Patents

Literature

275 results about "Aluminum Complex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

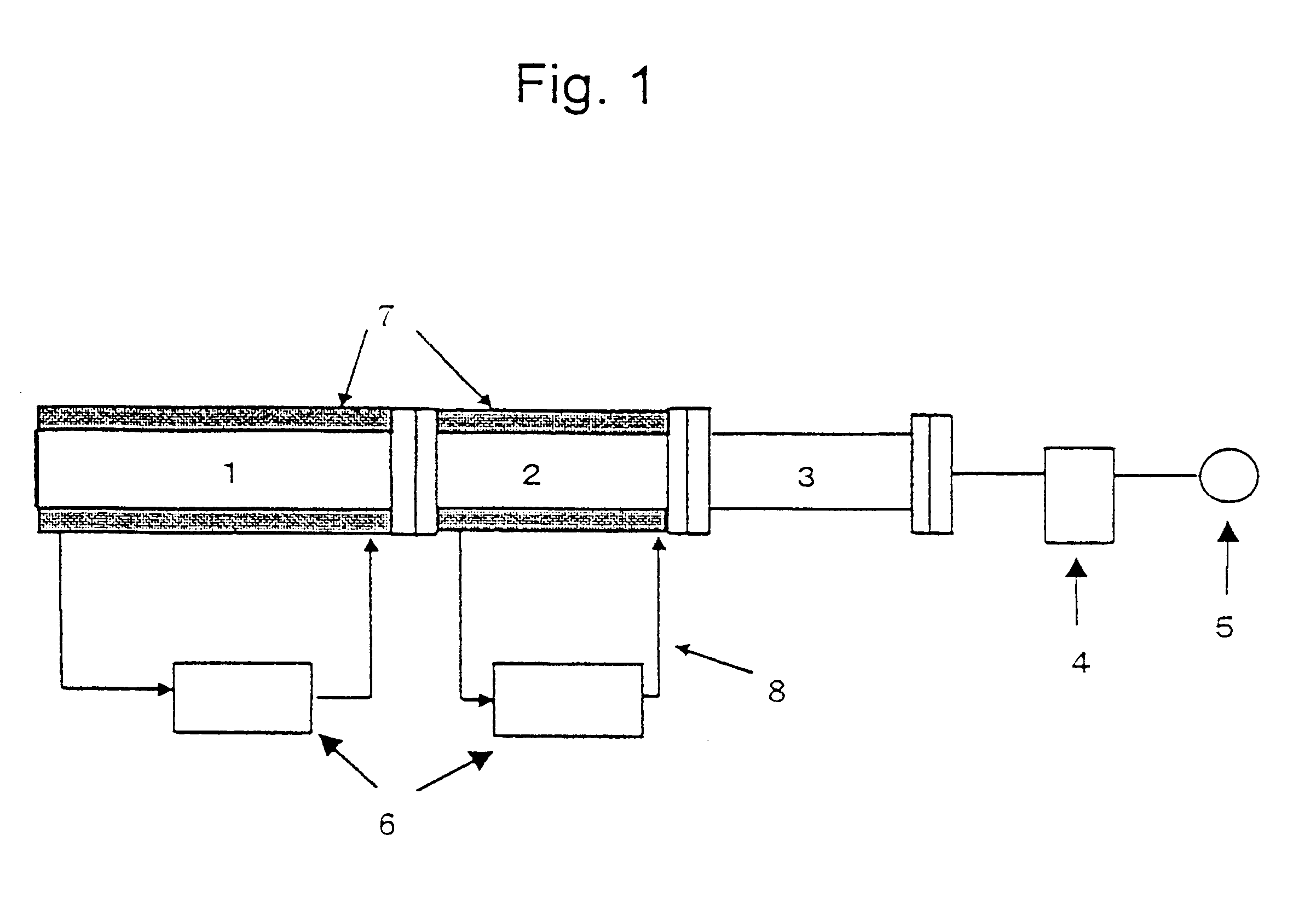

Process for production of aluminum complex comprising sintered porous aluminium body

ActiveUS20120135142A1Reduced strengthAvoid inhibitionTransportation and packagingElectrode carriers/collectorsWater insolubleCoordination complex

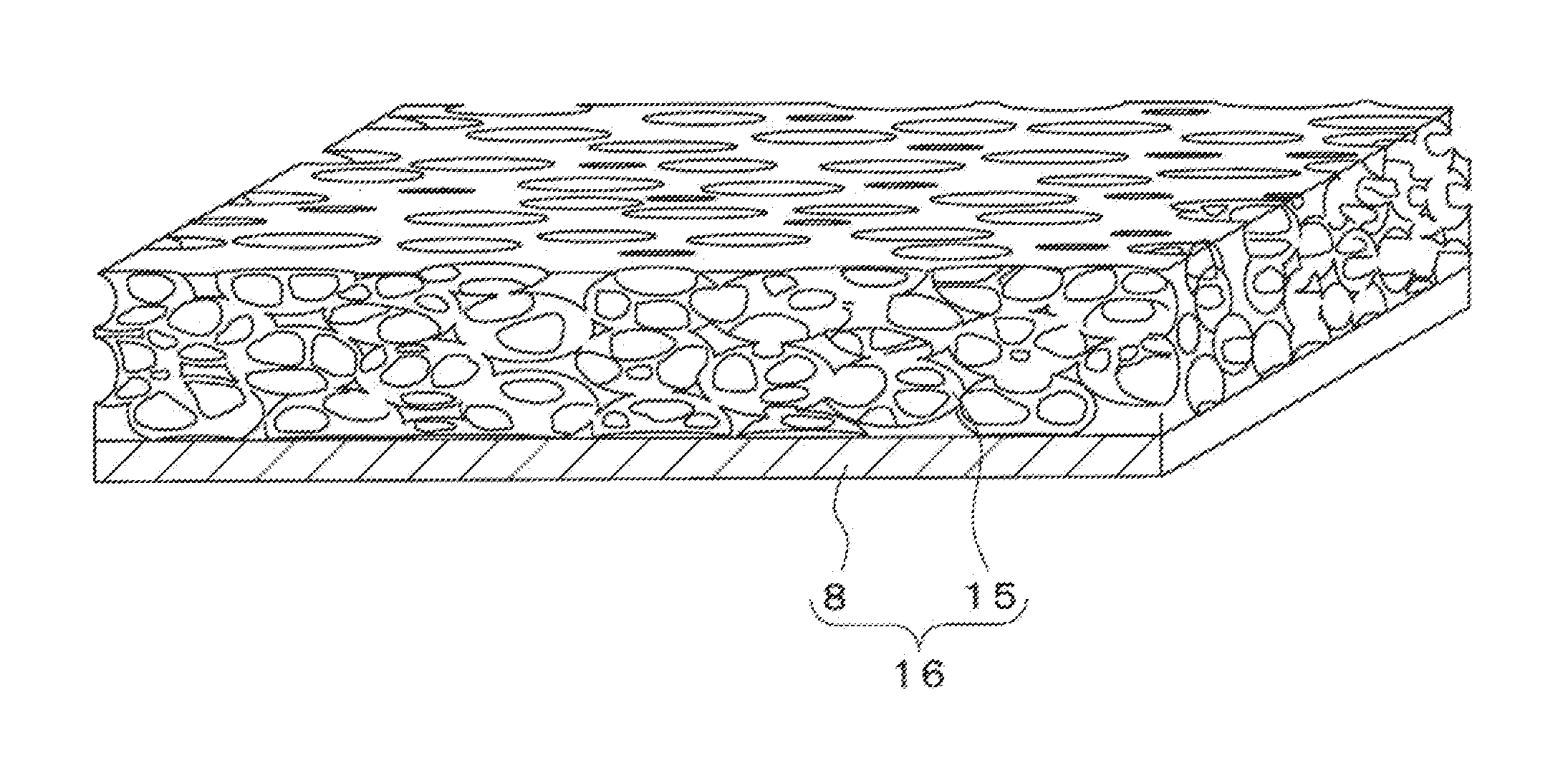

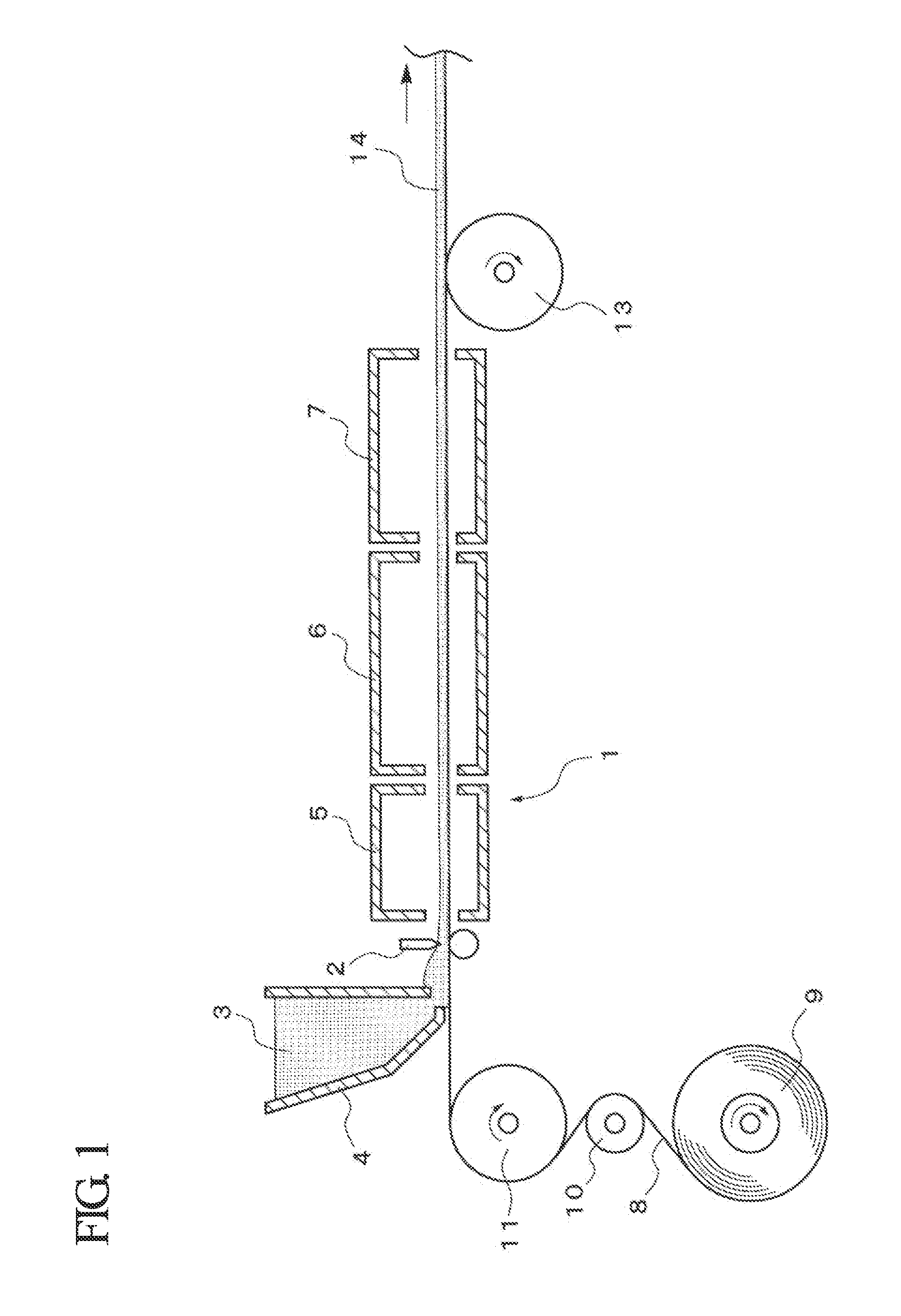

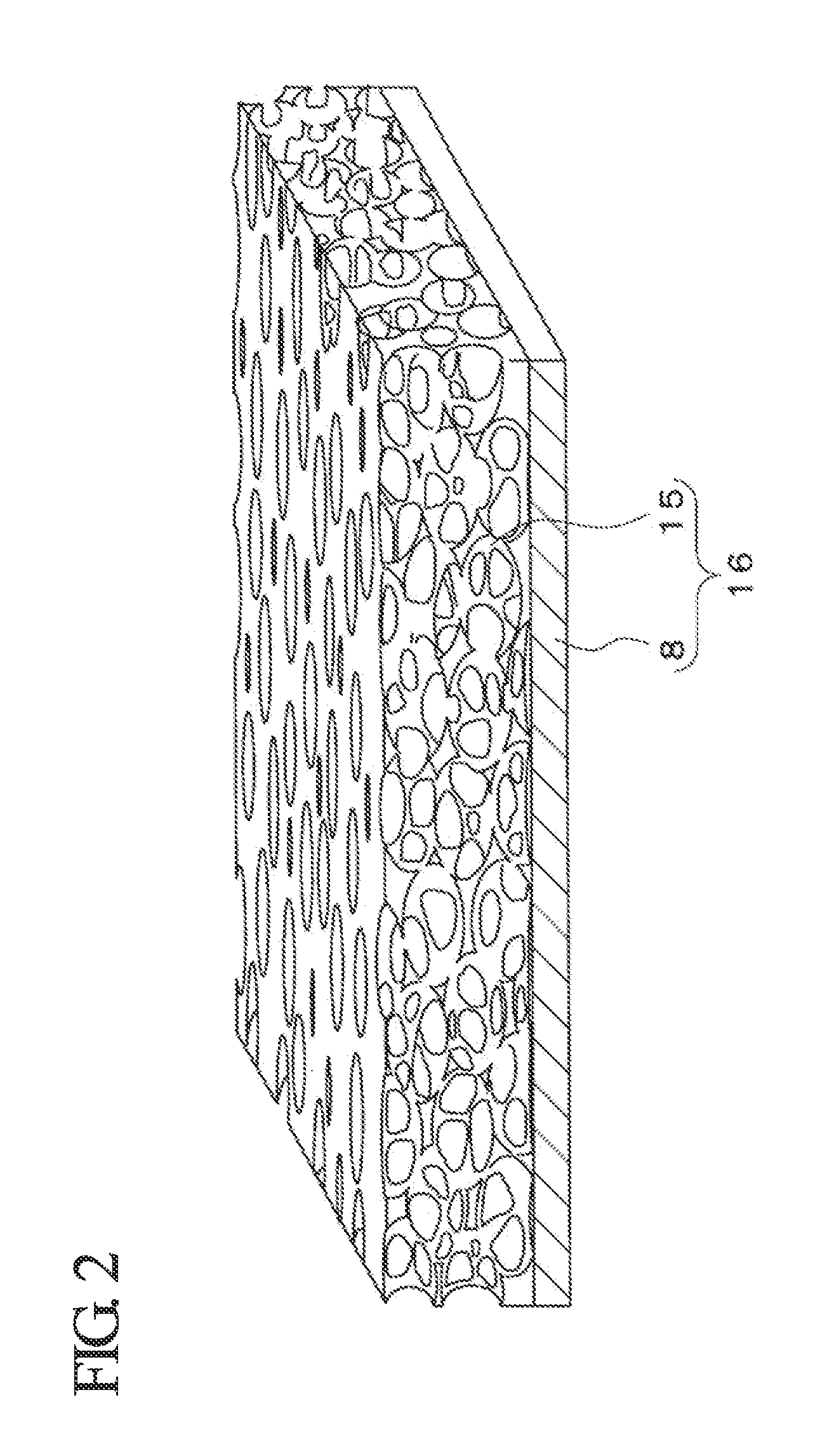

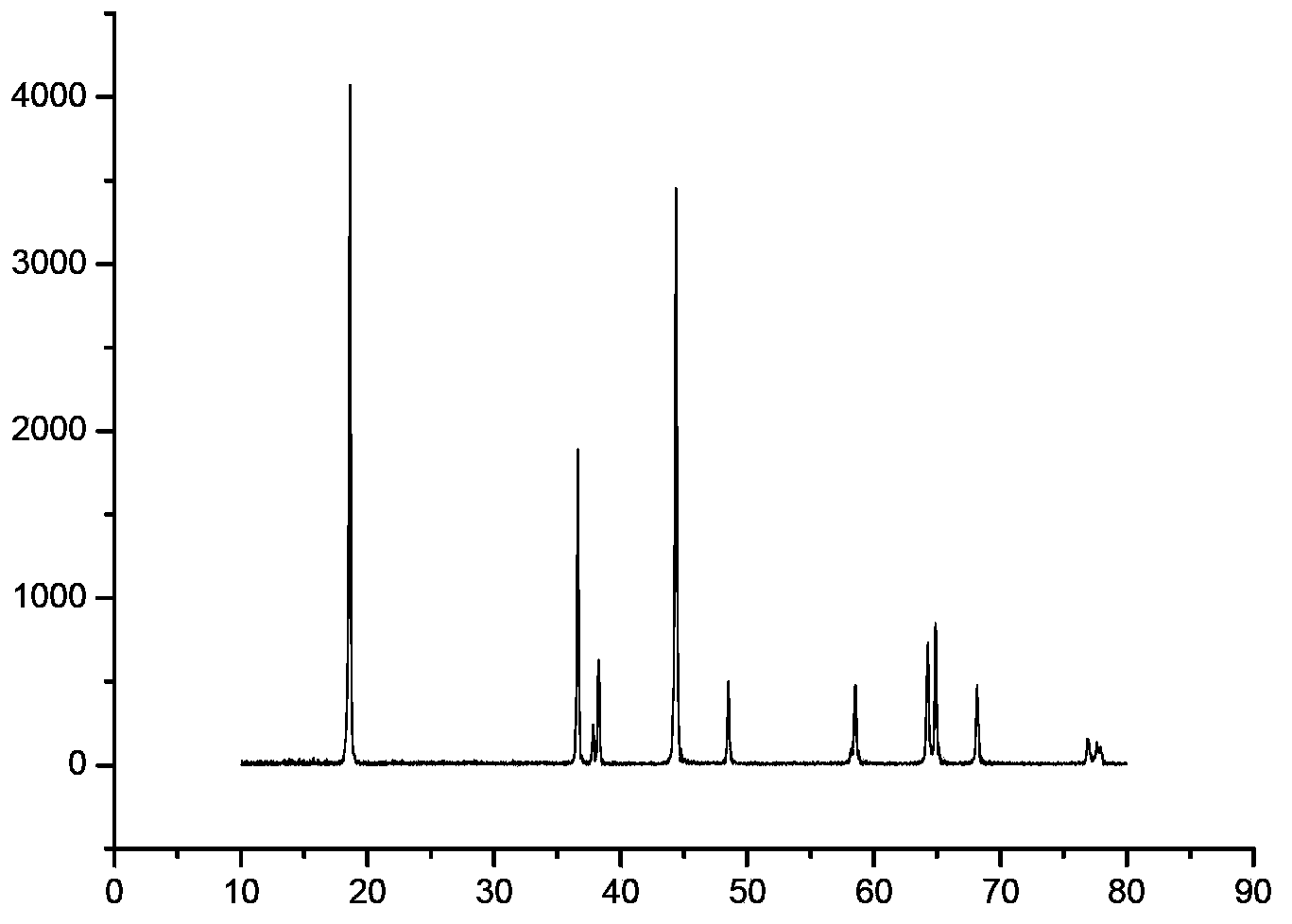

This method for producing an aluminum composite including porous sintered aluminum, includes: mixing aluminum powder with a sintering aid powder containing either one or both of titanium and titanium hydride to obtain a raw aluminum mixed powder; adding and mixing a water-soluble resin binder, water, a plasticizer containing at least one selected from polyhydric alcohols, ethers, and esters, and a water-insoluble hydrocarbon-based organic solvent containing five to eight carbon atoms into the raw aluminum mixed powder to obtain a viscous composition; shape-forming the viscous composition on an aluminum foil or an aluminum plate and causing the viscous composition to foam to obtain a formed object prior to sintering; and heating the formed object prior to sintering in a non-oxidizing atmosphere to obtain an aluminum composite which includes porous sintered aluminum integrally joined onto the aluminum foil or the aluminum plate, wherein when a temperature at which the raw aluminum mixed powder starts to melt is expressed as Tm (° C.), then a temperature T (° C.) of the heating fulfills Tm-10 (° C.)≦T≦685 (° C.).

Owner:MITSUBISHI MATERIALS CORP

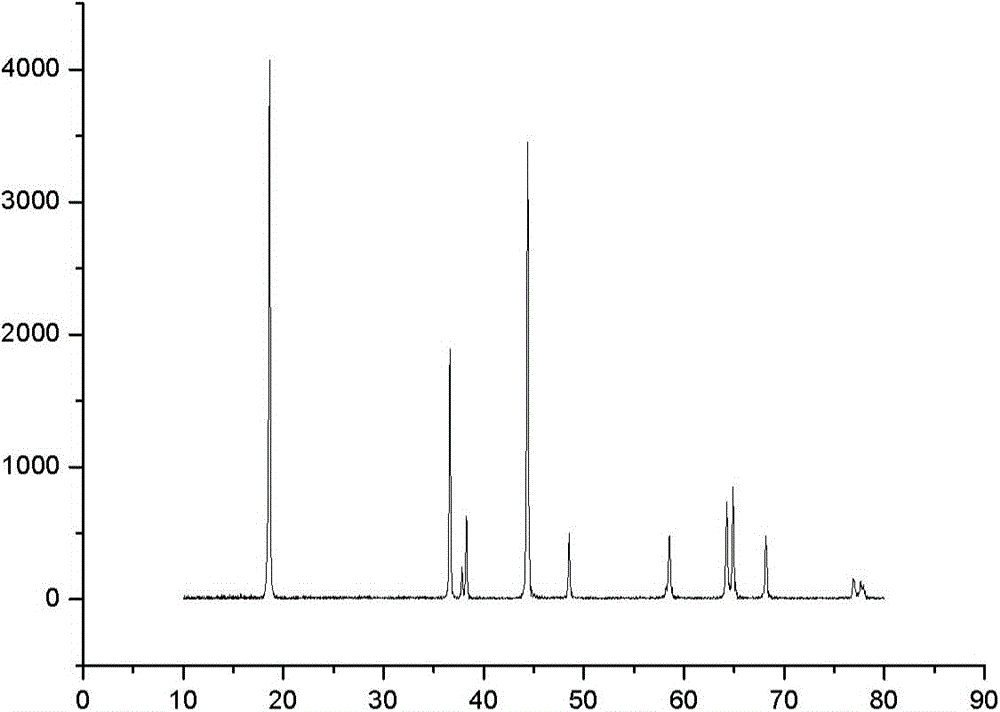

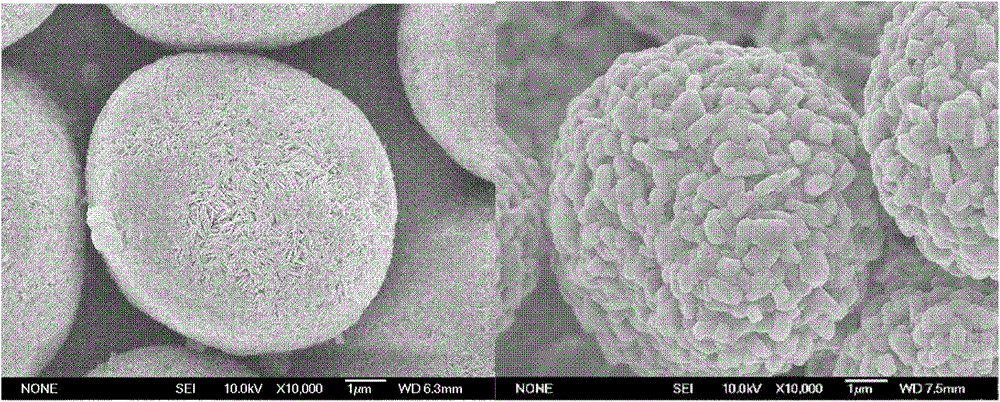

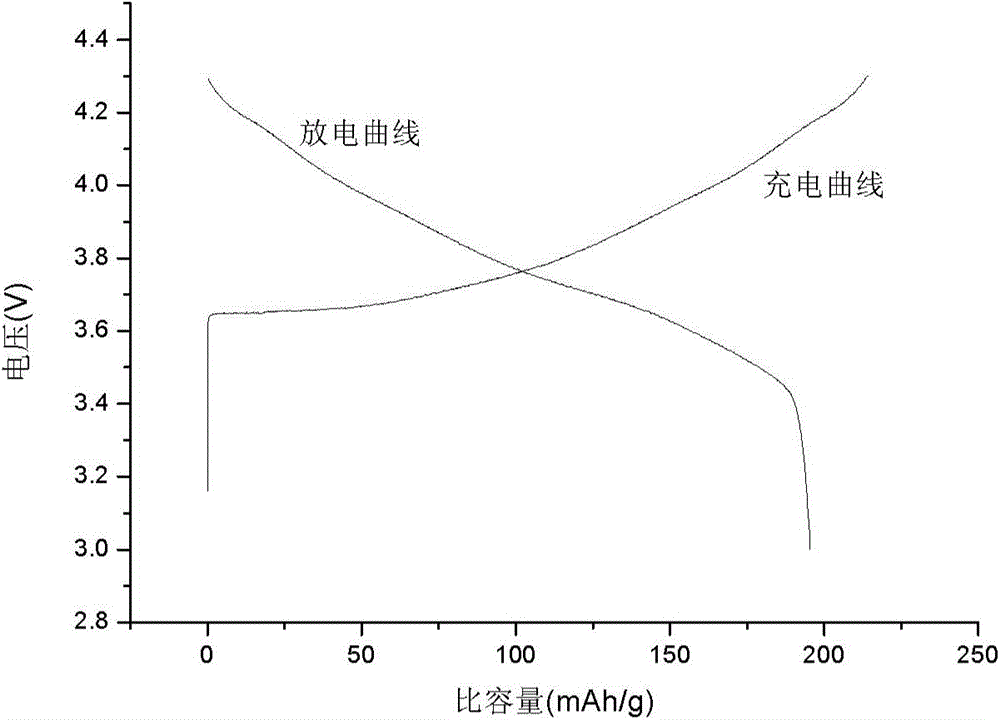

Nickel-cobalt lithium aluminate and preparation method of precursor thereof

ActiveCN103400973AHigh crystallinityHigh charge and discharge capacityCell electrodesHigh densityCobalt salt

The invention relates to a preparation method of a nickel cobalt aluminum material precursor. The method used in the invention comprises the steps: carrying out a complexation reaction of an aluminum salt and a complexing agent to form a stable aluminum complex, then injecting the aluminum complex simultaneously with a nickel-cobalt salt solution into a reaction kettle for carrying out a co-precipitation reaction to prepare a high-density precursor of nickel-cobalt lithium aluminate, and then carrying out a lithium mixed roasting to form a high-density spherical nickel-cobalt lithium aluminate material. At the same time, the invention also discloses an application of the nickel-cobalt lithium aluminate material used in a cathode material of a lithium ion battery. The high-density spherical nickel-cobalt lithium aluminate material which has atomic level mixture of nickel cobalt aluminum elements and good crystallinity can be produced under a premise without mass increase of cost, and the charge and discharge capacity and the first time efficiency have a certain improvement compared with those of current products. The process is simple and easy to implement, and can be used in large-scale industrialized production.

Owner:郭建

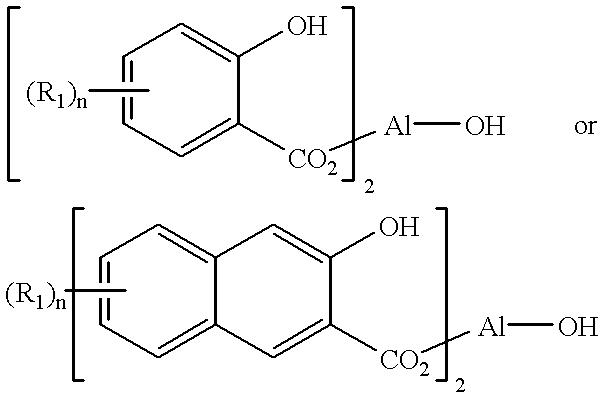

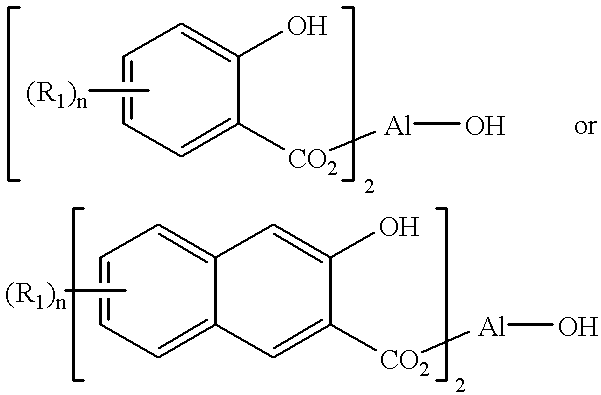

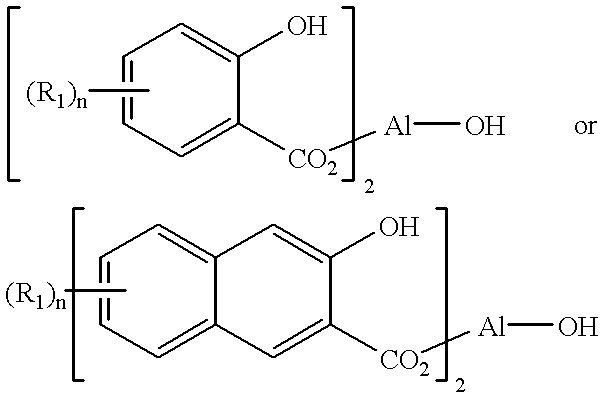

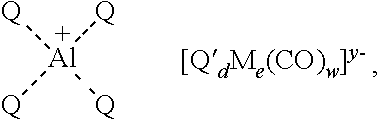

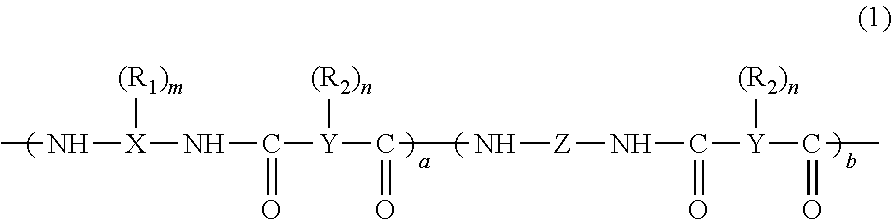

Imaging apparatuses and processes thereof containing a marking material with a charge acceptance additive of an aluminum complex

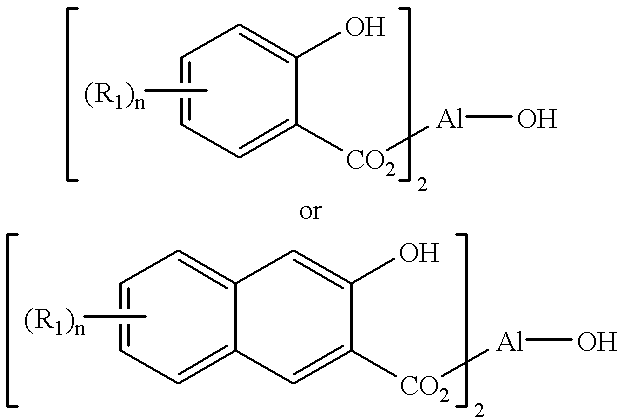

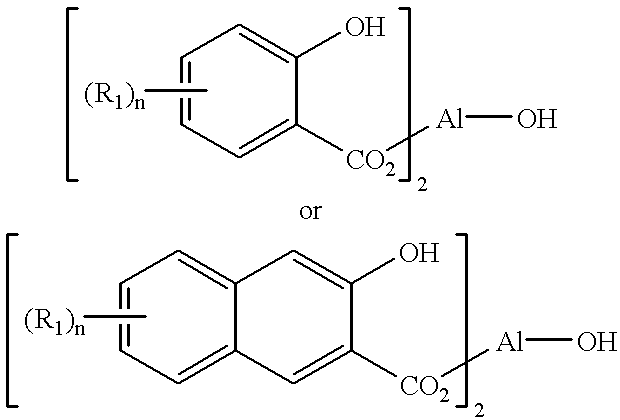

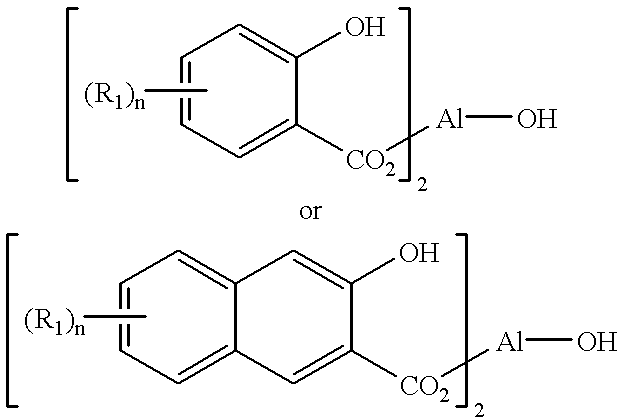

An imaging apparatus containingan imaging member with an electrostatic latent image formed thereon, the imaging member containing a surface capable of supporting marking material;an imaging device for generating the electrostatic latent image on the imaging member wherein the electrostatic latent image includes image areas defined by a first charge voltage and nonimage areas defined by a second charge voltage distinguishable from the first charge voltage;a marking material supply apparatus for depositing marking material on the surface of the imaging member to form a marking material layer thereon adjacent the electrostatic latent image on the imaging member;a charging source for selectively delivering charges to the marking material layer in an imagewise manner responsive to the electrostatic latent image on the imaging member to form a secondary latent image in the marking material layer containing image and nonimage areas corresponding to the electrostatic latent image on the imaging member; anda separator member for selectively separating portions of the marking material layer in accordance with the secondary latent image in the marking material layer to create a developed image corresponding to the electrostatic latent image formed on the imaging member, and wherein the marking material is comprised of developer containing an optional liquid, resin, colorant, and a charge acceptance additive of an aluminum complex of the formulas, or mixtures thereofwherein R1 is selected from the group consisting of hydrogen and alkyl, and n represents the number of R1 groups, and wherein the charge acceptance additive captures and retains negative ions or positive ions.

Owner:XEROX CORP

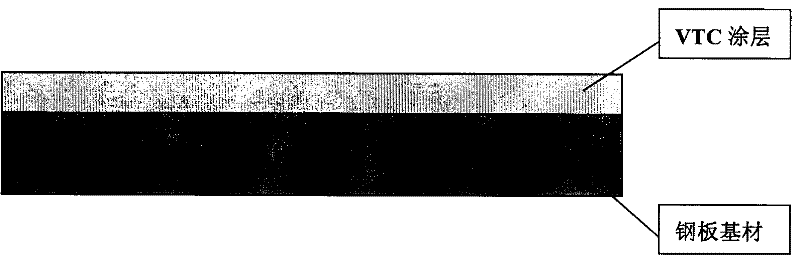

A copper adulterated aluminum complex flat line and its making method

ActiveCN101236798AImprove performanceEliminate processabilitySingle bars/rods/wires/strips conductorsCable/conductor manufactureCopperAluminum composites

The invention relates to a copper-clad aluminum composite flat wire and a preparation method thereof, relating to bimetal layered composite materials. The copper-clad aluminum composite flat wire is formed by composition of sandwich layer aluminum and clad copper, and the area ratio of the copper clad is 15 percent to 40 percent. The preparation steps are as follows: copper-clad aluminum composite blanks are directly compounded and formed by adoption of horizontal continuous casting; multi-pass groove rolling and / or multi-pass drawing is performed on the copper-clad aluminum blanks as required; the rolling speed of 3 to 60 meters per minute is adopted, and the single-pass relative percent reduction is 20 percent to 40 percent; or the drawing speed of 2 to 30 meters per minute is adopted, and the single-pass section scalage is 10 percent to 25 percent; under the condition of multi-pass processing and that the overall section scalage of the copper-clad aluminum composite materials reaches 75 percent to 95 percent, low-temperature intermediate annealing is performed on the copper-clad aluminum composite materials; the annealing temperature is 200 to 450 DEG C; the annealing time is 0.5 to 2 hours; the blanks after annealing are rolled or drawn further, and the copper-clad aluminum composite flat wire with required section shape and size is prepared. The invention not only can prepare the high performance copper-clad aluminum composite flat wire but also has high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

Developer compositions and processes

A liquid developer comprised of a nonpolar liquid, resin, colorant, and a charge acceptance component comprised of an aluminum complex of the formulas, or mixtures thereofwherein R1 is selected from the group consisting of hydrogen and alkyl, and n represents the number of R1 substituents.

Owner:XEROX CORP

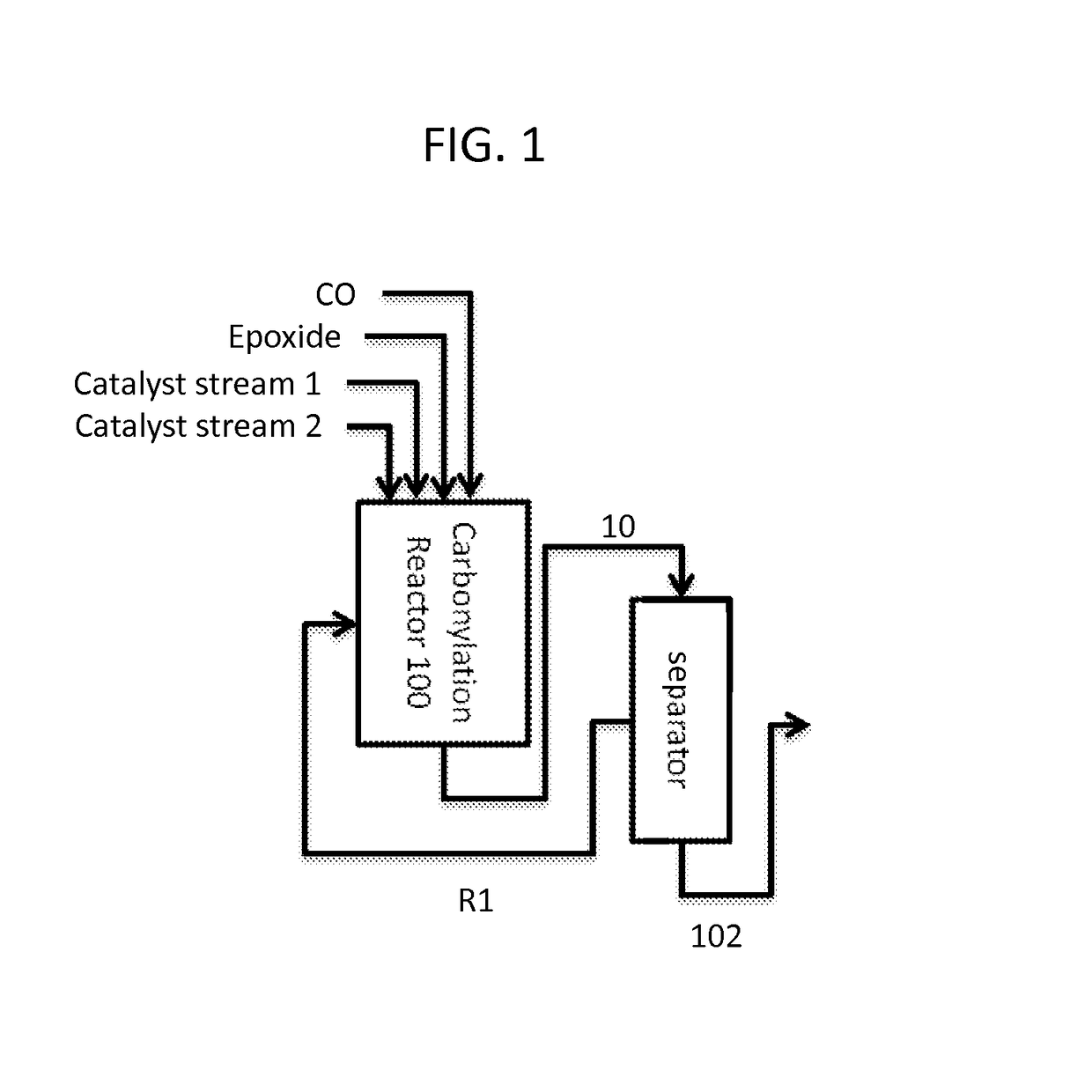

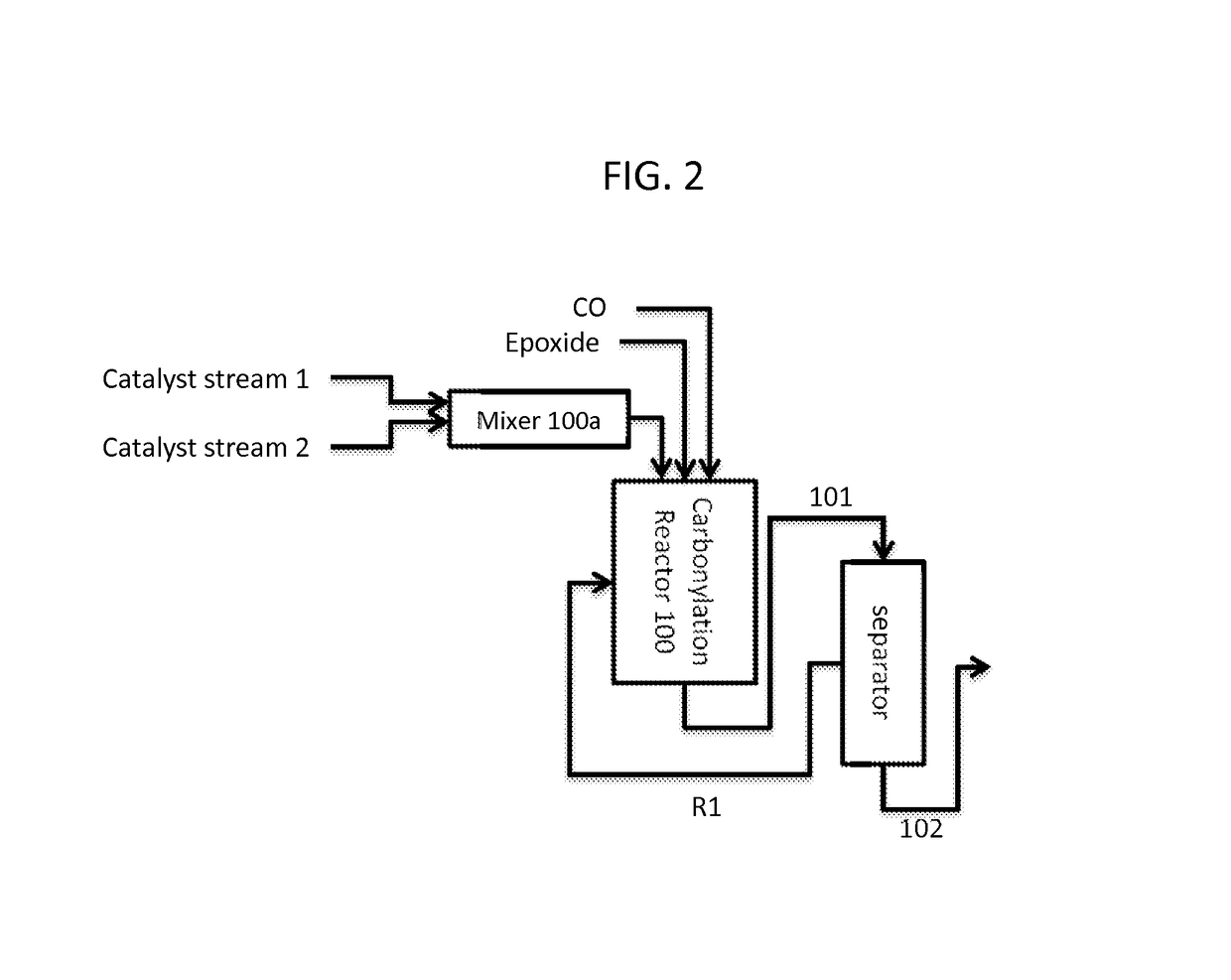

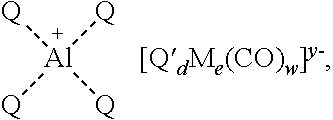

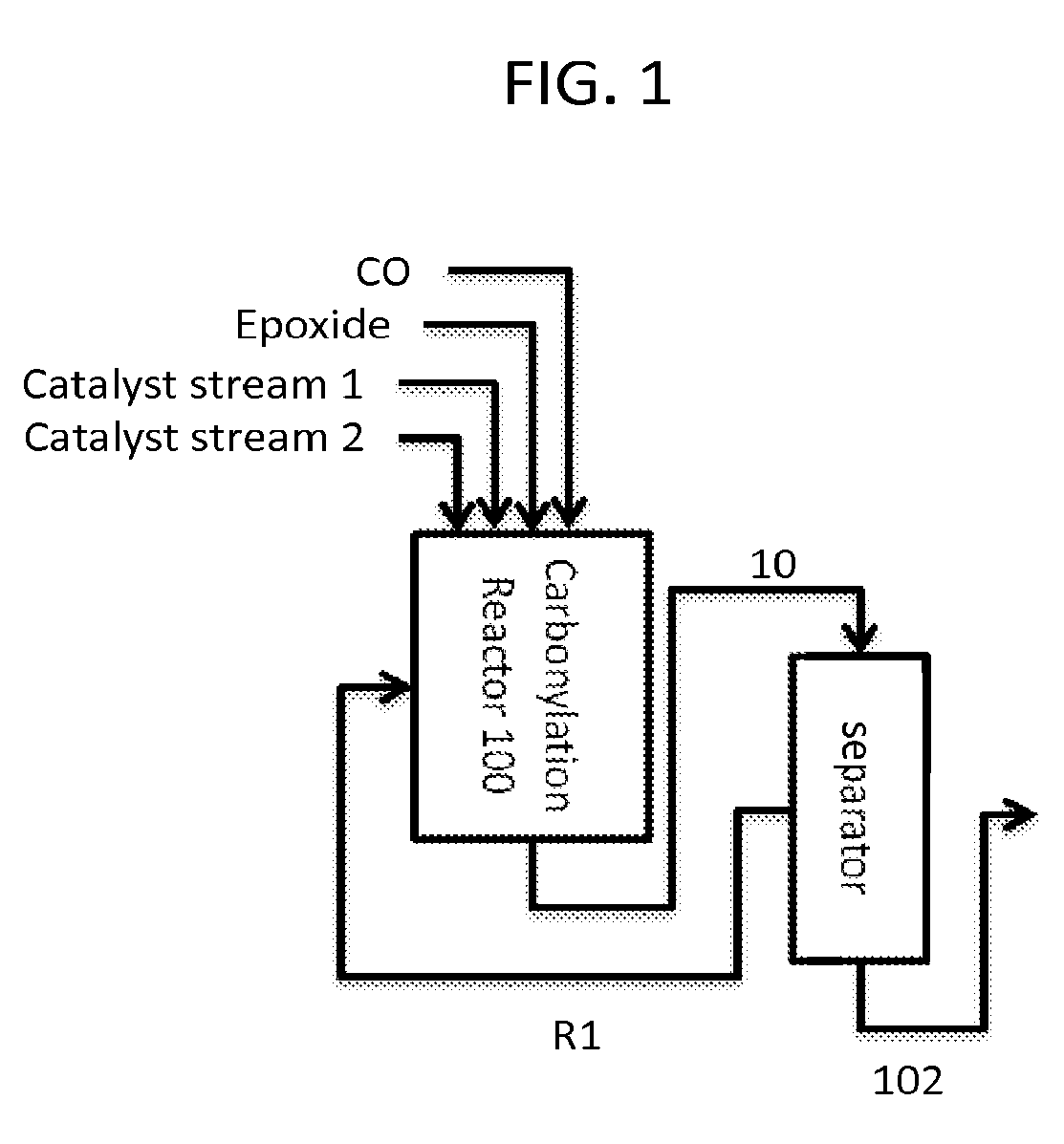

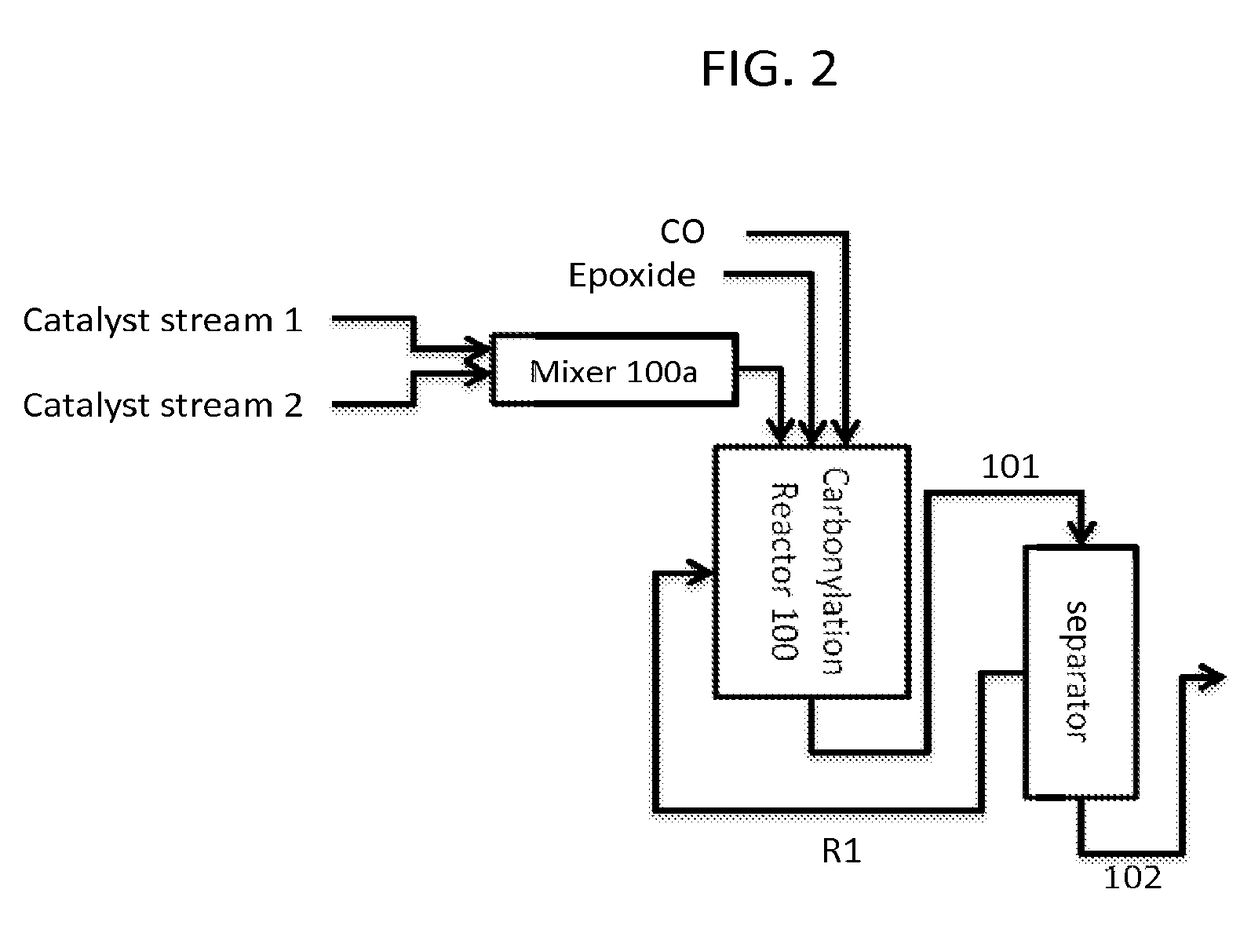

Synthesis of metal complexes and uses thereof

InactiveUS20170225157A1Little and no contaminationOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsCarbonylationProtein carbonyl

The present disclosure provides novel methods of making aluminum complexes with utility for promoting epoxide carbonylation reactions. Methods include reacting neutral metal carbonyl compounds with alkylaluminum complexes.

Owner:NOVOMER INC

Synthesis of metal complexes and uses thereof

ActiveUS20190030520A1Little and no contaminationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCompound (substance)Carbonylation

The present disclosure provides novel methods of making aluminum complexes with utility for promoting epoxide carbonylation reactions. Methods include reacting neutral metal carbonyl compounds with alkylaluminum complexes.

Owner:NOVOMER INC

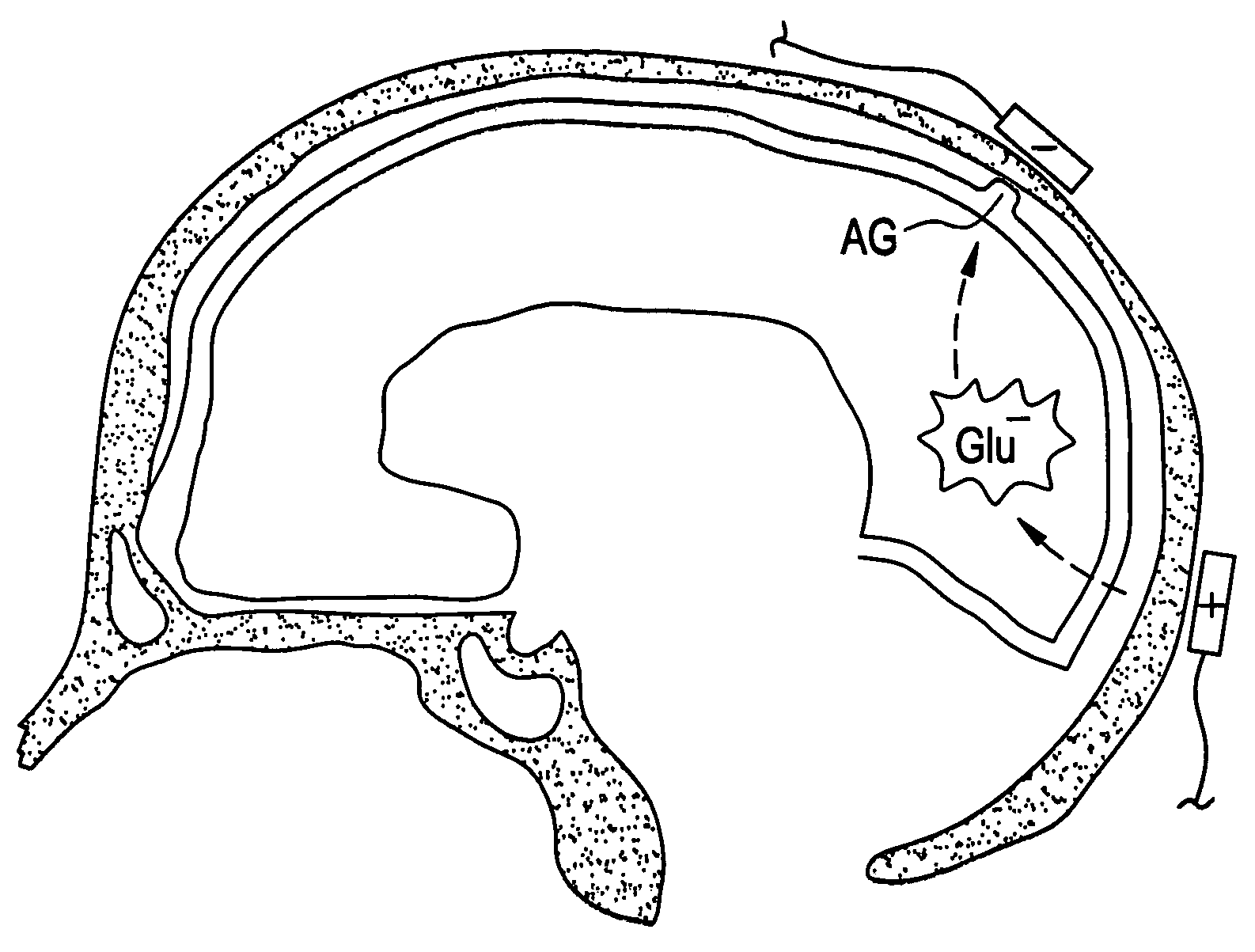

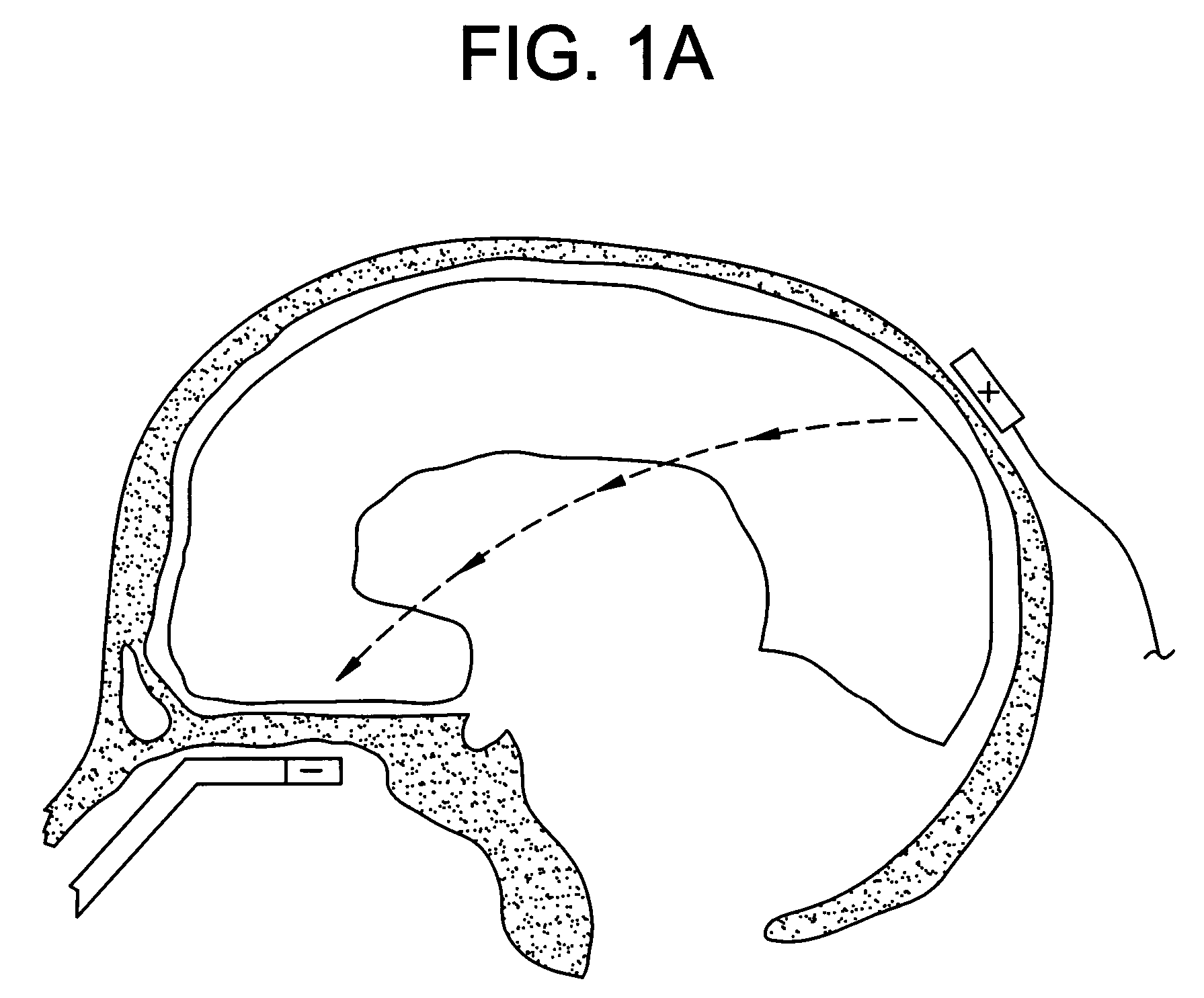

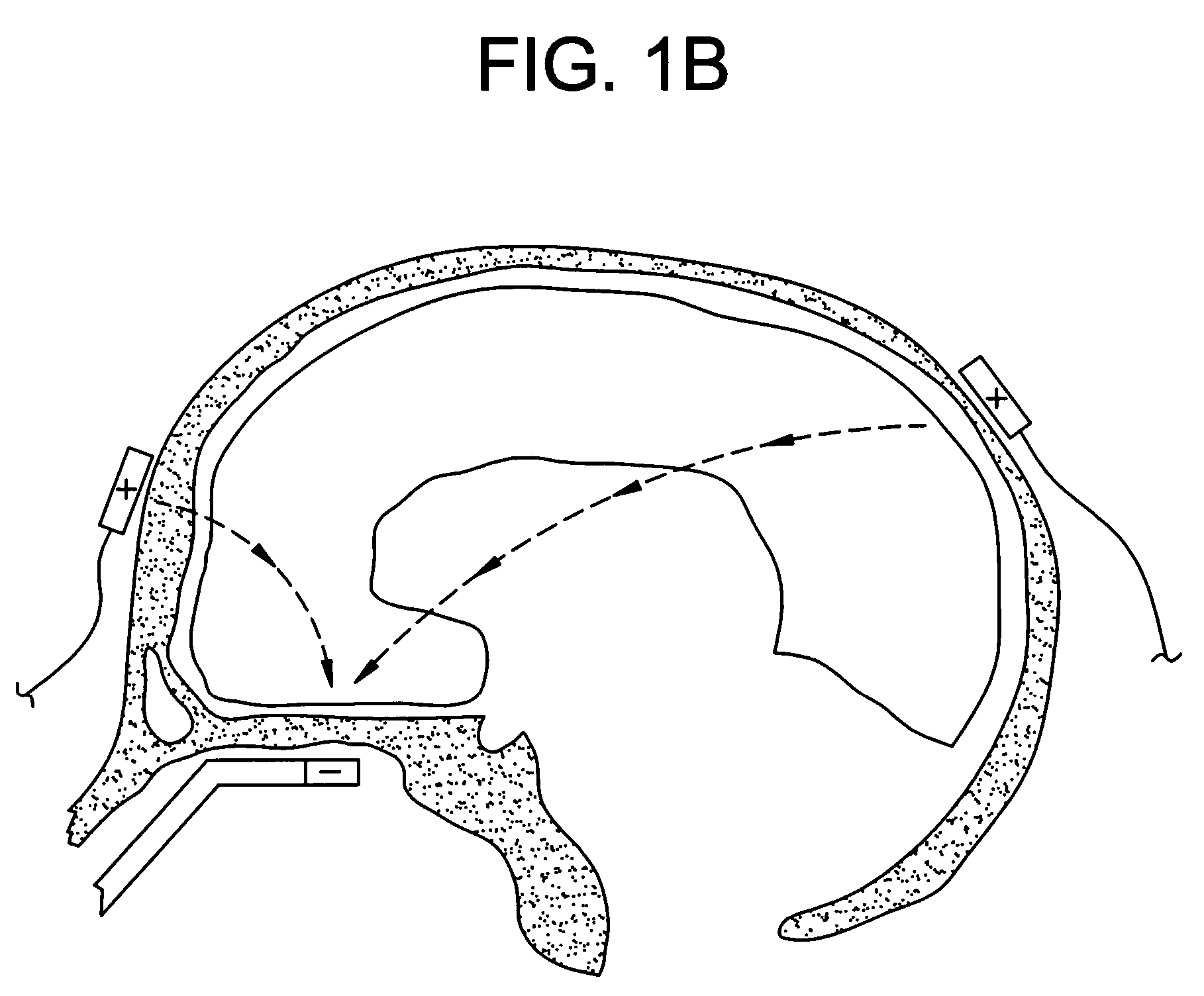

Method of removing deleterious charged molecules from brain tissue

Methods and devices for removing cationic glutamate or anionic aluminum complexes from brain tissue by applying a voltage to the brain tissue.

Owner:CODMAN & SHURTLEFF INC

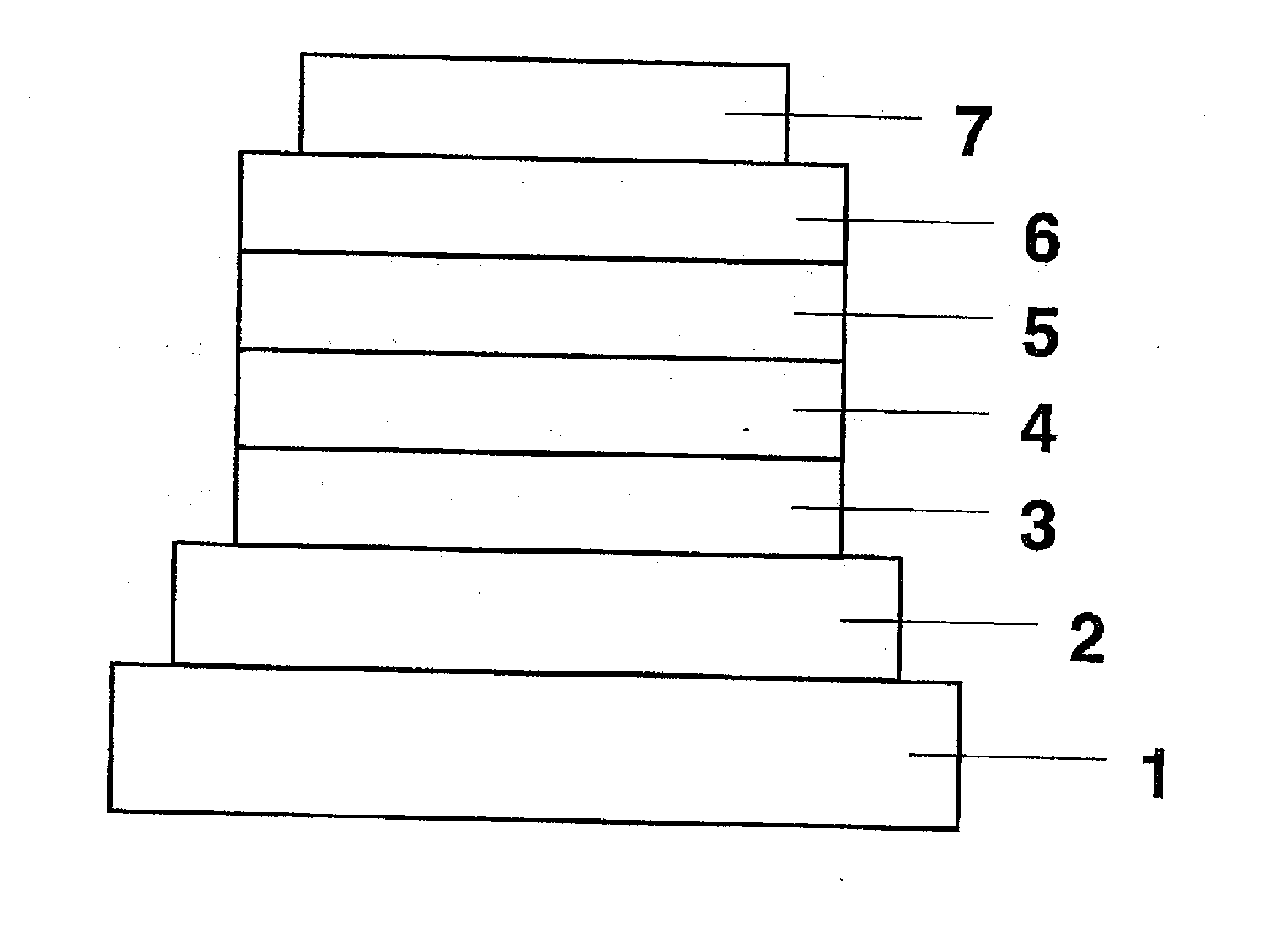

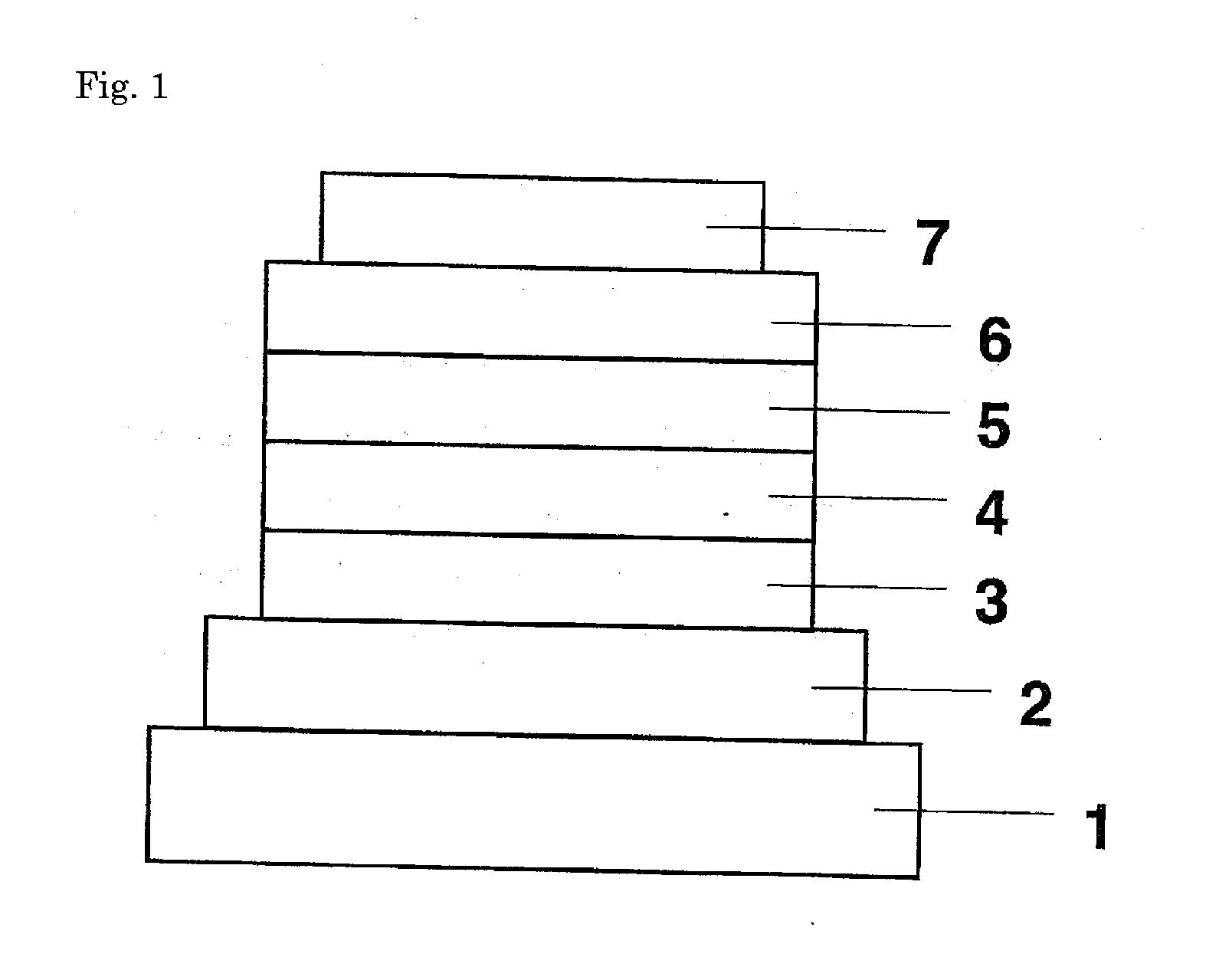

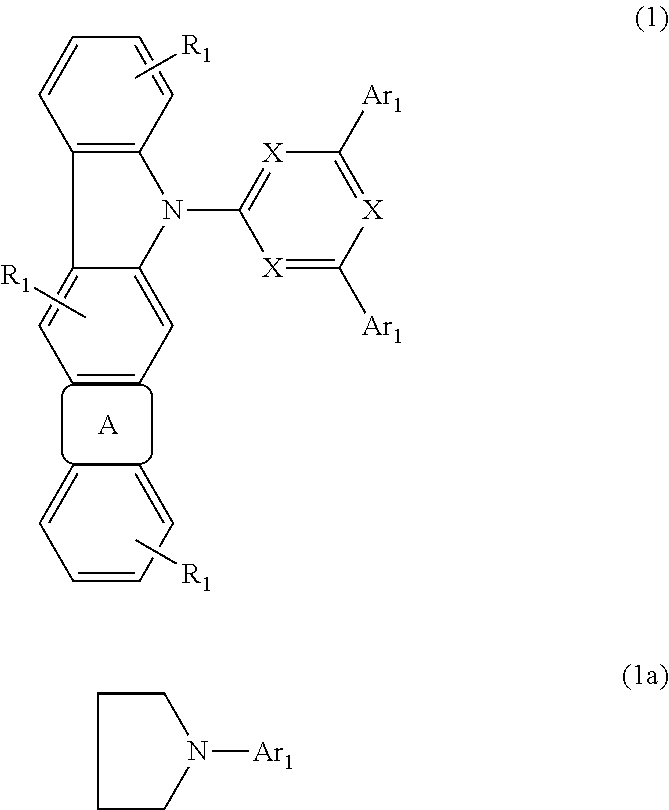

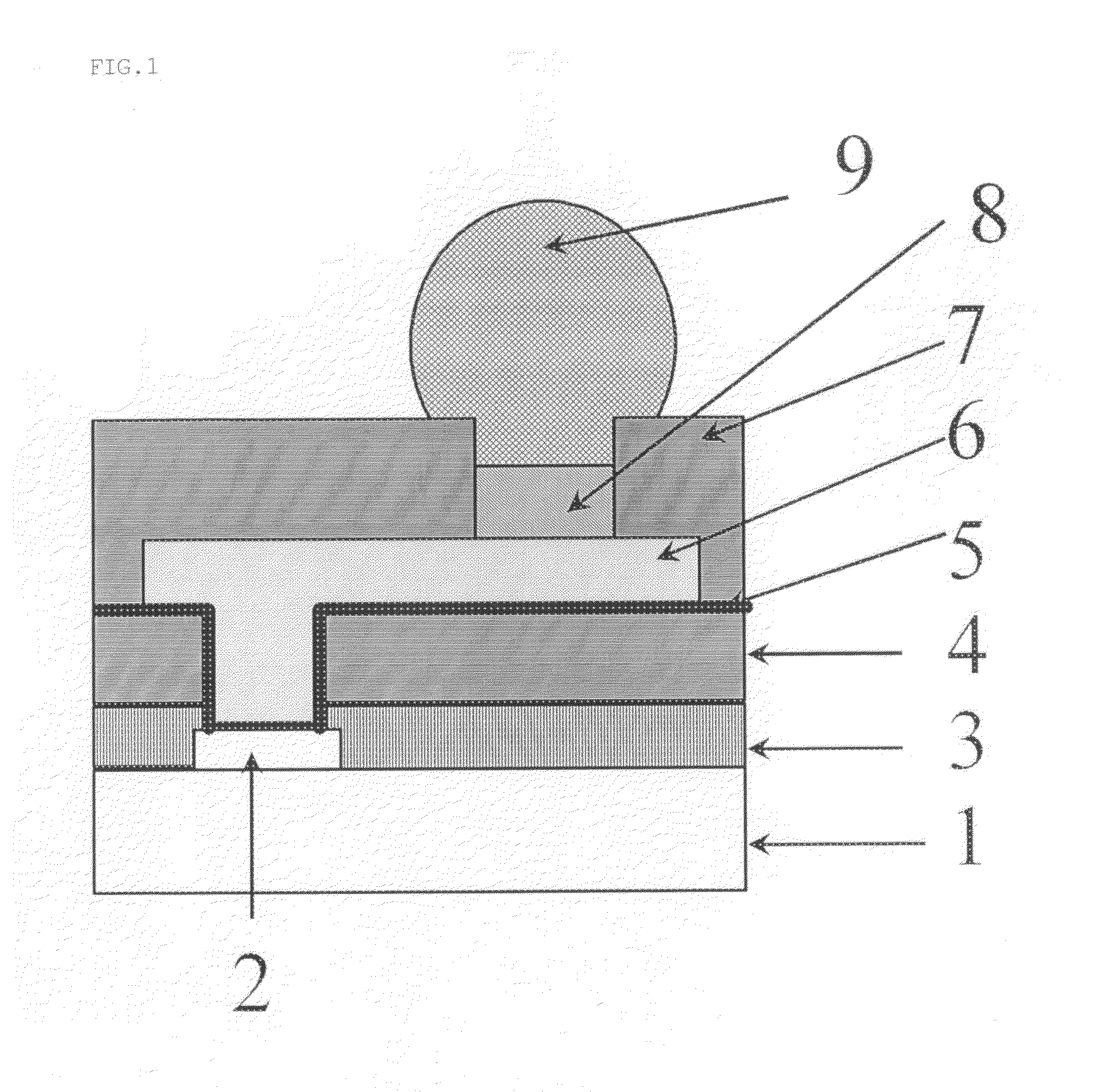

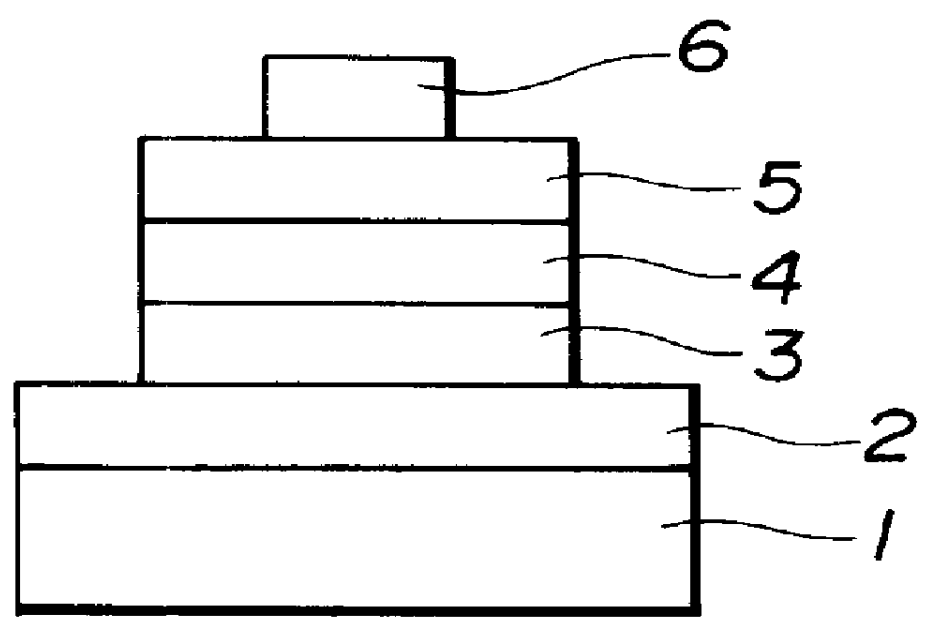

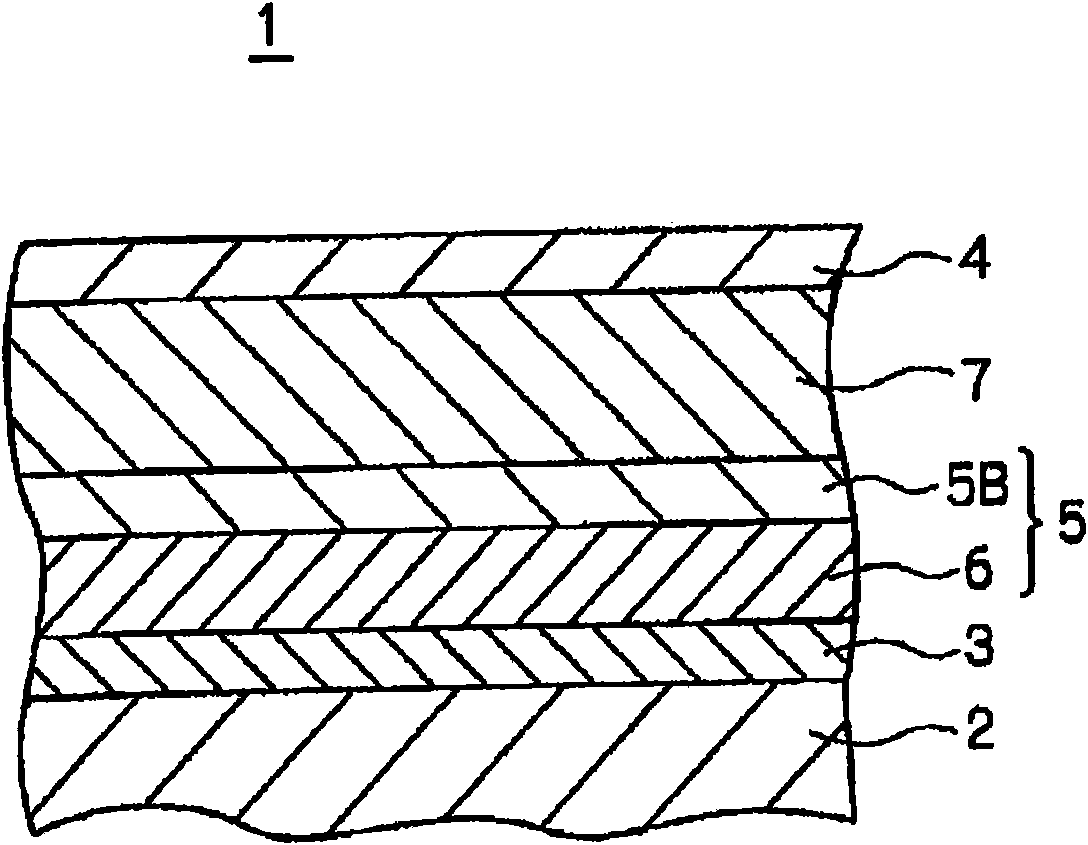

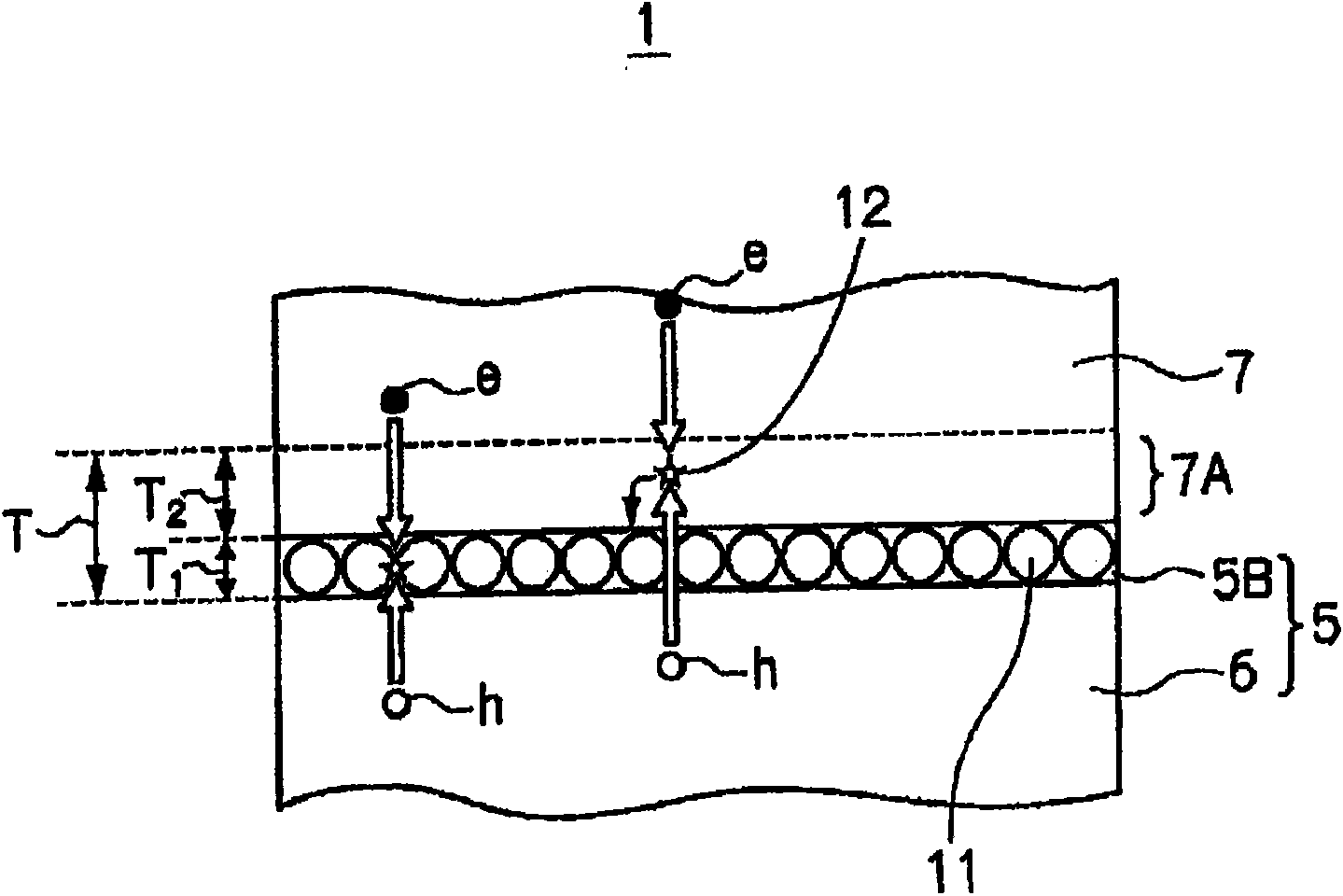

Organic electroluminescent device

InactiveUS20110062862A1Improve luminous efficiencySecuring drive stabilityOrganic chemistryDischarge tube luminescnet screensDopantHost material

Disclosed is an organic electroluminescent device (organic EL device) that is improved in the luminous efficiency, fully secured of the driving stability, and of a simple structure. The organic EL device comprises a light-emitting layer between an anode and a cathode piled one upon another on a substrate and the said light-emitting layer comprises (A) a phosphorescent dopant whose emission peak wavelength is longer than 600 nm and (B) a host material. The host material contains at least two kinds of compounds selected from two or more kinds of derivatives included in (b1) N-substituted indolocarbazole derivatives, (b2) derivatives of 8-hydroxyquinoline aluminum complex, and (b3) bisindolocarbazole derivatives.

Owner:PIONEER CORP +2

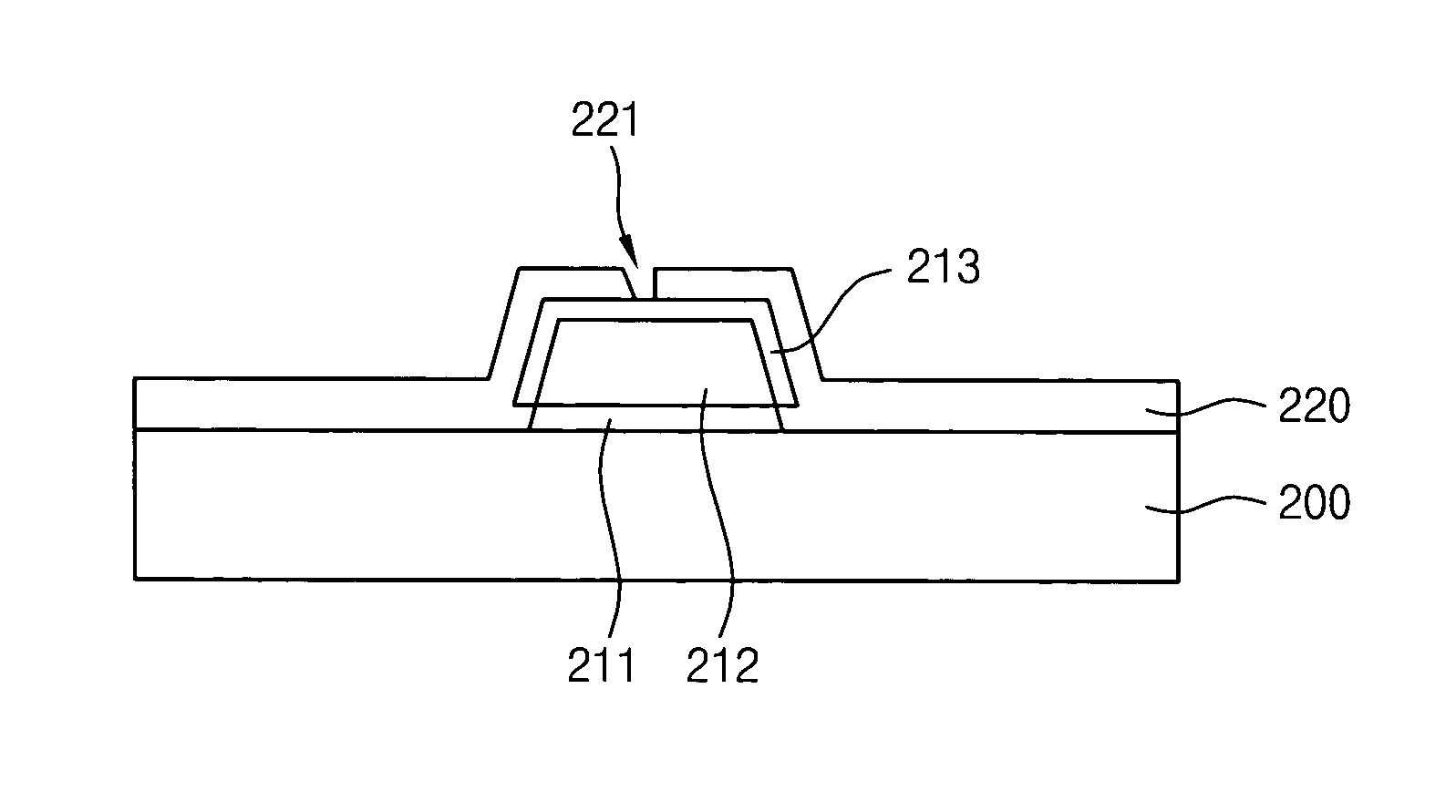

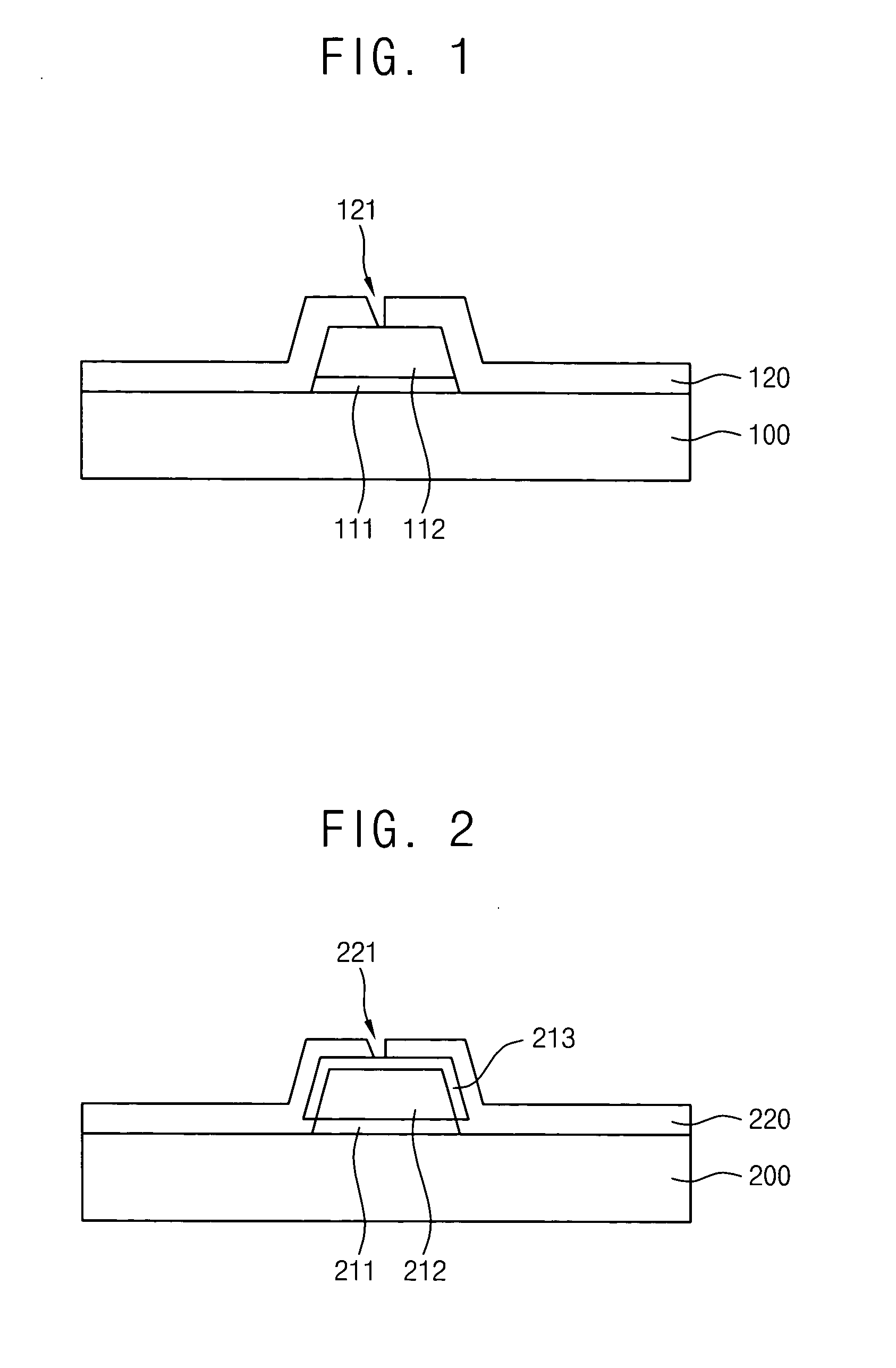

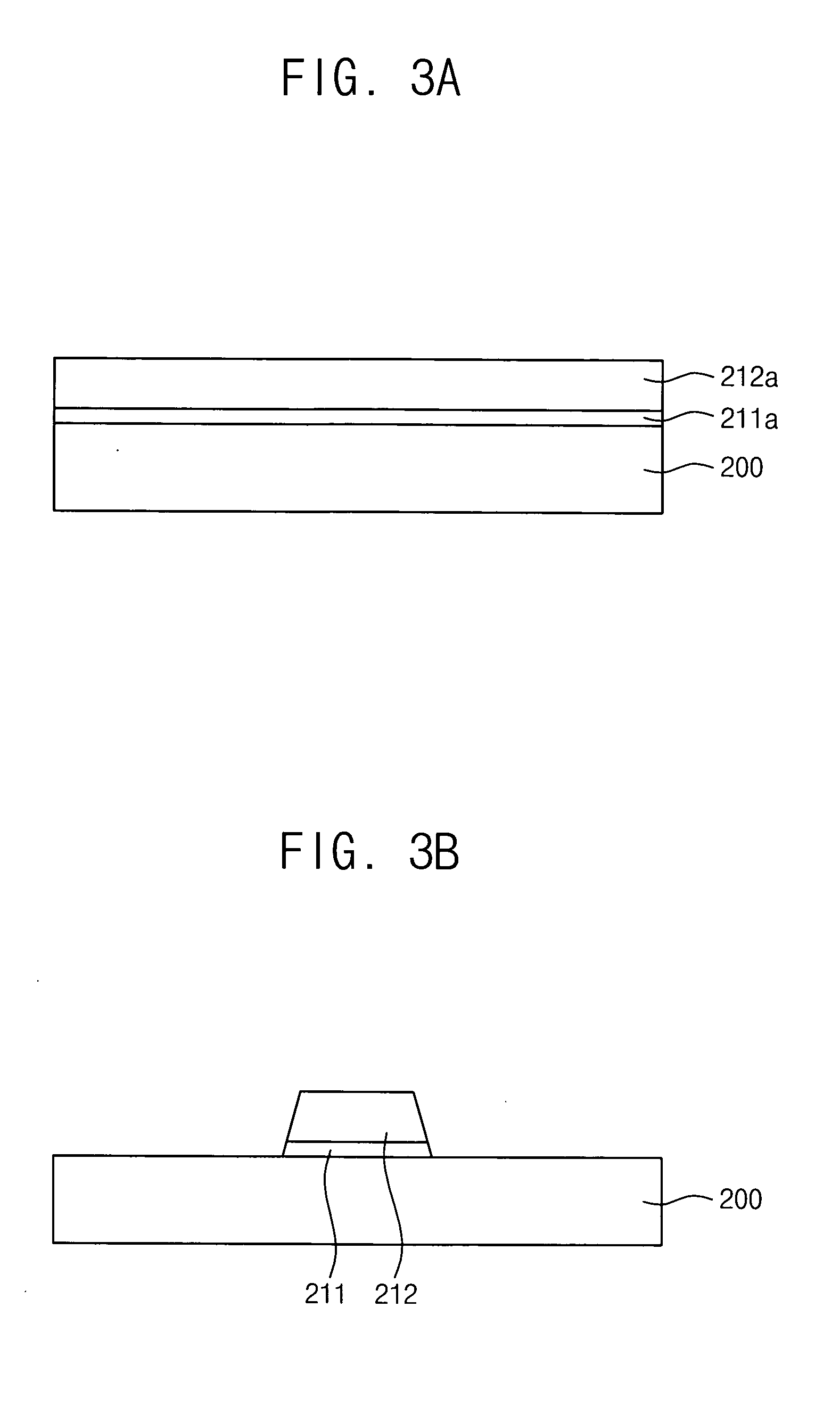

Thin film transistor substrate for liquid crystal display device and method of manufacturing the same

InactiveUS20070218601A1Reduce corrosionImprove corrosion resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayTungsten

A thin film transistor substrate for a liquid crystal display device includes a substrate, a metal layer on the substrate, and an aluminum complex oxide layer on the metal layer. The aluminum complex oxide layer comprises at least one selected from the group consisting of zirconium, tungsten, chromium and molybdenum. A passivation layer is formed on the aluminum complex oxide layer through a dipping process.

Owner:SAMSUNG DISPLAY CO LTD

Positive photosensitive resin composition, and semiconductor device and display therewith

InactiveUS8080350B2Reduce corrosionGood physical propertiesSemiconductor/solid-state device detailsSolid-state devicesChemical compoundDisplay device

Disclosed is a positive photosensitive resin composition containing (A) an alkali-soluble resin, (B) a diazoquinone compound, (d1) an activated silicon compound and (d2) an aluminum complex. Also disclosed is a positive photosensitive resin composition containing (A) an alkali-soluble resin, (B) a diazoquinone compound, (C) a compound having two or more oxetanyl groups in one molecule and (D) a catalyst for accelerating the ring-opening reaction of the oxetanyl groups of the compound (C).

Owner:SUMITOMO BAKELITE CO LTD

Aluminum-nitride-based composite material, method for manufacturing the same, and member for a semiconductor manufacturing apparatus

ActiveUS20100104892A1Improve thermal conductivityImprove electrical resistanceSemiconductor/solid-state device manufacturingCeramic shaping apparatusAlkaline earth metalRare earth

The aluminum-nitride-based composite material according to the present invention is an aluminum-nitride-based composite material that is highly pure with the content ratios of transition metals, alkali metals, and boron, respectively as low as 1000 ppm or lower, has AlN and MgO constitutional phases, and additionally contains at least one selected from the group consisting of a rare earth metal oxide, a rare earth metal-aluminum complex oxide, an alkali earth metal-aluminum complex oxide, a rare earth metal oxyfluoride, calcium oxide, and calcium fluoride, wherein the heat conductivity is in the range of 40 to 150 W / mK, the thermal expansion coefficient is in the range of 7.3 to 8.4 ppm / ° C., and the volume resistivity is 1×1014 Ω·cm or higher.

Owner:NGK INSULATORS LTD

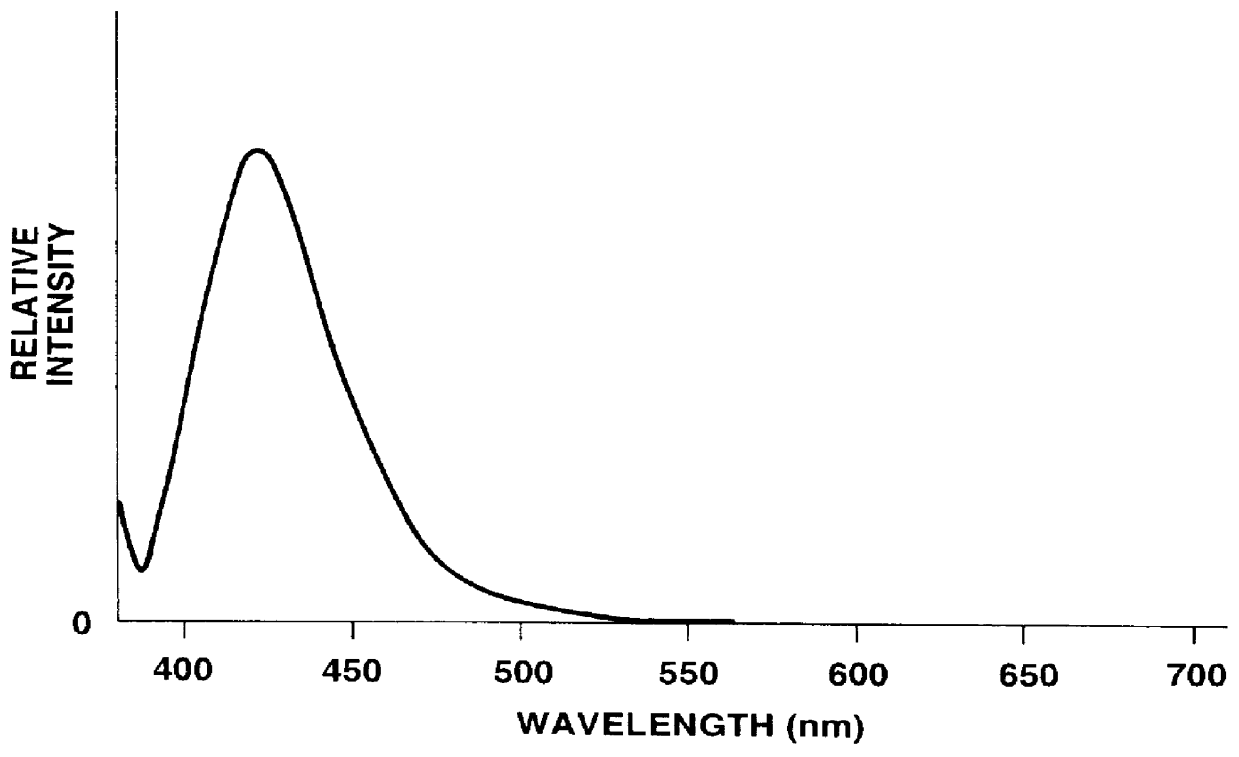

Organic electroluminescence device and organic electroluminescence device material

InactiveUS6048631ADischarge tube luminescnet screensGroup 8/9/10/18 element organic compoundsBenzoxazoleDevice material

An object of this invention is to provide an organic EL device material stable against heat, having a high purity in bluish light emission and a high efficiency. The organic EL device comprises a glass substrate, a transparent anode, a TPD which is an electron hole implanted transporting layer, an organic luminous layer, Alq3 which is an electron implanted transporting layer and a cathode. The organic luminous layer is an aluminum complex which is mu -oxozi [bis(2-(2-benzo oxazolyl)-phenolate) aluminum (III)]. Plus and minus DC voltages are applied to the anode and cathode respectively. The organic luminous layer indicates bluish light emission of 1314 cd / m2 at 16V. A peak wave length of the luminous spectrum is 420 nm and chromaticity coordinates are x=0.185 and y=0.178 and a high purity as bluish color is assured. The organic EL device material is stable against heat and difficult to deteriorate. Because the device structure is three-layer structure in which the organic luminous layer is sandwiched by an electron implanted transporting layer and an electron hole implanted transporting layer, diffusion of exciton to electrodes is prevented thereby improving the efficiency and reactive current is reduced thereby improving the service life.

Owner:FUTABA CORPORATION

Double-function catalyst for synthesizing cyclic carbonate and methyl carbonate

The double-function catalyst for synthesizing cyclic carbonate and methyl carbonate includes main catalyst quadridentate Schiff base aluminum complex (R1)(R2)SalenAlX, where R1 and R2 is H, Cl-C6 alkyl, alkoxy Cl, Br, NO2 and other group; and X is C1, Br, I, OR NO3, CH3COO, ClO4 BF4 and other one valent negative ion, and cocatalyst being organic compound YR3, where Y is group V element and R3 is C2-C12 alkyl or aryl, with the molar ratio between the main catalyst quadridentate schiff base aluminum complex and the cocatalyst being 0.05-1. The catalyst can catalyze the reaction of epoxy compound with Co2 to synthesize cyclic carbonate and catalyze the exchange reaction of cyclic carbonate with methoxide to synthesize methyl carbonate in high efficiency.

Owner:DALIAN UNIV OF TECH

Recycling method of waste hydrochloric acid containing aluminum

The invention discloses a recycling method of waste hydrochloric acid containing aluminum and belongs to the technical field of recycling of waste acid containing aluminum. The method comprises the following steps of: (A) carrying out sand filtration on a waste hydrochloric acid washing liquid of an aluminum casting to remove suspended matters; (B) passing the waste hydrochloric acid washing liquid without the suspended matters through a fixed bed adsorption tower which is filled with strong-alkali anion exchange resin and provided with a heat insulation jacket under the conditions that the temperature is 5-45 DEG C and the work flow is 0.5-3.0BV / h; C) adding industrial hydrochloric acid in the processed effluent liquid so that the concentration of HCl is increased to 8mol / L, and then returning the effluent liquid back to a production process to be used as an aluminum casting hydrochloric acid washing liquid for circulating use; and D) passing distilled water or deionized water which is used as a regenerating agent through a resin bed to exchange and elute aluminum complex anions on a strong-alkali anion exchange resin, so as to form an aqueous solution containing aluminum trichloride, wherein the aqueous solution containing aluminum trichloride can be directly used as a purifying agent byproduct. According to the invention, the strong-alkali anion exchange resin is applied to the treatment and resource recovery of the waste hydrochloric acid washing liquid of the aluminum casting, thereby achieving the zero emission of the waste hydrochloric acid washing liquid of the aluminum casting and realizing the complete recycling of hydrochloric acid.

Owner:张炜铭 +3

A copper-clad aluminum complex cable copper strip composition and machining process

InactiveCN101060023AImprove welding effectImprove the lubrication effectOther manufacturing equipments/toolsMetal/alloy conductorsHigh intensityMachining process

The disclosed copper strip for Cu-covered-Al composite cable comprises: 59. 9705-99. 9805% cathode copper, <40% waste red copper, 0. 002-0. 012% P, <0. 002% O, and <0. 0155% other impurity. The preparation method comprises: mixing, smelting, covering, deoxidizing, revolving furnace, covering, holding, detecting, casting, sawing, ingotting and heating, hot-rolling, milling surface, coarse rolling, end shearing, intermediate annealing, fine rolling, product annealing, surface passivating, and packaging. This product has high conductivity, strength, extensibility, and welding feature. The tension processing ratio can come up to 99. 99%.

Owner:LUOYANG COPPER PROCESSING GROUP

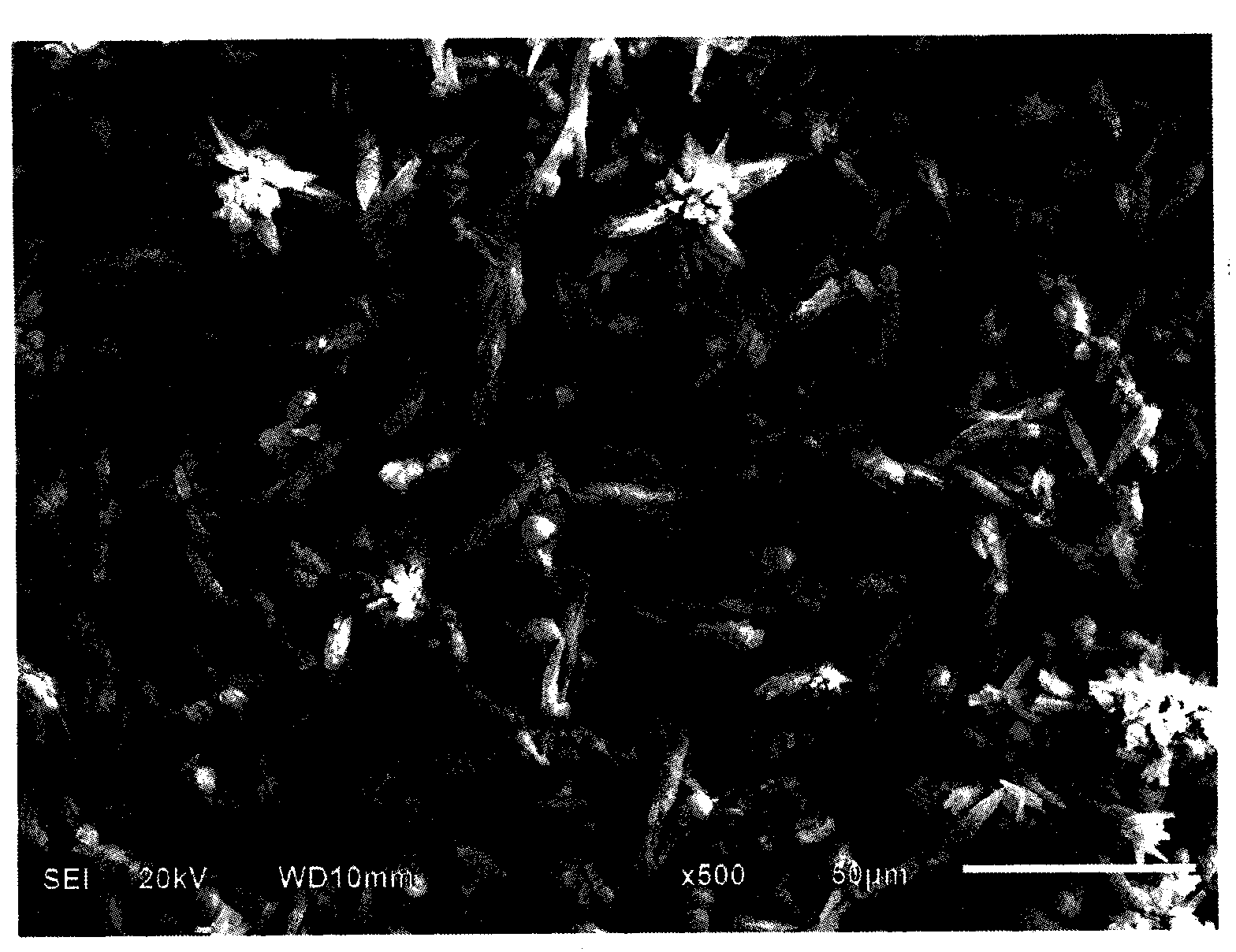

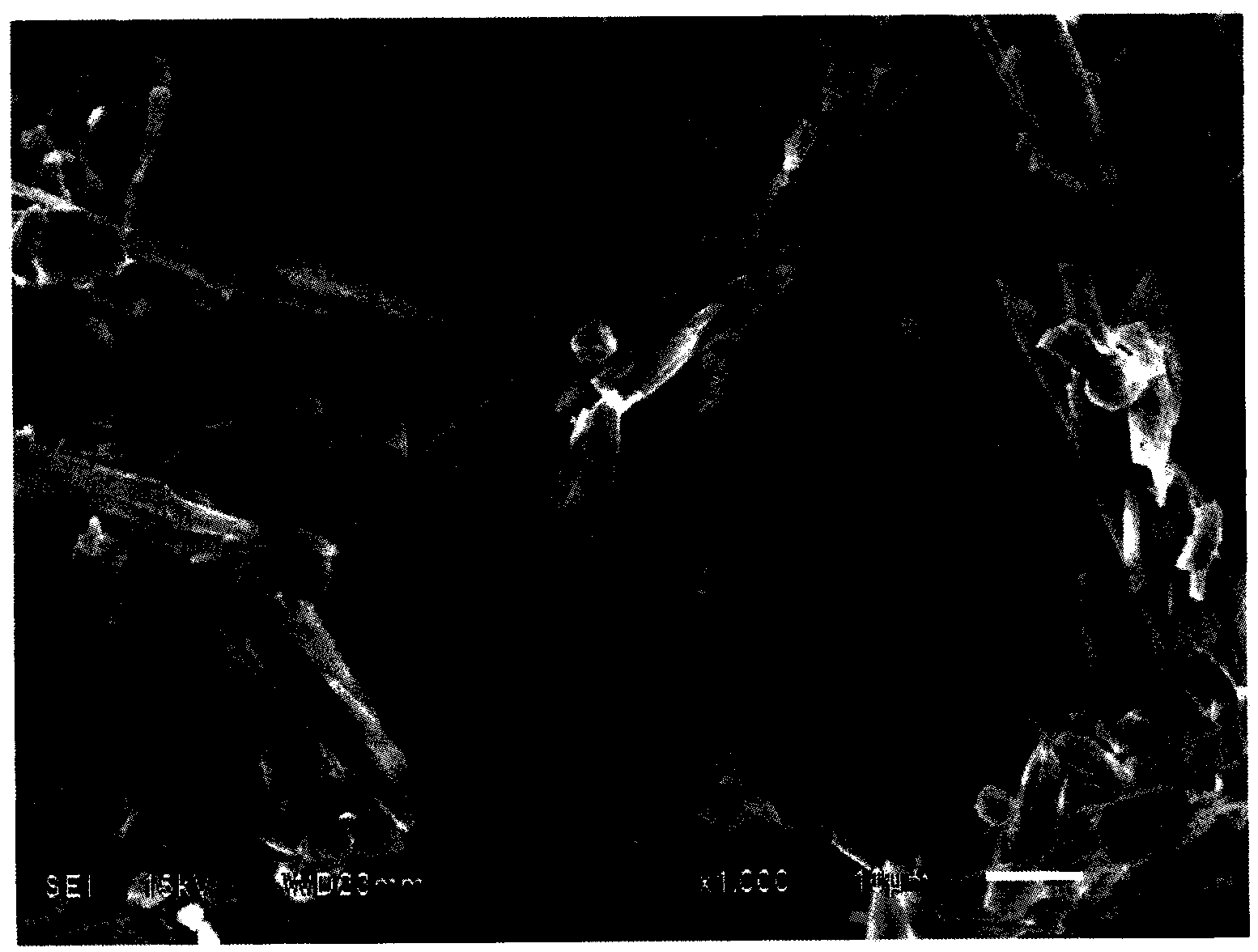

High-density spherical Ni-Co lithium aluminate material and preparation of precursor of the material

ActiveCN104425815AHigh crystallinityHigh charge and discharge capacityCell electrodesSecondary cellsAluminum IonHigh density

The invention relates to a method for preparing a Ni-Co-Al precursor material and a method for preparing a Ni-Co lithium aluminate material with the precursor material. The method for preparing the Ni-Co-Al precursor material comprises following steps: (1) preparing a solution A containing a nickel (II) salt and a cobalt (II) salt, a solution B containing an aluminum complex and an ammonia-containing inorganic strong alkali solution C, wherein the solution B is prepared by dissolving an inorganic aluminum salt and at least two complexing agents; (2) synchronously feeding the solution A and the solution B into a reactor with a flow speed controlled to enable a molar ratio of nickel ion, cobalt ion and aluminum ion to be (6-9):(0.5-2):(0.5-2) with addition of the solution C to maintain a pH value of the mixture system to be 10-12.7; and (3) after the solution A and the solution B are fed synchronously, performing solid-liquid separation and washing, drying and optionally sieving a separated solid product to obtain the Ni-Co-Al precursor material.

Owner:NEC (CHINA) CO LTD

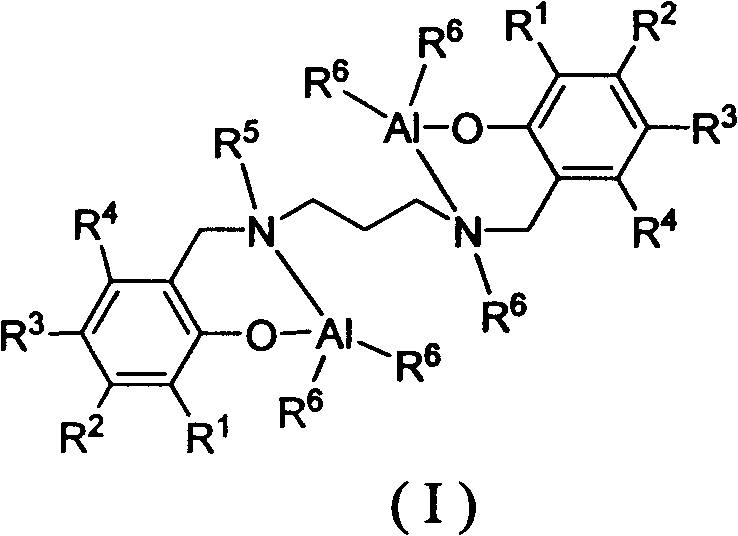

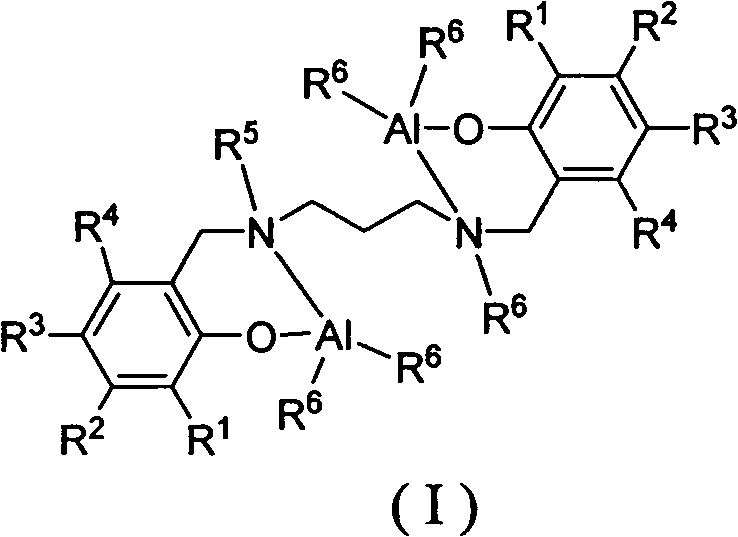

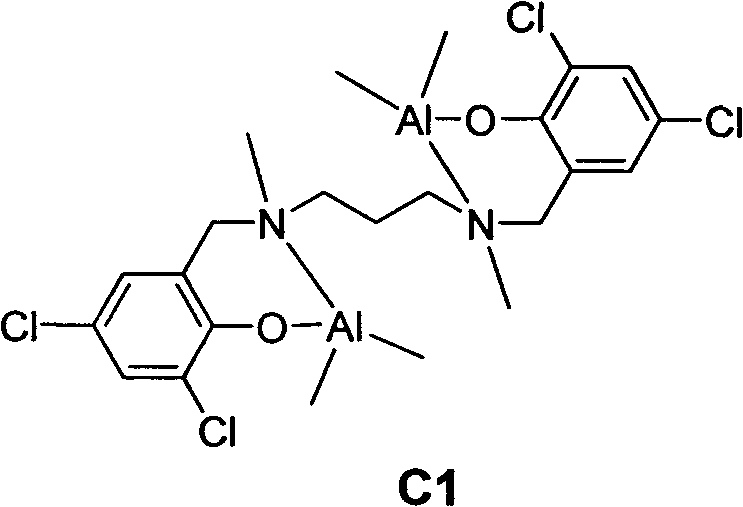

Lactide-epsilon-caprolactone copolymerization catalyst and copolymerization method

The invention relates to a lactide-epsilon-caprolactone copolymerization catalyst and a copolymerization method. The lactide-epsilon-caprolactone copolymerization catalyst relates to a nitrogenous bisphenol oxygen-based binuclear aluminum complex. The copolymerization method comprises the following steps of: adding lactide and epsilon-caprolactone into a reaction system sequentially or simultaneously, and carrying out copolymerization in a solvent-free system or an organic solvent medium under the catalysis of an appropriate of alcohol and nitrogenous bisphenol oxygen-based binuclear aluminum complex; and obtaining a lactide and epsilon-caprolactone copolymer through purifying after the copolymerization is finished. The high-efficiency lactide-epsilon-caprolactone copolymerization catalyst can realize synthesis of a lactide / epsilon-caprolactone segmented copolymer, a gradient copolymer, a wedge-shaped copolymer and a random copolymer. The lactide-epsilon-caprolactone copolymerization catalyst has very remarkably advantages of easily-obtained raw materials, simple polymerization method, various copolymer structures, regulating and controlling availability, higher catalysis activity and capabilities of obtaining the lactide and epsilon-caprolactone copolymer with high molecular weight and meeting requirements of the industrial department. A structural formula of the lactide-epsilon-caprolactone copolymerization catalyst is shown in a figure described in the specification.

Owner:EAST CHINA UNIV OF SCI & TECH

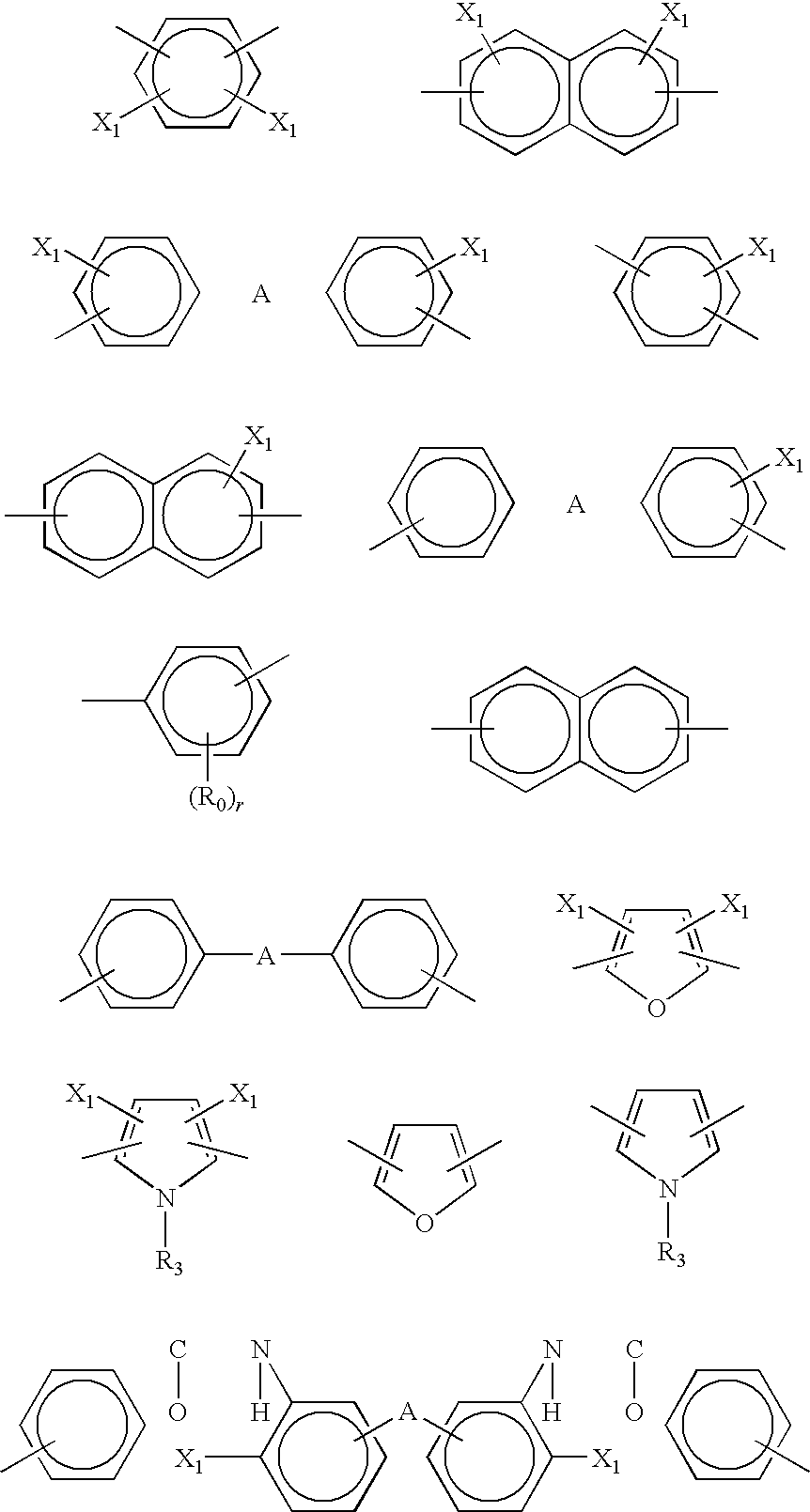

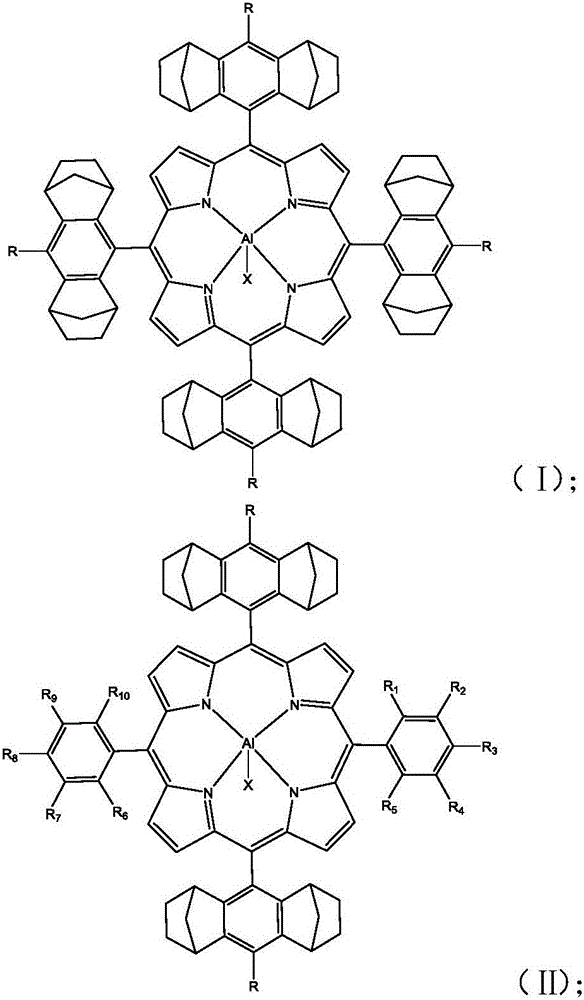

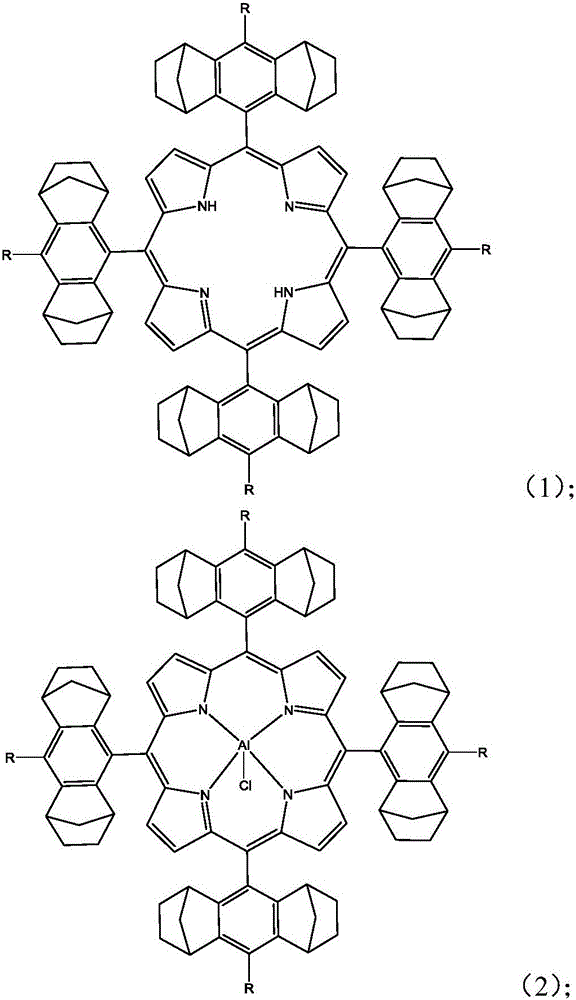

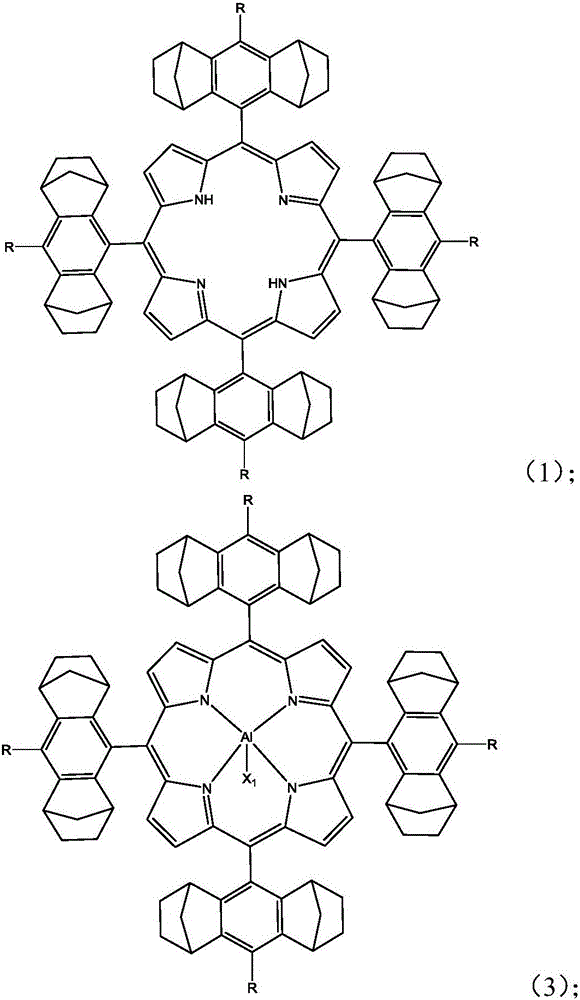

Preparation method of porphyrin aluminum complex and preparation method of polycarbonate

InactiveCN105753894AIncreased polycarbonate unit contentHigh content of polycarbonate unitsGroup 3/13 element organic compoundsPorphyrinEther

The invention provides a porphyrin aluminum complex with a structure as shown in a formula (I) or a formula (II), a preparation method of the porphyrin aluminum complex, and a preparation method of polycarbonate. Under the catalysis of a main catalyst and a cocatalyst of the porphyrin aluminum complex provided by the invention, carbon dioxide and epoxide are subjected to copolymerization, so that the polycarbonate is obtained. In a copolymerization process, the porphyrin aluminum complex participates in the reaction process and serves as the main catalyst, the porphyrin aluminum complex has high catalytic activity and particularly has excellent chemistry selectivity (which is greater than 99%), and the polycarbonate with low ether segments and high alternation is prepared.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

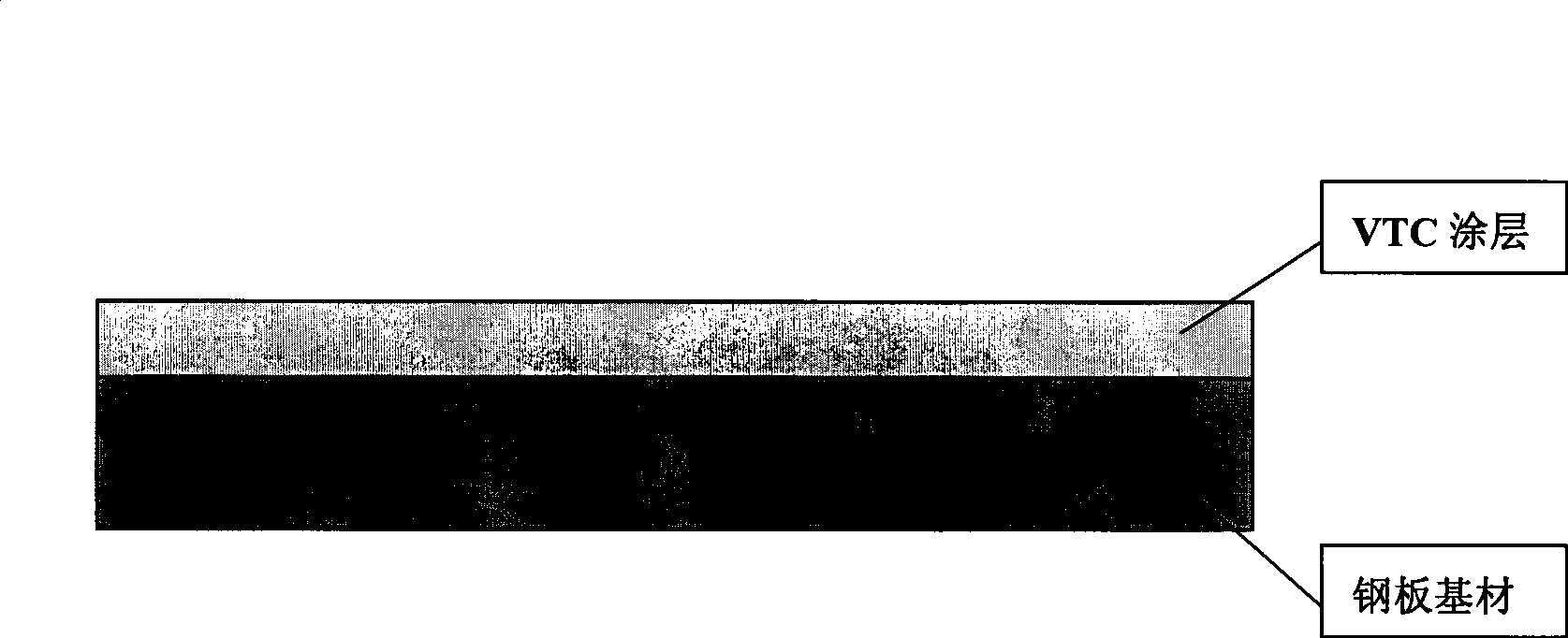

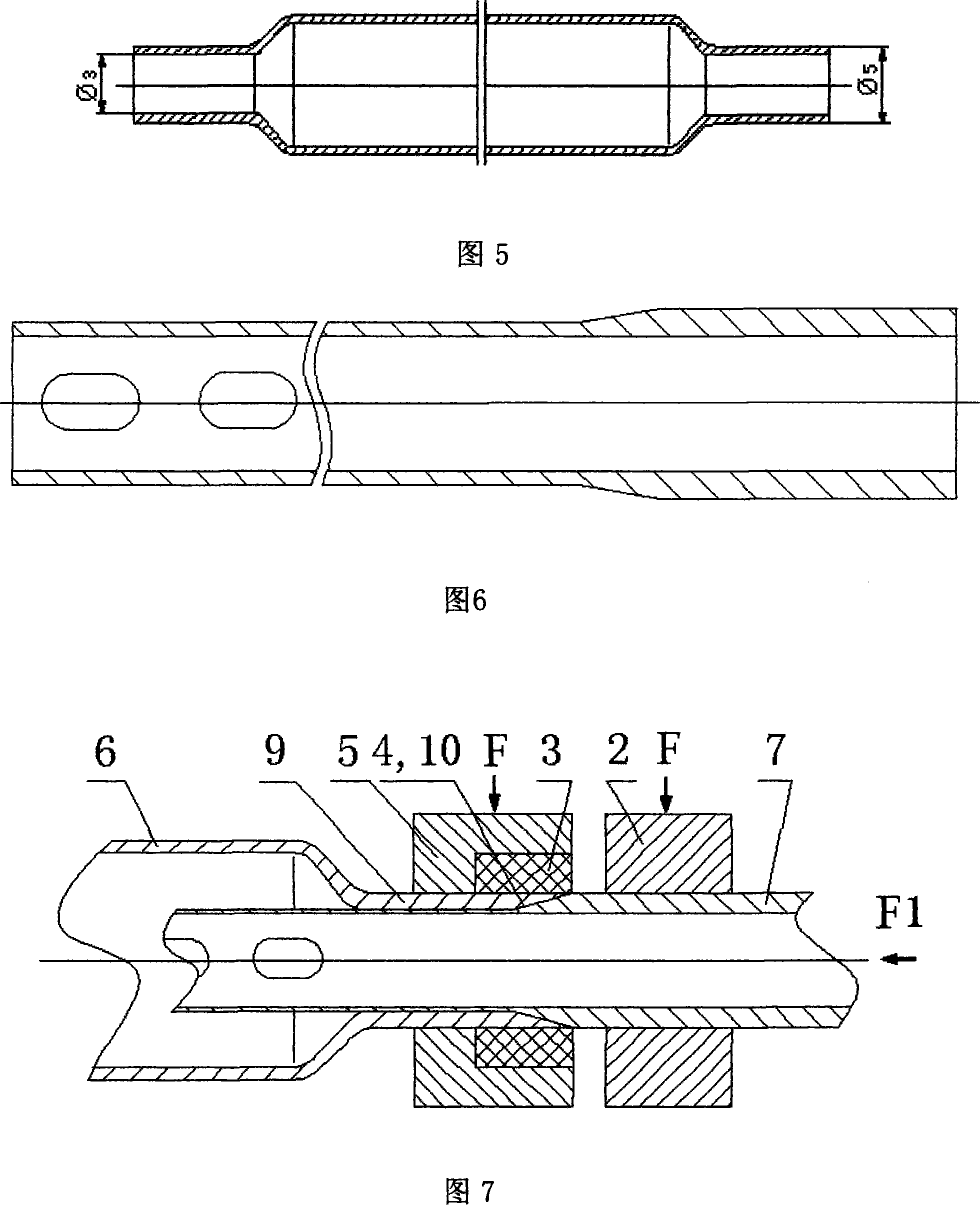

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413AHarsh salt spray resistanceGood anti-ultraviolet aging performanceAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

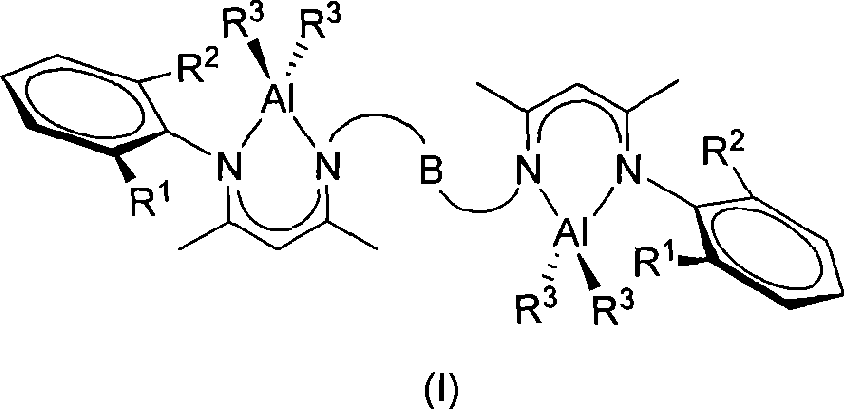

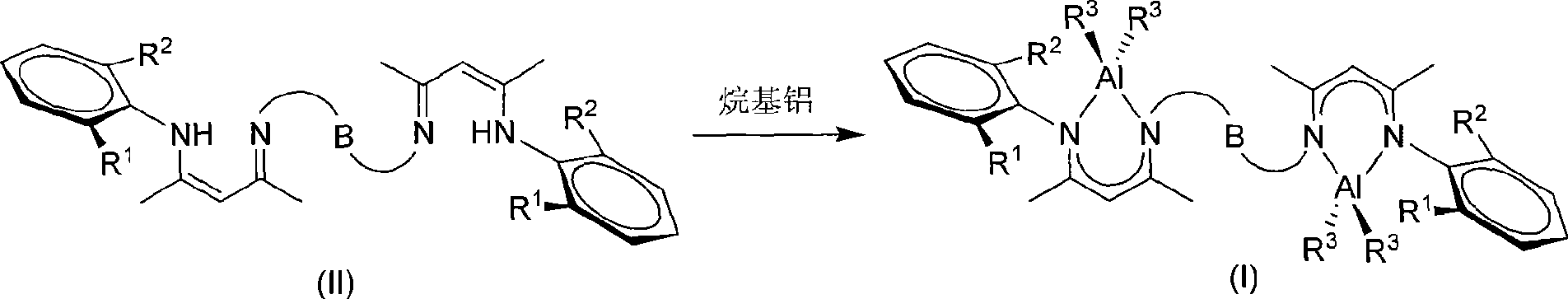

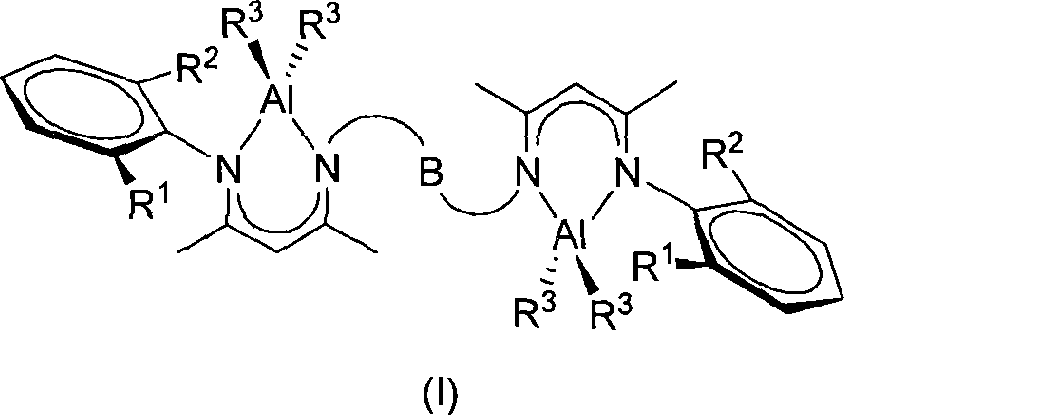

Novel bridged beta-diimido binuclear aluminum compound and preparation method and use thereof

InactiveCN101418010AHigh molecular weightGroup 3/13 element organic compoundsStructural formulaPolycaprolactone

The invention discloses a novel bridged beta-diketiminate homodinuclear aluminum compound, a preparation method thereof and application of the compound in polymerization of lactones. The preparation method is as follows: a bridged beta-diketiminate homodinuclear ligand compound and alkyl aluminum are reacted in an organic medium to give a homodinuclear aluminum complex for a bridged beta-diketminate ligand. The bridged beta-diketiminate homodinuclear aluminum compound is a high-efficiency catalyst which can be used for catalyzing the polymerization of lactones. The bridged beta-diketiminate homodinuclear aluminum compound has the advantages of producing polycaprolactone (Mw / Mn is between 1.4 and 2.3) with high and narrowly distributed molecular weight due to higher catalytic activities and meeting demands of industrial department, along with easily available raw materials, simple synthesis course, high product yield and stable properties. The structural formula of the compounded is shown above.

Owner:EAST CHINA UNIV OF SCI & TECH

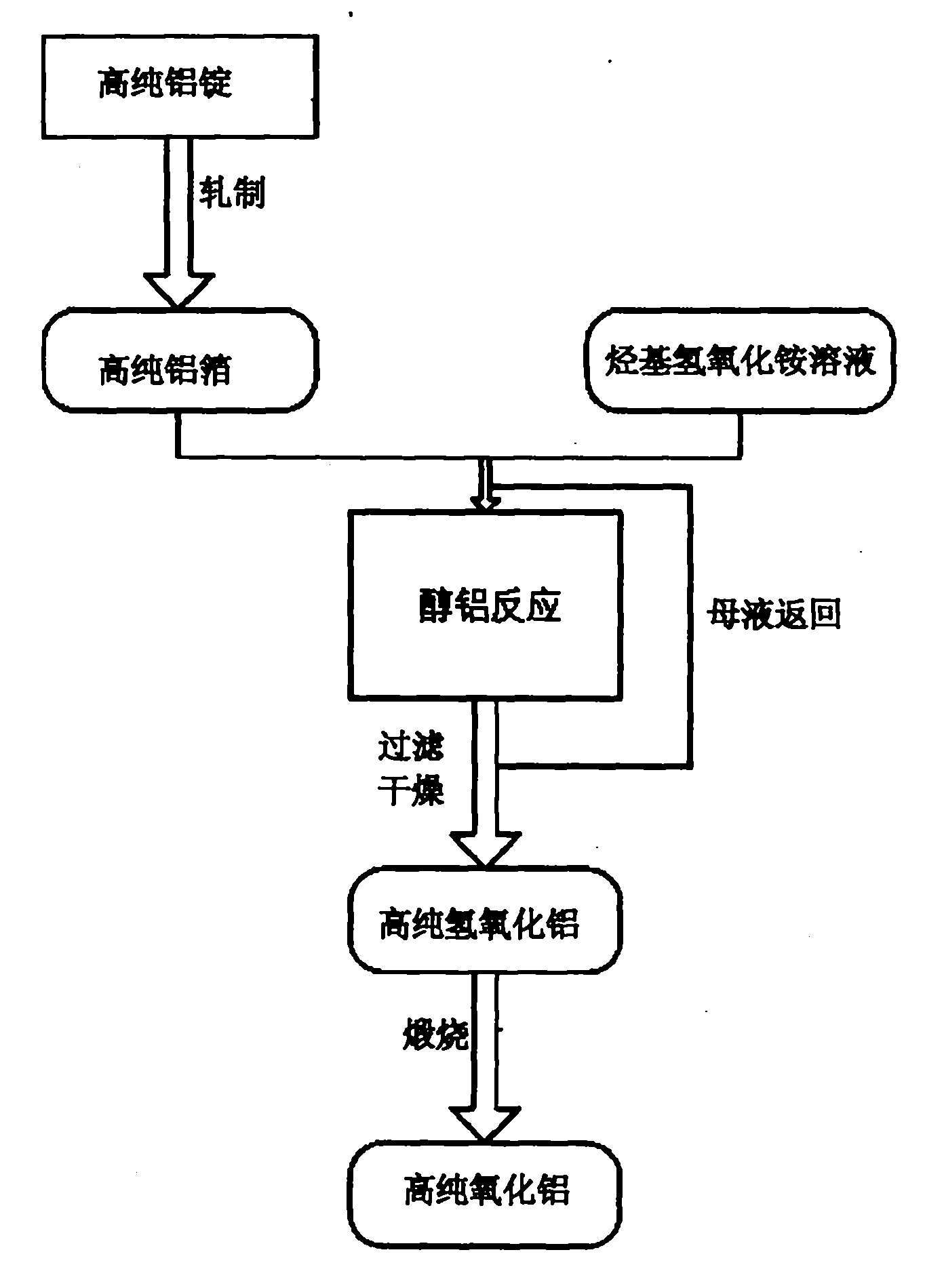

Preparation method of high-purity aluminum oxide

ActiveCN103523810ANo emissionsAvoid enteringAluminium oxide/hydroxide preparationAluminium hydroxideControllability

The invention provides a preparation method of high-purity aluminum oxide, which is mainly characterized by comprising the following steps: reacting high-purity aluminum and an electronic grade alkyl ammonium hydroxide solution to generate organic aluminum complex salt; further hydrolyzing the organic aluminum complex salt to obtain aluminum hydroxide and the alkyl ammonium hydroxide; and filtering the generated aluminum hydroxide, washing, performing vacuum drying, and performing high-temperature calcination to obtain high-purity aluminum oxide powder. The preparation method has the advantages of short production flow, high process controllability, no environmental pollution, high product purity, low cost and the like. The high-purity aluminum oxide powder prepared by the method is applicable to the fields of LED (light-emitting diode) sapphires, laser crystals, electronic ceramics, special ceramics, luminescent materials and the like.

Owner:何礼君 +2

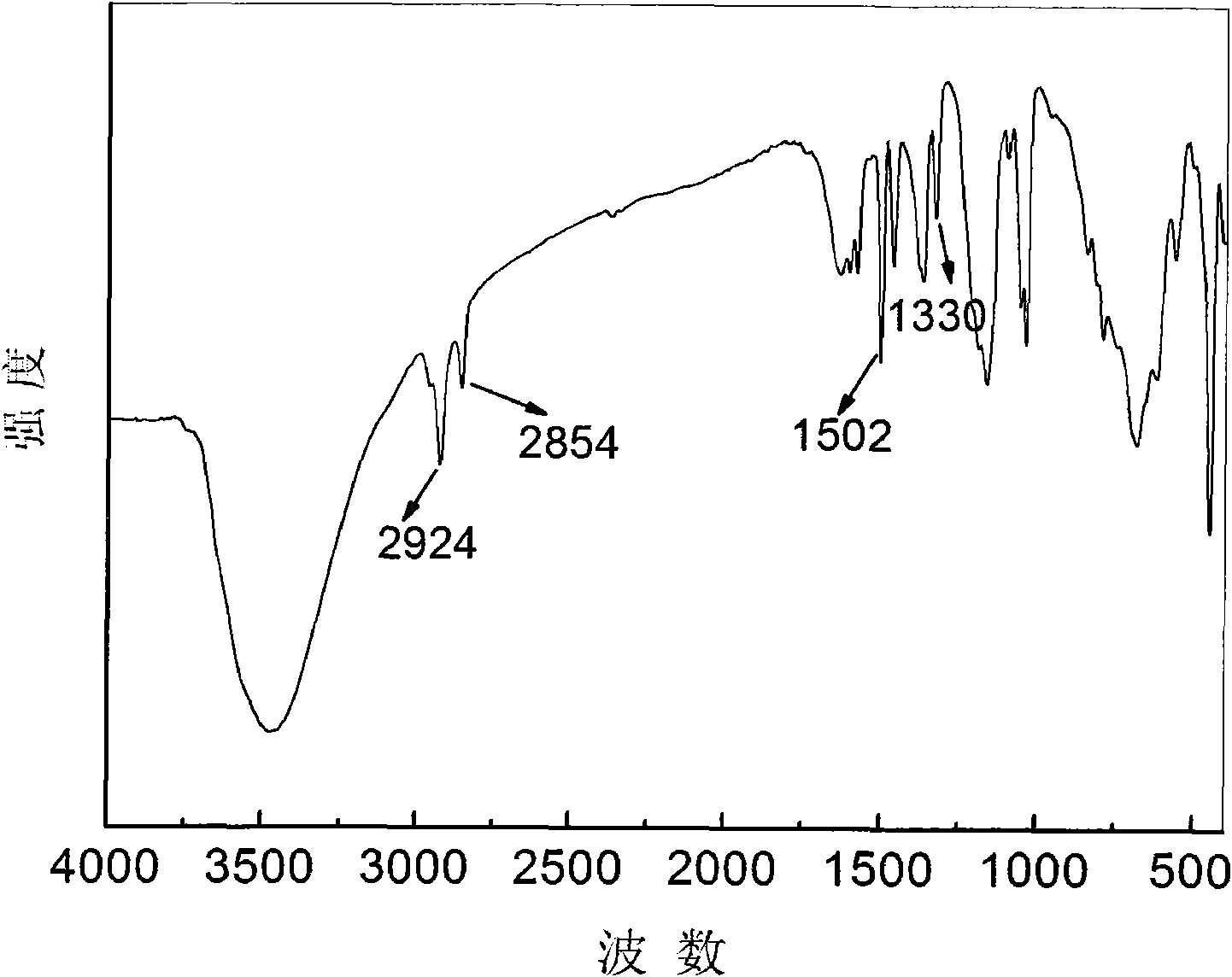

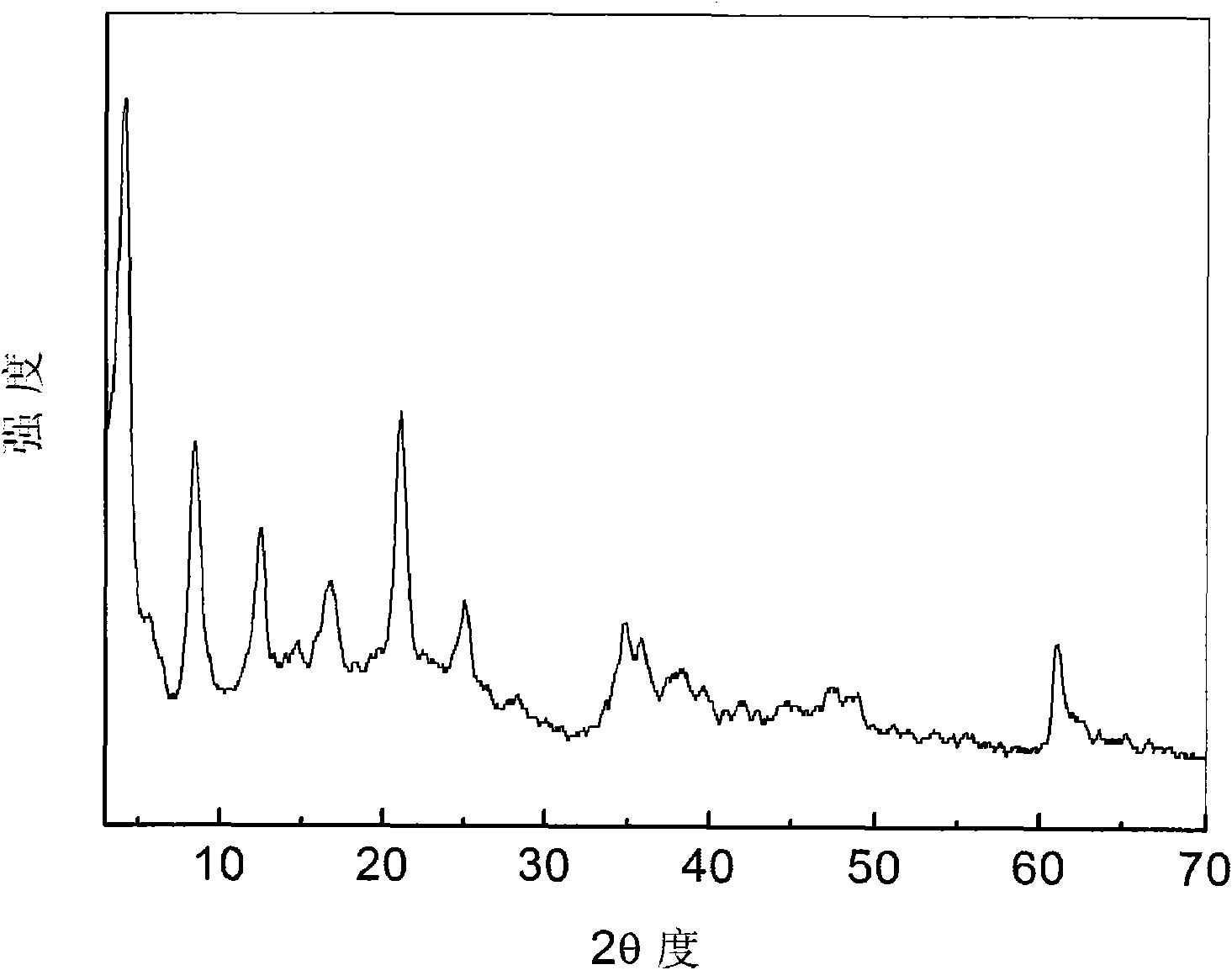

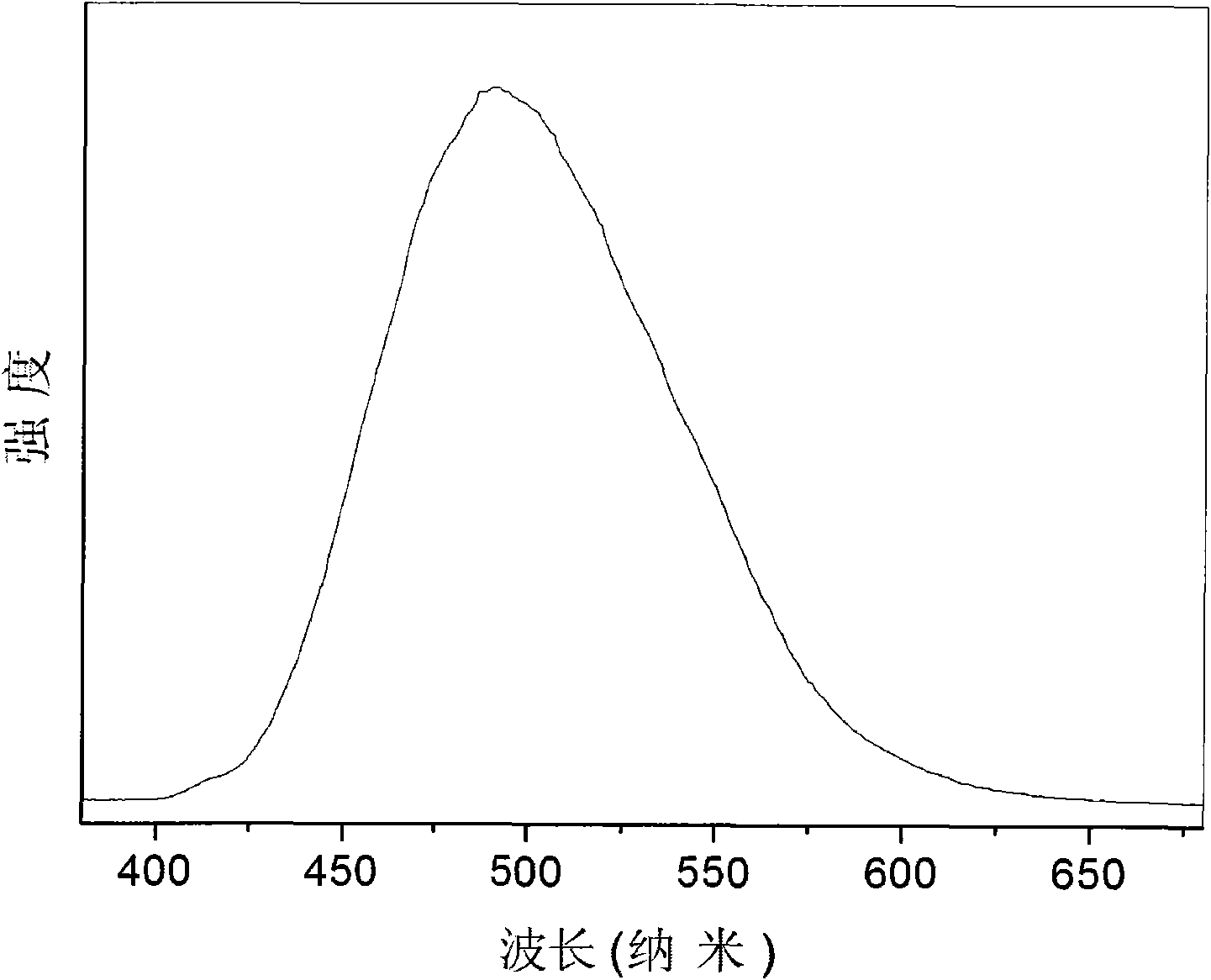

Tri(8-hydroxyquinoline-5-sulfonate) aluminum complex anion intercalated hydrotalcite composite luminescent material and preparation method thereof

InactiveCN101768435AImmobilizationLuminescent compositions8-hydroxyquinoline-5-sulfonateAnion intercalation

The invention discloses blue light emitting materials of tri(8-hydroxyquinoline-5-sulfonate) aluminum complex anion intercalated hydrotalcite and a preparation method thereof, and belongs to the technical field of inorganic / organic composite luminescent materials. In the method, a surfactant of which the molecular length is similar to that of tri(8-hydroxyquinoline-5-sulfonate) aluminum complex anions is selected so as to obtain the composite luminescent material, dispersed uniformly among hydrotalcite layers, of the tri(8-hydroxyquinoline-5-sulfonate) aluminum complex anion intercalated hydrotalcite by a coprecipitation method. The method realizes the immobilization of the tri(8-hydroxyquinoline-5-sulfonate) aluminum complex anions, improves the heat stability of luminescent molecules of the metal complex and realizes the conversion from the green light luminescent material tri(8-hydroxyquinoline-5-sulfonate) aluminum to the blue light luminescent materials of hydrotalcite intercalated products thereof.

Owner:BEIJING UNIV OF CHEM TECH

Norbornene, octafluorocyclopentene and cyclohexene ternary polymerization catalyst and ternary polymerization method

The invention relates to a norbornene, octafluorocyclopentene and cyclohexene ternary polymerization catalyst and a ternary polymerization method. The catalyst is characterized in that a preparation method for the catalyst comprises the following steps: rhodium(I) tris(triphenylphosphine) chloride, alkyl aluminium and a ligand ompound are dissolved in a first solvent in a single-mouth glass bottle with the dry inert atmosphere, the bottle mouth is sealed through a latex tube, and heat preservation is carried out for 20-30 minutes at 20-30 DEG C, so as to obtain a rhodium-aluminum complex catalyst, wherein the mole ratio of rhodium(I) tris(triphenylphosphine) chloride to the ligand is (1:8)-(8:1). The catalyst provided by the invention is a novel rhodium-aluminum complex catalyst mixture, raw materials of the catalyst are cheap and accessible, norbornene, octafluorocyclopentene and cyclohexene ternary polymerization can be catalyzed since catalytic activity can be generated at lower temperature, the reaction temperature is low, catalytic efficiency is high, the product is easy to wash and separate, and the yield of the copolymer is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

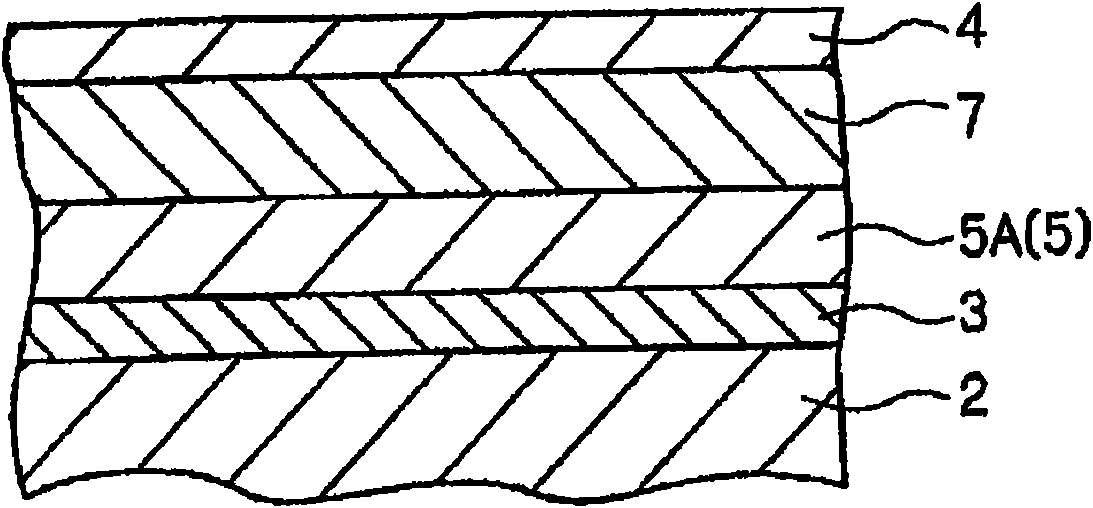

Light-emitting device

InactiveCN101810055AExpanded recombination areaImprove luminous efficiencyMaterial nanotechnologyElectroluminescent light sourcesQuantum dotElectron transporting layer

Owner:DAI NIPPON PRINTING CO LTD

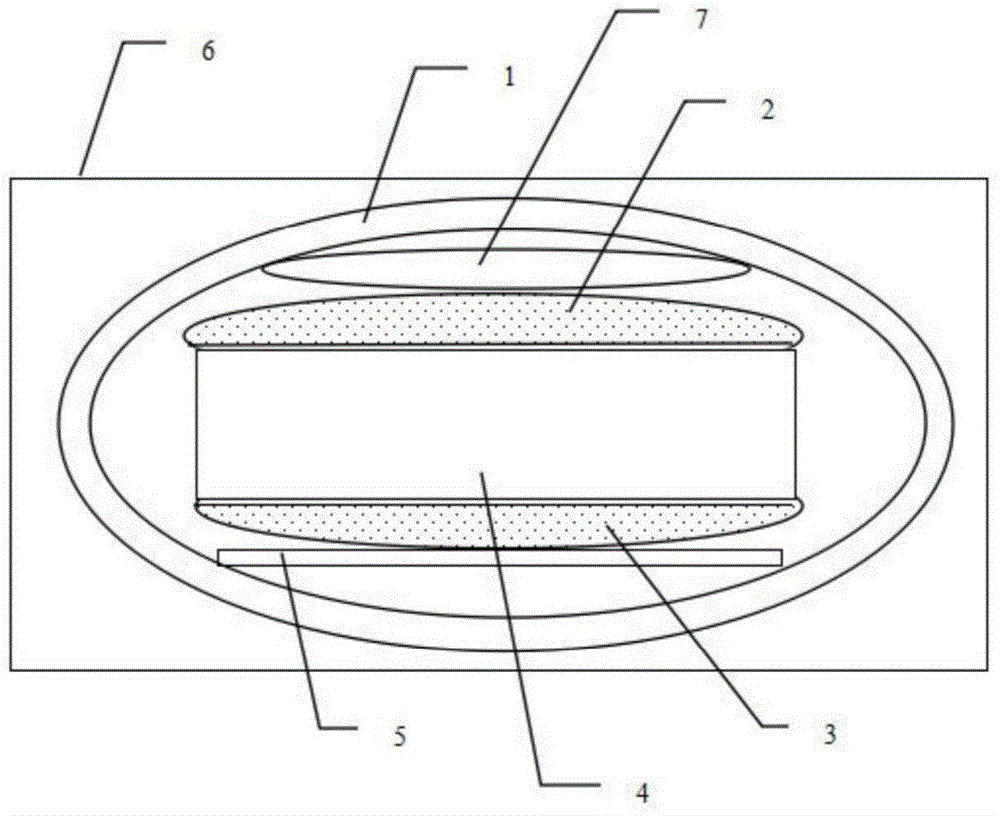

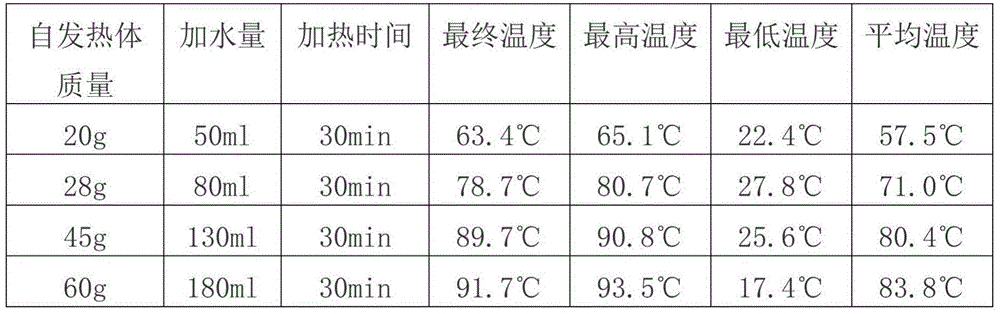

Self-heating disaster-proof emergency food package and heating method thereof

InactiveCN104555116AHeating fastImprove the heating effectContainers for heating foodPackaging foodstuffsEngineeringFood packaging

The invention discloses a self-heating disaster-proof emergency food package and a heating method thereof. The self-heating disaster-proof emergency food package comprises a heat-insulating shell and a self-heating bag, wherein the heat-insulating shell is made of aluminum complex foil pearl wool; the self-heating bag is prepared by arranging a self-heating element in a sealing bag; a mixture of calcium oxide and aluminum powder or magnesium powder serves as the self-heating element; the self-heating bag is wrapped in the heat-insulating shell; a water bag is also arranged in the heat-insulating shell; food with a sealing package is arranged in the heat-insulating shell. During a use process, two heating bags are taken out and are respectively placed on the two sides of the food with the sealing package and are put into the heat-insulating shell, the water bag with metering scales is opened, and then water, the mass of which is 2-3 times of the mass of the self-heating element, is poured onto the self-heating bag, the self-heating bag absorbs water, and then the longer side of the opening port of the heat-insulating shell is bent toward the shorter side so that the opening port of the heat-insulating shell is sealed, and then the sealing is kept for more than 15 minutes till reaching the proper temperature, so that the heating is finished.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

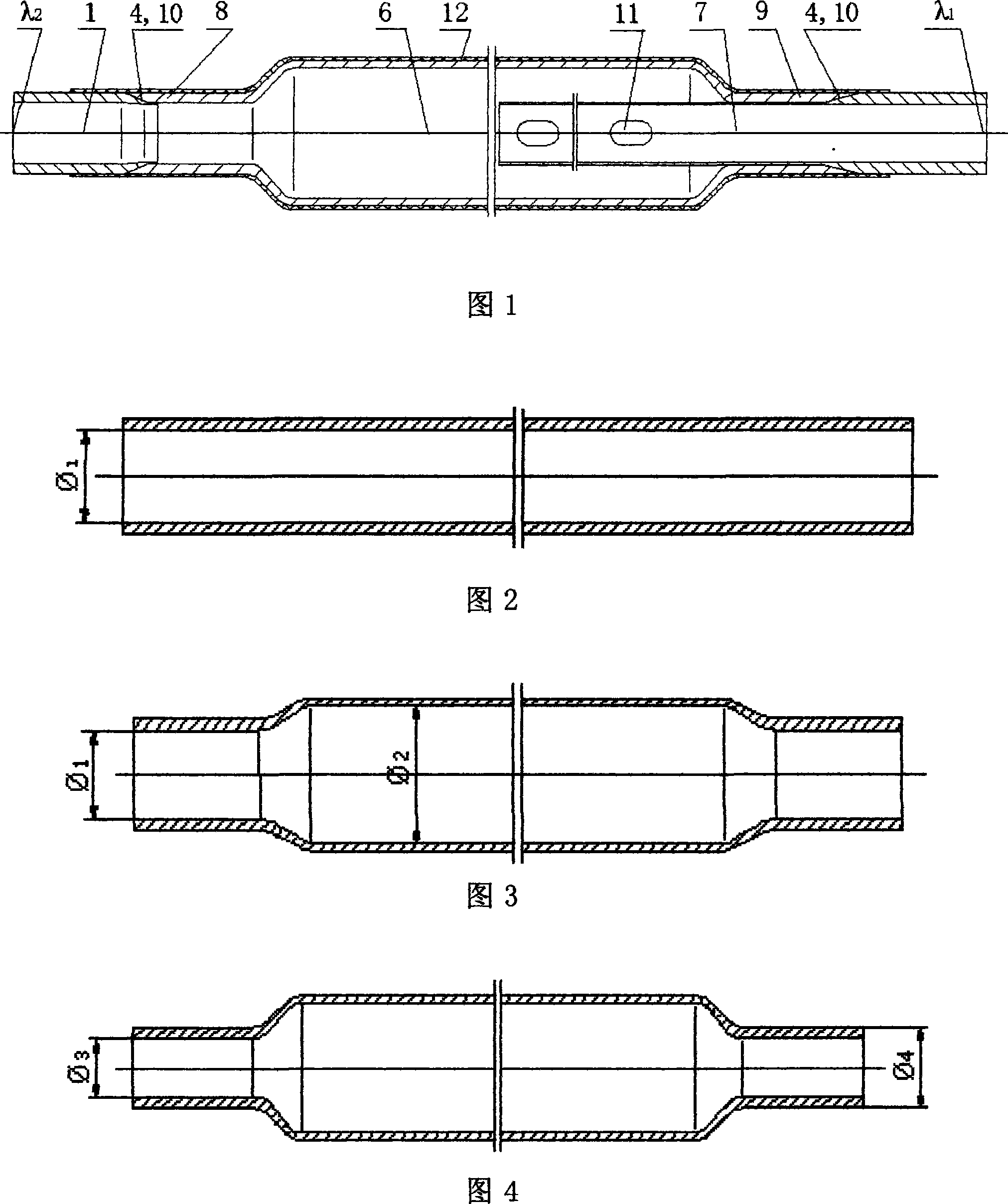

Method for preparing cuprum aluminum complex structure metallic can

InactiveCN101176961AReduce manufacturing costHigh compressive strengthResistance welding apparatusAluminum compositesMachining

The invention relates to a manufacture method for copper-aluminum composite structure metal cans, belonging to metal composite structure processing technology field, which comprises an aluminum tube, an inlet copper tube and an outlet copper tube joining together. The invention adopts the steps that: firstly, the middle part of the aluminum tube is squeezed by hydraulic pressure to an enlarged drum aluminum tube, which has invariant diameter on both ends and a raised middle part; secondly, one port of the inlet copper tube and the outlet copper tube is mechanically processed into a conical surface; finally, the conical surface port of the inlet copper tube and the outlet copper tube is inserted into the taper end of the drum aluminum tube. As the conical surface port is pressured into the taper end while being electrically heated, a fixed metallic bond joint of copper-aluminum tube is formed at the contacting segment.

Owner:赵越 +1

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413BNo pollution in the processImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

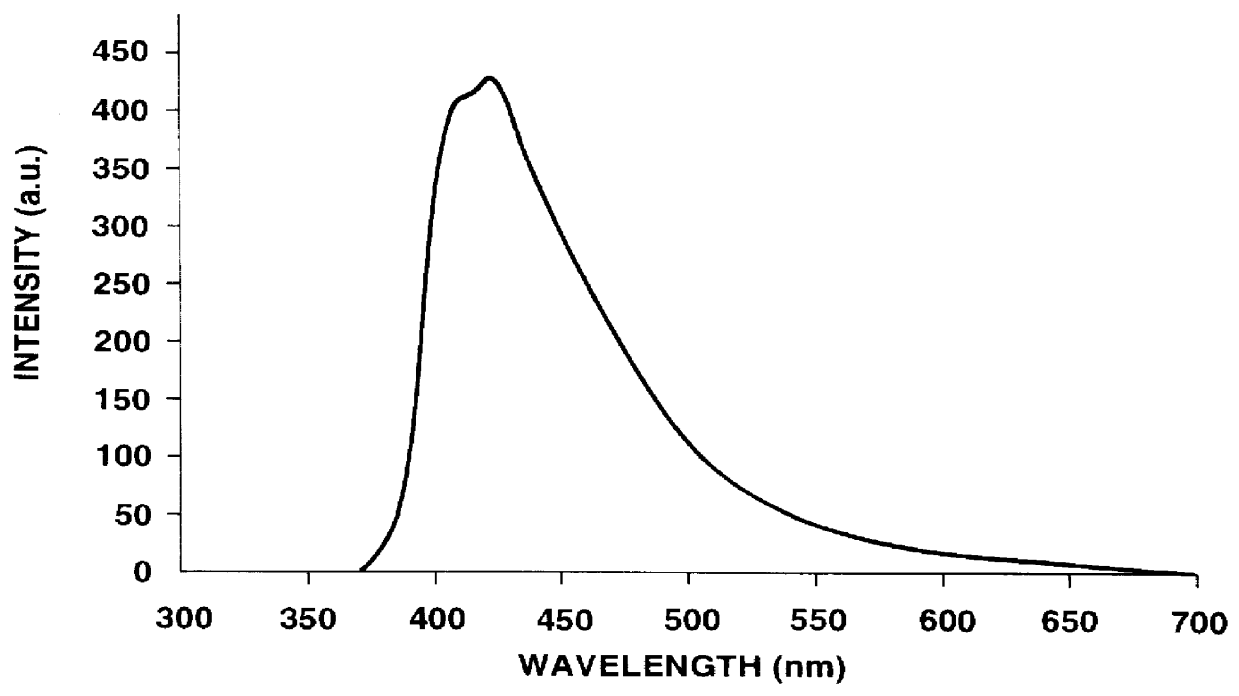

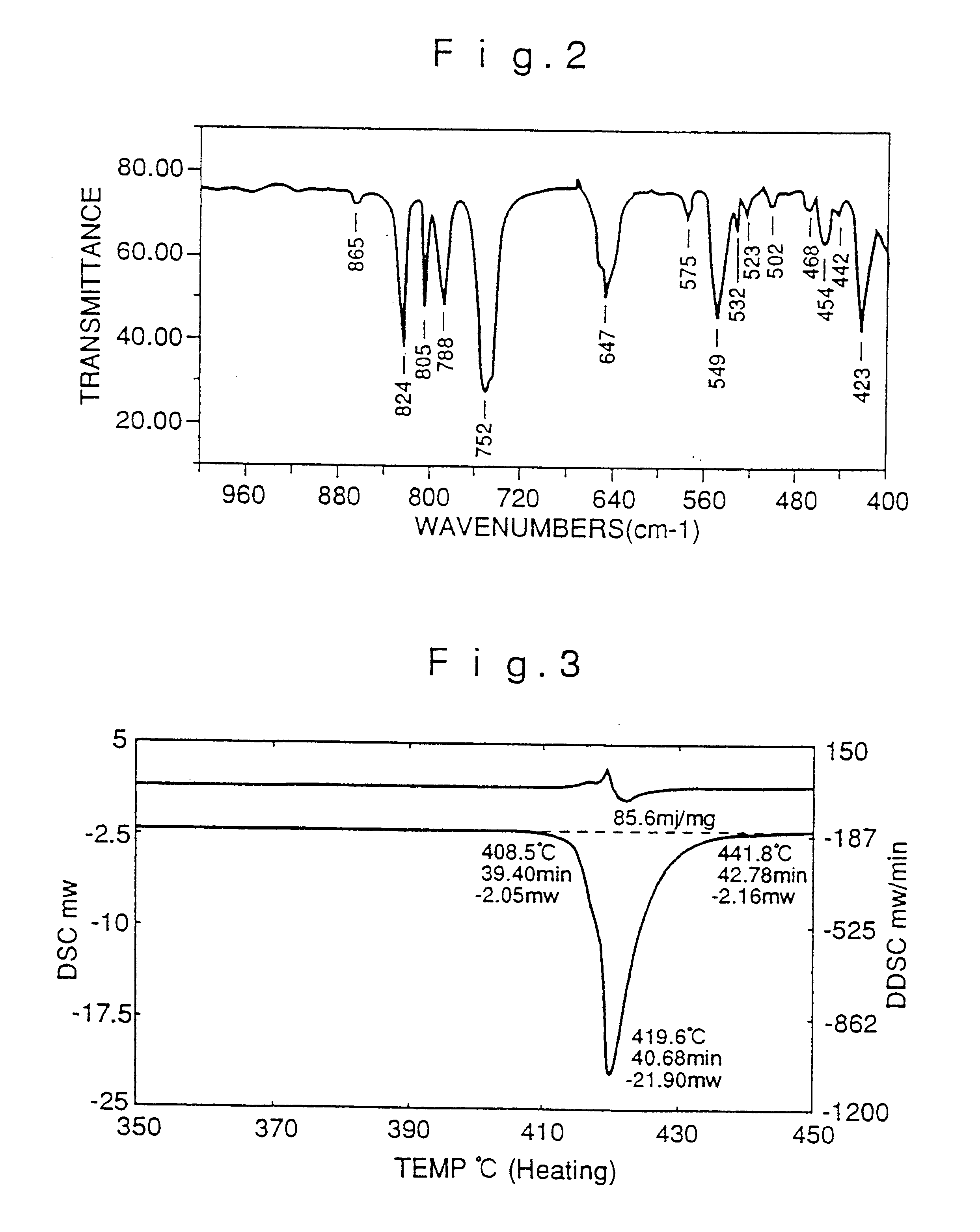

Organic el material

InactiveUS6583583B1Easy to detectQuality improvementStatic indicating devicesSolid-state devices8-HydroxyquinolineCoordination complex

This invention relates to an organic aluminum complex manifesting excellent performance when used in an organic EL device and to a process for preparing said complex. The organic EL material of this invention comprises an organoaluminum complex which generates heat of 2 J / g or less In the range of 350-400° C. and absorbs heat of 70-120 j / g, in the range of 400-450° C., with the maximum of an endothermic peak being located near 420° C. on analysis by differential scanning calorimetry. The organic EL material can be obtained by refining the raw material (8-quinolinolato)aluminum by sublimation under reduced pressure of 20 Torr or less while maintaining the temperature in the sublimation zone above 300° C. and below 420° C. and the temperature in the product recovery zone above 100° C. and below 250° C.

Owner:NIPPON STEEL CHEMICAL CO LTD

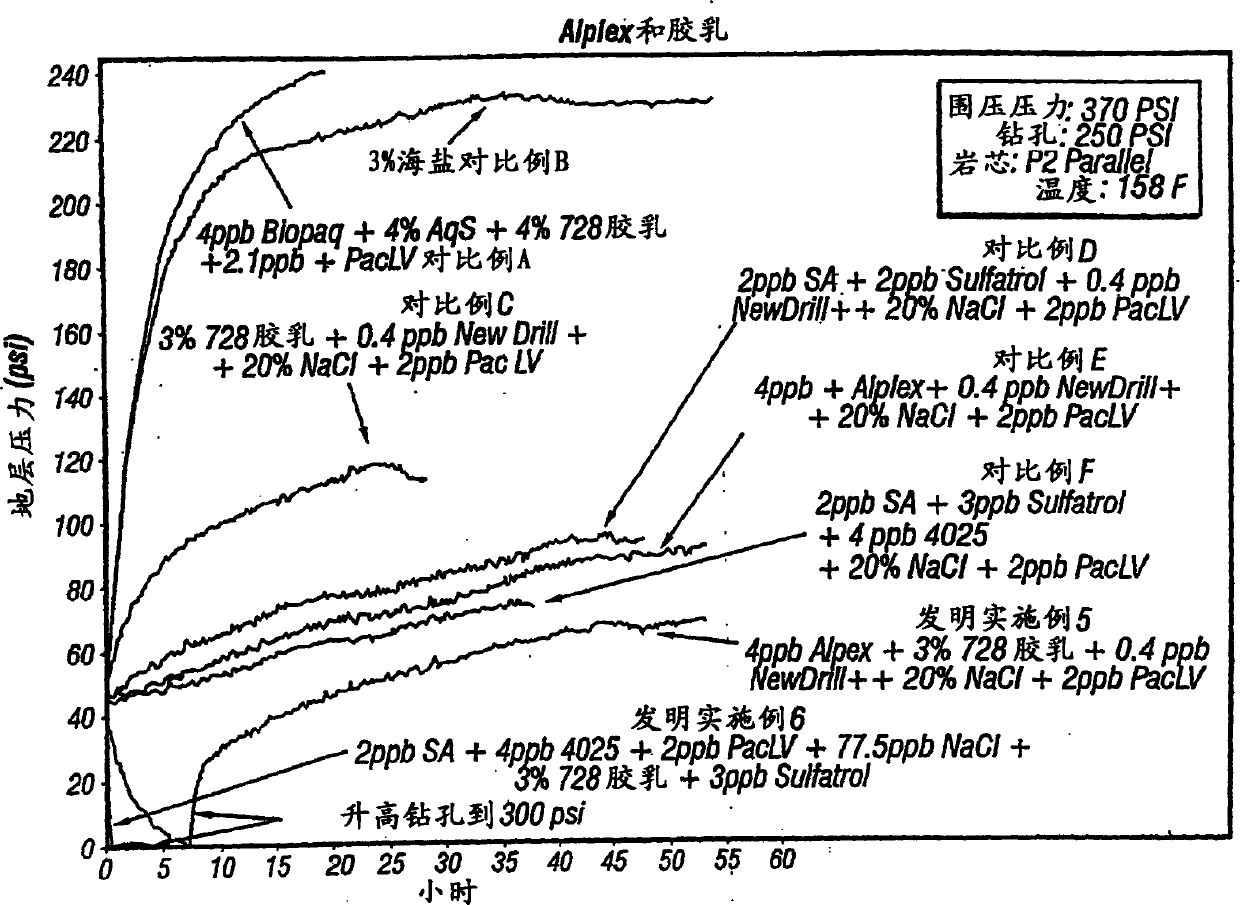

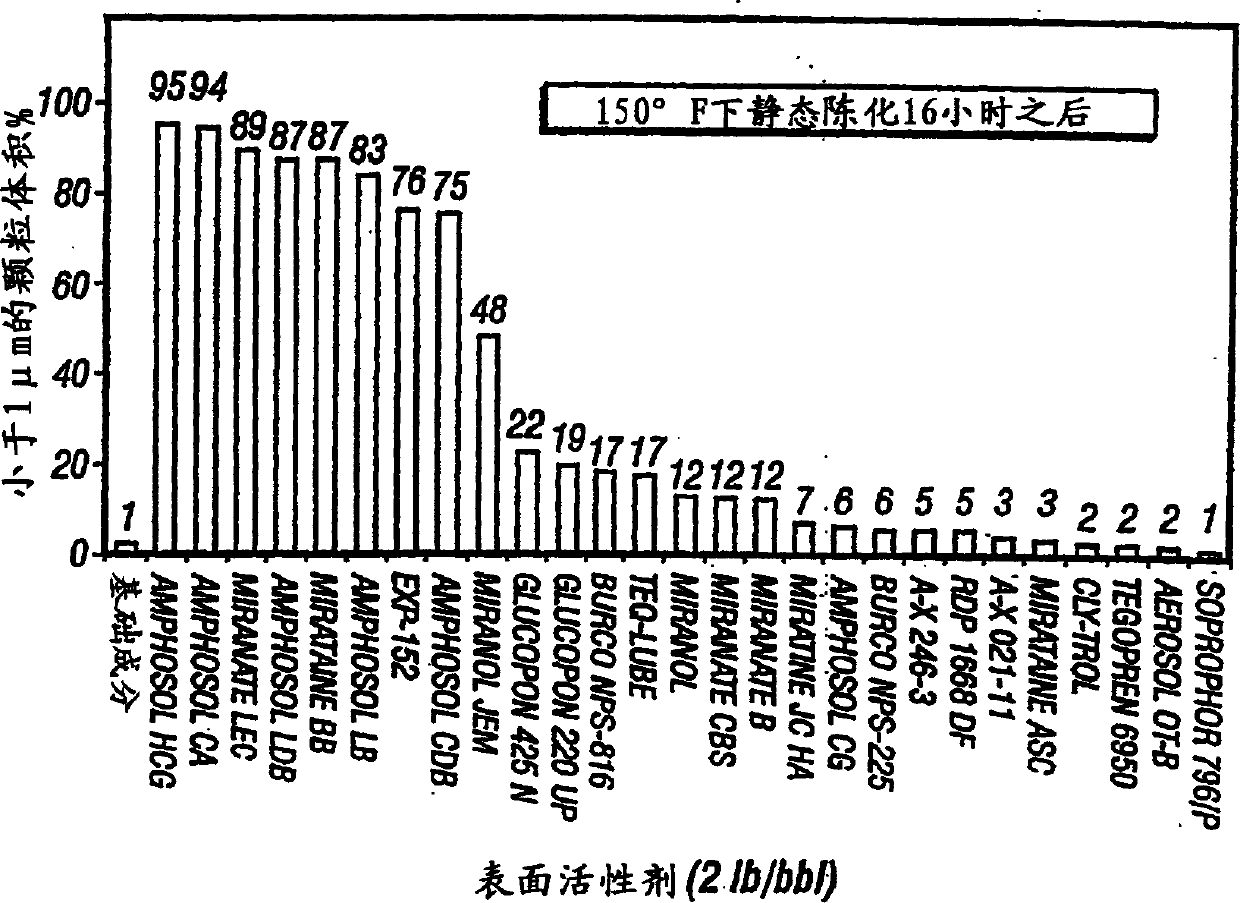

Water-based drilling fluids using latex additives

A water-based drilling fluid having a polymer latex capable of providing a deformable latex film on at least a portion of a subterranean formation has been discovered to provide reduced drilling fluid pressure invasion when used to drill in shale formations for hydrocarbon recovery operations. A precipitating agent such as a silicate or an aluminum complex (e.g. sodium aluminate) is preferably used in conjunction with the polymer. Typically, the water present contains a salt to form a brine, often to saturation, although the invention may be practiced with fresh water. If a salt is employed, it is often helpful to additionally employ a surfactant, such as a betaine, for example.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com