Patents

Literature

3251results about How to "Effective dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

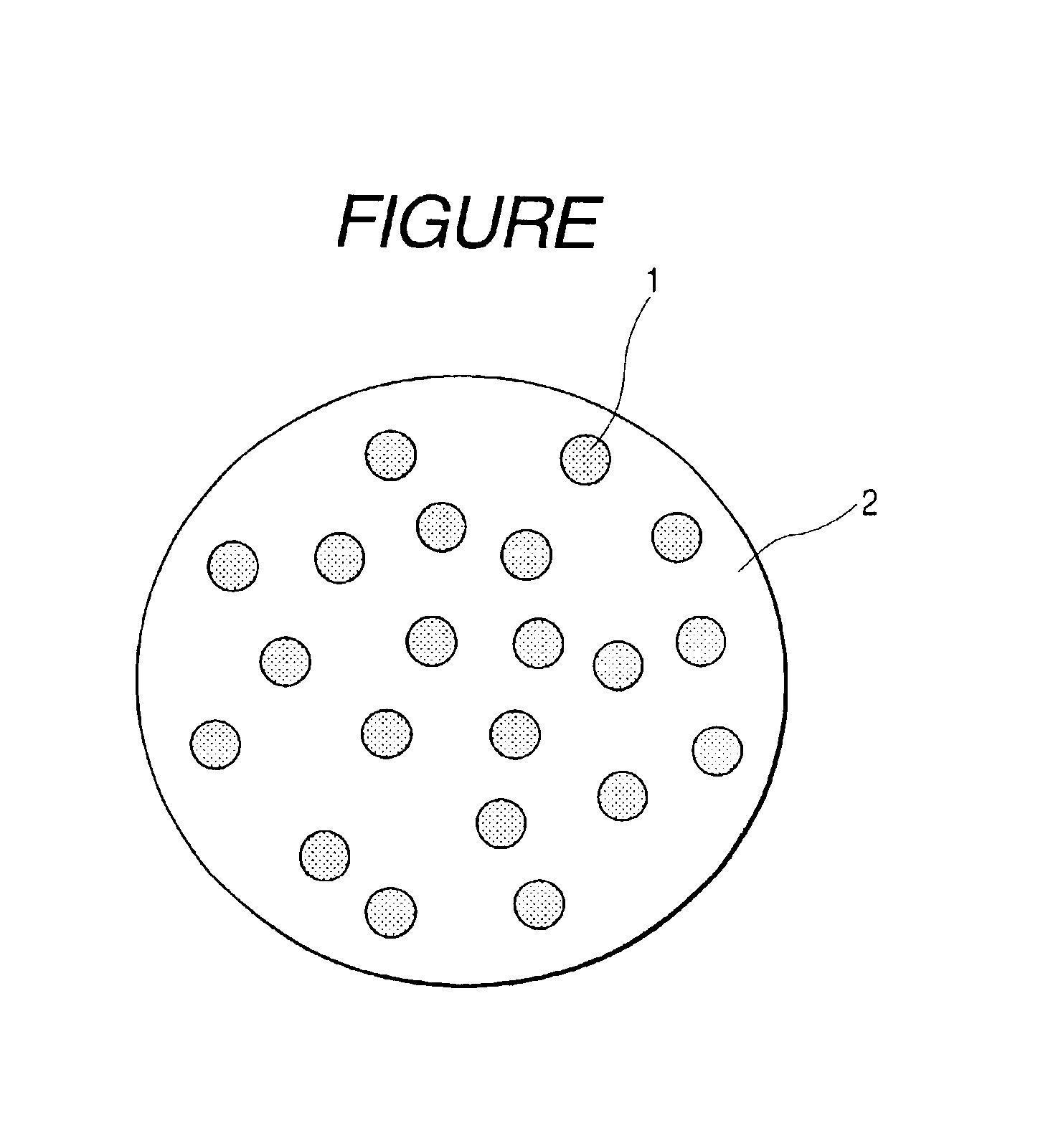

Process for producing modified epoxy resin

ActiveUS20070027233A1Reduce removalEasy to excludeFilm/foil adhesivesCircuit susbtrate materialsSolubilityPolymer chemistry

This invention provides a process for producing an epoxy resin composition having core / shell rubber particles (rubber-like polymer particles) dispersed in an epoxy resin, wherein an epoxy resin composition excellent in the dispersed state of rubber-like polymer particles in an epoxy resin with a reduced amount of contaminants is produced easily and efficiently. The epoxy resin composition having rubber-like polymer particles dispersed well in an epoxy resin with less contaminant is obtained by bringing an aqueous latex of rubber-like polymer particles (B) into contact with an organic medium (C) showing partial solubility in water, then bringing an organic medium (D) having lower partial solubility in water than that of the organic medium (C) into contact therewith to separate water substantially, to remove the rubber-like polymer particles as a dispersion (F) having the polymer particles dispersed in the organic medium, and mixing it with an epoxy resin (A), followed by distilling volatile components away.

Owner:KANEKA CORP

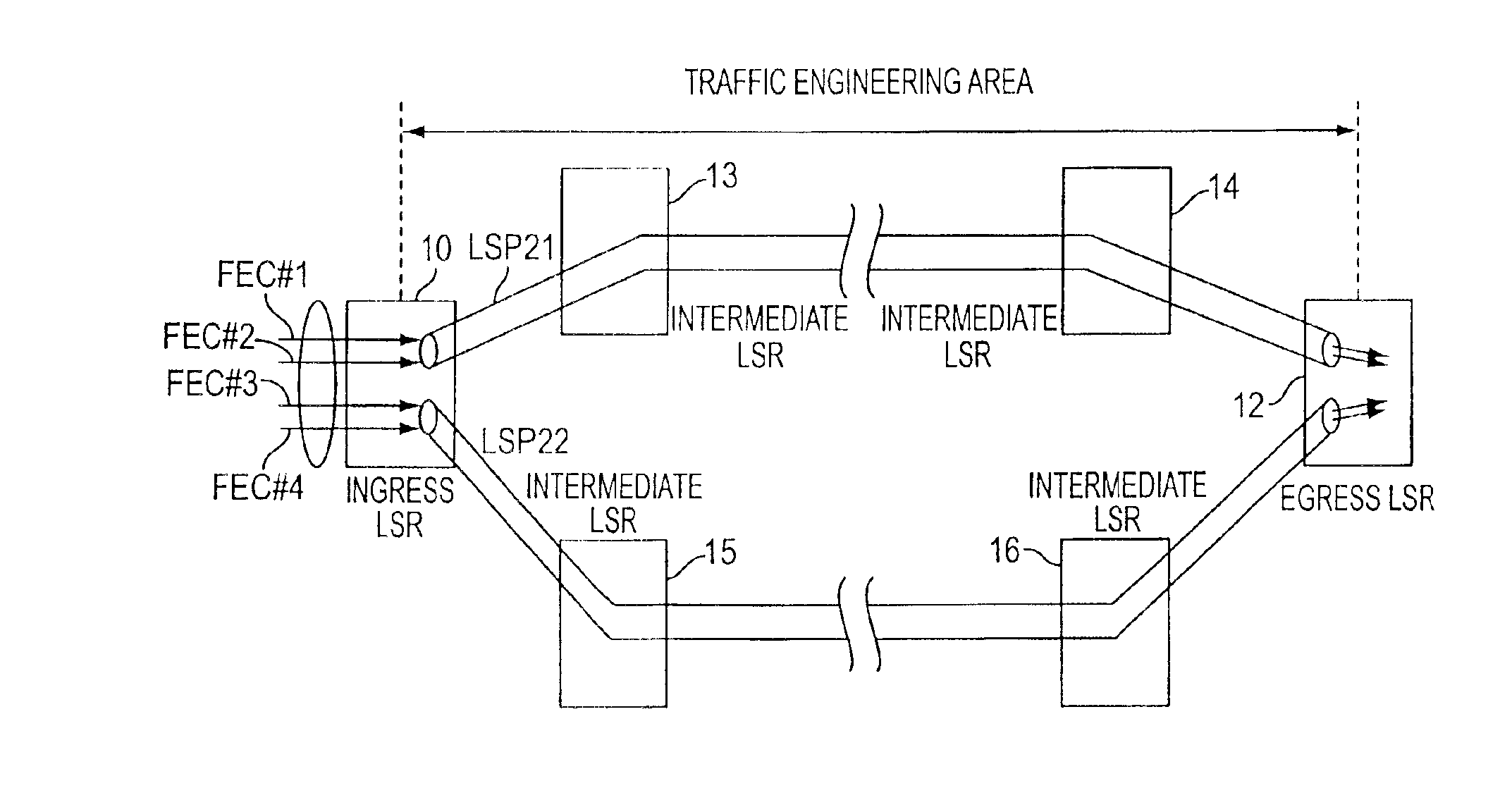

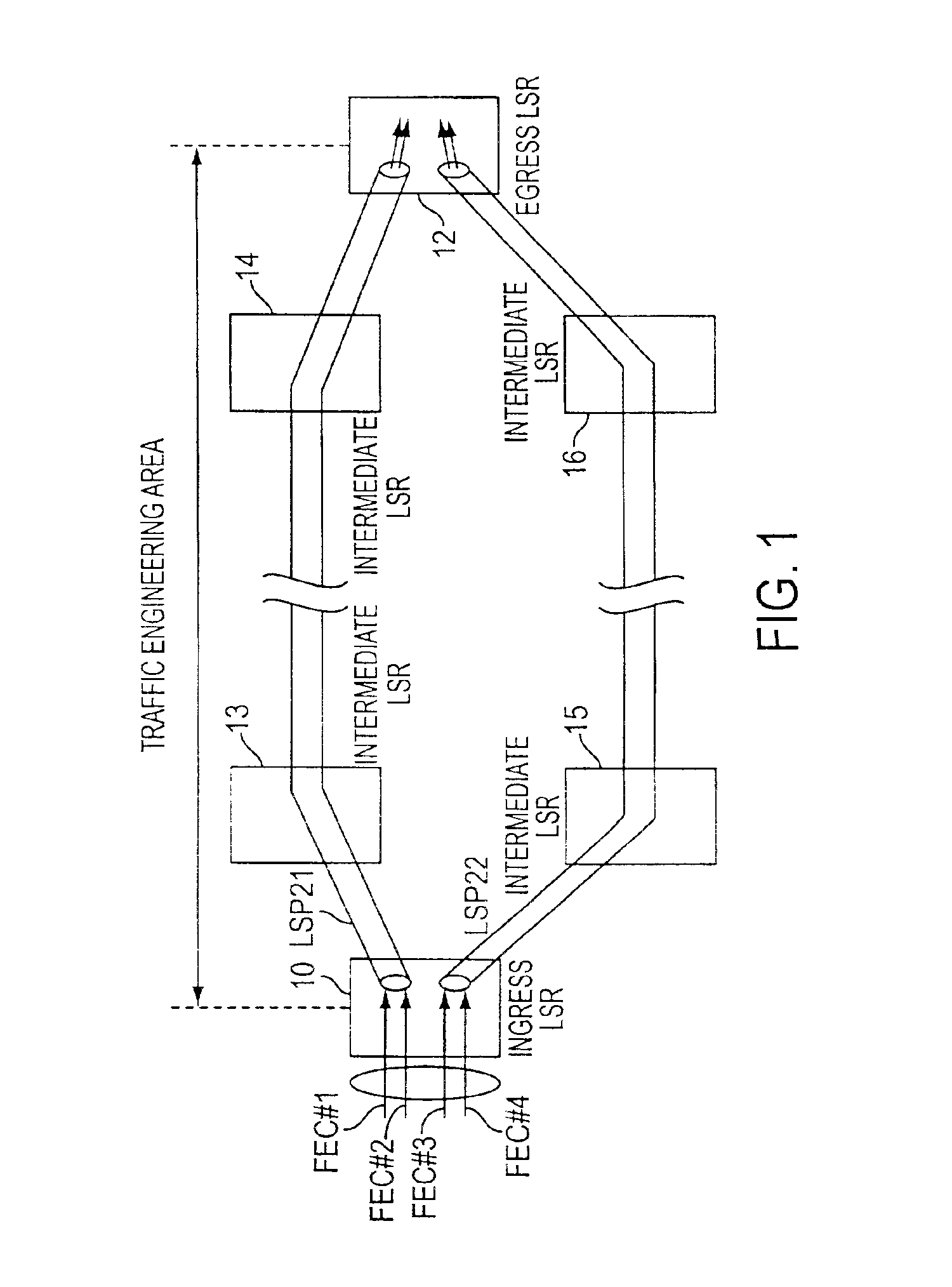

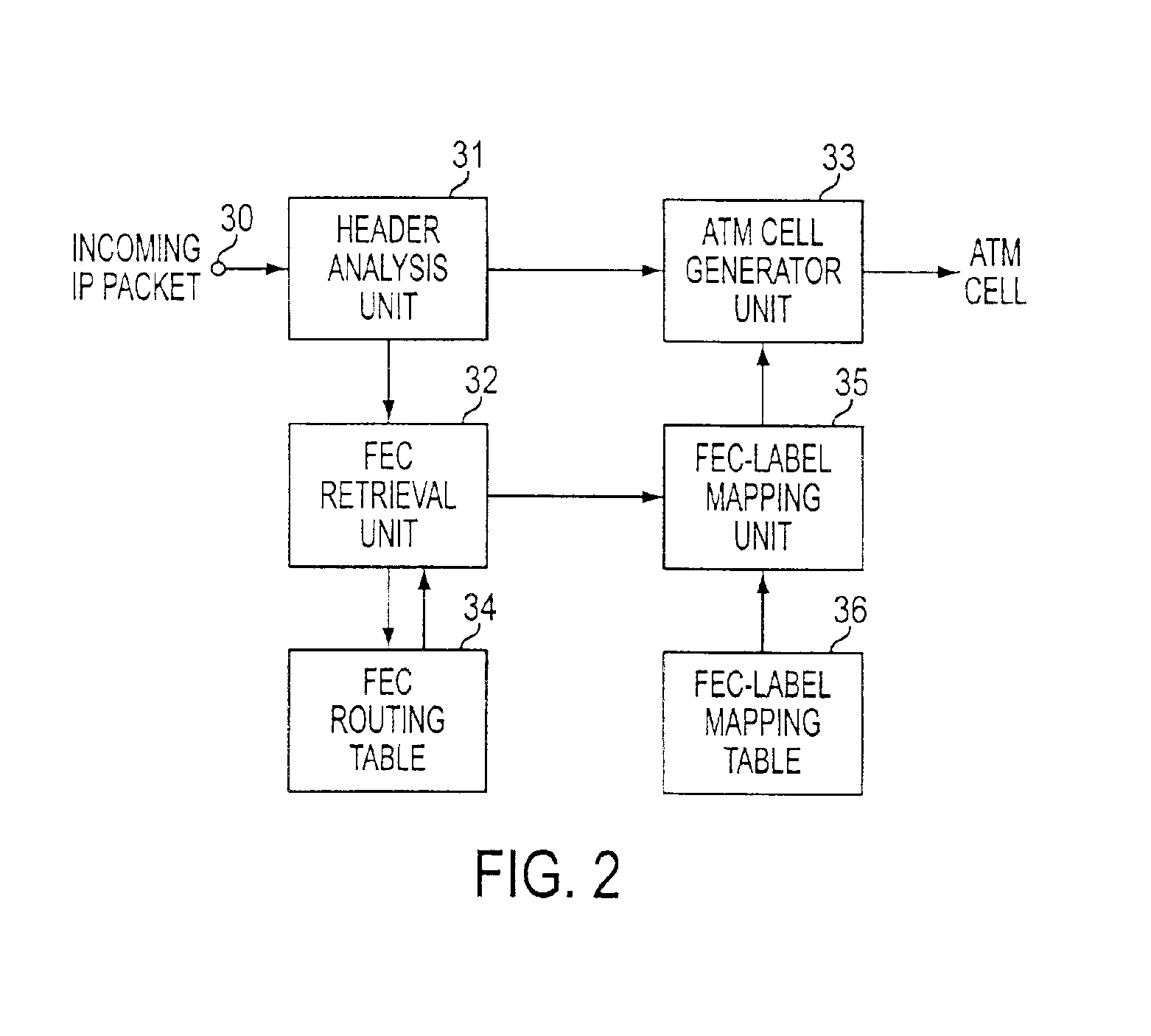

Method and apparatus for selection of paths on a communication network

InactiveUS6859842B1Easy to useIncrease flexibilityDigital computer detailsAutomatic exchangesTraffic capacityForwarding equivalence class

A method and apparatus for selecting paths to route incoming traffic through a data communication network, which is capable of effectively dispersing the traffic load to the selected paths on the network and effectively optimizing the use of network resources. In a communication network, a plurality of label switched paths between an ingress node and an egress node are provided. Incoming traffic at the ingress node is labeled and delivered through the network to the egress node. In a method and apparatus for selecting paths to route the incoming traffic through the network, a plurality of forwarding equivalent class elements (FEC) of the incoming traffic at the ingress node are allocated for the plurality of label switched paths. The labeled traffic is delivered on the plurality of label switched paths on an FEC-element basis so as to route the labeled traffic through the network to the egress node. The traffic load on the respective label switched paths can be effectively dispersed and the sequence of data packets, sent by the same terminal, may be maintained.

Owner:FUJITSU LTD

Methods for dispersing fibers within aqueous compositions

InactiveUS6379446B1Quantity maximizationMinimize interstitial spaceNon-fibrous pulp additionProtein adhesivesFiberSolid component

Compositions and methods in which dry-committed fibers are substantially homogeneously dispersed throughout a fibrous composition. The fibrous composition is characterized as having sufficient yield stress and viscosity such that the shearing forces from the mixing apparatus are effectively transferred down to the fiber level. This is accomplished by means of an appropriate thickening agent, e.g, gelatinized starch. The dry-committed fibers are exemplified by flash dry fibers or fibrous sheets that have been cut or torn into fragments less than 2 cm across. Providing fibers that have been dry-committed greatly reduces the time that it takes to obtain substantially homogeneous dispersion of the fibers throughout the fibrous composition. This, in turn, reduces the risk of mixture spoilage and mechanical or chemical damage to the solid components within the fibrous composition.

Owner:E KHASHOGGI INDS

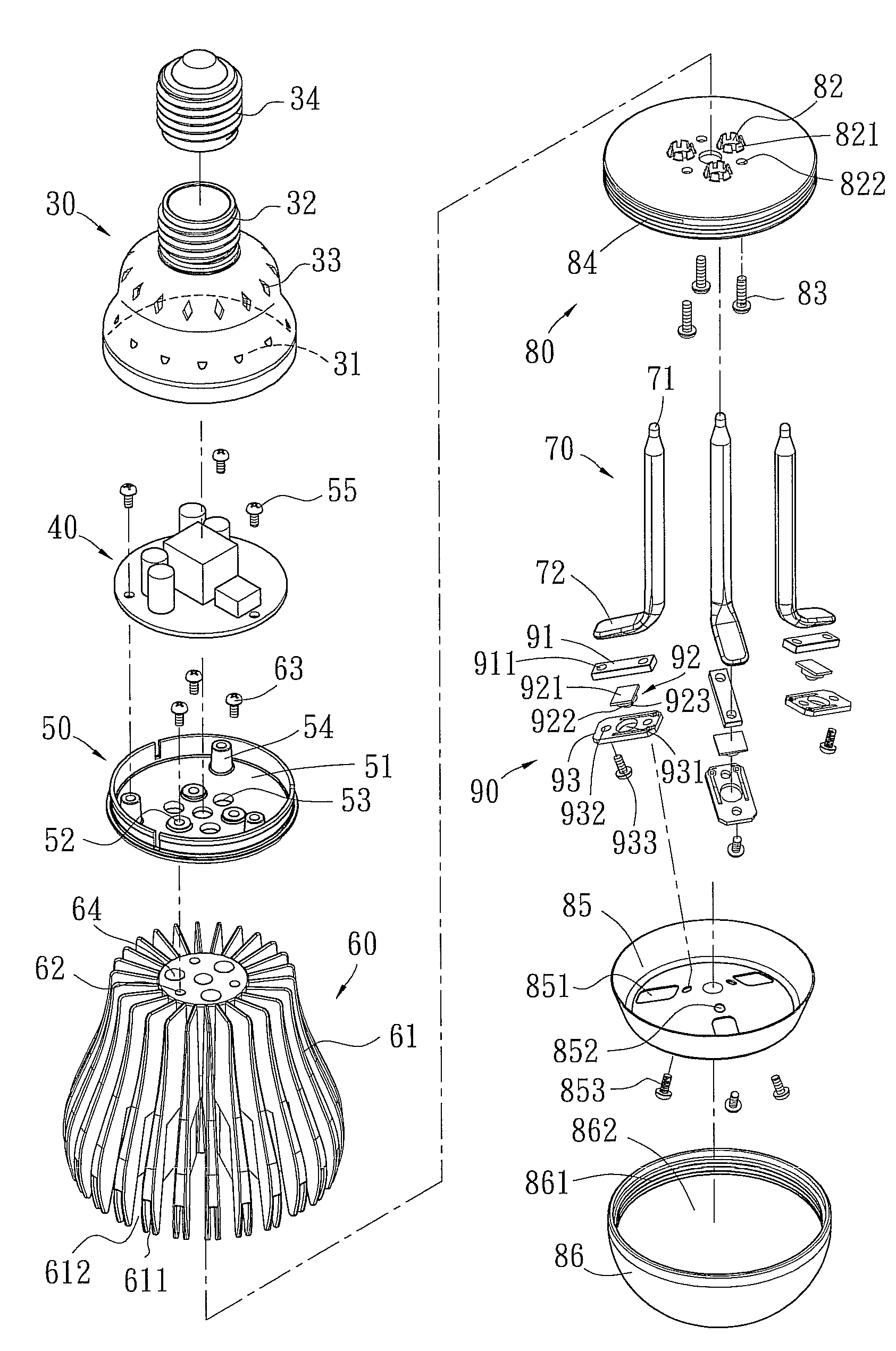

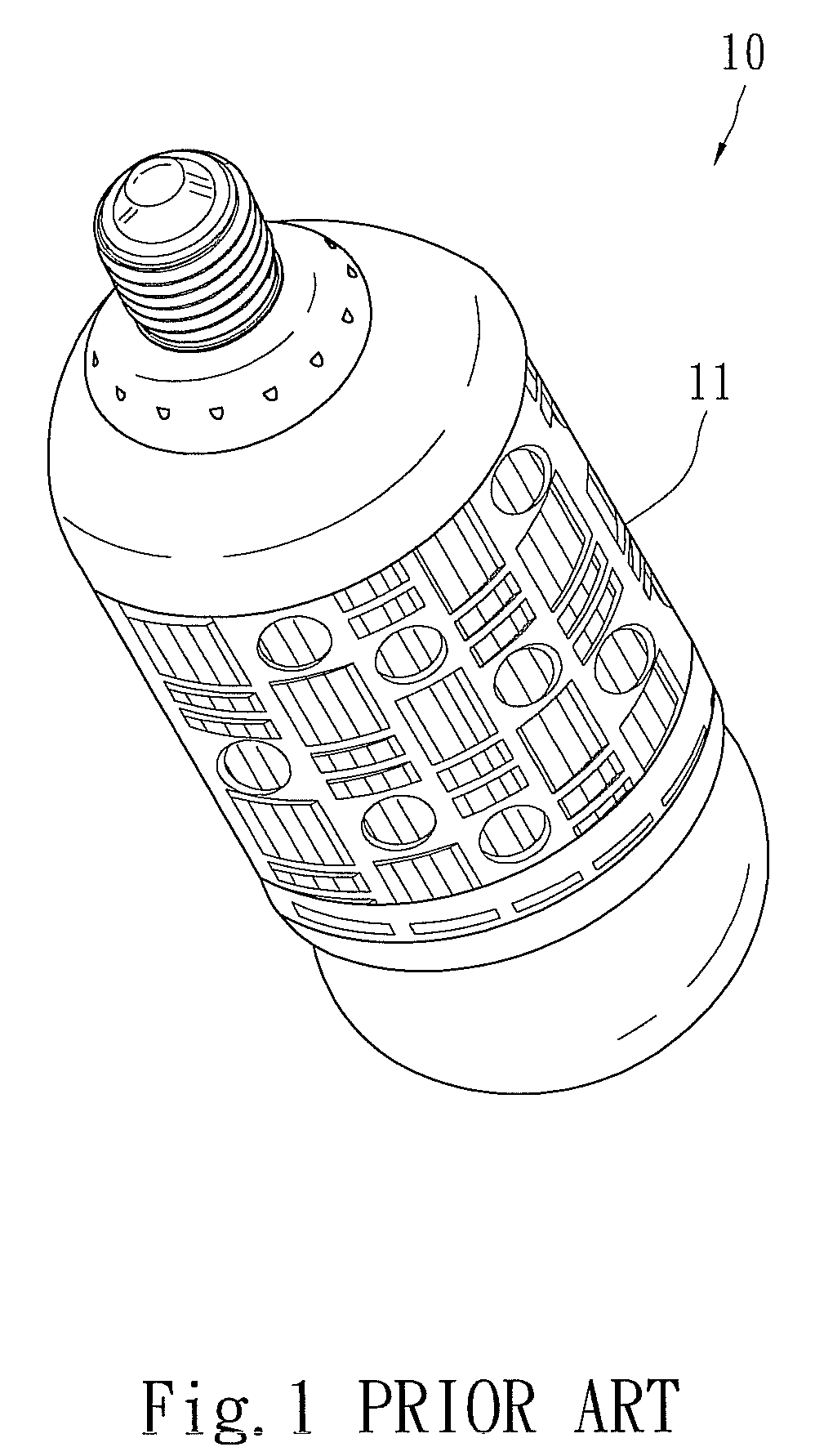

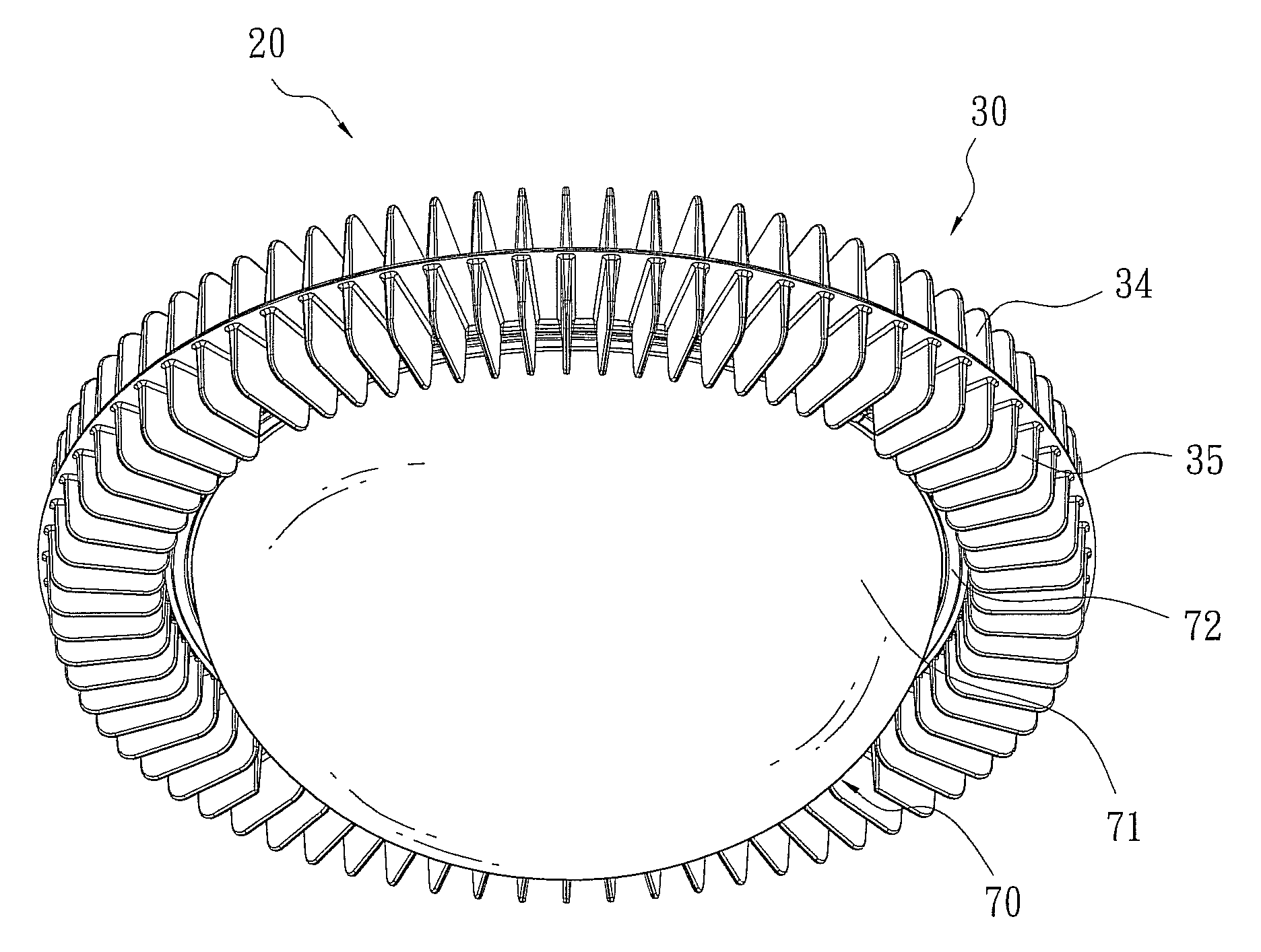

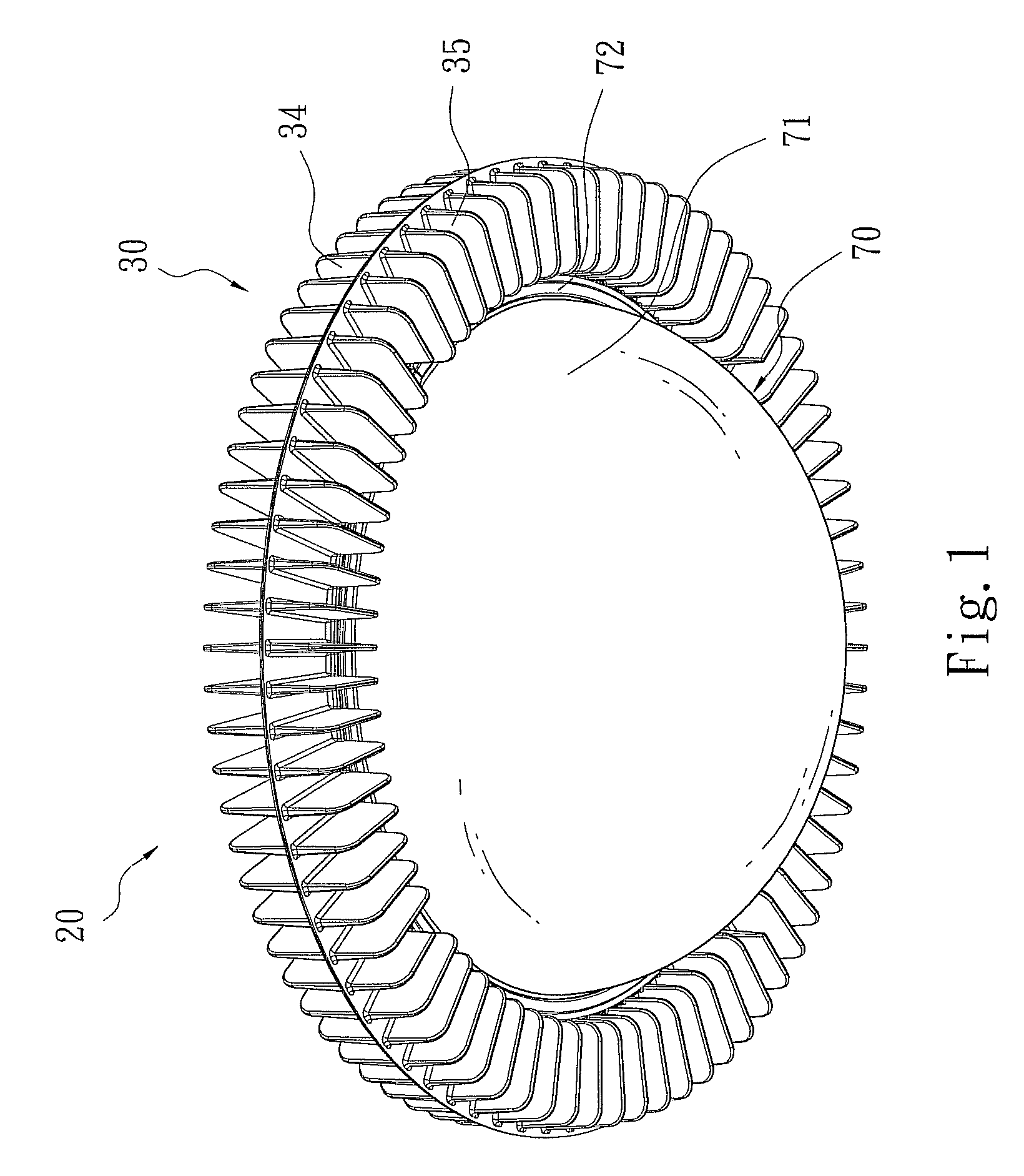

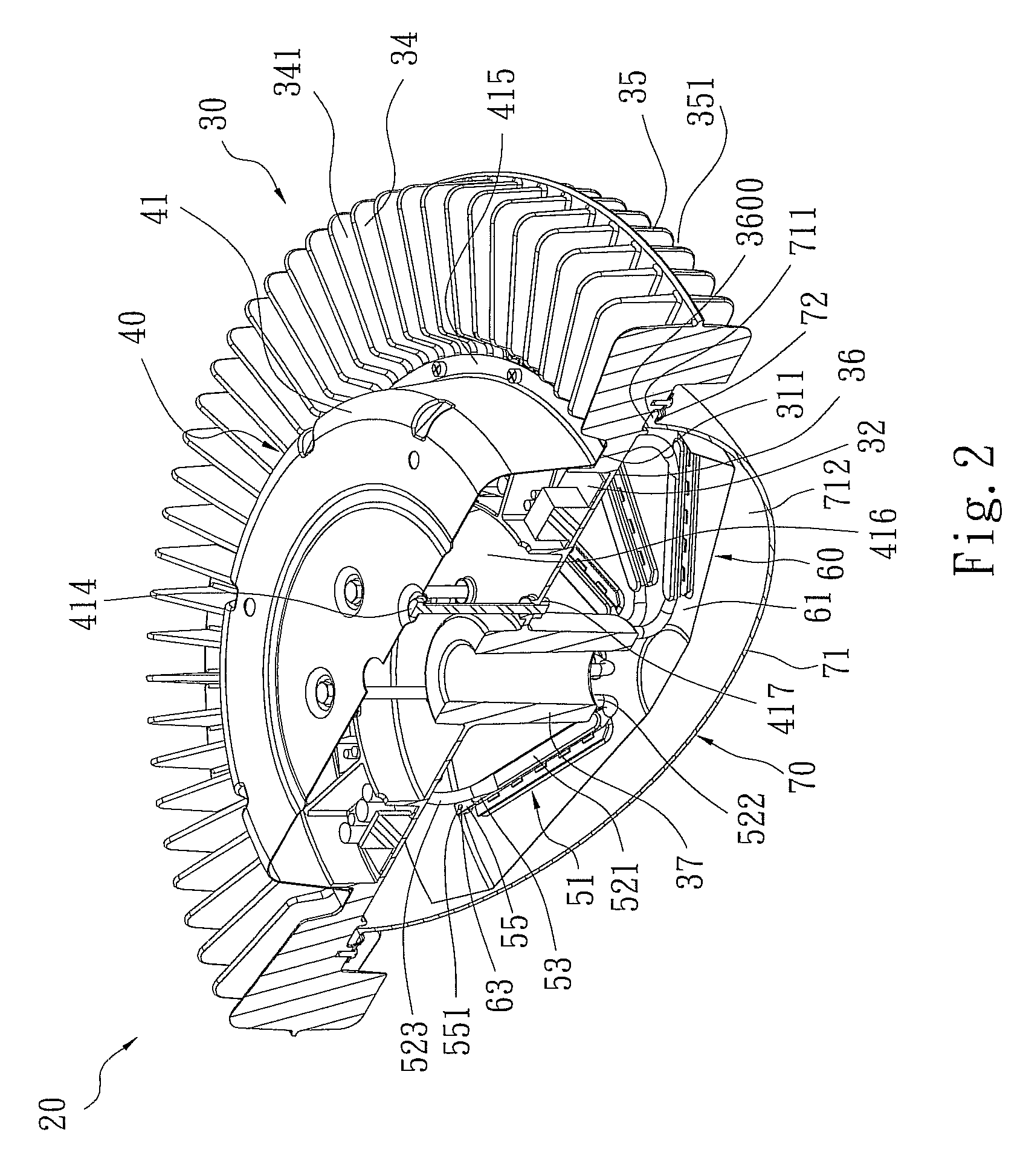

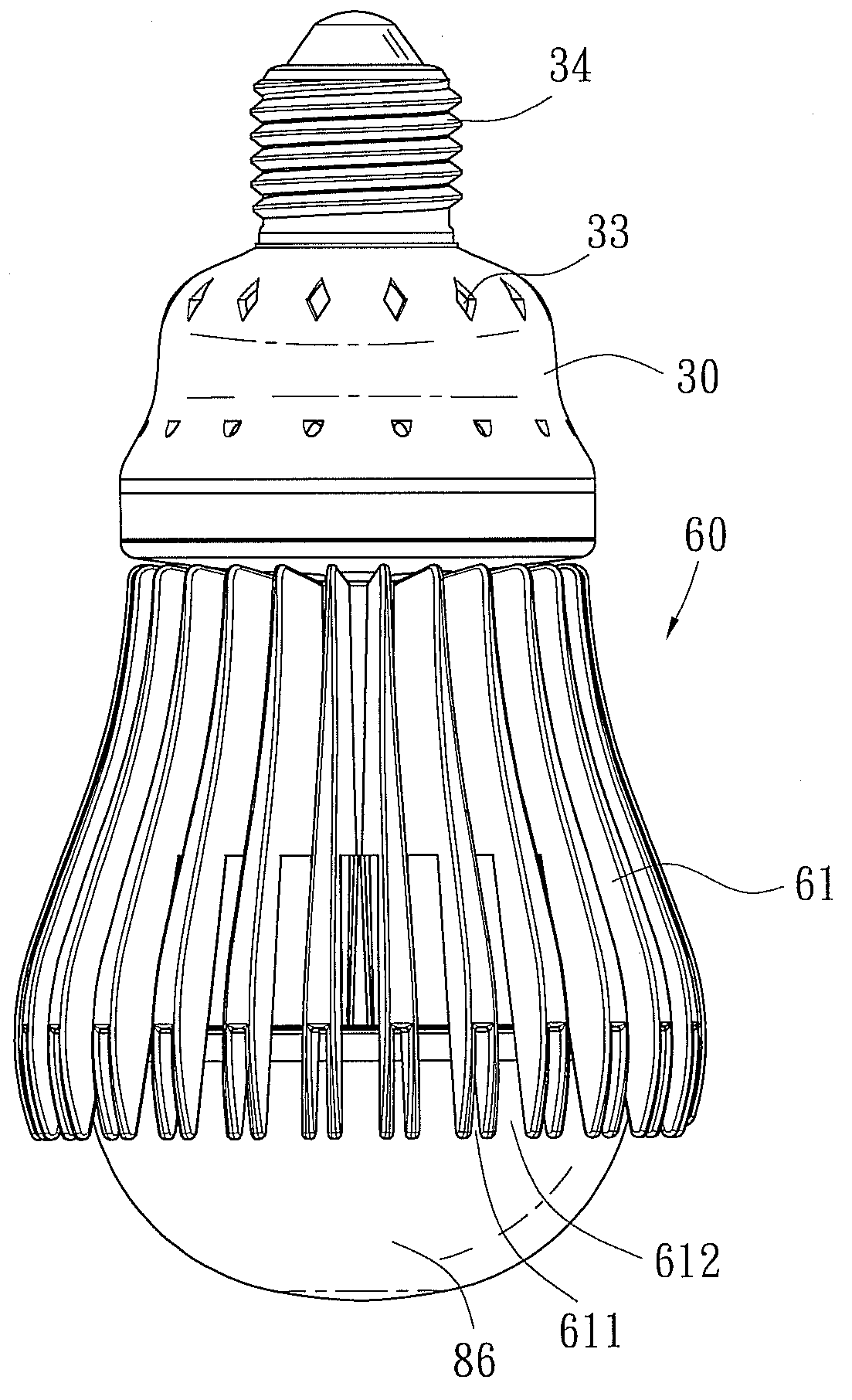

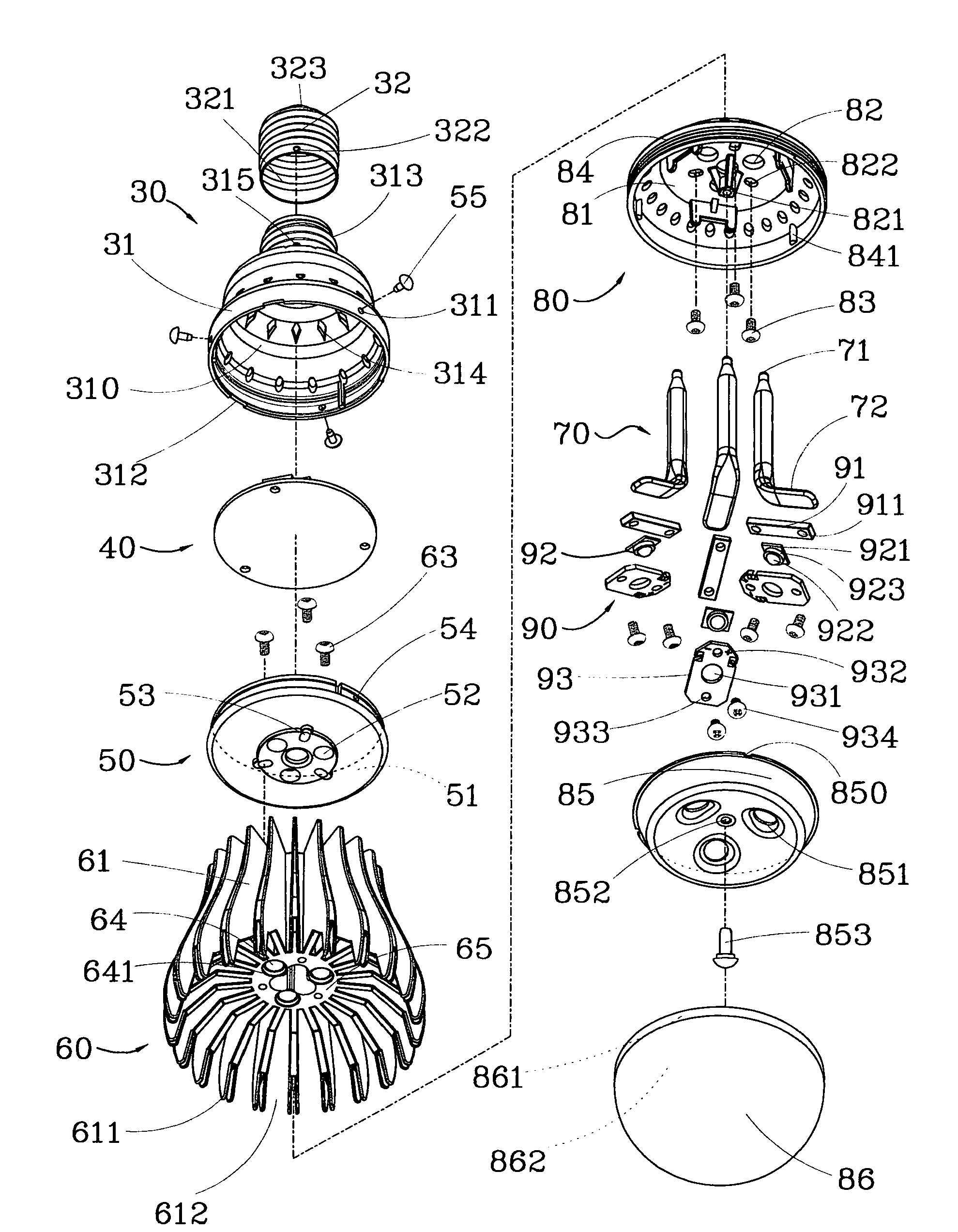

LED lamp bulb structure

InactiveUS7748870B2Effective dispersionGood dispersionPoint-like light sourceElectric circuit arrangementsHeat conductingEngineering

A LED lamp bulb structure is disclosed, wherein a lamp controller is installed inside a lamp head and the bottom surface thereof is fixed by an upper cover. At the bottom surface of the upper cover, a heat dispersing fin set, which has at least a heat conducting tube installed therein, and a lower cover are fixed therein. Furthermore, a bulb housing, which has a tray mounted therein, is screwed around the peripheral edge of the lower cover, and at the bottom of the tray, plural LED lamp sets corresponding to plural heat conducting tubes are outwardly extended. Therefore, the heat produced by the LED lamp set can have a heat exchange through plural heat conducting tubes and heat dispersing fin set for achieving a better heat dispersing efficiency and for more effectively dispersing the heat.

Owner:LI HONG TECHNOLOGICAL

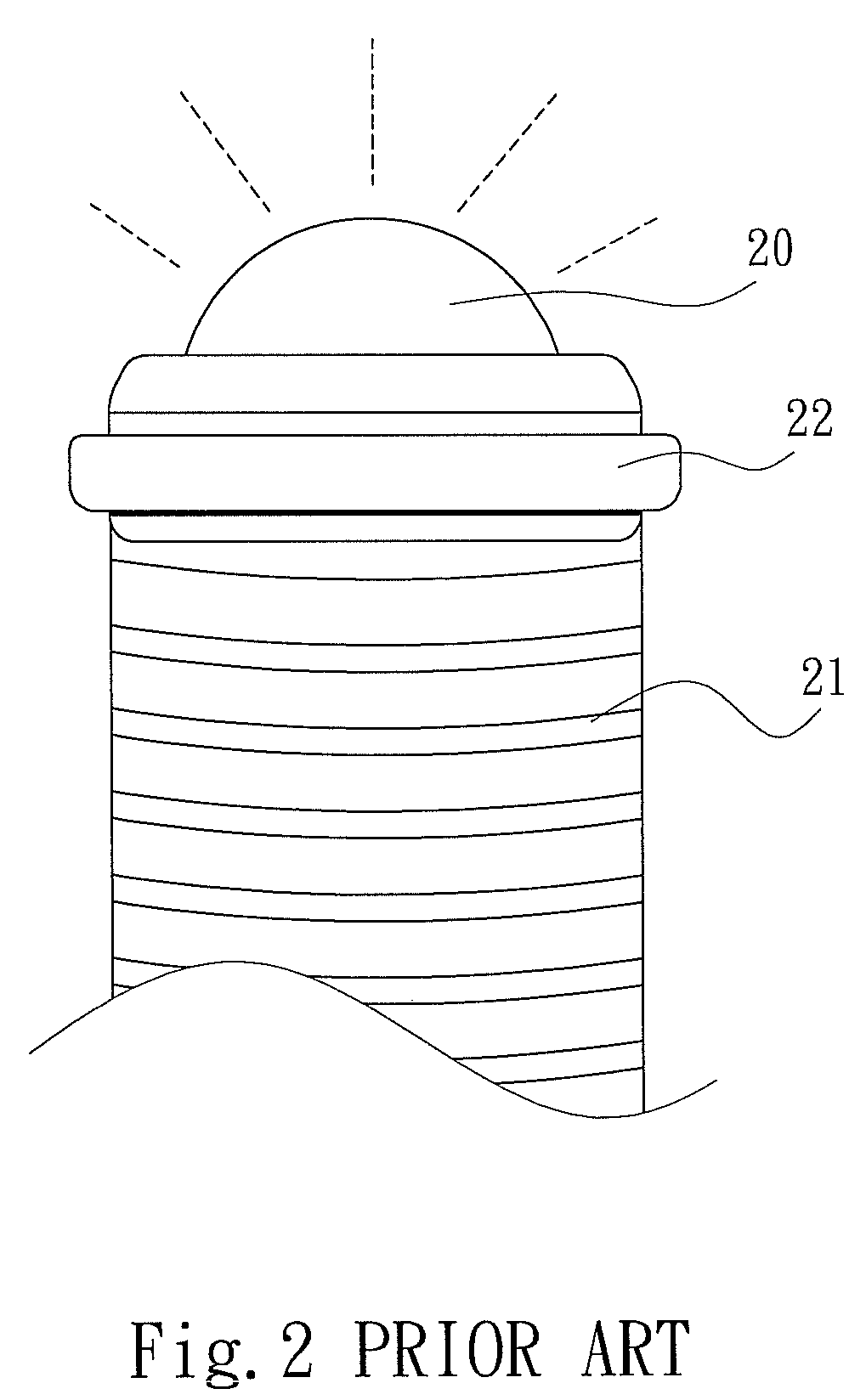

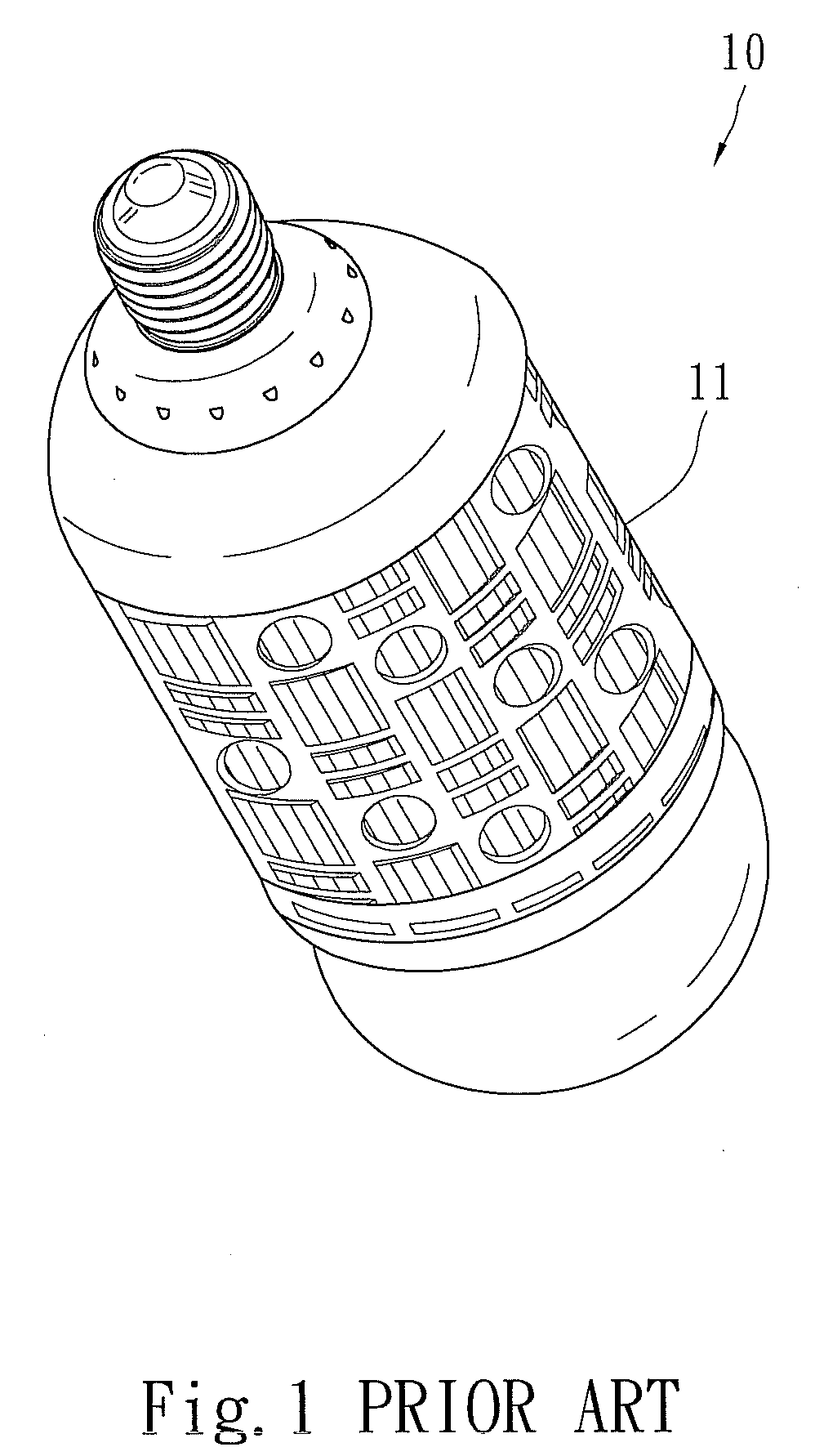

LED lamp

InactiveUS7611264B1Not easy to disperseEffective lightingMechanical apparatusLighting support devicesEngineeringLED lamp

A LED lamp includes a main body surrounded by a fin assembly on the periphery at an upper side and a lower side, a power supply holder located at the upper side and a plurality of LED lamp assemblies located at the lower side. The LED lamp assemblies are encased by a light converging plate which is further encased by a transparent lamp shade fastening to the lower side of the main body. The LED lamp thus formed may be fastened to a ceiling for indoor use through an upper cap of a fastening assembly, or an outdoor electric wire pole through a fastening tray. Each of the LED lamp assemblies has a heat transfer tube to transfer the generated heat to the main body for dispersing through the fin assembly. Thus desired heat dissipation can be accomplished.

Owner:LI HONG TECHNOLOGICAL

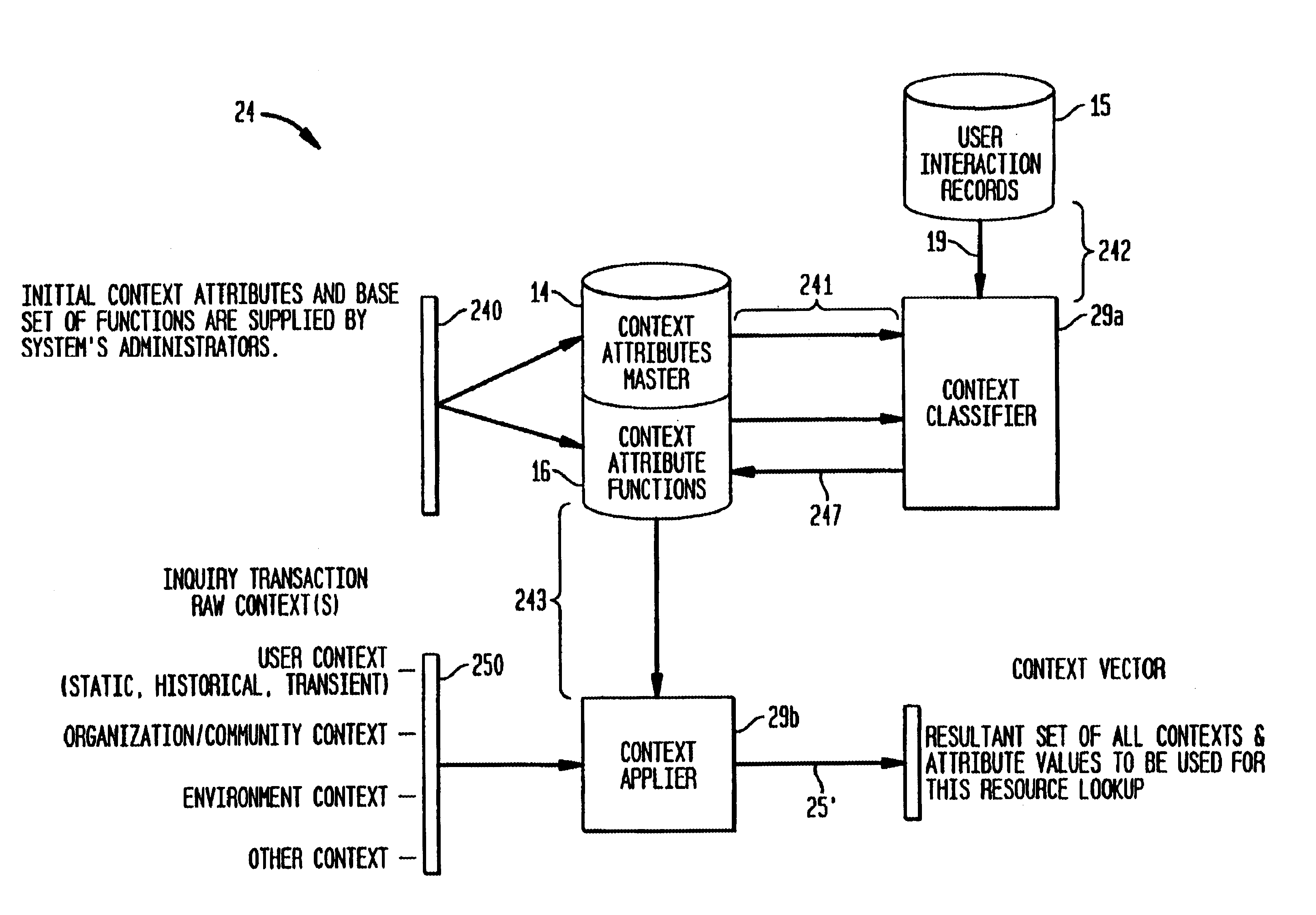

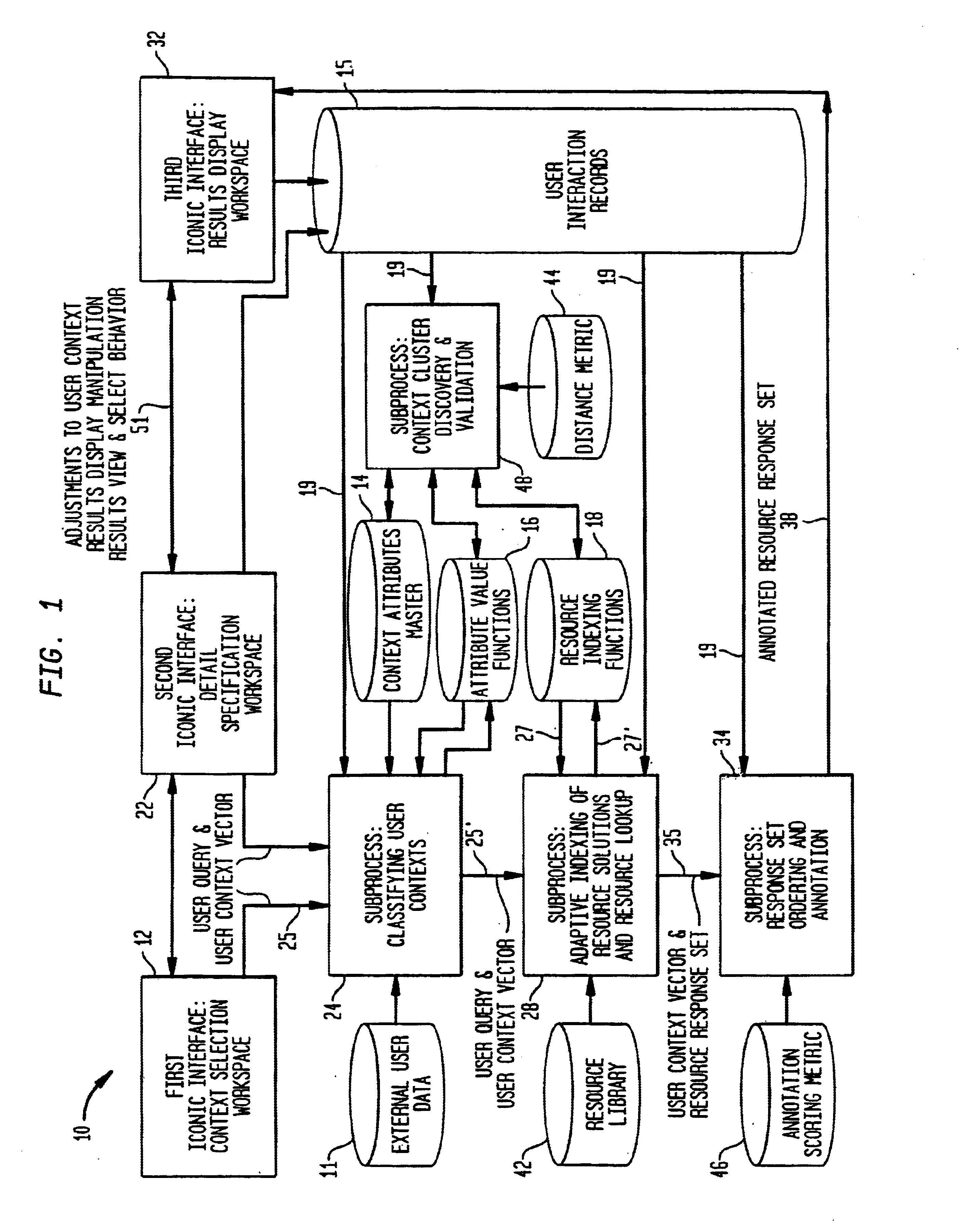

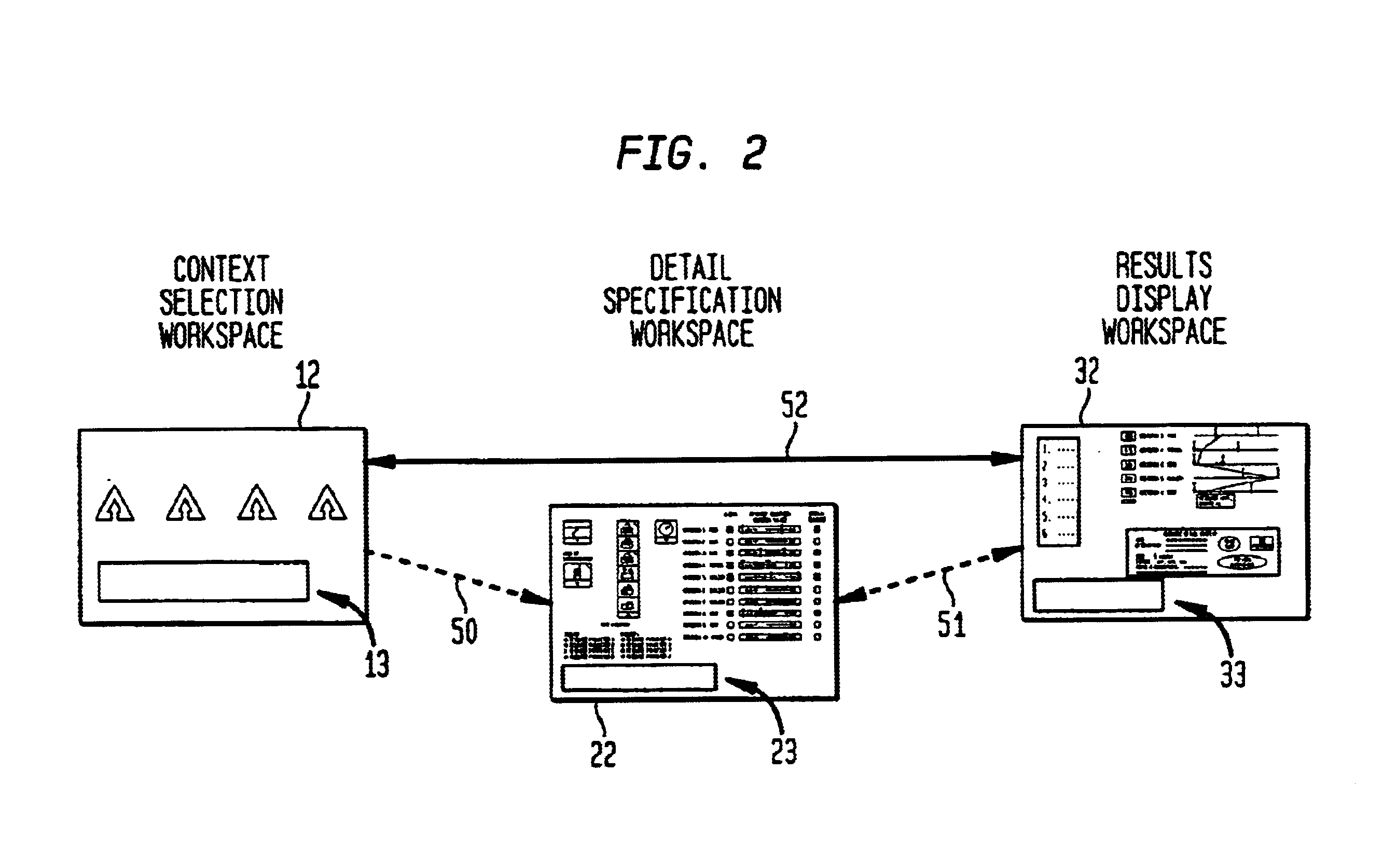

Customer self service subsystem for classifying user contexts

InactiveUS6853998B2Reduce search timeEffective dispersionData processing applicationsDigital data information retrievalPopulationContext property

A system and method for classifying user context in a customer self service system that performs resource search and selection and includes a context attribute database comprising types of user contexts and one or more context attributes associated with each user context for processing by the system, and context attribute function database comprising functions for computing values for each context attribute. The classifying system comprises a computing device for receiving a user query and a context vector comprising data associating an interaction state with the user and, processing the query and context vector against data included in the context attribute database and context attribute function database for predicting a particular user context. The classifier populates the user context vector with context parameters specifying a user interaction state for use in a subsequent resource search. The result of this invention is an ability to relieve the user of the nonproductive work of describing their context and the ability to improve the search value by including criteria derived from both data and behaviors in the general population which may be unknown to the user. The system and method is especially applicable for a self service system in a variety of customer self service domains including education, real estate and travel.

Owner:IBM CORP

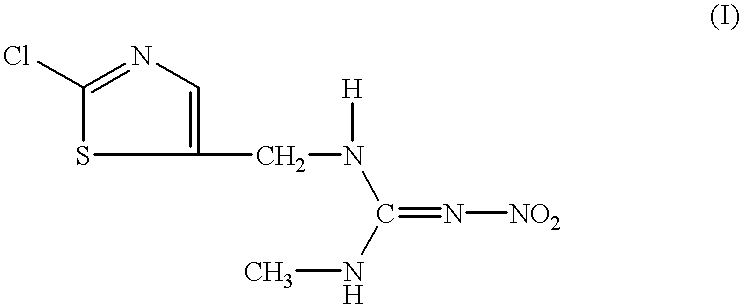

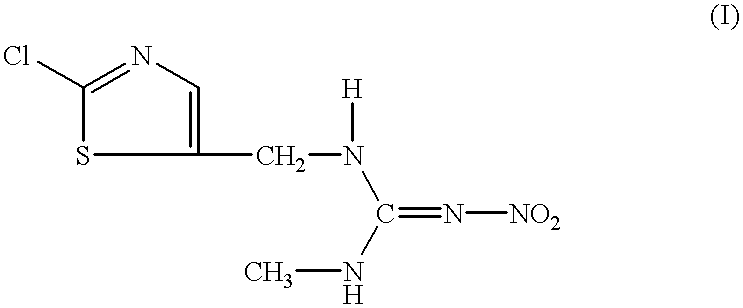

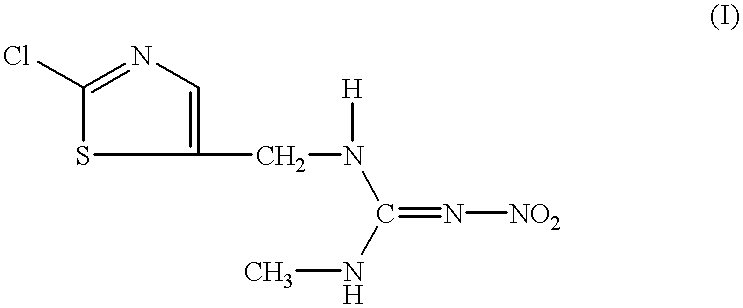

Aqueous suspension of agrochemical

InactiveUS6306414B1Low viscosityEffective dispersionOrganic active ingredientsBiocideSuspended particlesPhenyl Ethers

The present invention relates to an aqueous suspension comprising (i) a compound of the formula:or a salt thereof, (ii) a condensate of formaldehyde with an aromatic sulfonic acid or a salt thereof or a polyoxyalkylene allyl phenyl ether sulfate, and (iii) an absorptive water-soluble polymer. The aqueous suspension of the invention can be used with advantage as a stable aqueous suspension of low viscosity providing for excellent delivery from a container, with excellent dispersibility in diluent water and excellent long-term fluidity free from caking due to precipitation of the suspended particles.

Owner:SUMITOMO CHEM CO LTD

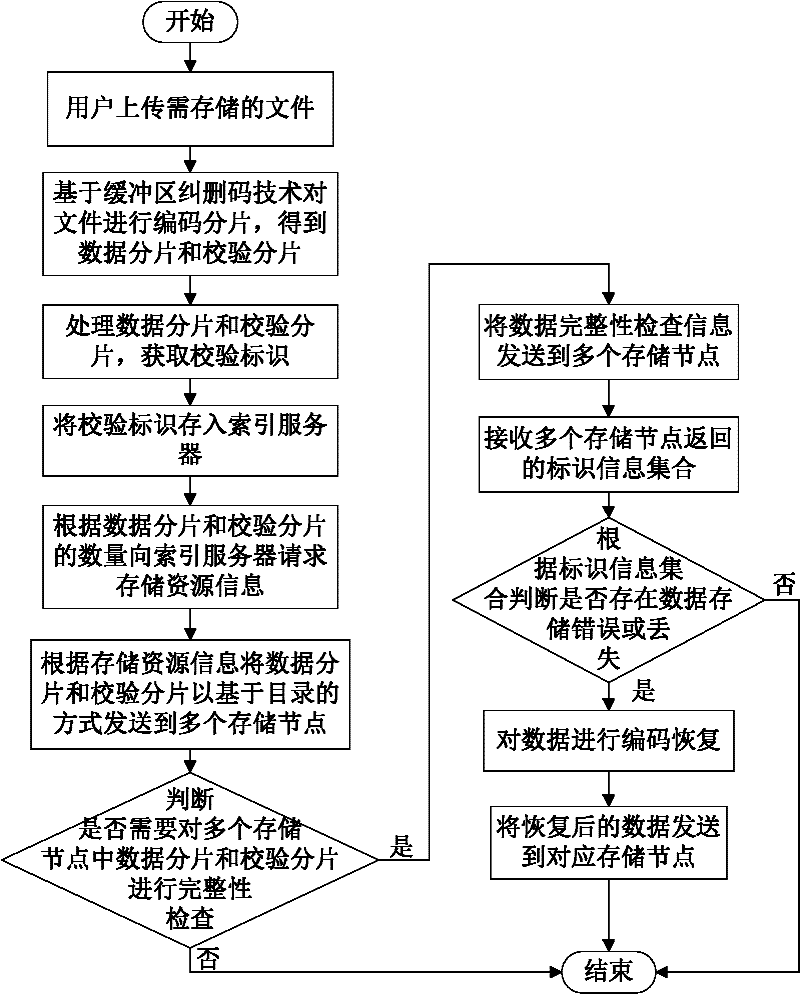

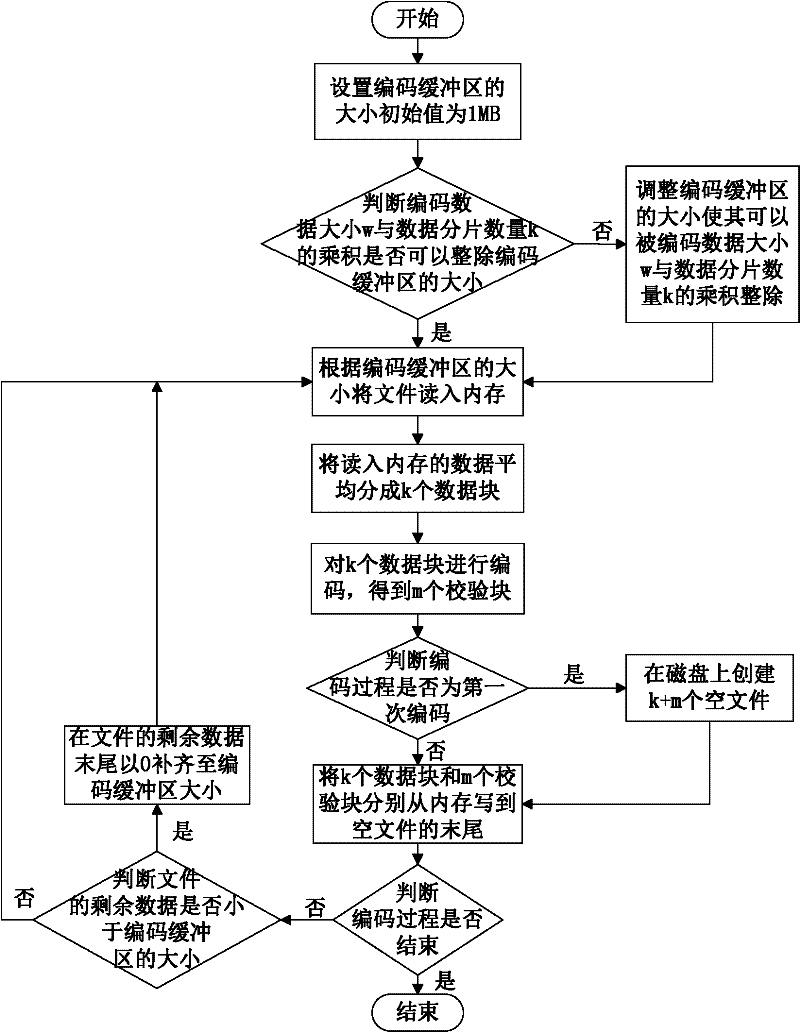

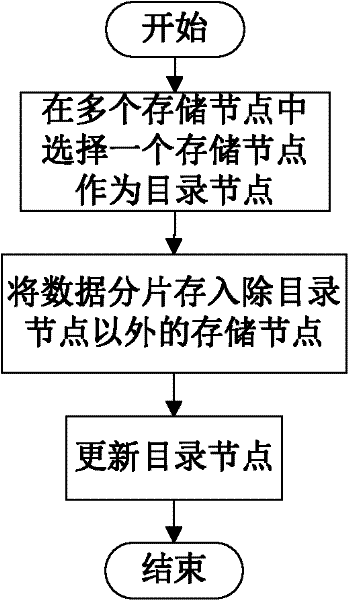

Data storage method of cloud storage system

InactiveCN102546755ADoes not affect recoveryImprove data availabilityTransmissionSpecial data processing applicationsComputer hardwareData integrity

The invention discloses a data storage method of a cloud storage system, which comprises the steps of: carrying out coding fragmentation on a file on the basis of a buffer zone erasure code technology to obtain data fragments and check fragments; processing the data fragments and the check fragments to obtain a check identification; storing the check identification in an index server; requesting storage resource information to the index server according to the quantity of the data fragments and the check fragments; sending the data fragments and the check fragments to a plurality of storage nodes according to the storage resource information; judging whether needing to carry out integrity check on the data fragments and the check fragments in the storage nodes; if needing to carry out integrity check on the data fragments and the check fragments in the storage nodes, sending the data integrity check information to the storage nodes, receiving an identification information set returned by the storage nodes, and judging whether data storage errors or data losses exist according to the identification information set, if yes, coding for recovering the data, and sending the recovered data to the corresponding storage nodes.

Owner:HUAZHONG UNIV OF SCI & TECH

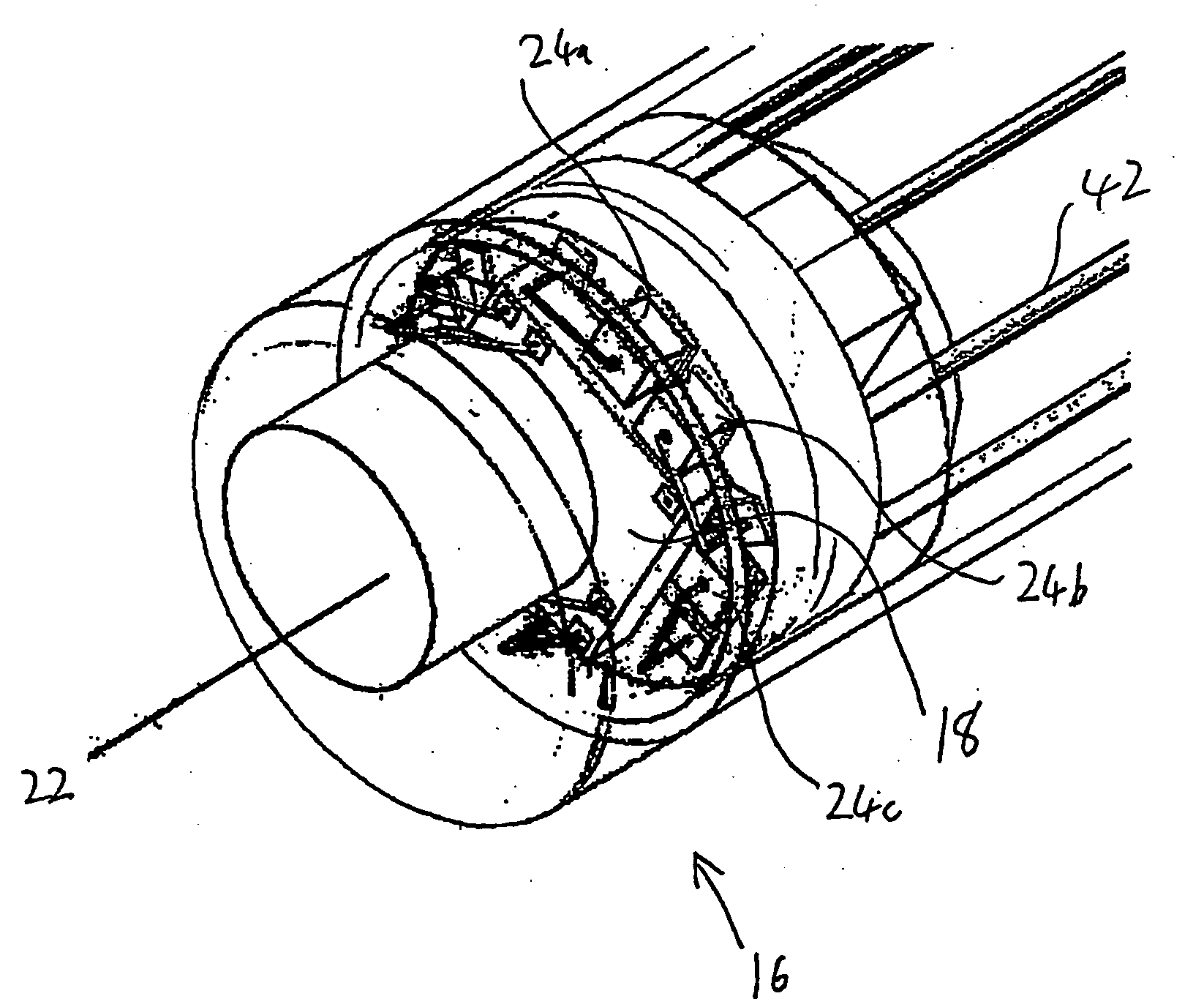

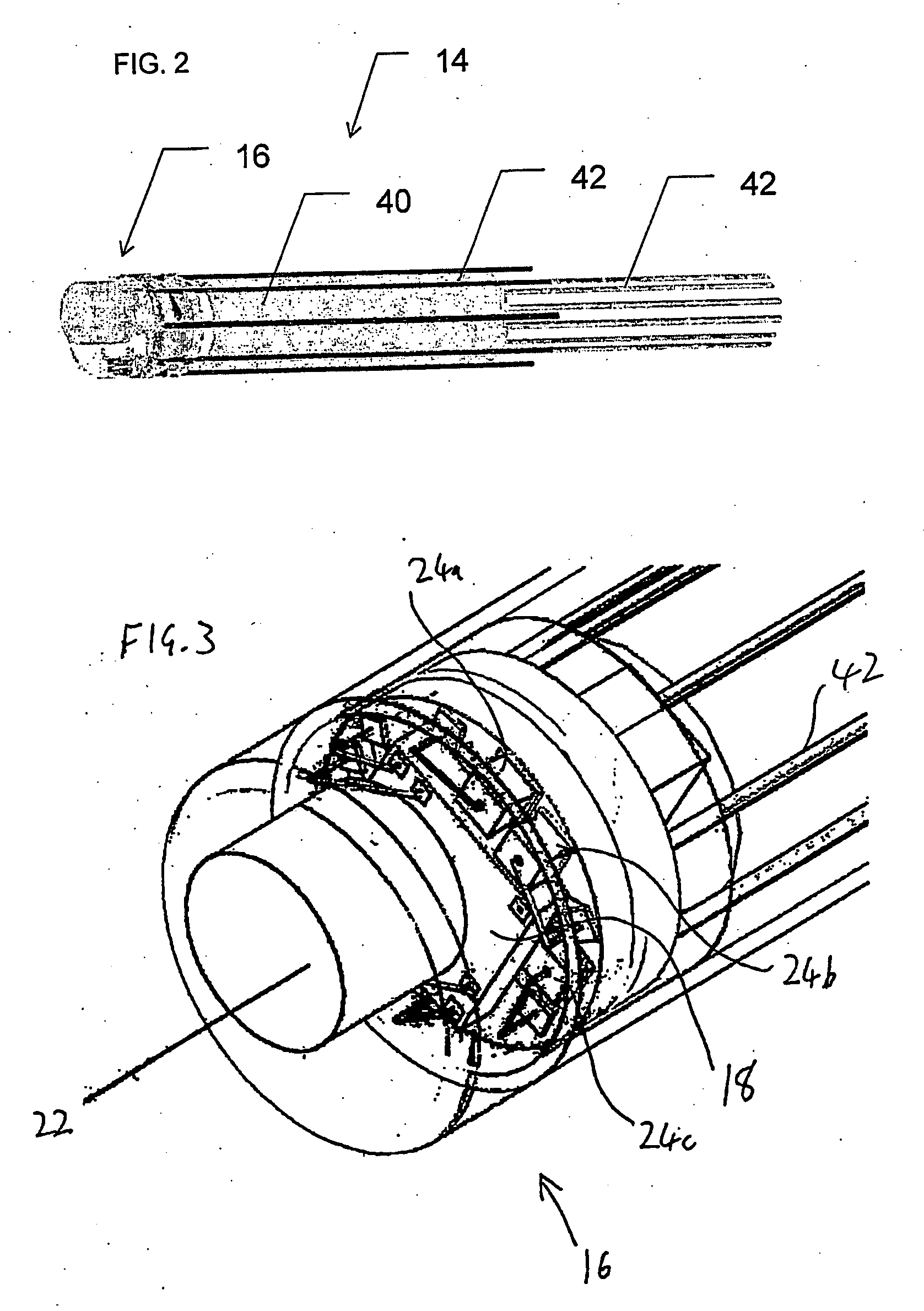

Endoscope with Miniature Imaging Arrangement

A miniature endoscope with an imaging arrangement associated with its distal tip portion includes an image sensor chip with a two-dimensional array of light-sensitive pixels and a lens arrangement deployed for focusing light from a field of view onto the image sensor chip so as to generate an image of a scene viewed from the distal tip portion. The lens arrangement is preferably directly affixed to the image sensor chip by a quantity of transparent adhesive. Use of bidirectional communication along data lines to the image sensor chip allows use of only four wires connecting to the chip. These and other features allow miniaturization of the endoscope to a diameter of about 2 millimeters while still generating color images of high dynamic range.

Owner:SUPER DIMENSION

LED lamp bulb structure

InactiveUS20090296402A1Heat dispersing efficiencyEfficiently dispersedPoint-like light sourceElectric circuit arrangementsEngineeringHeat conducting

A LED lamp bulb structure is disclosed, wherein a lamp controller is installed inside a lamp head and the bottom surface thereof is fixed by an upper cover. At the bottom surface of the upper cover, a heat dispersing fin set, which has at least a heat conducting tube installed therein, and a lower cover are fixed therein. Furthermore, a bulb housing, which has a tray mounted therein, is screwed around the peripheral edge of the lower cover, and at the bottom of the tray, plural LED lamp sets corresponding to plural heat conducting tubes are outwardly extended. Therefore, the heat produced by the LED lamp set can have a heat exchange through plural heat conducting tubes and heat dispersing fin set for achieving a better heat dispersing efficiency and for more effectively dispersing the heat.

Owner:LI HONG TECHNOLOGICAL

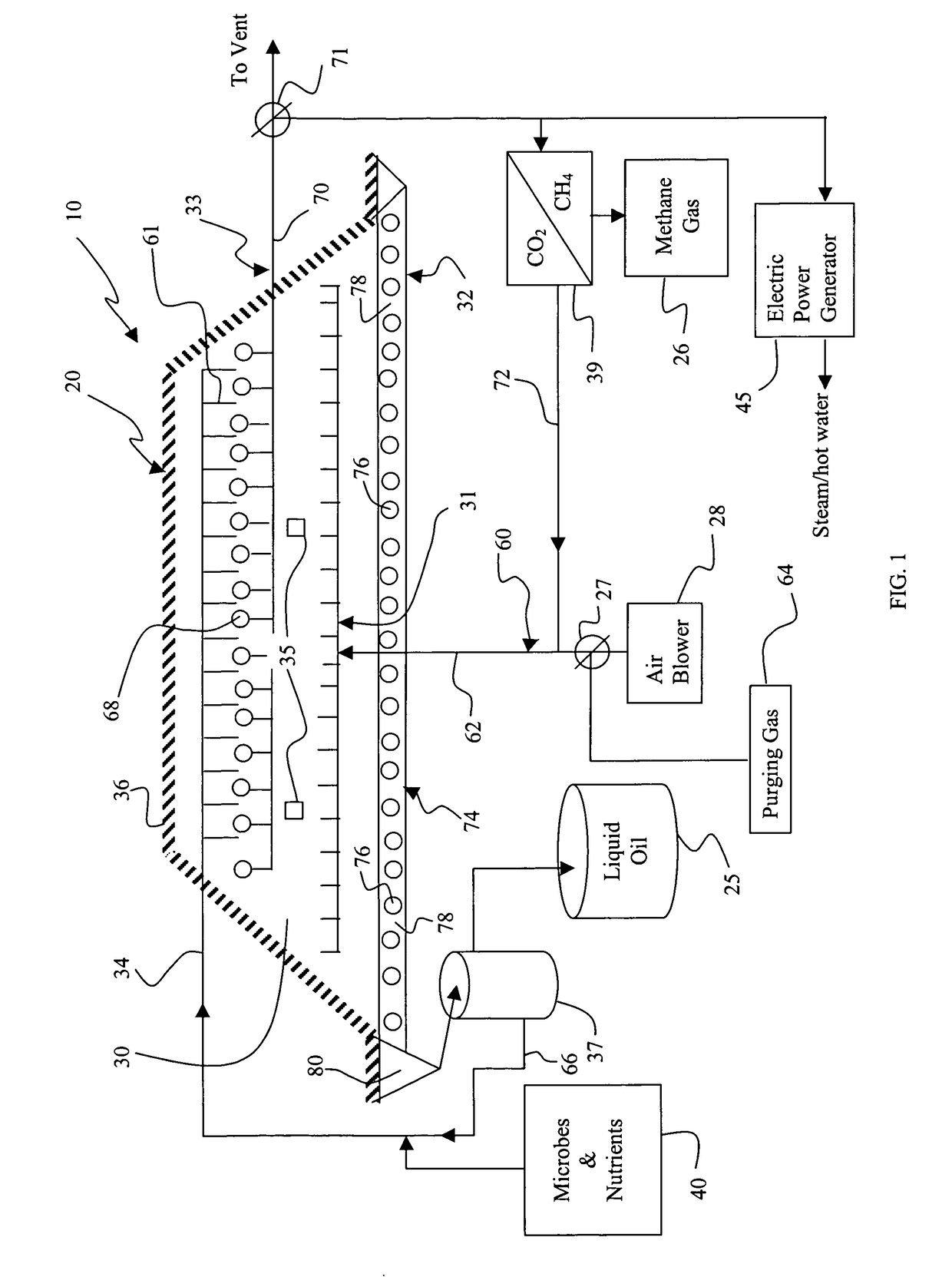

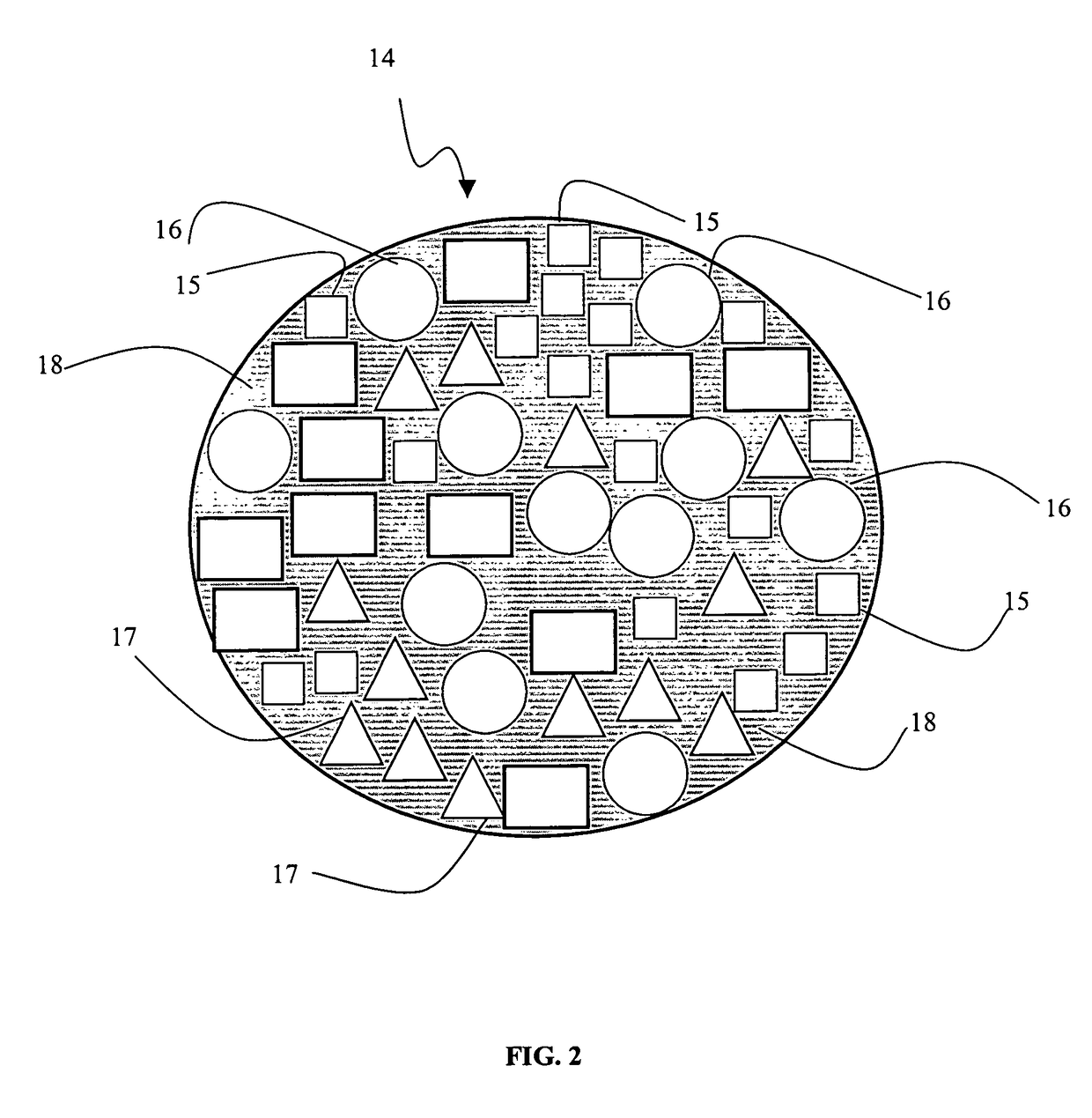

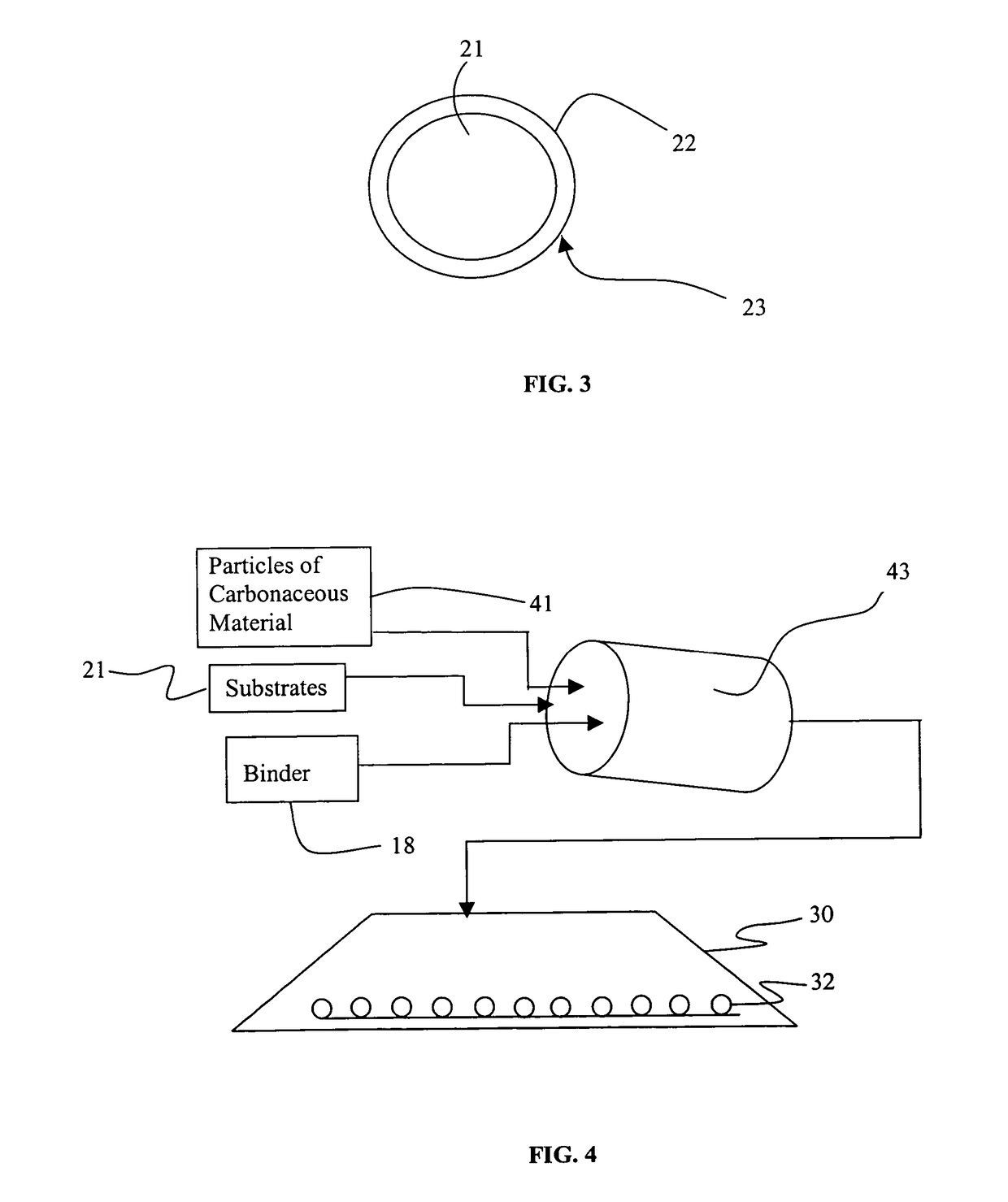

Method and bioreactor for producing synfuel from carbonaceous material

InactiveUS7906304B2Easily biodegradableImprove concentrationGas production bioreactorsWaste based fuelPetroleumBioreactor

A method of producing fuel from biodegradable carbonaceous material using a stacked particle bioreactor is provided. A stacked particle bioreactor is formed from particles including biodegradable carbonaceous material. The biodegradable carbonaceous material in the stacked particle bioreactor is aerobically and / or anaerobically bioconverted into one or more synfuels, which are collected from the reactor. The synfuels produced by the method may include synthetic petroleum, alcohol, and / or a gaseous fuel containing methane. Preferably the method includes an aerobic biotreatment phase followed by an anaerobic bioconversion phase. A stacked particle bioreactor for carrying out the anaerobic, and preferably aerobic, degradation is also described.

Owner:GEOSYNFUELS

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

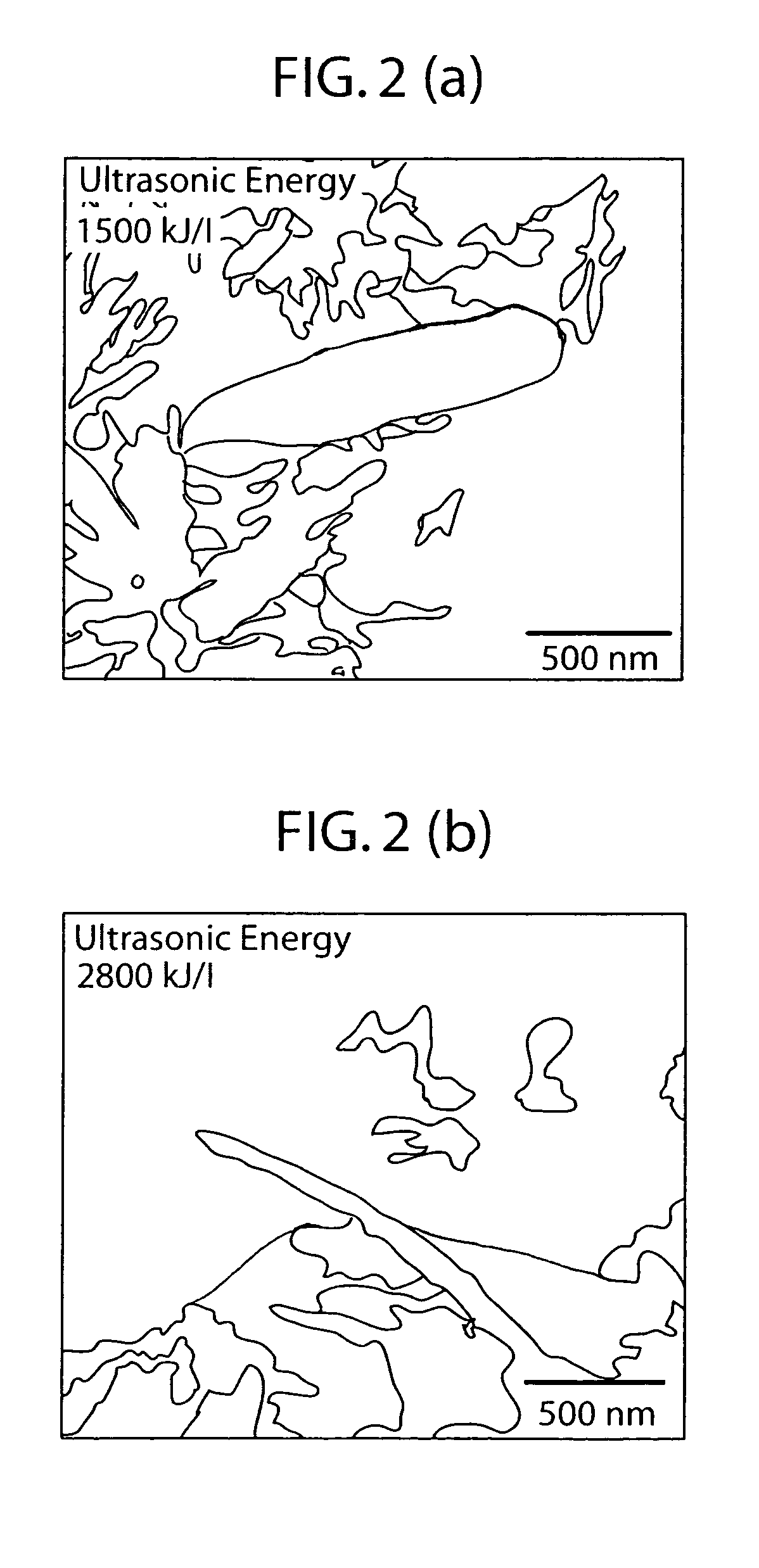

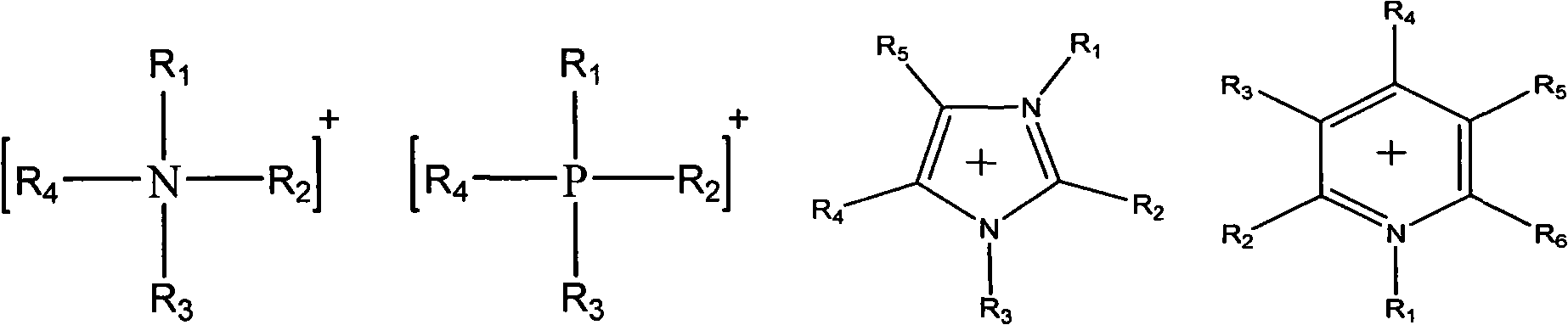

Carbon Nanotube Dispersed Polar Organic Solvent and Method for Producing the Same

ActiveUS20070224106A1Effective dispersionAvoid regroupingMaterial nanotechnologyOther chemical processesOrganic solventCarbon nanotube

In the present invention, a nonionic surfactant is noticed for a function of dispersing a carbon nanotube, and it is found that a mixture solution of an amide-based organic solvent and a polyvinylpyrrolidone (PVP) or of the amide-based organic solvent, the nonionic surfactant, and the polyvinylpyrrolidone (PVP) has an excellent function as a dispersant for the carbon nanotube. Ultrasonication is required for dispersing a carbon nanotube in the dispersant. The ultrasonication maybe carried out in the step of dispersing the carbon nanotube in the nonionic surfactant and / or the amide-based polar organic solvent, and then the polyvinylpyrrolidone (PVP) may be mixed with the resultant dispersion. Alternatively, a mixture solution of the nonionic surfactant and / or the amide-based polar organic solvent, and the polyvinylpyrrolidone (PVP) is prepared, and then the ultrasonication may be carried out in the step of dispersing the carbon nanotube therein.

Owner:NAT INST OF ADVANCED IND SCI & TECH

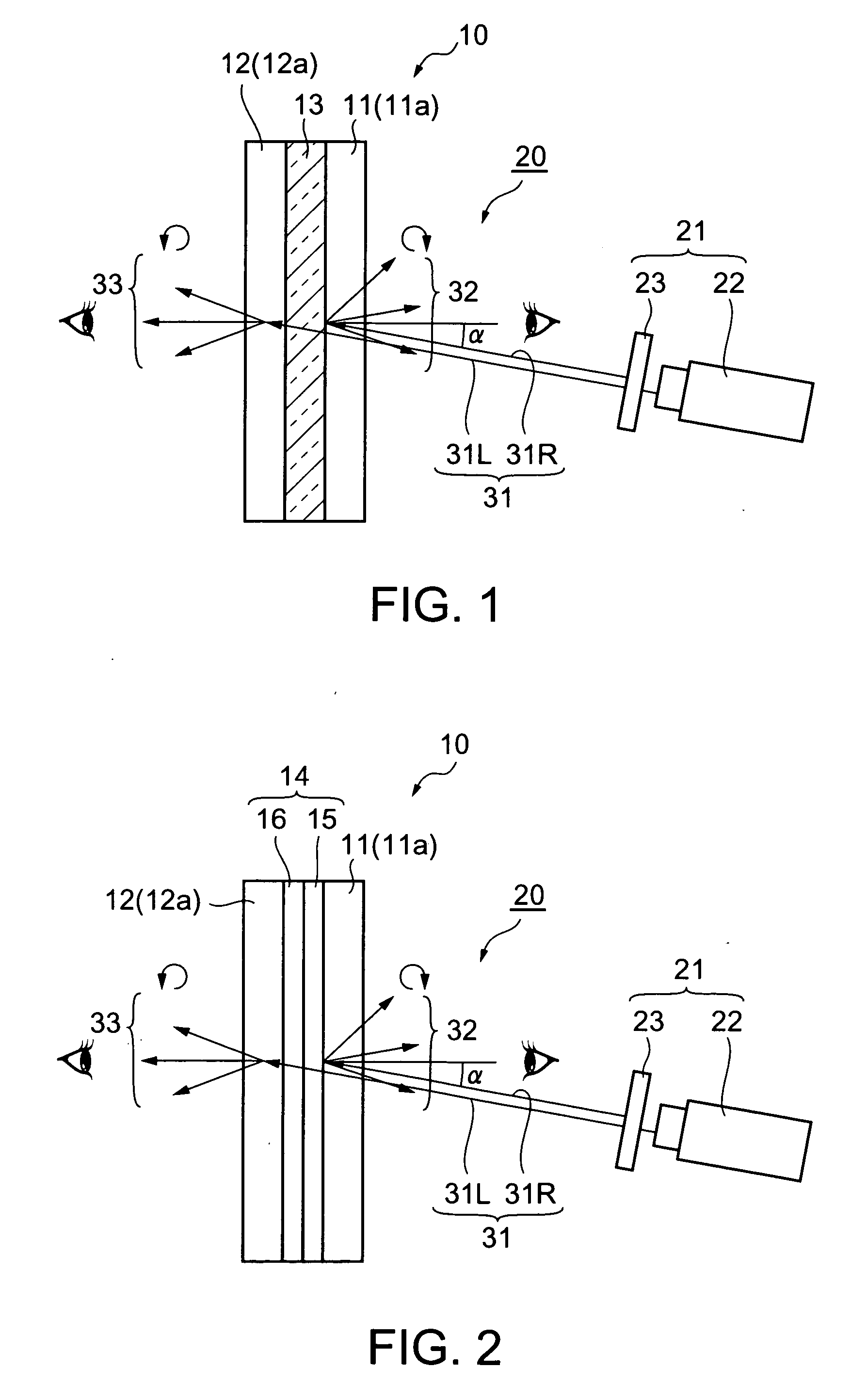

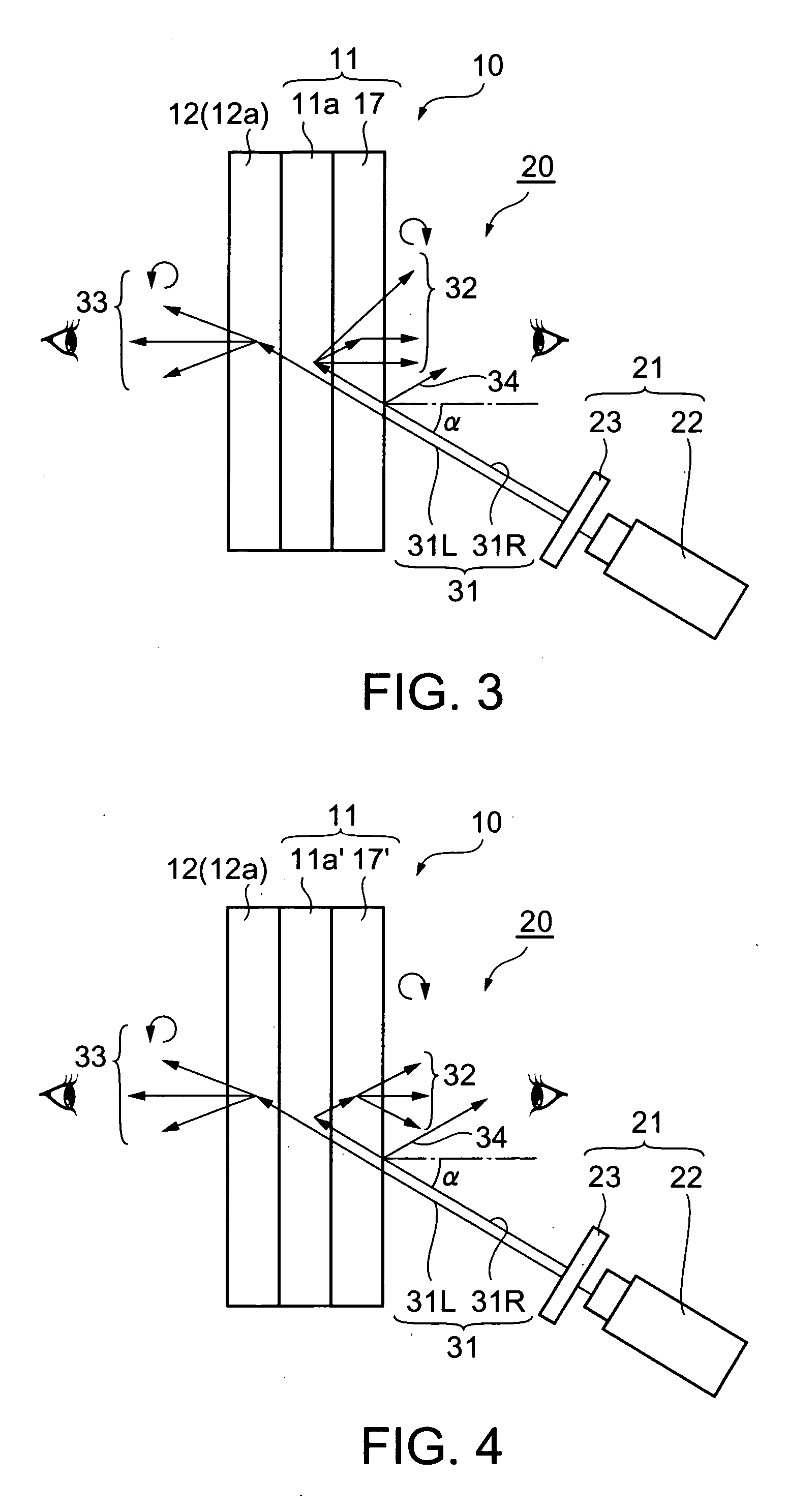

Transmitting-reflecting projection screen, and projection system comprising the same

InactiveUS20060181769A1Improve image contrastReduce brightnessProjectorsPolarising elementsProjection screenProjection system

The present invention provides a see-through transmitting-reflecting projection screen excellent in transparency, capable of sharply displaying, on its both sides, identical or different images even under bright environmental light. A transmitting-reflecting projection screen 10 comprises a reflection-type screen 11 and a transmission-type screen 12. The reflection-type screen 11 reflects a specific polarized component of imaging light projected. The reflection-type screen 11 does not reflect a polarized component, different from the specific polarized component, of the imaging light, and this polarized component passes through the reflection-type screen 11 and the transmission-type screen 12.

Owner:DAI NIPPON PRINTING CO LTD

Cationic Surfactant Systems Comprising Microfibrous Cellulose

ActiveUS20080146485A1Increase shearEnhanced mixing processCosmetic preparationsCationic surface-active compoundsParticulatesCellulose

Cationic surfactant systems, using microfibrous cellulose to suspend particulates therein, are described. Methods of making these systems are also described.

Owner:CP KELCO U S INC

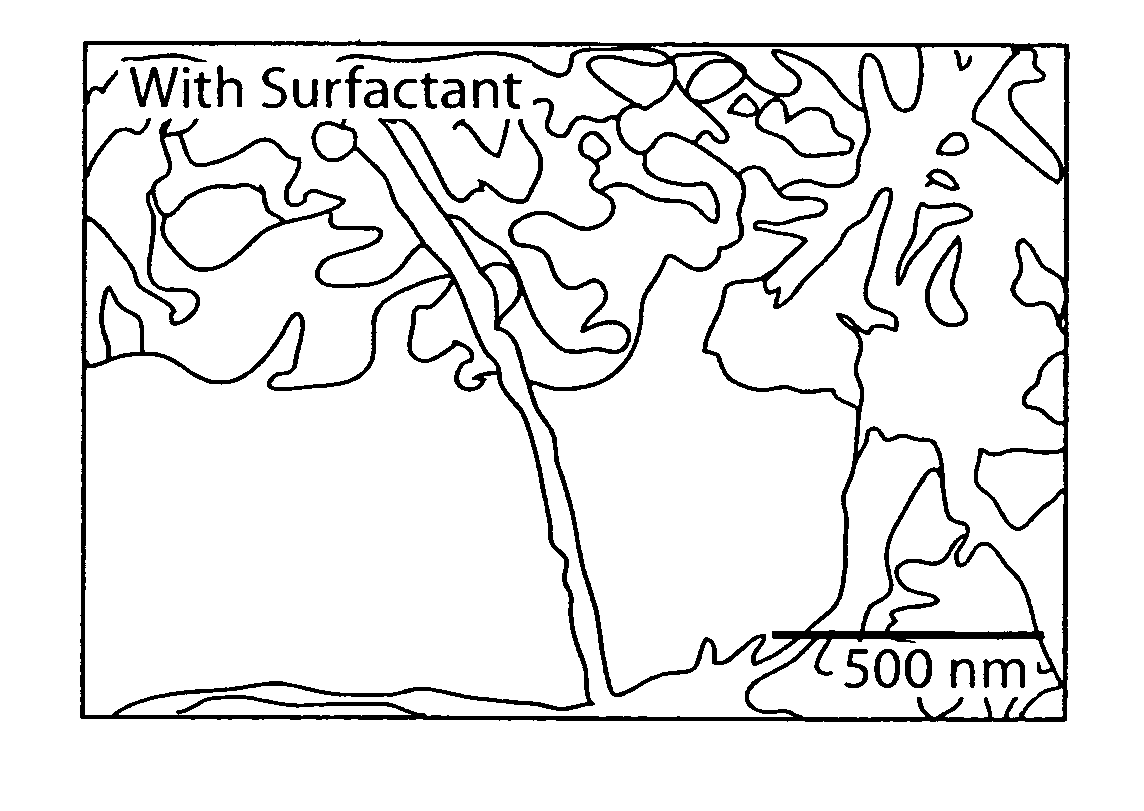

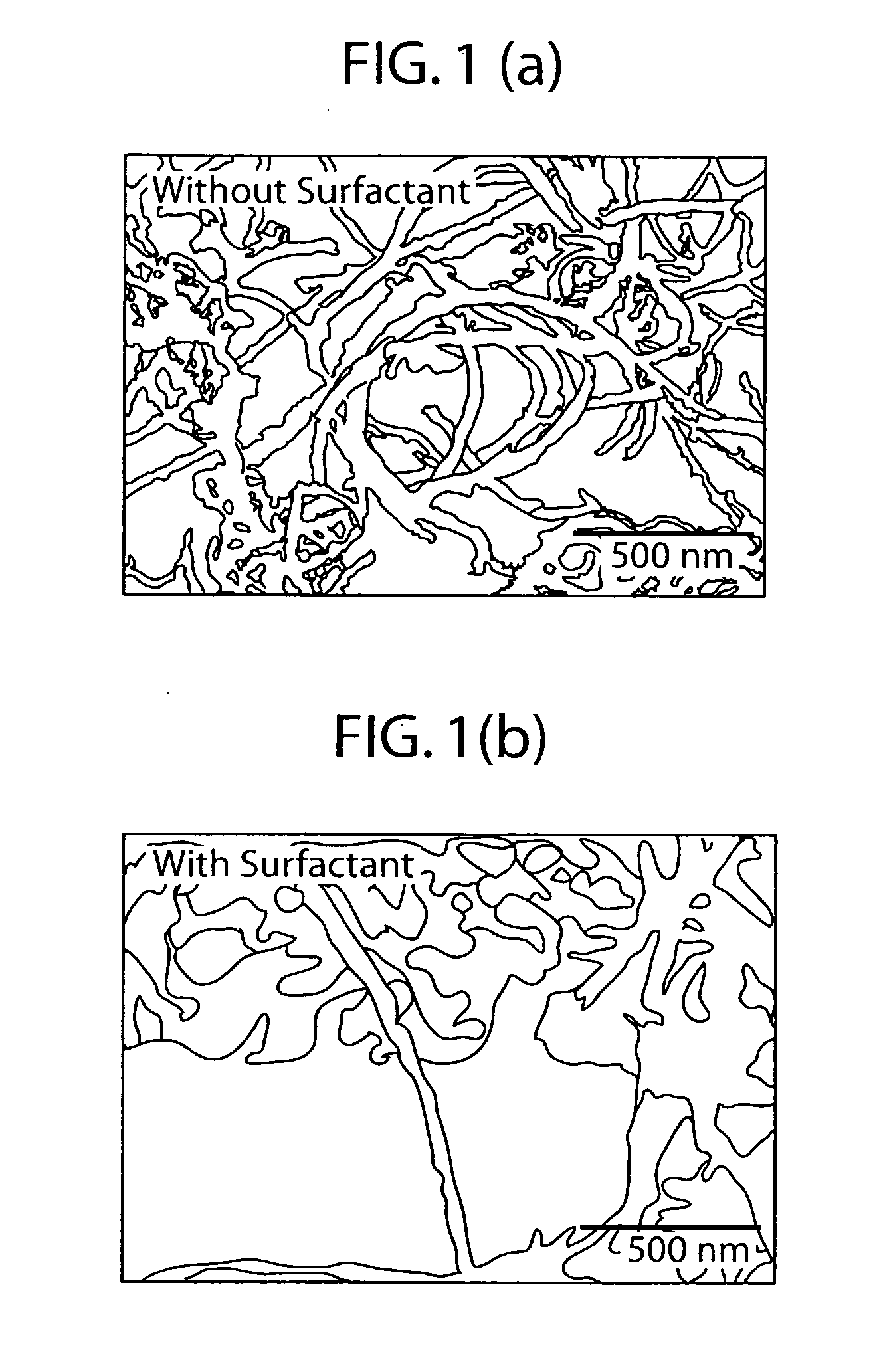

Highly-dispersed carbon nanotube-reinforced cement-based materials

A composite cement material is prepared from cement material and carbon nanotubes, wherein the carbon nanotubes are present from about 0.02 wt % to about 0.10 wt % based on weight of cement material. The process for preparing such cement compositions includes sonicating a mixture of a surfactant, water, and carbon nanotubes; and blending the dispersion and the cement material to form a cementitious paste. The process may also include curing the cementitious paste. The composite cement materials are useful in a variety of cement applications where a reduction in nanoscale flaws and fractures is desired.

Owner:NORTHWESTERN UNIV

Electrically conductive composite fibre containing carbon nanotube and method for making same

InactiveCN1840750AGood electrical propertiesIncreased durabilityFilament/thread formingArtifical filament manufactureFiberConductive polymer

The disclosed conductive composite fiber with carbon nano tube comprises a conductive core layer with 60~99.5wt% thermoplastic polymer, 0~5% carbon nano tube, 0~15% conductive carbon black, and 0.5~20% dispersant; and a shin layer with fiber-forming polymer. Wherein, the preparation method comprises mixing, extruding for granulation, and mixed spinning. This invention improves product performance.

Owner:DONGHUA UNIV

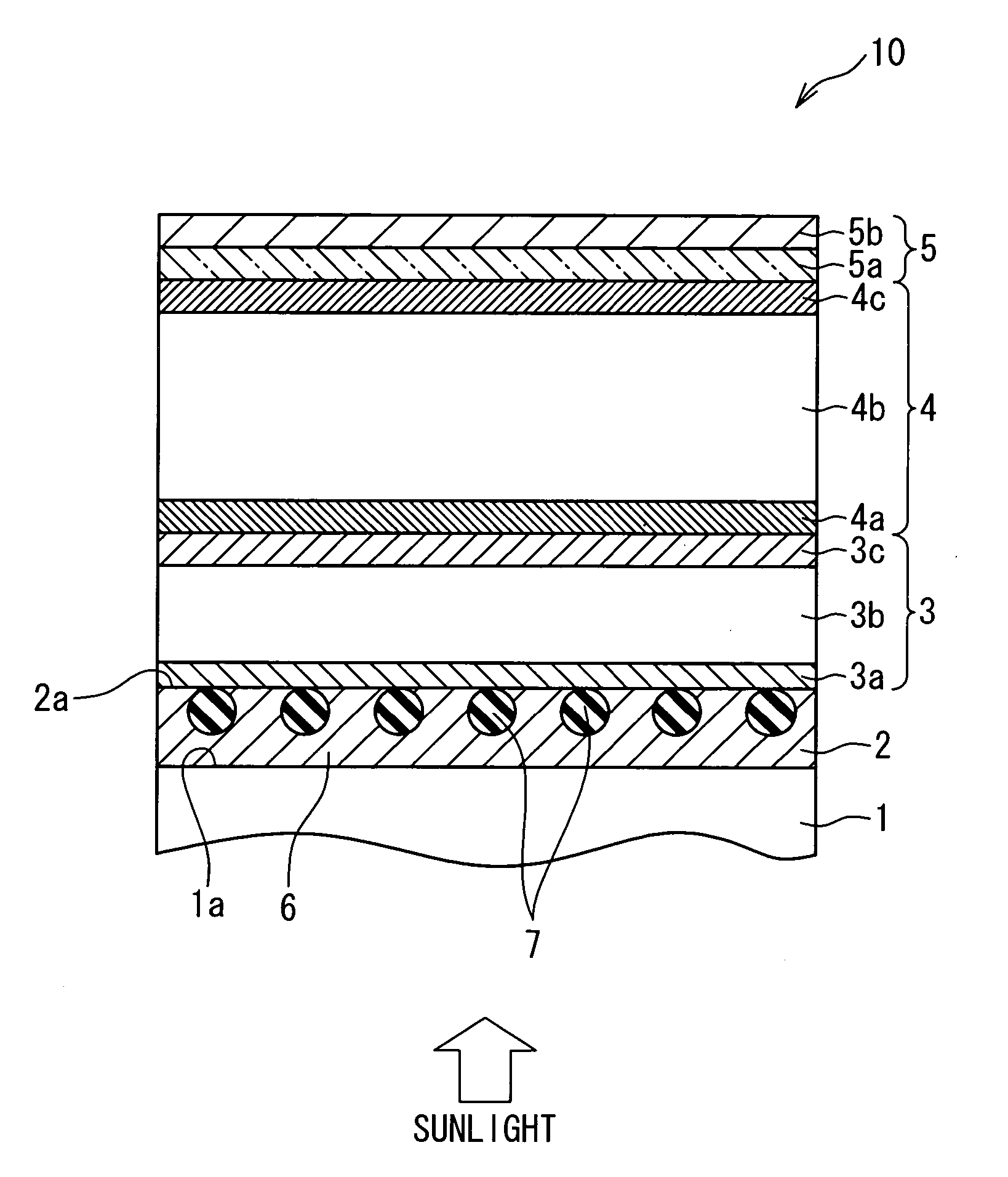

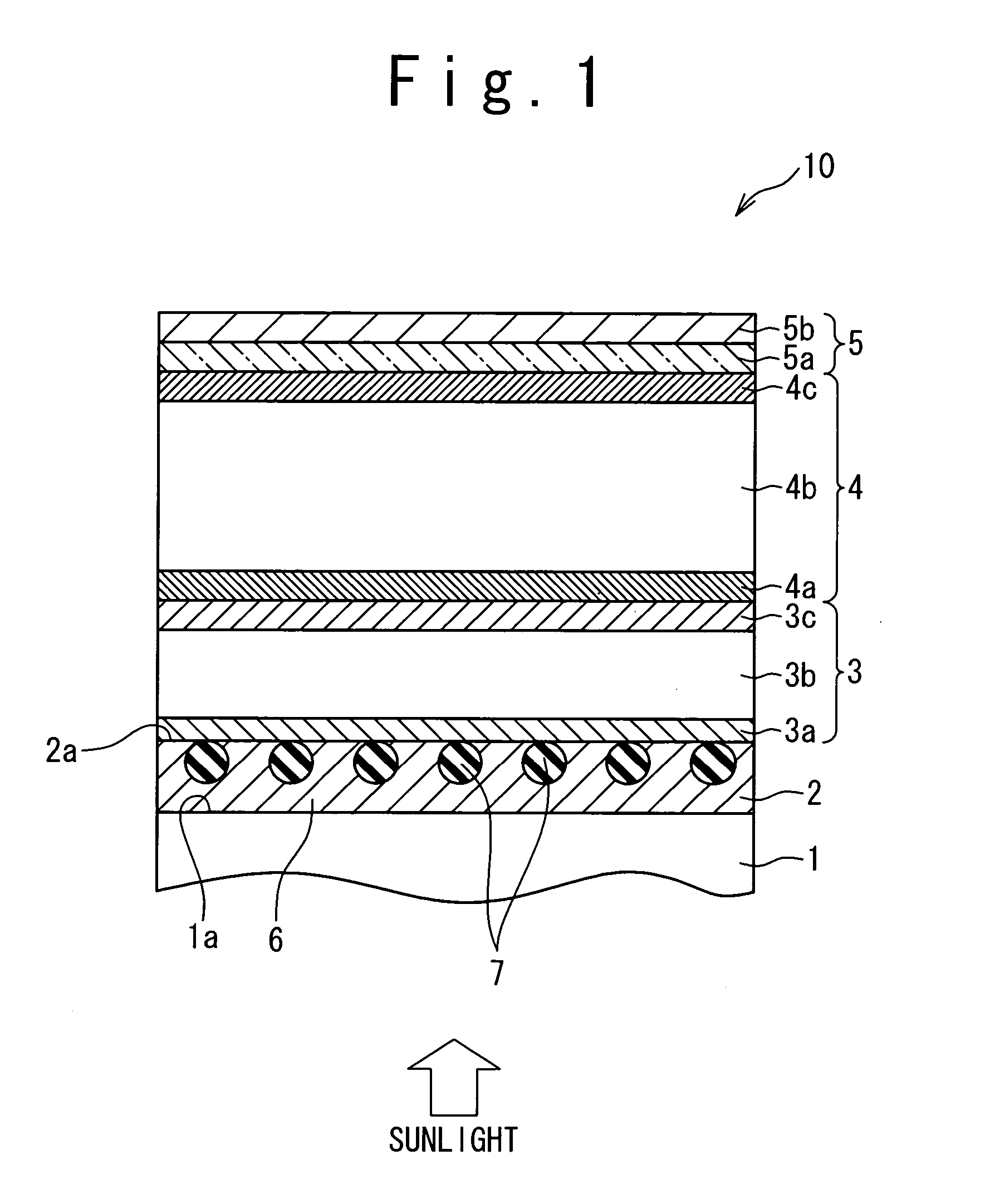

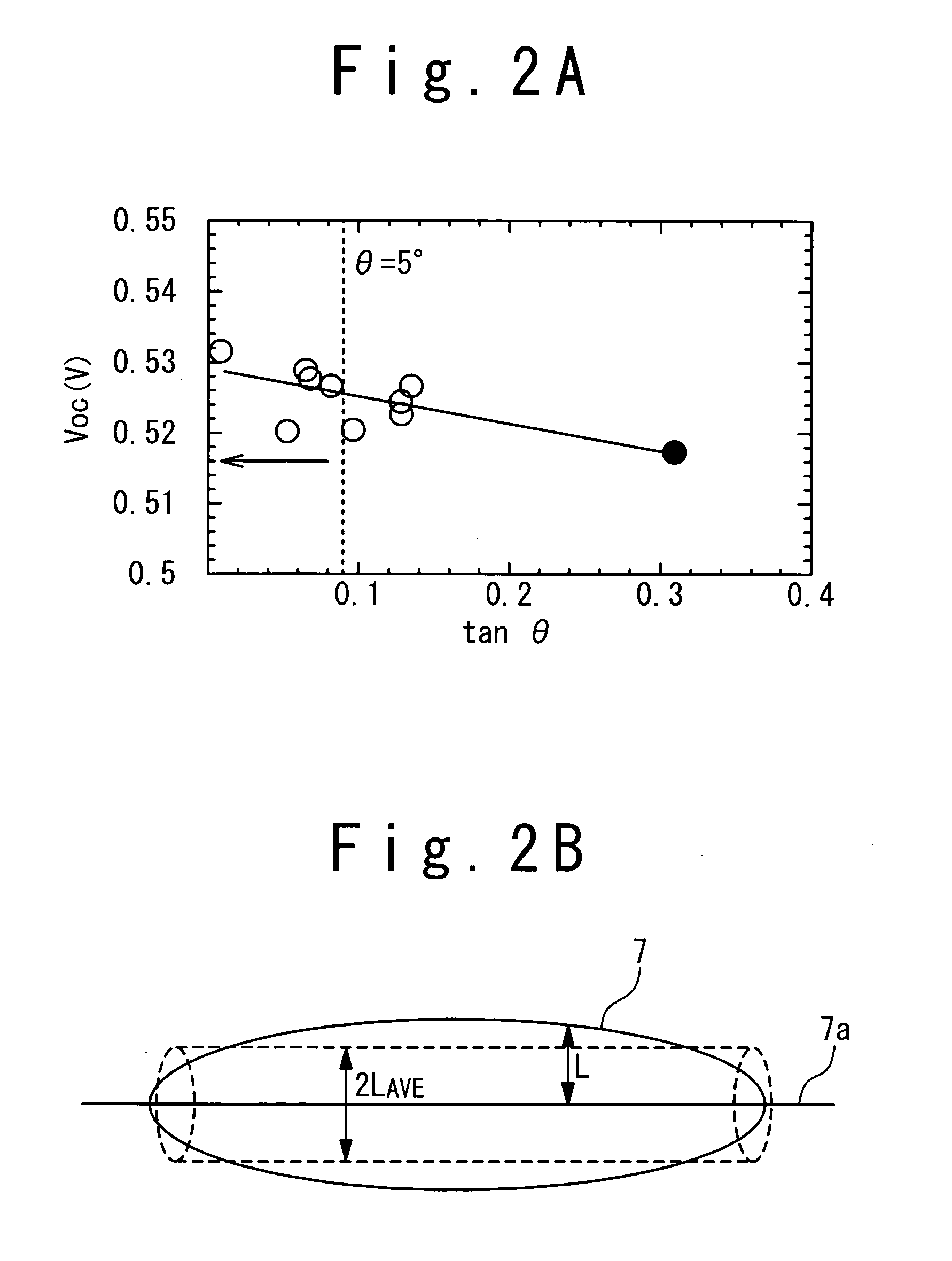

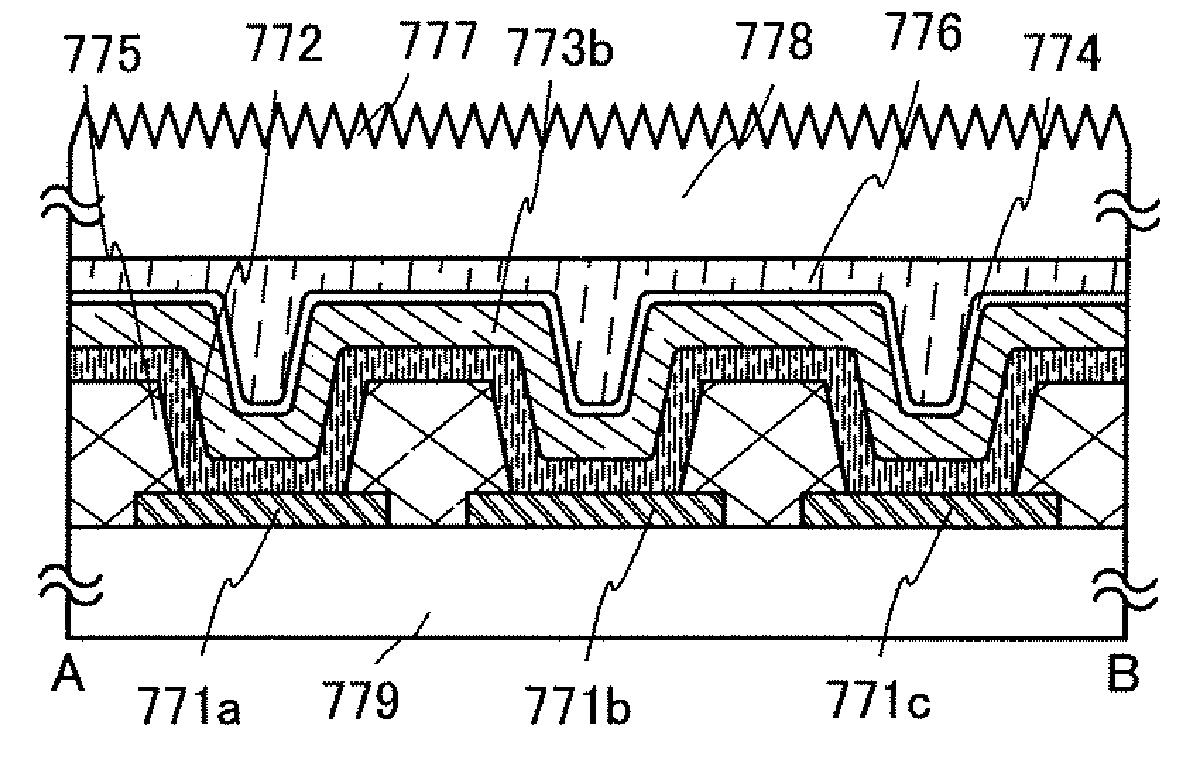

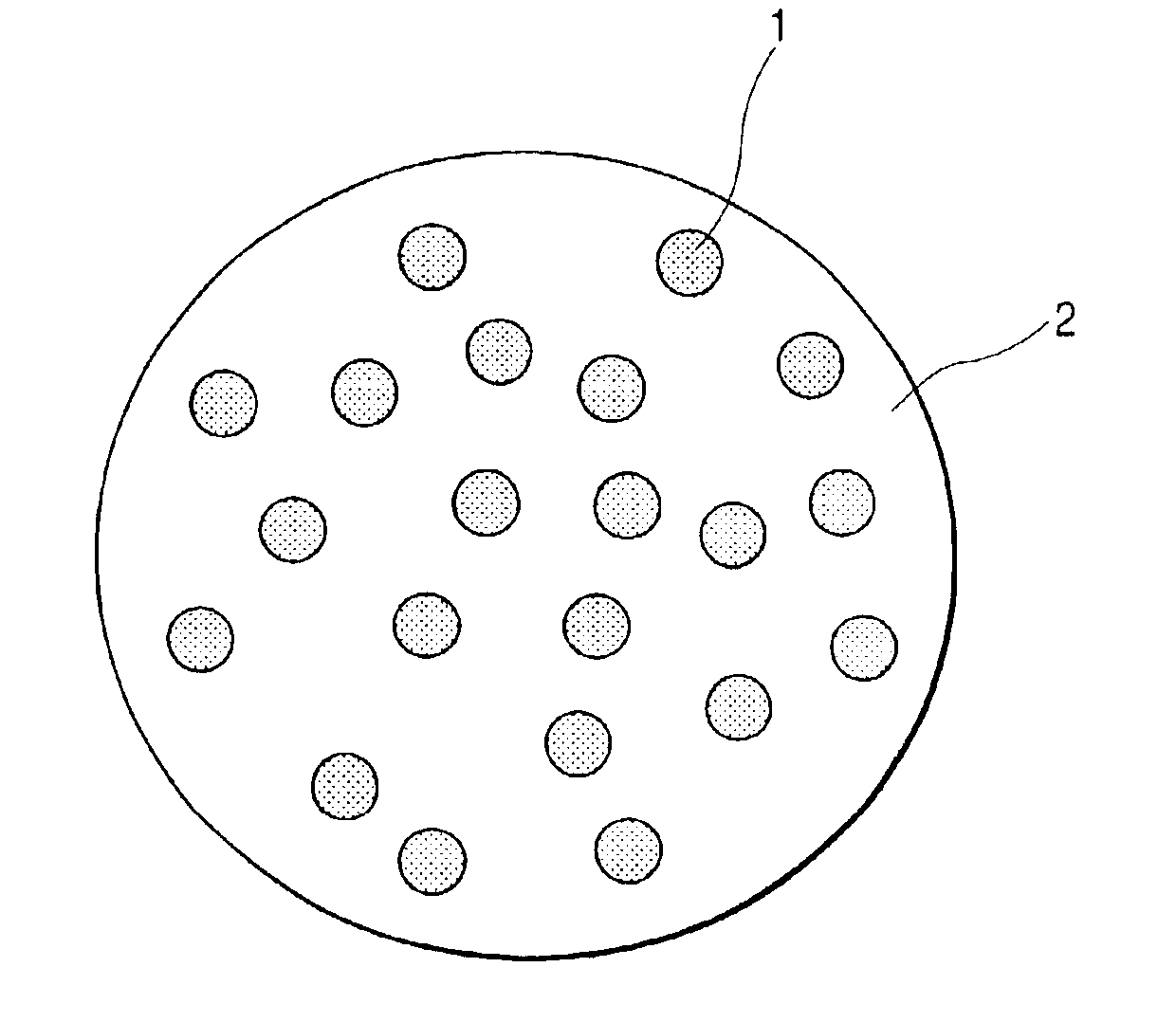

Photoelectric conversion device

InactiveUS20060090790A1Improve conversion efficiencyIncrease the lengthSemiconductor/solid-state device manufacturingPhotovoltaic energy generationConductive materialsPhotoelectric conversion

A photoelectric conversion device is composed of a substrate, a lower electrode layer formed to cover the substrate, and a first semiconductor layer formed on the lower electrode. The lower electrode layer includes a first matrix formed of transparent conductive material, and light scattering granules embedded within the first matrix.

Owner:MITSUBISHI HEAVY IND LTD

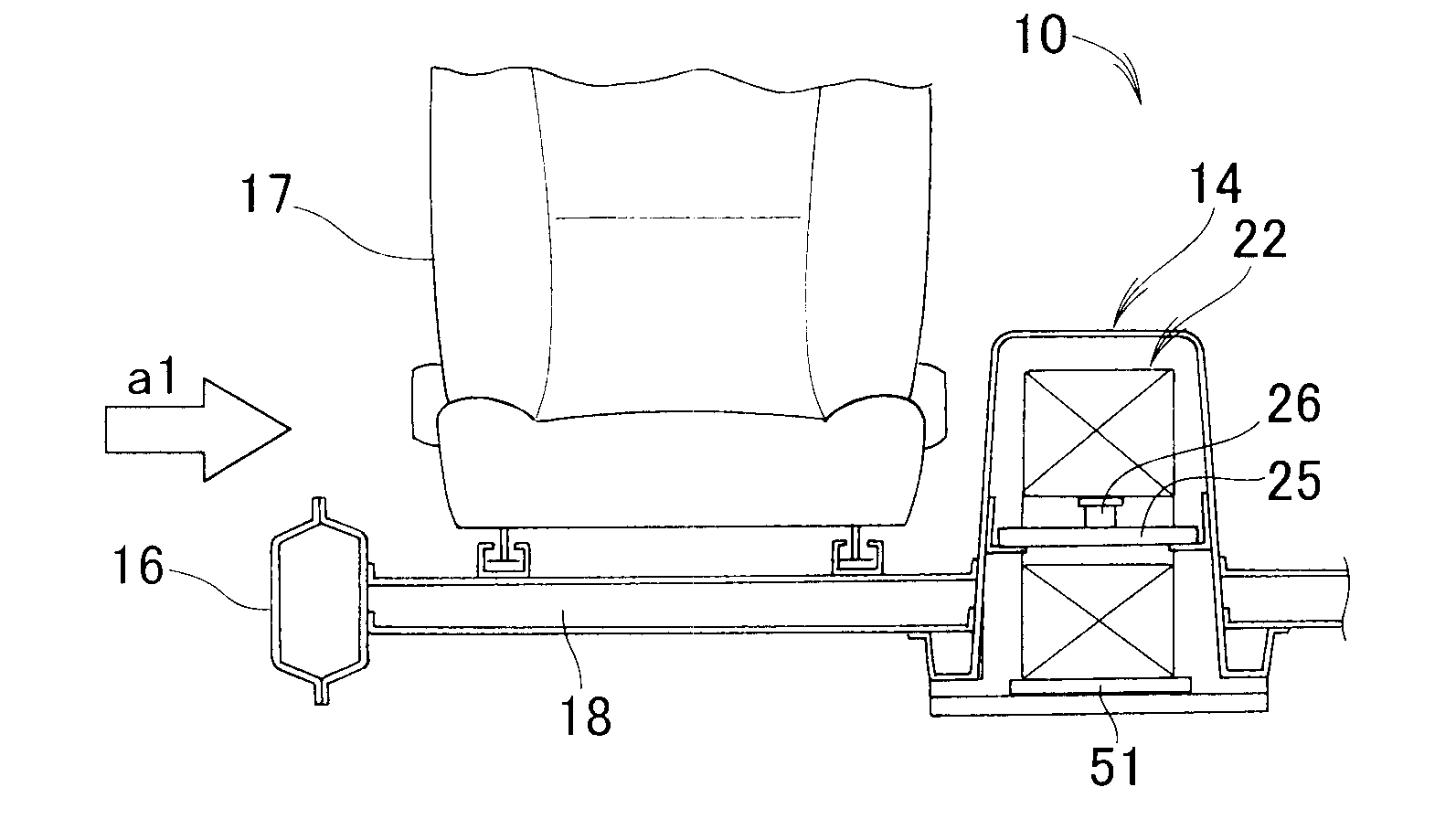

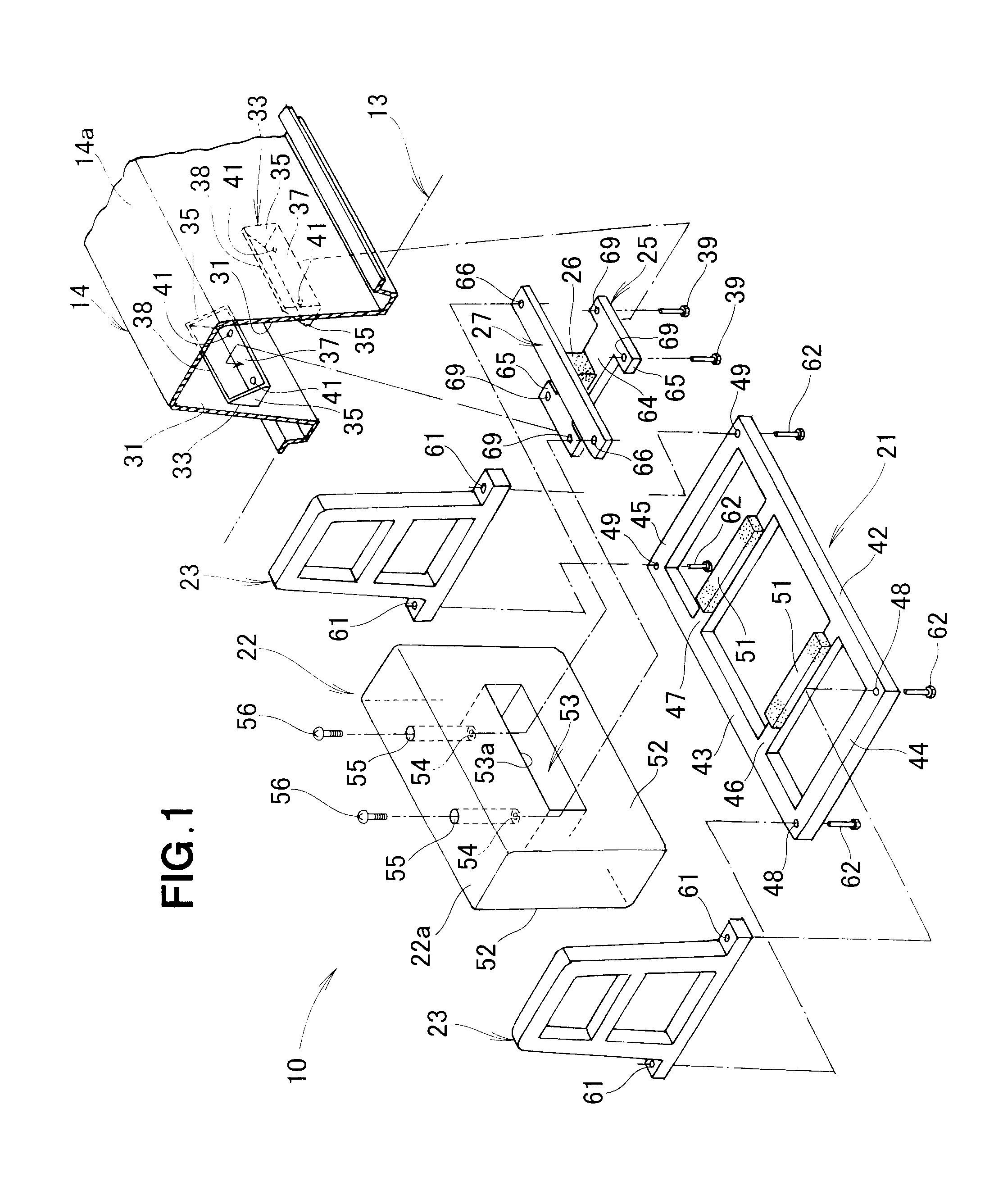

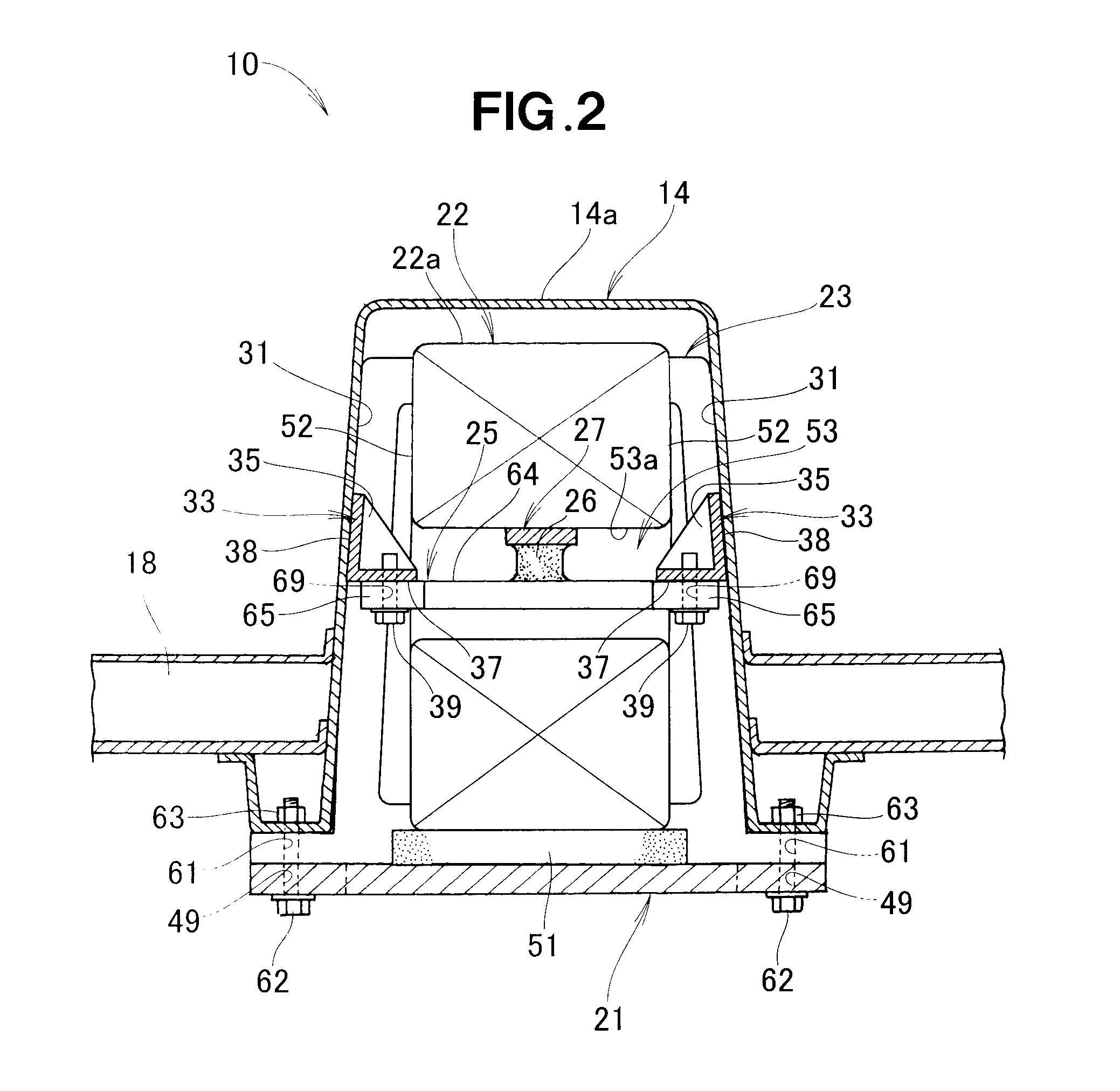

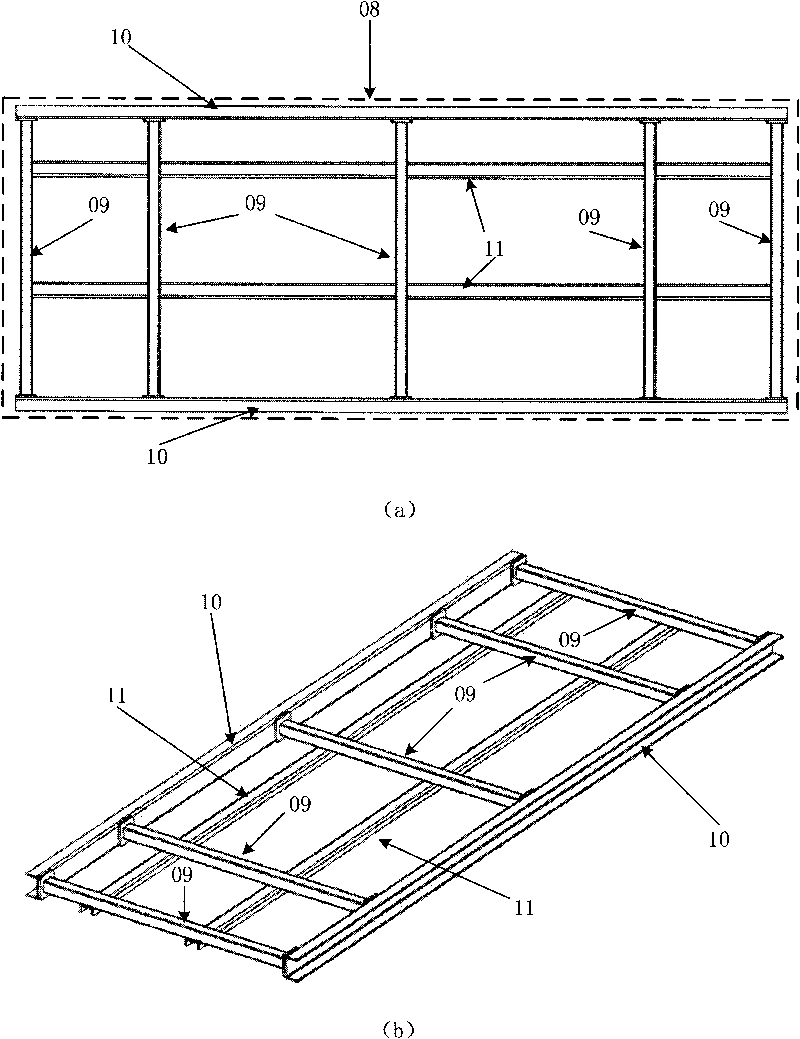

Vehicle body floor structure

InactiveUS20100213741A1Effective dispersionImprove protectionVehicle seatsElectric propulsion mountingEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

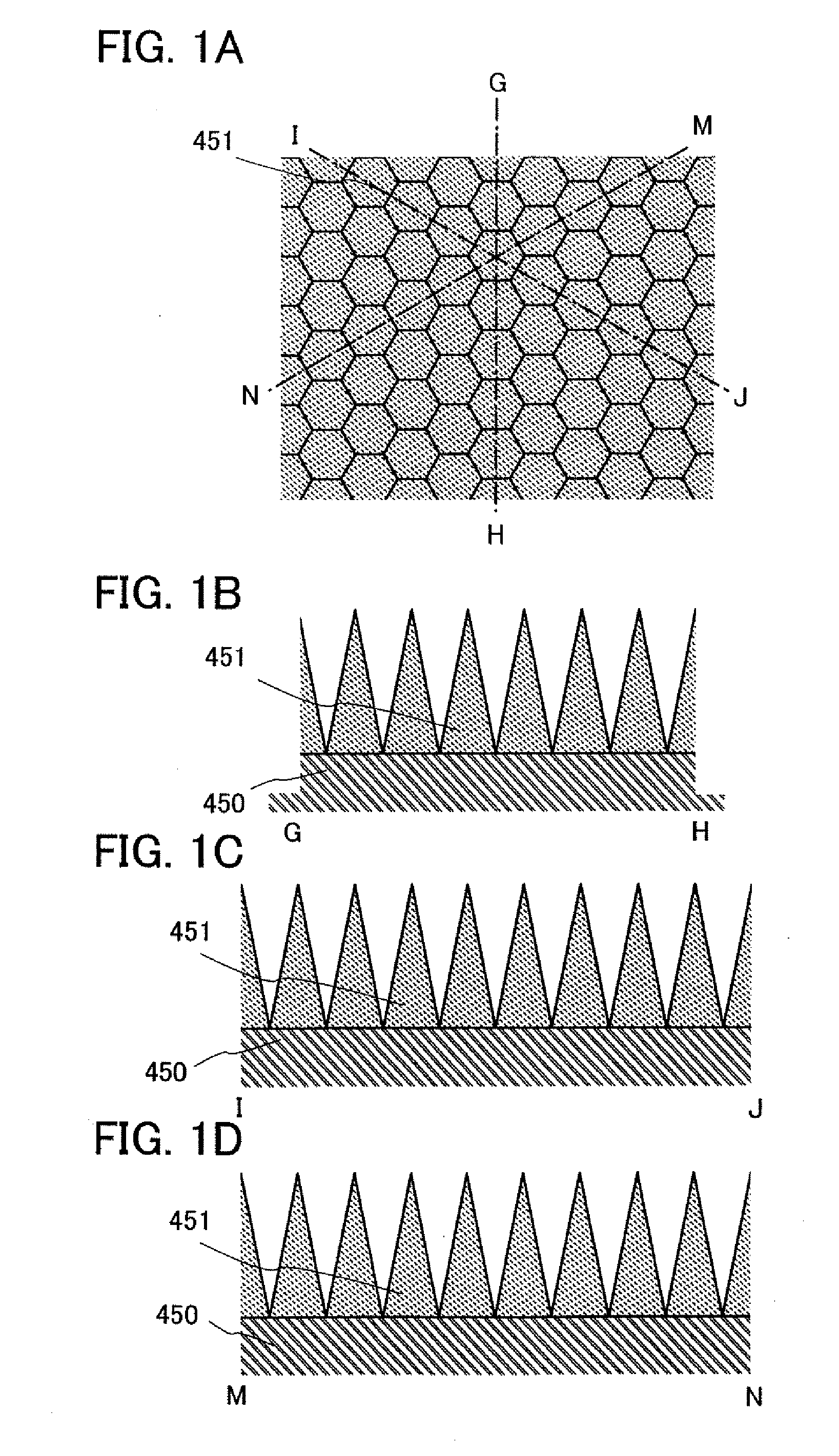

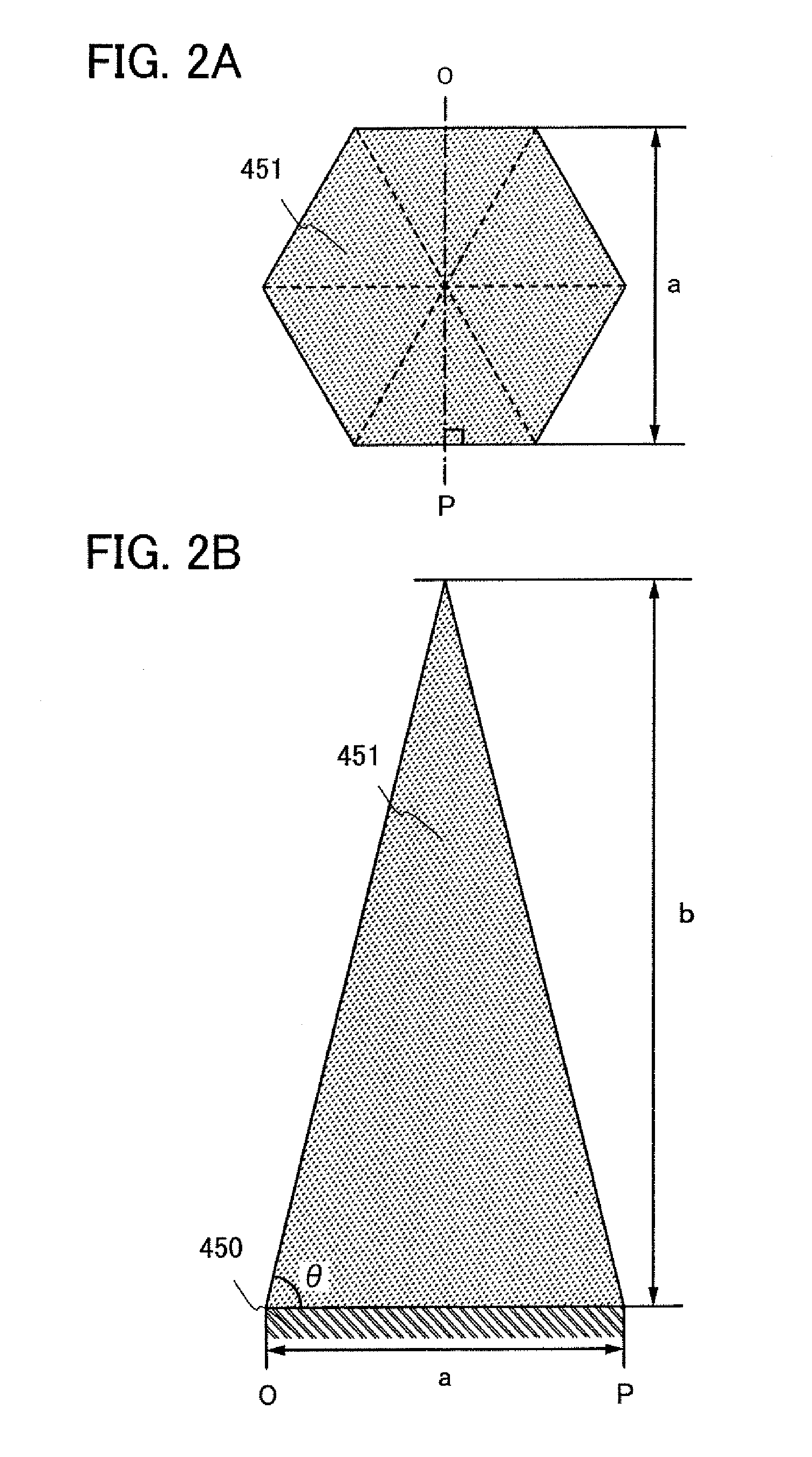

Antireflective film and display device

InactiveUS20080165315A1Reduce reflectionImprove anti-reflection functionElectroluminescent light sourcesSolid-state devicesVisibilityDisplay device

An object of the present invention is to provide an antireflective film having an anti-reflection function with which reflection of incident light from external can be further reduced and a high-visibility display device having such an antireflective film. The tops of the plurality of pyramidal projections are evenly spaced and each side of the base of a pyramidal projection is in contact with one side of the base of an adjacent pyramidal projection. That is, one pyramidal projection is surrounded by other pyramidal projections, and the base of the pyramidal projection and the base of the adjacent pyramidal projection have a side in common.

Owner:SEMICON ENERGY LAB CO LTD

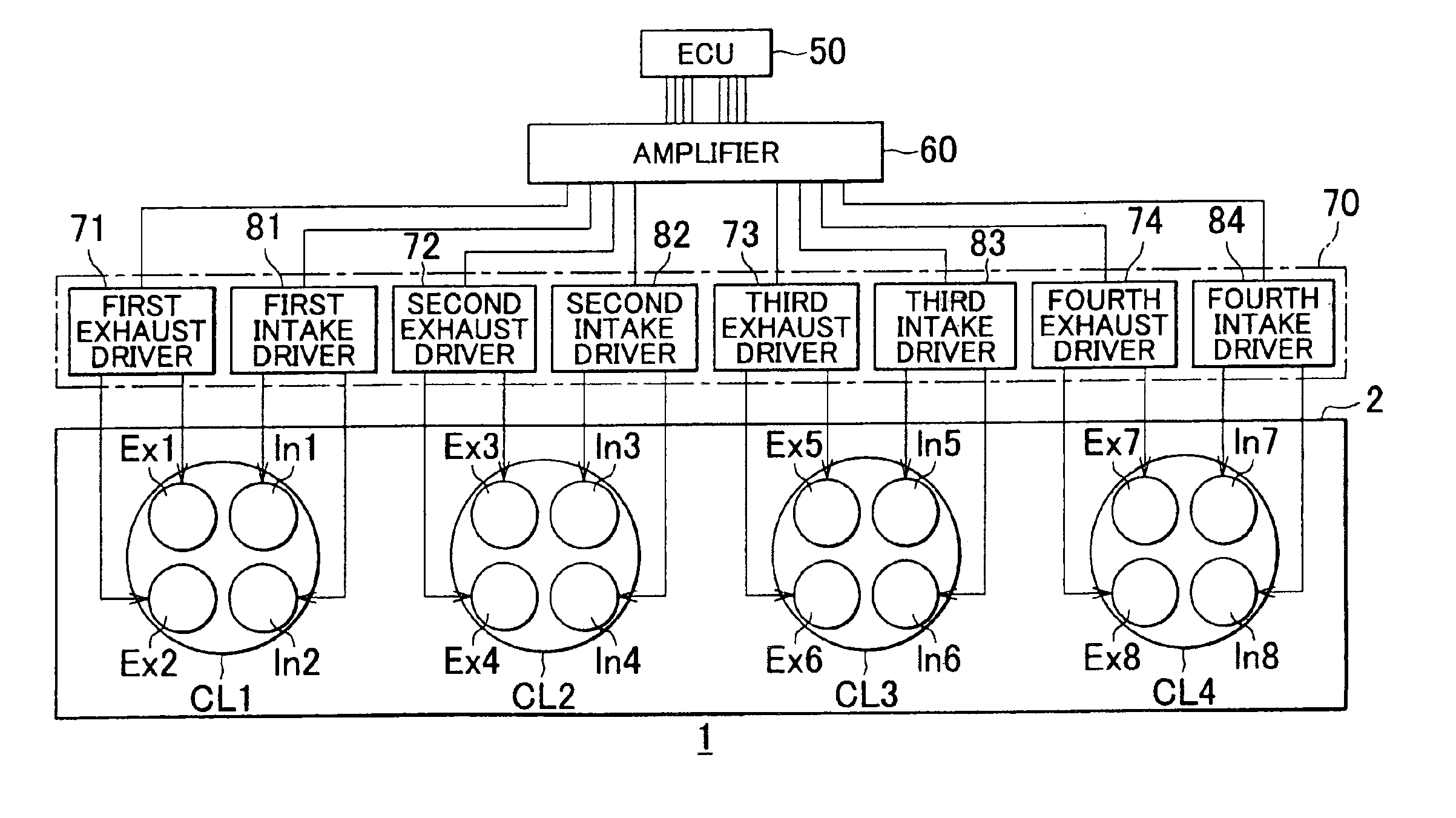

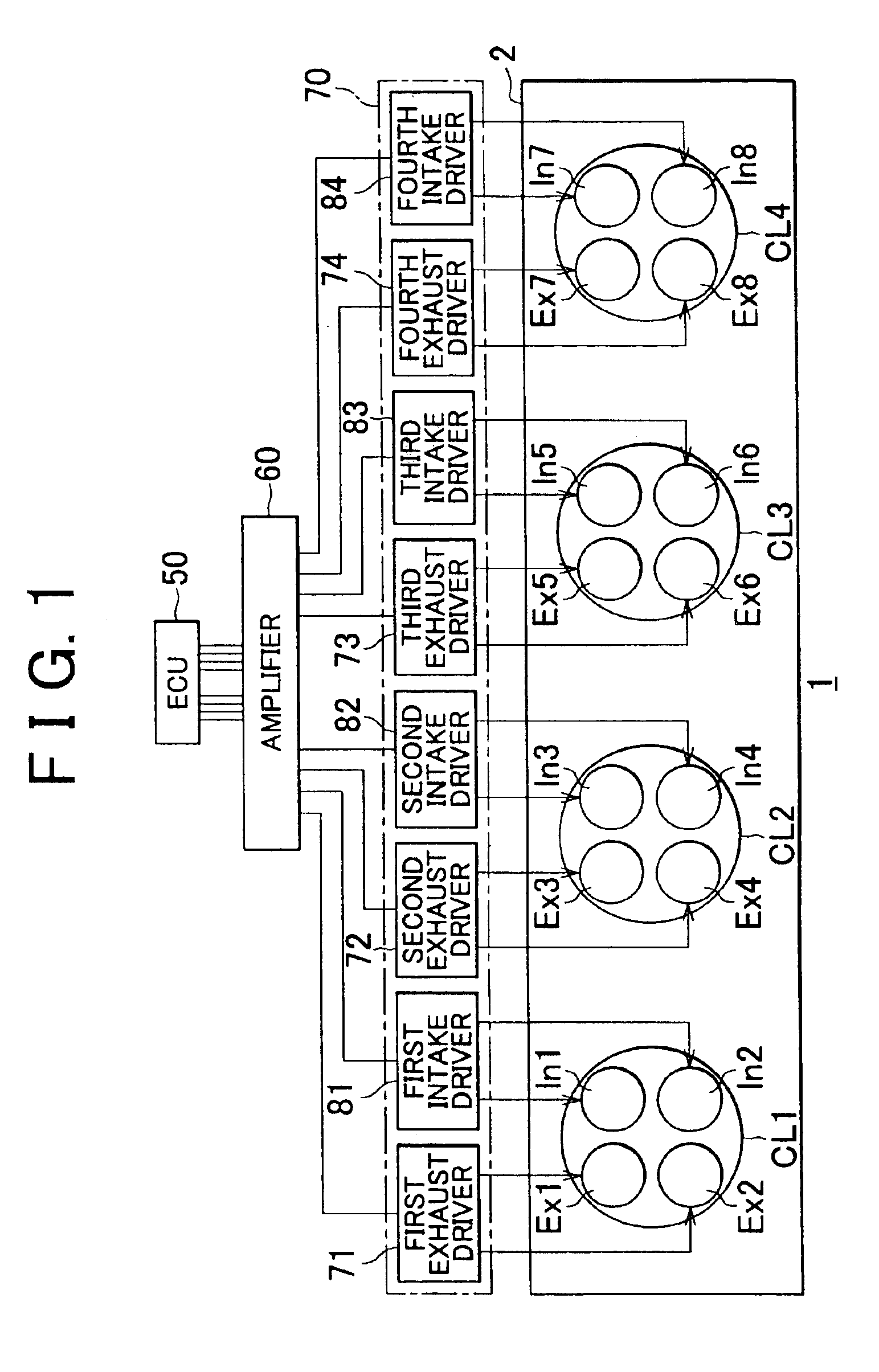

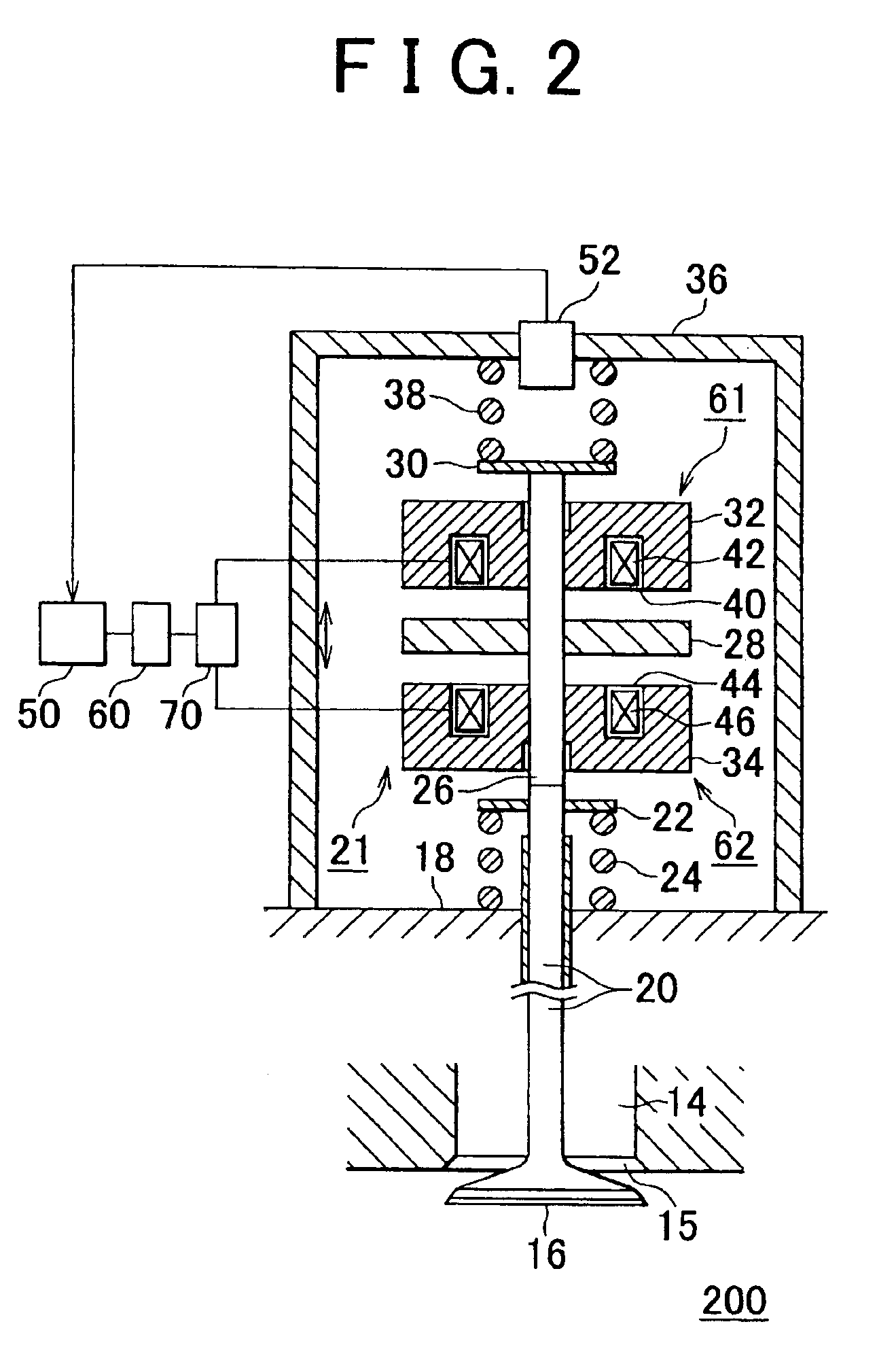

Electromagnetically driven valve control apparatus and electromagnetically driven valve control method for internal combustion engine

InactiveUS6866012B2Increase the number ofEffective controlAnalogue computers for vehiclesElectrical controlHigh speed controlLow speed

A main CPU determines whether or not there is a request for one valve driving based on an engine operating state such as an engine speed and a load factor, with reference to a control map. When it is determined that there is a request for one valve driving, it is determined whether or not there is an overlapping period between opening periods. When it is determined that there is no overlapping period, a high speed control is performed for controlling electromagnetically driven valves. When it is determined that there is no request for one valve driving, or when it is determined that there is the overlapping period, a low speed control is performed for controlling electromagnetically driven valves.

Owner:TOYOTA JIDOSHA KK

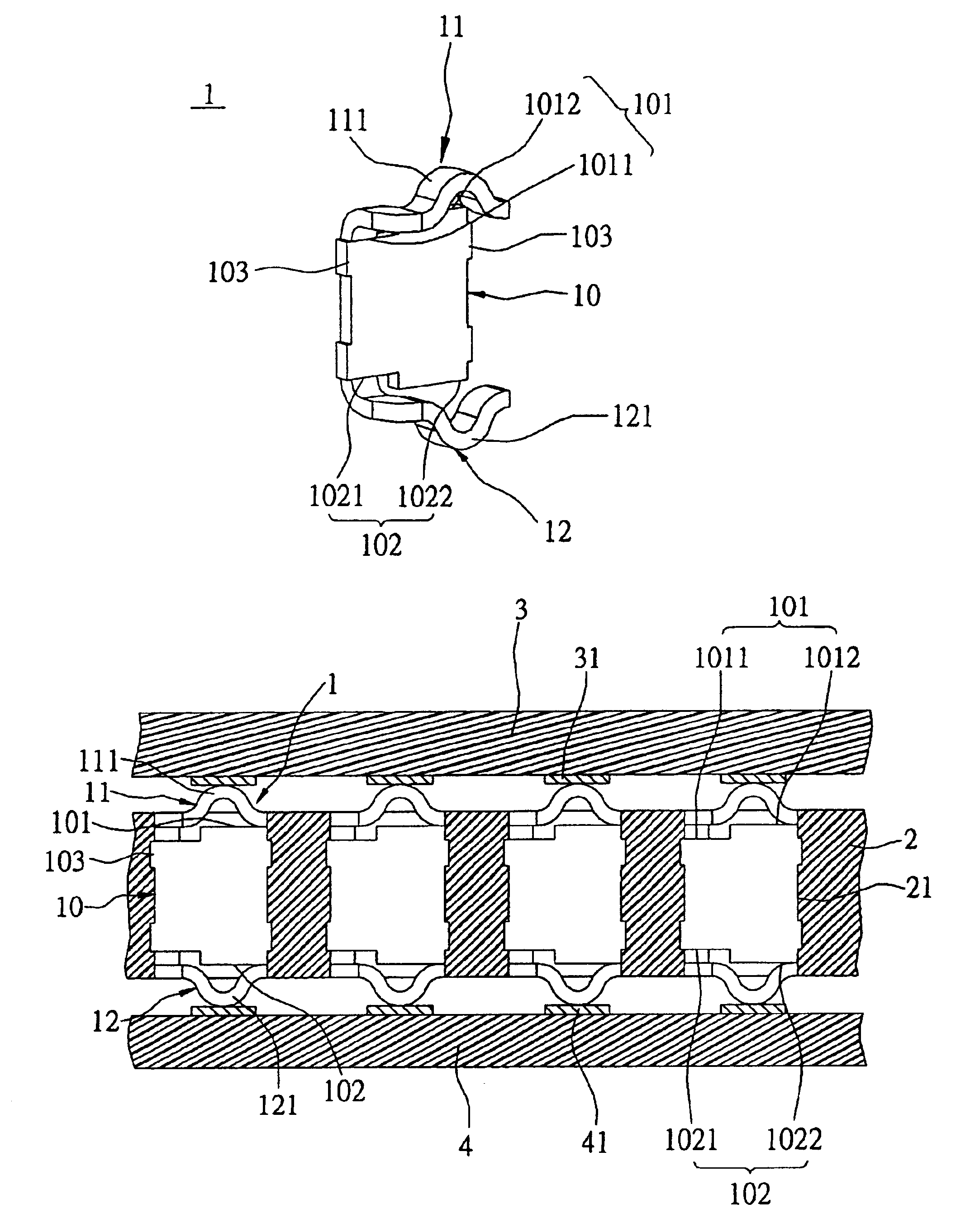

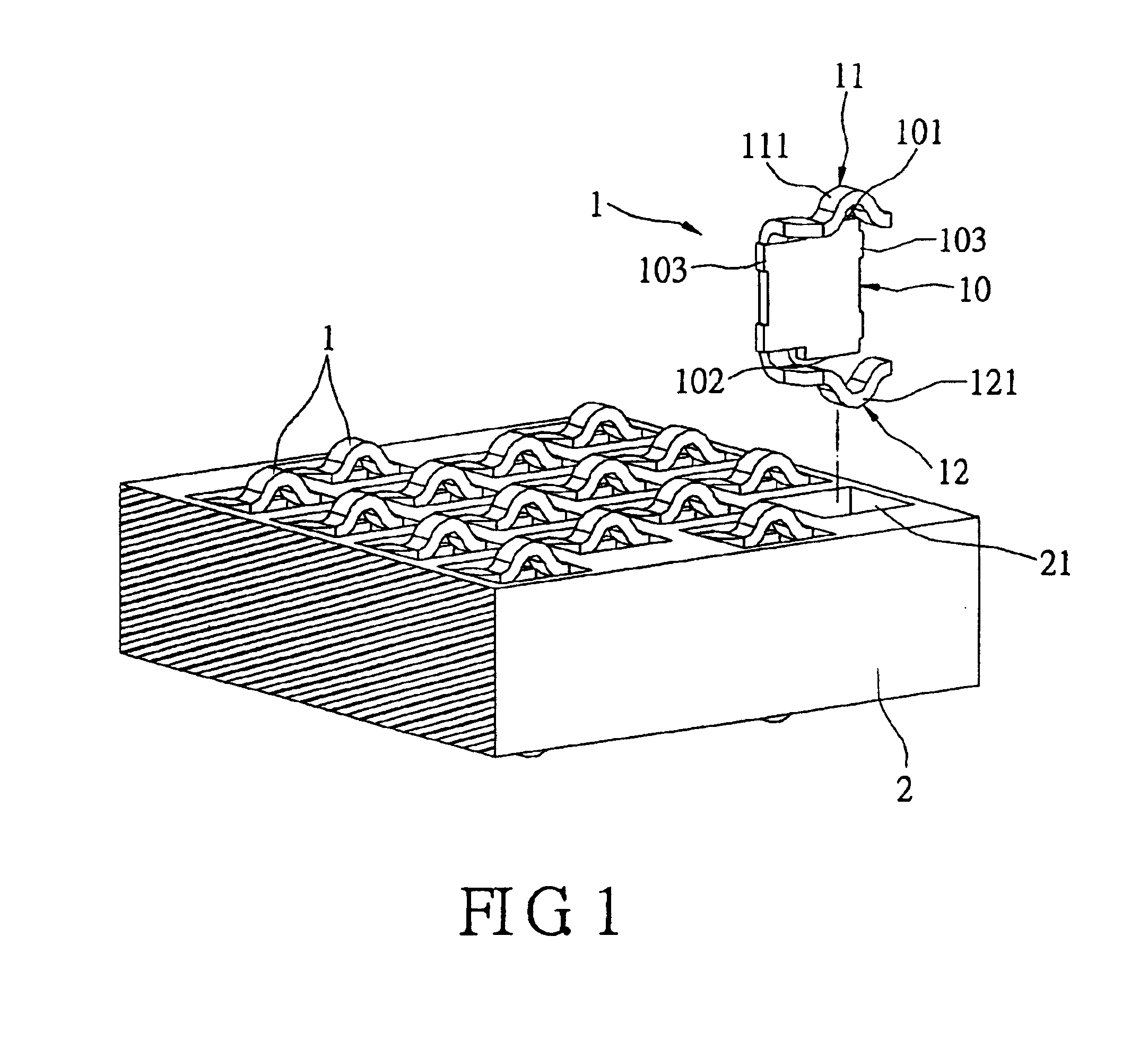

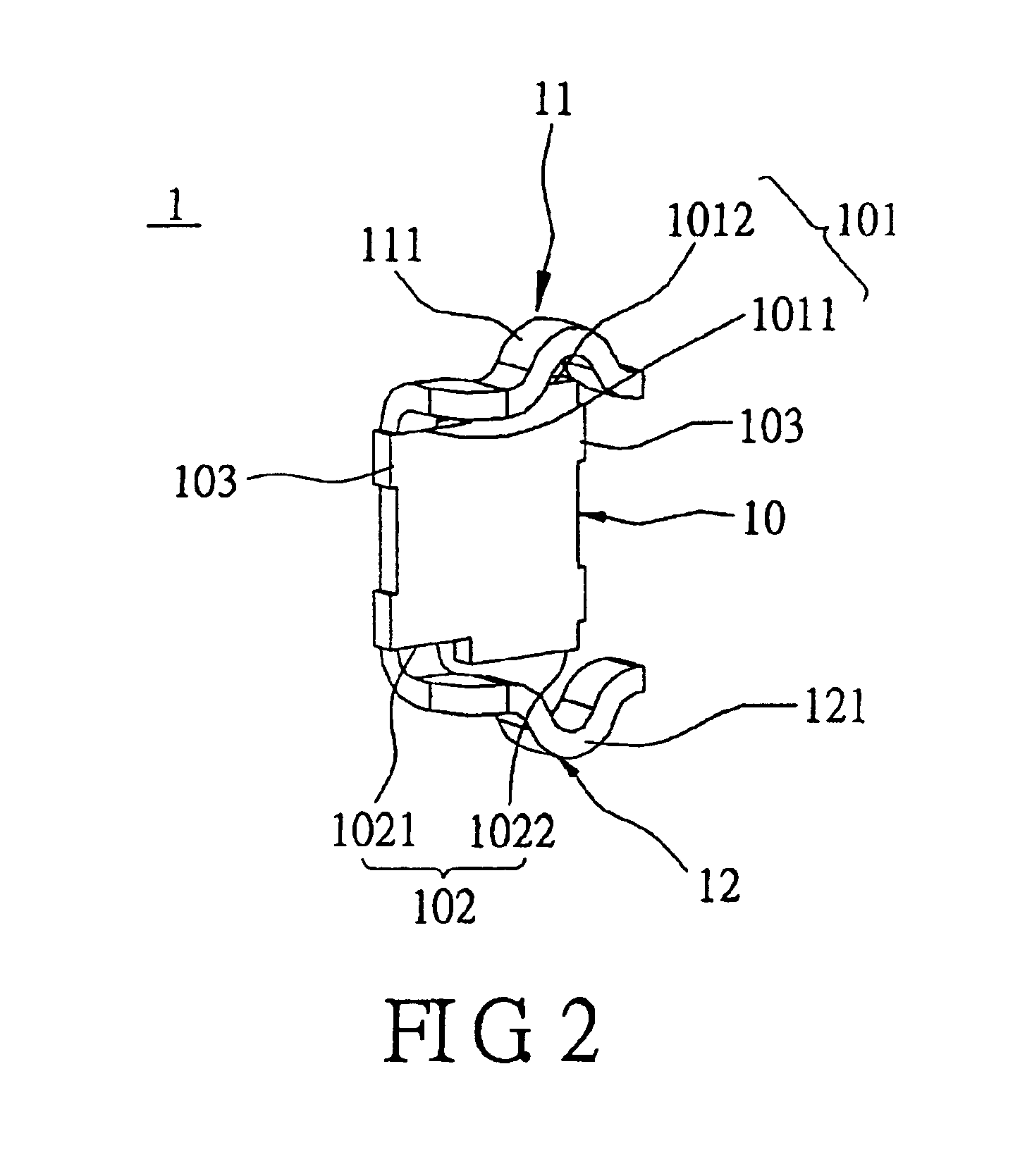

LGA connector and terminal thereof

ActiveUS6881070B2Effective dispersionImprove stabilityCoupling contact membersPrinted circuitsEngineeringMechanical engineering

Owner:MOLEX INC

Novel nano calcium carbonate used for plastic film and preparation method thereof

InactiveCN101967298AImprove hydrophobicityAvoid reunionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPolyolefinMechanical property

The invention discloses novel nano calcium carbonate used for a plastic film and a preparation method thereof. A Ca(OH)2 suspension and CO2 are carbonized in a reactor to generate the nano calcium carbonate, and then the obtained nano calcium carbonate is subjected to liquid phase coating treatment or is directly subjected to mixed coating by using dried nano calcium carbonate and a surfactant to obtain nano calcium carbonate powder which is highly dispersed and surface-activated. The invention has the advantages that: the process is simple, the nano calcium carbonate is effectively dispersed in a polymer and a remarkable enhancement effect can be achieved on the premise of ensuring the transparency. The nano calcium carbonate prepared by adopting the invention can remarkably improve the mechanical property of a polyolefin material; after the nano calcium carbonate is used for polyethylene plastic, the tension strength of the material is greatly improved; and after the nano calcium carbonate is used for a polyolefin film, a fish eye is free, and the high transparency of the film is maintained.

Owner:山东海泽纳米材料有限公司

Aqueous dispersion of water-insoluble-colorant-containing particle and preparation process thereof, water-insoluble-colorant-containing particle and preparation process thereof, and ink

InactiveUS6921433B2Good colorHigh transparencyLiquid surface applicatorsInorganic pigment treatmentWater insolublePeak value

An embodiment of the invention relates to an aqueous dispersion containing pigment-containing particles. The dispersion is an aqueous dispersion comprising particles containing a water-insoluble colorant dispersed in a water-containing medium, wherein the light-scattering intensity of the dispersion is at most 30,000 cps when the absorbance peak value of the dispersion in a visible region is regarded as 1.

Owner:CANON KK

A 3D printing polymer material and a preparing method thereof

ActiveCN105524399AGood dimensional stabilityGood bridgingAdditive manufacturing apparatusAntioxidantTactile sensation

The invention relates to the technical field of resin composition preparation and particularly relates to a 3D printing polymer material with special beautifying effects and a preparing method thereof. The polymer material comprises following raw materials by weight: 60-90 parts of matrix resin, 4.0-10 parts of a compatilizer, 0-30 parts of an inorganic filler, 0.3-2.0 parts of white oil, 0.4-0.6 part of an antioxidant, 0.5-1.0 part of a processing auxiliary agent and 1.0-5 parts of a toner. The polymer material is good in dimension stability, good in bridging effect and excellent in draping performance. The appearance of the polymer material is strong in metallic tactile sensation and pearl effects. The polymer material has one or a plurality of effects selected from heat discoloration, photochromic effects, effects of color changing when sensing water, and the like, and is of great significance for promoting material diversification and functionalization of 3D printing. The preparing method is simple, improves shearing and dispersion for the inorganic filler and the toner to the utmost, and improves properties of the polymer material.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

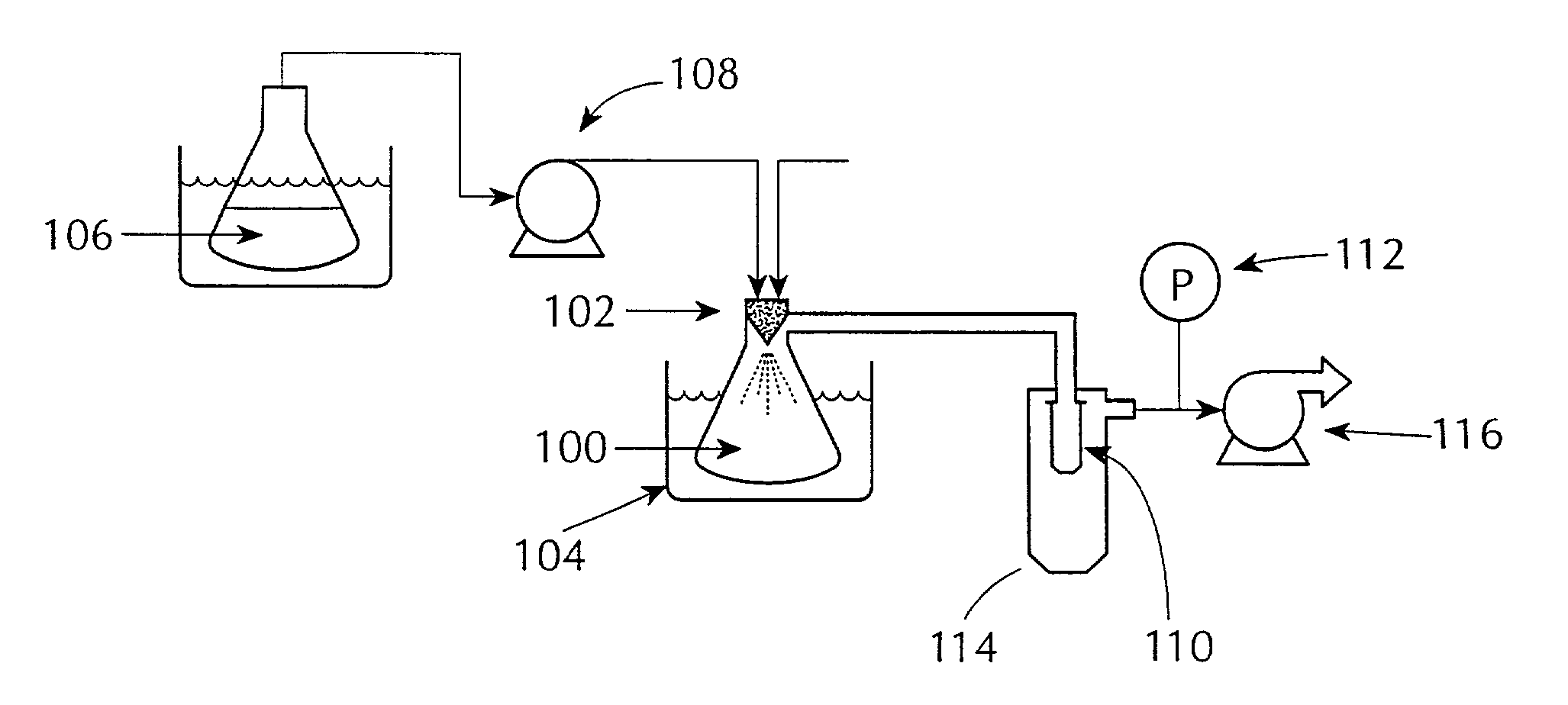

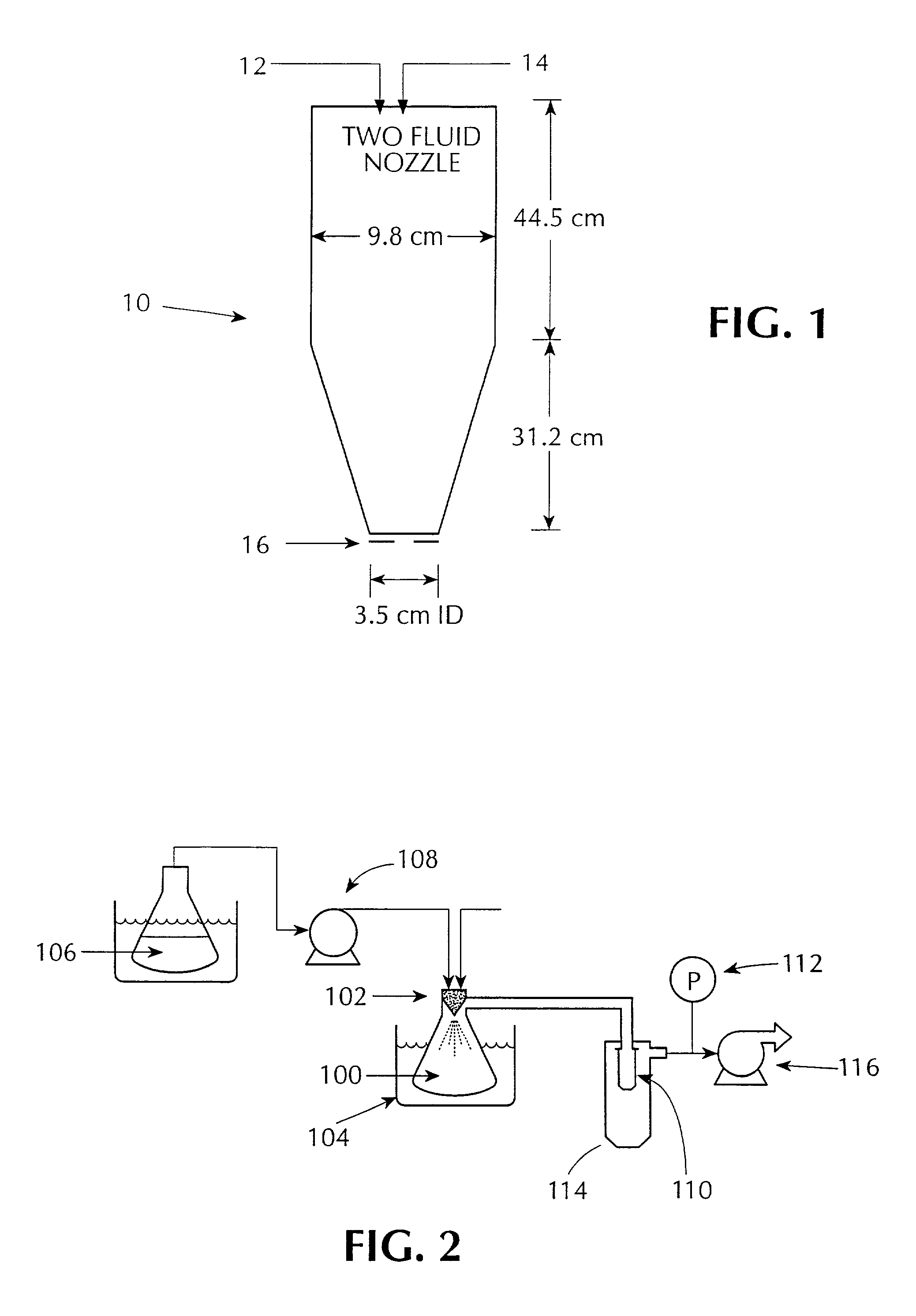

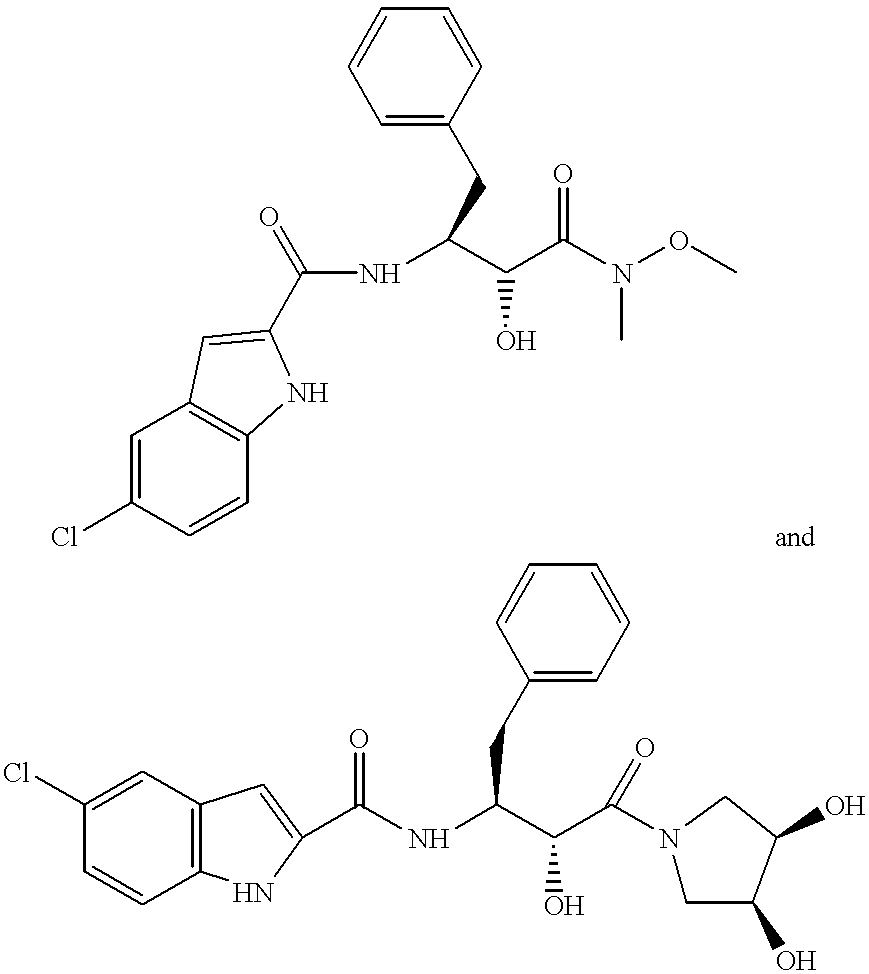

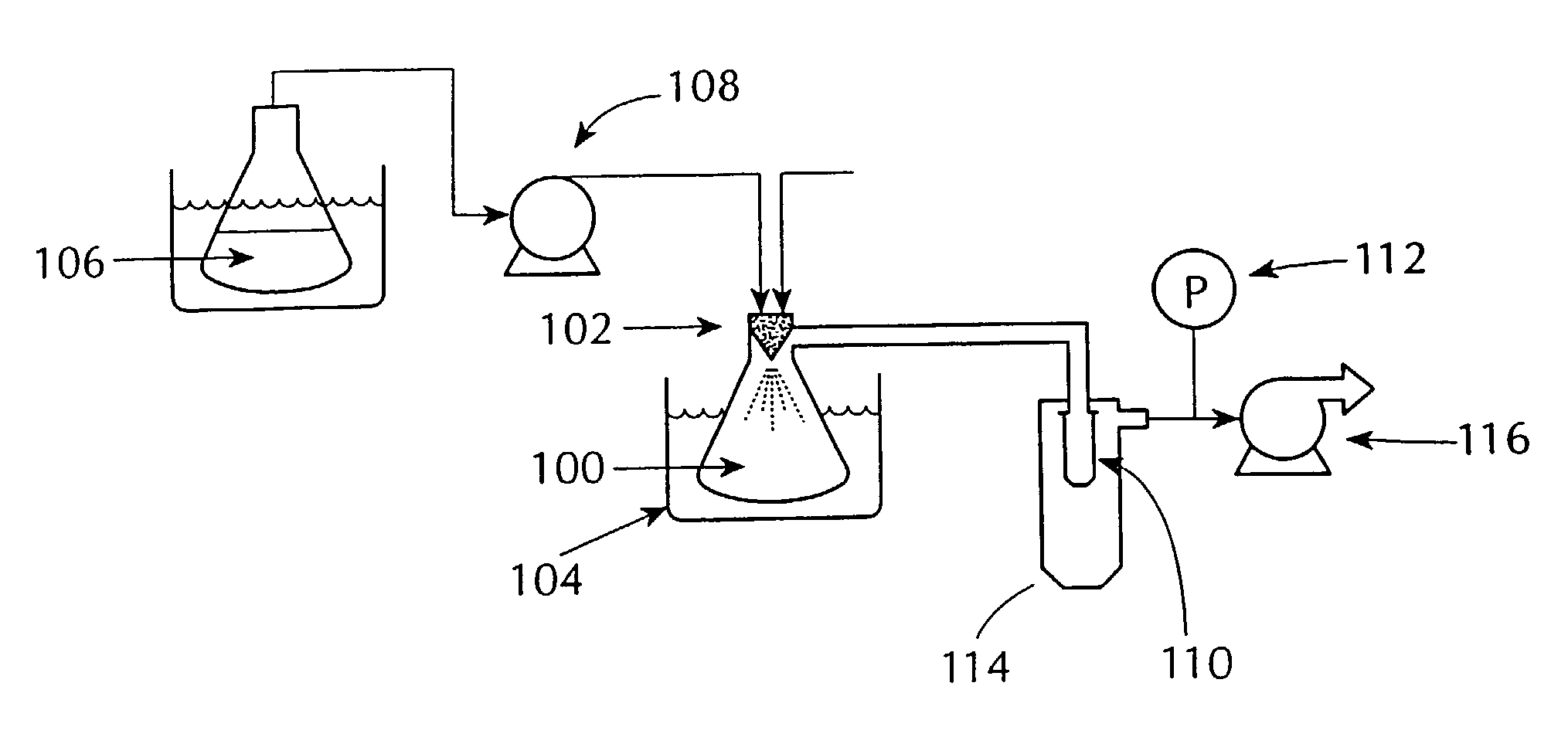

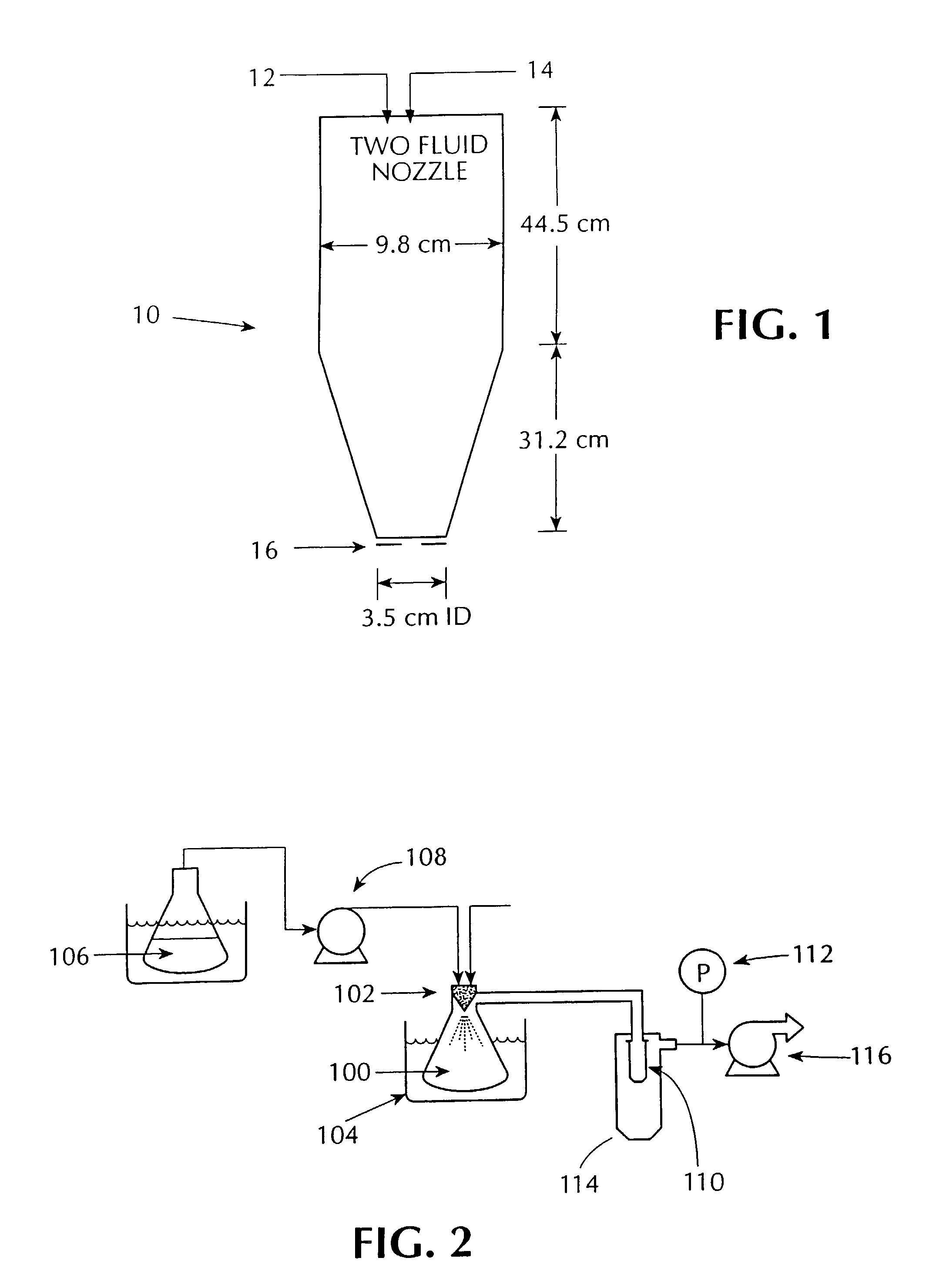

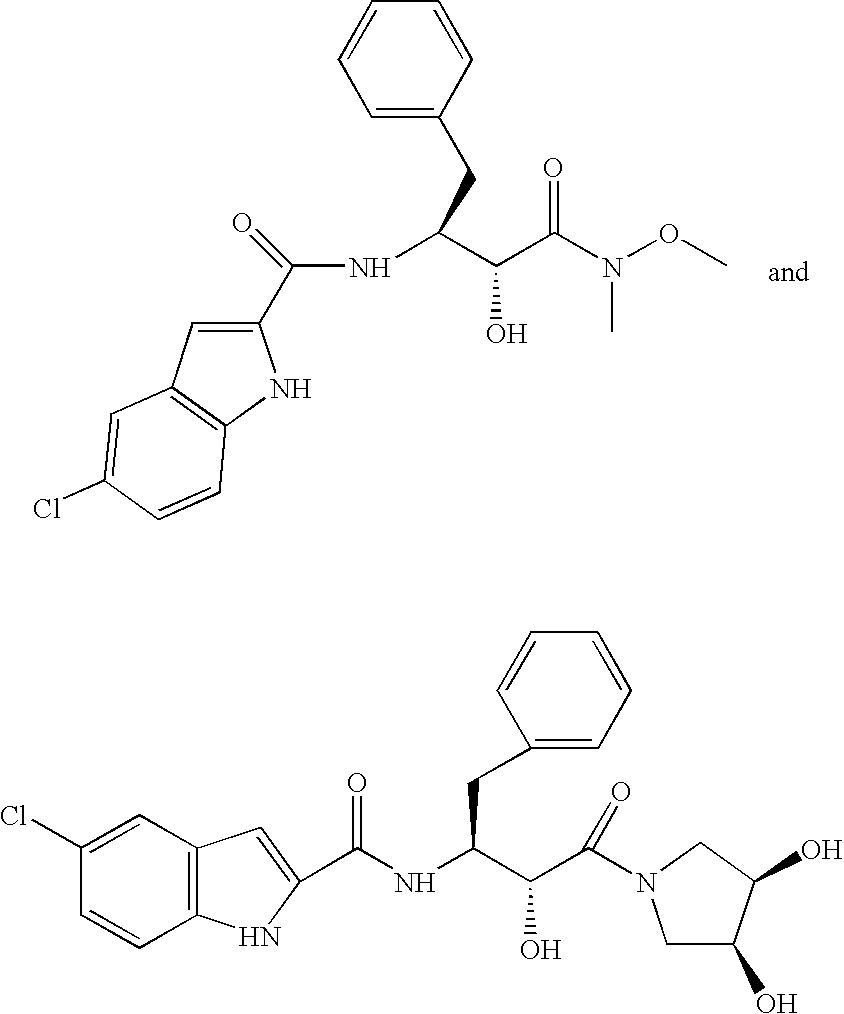

Solid pharmaceutical dispersions with enhanced bioavailability

InactiveUS8263128B2Improve bioavailabilityPreventing and retarding ratePowder deliveryBiocideAcetic acidHydroxypropylmethylcellulose acetate succinate

Spray dried solid dispersions comprising a sparingly soluble drug and hydroxypropylmethylcellulose acetate succinate (HPMCAS) provide increased aqueous solubility and / or biavailability in a use environment.

Owner:BEND RES

Solid pharmaceutical dispersions with enhanced bioavailability

InactiveUS8257741B2Improve solubilityEffective dispersionPowder deliveryBiocideAcetic acidHydroxypropylmethylcellulose acetate succinate

Spray dried solid dispersions comprising a sparingly soluble drug and hydroxypropylmethylcellulose acetate succinate (HPMCAS) provide increased aqueous solubility and / or biavailability in a use environment.

Owner:BEND RES

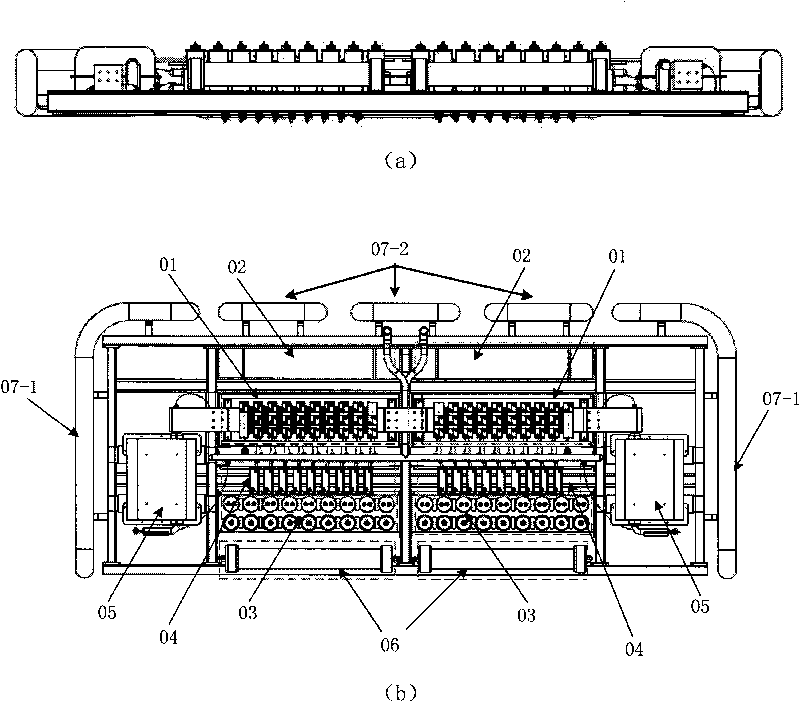

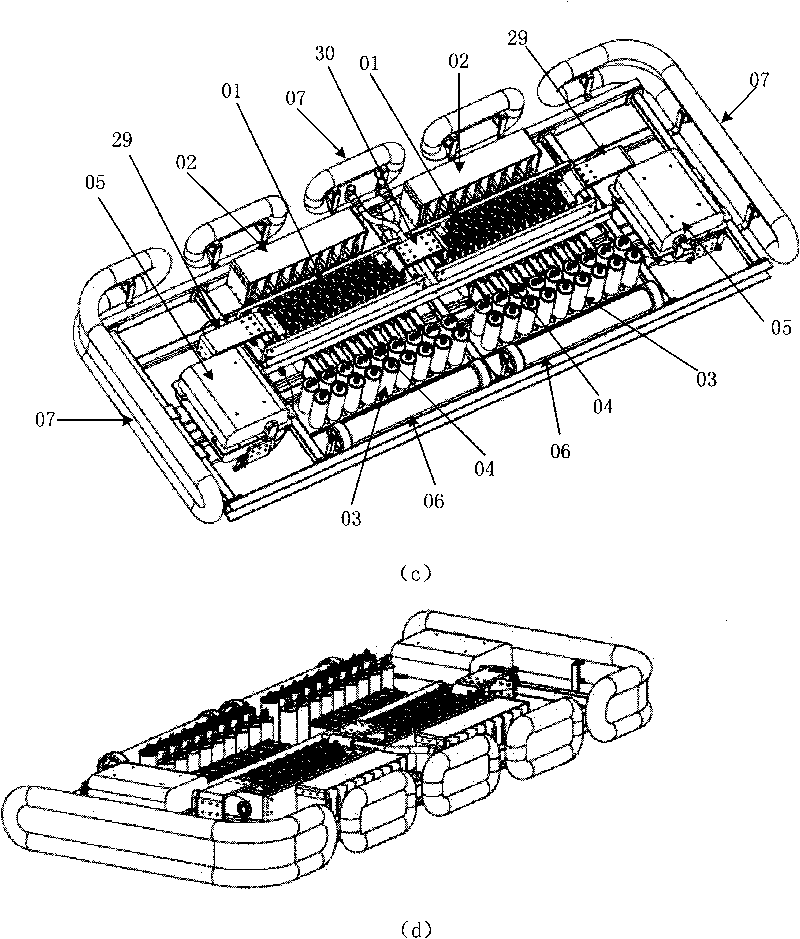

Novel thyristor converter valve module

ActiveCN101719719AReduce weightSmall geometryConversion constructional detailsElectric power transfer ac networkCapacitanceMechanical engineering

The invention provides electronic equipment with high voltage and high power, which is used for converting alternating current (AC) voltage into direct current (DC) voltage or converting DC voltage into AC voltage, in particular a thyristor converter valve module. A whole valve module is divided into two same segments, and each segment comprises a saturable reactor, a thyristor, a DC equalizing resistor unit, an energy-extracting resistor unit, a damping resistor unit, a damping capacitor unit, a gate electrode unit and a water cooling system, wherein the reactors of the electronic equipment are connected in series to meet the requirements on different transmission powers and different power voltage grades. The equipment is core equipment for high-voltage DC power transmission and can be applied to a DC-AC converting system, meet the requirements of different voltage grades and for the DC converting system with different voltage grades, including the super high voltage of 800 kV or above.

Owner:CHINA ELECTRIC POWER RES INST

LED lamp bulb structure

InactiveUS20100103666A1Heat dispersing effectEffective dispersionPoint-like light sourceLighting elementsHeat conductingEngineering

An LED lamp bulb structure is disclosed, in which a lamp controller is installed inside a lamp head and the bottom surface of the lamp controller is fixed by an upper cover. At the bottom surface of the upper cover, a heat dispersing fin set, which has at least one heat conducting tube installed therein, and a lower cover are fixed. Furthermore, a bulb housing, which has a tray mounted therein, is screwed around the peripheral edge of the lower cover, and at the bottom of the tray, plural LED lamp sets corresponding to plural heat conducting tubes are outwardly extended. Therefore, the heat produced by the LED lamp sets can have a heat exchange through plural heat conducting tubes and the heat dispersing fin set for achieving a better heat dispersing effect and for more effectively dispersing the heat.

Owner:LI HONG TECHNOLOGICAL

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com