A thermoplastic polymer-based thermally conductive composite material and its preparation method

A thermoplastic polymer, thermally conductive composite material technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as increasing material cost, low thermal conductivity of composite materials, and inability to meet application requirements, and achieve high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

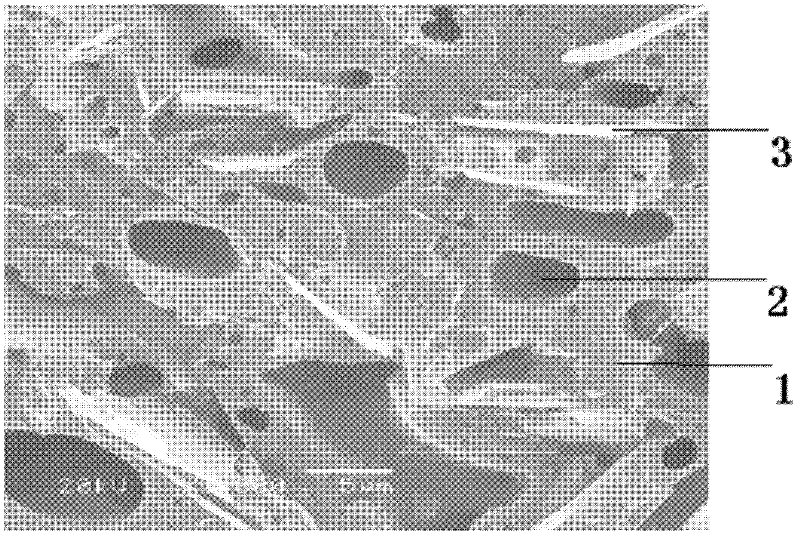

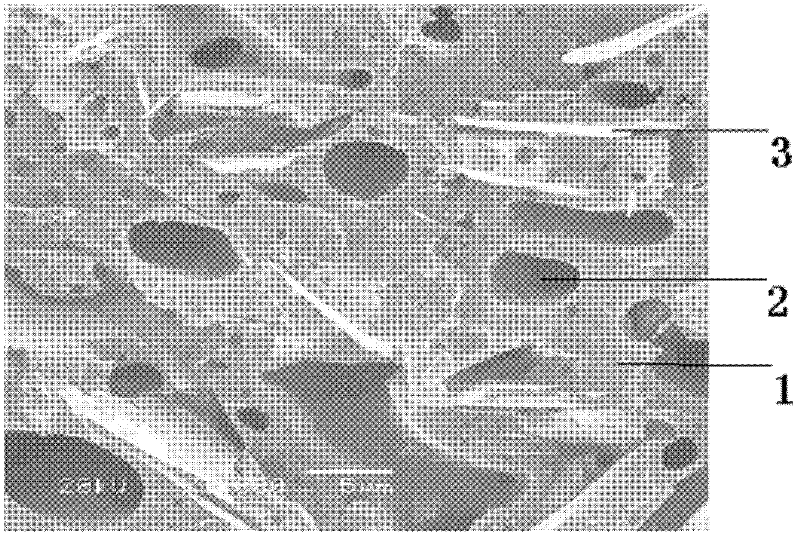

Image

Examples

Embodiment 1

[0023] 1kg PPS, 0.1kg graphite, 0.83kgPA6 and other processing aids are added to the twin-screw extruder at one time and blended (the volume ratio of PPS and PA6 is 50 / 50, and the graphite addition is 10% of the PPS mass), extruded The output temperature is 300°C, and the PPS-based thermal conductive composite material is obtained. The measured thermal conductivity of the PPS-based thermally conductive composite material is 0.5701W / mK, the tensile strength is 64.85MPa, the bending strength is 93.27MPa, and the impact strength is 32.34Kj / m 2 .

Embodiment 2

[0028] Add 1.3kg ABS, 0.13kg BN, and 1kg PC to the twin-screw extruder at one time for blending (the volume ratio of ABS and PC is 60 / 40, and the amount of graphite added is 10% of the mass of ABS), and the extrusion temperature is 280 °C, the ABS-based thermally conductive composite material was obtained; the measured thermal conductivity of the ABS-based thermally conductive composite material was 0.5209W / mK, the tensile strength was 52.73MPa, the bending strength was 58.91MPa, and the impact strength was 44.85Kj / m2 .

[0029] Comparative example 1: 1.2kgABS and 0.12kgBN were added to a twin-screw extruder for blending, and the extrusion temperature was 280°C to obtain an ABS / BN composite material. The measured thermal conductivity was 0.3073W / mK, and the tensile strength was 56.29MPa, bending strength is 61.24MPa, impact strength is 48.32Kj / m 2 .

[0030] By comparing the examples of the present invention with the comparative examples, it can be seen that, using the method...

Embodiment 3

[0032] Add 2kg PA6, 0.48kg aluminum powder, and 0.1kg PE to the twin-screw extruder at one time for blending (the volume ratio of PA6 and PE is 95 / 5, and the amount of graphite added is 20% of the mass of PA6), and the extrusion temperature is At 250°C, a PA6-based thermally conductive composite material was obtained; the measured thermal conductivity of the PA6-based thermally conductive composite material was 0.6427W / mK, the tensile strength was 58.49MPa, the bending strength was 81.94MPa, and the impact strength was 30.51Kj / m 2 .

[0033] Comparative example 1: 1.6kg PA6 and 0.32kg aluminum powder were added to the twin-screw extruder for blending, and the extrusion temperature was 250°C to obtain a PA6 / aluminum powder composite material. The measured thermal conductivity was 0.4193W / mK. The tensile strength is 61.86MPa, the bending strength is 92.58MPa, and the impact strength is 31.74Kj / m 2 .

[0034] By comparing the examples of the present invention with the comparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com