A modified sulfonated phenolic resin and a drilling mud treatment agent containing it

A technology of sulfonated phenolic resin and sulfonating agent, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve the problems of fluid loss control and rheology, high temperature resistance, salt resistance and anti-slump ability poor performance, poor use effect in medium-deep well sections, etc., to achieve excellent fluid loss resistance, excellent high temperature resistance, and excellent fluid loss reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

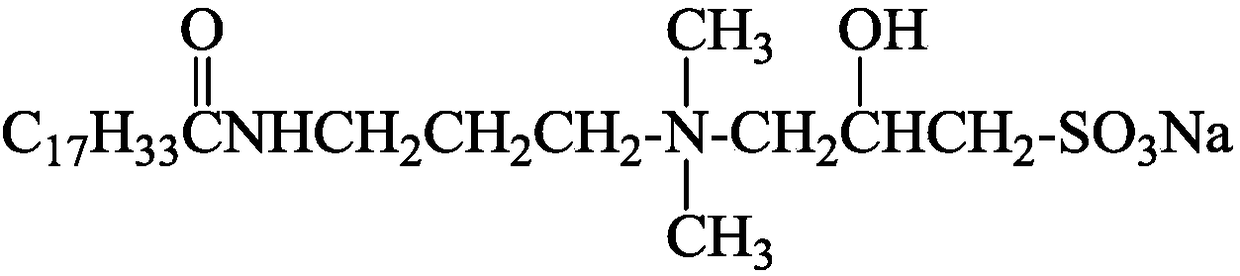

Image

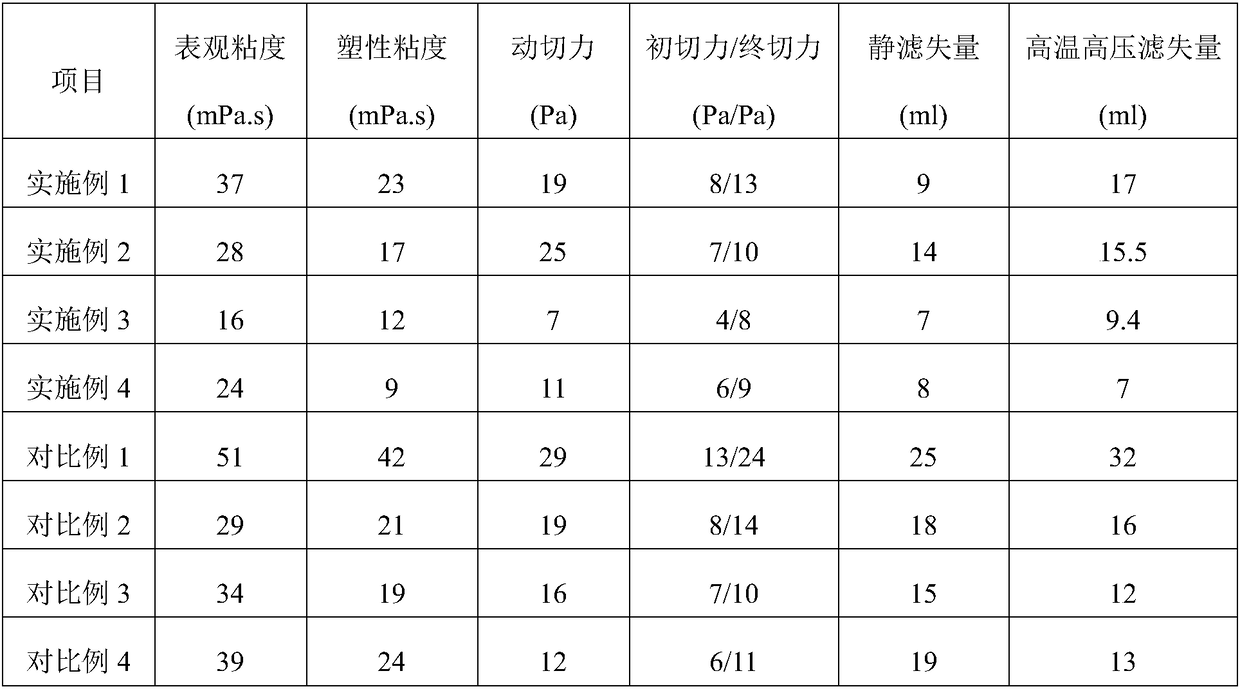

Examples

Embodiment 1

[0075] (1) Add 2.6g of phenol, 1.0g of catechol, and 2.0g of formaldehyde in sequence in a reaction kettle equipped with a reflux device, raise the temperature to 99°C, add 0.03g of 20% hydrochloric acid in four times, react for 10 minutes, and the solution becomes milky;

[0076] (2) 0.8g of 20% sodium hydroxide solution was added thereto to adjust the pH value of the reaction solution, then 1.5g of sulfonating agent was added, heated to 99°C, and reacted under reflux for 90 minutes, the reaction solution became clear; , the composition of sulfonating agent is: water 18g, formaldehyde 36.5g, sodium metabisulfite 45.5g;

[0077] (3) Add 1.5g of sulfonating agent, 0.06g of formaldehyde, 0.05g of polymethylmethacrylate nanoparticles, 0.03g of γ-methacryloxypropyltrimethoxysilane to it for the second time, at 99°C Reflux reaction for 90 minutes;

[0078] (4) Add 1.5 g of sulfonating agent for the third time, and reflux reaction at 99° C. for 90 minutes;

[0079] (5) Add 1.5 g ...

Embodiment 2

[0083] (1) Add 3.0 g of phenol, 1.1 g of hydroquinone, and 2.3 g of formaldehyde in sequence in a reaction kettle equipped with a reflux device, raise the temperature to 102° C., add 0.05 g of 20% hydrochloric acid in four times, react for 10 minutes, and the solution becomes milky;

[0084] (2) Add 1.2 g of 20% sodium hydroxide solution to it to adjust the pH value of the reaction solution, then add 1.6 g of sulfonating agent, heat to 102° C., react under reflux for 90 minutes, and the reaction solution becomes clear; , the composition of sulfonating agent is: water 18g, formaldehyde 36.5g, sodium metabisulfite 45.5g;

[0085] (3) Add 1.6g of sulfonating agent, 0.07g of formaldehyde, 0.06g of polystyrene nanoparticles, 0.04g of γ-methacryloxypropyltrimethoxysilane to it for the second time, and reflux at 102°C for 90 minute;

[0086] (4) Add 1.6 g of sulfonating agent for the third time, and reflux at 102°C for 90 minutes;

[0087] (5) Add 1.6 g of sulfonating agent for th...

Embodiment 3

[0092] (1) 18g of the sulfonated phenolic resin prepared in Example 1 and 10g of sodium hydroxypropyl sulfonate were mixed under stirring, and reacted at 55°C for 15 minutes;

[0093] (2) Add 8g oleamide hydroxysultaine and 6g trifluoropropylmethylcyclotrisiloxane to the product of step (1), stir evenly;

[0094] (3) Preparation of polyacrylamide nano-titanium dioxide composites

[0095] Add 15g of acrylamide, 2g of nano-titanium dioxide, 5g of sodium bicarbonate and 100ml of water into the reactor, and stir evenly; then add 0.05g of ammonium persulfate, react for 2 hours, then raise the temperature to 90°C for 2 hours; after the reaction, The product is dried to obtain a polyacrylamide nano-titanium dioxide composite material;

[0096] (4) adding the polyacrylamide nano-titanium dioxide composite material prepared in step (3) to the product of step (2) to obtain a drilling mud treatment agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com