VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

A technology of cold galvanizing and aluminum coating, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems affecting the coating weight and construction efficiency, the formation of air bubbles in the topcoat, and the easy porosity of the coating. Excellent performance, strong metal texture, good coating gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

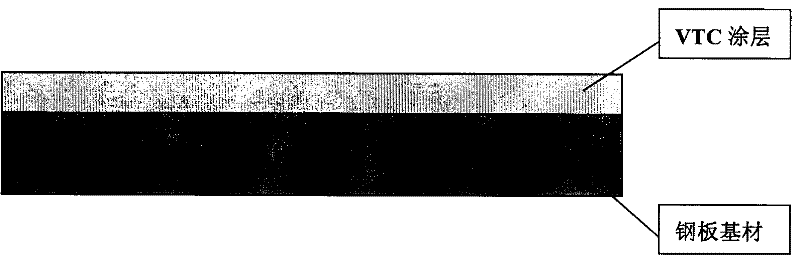

[0047] Preparation of test panels

[0048] Unless otherwise specified, test panels are usually cold-rolled low-carbon steel plates. Before the steel plate is coated with alcohol-soluble (or water-based) VCI flake-type cold-dip galvanized aluminum coating, it will first be subjected to Sa2.5 level sandblasting treatment.

[0049] Coating of Test Parts

[0050] After mixing the two components of the alcohol-soluble (or water-based) VCI flake-type cold galvanized aluminum paint in proportion, spray the prepared paint on the above-mentioned prepared test sample board with an air spray gun. After spraying, let it dry naturally for at least two weeks, then carry out the following tests.

[0051] bending experiment

[0052] Achieved through the test procedures of ASTM-D522. Use a piece of tape coated with pressure-sensitive adhesive to stick to the coated surface of the deformed part of the test panel, and then quickly peel it off. Coatings are calculated based on the amount of ...

Embodiment 1

[0056] Embodiment 1 (preparation of alcohol-soluble VCI flake type cold galvanized aluminum coating)

[0057] Preparation of component A: Add 300 grams of flake-type zinc powder with a thickness of ≤0.2 μm and a diameter of ≤20 μm and 100 grams of flake-type aluminum powder with a thickness of ≤0.1 μm and a diameter of ≤25 μm into 100 mL of 95% ethanol Stir for more than 0.5 hours to fully mix the two, add 2 grams of modified polysiloxane type leveling agent, 150 grams of polyvinyl butyral and 10 grams of cyclohexylamine nitrite, and stir for more than 0.5 hours until uniform .

[0058] Preparation of component B: Dissolve 160 grams of alkyl silicate in 100 mL of 95% ethanol, stir well and mix evenly, add 2 grams of organic bentonite, and stir evenly.

[0059] Before coating, mix the two components A and B and stir them evenly to get the finished silver-gray alcohol-soluble VCI flake-type cold-dip galvanized aluminum coating.

Embodiment 2

[0060] Embodiment 2 (preparation of alcohol-soluble VCI flake type cold galvanized aluminum coating)

[0061] Preparation of component A: Add 150 grams each of flake-type zinc powder and flake-type aluminum powder with a thickness ≤ 0.4 μm and a diameter ≤ 40 μm, add to 200 mL, 95% n-butanol and stir for more than 0.5 hours to fully mix the two Evenly, add 5 grams of leveling agent M, 200 grams of epoxy resin and 20 grams of hexamethylenetetramine, and stir for more than 0.5 hours until uniform.

[0062] Preparation of component B: Dissolve 180 grams of alkyl silicate in 100 mL of 95% n-butanol, stir and mix well, add 10 grams of fumed silica, and stir evenly.

[0063] Before coating, the two components A and B are mixed, and after stirring evenly, the silver-gray finished alcohol-soluble scale-type cold-dip galvanized aluminum coating is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com