Nickel-cobalt lithium aluminate and preparation method of precursor thereof

A nickel-cobalt-aluminate, precursor technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult to fully exert performance, complex process, poor performance, etc., and achieve compact structure, low price, and low product cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

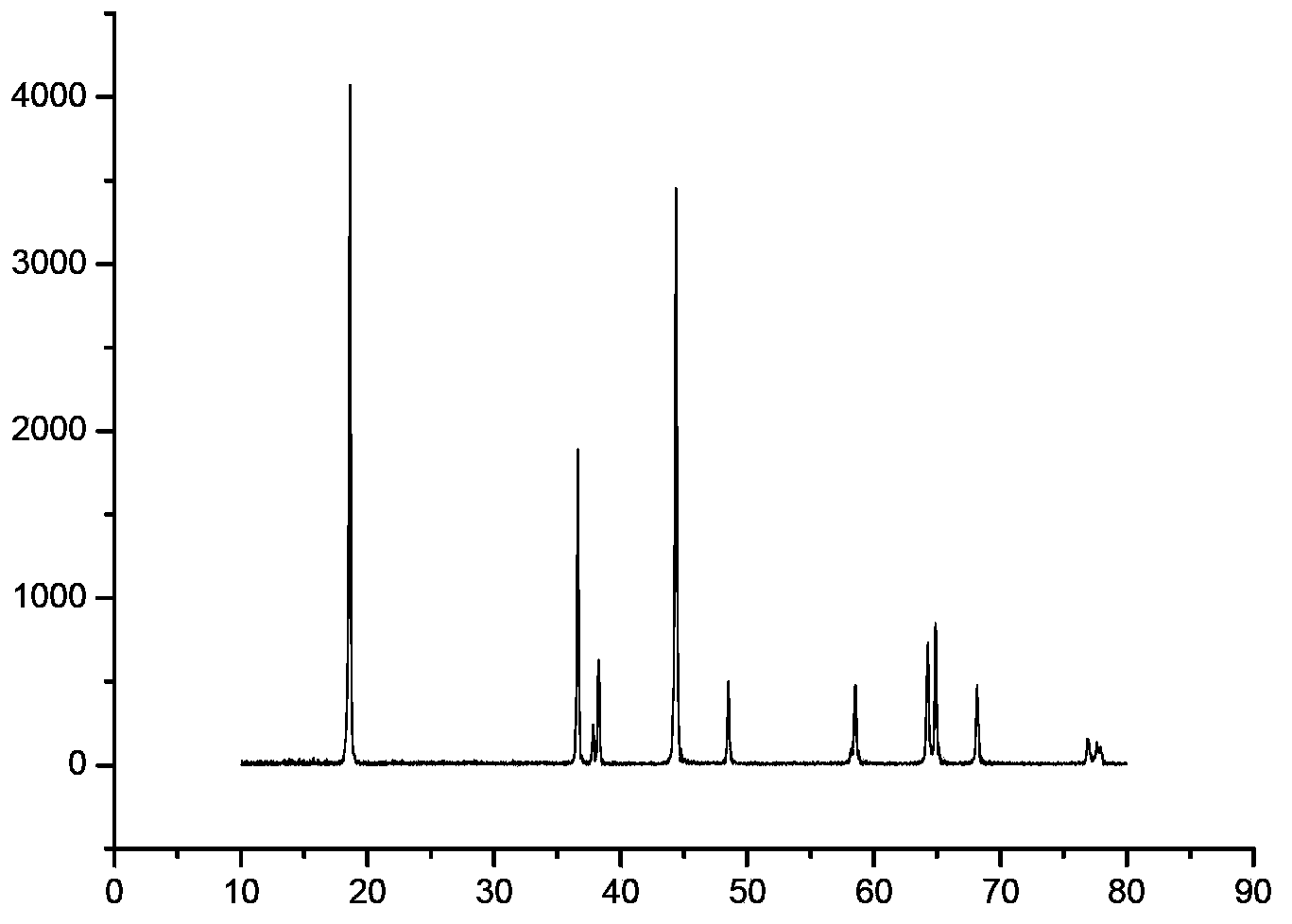

Image

Examples

Embodiment 1

[0023] Dissolve 3400g of nickel sulfate and 660g of cobalt sulfate in 8L of deionized water to form salt solution A; add 300g of aluminum nitrate and 300g of EDTA to 4L of deionized water and add sulfuric acid to adjust the pH to 3 to form salt solution B. The total molar ratio of nickel, cobalt, and aluminum ions contained in salt solution A and salt solution B is the same as the molar ratio of nickel-cobalt-aluminum in the nickel-cobalt-aluminate lithium to be prepared, which is 8:1.5:0.5, to ensure The ratio of the formed precursor nickel-cobalt-aluminum is consistent with the ratio of the required nickel-cobalt-lithium aluminate material at any time during the reaction process, and the composition of the material is uniform at any time; the concentration of the prepared 4L is 6M Sodium hydroxide solution, add ammonia water and mix to make the ammonia concentration in the mixed solution be 4M, as strong alkali solution C;

[0024] Add 4L of bottom solution to a 30L reaction...

Embodiment 2

[0028]3400g of nickel sulfate and 390g of cobalt acetate were dissolved in 8L of deionized water to form solution A, 274g of aluminum sulfate and 400g of tartaric acid were dissolved in 4L of deionized water, and sulfuric acid was added to adjust the pH=2 to form a salt solution B. The salt solution A and The total molar ratio of nickel, cobalt, and aluminum ions contained in the salt solution B is the same as the molar ratio of nickel, cobalt, and aluminum in the nickel-cobalt-aluminate lithium to be prepared, which is 8:1:1; prepare 8L of 10M Sodium hydroxide solution, add ammonia water and mix evenly to make the ammonia concentration in the mixed solution 1M, as strong alkali solution C;

[0029] Add 4L of bottom liquid into a 30L reaction kettle, after heating to 50°C, control the flow rate of salt solution A and salt solution B at 0.4L / h, and add salt solution A and salt solution B into the reaction kettle together , at the same time, open the pipeline leading into the st...

Embodiment 3

[0034] Dissolve 3291g of nickel chloride and 770g of cobalt sulfate in 8L of deionized water to form solution A, dissolve 266.7g of aluminum chloride and 1140g of sulfosalicylic acid in 8L of deionized water, add sulfuric acid to adjust the pH to 3, and then form the solution into a salt Solution B, the total molar ratio of nickel, cobalt, and aluminum ions contained in the salt solution A and salt solution B is the same as the molar ratio of nickel-cobalt-aluminum in the nickel-cobalt-aluminate lithium that needs to be prepared, both are 7:1.75 : 1.25; preparation 8L concentration is the sodium hydroxide solution of 2M, after adding ammoniacal liquor and mixing, make the ammonia concentration in the mixed solution be 8M, as strong alkali solution C;

[0035] Add 4L of bottom solution into the 30L reactor, heat it to 50°C, control the flow rate of salt solution A and B at 0.3L / h and add salt solution A and B together, and open the alkali solution at the same time to adjust the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com