Method for producing laser-type packing paper

A production method and technology of tipping paper, applied in wrapping paper, wrapping paper, special paper, etc., can solve the problems of inconspicuous laser effect of transfer paper, inability to distinguish similar products, inconvenience of mass production, etc. Good reflection ability and reasonable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

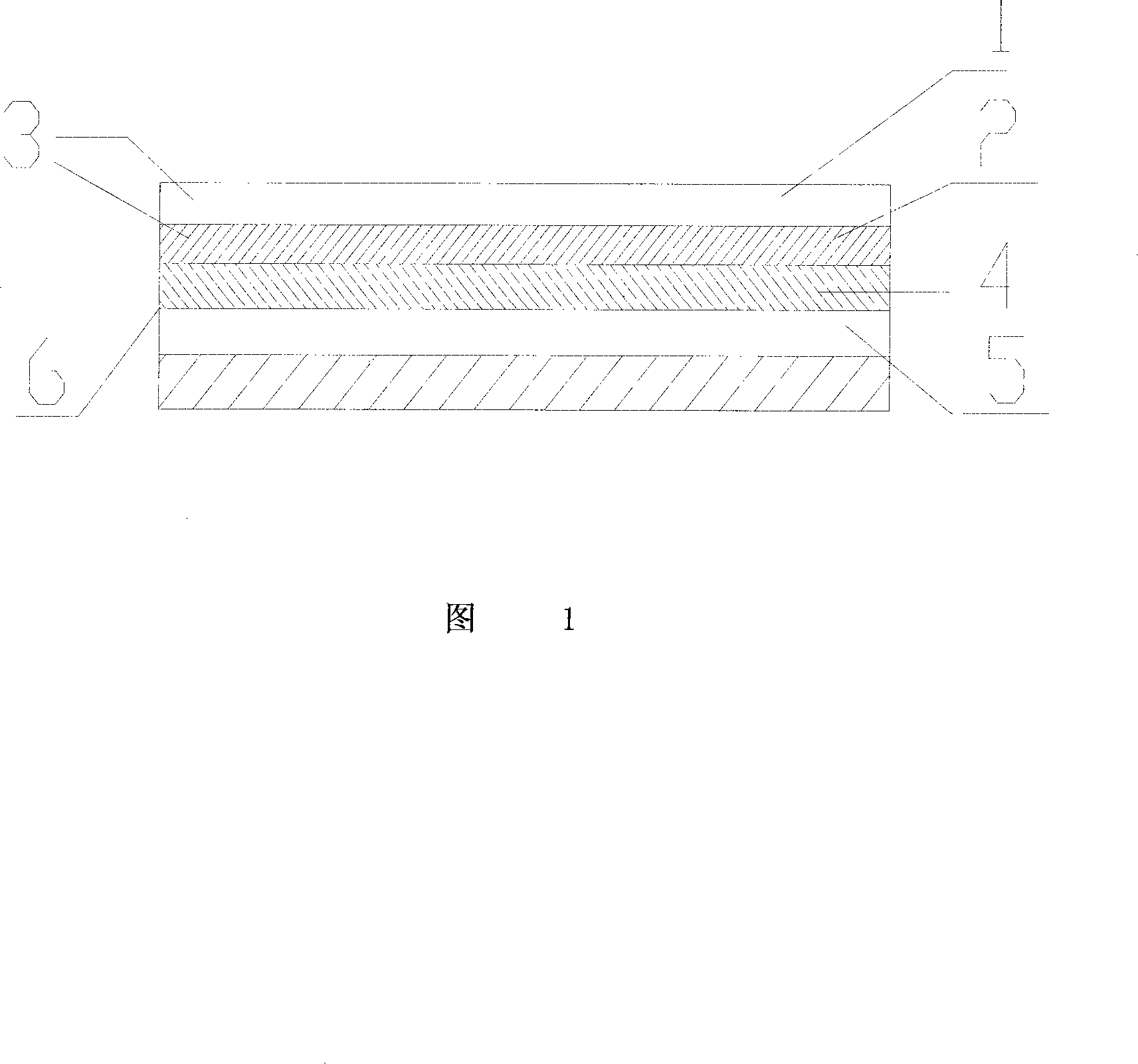

[0018] Example 1: The production method of laser-type tipping paper of the present invention includes the following steps:

[0019] a. Coating: PET plastic light film is used as the substrate, and a layer of polymer resin material is uniformly coated on the substrate, and after drying and solidification, a transparent surface coating 1 with peelable properties is formed;

[0020] b. Molding: After coating, the surface of the PET plastic light film substrate with transparent surface coating 1 is at a pressure of 3Kg / cm 2 , The temperature is 165℃, and the speed is 40m / min. The transparent surface coating 1 is slightly deformed by pressing the molded plate with characters or patterns, and the characters or patterns on the molded plate are transferred to the transparent surface coating 1 to produce a printing layer attached to the transparent surface coating 1 2. Form surface layer 3;

[0021] c. Aluminum plating: After the substrate is coated and molded, the transparent surface coat...

Embodiment 2

[0027] Embodiment 2: The production method of laser-type tipping paper of the present invention includes the following steps:

[0028] a. Coating: PET plastic light film is used as the substrate, and a layer of polymer resin material is uniformly coated on the substrate, and after drying and solidification, a transparent surface coating 1 with peelable properties is formed;

[0029] b. Molding: After coating, the surface of the PET plastic light film substrate with transparent surface coating 1 is at a pressure of 4Kg / cm 2 , The temperature is 175℃, and the speed is 45m / min. The transparent surface coating 1 is slightly deformed by pressing the molded plate with characters or patterns, and the characters or patterns on the molded plate are transferred to the transparent surface coating 1 to produce a printing layer attached to the transparent surface coating 1 2. Form surface layer 3;

[0030] c. Aluminum plating: After the substrate is coated and molded, the transparent surface c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com