Patents

Literature

100results about How to "Strong hydration ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

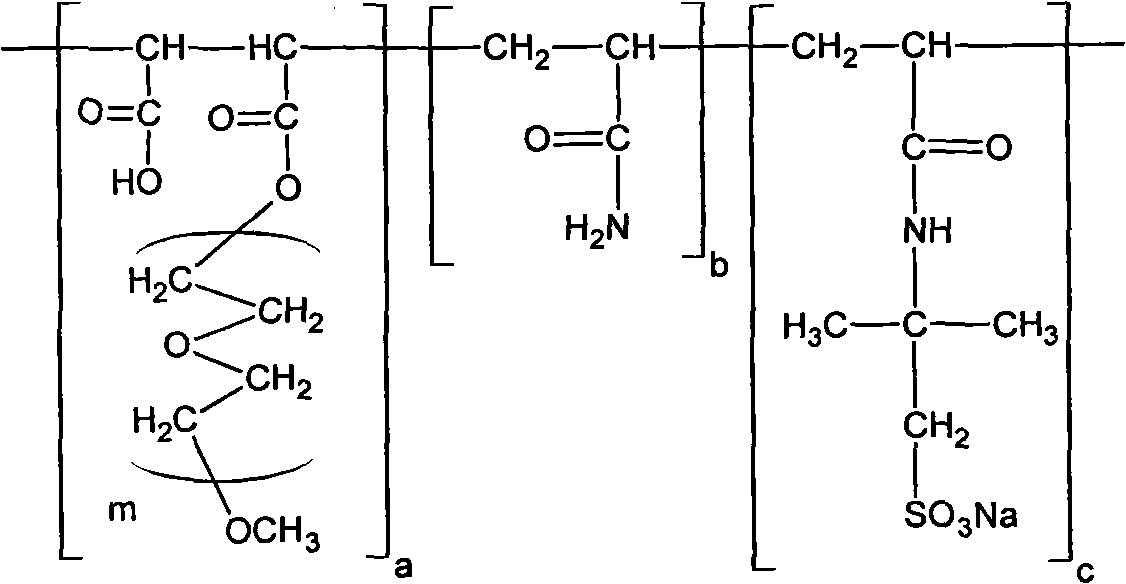

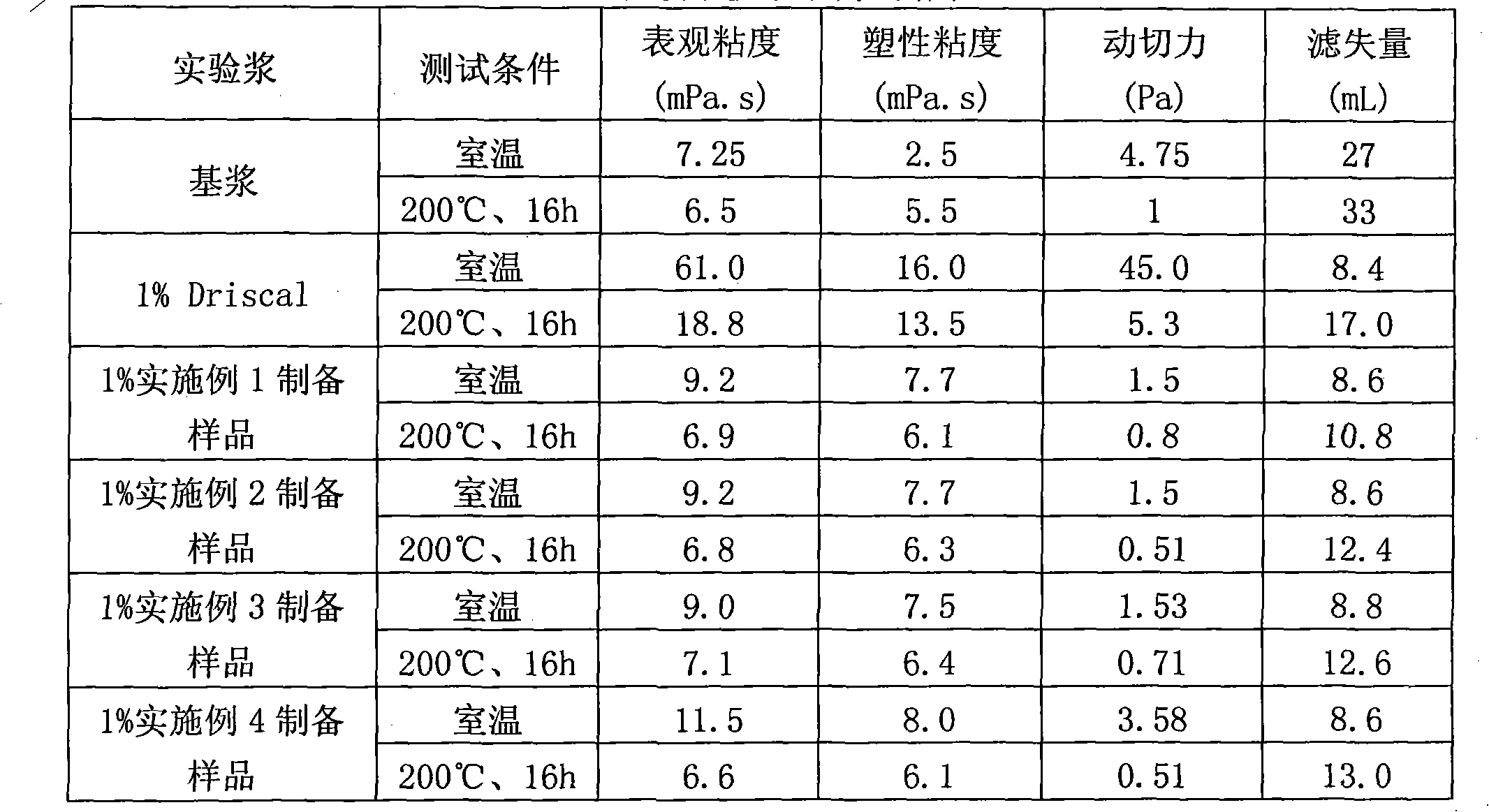

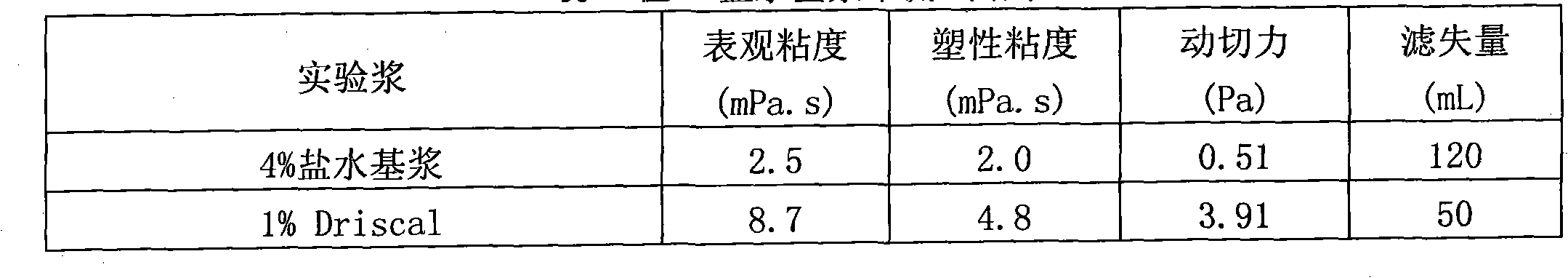

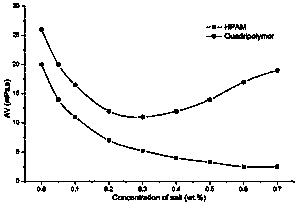

Comb-like polymer fluid loss additive for drilling fluid and preparation method thereof

InactiveCN101967369AStrong hydration abilityMild reaction conditionsDrilling compositionSide chainSalt resistance

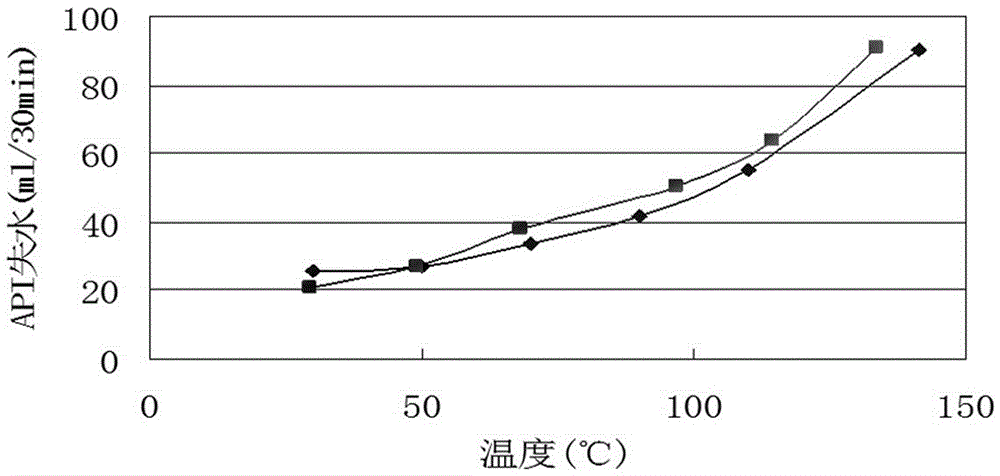

The invention provides a comb-like polymer fluid loss additive for drilling fluid and a preparation method thereof. The preparation method comprises the following steps of: performing esterification on polyethylene glycol monomethyl ether (PEGM) and maleic acid (MA) to obtain macromonomers; and adding two monomers, namely acrylamide (AM) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) into the macromonomers to perform copolymerization so as to obtain the comb-like polymer fluid loss additive with a long side chain by a solution polymerization method. The prepared comb-like polymer fluid loss additive has the advantages of resisting the temperature of 200 DEG C in the drilling fluid, along with good fluid loss reducing effect on the drilling fluid such as fresh water, saline and the like, capacity of controlling the drilling liquid to keep high rheological property under the condition of high temperature and high salinity, high temperature and salt resistance, stable fluid rheological property, mild synthesis condition, low equipment requirement and simple process.

Owner:SHANDONG UNIV +1

Polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and preparation method thereof

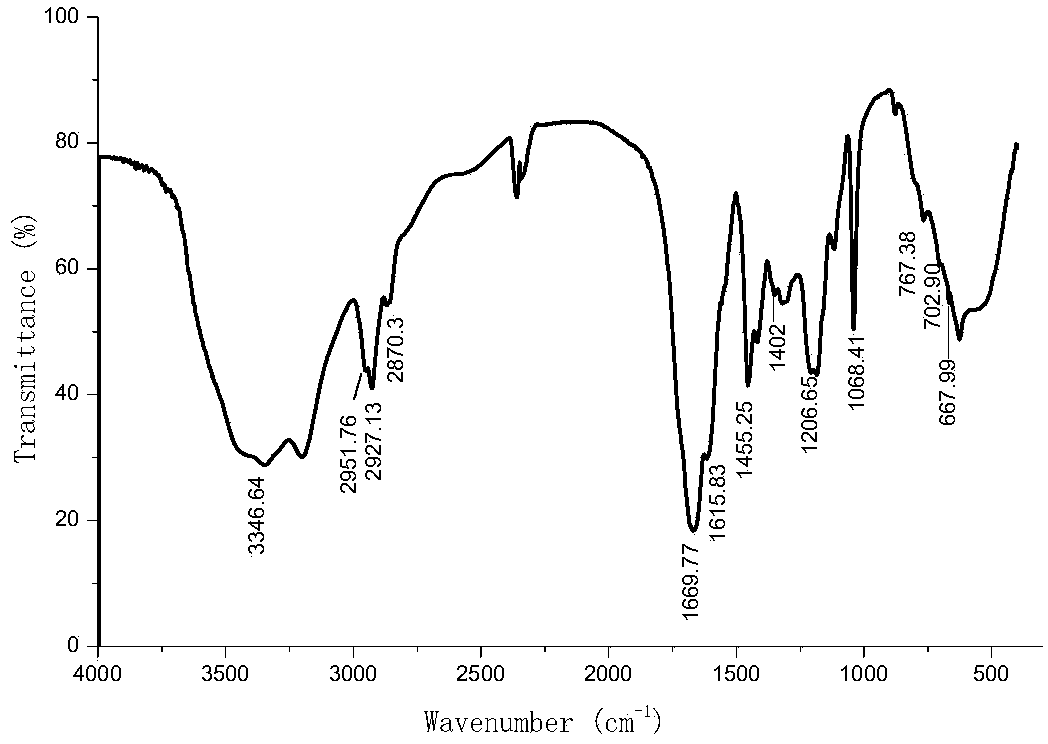

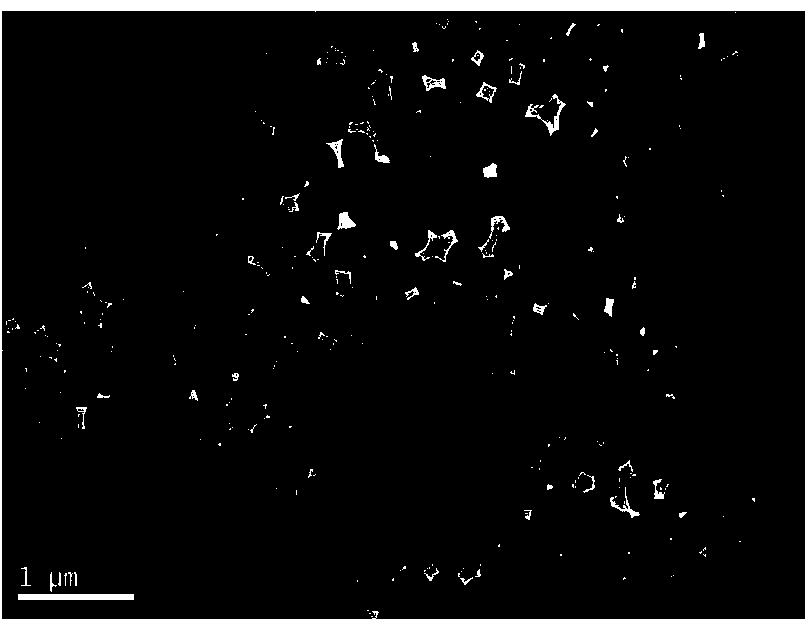

InactiveCN103525379ANew features of strong high temperature resistanceGood temperature and salt resistanceDrilling compositionPolymer scienceEmulsion polymerization

The invention discloses a polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and a preparation method thereof. According to the preparation method, in the presence of nano-silica, a polymer-base nanometer composite material with amphiphilic block hydrophobic associating polymer wrapping inorganic nano-silica is successfully synthesized by virtue of a micellar emulsion polymerization method and combines the rigidity and the heat stability of the inorganic nano-silica and the characteristics of the amphiphilic block hydrophobic associating polymer together, and the temperature resistance, the salt tolerance and the thickening property of the polymer are obviously improved by virtue of the polymer-base nanometer composite material on the basis of the existing good performances of the amphiphilic block hydrophobic associating polymer. As a temperature-resistant, salt-tolerant and fluid loss reducing agent for a drilling fluid in the drilling engineering, the polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent has a remarkable fluid loss reducing effect under high temperature and high salinity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

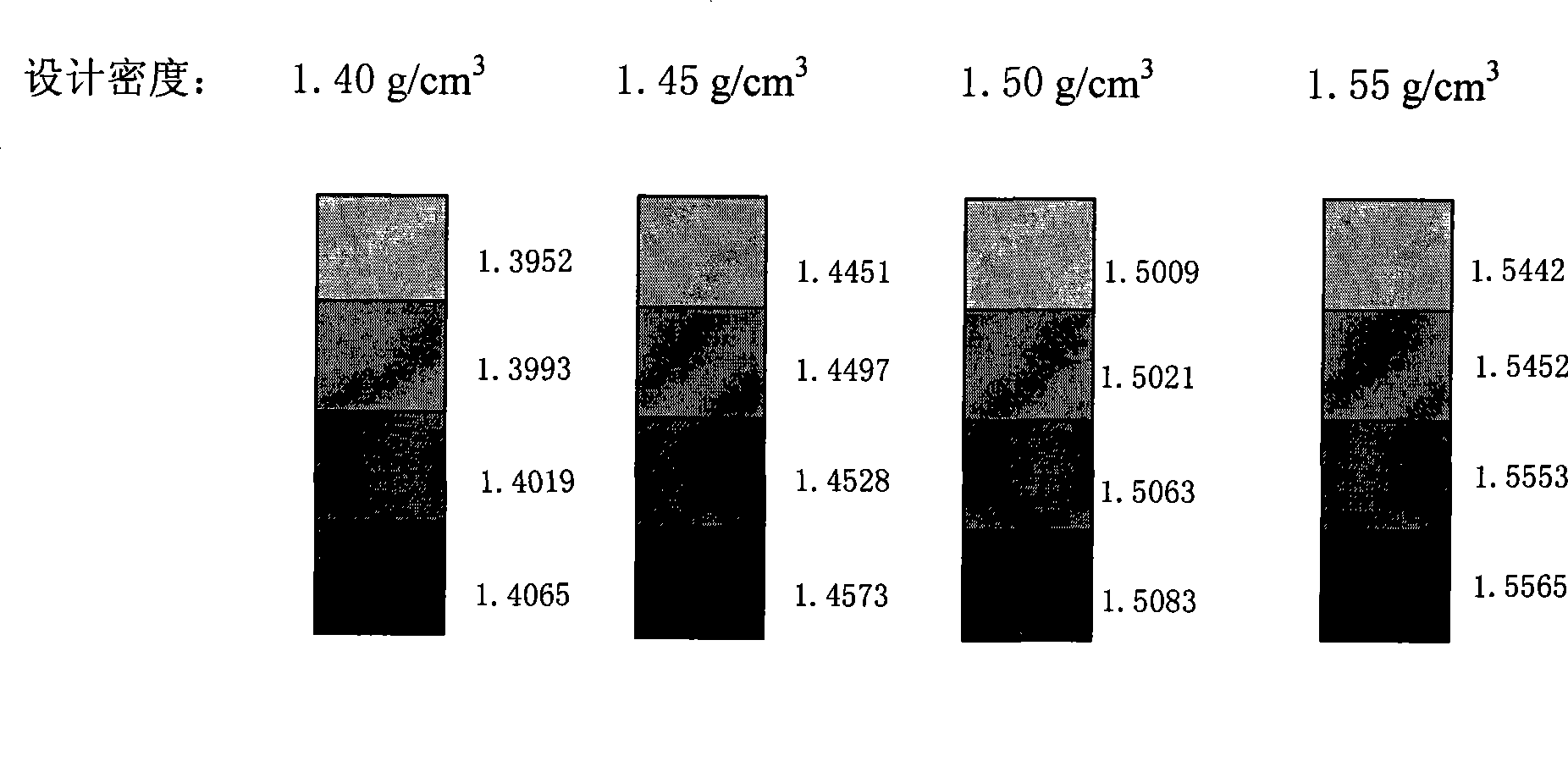

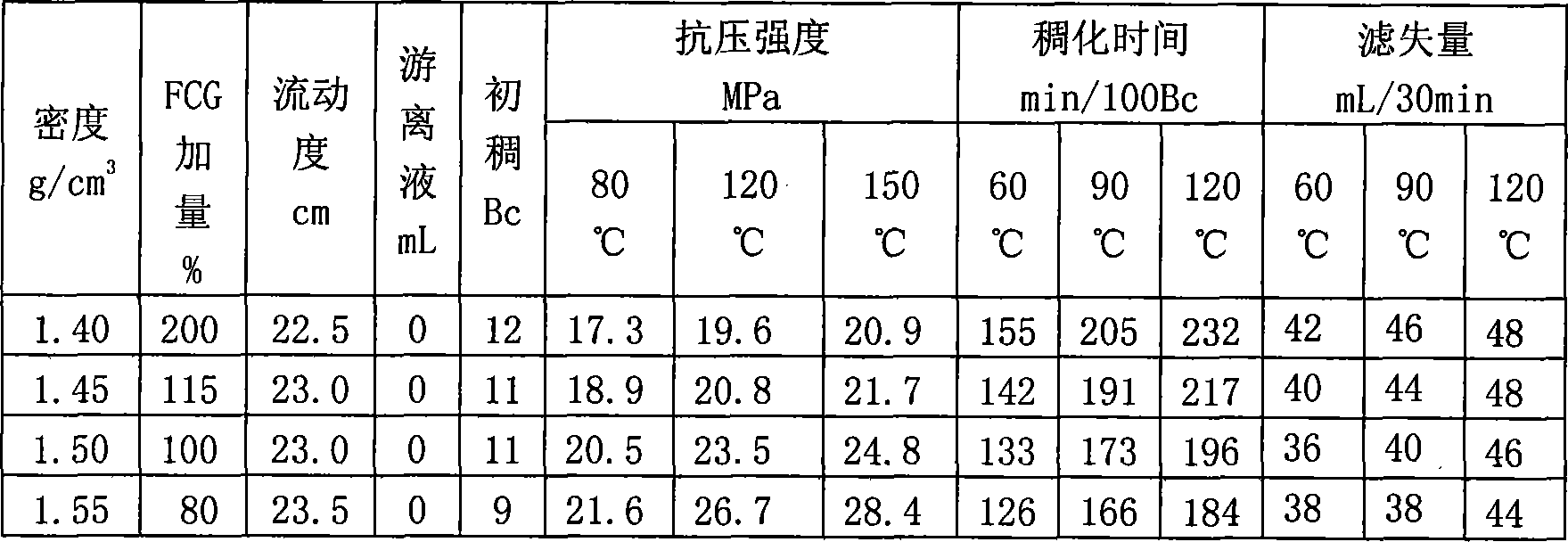

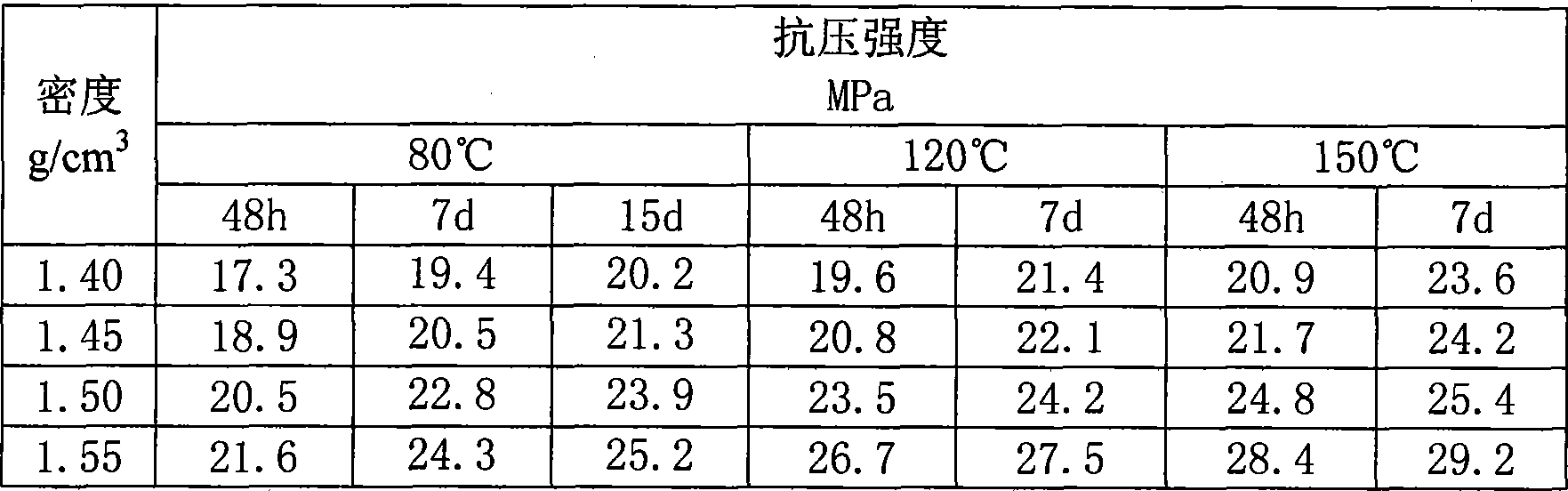

Non-floating bead low-density cement mortar

InactiveCN101475347AGood settlement stabilityMeet technical needsSolid waste managementMicrofine cementParticle density

The invention relates to a non-cenosphere light weight cement slurry, which mainly solves the problem that the cement slurry cannot keep the density thereof under a high pressure condition. The non-cenosphere light weight cement slurry is characterized by comprising the following components in portion by weight: 100 portions of cement, 116 to 321 portions of water, 52 to 136 portions of fly ash, 14 to 38 portions of silica fume, 14 to 38 portions of superfine cement, and 6 to 11 portions of early strength agent, wherein the particle diameter of the silica fume (of which the SiO2 content is more than 90 percent) is more than 0 and less than 0.5 mu m, the particle density of the silica fume and the fly ash is 2.0 grams per cubic meter, and the particle diameter of the superfine cement is more than 0 and less than 2 mu m. The light weight cement slurry forms a set of incompressible light weight cement slurry system of which the density is between 1.40 and 1.55 grams per cubic meter through preferentially selecting external additives and applying a grain composition principle, wherein the flowability and the sedimentation stability of the cement slurry are good, the set cement strength is more than 15 MPa and cannot decline at a temperature of 150 DEG C so as to satisfy the technical requirements on oil field exploration and development.

Owner:DAQING OILFIELD CO LTD +1

Underwater oil-adsorption-resistant oil-adhesion-resistant material, membrane, and coating, and preparation method and application thereof

ActiveCN107096402ASuper oleophobicStrong hydration abilityMembranesSemi-permeable membranesFuel oilOil phase

The invention discloses an underwater oil-adsorption-resistant oil-adhesion-resistant material (an oil-adhesion-resistant material for short), membrane, and coating, and a preparation method and application thereof. The oil-adhesion-resistant material is made from a macromolecular compound containing ionizable hydrophilic groups, and the macromolecular compound is subjected to phase inversion and the hydrophilic groups are ionized to form the oil-adhesion-resistant material. For multiple oil-phase systems underwater, the oil-adhesion-resistant material has a static contact angle greater than 140 degrees and the anchoring strength less than 10 [mu]N. The oil-adhesion-resistant material has underwater super hydrophobic property and adhesion resistance for light low viscosity oil, such as diesel and edible oil, organic reagents immiscible to water, and high viscosity oil, such as petroleum, heavy oil, silicone oil, and heavy diesel fuel. The membrane and the coating formed from the materials have effects of oil adhesion resistance, oil pollution resistance, and self-cleaning in water, and have broad application prospects to the fields of oil adhesion resistance, oil pollution resistance, oil / water separation, oil-resistant coating, ocean oil spill treatment and underwater high-viscosity oil separation and collection.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

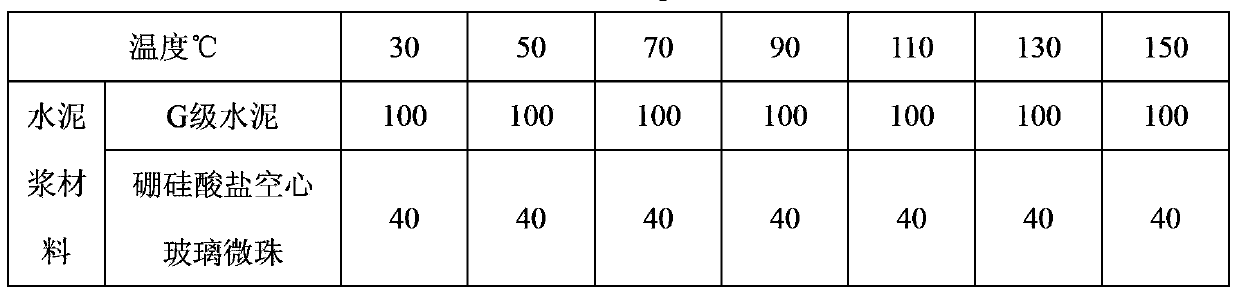

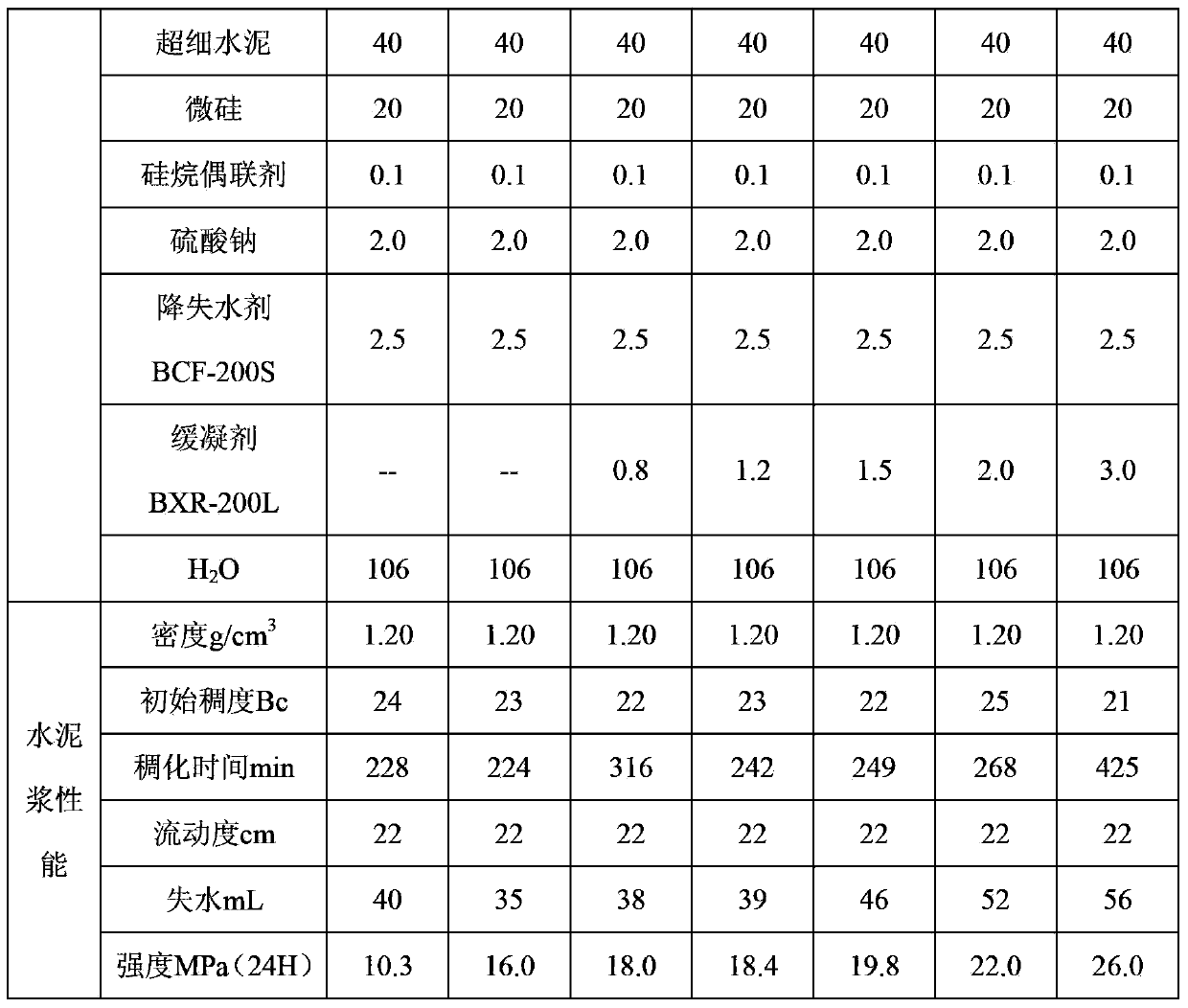

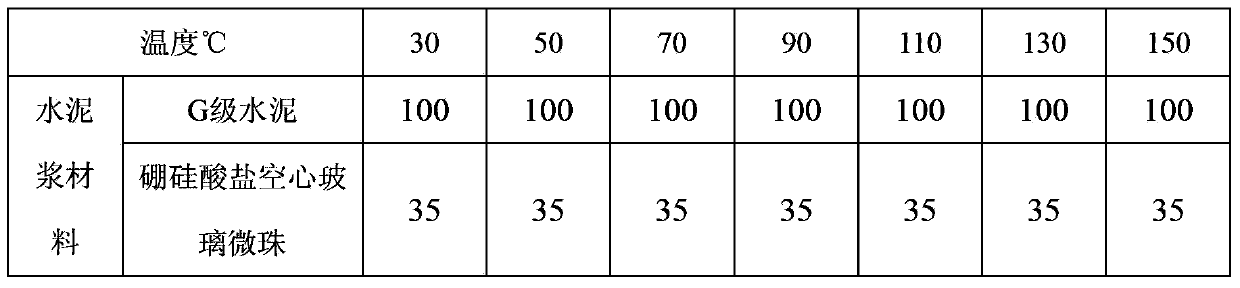

Low-density cement paste system

InactiveCN104178096AStrong hydration abilityFast hydrationDrilling compositionWell cementingVolumetric Mass Density

The invention relates to a low-density cement paste system. The cement paste system comprises following components by weight: 100 parts of oil well cement, 65-106 parts of water, 6-40 parts of borosilicate hollow glass beads, 0.05-0.1 part of a silicone coupling agent, 25-40 parts of ultrafine cement, 10-20 parts of microsilica, 2-2.5 parts of a fluid loss agent, and 0.5-1.5 parts of sodium sulfate. The particle size of the microsilica having a SiO2 content larger than 94% is 0.1-0.5 [mu]m. The particle size of the ultrafine cement is 2-10 [mu]m. The density range of the cement paste is 1.20-1.60 g / cm<3>. The particle size of the borosilicate hollow glass beads is 25 [mu]m. The thickening time of the cement paste is adjustable. The 24-h compressive strength (taking 1.50 g / cm<3> as an example) is higher than 16 MPa. The cement paste system has good sedimentation stability and incompressibility, and improves construction safety of the low-density cement paste in well cementing operation.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Hyaluronic acid and silica gel composition for scar prevention and early repair and preparation method of hyaluronic acid and silica gel composition

ActiveCN105012228AGood chemical stabilityImprove breathabilityAerosol deliveryOintment deliveryDimethyl siloxaneHyaluronic acid

The invention provides a hyaluronic acid and silica gel composition for scar prevention and early repair and a preparation method of the hyaluronic acid and silica gel composition. The method includes the steps of adding purified water to hyaluronic acid to be evenly stirred to prepare a hyaluronic acid solution, adding purified water to onion extract to prepare an onion extract solution, adding carbomer and purified water to glycerol to be evenly stirred to prepare a carbomer solution, sequentially adding the hyaluronic acid solution and the onion extract solution to the carbomer solution to be stirred, adding polydimethylsiloxane and dimethyl siloxane cross-linked polymers to be evenly stirred, making the mixture pass through a colloid mill, and obtaining the hyaluronic acid and silica gel composition. By adding natural plant extract for promoting skin wound healing, natural moisturizing factors, namely, hyaluronic acid, and siloxane polymers, the good effect of preventing scars from being formed is achieved, the effect of rapidly repairing scars in the early stage is achieved, and good effects are achieved for prevention and early repair of scars caused by general operations, traumas and burns.

Owner:郑州和济生物科技股份有限公司

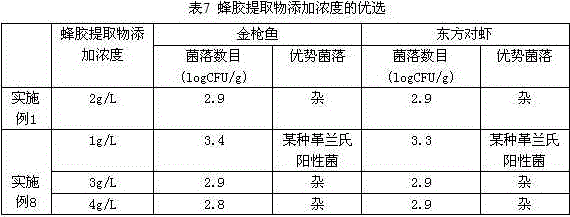

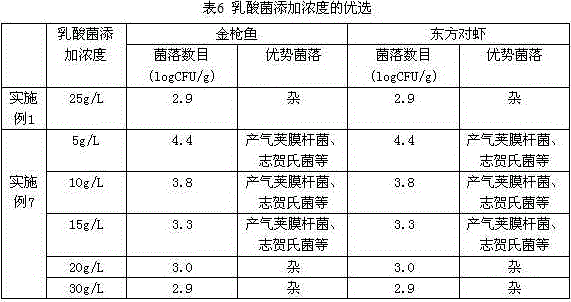

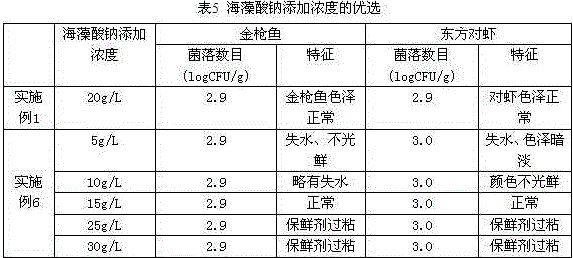

Biological-source nutritional preservative for seafood

InactiveCN106070538AStrong Broad Spectrum ResistanceEnhanced inhibitory effectStrepto/lacto-coccusNatural extract food ingredientsPropolisRosmarinus

The invention relates to a biological-source nutritional preservative for seafood. The biological-source nutritional preservative is characterized in that each liter of the distilled water of the biological-source nutritional preservative contains 0.4-0.6g of lysozyme, 2.5-3.5g of tea polyphenols, 20-28g of carboxymethyl chitosan, 10-14g of nisin, 17-23g of sodium alginate, 20-30g of lactobacillus, 1.5-2.5g of propolis extract and 10-14g of spice extract, wherein the spice extract is made of rhizoma galangae, garlic, onion, cinnamon, clove and rosemary. The biological-source nutritional preservative has the advantages that the biological-source nutritional preservative is compound by biological preservatives and is safe, nontoxic, simple in preparation and application method, outstanding in microorganism inhibition effect, good in preservation effect, capable of greatly prolonging the shelf life of the seafood and high in industry value.

Owner:黎建波

Thermal insulation sheet material and preparation method thereof

The invention, belonging to the field of building materials, particularly relates to a lightweight thermal insulation sheet material for building walls. The thermal insulation sheet material comprises the following ingredients: 8.5-10.5 weight portions of fly ash floating bead, 30-38 weight portions of closed cell perlite, 43-52 weight portions of cement, 7-8.5 weight portions of bentonite, 0.04-0.06 weight portions of cellulose ether, 0.07-0.09 weight portions of short fiber, 0.04-0.06 weight portions of wood fiber, and 0.3-0.4 weight portions of gelatine powder. The thermal insulation sheetmaterial is prepared by using organic materials, and has the characteristics of no toxicity, good thermal insulation property, high temperature resistance, low temperature resistance, non-inflammableproperty, high efficiency, and aging resistance. When the thermal insulation sheet material is used for building walls, the thermal insulation property of the sheet material can not be reduced with time, and the sheet material has the same service life with the building.

Owner:安徽瑞蒙科技有限公司

Cyclodextrin grafted copolymer type ceramic water reducer and preparation method thereof

The invention belongs to the technical field of preparation of ceramic water reducers and discloses a cyclodextrin grafted copolymer type ceramic water reducer and a preparation method thereof. The water reducer is prepared from cyclodextrin or a cyclodextrin derivative, 3-(2-methylacryloyl ethoxyl dimethylamine) propanesulfonate, a chain transfer agent, an initiator, a chain terminator and deionized water. Due to a special molecular structure of cyclodextrin, the water reducer prepared by the preparation method has very good water-reducing and dispersing effects and meanwhile the water reducer which is amphoteric ionic polyelectrolyte is good in chemical property and thermal stability, strong in hydratability and insusceptible to the pH value of a solution. In addition, the water reducer prepared by the preparation method provided by the invention further has an enhancing effect on ceramic.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Solid-liquid separation technique for waste slurry of water-based system artesian well

InactiveCN101269888AStrong hydration abilityImprove binding stabilityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationWater basedWell drilling

The invention discloses a solid and liquid separation technique of water based system well drilling waste slurry, which includes the procedures that: (1) slurry preparation, water or well drilling wastewater is added to adjust the density of the water based system well drilling waste slurry not to be more than 1.20 g / cm<3>; (2) acidification and gelout, gel breaker sulphuric acid is added to adjust the pH value of the waste slurry after the density is adjusted not to be more than 5, and the acidification and gelout and stability elimination reaction are performed; (3) solid and liquid separation, the waste slurry liquid after being performed the full acidification and gelout and stability elimination reaction is fed into a solid and liquid separation device for the solid and liquid separation, so as to cause the solid phase and the liquid phase of the waste slurry to be separated. The solid and liquid separation technique of the water based system well drilling waste slurry provided by the invention fully solves the key technical problem that the water based system well drilling waste slurry is difficult to perform the solid and liquid separation, and establishes the reliable base for the innocent treatment of the water based system well drilling waste slurry.

Owner:SICHUAN UNIV

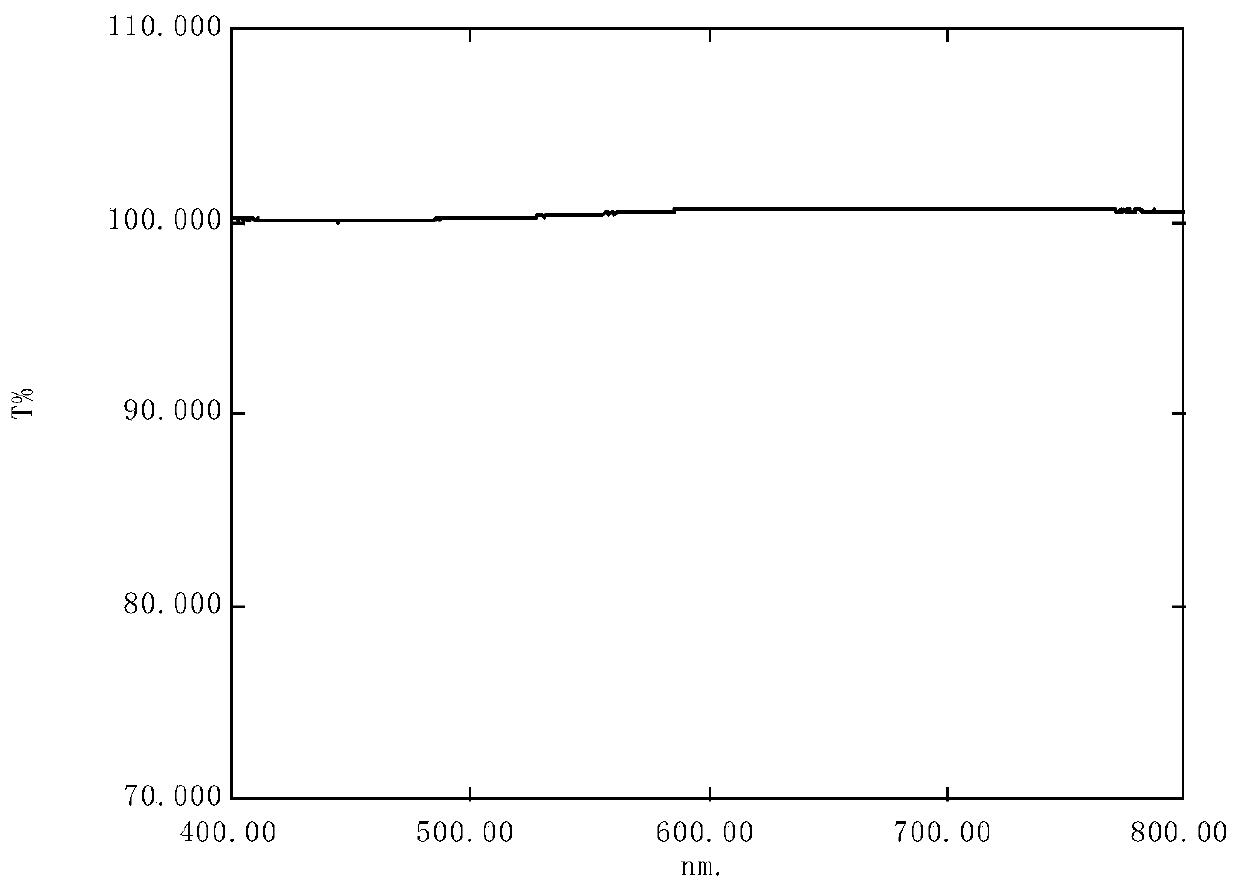

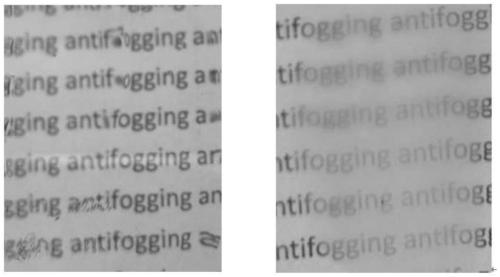

Preparation method of hydrophilic polymer anti-fog coating

The invention relates to a preparation method of a hydrophilic polymer anti-fog coating. The method comprises the following steps: immersing an activated base material in a mixed solution of a silanecoupling agent and a catalyst, coating a obtained silane coupling agent modified base material with the mixed solution of a hydrophilic monomer and an initiator, and initiating free radical polymerization through ultraviolet light or heat. The coating obtained through the method has good transparency and anti-fog performance, and the light transmittance in the visible light wavelength range is about 100%.

Owner:DONGHUA UNIV

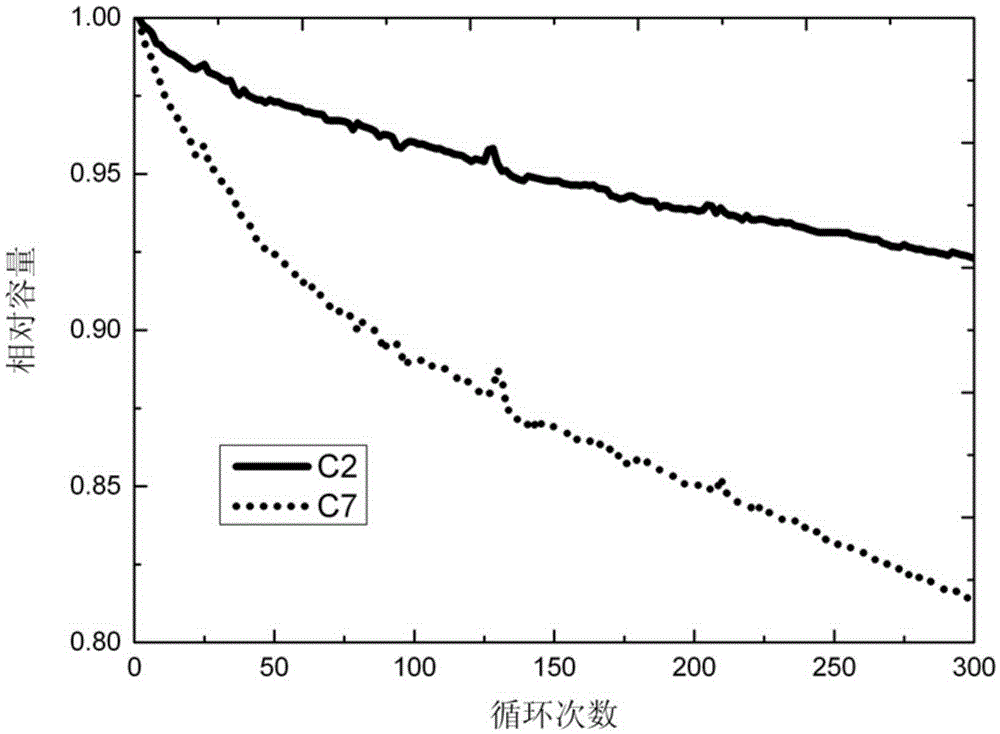

Negative electrode material for lithium ion battery, lithium ion battery negative electrode sheet and lithium ion battery

PendingCN106549158AIncrease energy densityHigh molecular weightCell electrodesSecondary cellsKonjac glucomannanLithium electrode

The invention relates to a negative electrode material for a lithium ion battery. The negative electrode material for the lithium ion battery is characterized by including a negative electrode active material, a conductive agent, a binder and a thickening agent; the thickening agent is selected from at least one of konjac glucomannan and konjac glucomannan derivatives. The thickening effect of the thickening agent in the negative electrode material of the lithium ion battery is relatively good.

Owner:SHENZHEN BAK POWER BATTERY CO LTD +1

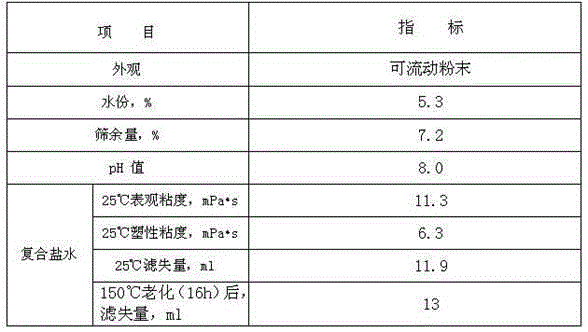

Salt-resistant filtrate loss reducer for grafted starch drilling fluid

The invention relates to a salt-resistant filtrate loss reducer for a grafted starch drilling fluid. The salt-resistant filtrate loss reducer is prepared from acrylamide, 2-acrylamide-2-methyl propane sulfonic acid, sodium carbonate and starch as raw materials by the processes of raw material preparation, polymerization reaction, hydrolysis reaction and modified drying. The salt-resistant filtrate loss reducer has the advantages of relatively high compatibility, relatively high filtration reducing ability in fresh water, saline water, saturated salt water and composite saltwater drilling fluid, and high-temperature resistance; and the drilling efficiency and the oil quality can be effectively improved.

Owner:HEBEI GUANGDA PETROCHEM

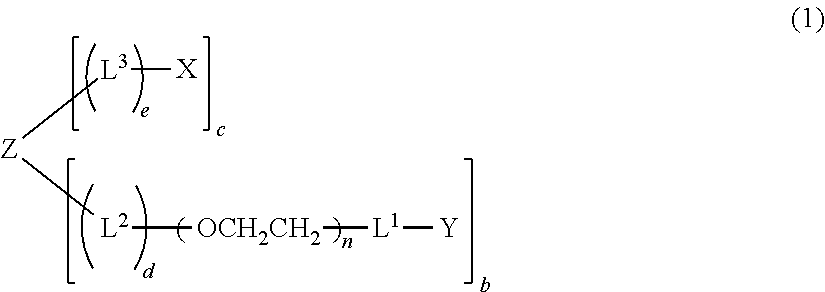

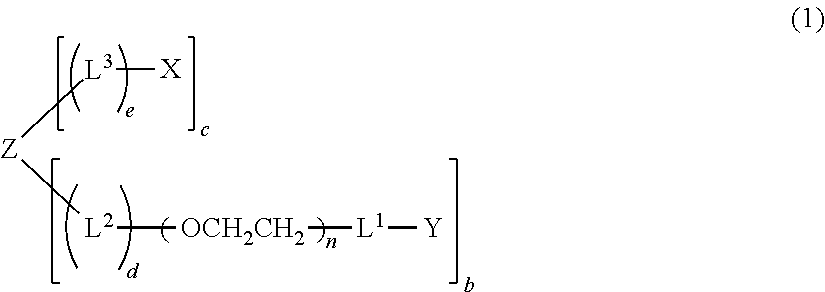

Polyoxyethylene derivative having plural hydroxyl groups at terminal end thereof

ActiveUS20120322955A1Easy to useEfficient preparationPharmaceutical non-active ingredientsHydrogenHydrogen atom

A polyoxyethylene derivative represented by the formula (1):wherein a whole molecular weight of the polyoxyethylene derivative is 500 to 160,000; n is 5 to 3650; L1, L2, and L3 each independently represent an alkylene group, a phenylene group, an ester bond, an amide bond, an ether bond, a urethane bond, a carbonate bond, a secondary amino group, or a combination thereof; X represents a functional group capable of reacting with a bio-related substance; Y represents a hydrophilic group having plural hydroxyl groups made from a residual group of xylitol or volemitol or a residual group of polyglycerin of trimer to 31-mer; Z represents a residual group of a compound having 2 to 5 active hydrogen atoms; b and c are as follows: 1≦b≦4, 1≦c≦4, and 2≦b+c≦5; and d and e each independently are 0 or 1.

Owner:NOF CORP

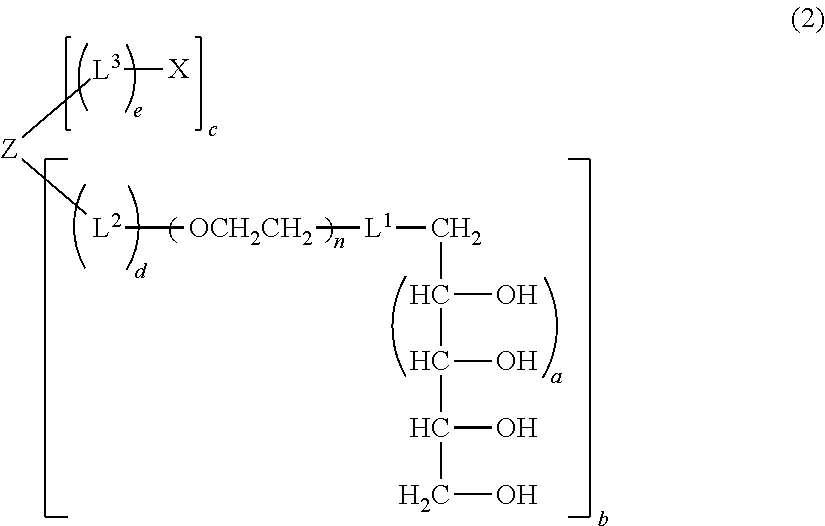

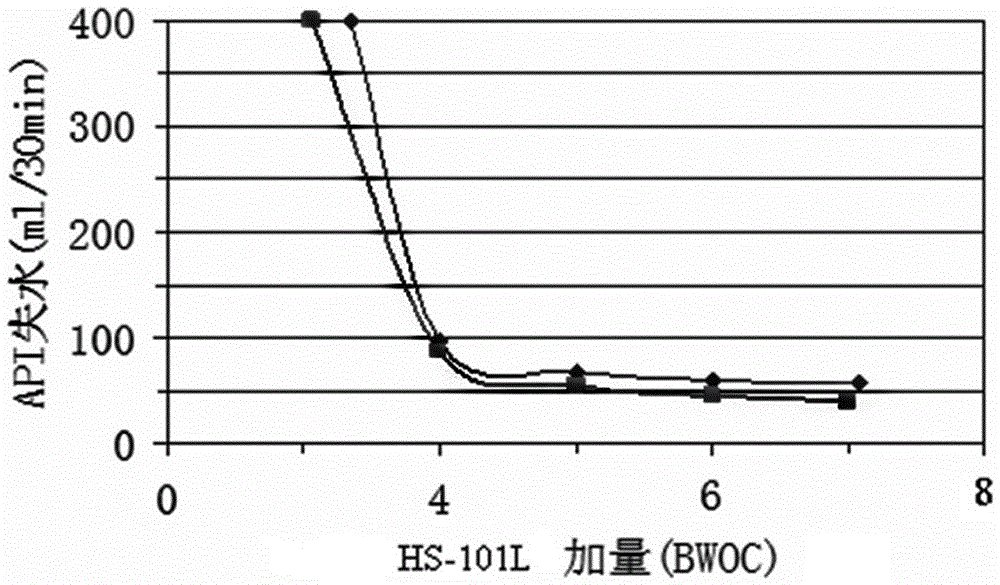

High-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in oil field

ActiveCN105694832AExcellent dehydration performanceGood adaptabilityDrilling compositionSolid phasesSilica fume

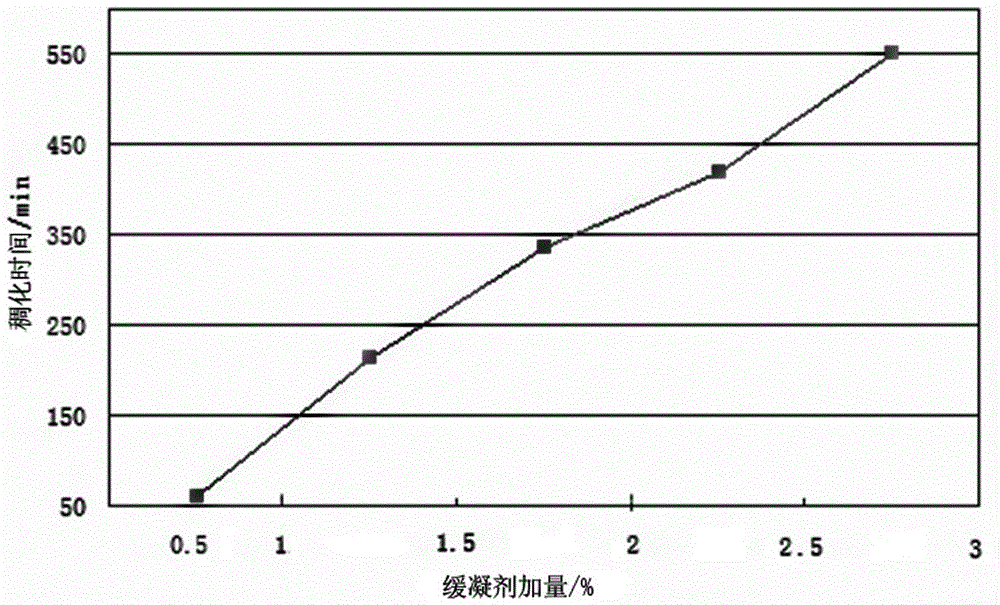

The invention relates to high-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in an oil field. The cement grout is prepared from components of raw materials in parts by weight as follows: 600 parts of G-grade oil well cement, 30-36 parts of an HS101L fluid loss agent, 8-20 parts of an HS201L retarder, 1.8 parts of an HS-301S dispersant, 150 parts of quartz sand, 30 parts of silica fume, 1.8 parts of an HS-XF1S suspension stabilizer, 280-300 parts of water and 1 part of bis(2-ethylhexyl) sulfosuccinate sodium salt, wherein the grain size of the quartz sand is 80-120 meshes, the grain size of the silica fume is 300-400 meshes, and the content of silicon dioxide is 90% or higher. Liquid-phase raw materials are added to a grout mixing container and mixed uniformly; solid-phase substances are added to a solid-phase container and stirred uniformly, the solid-phase mixture is added to the grout mixing container, finally, a defoaming agent is added, and the mixture is stirred uniformly. The cement grout can be used under the condition of 50-180 DEG C, has prominent large-temperature-difference-resistant performance and can effectively avoid a super-retarding phenomenon caused by large temperature difference.

Owner:CHINA PETROCHEMICAL CORP +2

Moisturizing, anti-inflammatory and anti-aging essence and preparation method thereof

InactiveCN111419767AImprove repair effectEnhance anti-inflammatoryCosmetic preparationsAntipyreticButanediolAcetophenone

The invention discloses a moisturizing, anti-inflammatory and anti-aging essence and a preparation method thereof. The essence of the invention consists of betaine, EDTA-disodium, dipotassium glycyrrhizinate, xanthan gum, carbomer, ruscus aculeate root extract, pigments, a pH regulator, ceramide-3, butanediol, p-hydroxyacetophenone, a preservative, sodium hyaluronate, beta-glucan, bio-saccharide gum-1, argania spinosa kernel oil, an emulsifier, hydrolyzed elastin, hydrolyzed collagen and water. The preparation method is simple, and uniformly mixes the raw materials in batches. The essence of the invention is added with active ingredients such as the ruscus aculeate root extract, the argania spinosa kernel oil, the sodium hyaluronate, the beta-glucan, the hydrolyzed elastin, the hydrolyzedcollagen and the like, and has excellent anti-inflammatory, whitening, moisturizing and skin tightening effects, namely has a good repairing effect on aged and damaged skin.

Owner:安婕妤化妆品科技股份有限公司

Fat emulsifier for feed use, preparation method and application thereof

ActiveCN103976150ALarge emulsification rangeReduce the cost of farmingAnimal feeding stuffAccessory food factorsMonoglycerideSucrose

The invention discloses a fat emulsifier for feed use. The fat emulsifier contains the following components, by weight, 200-300 parts of granulesten, 10-50 parts of sucrose ester, 10-50 parts of monoglyceride, 10-20 parts of taurine and 580-770 parts of an excipient. A preparation method of the fat emulsifier contains the following steps: mixing granulesten and monoglyceride in proportion, heating to 60 DEG C, spraying the mixture into the excipient, uniformly mixing and drying to prepare a mixture; adding components excluding granulesten, monoglyceride and the excipient into the mixture; placing the mixture obtained from the step (3) into an agitator, stirring for 1-2 hours, putting the mixture into a pulverizer for primary crushing, taking out the crushed mixture and putting the crushed mixture into a ultrafine grinder for secondary crushing so as to obtain fine particles, sieving through a 100-mesh sieve, sealing and packaging so as to obtain the fat emulsifier for feed use. The fat emulsifier can emulsify most mixed lipid and has a large emulsification range. Meanwhile, the emulsifier can be added in the most economic mode, thus remarkably reducing breeding cost.

Owner:WEIFANG KENENG BIOTECH CO LTD

Light-weight high-strength concrete material and preparation method thereof

The invention discloses a light-weight high-strength concrete material and a preparation method thereof. The light-weight high-strength concrete material is prepared from the following components in parts by weight: 1100 to 1200 parts of coarse aggregate, 1000 to 1100 parts of cement, 800 to 900 parts of pottery sand, 150 to 200 parts of silica fume, 10 to 15 parts of dispersing agent, 50 to 60 parts of modified hollow glass beads, and 200 to 250 parts of water; the coarse aggregate is shale ceramisite; cement is grade-G oil-well silicate cement; and the dispersing agent is sulfonated alkyl naphthalene methyl resin. The method comprises the following steps: placing the dispersing agent into a stirrer, adding an appropriate amount of water, stirring, pouring the ceramsite, the pottery sand,the cement and the remaining water, continuously stirring, finally adding the silica fume and the modified hollow glass beads, uniformly stirring, pouring into a strength mold, wrapping and sealing,and maintaining in a water-bath maintenance box. By adopting the light-weight high-strength concrete material, the pressure resisting strength and the corrosion resistance of the existing light-weighthigh-strength concrete can be improved, the light-weight high-strength concrete is also ensured to have good durability, the production period is short, and the market prospect is wide.

Owner:SOUTHWEST PETROLEUM UNIV

Comb polyelectrolyte type dispersing agent with dispersed nano particles and preparation method of dispersing agent

The invention belongs to the technical field of dispersing agent preparation, and discloses a comb polyelectrolyte type dispersing agent with dispersed nano particles and a preparation method of the dispersing agent. The dispersing agent comprises 3-(2-methacryloyloxyethyl trimethyl dimethylamino) propanesulfonic acid salt, enol polyoxyethylene ether, a chain transfer agent, an initiator, a chain terminator and deionized water. The prepared dispersing agent disclosed by the invention is comb polyamphoteric electrolyte; and after the nano particles adsorb the dispersing agent disclosed by the invention, steric hindrance effect among nano particles is relatively strong, and sedimentation is hardly caused. Therefore, the dispersing effect is good. Meanwhile, quaternary ammonium salt cation is introduced into a macromolecule main chain, so that the hydratability and the heat stability of the dispersing agent are enhanced.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Heat insulation decoration plate and preparation method thereof

The invention belongs to the field of building material and specifically relates to a light heat insulation decoration plate with decoration function for building wall insulation and a preparation method thereof. The heat insulation decoration plate comprises a heat insulation blank body and a decoration coating sprayed to the outer layer of the heat insulation blank body; and the heat insulationblank body is prepared by closed cell perlite, fly ash floating bead, cement, bentonite, cellulose ether, short fiber, wood fiber and rubber powder in parts by weight. The heat insulation blank body of the heat insulation decoration plate is formed by processing inorganic material and is light in weight, insulated and longer in service life; the cosmetic layer with the preset pattern is sprayed to the outer surface of the heat insulation blank body, so that integration of the heat insulation plate and the decorativeness is realized; and the problem that the current inorganic heat insulation decoration plate is heavy and easy to drop is solved as well.

Owner:安徽瑞蒙科技有限公司

Sustained-release microcapsule-coated composite vitamin pre-mixed feed, preparation method and application thereof

The invention provides a sustained-release microcapsule-coated composite vitamin pre-mixed feed which has good stability and has sustained-release and bacterial inhibiting and sterilizing effects. 1 kg of the pre-mixed feed includes the following components, 20-100 g of microcapsule-coated composite vitamin, 20-50 g of amino acid chelated iron, 5-18 g of amino acid chelated copper, 20-45 g of amino acid chelated zinc, 4-5 g of manganese sulfate monohydrate, 0.10-0.11 g of 1% potassium iodate, 0.59-0.68 g of cobalt chloride, 0.05-0.14 g of 1% sodium selenite, 20-30 g of arginine, 5.9-6.4 g of threonine, 1.8-6.5 g of an enzyme preparation, 18-70 g of an acidification agent, 1.1-3.0 g of an anti-oxidizing agent, 8-50 g of a flavoring agent, 7.5-9.0 g of medicine additives, 78-95 g of 50% choline chloride and the balanced being a carrier which includes nano chelated attapulgite, and at least one of corn protein powder, stone powder, zeolite powder, medical stone or montmorillonite.

Owner:GUANGZHOU GREAT BIOLOGICAL TECH

Ice-cold fiber and its making method

InactiveCN102851785AStable chemical propertiesStrong hydration abilityMonocomponent polyesters artificial filamentArtifical filament manufactureFiberUltraviolet

The invention provides a making method of an ice-cold fiber. The method comprises the following steps: 1, drying: respectively drying 4% by mass of nanometer mica master batches and 96% by mass of polyamide-6 slices; 2, spinning fluid preparation: accurately adding the nanometer mica master batches through utilizing a master batch output injection pump, and mixing and fusing with the polyamide-6 slices; 3, spinning: extruding a fused fiber forming high-polymer from the spinning holes of a spinning head, and cooling in surrounding air to solidify to filaments; and 4, post-processing. The ice-cold fiber obtained through the method has the advantages of stable chemical performances, ultraviolet resistance, high temperature resistance, strong hydratability, pearl luster and high refraction brightness, and is a novel fiber really having a natural ice-cold effect.

Owner:KUNSHAN TIENIU SHIRT FACTORY

Boiled dumpling rich in unsaturated fatty acids

The invention discloses a boiled dumpling rich in unsaturated fatty acids. The boiled dumpling comprises a boiled dumpling wrapper and boiled dumpling stuffing, wherein the boiled dumpling wrapper is added with linseed meal, and the boiled dumpling stuffing is added with the linseed meal and Plukenetia volubilis flour. According to the boiled dumpling rich in unsaturated fatty acids, the boiled dumpling wrapper is properly added with the linseed meal, so that the frost crack resistance and taste of the boiled dumpling wrapper are improved; the boiled dumpling stuffing is added with the linseed meal and the Plukenetia volubilis flour, so that the water retention property, taste and nutritive value of the boiled dumpling stuffing are improved; particularly, the boiled dumpling is rich in unsaturated fatty acids, the boiled dumpling stuffing can be effectively inhibited from oxidative deterioration during frozen preserving, the texture, taste, nutrition and oxidation resistance of quick-frozen boiled dumplings are improved, and the quality defect of the traditional quick-frozen boiled dumplings is overcome.

Owner:SOUTH CHINA AGRI UNIV

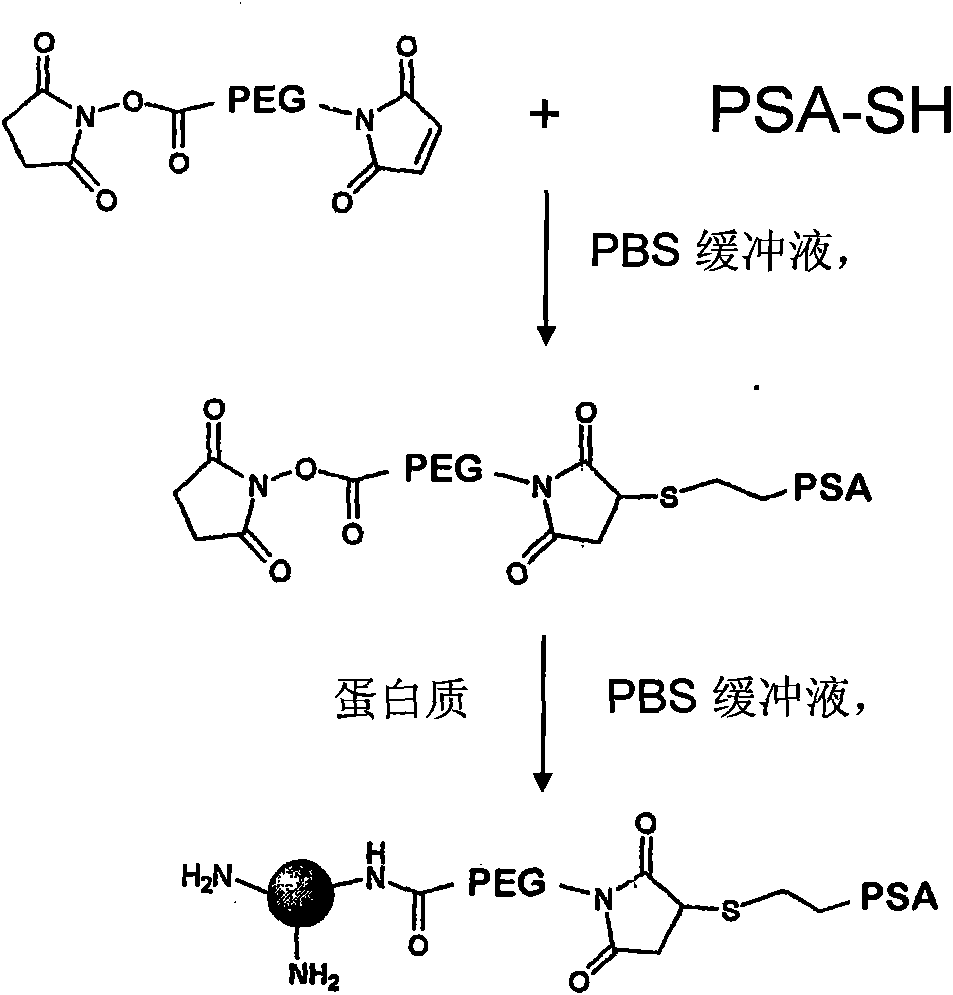

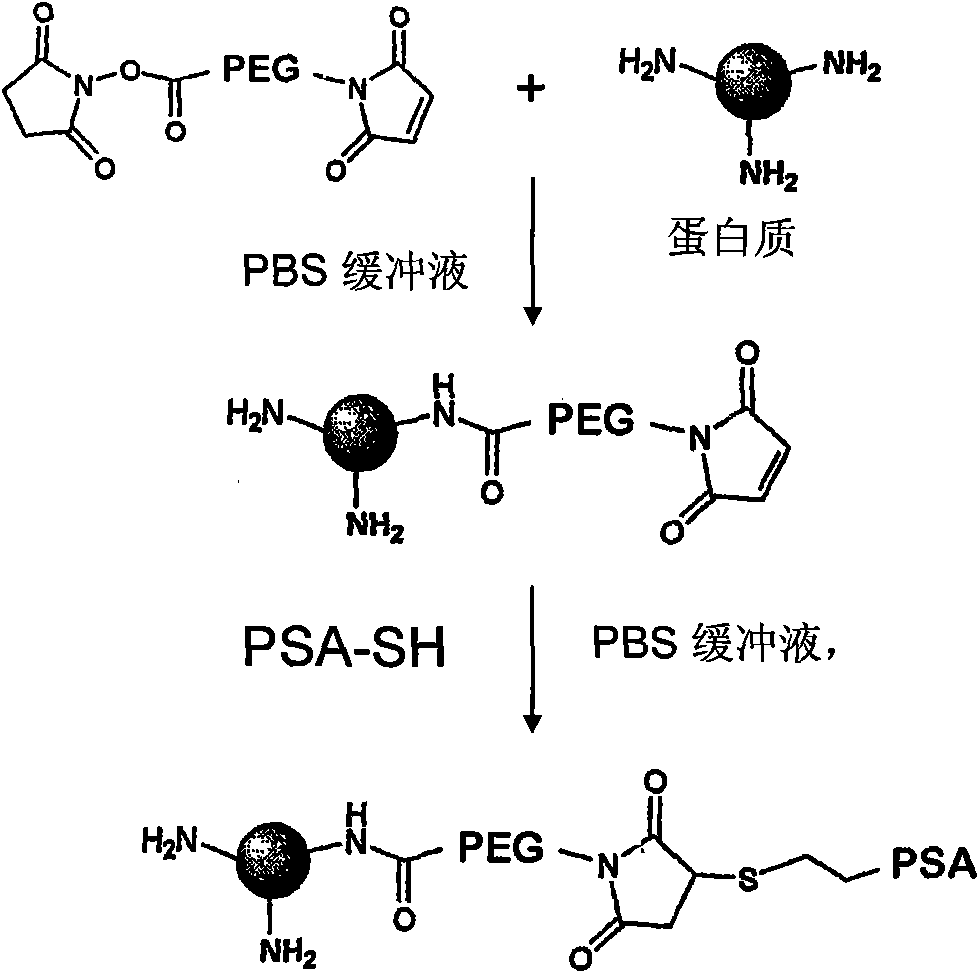

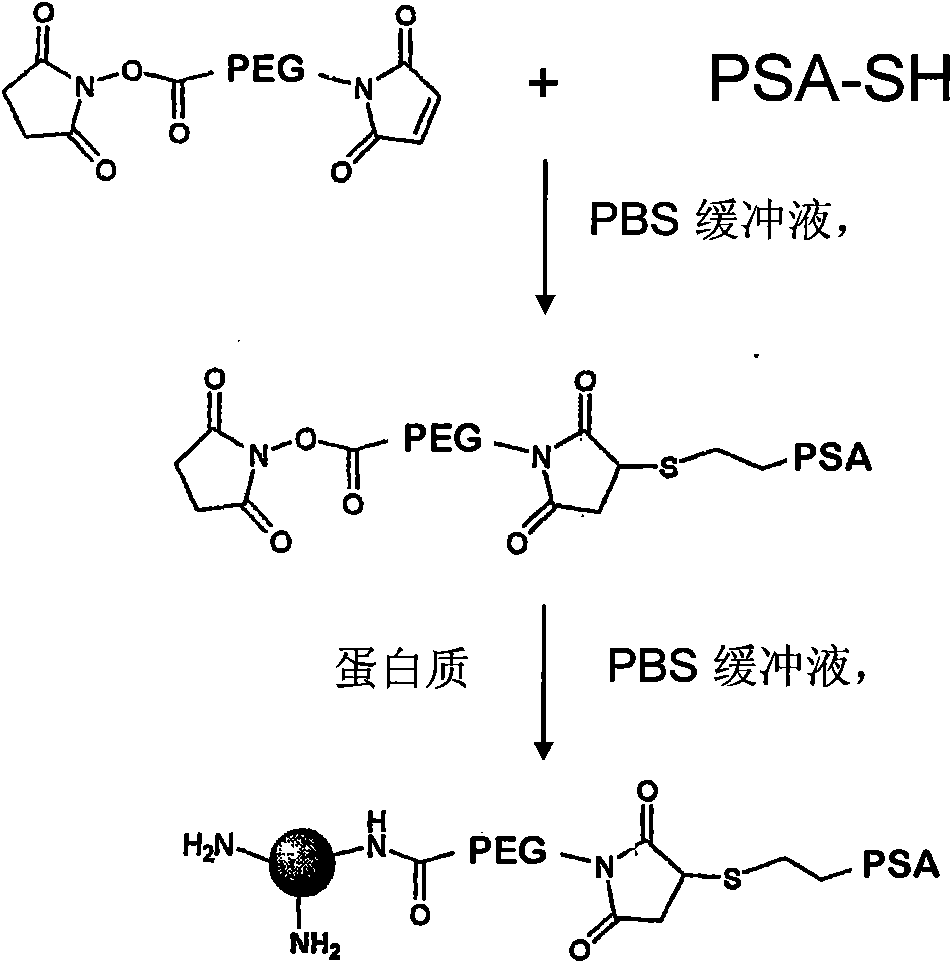

Preparation method and application of polyethylene glycol-polysialic acid block copolymers

InactiveCN101787117AWill not accumulateImproving immunogenicityPeptide/protein ingredientsPeptide preparation methodsSolubilityHalf-life

The invention provides a preparation method and application of polyethylene glycol-polysialic acid block copolymers, which belong to the technical field of polymer materials. The copolymers are formed by connecting activated polysialic acid with different-base bifunctional polyethylene glycol, and are expressed as X-PEG-F-PSA, wherein X is one of active groups of different-base bifunctional PEG and is used to be connected with the active groups on protein or polypeptide; F is another active group of the different-base bifunctional PEG and is used to be connected with activated polysialic acid PSA; the block copolymers X-PEG-F-PSA are connected with Protein so as to form Protein-PEG-PSA products. The products can be widely used to modify amino-containing biological functional molecules, particularly protein or polypeptide and other macromolecules, and by utilizing the strong hydration performance of PEG and the immunogenicity of PSA, low-molecular-weight PEG and PSA are connected to modify various protein or polypeptide medicaments in order to improve the dissolvability, stability and immunogenicity of the medicaments, prolong the half-life period of the medicaments and improve therapeutic effects..

Owner:山东弥美生物科技股份有限公司

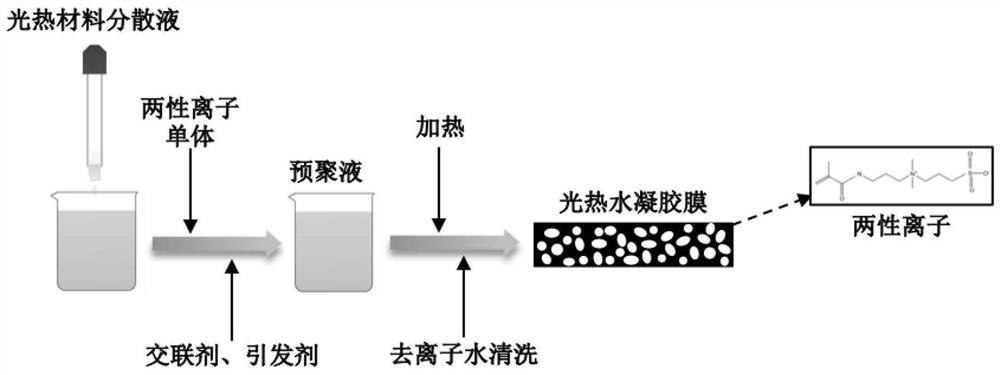

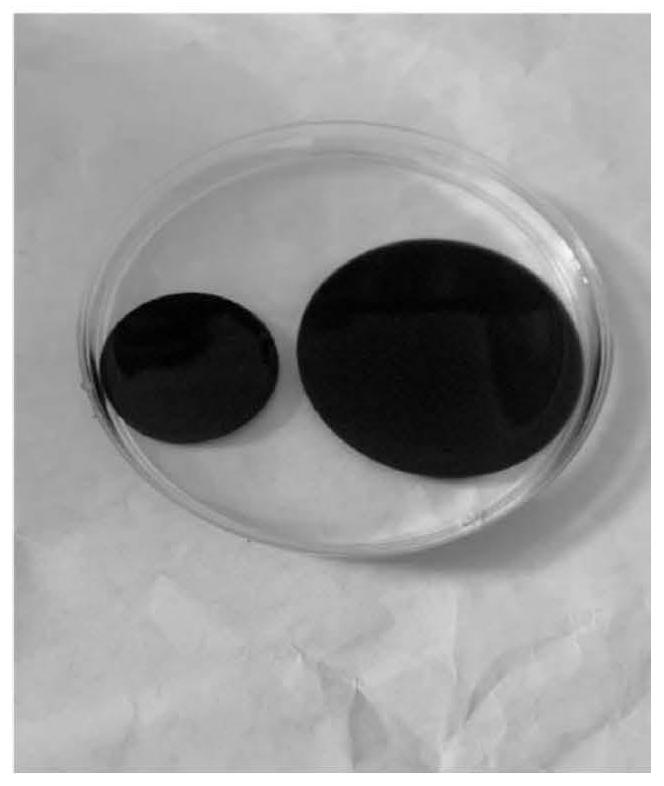

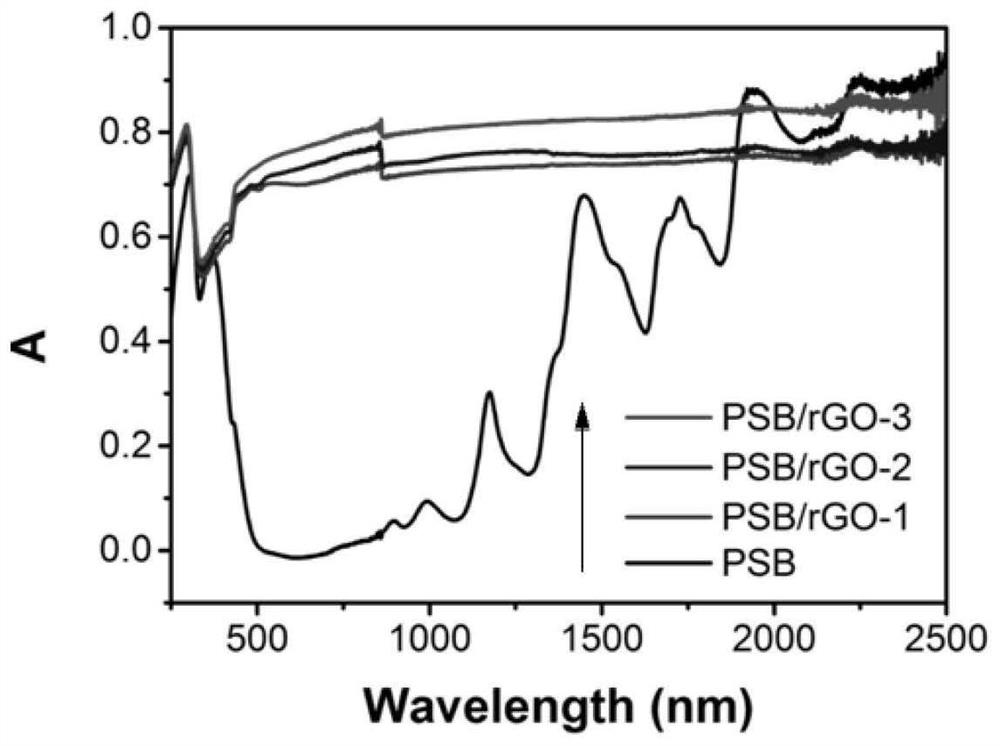

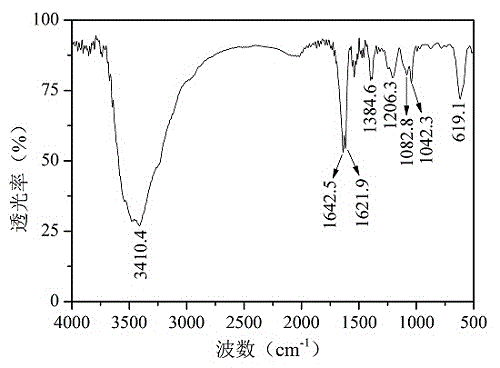

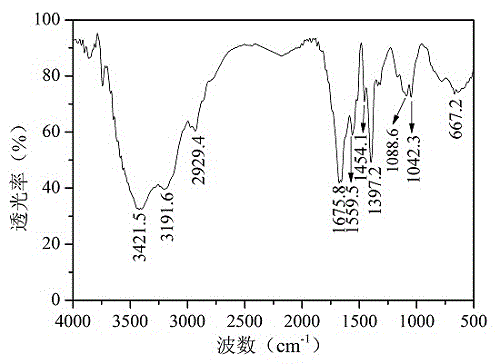

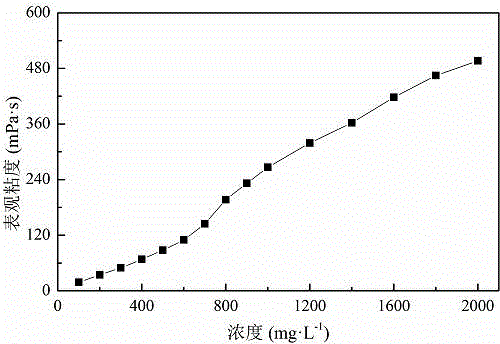

Amphoteric polyelectrolyte photo-thermal hydrogel as well as preparation and application thereof

ActiveCN113527828AAchieve antifouling functionEnhance water evaporationGeneral water supply conservationWater/sewage treatmentPolyelectrolytePolymer science

The invention belongs to the field of functional polymer materials and particularly relates to amphoteric polyelectrolyte photo-thermal hydrogel as well as preparation and application thereof. The amphoteric polyelectrolyte photo-thermal hydrogel comprises amphoteric polyelectrolyte hydrogel and a photo-thermal material, wherein the photo-thermal material is dispersed in the amphoteric polyelectrolyte hydrogel; the amphoteric polyelectrolyte photo-thermal hydrogel is obtained by copolymerization of an amphoteric polyelectrolyte monomer, a cross-linking agent, an initiator and a photo-thermal material mixture. By utilizing the biological pollution prevention capacity of the amphoteric polyelectrolyte hydrogel, the defect that the surface of a traditional photo-thermal steam conversion material is easily polluted when the traditional photo-thermal steam conversion material is used for treating sewage such as high-concentration brine, seawater and industrial wastewater is overcome, and the service life of the photo-thermal steam conversion material in photo-thermal steam conversion application is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Acrylamide copolymer oil-dispelling agent with sulfitobetaine structure and synthesis method

InactiveCN104403052APromote hydrationStrong hydration abilityDrilling compositionSynthesis methodsSulfite

The invention discloses an acrylamide copolymer with a sulfitobetaine structure and a synthesis method of a monomer with a sulfitobetaine structure. The acrylamide copolymer is composed of the following monomers in parts by weight: 55 to 75 parts of acrylamide, 24 to 38 parts of acrylic acid, and 1 to 7 parts of 2-(3-methylacrylamidepropyldimethylamino)ethyl sulfurous acid inner salts, and is synthesized in the presence of an initiator namely 0.1 to 0.5 part of NaSO3-(NH4)2S2O8 in a water solution with a pH value of 5 to 9 at a temperature of 30 to 40 DEG C for 6 to 10 hours. The monomer with a sulfitobetaine structure is prepared by carrying out reflux reactions between 1 part of N-(3-dimethylaminopropyl)methacrylamide and 1 to 1.2 parts of ethylene sulfite in 1,4-dioxane for 2 to 5 hours.

Owner:SOUTHWEST PETROLEUM UNIV

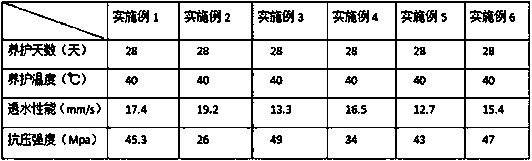

High-strength pervious concrete material and preparation method thereof

InactiveCN107840610AHigh compressive strengthImprove protectionSolid waste managementCeramicwareWater bathsFiber

The invention discloses a high-strength pervious concrete material and a preparation method thereof. The high-strength pervious concrete material is composed of the following components in parts by weight: 1400-1500 parts of coarse aggregate, 400-500 parts of cement, 3.2-4 parts of a dispersing agent, 3.2-4 parts of toughening fibers and 110-120 parts of water. The coarse aggregate is limestone and has a particle size of 5-10mm; the cement is G-level high-sulfate-resistance oil well cement; the dispersing agent is sulfonated sodium tannin; and the toughening fibers are plasma treatment cellulosic fibers. The preparation method comprises the following steps: adding cement and water into a stirrer, stirring to be in a slurry state, sequentially adding the coarse aggregate, the dispersing agent and the toughening fibers, stirring to be uniformly mixed, pouring the mixture in a strength test mold, vibrating and compacting, and curing in a water bath curing box. According to the high-strength pervious concrete material disclosed by the invention, the compressive strength and corrosion resistance of the current pervious concrete are improved, good water permeability and durability of thepervious concrete are ensured, the production cycle is short, and the high-strength pervious concrete material has wide market prospects.

Owner:SOUTHWEST PETROLEUM UNIV

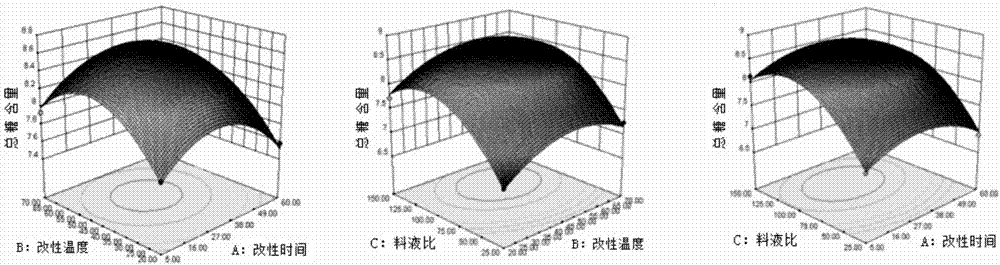

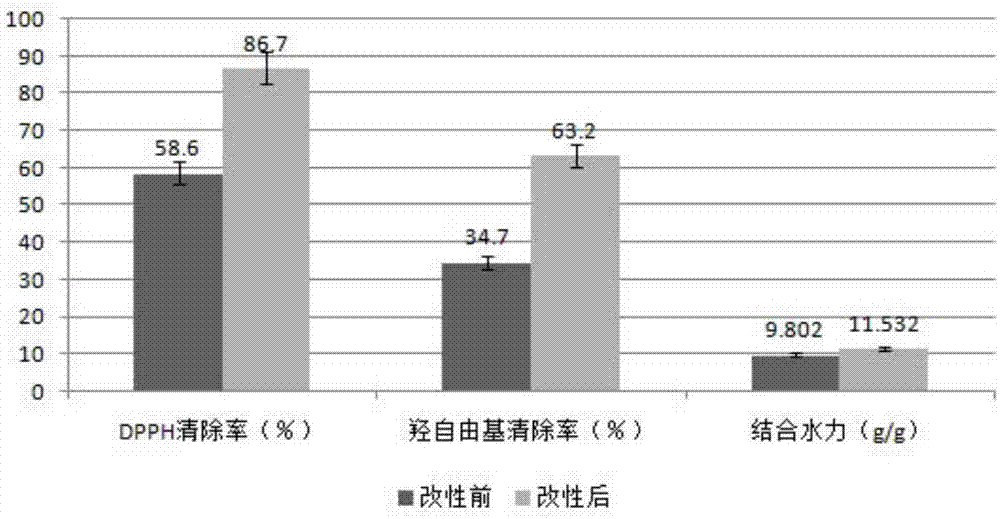

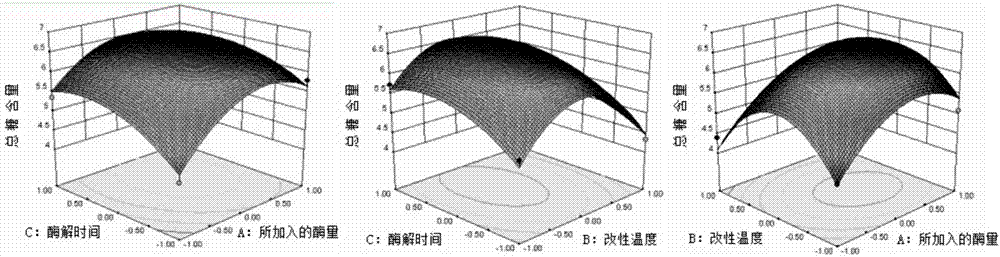

Modification method for dietary fiber of black fungus

ActiveCN106901381AIncrease soluble sugar contentReduce fatFood ingredient functionsFood ultrasonic treatmentSlagCentrifugation

The invention provides a modification method for dietary fiber of black fungus. The modification method comprises the following steps: taking dry black fungus, mechanically crushing, sieving, mixing obtained rough black fungus powder with deionized water, stirring, extracting, then carrying out centrifugation, removing supernatant, cleaning slags, carrying out vacuum drying, crushing, and thus obtaining the dietary fiber of the black fungus; mixing the dietary fiber of the black fungus with the deionized water, then adding cellulase, carrying out ultrasonic treatment for 5-20 minutes at the temperature of 40-60 DEG C, then maintaining the temperature to carry out enzymolysis for 240-280 minutes, then supplementing the deionized water, then carrying out ultrasonic treatment for 10-25 minutes, and then freezing and drying to obtain the modified dietary fiber of the black fungus. The modification method provided by the invention has the advantages that the black fungus is adopted as a raw material, the dietary fiber of the black fungus is modified by adopting a modifying treatment process with optimized ultrasound and conjugated enzyme under specific conditions, soluble sugar in the dietary fiber of the black fungus can be effectively dissolved out, and active groups are fully exposed, so that the characteristics such as hydratability and oxidation resistance can be effectively improved.

Owner:CHINA JILIANG UNIV

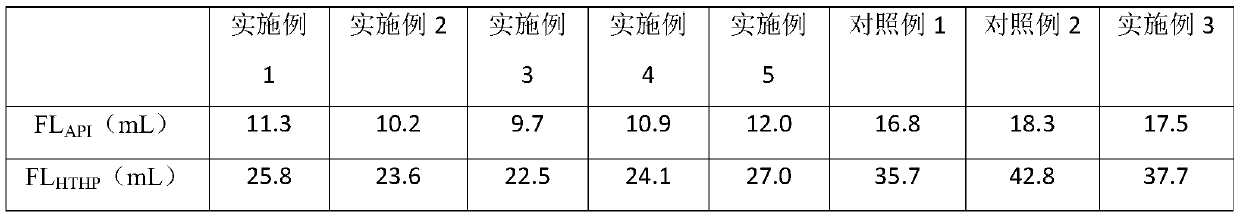

Temperature-resistant and salt-resistant filtrate reducer for drilling fluid, and preparation method thereof

InactiveCN110577622AImprove temperature resistanceRich sourcesDrilling compositionMaleic anhydrideTemperature resistance

The invention discloses a temperature-resistant and salt-resistant filtrate reducer for a drilling fluid, and a preparation method thereof, and belongs to the technical field of oilfield exploitationdrilling treatment agents. The filtrate reducer comprises, by weight, 20-50 parts of a modified rice husk powder, 20-50 parts of modified bagasse, 20-60 parts of a modified sulfonated lignite resin, 10-40 parts of acrylamide, 10-40 parts of acrylic acid, 10-30 parts of 2-acrylamido-2-methylpropanesulfonic acid, 10-25 parts of maleic anhydride, 5-20 parts of N-vinylpyrrolidone and 10-15 parts of dimethyl diallyl ammonium chloride. Rice husks and bagasse are modified, and then are compounded with the sulfonated lignite resin, and the obtained mixture and other monomers undergo graft copolymerization, so the temperature resistance of the cellulose filtrate reducer can be effectively improved.

Owner:中国石油集团川庆钻探工程有限公司钻井液技术服务公司 +1

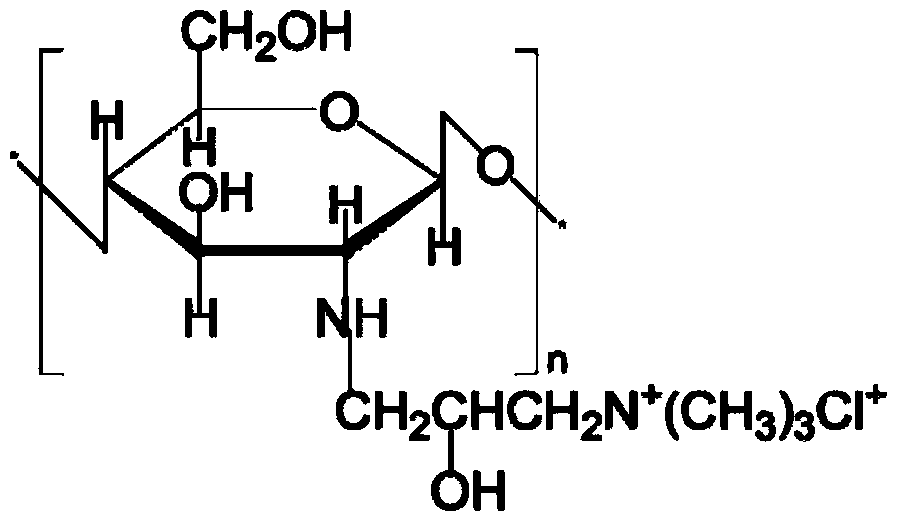

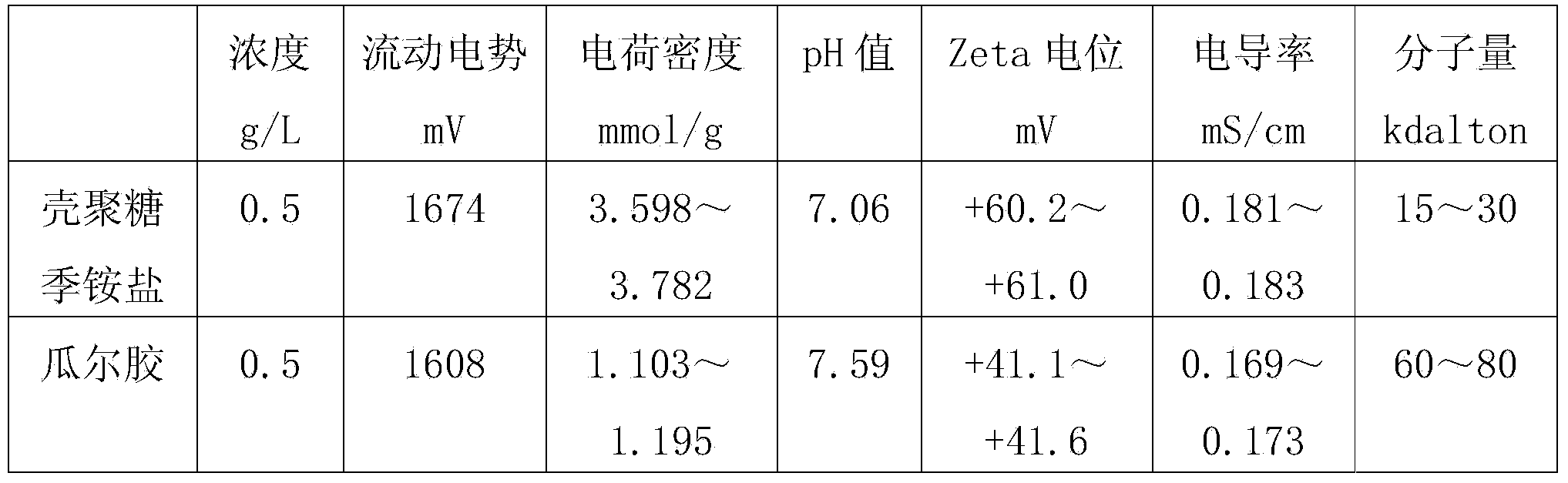

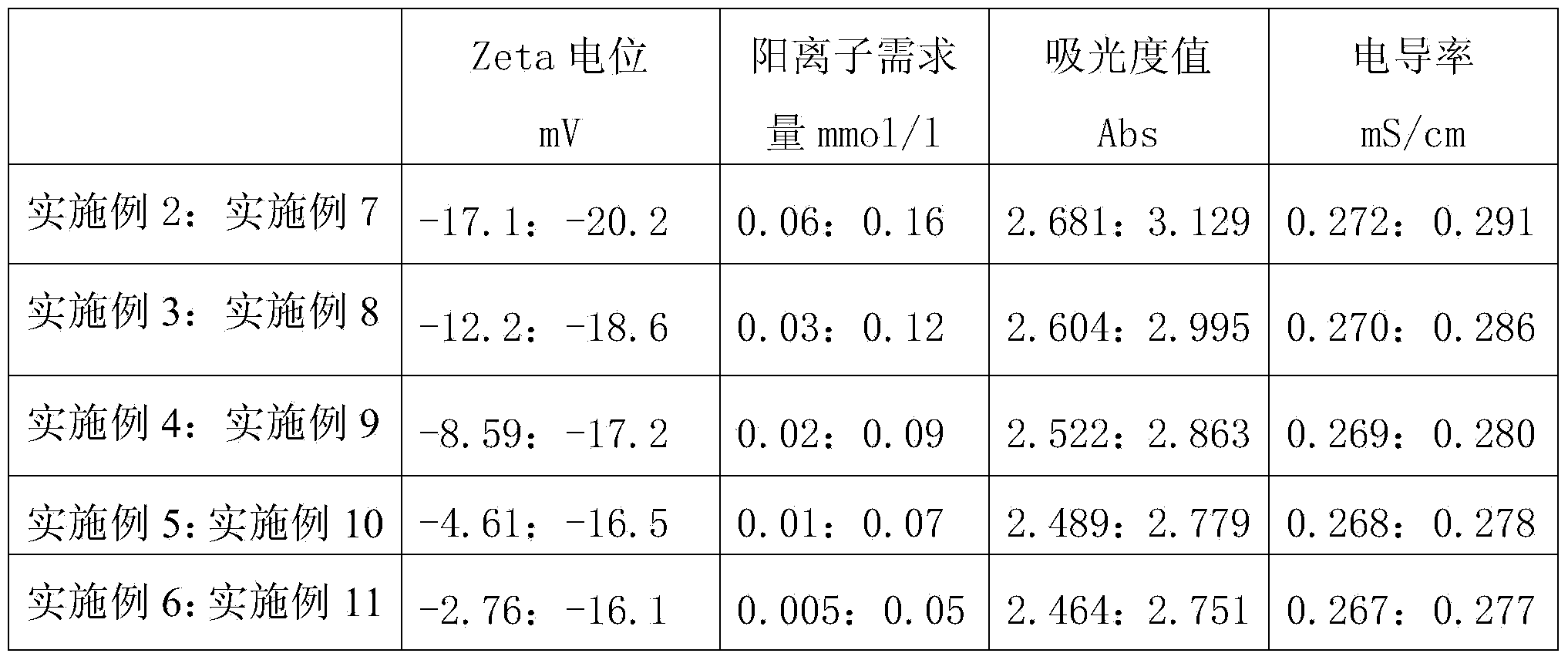

Application of chitosan quaternary ammonium salt to wastepaper recirculation

InactiveCN103510428ASmall molecular weightHigh charge densityNon-fibrous pulp additionPaper/cardboardAmmoniumQuaternary

The invention discloses application of a chitosan quaternary ammonium salt to wastepaper recirculation. The chitosan quaternary ammonium salt is used as an anionic trash catcher for the wastepaper recirculation. The application of the chitosan quaternary ammonium salt to the wastepaper recirculation comprises the steps including taking out wastepaper, performing floatation and deinking, performing pulping treatment, preparing extra-dry wastepaper pulp, fully agitating the extra-dry wastepaper pulp, and adding the chitosan quaternary ammonium salt to the extra-dry wastepaper pulp. The chitosan quaternary ammonium salt applied in the wastepaper recirculation is used as the anionic trash catcher, which is natural and macromolecular and realizes biodegradation, and a degradation product has no toxic effect on the environment. The chitosan quaternary ammonium salt is remarkable in catching efficiency, stable and efficient.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com