Patents

Literature

1976 results about "Conductive composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

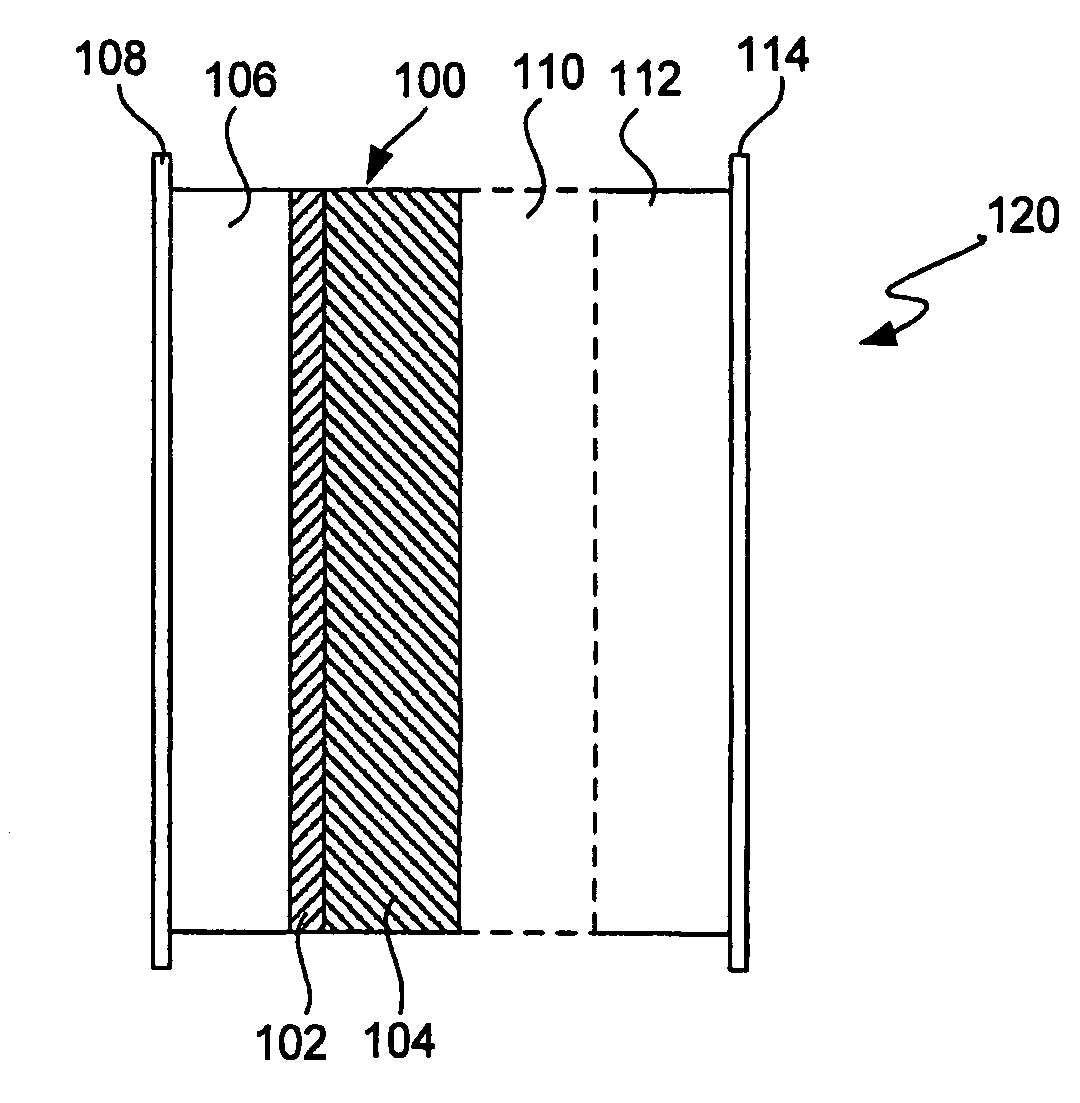

Ionically conductive composites for protection of active metal anodes

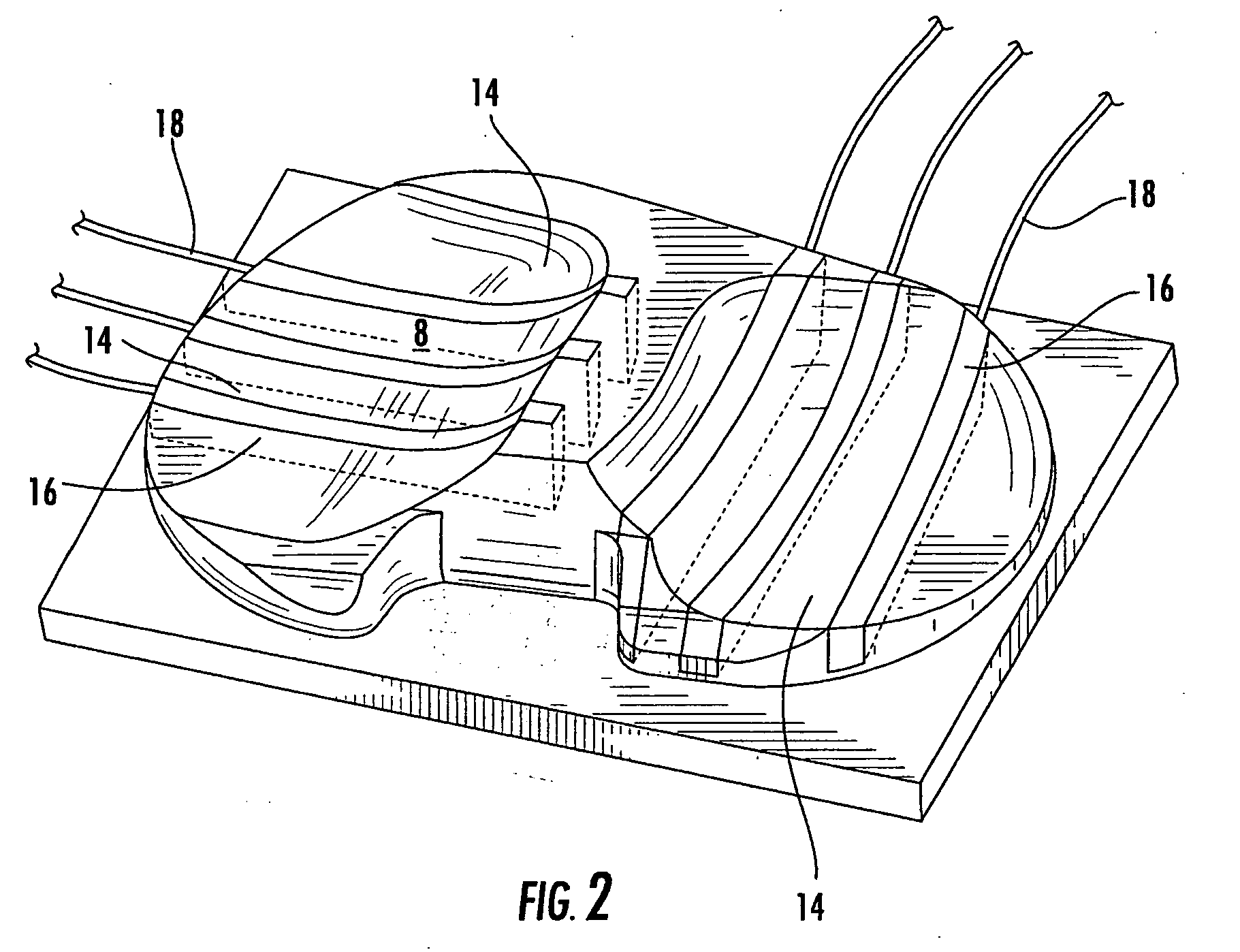

ActiveUS7282296B2Easy to manufactureImprove battery performanceFinal product manufactureElectrode carriers/collectorsChemical stabilityIonic conductivity

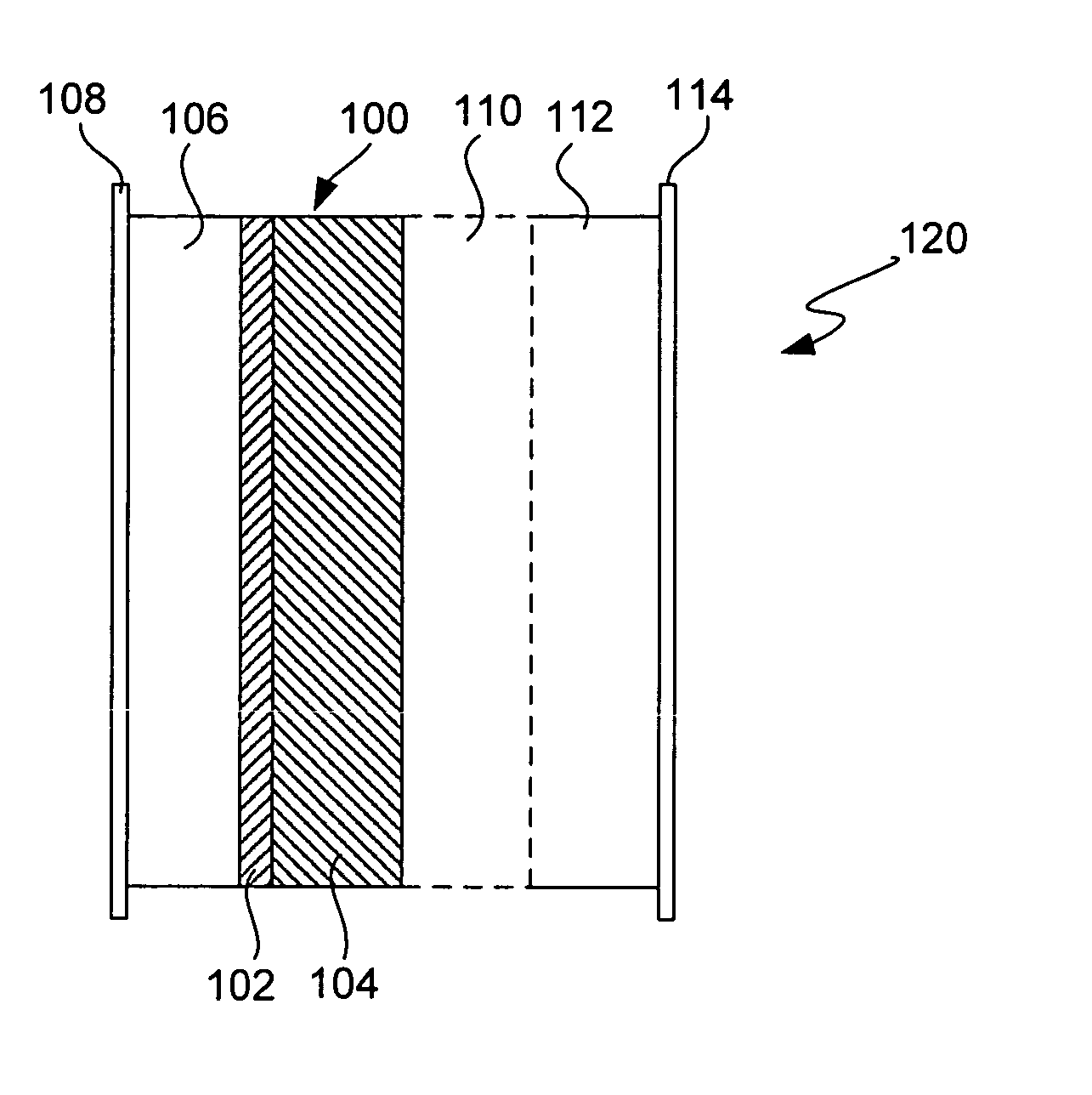

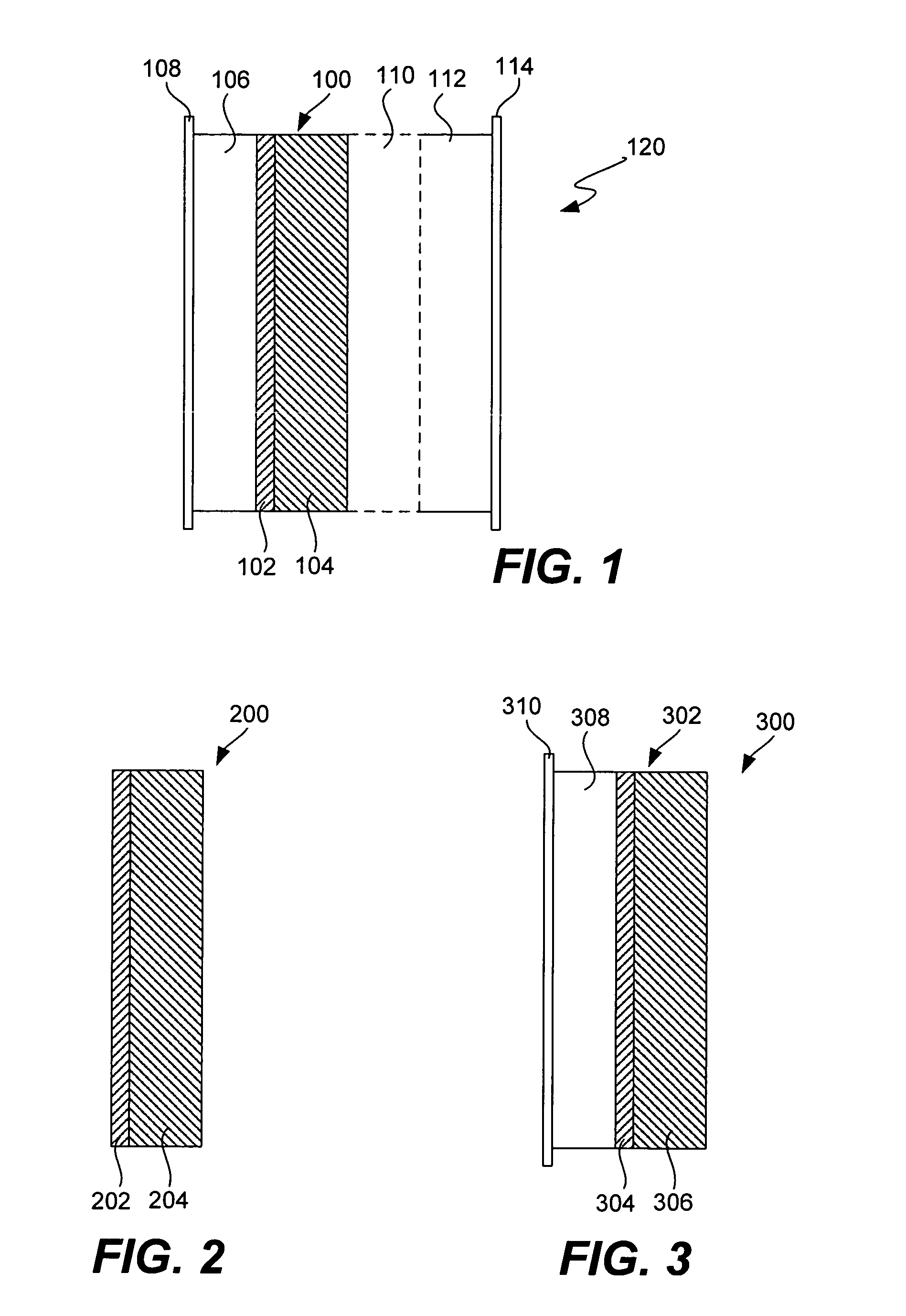

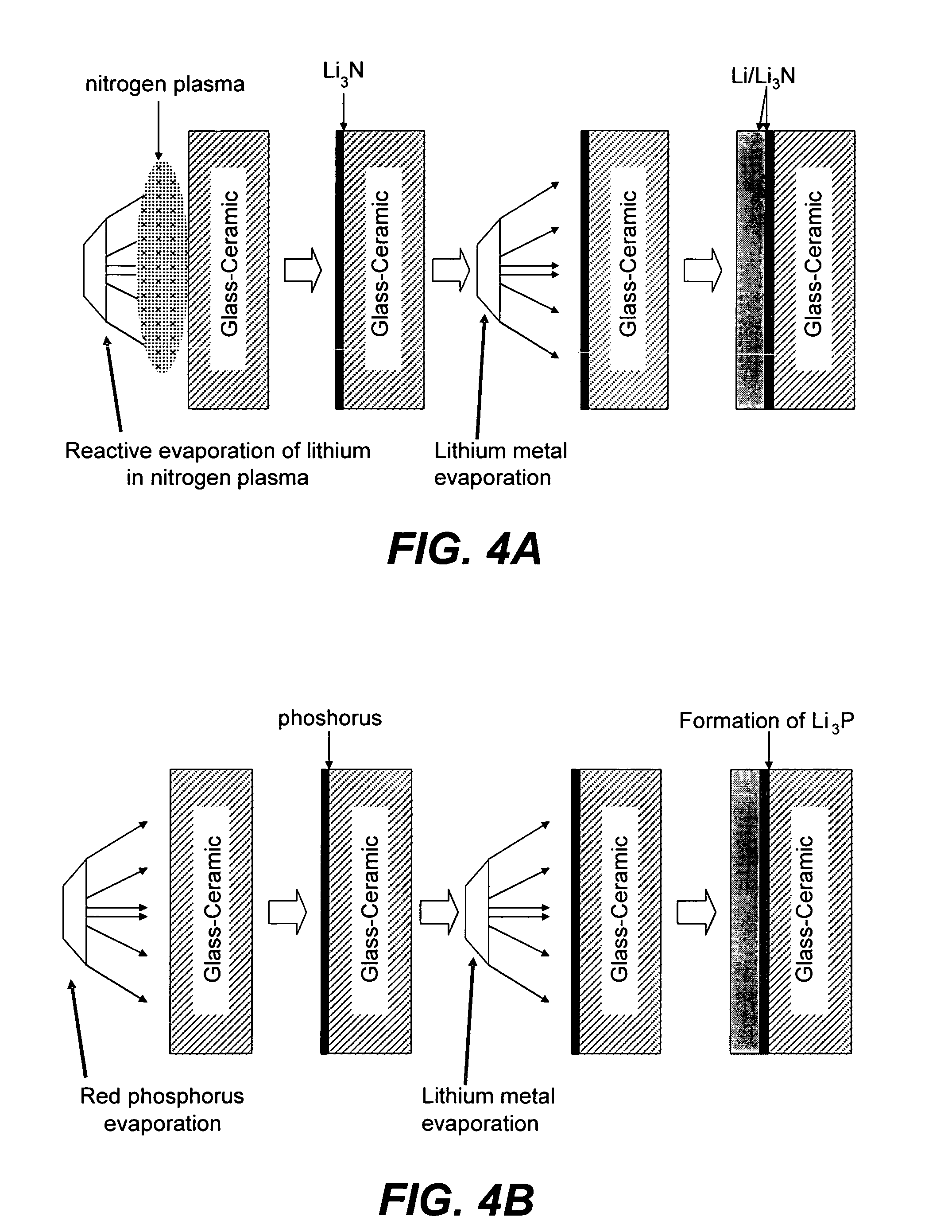

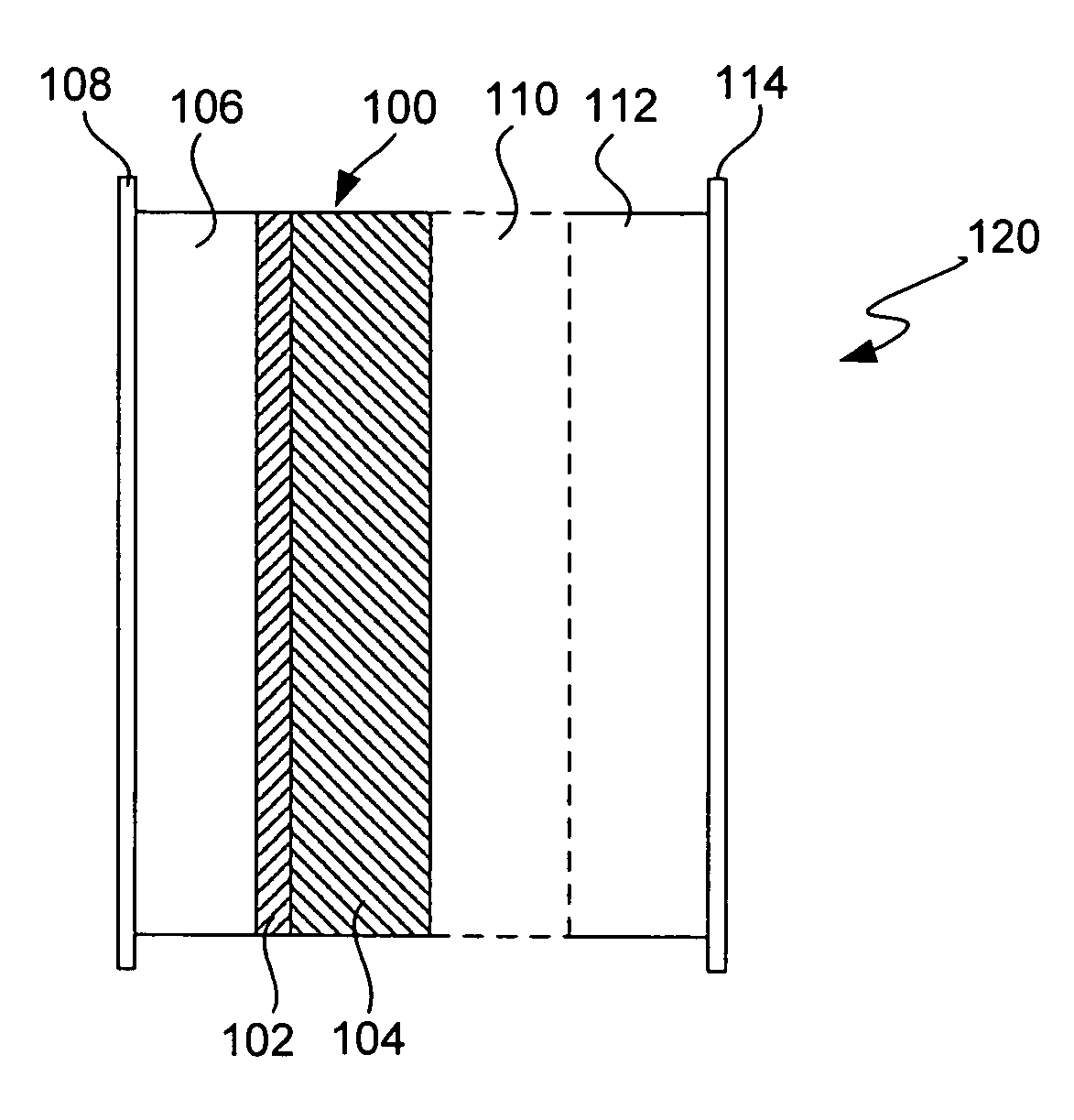

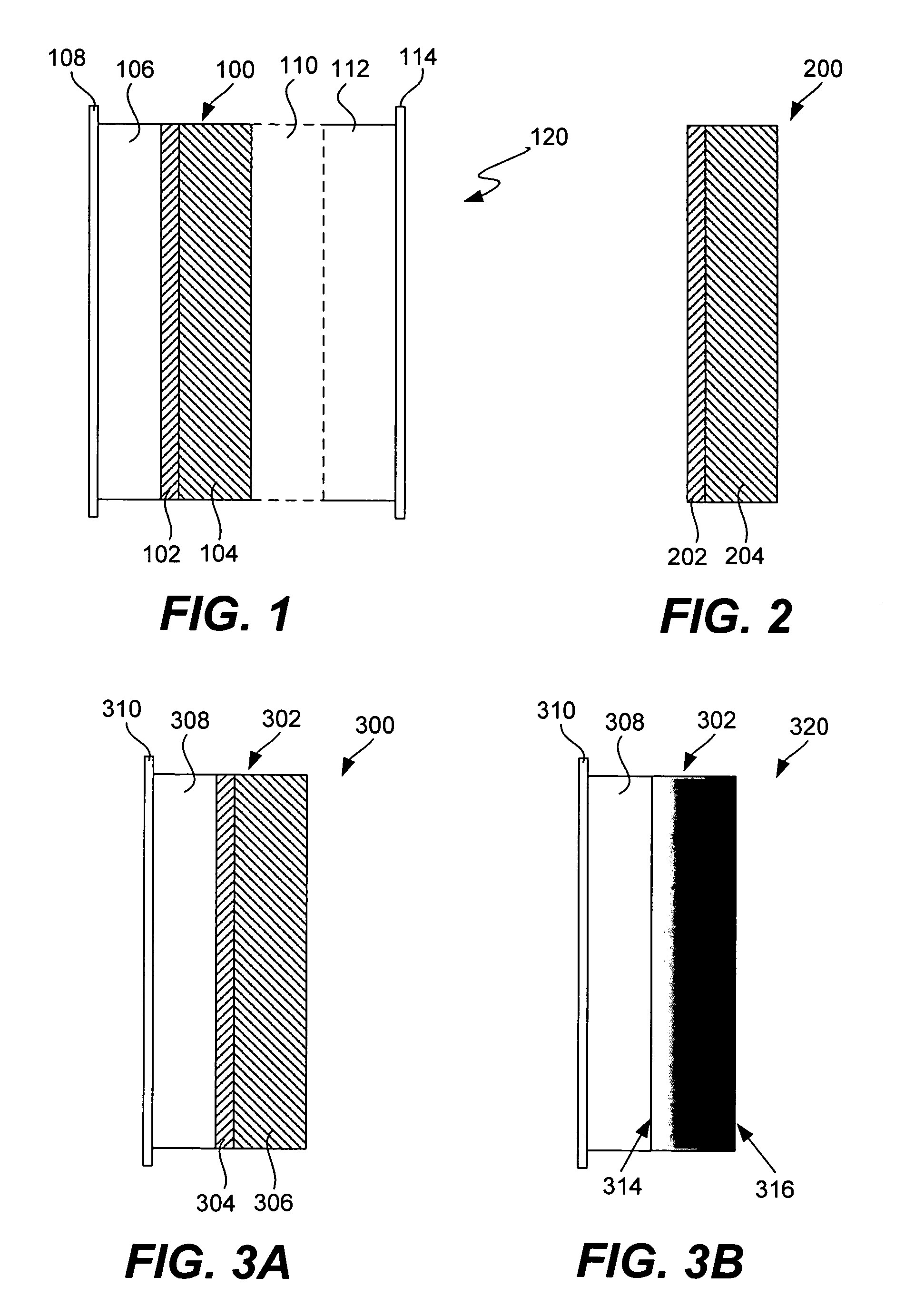

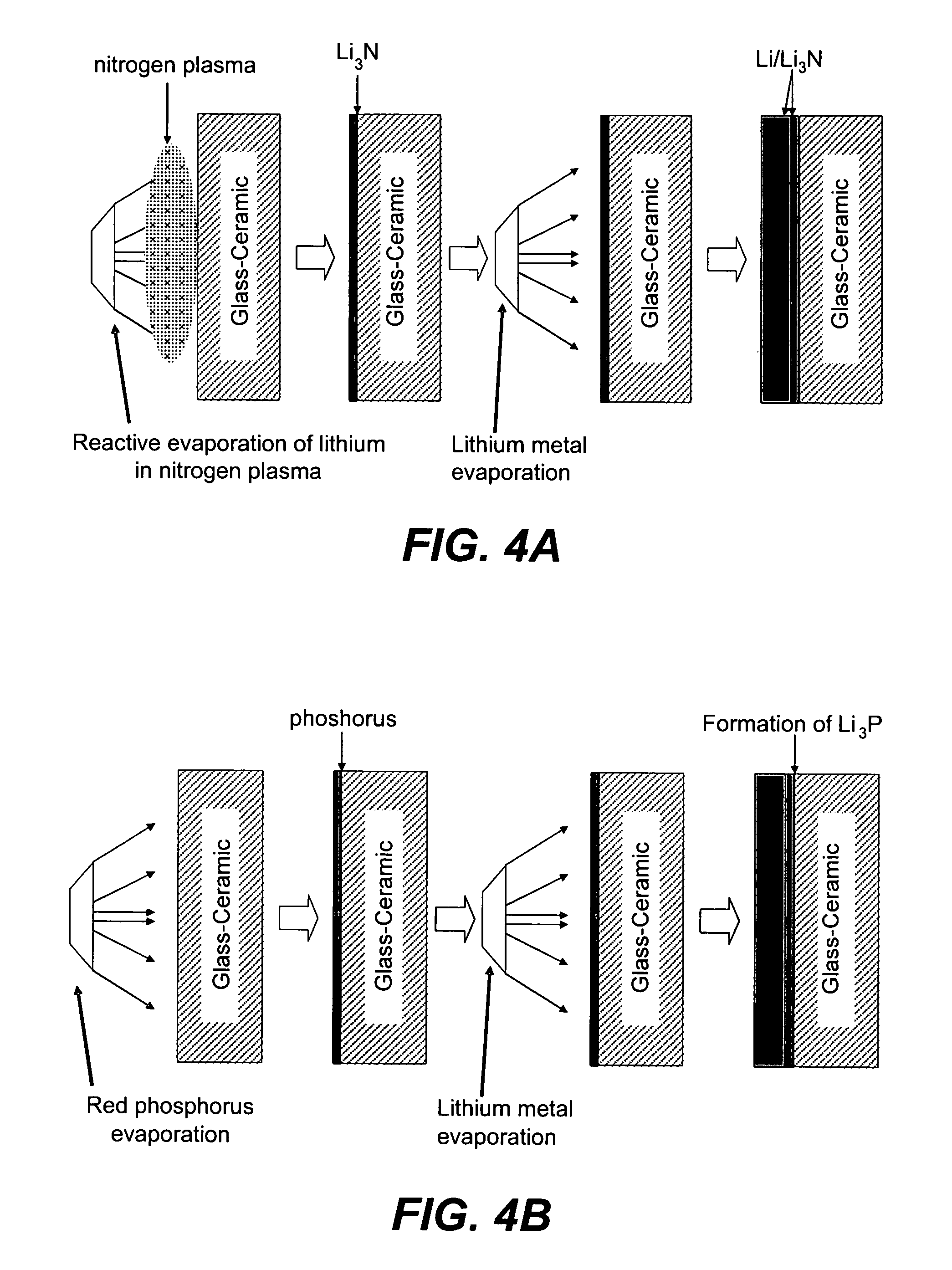

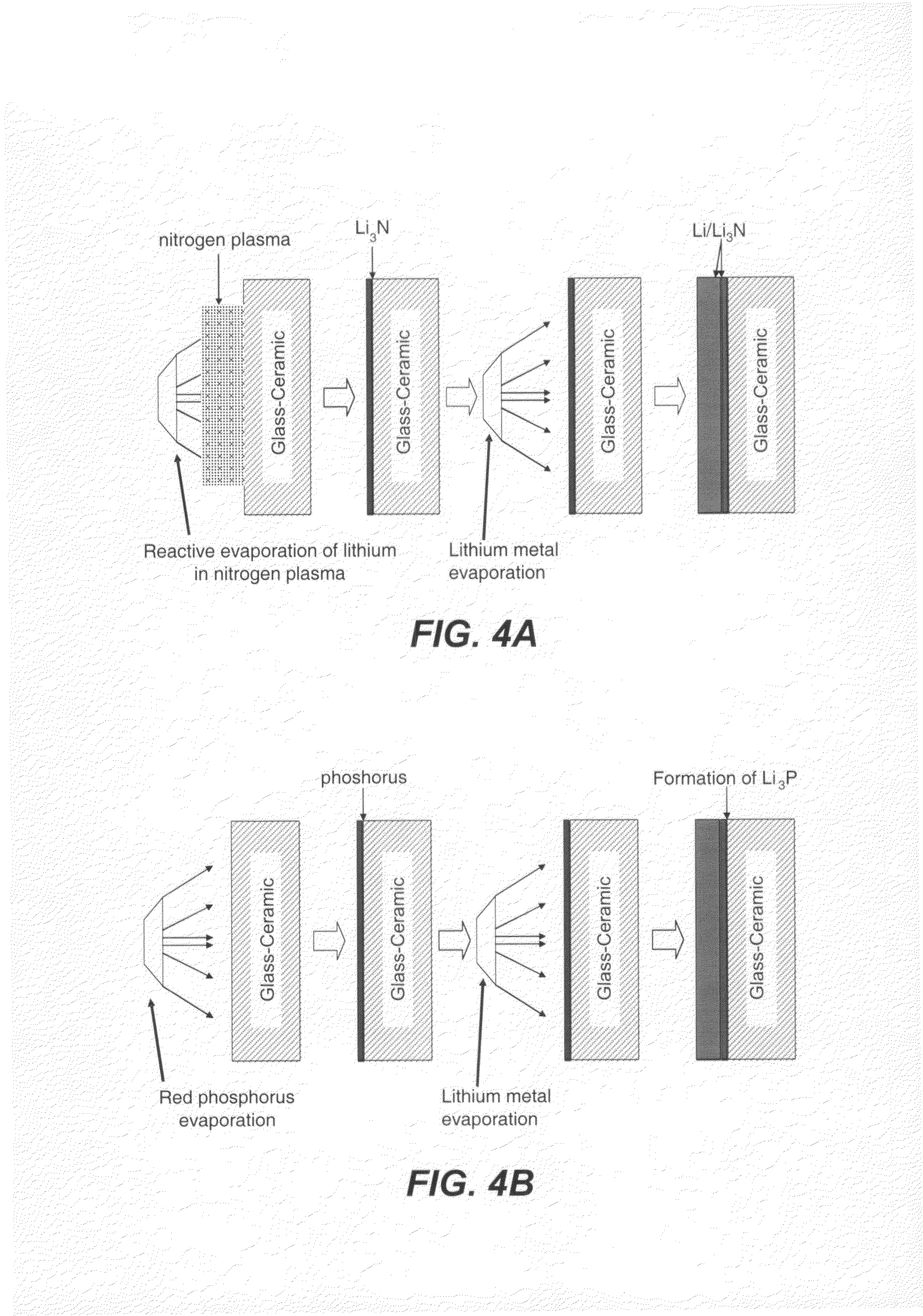

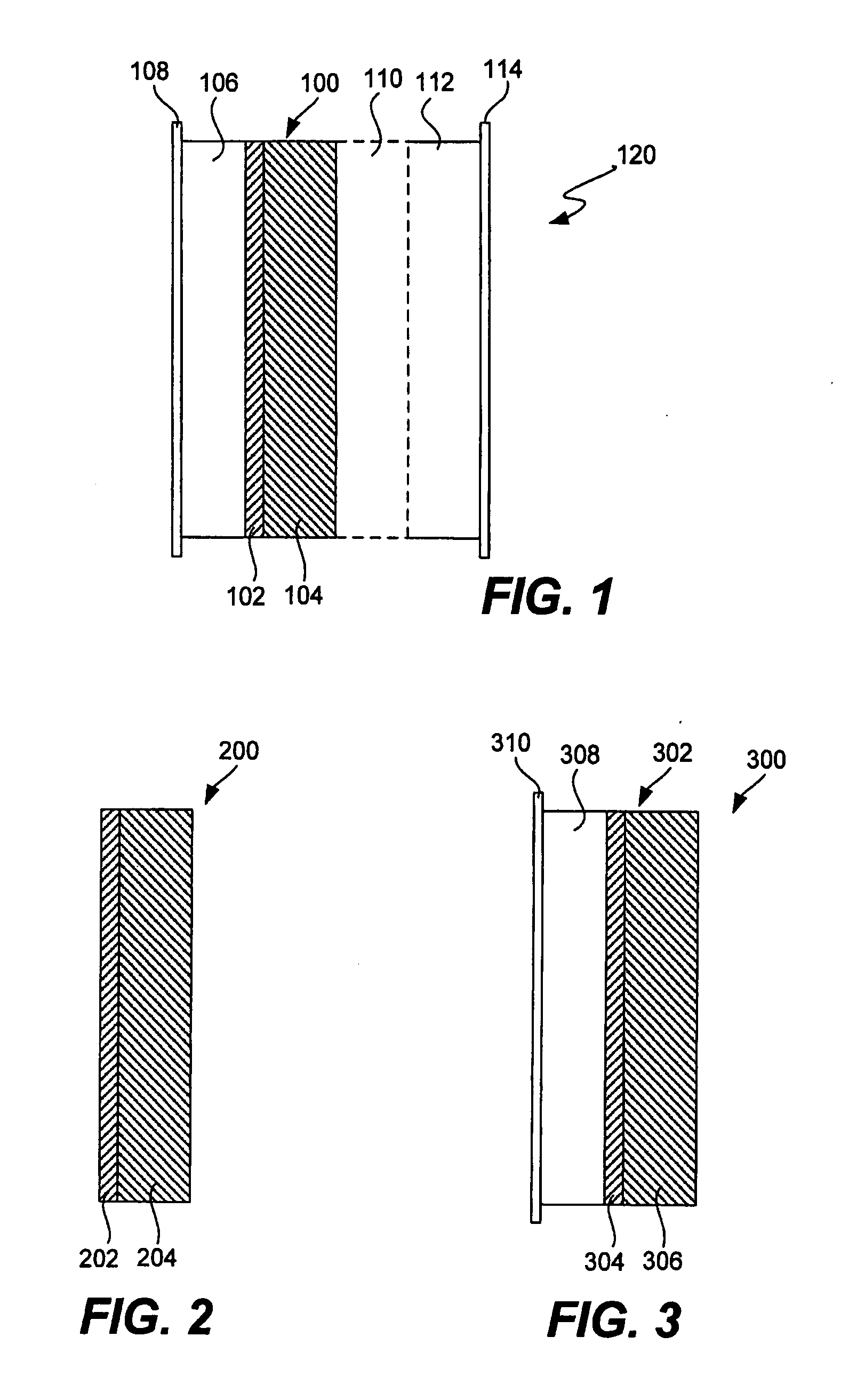

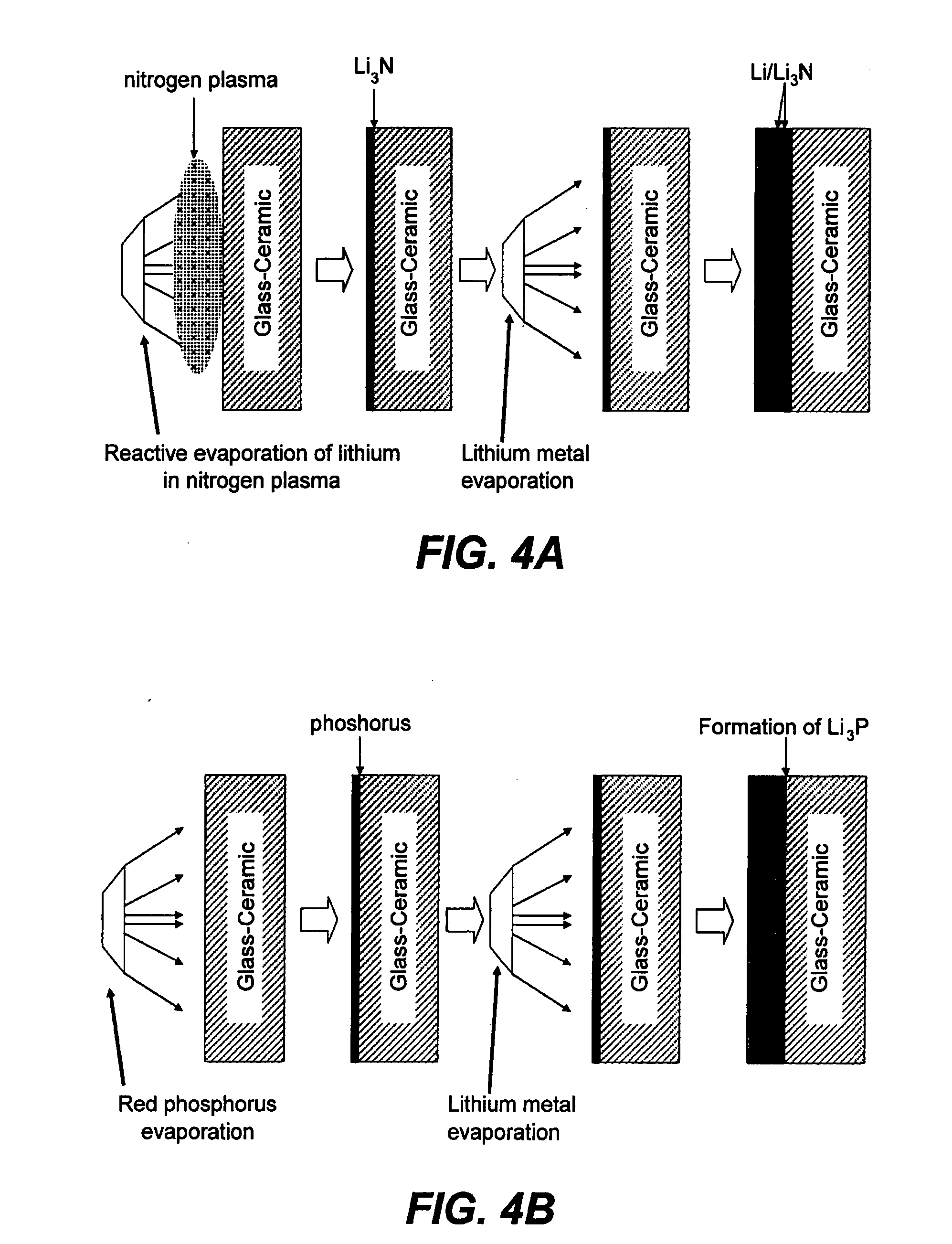

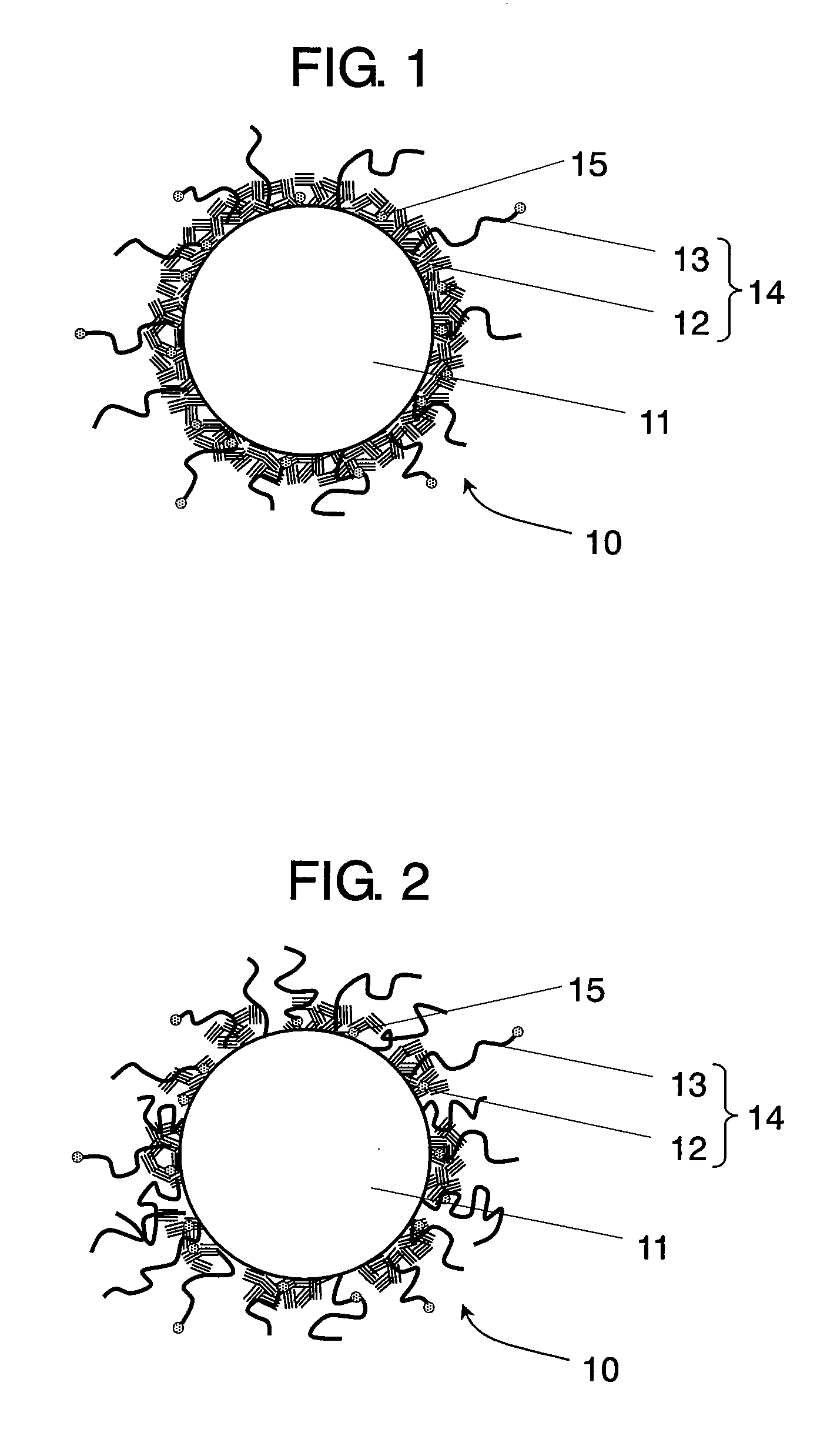

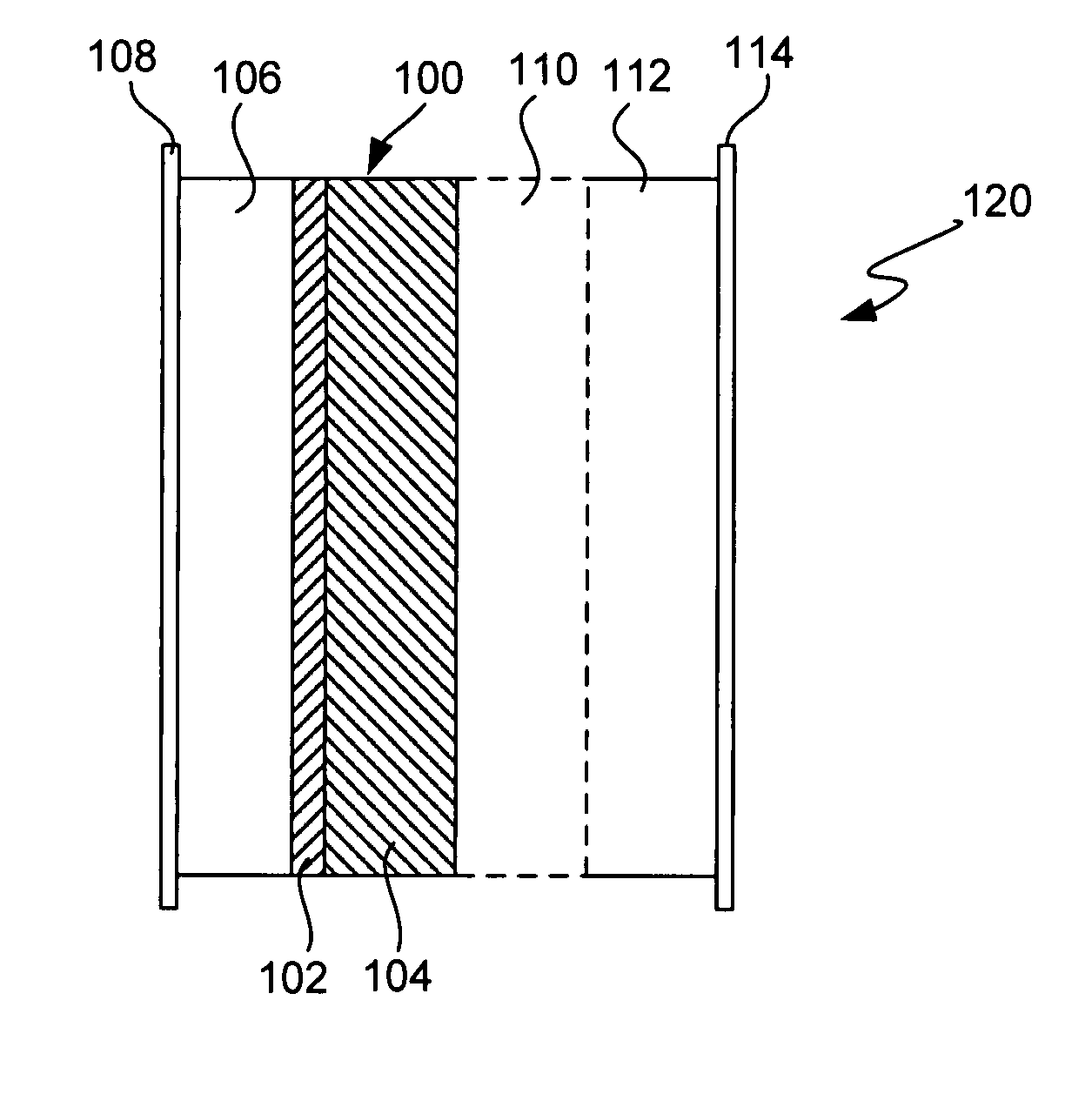

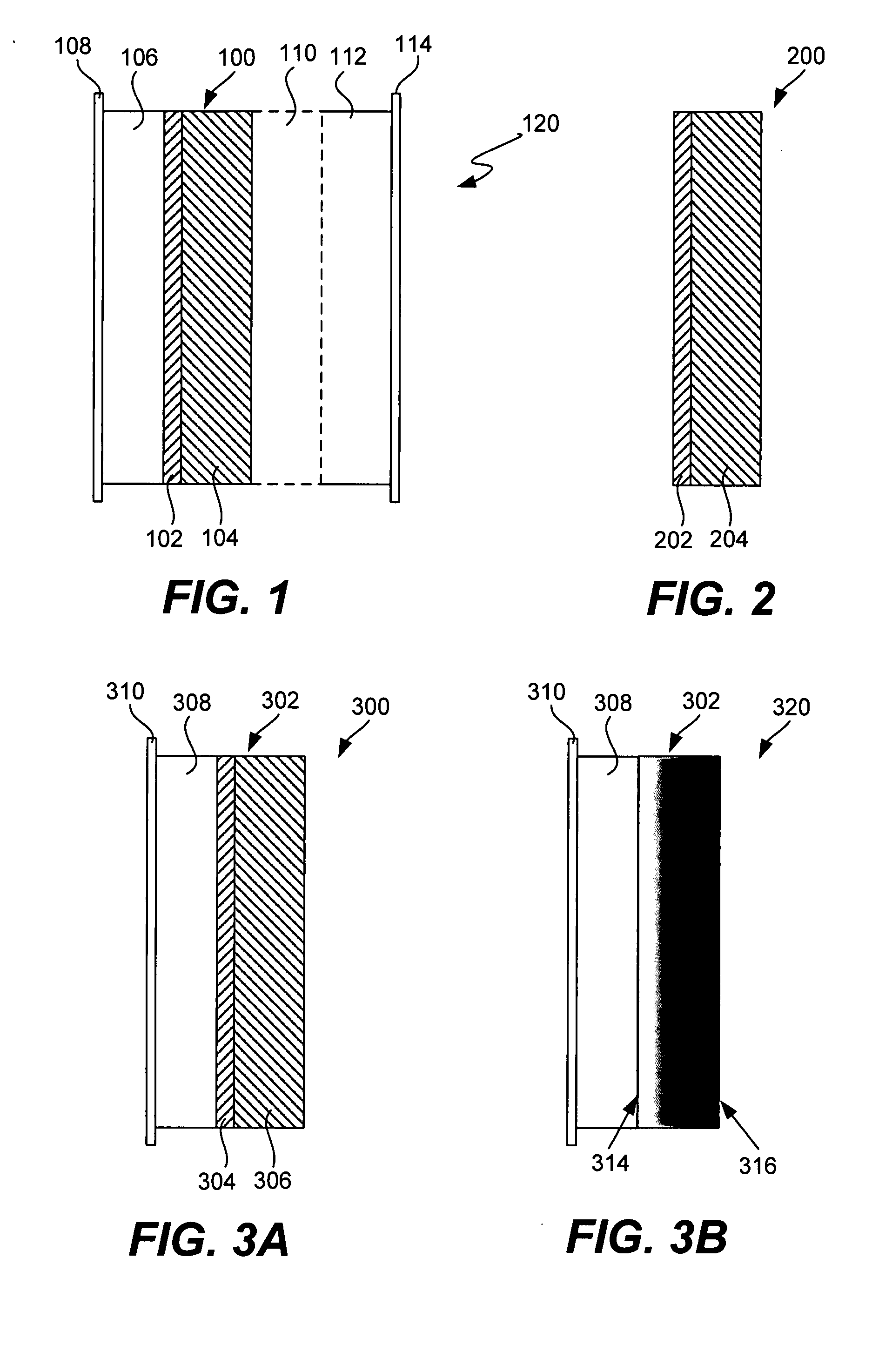

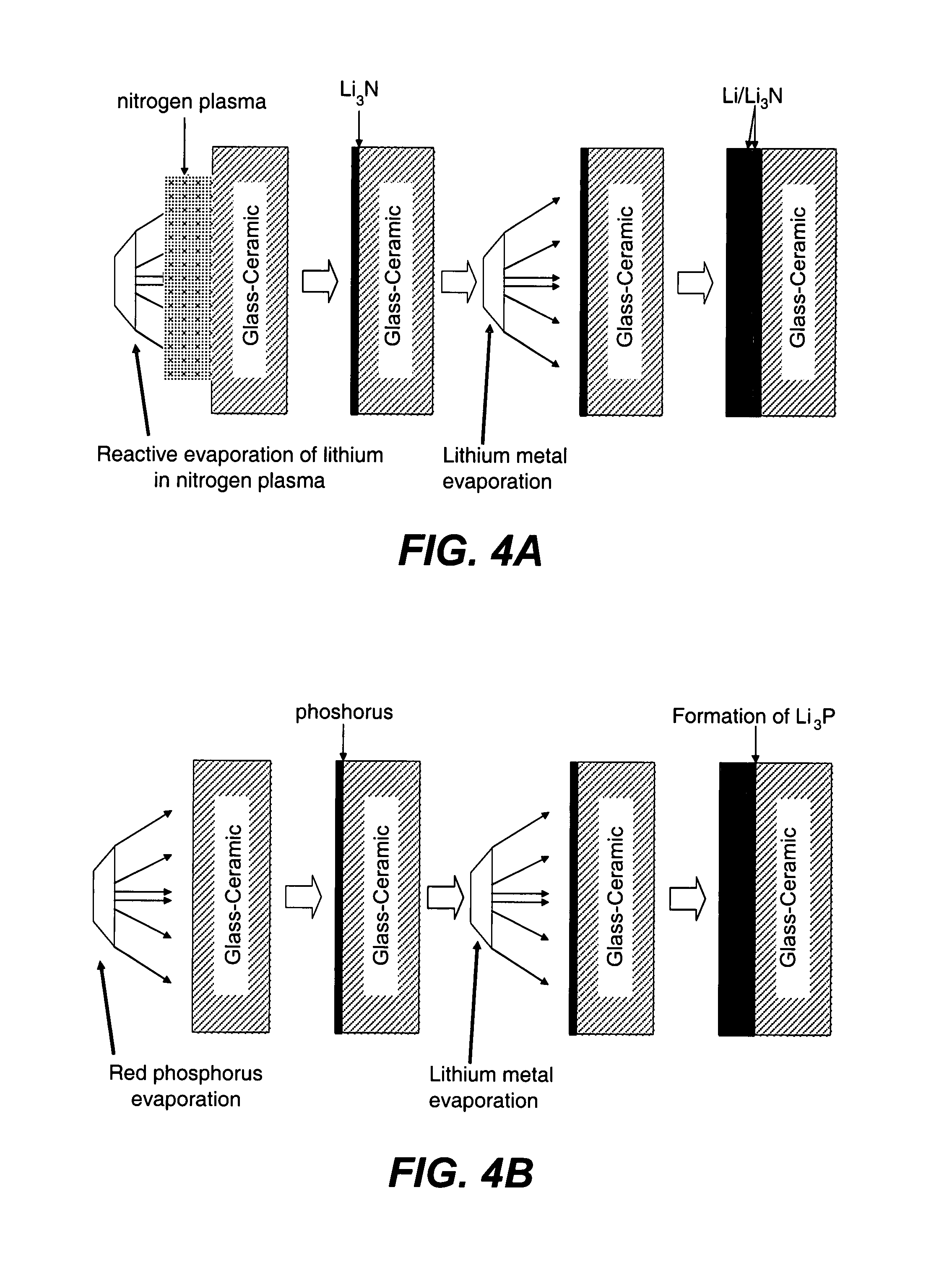

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

Ionically conductive composites for protection of active metal anodes

ActiveUS7282302B2Good chemical stabilityImprove ionic conductivitySolid electrolytesCell seperators/membranes/diaphragms/spacersChemical stabilityBattery cell

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

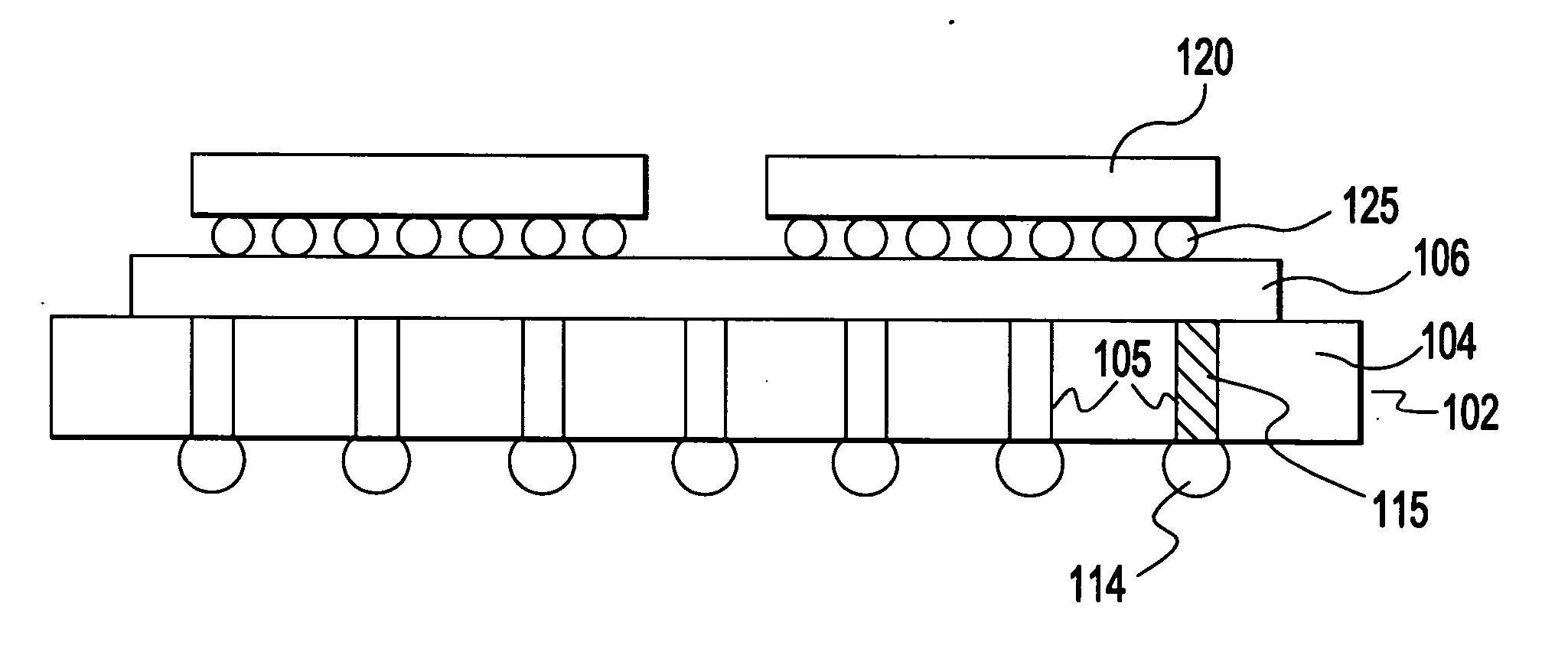

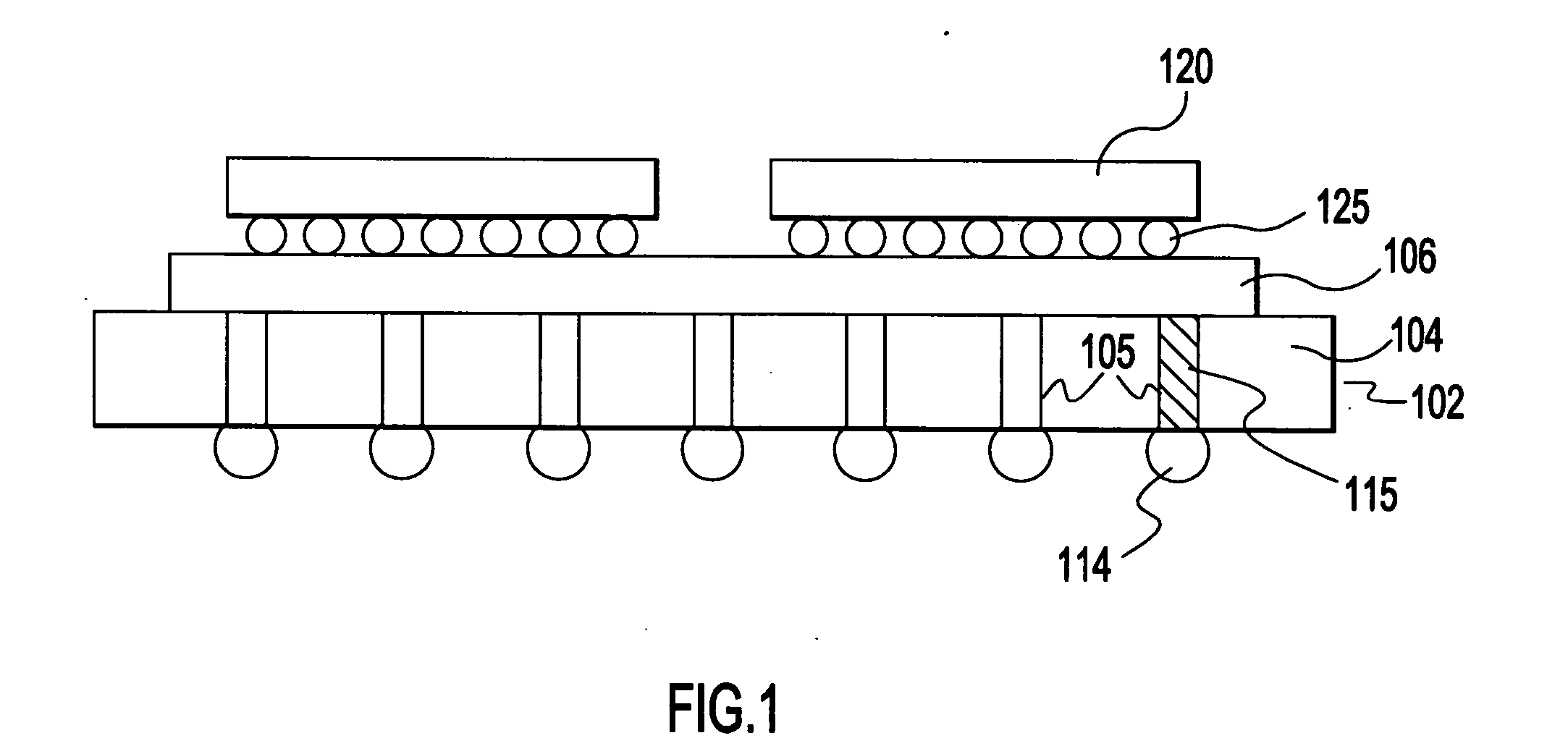

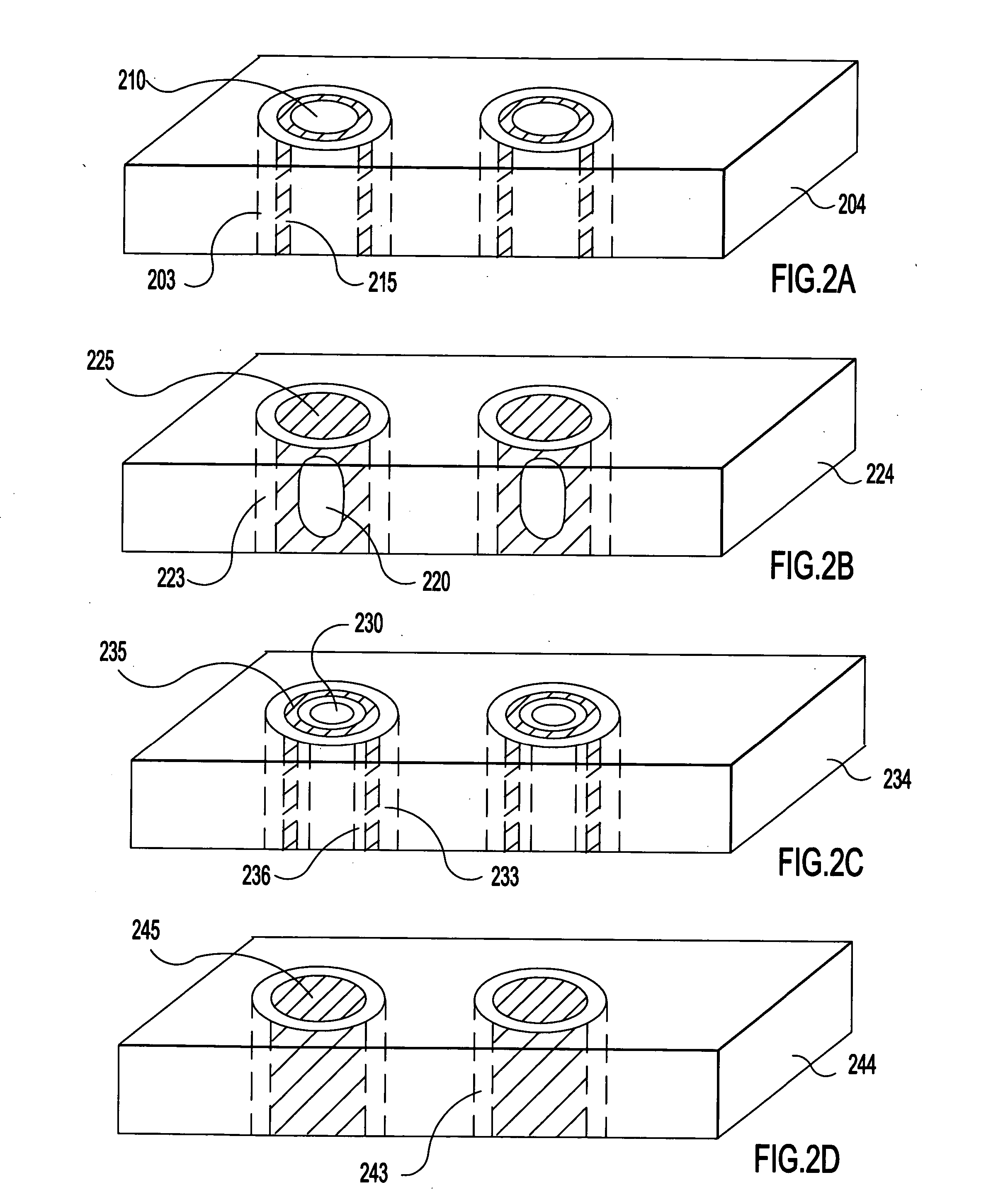

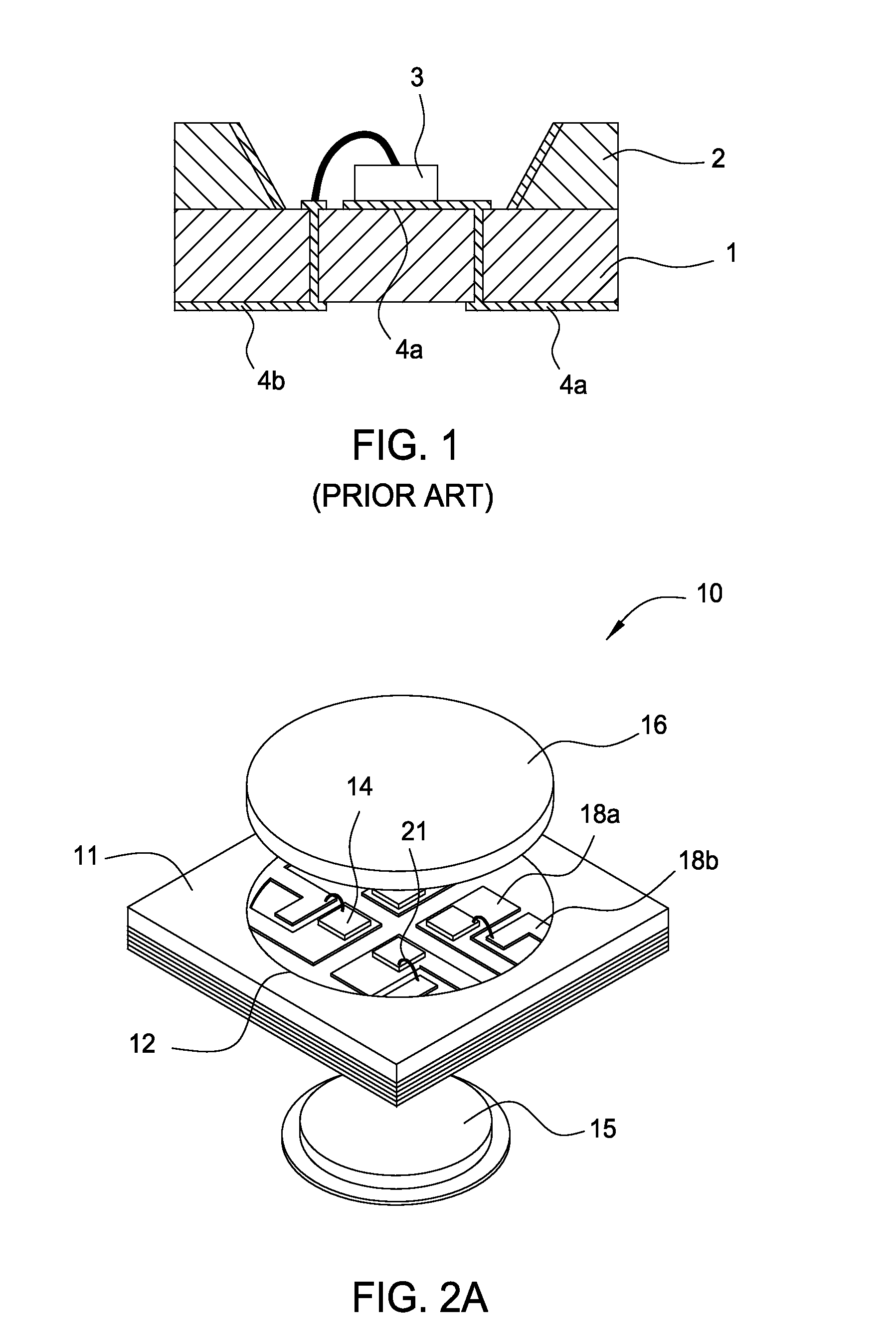

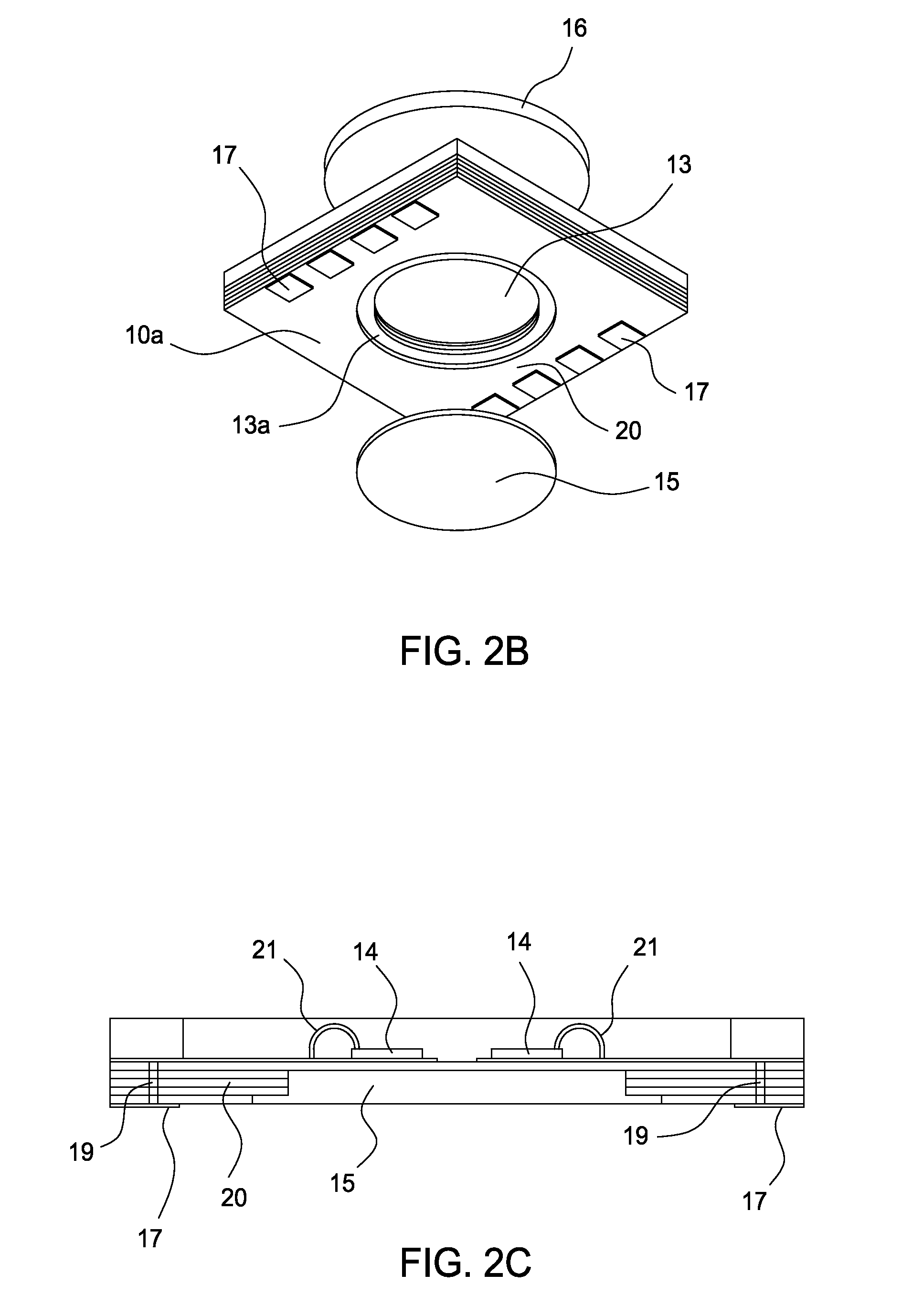

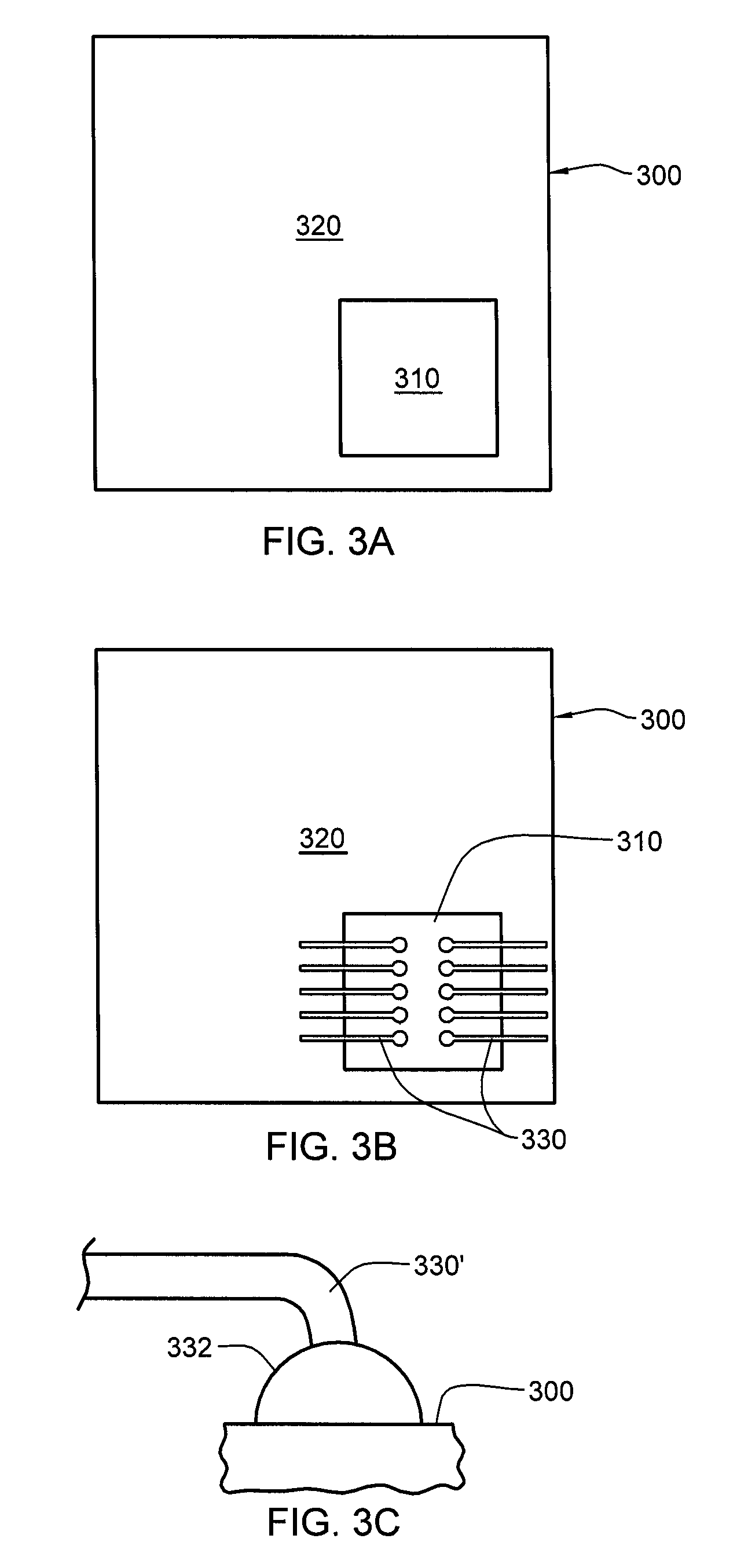

Silicon chip carrier with conductive through-vias and method for fabricating same

InactiveUS20060027934A1Semiconductor/solid-state device detailsSolid-state devicesOptoelectronicsThermal expansion

A carrier structure and method for fabricating a carrier structure with through-vias each having a conductive structure with an effective coefficient of thermal expansion which is less than or closely matched to that of the substrate, and having an effective elastic modulus value which is less than or closely matches that of the substrate. The conductive structure may include concentric via fill areas having differing materials disposed concentrically therein, a core of the substrate material surrounded by an annular ring of conductive material, a core of CTE-matched non-conductive material surrounded by an annular ring of conductive material, a conductive via having an inner void with low CTE, or a full fill of a conductive composite material such as a metal-ceramic paste which has been sintered or fused.

Owner:GLOBALFOUNDRIES INC

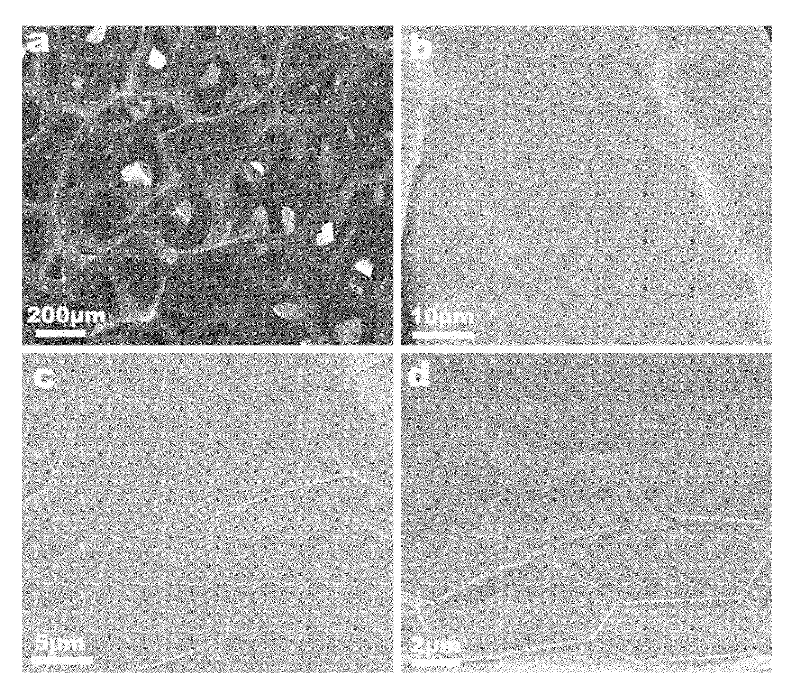

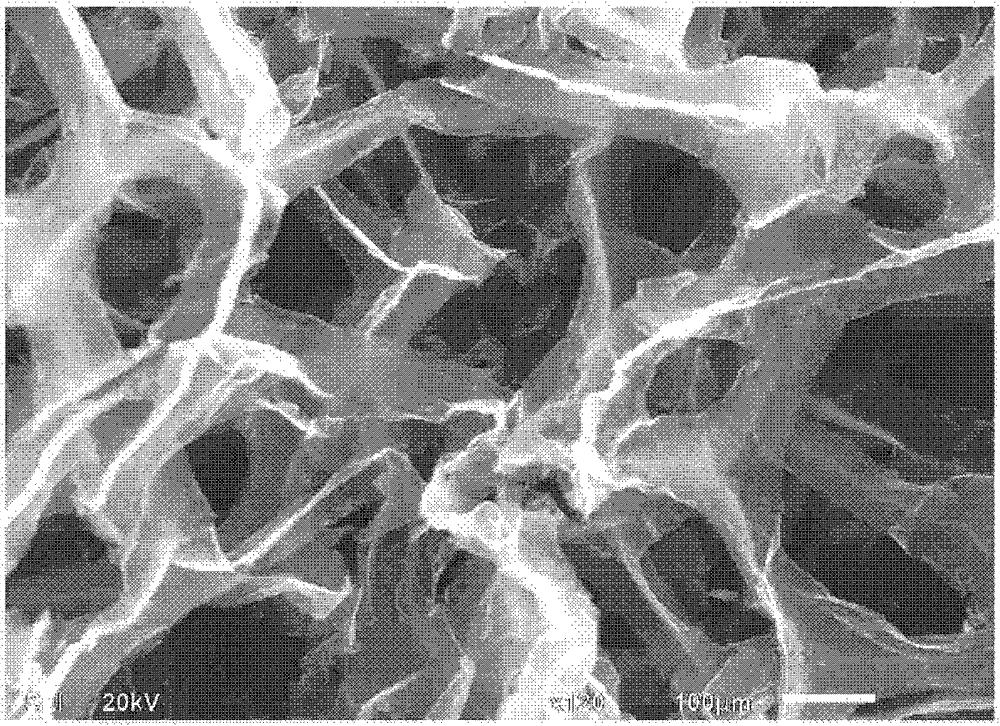

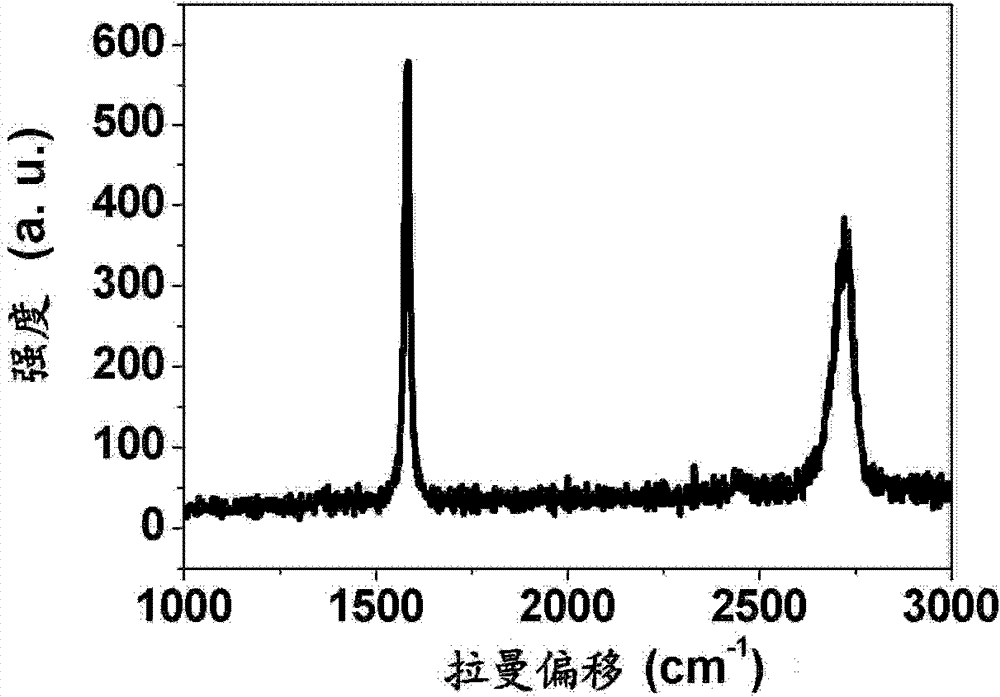

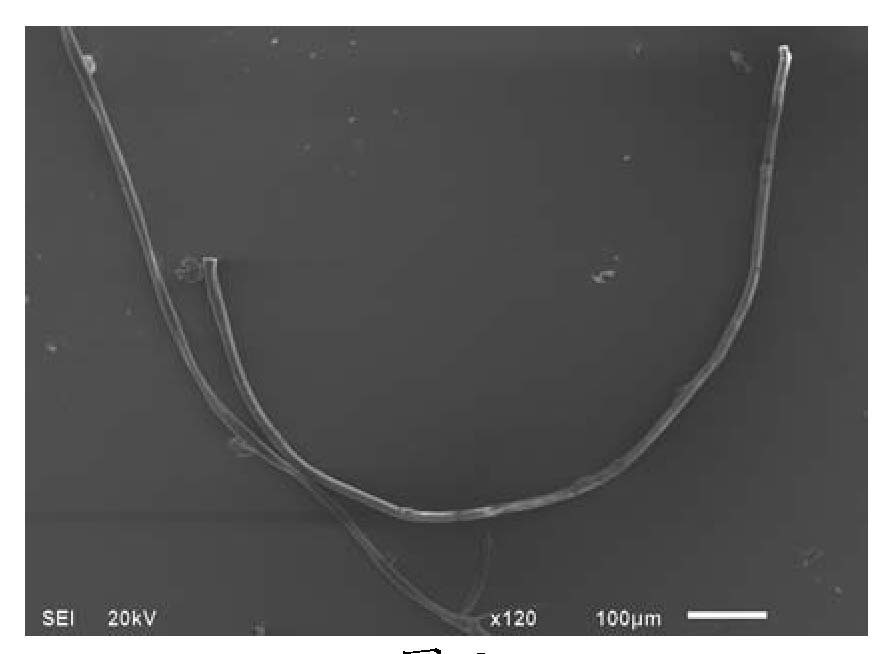

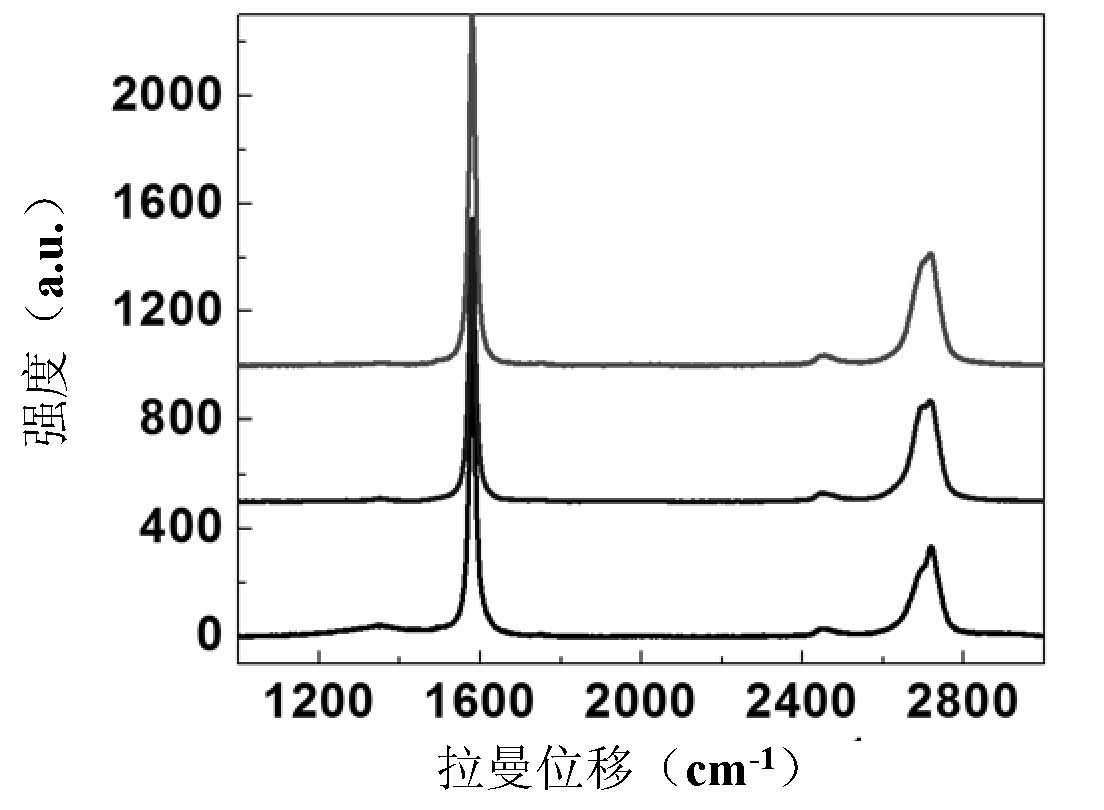

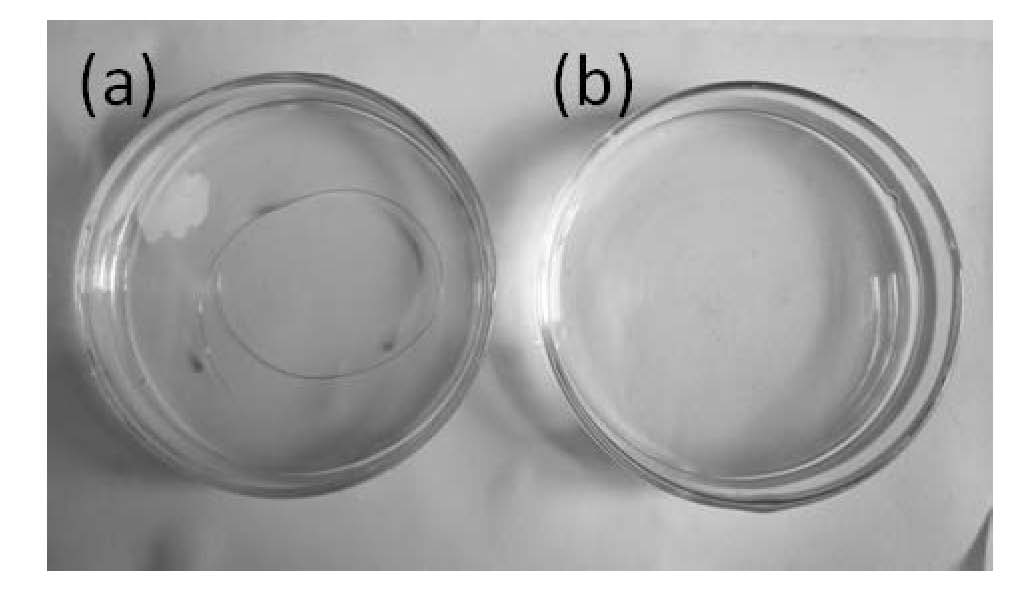

Graphene foam with three dimensional fully connected network and macroscopic quantity preparation method thereof

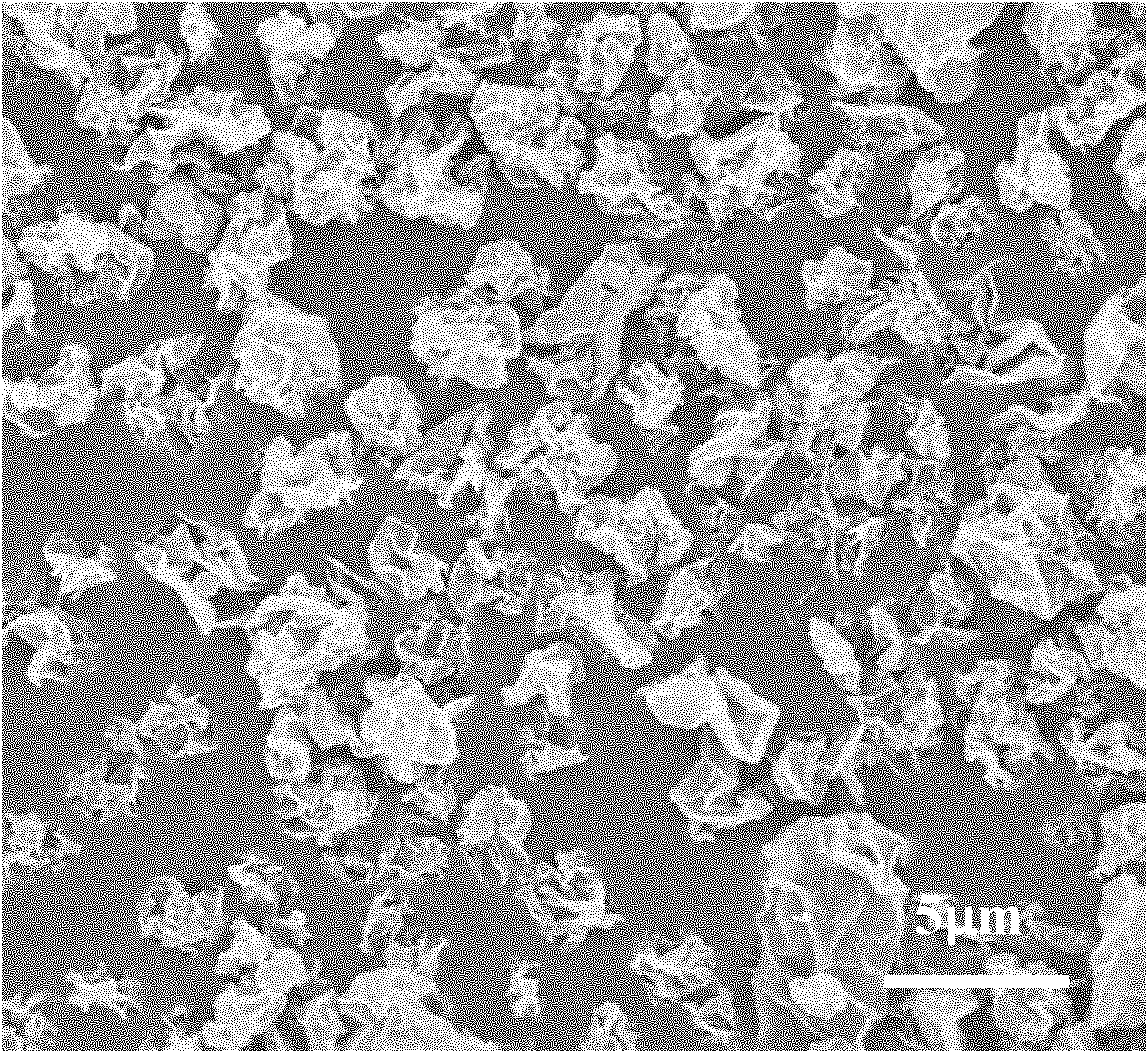

The invention relates to a graphene-based novel material and a chemical vapor deposition preparation technology thereof, in particular to graphene foam with a three dimensional fully connected network and a macroscopic quantity preparation method thereof. The method is suitable for a mass preparation of the graphene foam with high qualities. Three dimensional connected graphene can grow by catalytic cracking of carbon source gases on the surface of a three dimensional porous metal through the chemical vapor deposition technology, and a porous foam-shaped graphene three dimensional macroscopic body can be obtained after a porous metal base is removed by dissolving subsequently. According to the graphene foam with the three dimensional fully connected network and the macroscopic quantity preparation method thereof, a simple template replication method is used for preparing the three dimensional connected graphene macroscopic body, and the method has the advantages that the operation is simple and convenient, the rate of production is high, and the adjustment and control of the structure are easy. The graphene foam forms the fully connected network in a seamless connection mode, has a low density, a high porosity and specific surface area and excellent capabilities of charge conduction and heat conduction and establishes a foundation for applications of graphene in fields of electric conduction, thermally conductive composite materials, electromagnetic shielding, wave absorbing, catalysis, sensing and energy storage materials and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

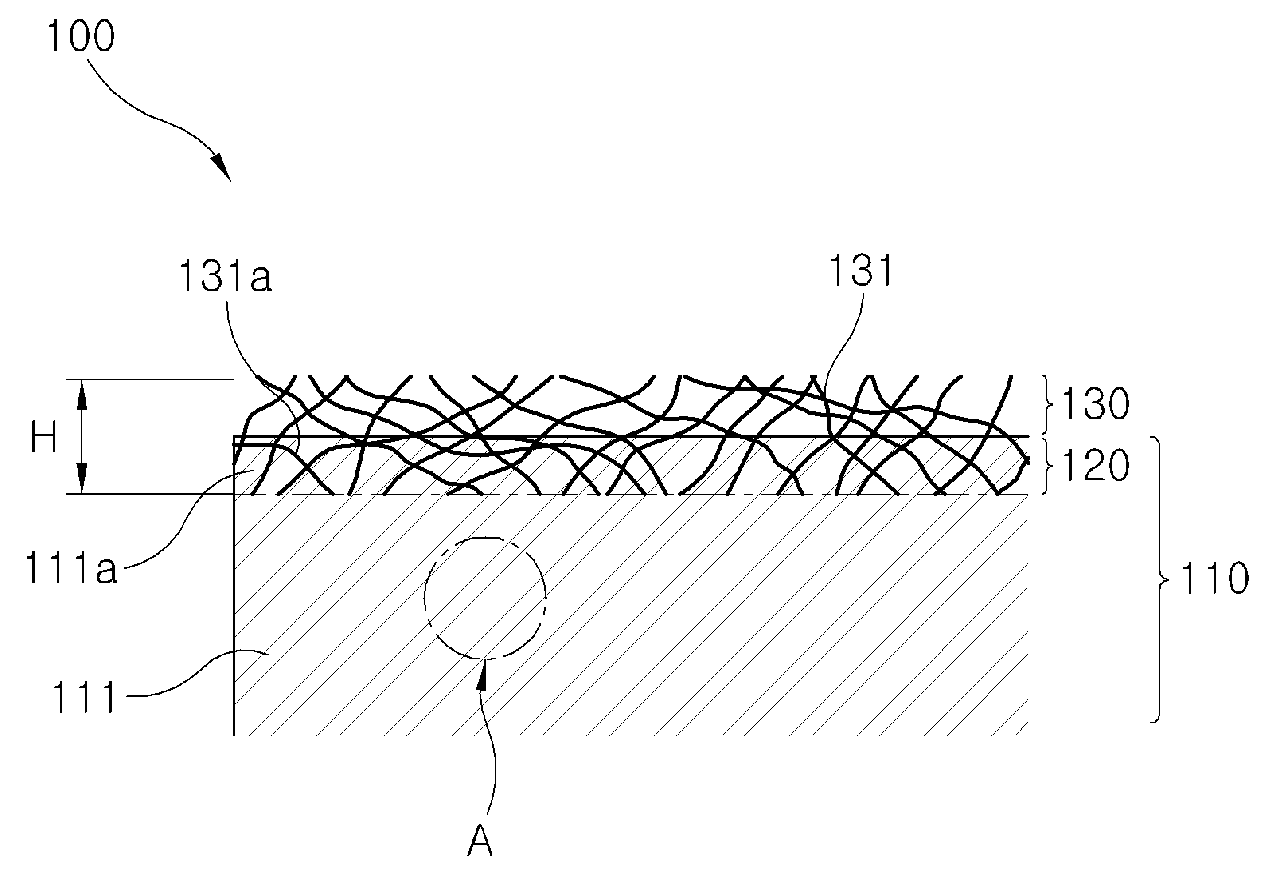

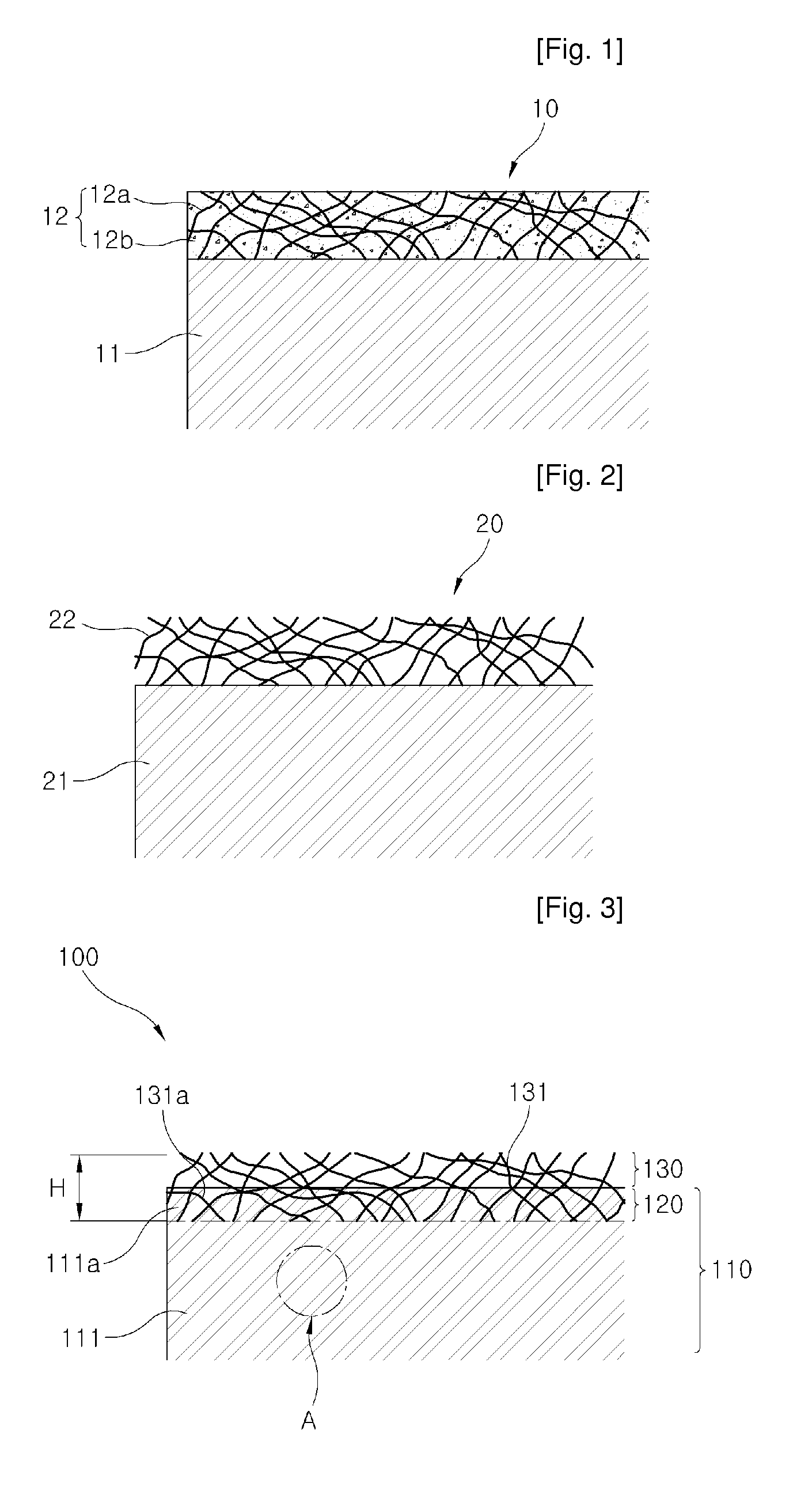

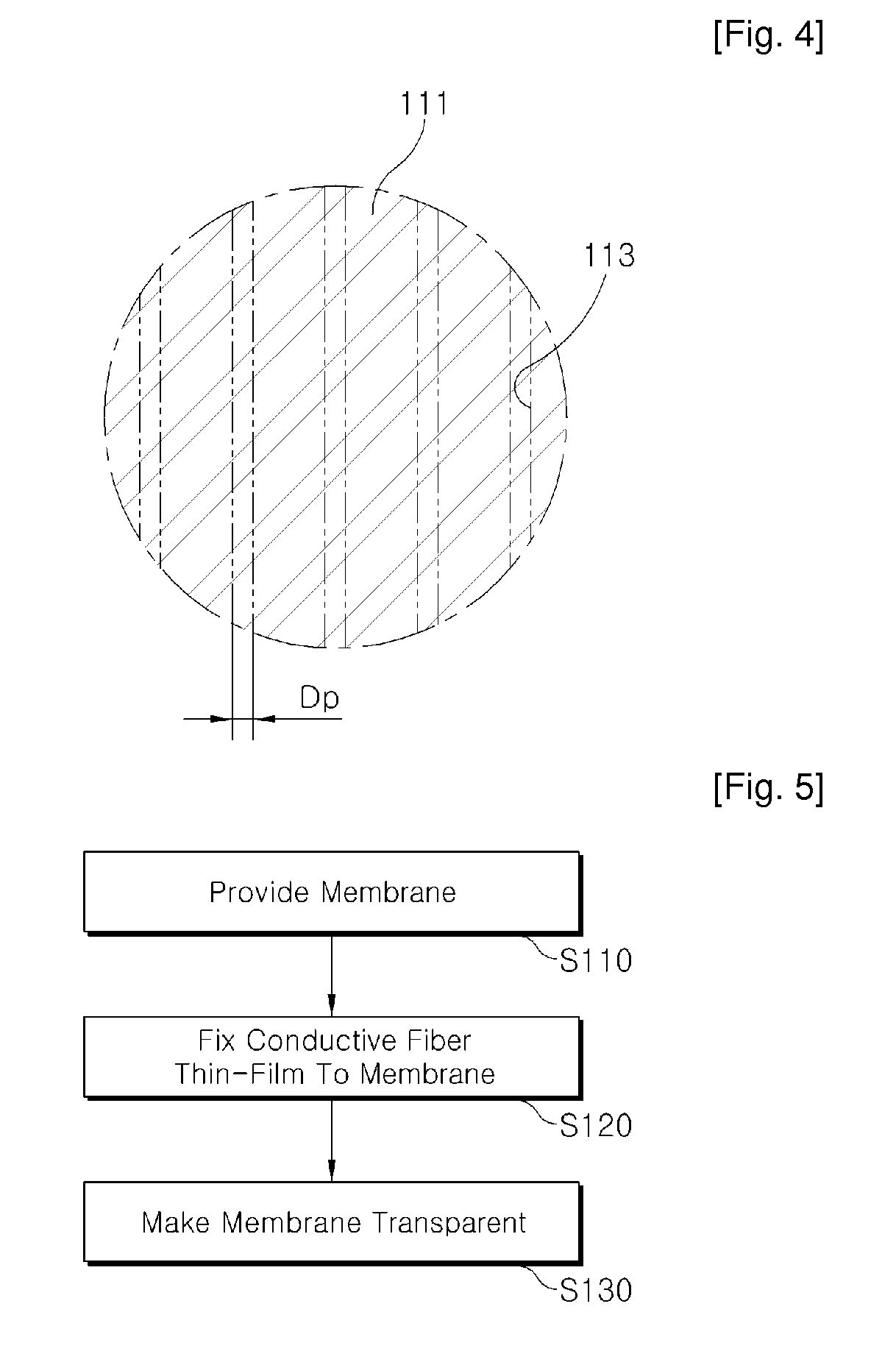

Method for manufacturing conductive composite material

InactiveUS20090056854A1Reduce thicknessHigh transparencyCathodes manufactureElectric discharge tubesFiberOptoelectronics

A conductive composite material is provided, including: a base layer; a conductive fiber thin-film made of conductive fiber and formed on the base layer; and a mixture layer in which part of the conductive fiber is inserted into part of the base layer.

Owner:TOPNANOSIS

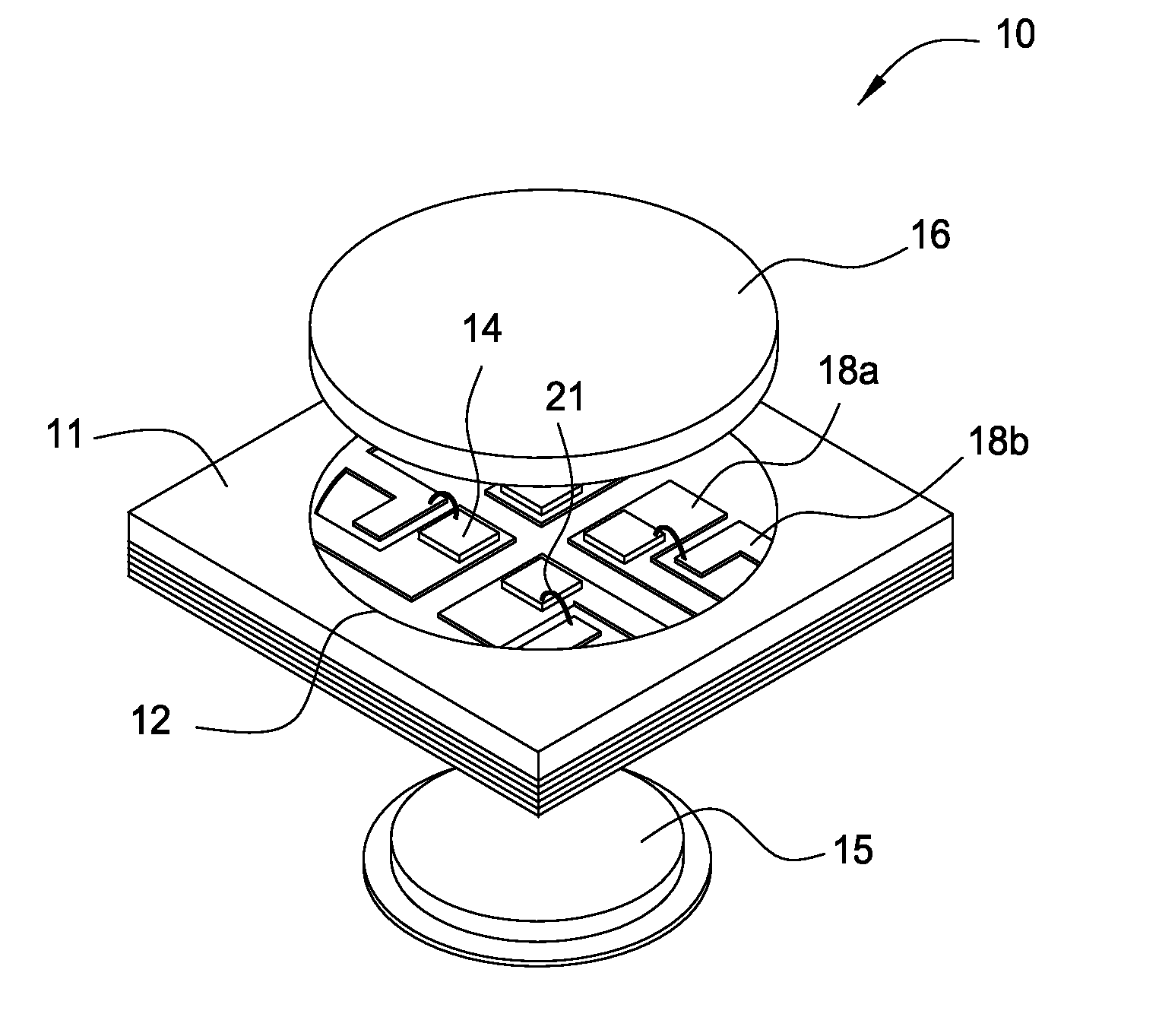

Ceramic LED package

InactiveUS20080179618A1Circuit optical detailsPrinted circuit aspectsLight-emitting diodeCeramic substrate

Light-emitting diode (LED) packages with improved heat transfer paths for LED dies encased therein when compared to conventional LED packages are provided. For some embodiments, the LED package includes a ceramic substrate having a top cavity with one or more LED dies disposed within and having a bottom cavity for receiving a metallic insert to dissipate heat away from the LED dies. For other embodiments, an LED package is provided that includes a ceramic substrate having a heat spreader coupled to thermal vias filled with a highly thermally conductive composite.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

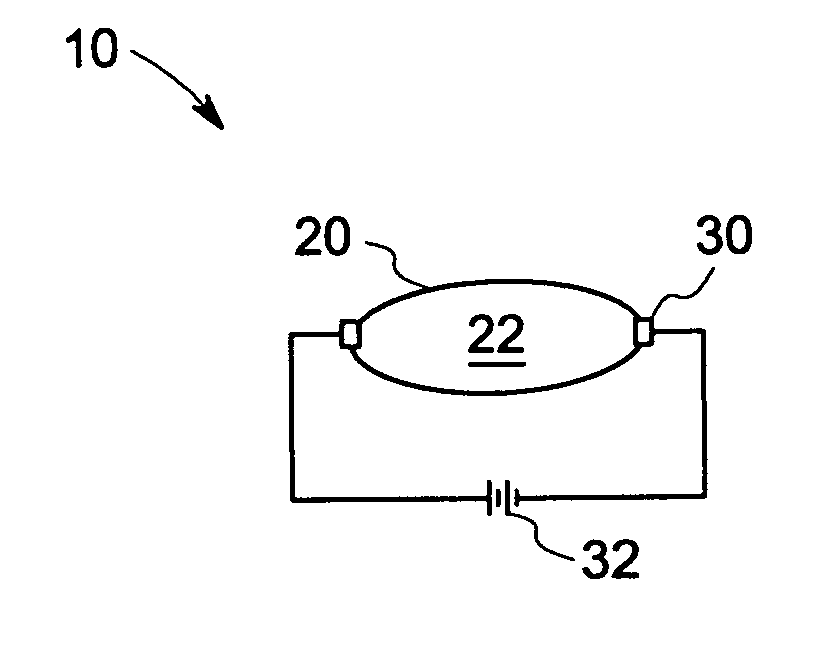

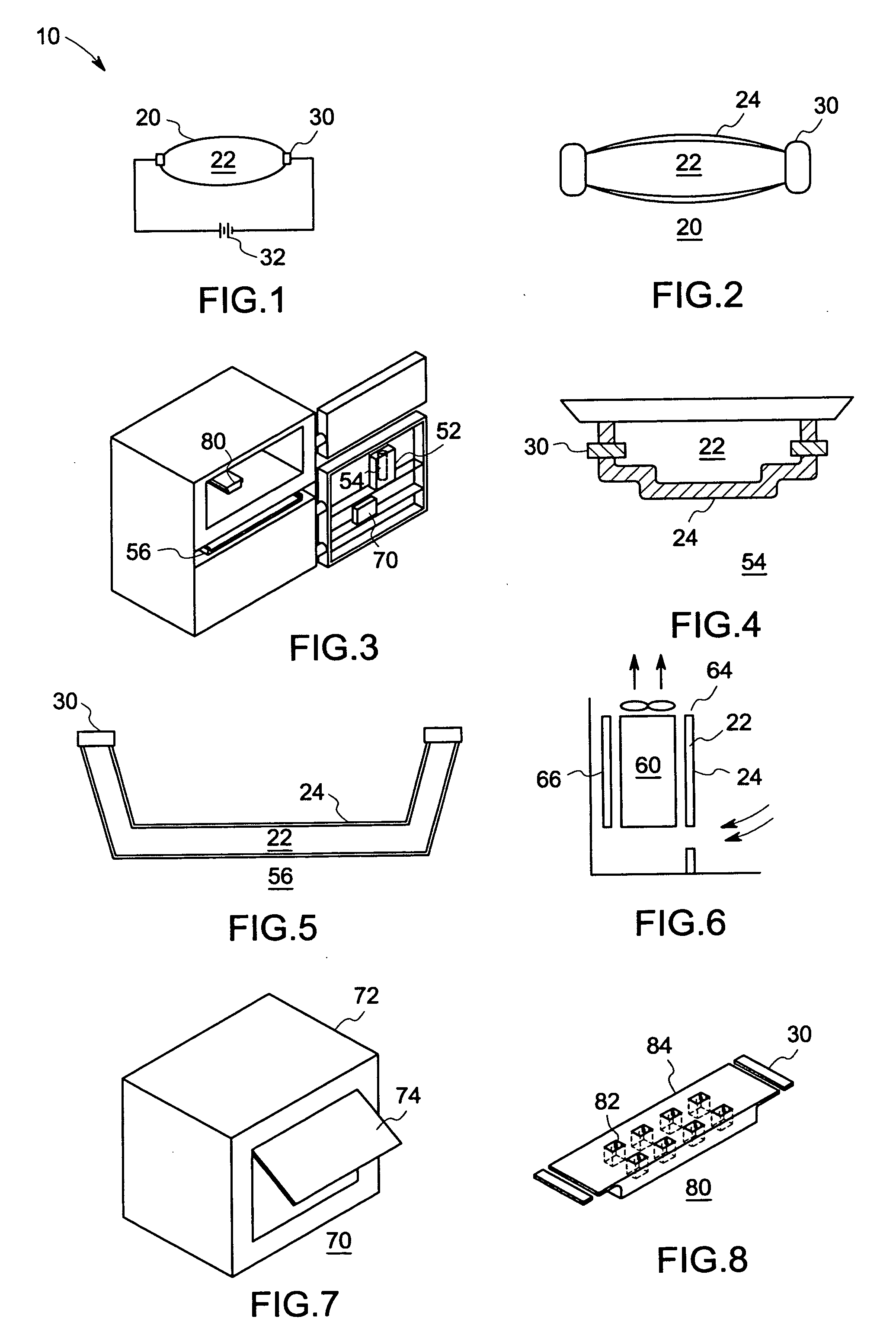

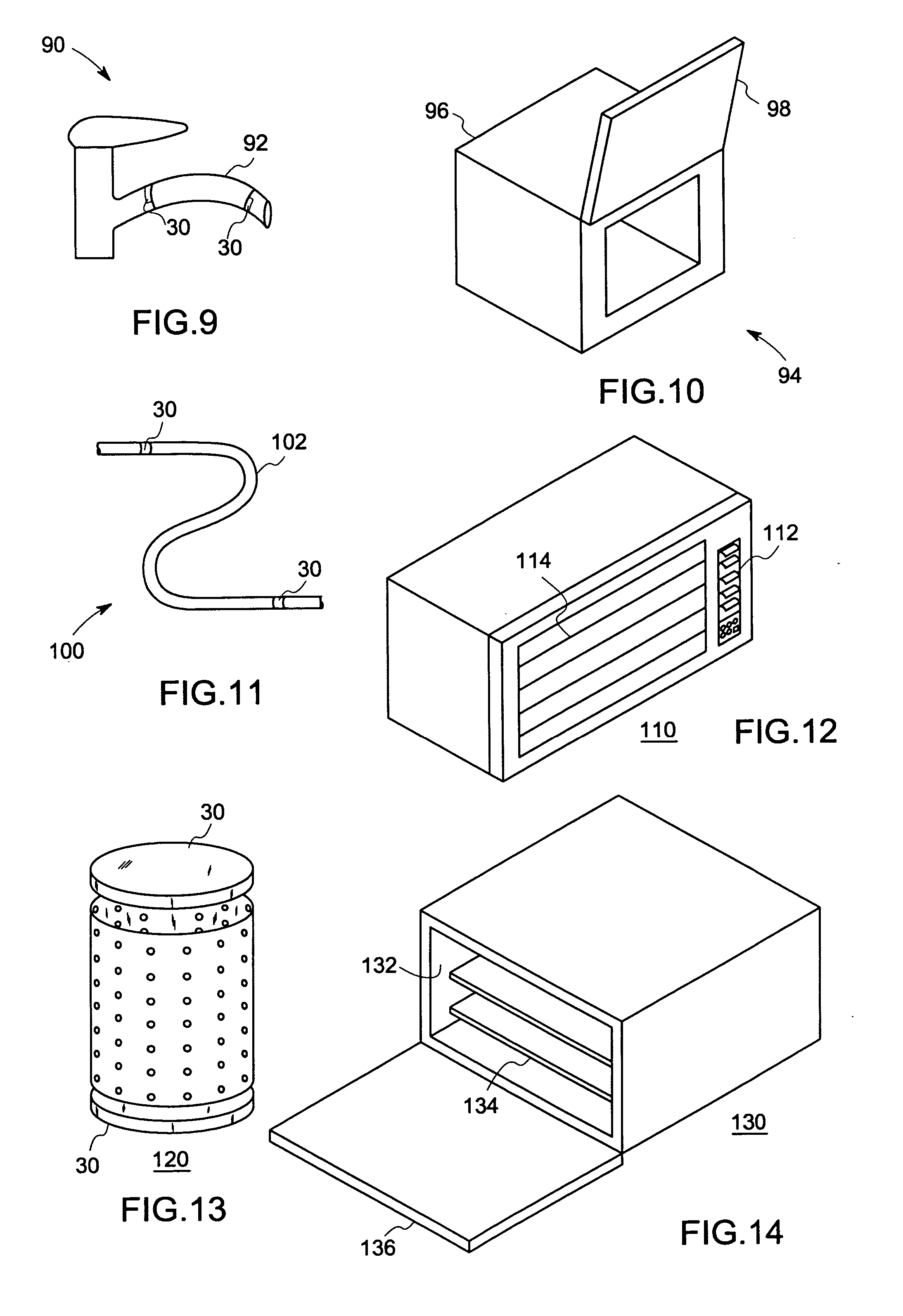

Self heating apparatus

InactiveUS20050067406A1Material nanotechnologyLighting and heating apparatusElectricityConductive composites

An apparatus with a self heating feature includes a conductive component of the apparatus having conductive composite. The conductive component is adapted to couple with a source of electricity, and the conductive component heats up on passage of electricity. According to another aspect, a domestic appliance that requires heating for its operation, includes at least one part comprising a conductive composite, which heats up on passage of electricity and the part is adapted to couple with a power supply. According to another aspect a method for providing heating in an apparatus includes heating at least one conductive component of the apparatus. The heating is done by passing an electric current through the conductive component, and the conductive component comprises a conductive composite.

Owner:GENERAL ELECTRIC CO

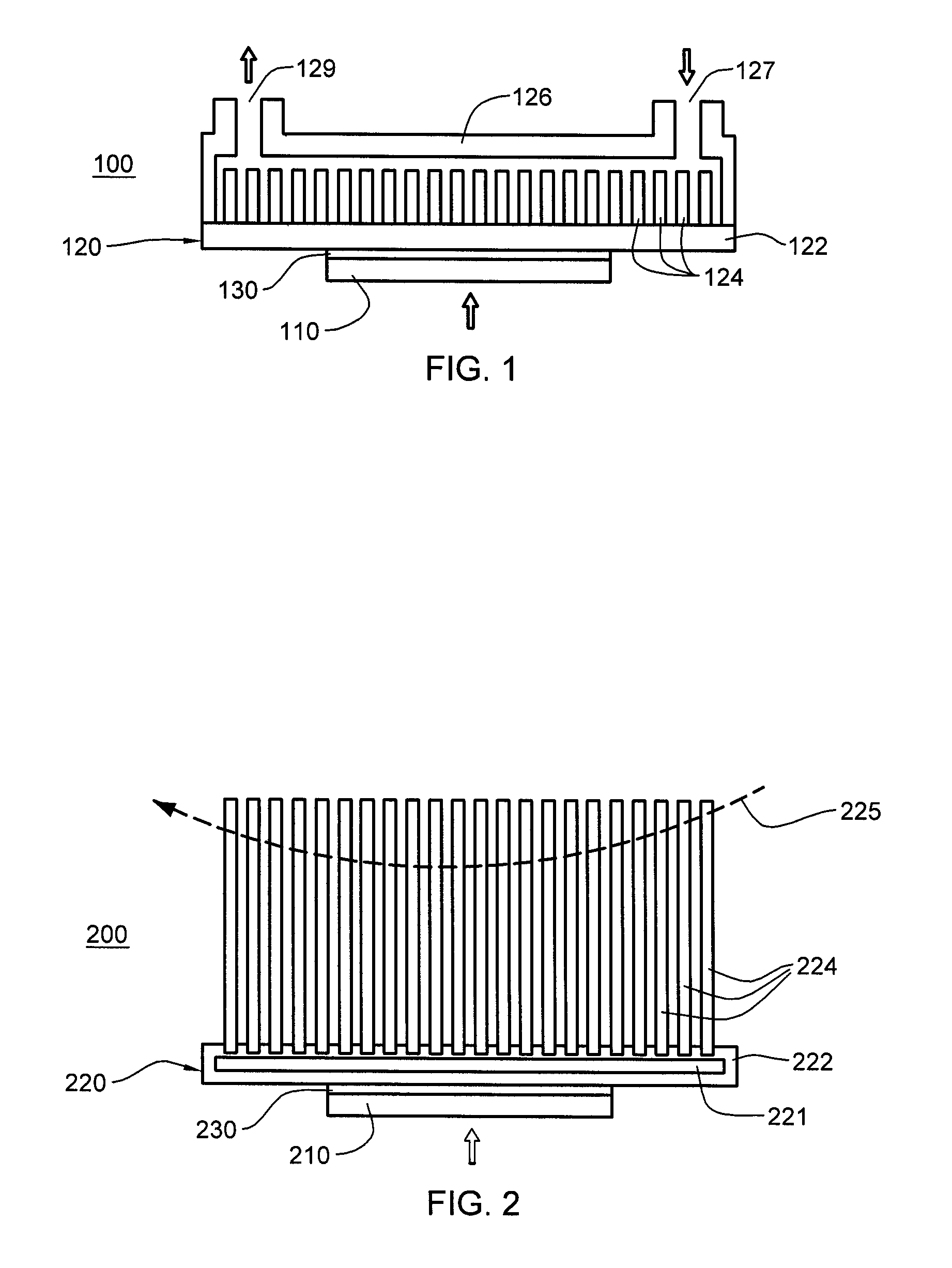

Thermally conductive composite interface, cooled electronic assemblies employing the same, and methods of fabrication thereof

ActiveUS7967062B2Enhanced couplingImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesHeat fluxElectronic assemblies

A composite interface and methods of fabrication are provided for coupling a cooling assembly to an electronic device. The interface includes a plurality of thermally conductive wires formed of a first material having a first thermal conductivity, and a thermal interface material at least partially surrounding the wires. The interface material, which thermally interfaces the cooling assembly to a surface to be cooled of the electronic device, is a second material having a second thermal conductivity, wherein the first thermal conductivity is greater than the second thermal conductivity. At least some wires reside partially over a first region of higher heat flux and extend partially over a second region of lower heat flux, wherein the first and second regions are different regions of the surface to be cooled. These wires function as thermal spreaders facilitating heat transfer from the surface to be cooled to the cooling assembly.

Owner:INT BUSINESS MASCH CORP

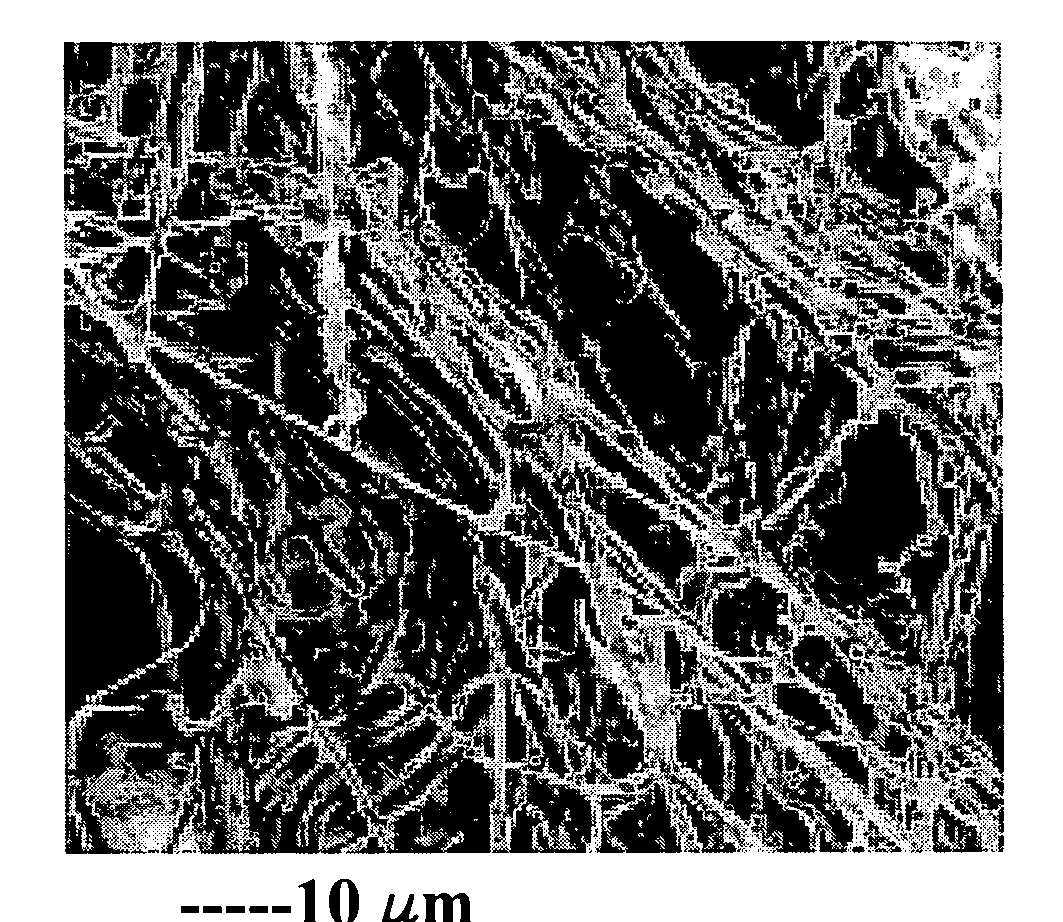

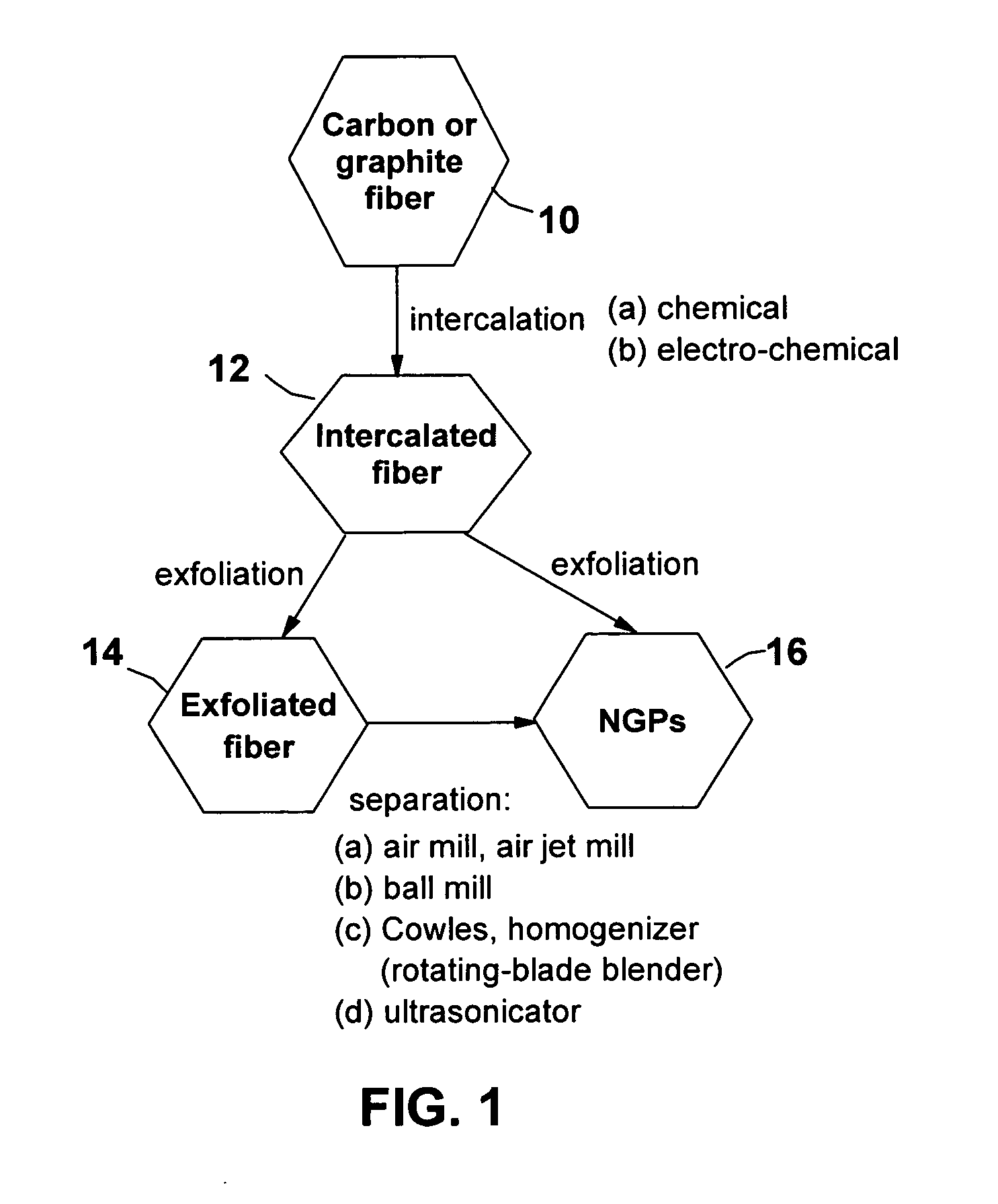

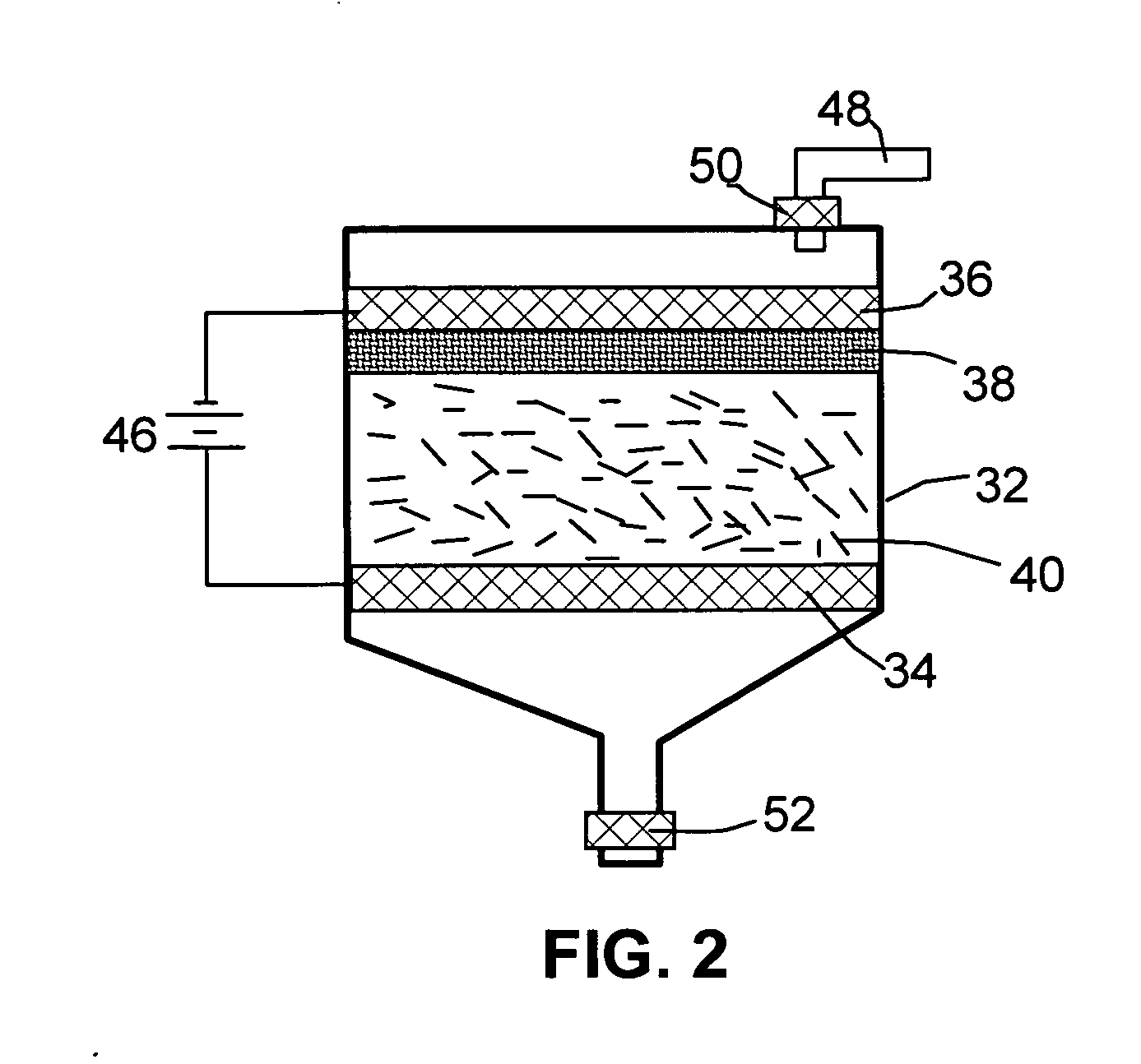

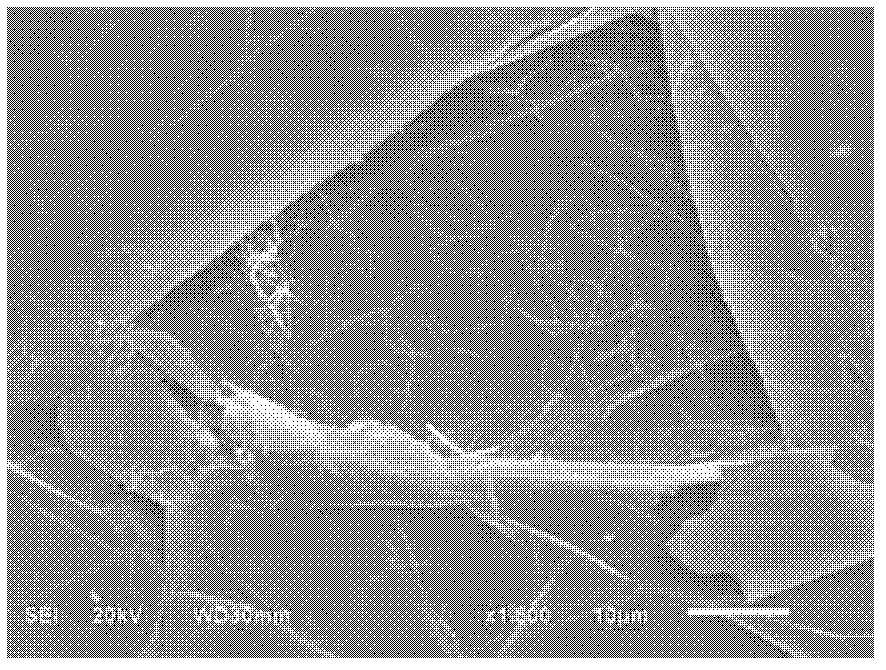

Nano-scaled graphene platelets with a high length-to-width aspect ratio

ActiveUS20090155578A1High aspect ratioHigh stiffnessMaterial nanotechnologyShielding materialsFiberCarbon fibers

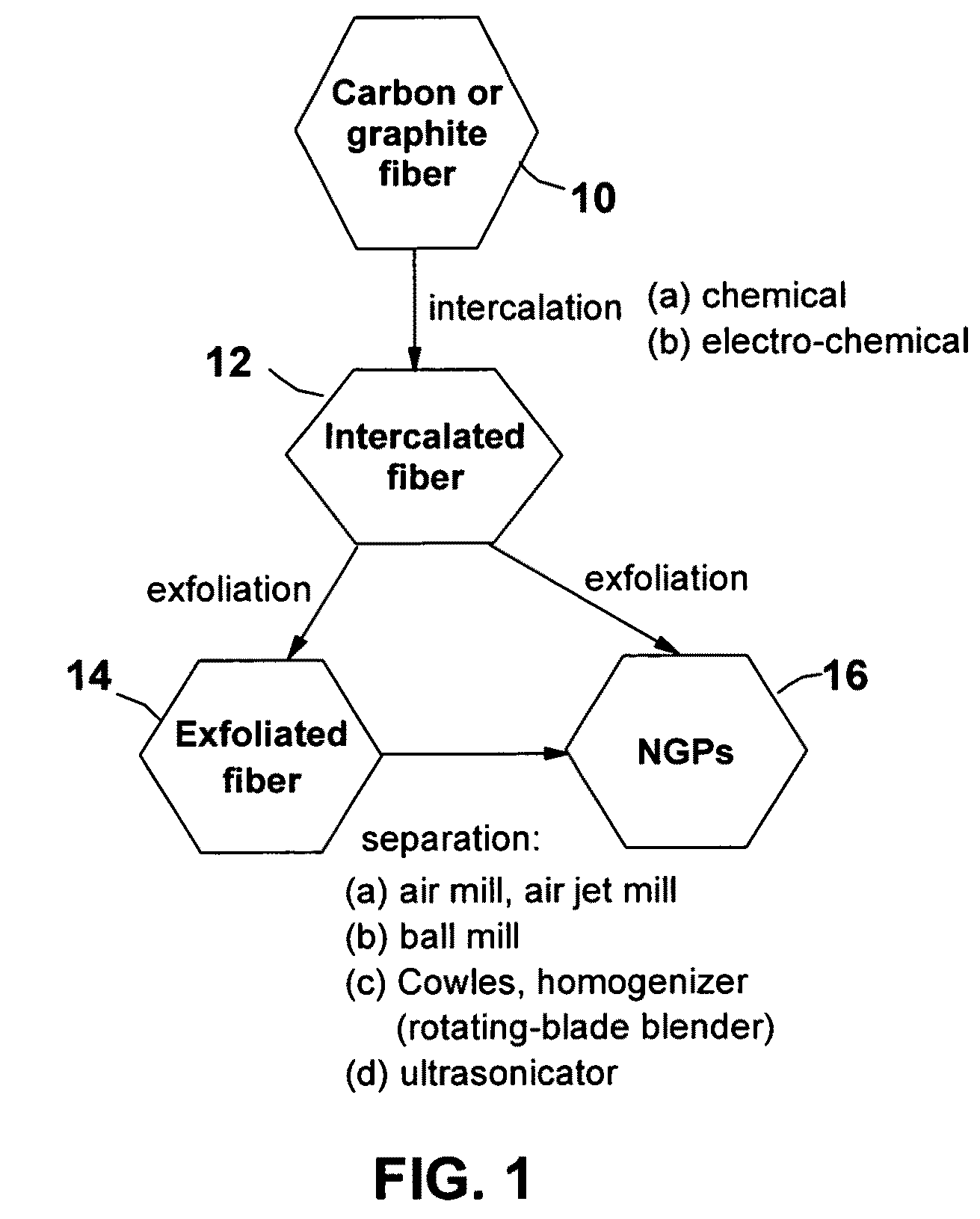

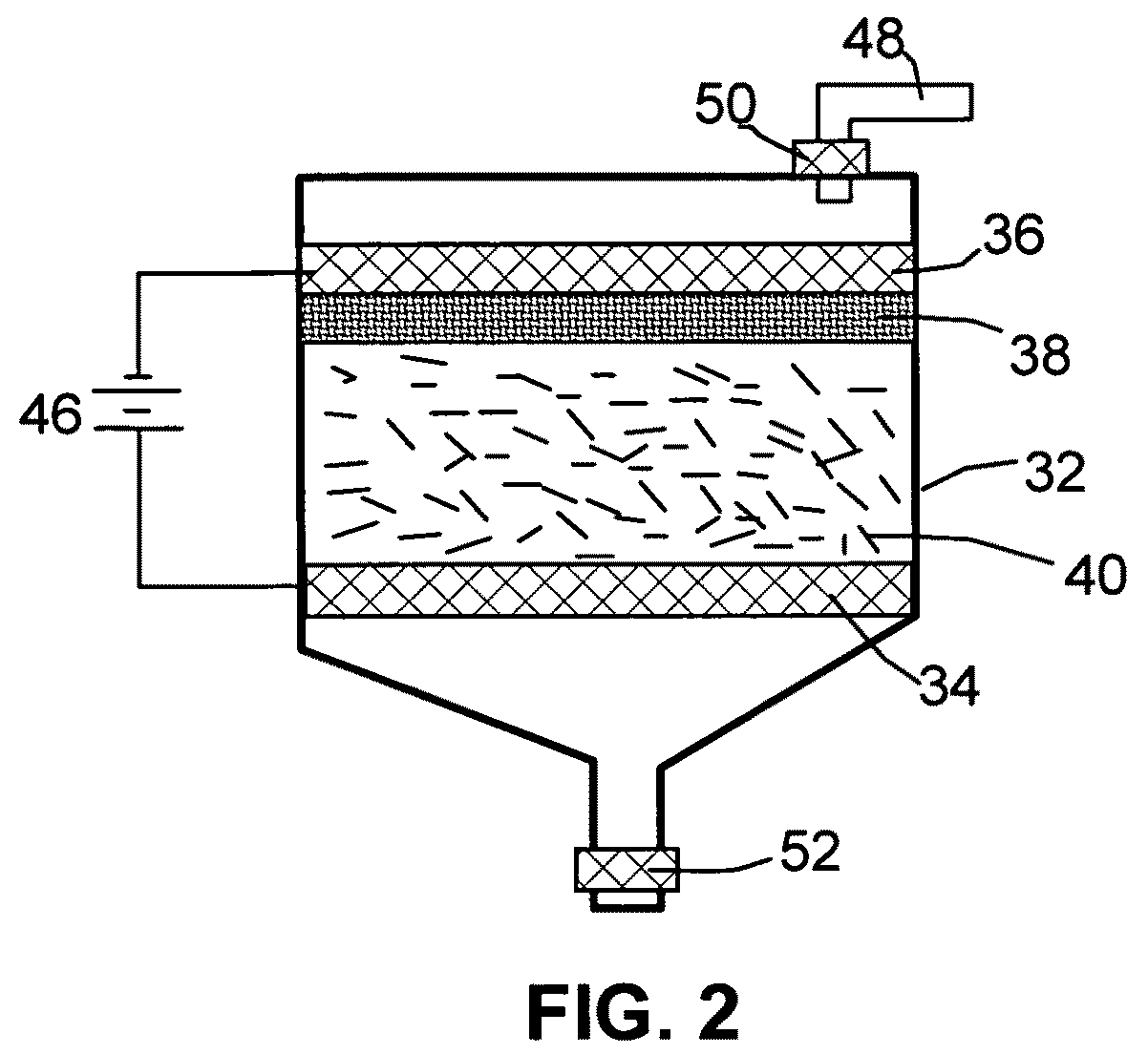

This invention provides a nano-scaled graphene platelet (NGP) having a thickness no greater than 100 nm and a length-to-width ratio no less than 3 (preferably greater than 10). The NGP with a high length-to-width ratio can be prepared by using a method comprising (a) intercalating a carbon fiber or graphite fiber with an intercalate to form an intercalated fiber; (b) exfoliating the intercalated fiber to obtain an exfoliated fiber comprising graphene sheets or flakes; and (c) separating the graphene sheets or flakes to obtain nano-scaled graphene platelets. The invention also provides a nanocomposite material comprising an NGP with a high length-to-width ratio. Such a nanocomposite can become electrically conductive with a small weight fraction of NGPs. Conductive composites are particularly useful for shielding of sensitive electronic equipment against electromagnetic interference (EMI) or radio frequency interference (RFI), and for electrostatic charge dissipation.

Owner:GLOBAL GRAPHENE GRP INC

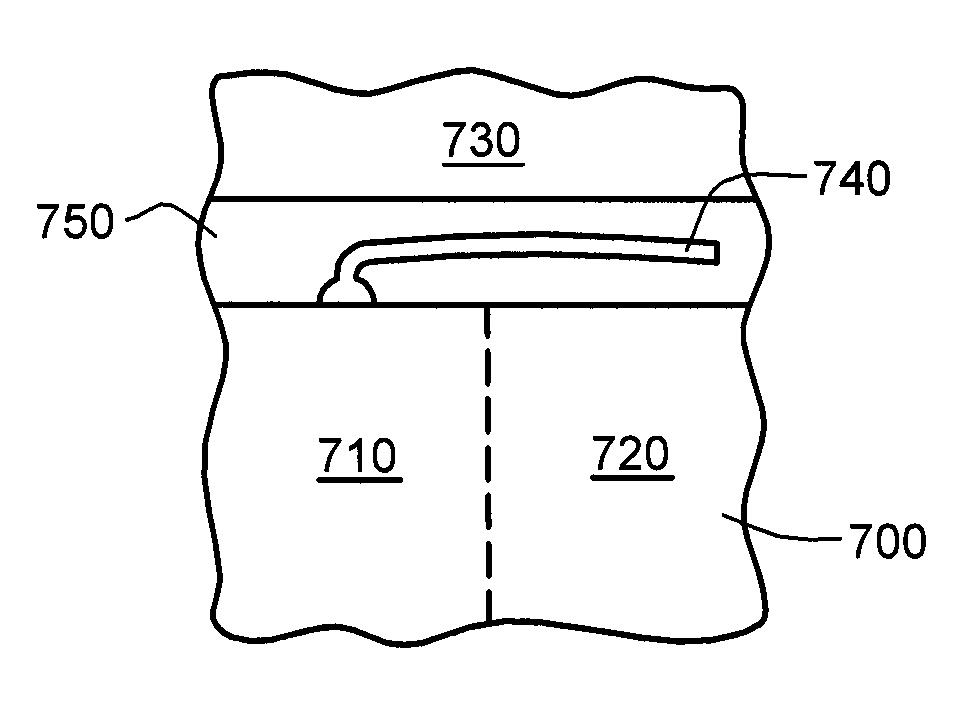

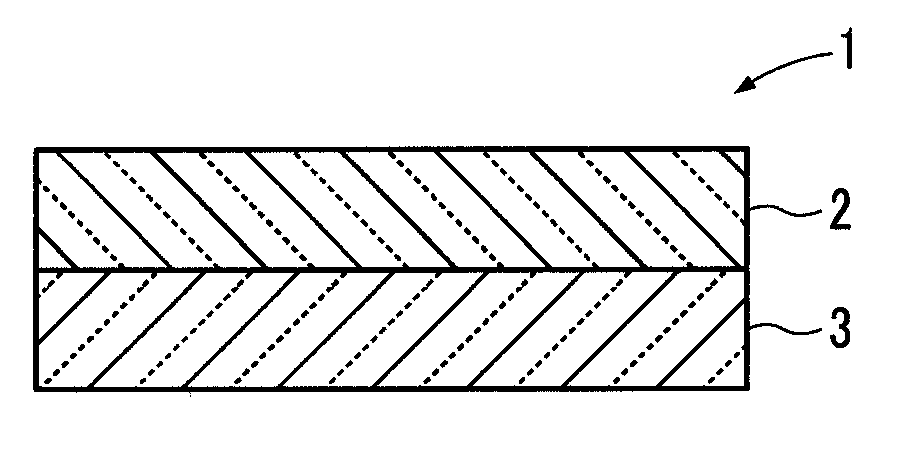

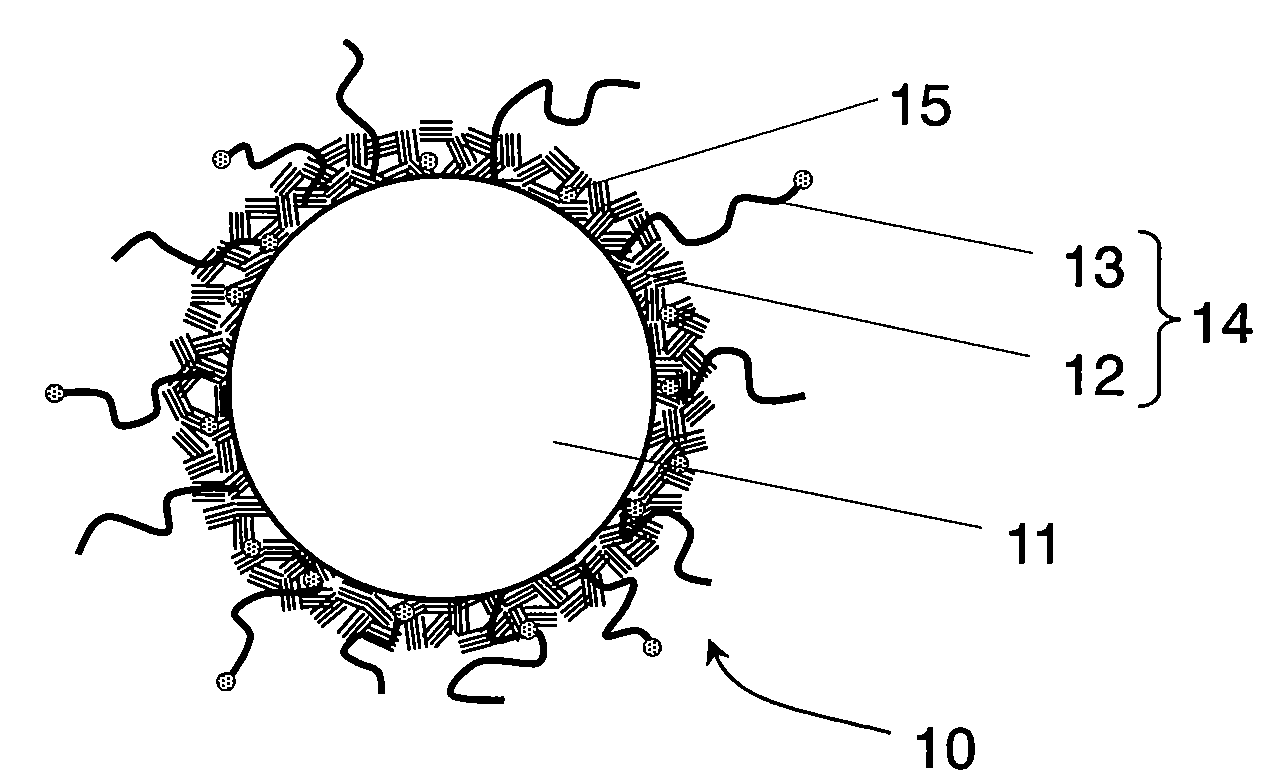

Lithium ion conductive composite electrolyte and lithium ion secondary battery using same

ActiveUS20130230778A1Improve cycle performancePrevent electrolyte leakageNon-aqueous electrolyte cellsSecondary cellsComposite electrolyteConductive polymer

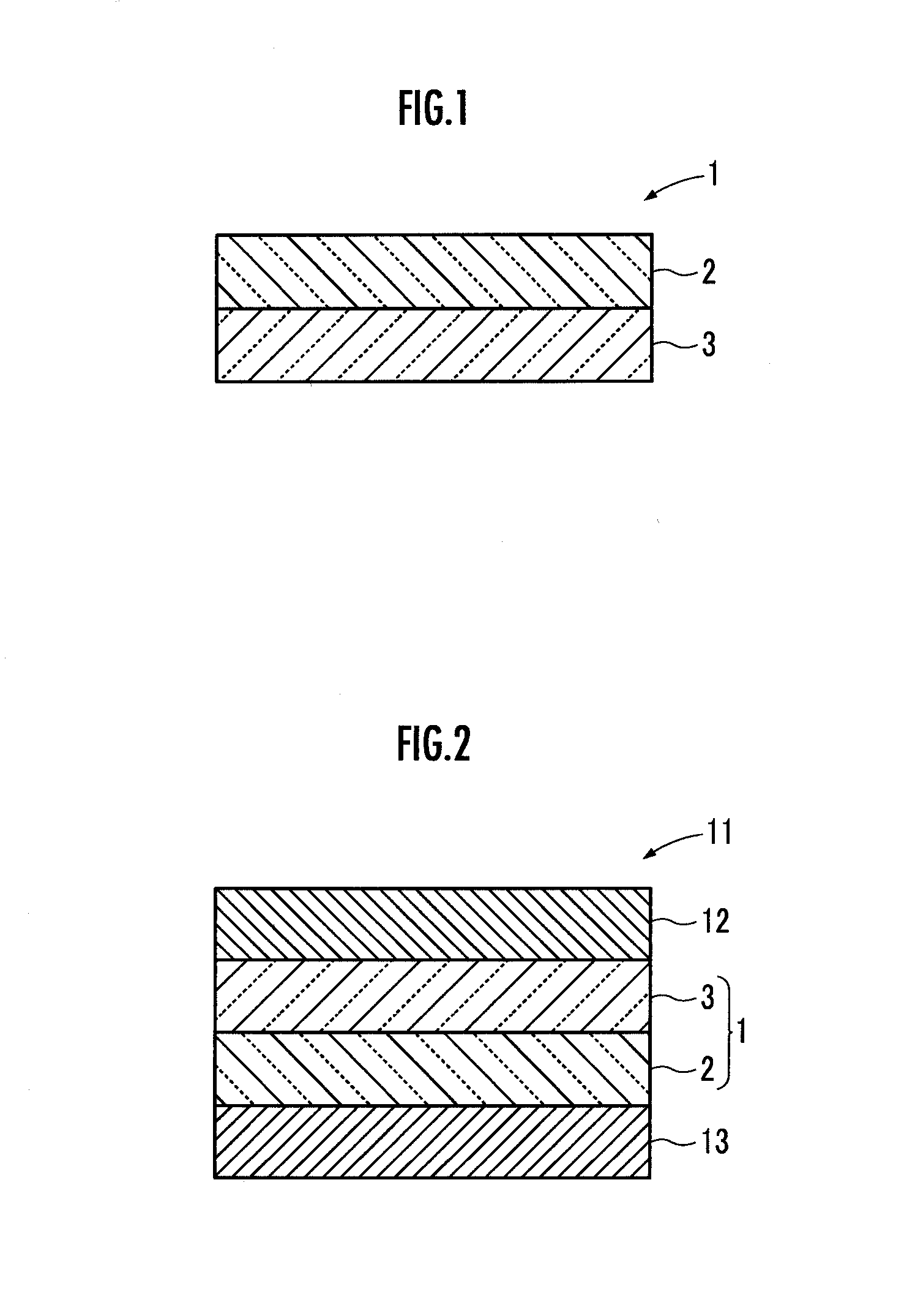

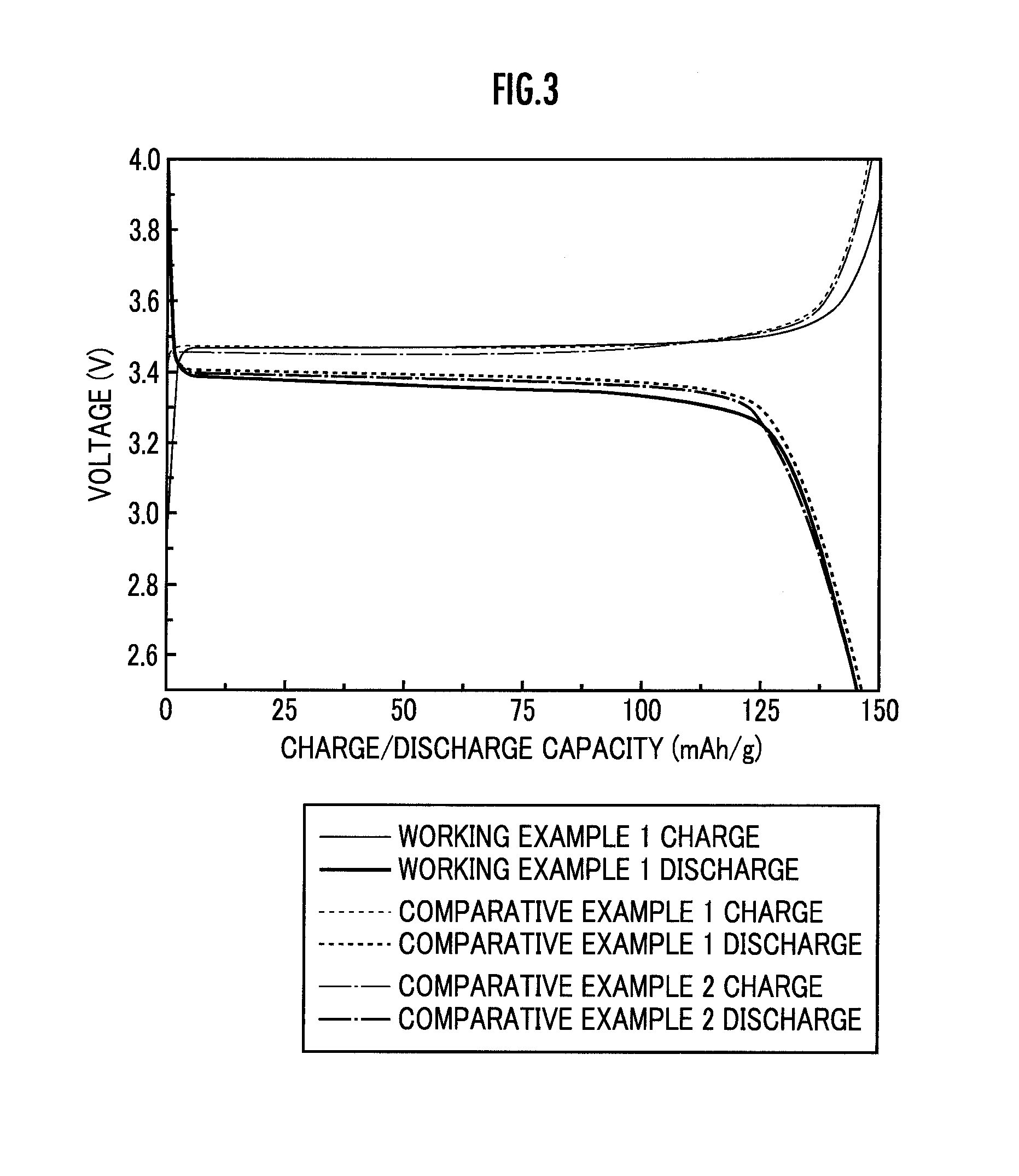

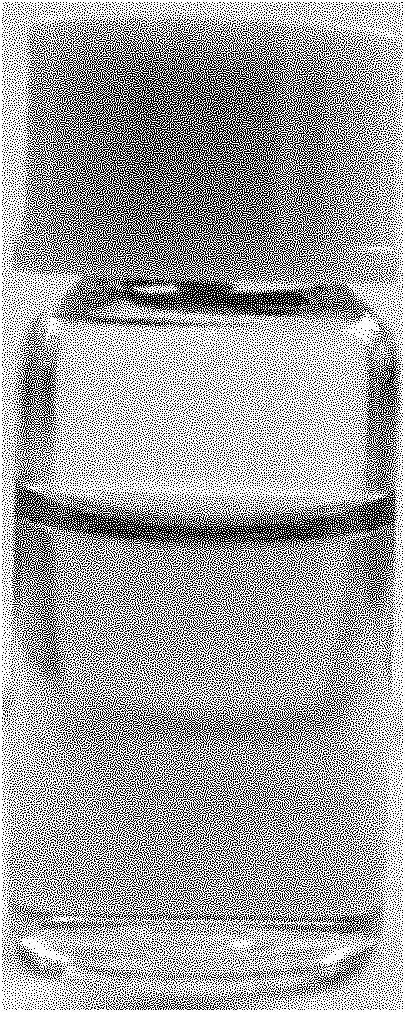

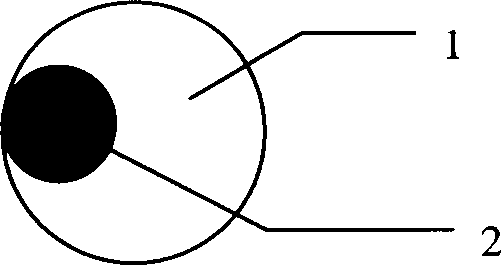

Provided is a lithium ion conductive composite electrolyte that can prevent leakage of electrolyte solution, and that have excellent cycle performance and lithium ion conductivity, and a lithium ion secondary battery. A lithium ion conductive composite electrolyte 1 is formed so that a lithium ion conductive polymer gel electrolyte is held in a porous body 2 formed from lithium ion conductive inorganic solid electrolyte particles and an organic polymer. The lithium ion conductive inorganic solid electrolyte particles are formed from a composite metal oxide that has a garnet structure, and is represented by the chemical formula Li7−yLa3−xAxZr2−yMyO12 (wherein 0≦x 3, 0≦y≦2, A is one of Y, Nd, Sm, and Gd, and M is Nb or Ta). A lithium ion secondary battery 11 includes the lithium ion conductive composite electrolyte 1 between a positive electrode 12 and a negative electrode 13.

Owner:HONDA MOTOR CO LTD

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

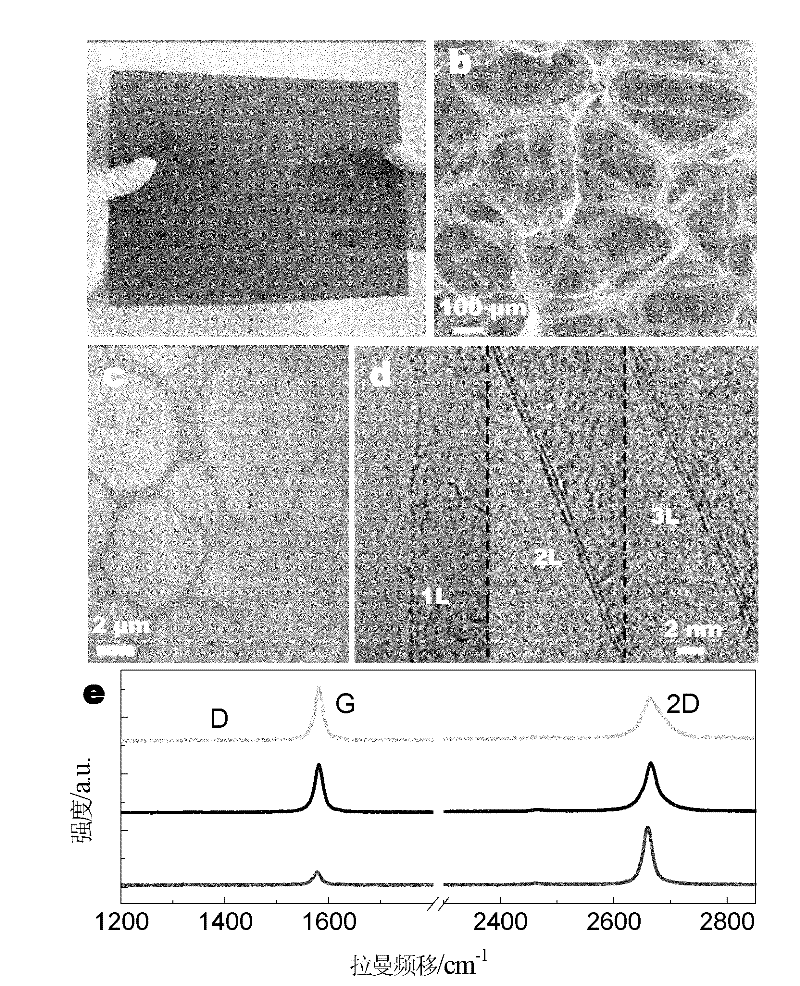

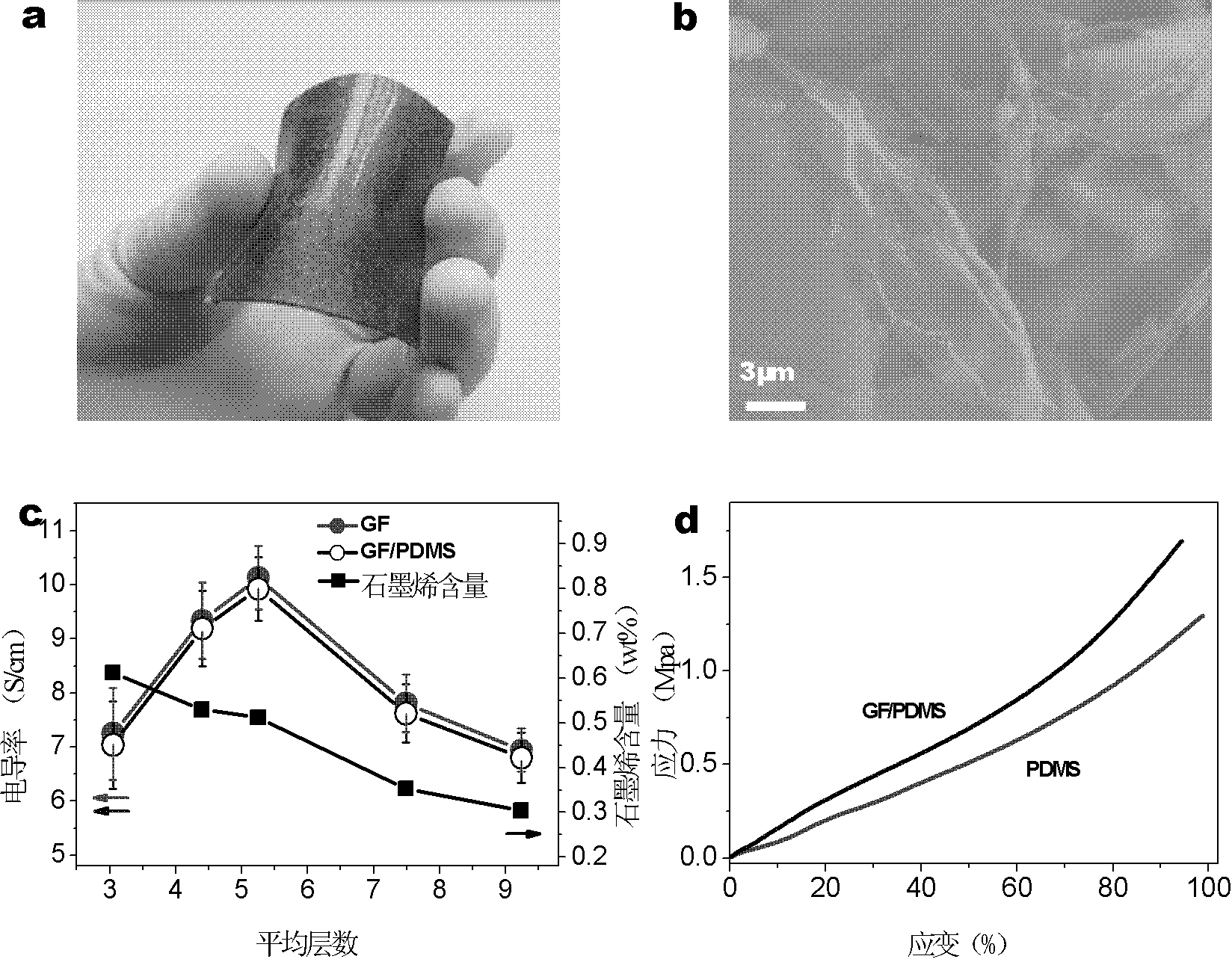

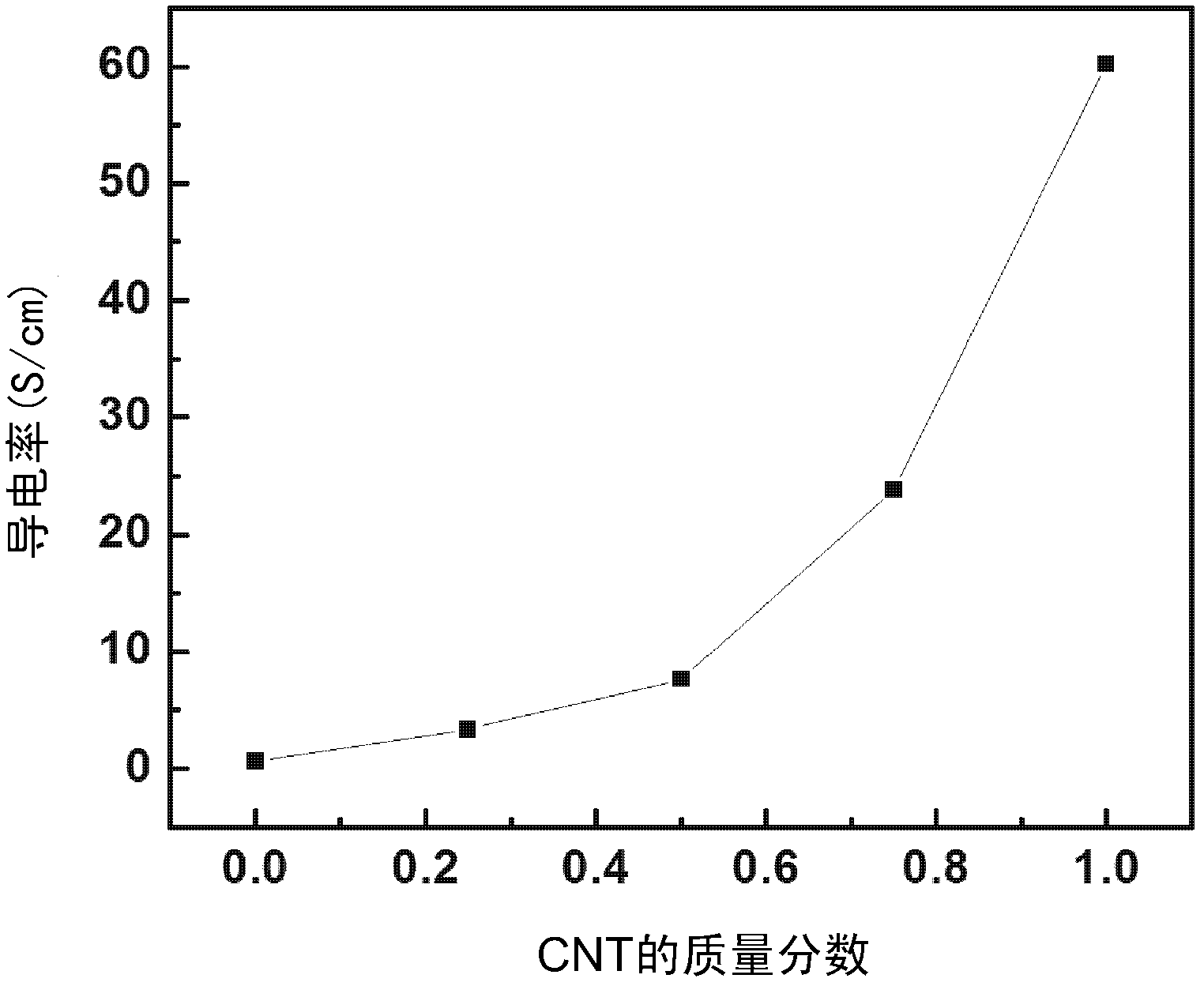

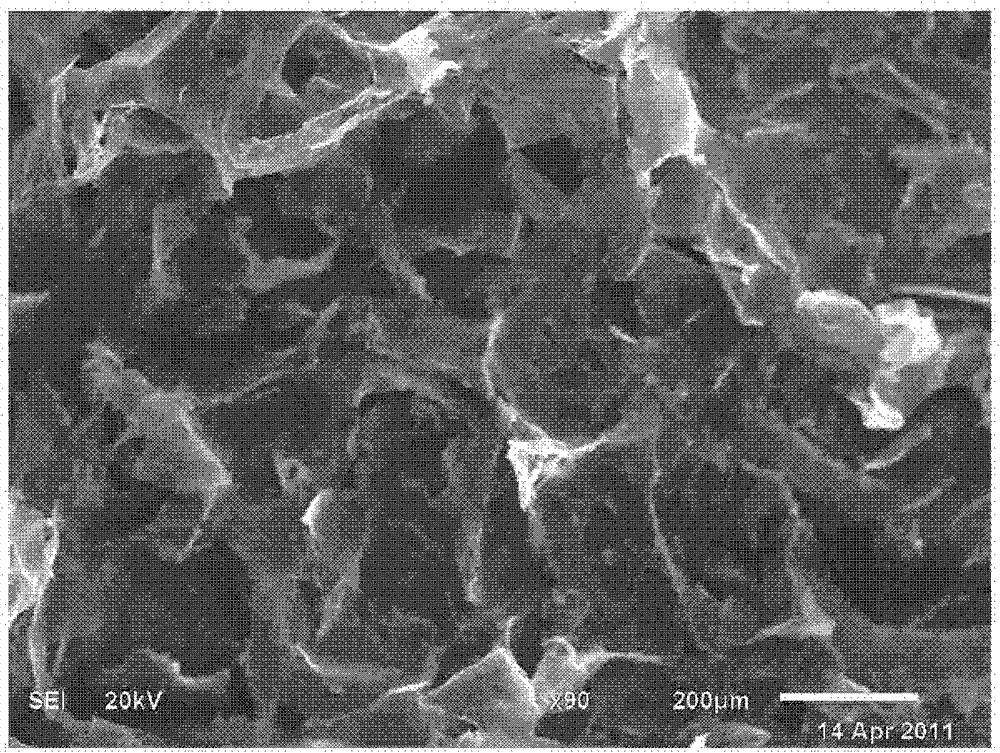

Graphene foam/polymer high-conductivity composite material preparation method and application thereof

ActiveCN102732037AImprove conductivityEasy to manufactureChemical vapor deposition coatingMaterials preparationGraphite

The invention relates to the graphene composite material field, and particularly to a graphene foam / polymer high-conductivity composite material, a preparation method and applications thereof. Steps of the method comprises as follows: providing a fully communicated three-dimension grapheme foam network and a precursor solution of a high-molecular polymer; mixing the graphene foam with the precursor solution of the high-molecular polymer to form a graphene foam / high-molecule polymer precursor mixture; and solidifying the precursor of the high-molecular polymer in the mixture to form a high-conductivity graphene foam composite material. The invention adopts the three-dimension graphene foam to form a fully- communicated graphite rapid transmission network by a seamless connection, which enables the graphene foam composite material to possess great conductivity and mechanical property and can be widely applied to the conductive composite materials and elasticity conductor field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A thermoplastic polymer-based thermally conductive composite material and its preparation method

InactiveCN102286207AImprove thermal conductivityHeat-exchange elementsPolymer scienceVolumetric Mass Density

The invention discloses a thermoplastic polymer-based heat-conducting composite material, which belongs to the technical field of polymer materials. The thermoplastic polymer-based thermally conductive composite material provided by the present invention has a higher thermal conductivity when adding less thermally conductive filler; the thermally conductive composite material includes a thermoplastic polymer matrix and a thermally conductive filler, and also includes compatible polymers. The present invention introduces a polymer that is incompatible with the polymer matrix into the composite system, so that the thermally conductive filler is selectively distributed in one of the phases, thereby significantly increasing the packing density of the thermally conductive filler in the polymer component of this phase, thereby improving the The overall thermal conductivity of the material; when the ratio of the two is 50 / 50, the thermal conductivity of the material can reach the thermal conductivity when the amount of thermal conductive filler is doubled.

Owner:SICHUAN UNIV

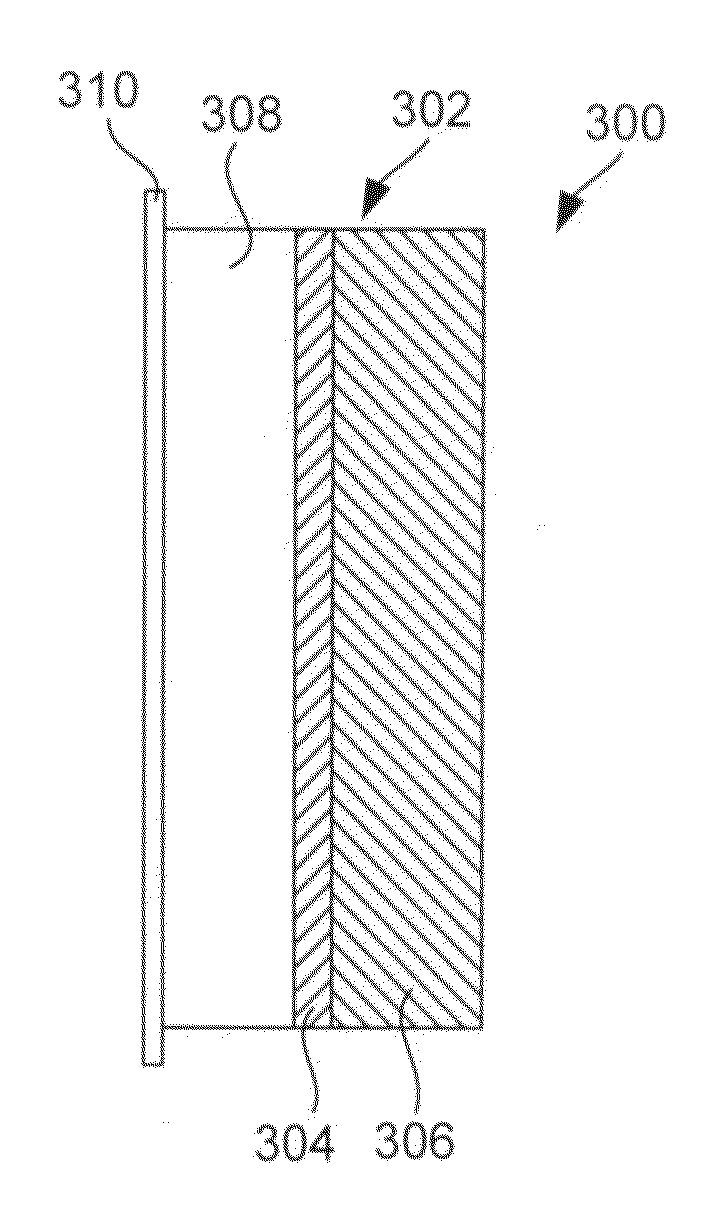

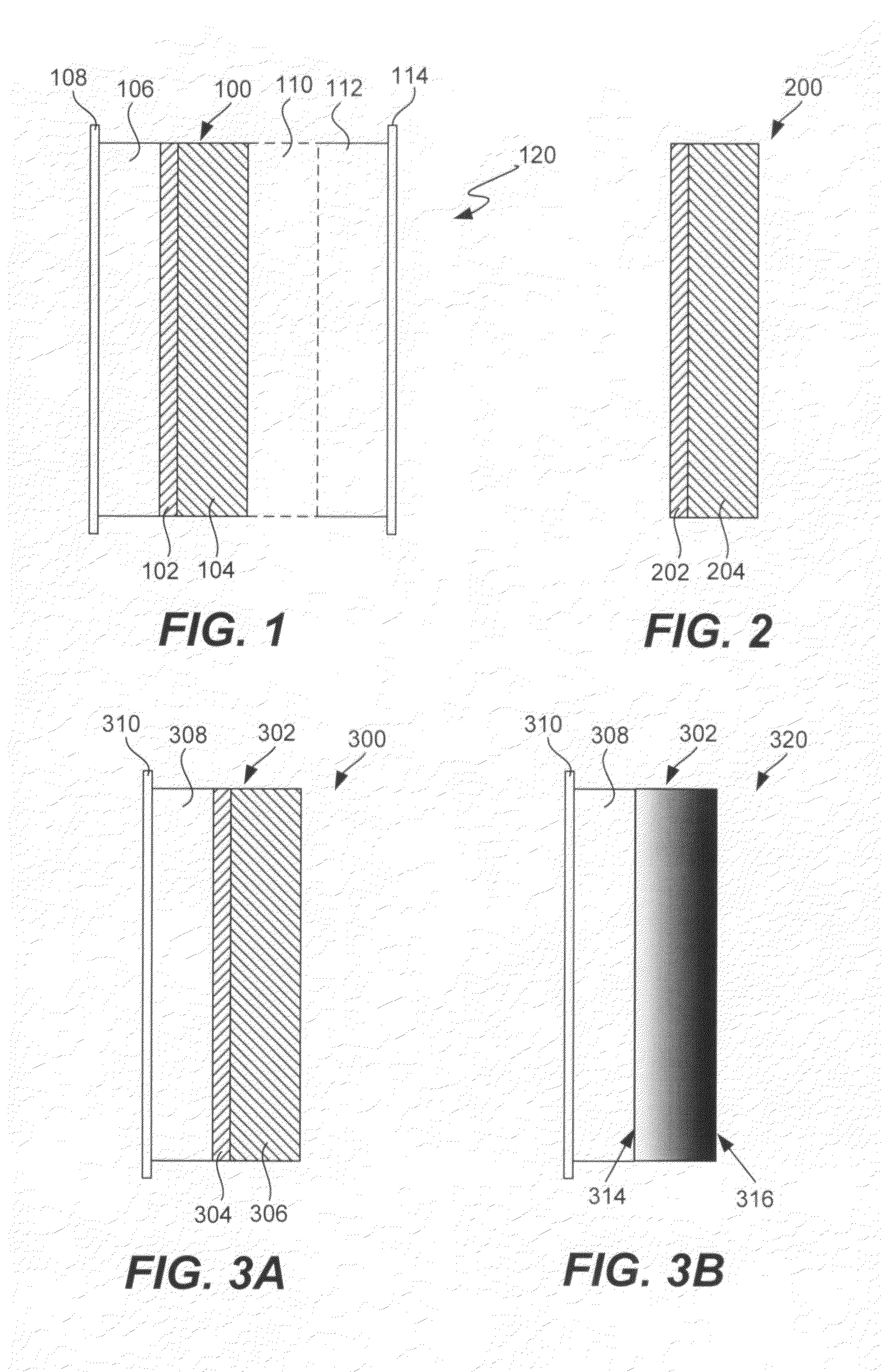

Electrochemical device component with protected alkali metal electrode

InactiveUS7858223B2Easy to manufactureImprove battery performanceSolid electrolytesCell seperators/membranes/diaphragms/spacersElectrochemistryChemical stability

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

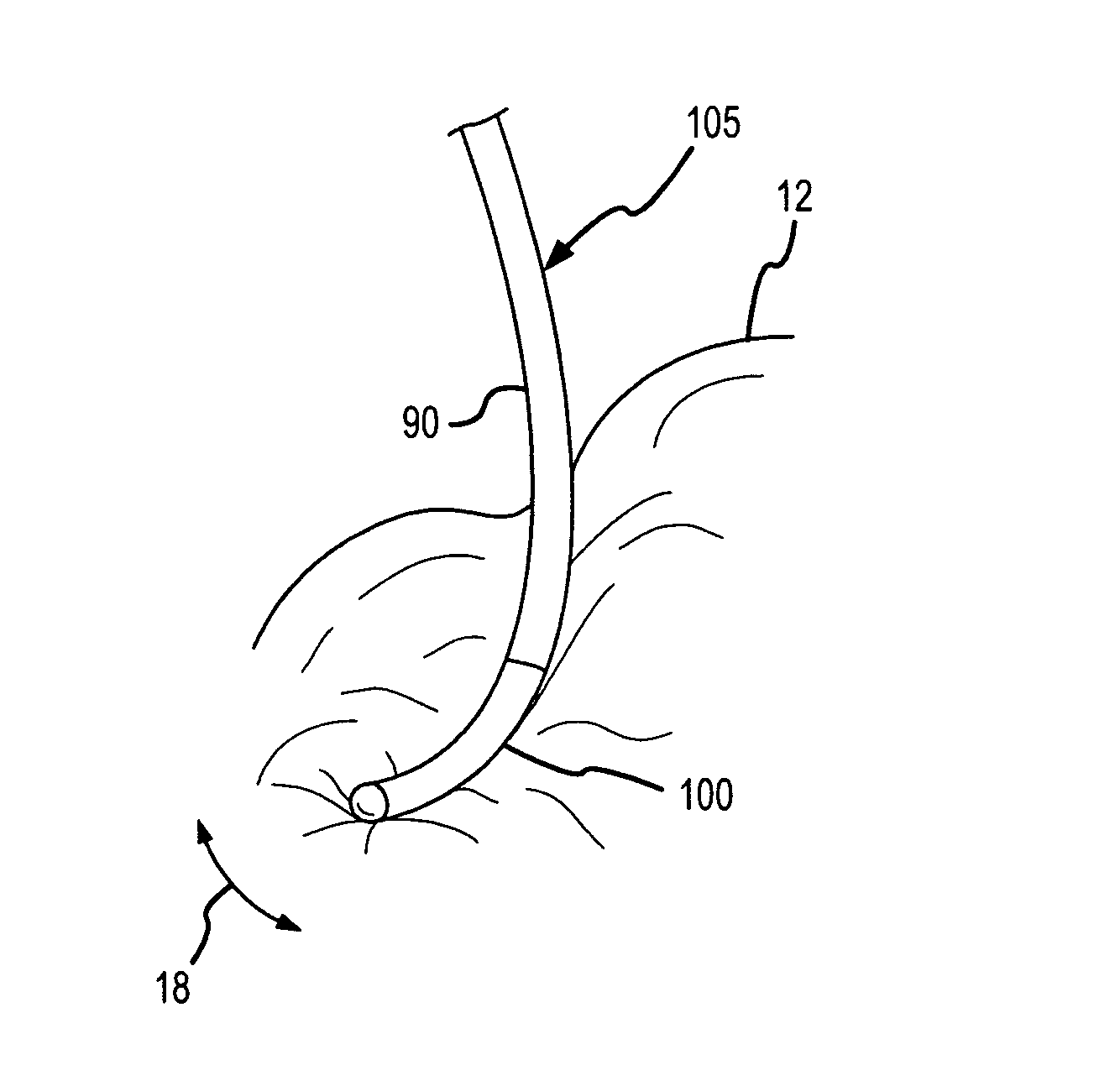

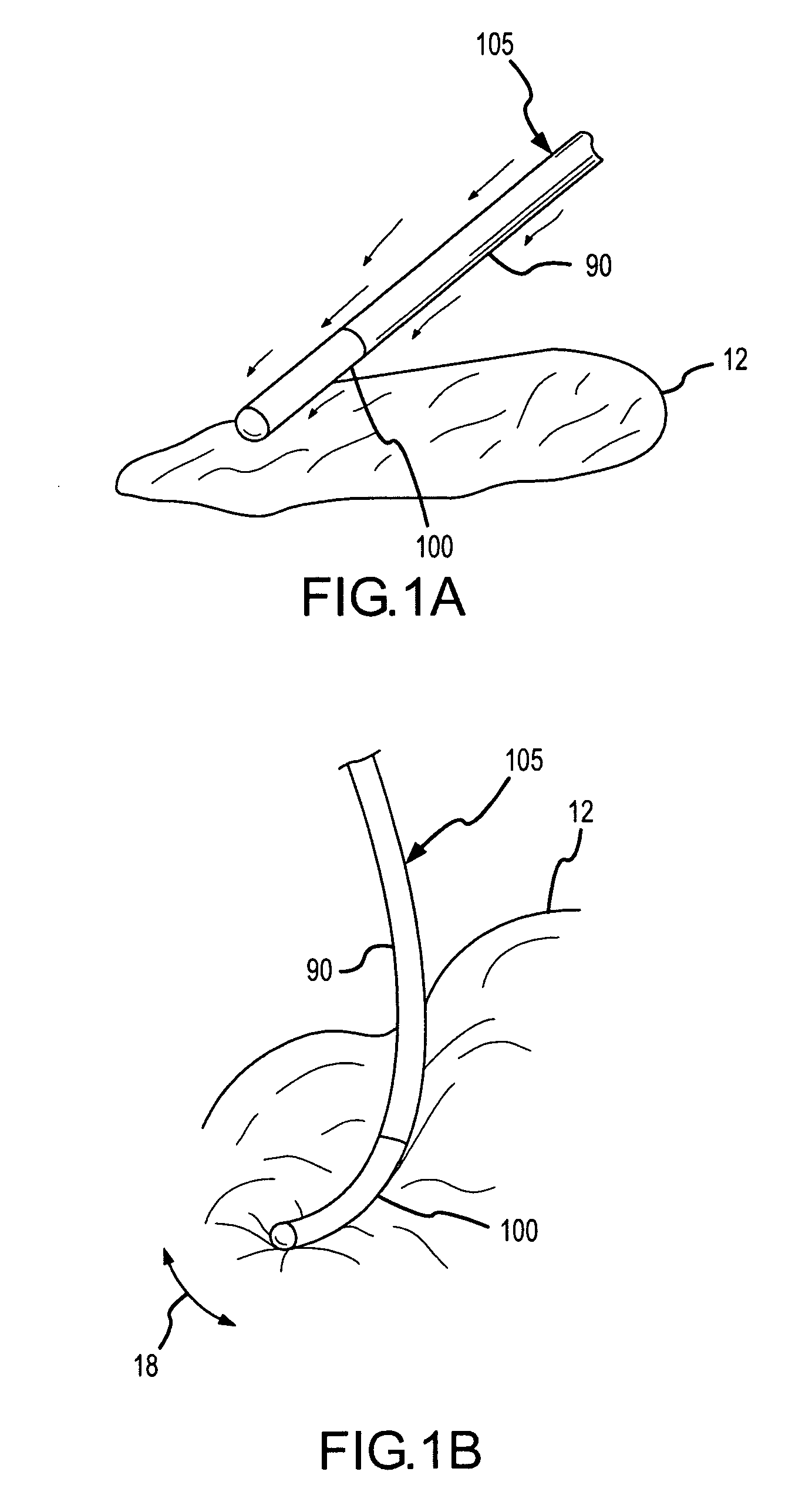

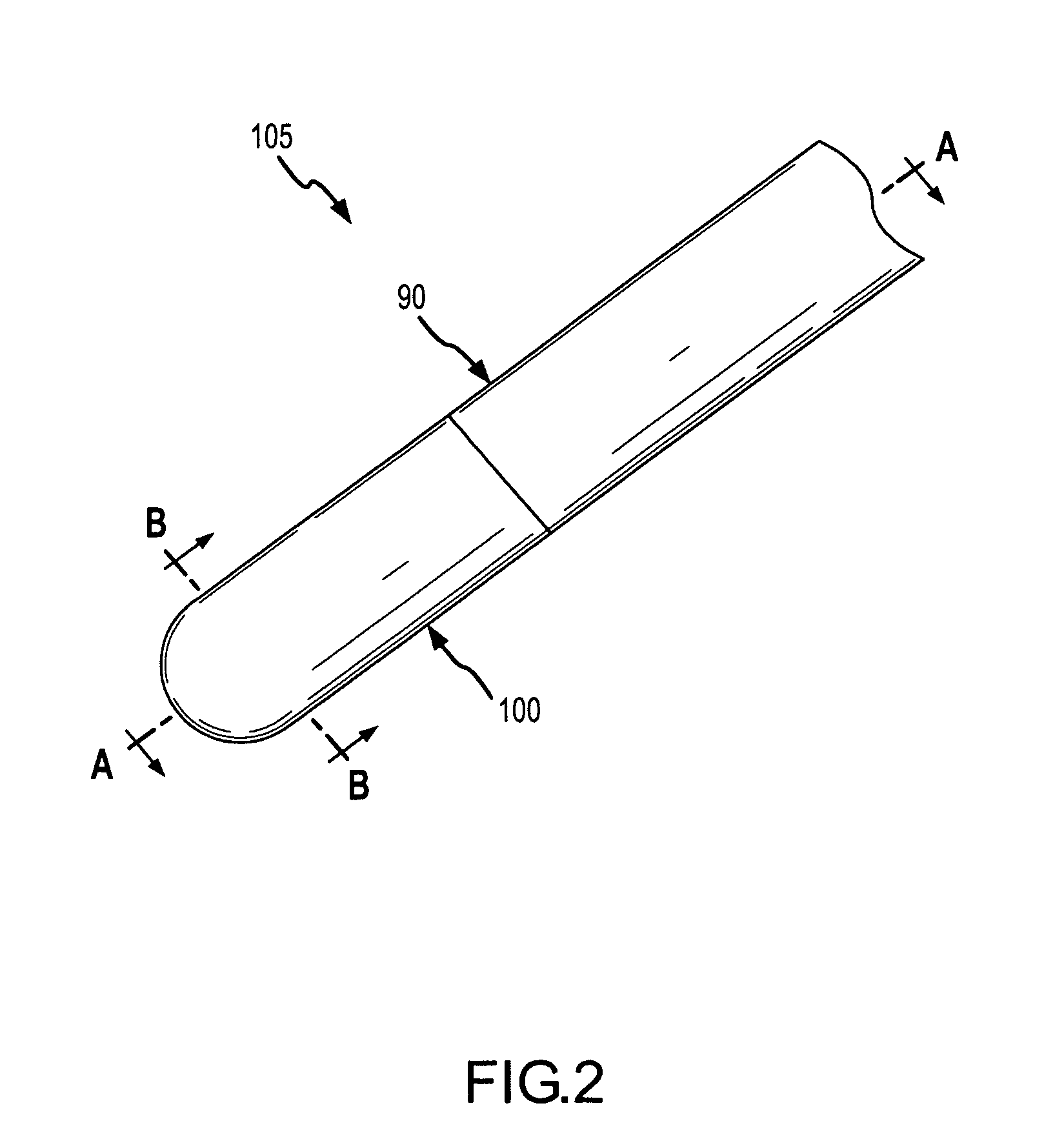

Contact-sensitive pressure-sensitive conductive composite electrode and method for ablation

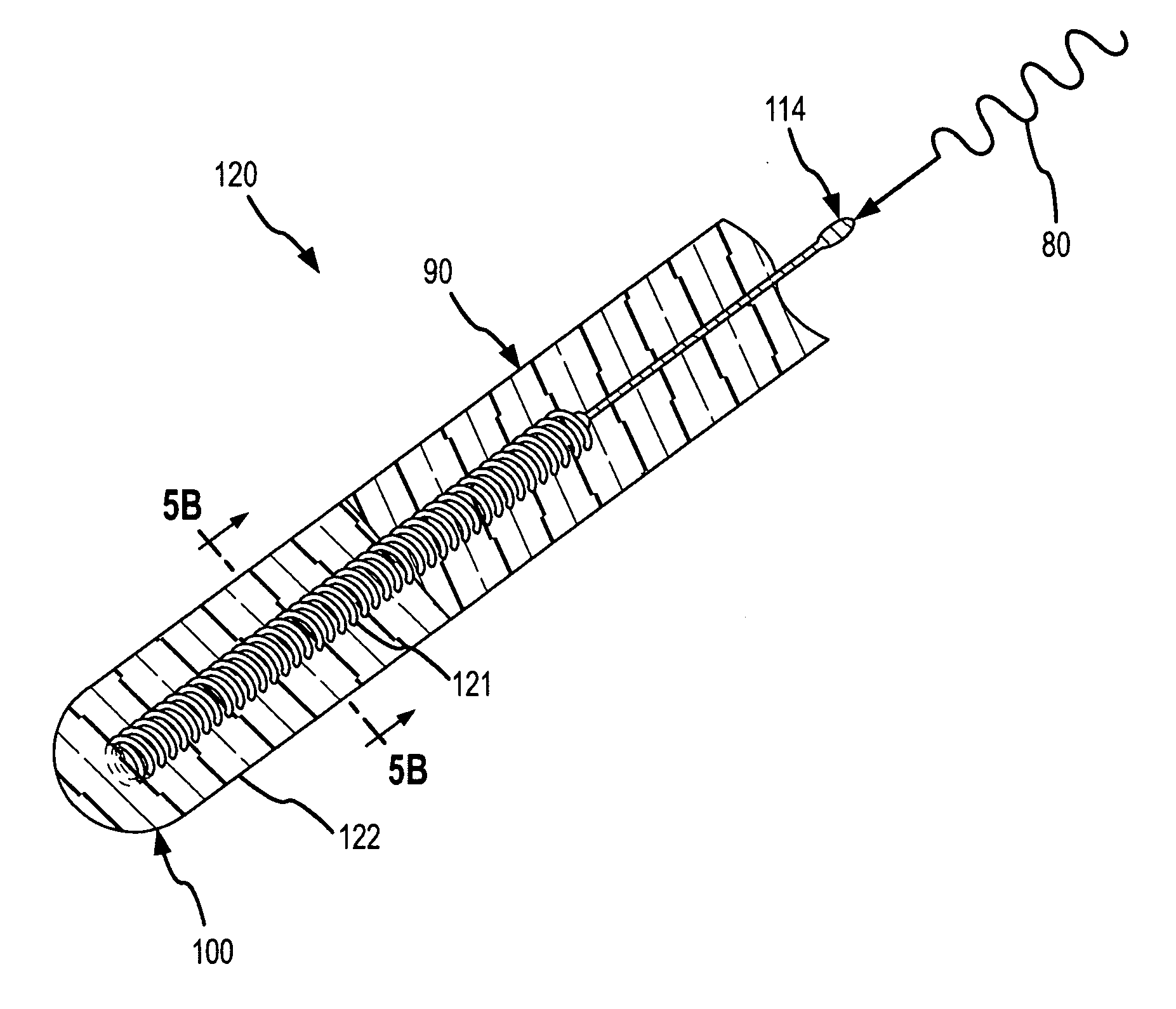

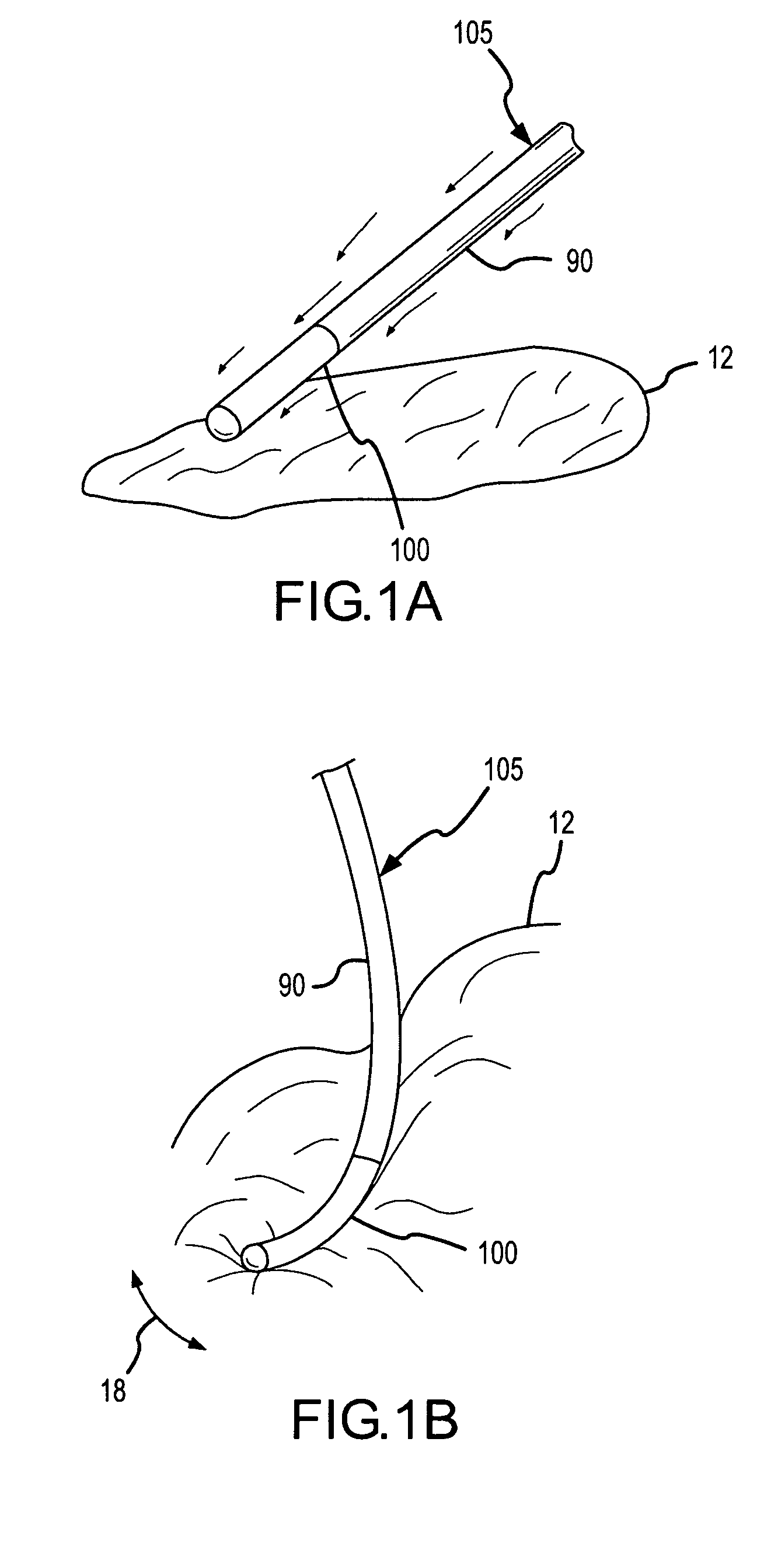

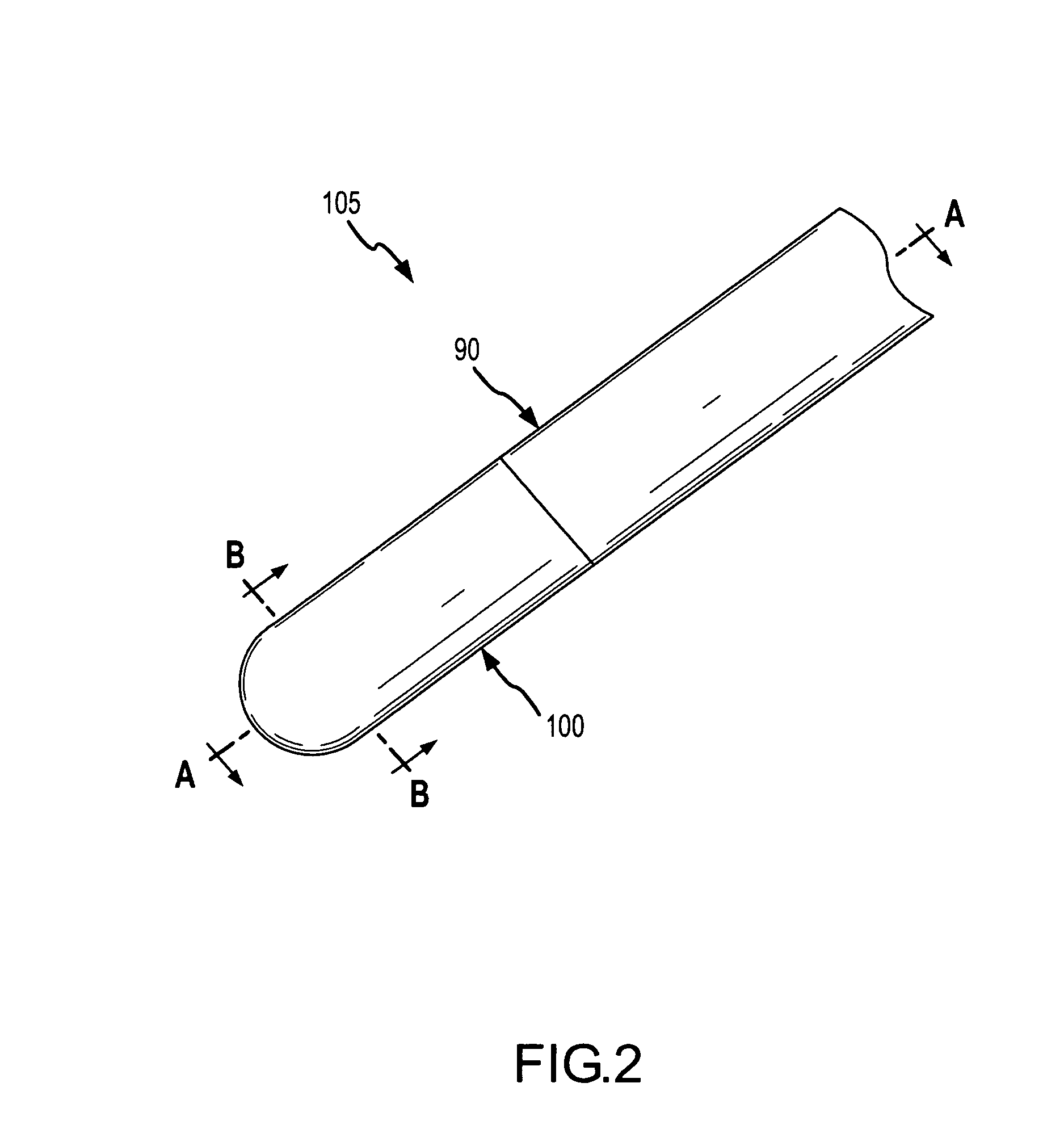

InactiveUS20080161789A1Reduce arcingReduce manufacturing costDiagnosticsCatheterBiomedical engineeringCatheter device

A catheter assembly for pressure-sensitive control of ablation treatment is disclosed. The assembly includes a conductive element, an electrode, and a pressure sensitive conductive composite member positioned between the conductive element and the electrode. At least one of the conductive pin, the pressure sensitive conductive composite element and the ablation electrode are moveable to create an engagement position and a non-engagement position. In the engagement position, the elements are electrically coupled such that ablation energy may be delivered from the conductive pin to the ablation electrode via the pressure sensitive conductive composite element. In the non-engagement position, the elements are electrically decoupled such that ablation energy is not delivered to the ablation electrode. A related method for pressure-sensitive control of ablation is also disclosed.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

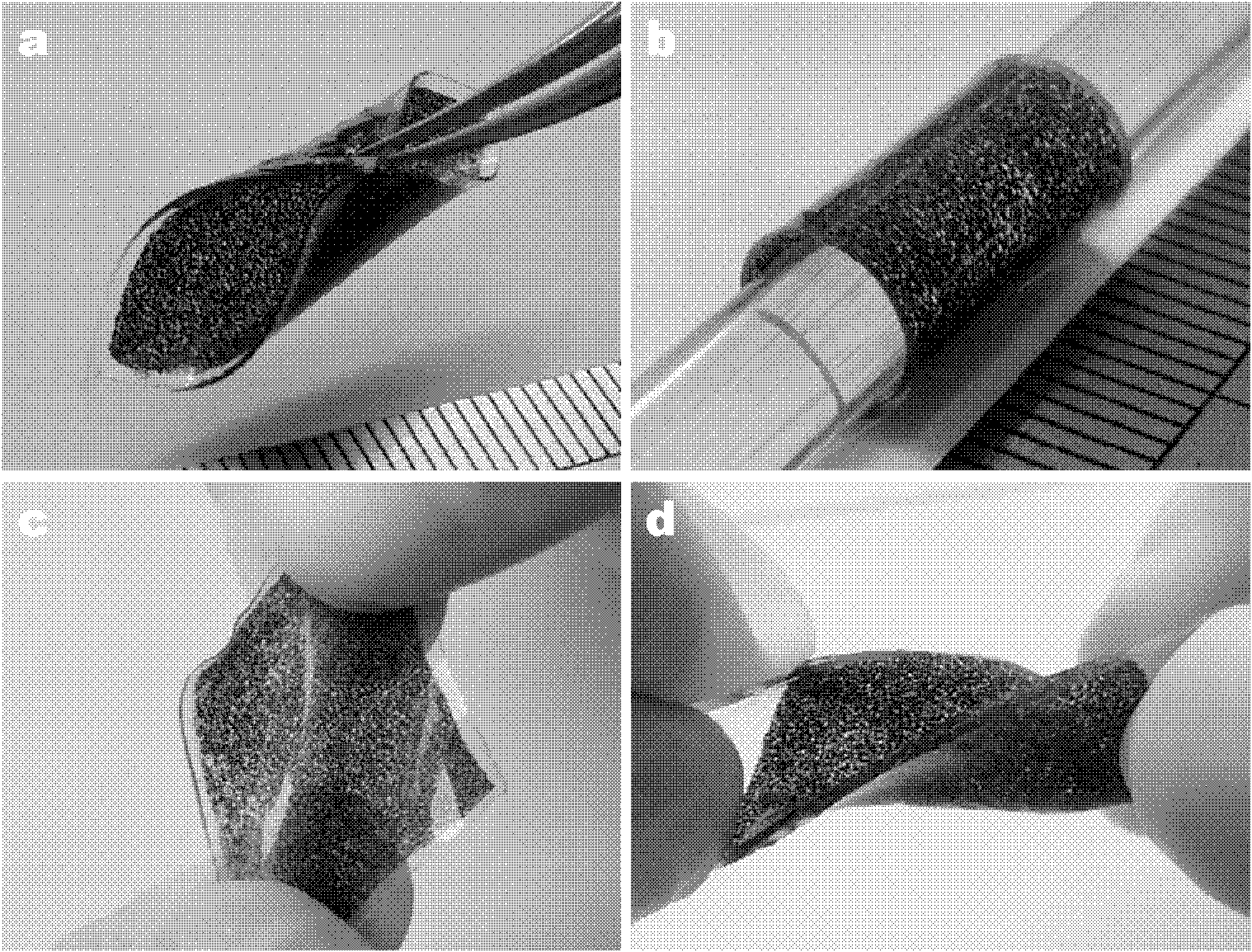

Flexible conductive thin film compositing two-dimensional graphene and one-dimensional nanowire and preparation method thereof

ActiveCN103219066AHigh strengthImprove flexibilityConductive layers on insulating-supportsCarbon-silicon compound conductorsComposite filmNanowire

The invention relates to a flexible conductive thin film compositing a two-dimensional graphene and a one-dimensional nanowire and a preparation method of the flexible conductive thin film. The preparation method includes the following steps: dispersing the graphene, the nanowire and dispersion auxiliary in solvent, obtaining graphene / nanowire solvent which is well dispersed after the solvent is processed through ultrasound concussion, and obtaining a graphene / nanowire composite thin film after the graphene / nanowire solvent is processed through vacuum filtration and drying. The thickness of the composite thin film is 10 nanometers to 1000 micrometers, the composite thin film has good strength and flexibility, square resistance is between 0.001 ohm per square and 3000 ohms per square, and electrical conductivity is between 0.01 siemens per centimeter to 5000 siemens per centimeter. The graphene / nanowire composite thin film which is obtained with the adoption of the preparation method has good strength, flexibility, and electrical conductivity, and is controllable in thickness, cuttable in shape, simple in preparing process, easy to operate, low in manufacturing cost, and suitable for solar batteries, energy storage, heat dissipation, catalysis, sensing, and conductive composite material fields.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ionically conductive composites for protection of active metal anodes

InactiveUS20080057399A1Easy to manufactureImprove battery performanceFinal product manufactureCell electrodesChemical stabilityIonic conductivity

Disclosed are ionically conductive composites for protection of active metal anodes and methods for their fabrication. The composites may be incorporated in active metal negative electrode (anode) structures and battery cells. In accordance with the invention, the properties of different ionic conductors are combined in a composite material that has the desired properties of high overall ionic conductivity and chemical stability towards the anode, the cathode and ambient conditions encountered in battery manufacturing. The composite is capable of protecting an active metal anode from deleterious reaction with other battery components or ambient conditions while providing a high level of ionic conductivity to facilitate manufacture and / or enhance performance of a battery cell in which the composite is incorporated.

Owner:POLYPLUS BATTERY CO INC

Contact sensors and methods for making same

InactiveUS20060184067A1SurgeryForce measurementElectrical resistance and conductanceArtificial joints

The present invention is directed to novel contact sensors. The contact sensors of the invention include a conductive composite material formed of a polymer and a conductive filler. In one particular embodiment, the composite materials can include less than about 10 wt % conductive filler. Thus, the composite material of the contact sensors can have physical characteristics essentially identical to the polymer, while being electrically conductive with the electrical resistance proportional to the load on the sensor. If desired, the sensors can be formed of the same polymeric material as the bearing that is being examined. The sensors can provide real time dynamic contact information for joint members under conditions expected during use. In one particular embodiment, the sensors can be used to examine dynamic wear characteristics of artificial joint bearings such as artificial knee, hip, or shoulder bearings.

Owner:CLEMSON UNIV RES FOUND

Pressure-sensitive conductive composite electrode and method for ablation

InactiveUS7955326B2Energy concentrationReduce arcingDiagnosticsSurgical instruments for heatingConductive polymerQuantum tunnelling composite

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

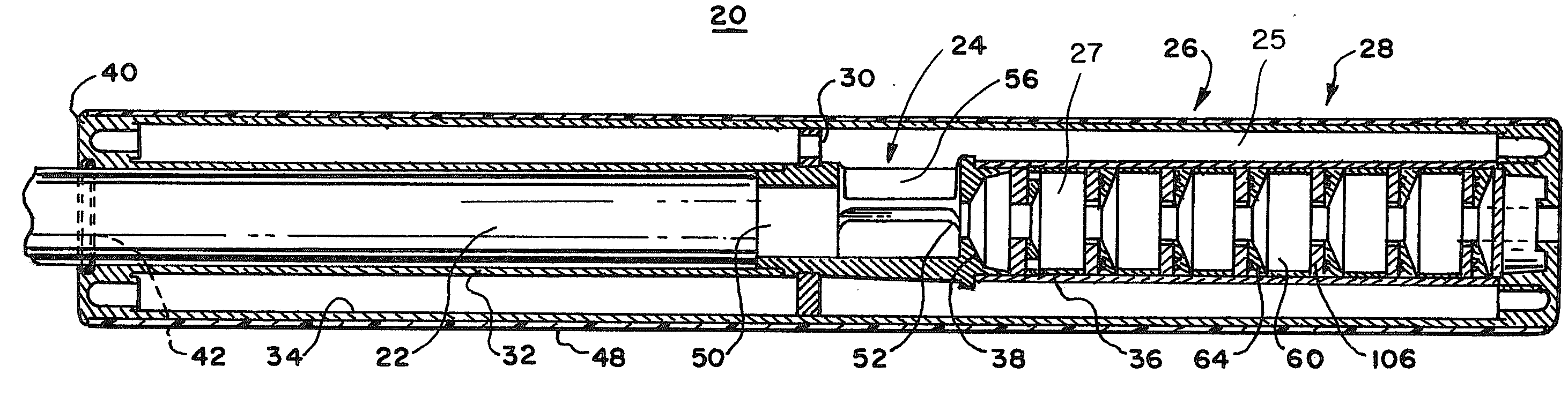

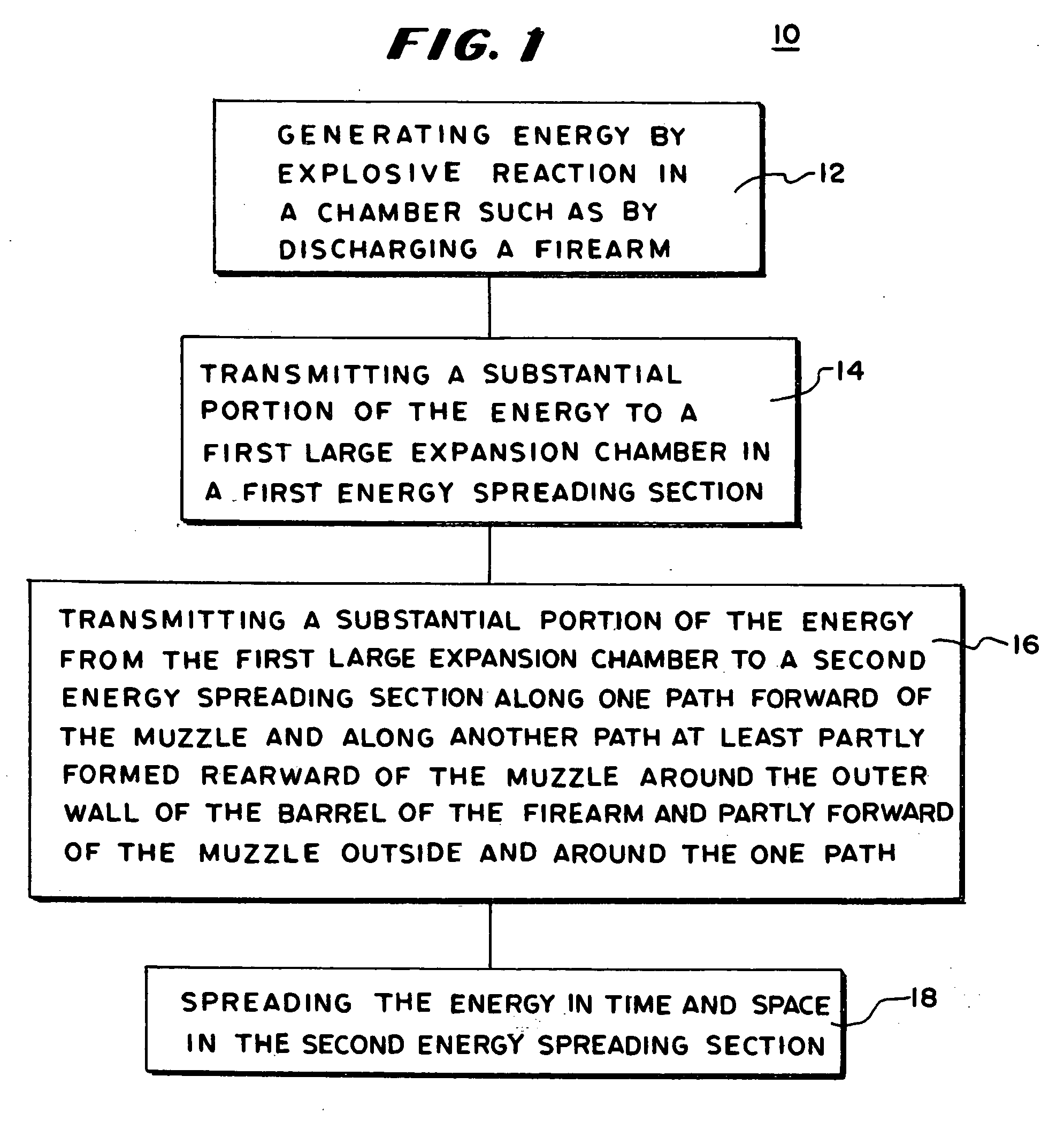

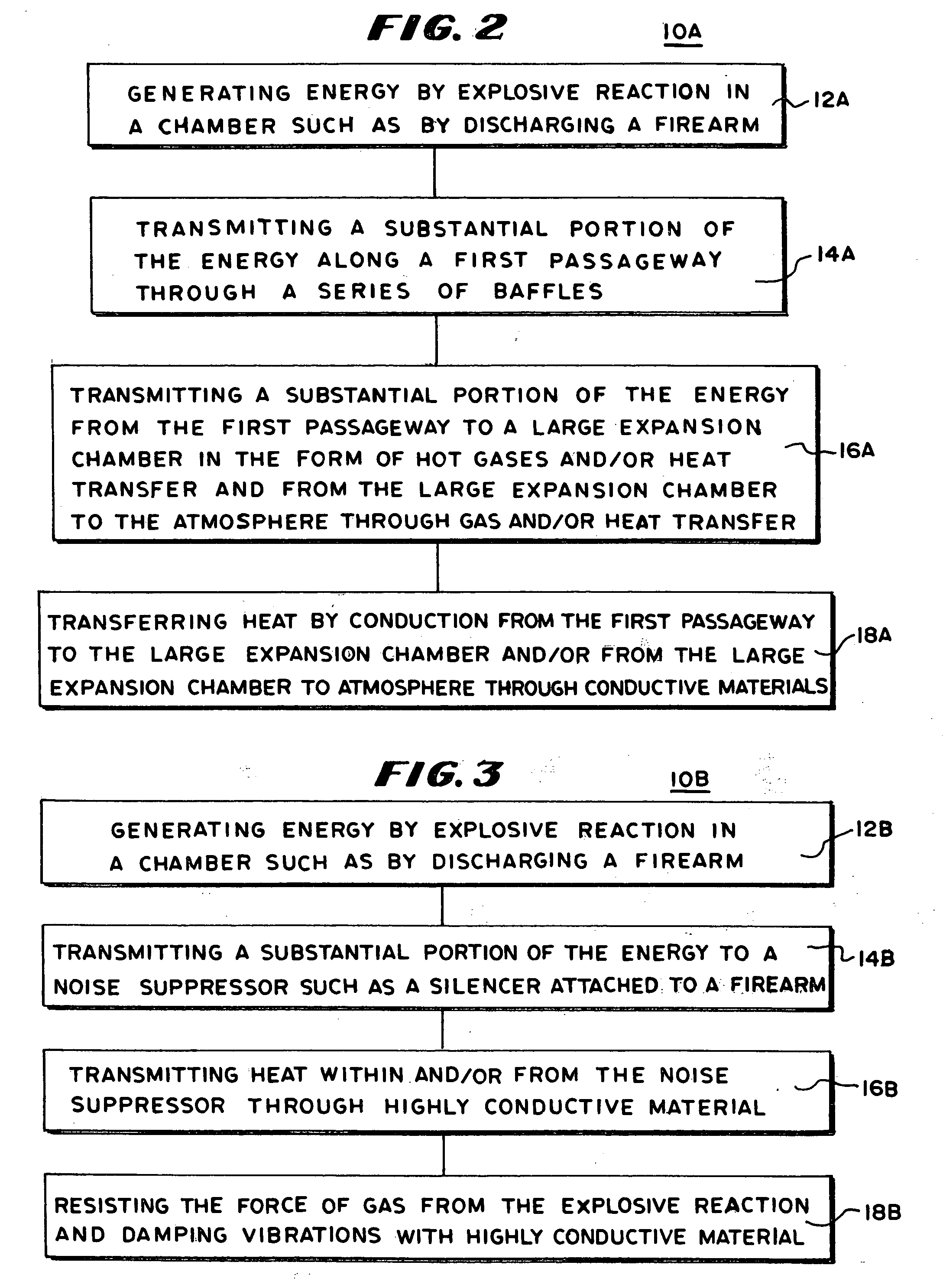

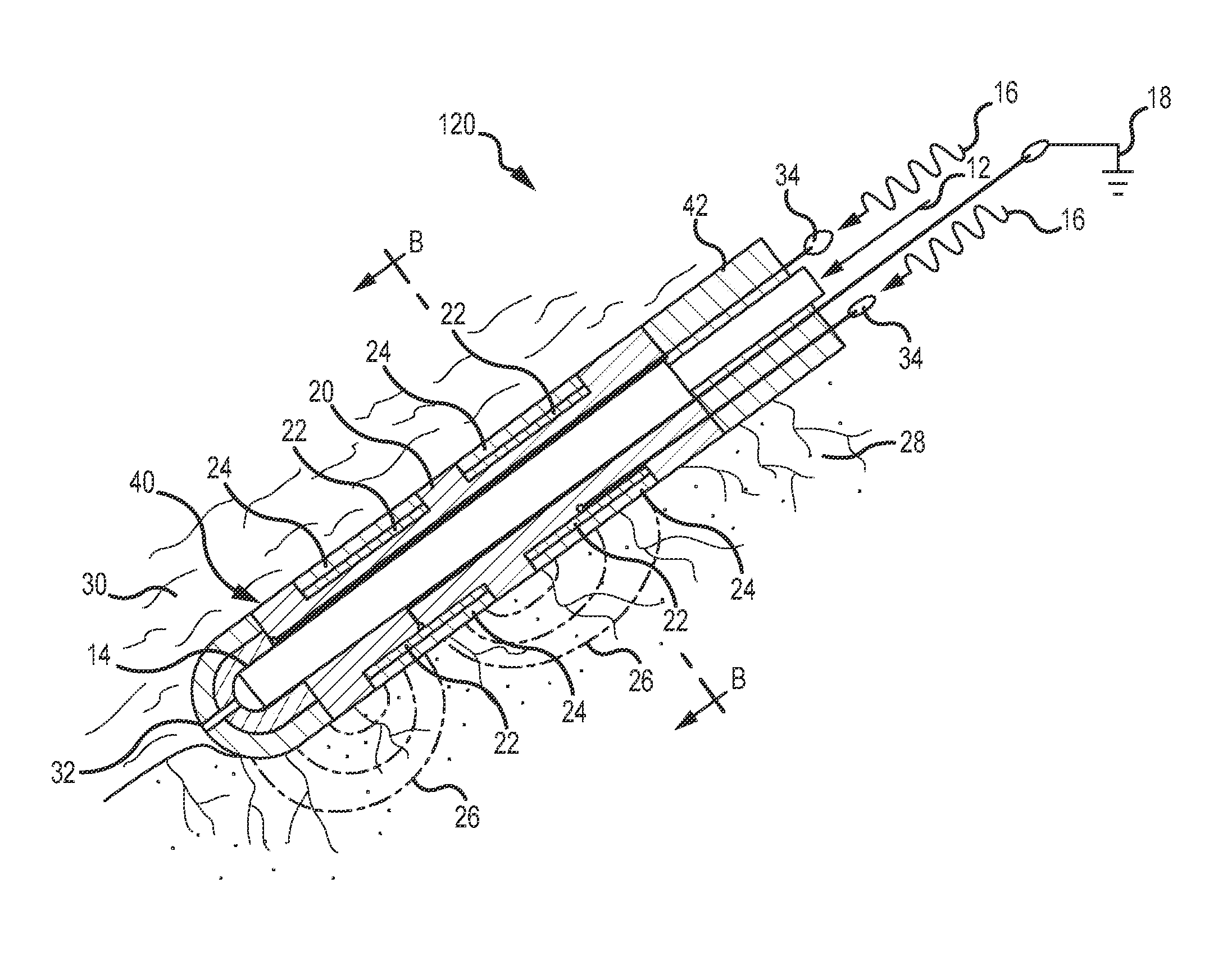

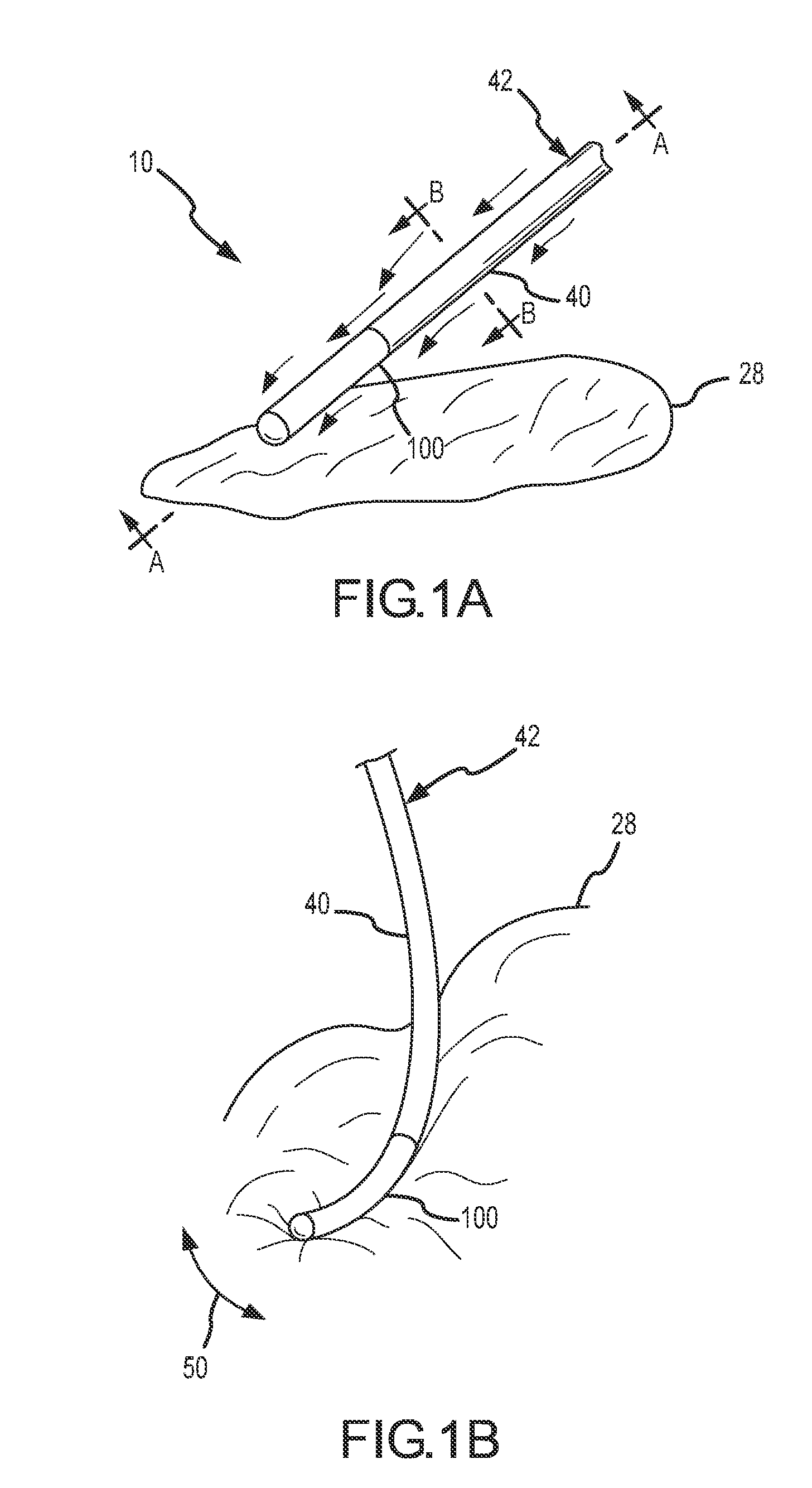

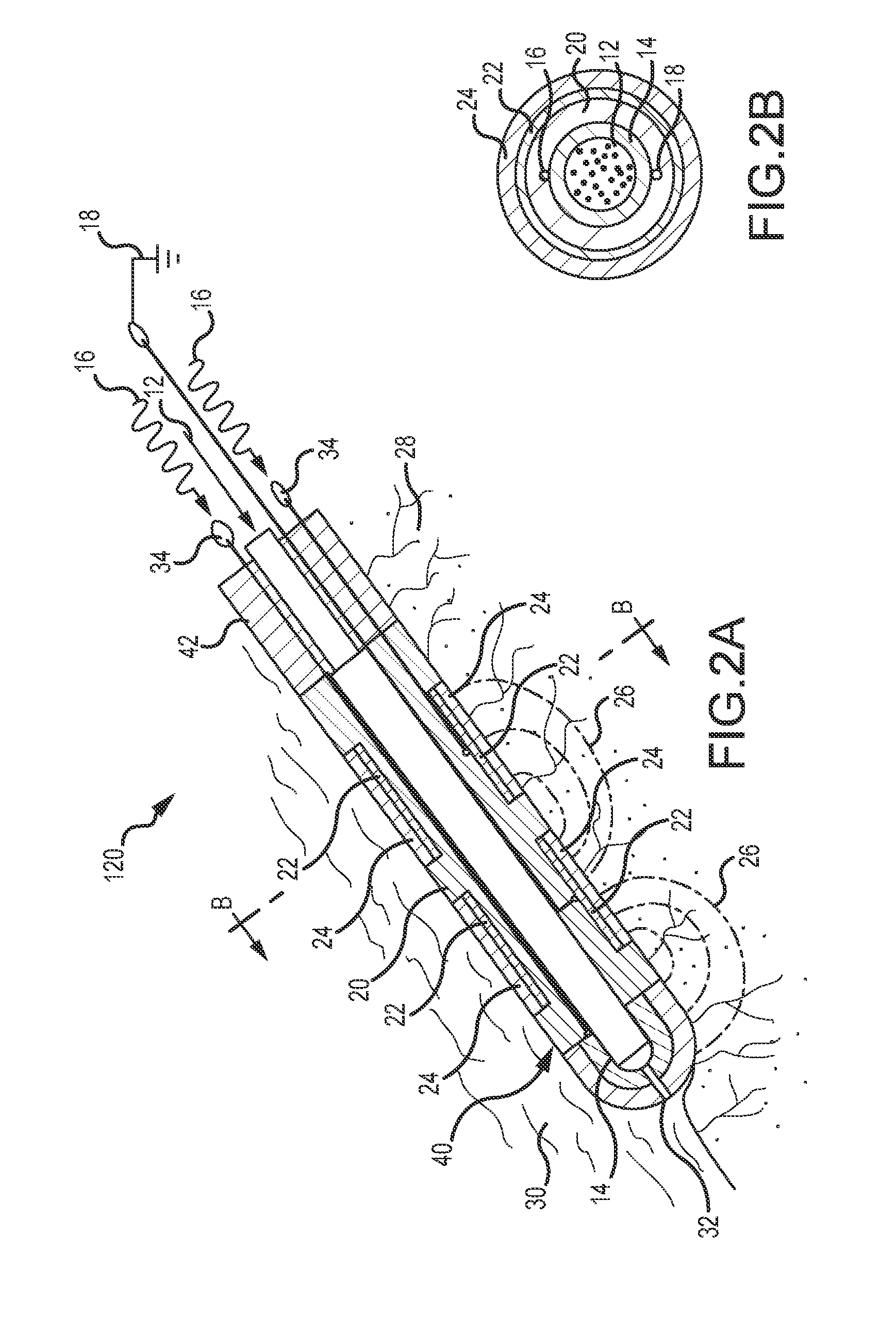

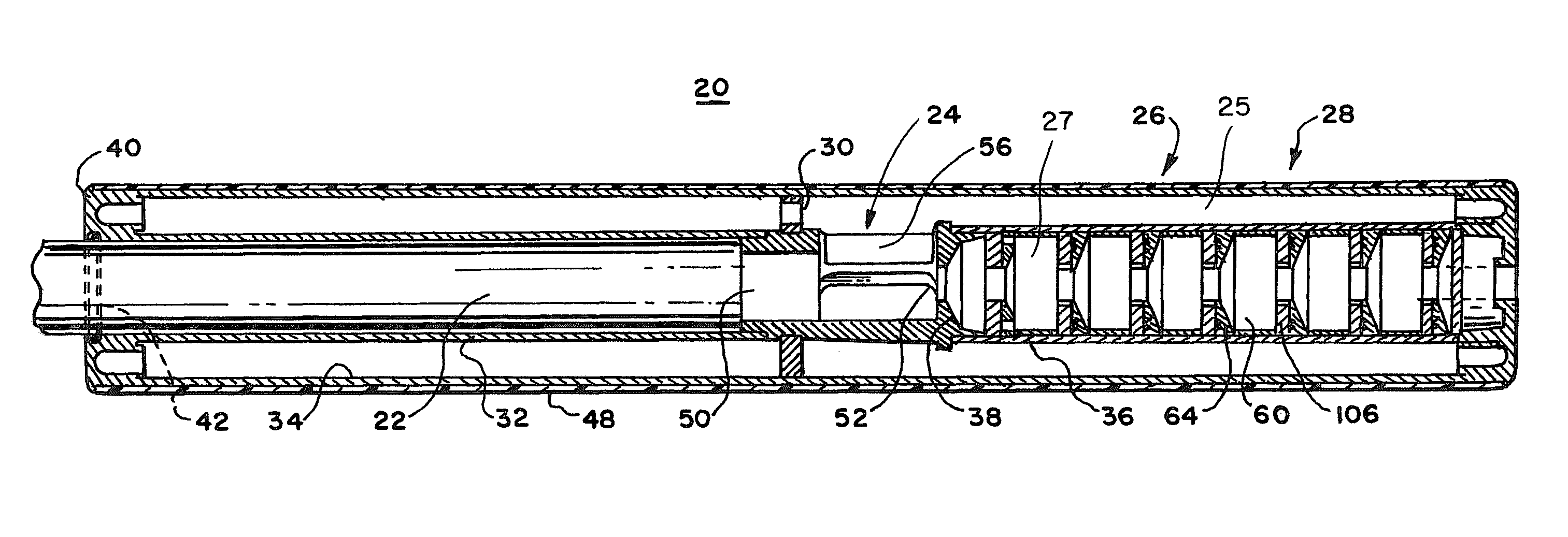

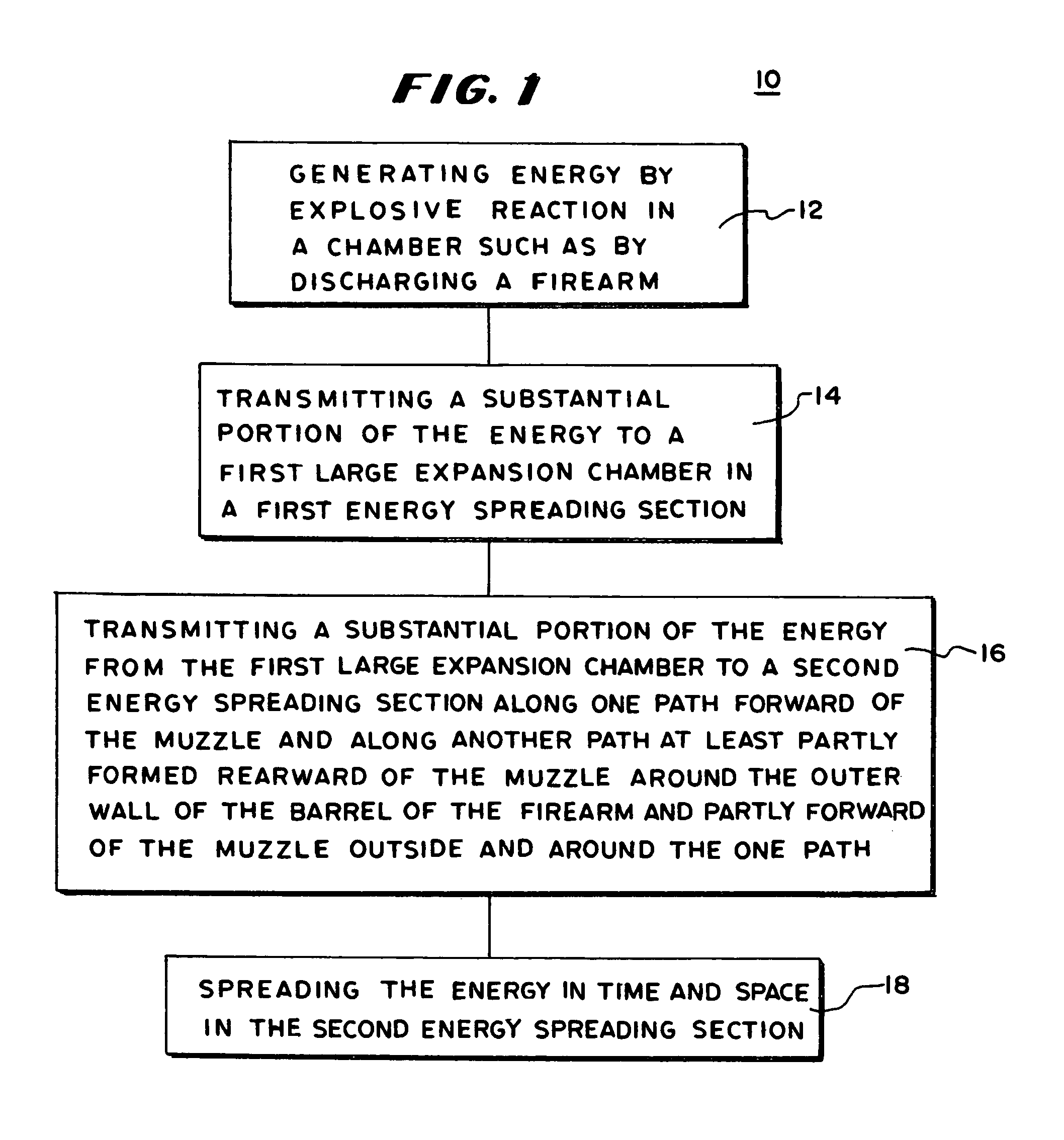

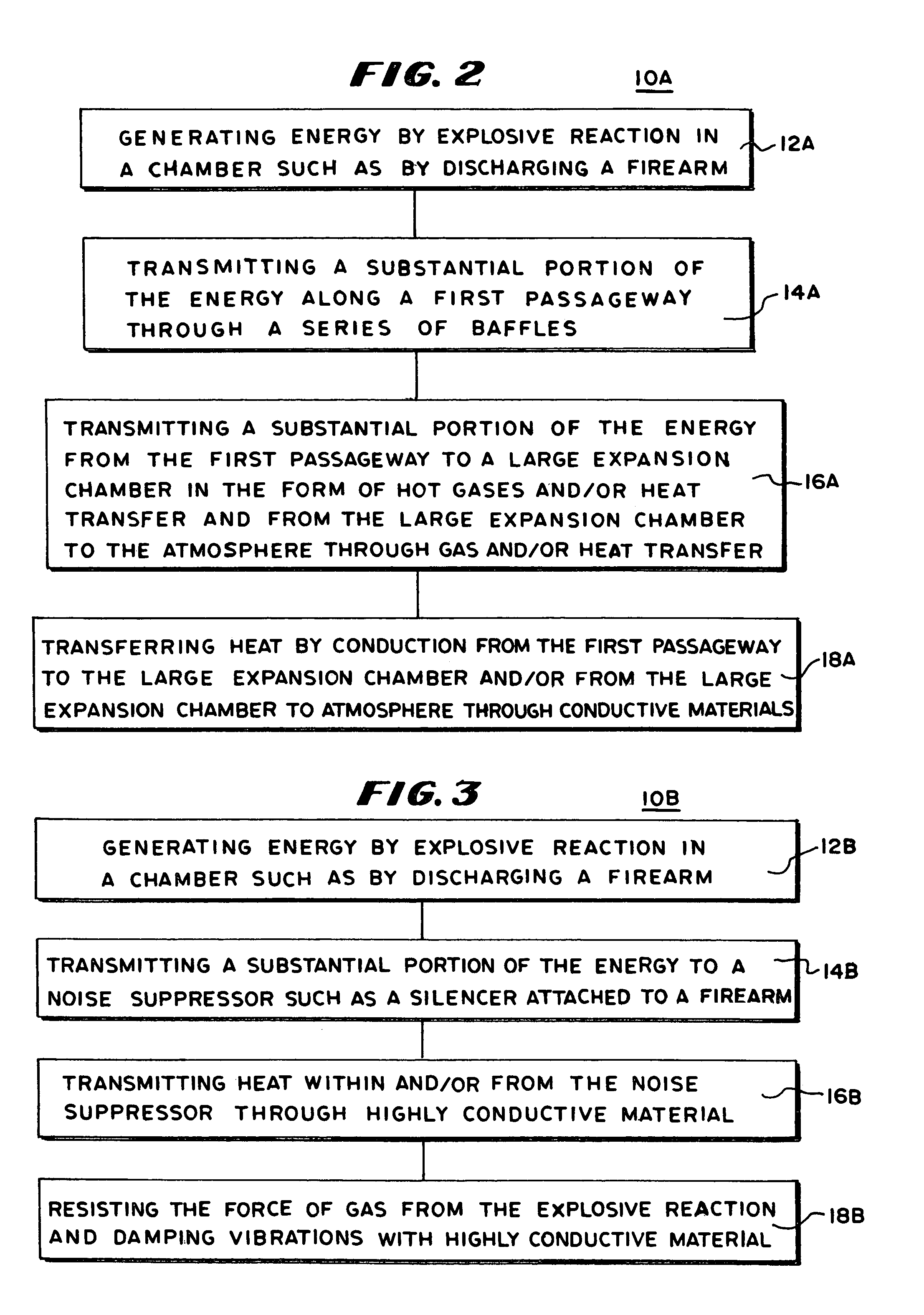

Energy suppressors

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

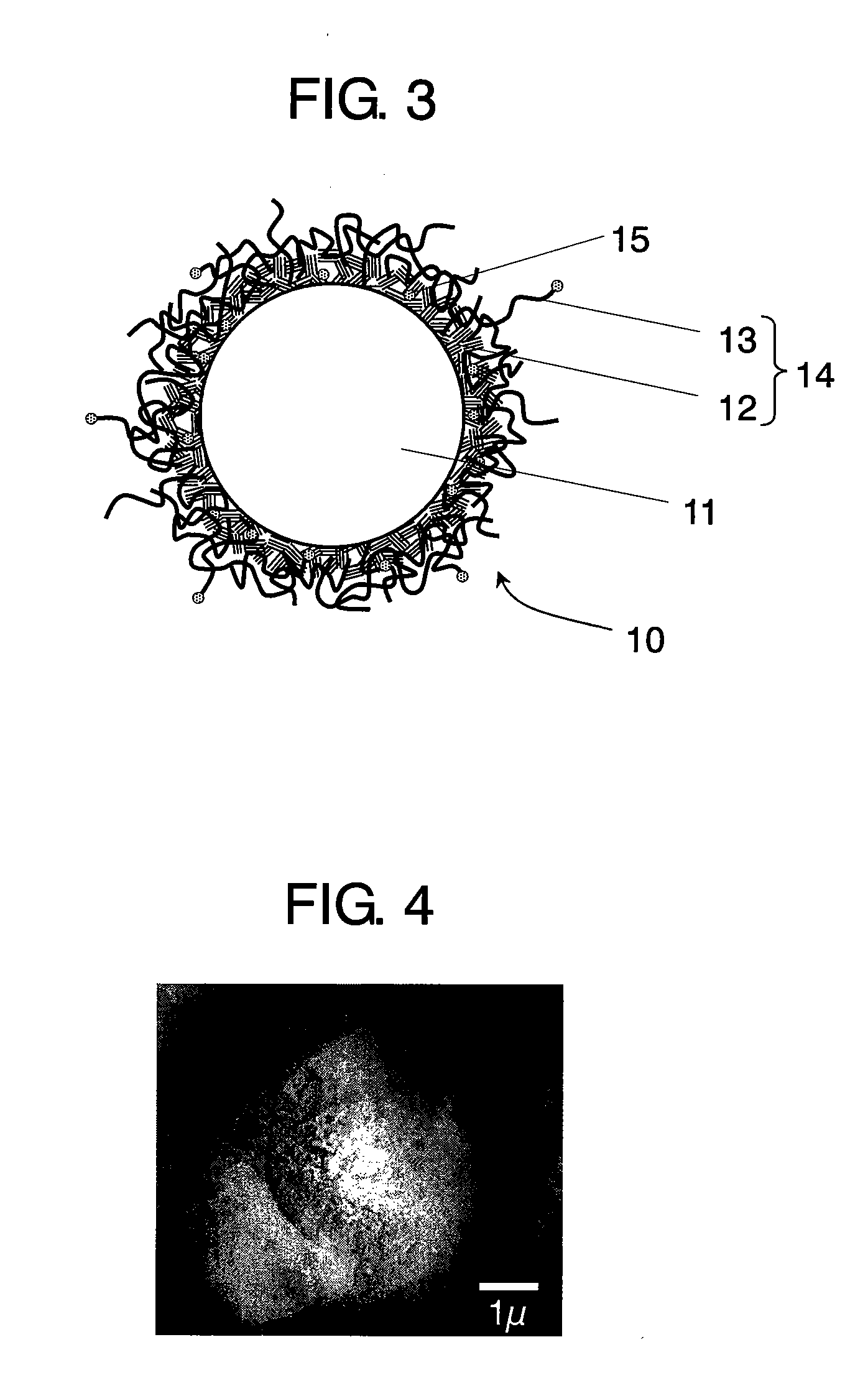

Conductive composite particle, method of manufacturing the same, electrode using the same, lithium ion secondary battery

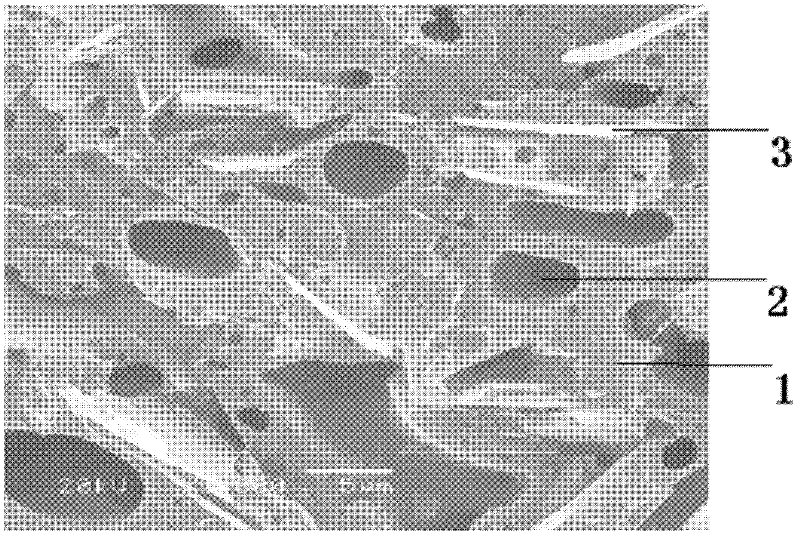

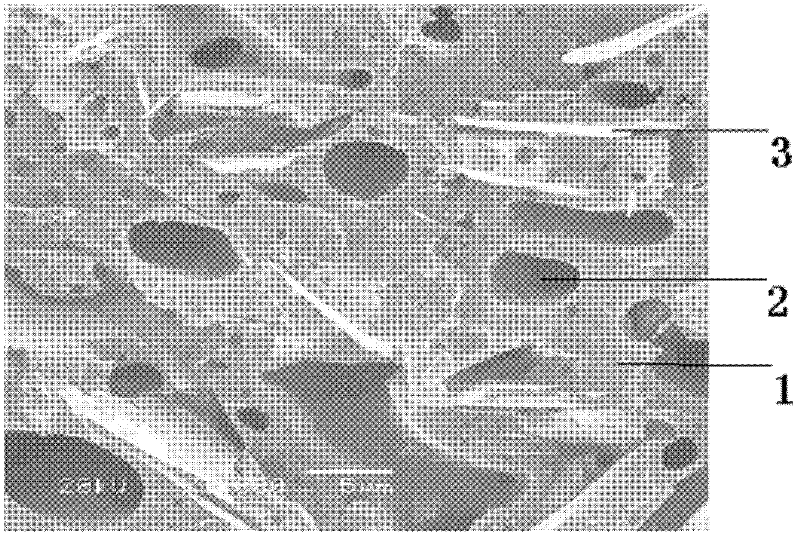

In a manufacturing method of a conductive composite particle, a conductive composite particle is manufactured that is formed of an active material particle having a region capable of electrochemically inserting and desorbing lithium and a carbon layer joined to the particle surface. In the carbon layer, fine metal particles are dispersed. This method has the following three steps. In the first step, a polymer material containing the metal element composing the fine metal particles is prepared. In the second step, the active material particle surface is coated with the polymer material containing the metal element. In the third step, a carbon layer having a porous structure including a fibrous structure is formed as the surface layer section from the polymer material by a treatment where the active material particle coated with the polymer containing the metal element is heated in an inert atmosphere to carbonize the polymer material.

Owner:PANASONIC CORP

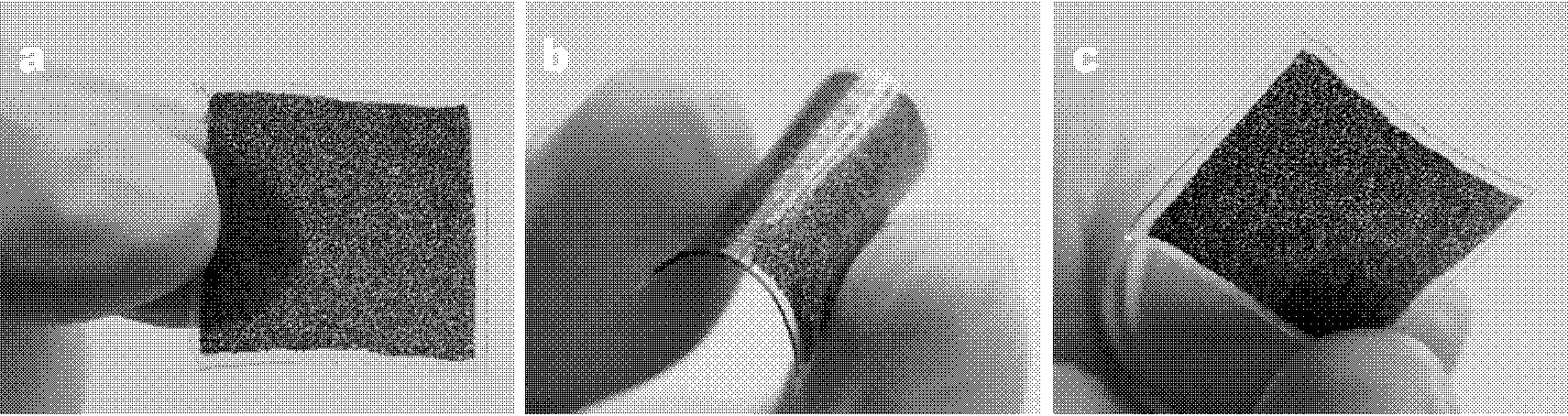

Three-dimensional continuous graphene network composite material and its preparation method

InactiveCN102786756ASimple preparation processEasy to controlNon-conductive material with dispersed conductive materialChemical vapor deposition coatingPtru catalystElectrical battery

The invention belongs to the nanocomposite material field, and relates to a preparation method of a novel three-dimensional graphene network composite material. The method comprises the following steps: obtaining a three-dimensional continuous graphene skeleton composite structure by adopting a metal template having a three-dimensional continuous pore structure as a catalyst, by growing the graphene through utilizing a chemical vapor deposition method until the graphene sklayer number is 1-20, and by adopting an etching liquid to remove the metal template; and compositing the graphene composite structure with a high polymer material to obtain the three-dimensional graphene network composite material. The three-dimensional graphene network composite material has the advantages of simple technology, easily controlled processes, excellent conductivity, and low preparation cost, and is suitable for the fields of solar cells, energy storage cells and conductive composite materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

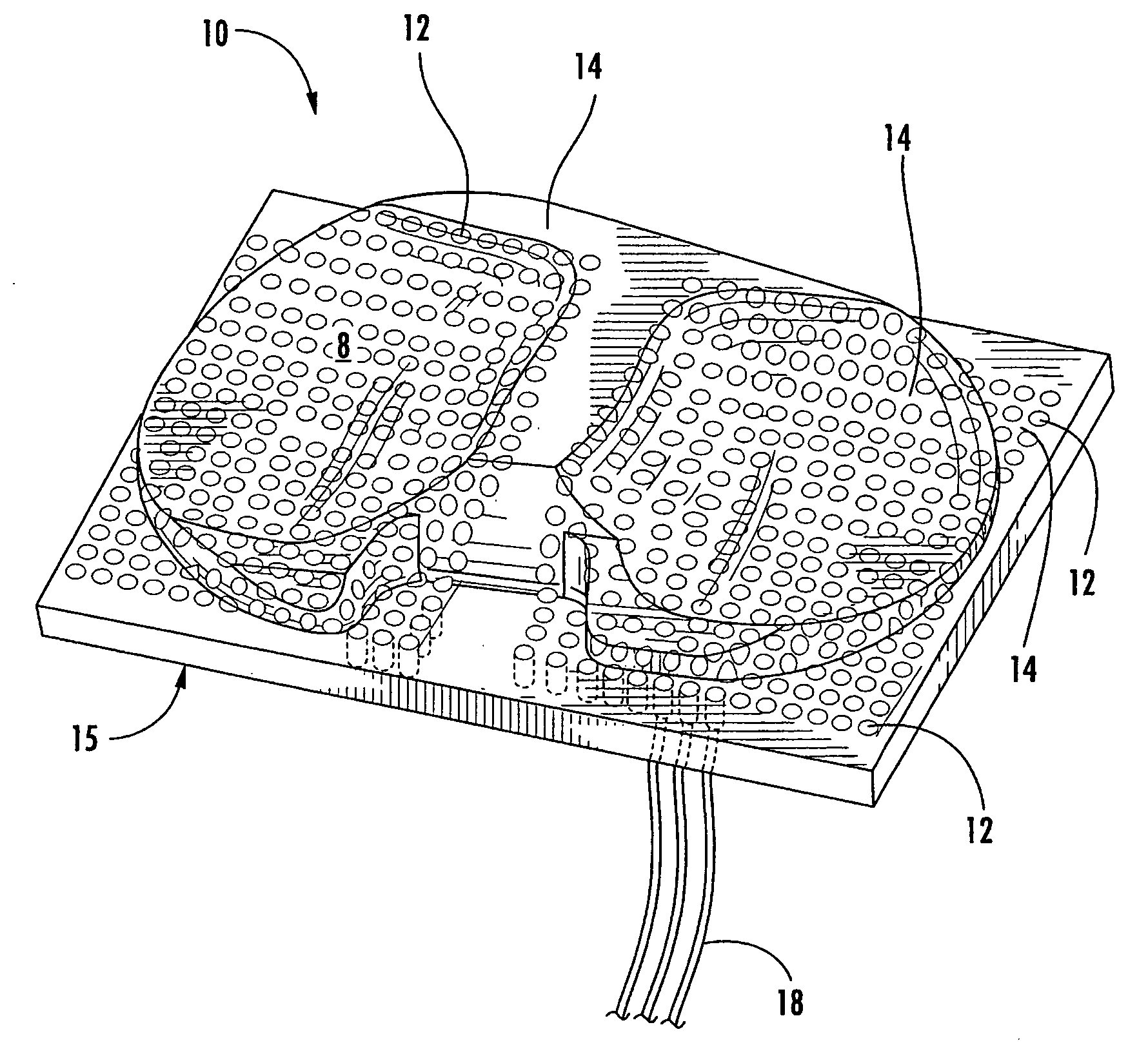

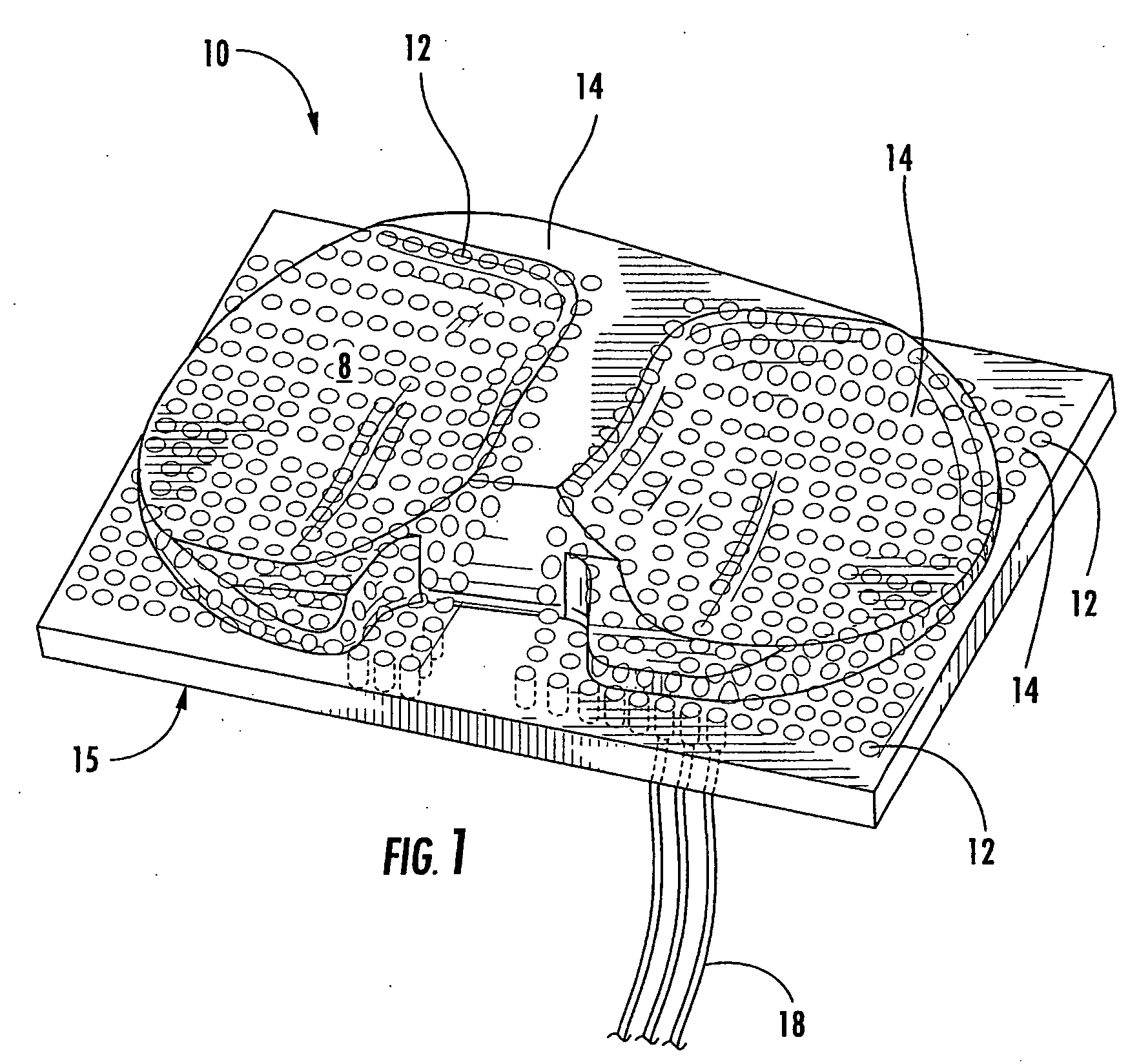

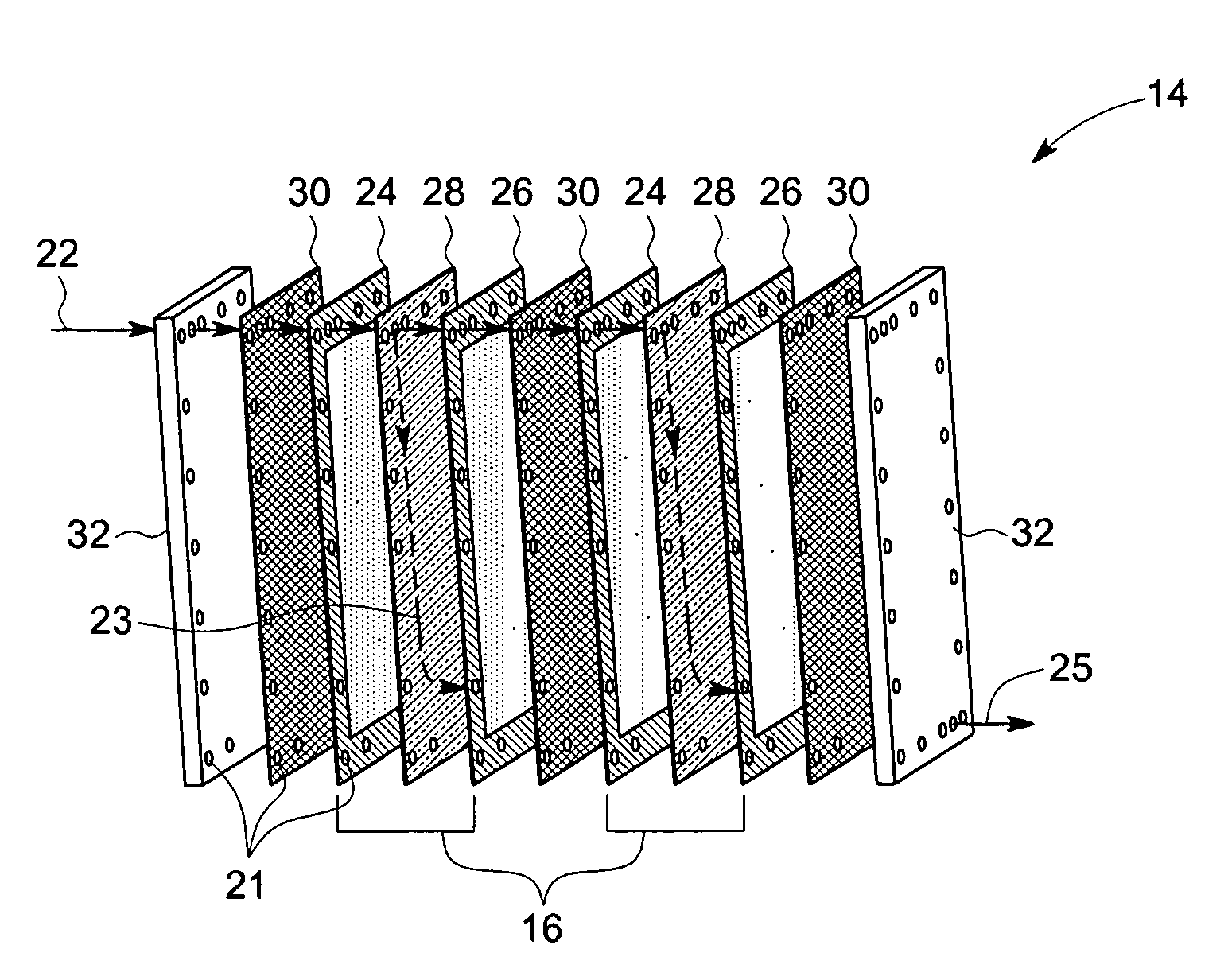

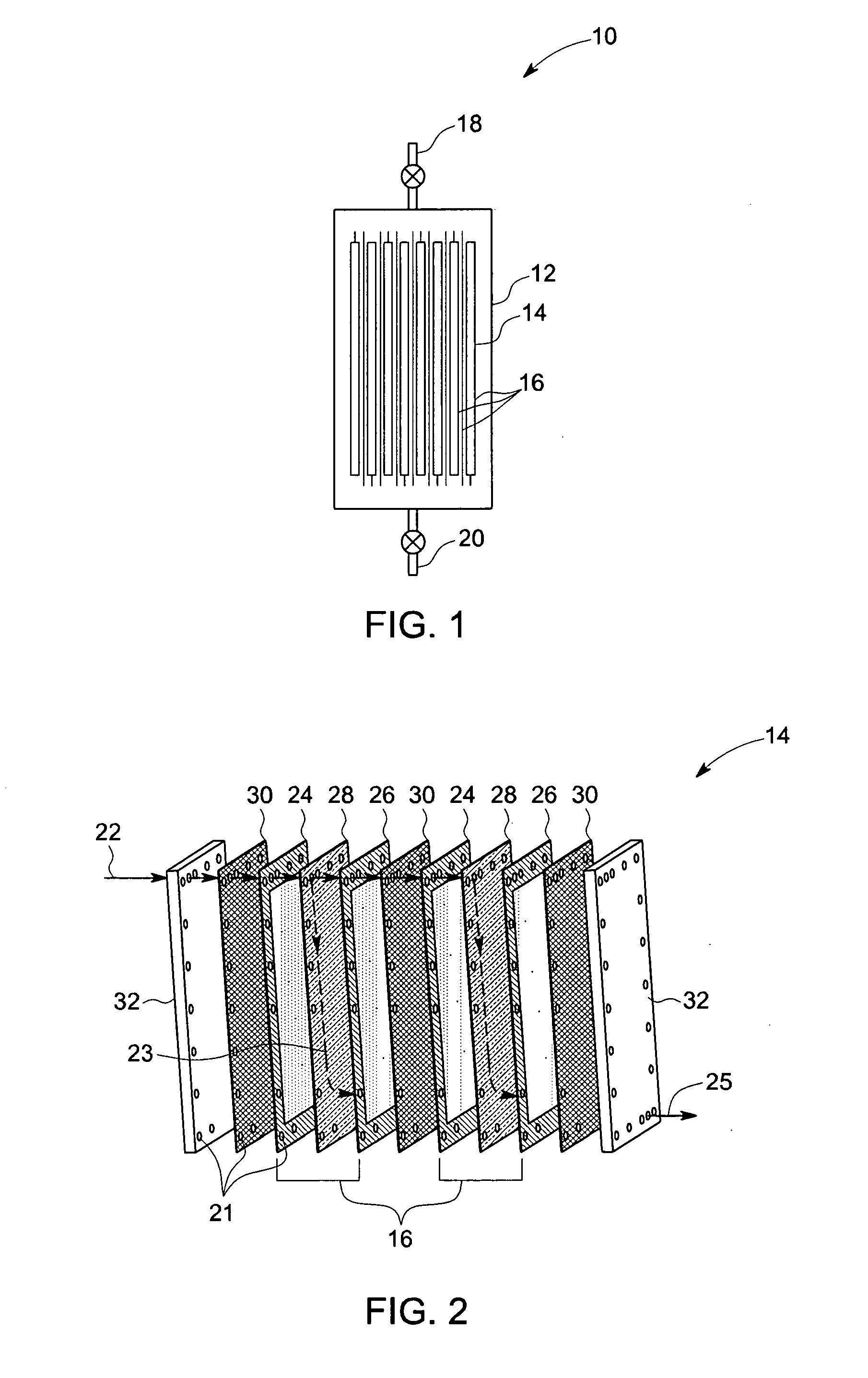

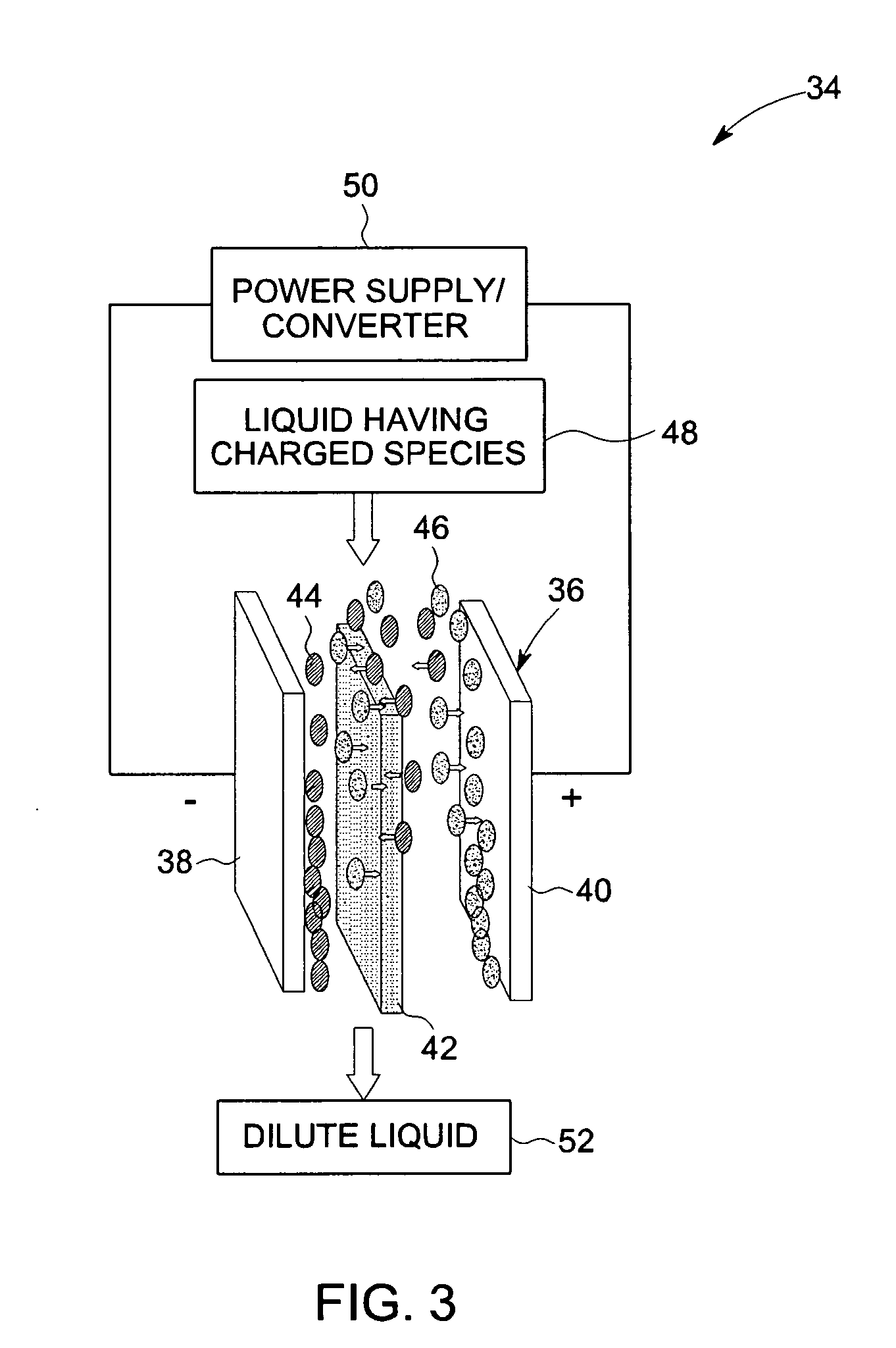

Supercapacitor desalination devices and methods of making the same

A supercapacitor desalination cell is provided. The cell includes electrodes formed of conducting materials that are configured to adsorb ions in a charging state of the cell and desorb the ions in a discharging state of the cell. The conducting materials comprise conducting composites. An insulating spacer is disposed between the two electrodes and is configured to electrically isolate one electrode from the other. Further, the cell includes a first current collector coupled to the first electrode, and a second current collector coupled to the second electrode. Further, an energy recovery converter may be operatively associated with the cell and configured to recover energy released by the cell while transforming from a charging state to a discharging state. The converter is configured to transfer at least a portion of the recovered energy to a grid in the discharging state of the cell.

Owner:GENERAL ELECTRIC CO

Pressure-sensitive flexible polymer bipolar electrode

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Nano-scaled graphene platelets with a high length-to-width aspect ratio

ActiveUS7790285B2High aspect ratioHigh stiffnessMaterial nanotechnologyShielding materialsFiberCarbon fibers

This invention provides a nano-scaled graphene platelet (NGP) having a thickness no greater than 100 nm and a length-to-width ratio no less than 3 (preferably greater than 10). The NGP with a high length-to-width ratio can be prepared by using a method comprising (a) intercalating a carbon fiber or graphite fiber with an intercalate to form an intercalated fiber; (b) exfoliating the intercalated fiber to obtain an exfoliated fiber comprising graphene sheets or flakes; and (c) separating the graphene sheets or flakes to obtain nano-scaled graphene platelets. The invention also provides a nanocomposite material comprising an NGP with a high length-to-width ratio. Such a nanocomposite can become electrically conductive with a small weight fraction of NGPs. Conductive composites are particularly useful for shielding of sensitive electronic equipment against electromagnetic interference (EMI) or radio frequency interference (RFI), and for electrostatic charge dissipation.

Owner:GLOBAL GRAPHENE GRP INC

Electrically conductive composite fibre containing carbon nanotube and method for making same

InactiveCN1840750AGood electrical propertiesIncreased durabilityFilament/thread formingArtifical filament manufactureFiberConductive polymer

The disclosed conductive composite fiber with carbon nano tube comprises a conductive core layer with 60~99.5wt% thermoplastic polymer, 0~5% carbon nano tube, 0~15% conductive carbon black, and 0.5~20% dispersant; and a shin layer with fiber-forming polymer. Wherein, the preparation method comprises mixing, extruding for granulation, and mixed spinning. This invention improves product performance.

Owner:DONGHUA UNIV

Ionically conductive composites for protection of active metal anodes

InactiveUS20080057387A1Easy to manufactureImprove battery performanceSolid electrolytesCell seperators/membranes/diaphragms/spacersChemical stabilityBattery cell

Owner:POLYPLUS BATTERY CO INC

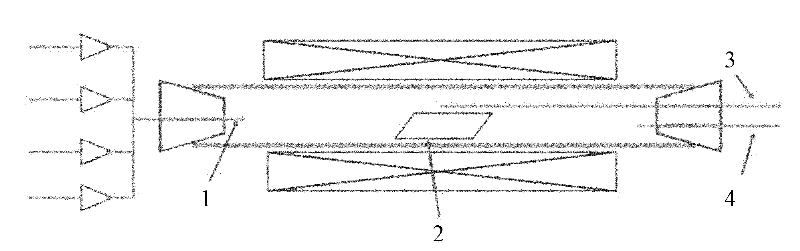

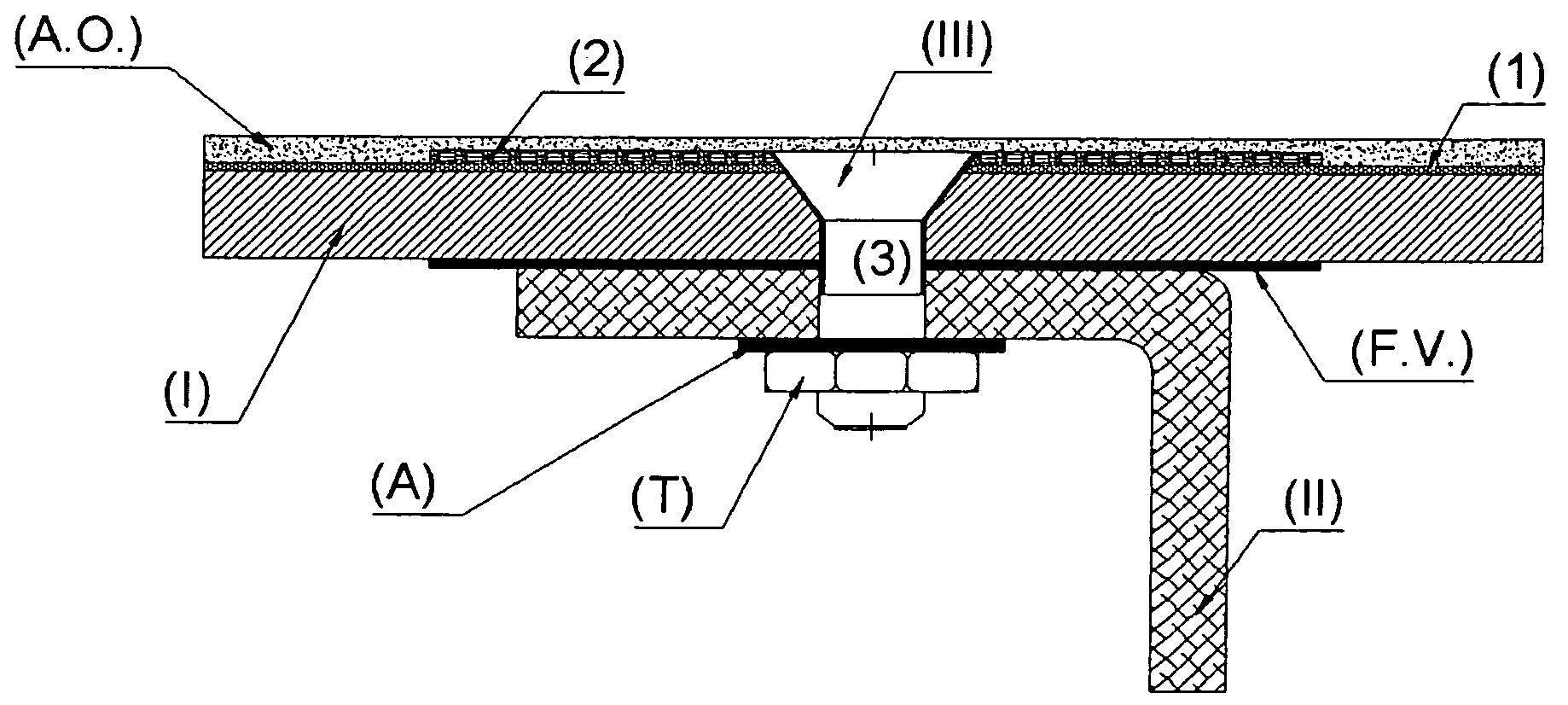

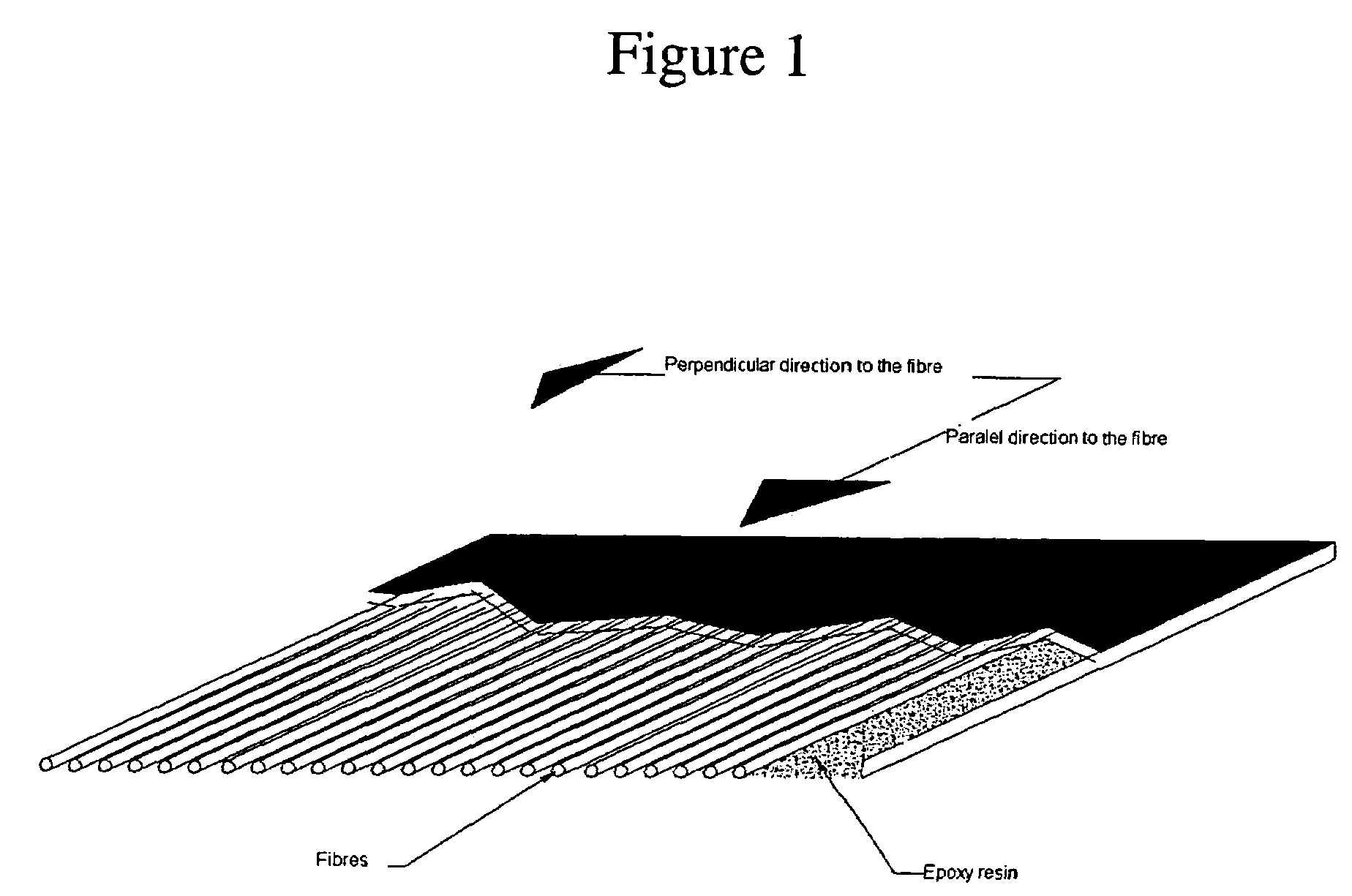

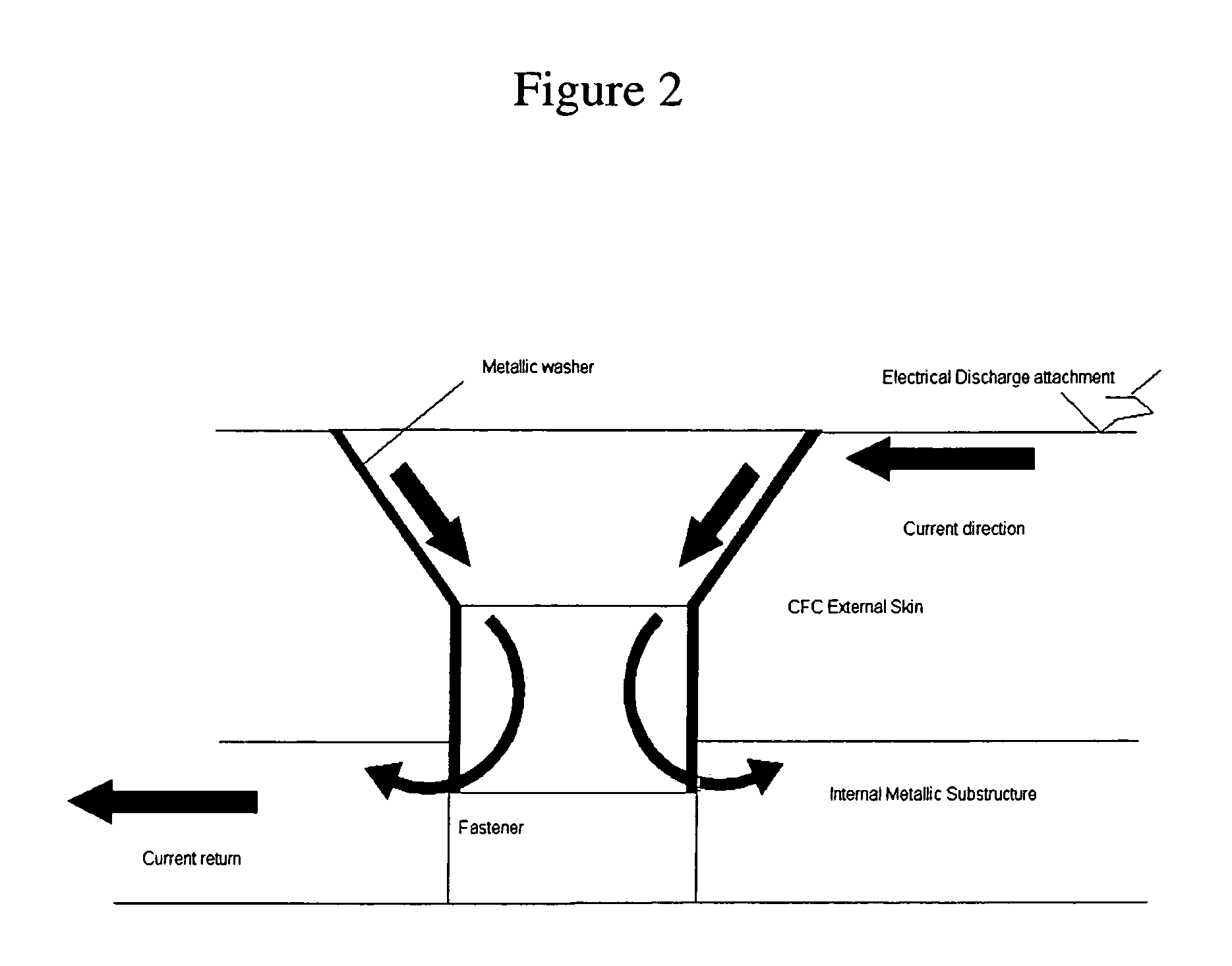

Lightning strike protection system for aircraft fuel tanks made of low electrical conductivity composite material

ActiveUS7307825B2Severe structural damage can be avoidedMinimize damageFuel tank safety measuresAircraft lighting protectorsLightning strikeFuel tank

Lightning strike protection system for aircraft fuel tanks made of low electrical conductivity composite material. The system comprises an electrical conductive thin wire mesh (1) that covers the whole external surface of the tank outer skin (I) made of composite and a thick wire metallic mesh (2) overlapping the mesh (1) at a minimum distance of 50 mm to both sides of a row of fasteners (III) joining the said outer skin (I) to one internal part (II) of either composite or metallic material. Both metallic meshes (1, 2) maintain electrical contact by their installation / assembly and by means of metallic countersunk head washers (3) connected to bonding points and set to the gap existing between the fastener (III) and the outer skin (I). The corresponding fabrication process is also described.

Owner:AIRBUS OPERATIONS SL

Energy suppressors

ActiveUS7789008B2Good noise suppression characteristicsReduce the amplitudeWeapon componentsBursting strengthFiber

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

Three-dimensional graphene/metal line or metal wire composite structure and preparation method thereof

InactiveCN102560415AImprove conductivityThe structure is complete and free of defectsMaterial nanotechnologyPolycrystalline material growthGraphene coatingElectrical battery

The invention provides a three-dimensional graphene / metal line or metal wire composite structure and a preparation method thereof. According to the invention, metal lines or metal wires are adopted as a catalyst template; with a chemical vapor deposition method, a carbon source directly form graphene coatings on the outer surfaces of the metal lines, such that the graphene / metal line or metal wire composite structure is formed. The diameters of the metal lines or metal wires are 10nm-5000mum. The layer number of graphene is 1-100. The three-dimensional graphene / metal line or metal wire composite structure or graphene tube provided by the invention has excellent electric conductivity and corrosion resistance. The technology provided by the invention is simple, and the process is easy to control. The composite structure is advantaged in excellent electric conductivity and low preparation cost, and is suitable to be used in fields of solar energy devices, storage batteries, conductive composite materials, and corrosion resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com