Electrically conductive composite fibre containing carbon nanotube and method for making same

A technology of conductive composite fibers and carbon nanotubes, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc. It can solve the problems of destroying the rheological properties of high polymers, poor spinnability and mechanical properties of mixtures, etc. , achieve excellent electrical properties, improve spinnability and mechanical properties, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

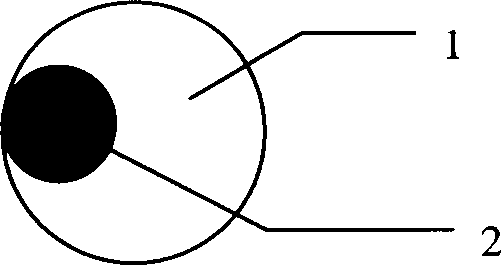

[0030] Refer to attached figure 1 , a conductive composite fiber containing carbon nanotubes, consisting of a core layer and a skin layer, wherein the core layer is a conductive core material 2, and the skin layer is a fiber-forming polymer 1; the weight percentage content of the conductive core material includes: polypropylene 84%, carbon nanotubes 1%, conductive carbon black 5%, silicone resin 15%; carbon nanotubes are single-walled carbon nanotubes with an average diameter of 10nm and an aspect ratio of 400; Conductive carbon black with an amount of 1000; the sheath-core composite ratio is: 1:1, volume ratio.

[0031] Its preparation method comprises the following steps:

[0032] a. The thermoplastic polymer, carbon nanotubes, and conductive carbon black are dried separately, and polypropylene, carbon nanotubes, conductive carbon black, and silicone resin are added to a high-speed mixer, and mixed evenly at a temperature of 160°C;

[0033] b. Extruding and granulating the...

Embodiment 2

[0037] Refer to attached figure 1, a conductive composite fiber containing carbon nanotubes, consisting of a core layer and a skin layer, wherein the core layer is a conductive core material, and the skin layer is a fiber-forming polymer; the weight percentage content of the conductive core material includes: polyethylene 99.5% , carbon nanotubes 5%, conductive carbon black 15%, gum arabic 0.5%; carbon nanotubes are multi-walled carbon nanotubes with an average diameter of 100nm and an aspect ratio of 100; conductive carbon black has a particle diameter of 150nm and an oil absorption of 100 Conductive carbon black; skin-to-core composite ratio of 1:5, volume ratio.

[0038] Its preparation method comprises the following steps:

[0039] a. Dry the thermoplastic polymer, carbon nanotubes, and conductive carbon black separately, add polyethylene, carbon nanotubes, conductive carbon black, and gum arabic to a high-speed mixer, and mix evenly at a temperature of 180°C;

[0040] b...

Embodiment 3

[0044] Refer to attached figure 1 , a conductive composite fiber containing carbon nanotubes, consisting of a core layer and a skin layer, wherein the core layer is a conductive core material, and the skin layer is a fiber-forming polymer; the weight percentage content of the conductive core material includes: polyacrylonitrile 60 %, carbon nanotubes 2.5%, conductive carbon black 5%, polyethylene terephthalate 20%; carbon nanotubes are multi-walled carbon nanotubes with an average diameter of 50nm and an aspect ratio of 200; conductive carbon black is a particle diameter of 100nm, conductive carbon black with an oil absorption of 500; the skin-to-core composite ratio is 1:10, and the volume ratio.

[0045] Its preparation method comprises the following steps:

[0046] a. Dry the thermoplastic polymer, carbon nanotubes, and conductive carbon black separately, add polyethylene, carbon nanotubes, conductive carbon black, and gum arabic to a high-speed mixer, and mix evenly at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com