A 3D printing polymer material and a preparing method thereof

A polymer material, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of affecting production efficiency, easy to be broken by shearing, complex preparation process, etc., to achieve good bridging effect, excellent drape performance, and good dimensional stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A 3D printed polymer material in this embodiment is composed of the following raw material components in parts by weight: 90 parts of matrix resin, 4.0 parts of compatibilizer, 0 part of inorganic filler, 0.5 part of white oil, 0.5 part of antioxidant, 0.5 part of processing aid, 1 part of toner.

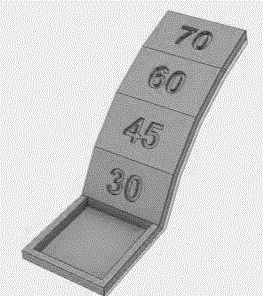

[0083] Wherein, the toner is a microcapsule thixotropic toner with a particle size of 30 microns. The thixotropic toner is 45°C red thixotropic toner, produced by Shenzhen Qiansechang Pigment Co., Ltd. with model number 8891.

[0084] Wherein, the matrix resin is a terpolymer MABS of methyl methacrylate (M), butadiene (B) and styrene (S), the brand name is TR557, produced by LG Chemical Co., Ltd.

[0085] Wherein, the compatibilizer is ethylene acrylic acid copolymer, brand name EMAAX8900, produced by Akema, France;

[0086] Wherein, the white oil has a kinematic viscosity of 10m 2 / s industrial grade No. 15 white oil, produced by Shenzhen Kaipu Lubrication Technology Co.,...

Embodiment 2

[0094] A 3D printed polymer material in this embodiment is composed of the following raw material components in parts by weight: 80 parts of matrix resin, 5 parts of compatibilizer, 10 parts of inorganic filler, 0.8 part of white oil, 0.4 part of antioxidant, 0.6 parts of processing aid, 2 parts of toner.

[0095] Wherein, the toner is pearl powder, the particle size is preferably 30 microns, the grade is 125, and it is produced by Aika Special Effect Pigment Co., Ltd.

[0096] Wherein, the matrix resin is polypropylene PP, the grade is HP500N, produced by China Shipping Shell;

[0097] Wherein, the compatibilizer is an ethylene-octene copolymer produced by DuPont under the brand name 8150POE;

[0098] The inorganic filler is calcium carbonate, the brand is ML5000, produced by Meilin Chemical Industry, and the particle size is 0.8 microns;

[0099] Wherein, the white oil has a kinematic viscosity of 15m 2 / s industrial grade No. 15 white oil, produced by Shenzhen Kaipu Lubr...

Embodiment 3

[0107] A 3D printed polymer material in this embodiment is composed of the following raw material components in parts by weight: 75 parts of matrix resin, 6 parts of compatibilizer, 15 parts of inorganic filler, 1.2 parts of white oil, 0.4 parts of antioxidant, 0.8 parts of processing aid, 3 parts of toner.

[0108] Wherein, the toner is pearlescent powder, the particle size is preferably 35 microns, the grade is 125, produced by Aika Special Effect Pigment Co., Ltd.

[0109] Wherein, the matrix resin is polyamide PA6, brand F126-C, produced by DSM Group;

[0110] Wherein, the compatibilizer is ethylene-octene grafted glycidyl methacrylate, grade SOG02, produced by Shanghai Rizhisheng;

[0111] Wherein, the inorganic filler is a mixture of calcium carbonate and mica with a mass ratio of 2:1, and the particle size of the inorganic filler is 1 micron;

[0112] Wherein, the white oil has a kinematic viscosity of 12m 2No. 15 industrial grade white oil of / s is produced by Shenz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com