Low-density cement paste system

A cement slurry, low-density technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as incompressibility, and achieve the effects of fast hydration, improved construction safety, and improved early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

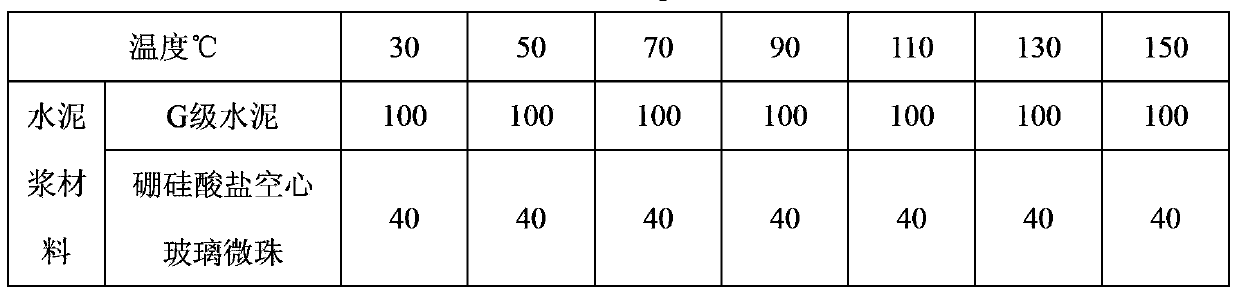

[0016] Weigh 100 parts by weight of cement, 40 parts by weight of borosilicate hollow glass microspheres (25 microns), 40 parts by weight of ultrafine cement, 20 parts by weight of microsilicon, 0.1 parts by weight of silane coupling agent, 2.0 parts by weight Sodium sulfate by weight, 106 parts by weight of water, 2.5 parts by weight of fluid loss reducer BCF-200S, and then add a certain amount of retarder BXR-200L to prepare 1.20g / cm 3 low density cement paste. (Silane coupling agent, sodium sulfate, fluid loss reducer BCF-200S and other drugs are commercially available)

[0017] Table 1 1.20g / cm at different temperatures 3 Comprehensive performance of cement slurry

[0018]

[0019]

Embodiment 2

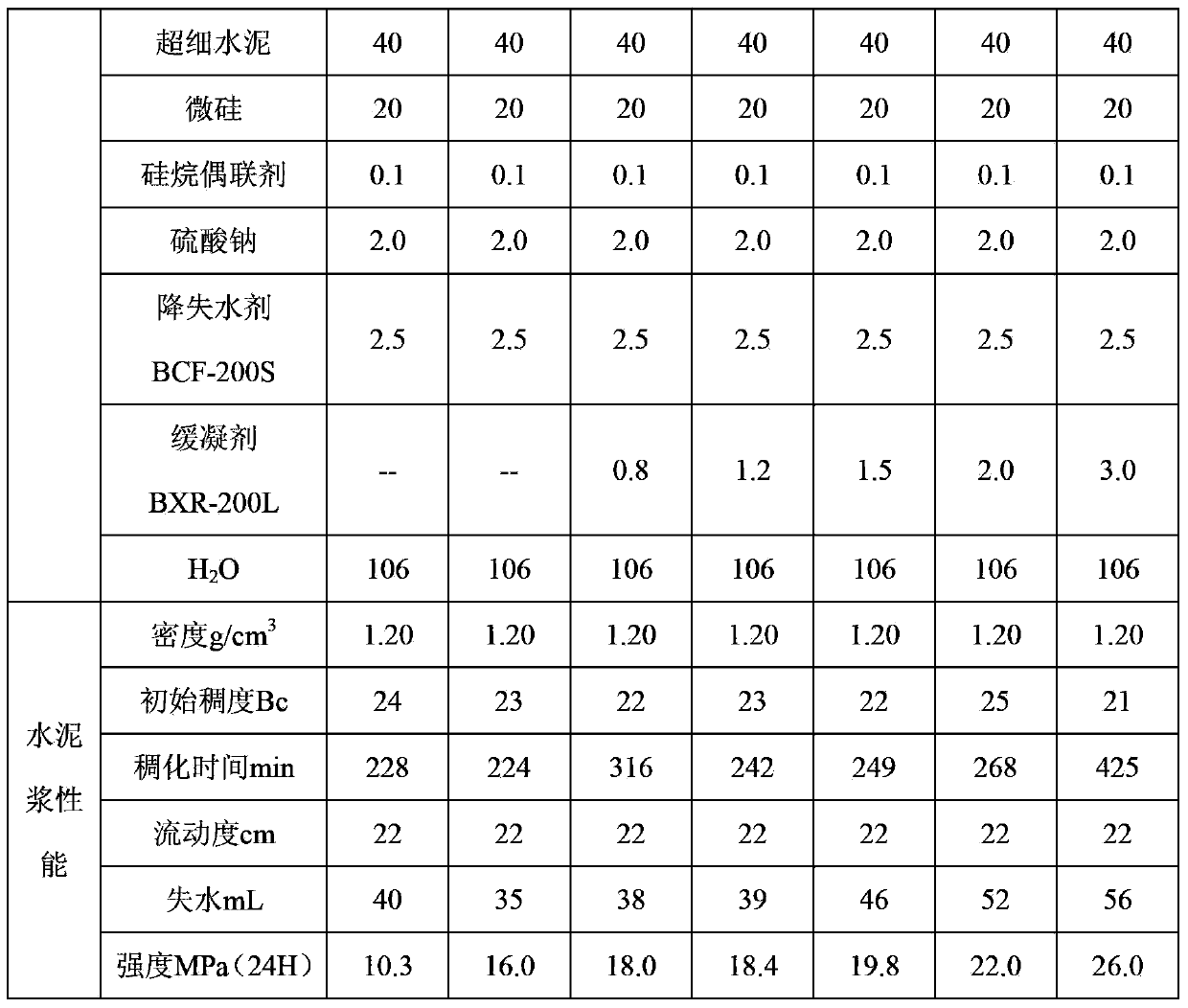

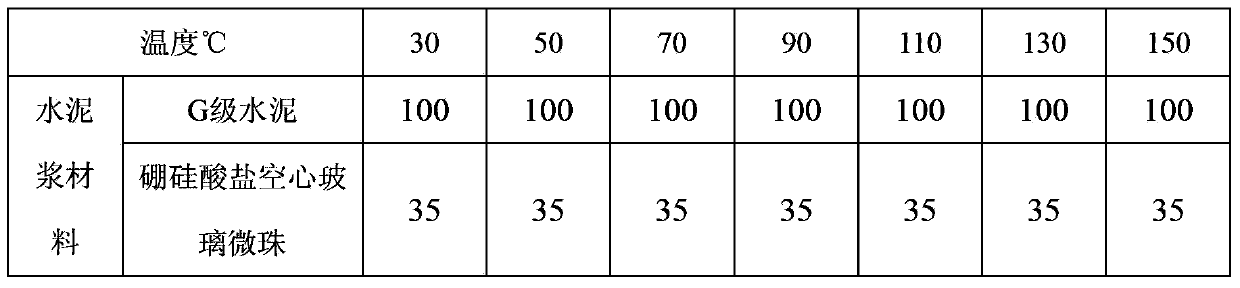

[0021] Weigh 100 parts by weight of cement, 35 parts by weight of borosilicate hollow glass microspheres (25 microns), 35 parts by weight of ultrafine cement, 15 parts by weight of microsilica, 95 parts by weight of water, and 0.08 parts by weight of silane Coupling agent, 1.5 parts by weight of sodium sulfate, 2.5 parts by weight of fluid loss reducer BCF-200S, and then add a certain amount of retarder BXR-200L to prepare 1.30g / cm 3 low density cement paste. (Silane coupling agent, sodium sulfate, fluid loss reducer BCF-200S and other drugs are commercially available)

[0022] Table 2 1.30g / cm at different temperatures 3 Comprehensive performance of cement slurry

[0023]

[0024]

Embodiment 3

[0026] Weigh 100 parts by weight of cement, 6-18 parts by weight of borosilicate hollow glass microspheres (25 microns), 25-30 parts by weight of ultrafine cement, 10-12.5 parts by weight of microsilicon, and 0.05 parts by weight of silane Coupling agent, 1.2 parts by weight of sodium sulfate, 65-85 parts by weight of water, 2.0 parts by weight of fluid loss reducer BCF-200S, and then add a certain amount of retarder BXR-200L to make 1.40-1.60g / cm 3 low density cement paste. (Silane coupling agent, sodium sulfate, fluid loss reducer BCF-200S and other drugs are commercially available)

[0027]

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com