Polymer matrix conductive composite material and method for preparing temperature self-limiting heat tracing cable from same

A conductive composite material, polymer-based technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of affecting the service life, complex surface treatment process, and low physical "entanglement" force, etc., to achieve Effects of extended service life, good resistance reproducibility and stability, and high stability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

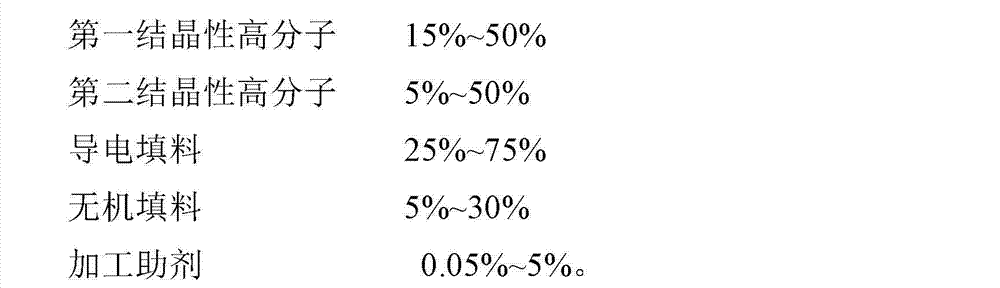

[0025] The volume percentage of the polymer-based conductive composite material prepared from the self-limiting temperature heating cable is:

[0026] The first crystalline polymer (melting temperature is 111°C and density is 0.925g / cm 3 low-density polyethylene), the volume percentage is 40%;

[0027] The second crystalline polymer is selected with a melting temperature of 130°C and a density of 0.947g / cm 3 The low-density polyethylene grafted with maleic anhydride, its volume percentage is 3%;

[0028] Conductive filler is nano carbon black, and its volume percentage is 48%;

[0029] The inorganic filler is zinc oxide, and its volume percentage is 7%;

[0030] The volume percentage of processing aids is 2%.

[0031] The preparation process of the self-limiting temperature heating cable is as follows:

[0032] Set the temperature of the internal mixer at 180°C and the speed at 30 rpm, first add the first crystalline polymer, the second crystalline polymer and various pro...

Embodiment 2

[0039] Compared with Example 1, the volume percentage of the first crystalline polymer is reduced from 40% to 37%, the volume percentage of the second crystalline polymer is increased from 3% to 6%, and the volume percentage of the remaining components and The preparation method remains the same.

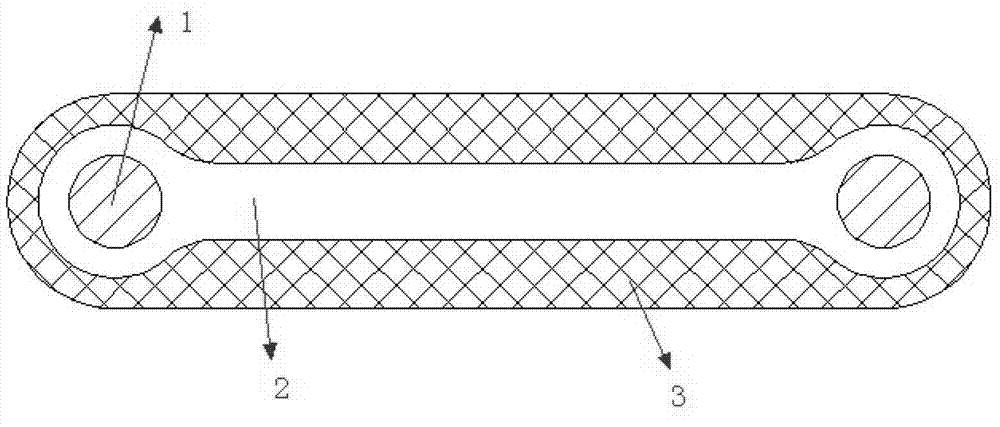

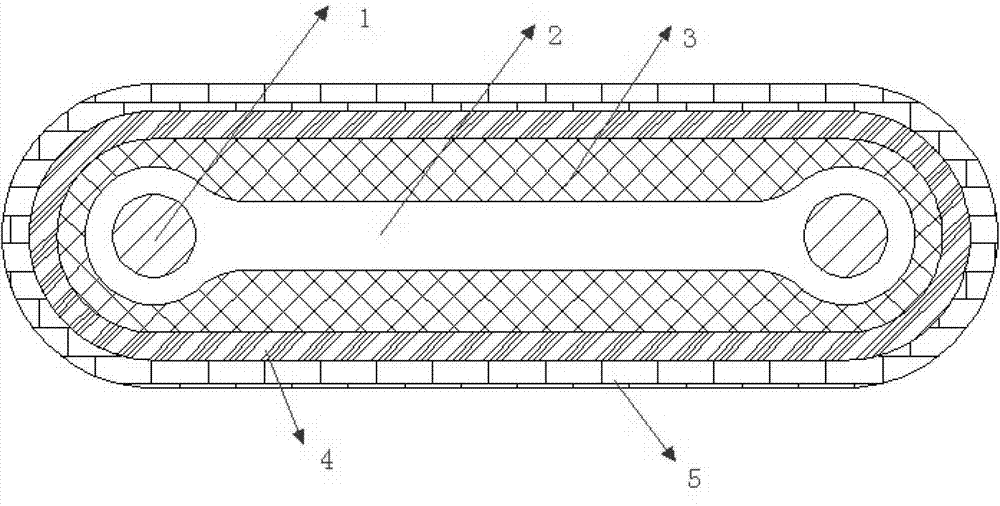

[0040] This embodiment takes figure 1 The electrical characteristics of the ordinary self-limiting temperature heating cable shown are shown in Table 1.

Embodiment 3

[0042] Compared with Example 1, the volume percentage of the first crystalline polymer is reduced from 40% to 34%, the volume percentage of the second crystalline polymer is increased from 3% to 9%, and the volume percentage of the remaining components and The preparation method remains the same.

[0043] This embodiment takes figure 1 The electrical characteristics of the self-limiting heating cable shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com