Patents

Literature

1231 results about "Aluminum nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

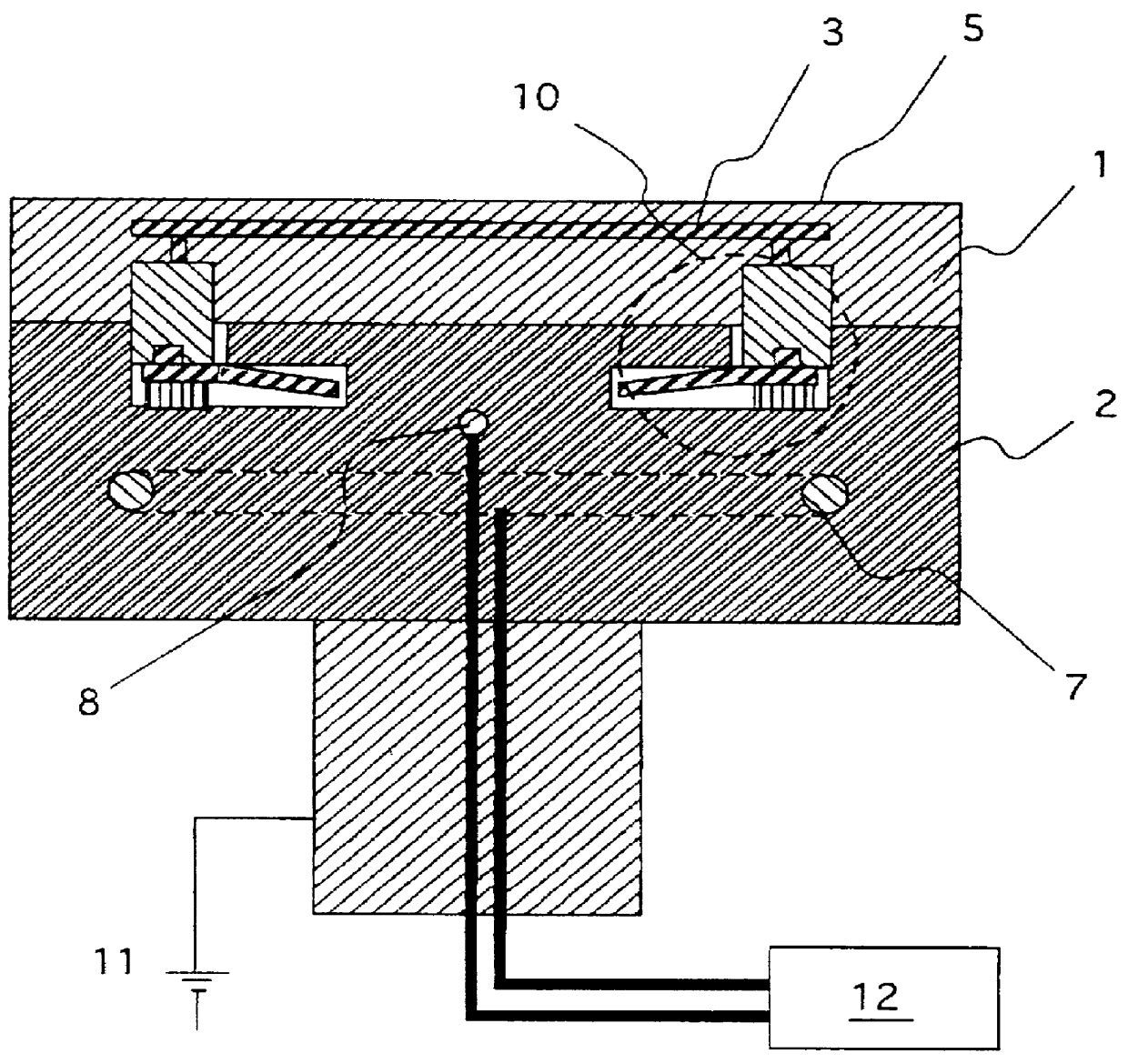

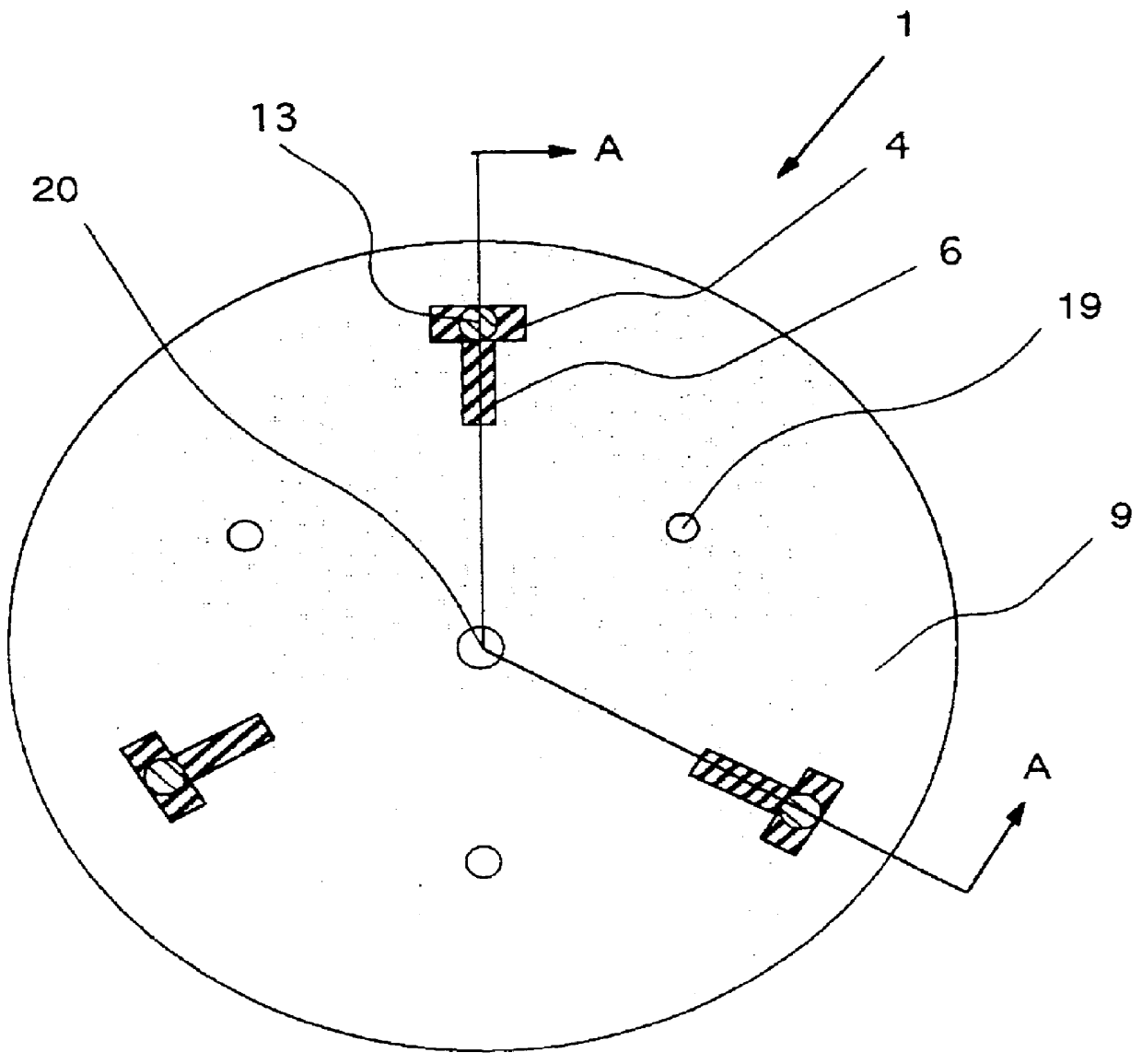

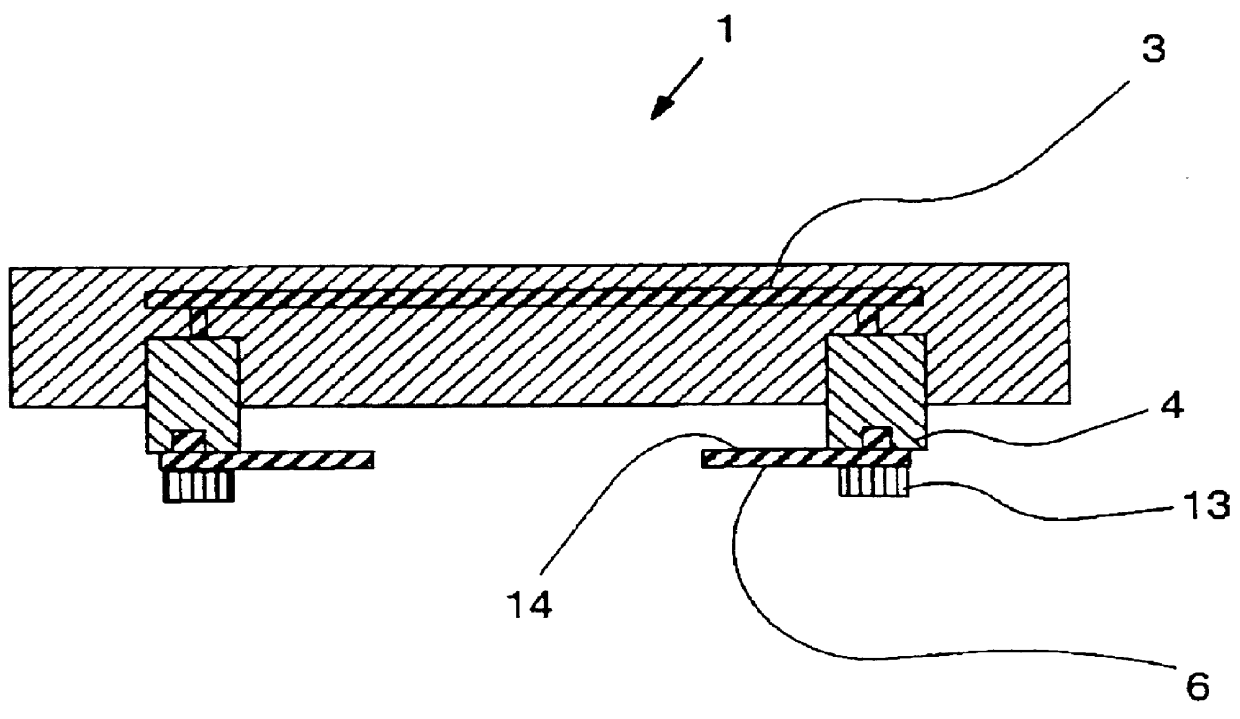

Substrate holding apparatus for processing semiconductor

InactiveUS6159301AEasy to cleanEasy to replaceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAlloySemiconductor

A substrate-holding apparatus for holding a semiconductor substrate in a semiconductor processor is characterized in that the apparatus includes a mount block made of, e.g., aluminum nitrate with a high-frequency electrode embedded therein and a heating block made of, e.g., an aluminum alloy with a heating body embedded therein. The mount block is tightly attached to the heating block by engaging the bottom surface of the mount block with the top surface of the heating block, for example, by using a latching mechanism.

Owner:ASM JAPAN +1

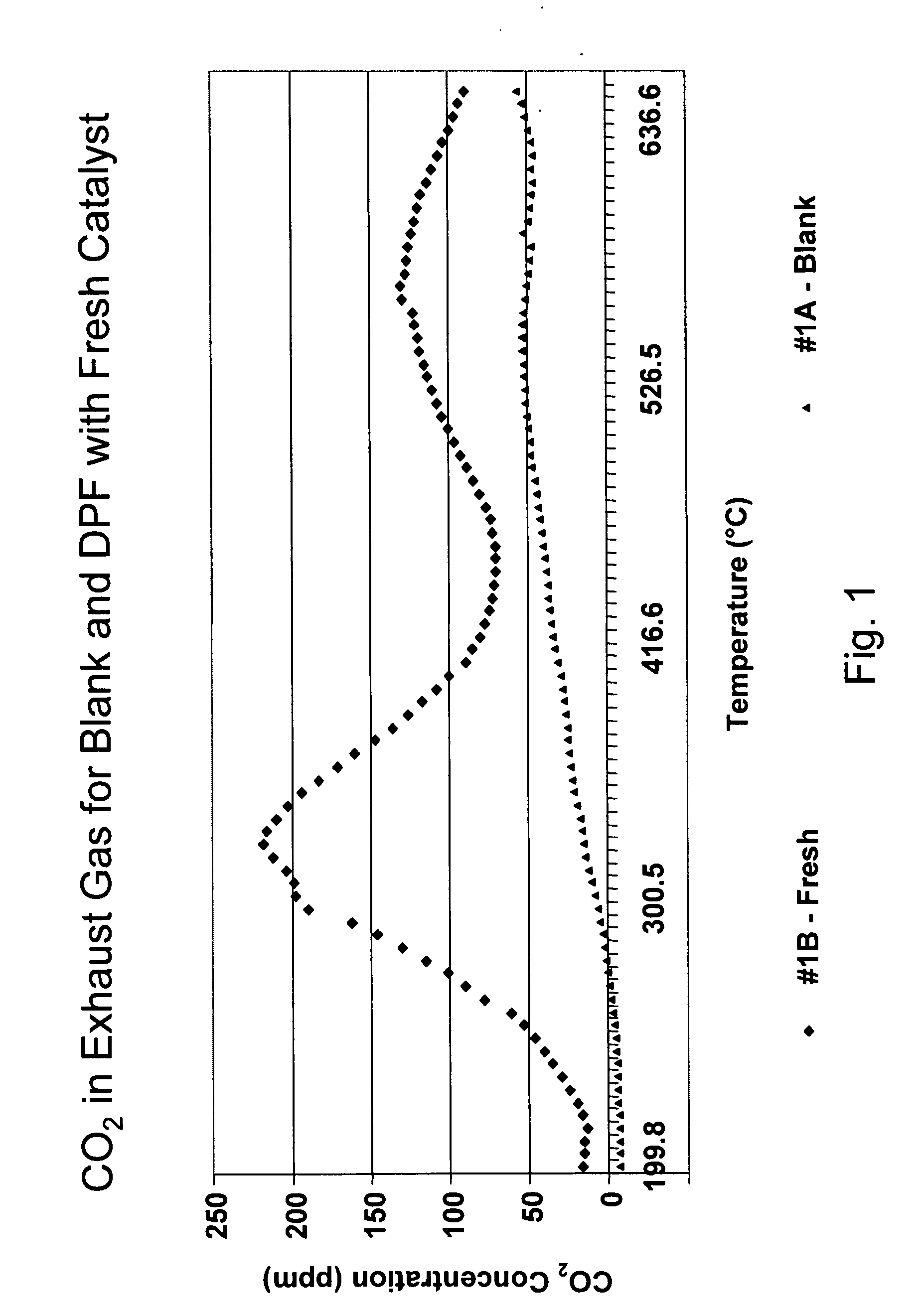

Platinum group metal-free catalysts for reducing the ignition temperature of particulates on a diesel particulate filter

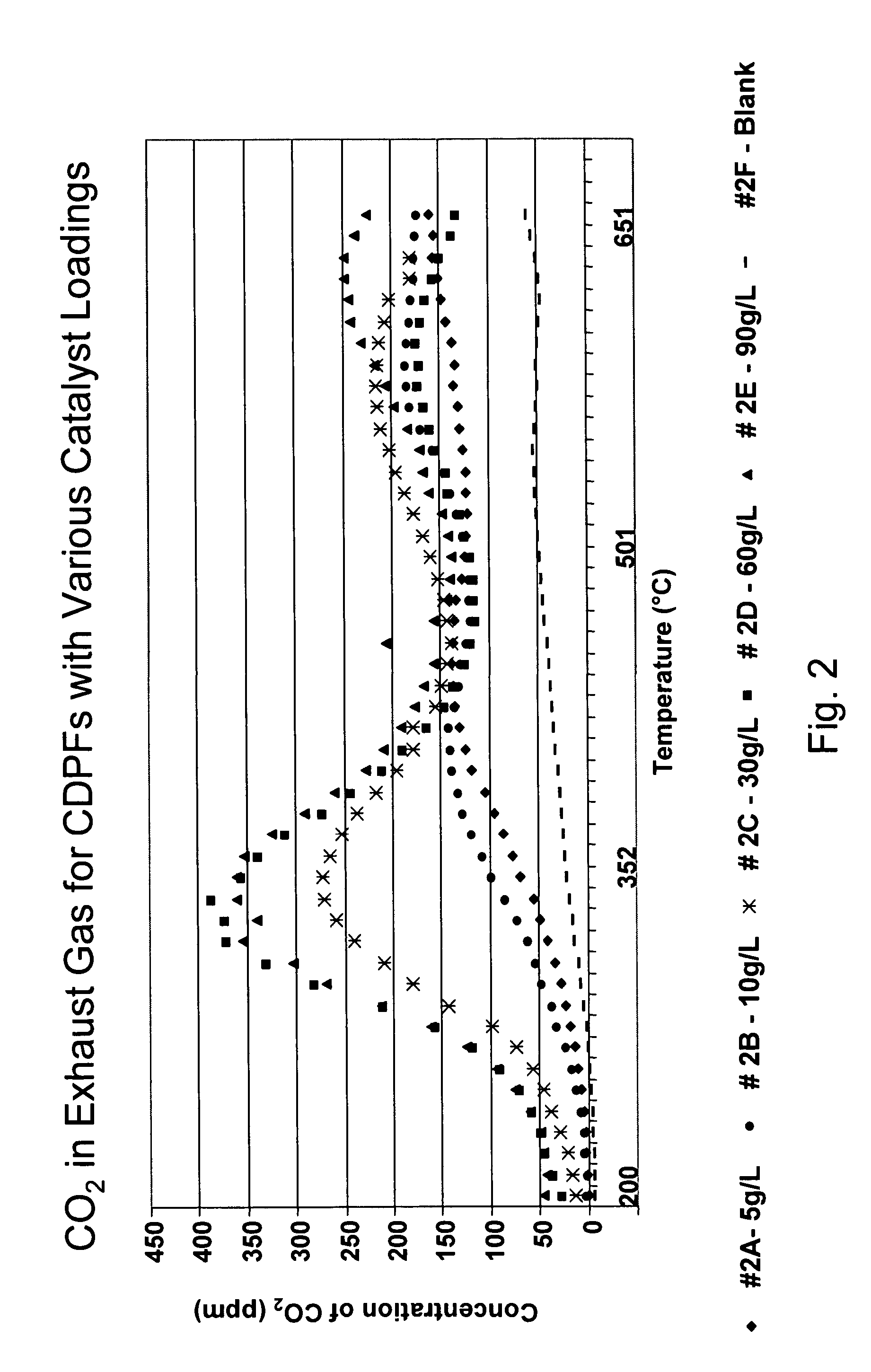

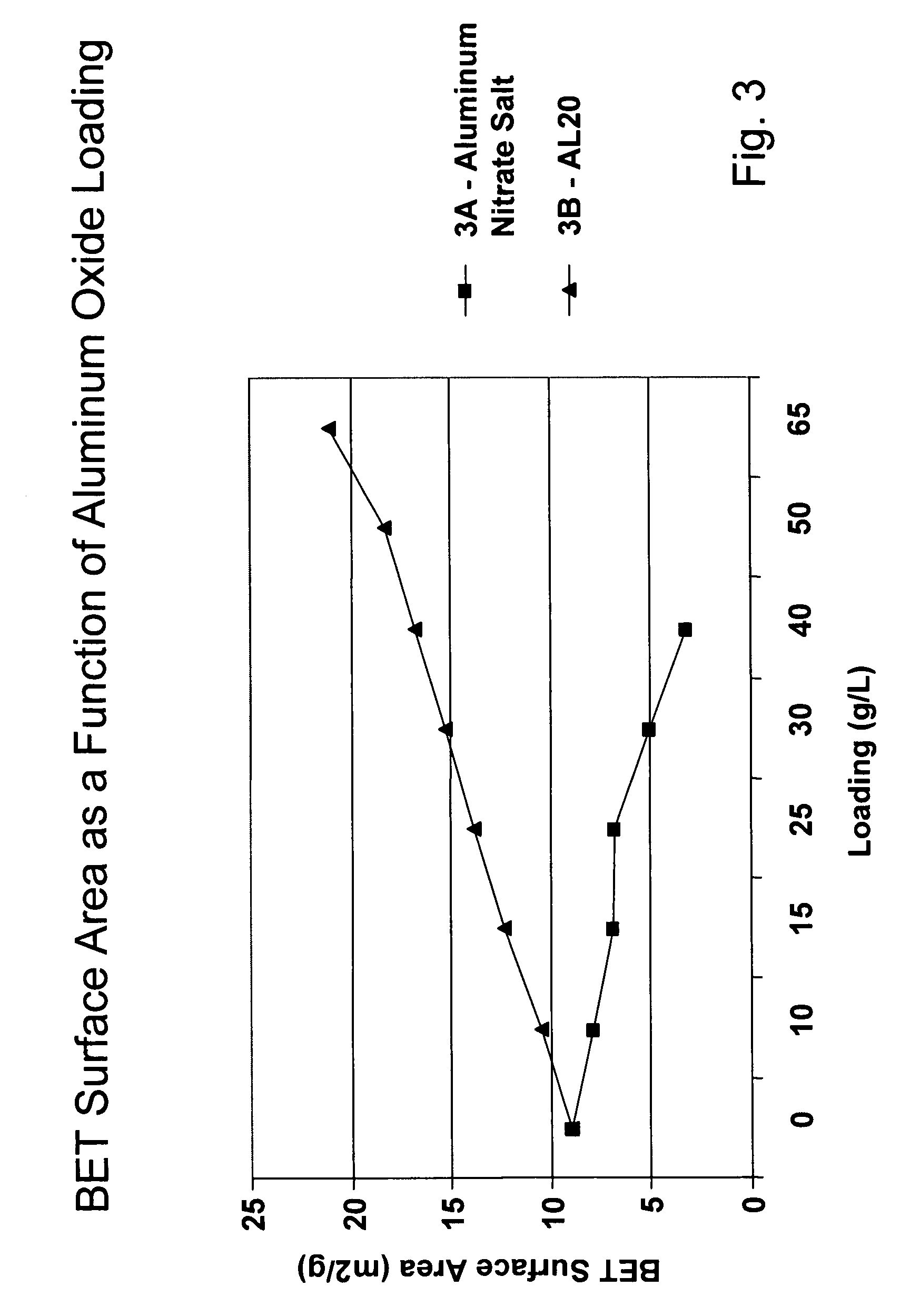

A catalyzed diesel particulate filter (CDPF) and a method for filtering particulates from diesel engine exhaust are provided, where the catalyzed diesel particulate filter includes a substrate and a catalyst composition, where the catalyst composition contains at least one first component, at least one second component, and at least one third component, where the first component is at least one first component selected from the group consisting of cerium and a lanthanide and mixtures thereof, the at least one second component is selected from the group consisting of cobalt, copper, manganese and mixtures thereof; and the third component comprises strontium, where the first component, the second component, and the third component are in an oxide form after calcination. The catalyst on the catalyzed diesel particulate filter lowers the temperature at which particulates are removed from the CDPF by oxidizing the particulates on the filter. The catalyzed diesel particulate filter may also include a washcoat. Washcoats prepared from colloidal aluminum oxide may have higher surface areas and pore volumes loadings than washcoats containing aluminum oxide prepared from aluminum nitrate.

Owner:CATALYTIC SOLUTIONS INC

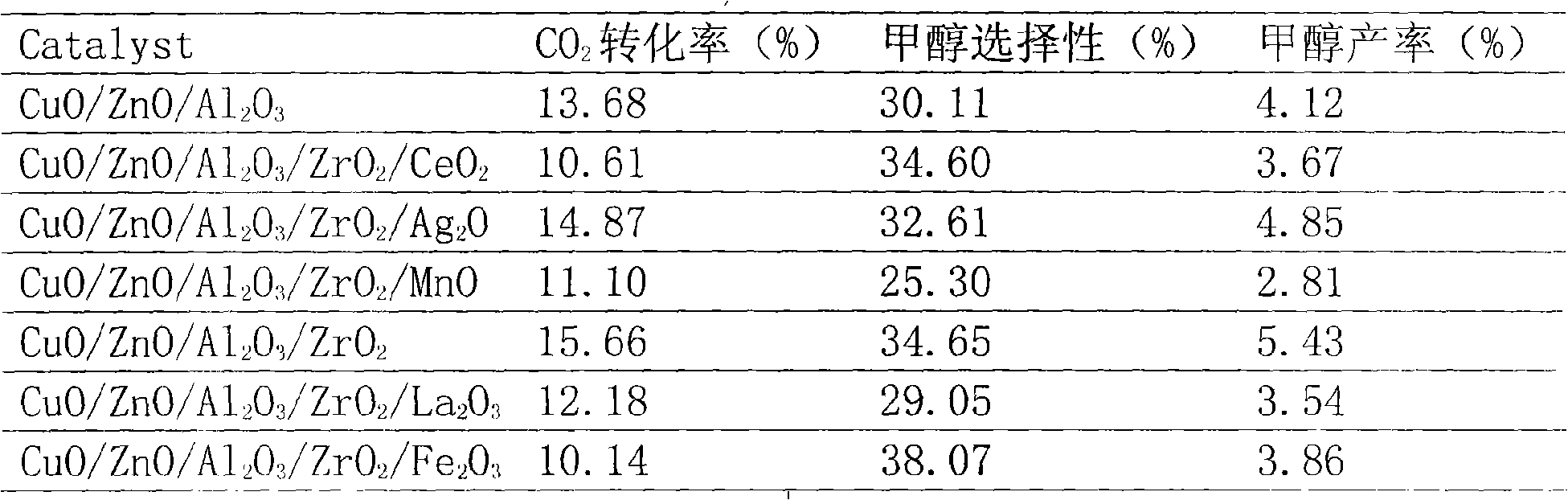

Carbon dioxide-synthesized methanol catalyst and preparation method thereof

ActiveCN101513615AImprove conversion rateHigh activityOrganic compound preparationHydroxy compound preparationCopperZinc

A carbon dioxide-synthesized methanol catalyst and a preparation method thereof are disclosed, belonging to the technical field of catalyst. The invention is characterized in that the carbon dioxide-synthesized methanol catalyst has the molar ratio of components of Ci to Zn to Al to Zr to M being 45 to 45 to 10 to 5 to 2, wherein M is MnO, CeO2, Ag2O, Fe2O3, La2O3, and is prepared by stepped co-deposition. The preparation steps are that: (1) a mixed liquid of aluminum nitrate solution and zirconium nitrate solution is in concurrent flow and co-deposition with carbonate solution to prepare a carrier precursor; (2) copper-zinc M mixed nitrate is in concurrent flow and co-deposition with the carbonate solution and added into (1), and then the synthesized methanol catalyst is prepared by aging, filtering, drying and roasting. The inventive effect and benefit are that the prepared catalyst is excellent in activity and thermal resistance and can effectively decompose carbon dioxide with high one-step conversion rate, therefore, the invention provides an effective catalyst for synthesizing methanol by hydrogenising the carbon dioxide.

Owner:DALIAN UNIV OF TECH

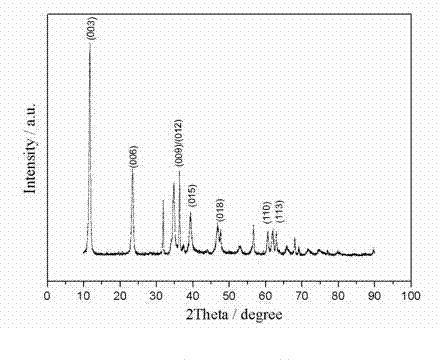

Preparation method for photocatalytic material with strong adsorption and high visible light degradation of performance

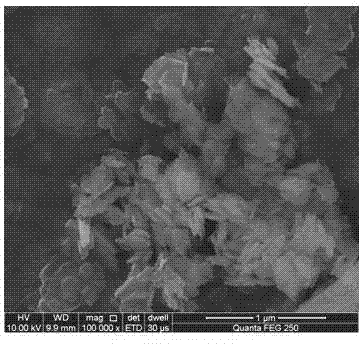

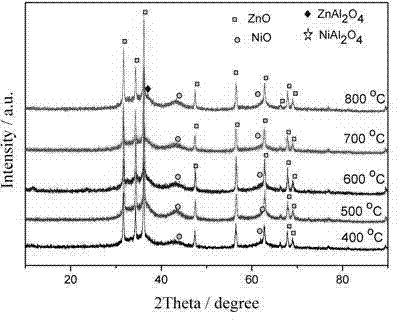

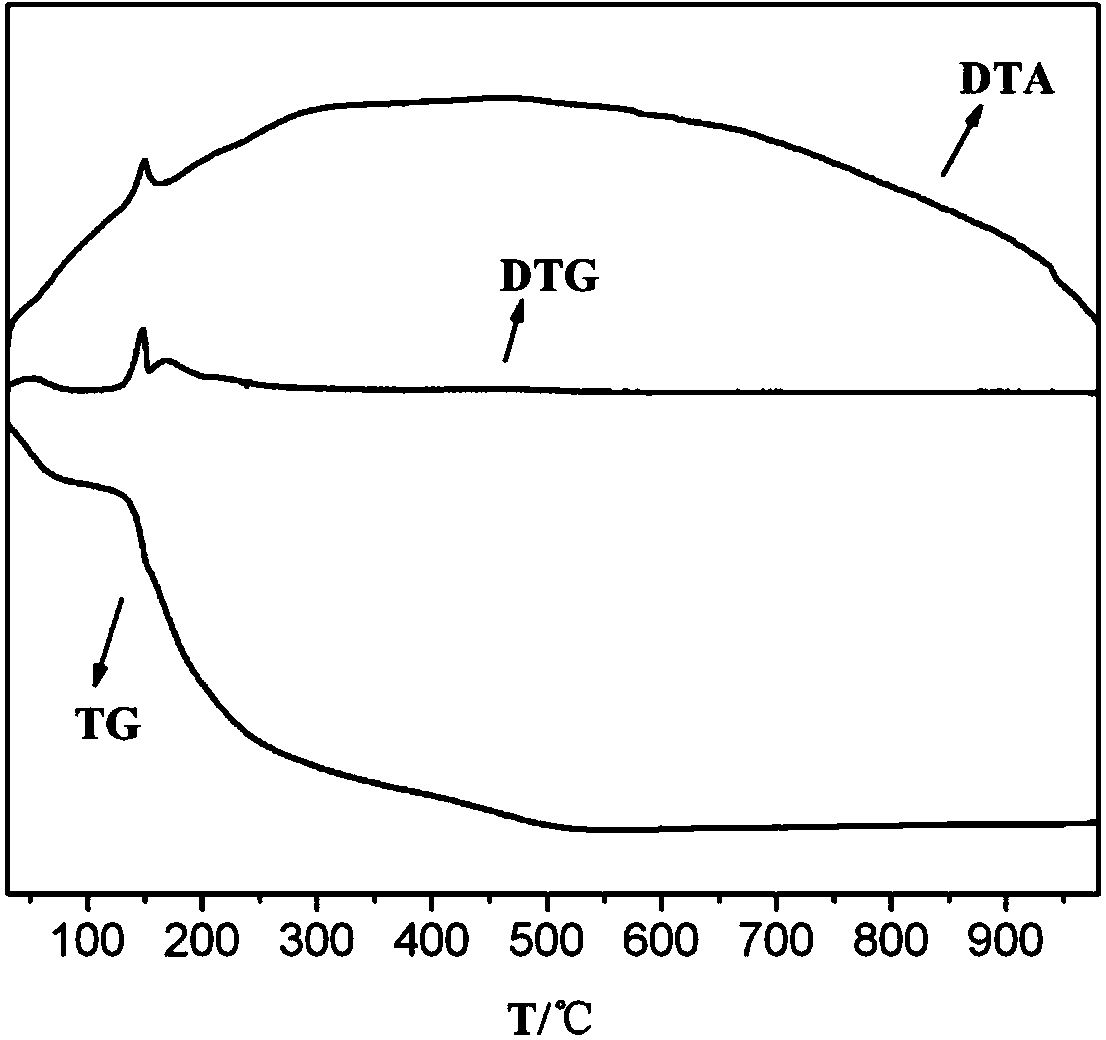

The invention discloses a gahnitem, zinc oxide and nickel zinc nano-composite photocatalytic material which has a high specific surface area and a mesoporous structure and is prepared by roasting at high temperature by taking ternary hydrotalcite as a precursor. The material is used for the adsorption and the degradation of organic pollutants. The photocatalytic material is prepared by taking zinc nitrate, nickel nitrate, aluminum nitrate, sodium carbonate, sodium hydroxide and the like as raw materials; preparing the raw materials into salt solutions and alkali solutions respectively; mixing the solutions by using a constant-flow pump at the temperature of 80 DEGC with magnetic stirring, transferring the mixed solution into a hydrothermal reaction kettle; performing hydrothermal treatment at 130 to 180 DEG C; performing suction filtration, washing and drying to the precursor; roasting the precursor in Muffle furnace for 2 to 6 hours at the temperature of 400 to 600 DEG C to obtain the product, wherein the specific surface area is greater than 150 m<2>.g<-1>. The photocatalyst disclosed by the invention has regular shape, large specific surface area, and super-high capacity for adsorbing and degrading organics, and can be reused; the raw materials for preparing the composite photocatalyst are abundant, the cost is low, and the process is simple.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

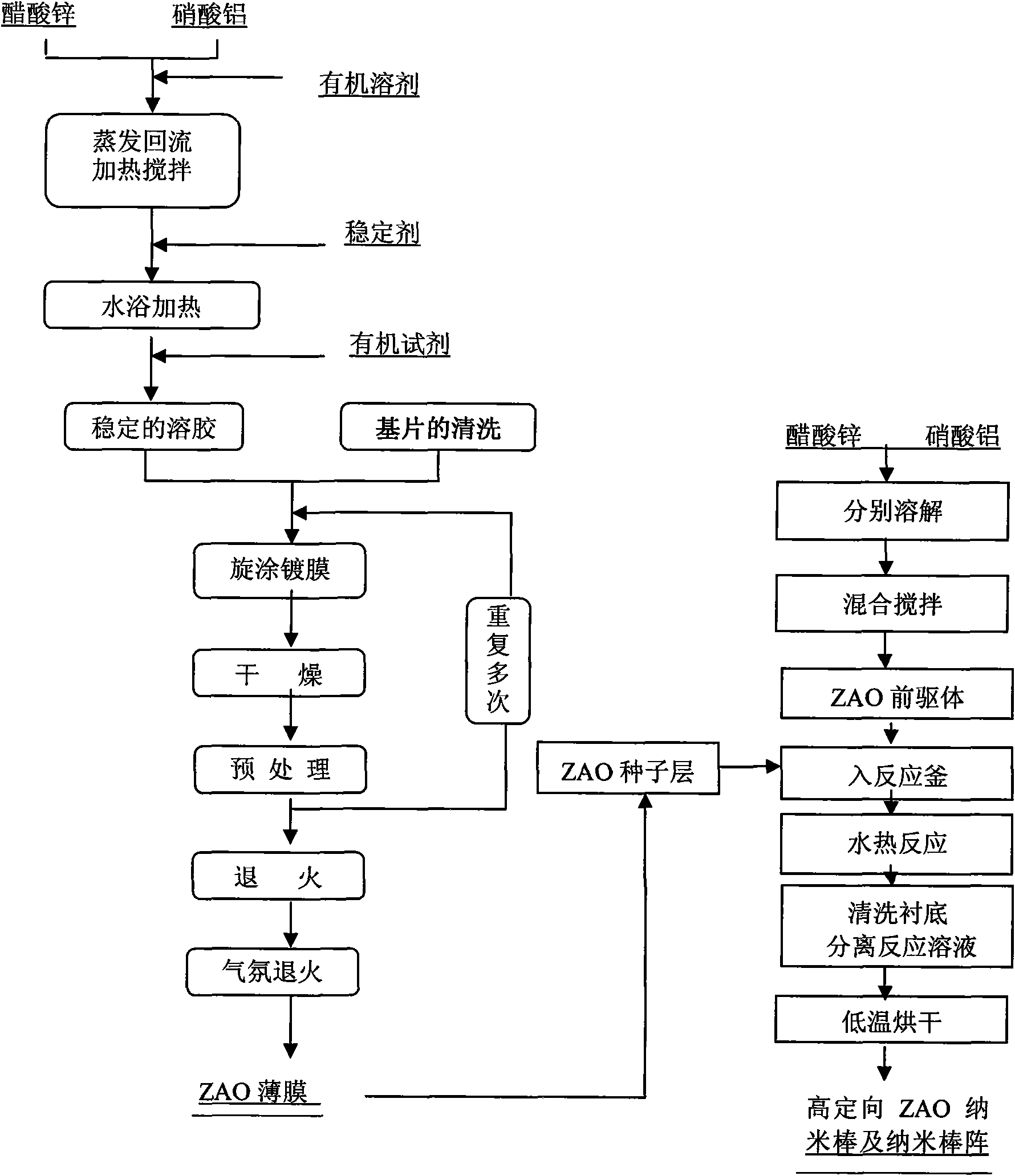

Aluminum-doped zinc oxide film coating and nano-rod array material as well as preparation method thereof

InactiveCN101560059ALow resistivityHigh light transmittanceNanostructure manufactureZinc Acetate DihydrateSol-gel

The invention discloses an aluminum-doped zinc oxide film coating and nano-rod array material as well as a preparation method thereof. The aluminum-doped zinc oxide film coating and nano-rod array material comprises the components based on the weight percentage: 95-99% of zinc oxide and 1-5% of aluminum-doped quantity. The preparation method adopts a sol-gel method, zinc acetate and aluminium nitrate are added with organic solvent according to the proportion for heating under reflux; the mixed solution is then added with certain quantity of stabilizing agent for water bath heating at certain temperature and added with organic reagents such as absolute ethyl alcohol, methanamide or methanol and the like to prepare sol according to the need; after that, a spin coating method is adopted to form a film, and the aluminum-doped zinc oxide nano film coating material can be obtained by the processes such as drying, pretreating, repeatedly spin coating, annealing, secondary annealing under the atmosphere of hydrogen and nitrogen and the like; then, a hydrothermal method is adopted for preparing highly oriented aluminum-doped zinc oxide nano-rod and array thereof. The invention has high utilization rate of the raw materials, low cost and simplified preparation technique, and can control the performance and the particle size of the material from the molecular design level.

Owner:CENT SOUTH UNIV

Process for preparing fraction oil hydrogenation treatmnt catalyst

InactiveCN1458232APromote formationModulation of surface propertiesHydrocarbon oils refiningDistillates petroleumActive component

The preparation process of fraction oil hydrogenation treatment catalyst includes assistant adding modification of gamma-alumina precursor and subsequent conventional preparation process. The fraction oil hydrogenation treatment catalyst includes gamma-alumina precursoe prepared through carbonation process, aluminum nitrate process, aluminum sulfate process or aluminum chloride process; F an / or Bas assistant and W and Ni as active component. Compared with available technology, the present invention has the advantages of simple preparation process, low cost, low power consumption, and excellent catalyst performance. The catalyst of the present invention is suitable for hydrogenation treatment of 130-390 deg.c fraction oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

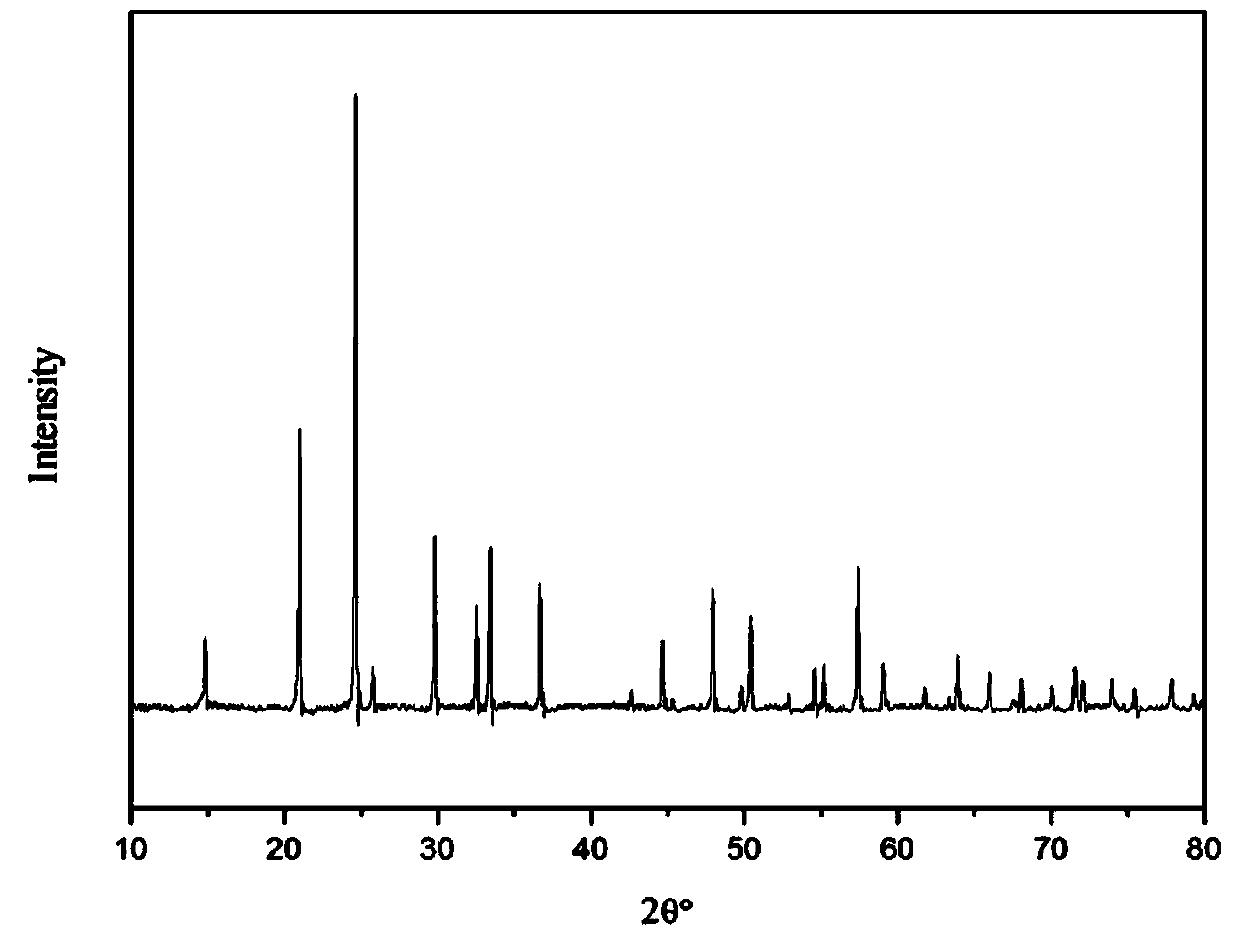

Preparation method of NASICON-type lithium ion solid electrolyte

ActiveCN103825052AOvercome purityOvercome the cycleFinal product manufactureElectrolyte accumulators manufactureSaturated aqueous solutionElectrolyte

The invention discloses a preparation method of an NASICON-type lithium ion solid electrolyte. The method comprises the following steps: dissolving lithium nitrate and aluminum nitrate in a citric acid solution, and stirring to form a transparent and uniform nitrate mixed solution; dissolving tetrabutyl titanate in anhydrous ethanol, and stirring to form an alcoholic solution of tetrabutyl titanate; slowly adding the alcoholic solution of tetrabutyl titanate to the nitrate mixed solution, and stirring to a transparent mixed solution; dissolving ammonium biphosphate in water to obtain a saturated aqueous solution of ammonium biphosphate, adding the saturated aqueous solution of ammonium biphosphate to the transparent mixed solution in a dropwise manner, and stirring to obtain an emulsion; adjusting the pH value of the emulsion, and drying the emulsion to obtain an xerogel; carrying out heat treatment of the xerogel, and grinding the obtained xerogel to form fine powder which is precursor powder; and compacting the precursor powder to form a green body, and sintering to obtain NASICON-type lithium ion solid electrolyte slices. The method has the advantages of low energy consumption, simplicity, easy implementation, and convenience for large-scale industrialized production, and the obtained solid electrolyte has a high conductivity.

Owner:HUAZHONG UNIV OF SCI & TECH

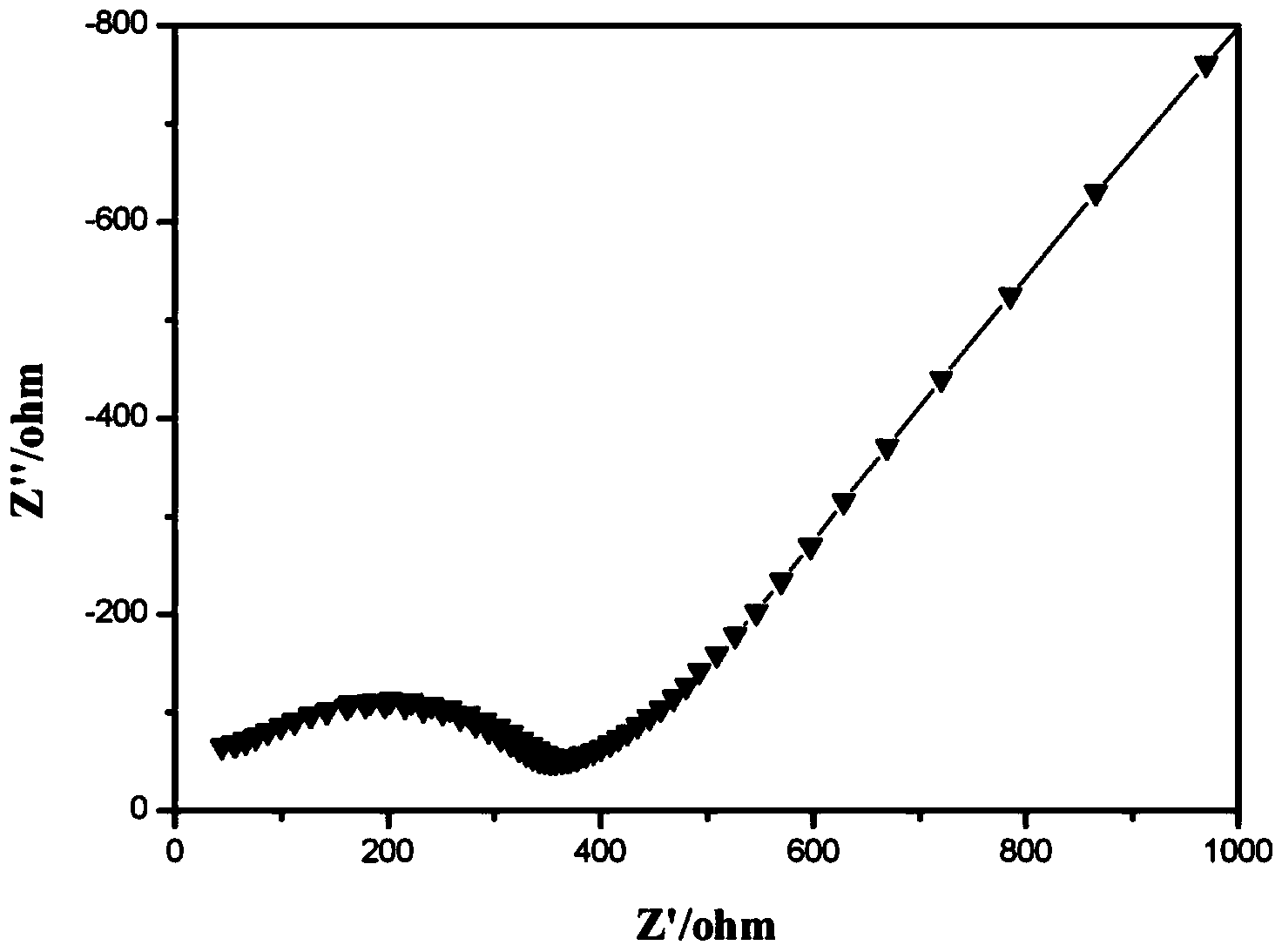

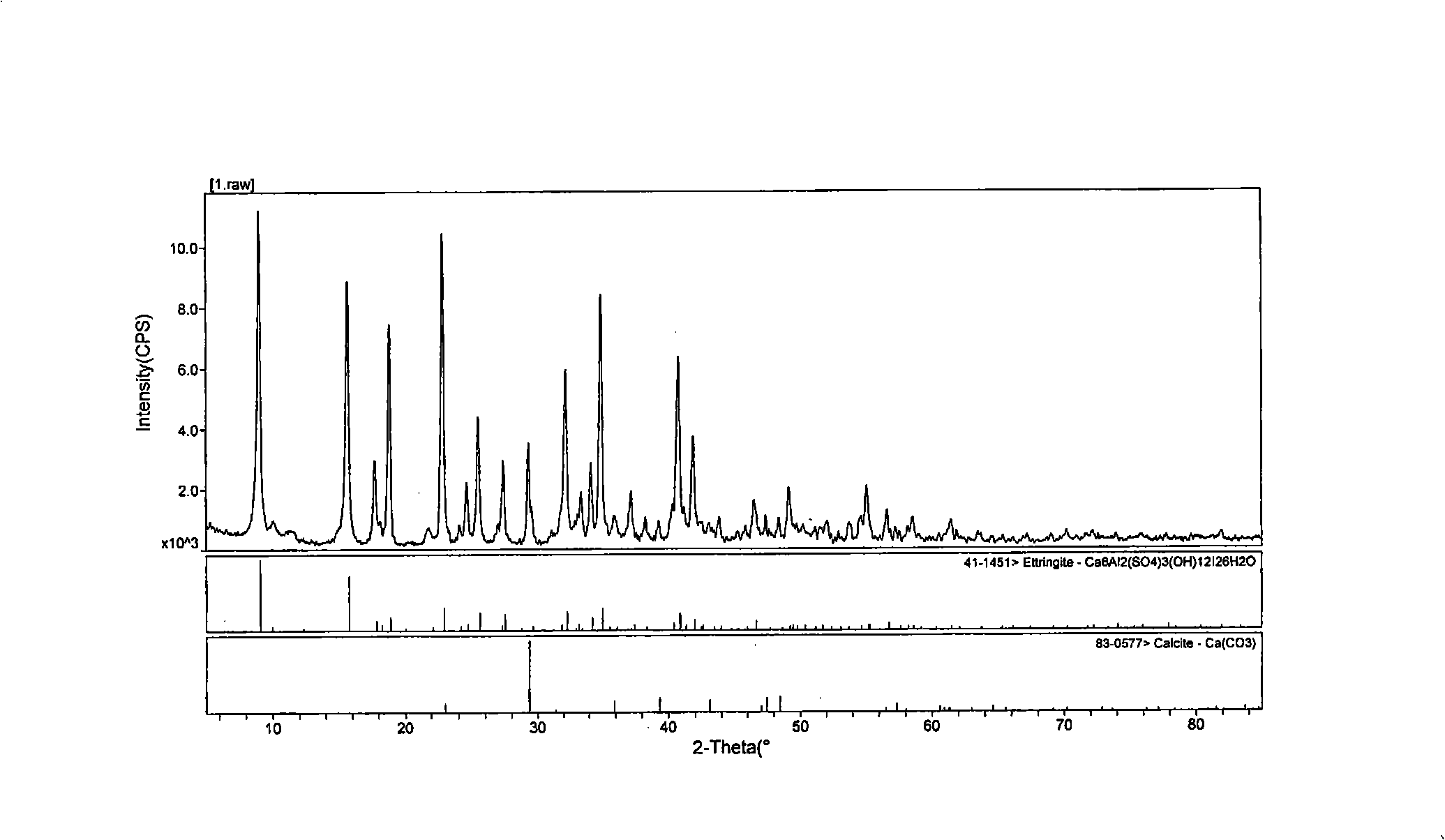

Method for removing sulfate radical in waste water

The invention discloses a sulfate radical wastewater treatment method by using a complex salt method, proposing that hydration aluminum nitrate and calcium hydroxide are taken as removing agents to remove the sulfate radical ions in the wastewater. Al (NO3)3 question mark 9H2O is added into metallurgy and mining industry sulfate radical wastewater with the initial concentration of 1300 to 2000mg / L according to the mol ratio of 0.8-1.1:1 of SO4<2-> / Al<3+>, reaction temperature is controlled at 20-40 DEG C, the pH value of the calcium hydroxide regulation system is 9-12, stirring reaction is carried out for 30-90min, SO4<2-> in the system, Ca<2+> and Al<3+> form compound Ca6Al2(SO4)3(OH)12 question mark 26H2O (ettringite) precipitation, then solid-liquid separation is carried out, and purifying water with water sulfate radical ion concentration of less than 100mg / L is obtained. The invention has the advantages of simple operation, high reaction speed, small temperature affect, highly-efficient treatment and the like.

Owner:CENT SOUTH UNIV

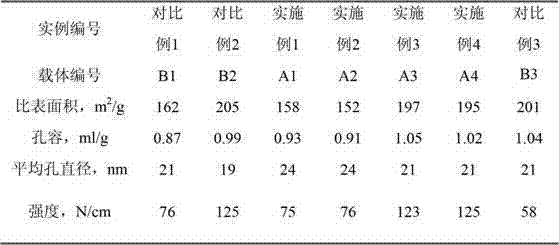

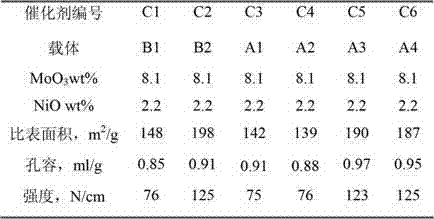

Coal tar hydrodemetalization catalyst and preparation method thereof

ActiveCN102847541AUnobstructed pore structureIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPtru catalyst

The invention discloses a coal tar hydrodemetalization catalyst and a preparation method thereof. The method comprises the steps of: (1) taking or preparing an alumina carrier; (2) treating the alumina carrier from the step (1) with an organic acid solution with pH value lower than 3; then impregnating the alumina carrier subjected to acid treatment with an aluminium nitrate solution; and drying and roasting to obtain a modified alumina carrier; and (3) loading and hydrogenating an active component by an impregnation method to obtain the coal tar hydrodemetalation catalyst. Compared with the prior art, the coal tar hydrodemetalation catalyst provided by the invention has better activity and activity stability, and longer operation cycle.

Owner:上海竣铭化工工程设计有限公司

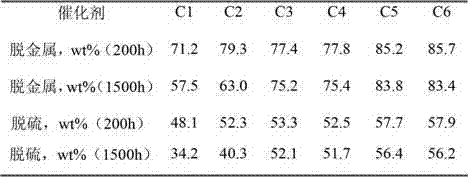

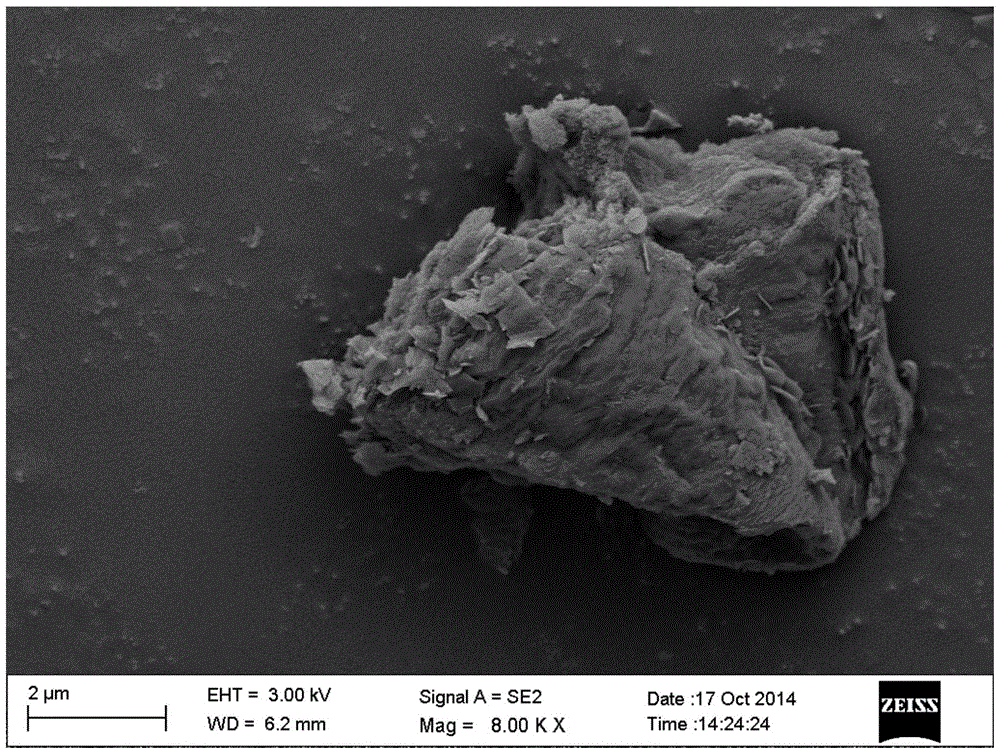

Preparation method of alumina-coated hexagonal boron nitride composite powder for self-lubricating cutter material

The invention relates to a preparation method of alumina-coated hexagonal boron nitride composite powder for a self-lubricating cutter material. The preparation method comprises preparing a hexagonal boron nitride suspension liquid, carrying out ultrasonic dispersion, adding an aluminum nitrate solution into the suspension liquid, slowly and dropwisely adding ammoniacal liquor with pH of 6.5-8.5 into the suspension liquid, carrying out a reaction process at a temperature of 30-40 DEG C until the reaction liquid pH is in a range of 7.0-7.5, stopping ammoniacal liquor dropwise addition, carrying out reaction stirring for 1.5-2.5h, carrying out standing, carrying out deposition and filtration, carrying out centrifugation and washing, carrying out drying to obtain aluminum hydroxide-coated hexagonal boron nitride composite powder, and carrying out vacuum calcination to obtain the alumina-coated hexagonal boron nitride composite powder with the average particle size of 4-12 microns. Through use of the alumina-coated hexagonal boron nitride composite powder in a ceramic matrix, ceramic cutter mechanical properties are improved and self lubricating effects are obtained.

Owner:QILU UNIV OF TECH

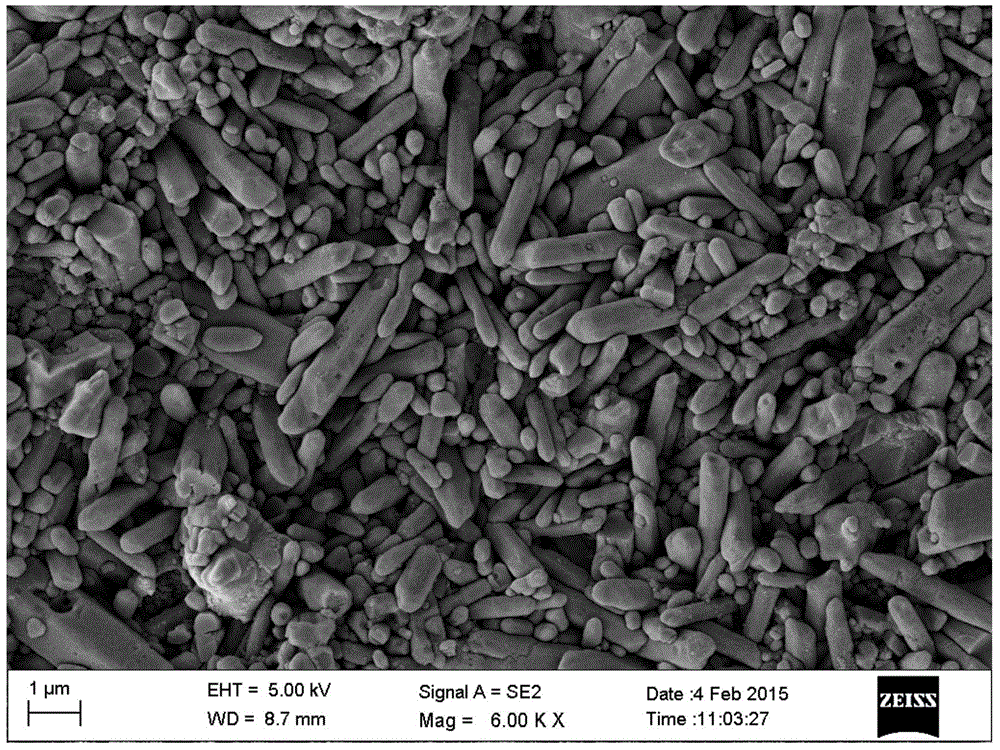

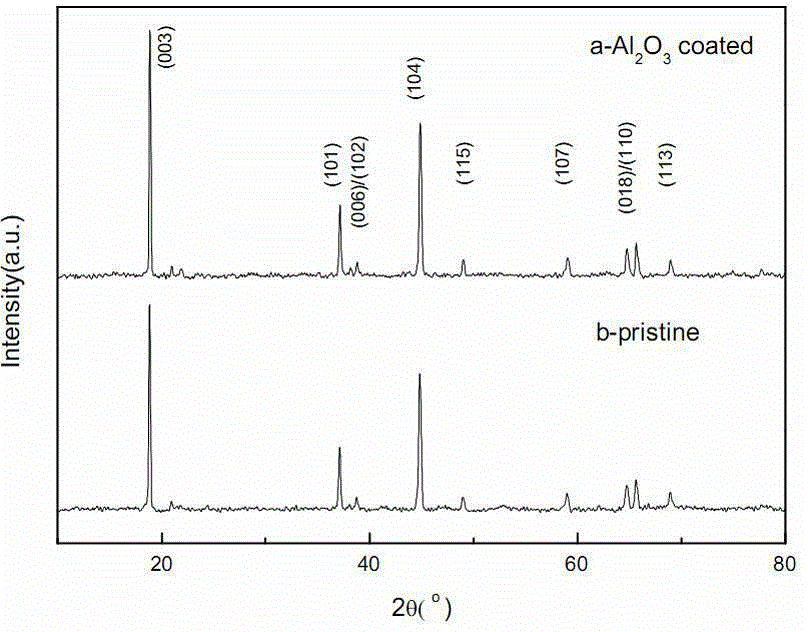

Alumina coating method of lithium ion battery positive electrode material

InactiveCN104577128AImprove cycle stabilitySmall capacity attenuationCell electrodesSecondary cellsAir atmosphereLithium-ion battery

Owner:WUXI XINGBO ENERGY TECH

Catalyst for hydrogenating cis-butenedioic anhydride to prepare butanedioic anhydride and its prepn and application

InactiveCN1453066AHigh surface areaImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCarboxylic acid anhydrides preparationButanedioic acidPtru catalyst

The catalyst has active component Ni and carrier SiO2 and Al2O3 in the molar ratio of 1 to 1.47-5.98 to 0-3.3. The catalyst is prepared with Ni(NO3)2, ethyl metasilicate with or without aluminum nitrate and ethanol, and through pH regulation to 3-5 or 7-9 with acetic acid, ammonia water or urea, heating at 80-120 deg.c to form gel, roasting at 400-550 deg.c and reduction at 400-580 deg.c. One technological process of catalytically hydrogenating cis-butenedioic anhydride to prepare butasnedioic anhydride in the state with or without solvent is provided. The catalyst has the features of highspecific surface area, high dispersion of metal in carrier, high heat stability, high catalytic activity, high selectivity, capacity of being reused, easy separation from the product, low cost, low consumption and mild reaction condition.

Owner:SHANXI UNIV

Preparation method of composite nanomaterial of nano ZnO and graphene nanosheet

InactiveCN103252228AGood chemical stabilitySimple manufacturing methodMetal/metal-oxides/metal-hydroxide catalystsElectronic band structureChemical stability

The invention discloses a preparation method of a composite nanomaterial of a nano ZnO substrate and a graphene nanosheet. Nano ZnO and the graphene nanosheet are composited to form the composite nanomaterial in a sol-gel method and mechanical alloying combined mode, so that the preparation method is simple and easy to realize and short in reaction time; the finished composite nanomaterial is good in chemical stability; graphene has higher conductivity and can adjust an energy band structure of nano ZnO; nano ZnO has a higher seebeck coefficient, and the nano ZnO substrate and the graphene nanosheet are synthesized, so that interface scattering of phonons can be increased significantly; a recombination rate of an electron-hole pair can be reduced; the appearance of nano ZnO can be adjusted; the heat conductivity of nano ZnO can be reduced; and the photocatalytic efficiency of nano ZnO can be improved. Nitrate of to-be-doped ions comprises any one of aluminum nitrate, ferric nitrate, cobalt nitrate, nickel nitrate, silver nitrate and gold nitrate.

Owner:JIANGSU YUEDA NEW MATERIAL TECH +1

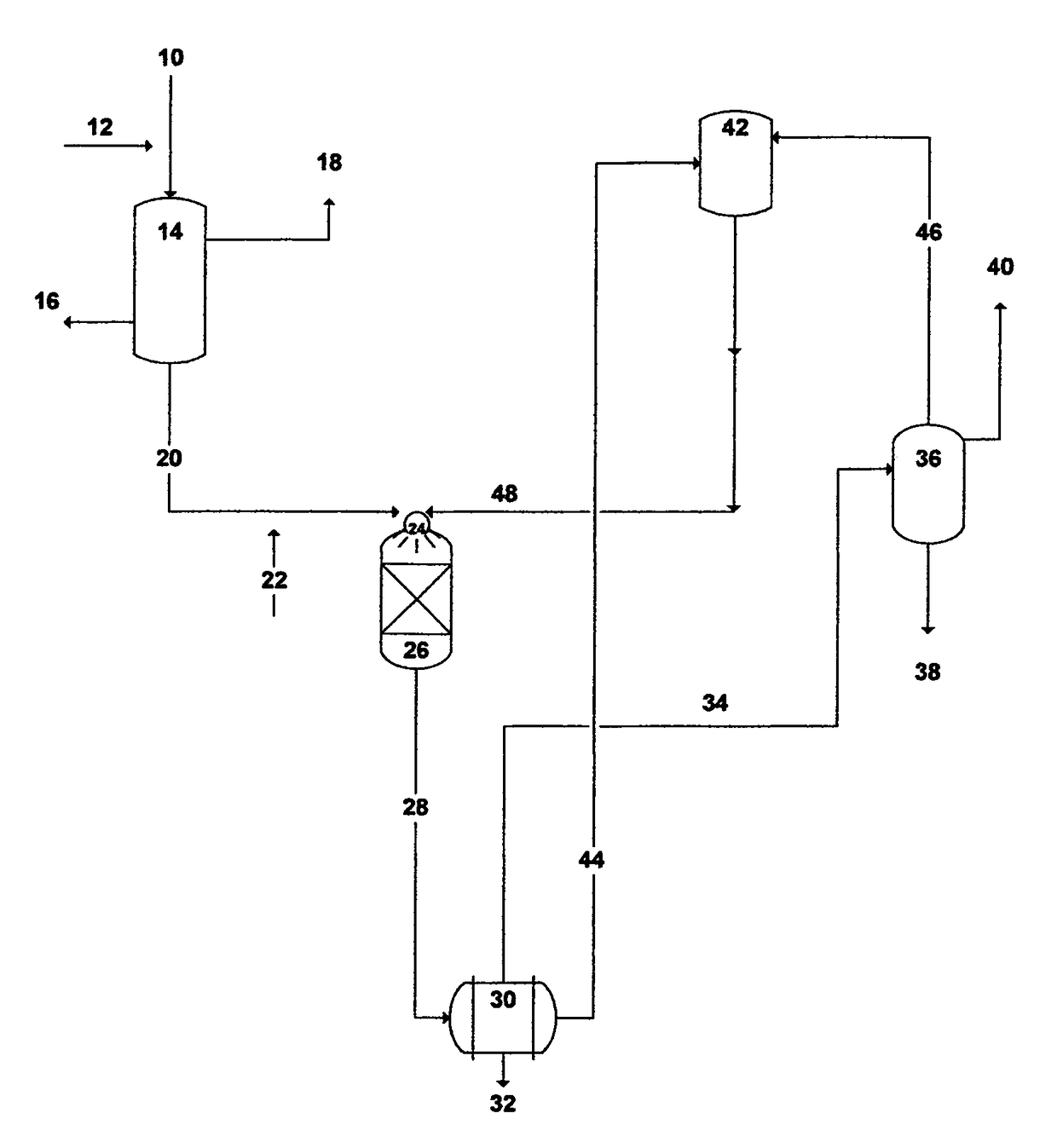

Methods to treat source water for oil-fields heavy oil and other applications

ActiveUS9701558B1Avoid pollutionSpecific water treatment objectivesTreatment involving filtrationNitrateFuel oil

There is provided herein a system and method for treating source water to remove contaminants such as oil from oil-fields produced water. In some embodiments, source water containing CO2, endotoxins, foulants, sulfate, and oxygen will be treated with aluminum nitrate or iron nitrate, separating the CO2 and endotoxins from the treated water, removing the foulants by mixing hydrated lime and an amine solvent with the treated water, and separating the dissolved oxygen and recovering the amine solvent using a hydrophobic membrane.

Owner:BADER MANSOUR S

Preparation method of NASICON type lithium fast ion conductor

InactiveCN103466588AImprove ionic conductivitySecondary cellsPhosphorus compoundsElectrical conductorDiammonium phosphate

The invention discloses a preparation method of an NASICON type lithium fast ion conductor. The preparation method comprises the following steps: adding butyl titanate into a citric acid solution, uniformly stirring the solution, adding a citric acid solution of lithium nitrate, aluminum nitrate and diammonium phosphate, uniformly stirring the solution and adding ethylene glycol, heating the solution to a certain temperature, and stirring the solution to completely gelatinize the same; drying the gel to obtain dry gel, and grinding and calcining the dry gel to obtain precursor powder; and grinding the precursor powder fine powder, carrying out isostatic press molding on the fine powder on a tablet press to obtain an electrolyte sheet of the NASICON type lithium fast ion conductor. The preparation method is used for reducing the sintering temperature of the material, perfecting the sintering performance of the material and improving the density of the material to improve the ionic conductivity of the material. The ionic conductivity of the NASICON type lithium fast ion conductor prepared by the preparation method reaches 6.34*10<-4> S / cm (25 DEG C), so that compared with a traditional preparation method, the ionic conductivity is significantly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Sponge composite metallic organic framework material for adsorption separation

ActiveCN110038540AStrong loadHigh load rateGas treatmentOther chemical processesFragilityMetal-organic framework

The invention relates to a sponge composite metallic organic framework material for adsorption separation and belongs to the technical field of materials. According to the invention, a two-step in-situ growth method is adopted for loading MOFs (metallic organic framework material) into a duct in a sponge carrier. The MOFs is synthesized from following organic ligands and metal salts, wherein the organic ligands include pyrazine, trimesic acid, terephthalic acid, 2,5-dihydroxyterephthalic acid, and the metal salts include cupric fluosilicate, magnesium nitrate, zirconium chloride, cupric nitrate, chromic nitrate, ferric nitrate, aluminum nitrate and hydrates thereof. According to a preparation method provided by the invention, a large amount of MOFs loaded in the duct in the sponge carriercan be realized; MOFs load rate is high; load is stable; the defects of fragility and easiness in loss of MOFs powder can be overcome; a breakthrough experiment proves that the material provided by the invention has the characteristics of high CO2-absorbing capacity, high adsorption separation selectivity, stable adsorption separation property, and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

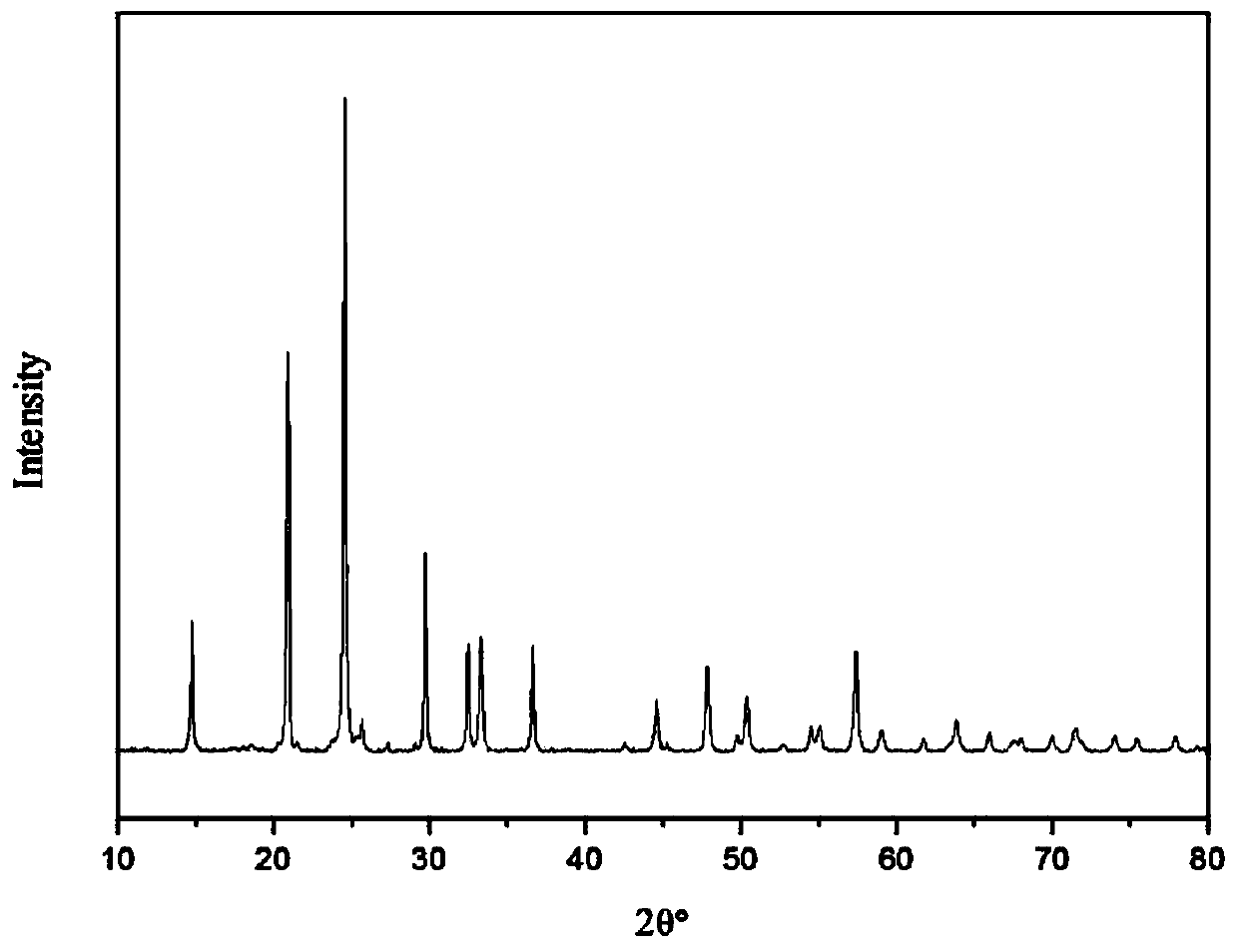

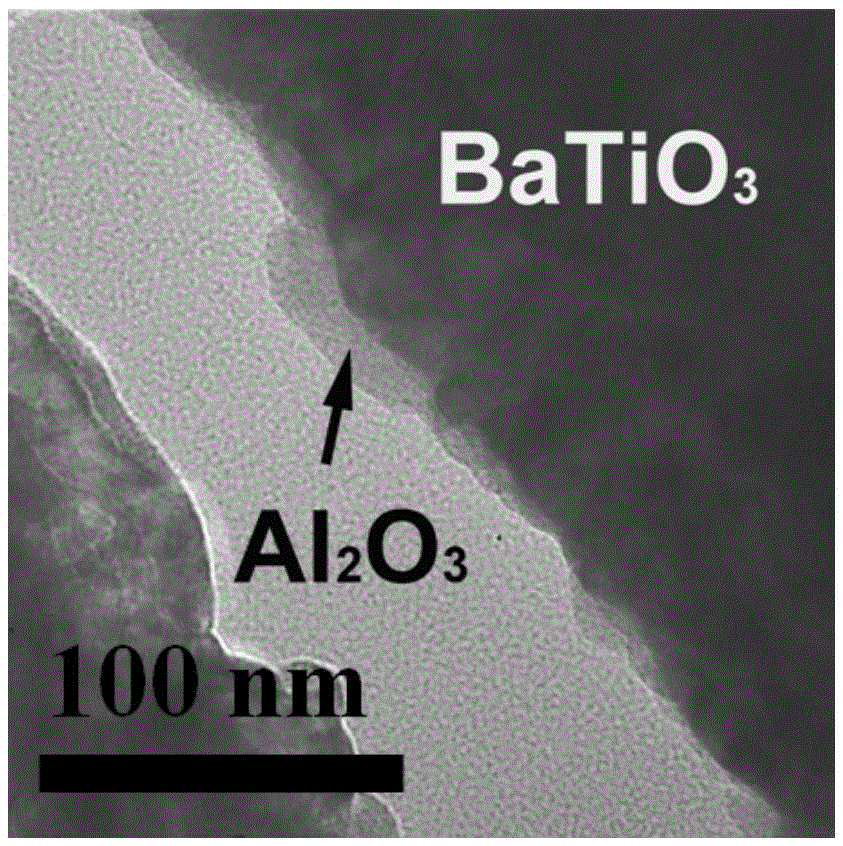

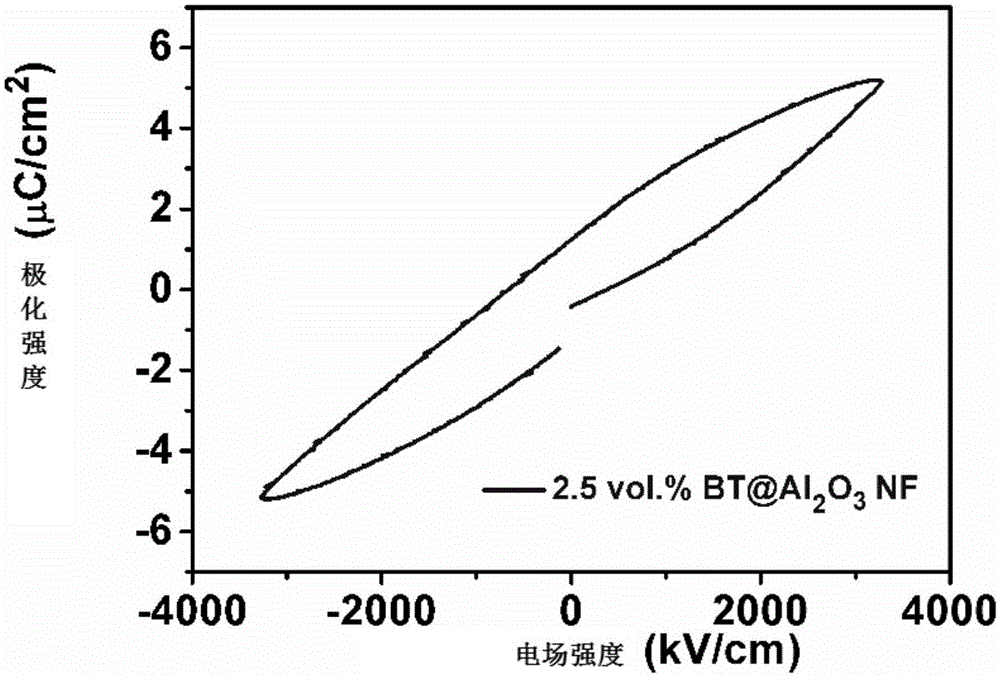

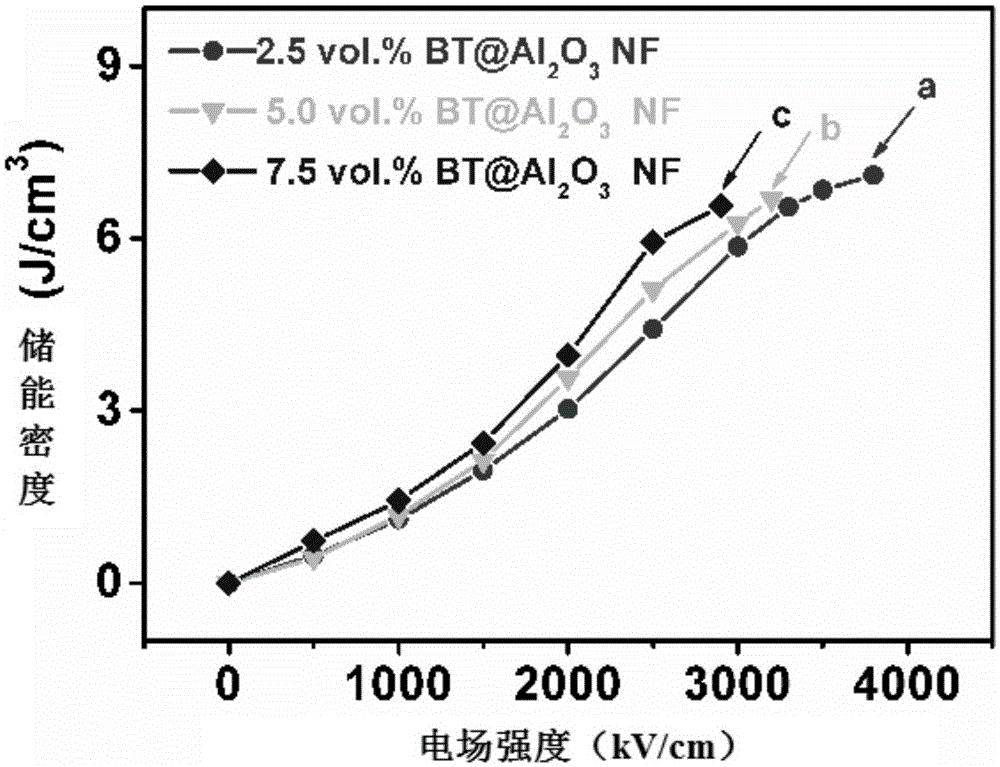

Polymer matrix composite and preparation method thereof

The invention relates to a polymer matrix composite and a preparation method thereof. The composite is a laminated film composed of a polyvinylidene difluoride matrix and a nano-fiber material dispersed in the polyvinylidene difluoride matrix. The nano-fiber material is of a core-shell structure, wherein a core layer is made of a ceramic fiber, and a shell layer is an aluminum oxide coating layer. The polymer matrix composite is prepared through the method comprises the following steps: (1) placing the ceramic fiber in mixed solution of aluminum nitrate, polyvinyl pyrrolidone and ethyl alcohol, and after uniform mixing, obtaining the nano-fiber material through sintering; (2) causing the nano-fiber material to undergo surface modification through a coupling agent, then adding the nano-fiber material into mixture of polyvinylidene difluoride and dimethylformamide, performing uniform mixing, pouring the mixture in a casting film machine to form a film through flow-casting, and performing drying to obtain the laminated film; (4) and causing the laminated film to undergo heating and heat insulation, quenching and drying, and obtaining the polymer matrix laminated film. Compared with the prior art, the polymer matrix composite has the advantages that the laminated film is high in energy density, good in energy storage efficiency, simple in preparation process and low in cost.

Owner:TONGJI UNIV

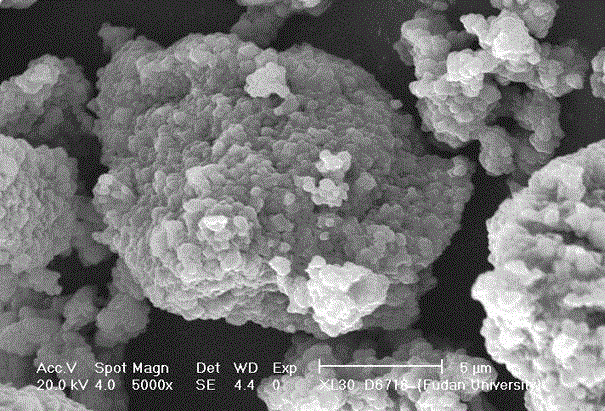

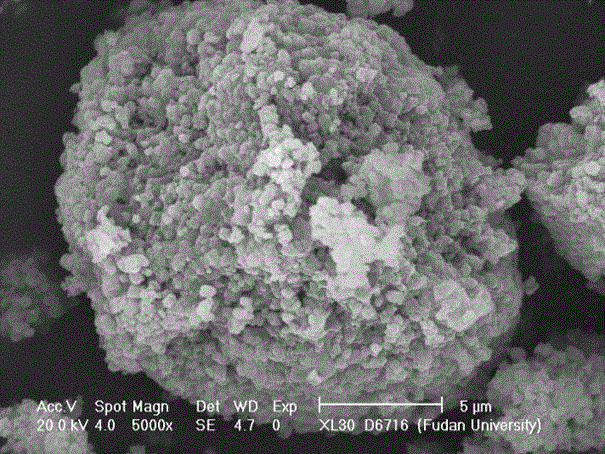

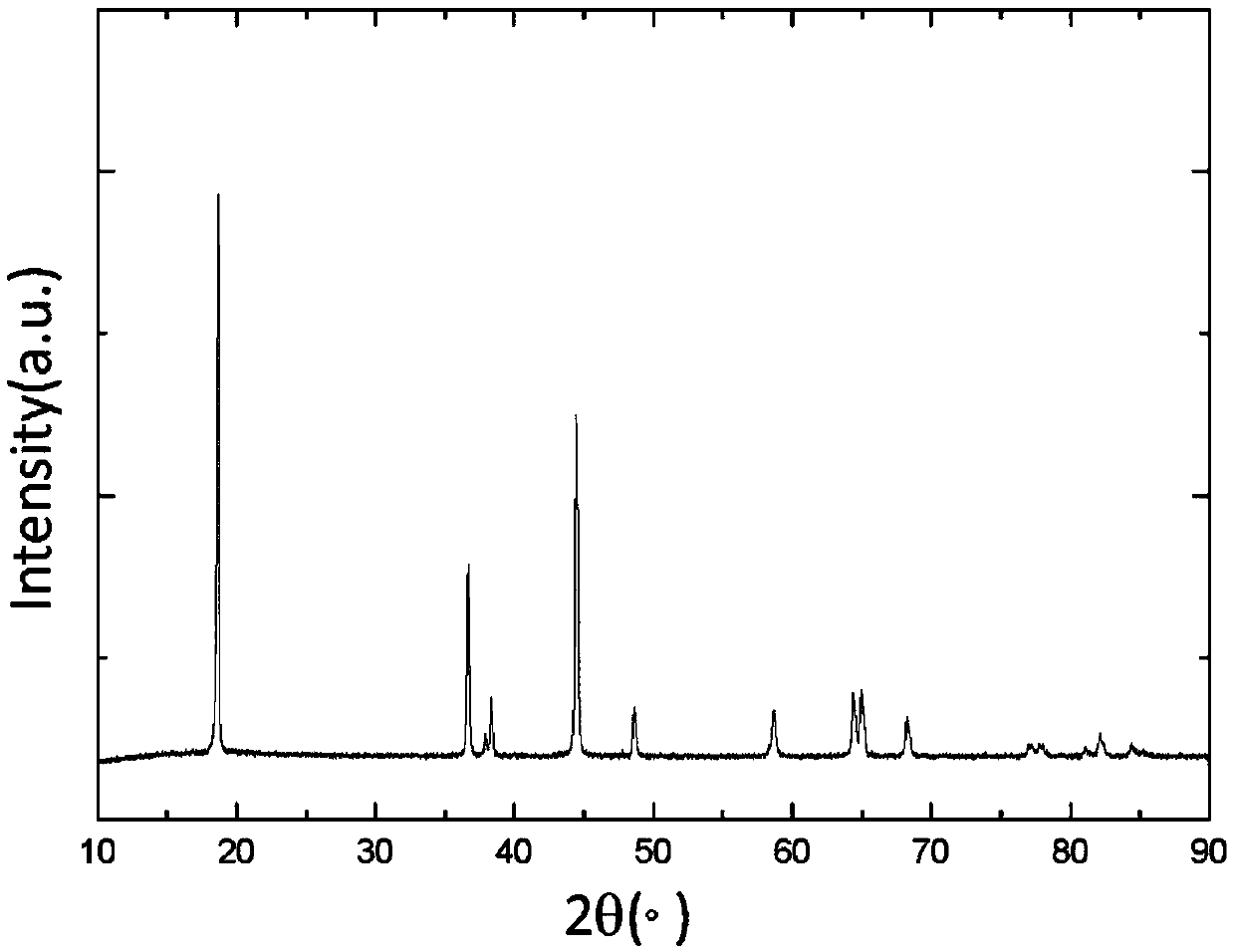

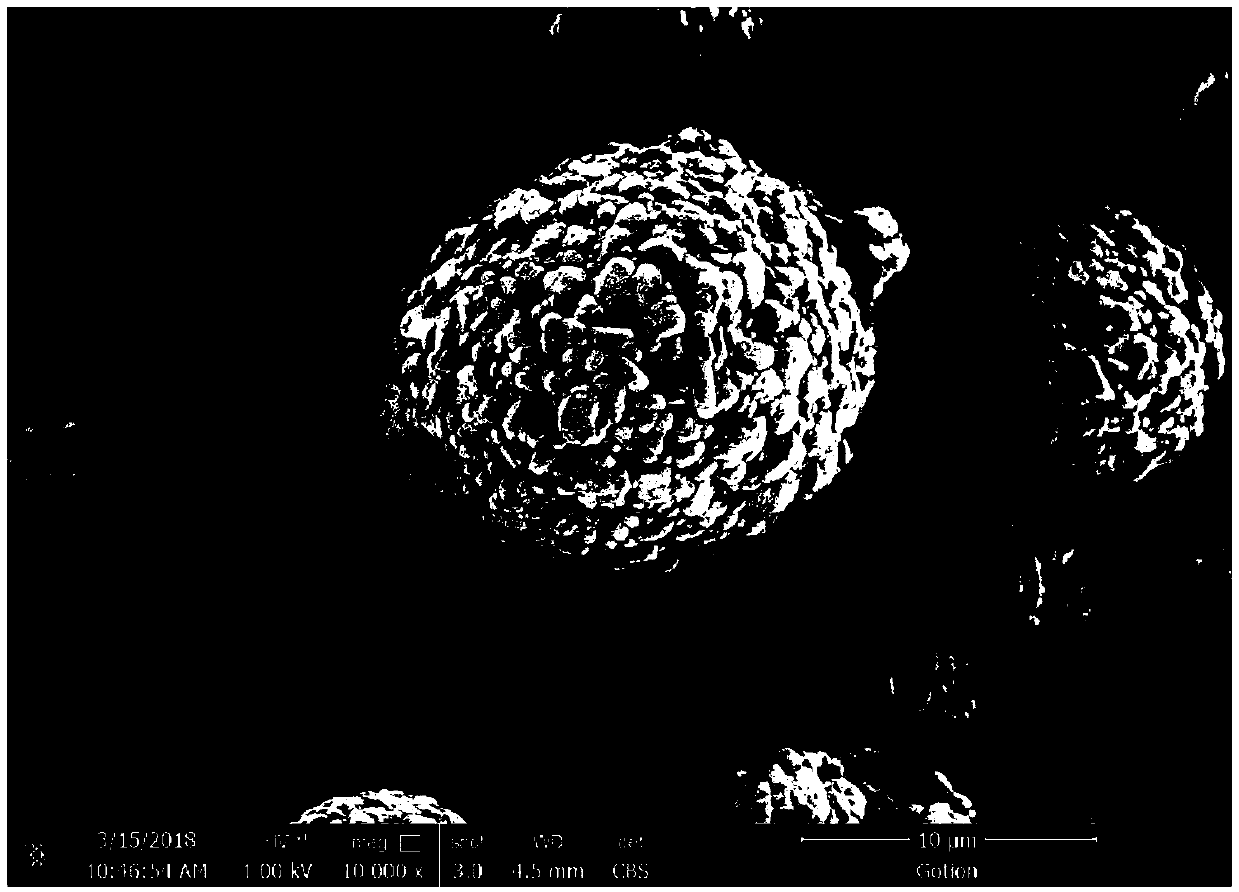

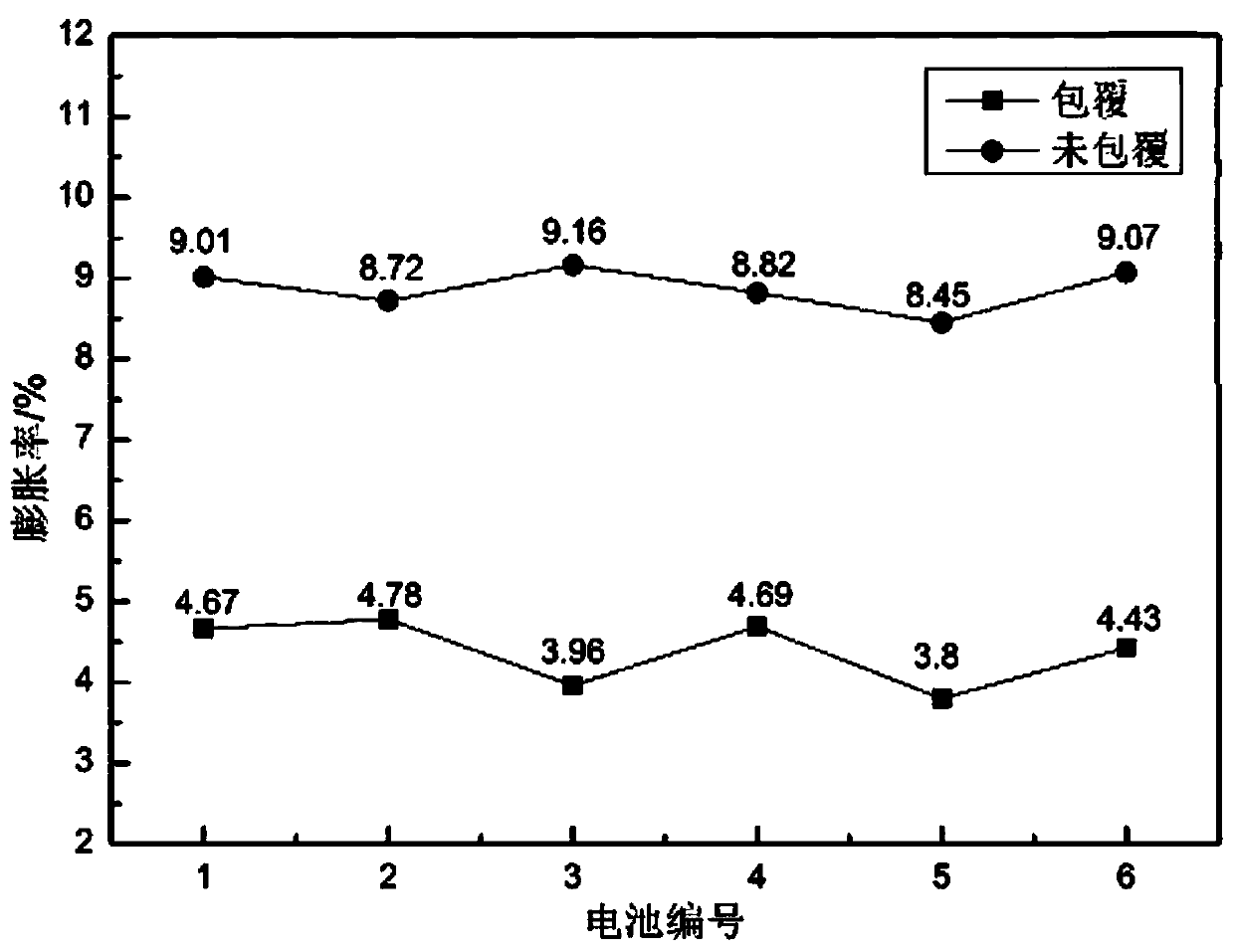

Aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material, preparation method and application thereof

InactiveCN109585839AImprove cycle performanceImprove securitySecondary cellsPositive electrodesManganeseSide reaction

The invention discloses an aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material, a preparation method and application thereof. The preparation method of the material comprises the following steps: (1) dripping aluminum nitrate into ammonium hydroxide, reacting until precipitates are not increased any longer, adding citric acid and nitric acid, and preparing an AlOOH sol; (2) mixing a nickel-cobalt-manganese precursor and a lithium source uniformly, and sintering to obtain a nickel-cobalt-manganese ternary material; and (3) putting the nickel-cobalt-manganese ternary material into the AlOOH sol, carrying out calcinations after drying, and finally obtaining the aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material. An aluminum oxide coating layer is coated on the surface of the nickel-cobalt-manganese ternary material, so that the amount of residual alkali on the surface of the material is reduced, a side reaction between the material and an electrolyte is inhibited effectively, and the safety performance of a battery is improved; moreover, in the battery prepared from the material, an Li-Al-Co-O protective layer is formed by the aluminum oxide coating layer during working on the surface of the material, and the protective layer can resist the corrosion of HF on active materials, so that the cycle performance of the batteryis improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

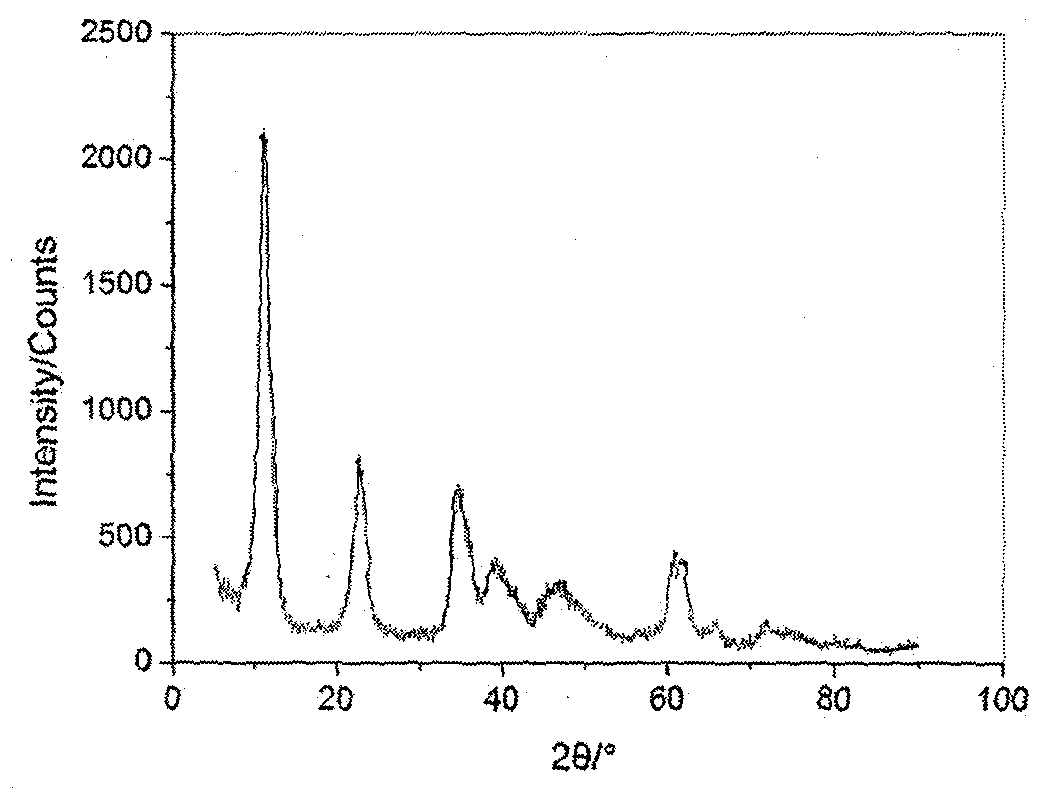

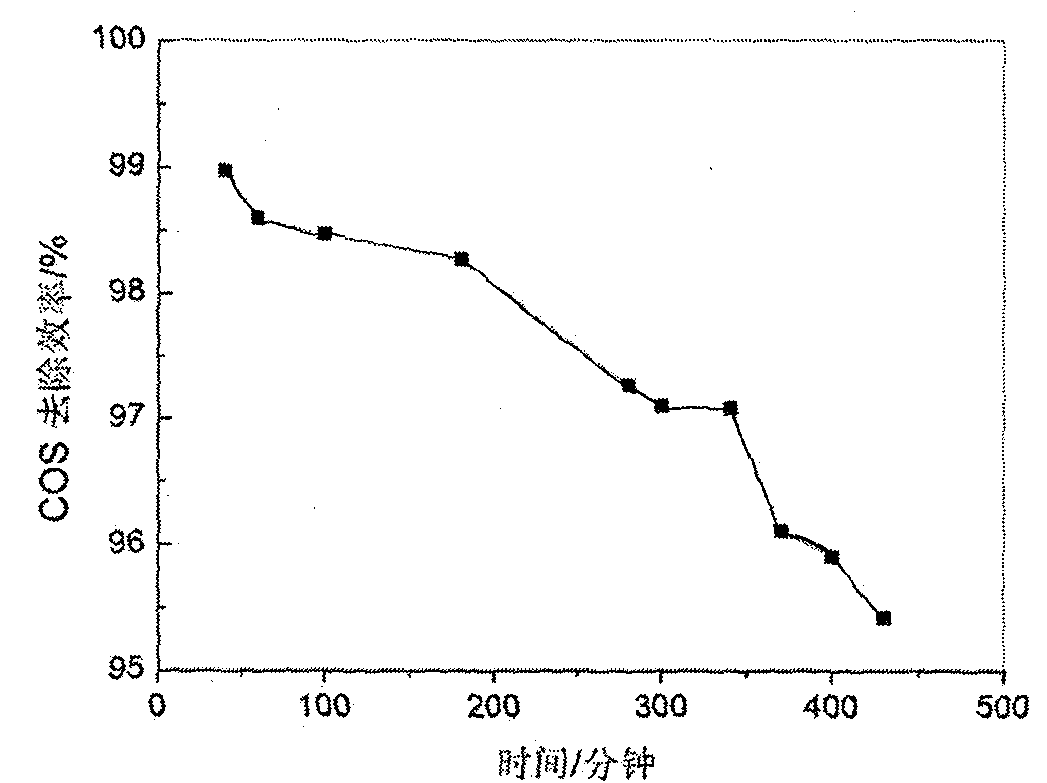

Carbonyl sulfide hydrolysis catalyst prepared by using cobalt(Co)-nickel(Ni)-aluminum(Al) hydrotalcites as precursor and preparation method thereof

InactiveCN101811051AHigh desulfurization precisionReduce energy consumptionMetal/metal-oxides/metal-hydroxide catalystsWater bathsFiltration

The invention provides a carbonyl sulfide hydrolysis catalyst prepared by using Co-Ni-Al-like hydrotalcite as a precursor and a preparation method thereof. The preparation method comprises the following steps of: at room temperature, dissolving cobalt nitrate, nickel nitrate and aluminum nitrate in distilled water to prepare solution A, wherein the total metal molar number is 0.75mol, n(Co2+):n(Ni2+) is equal to 0.25 to 1, and n(Co2++Ni2+):n(Al3+) is equal to 1.5 to 4; by using NaOH and Na2CO3 as precipitators, dissolving 0.05 moles of the NaOH and the Na2CO3 in the distilled water to prepare solution B; adding the solution A into the solution B dropwise to obtain suspension; and crystallizing the suspension in water bath, and then performing vacuum filtration, washing the crystals by the distilled, drying the crystals, baking the crystals in air, milling the crystals, tabletting the powder and screening the powder to obtain the hydrotalcite derivational compound oxide catalyst. The hydrolysis catalyst prepared by the method can be remove COS in gases, and simultaneously remove H2S generated in hydrolysis, and the desulfurization precision is high; and the hydrolysis catalyst can be used at the low temperature, the operational temperature is between 30 and 80 DEG C, and the energy consumption is low.

Owner:KUNMING UNIV OF SCI & TECH

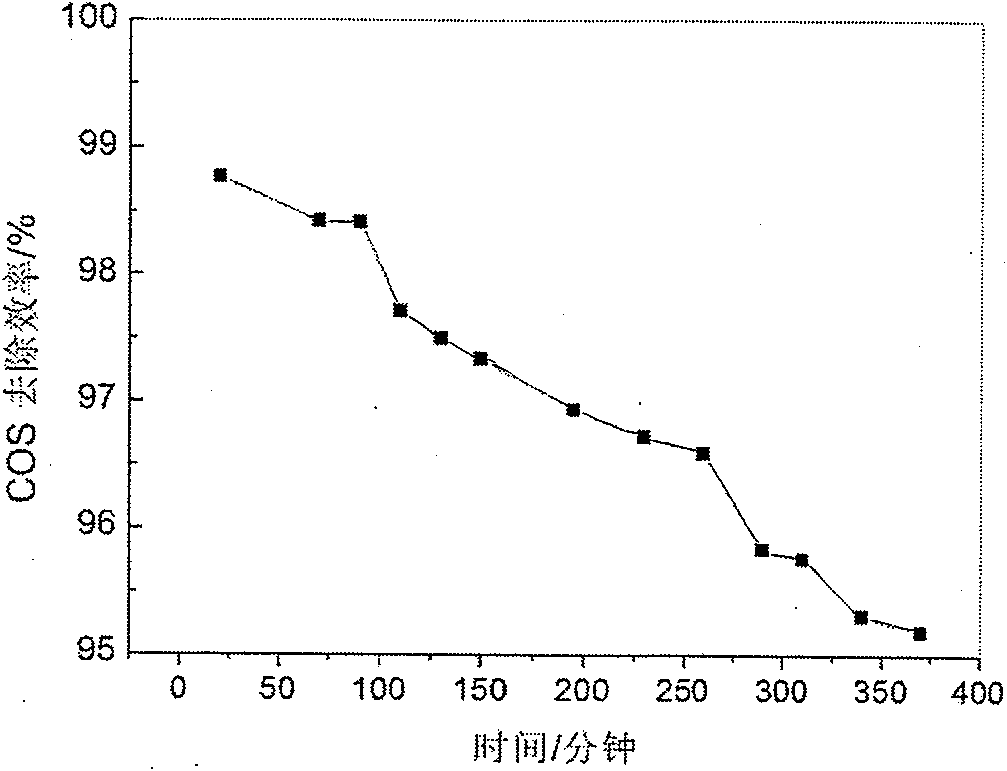

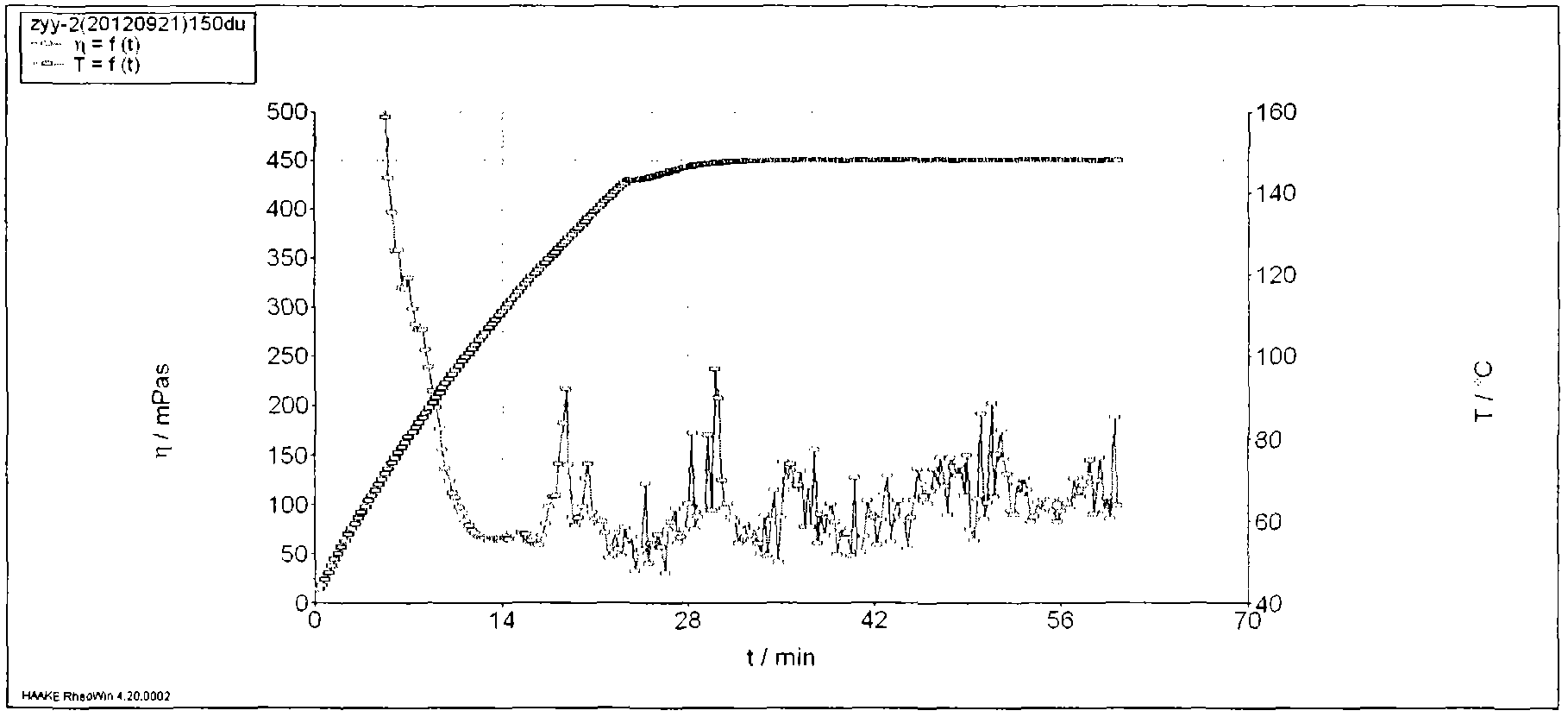

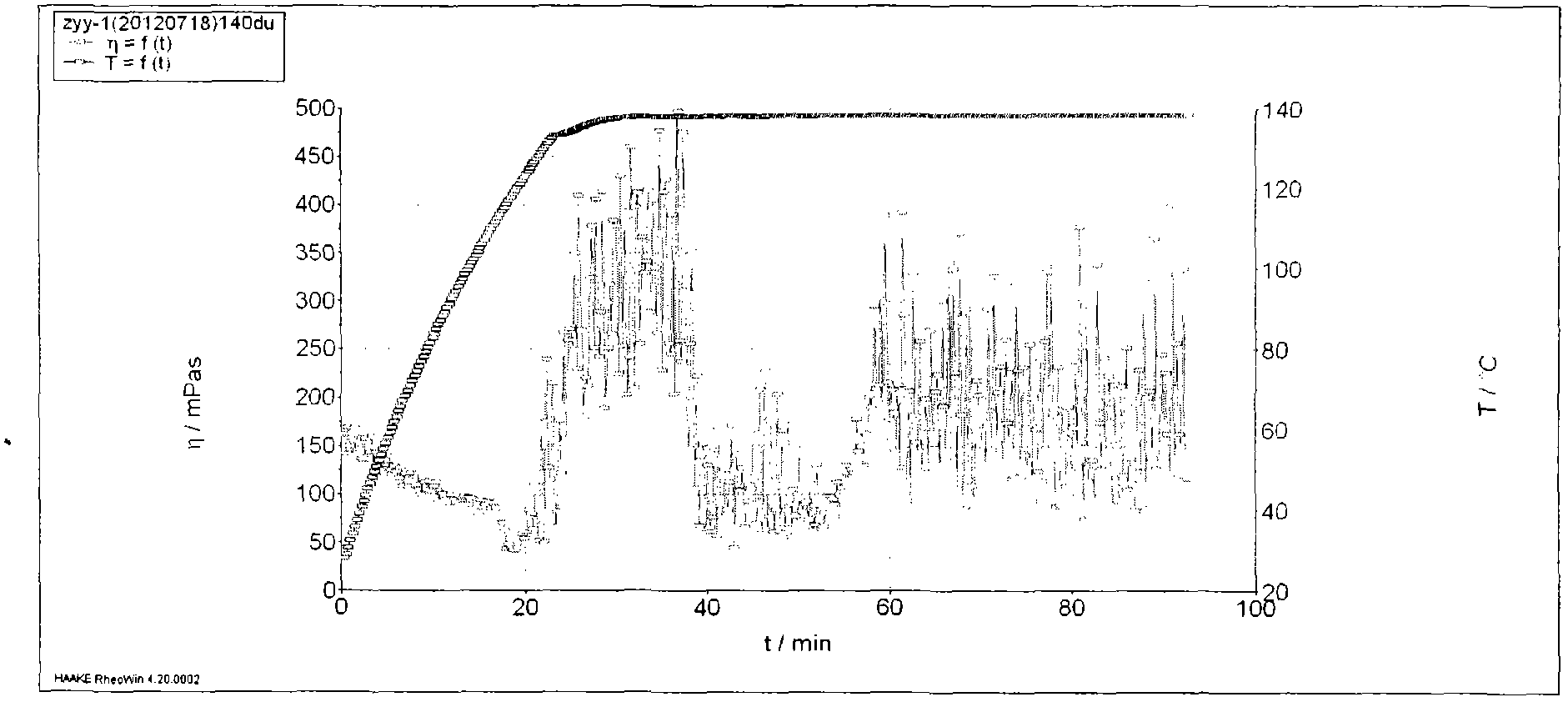

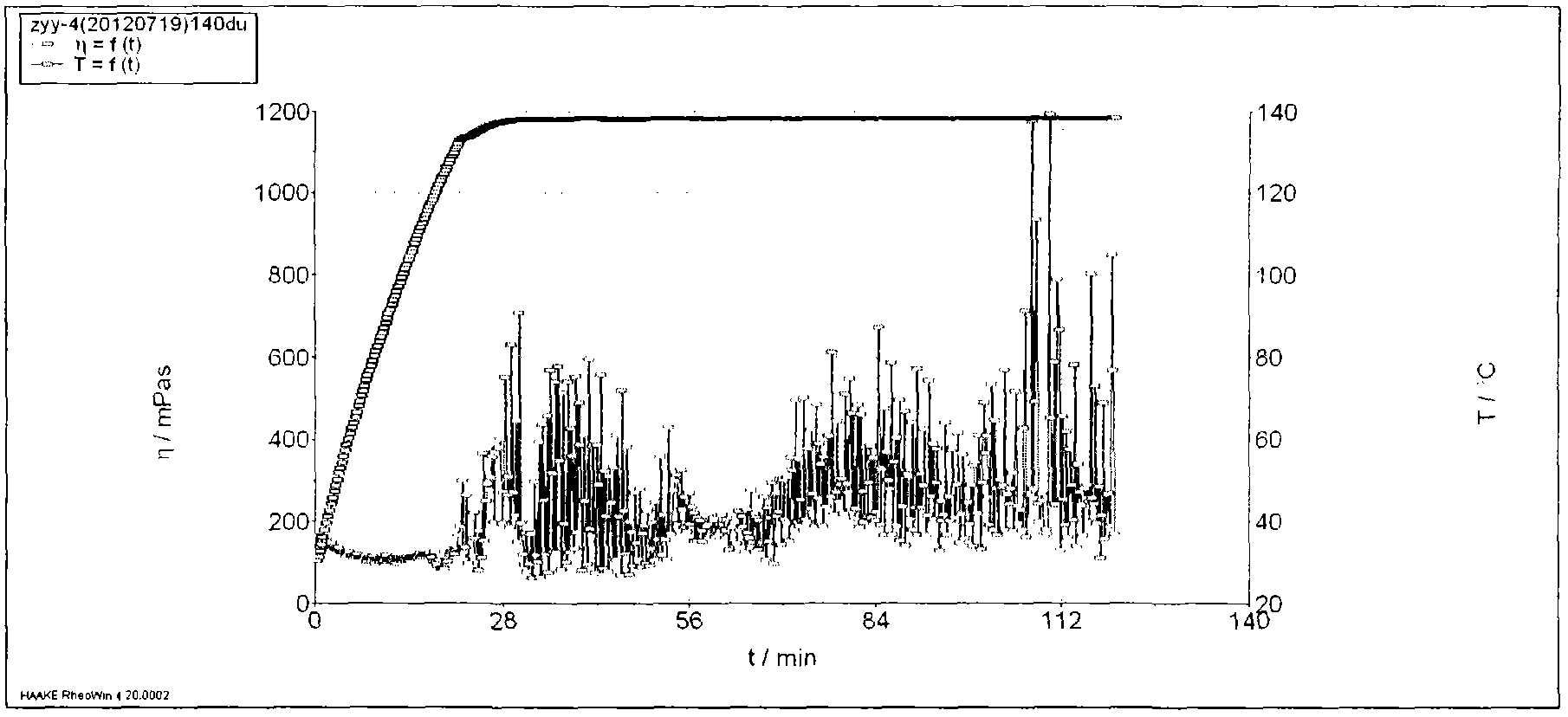

Preparation method of polyacrylamide nano composite fracturing fluid

ActiveCN104109525AHigh temperature resistantSalt resistantDrilling compositionIn situ polymerizationFracturing fluid

The invention adopts polyacrylamide and a nano inorganic phase to prepare a polyacrylamide nano composite material through an in-situ polymerization method and then forms a fracturing fluid thickening agent. The nano inorganic phase is prepared by mixing the products of intercalation reactions between an organic long-chain intercalator and layered silicate with magnesium nitrate and aluminum nitrate. The nano inorganic phase, acrylamide monomer, a coupling agent, a complexing agent, an initiator, an oxidant, a reductant, a cosolvent, an auxiliary agent, and deionized water form a suspension fluid reaction system, and the polyacrylamide nano composite material is formed after the polymerization-intercalation composite reactions. The polyacrylamide nano composite material with a mass percentage of 0.25% is taken as the thickening agent, and then is mixed with a crosslinking agent with a mass percentage of 0.20%, a gel breaker with a mass percentage of 0.20%, and other auxiliary agents to form a fracturing fluid system. The system is sheared for 70 minutes under a shearing speed of 170 s<-1> at a temperature of 150 DEG C so as to form a fracturing fluid with a viscosity larger than 50 mPa.s, and the fracturing fluid has the characteristics of high temperature resistance, shearing resistance, low frictional resistance, complete glue breaking effect, and good compatibility with the formation fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

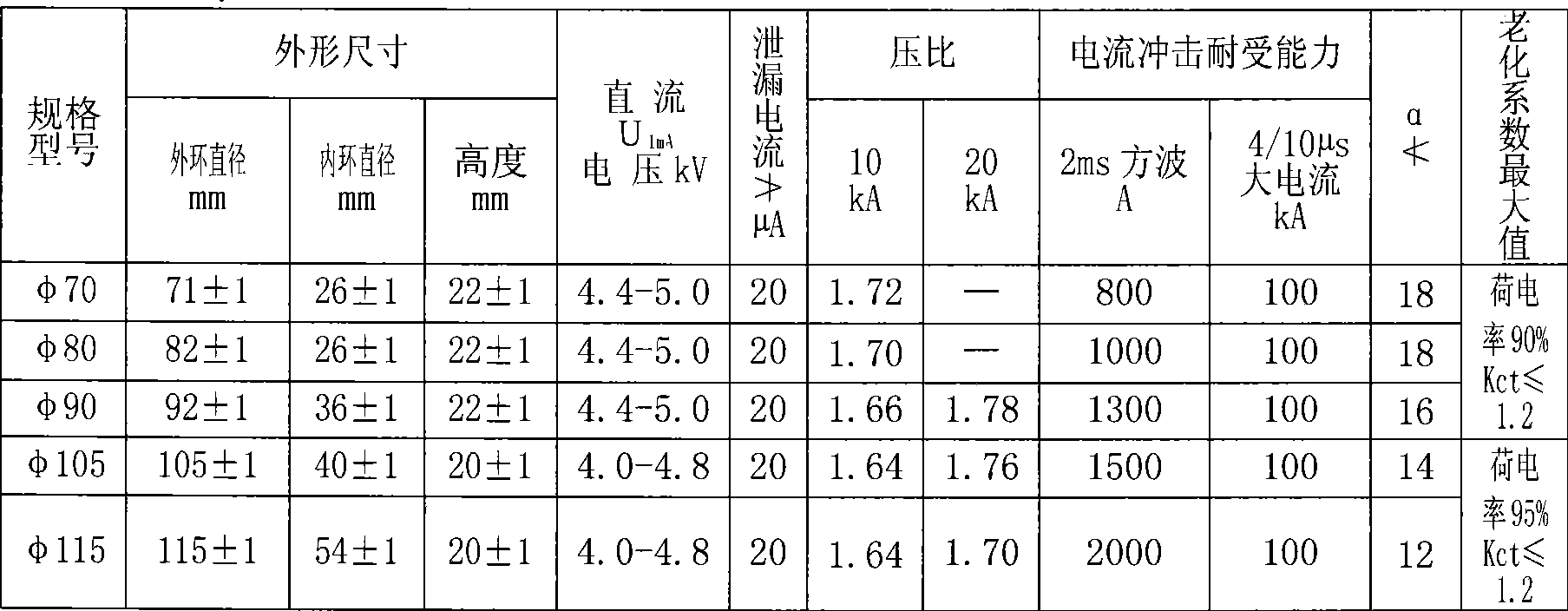

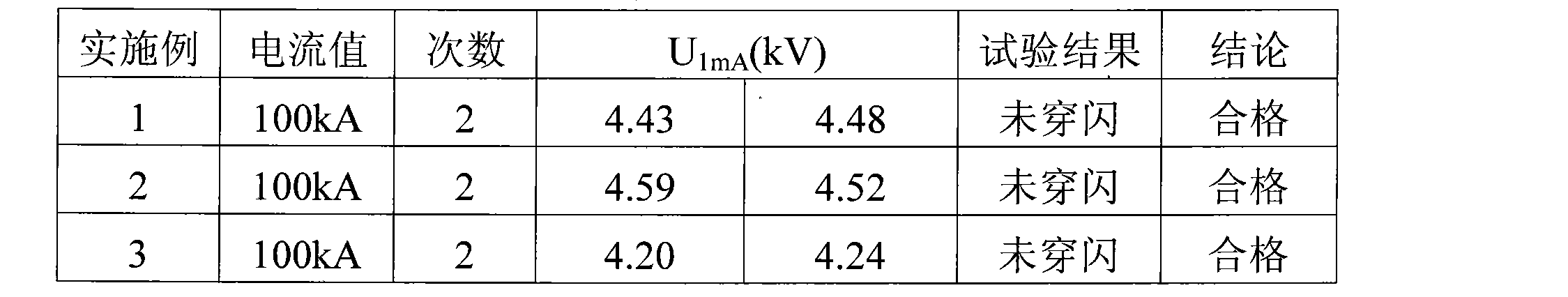

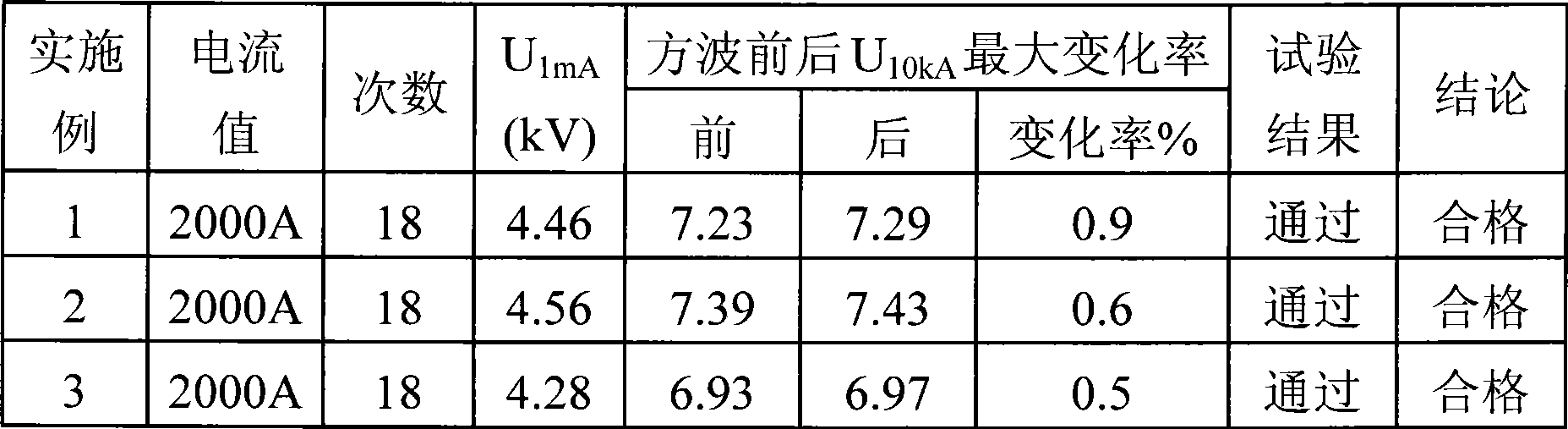

Formula of direct current zinc oxide resistance chip

ActiveCN101503292AUniform and stable structureReduce defect concentrationVaristor coresSesquioxideAntimony trioxide

The invention discloses a formulation of an AC zinc oxide resistance chip. The formulation is characterized by comprising the following additives and a main material ZnO by weight percentage: 4.0 to 4.9 percent of Bi2O3, 3.0 to 4.0 percent of Sb2O3, 0.5 to 1.0 percent of SiO2, 2.0 to 3.0 percent of Co2O3, 0.50 to 0.80 percent of Cr2O3, 0.50 to 0.80 percent of MnCO3, 0.70 to 0.90 percent of NiO, 0.03 to 0.05 percent of aluminum nitrate, 0.10 to 0.20 percent of glass dust, 0.07 to 0.10 percent of B2O3 and 85.0 to 88.0 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the internal structure of the resistance chip is more excellent; and 2, dosage of cobalt sesquioxide, dibismuth trioxide and diantimony trioxide are added in the formulation, the mixture ratio of each composition is more reasonable, and the non-linearity coefficient of the resistance chip can be improved, the pressure ratio is reduced, the circulation capability is improved, and the comprehensive performance is excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

Preparation method of flake silver-plated copper powder

InactiveCN101905321ALow costSimple processLiquid/solution decomposition chemical coatingSilver plateLow speed

The invention relates to a preparation method of flake silver-plated copper powder, which comprises four steps of pre-treating, silver plating, desorbing and post-treating, and concretely comprises the following steps: performing ball milling on copper powder to obtain flake copper powder under inert-gas shielding; in a chelating agent / dispersing agent compound system, performing chemical replacement for silver plating by an aluminum nitrate and silver nitrate compound system; reducing the residual silver ions in the solution by a reducing agent; washing by an acid water solution; and performing ball milling at low speed under the inert atmosphere shielding for spreading the silver particles on the surface of the silver-plated copper powder, thereby densifying and homogenizing the silver layer, simultaneously increasing the bonding strength of the silver and the copper, and improving the conductivity and oxidation resistance of the silver-plated copper powder. The method of the invention has the characteristics of environmental protection, simple process, low cost and the like, and can obtain flake silver-plated copper powder with low silver plating content, good conductivity, even plating and strong oxidation resistance. The flake silver-plated copper powder prepared by the method can be used as conductive filler for manufacturing and processing products such as paint, rubber, adhesive and the like with high conductivity, and has wide application prospect.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Antibacterial corrosion-resistant ceramic coating of non-stick pan and preparation method of coating

ActiveCN103483885AImprove mechanical propertiesImprove performanceAntifouling/underwater paintsPaints with biocidesEpoxyPolyester

The invention relates to an antibacterial corrosion-resistant ceramic coating of a non-stick pan and a preparation method of the coating, and belongs to the technical field of ceramic machining. The antibacterial corrosion-resistant ceramic coating comprises the components in parts by weight as follows: 35-40 parts of silicon oxide sol, 5-9 parts of aluminum oxide sol, 1-3 parts of zirconium oxide sol, 5-8 parts of a water soluble polyester modified epoxy resin, 1-3 parts of black iron oxide, 5-8 parts of spherical ceramic micro powder, 8-12 parts of absolute ethyl alcohol, 1-3 parts of silver nitrate, 1-3 parts of aluminum nitrate, 1-3 parts of and fluoride silicone oil and 10-15 parts of deionized water. The preparation method comprises the steps as follows: the materials are mixed according toin the ratio, stirred for 4-6 h in a sealing manner at a temperature of 35-42 DEG C and a rotating speed of 300-350 rpm (revolutions per minute), and then calcinated at a high temperature of 300-350 DEG C; and composite ceramic material powder is composited. The coating of the non-stick pan has good mechanical property, is high in strength, high-temperature-resistant, abrasion-resistant and scratch-resistant, and has an antibacterial function; and the preparation technology is simple, and the coating is non-toxic and harmless to the environment.

Owner:浙江飞哲科技股份有限公司

Preparation method of nitrogen-doped hierarchical pore carbon materials

InactiveCN103537262AQuality improvementWith tunable specific surface areaOther chemical processesAlkali metal oxides/hydroxidesAluminum IonBiocompatibility Testing

The invention discloses a preparation method of nitrogen-doped hierarchical pore carbon materials. The method comprises the steps of soaking waste banana peel, which serves as a nitrogen source and a carbon source, into an aluminum nitrate aqueous solution with a certain concentration, thus forming a multi-pore-channel metalloid organic skeleton coordination complex material through coordination and modification of metal aluminum ions; constructing a large mesoporous mesostructure by using the multi-pore-channel metalloid organic skeleton coordination complex material as a template; carrying out microstructure regulation and guidance by using an amphiphilic triblock copolymer Planck F127 as a soft template to prepare a series of nitrogen-doped hierarchical pore carbon materials with high specific surface area, large pore volume and adjustable average mesoporous size. The raw materials are cheap, easily available and environment-friendly; the preparation method is simple and mild in condition; the obtained hierarchical pore carbon materials have stable quality, can be applied to CO2 gas adsorption with high selectivity, can also be applied to bilirubin adsorption with high selectivity, large adsorption capacity and excellent biocompatibility, and are expected to be a potential blood purification and separation medium material in the aspect of clinical medicine.

Owner:SHAANXI NORMAL UNIV

Method for preparing silicon carbide-aluminum nitride (SiC-AlN) solid solution ceramic powder

A method for preparing silicon carbide-aluminum nitride (SiC-AlN) solid solution ceramic powder belongs to the field of ceramic powder preparation, which enables submicron with small particle size to be directly contacted reacted through improvement of a raw material mixing method to improve reactivity of a precursor, and is favorable to preparation of the SiC-AlN solid solution ceramic submicron powder which is high in purity, fine in particle size, and good in uniformity and the reactivity under the condition of low temperature. An aluminum source is aluminum nitrate, a silicon source is silica solution, a carbon source is dextrose, and an annexing agent is urea, polyacrylamide and nitric acid. Molar ratio between the aluminum source and the silicon source is Si:Al=1: (0.2-5), molar ratio between the aluminum source and the silicon source and the carbon source is (Si+Al): C=1: (5-16), molar ratio between +5 valent nitrogen and -3 valent nitrogen is N+5:N-3=1: (0.1-10), and mass ratio between the polyacrylamide and the silica solution is (0.5-2):1. The method for preparing the SiC-AlN solid solution ceramic powder is wide in raw material source and low in prize and production cost, and prepared SiC-AlN solid solution ceramic submicron powder is stable in performance, simple in production process and capable of achieving mass production.

Owner:UNIV OF SCI & TECH BEIJING

Method for synthesizing molecular sieve by using solid phase

InactiveCN103979574ALow costImprove efficiencyPentasil aluminosilicate zeoliteSodium metasilicateCrystallinity

The invention discloses a method of synthesizing a molecular sieve by using a solid phase. In the method, ammonium fluoride is used as a mineralizing agent and a brominized organic template is used as a guiding agent; and the method comprises the following steps: mixing a certain amount of water with anhydrous sodium metasilicate and recrystallizing to form crystal water-containing sodium metasilicate; then, mixing and grinding the certain amount of crystal water-containing sodium metasilicate, white carbon black, the brominized organic template, ammonium fluoride and / or aluminum nitrate together till mixing uniformly, then putting the ground mixture into a glass tube and sealing with flame; and crystallizing the sealed glass tube in an oven at 180 DEG for 4 weeks, washing the reaction products and drying the reaction products in an oven with the temperature of 60 DEG C till the reaction products are completely dried. By using ammonium fluoride as the mineralizing agent, an ITO (Indium tin oxide)-13 molecular sieve which cannot be obtained in an alkaline synthesis route and an F-ZSM (Zeolite Socony Mobil)-5 zeolite molecular sieve are obtained, and good degree of crystallinity and purity are kept. The reactant cost is lowered, the energy consumption is reduced and the product purity is high.

Owner:ZHENGZHOU UNIV

Controlled release of surfactants for enhanced oil recovery

ActiveUS8946132B2Reduce surface tensionEnhanced overall recoveryFlushingDrilling compositionCalcium Chloride HexahydrateMetal salts

A controlled release composition comprising an aqueous sulfonate solution; an anionic surfactant; and a salt selected from aluminum nitrate nanohydrate, calcium chloride dehydrate, magnesium chloride hexahydrate, cobalt chloride hexahydrate, and other metal salts. Methods of delivering a controlled release of surfactants composition, the method comprising the steps of: delivering a solution into a reservoir, the solution comprising an aqueous sulfonate solution; an anionic surfactant; and a salt selected from aluminum nitrate nanohydrate, calcium chloride dehydrate, magnesium chloride hexahydrate, cobalt chloride hexahydrate, and other metal salts; and delivering water to the reservoir.

Owner:SAUDI ARABIAN OIL CO

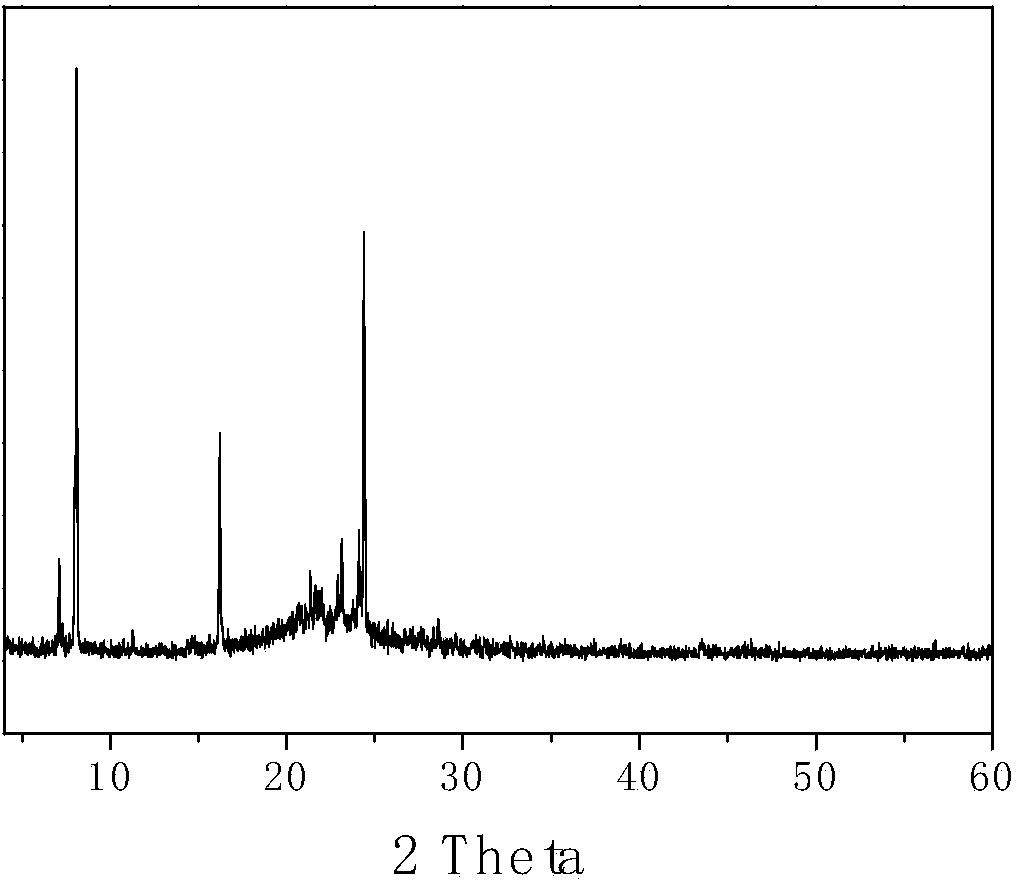

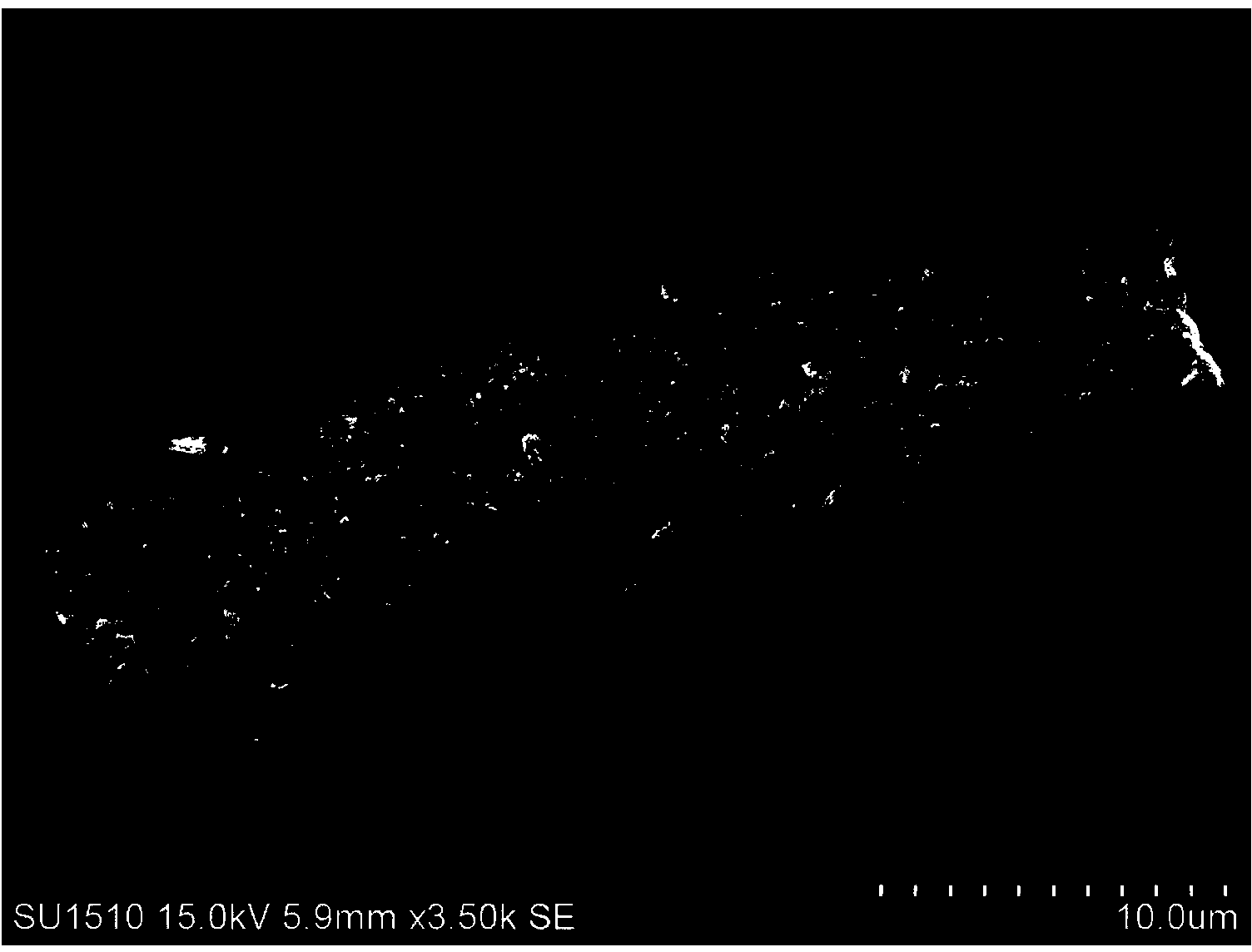

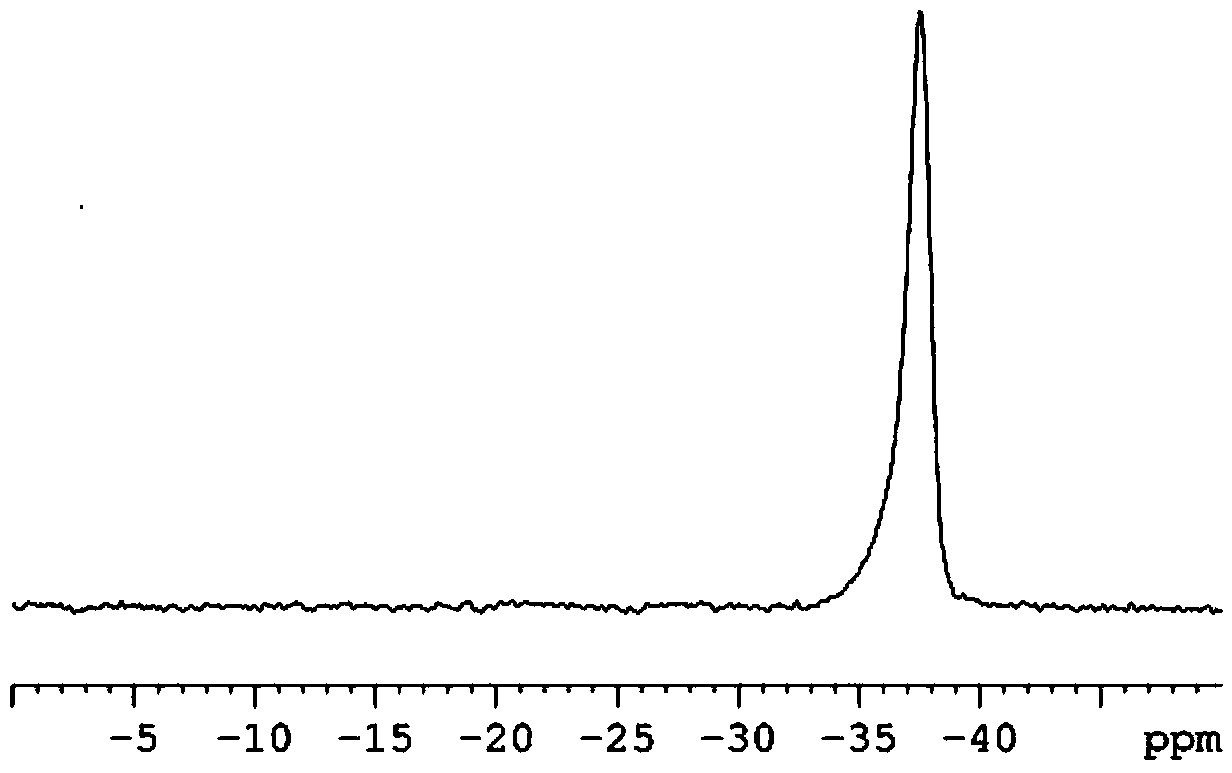

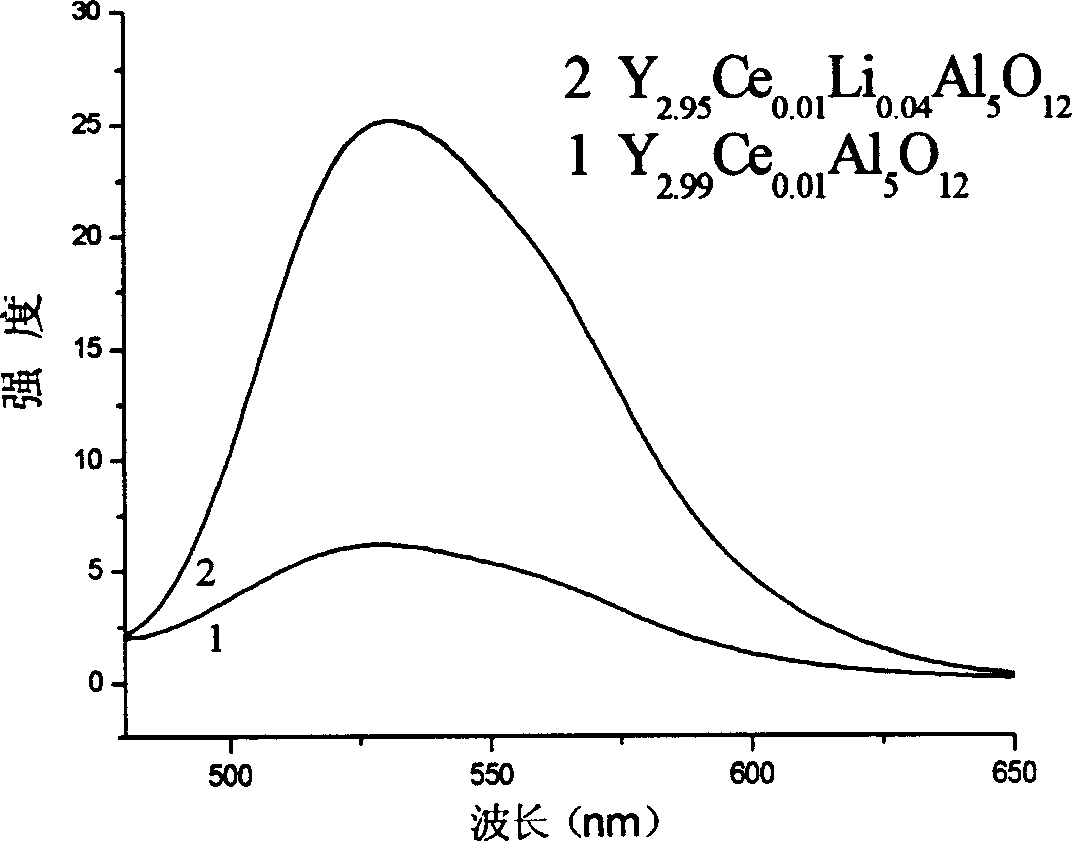

Carbuncle type yellow fluorescent material Y3Al5O12:Ce,Li preparation method

The preparation method for garnet yellow-light fluorescent material Y3Al5O12:Ce,Li comprises following steps: selecting material with mole proportion: (3-x-y) yttrium nitrate, x cerous nitrate, y lithium nitrate and 5 aluminum nitrate, wherein, 0.01<=x<=0.1, 0.01<=y<=0.08; determining x and y for proper nitrate to dissolve into deionized water; mixing evenly, adding citrate complexing agent with mole number as 1.6-3.2 times to the aluminum nitrate; heating and evaporizing the solution in water bath at 60-90Deg; adding nitric acid to control solution pH value between 4 and 7; mixing continually to form gel; combusting the gel slowly at 200-280Deg to obtain the precursor powder; calcining the powder at 800-1200Deg to obtain the product.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

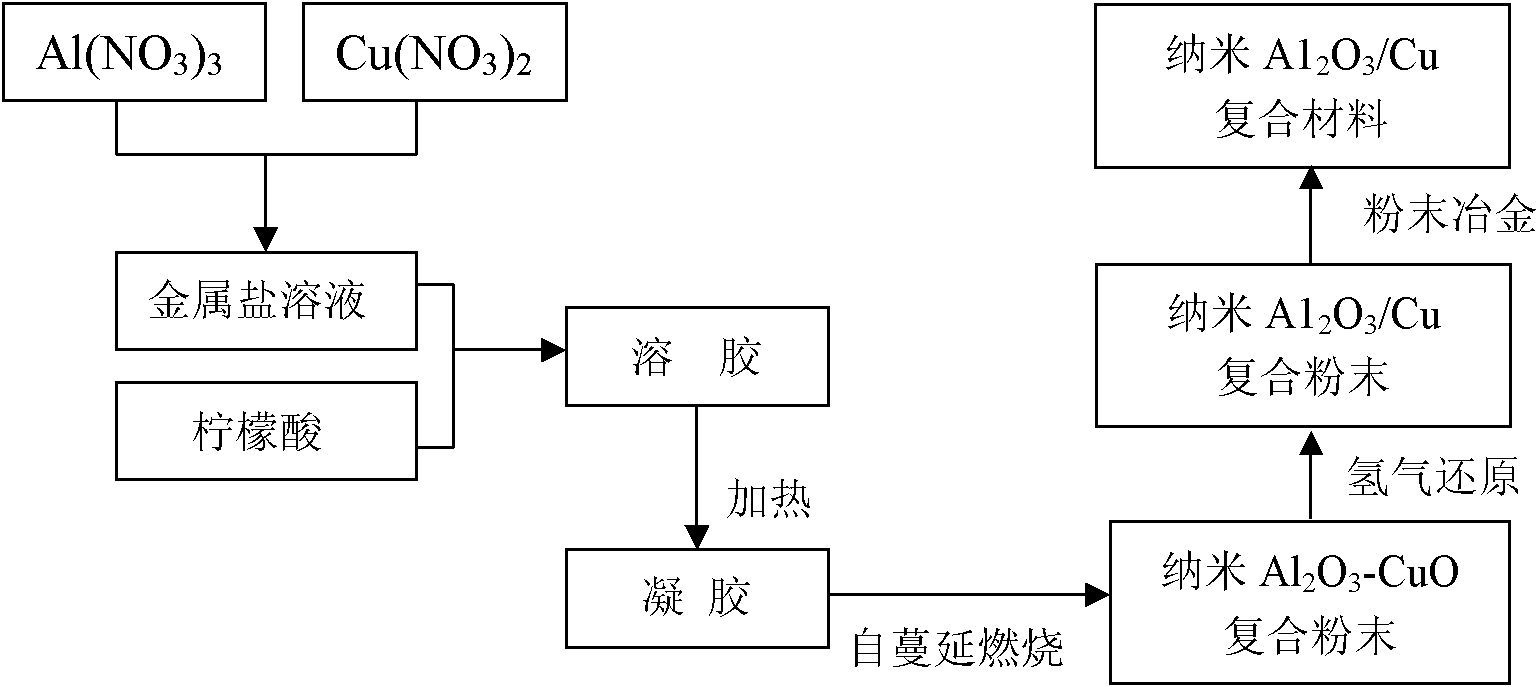

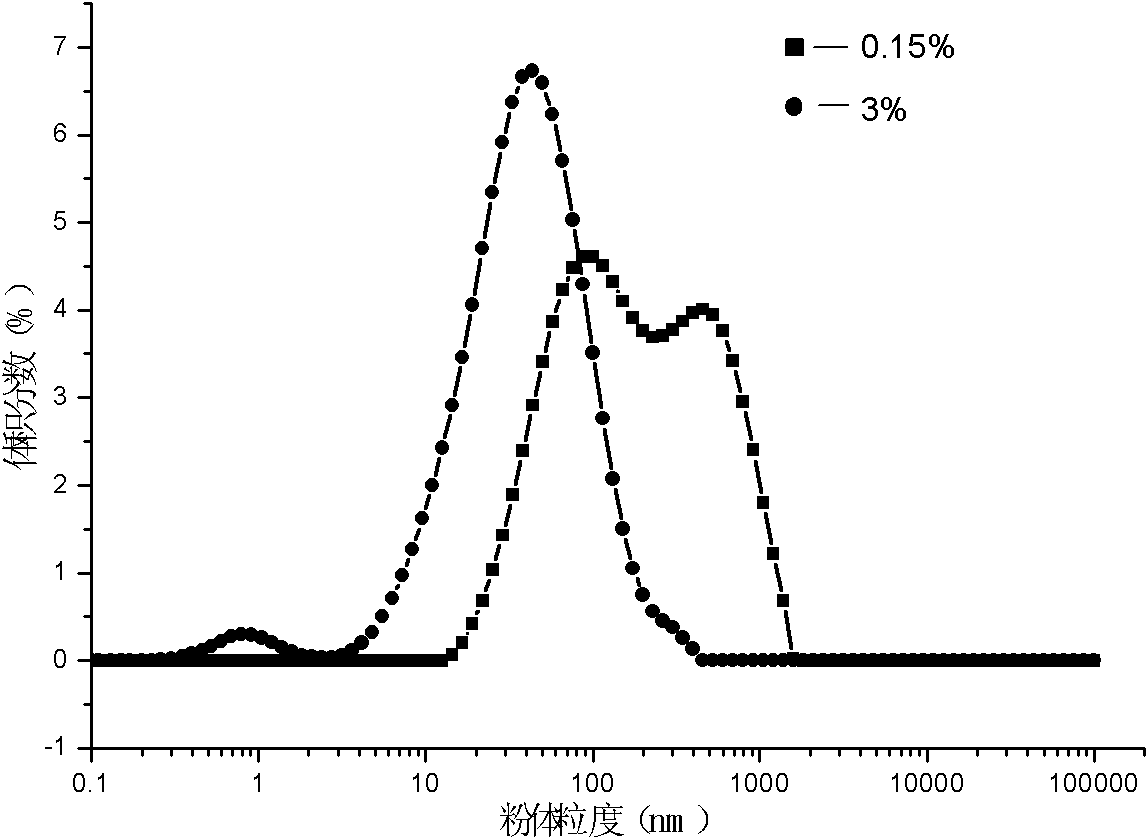

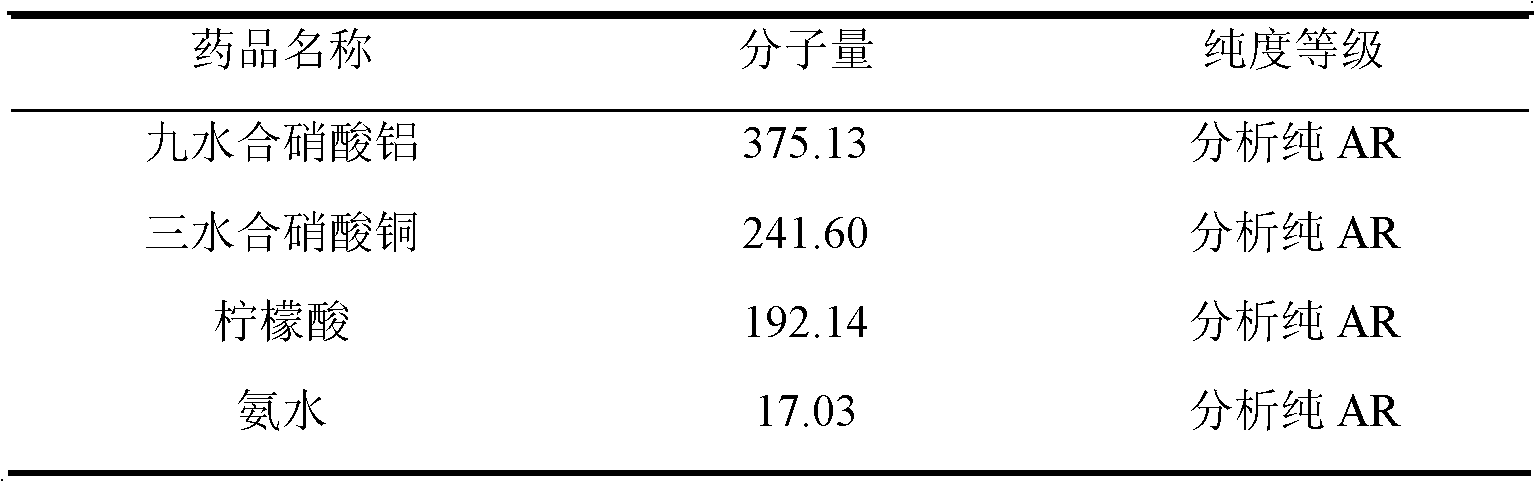

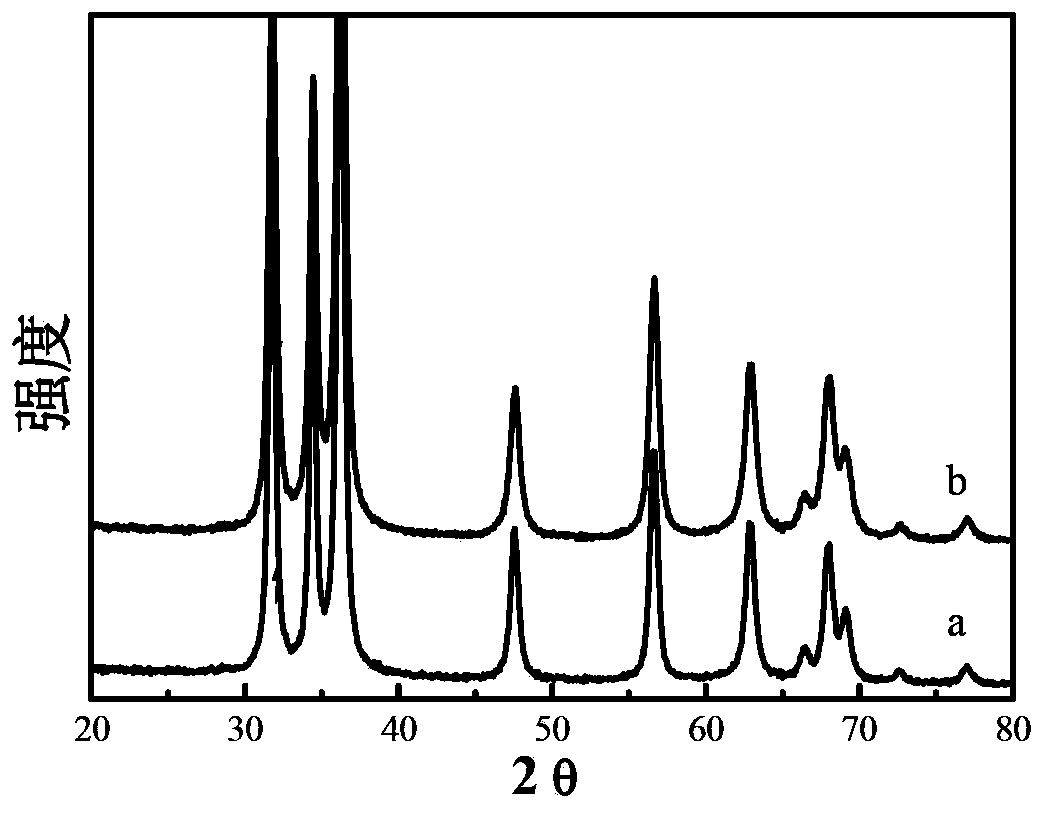

Preparation method of nano-alumina reinforcing copper-based composite

The invention relates to a preparation method of a nano-alumina reinforcing copper-based composite, comprising sol-gel preparation, self-spreading burning and reduction sintering. The preparation method is characterized by comprising the following steps of: mixing an aluminum nitrate solution and a copper nitrate solution, adding citric acid as a chelant, regulating pH value of the mixed solution to be less than seven to obtain sol, placing the sol in the environment with the temperature of 90 DEG C to 120 DEG C for more than 10 hours to form gel, heating the gel to 300 DEG C to 500 DEG C to carry out self-spreading burning, grinding to obtain black nano-alumina and copper oxide powder, sintering the black powder for more than 8h at 300-400 DEG C under a reducing atmosphere to obtain nano-alumina and copper composite powder, molding the composite powder by compression, and sintering in the reducing atmosphere of 800 DEG C to 900 DEG C for one to three hours to obtain the composite with the volume percentage content of Al2O3 is 0.1% to 3%. The composite can be widely used in the fields of machinery, electron, space flight and aviation, and the like.

Owner:HEFEI UNIV OF TECH

Preparation method of aluminum doped zinc oxide nano powder

InactiveCN103395826AHigh purityGood dispersionMaterial nanotechnologyZinc oxides/hydroxidesPolyvinyl alcoholAluminum doped zinc oxide

The invention discloses a preparation method of aluminum doped zinc oxide nano powder. A technological process of the preparation method is shown as follows: first synthesizing a zinc nitrate-urea white sol microemulsion, standing, then filtering, adding aluminum nitrate into a filtering liquid to form a zinc nitrate aluminum mixed solution; preparing a sodium carbonate solution, dropping both the sodium carbonate solution and the zinc nitrate aluminum mixed solution into a polyvinyl alcohol aqueous solution to synthesize a white precipitate precursor; standing and filtering, and thus obtaining the aluminum doped zinc oxide nano powder through deionized water leaching, drying, grinding, sieving and calcining of a filter cake. The aluminum doped zinc oxide nano powder obtained by the method has good dispersibility and less agglomeration, the powder particle size is between 5 and 30 nm, the particle size distribution range is narrow, and the morphology is spherical or quasi spherical. The method has the advantages of simple process, low cost, short reaction period, high yield, and easy control of the reaction processes, and is suitable for mass production; and compared with traditional methods, the powder produced by the method contains no chlorine ion which can influence the performance of the powder, and the method needs no ethanol for washing, and no alkali for neutralization.

Owner:DALIAN JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com