Patents

Literature

51results about How to "Salt resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylamide polymer thickener and preparation method thereof, and fracturing fluid

ActiveCN106146730AHigh temperature resistanceImprove high temperature resistanceDrilling compositionPolymer scienceFracturing fluid

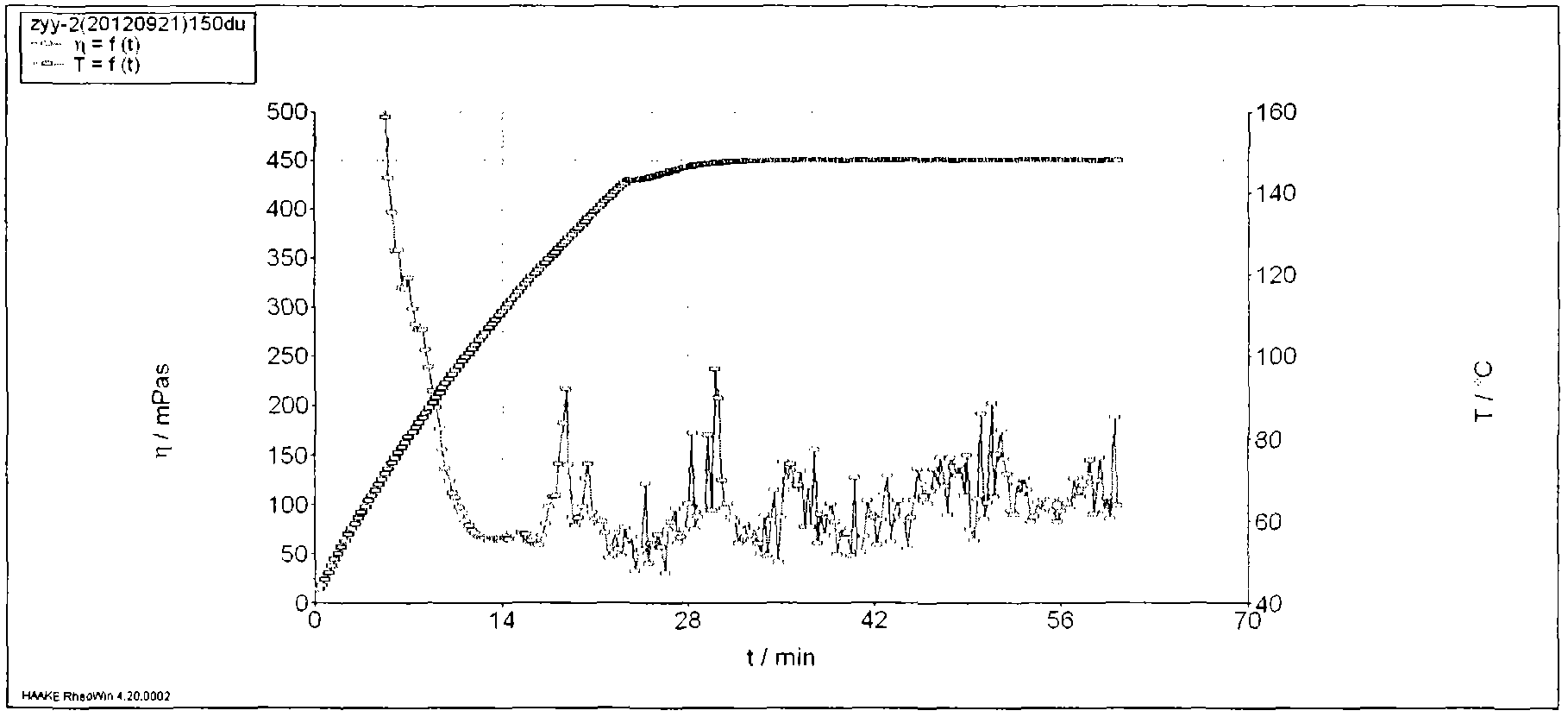

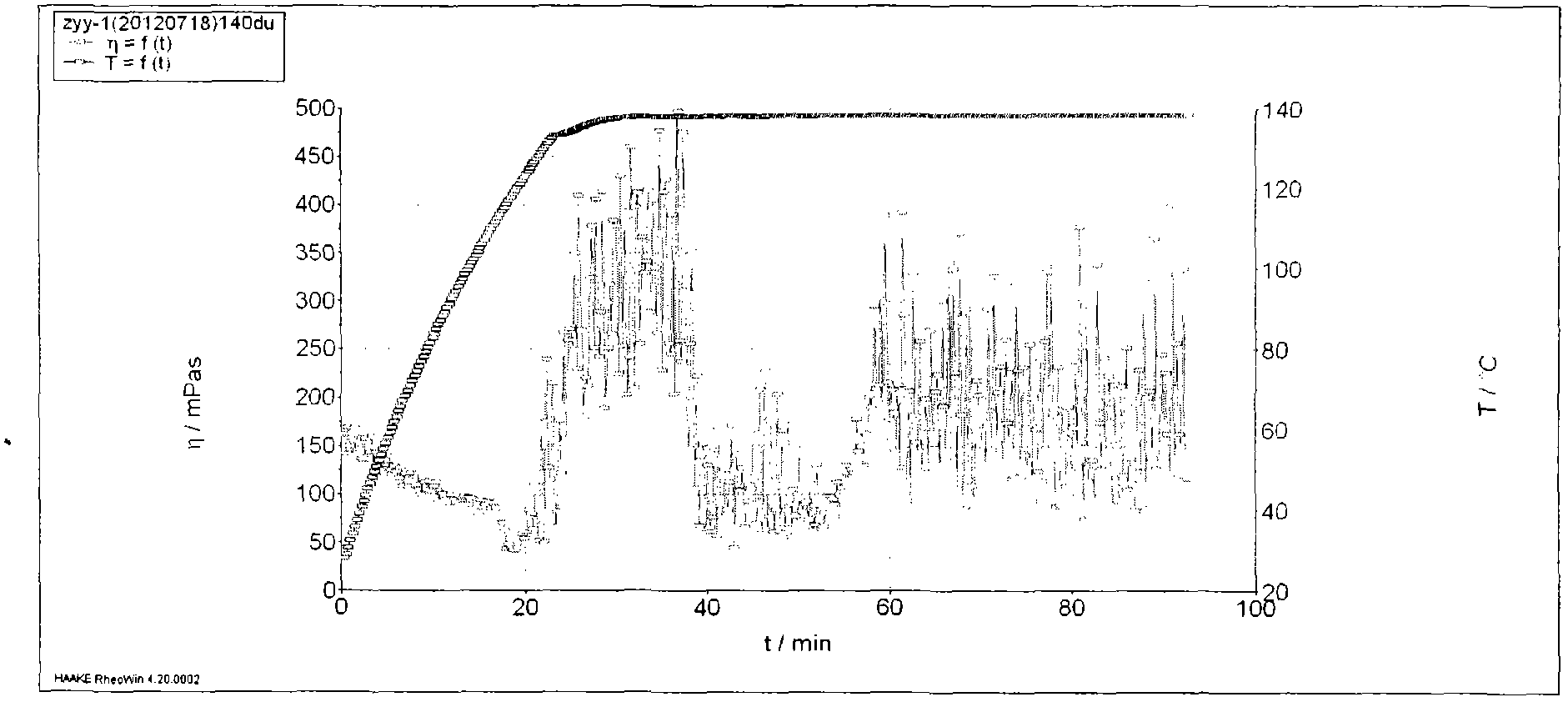

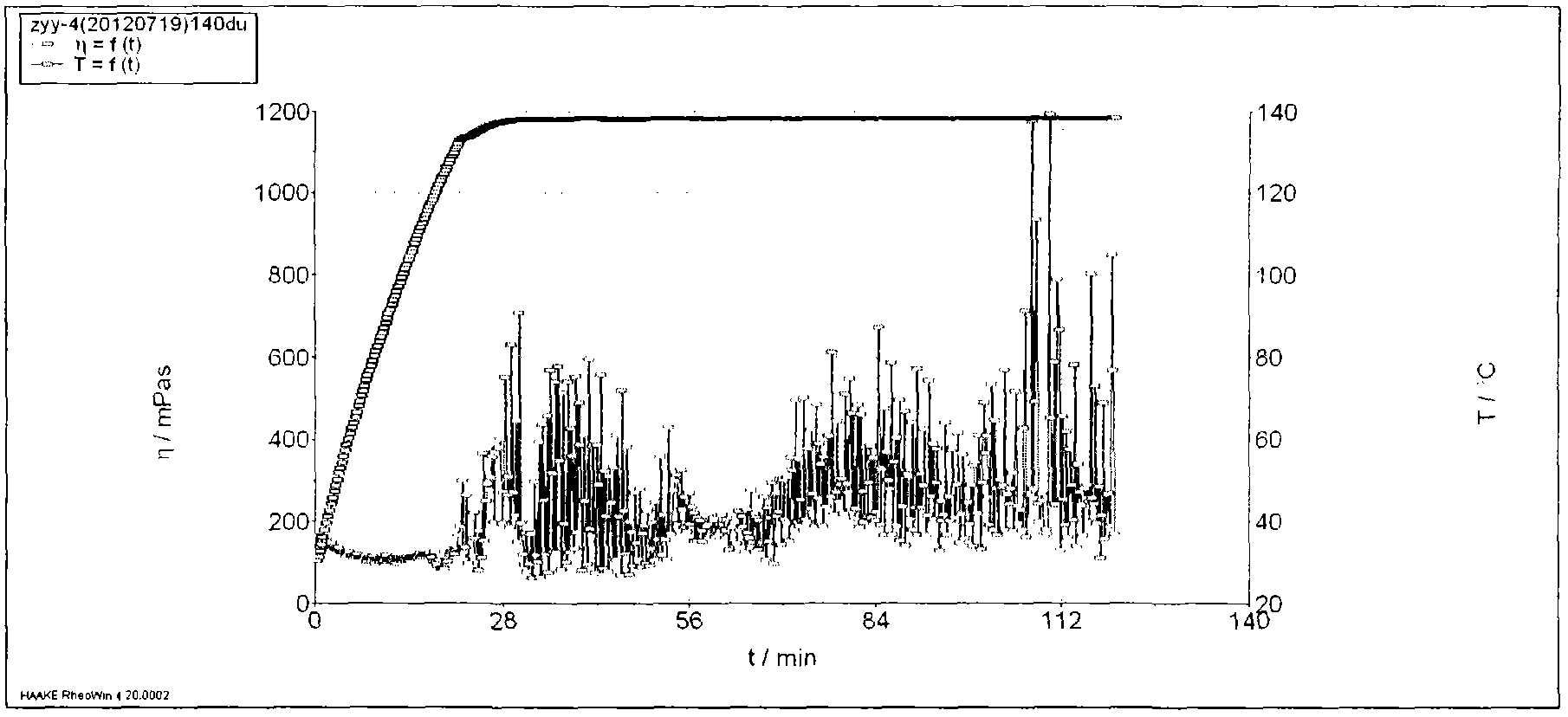

The invention provides an acrylamide polymer thickener and a preparation method thereof, and a fracturing fluid, wherein the acrylamide polymer thickener is composed of the components by the mass percentage: 20%-45% of a hydrophilic propenyl monomer, 4%-6% of a hydrophobic propenyl monomer, 1%-2% of an emulsifier, 0.2%-0.5% of an initiator, a latent crosslinking agent and the balance water, wherein the latent crosslinking agent accounts for 0.5%-1.8% of the total mass of the hydrophilic propenyl monomer and the hydrophobic propenyl monomer; the acrylamide polymer thickener provided by the invention solves the technical problems in the prior art that a polymer thickener has poor temperature resistance and salt tolerance and poor shearing stability, and the prepared acrylamide polymer thickener has high-temperature performance, and can effectively meet the requirements of on-site construction of slick water fracturing.

Owner:PETROCHINA CO LTD

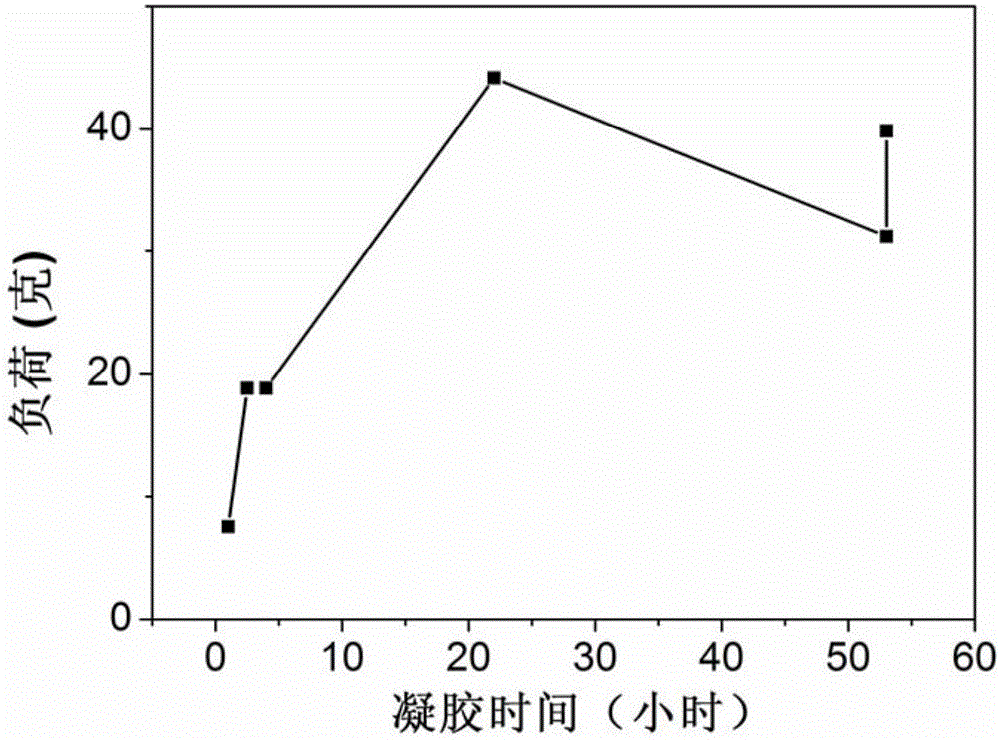

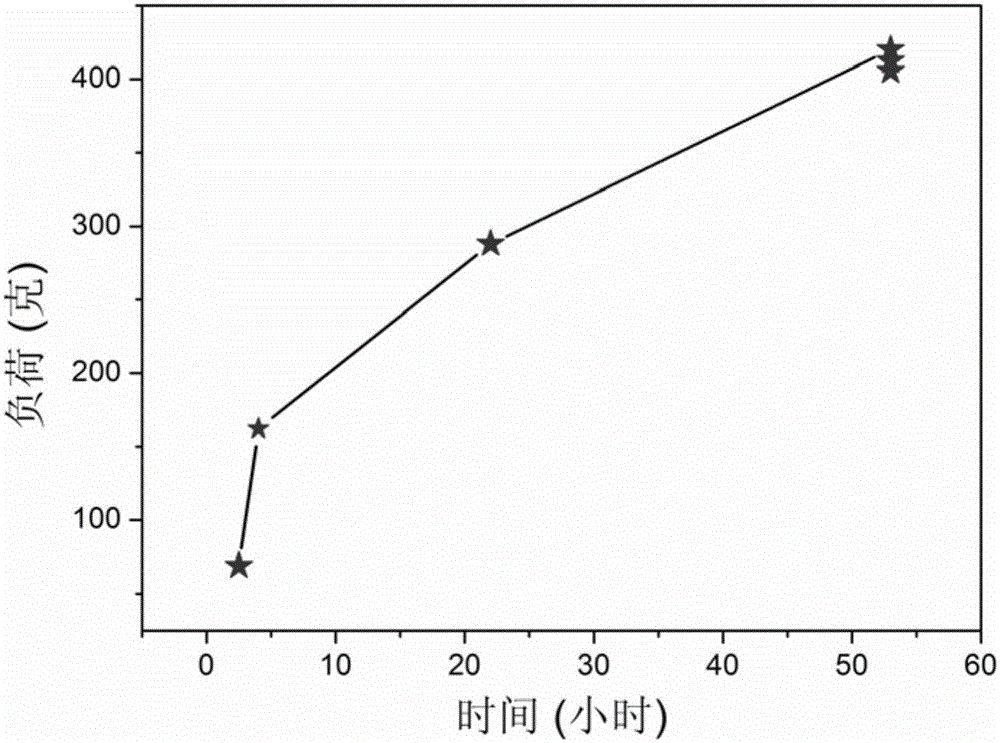

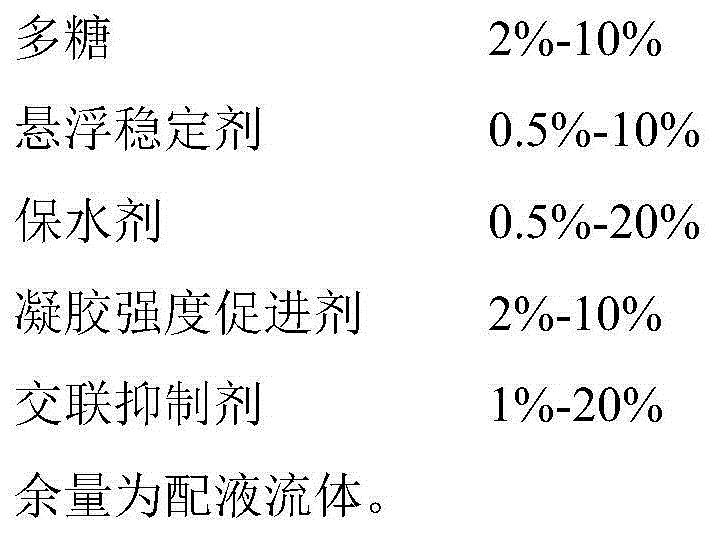

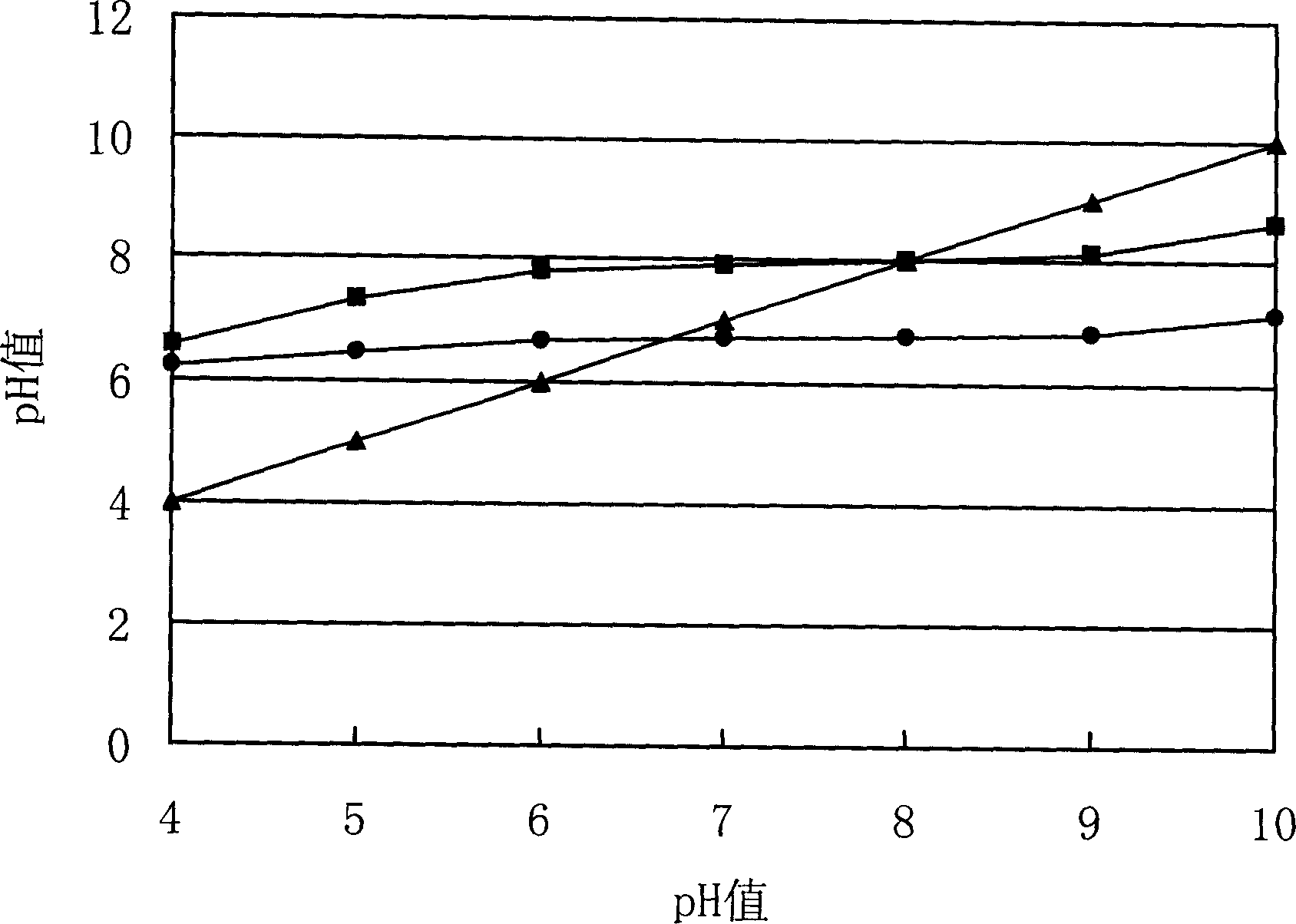

Profile modifying/water plugging agent and preparation method and application thereof

The invention relates to the technical field of oil field development, and in particular relates to a profile modifying / water plugging agent for oil well water plugging and profile modification. The water plugging agent is prepared from the following components in mass percent: 1-15% of polysaccharide, optimally 2-10% of the polysaccharide; 0.5-10% of a suspension stabilizer, optimally 1-6% of the suspension stabilizer; 0.5-20% of a gel strength accelerating agent, optimally 2-10% of the gel strength accelerating agent; and the balance of preparation fluid. The invention also provides a method for preparing the water plugging agent and application thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing poly-aspartic-acid resin

This invention relates to a preparation method for poly-asparagic acid resin, which takes poly-pyrrolidine dione as the raw material to make crosslink poly-pyrrolidine dione with method of non-even phase suspended emulsion crosslink or non-even phase suspension crosslink and processes poly-asparagic acid resin by hydrolyzation characterizing that the crosslink poly-pyrrolidine dione is prepared by multi-section crosslink reaction, in which, the crosslinker is fed in for 2-4 times in equal volume and equal time interval, the crosslink poly-pyrrolidine dione and the resin are aged and crystallized and quickly dried, A ageing and crystallization process for 1-10 days under room temperature, B, quick drying process is carried out under -54-40deg.C.

Owner:BEIJING UNIV OF CHEM TECH

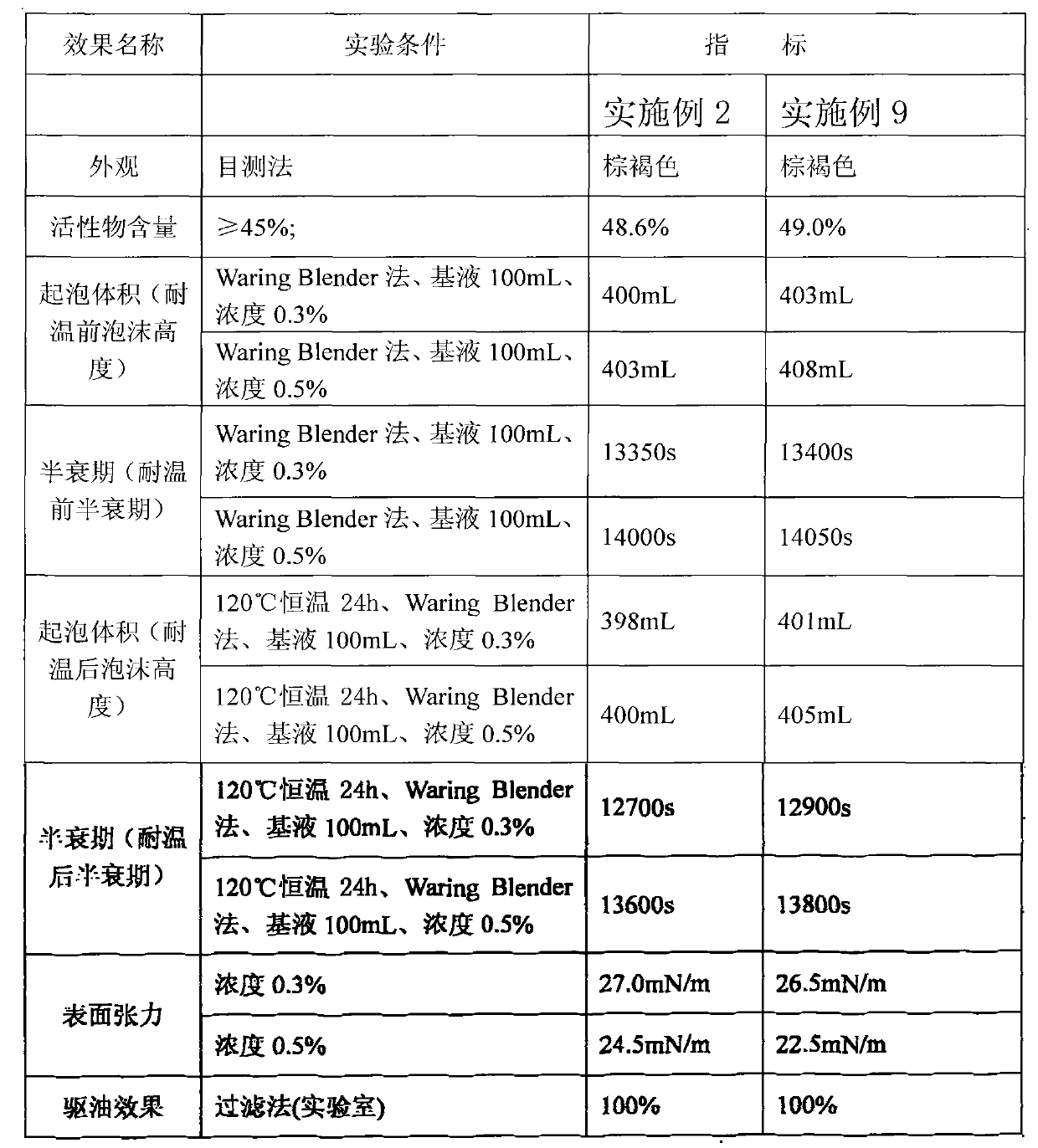

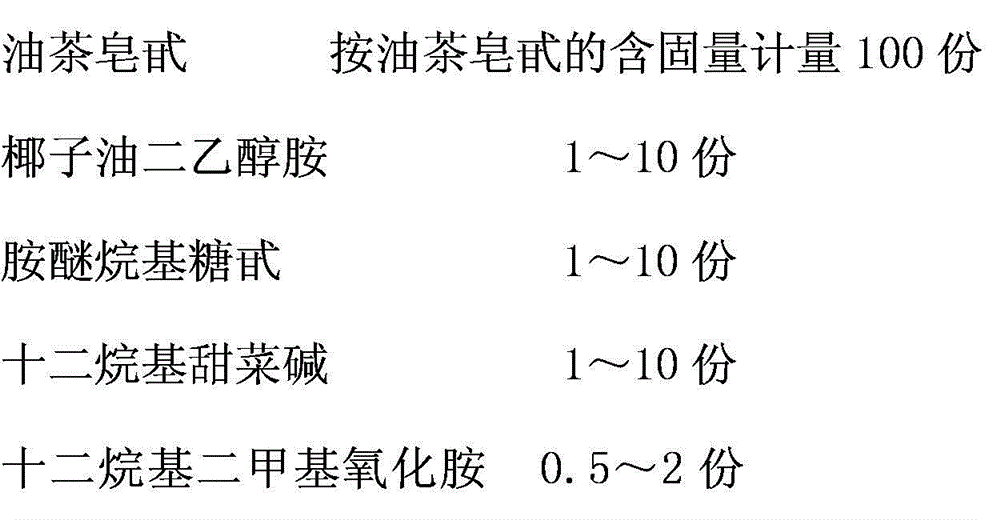

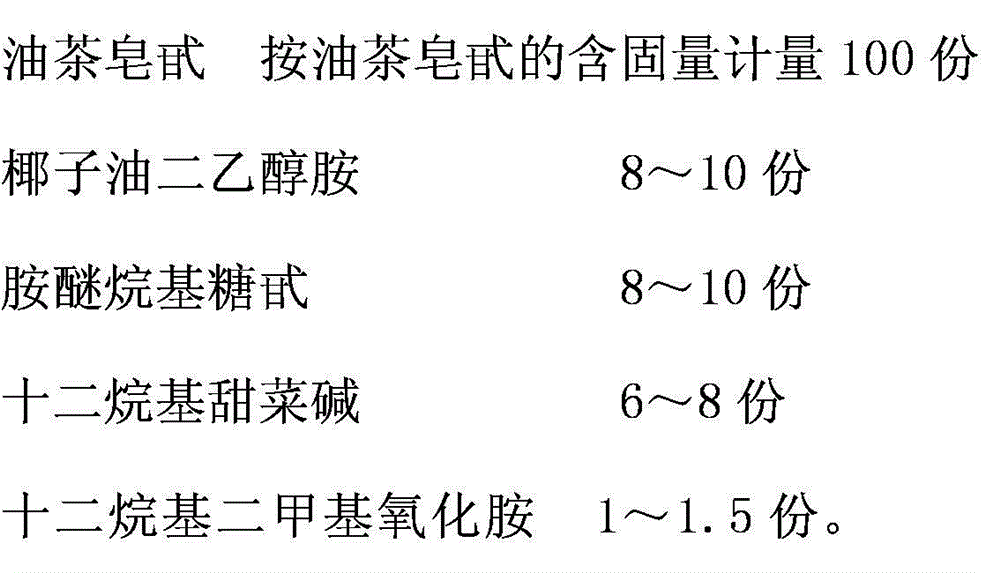

Camellia saponin type oilfield foaming agent and preparation method and application thereof

ActiveCN101906296AHigh foaming ratioLong bubble timeDrilling compositionChemical recyclingChemistryChemical synthesis

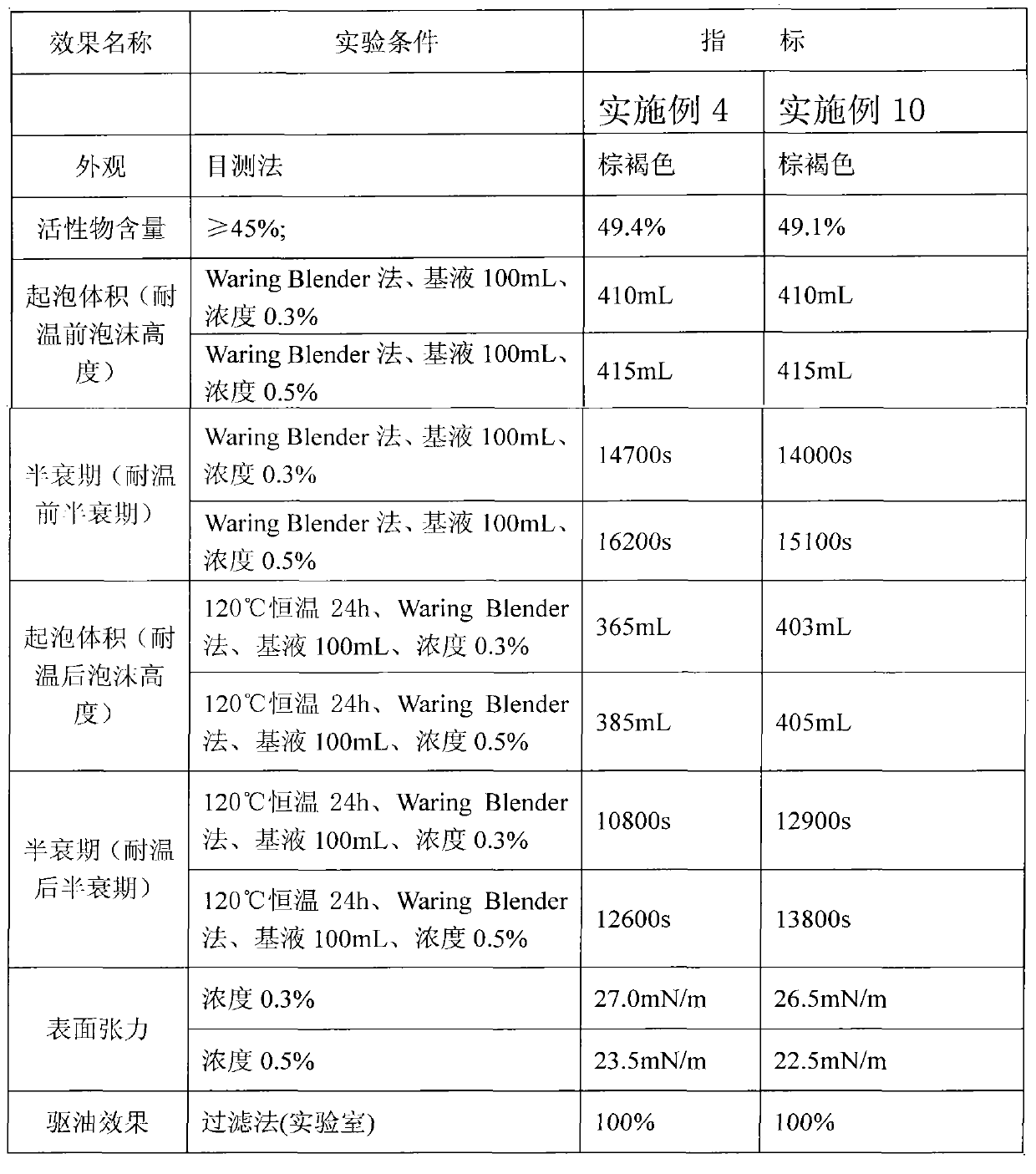

The invention relates to a camellia saponin type oilfield foaming agent and a preparation method and application thereof. The oilfield foaming agent comprises the following components in part by mass: 100 parts of camellia saponin based on the solid content, 1 to 10 parts of cocoanut oil diethanol amide, 1 to 10 parts of amine ether alkyl glucoside, 1 to 10 parts of dodecyl betaine, and 0.5 to 2 parts of lauryl dimethy amine oxide, wherein the camellia saponin is natural plant source camellia saponin or structure-modified camellia saponin. The camellia saponin type oilfield foaming agent is used as an oilfield foaming agent in oil recovery, has the characteristics of acid, alkali and salt resistance, temperature resistance, high foam expansion ratio, long stable foam time and the like, can meet oil extraction requirements under different geological and weather conditions, cannot pollute an oilfield soil layer employing the foaming agent, can prevent a chemically synthesized foaming agent from harming the oilfield stratum, and has remarkable environmental protection characteristic.

Owner:青田中野天然植物科技有限公司

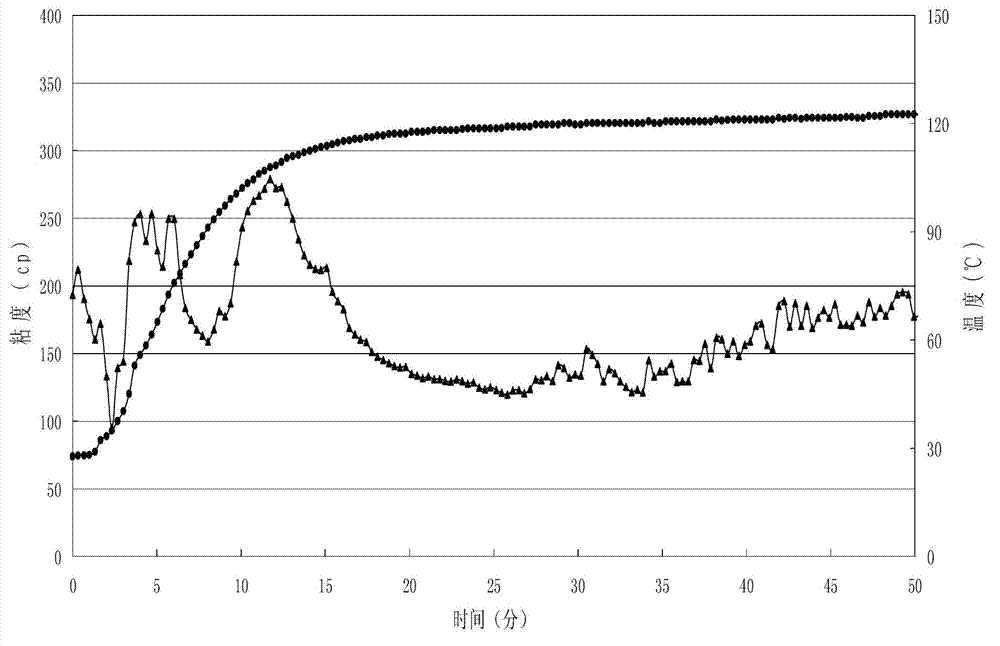

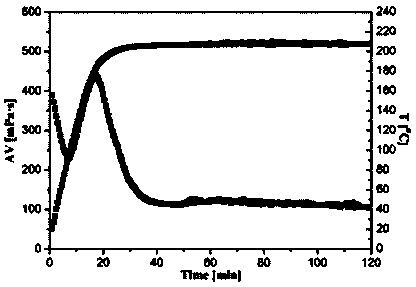

Preparation method of polyacrylamide nano composite fracturing fluid

ActiveCN104109525AHigh temperature resistantSalt resistantDrilling compositionIn situ polymerizationFracturing fluid

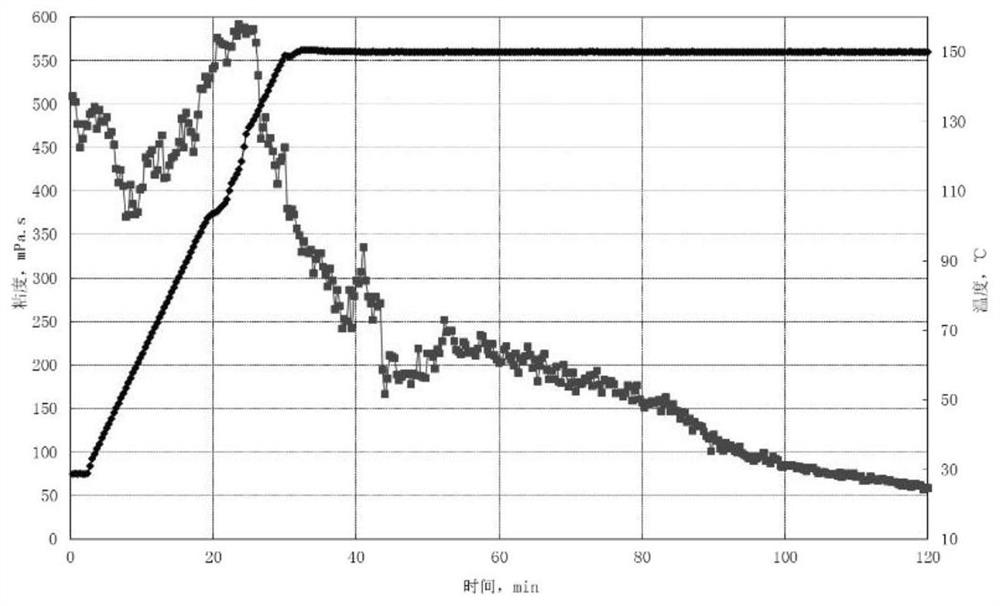

The invention adopts polyacrylamide and a nano inorganic phase to prepare a polyacrylamide nano composite material through an in-situ polymerization method and then forms a fracturing fluid thickening agent. The nano inorganic phase is prepared by mixing the products of intercalation reactions between an organic long-chain intercalator and layered silicate with magnesium nitrate and aluminum nitrate. The nano inorganic phase, acrylamide monomer, a coupling agent, a complexing agent, an initiator, an oxidant, a reductant, a cosolvent, an auxiliary agent, and deionized water form a suspension fluid reaction system, and the polyacrylamide nano composite material is formed after the polymerization-intercalation composite reactions. The polyacrylamide nano composite material with a mass percentage of 0.25% is taken as the thickening agent, and then is mixed with a crosslinking agent with a mass percentage of 0.20%, a gel breaker with a mass percentage of 0.20%, and other auxiliary agents to form a fracturing fluid system. The system is sheared for 70 minutes under a shearing speed of 170 s<-1> at a temperature of 150 DEG C so as to form a fracturing fluid with a viscosity larger than 50 mPa.s, and the fracturing fluid has the characteristics of high temperature resistance, shearing resistance, low frictional resistance, complete glue breaking effect, and good compatibility with the formation fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

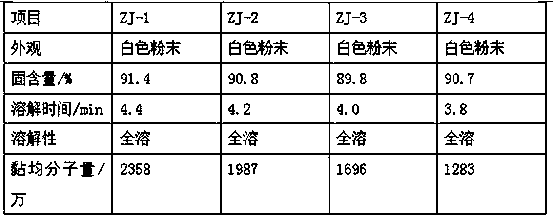

Shale gas well slickwater fracturing fluid system high-efficiency emulsion quick water-soluble drag reducer

ActiveCN103937484AEasy to useGood drag reduction effectDrilling compositionFracturing fluidDouble bond

The invention relates to a shale gas well slickwater fracturing fluid system high-efficiency emulsion quick water-soluble drag reducer, belonging to the technical field of oilfield drag reducers. The drag reducer is prepared by initiating polymerization of a component A, a component B and a component C by a free-radical initiator in water, wherein the component A is composed of a plurality of nonionic water-soluble monomers with carbon-carbon double bond; the component B is a water-soluble polymer stabilizer of univalent cationic monomers; and the component C is a univalent cationic inorganic salt. The drag reducer is simple to use, quick to hydrate and convenient to add, is green and environment-friendly, and has the advantages of high dissolution rate, no bubbling, salt resistance, calcium resistance, pollution resistance, high temperature resistance, favorable compatibility, no need of adding defoaming agent and the like; and the drag reduction efficiency can reach 70% when the drag reducer is used in fracturing. The drag reducer solves the problems of high tendency to granulation and low tendency to hydration in the use process of the existing drag reducer using dry powder, and the problem that the poor compatibility among various different ions and chemical assistants in the fracturing fluid can directly influence the feasibility and effectiveness of the slickwater fracturing.

Owner:荆州市现代菲氏化工科技有限公司

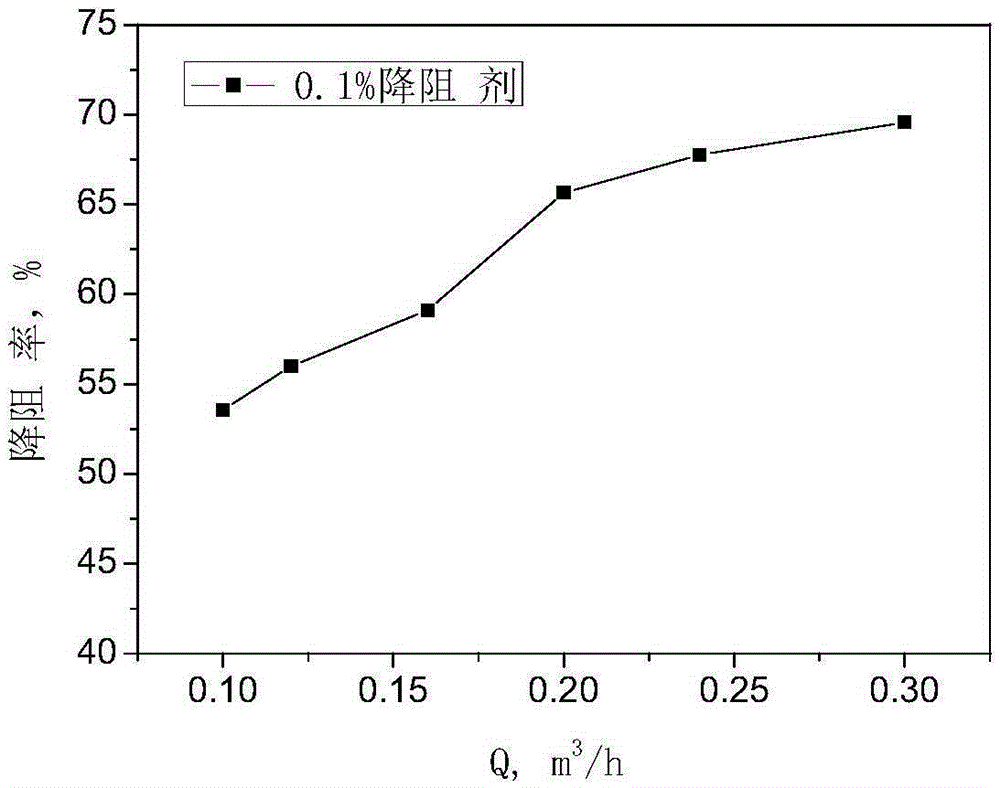

Instant water-in-oil resistance-reducing agent and preparation method thereof

The present invention provides an instant water-in-oil resistance-reducing agent and a preparation method thereof. The resistance-reducing agent is synthesized by inverse emulsion polymerization. In particular, the preparation method comprises the steps of dissolving a water-soluble monomer into an aqueous phase; dispersing the monomer into a nonpolar liquid to form a water-in-oil emulsion by an emulsifier while stirring, wherein an initiator performs initiation to carry out a polymerization reaction; basic composition of an aqueous phase is acrylamide, methacrylate and 2-acrylamide-2-methylpropanesulfonic acid; and basic composition of an oil phase is white oil and a mixed surfactant. The water-in-oil resistance-reducing agent synthesized by the preparation method is an ivory emulsion liquid which is a high molecular polymer; the agent has good stability and a certain degree of fluidity, and can be directly used and rapidly dissolved in water. By using the resistance-reducing agent to prepare a slippery water fracturing fluid, the agent has the characteristics of small dosage, high temperature resistance, salt resistance and shearing resistance; the agent is suitable for an online continuous mixing technological process; the resistance-reducing rate can reach 69.6%; and damage to a reservoir is very low.

Owner:CNPC BOHAI DRILLING ENG

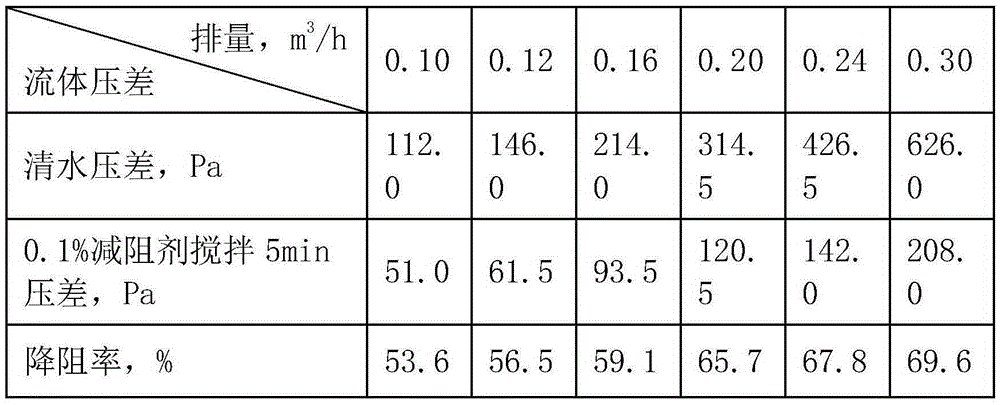

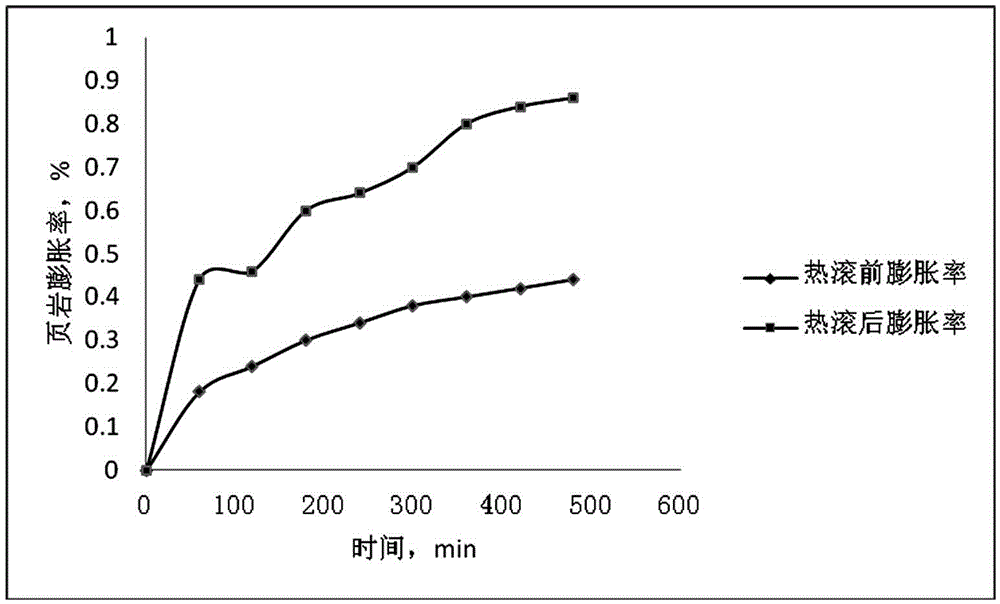

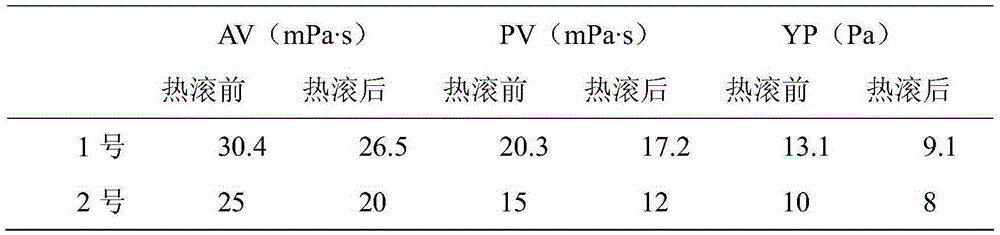

High-temperature resistant clay stabilizer and preparation method thereof

ActiveCN104418984AInhibits hydration swellingHigh freedom of movementDrilling compositionEpoxySulfonate

The invention discloses a high-temperature resistant clay stabilizer and a preparation method thereof. The preparation method comprises the following steps: carrying out initiation reaction on epoxy chloropropane, dimethylamine and unsaturated quaternary ammonium salt with a sulfonate-containing anionic monomer under a certain condition; and then adding a chain transfer agent in the reaction process to control the molecular weight and after reaction, obtaining the clay stabilizer, wherein both the main and side chains contain cations and the side chain further contains anions. The clay stabilizer has the abilities of resisting temperature, preventing salt and resisting pollution; the clay stabilizer is small in use level, scouring resistant and good in anti-swelling effect; and the molecular weight is ranged from 1500 to 6000, so that the high-temperature resistant clay stabilizer is suitable for a low permeability reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

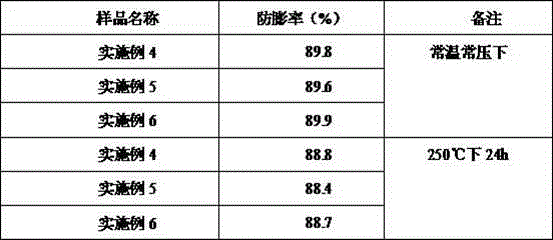

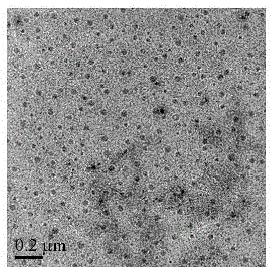

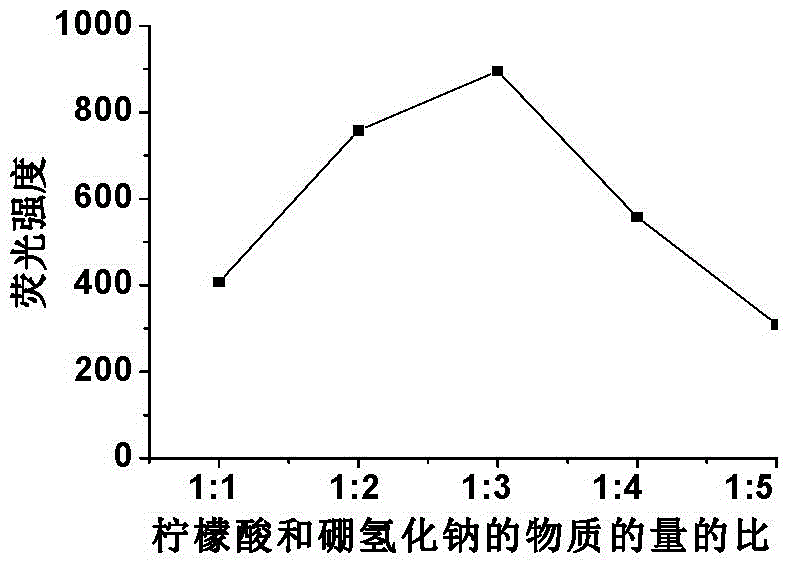

Silicon quantum dot aqueous phase preparation method

InactiveCN105969344ASynthetic operation is simpleSimplify the experimental operation stepsNanoopticsLuminescent compositionsUreaOrganic solvent

The invention discloses a water-phase preparation method of silicon quantum dots, comprising the following steps: (1) taking a reducing agent and a silane coupling agent and dissolving them in water under the protection of an inert gas, and the molar ratio of the silane coupling agent to the reducing agent is: 1:0.2~10; (2) Transfer the mixed solution obtained in step (1) into a high-pressure reactor and heat it to 140-220°C, and the silicon quantum dot solution can be obtained after the reaction; or the mixed solution obtained in step (1) The solution is transferred to a microwave reactor and heated to 140-220°C, and the silicon quantum dot solution can be obtained after the reaction; (3) the silicon quantum dot solution obtained in step (2) is mixed with an organic solvent, centrifuged, and the supernatant is removed. dry to obtain solid silicon quantum dots; wherein the reducing agent is citric acid, sodium sulfite, sodium borohydride, sodium citrate, ascorbic acid, urea, thiourea, hydrazine hydrate, L-cysteine, bovine serum albumin or Mixture of two or more in denatured bovine serum albumin.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

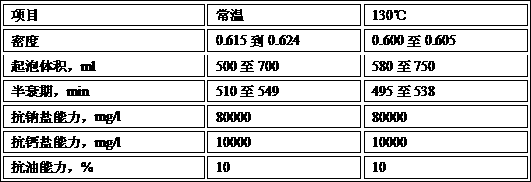

High-temperature ebonite foam for unbalanced drilling and preparation method thereof

ActiveCN103013477ATemperature resistantSalt resistantDrilling compositionSalt resistanceFoaming agent

The invention relates to the technical field of unbalanced drilling, and particularly relates to high-temperature ebonite foam for unbalanced drilling and a preparation method thereof. The high-temperature ebonite foam for unbalanced drilling comprises the following components in percentage by weight: 1-3% of bentonite, 3-6% of composite foaming agent, 0.3-0.6% of foam stabilizer and the balance of water. Through the synergistic effect of the composite foaming agent and the foam stabilizer, the high-temperature ebonite foam provided by the invention has the characteristics of dense foam, temperature resistance, salt resistance, strong oil resistance and stable foam performance; and the sand carrying ability is enhanced, and the requirements for drilling construction are met better.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

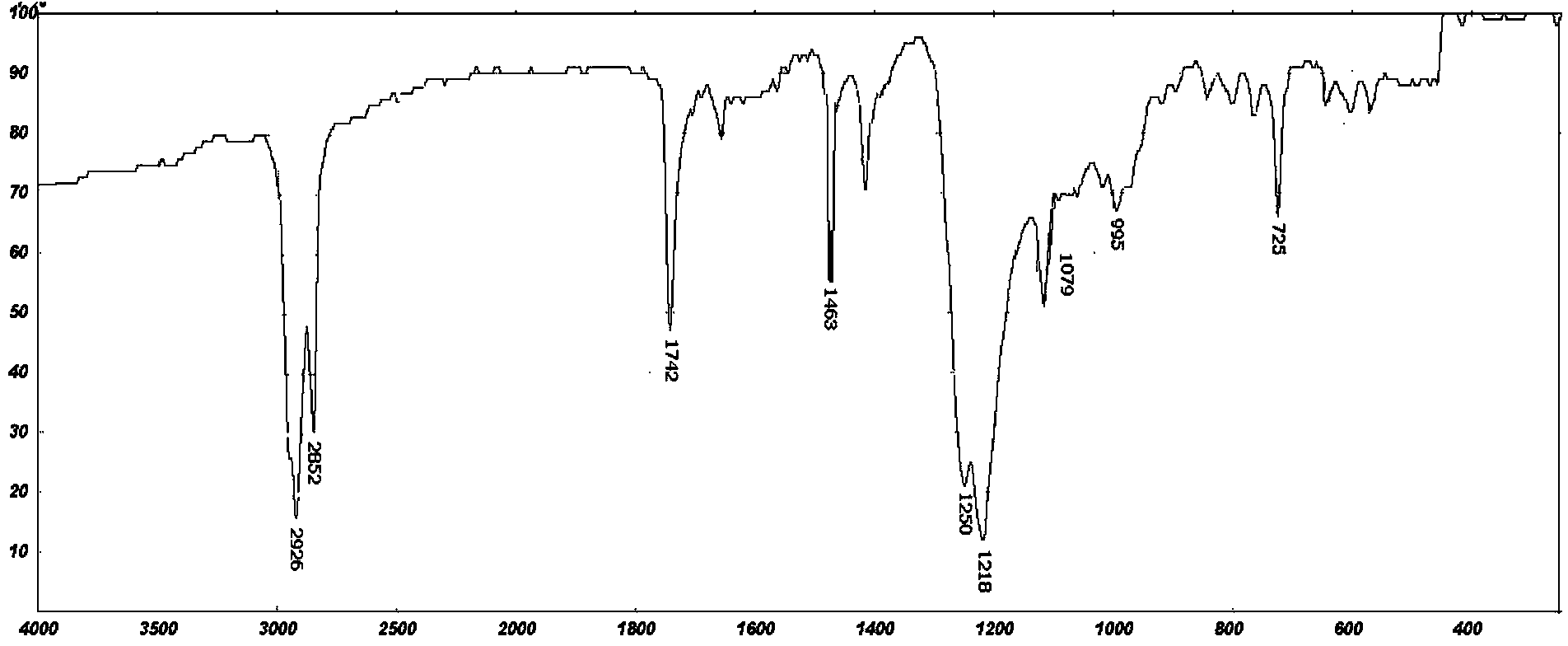

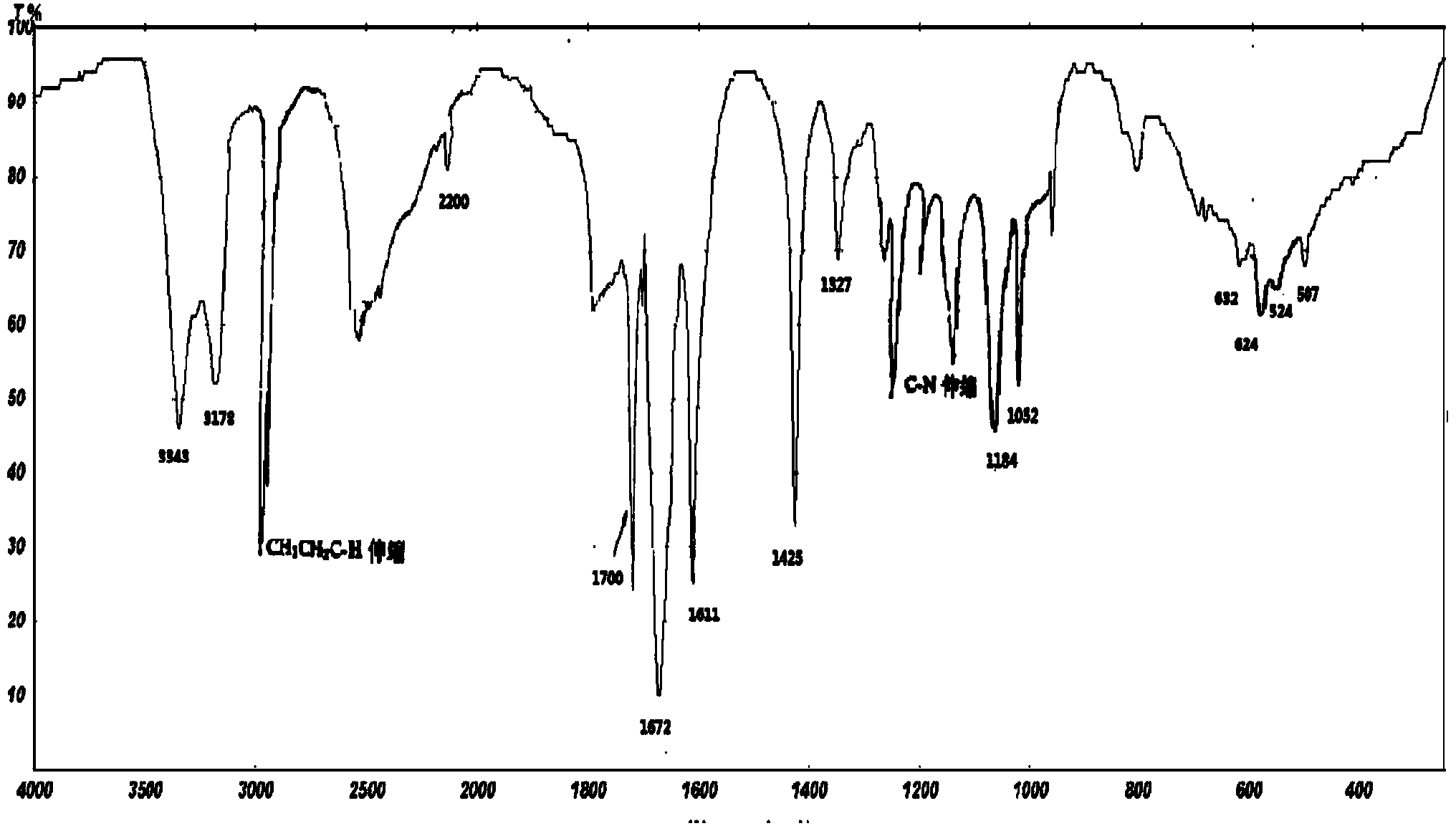

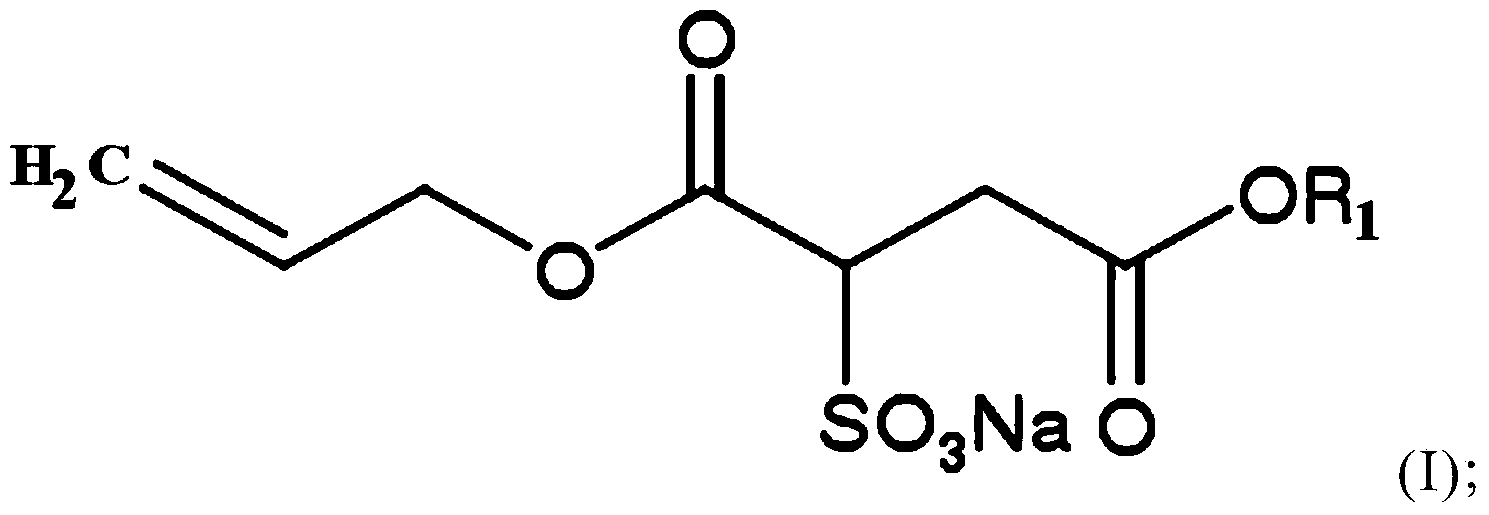

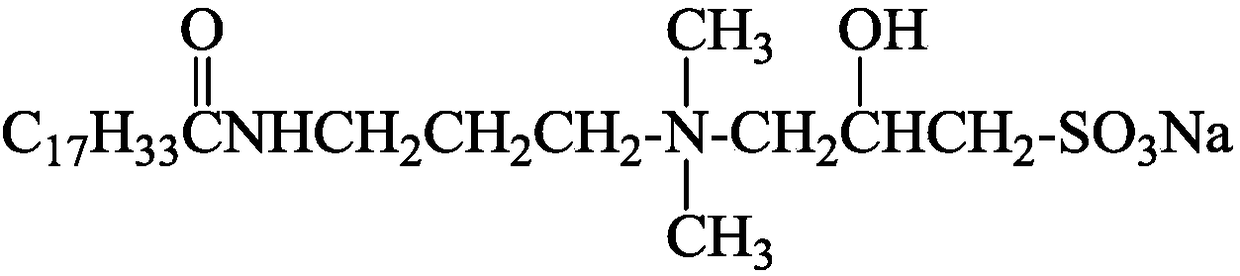

Preparation method and application of novel polymeric surfactant

ActiveCN103408469AReduce heavy oil viscosityStrong oil washing abilitySulfonic acids salts preparationDrilling compositionIonTemperature resistance

The invention provides an active monomer shown in a formula (I). The invention further provides a polymeric surfactant shown in formula (II). The preparation method comprises the following step of: performing a chain transfer reaction on 1-40 parts by weight of acrylamide, 1-20 parts by weight of anion monomers with double bonds, 1-30 parts by weight of the active monomer according to the claim 1, 50-100 parts by weight of deionized water and 0.001-2 parts by weight of chain transfer agent under the effect of an initiator. The polymeric surfactant has the double performances of the polymer and the surfactant, has good oil scrubbing capacity, can be used for improving the recovery efficiency of petroleum, and has wide application prospect in thickened oil recovery. In addition, the polymeric surfactant further has solubilizing power, reversible gathering capacity, salt resistance, temperature resistance, and resistance to mechanical, biological and oxydative degradation.

Owner:华鼎鸿基采油技术服务(北京)有限公司

Granular volume expansion profile control agent for oil recovery and preparation

The invention relates to a granular volume expansion profile control agent for oil recovery and a preparation, and the preparation comprises the following steps: uniformly mixing and stirring 25-40g of 30% bentonite water solution and 20-35g of 30% acrylamide water solution, further adding 0.2-0.5g of sodium sulfate, 0.7-1.2g of sodium sulfite and 3.0-6.0ml of 40% NaOH water solution, fully mixing, uniformly stirring, reacting for 15-30 minutes at room temperature, further rising temperature to 50 DEG C, standing for 3 hours at the constant temperature, and further performing drying, granulation, pulverization and screening, thereby preparing the granular volume expansion profile control agent for oil recovery. Polyacrylamide with low degree of hydrolysis is used as a raw material main agent, thereby having the characteristics of high gel strength, good toughness and effective expansion; and phenols and organic acid are selected as gel combination agents, thereby having the characteristics of stable gel combination, no gel breaking, no hydrolysis, salt resistance and biodegradation resistance. The granular volume expansion profile control agent for oil recovery adopts a formula system which combines the granular volume expansion profile control agent and a gel type profile control agent into a whole, thereby having the characteristics of having high volume expansion coefficient and long effective period, and being applicable to crack oil-bearing structures and pore oil-bearing structures.

Owner:张建军

Horizontal well water shutoff agent formula and using method thereof

InactiveCN105368419ATemperature resistantSalt resistantDrilling compositionSealing/packingSlagUltimate tensile strength

The invention relates to a horizontal well water shutoff agent formula and a using method thereof. The horizontal well water shutoff agent comprises a main component and a chemical activating agent component. The main component is prepared from, by weight, 4-15 parts of blast furnace slag powder, 3-10 parts of bentonite, 0-10 parts of calcium carbonate powder or vermiculite powder and 75-93 parts of water. The chemical activating agent component is prepared from 3-15 parts of strong base and 85-97 parts of water. The horizontal well water shutoff agent formula has the advantages of resisting temperature and salt, being high in shutoff strength and long in water shutoff validity period and the like, and the main technical problems that a gel type water shutoff agent cannot achieve shutoff or is short in water shutoff validity period, however, a particle cementation and solidification type water shutoff agent is large in shutoff strength and unsafe in construction are solved. According to the using method of the horizontal well water shutoff agent formula, a mechanical packer is used in an assisted mode, a two-stage separation injection construction method is adopted, and therefore construction risks such as tubular column clamping and flagpole inserting are avoided.

Owner:黄志华 +1

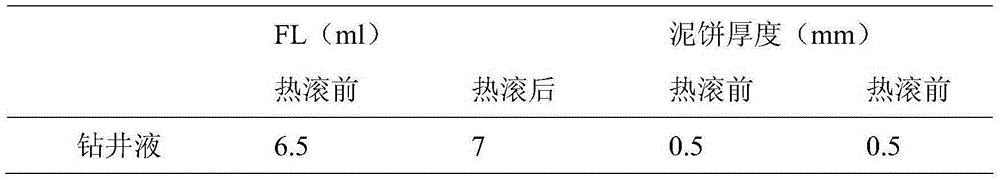

Sodium silicate containing polyalcohol drilling fluid for offshore drilling

InactiveCN105331339AMeet rheological requirementsGood and strong inhibition of blockingDrilling compositionWell drillingSodium silicate

The invention relates to a sodium silicate containing polyalcohol drilling fluid for offshore drilling. The drilling fluid is prepared from seawater, bentonite, sodium carbonate, a tackifier, a filtrate reducer and an inhibitor in weight part ratio. The drilling fluid is a high-blocking type drilling fluid which has higher inhibitive ability and lubricity and is suitable for being used for offshore drilling, is simple to prepare and is easily operated for site operation.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

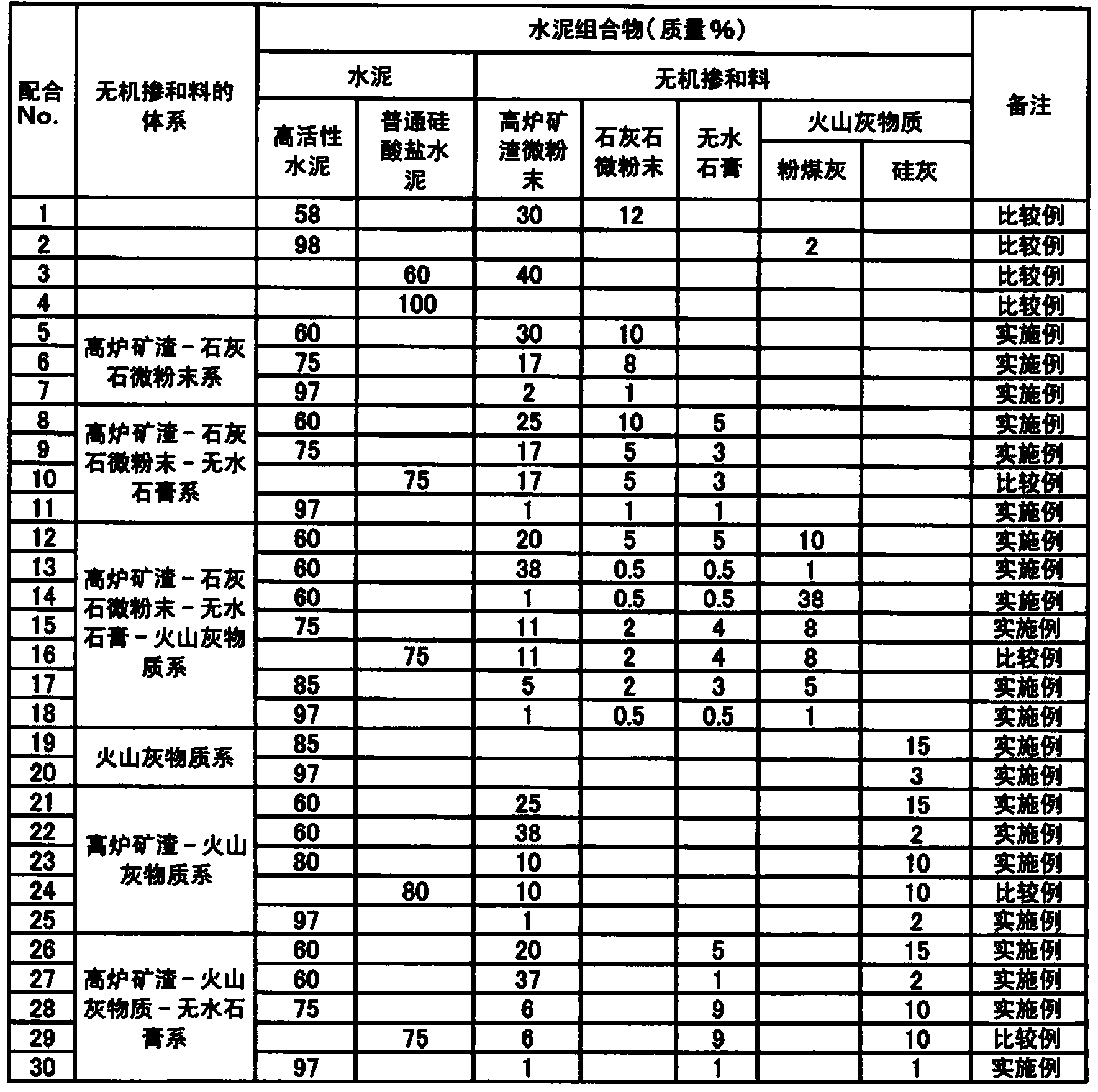

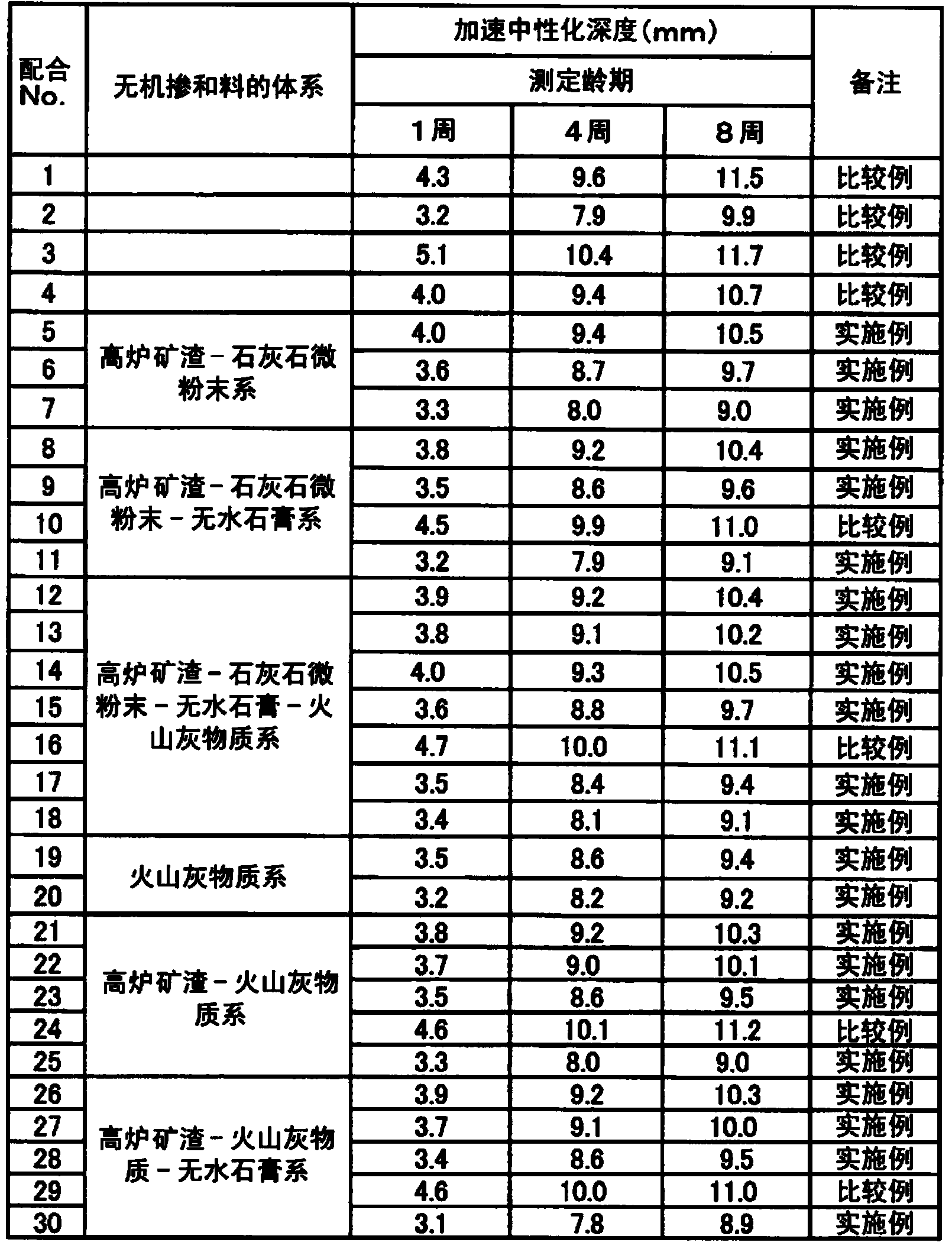

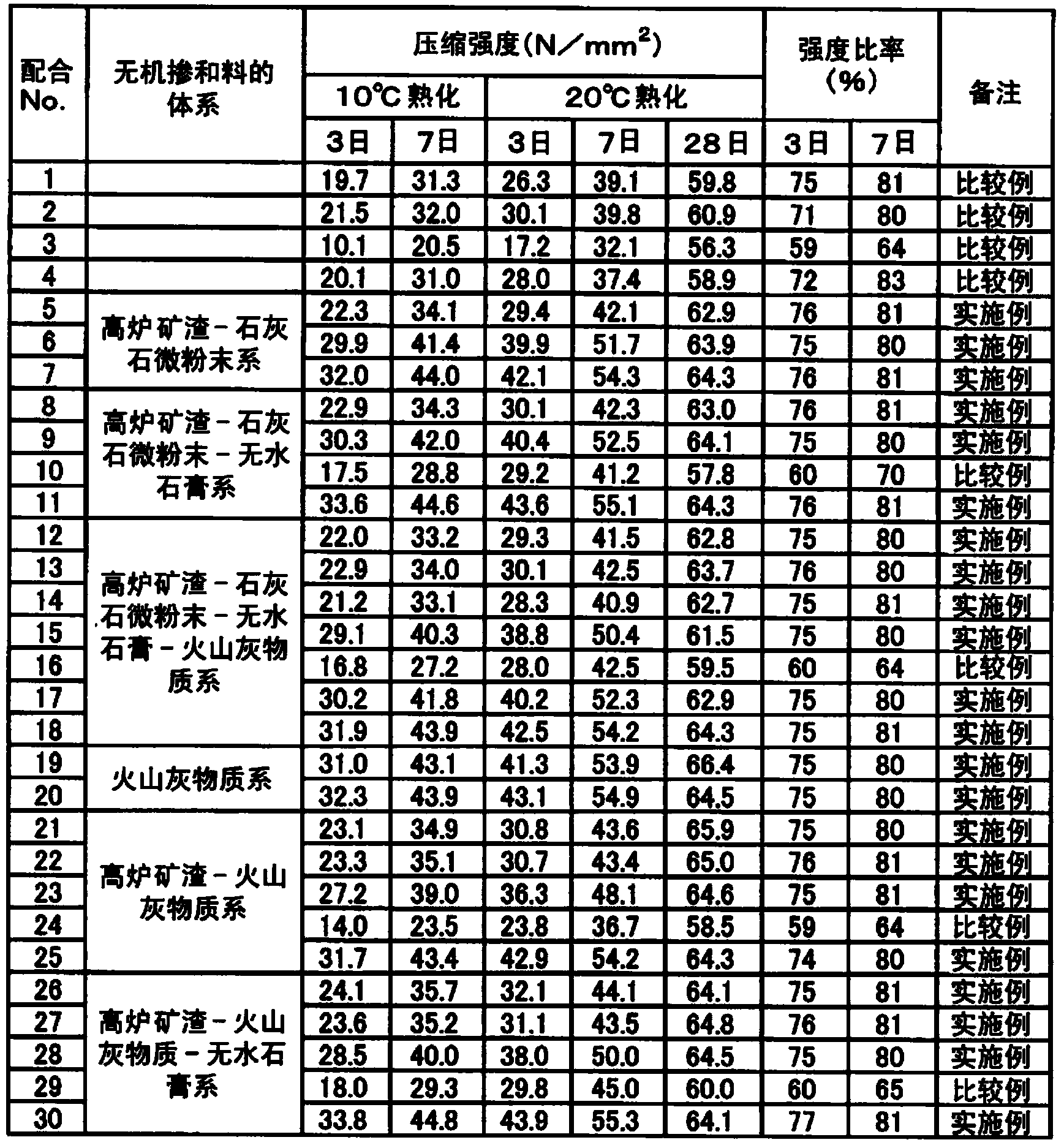

Neutralization-preventive high-early-strength cement composition

ActiveCN103764588AImprove the mix ratioExcellent short-term strength performanceSolid waste managementSlagPolymer chemistry

Provided is a neutralization-preventive high-early-strength cement composition characterized by comprising 60 to 97 wt% of a highly reactive cement and 3 to 40 wt% of an inorganic admixture, wherein the highly reactive cement is produced by adding 1.5 to 4.0 wt% of gypsum in terms of SO3 content to a highly reactive cement clinker that has a mineral composition comprising more than 70% of C3S and less than 5% of C2S as calculated in accordance with a Bouge's equation, an L. S. D. value of more than 1 and a free lime content of 0.5 to 7.5 wt%, and the inorganic admixture comprises at least one material selected from a blast furnace slag, an anhydrite, a limestone micropowder and a pozzolan substance. The neutralization-preventive high-early-strength cement composition enables the efficient use of a previously developed highly reactive cement having a high C3S content and an extremely low C2S content, and is suitable as a cement for a concrete or a mortar which is used under a low-temperature environment such as a cold region or an environment in which neutralization is likely to progress.

Owner:DC & BV FRANCE HLDG

Preparation of quaternaries hyper branched polycation electrolyte

The invention discloses a synthesis method to prepare hyperbranched polycation electrolyte based on self-condensing atom transfer radical (co)polymerization and is characterized in that the method makes use of an initiated monomer containing quaternary ammonium salt structures to obtain hyperbranched polycation electrolytes through the aqueous phase self-condensing atom transfer radical copolymerization of the initiated monomer, or through the aqueous phase self-condensing atom transfer radical copolymerization of other cationic unsaturated monomers. The method can obtain the polycation electrolyte simultaneously provided with high branching degree and high charge density in one step, and is simple in procedures; the obtained hyperbranched polycation electrolyte can be used for phase transfer catalysis, flow modification, immune diagnostic reagent and other occasions.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

High temperature resistance intercalation adsorption inhibitor and preparation method thereof

ActiveCN108753268AInhibition of hydrationHigh temperature resistantDrilling compositionSalt resistanceWell drilling

The invention relates to the technical field of drilling fluid additives in oil field well drilling and especially relates to a high temperature resistance intercalation adsorption inhibitor and a preparation method thereof. The inhibitor is prepared from the ingredients in parts by mole: 0.4 to 0.8 part of 1,3-propanesultone, 1 part of polyethylene polyamine and 0.01 to 0.03 part of phenothiazine. The high temperature resistance intercalation adsorption inhibitor disclosed by the invention can completely inhibit clay surface hydration, can dehydrate surface hydrated clay and has the advantages of superstrong inhibition characteristic, high temperature stability, high temperature resistance, salt resistance, small added amount, low cost and easiness in biodegradation at the same time.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling mud treating agent containing humic acid

InactiveCN112521920AWith the function of fluid loss control agentWith high temperature resistanceDrilling compositionCelluloseMicrocrystalline wax

The invention provides a drilling mud treating agent containing humic acid. The treating agent is prepared from the following substances by weight: 5-15 parts of modified humic acid, 1-10 parts of maleic anhydride acylated chitosan, 2-9 parts of modified potassium hexatitanate whiskers, 9-18 parts of nonylphenol polyoxyethylene ether, 2-15 parts of linear polysiloxane, 5-20 parts of microcrystalline wax, 1-6 parts of hydroxyl aluminum, 45-50 parts of polyacrylamide, 8-12 parts of potassium hydroxide, 20-30 parts of carboxymethyl cellulose, 8-10 parts of sodium lignosulphonate, 0.1-0.5 part ofsodium tetraborate, and 0.2-0.9 part of a polyacrylonitrile amine salt. Through compounding of the components, the drilling mud treating agent has the functions of a filtrate reducer, also has the functions of high temperature resistance and salt resistance, and is stable in property.

Owner:江西省三汇科技有限公司

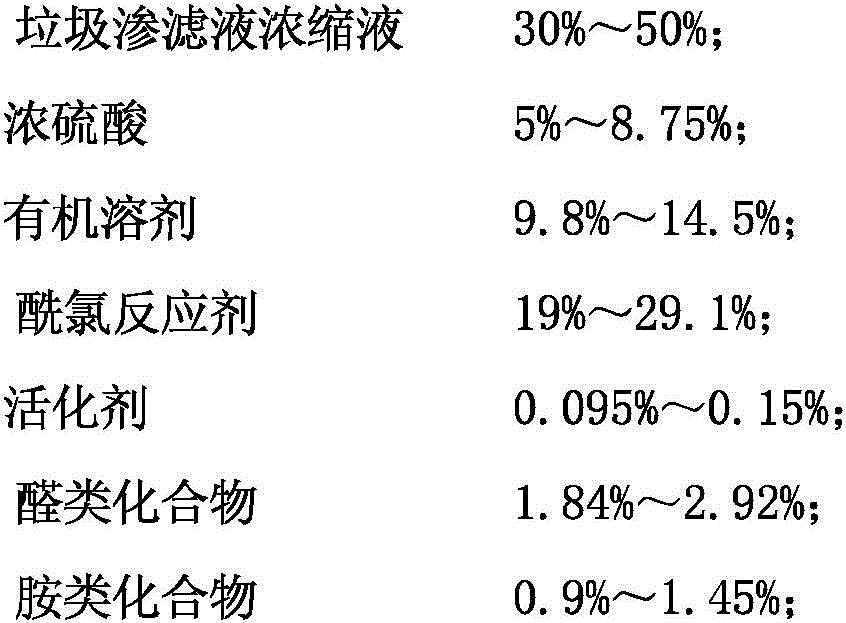

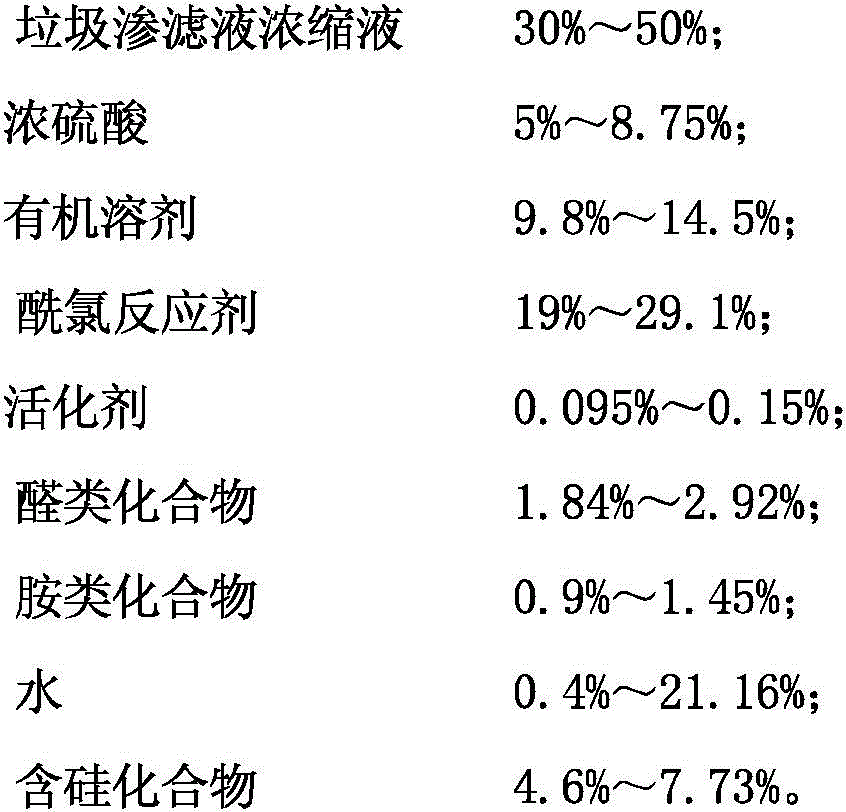

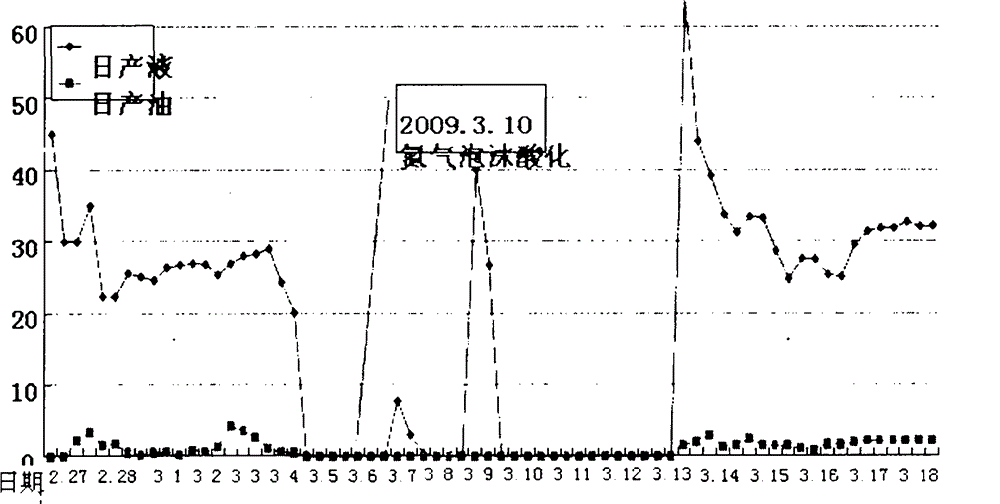

Method for preparing efficient drilling fluid viscosity reducer by utilizing refuse leachate and application of efficient drilling fluid viscosity reducer

ActiveCN106833555AGood viscosity reduction effectImprove stress resistanceDrilling compositionSalt resistanceMannich reaction

The invention discloses a method for preparing an efficient drilling fluid viscosity reducer by utilizing refuse leachate and application of the efficient drilling fluid viscosity reducer. The refuse leachate is subjected to concentration treatment by utilizing sulfuric acid so as to improve the structure activity of effective molecules in the refuse leachate; then an acyl chloride reaction agent is further added to react and conditions are provided for subsequent Mannich reaction and quaternization reaction, so that the molecular weight of a product is effectively improved; then prepared black loose powder is mixed and compounded with a silicon-containing compound to further improve the performance of the prepared viscosity reducer, so that the obtained viscosity reducer has high-temperature-resisting and compression-resisting viscosity reducing effects and also has salt resistance and rheological property and certain leakage reduction performance.

Owner:FUZHOU UNIV +1

Camellia saponin type oilfield foaming agent and preparation method and application thereof

ActiveCN101906296BAcid resistantAlkali resistantDrilling compositionChemical recyclingChemical synthesisBetaine

The invention relates to a camellia saponin type oilfield foaming agent and a preparation method and application thereof. The oilfield foaming agent comprises the following components in part by mass: 100 parts of camellia saponin based on the solid content, 1 to 10 parts of cocoanut oil diethanol amide, 1 to 10 parts of amine ether alkyl glucoside, 1 to 10 parts of dodecyl betaine, and 0.5 to 2 parts of lauryl dimethy amine oxide, wherein the camellia saponin is natural plant source camellia saponin or structure-modified camellia saponin. The camellia saponin type oilfield foaming agent is used as an oilfield foaming agent in oil recovery, has the characteristics of acid, alkali and salt resistance, temperature resistance, high foam expansion ratio, long stable foam time and the like, can meet oil extraction requirements under different geological and weather conditions, cannot pollute an oilfield soil layer employing the foaming agent, can prevent a chemically synthesized foaming agent from harming the oilfield stratum, and has remarkable environmental protection characteristic.

Owner:青田中野天然植物科技有限公司

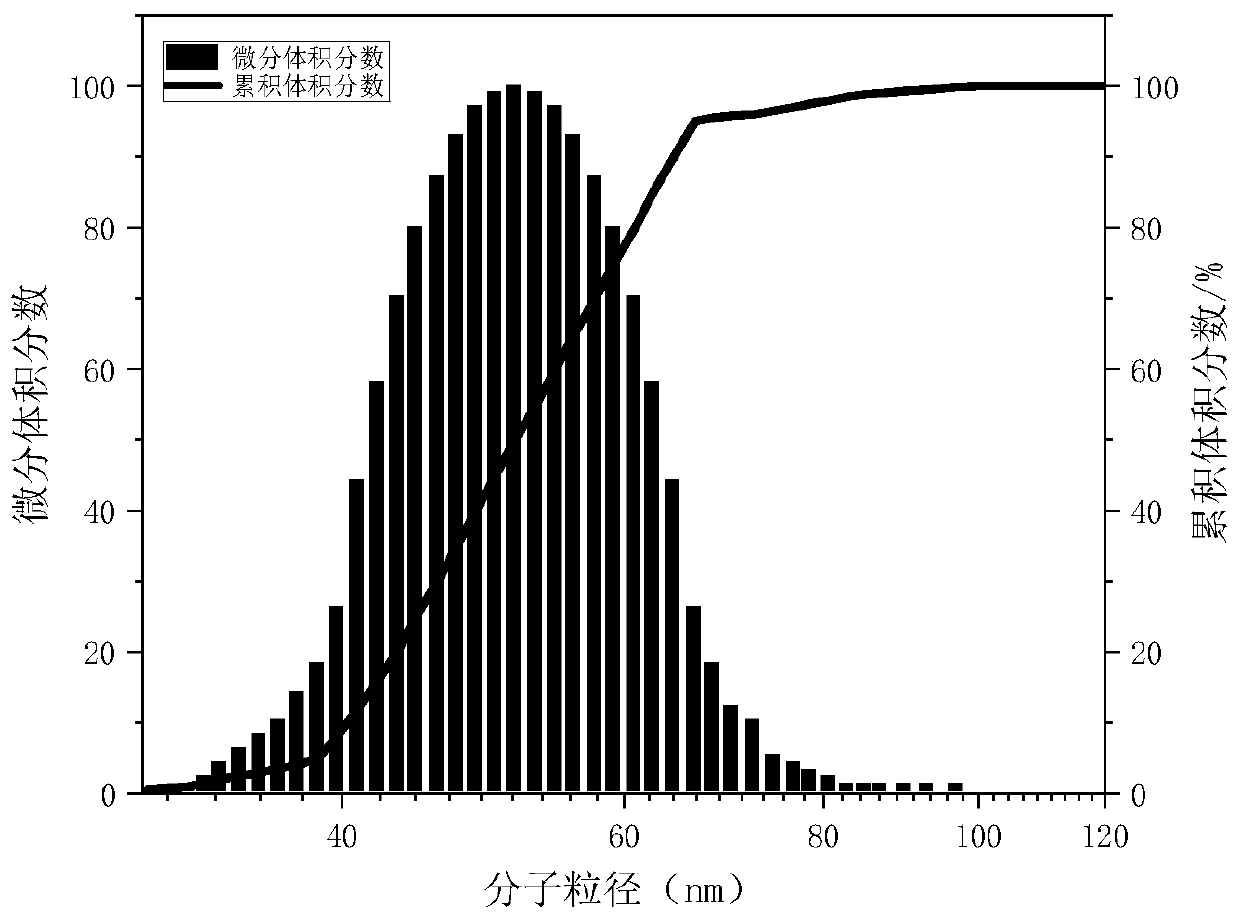

Supramolecular star polymer taking beta-CD (beta-cyclodextrin) as core and preparation method of supramolecular star polymer

ActiveCN114106249AEnhanced hydrophobic associationReduced risk of hydrolysisDrilling compositionMethacrylamideChemistry

The invention relates to a supramolecular star polymer taking beta-CD as a core and a preparation method of the supramolecular star polymer. The supramolecular star polymer takes a beta-cyclodextrin modified branched monomer F-beta-CD as an inner core and is grafted with acrylamide, acrylic acid, a hydrophobic monomer and a surface active macromonomer; the hydrophobic monomer is one or more of N-benzyl-N alkyl (methyl) acrylamide and N-phenethyl-N alkyl (methyl) acrylamide; the surface active macromonomer is one or more of allyl polyoxyethylene ether, alkylphenol polyoxyethylene ether (methyl) acrylate, alkylphenol polyoxyethylene ether allyl ether, alkyl alcohol polyoxyethylene ether (methyl) acrylate and alkyl alcohol polyoxyethylene ether allyl ether. The preparation method has the advantages of cheap and easily available raw materials, easily controllable synthesis conditions and high yield. The tackifying agent has excellent tackifying performance, temperature resistance, salt resistance and hydrolysis resistance, and shows good application prospects in the aspects of oil field recovery efficiency improvement and hydraulic fracturing.

Owner:SOUTHWEST PETROLEUM UNIV

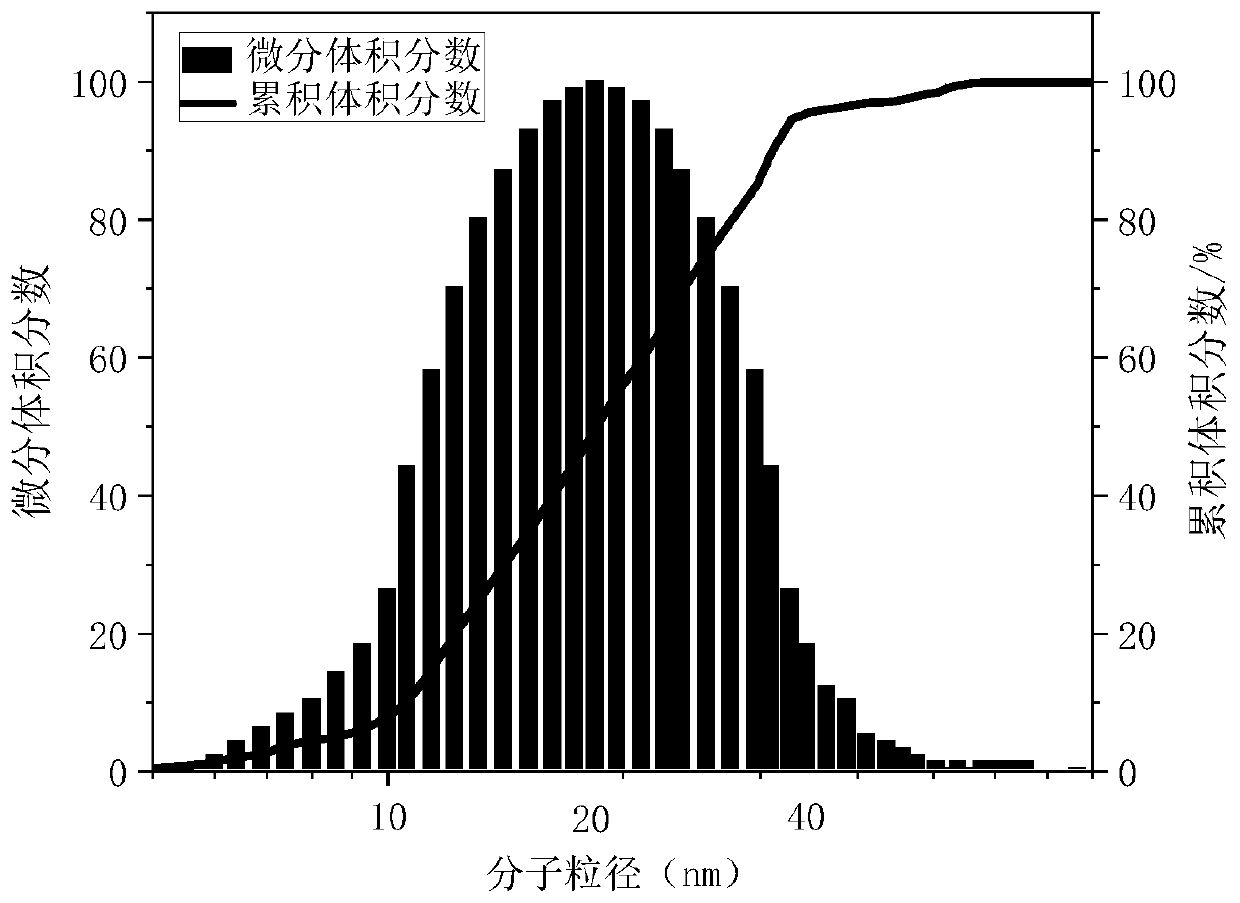

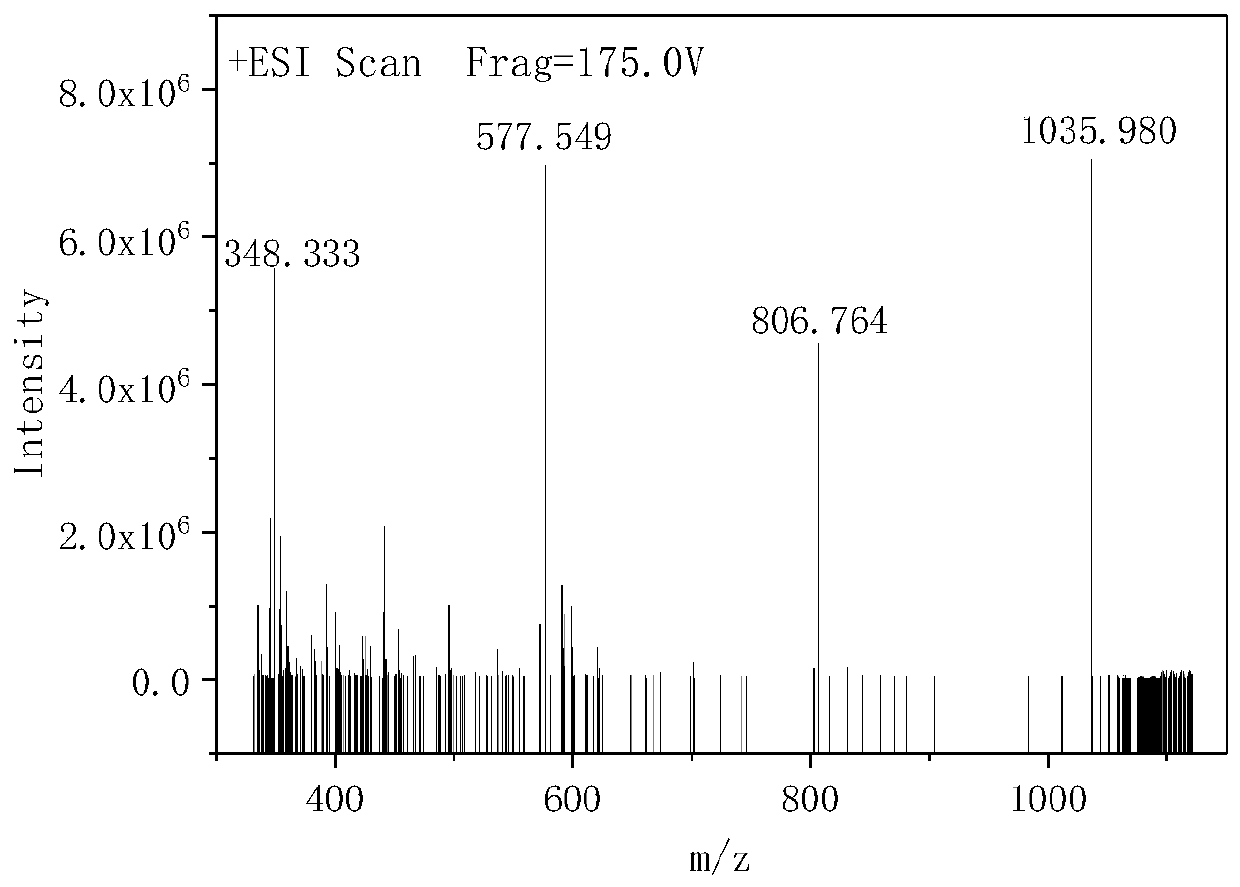

Branched sulfamic acid nano plugging agent and water-based drilling fluid thereof

The invention discloses a branched sulfamic acid nano plugging agent and a water-based drilling fluid thereof, and belongs to the technical field of drilling fluid. The nano plugging agent is a polymer prepared by taking diallyl methylamine and 2-hydroxyethylamine propylamine as the raw materials, carrying out Michael addition reaction, and then taking vinyl sulfonic acid as an end-capping reagent. The branched sulfamic acid nano plugging agent synthesized by the method has a molecular particle size of 0nm-100nm, is good in compatibility with other drilling fluid treating agents, does not gather or become large, and can be directly added into various drilling fluid base slurries to prepare the water-based drilling fluid, the synthetic raw materials are easily available, the synthetic method is simple and the branching degree is controllable, and the water-based drilling fluid can effectively plug stratum micro-cracks, improve the quality of mud cakes, stabilize a well wall and preventthe well wall from collapsing.

Owner:SOUTHWEST PETROLEUM UNIV

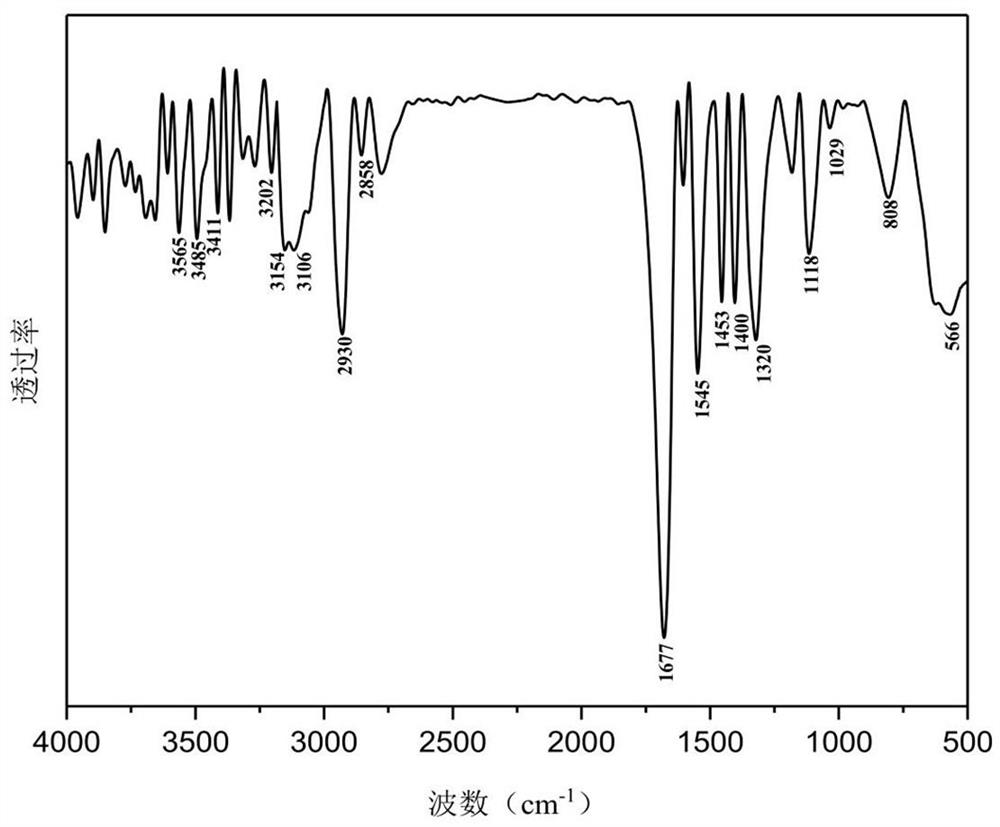

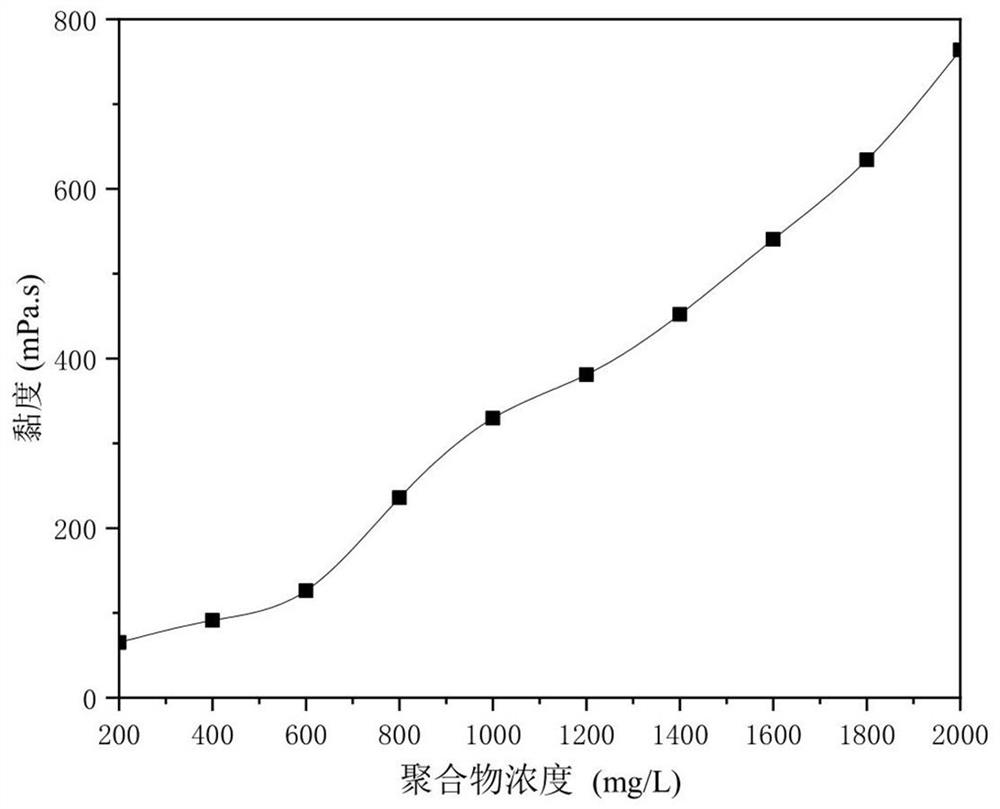

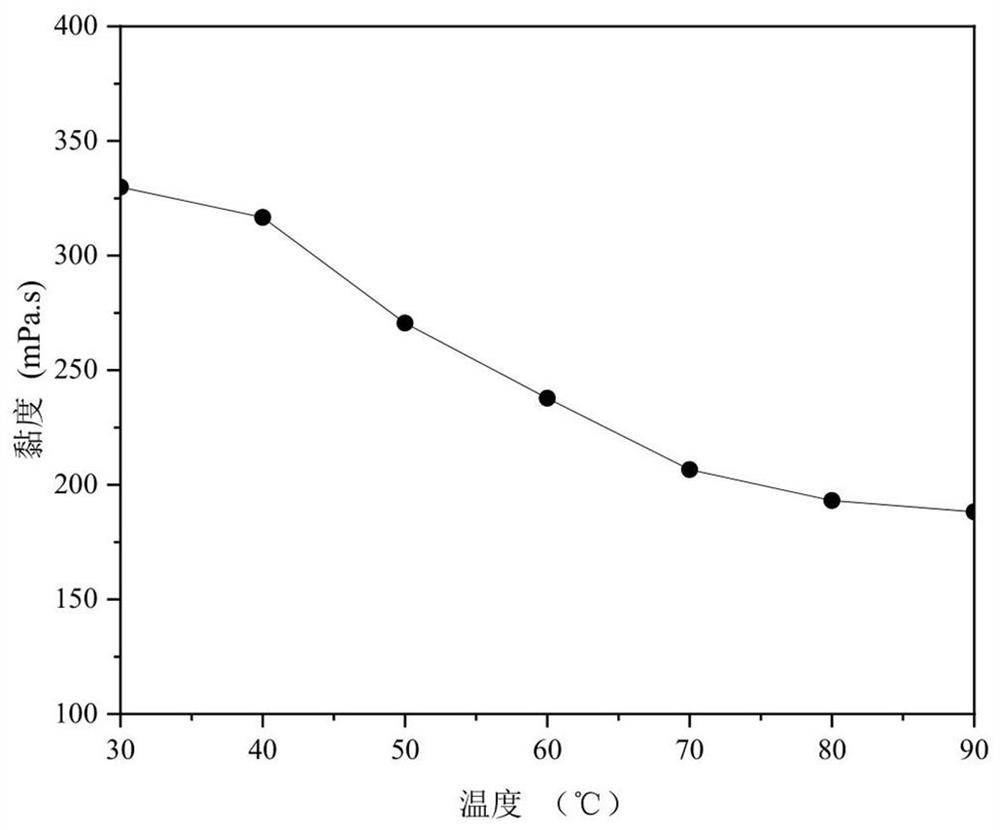

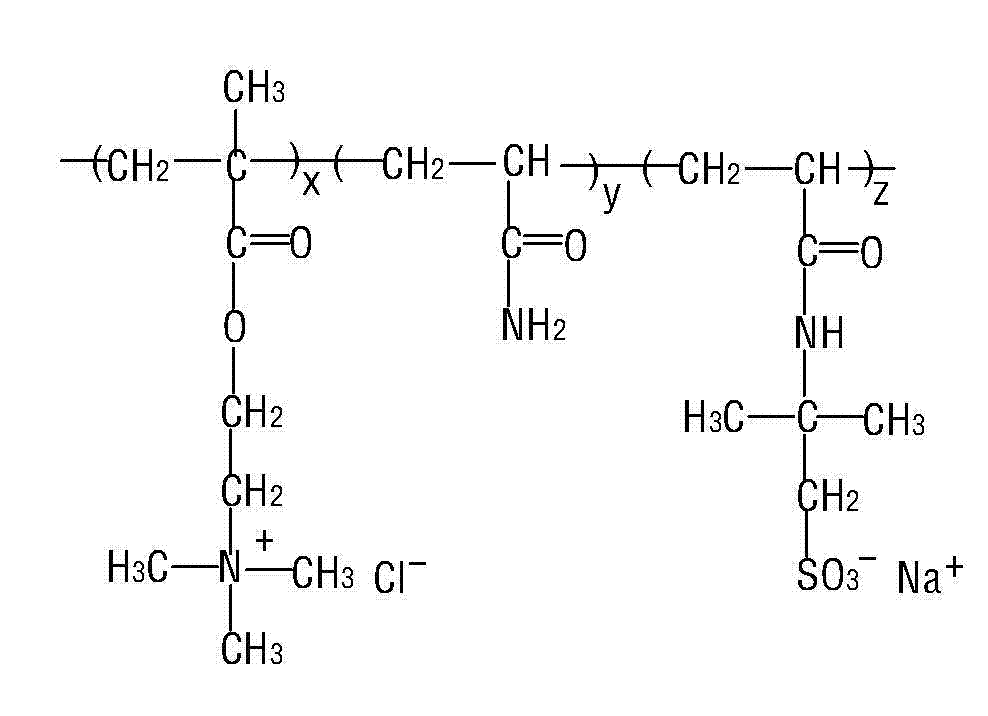

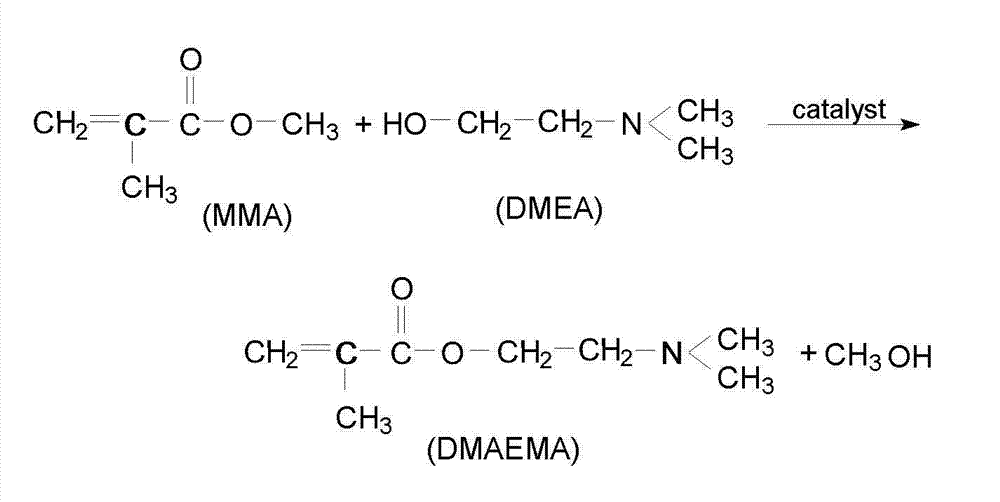

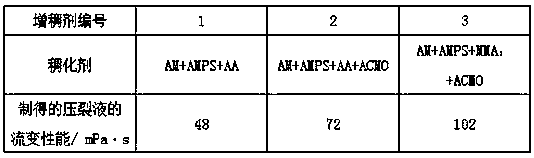

Zwitterionic polymer, preparation method of zwitterionic polymer and application in hydrochloric acid-base fracturing fluid

InactiveCN102702424BHigh temperature resistantSalt resistantDrilling compositionPolymer scienceFracturing fluid

The invention relates to a zwitterionic polymer, a preparation method of the zwitterionic polymer and application in hydrochloric acid-base fracturing fluid. The preparation method comprises the following steps of: carrying out transesterification of methyl methacrylate and N,N-dimethylethanolamine to obtain 2-(dimethylamino)ethyl methacrylate (DMAEMA); reacting DMAEMA with CH[3]Cl to obtain methacryloyloxyethyl trimethyl ammonium chloride (DMC); and carrying out ternary copolymerization of DMC, acrylamide (AM) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) to obtain the zwitterionic polymer. The polymer is used as a thickening agent and blended with a corrosion inhibitor, an iron ion stabilizer, a clay stabilizer and a cleanup additive to obtain hydrochloric acid-base fracturing fluid. The polymer has the properties of high temperature resistance, salt-resistance and shear resistance. The preparation method has the advantages of reliable principle and simple operation. The hydrochloric acid-base fracturing fluid using the polymer as the thickening agent can realize acid-carrying sand process, and thus the polymer is specially suitable for acid-sand reconstruction of complexlithologic reservoirs, high pollution and inefficient reservoirs and high alkali-sensitive mineral reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV

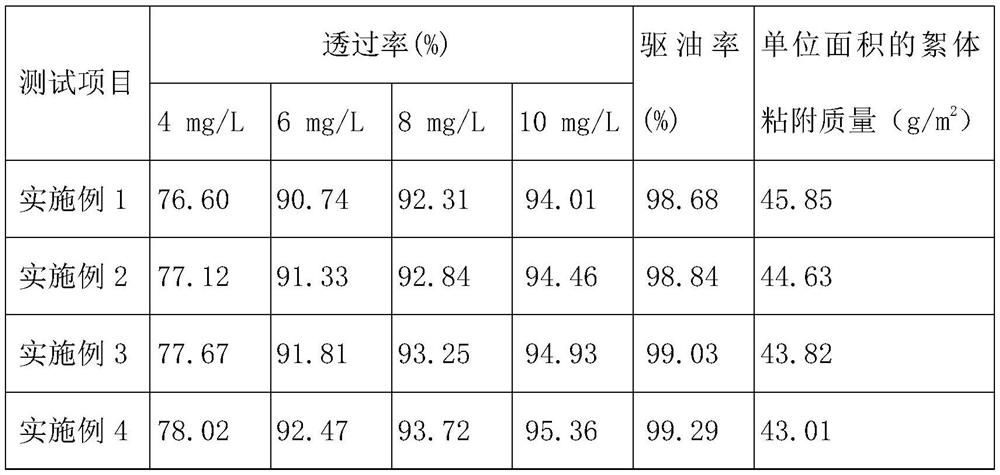

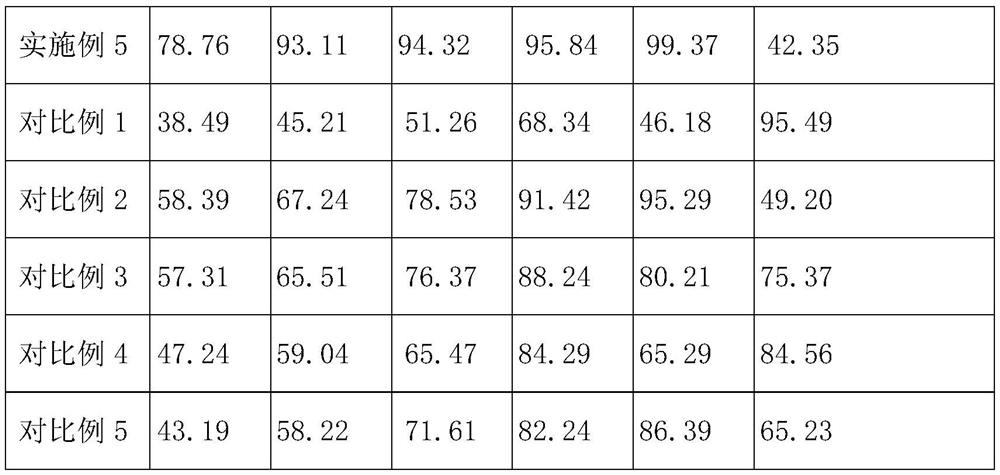

Oil field sewage flocculant and preparation method thereof

PendingCN112978890AImprove hydrophobicityGood hydrophobic association propertiesWaste water treatment from quariesFatty/oily/floating substances removal devicesMeth-Diethylenetriamine

The invention belongs to the technical field of oil field chemicals, and particularly relates to an oil field sewage flocculant which is characterized by comprising the following components in percentage by mass: 88-92% of a polymer and 8-12% of silicon oxide aerogel / diethylenetriamine propyl trimethoxy silane / glycidyl trimethyl ammonium chloride. The polymer is prepared by polymerizing sunflower seed oil-based pyridine quaternary ammonium salt / ethylenediamine modified oxidized walnut powder, vinyl (trifluoromethyl) dimethylsilane and 2-acrylamido-methylpropanesulfonic acid. The invention also provides a preparation method of the oil field sewage flocculant. The invention develops the oil field sewage flocculant which is salt-resistant, not easy to generate oil-containing flocs, good in oil displacement and flocculation effect, wide in raw material source, low in price, easy to biodegrade, safe and non-toxic.

Owner:西安威弗莱环境控制技术有限责任公司

Preparation method and using method for metal rust remover

InactiveCN108677205ASolubilizedSalt resistantMetallic material coating processesPhosphorous acidBenzoic acid

The invention belongs to the field of chemical rusting of metal surface treatment, and particularly relates to a preparation method and a using method for a metal rust remover. The preparation methodincludes the following steps that (1) phosphorous acid, tartaric acid and benzoic acid are used as raw materials to be mixed with deionized water to prepare basic acid liquor; (2) solid raw materialsincluding zinc sulfate, seignette salt, aluminum sulfate and potassium stannous phosphate sulfate are added into the basic acid liquor to be evenly mixed and stirred; and (3) auxiliaries composed of ametal ion chelating agent, naphthenic acid, triethanolamine, a corrosion inhibitor, a surface active agent, an emulgator, an antifreezing agent and vegetable oil are added to be evenly mixed and stirred. The preparation method and the using method are simple in step, the preparing cost is low, the prepared metal rust remover can effectively remove rust on the metal surface, a protection film canbe formed, and further application and popularization can be achieved.

Owner:泾县狸宣文化用品有限公司

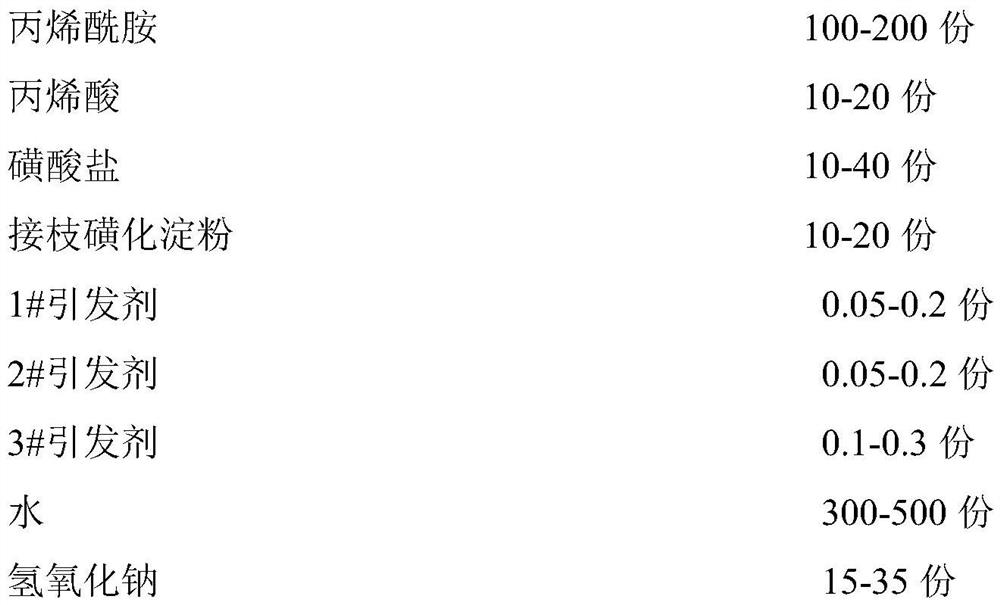

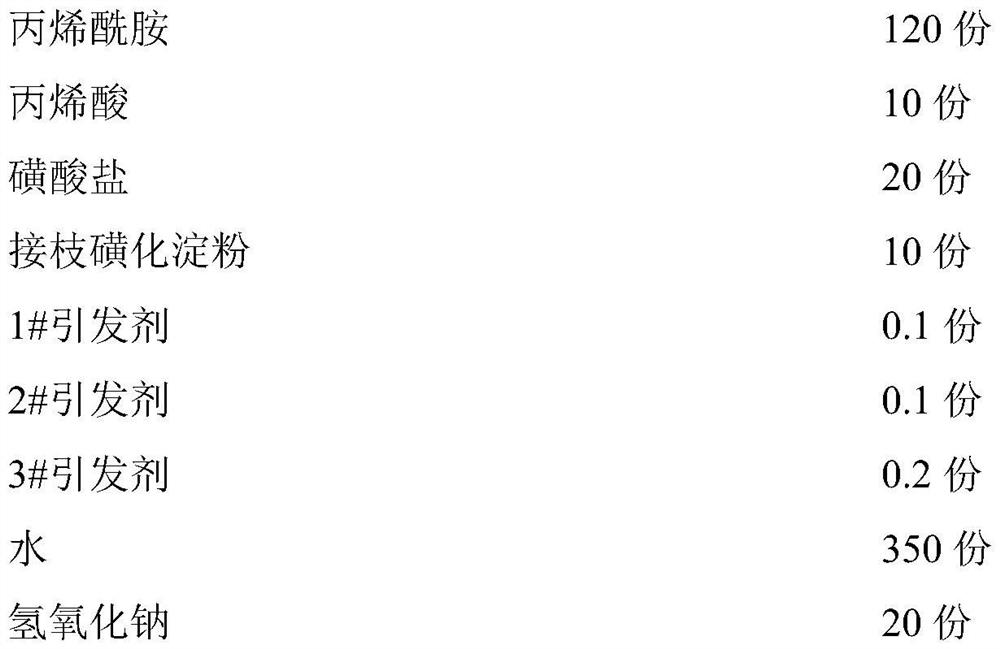

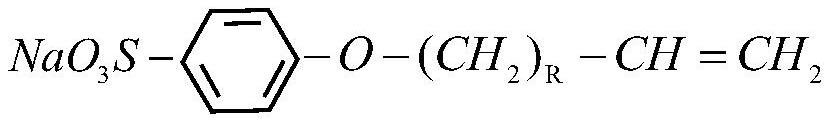

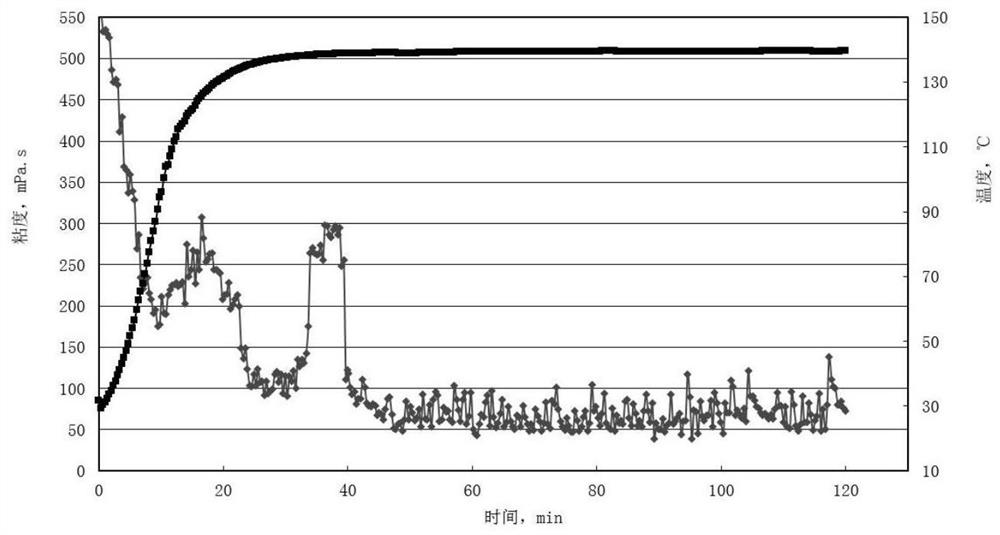

Sewage-resistant polymer for oil extraction and preparation method thereof

ActiveCN113248665ATemperature resistantSalt resistantFatty substance recoverySulfonateAnti bacterial

The invention discloses a sewage-resistant polymer for oil extraction and a preparation method thereof, and relates to the technical field of oil exploitation. The sewage-resistant polymer comprises acrylamide, acrylic acid, grafted sulfonated starch, sulfonate, an initiator and other components. The sewage-resistant polymer for oil extraction is prepared through polymerization of acrylamide, grafted sulfonated starch and sulfonate. The polymer has the characteristics of temperature resistance, salt resistance, antibiosis, high viscosity retention rate and capability of being prepared from oilfield produced sewage, can keep good solubility and tackifying effect under the sewage condition, and can improve the oil recovery rate to a relatively high extent.

Owner:黑龙江吉地油田服务股份有限公司

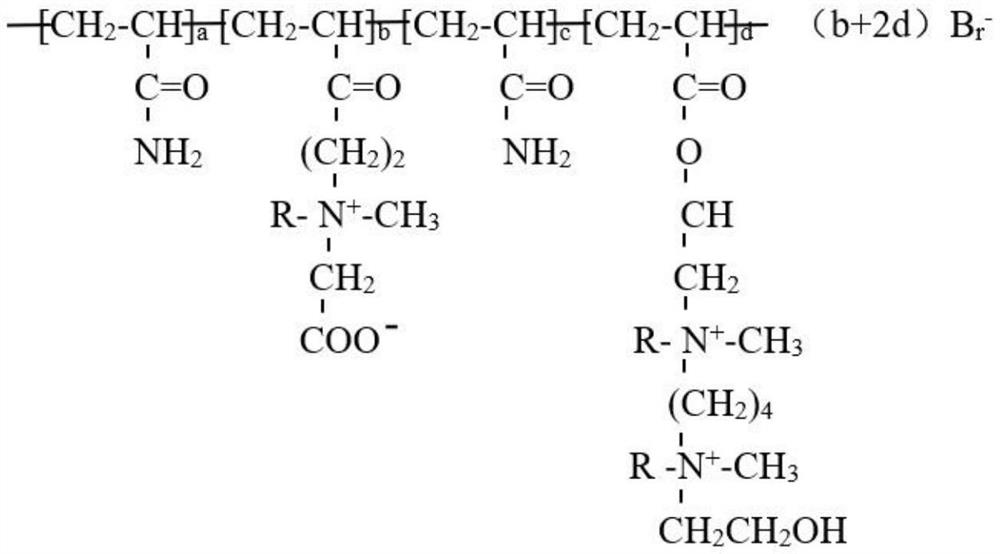

Supramolecular self-assembly clean fracturing fluid and preparation method thereof

ActiveCN113583173ASelf-assembled and self-crosslinkedWith drainage performanceDrilling compositionBulk chemical productionActive agentAqueous solution

The invention discloses a supramolecular self-assembly clean fracturing fluid and a preparation method thereof. The supramolecular self-assembly clean fracturing fluid comprises the following components in percentage by mass: 0.4-2.0% of a supramolecular self-assembly emulsion polymer and water, wherein the molecular structure of the supramolecular self-assembly emulsion polymer is shown in the description. Dication and amphoteric anions in the fracturing fluid structure have the function of forming a viscoelastic gel system by self-assembly winding in an aqueous solution, and the formed gel has high-temperature stability and salt resistance, can achieve the effects of temperature resistance, is degraded into a micromolecular surfactant without a cross-linking function after fracturing construction is finished, has discharge aiding performance, and realizes the characteristics of cleanness and no damage.

Owner:SHANDONG GUANGHE FINE CHEM CO LTD

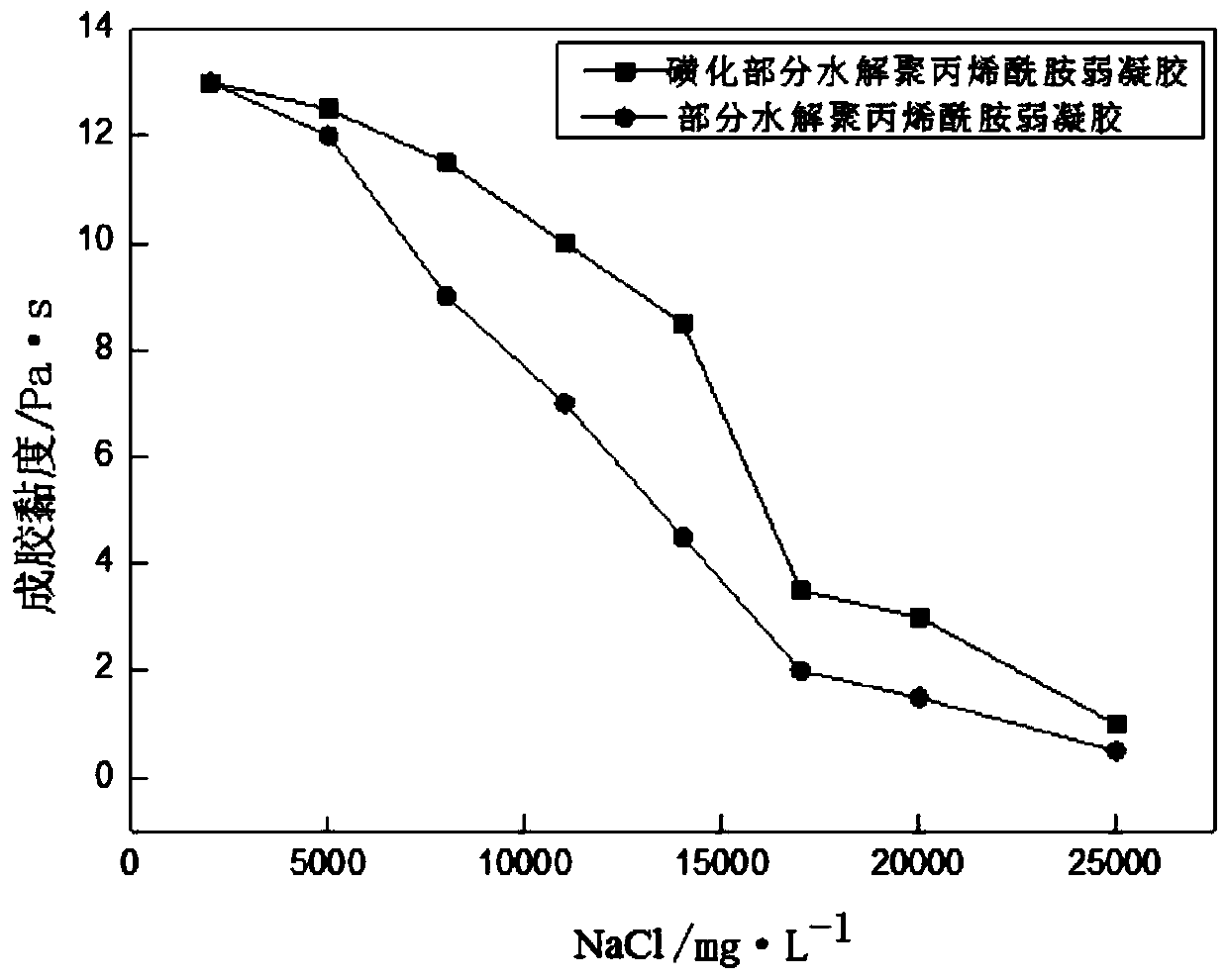

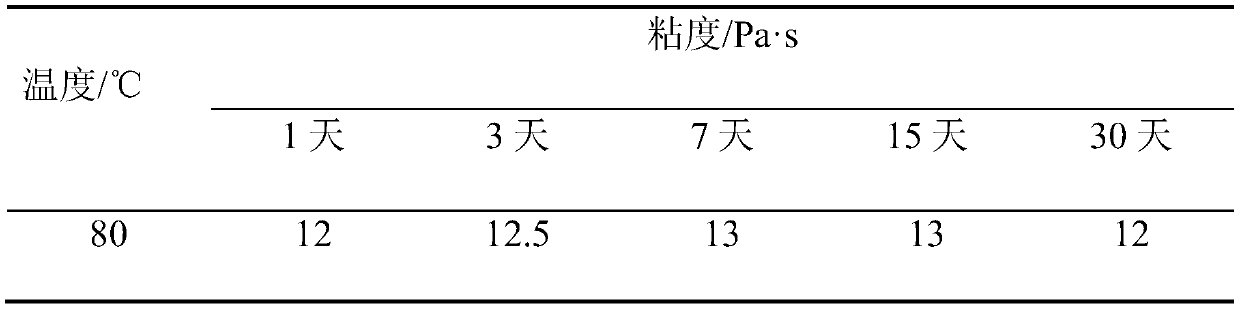

Sulfonated partially-hydrolyzed polyacrylamide weak gel and preparation method thereof

The invention relates to sulfonated partially-hydrolyzed polyacrylamide weak gel and a preparation method thereof. The method comprises: 1, placing a sulfonated partially-hydrolyzed polyacrylamide solution at a room temperature to obtain an aged sulfonated partially-hydrolyzed polyacrylamide solution, and adding a water-soluble phenol formaldehyde resin into the aged sulfonated partially-hydrolyzed polyacrylamide solution to obtain a mixed system A; 2, adding a sodium hydroxymethyl lignosulfonate solution into the mixed system A to obtain a mixed system B; and 3, carrying out a reaction on themixed system B for 12-72 h at a temperature of 60-110 DEG C 60 to obtain a sulfonated partially-hydrolyzed polyacrylamide weak gel. According to the invention, the polymer with a spatial three-dimensional network structure is formed, has good strength, god stability, goodsalt resistance and good dispersity, can be dissolved in water with any hardness, is good in aqueous solution chemical stability, has good temperature resistance and good salt resistance when being used for oilfield profile control, and has great application potential in the field of oilfield water shutoff and profile control.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of thickening agent for fracturing fluid with temperature of 200 DEG C or above and the fracturing fluid adopting the thickening agent

InactiveCN110483685AFine particleHigh temperature resistantDrilling compositionCross-linkSodium bicarbonate

The invention discloses a preparation method of a thickening agent for a fracturing fluid with the temperature of 200 DEG C or above and the fracturing fluid adopting the thickening agent. The preparation method comprises steps of solution preparation, polymerization and rubber block post-treatment. The fracturing fluid is characterized by being prepared by fully stirring and mixing, by mass, 1% of the thickening agent, 0.5% of a cross-linking agent that is diethylenetriamine, and a pH regulator that is sodium bicarbonate to adjust the pH to 6, with the balance being water for 10 minutes. Beneficial effects are that the thickening agent prepared by the method has the characteristics of fine particles, high-temperature resistance, salt resistance and the like; the fracturing fluid preparedfrom the thickening agent prepared by the method disclosed by the invention has the characteristics of good temperature resistance, shearing resistance, low friction resistance and the like.

Owner:北京宝丰春石油技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com