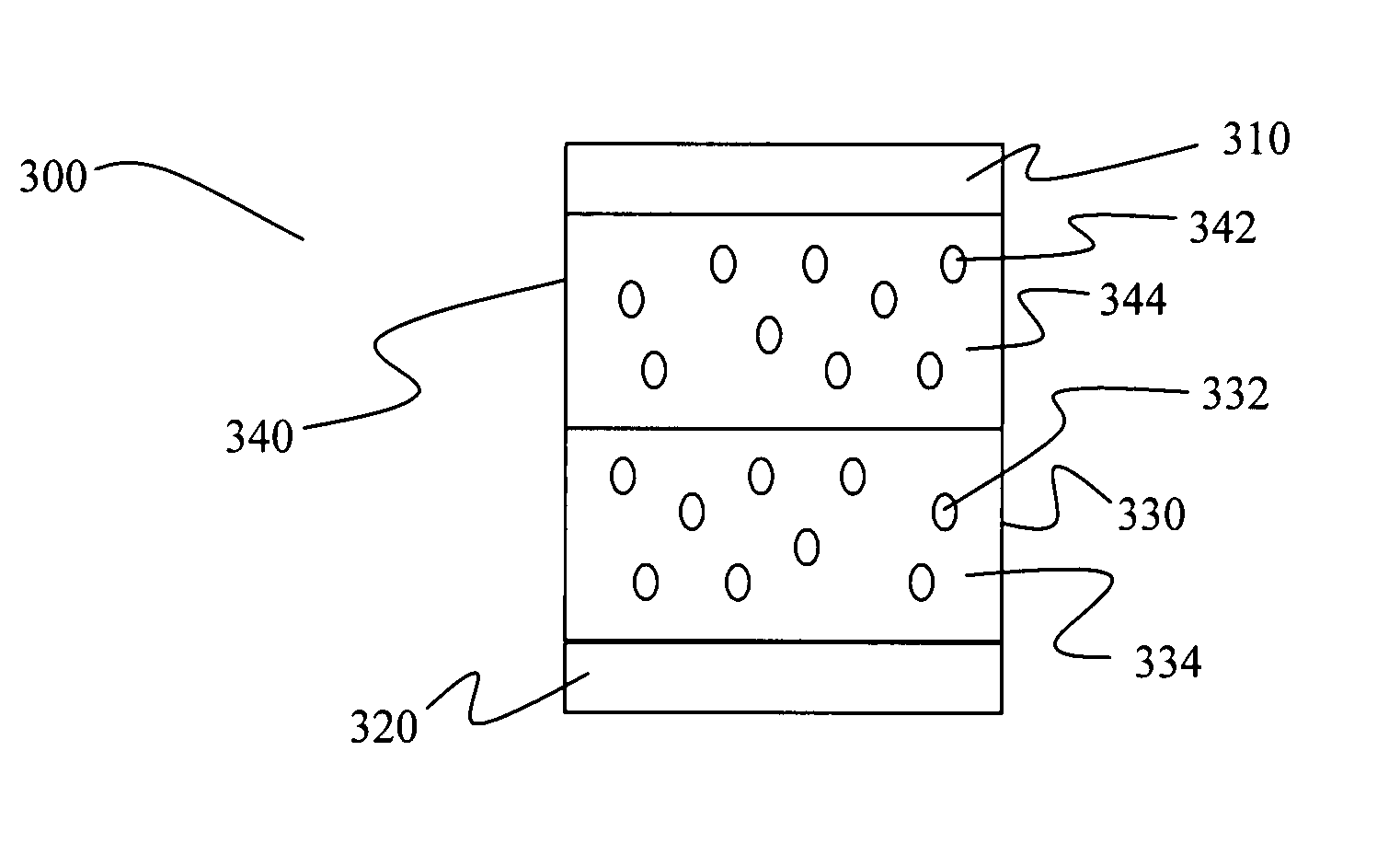

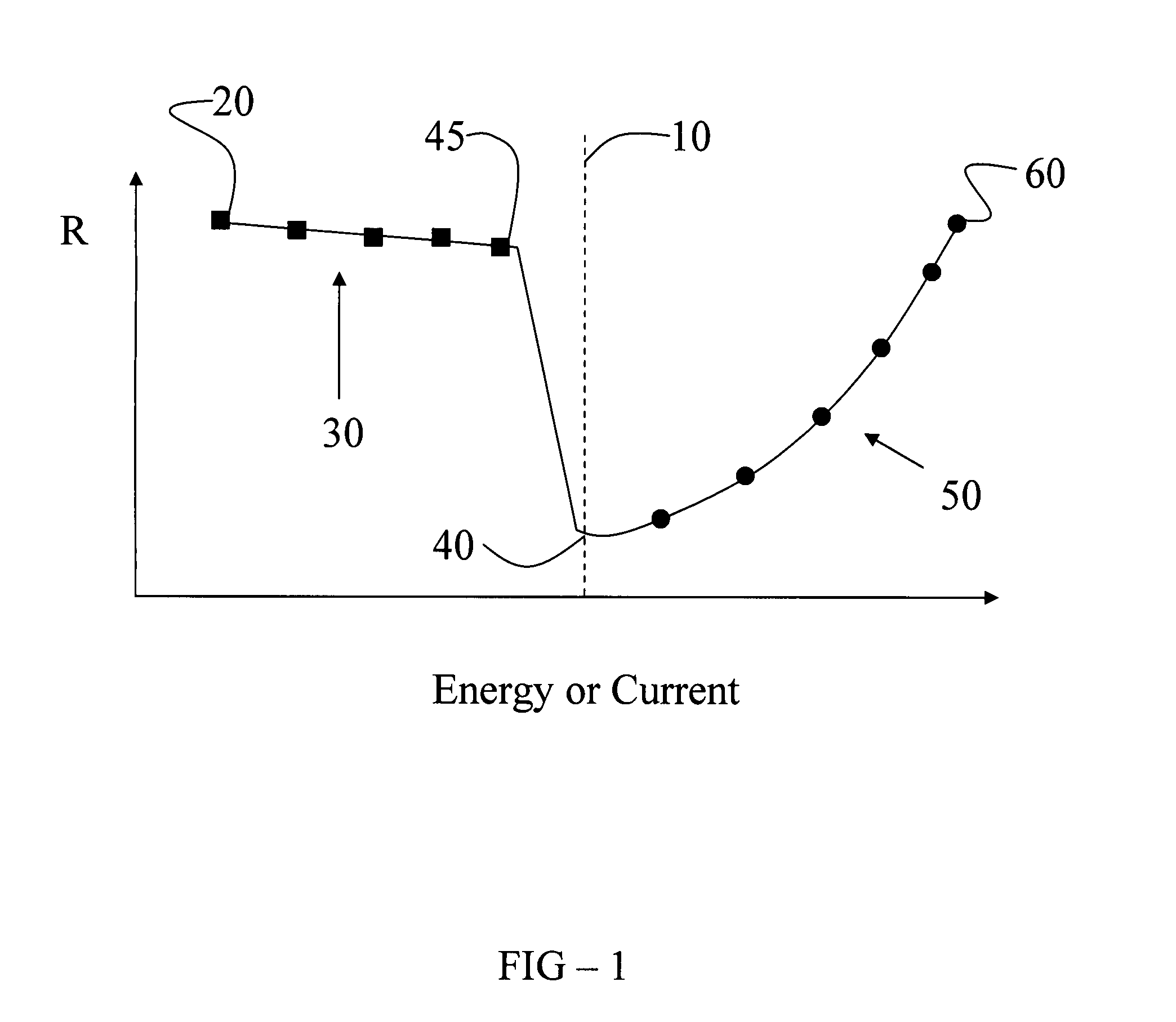

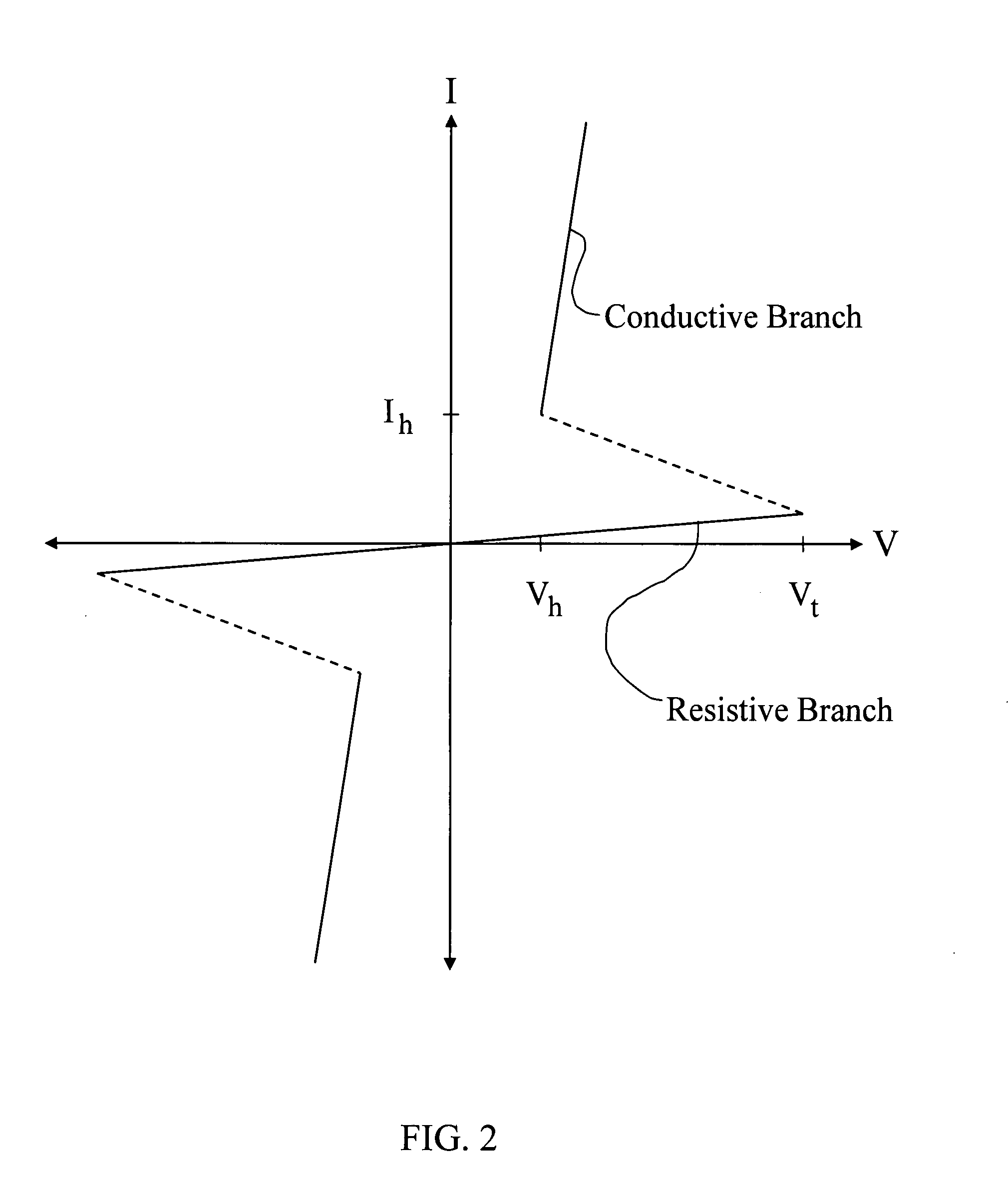

Multi-layered chalcogenide and related devices having enhanced operational characteristics

InactiveUS20080042119A1Reduce interface resistanceLess stringent conditionBulk negative resistance effect devicesPhase-change materialPhysics

A multi-layer chalcogenide, memory or switching device. The device includes an active region disposed between a first terminal and a second terminal. The active region includes a first layer and a second layer, where one of the layers is a heterogeneous layer that includes an operational component and a promoter component. The other layer may be a homogeneous or heterogeneous layer. In exemplary embodiments, the operational component is a chalcogenide or phase change material and the promoter component is an insulating or dielectric material. Inclusion of the promoter component provides beneficial performance characteristics such as a reduction in reset current or minimization of formation requirements.

Owner:OVONYX

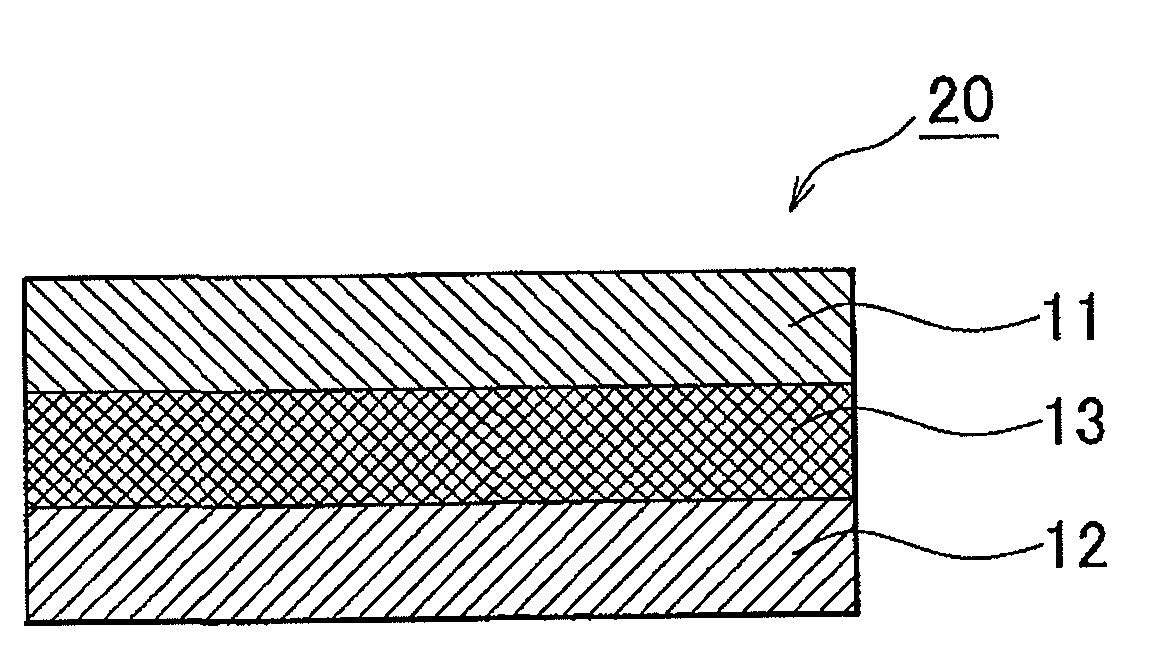

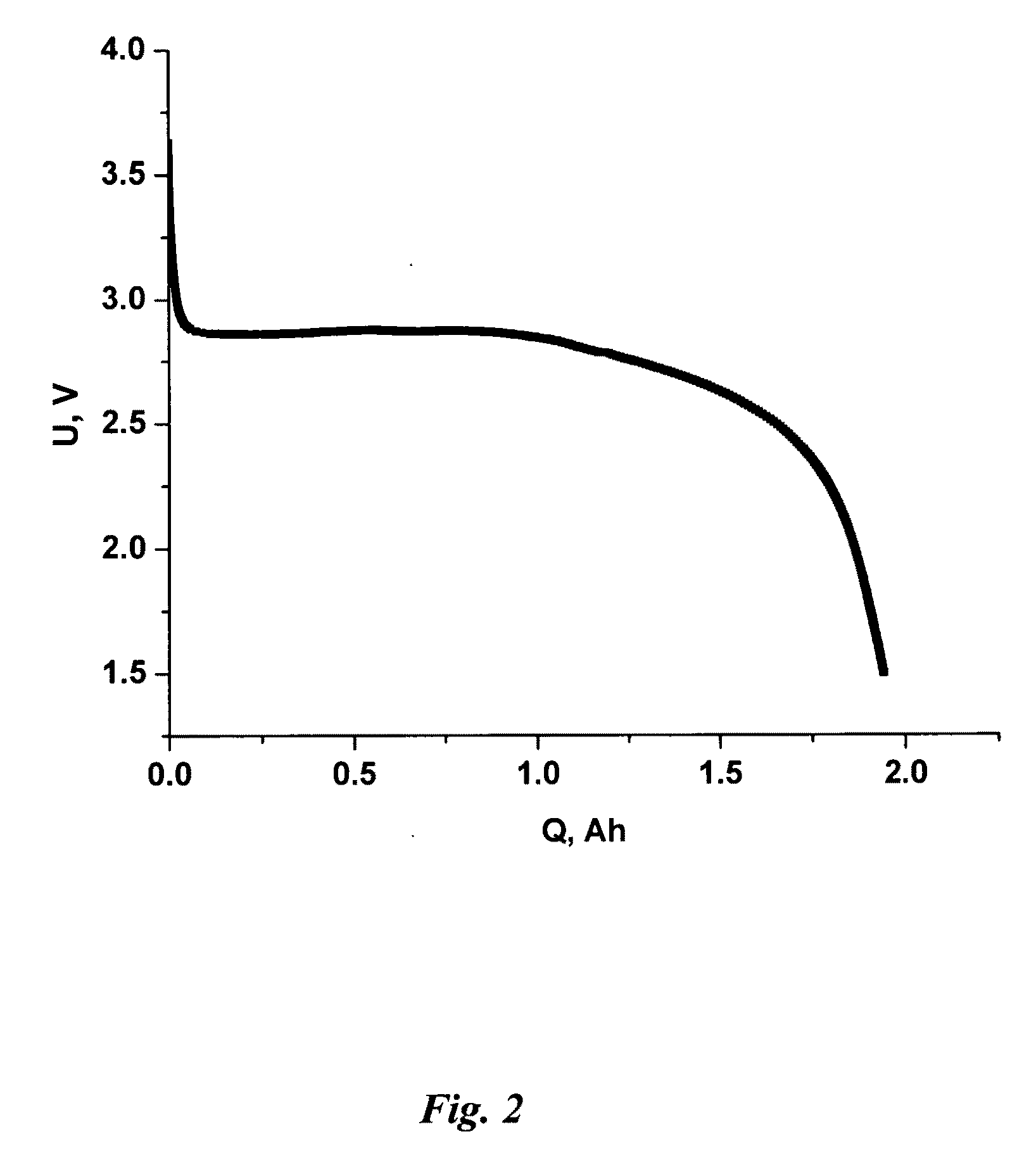

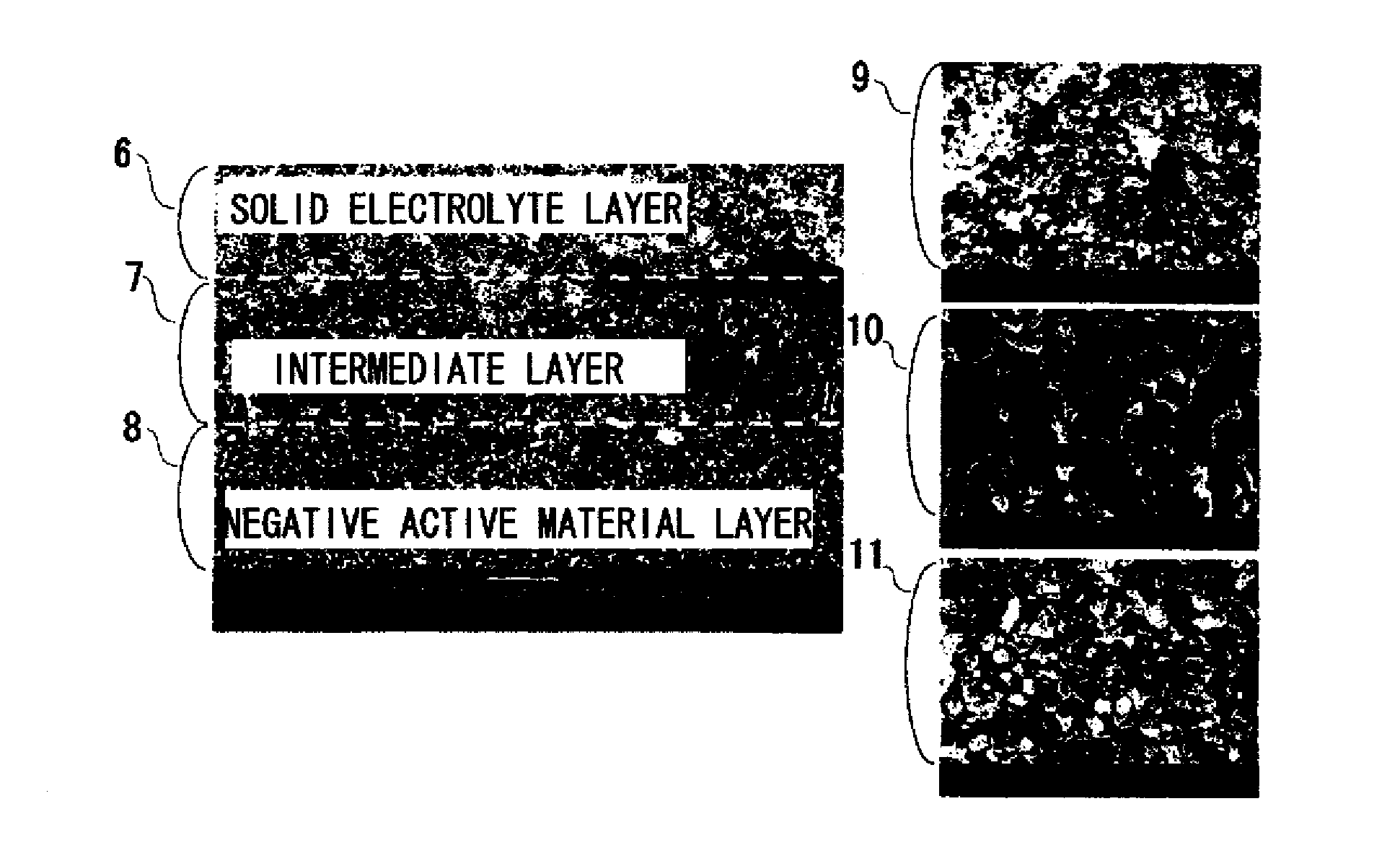

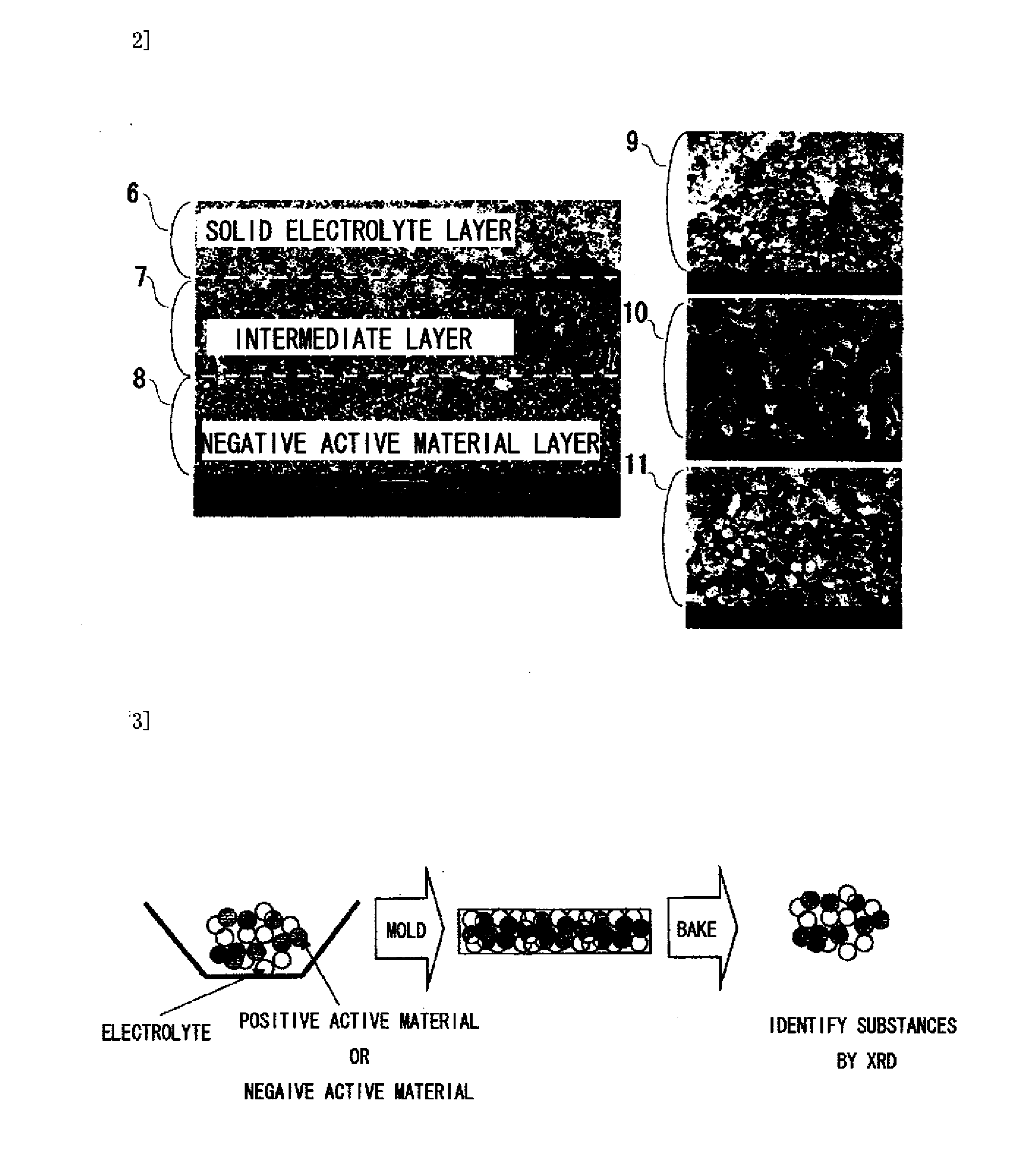

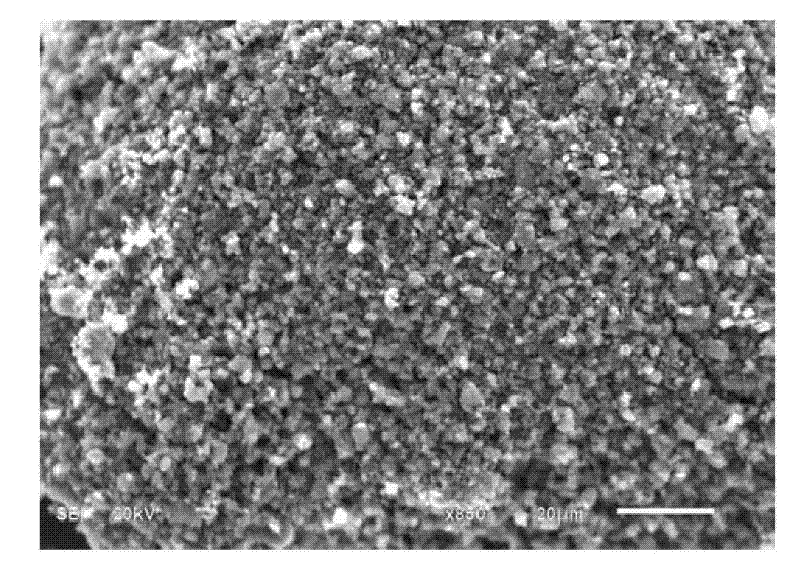

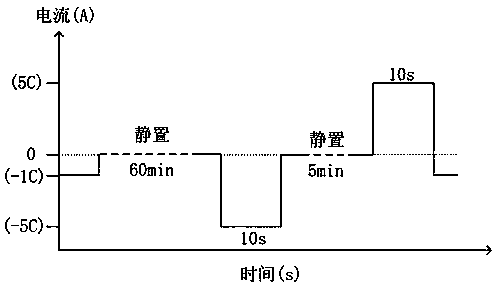

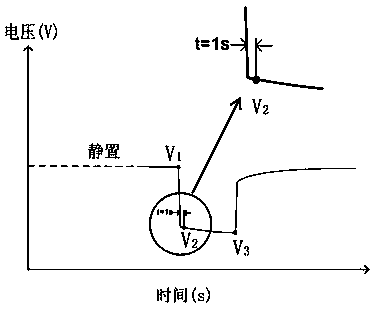

Lithium ion rechargeable battery and process for producing the lithium ion rechargeable battery

InactiveUS20100216032A1Enhanced interface bindingReduce interface resistanceFinal product manufactureElectrode carriers/collectorsCooking & bakingLithium

Conventional ion rechargeable batteries having an electrode layer on an electrolyte layer suffer from an impurity layer formed at the interface, degrading performance. Conventional batteries with no such impurity layer have a problem of weak interface bonding. In the present invention, in a baking process step after an electrode layer is laminated on an electrolyte layer, materials for an electrode layer and an electrolyte layer are selected such that an intermediate layer formed of a reaction product contributing to charging and discharging reactions is formed at the interface of the electrode layer and the electrolyte layer. In addition, a paste that an active material is mixed with a conductive material at a predetermined mixing ratio is used to form a positive electrode layer and a negative electrode layer. Reductions in electrode resistance and interface resistance and improvement of charging and discharging cycle characteristics are made possible.

Owner:NAMICS CORPORATION

Preparation method for graphene material with porous structure

InactiveCN102583337AReduce interface resistanceImprove conductivityGrapheneNanotechnologyCvd grapheneCarbon source

The invention aims at providing a preparation method for a graphene material with a porous structure. The invention adopts the technical scheme that the preparation method comprises the following steps: A, with a porous magnesium oxide / silicon composite material as a template, enabling a carbon source to grow graphene in a structure of the porous magnesium oxide / silicon composite material to form a magnesium oxide / silicon / graphene composite structure by using a chemical vapor deposition method; and B, etching to remove a template material of the composite structure, thereby obtaining the graphene material with the porous structure. According to the preparation method, the magnesium oxide / silicon composite material with the porous structure is used as the template and the macroscopic preparation can be carried out by using the chemical vapor deposition method. The preparation method for the graphene material with the porous structure is simple in process, easiness in control of the process and excellent material conductivity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Semiconductor device including a MOS transistor and production method therefor

ActiveUS8497548B2Reduce narrow width effectReduce interface resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

Owner:UNISANTIS ELECTRONICS SINGAPORE PTE LTD

Negative electrode material and preparation method thereof, negative electrode plate and lithium ion battery

PendingCN107946561AImprove cycle performanceReduce usageNegative electrodesSecondary cellsInternal resistanceCarbon nanotube

The invention discloses a negative electrode material of a lithium ion battery. The negative electrode material comprises the following components in parts by mass: 88-105 parts of active material, 0.01-0.1 parts of single-wall carbon nanotubes, 0.01-0.5 parts of graphene nanobelt, one or less parts of super conductive carbon black, one or less parts of less-wall or multi-wall carbon nanotubes, 0.05-0.5 parts of dispersing agent, 1-3 parts of thickening agent, 1-4 parts of binder and 25-60 parts of solvent; the active material comprises a silicon oxide material SiO<x> and synthetic graphite, wherein x is greater than 0 and less than 2; and the silicon element in the negative electrode material is less than or equal to 3.5mass%. The invention provides the negative electrode material comprising the silicon oxide material and the low-dimensional carbon conductive material of the lithium ion battery; by virtue of the negative electrode material of the lithium ion battery, the problems of capacity fading and increasing internal resistance caused by losing of effective electron channels due to low electrical conductivity and an expansion effect in the use process of a silicon oxide negative electrode active material can be solved; and meanwhile, the cycle performance of the lithium ion battery applying the negative electrode material is improved.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

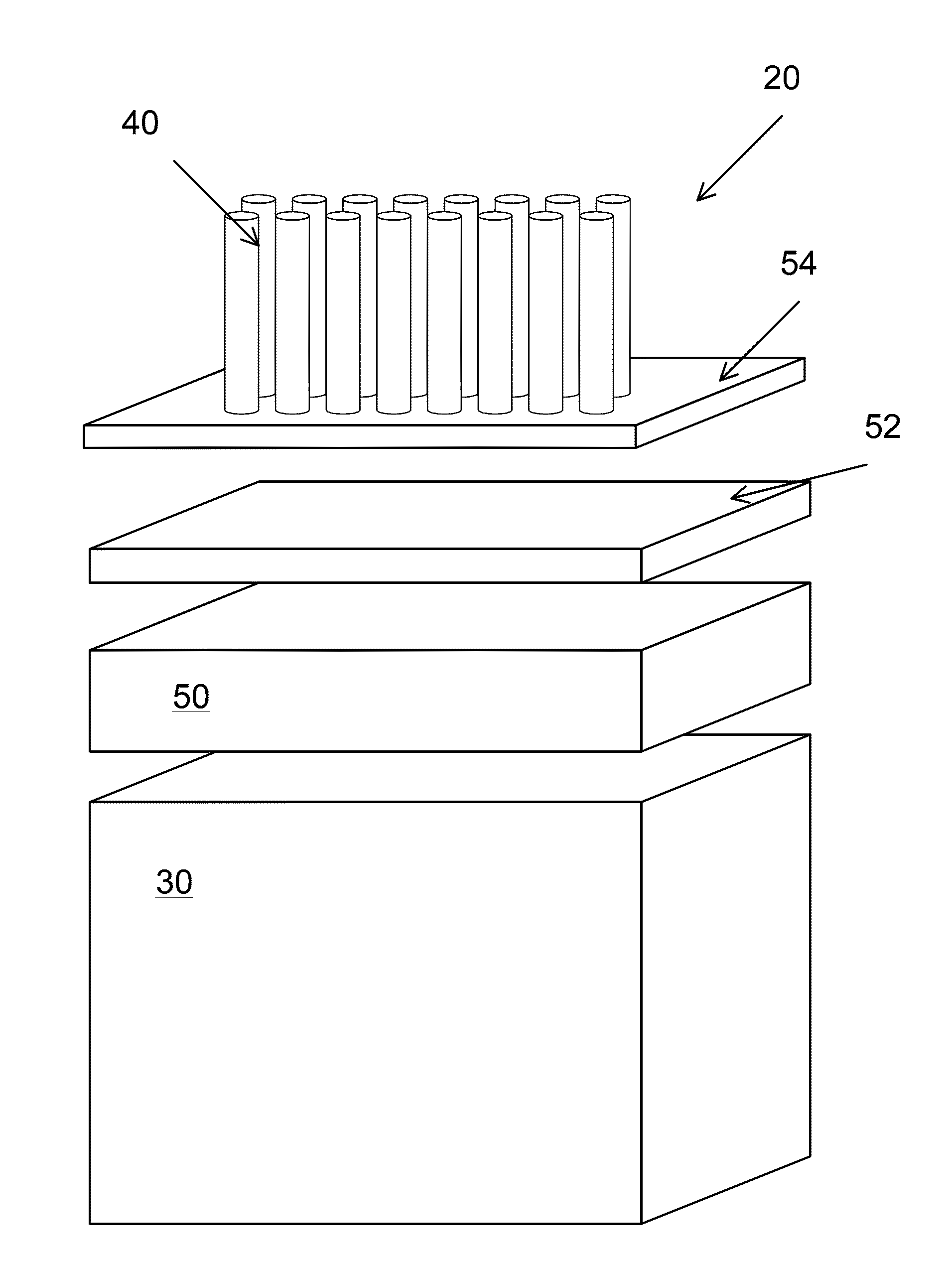

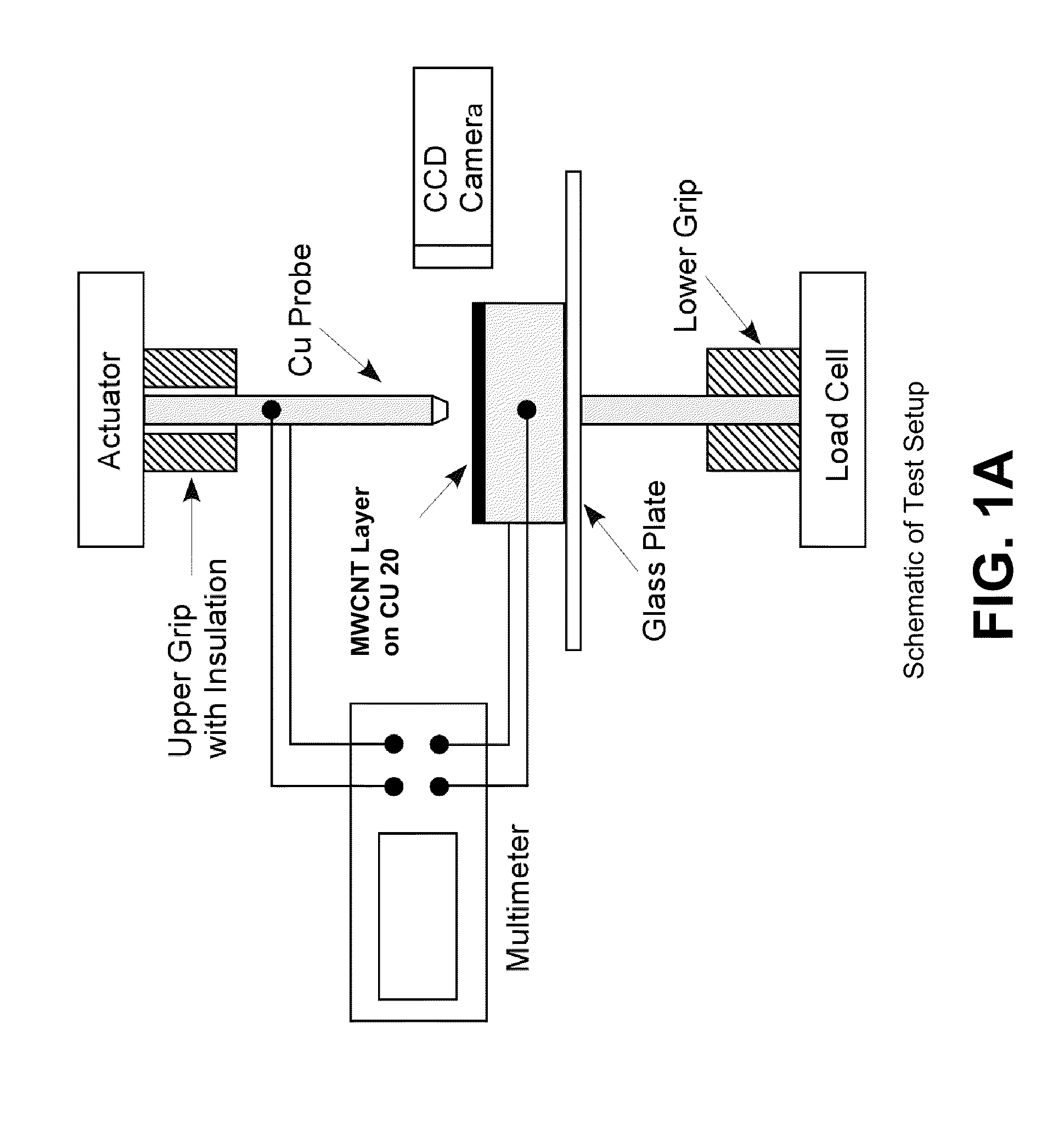

Methods for attaching carbon nanotubes to a carbon substrate

ActiveUS20100200208A1Reduce thermal (or electrical) interface resistanceHigh axial and in-plane thermal conductivityMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeGraphite

Vertically oriented carbon nanotubes (CNT) arrays have been simultaneously synthesized at relatively low growth temperatures (i.e., <700° C.) on both sides of aluminum foil via plasma enhanced chemical vapor deposition. The resulting CNT arrays were highly dense, and the average CNT diameter in the arrays was approximately 10 nm, A CNT TIM that consist of CNT arrays directly and simultaneously synthesized on both sides of various types of foil has been fabricated. The TIM is insertable and allows temperature sensitive and / or rough substrates to be interfaced by highly conductive and conformable CNT arrays. The use of foil, including substrates fabricated from carbon (CNT woven arrays, exfoliated graphite sheets, bucky paper, and the like) is disclosed.

Owner:PURDUE RES FOUND INC

Electrolyte film and porous substrate and preparation thereof, lithium ion secondary battery

InactiveCN101388441AHave mechanical strengthGood flexibilitySecondary cellsCell component detailsPorous substratePolymer electrolytes

The invention relates to a gel-type polymer electrolyte film for a lithium ion secondary battery and a process for preparation, and a lithium ion secondary battery which contains the electrolyte film. The gel-type polymer electrolyte film for the lithium ion secondary battery can be obtained through the following method: preparing polyvinylidene fluoride nonwoven through the electrostatic spinning method, making the surface of the polyvinylidene fluoride nonwoven activate through radiating electron beams for the obtained the polyvinylidene fluoride nonwoven in air, contacting a methyl methacrylate monomer and the polyvinylidene fluoride nonwoven after the surface activation, thereby obtaining the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate. Furthermore, the lithium ion battery electrolyte film can be obtained through making the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate absorbs a certain amount of electrolytic solution. The invention develops the respective advantages in the lithium ion battery owing to using the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate, compared with singly using polyvinylidene fluoride or polymethyl methacryate or the both simple composite, and eliminates the disadvantages caused by singly using one material or several materials. The electrolyte film has high ion electrical conductivity under ambient temperature after absorbing the electrolytic solution, and can manifest excellent heavy-current discharge performance and circulation stability after being assembled in the batteries.

Owner:PANASONIC CORP +1

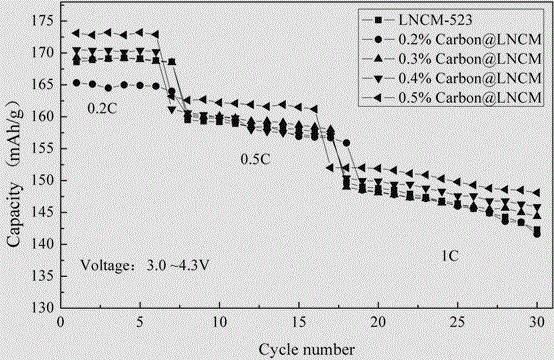

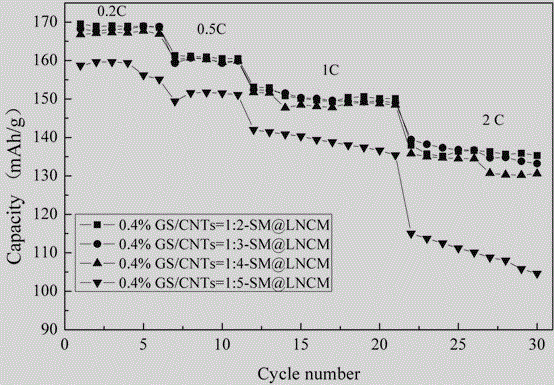

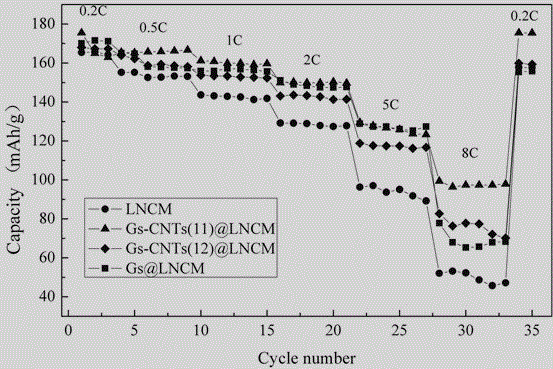

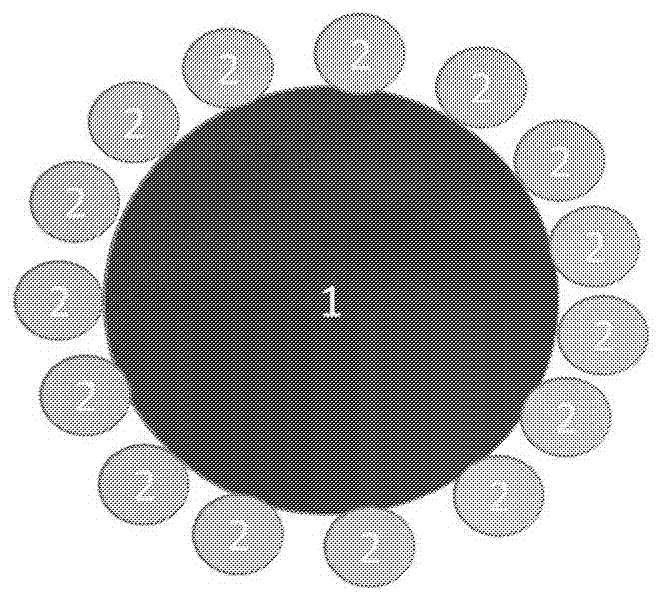

Coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material and preparation method thereof

ActiveCN105070888AImprove conductivityIncrease the diffusion coefficientMaterial nanotechnologyCell electrodesManganeseCarbon nanotube

The invention relates to the technical field of battery materials, in particular to a coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material and a preparation method thereof. According to the coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material, a nickel-cobalt-manganese ternary material, carbon nano tubes and graphene are taken as raw materials; and the ternary material is characterized by being prepared by the following steps: with polyvinyl pyrrolidone as a dispersing agent, through a liquid-phase self-assembling method, simultaneously connecting the graphene and the carbon nano tubes with a silane coupling agent to form a three-dimensional network structure; and evenly dispersing the coupled carbon nano tube-graphene composite material and the nickel-cobalt-manganese ternary material through a physical method, coating the surface of the nickel-cobalt-manganese ternary material, and sintering the nickel-cobalt-manganese ternary material in an inert atmosphere, so as to obtain the evenly coated product. The product provided by the invention has the advantages of high specific discharge capacity, long cycle life and simplicity in preparation process; and large-scale production is easy to realize.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

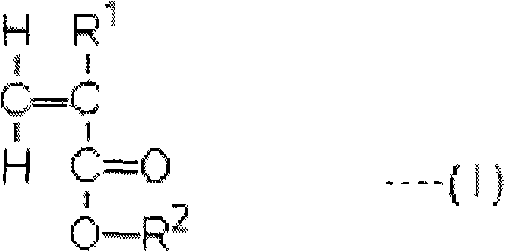

Binder for secondary battery electrode, secondary battery electrode, and secondary battery

ActiveCN101652884AReduce interface resistanceLower internal resistanceActive material electrodesNon-aqueous electrolyte accumulator electrodesMonomer compositionPolymer science

The present invention aims to improve bond durability as well as rate characteristics, cycle characteristics and short-circuit ratio of a secondary battery by decreasing the internal resistance of a secondary battery electrode. Specifically disclosed is a binder for secondary battery electrodes, which is composed of a polymer obtained by polymerizing a monomer composition containing a fluorine atom-containing monomer represented by the general formula (I) below and having a weight average molecular weight of 5,000-2,500,000. In the formula, R<1> represents a hydrogenor a methyl group, and R<2> represents a fluorine atom-containing hydrocarbon group having 6-18 carbon atoms.

Owner:ZEON CORP

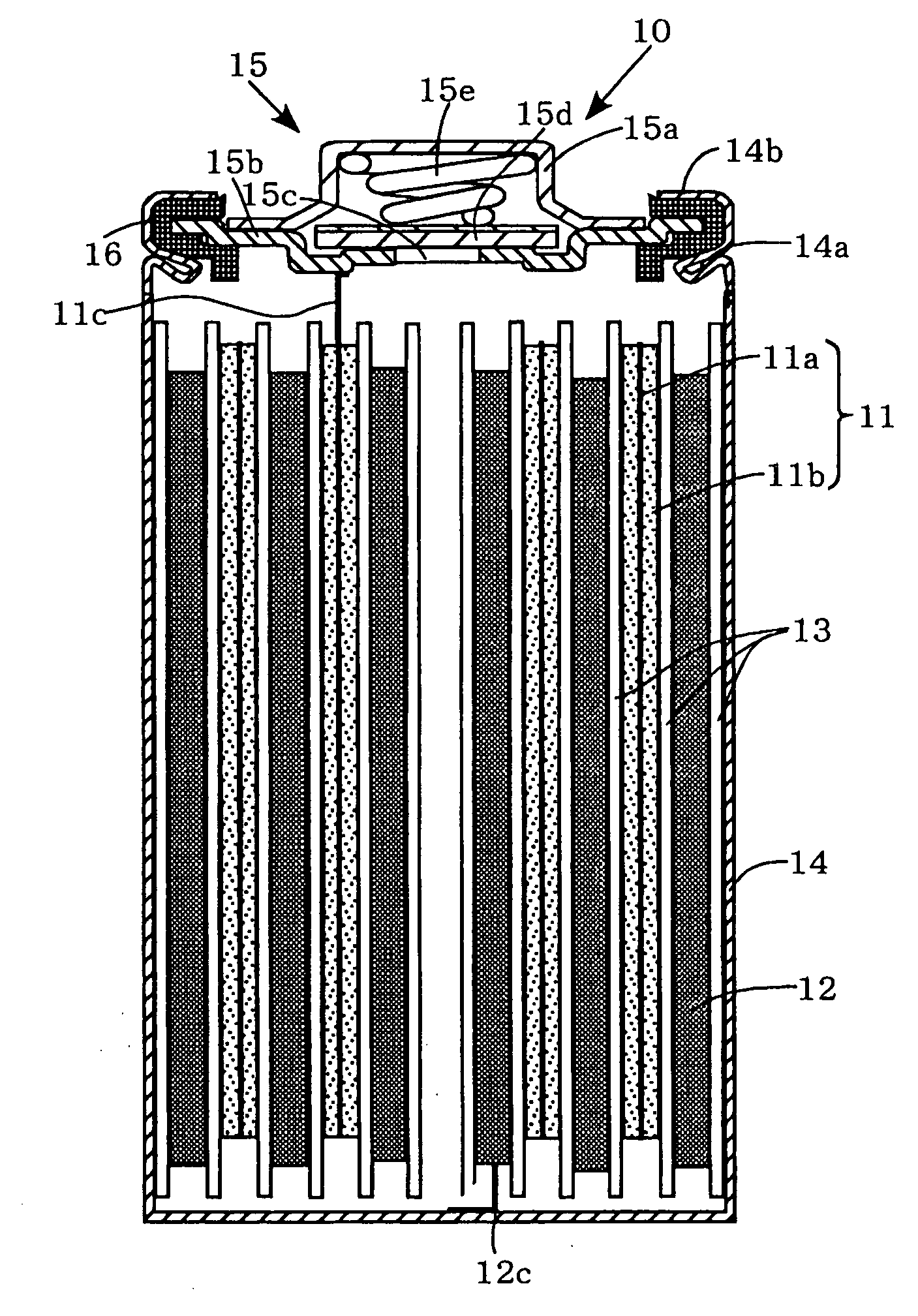

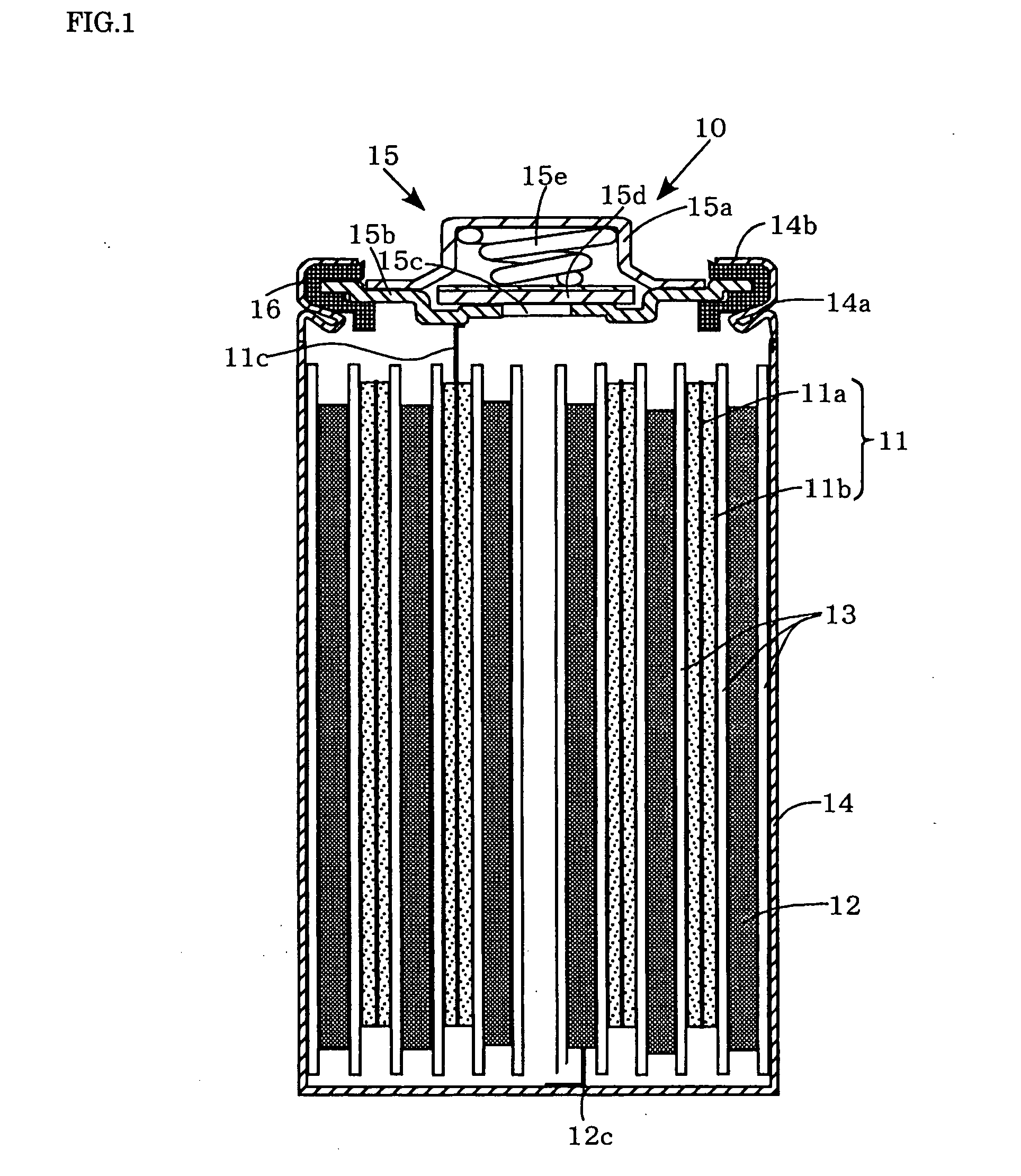

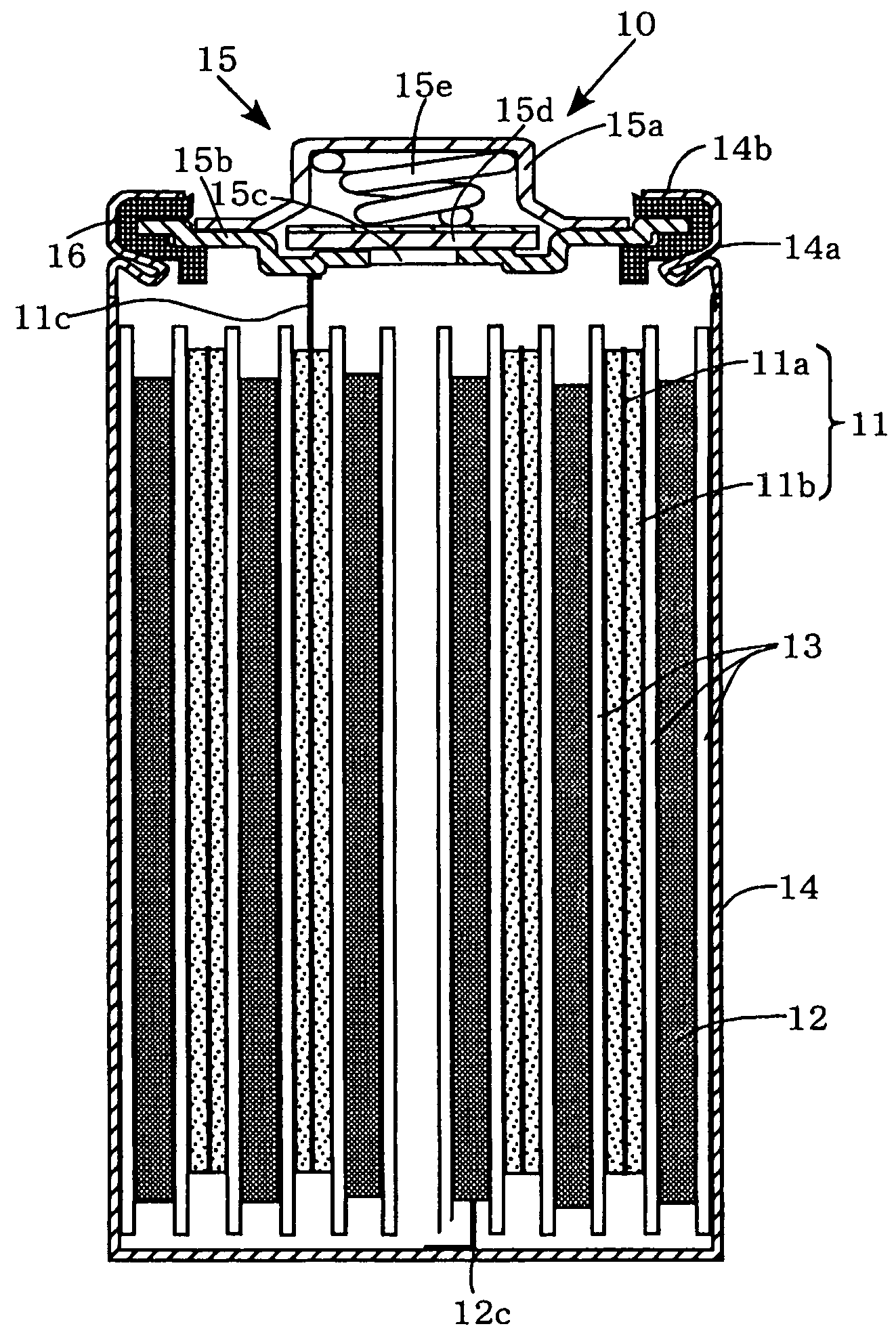

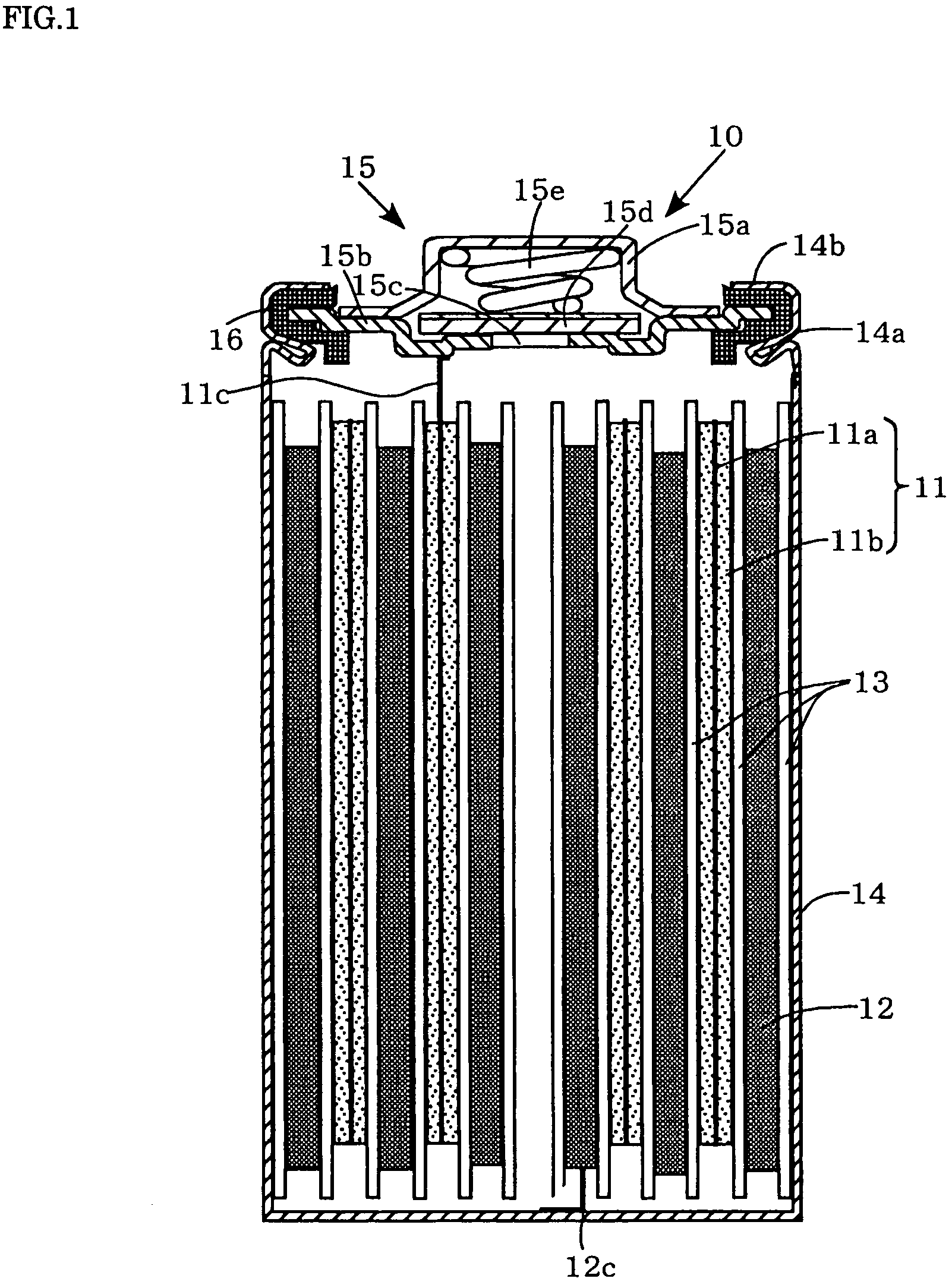

Nonaqueous electrolyte secondary battery

ActiveUS20070212607A1Increasing thicknessDegradation of output characteristicPositive electrodesLi-accumulatorsComposite oxideElectrolyte

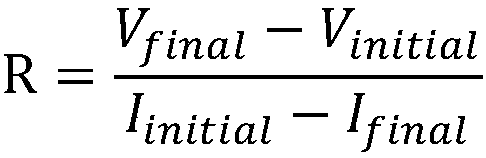

A nonaqueous electrolyte secondary battery 10 according to an embodiment of the present invention includes a positive electrode 11 having a positive electrode active material that can intercalate and deintercalate lithium, a negative electrode 12 having a negative electrode active material that can intercalate and deintercalate lithium, and a nonaqueous electrolyte having lithium ion conductivity. The positive electrode active material is a layered lithium transition metal composite oxide (for example, one represented by Li1+x(NiyCozMn1-y-z)1-xO2 (where 0≦x≦0.15, 0.1≦y≦0.6, and 0≦z≦0.5)) to which an IVa group element (Zr) and a Va group element (Nb) are added. According to these features, it is possible to provide a nonaqueous electrolyte secondary battery with a selected element to be added to the lithium transition metal composite oxide to reduce the I-V resistance (improve the I-V characteristic), and thereby improving the output / input characteristics.

Owner:SANYO ELECTRIC CO LTD

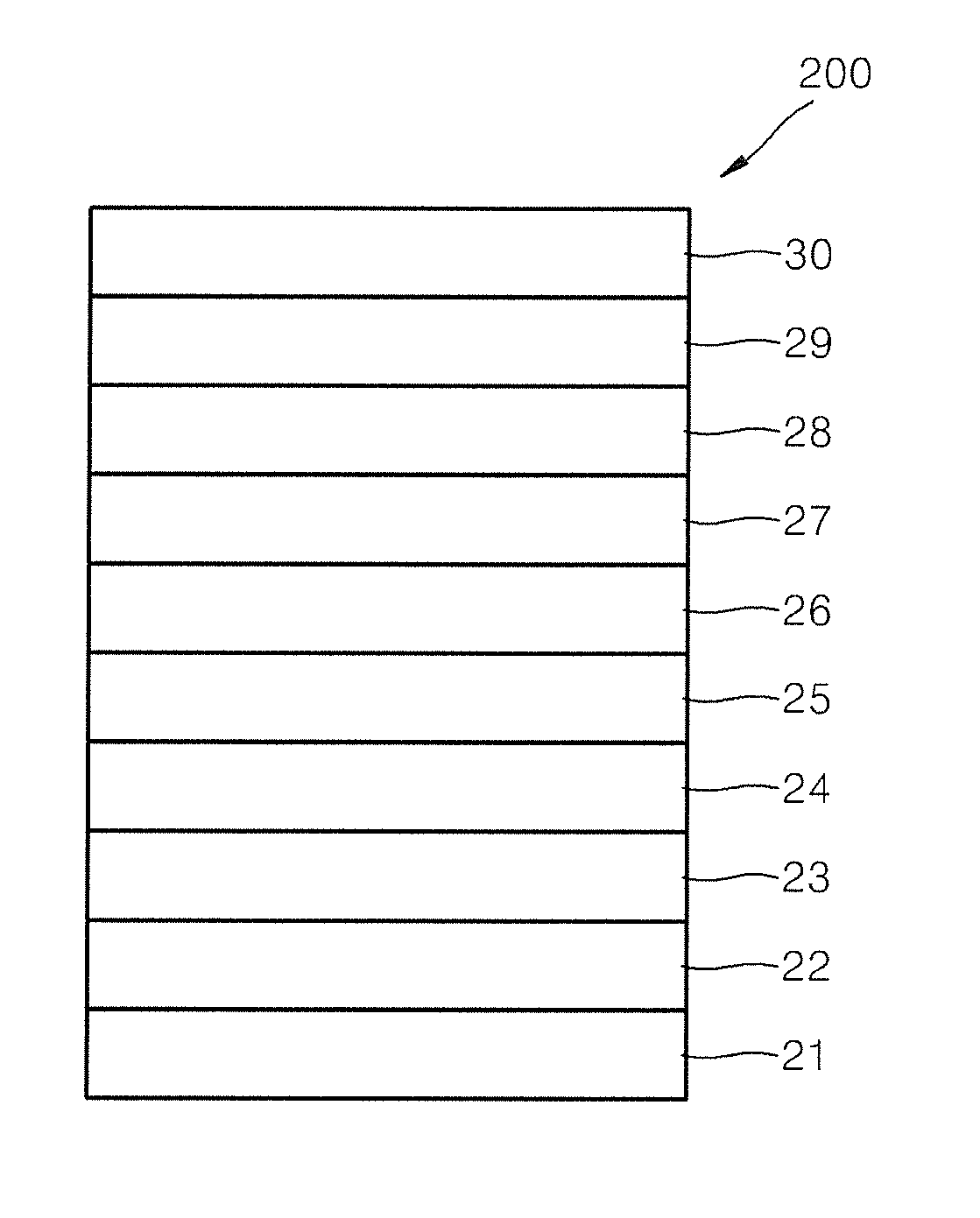

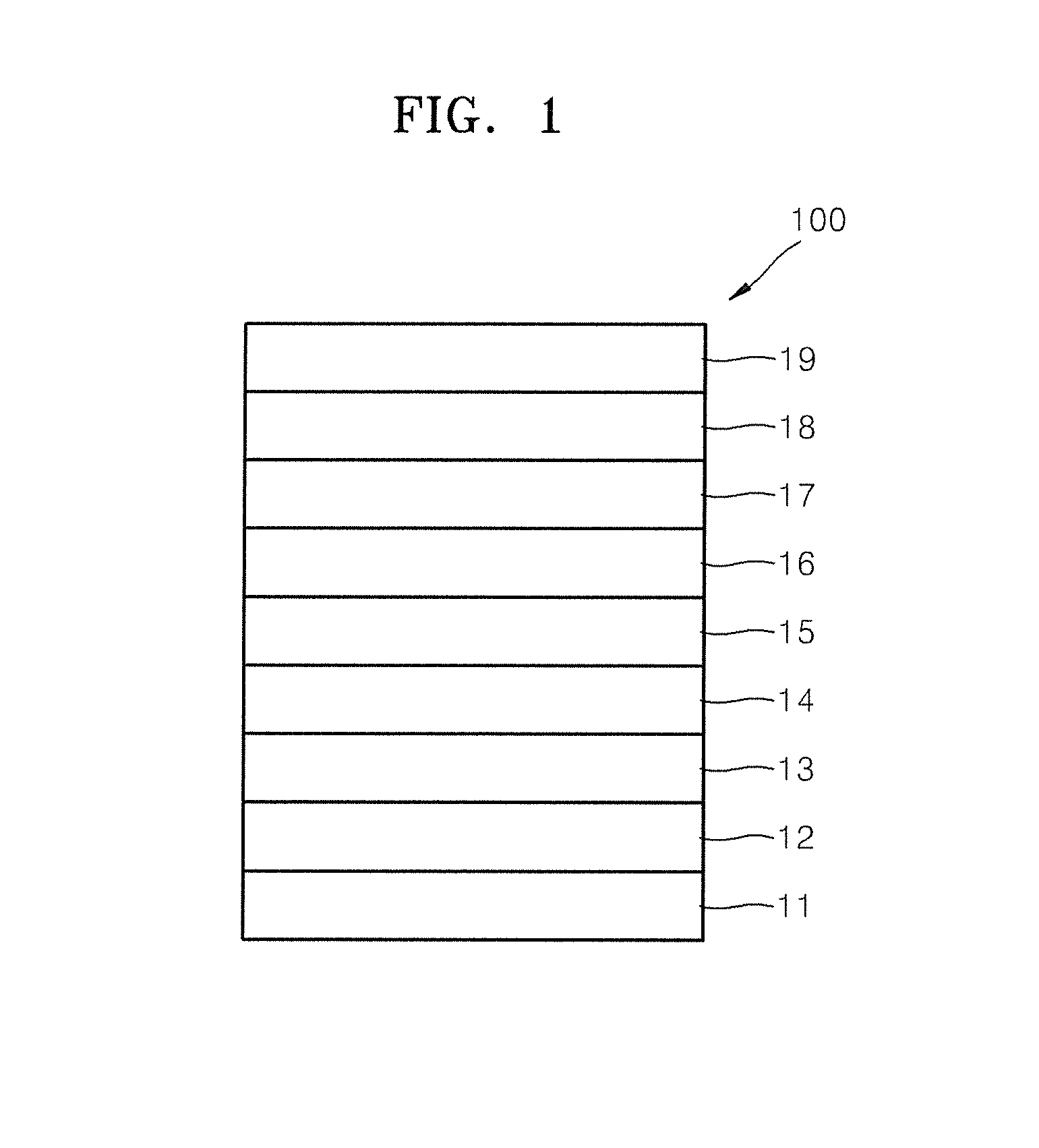

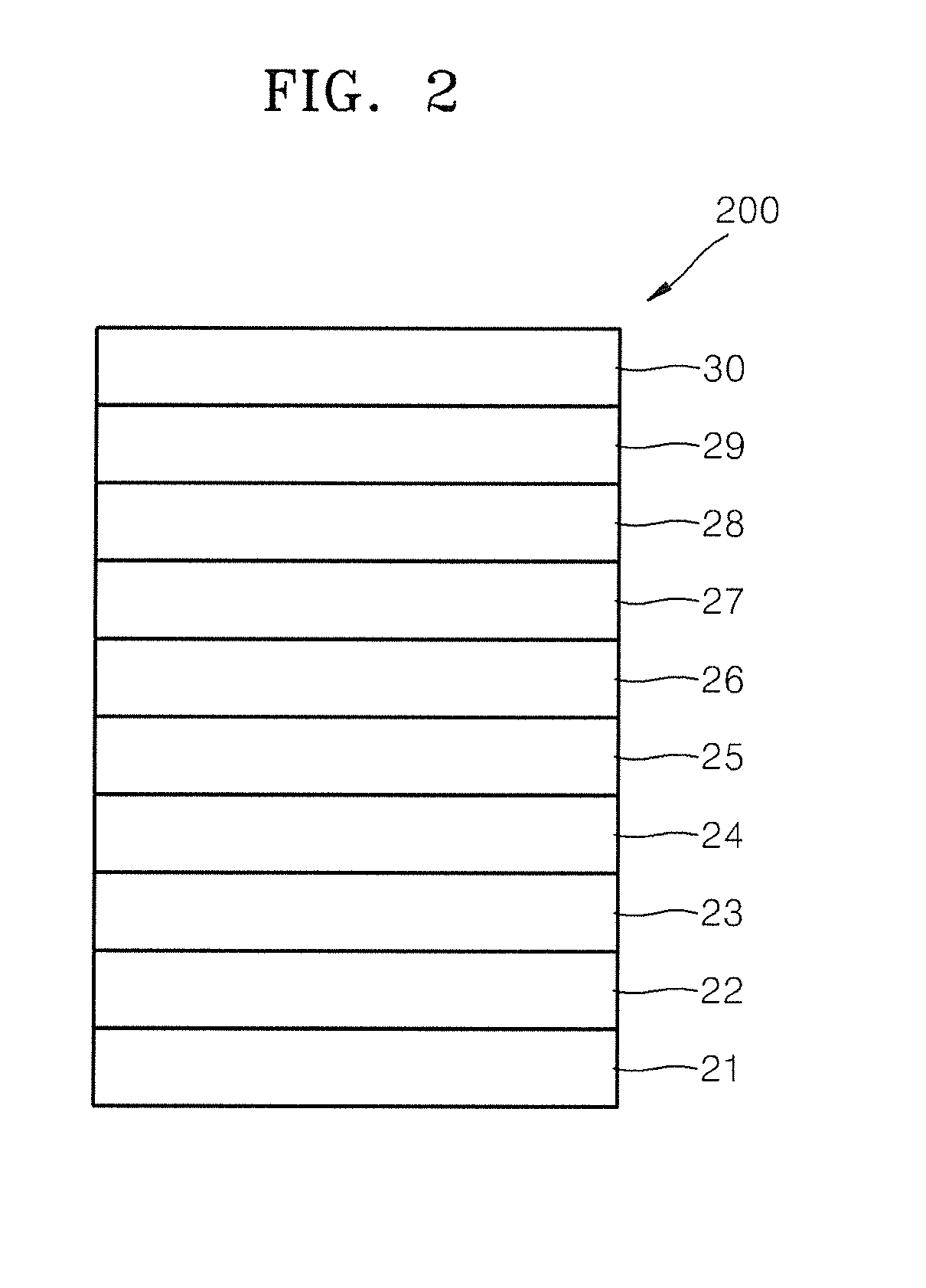

Organic light-emitting diode and flat display device including the same

ActiveUS20120326137A1Improve performanceReduce interface resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceCompound (substance)

An organic light-emitting diode including a first electrode; a second electrode facing the first electrode; an emission layer interposed between the first electrode and the second electrode; a first hole transport layer including a first hole transporting compound; a second hole transport layer including a second hole transporting compound, the first and second hole transport layers being interposed between the first electrode and the emission layer; an electron transport layer interposed between the emission layer and the second electrode; a first mixing layer interposed between the first electrode and the first hole transport layer, contacting the first hole transport layer, and including the first hole transporting compound and a first cyano group-containing compound; and a second mixing layer interposed between the first electrode and the second hole transport layer, contacting the second hole transport layer, and including the second hole transporting compound and a second cyano group-containing compound.

Owner:SAMSUNG DISPLAY CO LTD

Composite electrode material of solid-state lithium battery and preparation method thereof

InactiveCN106876668AIncrease conduction rateImproved magnification performanceCell electrodesSecondary cellsAll solid stateSolid state electrolyte

The purpose of the invention is to provide a composite electrode material suitable for a solid-state lithium battery, wherein the composite electrode material comprises an electrode active material layer and a solid electrolyte layer coated on the surface of the electrode active material layer. According to the invention, the composite electrode material is prepared by combining the mechanical mixing with the high temperature sintering. The invention also provides a all-solid-state lithium ion battery by means of the composite electrode material.

Owner:NIO NEXTEV LTD

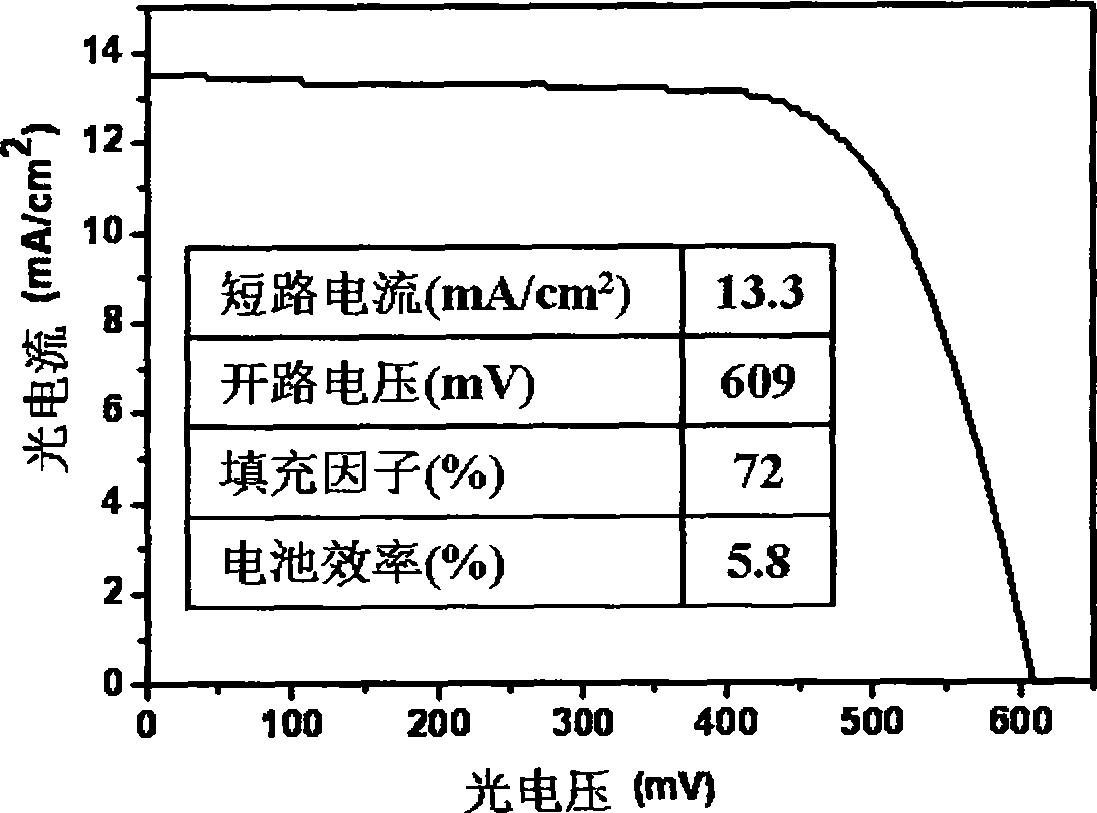

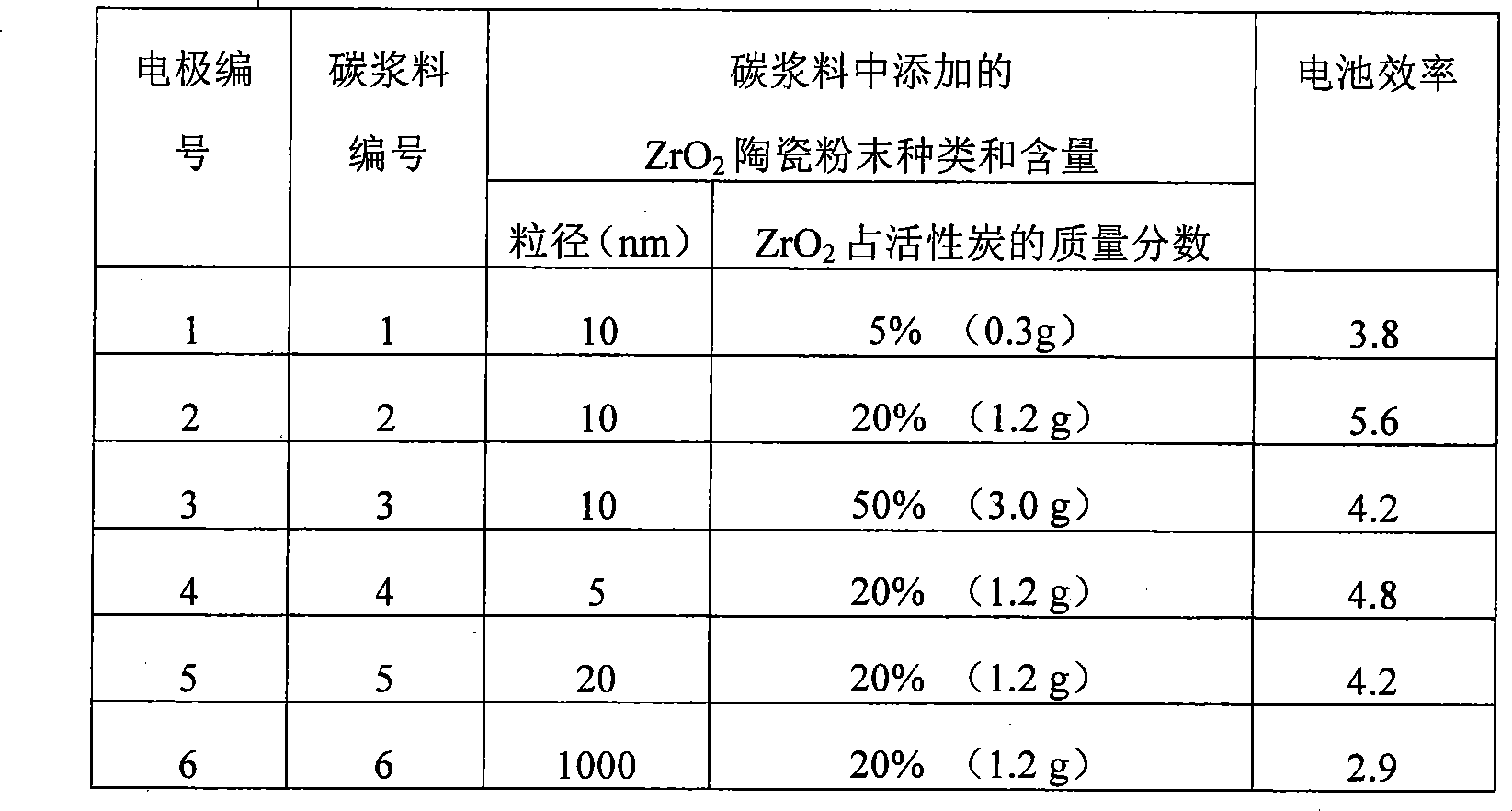

Full carbon counter electrode dye-sensitized solar cell and preparing method

ActiveCN101388294AGood mechanical properties such as friction resistanceImprove mechanical propertiesLight-sensitive devicesElectrode manufacturing processesElectrical batteryFilm coating

The invention relates to an all carbon counter electrode for a dye-sensitized solar cell and a process for preparation, wherein the all carbon counter electrode is formed by a carbon substrate A and a carbon catalytic active layer B which is coated on the carbon substrate. The process for preparing the all carbon counter electrode comprises firstly dispersing carbon catalytic active material and making into carbon paste according to the process of preparing carbon paste disclosed by the patient closure number CN101188257A, then transferring to the clean carbon substrate A through the methods of screen painting, spread coating, rotary film coating, film dropping or Czochralski method, and finally preparing the all carbon counter electrode through drying or kilning. The all carbon electrode of the invention can reduce series resistance and interface resistance, thereby increasing the short-circuit current (Jsc), filling factor (FF) and photoelectric transformation efficiency of the dye-sensitized solar cell. The substrate material adopted by the all carbon counter electrode of the invention has smaller resistance, can reduce using or avoid using metal flow concentration leads, and simplifies preparation technology.

Owner:深圳市华物光能技术有限公司

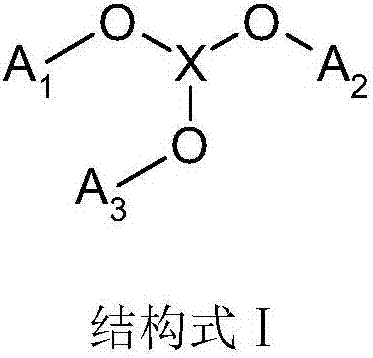

Electrolyte solution for silicon based lithium secondary battery and silicon based lithium secondary battery

InactiveCN107275676AImprove cycle performanceAlleviate volume effectLi-accumulatorsOrganic electrolytesHigh temperature storageOrganic solvent

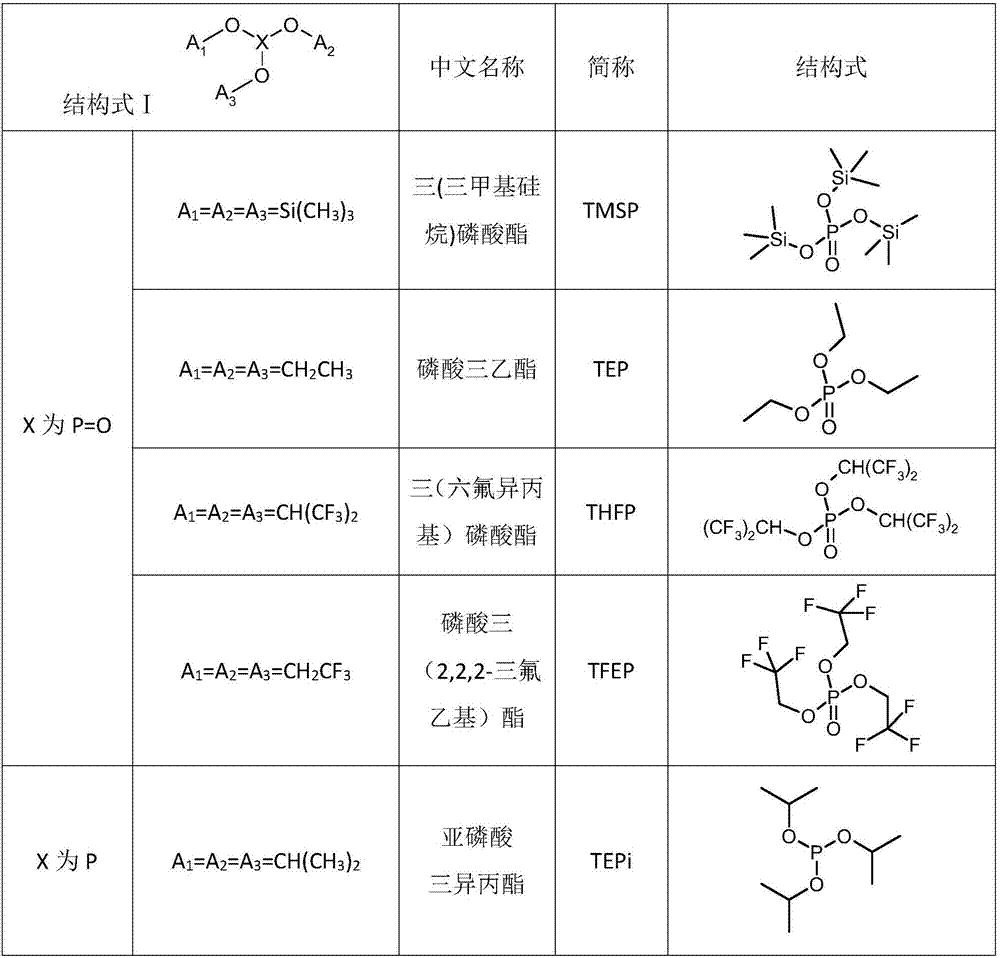

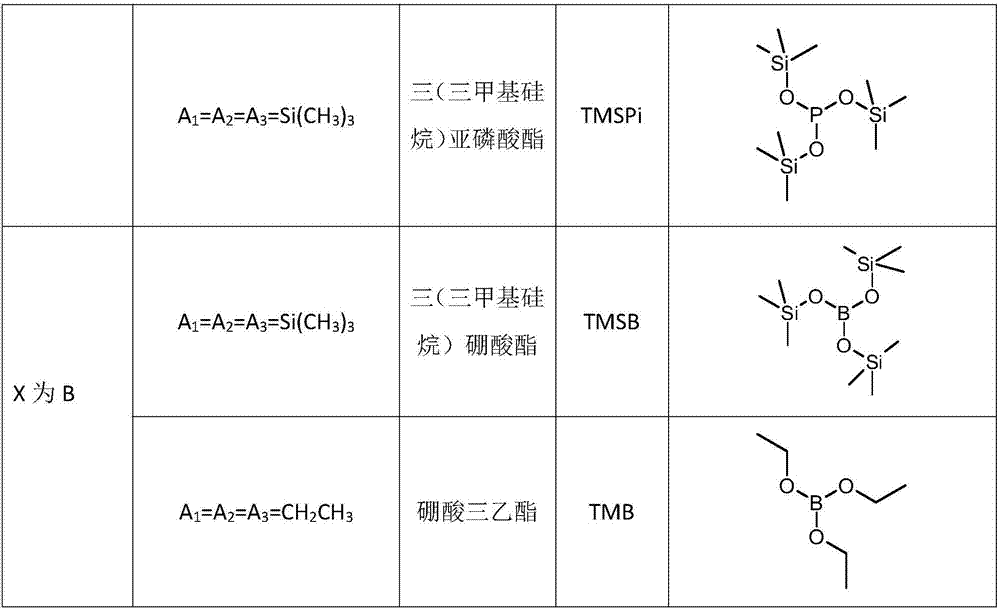

The invention discloses an electrolyte solution for a silicon based lithium secondary battery. The electrolyte solution comprises: a non-aqueous organic solvent, a lithium salt and an additive, wherein the additive comprises fluoroethylene carbonate, lithium difluoro(oxalato) borate and a compound with a structure shown as formula I in the specification, specifically in the formula I, X represents P=O group, P atom and B atom; A1, A2 and A3 are independently selected from one of alkyl, silicyl, and fluoroalkyl. At the same time, the invention also discloses a silicon based lithium secondary battery. The electrolyte solution can effectively improve the room temperature cycling performance, high temperature storage performance and low temperature discharge performance of the battery.

Owner:GUANGZHOU TINCI MATERIALS TECH

Nonaqueous electrolyte secondary battery

ActiveUS7544443B2Reduce resistanceImprove featuresPositive electrodesNon-aqueous electrolyte accumulator electrodesGroup elementComposite oxide

A nonaqueous electrolyte secondary battery 10 according to an embodiment of the present invention includes a positive electrode 11 having a positive electrode active material that can intercalate and deintercalate lithium, a negative electrode 12 having a negative electrode active material that can intercalate and deintercalate lithium, and a nonaqueous electrolyte having lithium ion conductivity. The positive electrode active material is a layered lithium transition metal composite oxide (for example, one represented by Li1+x(NiyCozMn1−y−z)1−xO2 (where 0≦x≦0.15, 0.1≦y≦0.6, and 0≦z≦0.5)) to which an IVa group element (Zr) and a Va group element (Nb) are added. According to these features, it is possible to provide a nonaqueous electrolyte secondary battery with a selected element to be added to the lithium transition metal composite oxide to reduce the I-V resistance (improve the I-V characteristic), and thereby improving the output / input characteristics.

Owner:SANYO ELECTRIC CO LTD

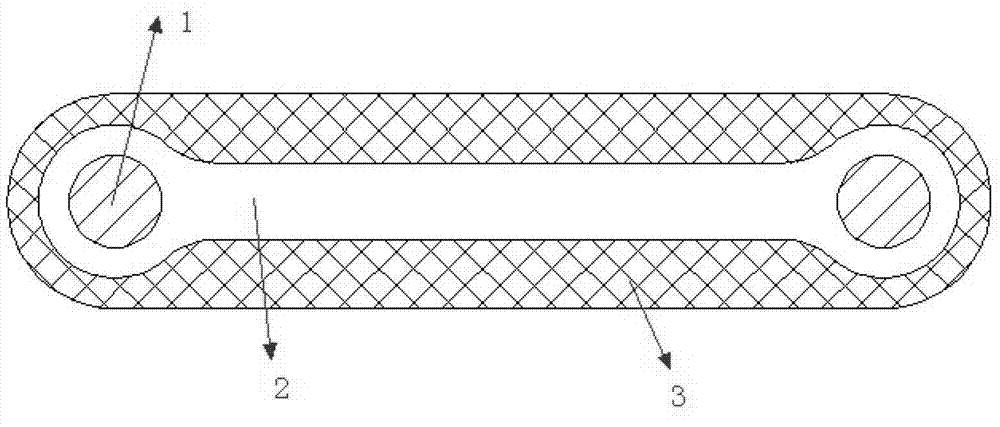

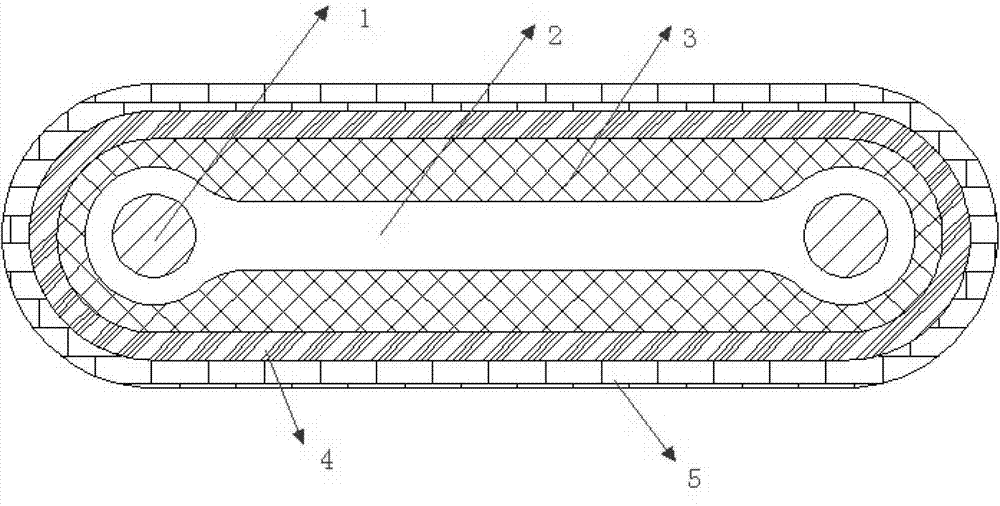

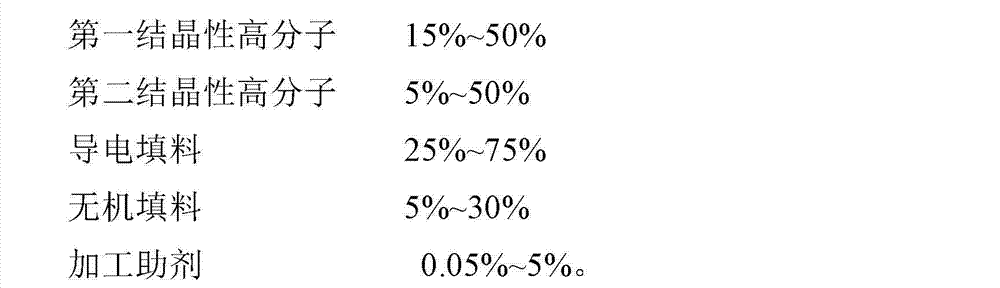

Polymer matrix conductive composite material and method for preparing temperature self-limiting heat tracing cable from same

InactiveCN103113668AImprove electrical performanceExtended service lifeCable/conductor manufactureElectrical resistance and conductanceSelf limiting

The invention discloses a polymer matrix conductive composite material, prepared from a first crystalline polymer, a second crystalline polymer, a conductive filler, an inorganic filler and a processing auxiliary. The invention also discloses a method for preparing a temperature self-limiting heat tracing cable from the composite material. The polymer matrix conductive composite material provided by the invention contains the second crystalline polymer which is capable of improving the interface bonding between the conductive filler carbon black and polyethylene, so that the stability of the conductive network in the composite material is enhanced and the interface resistance between the conductive composite material and the electrode after the heat tracing cable is placed at a high temperatures is reduced; and the prepared temperature self-limiting heat tracing cable has excellent resistance reproducibility and stability.

Owner:ANBANG ELECTRICAL GRP

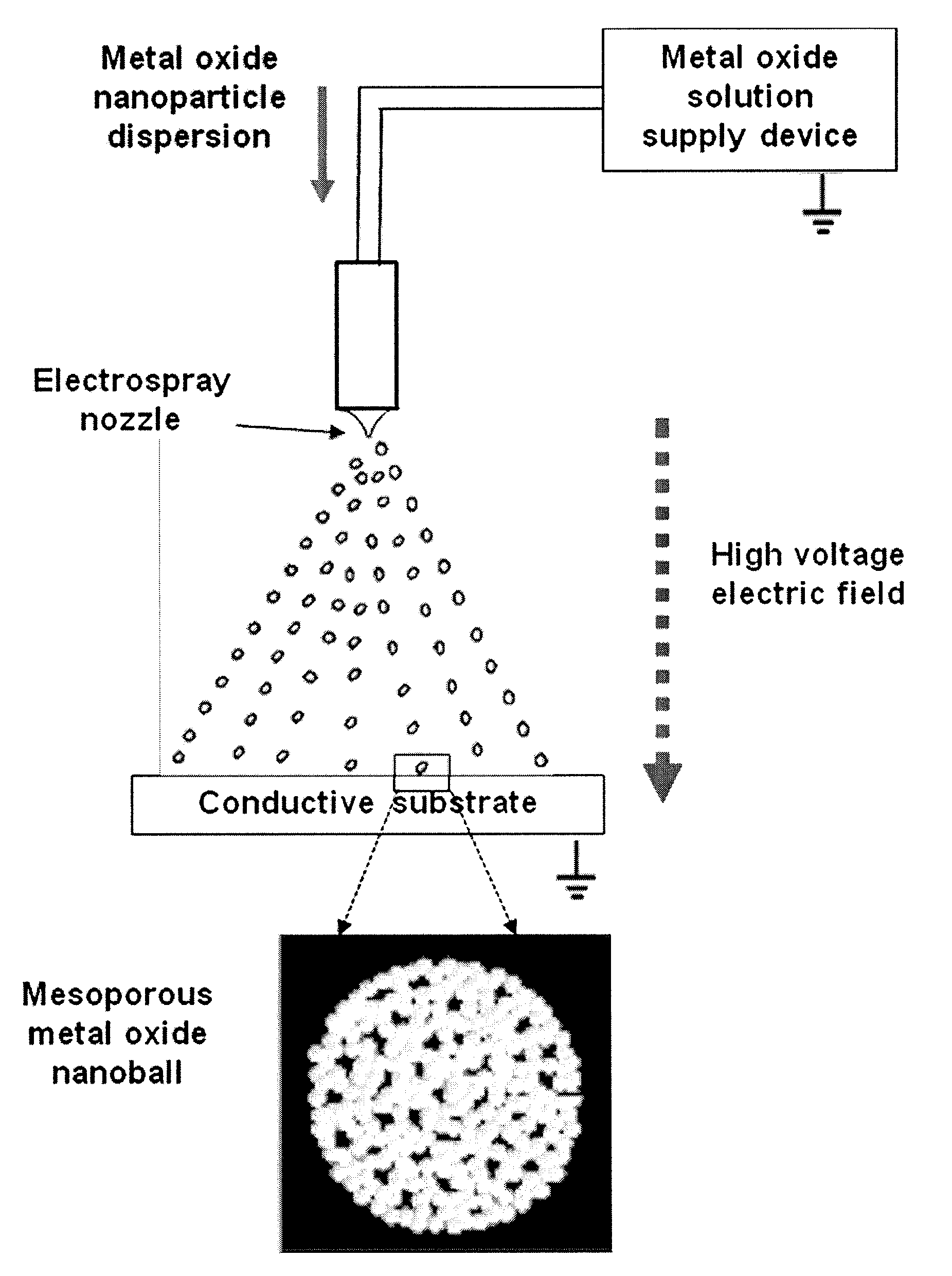

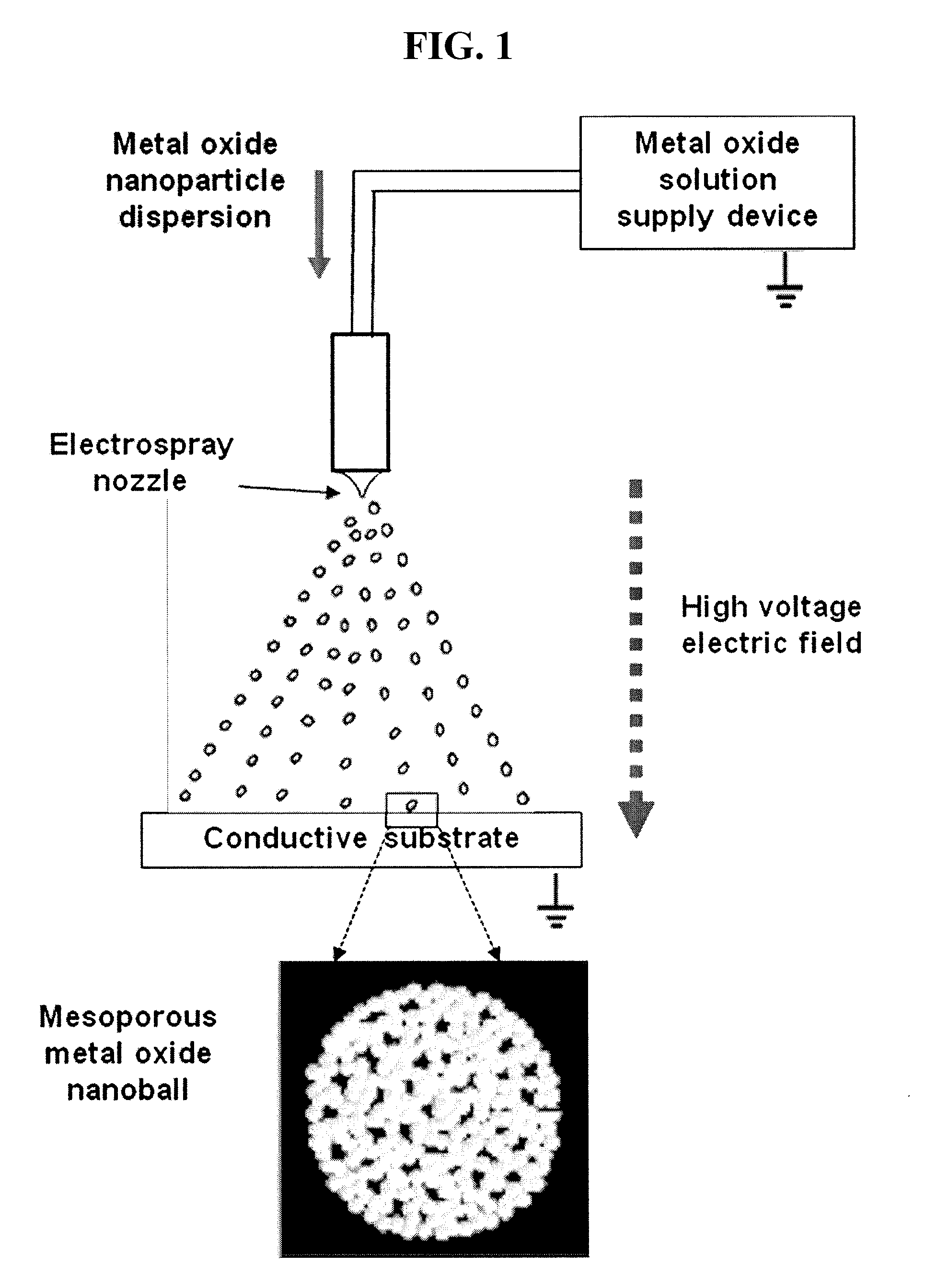

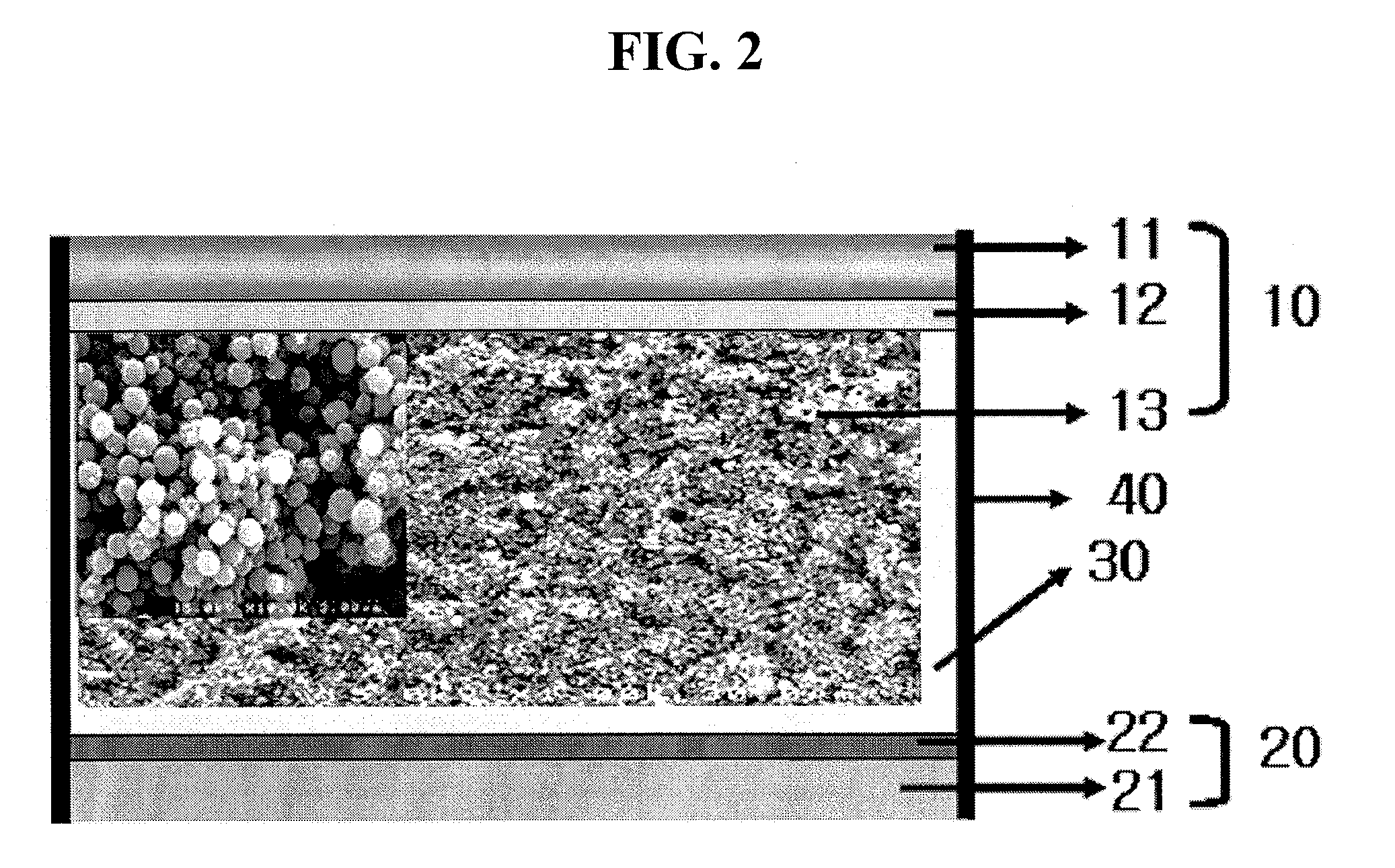

Dye-sensitized solar cell comprising metal oxide nanoball layer and preparation method thereof

ActiveUS20100084008A1Improve photoelectric conversion efficiencyImprove adsorption capacityNanotechElectrolytic capacitorsSemiconductor electrodePorosity

A dye-sensitized solar cell comprising a semiconductor electrode prepared by spraying a metal oxide nanoparticle dispersion on a conductive substrate using an electric field to form a metal oxide nanoball layer which is composed of agglomerated metal oxide nanoparticles and has a high porosity and specific surface area, exhibits improved photoelectric properties even when a gel or solid electrolyte is used.

Owner:KOREA INST OF SCI & TECH

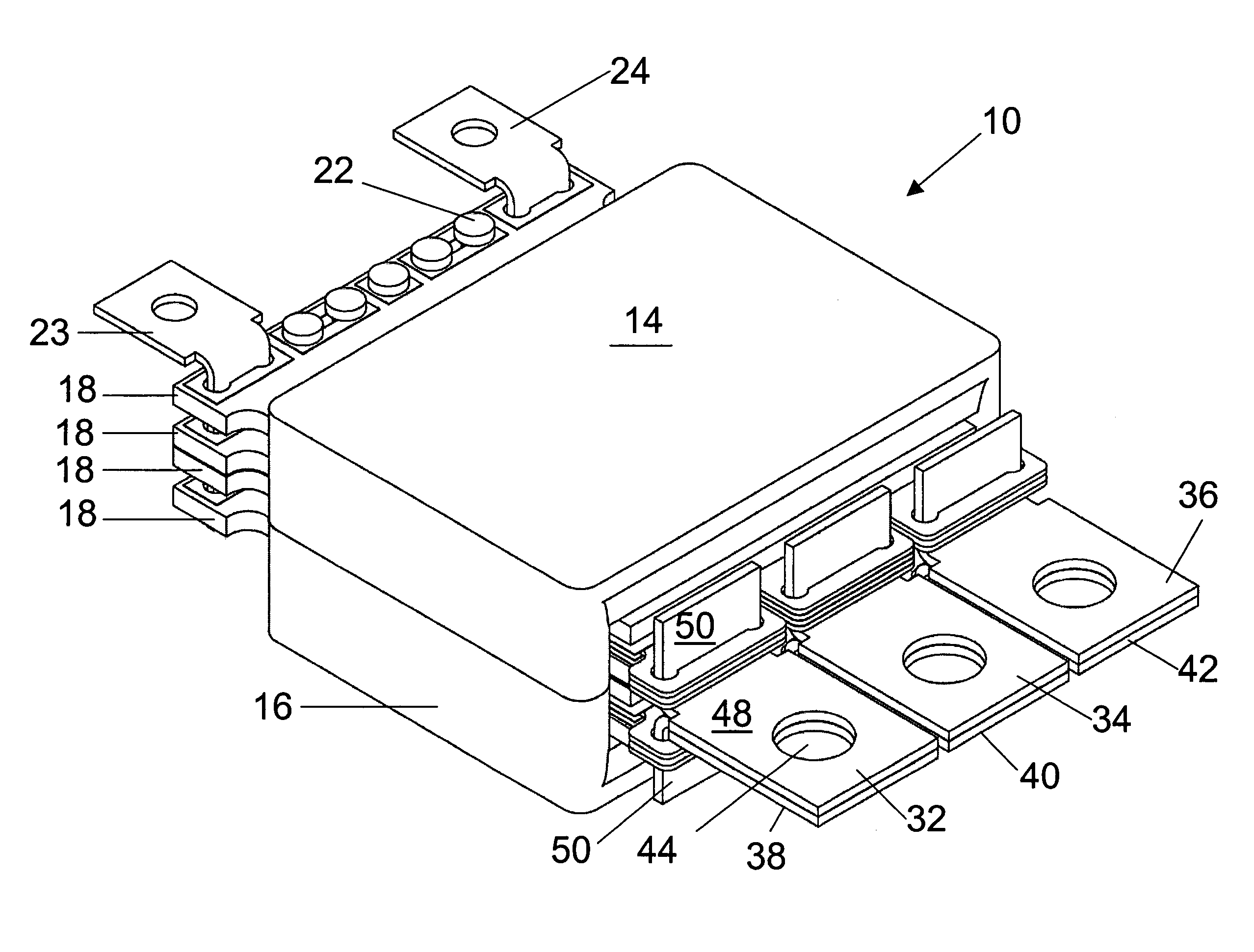

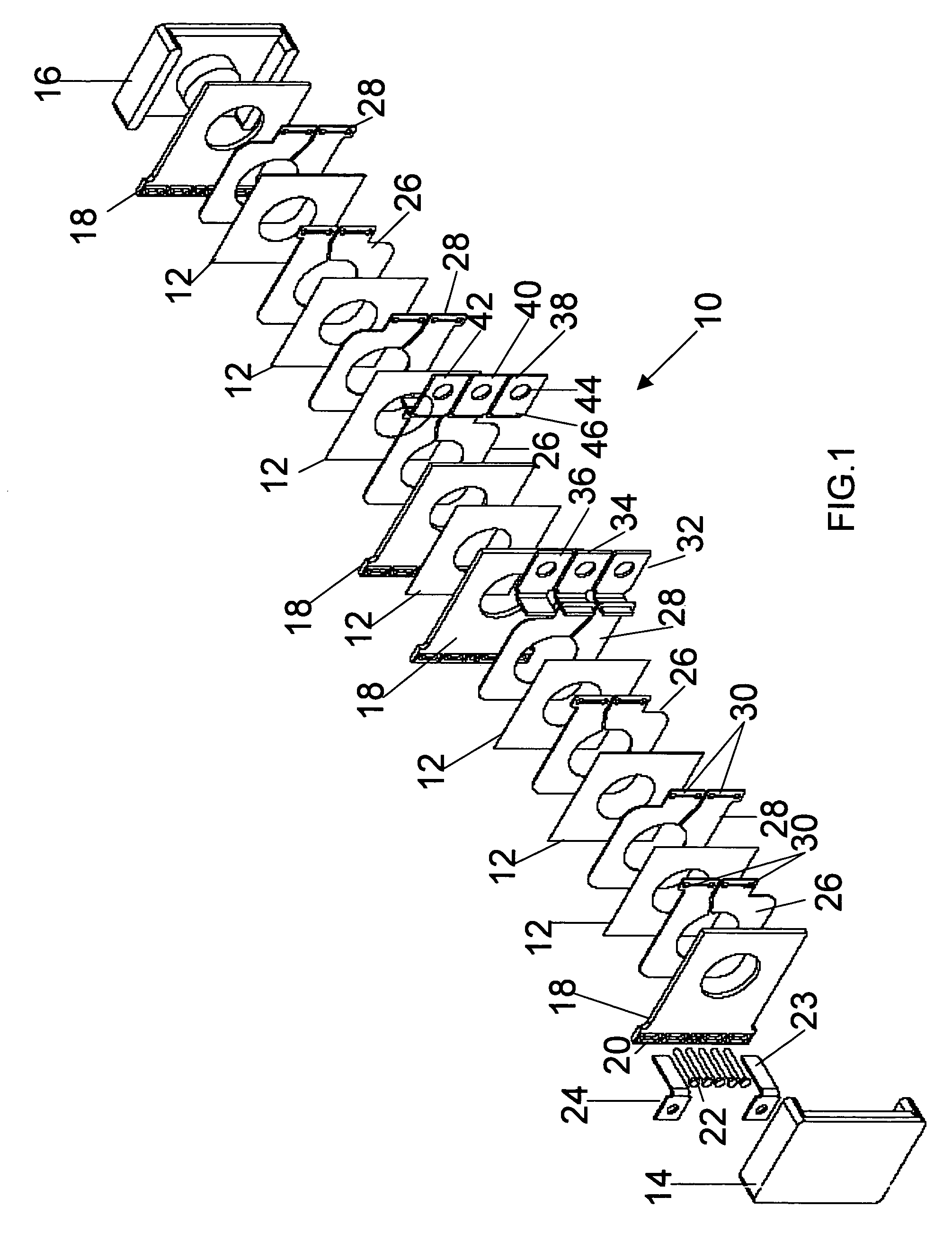

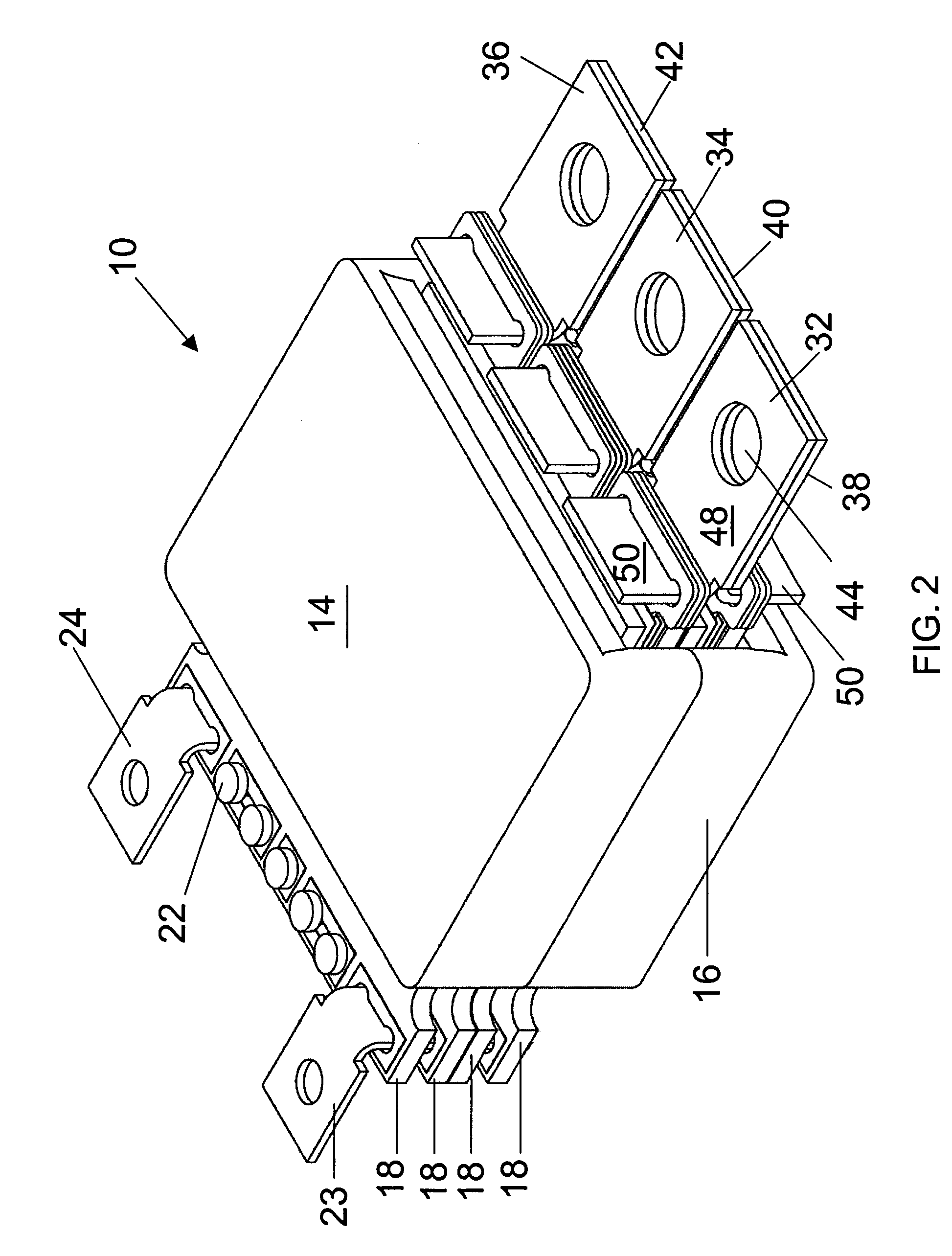

Terminal system for planar magnetics assembly

ActiveUS7460002B2Reduce resistanceImprove efficiencyTransformers/inductances coils/windings/connectionsCoilsEngineeringConductor Coil

Owner:STANDEX ELECTRONICS

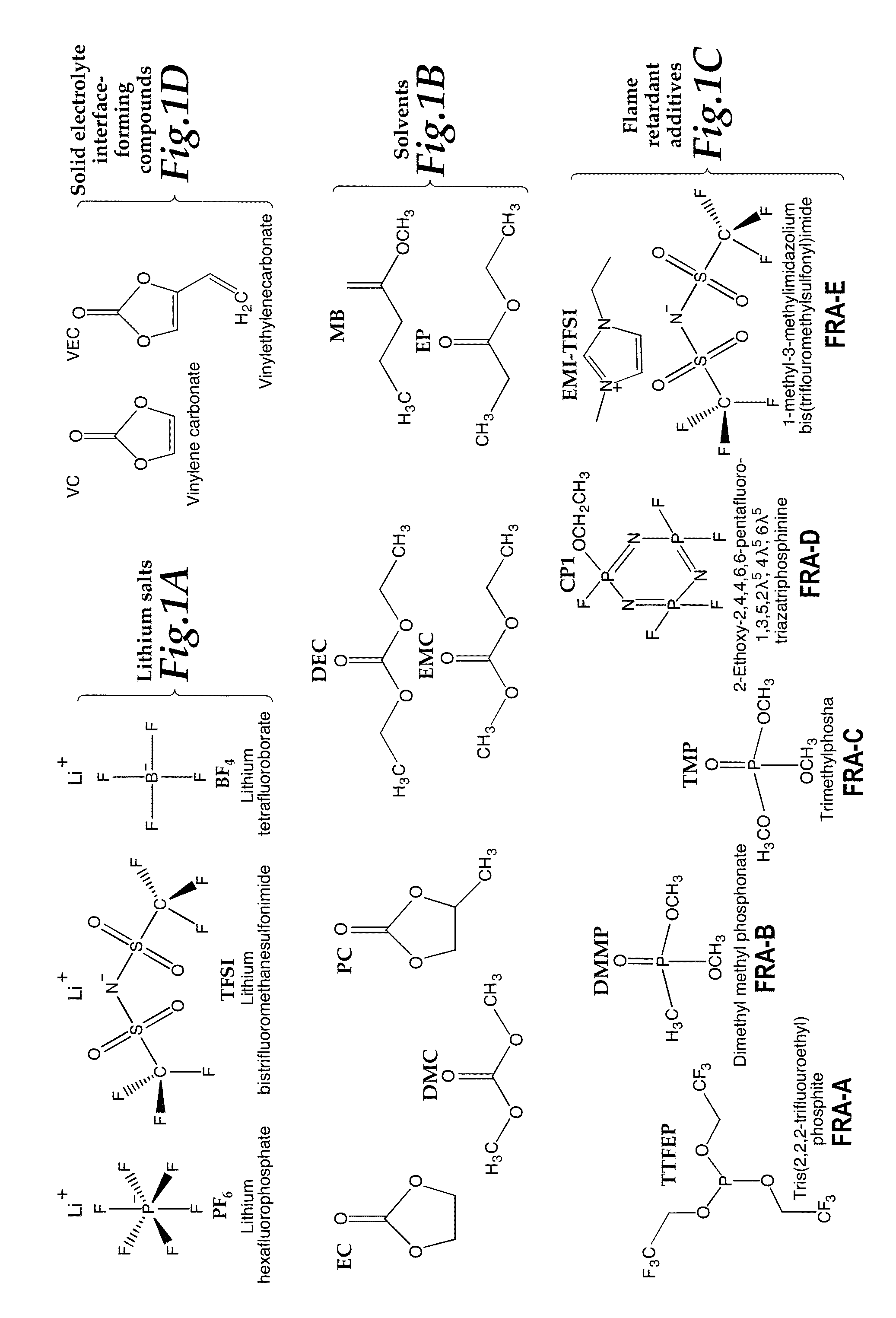

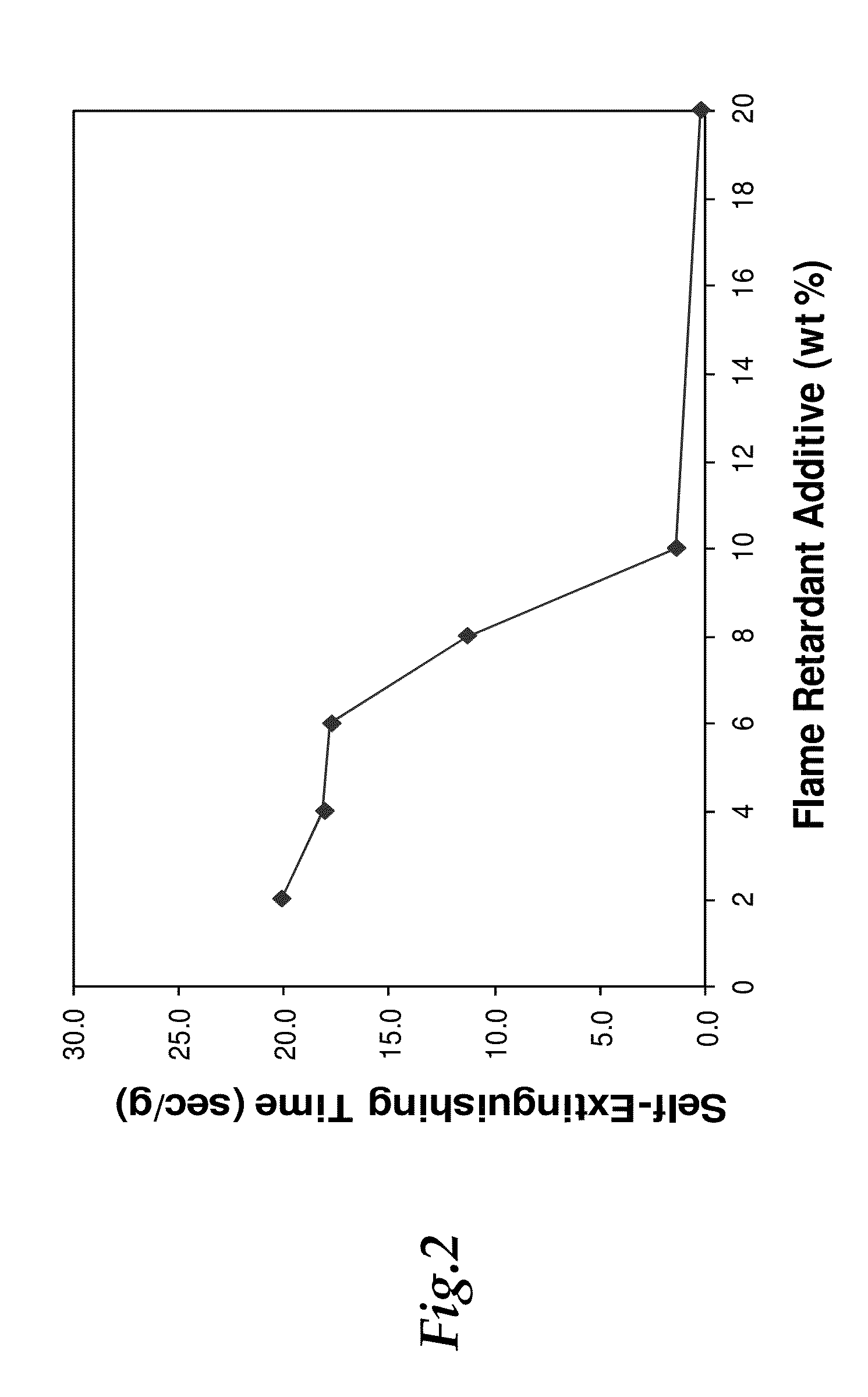

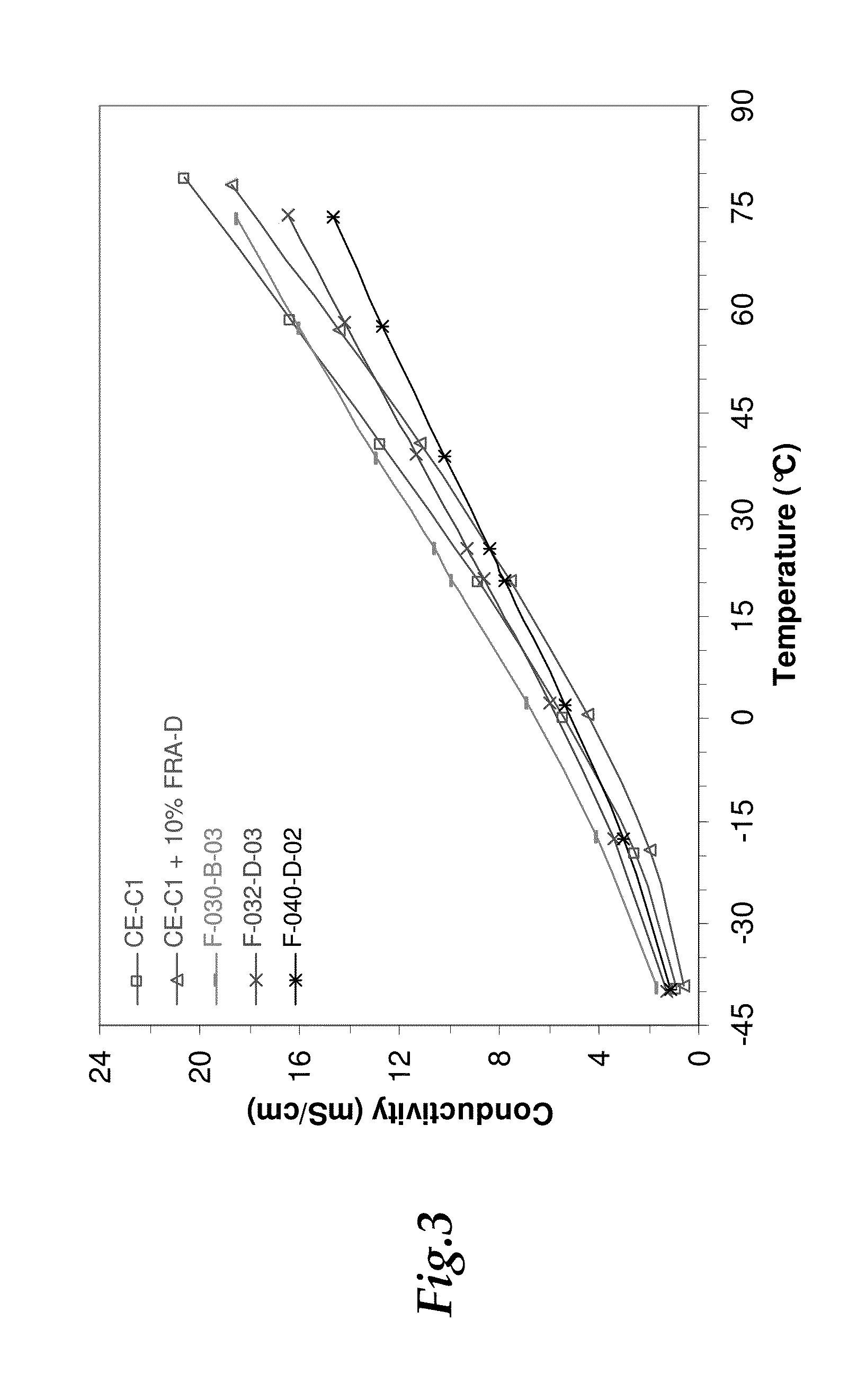

Electrolyte for Electrochemical Energy Storage Devices

ActiveUS20160020489A1Improve flammabilityImprove securityHybrid capacitor electrolytesElectrolytic capacitorsInterfacial resistanceOperating temperature range

An electrolyte for an electrochemical storage device is disclosed. In one embodiment, the electrolyte includes a lithium salt from about 3% to about 20% by weight, a primary solvent from about 15% to about 25% by weight, wide-temperature co-solvents from about 14% to about 55% by weight, interface forming compounds from about 0.5% to about 2.0% by weight, and a flame retardant compound from about 6% to about 60% by weight. The electrolyte interacts with the positive and negative electrodes of the electrochemical storage device to provide both high performance and improved safety such that the electrolyte offers adequate ionic conductivity over the desired operating temperature range, a wide electrochemical stability window, high capacities for both the cathode and anode, low electrode-electrolyte interfacial resistance, and reduced flammability.

Owner:LYNNTECH

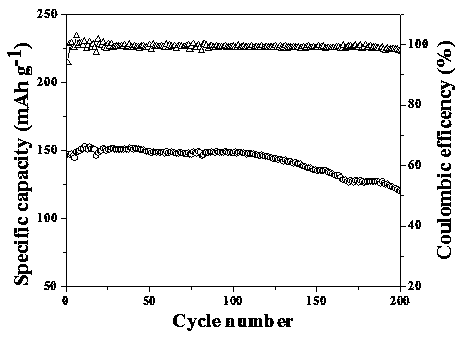

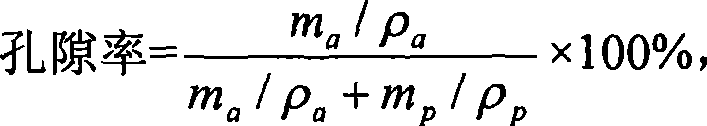

Preparation method of all-solid-state lithium battery with high specific energy

ActiveCN108258323AIncrease the interface contact areaReduce interface resistanceFinal product manufactureElectrolyte accumulators manufactureHigh energyInterfacial resistance

The invention discloses a preparation method of an all-solid-state lithium battery with high specific energy. The preparation method comprises the following steps: forming pores in coating processes of a positive pole piece and a negative pole piece by using a pore forming agent; rolling the prepared pole pieces, and then, coating a thin-layer polymer electrolyte solution on the surface of one side of each pole piece; and finally, winding or laminating the positive pole piece and the negative pole piece with electrolyte layers at one sides so as to be assembled into an all-solid-state lithiumion battery. Compared with the prior art, the method disclosed by the invention has the advantages that the polymer electrolyte solutions can permeate into the pole pieces through the pores obtained by the pore forming agent, and the interfacial contact area between each pole piece and the polymer electrolyte is larger, so that the ionic conductivity of an electrode material is increased; and theall-solid-state lithium battery prepared by the method has the advantages of low interfacial resistance, high energy density, high stability and safety and the like.

Owner:SHAANXI COAL & CHEM TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com