Preparation method of polyacrylamide nano composite fracturing fluid

A polyacrylamide and nano-composite technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of poor high temperature resistance and low application efficiency, and achieve the effect of less degradation residue and improving oil and gas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of nano-inorganic phase of polyacrylamide nanocomposite fracturing fluid

[0035] First, the co-precipitation method is used to prepare the hydrotalcite slurry, magnesium nitrate and aluminum nitrate are dissolved in a certain amount of distilled water according to the molar ratio of 2: 1, sodium hydroxide and 2-acrylamido-2-methylpropanesulfonic acid ( AMPS) was dissolved in a certain amount of distilled water at a molar ratio of 1:1, and the sodium hydroxide / AMPS aqueous solution was slowly added dropwise into the magnesium nitrate / aluminum nitrate mixed solution under high-speed stirring, and 3mol / L sodium hydroxide was slowly added dropwise after stirring evenly The solution adjusts the pH value of the solution to about 10 to prepare a hydrotalcite slurry.

[0036] Next, add 20g of montmorillonite and 400mL of deionized water into a 1000mL three-neck flask, disperse evenly and then heat. After the water bath is heated to 80°C, slowly add cetylt...

Embodiment 2

[0037] The preparation of embodiment 2 polyacrylamide nanocomposite thickener

[0038] Dissolve 300g of acrylamide in 600g of deionized water, add a certain amount of cosolvent urea to the acrylamide solution, complexing agent edetate disodium, add sodium hydroxide to adjust the pH to about 10.5, add 140mL of nano inorganic phase to suspend Put the above solution into the adiabatic polymerization device, pass nitrogen gas to remove oxygen for 20min, add 0.24g of azo initiator azobisisobutyronitrile, 0.24g of oxidizing agent ammonium persulfate and 0.18g of reducing agent sodium bisulfite every 3min, The polymerization reaction was started for 3h. Then adjust the temperature to 100°C and hydrolyze for 3h. The colloid is taken out and diced, dried at 80° C., and pulverized to obtain a polyacrylamide nano-composite material. The size of the inorganic dispersed phase is 20-25 nm, and a modified polyacrylamide nano-composite thickener is obtained.

Embodiment 3~6

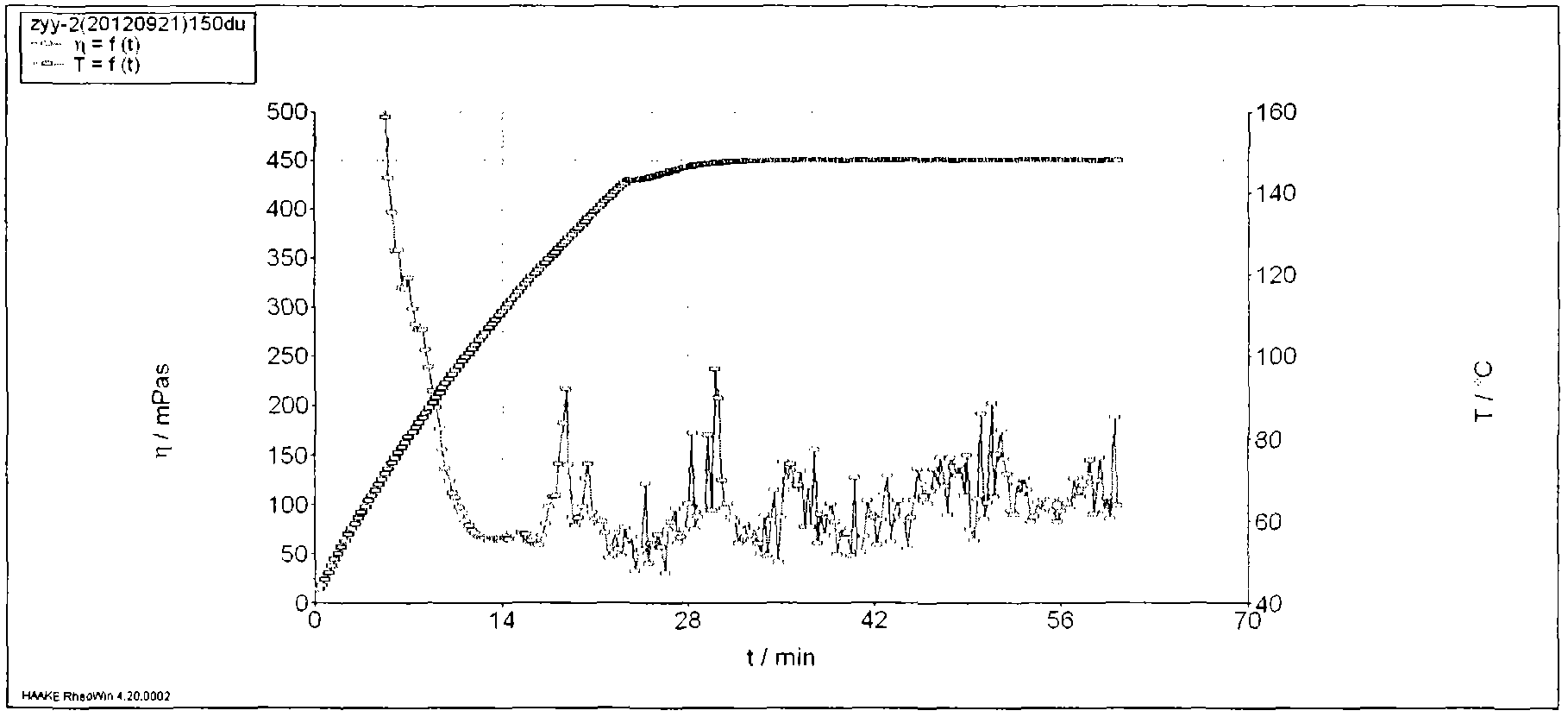

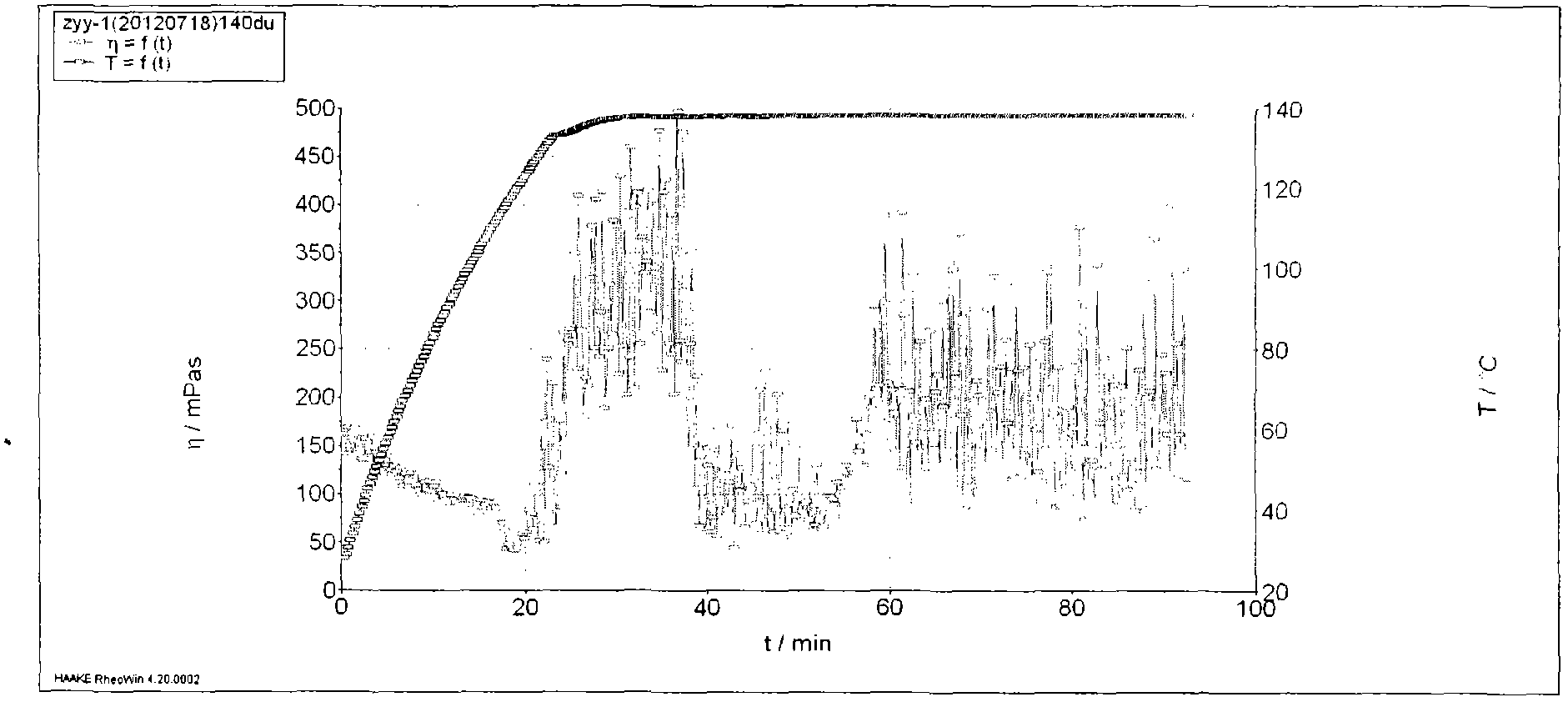

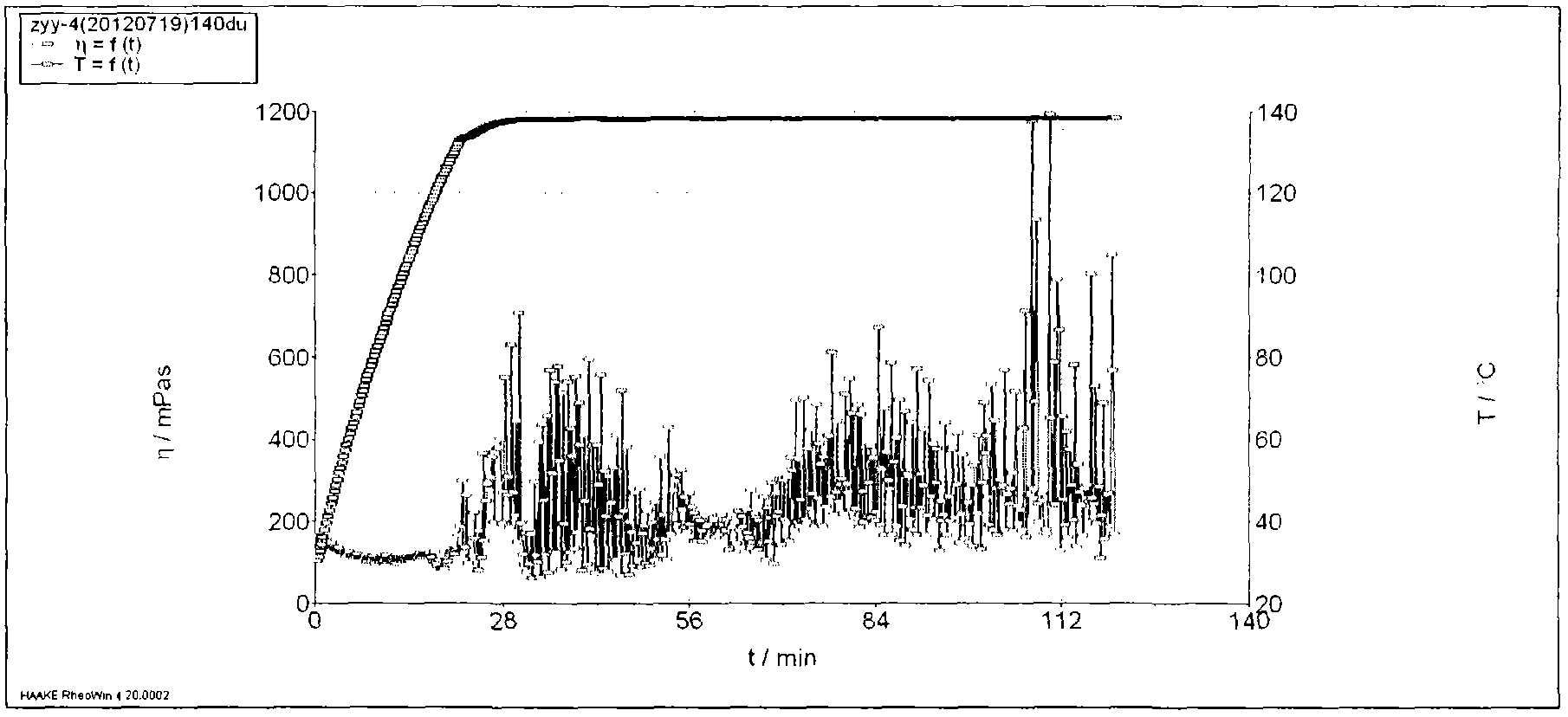

[0039] Example 3-6 Preparation of polyacrylamide nanocomposite fracturing fluid

[0040] Add 350mL of deionized water, 15.21g of montmorillonite, 4.97g of intercalation agent sodium dodecylsulfonate, and 0.1mol / L hydrochloric acid into a 1000mL three-neck flask to adjust the pH value to about 5, and perform intercalation in a water bath at 80°C. The layers were reacted for 12 hours. After stopping the reaction, when the temperature of the solution drops to room temperature, add the polyacrylamide inorganic nanocomposite thickener with the mass fraction set to 0.15%, 0.20%, 0.25%, and 0.30% respectively under high-speed stirring, and complete stirring until After the thickener is completely dissolved, add the crosslinking agent ZrOCl 2 2g, gel breaker ammonium persulfate 2g, clay stabilizer KCl 1.5g, bactericide tetradecyl quaternary ammonium salt 1.5g, drainage aid OP-10 1.5g, stir well to obtain polyacrylamide nanocomposite fracturing fluid. The measurement results with a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com