Novel thyristor converter valve module

一种晶闸管换流阀、阀模块的技术,应用在输出功率的转换装置、电力传输交流网络、变换设备结构零部件等方向,能够解决更新换代缓慢、阀模块重量增大、阀模块内部空间浪费等问题,达到降低应力集中程度、分散承重载荷、减小几何尺寸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

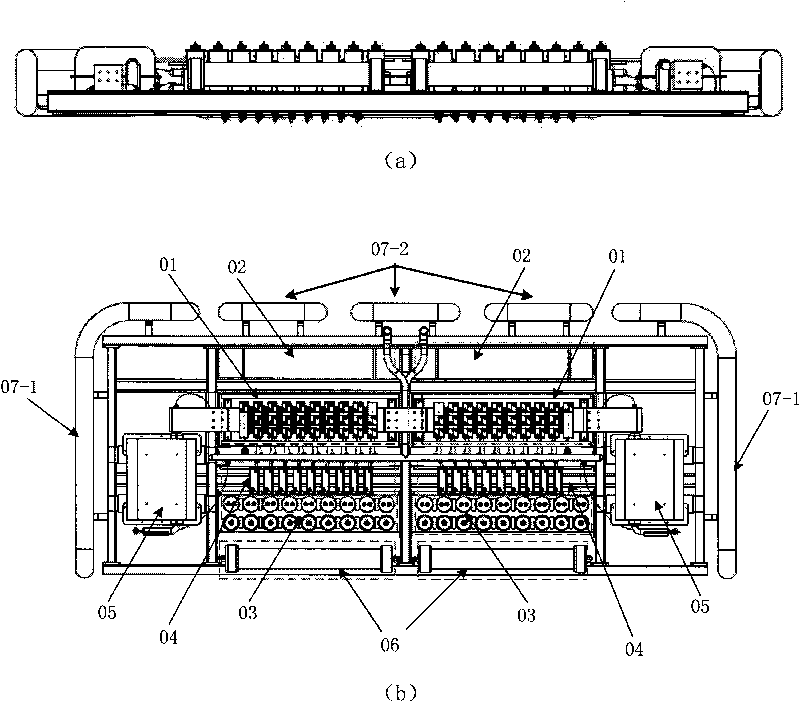

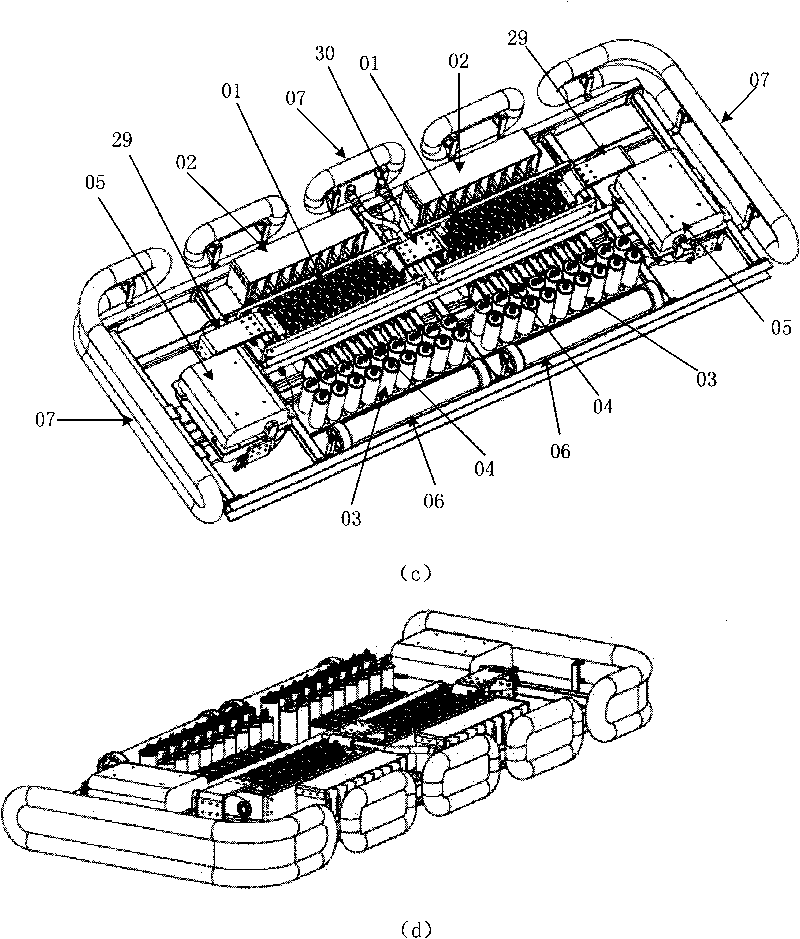

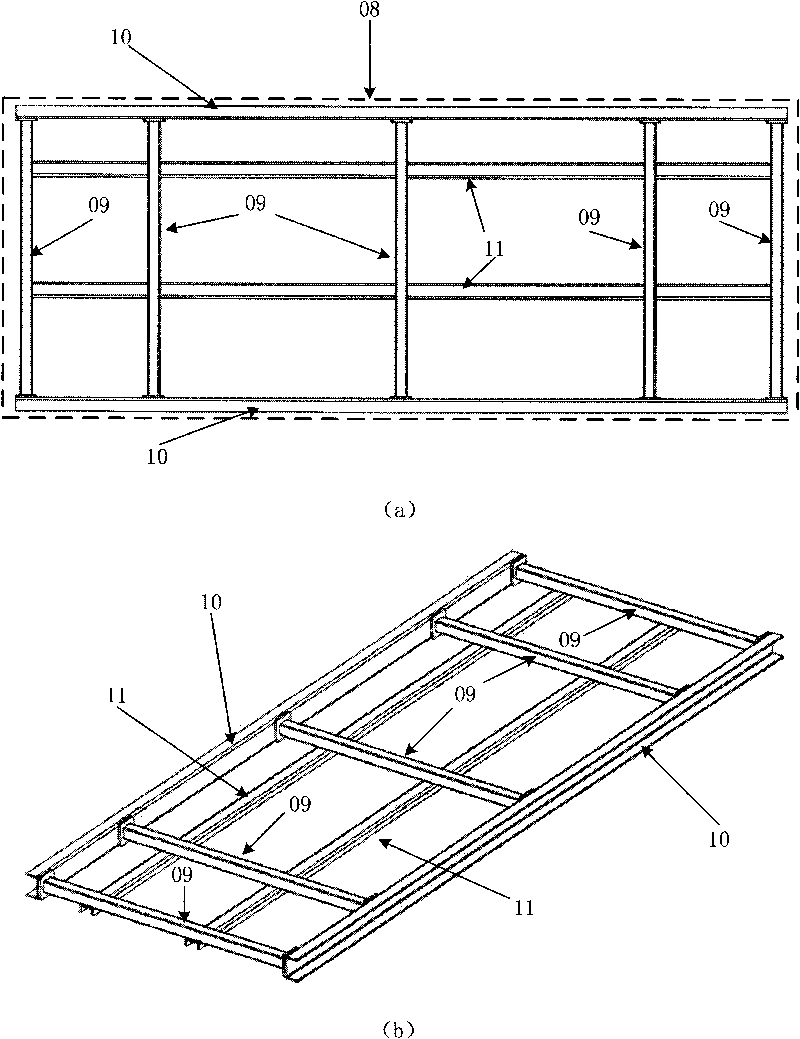

[0032]For a thyristor-level component, the gate unit 02, the damping resistance unit 04 and the damping capacitor unit 03 are respectively located on both sides of the thyristor unit 01. In terms of structural design, the deviation between the center of gravity and the geometric center of the thyristor-level component is not too large, which is conducive to improving The stress condition of the valve frame. For a valve section, the heaviest saturable reactor assembly 05 and thyristor unit 01 are arranged on the same axis of the valve section, and its center of gravity is close to the geometric center of the valve section structure, thereby improving the force condition of the entire valve section. For a thyristor stage, the damping capacitor unit 03 is placed next to the damping resistor unit 04, which shortens the distance between the terminal of the damping capacitor 03 and other electrical connection components, shortens the electrical wiring length of the thyristor stage, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com