Patents

Literature

201results about How to "Strong metal texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A 3D printing polymer material and a preparing method thereof

ActiveCN105524399AGood dimensional stabilityGood bridgingAdditive manufacturing apparatusAntioxidantTactile sensation

The invention relates to the technical field of resin composition preparation and particularly relates to a 3D printing polymer material with special beautifying effects and a preparing method thereof. The polymer material comprises following raw materials by weight: 60-90 parts of matrix resin, 4.0-10 parts of a compatilizer, 0-30 parts of an inorganic filler, 0.3-2.0 parts of white oil, 0.4-0.6 part of an antioxidant, 0.5-1.0 part of a processing auxiliary agent and 1.0-5 parts of a toner. The polymer material is good in dimension stability, good in bridging effect and excellent in draping performance. The appearance of the polymer material is strong in metallic tactile sensation and pearl effects. The polymer material has one or a plurality of effects selected from heat discoloration, photochromic effects, effects of color changing when sensing water, and the like, and is of great significance for promoting material diversification and functionalization of 3D printing. The preparing method is simple, improves shearing and dispersion for the inorganic filler and the toner to the utmost, and improves properties of the polymer material.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

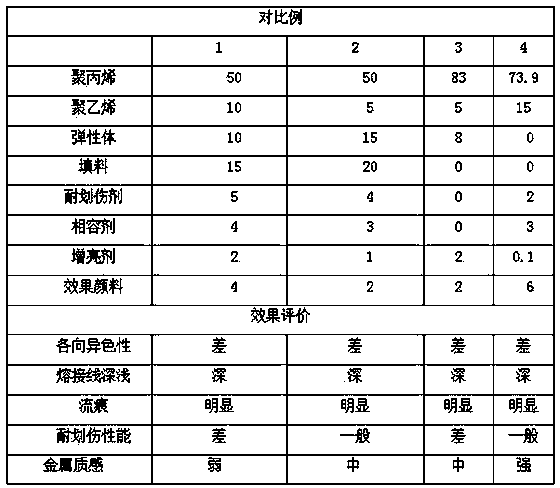

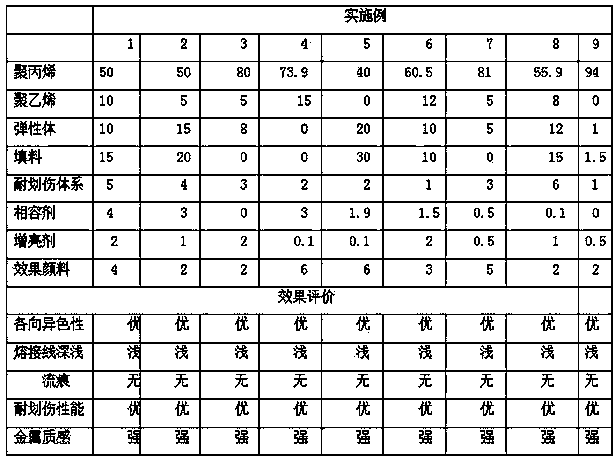

Scratch-resistant high-gloss spraying-free polypropylene composition with aesthetic effect as well as preparation method and application of composition

InactiveCN103910937AImprove scratch resistanceFlow behavior is reduced or even avoidedElastomerPolypropylene

The invention discloses a scratch-resistant high-gloss spraying-free polypropylene composition with aesthetic effect. The composition comprises the following components by weight percent: 40-94wt% of polypropylene, 0-15wt% of polyethylene, 0-20wt% of elastomer, 0-30wt% of filler, 1-6wt% of a scratch resistant agent system, 2-6wt% of effect pigment, 0.1-2wt% of brightener, and 0-4wt% of a compatilizer. Due to the synergistic effect of the scratch resistant agent system and the effect pigment, the spraying-free product is endowed with more excellent scratch resistance, thus having broader application prospect; in addition, the fluidity of the polypropylene composition is also affected, so that in injection molding or extruding, the change of the space position of the metal pigment of certain appearance shape along with melt flow is limited, the orientation of the metal pigment along with melt flow is reduced or even avoided, the defect of heterochromia of traditional spraying-free product is overcome, and the polypropylene composition has excellent metal texture, has no flow marks, and weakens and even eliminates dark appearance caused by a weld line.

Owner:KINGFA SCI & TECH CO LTD

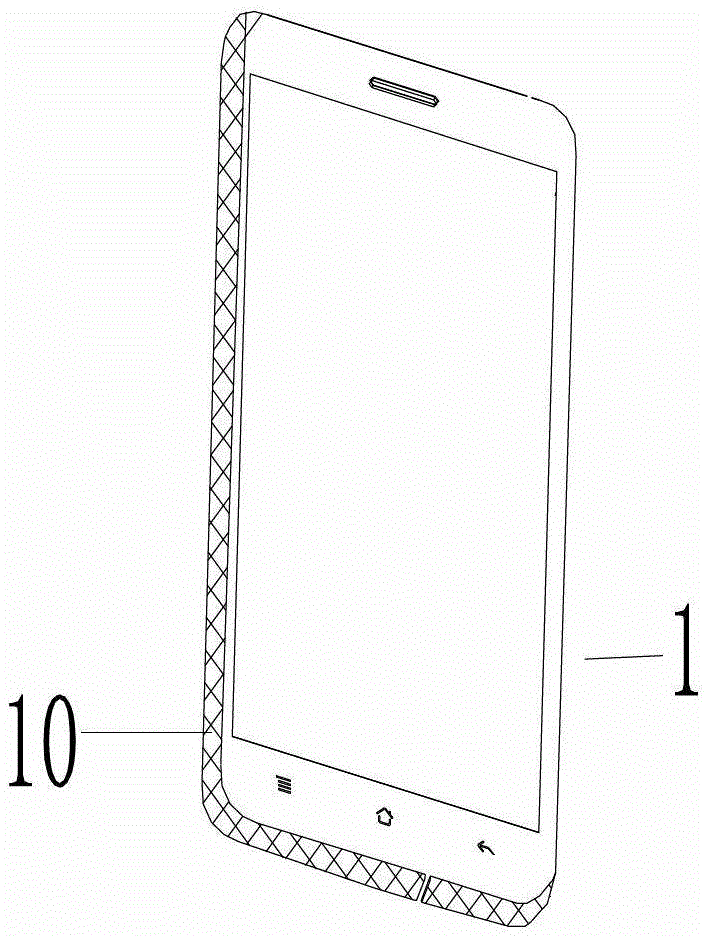

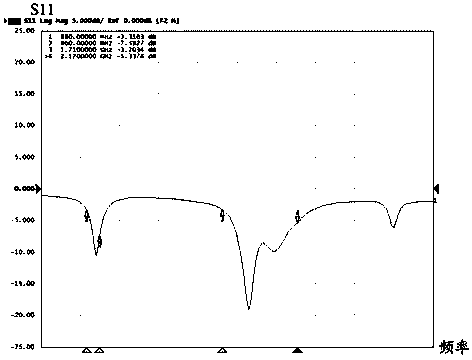

Coupling feed-in type antenna device of mobile terminal

ActiveCN103151613AReduce thicknessImprove structural performanceAntenna supports/mountingsRadiating elements structural formsCommunication qualityCoupling

The invention relates to the field of communication and discloses a coupling feed-in type antenna device of a mobile terminal. The coupling feed-in type antenna device of the mobile terminal comprises a metal shell. A first metal arm and a second metal arm stretch out of the lateral surface of the metal shell, wherein the first metal arm and the second metal arm form a fixed space in a enclosing mode, and a notch is formed in the arm end of the first metal arm and the arm end of the second metal arm. An antenna carrier is arranged inside the fixed space. The antenna is provided with an antenna. The antenna comprises a first antenna branch and a second antenna branch. A main board and an antenna connector are arranged inside the metal shell. The first antenna branch and the second antenna branch are respectively connected with the main board through the antenna connector. Due to the fact that the coupling feed-in type antenna device of the mobile terminal is adopted, the problem that communication quality is decreased when a user grips the mobile terminal is solved, and stronger metal texture is provided for the user.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

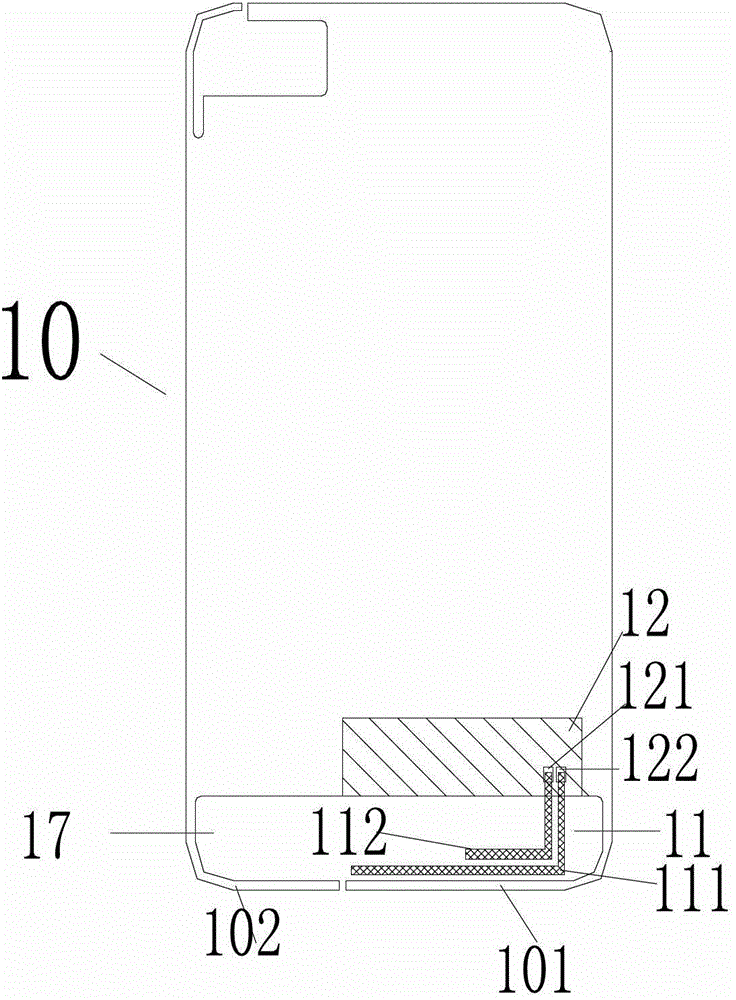

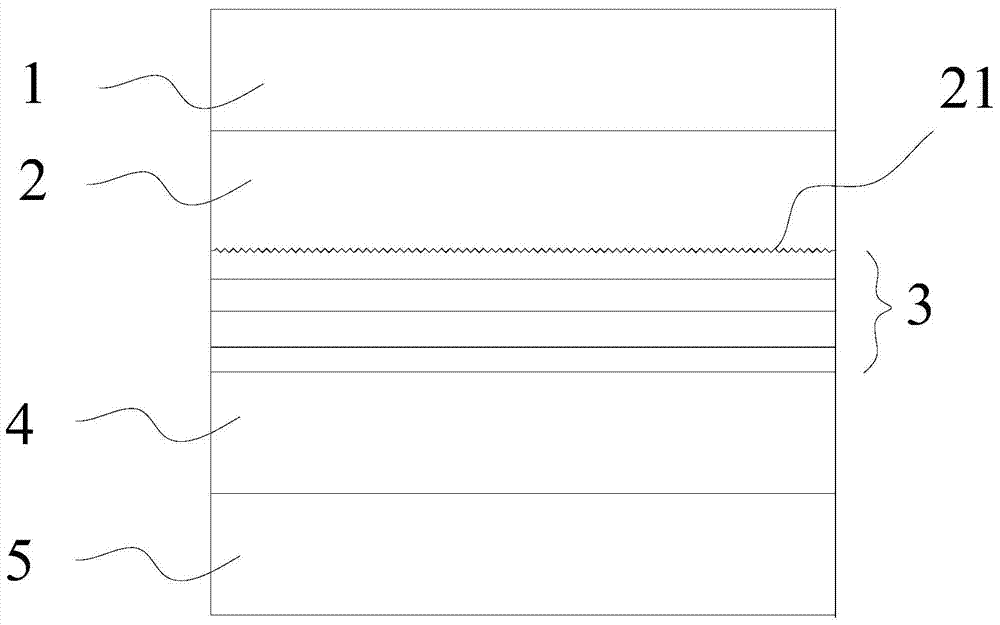

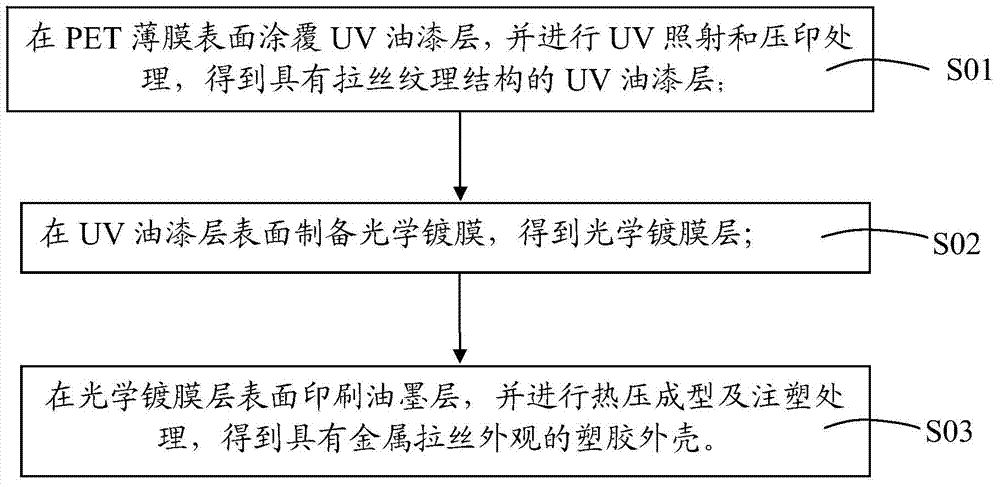

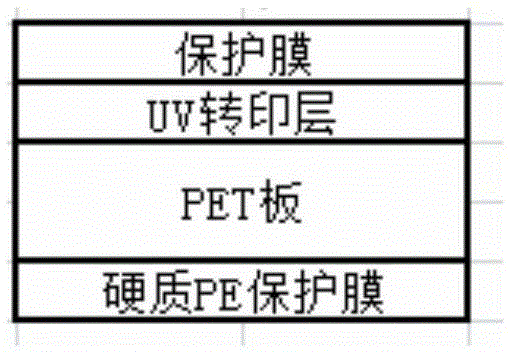

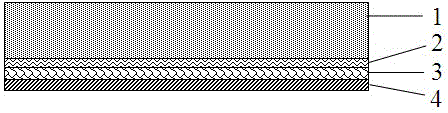

Plastic housing with metal brushed appearance and preparing method thereof

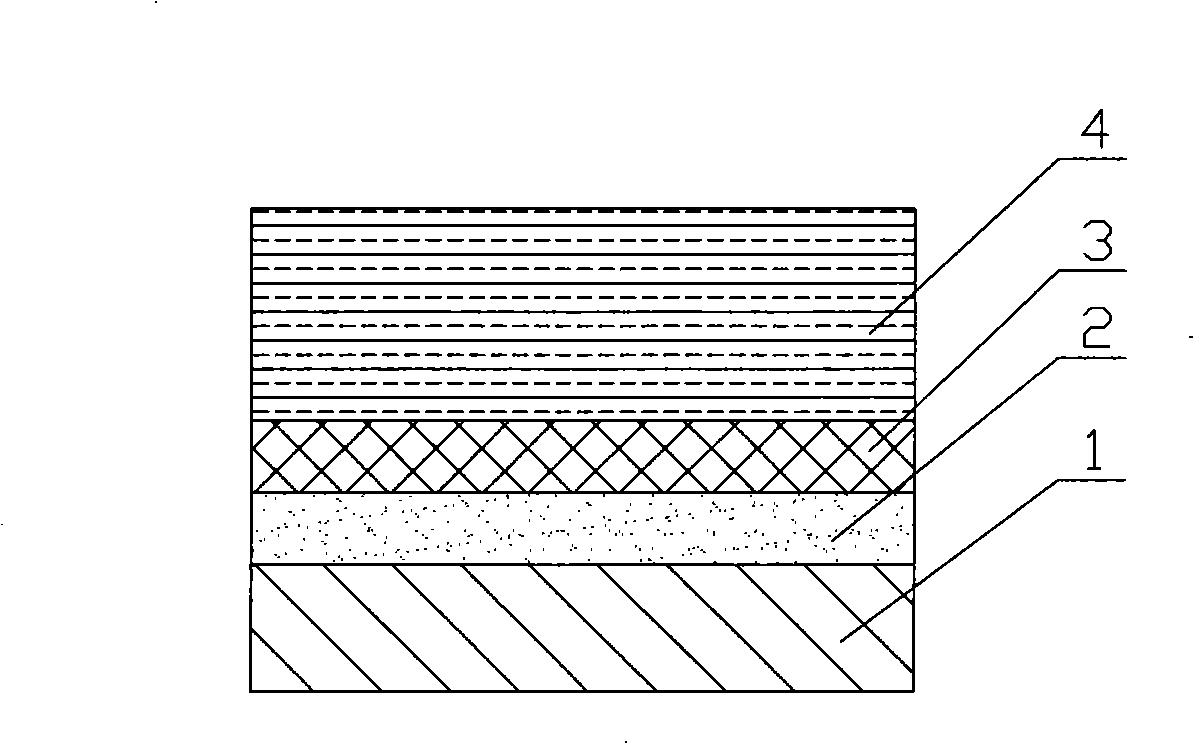

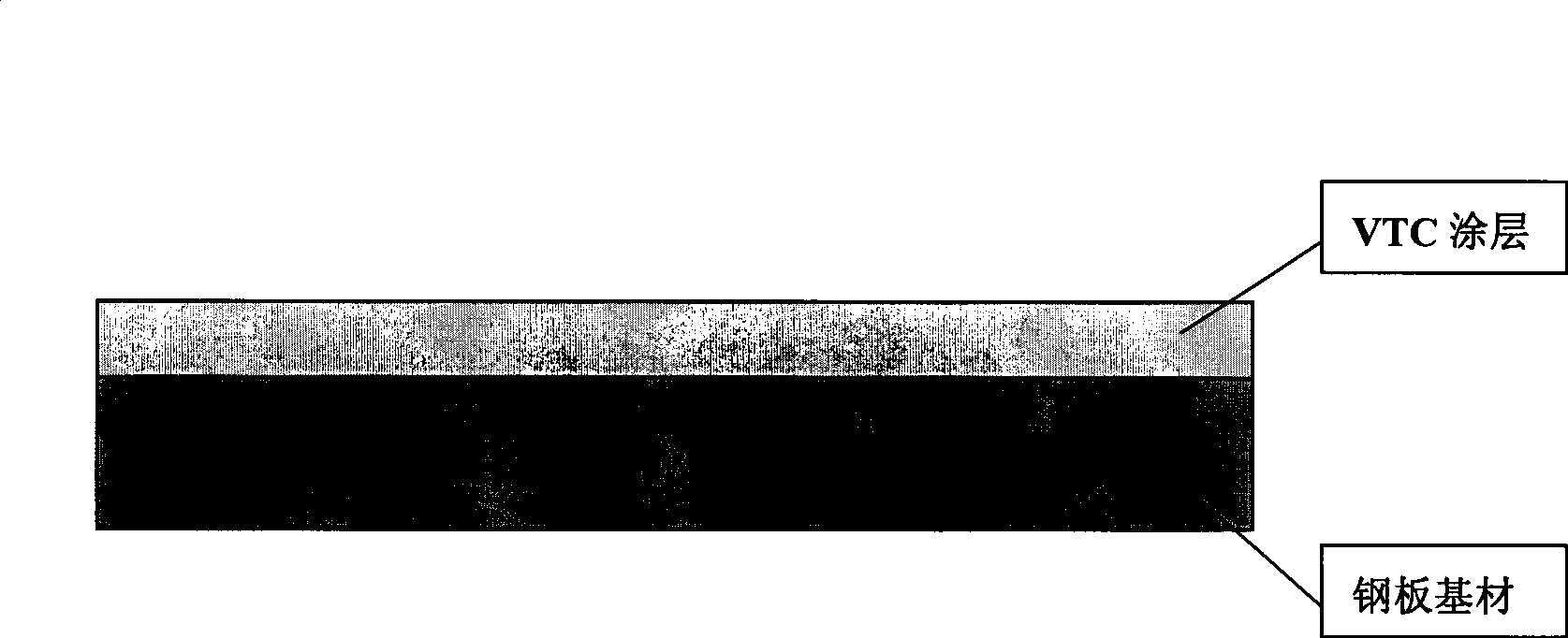

ActiveCN103780724AImprove wear resistanceHigh transparencySynthetic resin layered productsVacuum evaporation coatingHigh volume manufacturingEngineering

The present invention discloses a plastic housing with a metal brushed appearance and a preparing method thereof. The plastic housing comprises a PET film layer, a printing ink layer and a resin layer; wherein the PET film layer, the printing ink layer and the resin layer are successively laminated and combined. The plastic housing further comprises a UV paint layer and an optical plated film layer which are laminated and combined. Furthermore the resin layer, the printing ink layer, the optical plated film layer, the UV paint layer and the PET film layer are successively laminated and bonded from inside to outside. According to the plastic housing, through preparing the UV paint layer with a brushed pattern, wearing resistance and transparency of the plastic housing are improved, so that the brushed pattern is ordered and clear. Simultaneously through preparing the optical plated film layer, a remarkable metal qualitative sense is endowed to the plastic housing, so that the brushed effect is more stereo and clear. The invention further discloses a preparing method for the plastic housing with the metal brushed appearance. The preparing method of the invention has the functions of: eliminating mold machining and surface treating process in the prior art; shortening production period; facilitating batch production; and eliminating appearance problems of particle, impurity, oil accumulation, surface peeling, etc. in surface treating process.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

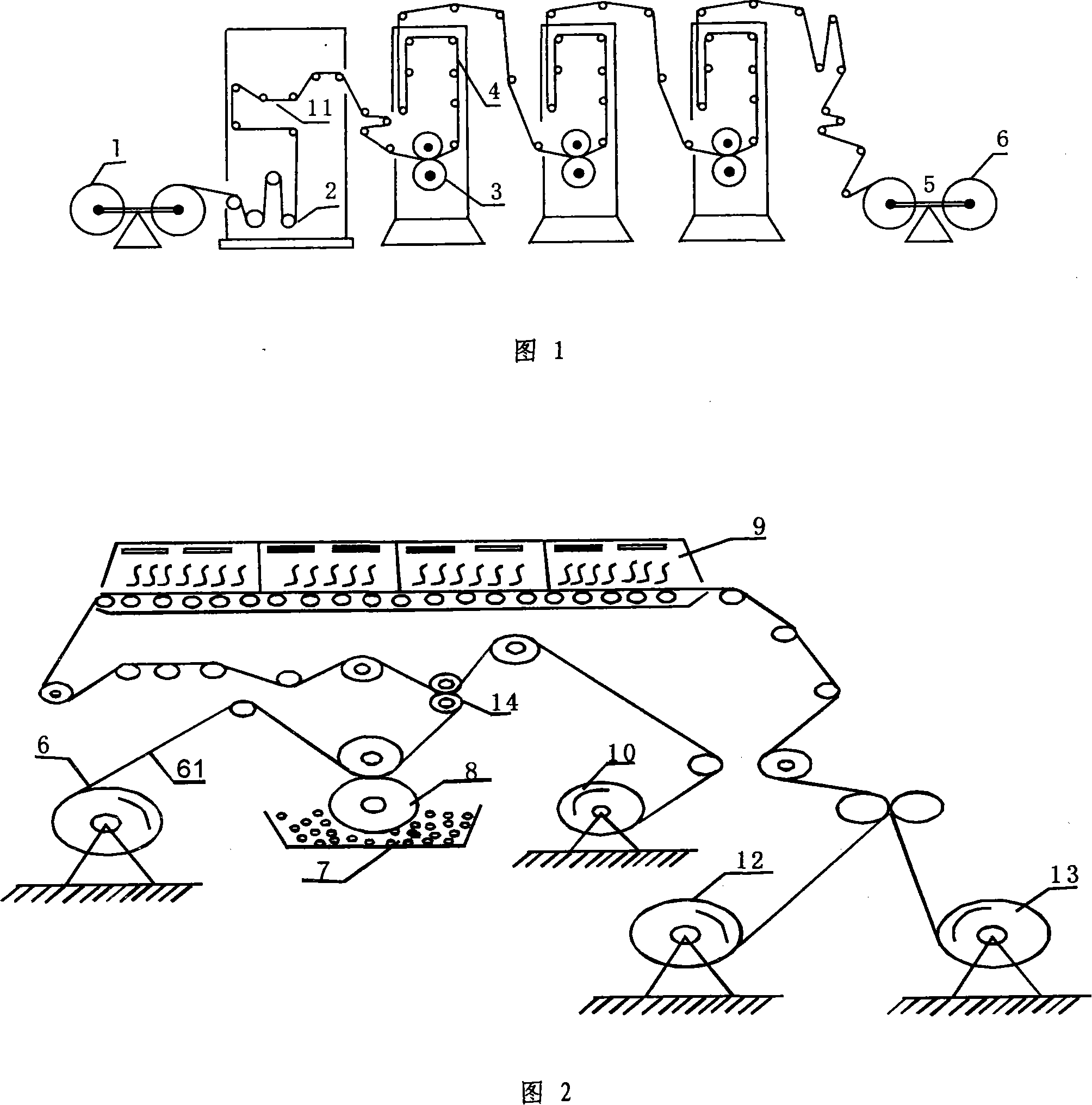

Film-transferring printing method

InactiveCN101148127AEffective peelingEfficient transferDecorative surface effectsPattern printingEngineeringPrinting ink

The film transfer printing process includes the following steps: 1. painting polyethylene terephthalate (PET) film with strippable layer of silica and methyl hydrazone acetaldehyde and in pH 7-8, solid content of 45+ / -2 % and proper viscosity; 2. printing graphic context on the PET film with intaglio printing or flexible plate printing ink; 3. painting water soluble glue of vinyl acetate-ethylene emulsion and in pH 8-10, solid content of 52+ / -2 % and proper viscosity; and 4. compounding the PET film to paper material and stripping to transfer the printed graphic context onto the paper material. The present invention can strip and transfer the printed ink layer effectively to obtain printed matter with strong metal texture in less influence of the paper quality on the printed matter quality.

Owner:SHENZHEN JINJIA GRP

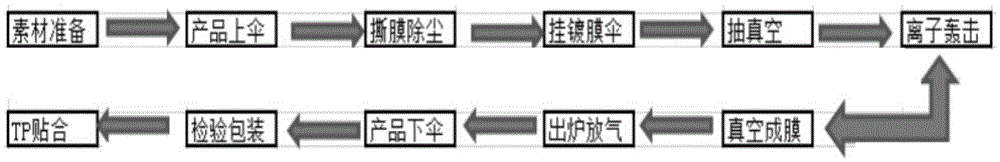

Treatment method allowing plastic surface to have high metal texture

ActiveCN103510049AStrong metal textureVacuum evaporation coatingSputtering coatingIndiumIon bombardment

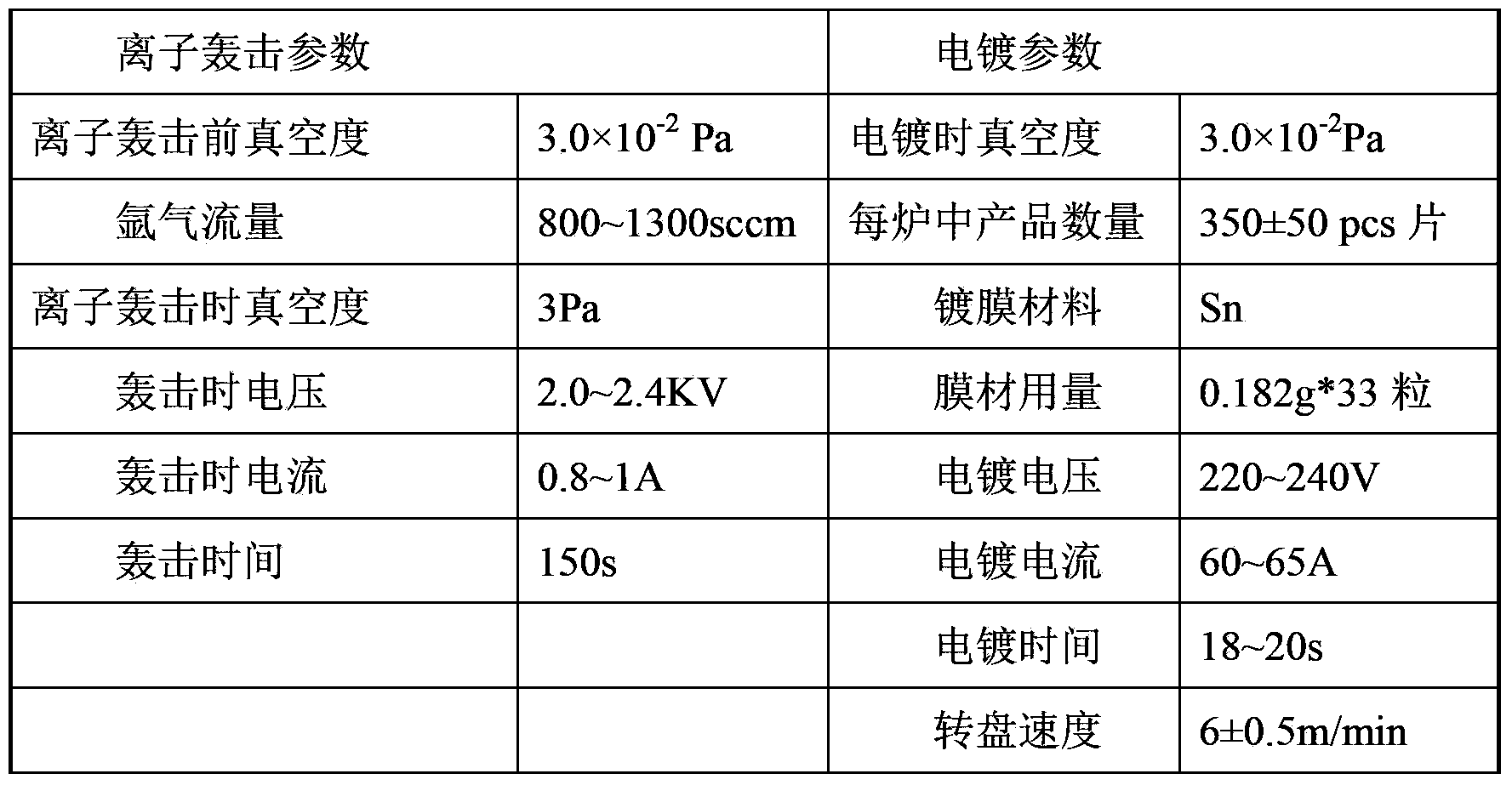

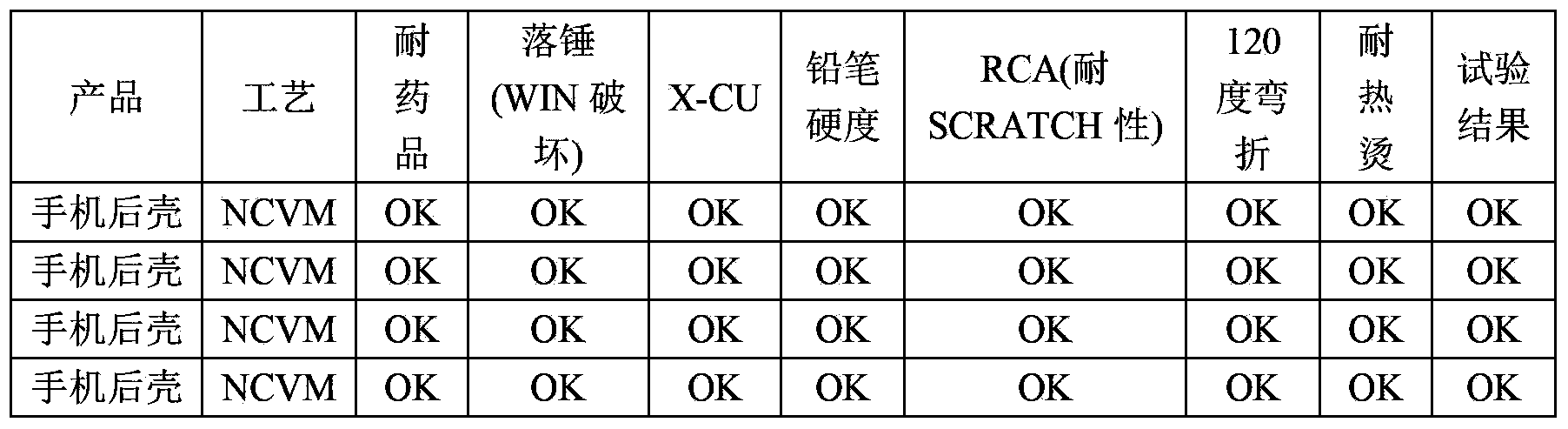

The invention discloses a treatment method allowing a plastic surface to have high metal texture. The treatment method comprises the steps of ion bombardment: putting a clean plastic product in a vacuum evaporation coating chamber, performing the ion bombardment on the surface of the plastic product as follows: vacuumizing the vacuum evaporation coating chamber to allow a vacuum degree in the vacuum evaporation coating chamber to be 2.0*10<-2>-3.0*10<-2>Pa, charging argon, keeping a flow rate at 800-1300sccm, allowing the vacuum degree in the vacuum evaporation coating chamber to reach 2-3Pa, and allowing the argon to produce ionization and bombard the surface of the plastic product for 150-180s under voltage of 2-2.4KV and current of 0.8-1A, and coating: vacuumizing the vacuum evaporation coating chamber to allow the vacuum degree in the vacuum evaporation coating chamber to be 2.0*10<-2>-3.0*10<-2>Pa, and coating a metal film on the surface of the plastic product as follows: allowing the voltage to be 220-240V, the current to be 60-65A, and the time to be 18-20s, and taking tin, indium or an indium and tin alloy as a coating material with the weight of 0.172-0.192g to ensure no conducting of the surface of the product. The plastic surface treated by the method has the higher metal texture.

Owner:DONGGUAN HUAQING OPTICAL TECH

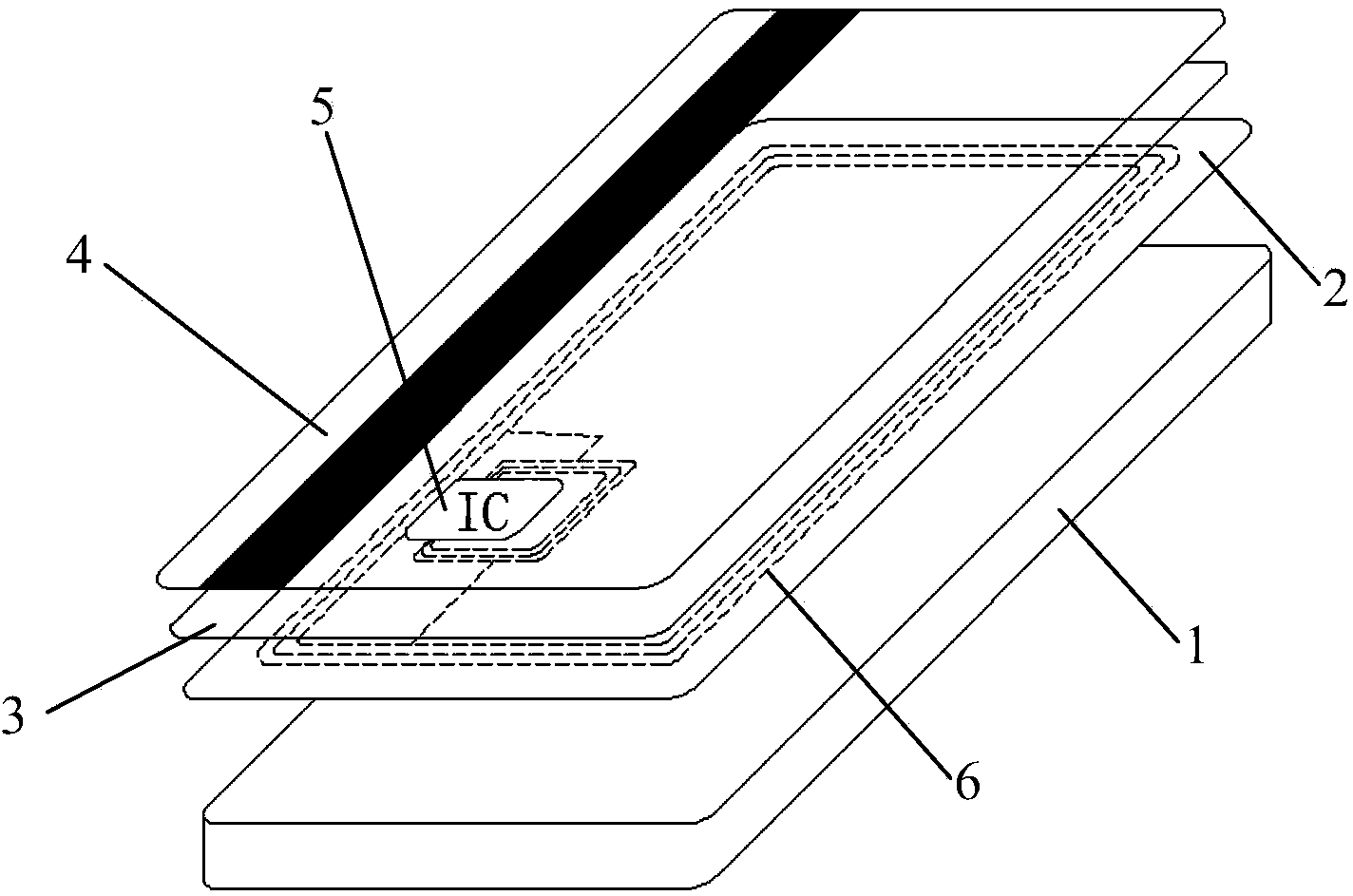

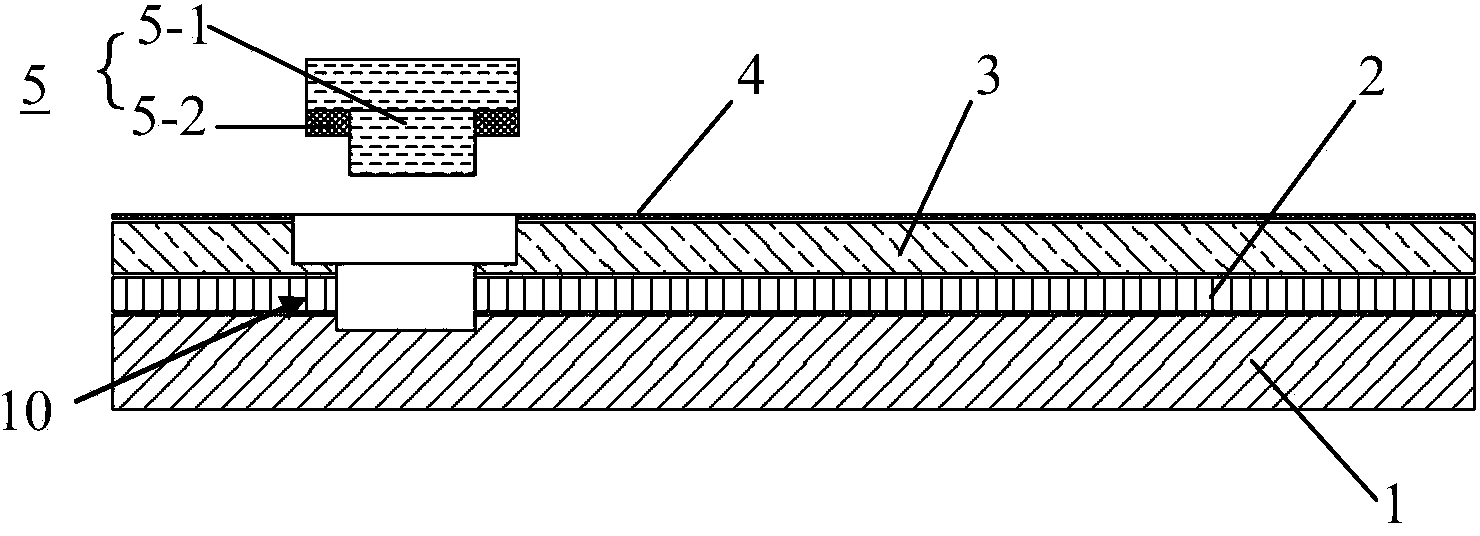

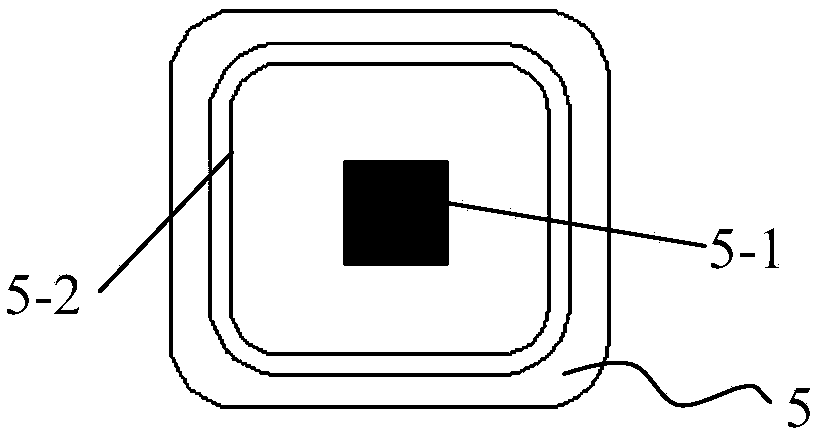

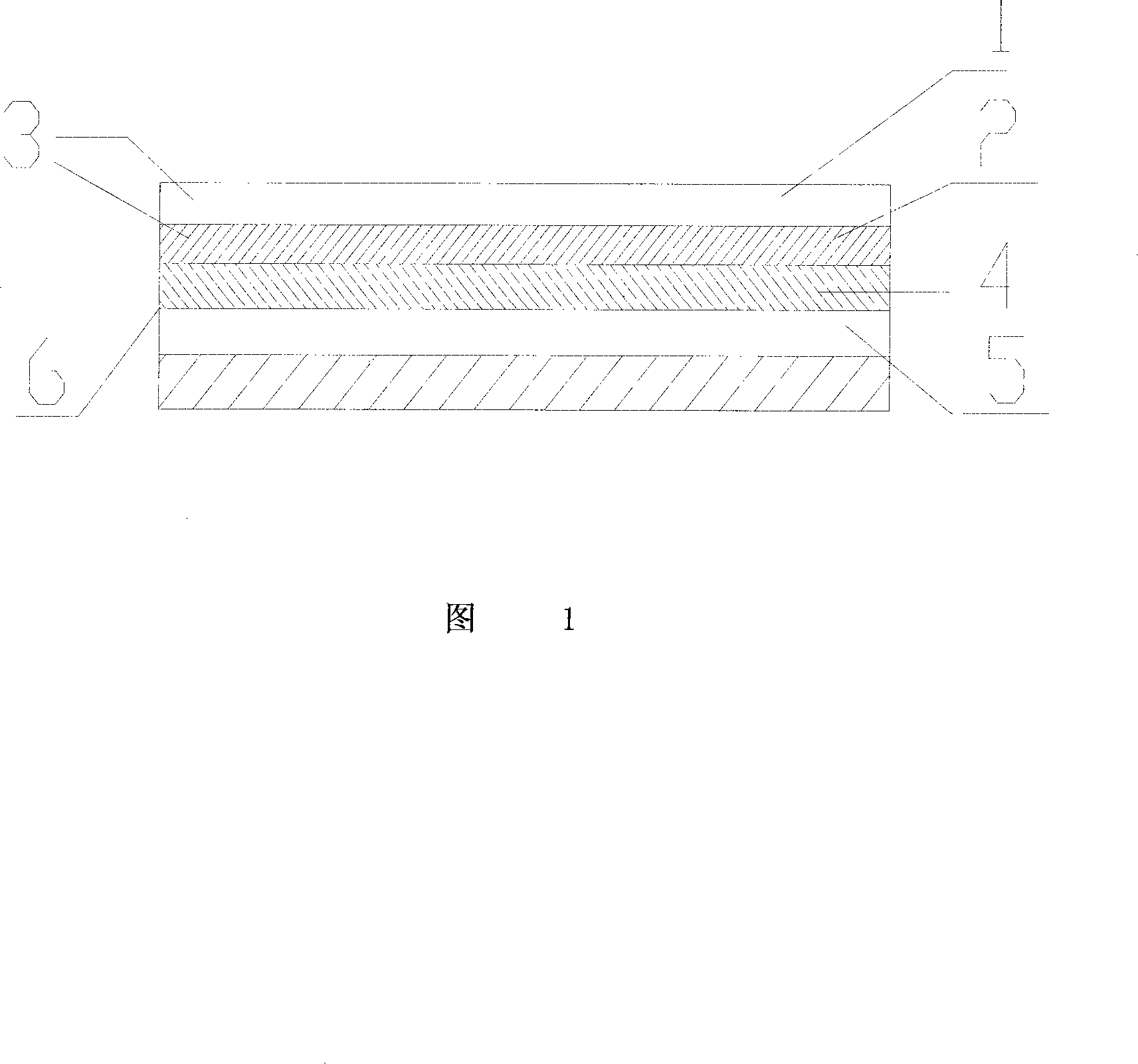

Double-interface metal intelligent chip card and manufacture method

ActiveCN104166870AImprove the anti-electromagnetic interference characteristicsExchangeRecord carriers used with machinesElectricityElectromagnetic coupling

The invention discloses a double-interface metal intelligent chip card and a manufacture method. The double-interface metal intelligent chip card comprises a metal card body. The metal card body is provided with an interlayer, a printing sheet layer and a transparent protection layer which are positioned on the metal card body. The metal card body, the interlayer, the printing sheet layer and the transparent protective layer constitute a card base for the intelligent chip card. The base card is provided with a concave cavity for containing an IC module; the metal card body is a wave-absorption material metal card body; the interlayer is provided with an induction antenna; the IC module comprises a chip and a coupling micro antenna which is electrically connected to the chip; and the IC module can perform the information exchange between the chip and a reader through electromagnetic coupling between the coupling micro antenna and the induction antenna and the electromagnetic coupling between the induction antenna and the induction coil of the reader. The invention solves the technical problem that the metal card hardly realizes double-interface chip clamping contact type function and a non-contact type communication function at the same time, and provides a new double-interface IC metal card which is good in touching, has metal texture and can realize a double-interface transaction function.

Owner:GOLDPAC GRP LTD

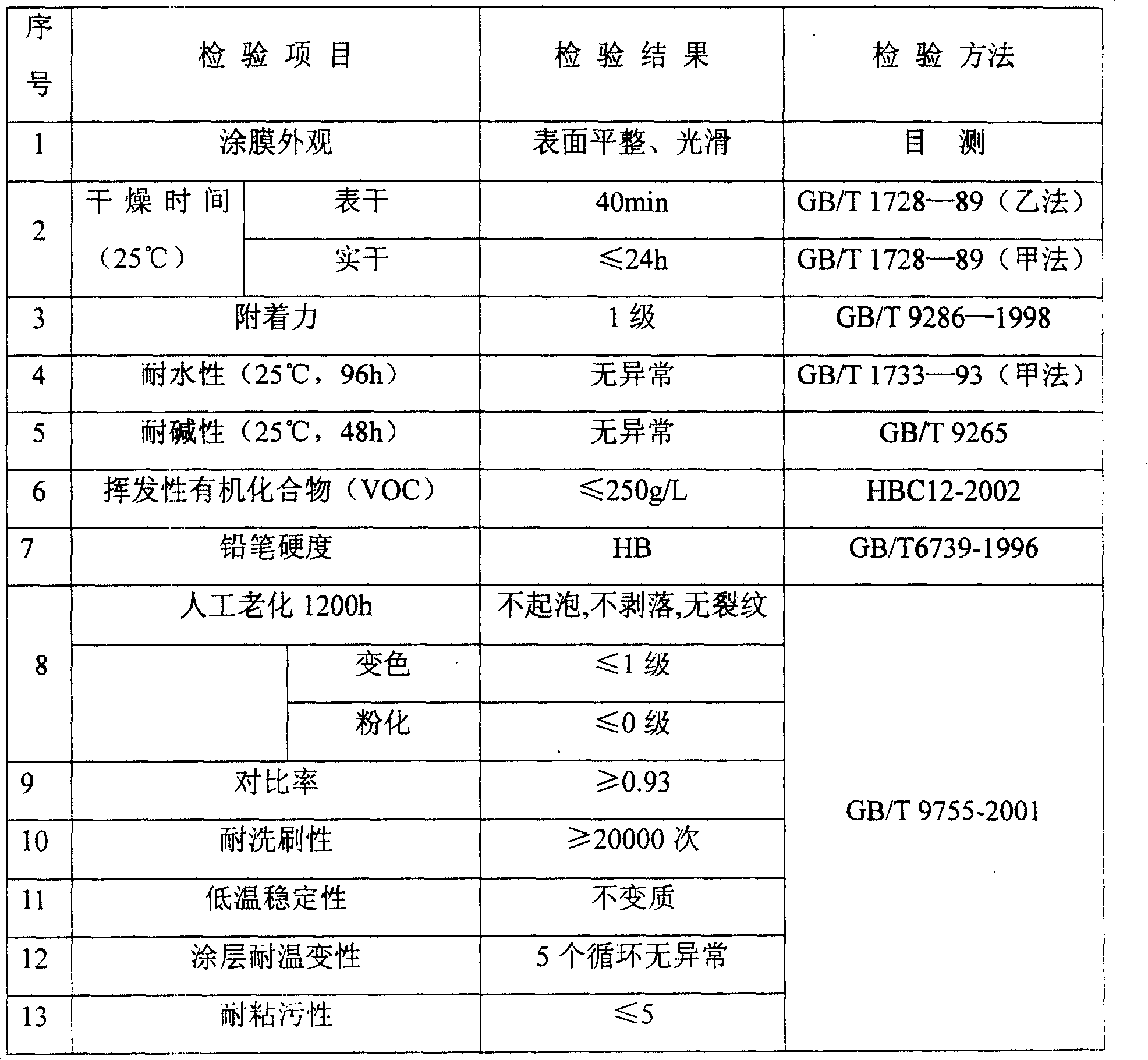

Aqueous curtain-imitating metallic luster paint

The invention discloses a water-based curtain wall imitation metal luster paint which comprises the following main components according to the following proportions by weight: water-based resin 40-80 percent, antifoam agent 0.05-0.8 percent, disperser 0.05-1.0 percent, coloring agent 5-35 percent, thickener 0.1-1 percent, anti-crinkling agent 0.1-1 percent, leveling agent 0.1-1 percent, antifreeze agent 1-10 percent, anti-bacterial agent 0.5-5 percent, fungicide and algaecide 0.5-5 percent, and water 5-40 percent. The water-based metal luster paint provided by the invention can be applied onto the surfaces of cement products like external and internal walls of buildings with high ornamental effect like aluminum / plastic plates. Furthermore, ornamental slits are integrated with plated surfaces and the invention has high-efficiency mildew proof and anti-alga effect, waterproof and pervious function for breathing, low cost, intense metal texture, good ornamental effect without environmental pollution, as well as high anti-soil anti-weathering performance.

Owner:上海展辰涂料有限公司 +2

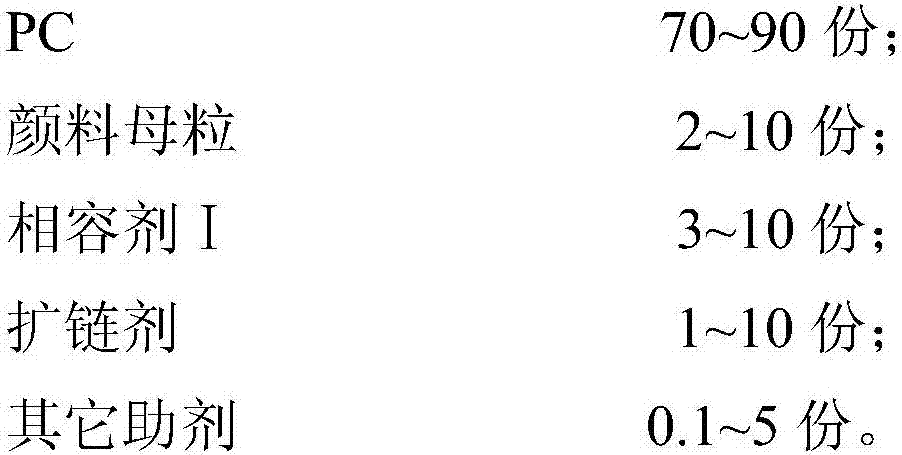

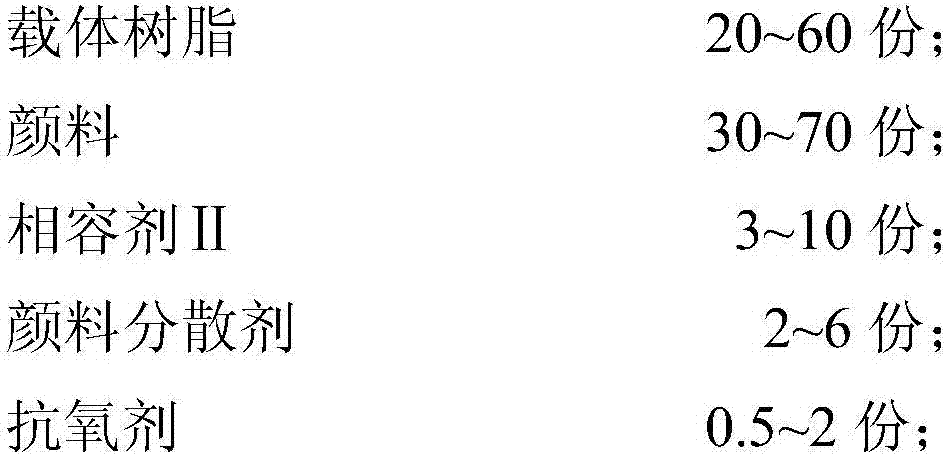

Spraying-free high-impact PC alloy material with metallic luster and preparation method thereof

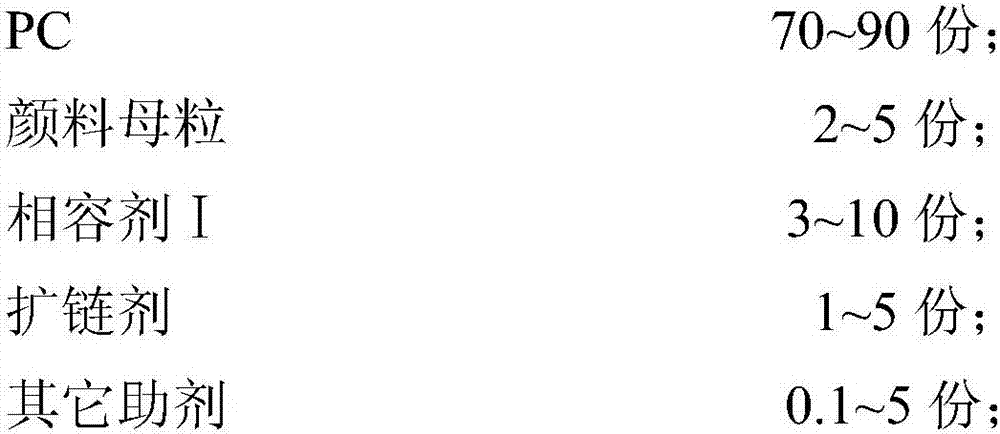

ActiveCN107987503AHigh impact resistanceIncrease the molecular weight of PCAlloyExtrusion Granulation

The invention discloses a spraying-free high-impact PC alloy material with metallic luster. The alloy material comprises the following raw materials in parts by weight: 70-90 parts of PC, 2-10 parts of pigment master batch, 3-10 parts of a compatilizer, 1-10 parts of a chain extender and 0.1-5 parts of other assistants. The invention discloses a PC alloy material formula. Due to matched use of thepigment master batch, the compatilizer and the chain extender, a spraying-free PC part with excellent appearance of obvious metal texture, pearlescent glitter and the like as well as high impact property is obtained after extruding granulation. The part has wide application prospects and is particularly suitable for being used in a stress environment.

Owner:CGN JUNER NEW MATERIALS +1

Uncontinuous high-metallic coating method

InactiveCN101565815AStrong metal textureHigh light transmittanceVacuum evaporation coatingSputtering coatingIndiumSpray coating

The invention belongs to the technical field of vacuum coating, and in particular relates to an uncontinuous high-metallic coating method, which comprises the following steps: firstly, spray coating of a UV primer, namely coating the UV primer on the coated surface of a product, roasting the coated product in an oven, and curing the roasted product in a UV furnace; secondly, stannum-indium coating, namely placing a tungsten filament of a coating machine into a stannum-indium coating material, placing the product after spray coating of the UV primer into a vacuum furnace turntable of the coating machine for electrostatic dust collection of the product, performing vacuum pumping after sealing the coating machine, performing preheating after vacuum pumping, and evaporating the stannum-indium coating material for coating; and thirdly, spray coating of a UV finishing coat, namely coating the UV finishing coat on the coated surface of the product after stannum-indium coating, roasting the coated product in the oven, and curing the roasted product in the UV furnace. The product coated by the method is not conductive; the membrane layer is white and bright; the light transmittance is good; the metallic texture is strong; and the weathering resistance is good.

Owner:GUANGDONG JANUS SMART GRP CO LTD

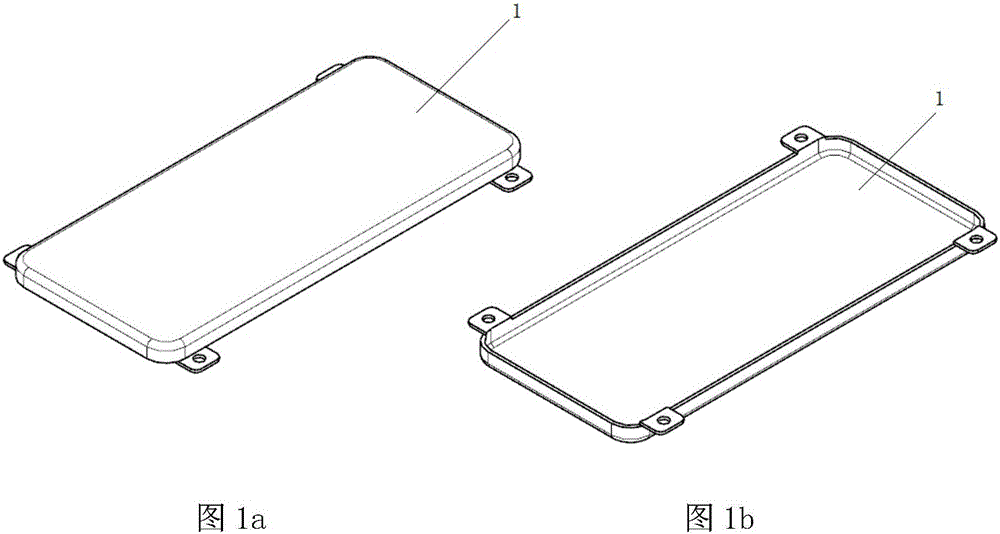

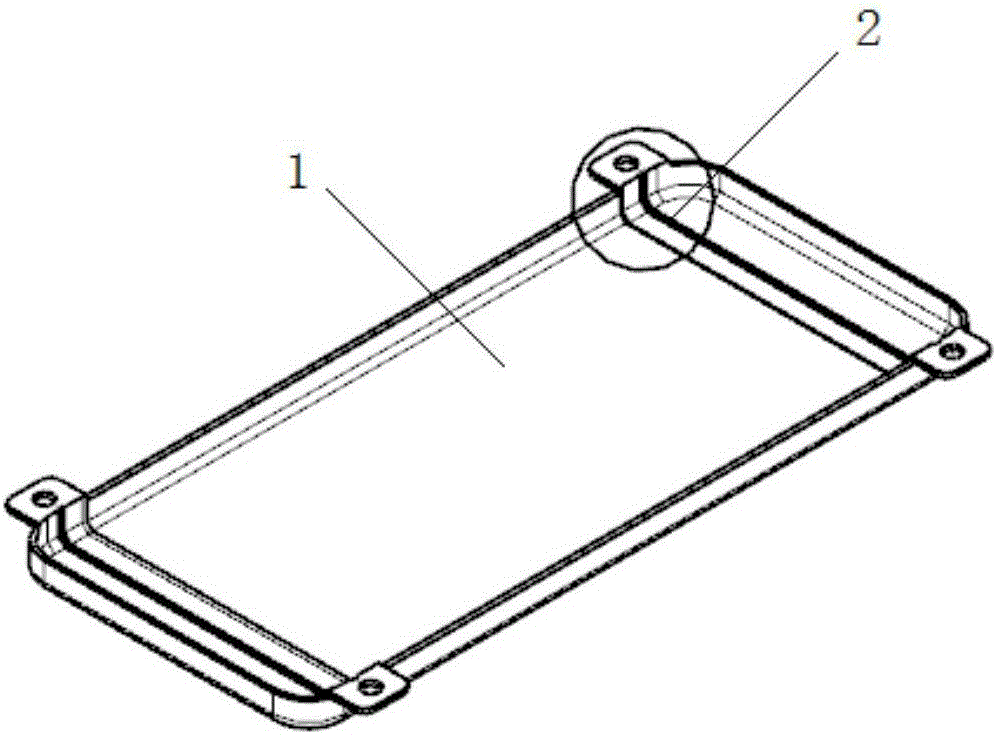

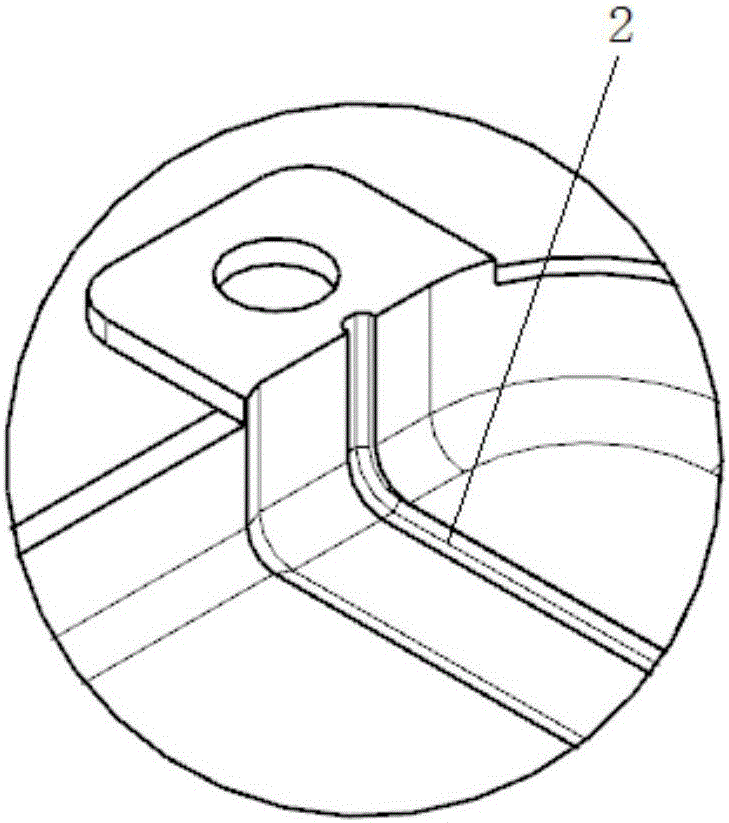

3C electronic product shell and manufacturing method thereof

InactiveCN105979741AEliminates the problem of slitting bit exposureMeet the appearance quality requirementsCasings/cabinets/drawers detailsMetal casingsEngineeringInjection moulding

The invention discloses a 3C electronic product shell and a manufacturing method thereof. The 3C electronic product shell comprises a metallic structure, an antenna slot penetrates through the back and the front of the metallic structure, the antenna slot comprises a slot cavity and an antenna cutting position slit penetrating through the front of the metallic structure from the slot cavity, the antenna cutting position slit is filled with a nonconductive matter, an integrally inject-molded plastic structure layer is arranged on the back of the metallic structure, and the slot cavity is filled with at least part of the plastic structure layer. The 3C electronic product shell is favorable for completely solving the problem that the antenna cutting position on the surface of the electronic product metal shell is exposed, so that the electronic product metal shell is coherent in overall appearance and strong in metallic texture; and the 3C electronic product shell is simple in manufacturing process, low in cost and suitable for large-scale production, meets the requirement of 3C electronic product structures for appearance quality, and simultaneously has the advantages of easiness in manufacturing, low cost and practicability.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Coating material and preparation method thereof

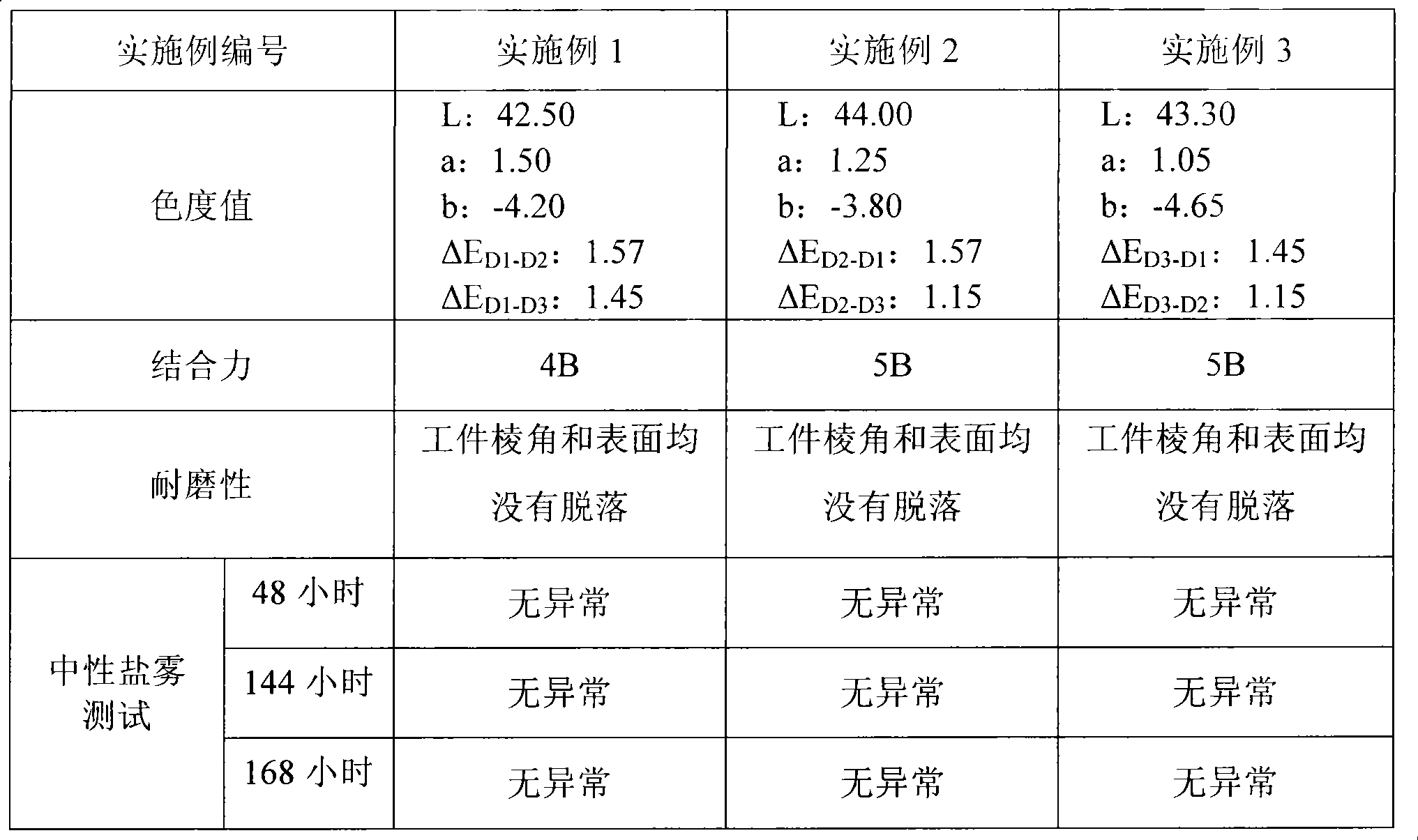

ActiveCN101468538AStrong metal textureImprove bindingLayered productsVacuum evaporation coatingSputteringTitanium zirconium

The invention provides a film plating material, which comprises a base material and a film layer plated on the base material. The film layer comprises a titanium-zirconium film layer and a titanium-zirconium nitrification film layer which are plated on the base material sequentially. The invention also provides a method for preparing the film plating material. The method comprises: a power supply is applied onto a magnetron target to make target substances on the magnetron target spatter and deposit on the base material under the condition of forming magnetron spattering of the titanium-zirconium film layer and the condition of forming magnetron spattering of the titanium-zirconium nitrification film layer sequentially, so as to form the titanium-zirconium film layer and the titanium-zirconium nitrification film layer which are plated on the base material sequentially. The target is a titanium-zirconium embedding target. The film plating material has the advantages of blue film layer, small color difference, even colors, strong metal texture of the film layer, good bonding strength, and good abrasion resistance and corrosion resistance.

Owner:JIANGSU HAIYU MACHINERY

High-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and preparation method thereof

InactiveCN105199294AImprove the lubrication effectImprove wettabilityAntioxidantAcrylonitrile butadiene styrene

The invention relates to the technical field of polymer materials, in particular to a high-gloss spraying-free ABS (acrylonitrile butadiene styrene) composite material with special effect and a preparation method thereof. The composite material comprises, by weight: 70-90 parts of ABS resin, 4.0-10 parts of a compatilizer, 5.0-10 parts of a toughener, 1.0-3.0 parts of white oil, 0.4-0.6 part of a composite antioxidant, 0.5-1.0 part of a lubricant, and 1.0-5 parts of pearl powder. The preparation method is simple, and the prepared ABS composite material has good mechanical properties, low aid emigration rate, significant pearl effect, smooth surface free of flow marks and scratch resistant, and long service life.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

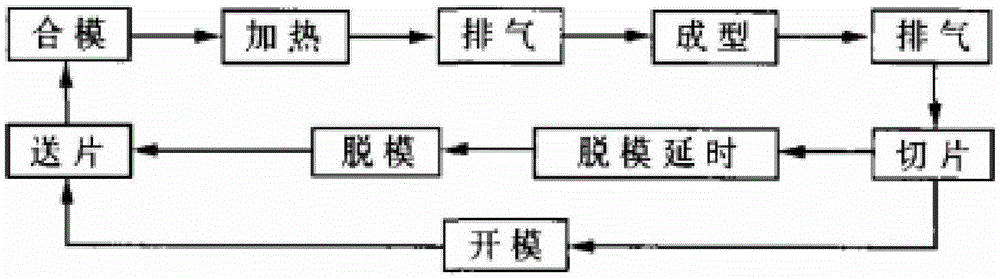

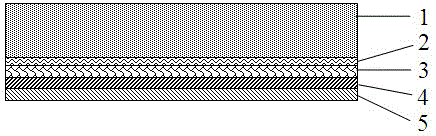

Coating film preparation process for electronic device shell

ActiveCN105331931AStrong three-dimensional appearanceStrong metal textureVacuum evaporation coatingSputtering coatingIndiumPolyethylene glycol

A coating film preparation process for an electronic device shell comprises the following steps that ion bombardment is conducted, i.e., a transparent polyethylene glycol terephthalate (PET) sheet with one face subjected to UV transfer treatment is put into a vacuum coating chamber, and the surface of the PET sheet is subjected to ion bombardment; and film coating is conducted, i.e., the surface of the PET sheet is sequentially coated with a SiO2 film, a TiO2 film, an indium film and a SiO2 film in a vacuum film coating mode, and the parameters of vacuum film coating are as follows: the vacuum degree during film formation is from 4.0*E-3Pa to 2.0*E-3Pa, the current during SiO2 film coating is 50-150 mA, the current during TiO2 film coating is 350-390 mA, the evaporation resisting current during indium film coating is 280-300 mA, and the thicknesses of the SiO2 film, the TiO2 film, the indium film and the SiO2 film are sequentially seen in the specifications. The surface of a product processed by the process has the 3D effect with high surface three-dimensional sense, the product has the golden appearance with high metal sense, and the film coating reliability is high.

Owner:DONGGUAN HUAQING OPTICAL TECH

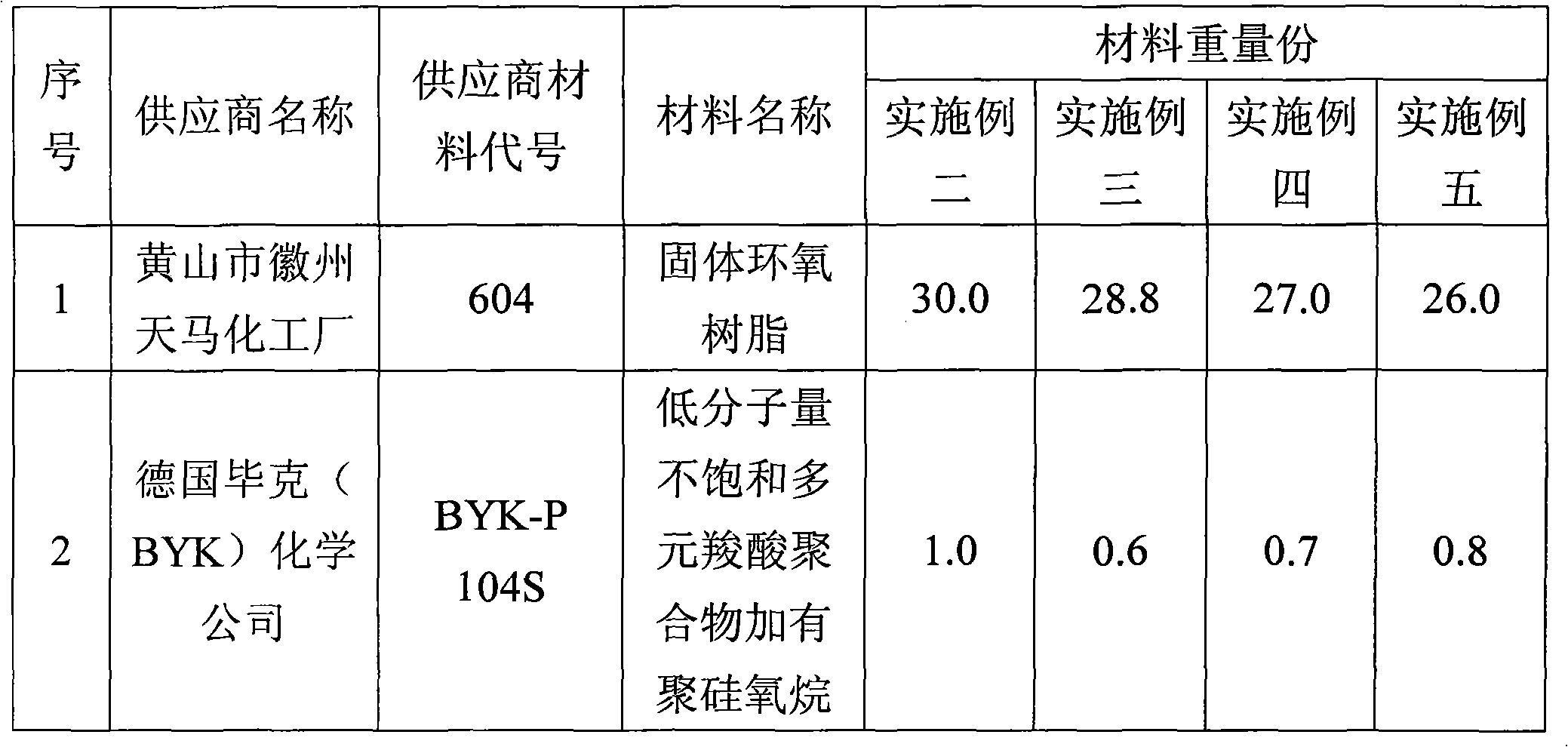

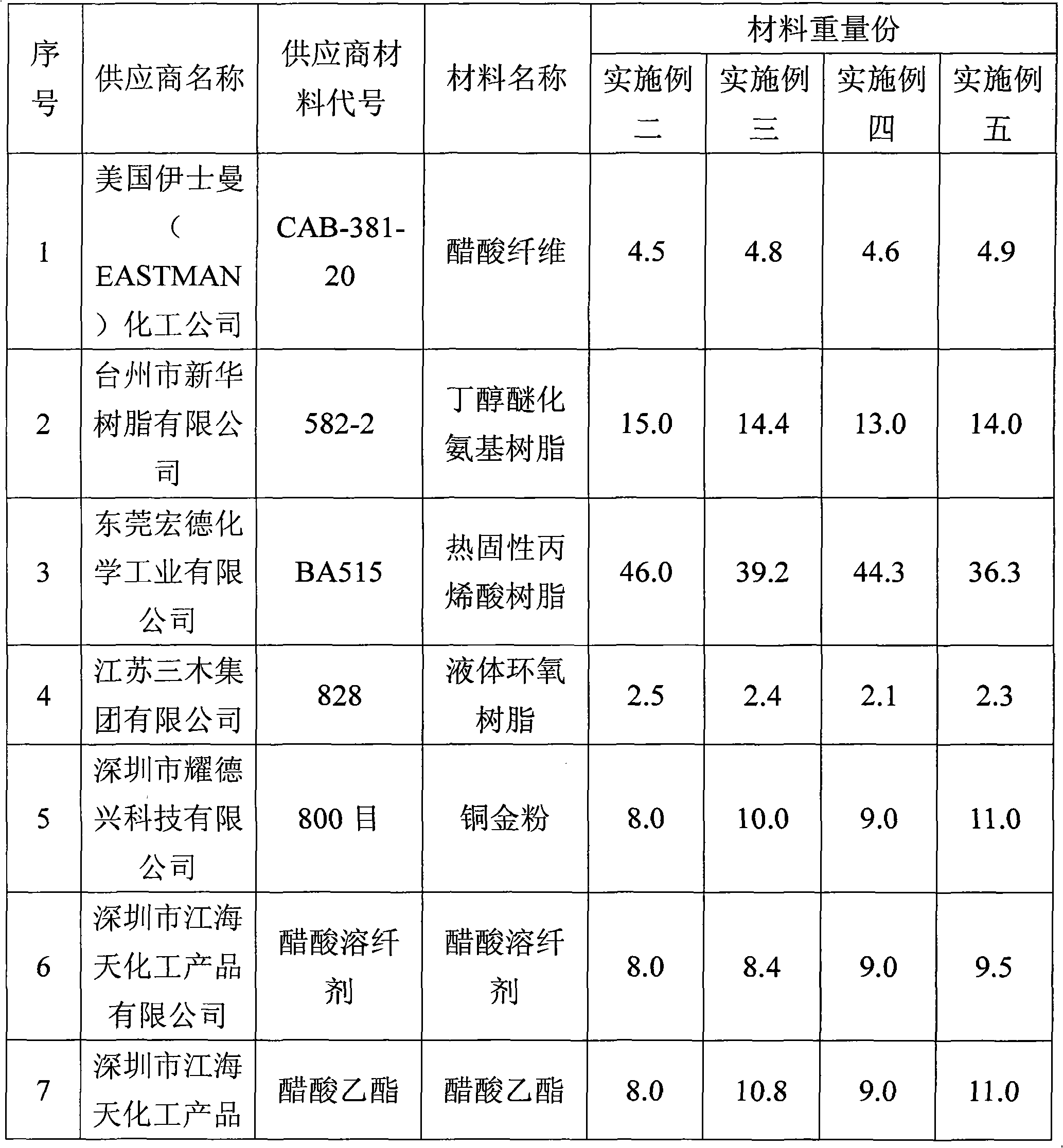

Metallic outdoor pattern powder coating and producing method thereof

ActiveCN105111899AGood weather resistanceStrong metal texturePowdery paintsPolyester coatingsPolyester resinMetal powder

The invention provides a metallic outdoor pattern powder coating and a producing method thereof. The metallic outdoor pattern powder coating is prepared from the following raw materials in part by mass: 60-78 parts of carboxyl polyester resin, 2.2-2.8 parts of curing agents, 10-29 parts of packing, 0.2-0.4 part of metallic pigments, 0.001-0.003 part of orange-peel agents, 0.1-0.2 part of special-effects pattern agents and 0.003-0.004 part of powder flowback preventing agents. The invention also provides a producing method of the metallic outdoor pattern powder coating. The metallic pattern powder coating is good in weather fastness, patterns of the outside of a film are clear, a metallic texture is strong, and after the metallic outdoor pattern powder coating is solidified into a film, the film has excellent weather fastness and good adhesive force. The problem that common metal powder is poor in weather fastness can be solved. Metallic patterns can be obtained. The metallic outdoor pattern powder coating can be used on aluminum profiles well.

Owner:湘江涂料科技有限公司

Imitation copper paint and preparation method and construction technology thereof

InactiveCN101962508ASimple construction processGood coloring effectSpecial surfacesEpoxy resin coatingsEpoxyColor effect

The invention relates to an imitation copper paint and preparation method and construction technology thereof. The imitation copper paint comprises epoxy grey primer, copper powder baking finish, a first layer of overprinting matte paint, semitransparent black finishing coat and a second layer of overprinting matte paint which are coated on a surface to be constructed layer by layer. The imitation copper paint of the invention has the advantages of good color effect, strong metal texture, no decoloration, high adhesive attraction, impact resistance, and excellent weather resistance, water resistance and acidity and alkaline resistance. The preparation method provided by the invention has the advantages of simple technology and is beneficial to mass production and the stability of product performance. The construction technology provided by the invention is simple and is easy for scale coating operation.

Owner:周荣华 +1

Method for blacking case of mobile phone

InactiveCN101338430AImprove bindingImprove wear resistanceSuperimposed coating processHigh pressureMaterials science

The invention discloses a manufacturing method for blackening mobile phone shell. The manufacturing method comprises the procedures as follows: a stainless punch forming shell is adopted; the shell is polished or wiredrawn; the shell is placed on an ultrasonic clean line to be cleaned; the shell is placed in a vacuum furnace; high voltage source is used for argon-ion bombardment for the shell; an Ion plating method is used for depositing a pure metal layer on the surface of the shell; a magnetron sputtering method is used for depositing a middle transition layer on the bottom layer of the pure metal; the magnetron sputtering method is used for coating a hard black film on the middle transition layer; the shell is passivated and cooled; and a static protective film is stuck on the shell for package. The manufacturing method has the characteristics of green environmental protection and energy saving. The tone range of a black nano film is that L is equal to 35 to 39, a is equal to -0.3 or 0.5 and b is equal to 0 to 3. The manufacturing method also has strong bonding capacity which can be over 8H under the loading below 1000g, so the wear-resisting property and the service life of the stainless cell phone casing are greatly improved.

Owner:高鸿镀膜科技(浙江)有限公司

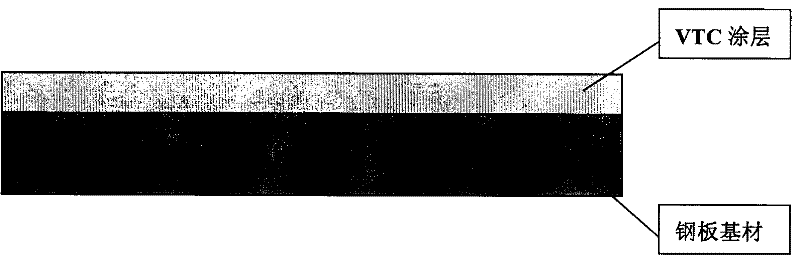

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413AHarsh salt spray resistanceGood anti-ultraviolet aging performanceAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

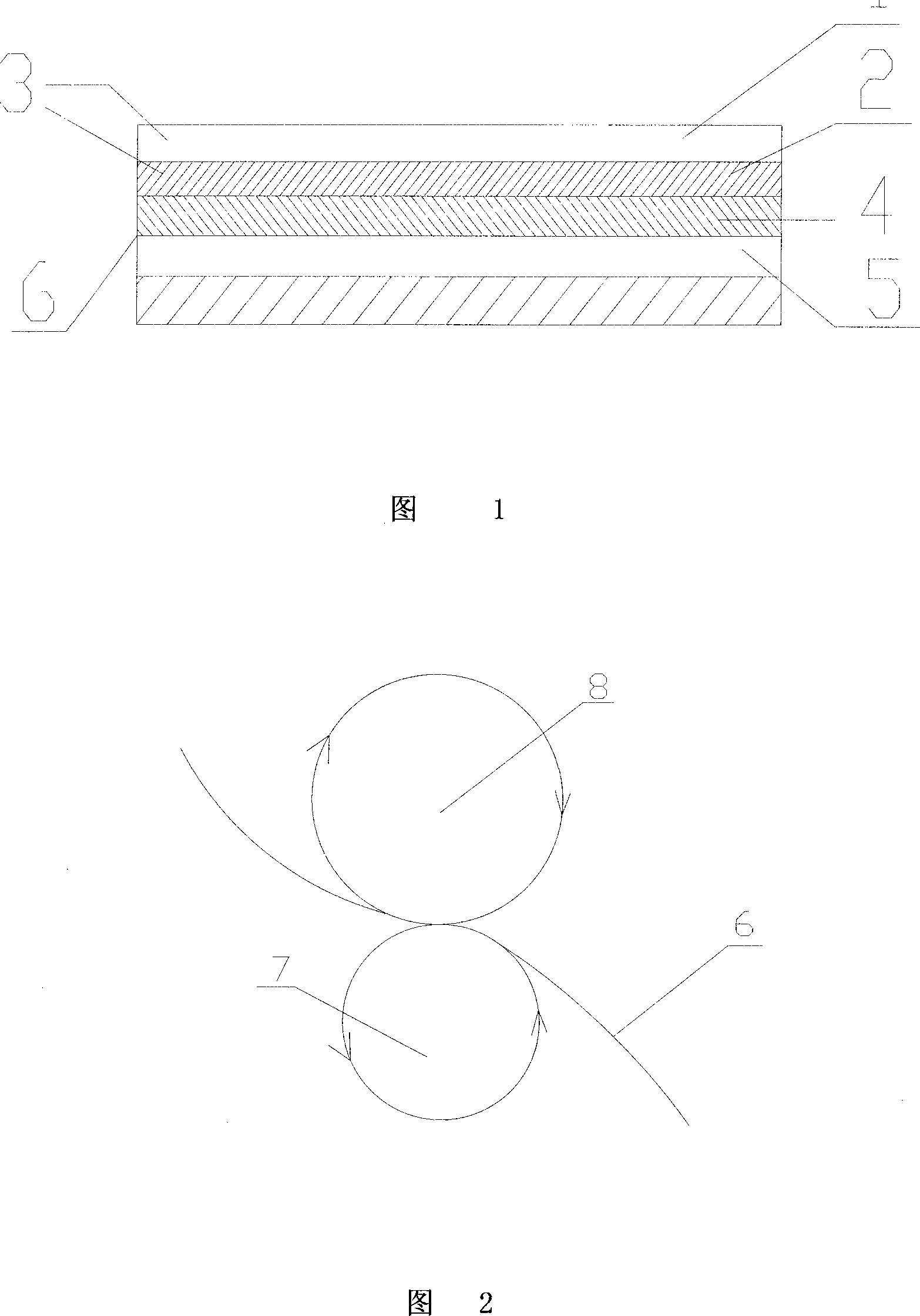

Production method of embossing form packing paper

InactiveCN101205695AStrong metal textureGood flexibilityFlexible coversMechanical working/deformationSurface layerPaper production

An embossing type tipping paper production method relates to the packaging material technical field. The invention comprises the following procedures that: a. coating: PET plastic light film is adopted as base material; a layer of macromolecule resin material is uniformly coated on the base material in advance; after drying and solidification, a layer of transparent surface coat with strippable performance is formed; b. mould pressing: after the coating, under the conditions of the pressure of 2Kg / cm<2> to 4Kg / cm<2>, the temperature of 160 to 180 DEG C and the speed of 35 to 45 m / min, characters or patterns on a mould pressing plate are transferred on the transparent surface coat of the PET plastic light film; a printing layer stuck on the transparent surface coat is produced to form a surface layer; c. aluminium plating; d. transferring; e. embossing: aluminum transferring paper achieved by the procedures is sleeved between a reverse rotating knaggy patterned roller and an elastic roller which are tangential. The invention has good anti-fake effect and suboptical effect and is easy to mass production.

Owner:DARE TECH

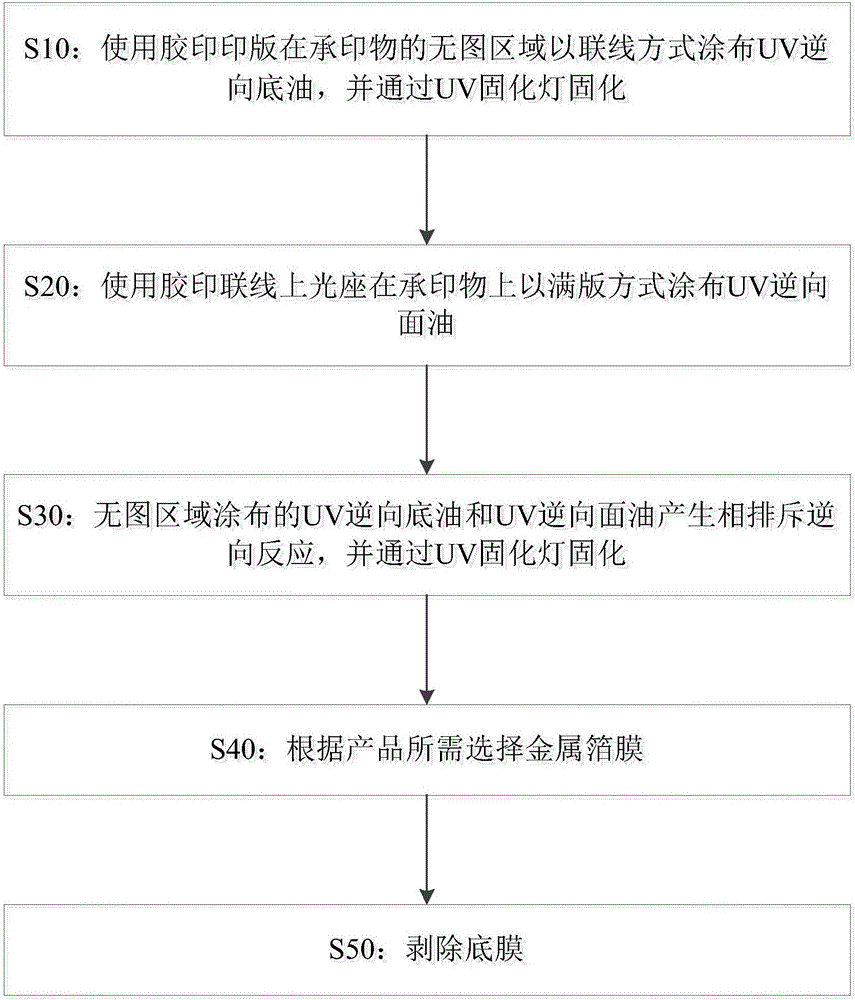

Intermediate-temperature gold stamping technology adopting double pro-cure manner

The invention belongs to the field of gold stamping and discloses an intermediate-temperature gold stamping technology adopting a double pro-cure manner. The intermediate-temperature gold stamping technology adopting the double pro-cure manner comprises the following steps that firstly, the non-image area of printing stock is coated with a UV pro-cure base coat in an online manner with an offset printing forme, and curing is conducted through an UV curing lamp; secondly, the printing stock is coated with a UV pro-cure finishing coat in a full-forme manner through an offset print online varnishing base; thirdly, the UV pro-cure base coat smeared in the non-image area and the UV pro-cure finishing coat generate a repelling background reaction, and curing is conducted through the UV curing lamp; fourthly, a metal foil film is selected according to product needs; and fifthly, the printing stock is placed on a gold stamping machine, a gold stamping copper plate is heated to 70-90 DEG C, the metal foil film and the UV pro-cure varnishing coat on the printing stock tightly adhere to each other under the press of the gold stamping machine, and a base film is stripped off. According to the intermediate-temperature gold stamping technology adopting the double pro-cure manner, the pro-cure technology and the cold gold stamping technology are combined, so that the equipment cost is reduced; and besides, the product produced through the intermediate-temperature gold stamping technology is fine and smooth in line and has strong metal texture.

Owner:SHANGHAI RUIZE IND DEVS

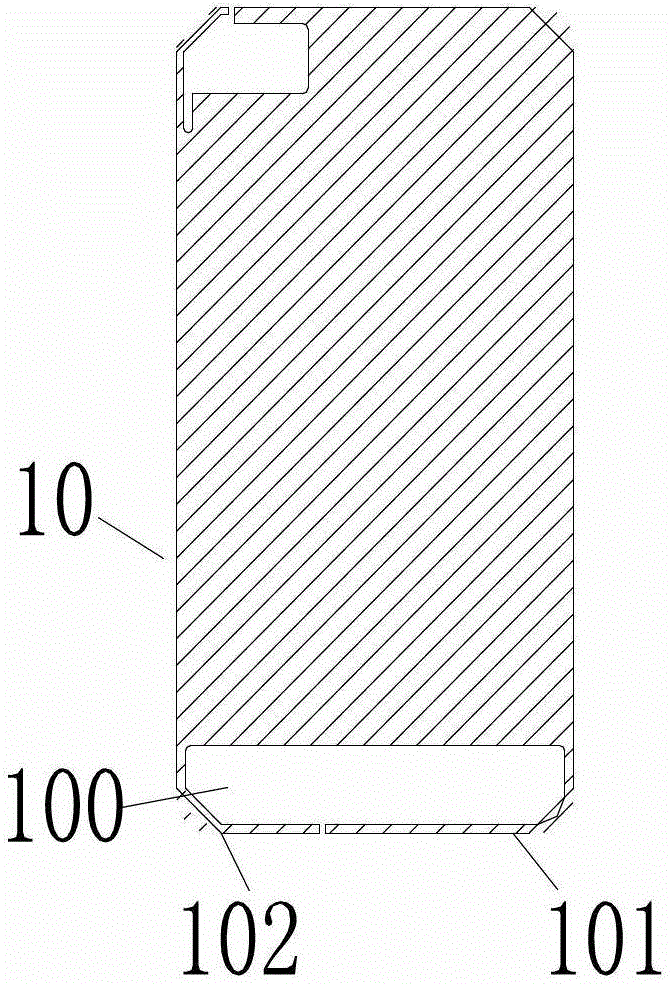

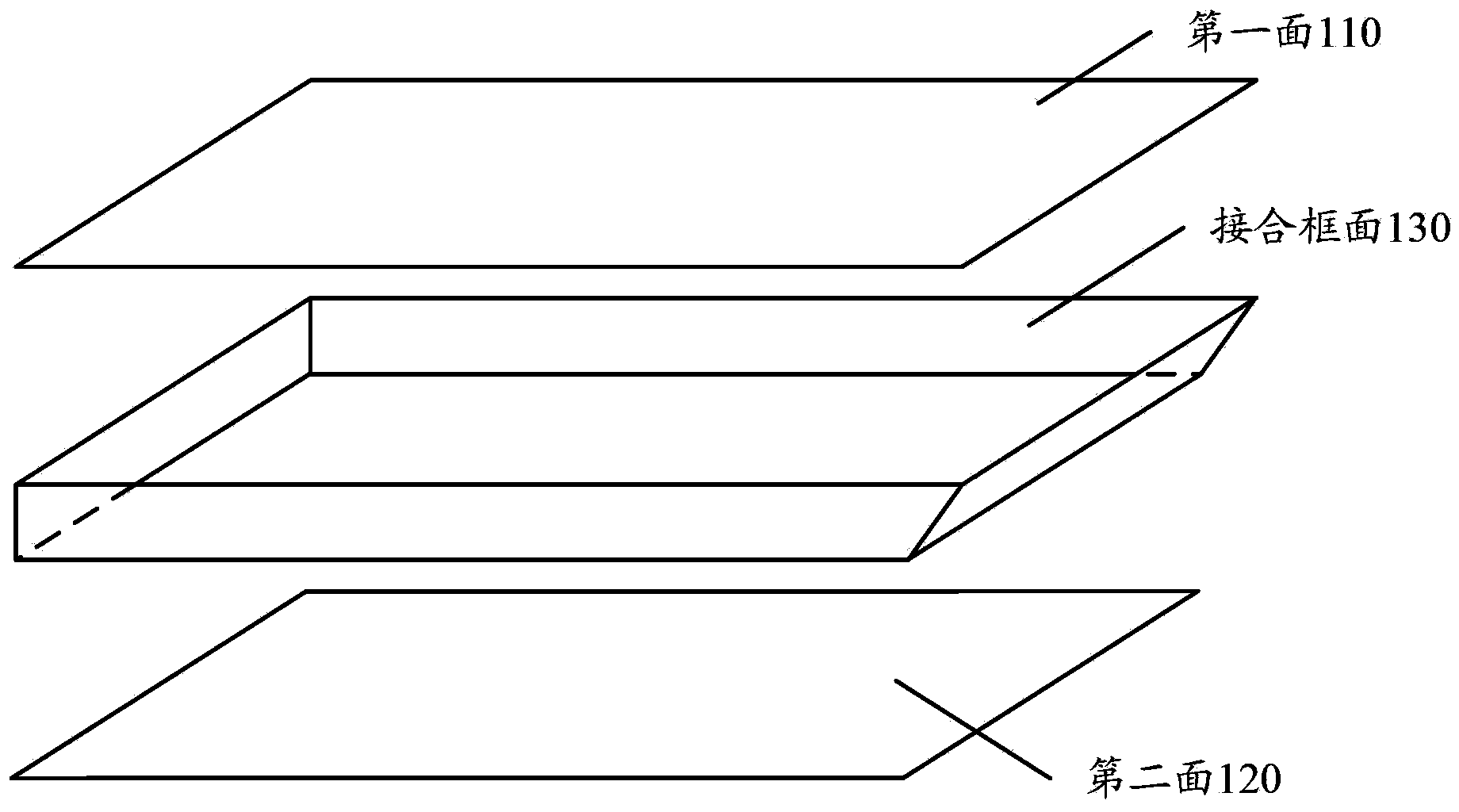

Electronic equipment, shell for electronic equipment and method for manufacturing shell

ActiveCN104244648AStrong metal textureImprove antenna performanceMetal casingsAntenna equipments with additional functionsMetallic materialsEngineering

The invention provides electronic equipment, a shell for the electronic equipment and a method for manufacturing the shell. The shell for the electronic equipment comprises a first face, a second face made of metal materials and a connecting frame face, the second face is opposite to the first face, the connecting frame face is located between the first face and the second face, and used for enabling the first face and the second face to be connected, the portion, close to an antenna device, in the connecting frame face protrudes out of or is inclined towards the outer side of the shell of the electronic equipment, and the connecting frame face is made of non-conducting materials. According to the technical scheme, the shell of the electronic equipment has the good metal feeling, and meanwhile an antenna in the electronic equipment is made to have good antenna performance.

Owner:LENOVO (BEIJING) LTD

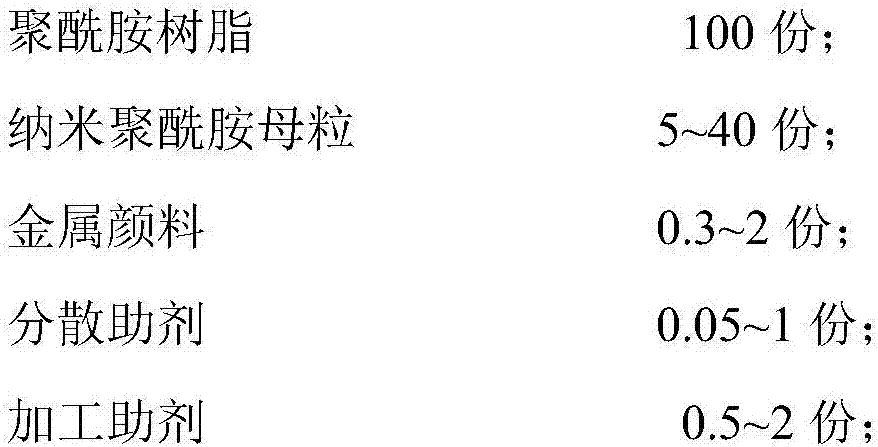

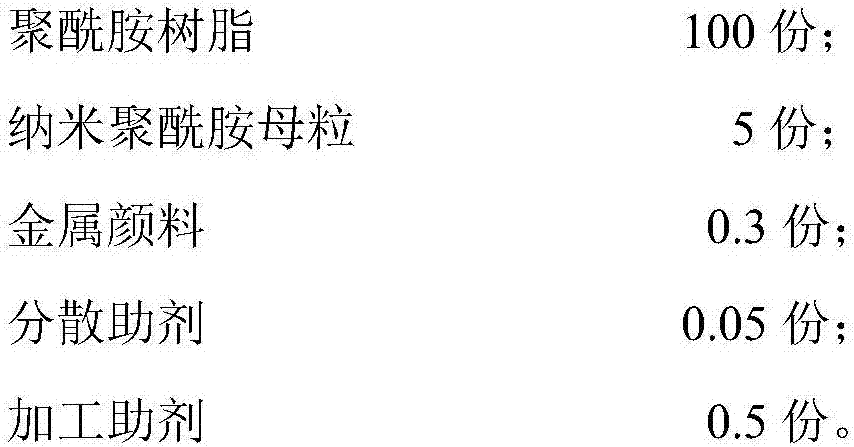

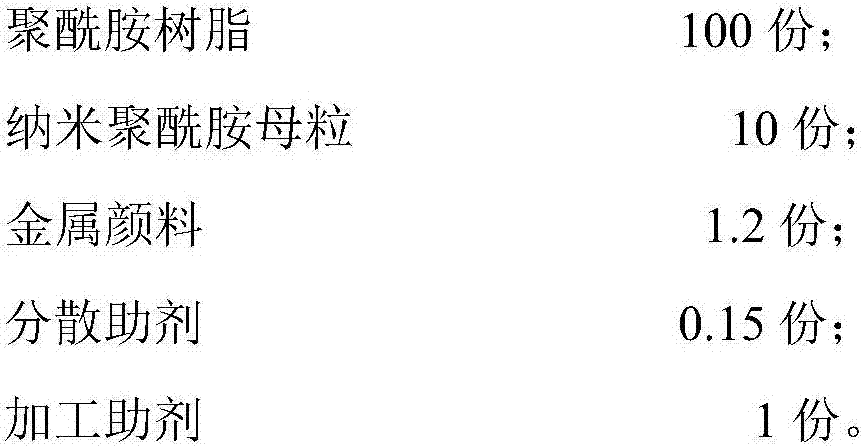

Nanometer polyamide composition with metal luster and preparation method of nanometer polyamide composition

The invention discloses a nano-polyamide composition with metallic luster and a preparation method thereof, which comprises the following raw material components in parts by weight: 100 parts of polyamide resin, 5-40 parts of nano-polyamide masterbatch, and 0.3 parts of metallic pigment ~2 parts, 0.05~1 part of dispersing aid, and 0.5~2 part of processing aid; wherein, the nano-polyamide masterbatch is a self-made product, including nanoparticles and dispersing aid, and the total amount contained in the nano-polyamide composition The weight ratio of nanoparticles to the total dispersion aid is 4:1~52:1. The present invention selects self-made nano polyamide masterbatch as reinforcing material, interacts with core-shell type dispersant, compound with polyamide resin, supplemented with corresponding processing aids, obtains a nano polyamide composition with metallic luster, It has good mechanical properties and surface properties, excellent surface rigidity, scratch resistance, oil resistance and adjustable gloss. It can be used in household appliances, automobiles and other non-spraying materials with metallic luster.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Simulated copper coating and production process thereof

ActiveCN103396725AGood gloss and color retentionImprove impact resistancePolyester coatingsCellulosePolymer science

The invention relates to the technical field of architectural decoration materials and application. The invention provides a simulated copper coating, and the simulated copper coating is prepared from the following raw materials: by weight, 670-700 parts of a mixed solvent, 60-70 parts of cellulose acetate butyrate, 60-70 parts of polyester resin, 40-50 parts of nitrocotton, 30-40 parts of amino resin, 2-5 parts of a leveling agent, 25-35 parts of an anti-settling agent, 55-75 parts of pearlescent pigments and 10-30 parts of a color pigment. The invention also provides a production process of the simulated copper coating, and the production process comprises the following steps: successively adding the mixed solvent, the cellulose acetate butyrate, the polyester resin, the nitrocotton, the amino resin, the leveling agent, the anti-settling agent, the pearlescent pigments and the color pigment into a vat, stirring and mixing evenly. During the production process of the simulated copper coating, a directional assistant with high glass transition temperature is introduced, various pearlescent pigments are selected and used, and through mixing in a certain proportion, a coating film can perfectly reproduce copper material effects and metal texture.

Owner:XINHE NEW MATERIALS CO LTD

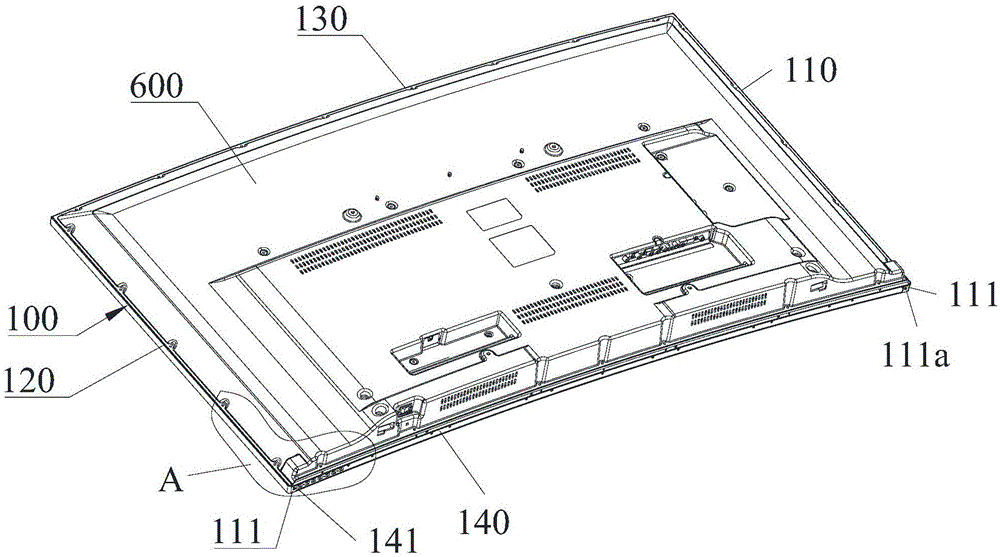

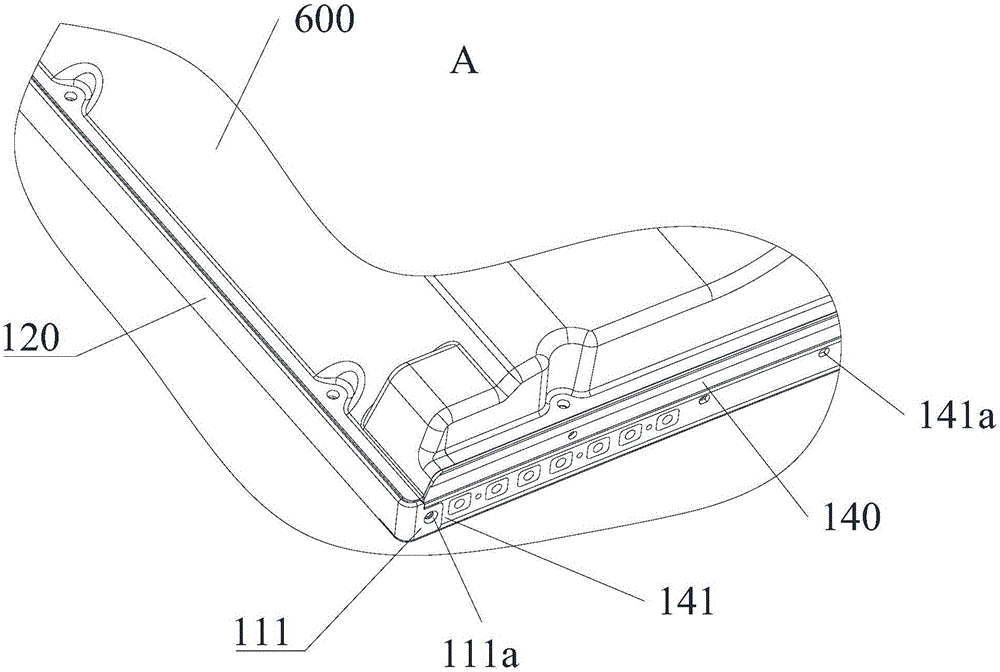

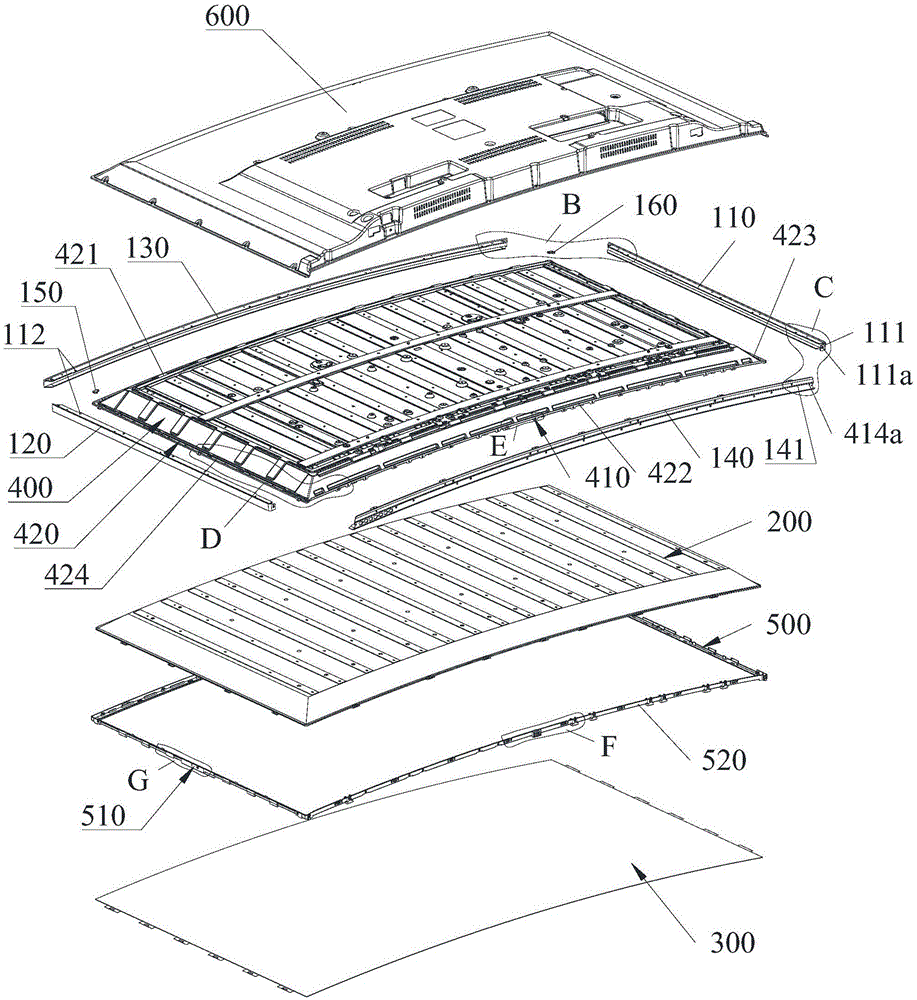

Surface frame and curved surface liquid crystal display device with same

ActiveCN105223717AControl Curvature AccuracyLarge assembly clearanceNon-linear opticsLiquid-crystal displayEngineering

The invention belongs to the technical field of liquid crystal display, and provides a surface frame and a curved surface liquid crystal display device with the surface frame. The surface frame comprises a left surface frame strip, a right surface frame strip, and an upper surface frame strip and a lower surface frame strip in curved shapes. Through using a method of segmented aluminum profile, the head end of the upper surface frame strip is directly fixedly connected with the tail end of the left surface frame strip through a first connecting plate piece. The tail end of the upper surface frame strip is also directly fixedly connected with the head end of the right surface frame strip through a second connecting plate piece, and the outer side wall of the lower surface frame strip is provided with a first groove. The head ends of the right surface frame strip and the left surface frame strip are arranged in a raised manner towards folded plates which bend inward, and each folded plate is embedded in the first groove. Thus, through controlling precision of the cooperated portion of each surface frame strip, curvature precision of the surface frame is rapidly and accurately controlled, and assembling precision among the surface frame and other components in the curved surface liquid crystal display device is ensured, and good metallic texture and various color selection are ensured.

Owner:HKC CORP LTD

Method for coating self-drying type metallic glittering paint on machine tool

InactiveCN101658836ASolve the problem of not being able to bake at high temperatureEliminate shadow markingsPretreated surfacesPolyurea/polyurethane coatingsLacquerPolyurethane coating

The invention discloses a method for coating self-drying type metallic glittering paint on a machine tool. The method comprise the following steps: carrying out pre-mounting finishing to a protectingcover of the machine tool, then carrying out normal-temperature degreasing, derusting, surface conditioning and phosphatizing treatment, then uniformly spraying epoxy iron red rust-proofing primer onthe protecting cover of the machine tool, scratching atomic grey (or vinyl perchloride putty), painting when in spraying, spraying off-white closed coating, and spraying self-drying type acrylic polyurethane and acrylic polyurethane coating varnish. The method adopts a coating-closed mode, eliminates the shadow speckle formed by different colors on the bottom layer, the metallic glittering paint adopts the self-drying type metallic glittering paint, therefore, the problem that the precise machine tool can not be baked at high temperature is solved, and the problem of floating can not occur when in spraying.

Owner:四川普什宁江机床有限公司

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413BNo pollution in the processImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

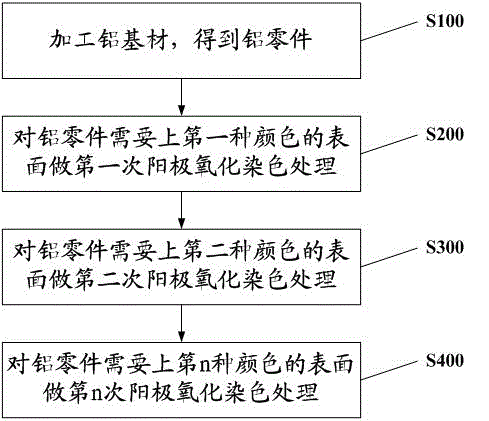

Processing method for aluminum components

ActiveCN102747401AStrong metal textureGuaranteed accuracySurface reaction electrolytic coatingComputer terminalDyeing

The invention discloses a processing method for aluminum components. The processing method is used for exterior processing of an exterior aluminum component of a mobile terminal so as to allow an exterior surface of the aluminum component to have n different colors, i.e., a first color, a second color,..., and an n color, wherein n is a natural number no less than 2. The processing method for aluminum components comprises the following steps: carrying out first exterior processing on the part of an aluminum component to be colored with the first color; carrying out first anodization dyeing treatment on the part of the aluminum component to be colored with the first color; carrying out second exterior processing on the part of the aluminum component to be colored with the second color; and carrying out second anodization dyeing treatment on the part of the aluminum component to be colored with the second color. The processing method for aluminum components provided in the invention has the advantages of simple operation, solid dyeing, a few processing procedures and capacity of realizing indiscriminate application of a plurality of colors on a same aluminum component.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Method for producing laser-type packing paper

InactiveCN101168946AStrong metal textureGood flexibilityFlexible coversMechanical working/deformationAluminum coatingSurface layer

The utility model relates a production method of laser type tipping paper, which relates to the packing material technical field, in particular to an environmental protection-typed metallization packing material with a printing pattern. The invention comprises the following steps: a. coating: a PET plastic light film is adopted as basis material, a layer of high molecule resin material is uniformly coated on the basis material in advance, after being dried and solidified, a transparent surface coating with strippable performance is formed; b. molding: the surface of the PET plastic light film with a transparent surface coating is provided after being coated, a character and the pattern on a molding printing plate is transferred on the transparent surface coating under the pressure of 2 Kg / cm <2> to 4 Kg / cm<2>, the temperature of 160 to 180 DEG C and the speed of 35 to 45m / min, thereby generating a printing layer covered on the transparent surface coating, and forming a surface layer; c. aluminum coating; d. transferring. The invention aims at good anti-counterfeit effect and being easy to be largely produced.

Owner:DARE TECH

Metal wire drawing-imitating decoration film

InactiveCN104416993AImprove adhesion fastnessEasy to useSynthetic resin layered productsSpecial ornamental structuresPrinting inkSteel plates

The invention provides a metal wire drawing-imitating decoration film which comprises a PET base film, a primer layer, a metal wire drawing-imitating pattern layer, and a printing ink layer; the primer layer is printed on the surface of the PET base film; the metal wire drawing-imitating pattern layer is printed on the surface of the primer layer; and the printing ink layer is printed on the surface of the metal wire drawing-imitating pattern layer. The decoration film of the invention is few in production procedures, low in manufacturing cost, and distinct in the metal wire drawing-imitating pattern, has different glossiness effects such as matt, common, highlight, and the like, has high combining strength with various sheet materials, has good aging resistance and long service life, is widely used in surface decoration of color steel plates, integrated furred ceilings, bureau doors, cabinets, and industrial products, and has very good anti-rust, protective, decorative, and beatifying effect on decorated color plates.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Method for preparing self-drying type metallic gleaming lacquer

InactiveCN101654591AImprove the quality of exterior decorationNice appearancePolyurea/polyurethane coatingsWaxLacquer

The invention discloses a method for preparing self-drying type metallic gleaming lacquer. The method comprises the following steps: firstly, mixing acrylic acid, polyurethane resin and a wax solutionevenly; afterwards adding cellulose acetate butyrate and an auxiliary agent; then dispersing for 5-10min and mixing evenly; soaking aluminium powder in a solvent for 10-15min, stirring evenly, preparing coloured aluminium slurry, adding the coloured aluminium slurry into the prepared resin of the acrylic acid and the polyurethane resin, dispersing for 10-20min, mixing lacquer liquid evenly; and finally, forming the self-drying type metallic gleaming lacquer. The metallic gleaming lacquer prepared by the method can be directly applied to the prior precise machine tool, can be naturally dried without high-temperature roasting and also can be dried at low temperature, enables the appearance of the machine tool to be attractive after being coated on the surface of the machine tool, and is beneficial to truly reflecting the intrinsic value and the brand value of the machine tool and enhancing the competitive capacity of domestic precise machine tools in the market.

Owner:四川普什宁江机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com