Acrylamide copolymer oil-dispelling agent with sulfitobetaine structure and synthesis method

A technology of acrylamide copolymerization and sulfite, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of temperature resistance, shear dilution resistance and poor solubility, and achieve enhanced oil recovery and good oil recovery. Salt resistance, water solubility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The synthesis of embodiment one monomer MAPES

[0044] The synthetic method of monomer 2-(3-methacrylamidopropyl dimethylamino) ethyl sulfite inner salt (MAPES) is as follows:

[0045] (1) Add a certain quality of N-(3-dimethylaminopropyl)methacrylamide, 1,4-dioxane and a small amount of hydroquinone into a 250mL three-necked flask;

[0046](2) After heating the temperature to the reflux temperature, slowly add a certain amount of vinyl sulfite dropwise to the flask under constant stirring;

[0047] (3) After vinyl sulfite has been added dropwise, react at reflux temperature for 2 to 5 hours;

[0048] (4) After the reaction is completed, the solvent is removed by rotation, recrystallized with acetonitrile, and the product obtained is vacuum-dried to obtain the inner salt of 2-(3-methacrylamidopropyldimethylamino)ethylsulfite in the form of white powder.

[0049] The volume ratio of N-(3-dimethylaminopropyl)methacrylamide to 1,4-dioxane is 1:1-2, wherein 1,4-dioxane is...

Embodiment 2

[0052] Synthesis of embodiment two polymer oil displacement agent AM / AA / MAPES

[0053] The synthetic method of polymer oil displacement agent AM / AA / MAPES is specifically as follows:

Embodiment 3

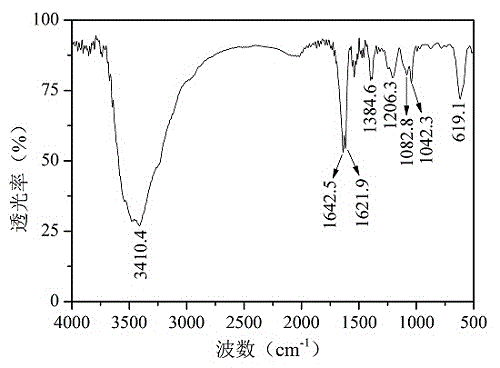

[0069] The structural characterization of embodiment three monomer MAPES

[0070] The sample prepared in Example 1 was analyzed structurally by infrared spectrum, and the structure of monomer MAPES was characterized by WQF-510A Fourier Transform Infrared Spectrometer by KBr tablet method, and the infrared spectrum was as follows figure 1 shown. from figure 1 It can be seen: 3410.4cm -1 H after moisture absorption of the monomer 2 Stretching vibration absorption peak of —OH in O; 1642.5cm -1 It is the stretching vibration absorption peak of C=O, 1621.9cm -1 It is the stretching vibration absorption peak of C=C; 1384.6cm -1 for CH 3 The bending vibration absorption peak of C—H in middle; 1206.3cm -1 It is the stretching vibration absorption peak of C—N; 1082.8cm -1 、1042.3cm -1 For—OSO 2 Stretching vibration absorption peak of S=O in middle; 619.1cm -1 It is the bending vibration absorption peak of N—H in amides. The structure of the sample was consistent with that o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com