Patents

Literature

662results about How to "Improve suspension stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing expandable polystyrene particles

A process for preparing expandable particulate styrene polymers wherein from 5 to 50% by weight of expanded graphite and also, if desired, from 2 to 20% by weight of a phosphorus compound, are present as flame retardants, by suspension polymerization of styrene in the presence of the flame retardants.

Owner:BASF AG

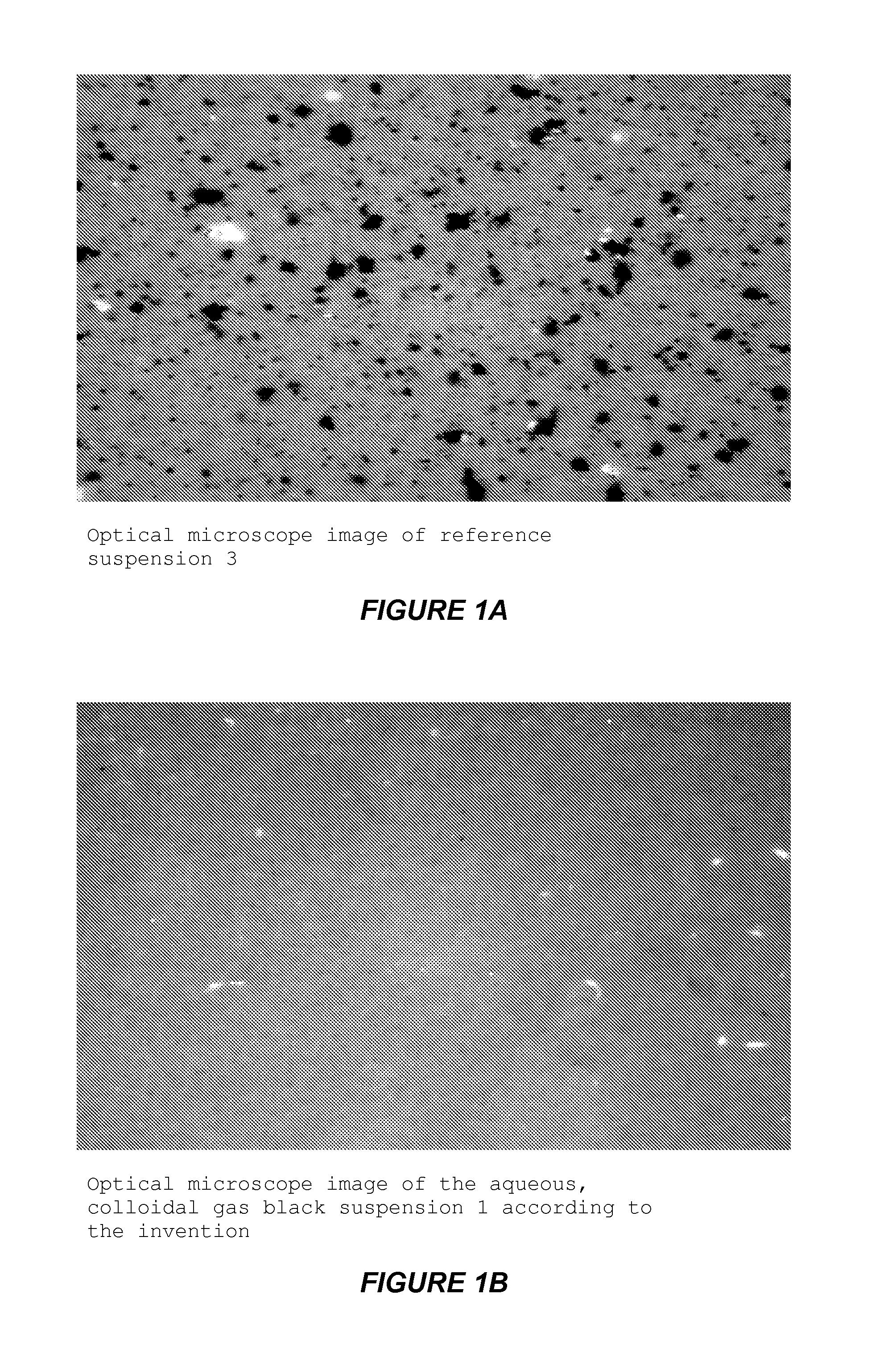

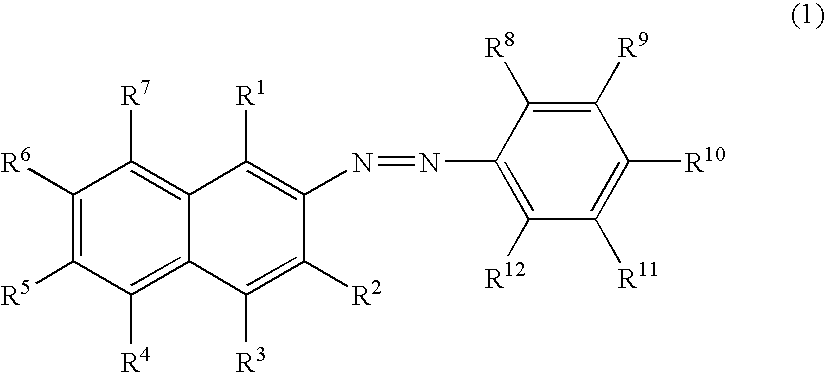

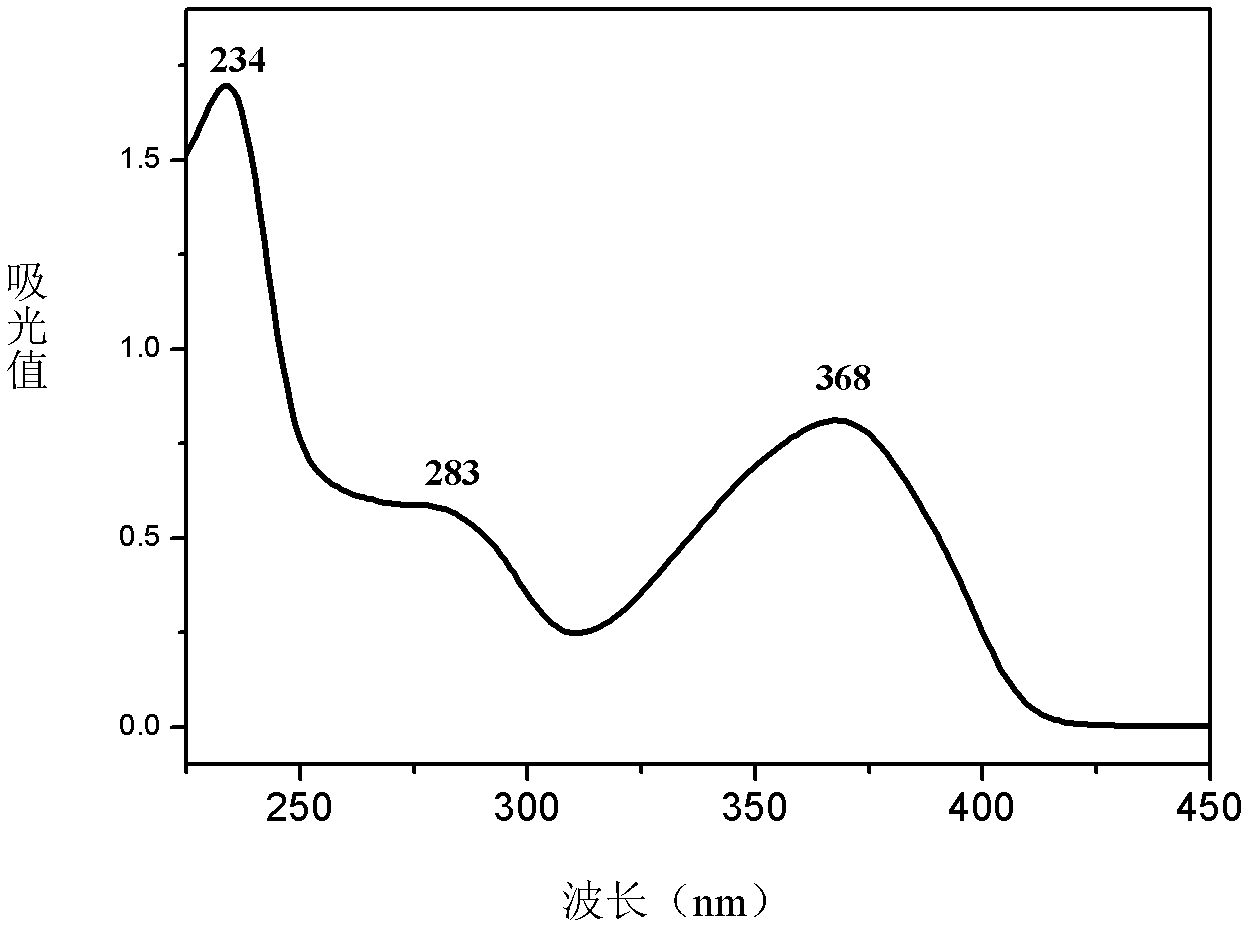

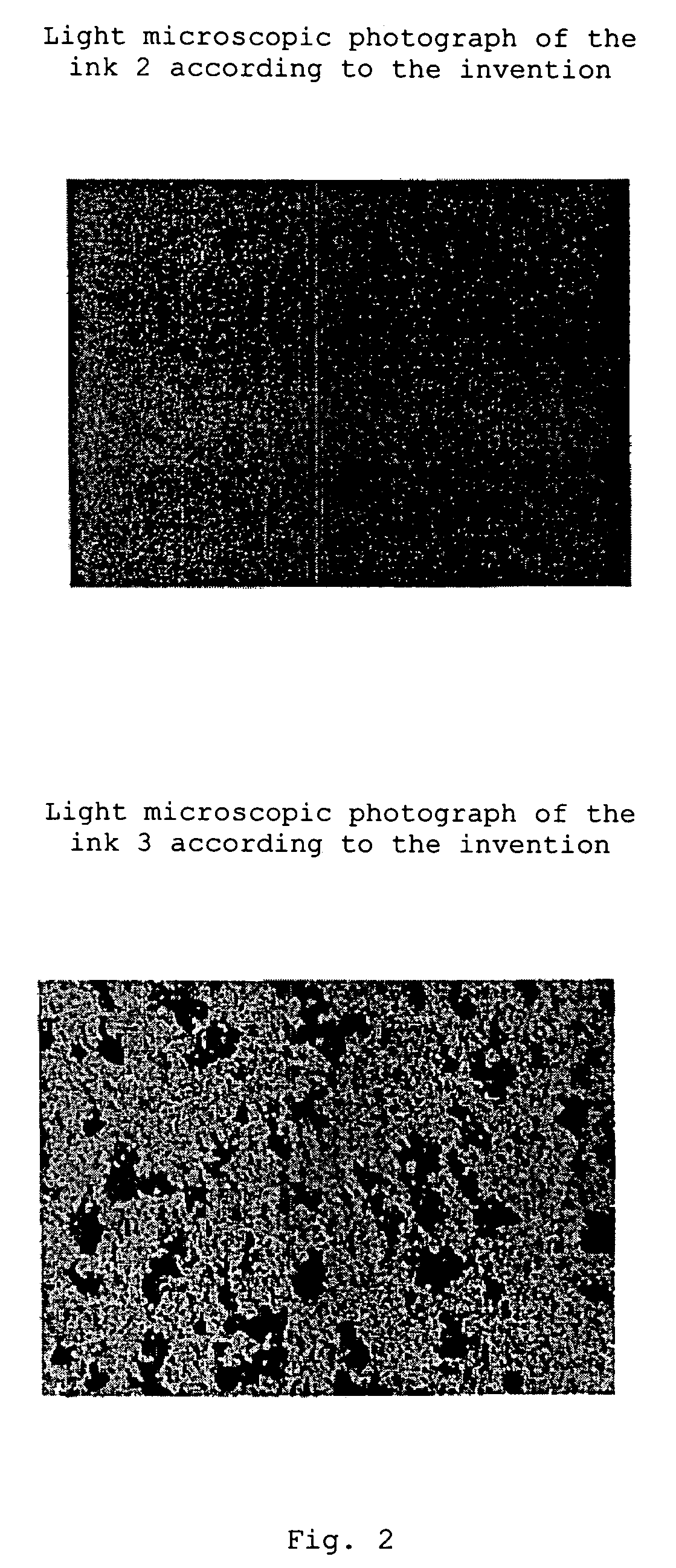

Aqueous, colloidal gas black suspension

ActiveUS7160377B2Improve suspension stabilityLow viscosityMaterial nanotechnologyPigmenting treatmentColloidPhotochemistry

Aqueous, colloidal gas black suspension containing:(a) a gas black, (b) an azo compound of the formula 1(c) and water. The aqueous, colloidal gas black suspension is produced by dispersing the gas black and the azo compound of the formula 1 in water. It can be used in the production of inks, ink-jet inks, surface coatings and colored printing inks.

Owner:UBS AG

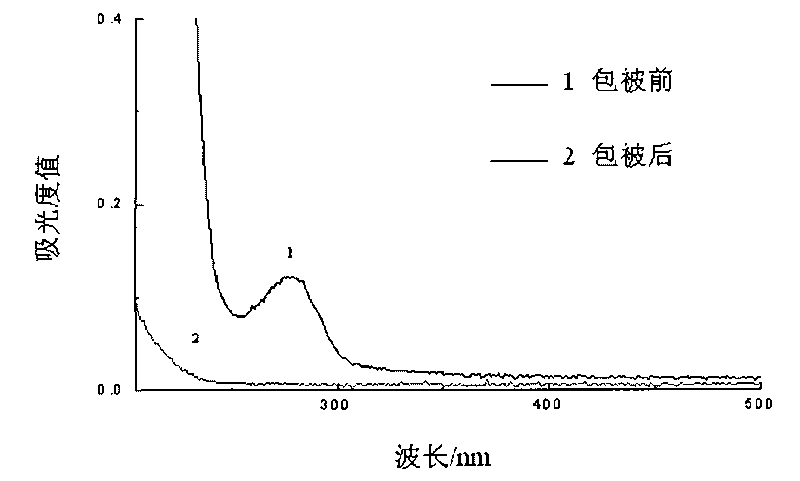

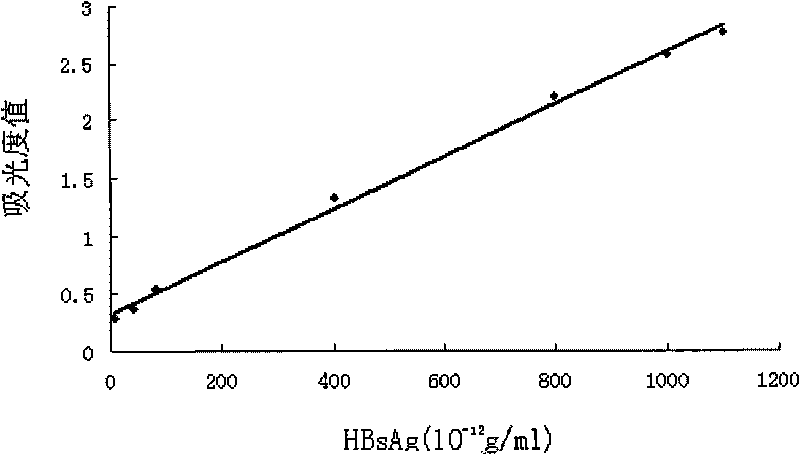

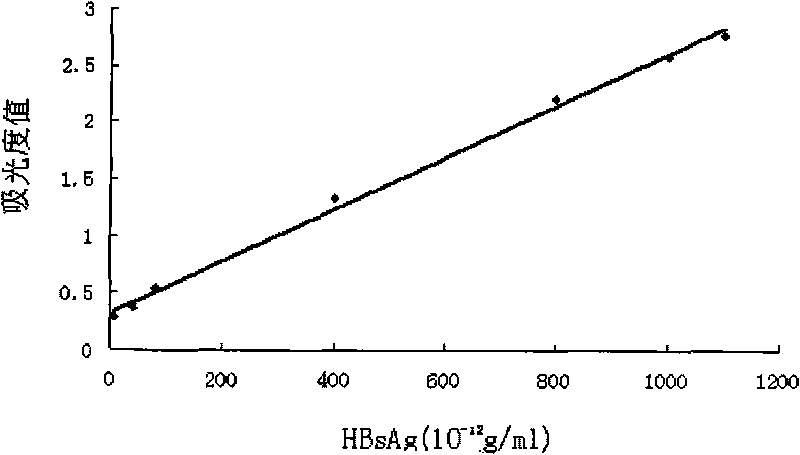

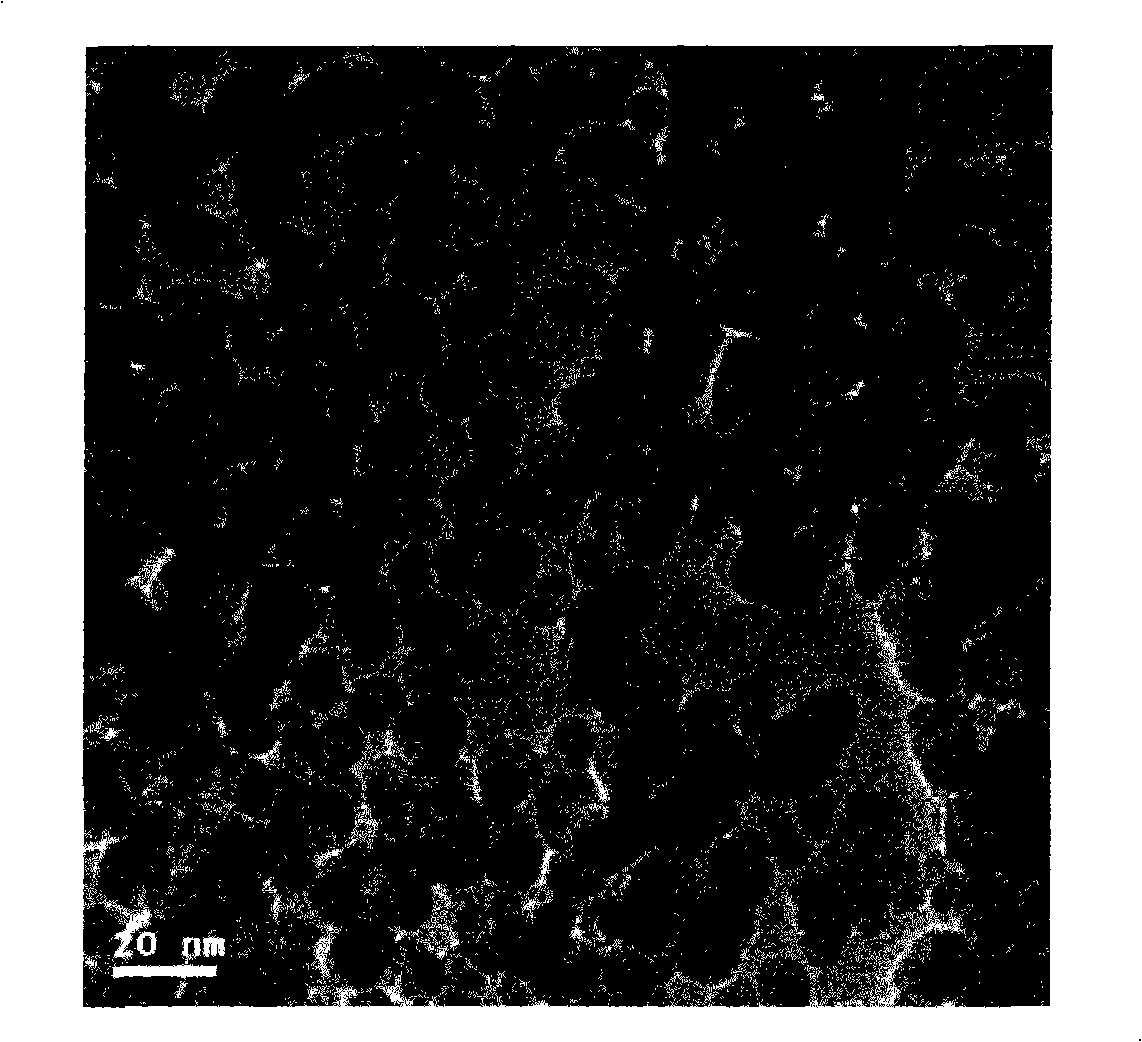

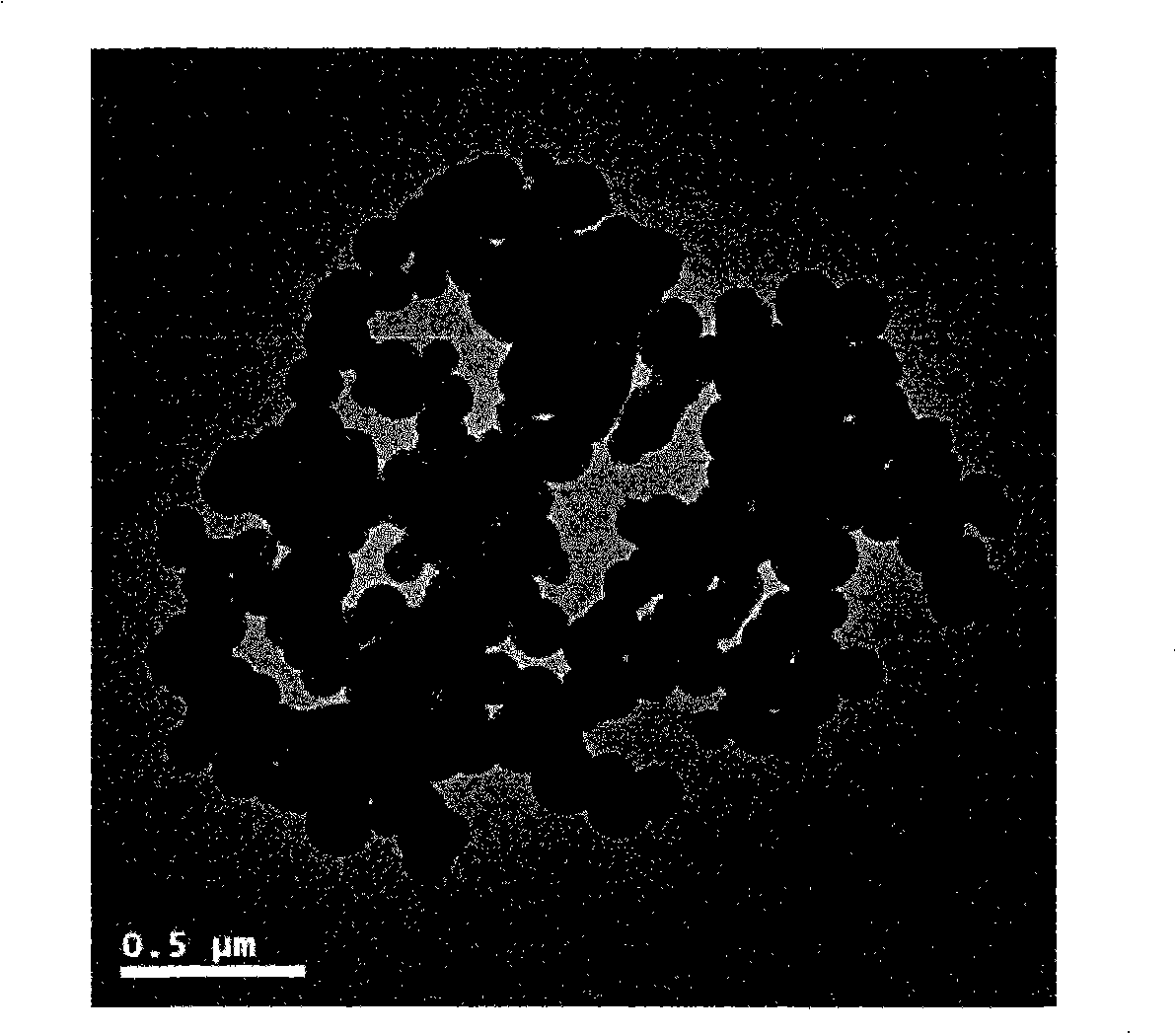

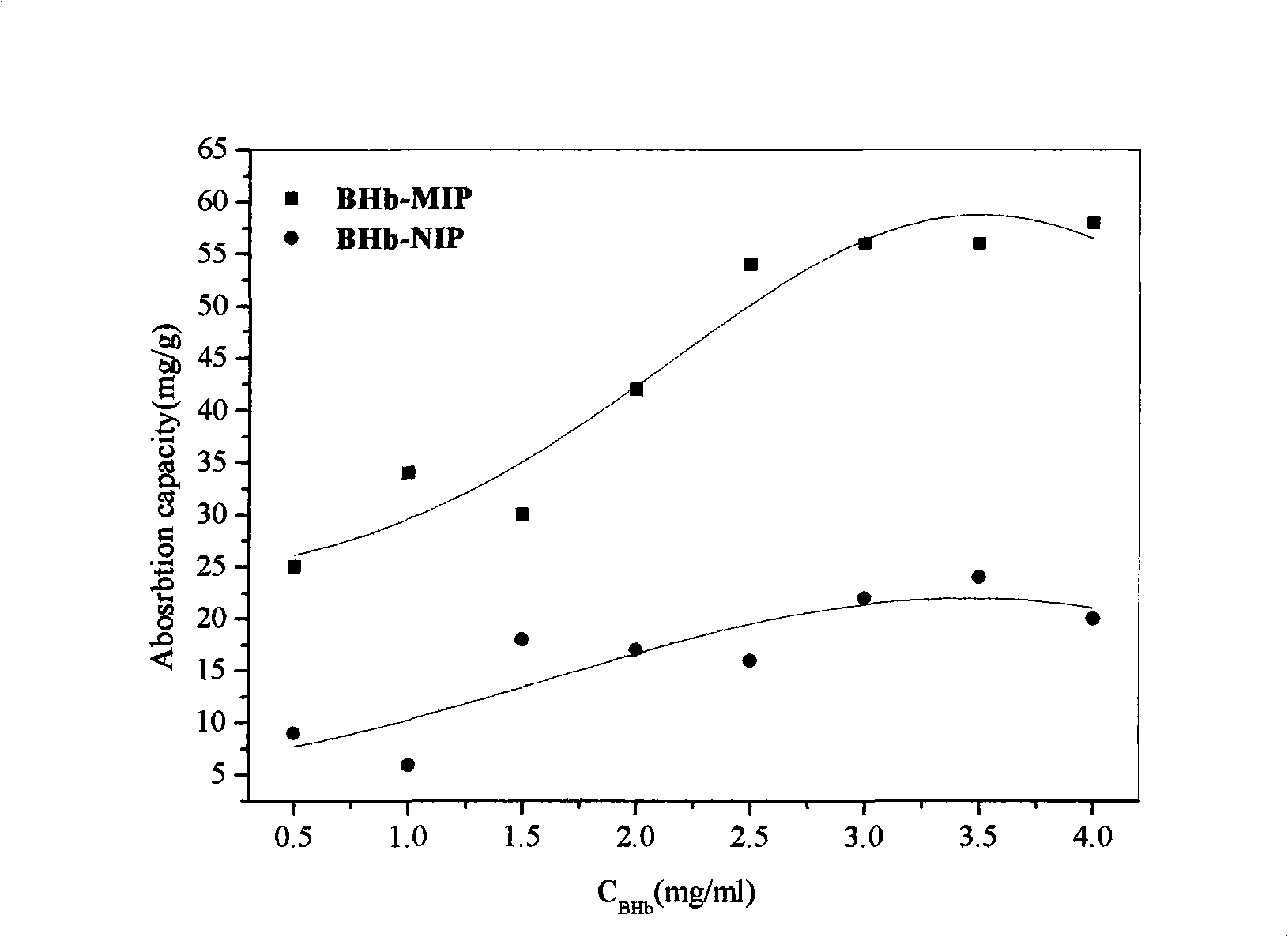

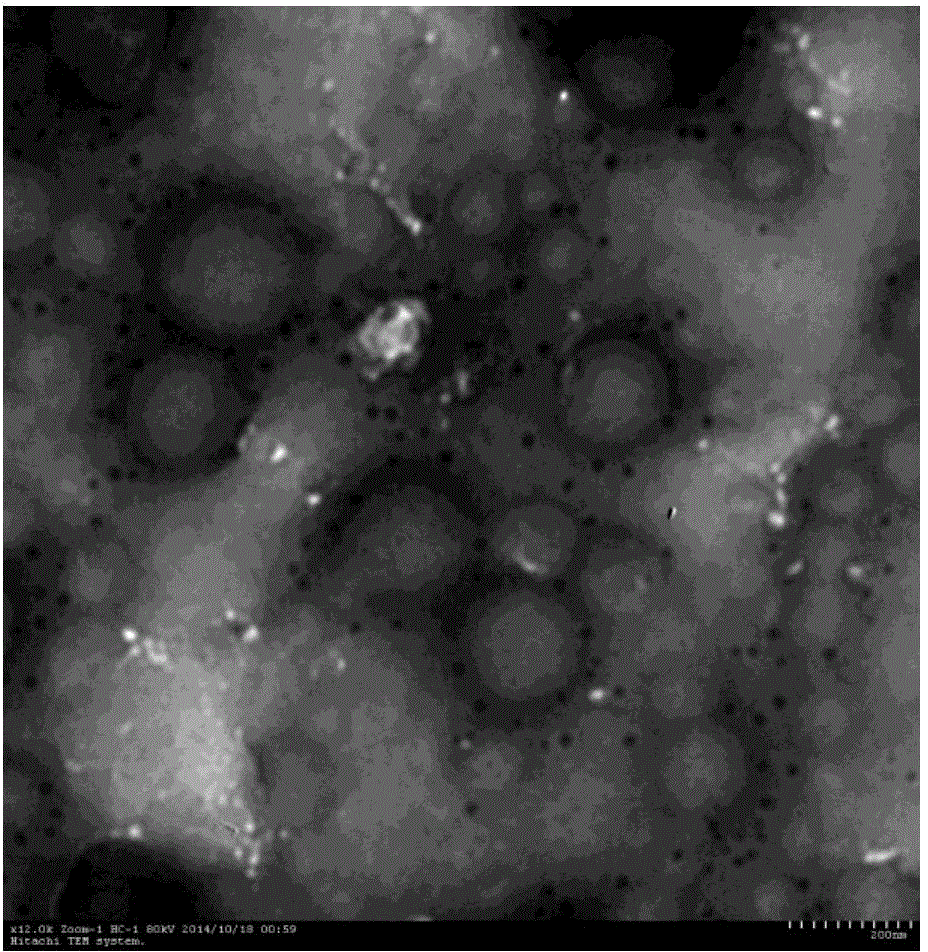

Method for performing immunological test on biomolecules by avidin/streptavidin magnetic composite particles

ActiveCN101713779ALarge coupling capacityImprove suspension stabilityMaterial analysisBiotin-streptavidin complexStrong binding

The invention relates to the immune analysis field, in particular relating to a method for performing an immunological test on biomolecules by avidin / streptavidin magnetic composite particles, which takes avidin / streptavidin magnetic composite particles as carriers, and comprises the following steps:, coating biotinylated antibody or antigen, adding a specimen to be tested and enzyme labeled antibody / enzyme labeled antigen / enzyme labeled anti-antibody, adding chromogenic substrate and testing.Biotin and avidin / streptavidin has strong binding capacity, can fix the antigen / antibody labeled by the biotin through the avidin / streptavidin labeled on the surface of the magnetic composite particles so as to use the system to test specific antibody / antigen. The test system has the advantages of high sensitivity, high specificity, high stability, strong adaptability and the like.

Owner:XIAN GOLDMAG NANOBIOTECH

Nano silicon dioxide emulsion, its preparation method and application

InactiveCN1536032AImprove hydrophilicityGood dispersionEmulsion paintsPigment treatment with non-polymer organic compoundsWater basedEmulsion

The present invention discloses a nano silicon dioxide emulsion, its preparation method and application. Said emulsion contains nano silicon dioxide, silane coupling agent, surfactant and water. The described nano silicon dioxide and the described silane coupling agent are combined into a hydrophobic particle, and the described hydrophobic particles are covered with surfactant, and dispersed in the water. Its preparation method includes the following steps: adding water-soluble alcohol into the colloid solution of silicon dioxide in the water, then adding silane coupling agent and adding surfactant and water; another preparation method includes the following steps: adding water-soluble alcohol or aqueous solution of described alcohol into nano silicon dioxide gel, then adding silane coupling agent, surfactant and water. Said emulsion can be directly added into the water-based paint, and can be used for modifying water-based paint and improving various properties of the water-based paint.

Owner:ZHEJIANG YUDA CHEM IND

Method for preparing protein magnetic blotting nanospheres

InactiveCN101347721AAvoid complicated centrifugationSimplified centrifugation processOther chemical processesPolymerSerum protein

The invention relates to a preparation method of a protein magnetic imprinting nano sphere, in particular to a preparation method of a protein magnetic imprinting nano sphere which takes one of hemoglobin, muramidase or serum protein as template molecules; the preparation method includes the following steps: synthesizing magnetic nano particles which are Fe3O4 nano particles covered with silicon dioxide on the surfaces; carrying out silanization to the amino-groups on the surface of the magnetic sphere; using glutaric dialdehyde to connect protein; using silylation agent to fix the space structure of template protein; alkaline eluting the protein on the surface of the magnetic sphere to form imprinting sites. The hemoglobin, muramidase or serum protein magnetic nano imprinting polymer sphere prepared by the invention combines the precise and specific identification property of molecular imprinting and the quick separation property of the magnetic nano sphere under the action of an external magnetic field, integrates the advantages of molecular imprinting and the magnetic nano sphere, avoids complex centrifugation operation, plays vital roles in the separation of cells, protein and nucleic acid, the detection of biomolecules, tumor diagnosis and medicine targeting therapy and has promising application prospect in the field of isolation analysis.

Owner:NANKAI UNIV

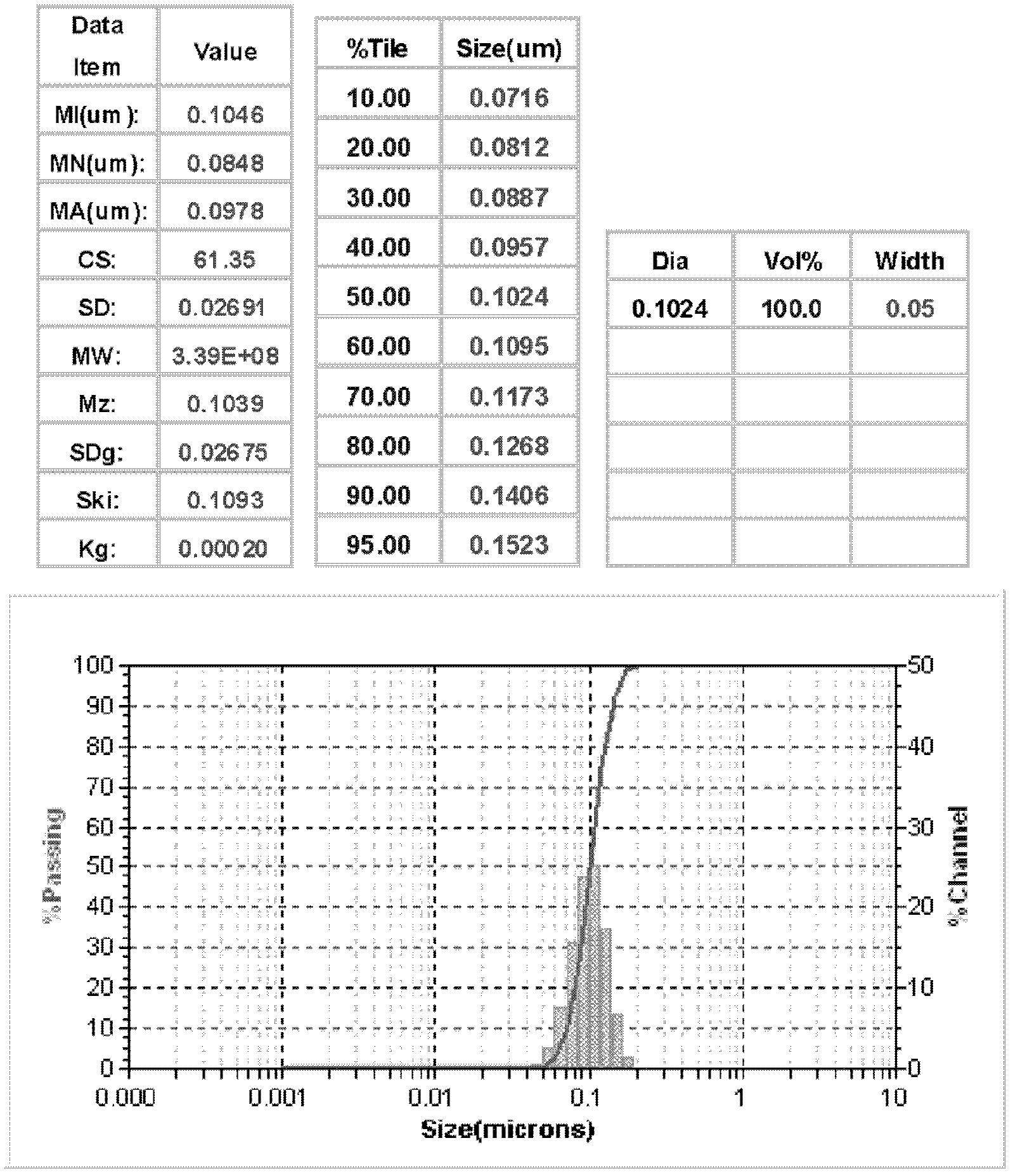

Polystyrene fluorescent nanometer particle as well as preparation method and applications thereof

InactiveCN103172941AElimination of Assay EffectsHigh measurement sensitivityLuminescent compositionsMaterial analysisRare-earth elementOrganic solvent

The invention discloses a polystyrene fluorescent nanometer particle as well as a preparation method and applications of the polystyrene fluorescent nanometer particle. The particle is the polystyrene fluorescent nanometer particle with a fluorescent material, wherein the fluorescent material is a chelate compound formed by the reaction of rare earth elements, beta-diketone substances and tri-n-octylphosphine oxide. The preparation method of the polystyrene fluorescent nanometer particle comprises the following steps of: (1), synthesizing the polystyrene fluorescent nanometer particle through an emulsion polymerization method, a seed emulsion polymerization method or a non-soap emulsion polymerization method; and (2), adding the polystyrene nanometer particle which is swelled by the organic solvent to the organic solvent dissolved with the fluorescent substances, wherein the organic solvent is removed after the fluorescent substances are diffused to the inner part of the polystyrene nanometer particle. The fluorescent nanometer particle has good mono-dispersion and suspension stability and is very suitable for being applied to immune-chromatographic assay.

Owner:SUZHOU SYM BIO LIFESCI CO LTD

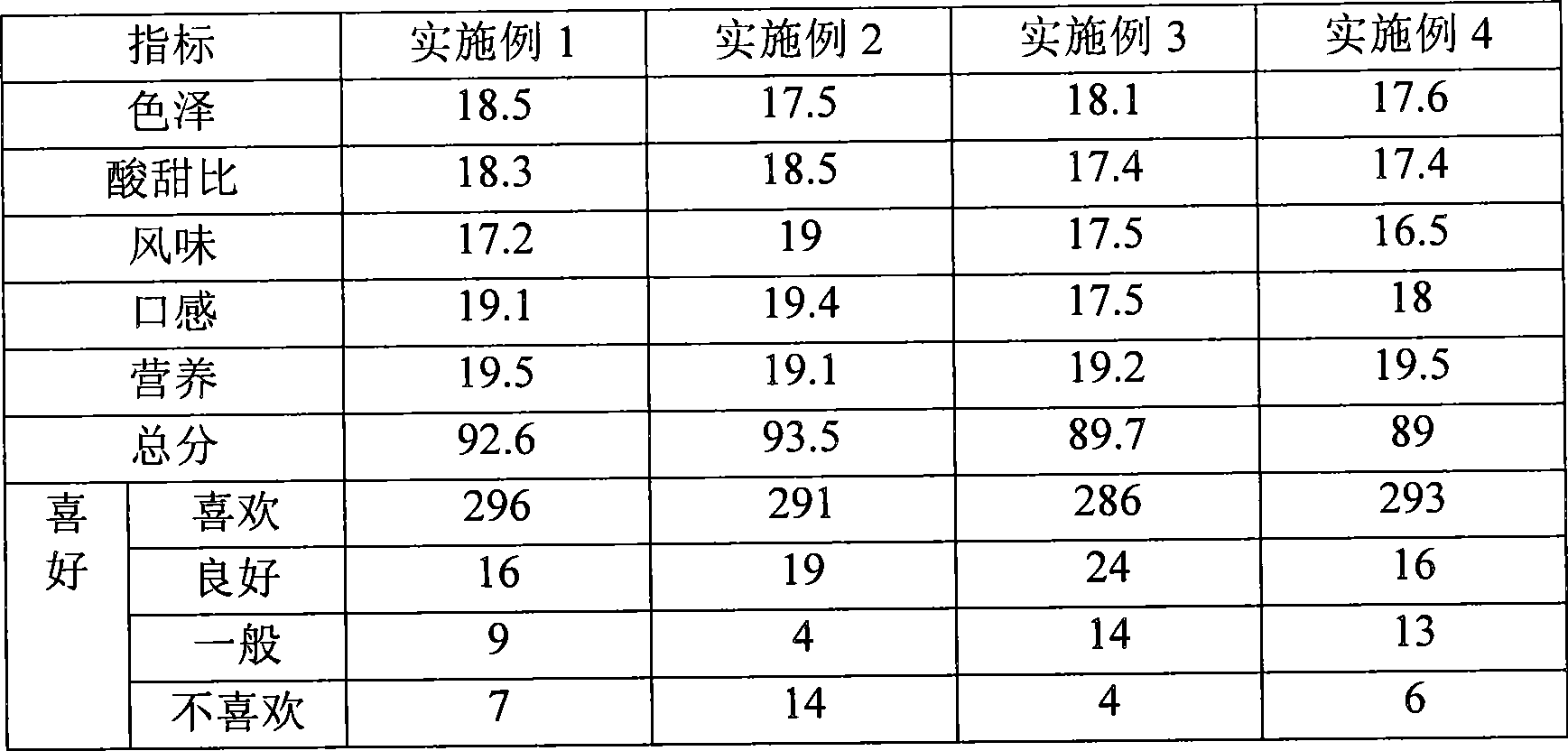

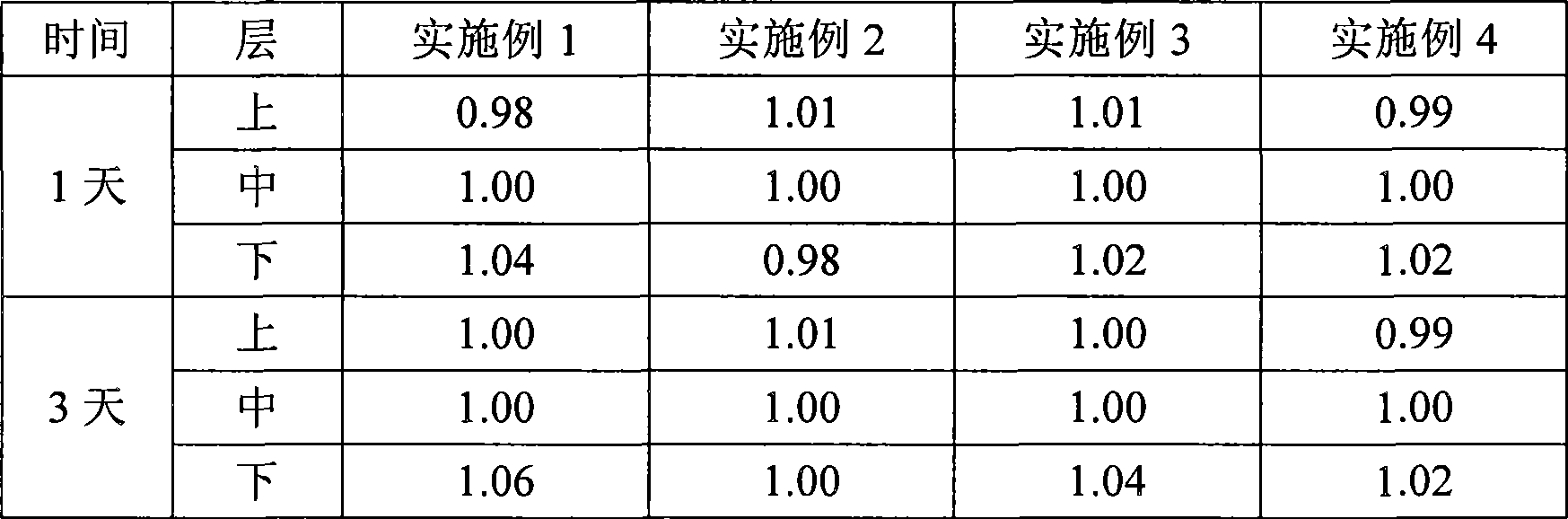

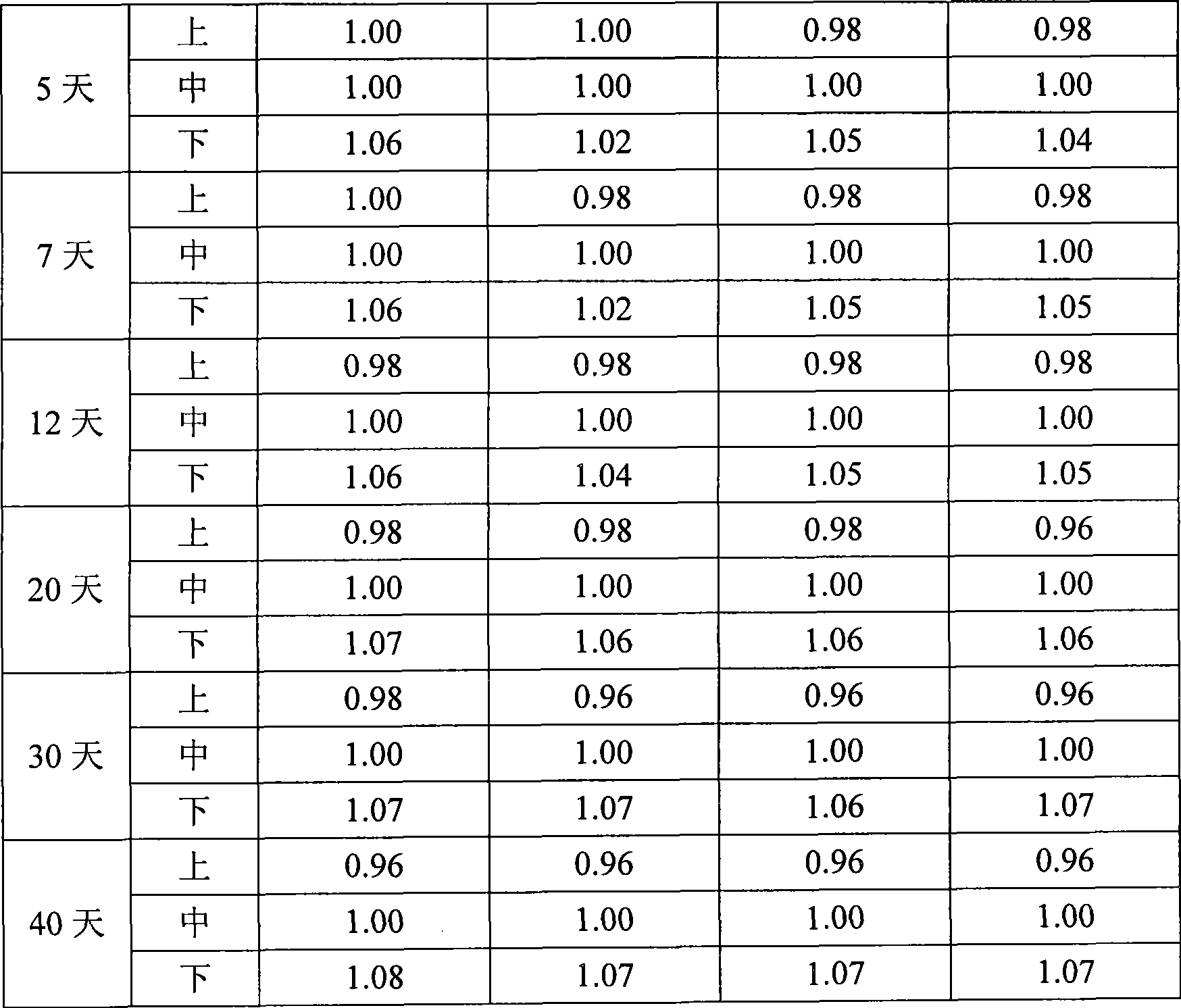

Active lactic acid bacteria beverage and method for producing the same

ActiveCN101467558AImprove suspension stabilityIncrease varietyMilk preparationStabilizing AgentsRaw material

The invention provides a kind of active lactobacillus beverage containing mastication particles. According to the total weight of active lactobacillus beverage as reference, the raw materials comprise 25-75% of milk, 3-20% of particle sauce, 0.2-0.7% of stabilizing agent and appropriate water by weight; the beverage contains live lactobacillus with concentration of 1*106cfu / ml or above. The active lactobacillus beverage in the invention contains masticatory particles, abundant product types and taste, cool taste and good stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

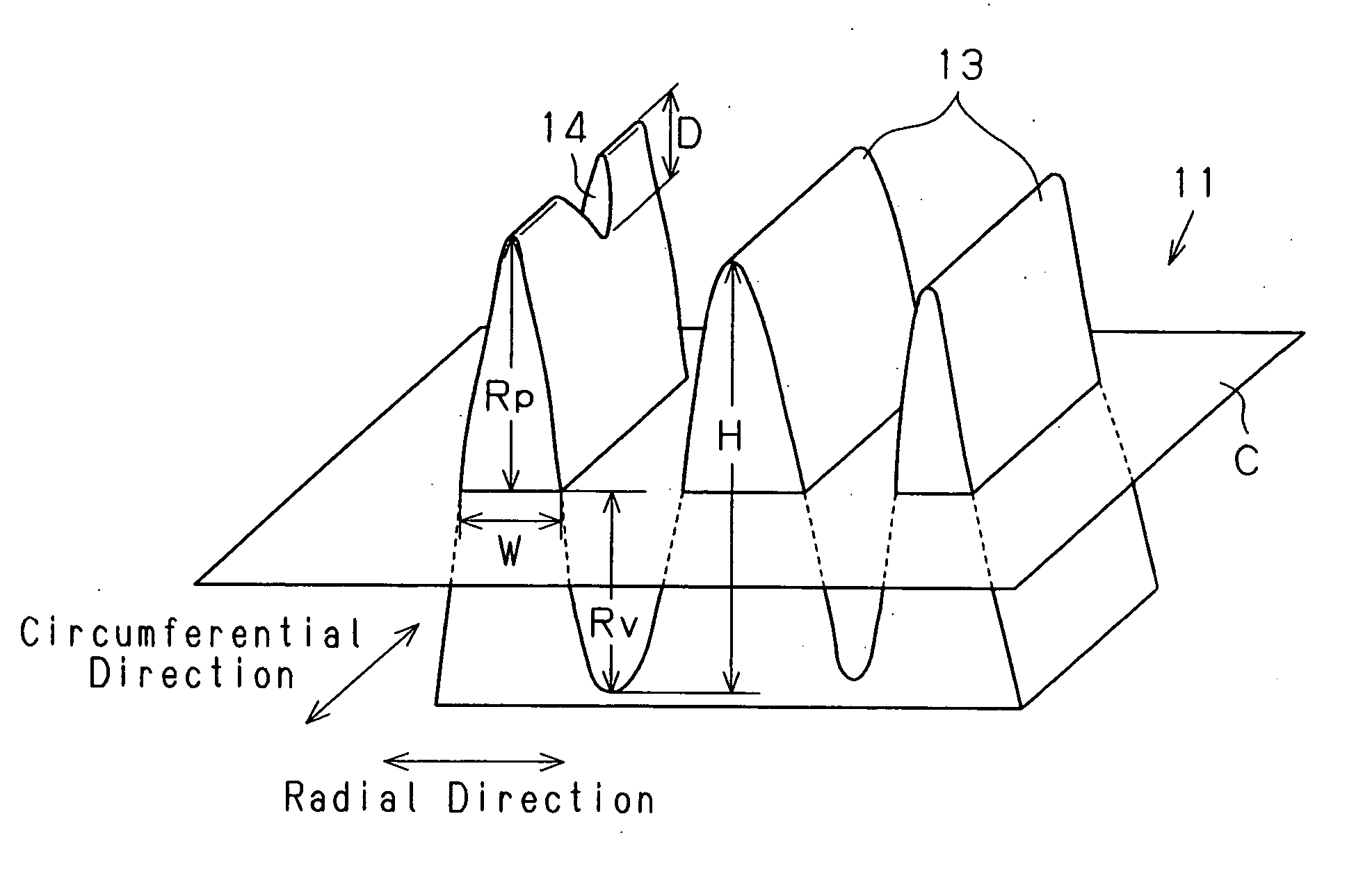

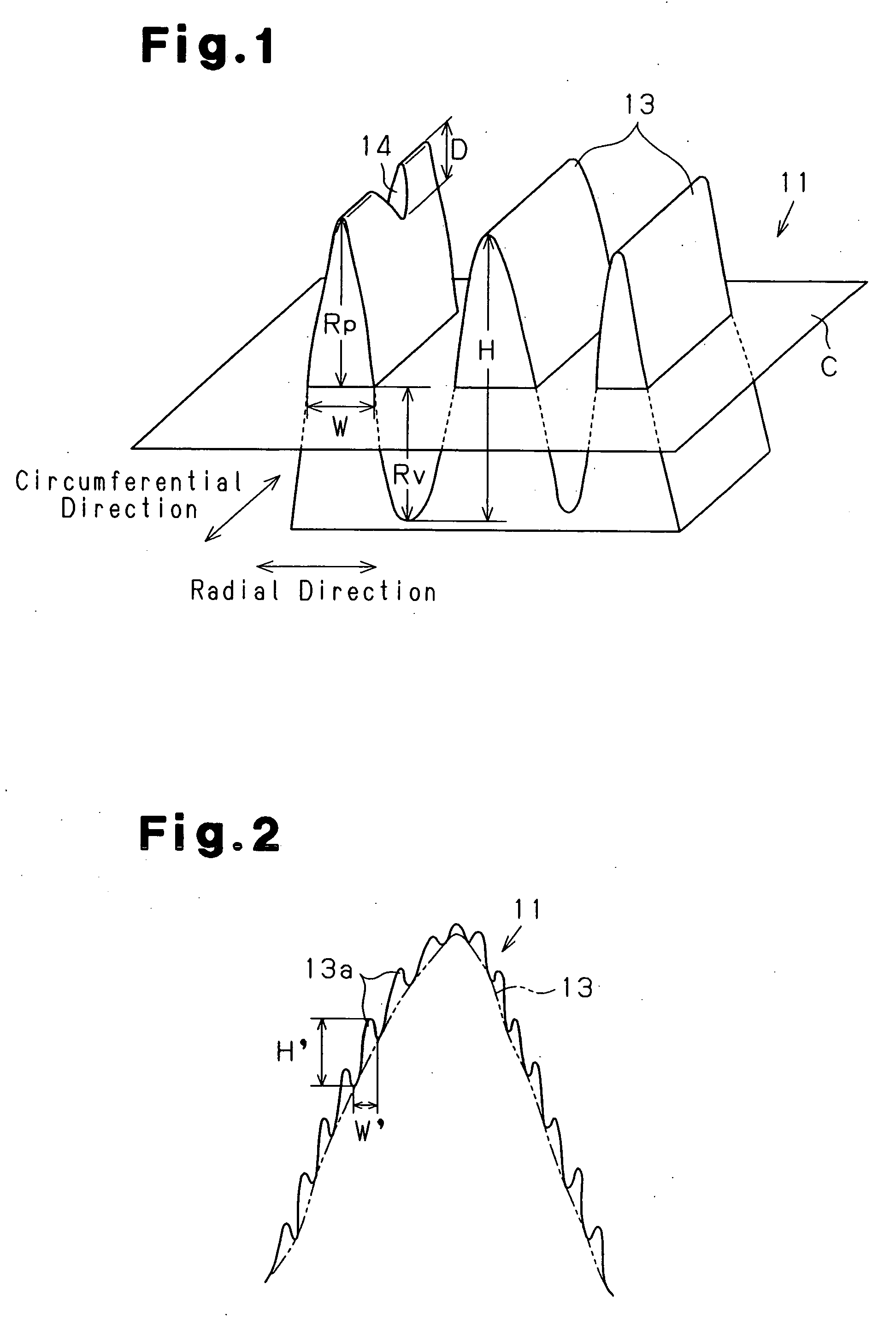

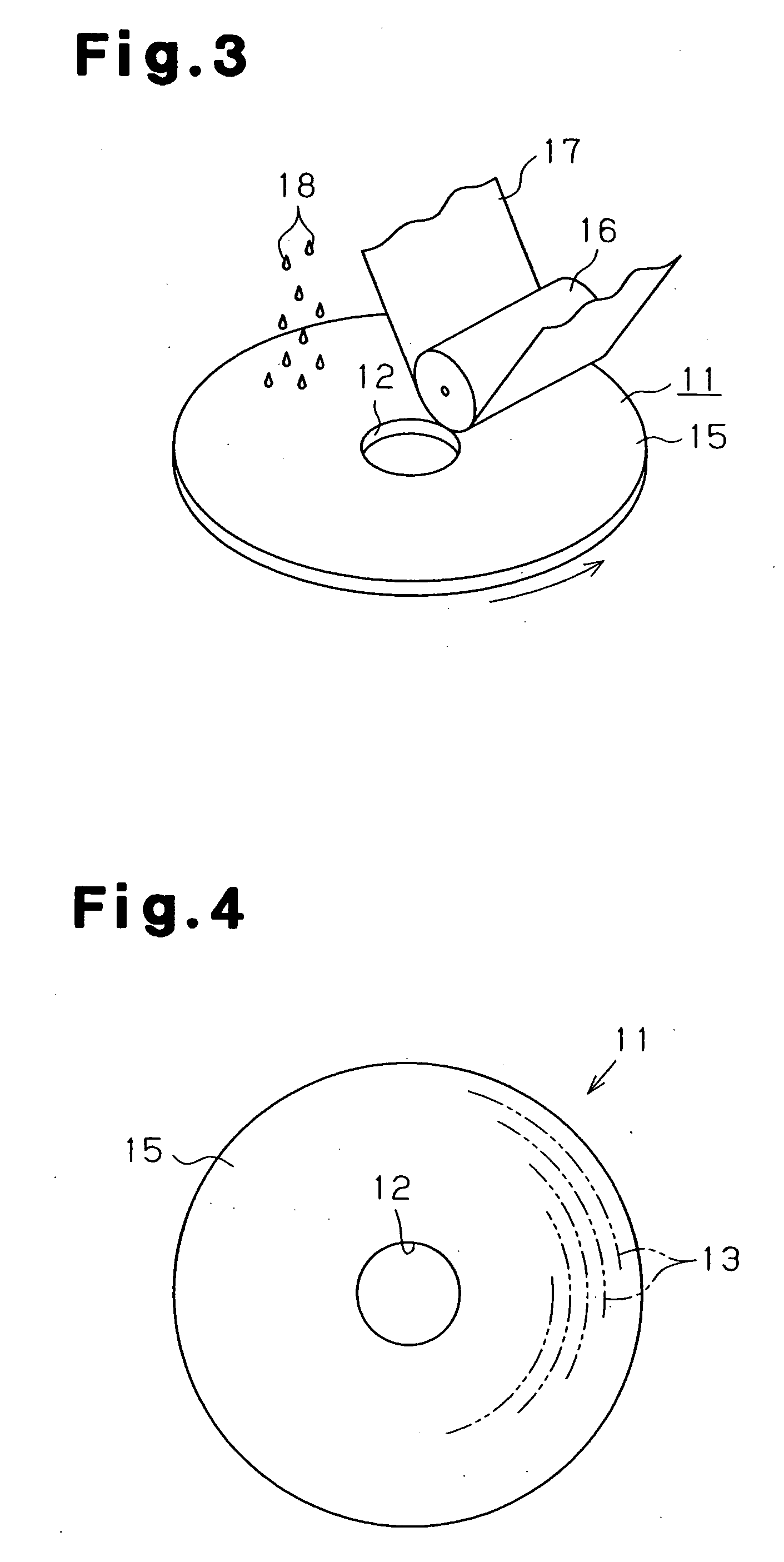

Magnetic recording medium glass substrate and method of producing the same

InactiveUS20060194080A1Reduce the amount requiredImprove suspension stabilityMagnetic materials for record carriersBase layers for recording layersRms roughnessRoot mean square

A glass substrate for a magnetic recording medium is formed to have a disc shape and includes ridge shaped textures 13 extending along concentric circles on a main surface. When measuring a 10 μm square range with an atomic force microscope, the textures have a width W that is between 10 and 200 nm. The textures have a height H that is between 2 and 10 nm. Further, the textures have a ratio (Rp / RMs) of a maximum mountain height with respect to a root mean square roughness that is less than or equal to 15. The textures include high frequency components superimposed on the low frequency components. It is preferable that the textures of the high frequency components have a width W′ that is between 0.1 and 20 nm, and the textures of the high frequency components have a height H′ that is between 0.1 and 1 nm.

Owner:HOYA CORP

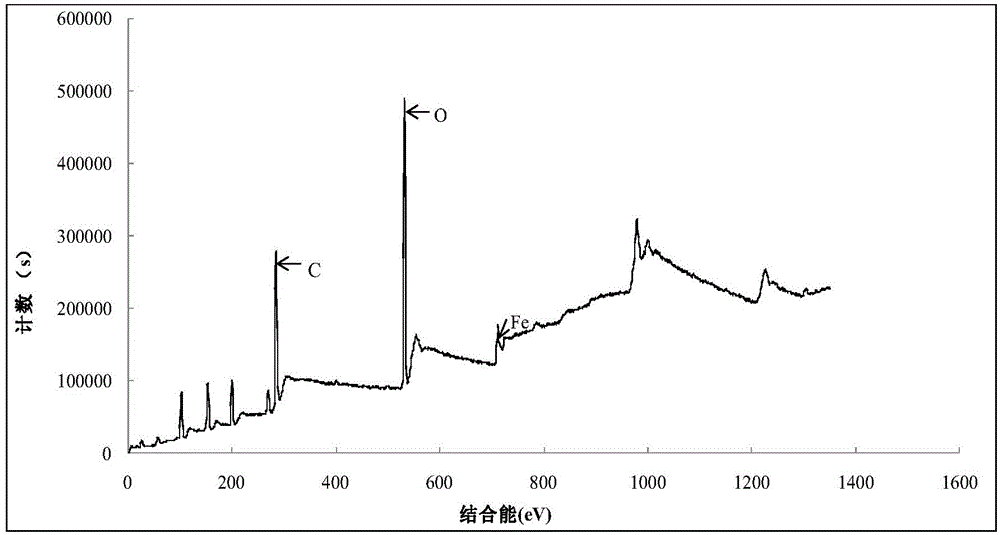

Method for preparing NZVI (nano-scale zero-valent iron) suspension from green tea as well as application of suspension

InactiveCN104857934ALarge specific surface areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionDissolutionSewage

The invention discloses a method for preparing NZVI (nano-scale zero-valent iron) from green tea as well as an application of a suspension of the NZVI. The method comprises technological steps as follows: A, preparing a green tea dissolution solution; B, preparing a ferric trichloride solution; C, preparing the GT-NZVI (green tea-NZVI) suspension. The prepared GT-NZVI has the advantages of good suspension stability, simple preparation technology, low cost, environment-friendliness, good stability, high penetrability in an aquifer and capability of quickly and thoroughly removing hexavalent chromium in sewage and underground water.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

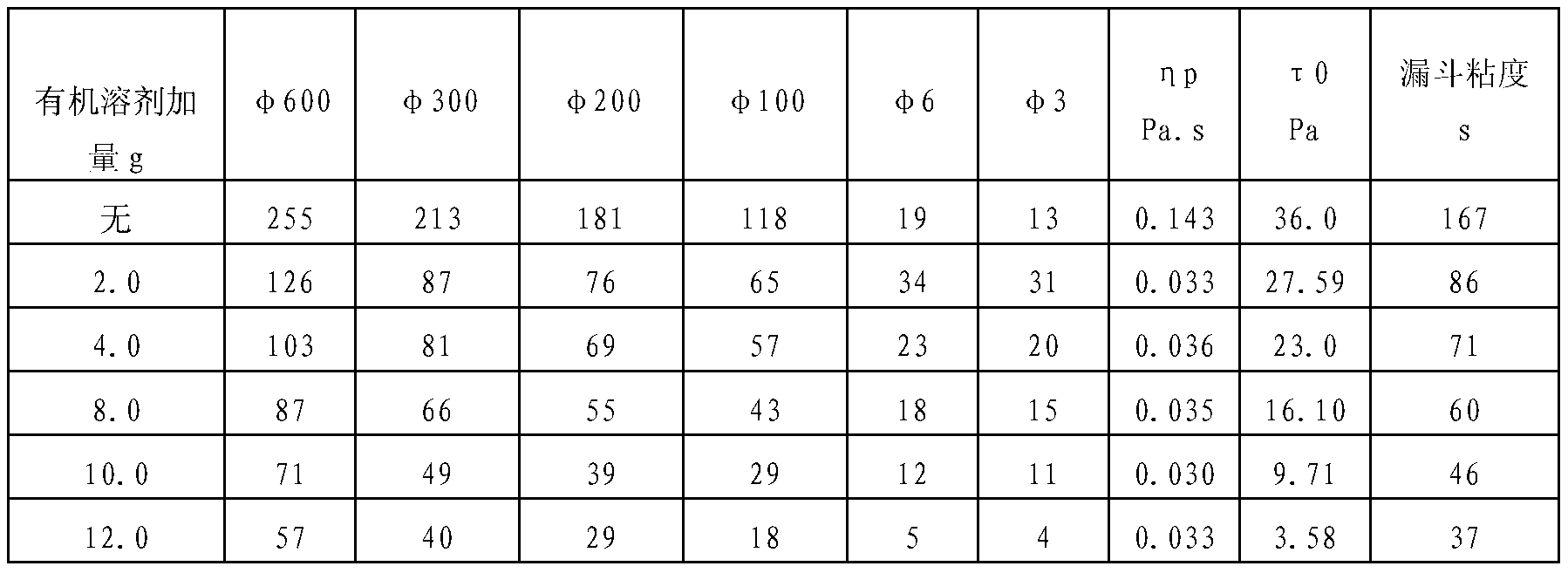

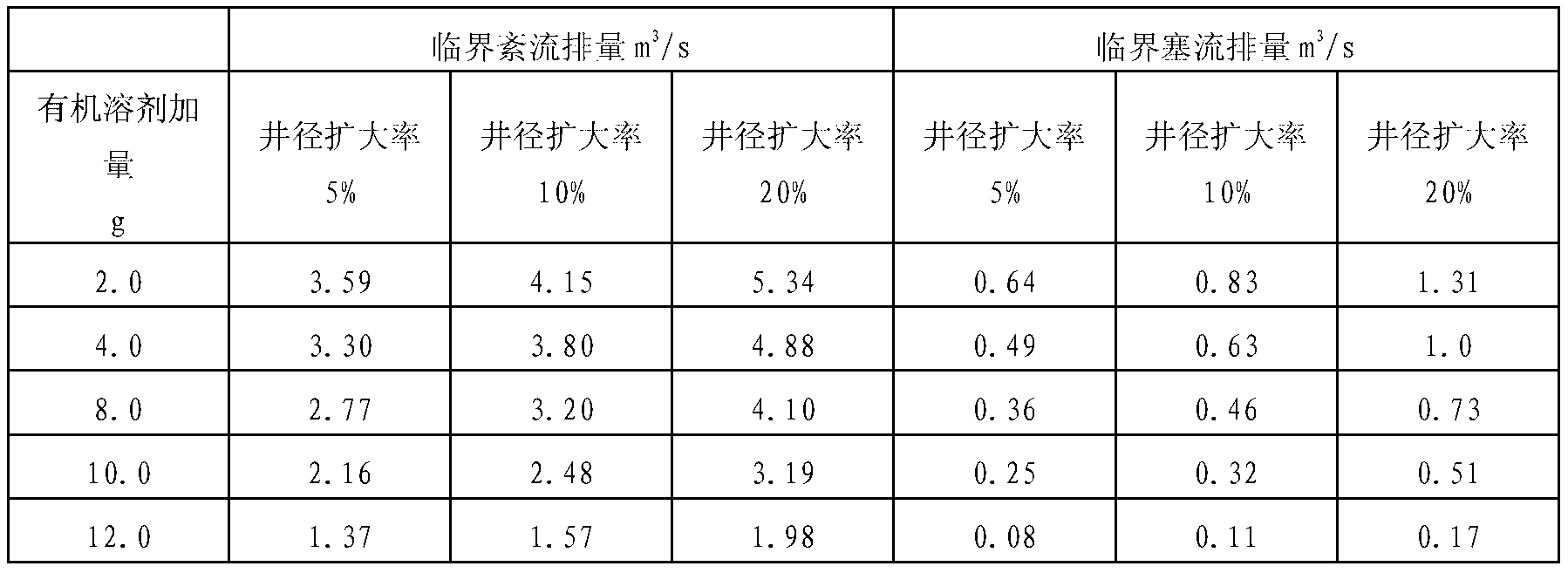

Magnesium aluminium spinel powder alcohol-based coating for heavy section steel castings and preparation method thereof

The invention discloses a magnesium aluminum spinel powder alcohol-based coating for heavy section steel castings, and relates to a casting coating. The alcohol-based coating comprises the following components in percentage by weight: 55 to 60 percent of magnesium aluminium spinel powder, 0.5 to 1.2 percent of binder, 0.11 to 0.18 percent of suspended thickening agent, 1.1 to 1.8 percent of suspending agent, 2.7 to 4.2 percent of fluxing agent, and the balance of organic solvent. In the magnesium aluminum spinel powder alcohol-based coating, the particle size of the magnesium aluminum spinel powder is between 270 and 320, and Al2O3 is more than or equal to 78 percent. The magnesium aluminum spinel powder is synthesized by electric smelting technology, has the characteristics of low expansion and high smelting point, and meets the requirement of serving as refractory aggregate of the coating for the steel castings; and the magnesium aluminum spinel powder has obvious price and resource advantages than zircon powder.

Owner:CHINA YITUO GROUP

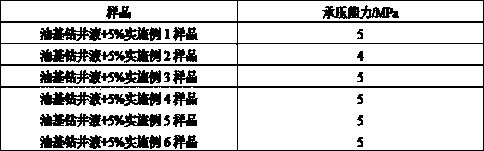

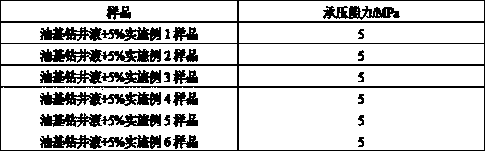

Non-floating bead low-density cement mortar

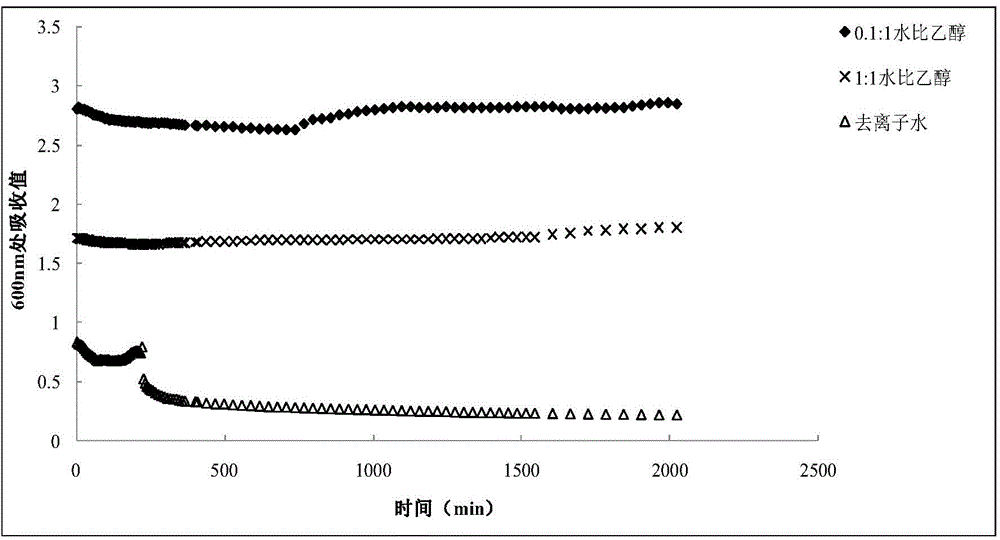

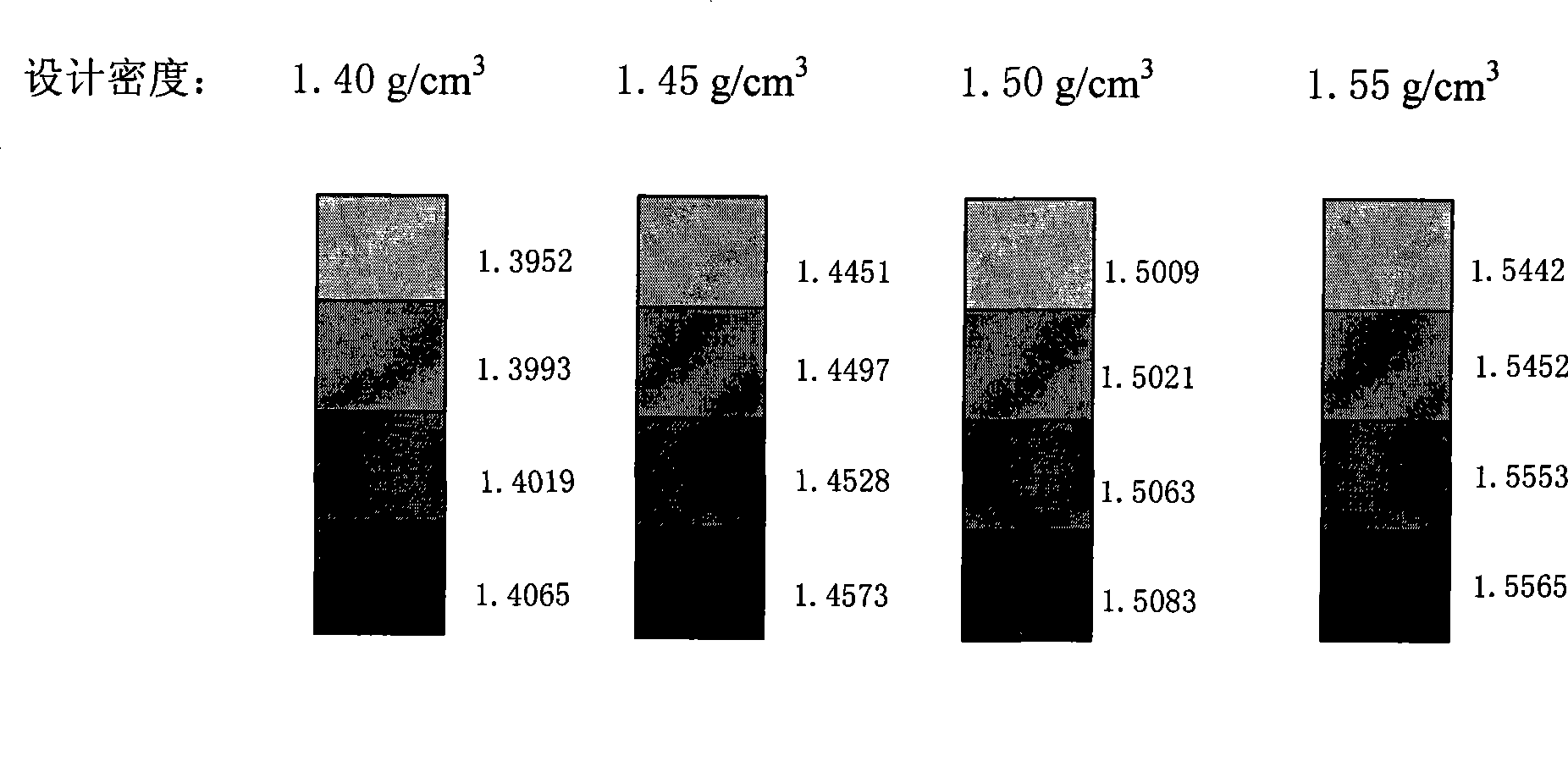

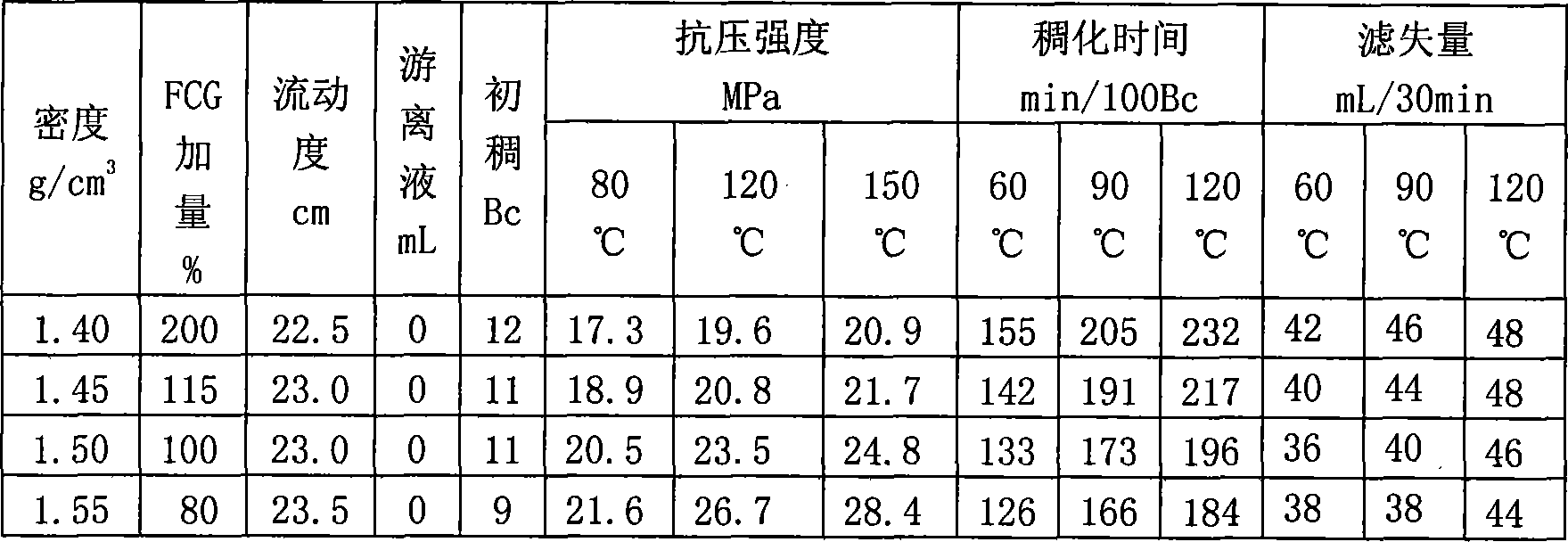

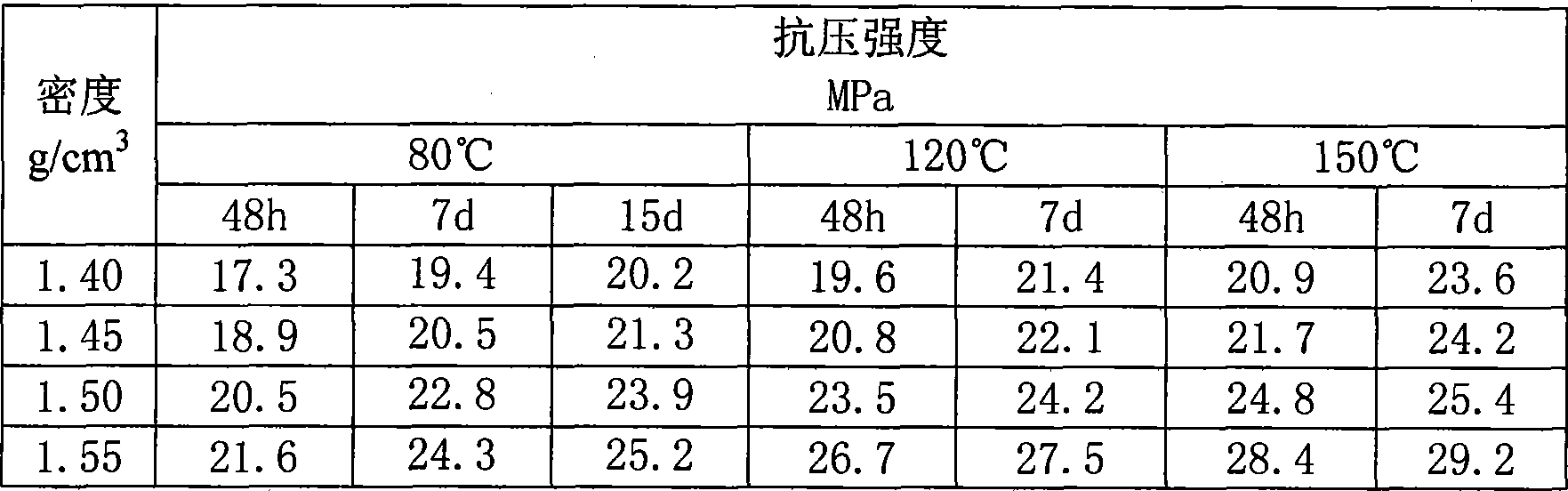

InactiveCN101475347AGood settlement stabilityMeet technical needsSolid waste managementMicrofine cementParticle density

The invention relates to a non-cenosphere light weight cement slurry, which mainly solves the problem that the cement slurry cannot keep the density thereof under a high pressure condition. The non-cenosphere light weight cement slurry is characterized by comprising the following components in portion by weight: 100 portions of cement, 116 to 321 portions of water, 52 to 136 portions of fly ash, 14 to 38 portions of silica fume, 14 to 38 portions of superfine cement, and 6 to 11 portions of early strength agent, wherein the particle diameter of the silica fume (of which the SiO2 content is more than 90 percent) is more than 0 and less than 0.5 mu m, the particle density of the silica fume and the fly ash is 2.0 grams per cubic meter, and the particle diameter of the superfine cement is more than 0 and less than 2 mu m. The light weight cement slurry forms a set of incompressible light weight cement slurry system of which the density is between 1.40 and 1.55 grams per cubic meter through preferentially selecting external additives and applying a grain composition principle, wherein the flowability and the sedimentation stability of the cement slurry are good, the set cement strength is more than 15 MPa and cannot decline at a temperature of 150 DEG C so as to satisfy the technical requirements on oil field exploration and development.

Owner:DAQING OILFIELD CO LTD +1

Aqueous, colloidal gas black suspension

ActiveUS7005004B2Good dispersionImprove stabilityPigmenting treatmentDoors/windowsBuilding materialPrinting ink

Aqueous, colloidal gas black suspension, containing a gas black, an azo compound of formula 1, and water.The aqueous, colloidal gas black suspensions is produced in that the gas black and the azo compound of general formula 1 are dispersed in water.It may be used to produce inks, ink jet inks, paints, printing inks, latices, textiles, leather, adhesives, silicones, plastics materials, concrete and construction materials.

Owner:UBS AG

Polishing solution for hard disk magnetic head and preparation method thereof

ActiveCN102174294AImprove suspension stabilityImprove dispersion uniformityOther chemical processesPolishing compositions with abrasivesHydrocarbon solventsMachined surface

The invention discloses polishing solution for a hard disk magnetic head and a preparation method thereof. The polishing solution is mainly prepared from diamond abrasive particles, a dispersing agent, a corrosion inhibitor, a phase transfer solvent, an oil phase medium regulator and a hydrocarbon solvent, wherein the average particle size of the diamond abrasive particles is 30 to 150nm, the particle size distribution of the particles is 20 to 300nm, and the length-diameter ratio of the particles is 1.0 to 2.0. The preparation method comprises the following steps of: mixing diamond powder and a surface modifier, grinding, removing impurities, and grading to obtain suspension slurry; adding the phase transfer solvent into the suspension slurry, and stirring and dispersing the system; removing fine particles and coarse particles in the phase transfer solvent system by grading to ensure that the particle size distribution and concentration of the diamond abrasive particles meet the requirements; and transferring to the hydrocarbon solvent, adding the oil phase medium regulator, the dispersing agent and the corrosion inhibitor, and uniformly stirring to obtain the polishing solution for the hard disk magnetic head. The polishing solution prepared by the method has high suspension stability and dispersion uniformity, and high polishing efficiency during polishing, and a machined surface has high quality.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

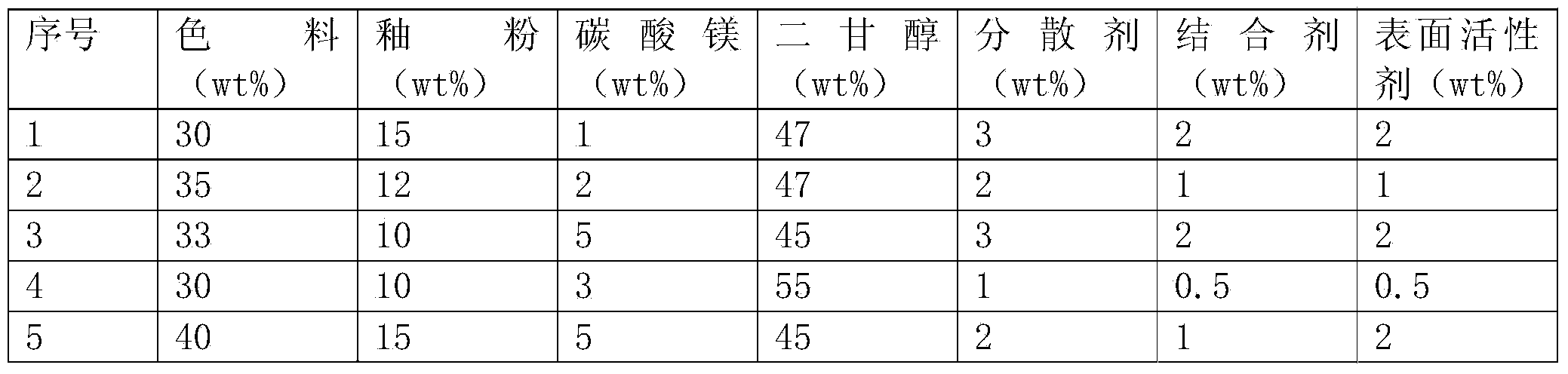

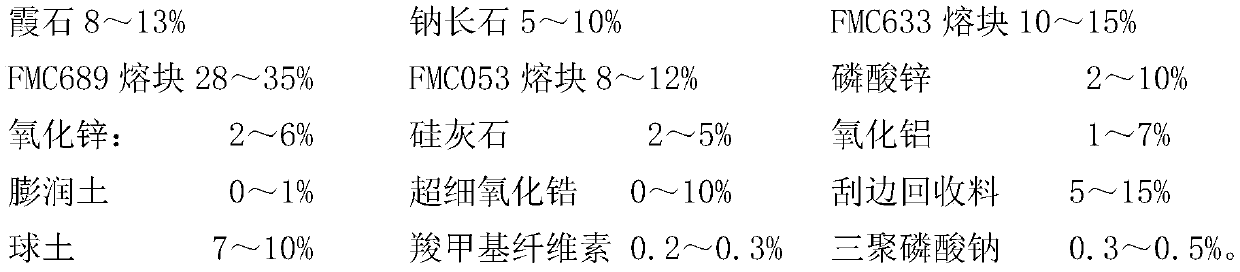

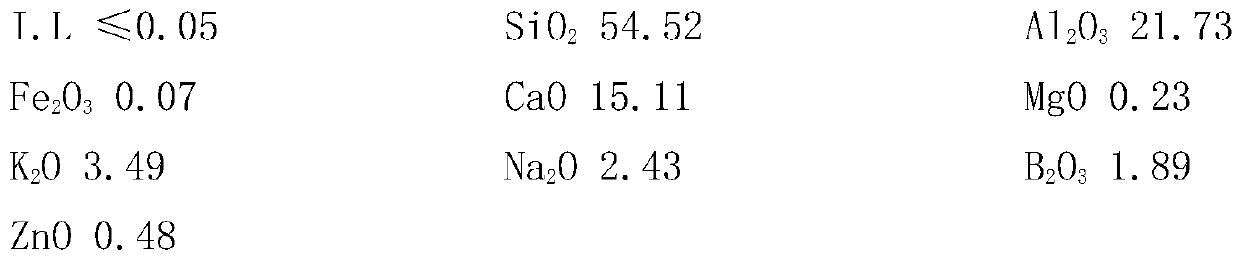

Colored glaze mixed type ink for ceramic ink-jet printing and preparation method thereof

The invention provides colored glaze mixed type ink for ceramic ink-jet printing and a preparation method thereof, belonging to the technology of ceramic tile decoration. The ink comprises the following components by mass percent: 30%-40% of pigment, 10%-15% of glaze powder, 1%-5% of magnesium carbonate, 45%-55% of diethylene glycol, 1%-3% of dispersing agent, 0.5%-2% of binding agent, and 0.5%-2% of surfactant. When the colored glaze mixed type ink for ceramic ink-jet printing is used for producing ceramic tiles for wall and floor, after ink-jet printing, the ceramic tiles can be directly sintered at high temperature without being applied with transparent protective glaze; the glaze in the ink is melted in sintering, so that the color development component of the ink is uniformly dispersed in the melted glaze, the formed ink-jet printing layer has good abrasion resistance, the production technology of the ink-jet printed ceramic tiles is greatly simplified, the production cost is lowered, and the production efficiency is improved.

Owner:LIXIAN XINPENG CERAMIC +1

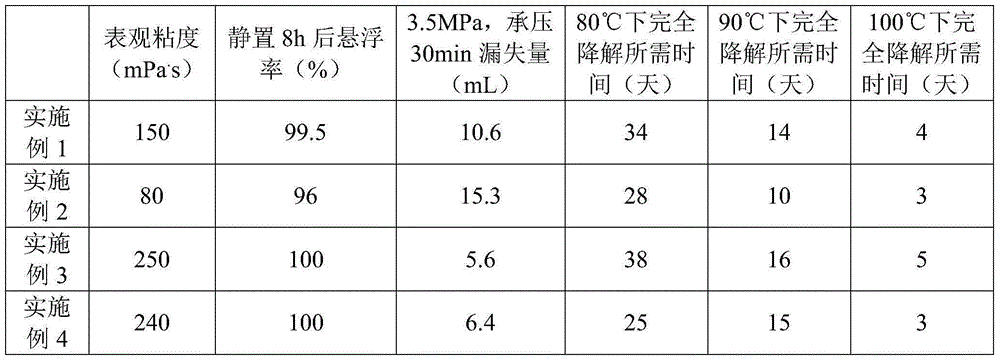

Self-decomposition temporary plugging agent for workover fluid and using method of temporary plugging agent

InactiveCN105086973AWith self-blocking functionImprove protectionDrilling compositionFiberWater based

The invention discloses a self-decomposition temporary plugging agent for a workover fluid and a using method of the temporary plugging agent. The self-decomposition temporary plugging agent comprises 10-40 parts of particles I with the particle size ranging from 1 mm to 10 mm by mass, 20-60 parts of particles II with the particle size ranging from 20 meshes to 40 meshes by mass, 0.2-1 part of staple fibers with the length ranging from 3 mm to 10 mm by mass and 18-40 parts of superfine powder with the particle size ranging from 100 meshes to 300 meshes by mass; the particles I, the particles II, the staple fibers and the superfine powder are any one of or a mixture of several of polylactic acid, poly lactic-glycolic acid and polycaprolactone in any ratio. The using method of the agent comprises steps as follows: the staple fibers are evenly mixed in the water-based workover fluid, other components of the self-decomposition temporary plugging agent are added, and the mixture is evenly mixed. The self-decomposition temporary plugging agent for the workover fluid can be completely degraded into carbon dioxide and water in an aqueous solution and causes no damage to stratums, and the using method of the agent is suitable for on-site preparation.

Owner:CNPC BOHAI DRILLING ENG

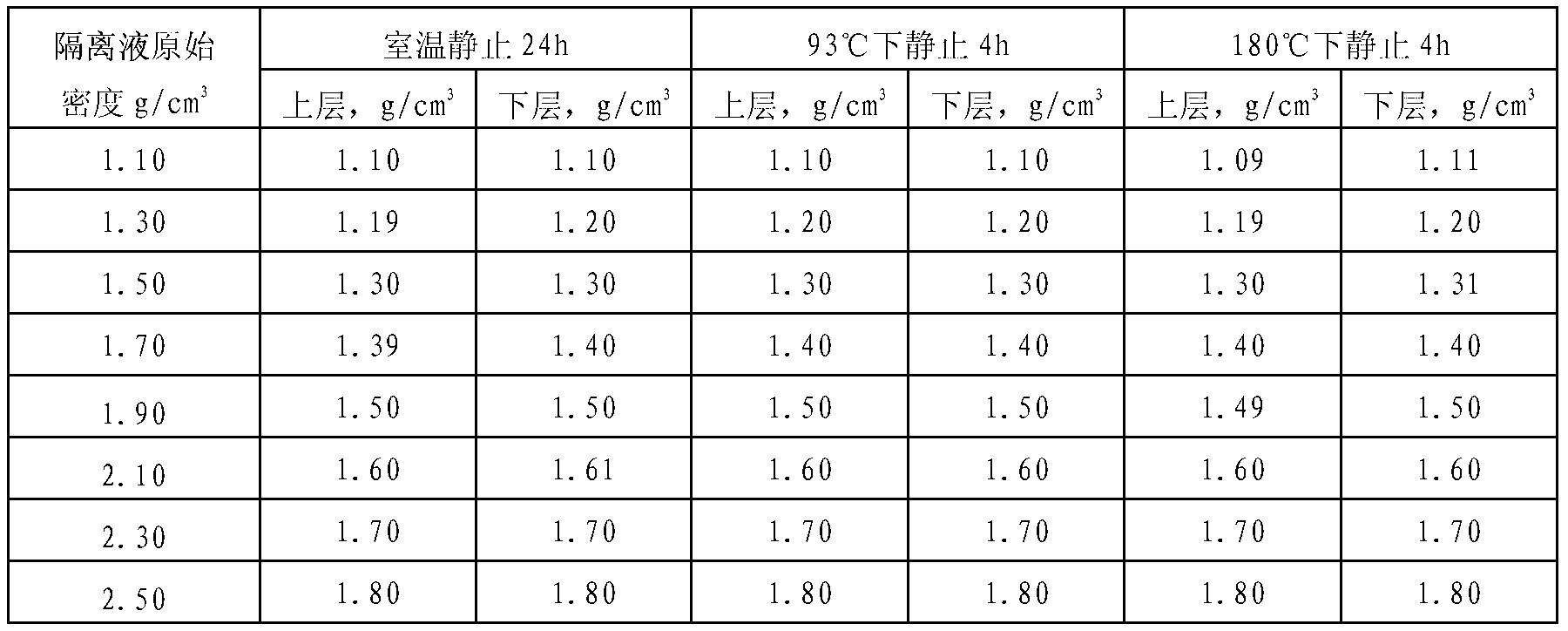

Dual-effect well cementing pad fluid using suspending agent as surfactant

ActiveCN103224774AWide range of density adaptationImprove cleanlinessDrilling compositionActive agentDual effect

The invention relates to a dual-effect well-cementing pad fluid using a suspending agent as a surfactant, and mainly solves problems that present well-cementing pad fluid is added with high-molecular polymer grade inorganic suspending agent which can influence compatibility and cement sheath cementation and thus influence sealing effect of well cementing and exploitation operation in a later stage. The dual-effect well-cementing pad fluid comprises the following components by weight parts: 12-20 parts of a flushing suspending agent, 0.2-1 part of an antifoaming agent, 0-420 parts of a weighting agent and 100 parts of water. The dual-effect well-cementing pad fluid using a suspending agent as a surfactant can eliminate adverse influences of inorganic soil and the high-molecular polymer in the well-cementing pad fluid on the compatibility and the cement sheath cementation, improve flushing and displacing effects on a drilling fluid, and guarantee quality of well cementing and the exploitation operation in the later stage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Attapulgite suspending agent for casting alcohol-based coating and preparation method thereof

InactiveCN101607298AAvoid growing upImprove suspension stabilityFoundry mouldsFoundry coresAlcoholNano sio2

The invention relates to an attapulgite suspending agent for casting alcohol-based coating, which is formed by coating inorganic nanometer grains on attapulgite grains containing 80-85 percent of magnesium aluminum silicate according to the mass percent, wherein the inorganic nanometer grains are nanometer Al2O3, nanometer SiO 2 or nanometer TiO2, the grain diameter is 10-20nm, and the specific surface area is 200-300m / g. The inorganic nanometer grains are added into a purified and acidized attapulgite system for modification so as to lead the organic nanometer to be covered around the attapulgite, on the one hand, the invention can change the surface state of the attapulgite to achieve the purpose of dewatering and affinity alcohol, on the other hand, can prevent highly dispersed attapulgite suspending agent grains from gathering and growing, thereby greatly improving the suspending stability and the harden-resisting property of the alcohol-based coating.

Owner:SHENYANG RES INST OF FOUNDRY

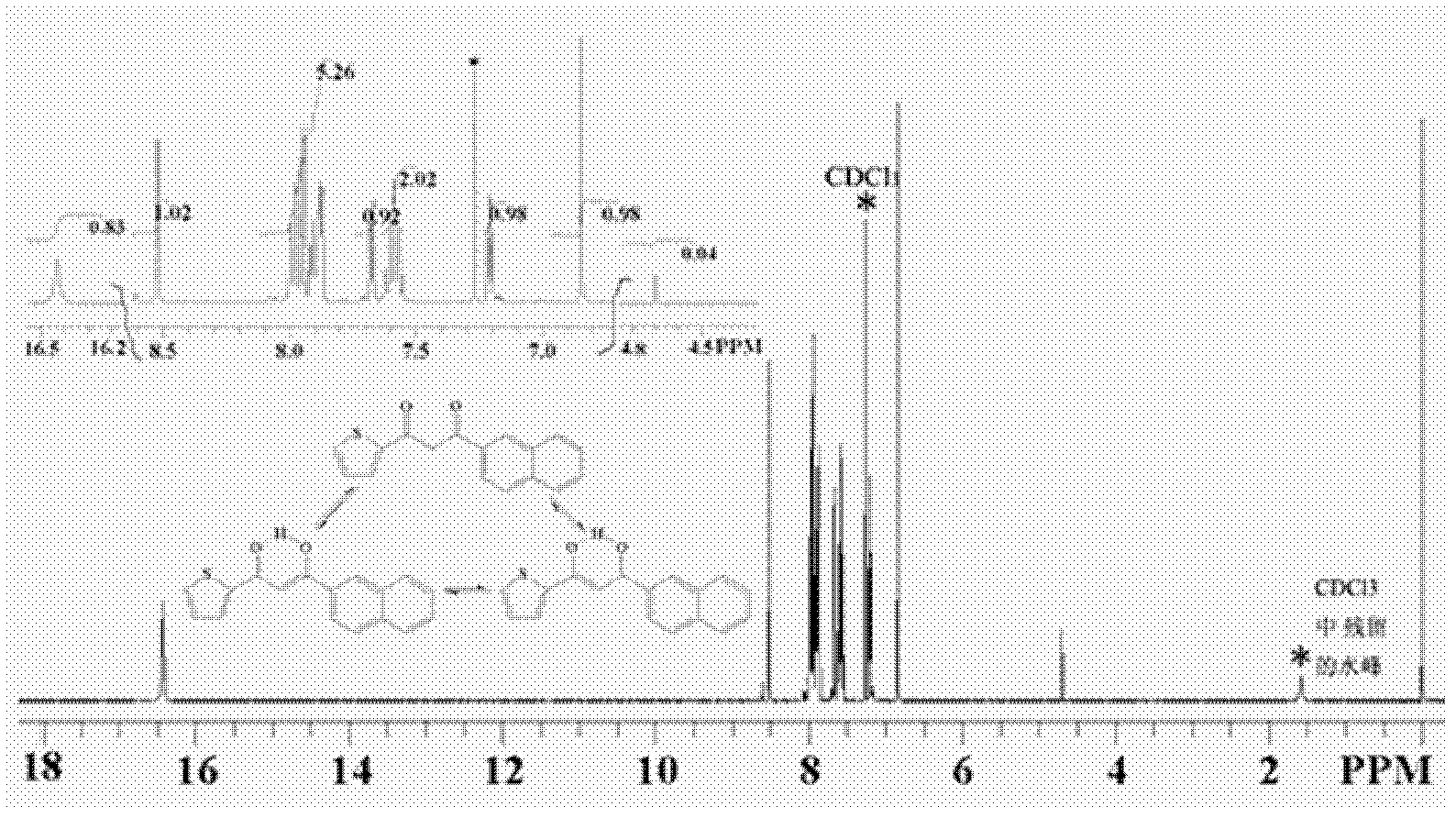

Fluorescent nanoprobe for detecting hydrogen peroxide and fabrication method thereof

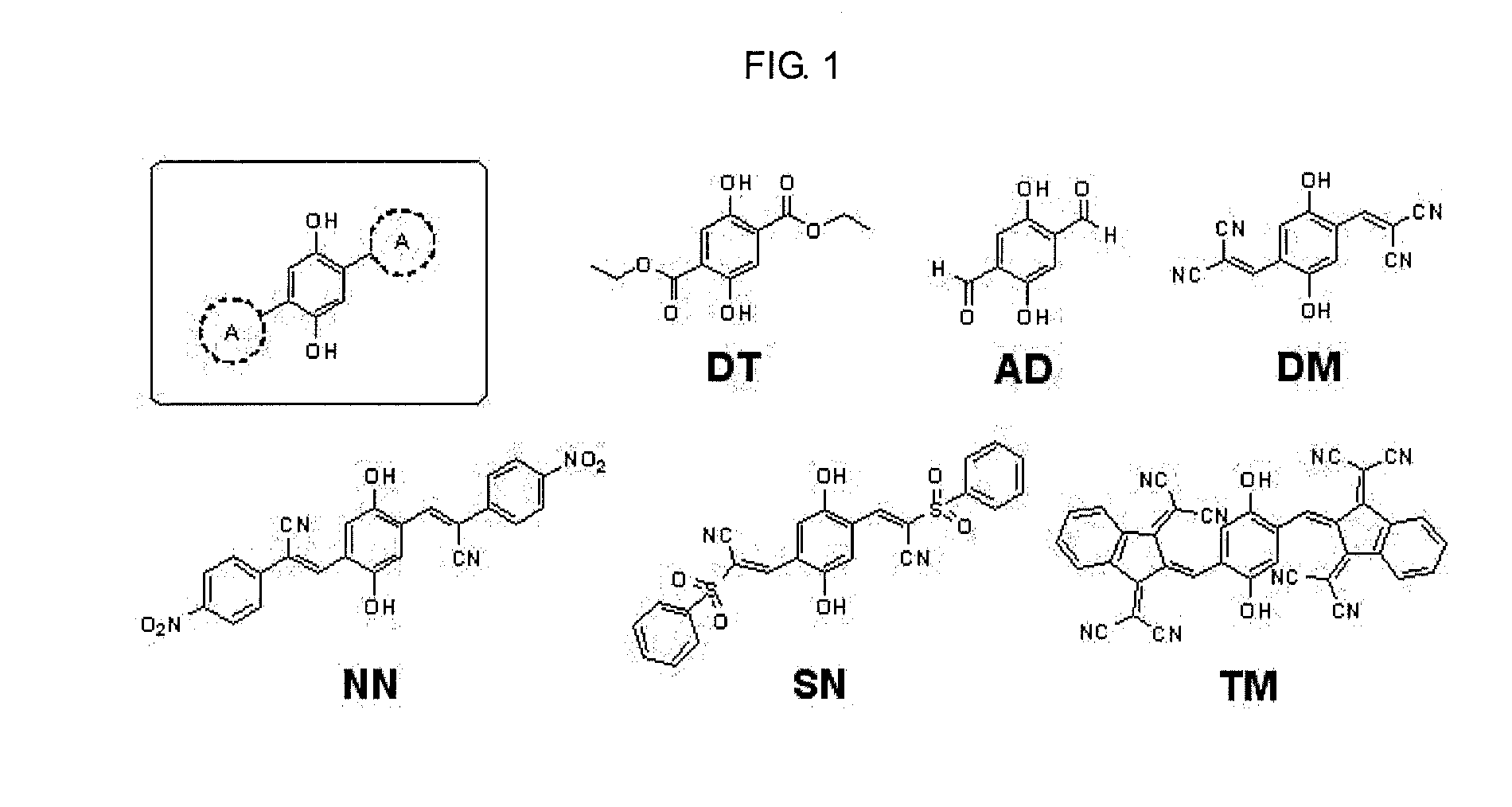

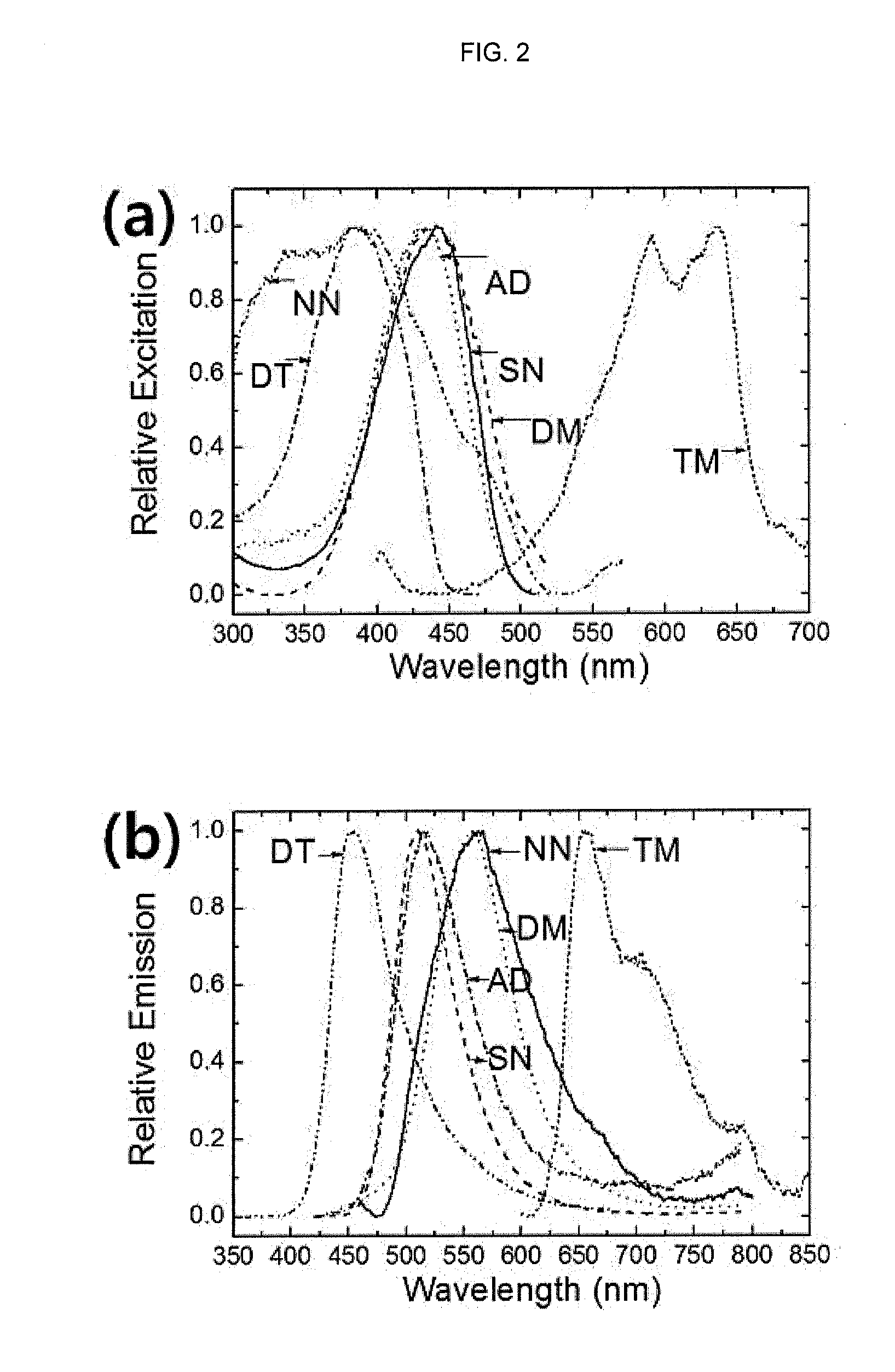

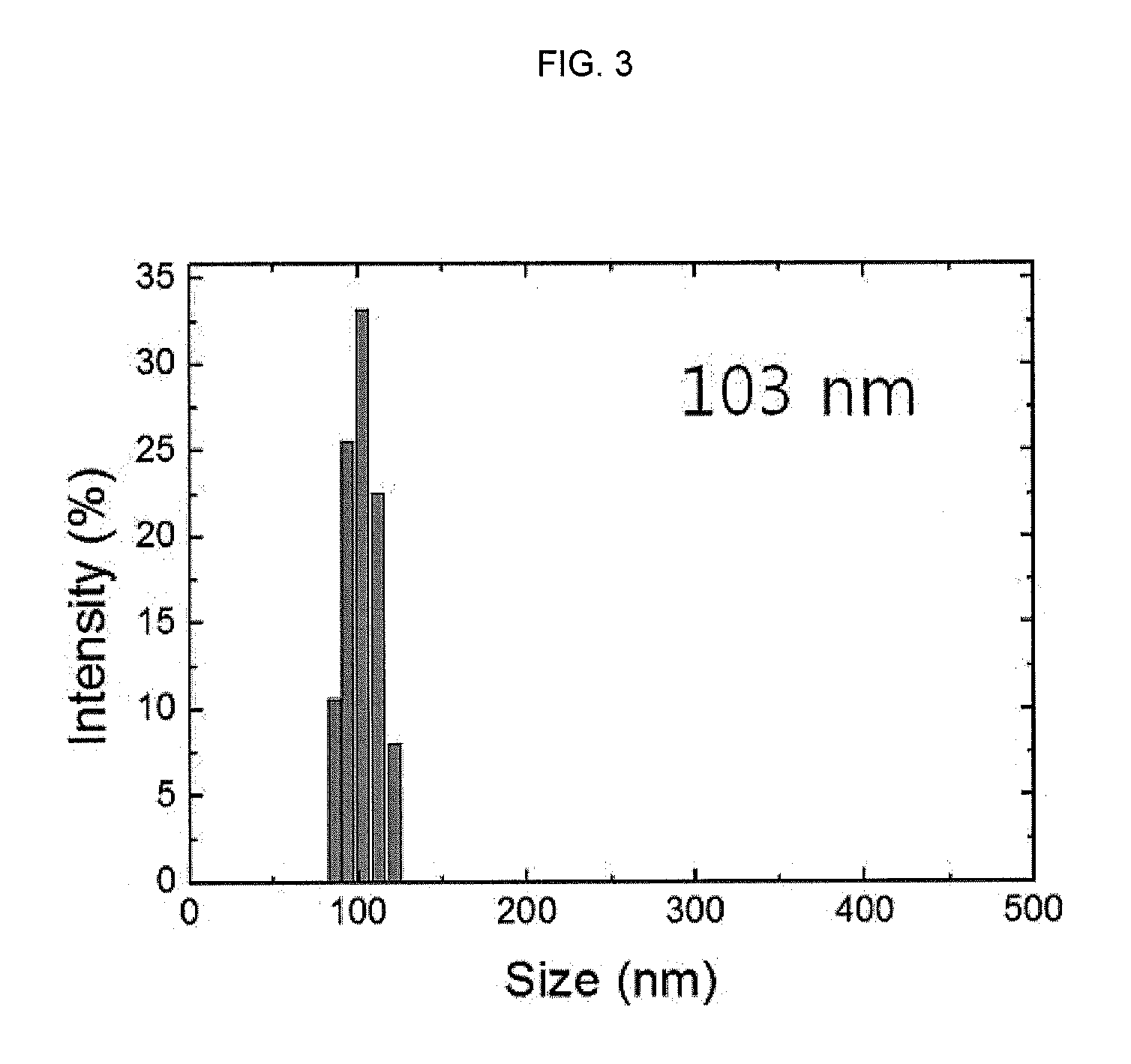

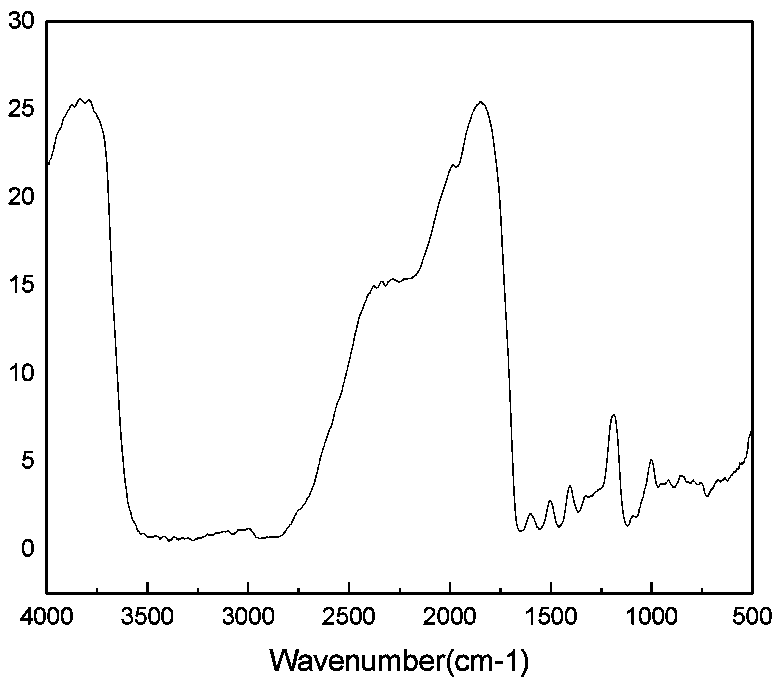

ActiveUS20120276651A1Fast reaction timeImprove efficiencyAnalysis using chemical indicatorsOrganic chemistryBenzeneFluorescence

The present disclosure relates to a sulfonated benzene compound emitting fluorescence by reaction with hydrogen peroxide, aqueous-dispersed fluorescent nanoprobes applicable for real-time detection of hydrogen peroxide, and a fluorescent nanoprobe fabrication method. The fluorescent nanoprobe contains the following sulfonated benzene compound and water.

Owner:KOREA INST OF SCI & TECH

Micro-nano blocking lubricant for drilling fluid and preparation method thereof

ActiveCN108239522AHigh fat contentImprove temperature resistanceDrilling compositionMicro nanoSolid particle

The invention relates to a micro-nano blocking lubricant for a drilling fluid and a preparation method thereof and belongs to the field of oil and gas field drilling and oilfield chemical auxiliary agents. The micro-nano blocking lubricant for the drilling fluid is prepared from the following components in parts by weight: 100-200 parts of a nano emulsion and 100 parts of composite graphite micropowder. The micro-nano blocking lubricant for the drilling fluid also contains a dispersant. The nanoemulsion is prepared from components including paraffin, white oil, a composite emulsifier, a co-emulsifier and water by a phase inversion emulsification method. The micro-nano blocking lubricant for the drilling fluid can resistant the temperature of 150 DEG C, does not have adverse effects to viscosity of the drilling fluid, can reduce the filter loss of the drilling fluid remarkably, improve the quality of mud cakes remarkably, reduce the frictional resistance of a drilling tool and improve the mechanical drilling speed, and can bridge and block micro-cracks of shale quickly by means of a small size effect to prevent solid particles and a filtrate from invading the stratum to achieve a good blocking effect, so that the micro-nano blocking lubricant for the drilling fluid is particularly suitable for blocking fine throats which are 0.05-50[mu]m.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength high-permeability chemical sand prevention agent, and preparation method and application thereof

InactiveCN104650840AObvious advantageObvious effectFluid removalDrilling compositionHigh humidityOil water

The invention provides a high-strength high-permeability chemical sand prevention agent, and a preparation method and an application thereof. The high-strength high-permeability chemical sand prevention agent is composed of a proppant, a cementing agent, an accelerator, a curing agent and a coupling agent according to a certain ratio. The preparation method comprises the following steps: above raw materials are mixed at a specific temperature, and are stirred, and the obtained mixture is cured for a certain period of time to obtain the high curing strength sand prevention agent. The sand prevention agent has good tolerance to acid, water, salt and oil, has high stability in high temperature and high humidity environment, and is mainly used in chemical sand prevention well extract production, serious casing deformation well sand prevention, and sand prevention of wells without mechanical sand prevention and oil water wells with low reservoir temperature in order to increase liquid production of the oil well, prolong the period of validity of well sand prevention, increase the amount of oil and reduce the production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature-resistant high-density reversible water-in-oil/oil-in-water drilling fluid and preparation method thereof

ActiveCN109097010AGood reversalComparable performanceOrganic compound preparationCarboxylic acid amides preparationOil phasePolyamine

The invention provides high-temperature-resistant high-density reversible water-in-oil / oil-in-water drilling fluid which is composed of the following raw materials in parts by weight: 30-70 parts of an oil phase, 30-70 parts of an aqueous phase, 2-5 parts of a reversible emulsifier, 1-3 parts of an auxiliary emulsifier, 0-2 parts of organic soil, 1-4 parts of a filtrate reducer, 0-1 part of an alkalinity regulator, 0-0.5 part of a wetting agent, 0-2 parts of an enhancer and 0-800 parts of weighting materials. The reversible emulsifier is fatty acyl polyamines and derivatives thereof, and has astructural general formula of R1(CH2)m(CONH)n(C6H4)x(NH)y(NH2)zR2; the filtrate reducer is an amphiphilic filtrate reducer. The amphiphilic filtrate reducer comprises but is not limited to an amphiphilic polymer filtrate reducer, a hydrophilic modified asphalt filtrate reducer and a hydrophobic modified humic acid filtrate reducer. The compounded auxiliary emulsifier is a high HLB (Hydrophile-Lipophile Balance) value surfactant. The drilling fluid disclosed by the invention has directly adjustable density of 0.8-1.8g / cm<3>, and has excellent properties such as rheological property, suspensionstability, filter cake clearance, filter loss control, environment friendliness and stable reversibility of water-in-oil emulsion and oil-in-water emulsion in a range of 100-180 DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

Superfine oil-base drilling fluid used for high temperature high temperatur high pressure superdeep well and preparation method thereof

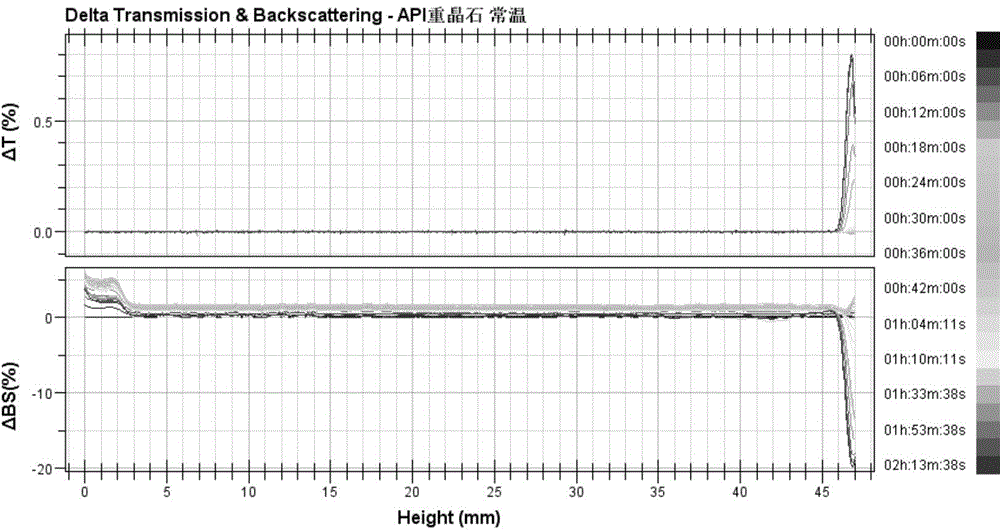

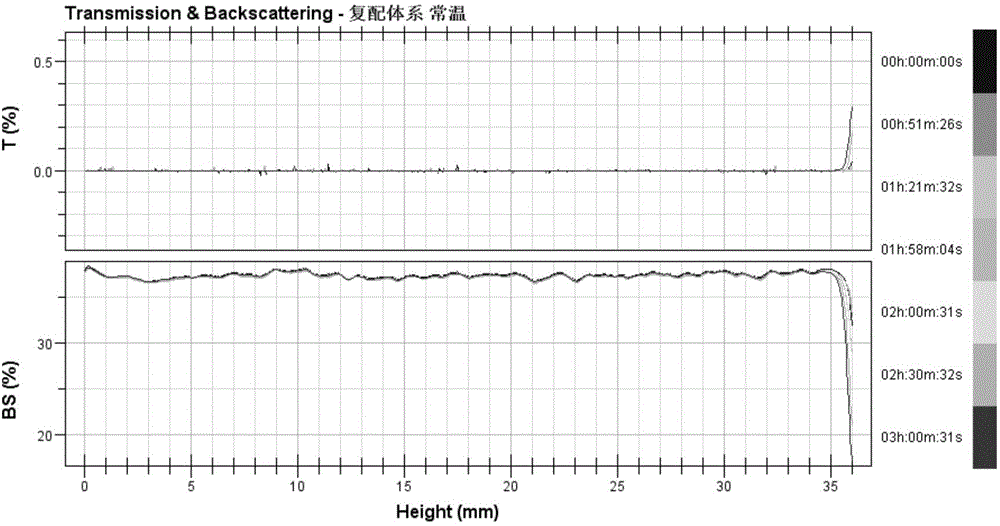

ActiveCN104610946AIncreased steric hindranceOvercoming the tendency to coalesceDrilling compositionFiltrationHigh pressure

The invention provides a superfine oil-base drilling fluid used for a high temperature high pressure superdeep well, the superfine oil-base drilling fluid contains the following raw materials by weight: 20-40 parts of water, 250-500 parts of diesel, 2-10 parts of an emulsifier, 3-15 parts of a wetting agent, 2-8 parts of organic soil, 15-25 parts of a filtrate loss agent, 5-10 parts of calcium chloride, 5-10 parts of calcium oxide, 450-800 parts of API barite, and 350-660 parts of an ultra aggravating material. The oil-base drilling fluid is weighted by compounding superfine mineral powder and ordinary barite, the superfine high density oil-base drilling fluid density can reach 2.8g / cm<3>, has better settling stability and high temperature and high pressure filtration loss compared with that of ordinary barite weighted drilling fluid, and can meet drilling of deep wells, superdeep wells and composite salt formations.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

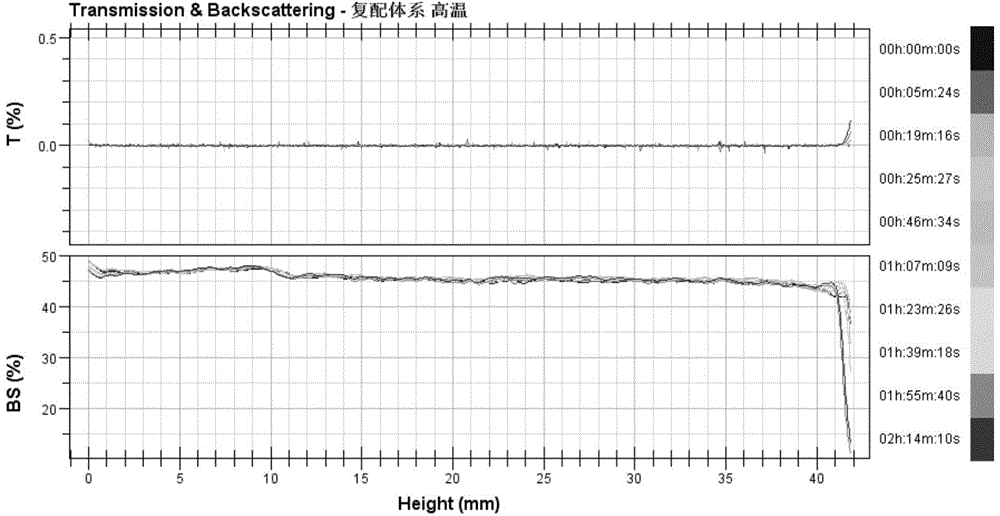

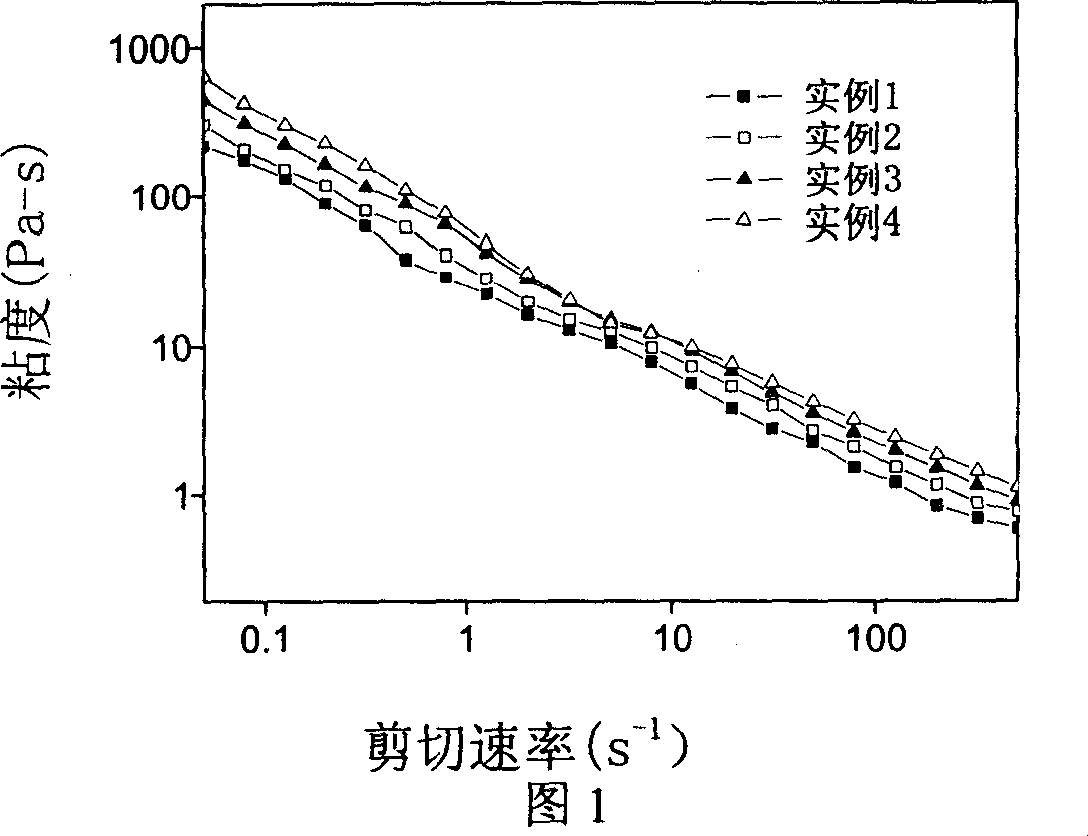

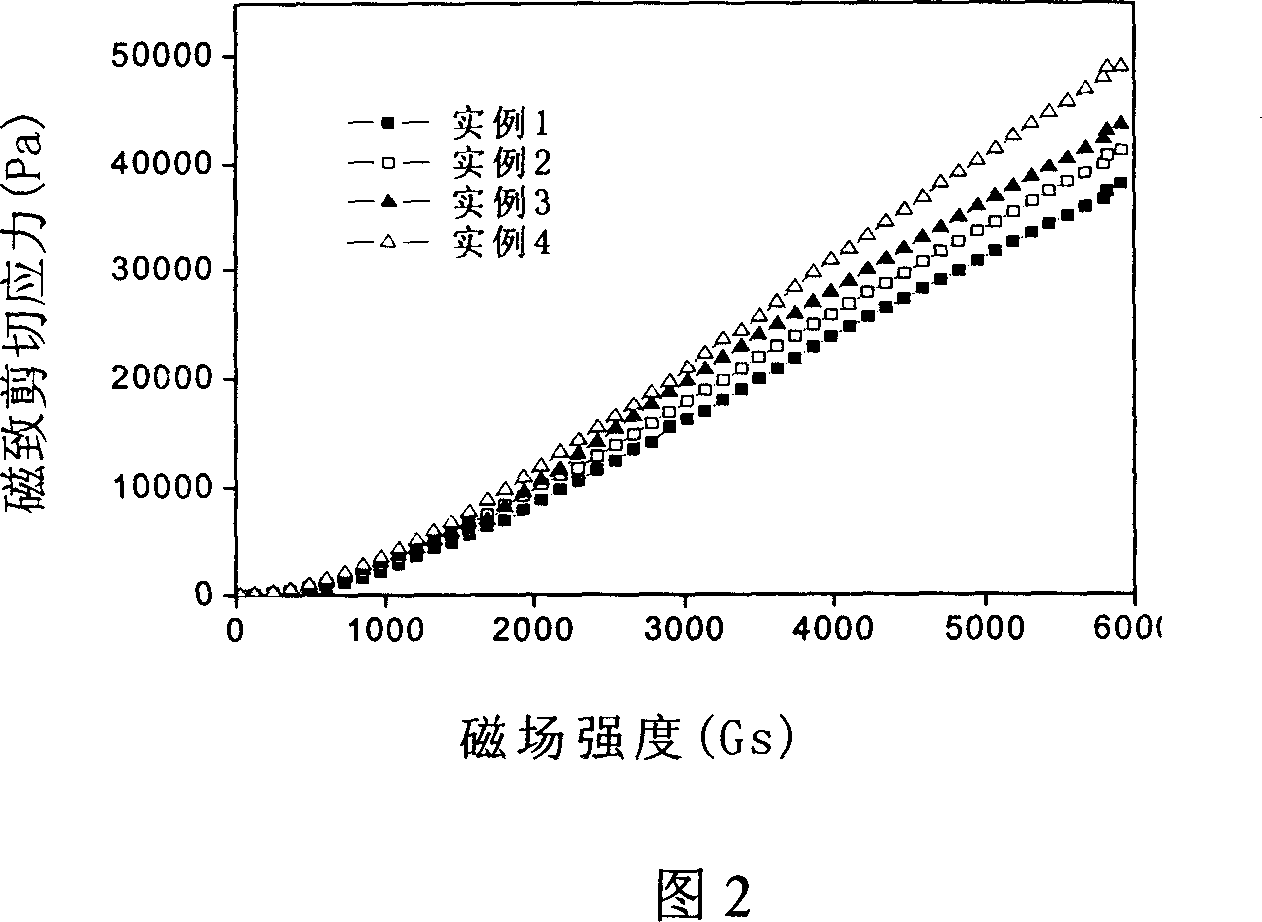

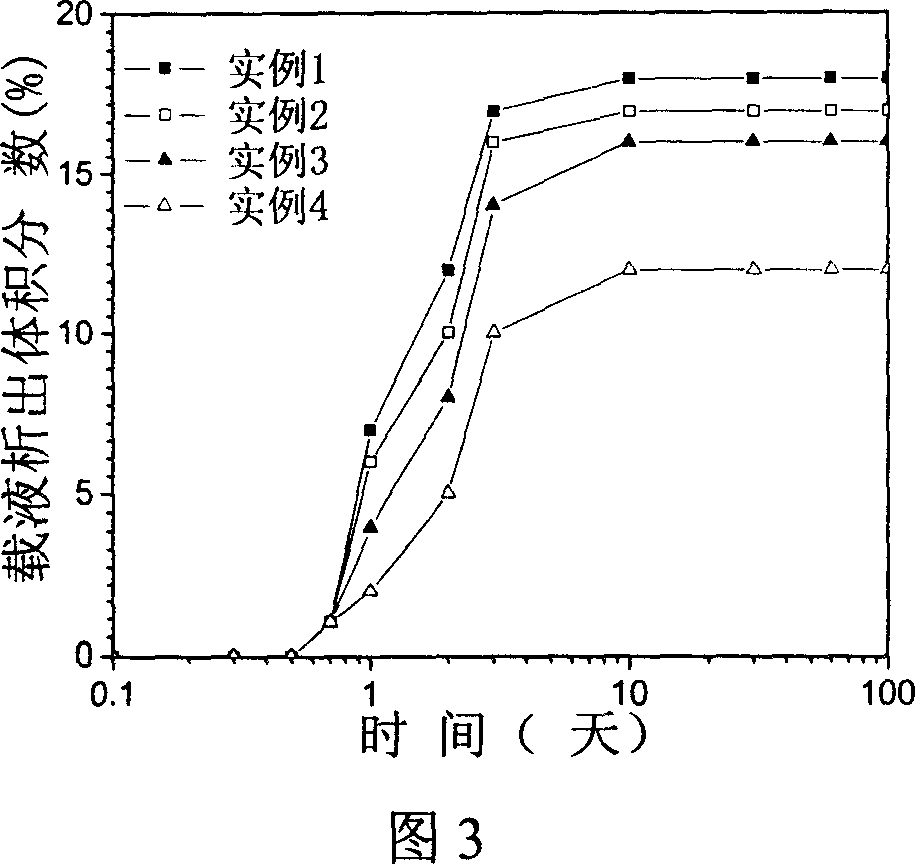

Stable silicone oil based magnetic rheologic liquid, and preparation method

InactiveCN1959872AGood settlement stabilityImprove antioxidant capacityMagnetic liquidsInductances/transformers/magnets manufactureCarrier fluidSilicone oil

The magnetic rheologic liquid is composed of components: chelation type surfactant / carbonyl iron hull type magnetic compound particles, and silicone oil based compound assorted carrier liquid prepared from silicone oil and additive. The additive includes thixotropic agent, antioxidant, antiwear additive, and surfactant. The method for preparing the liquid includes steps: mixing round surfactant being added to silicone oil; next, adding antioxidant, thixotropic agent, and antiwear agent, then mixing them to obtain silicone oil based compound assorted carrier liquid; adding magnetic compound particles to the carrier liquid, and after procedures of mixing, ballmilling, and separating out friction balls, then sealing the liquid inside plastic bottle; stable silicone oil based magnetic rheologic liquid is obtained after series of procedure: placing the plastic bottle in magnetic field, taking out the liquid, and mixing etc. The liquid is applicable to damper, variator for cars etc.

Owner:WUHAN UNIV OF TECH +1

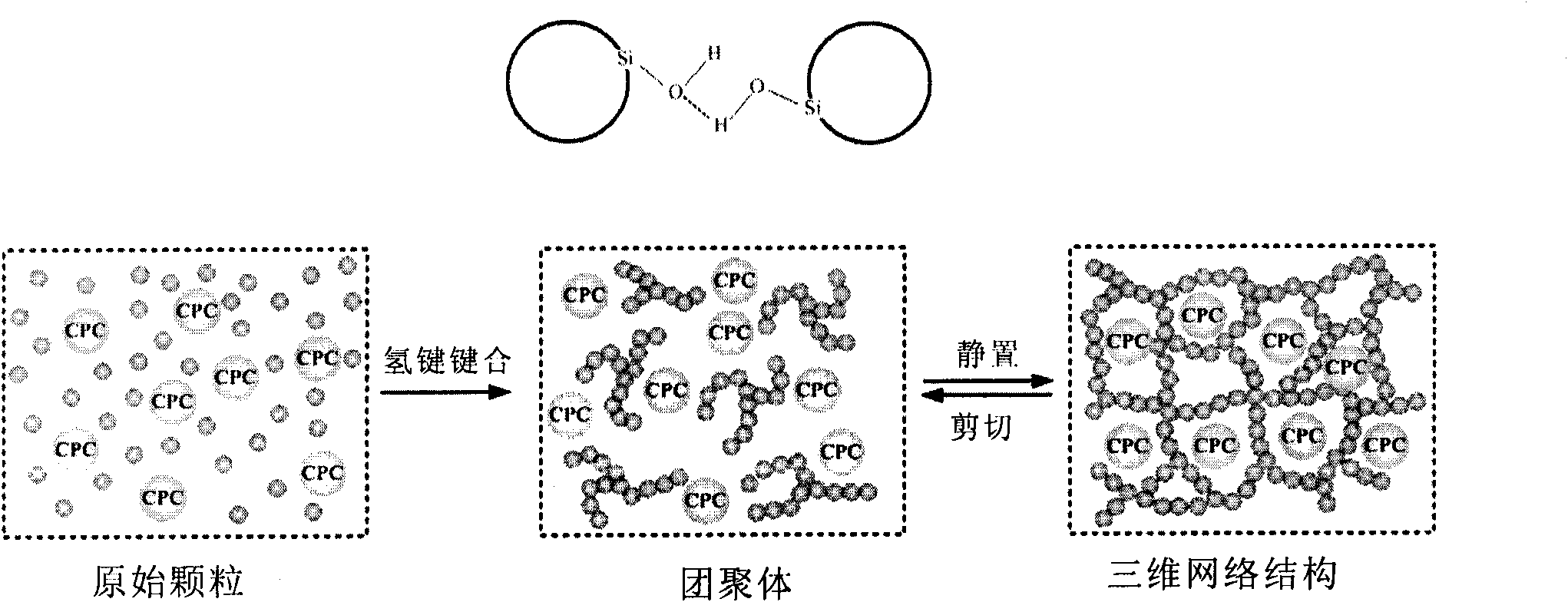

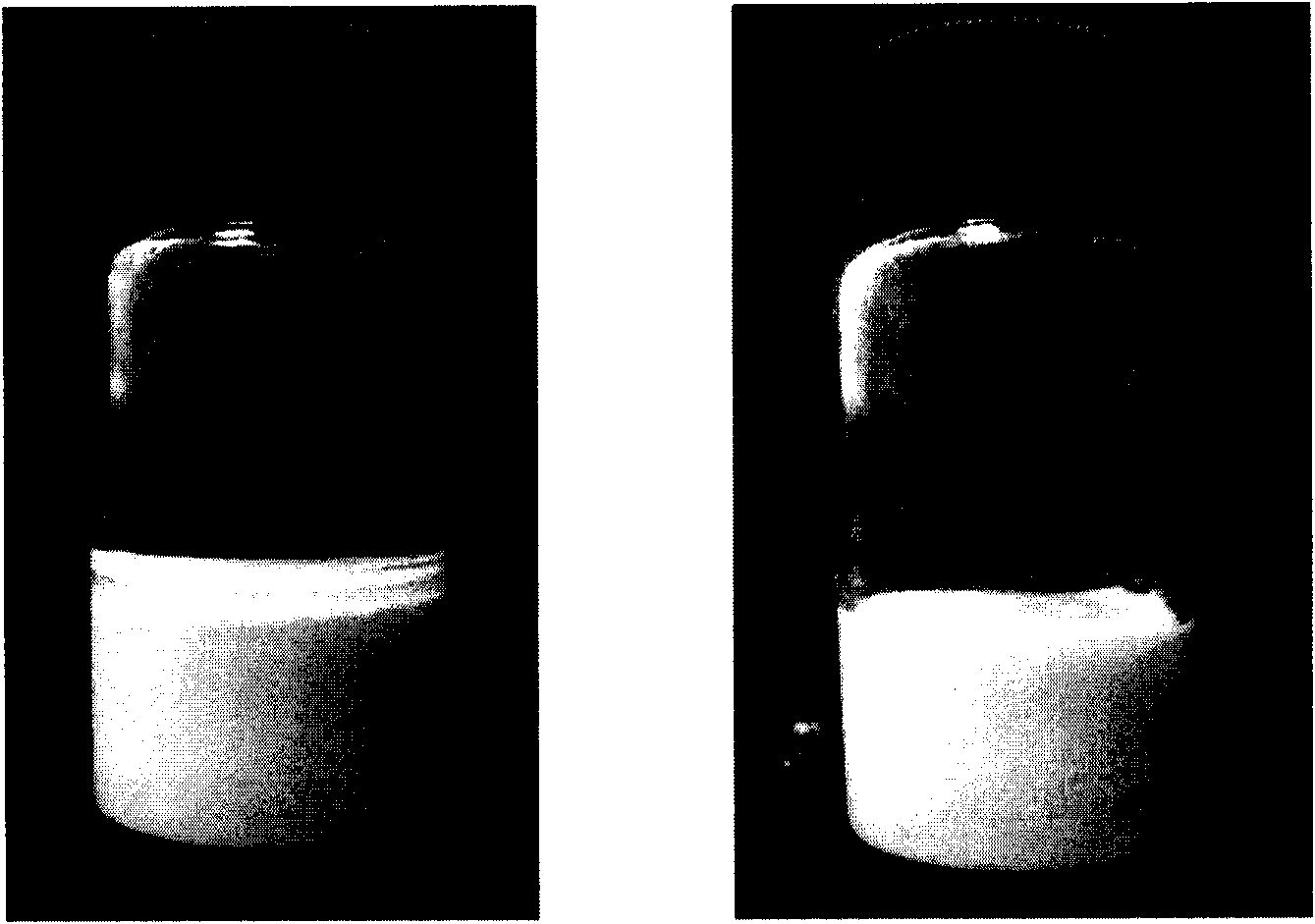

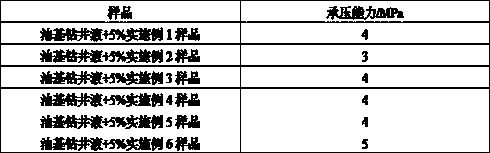

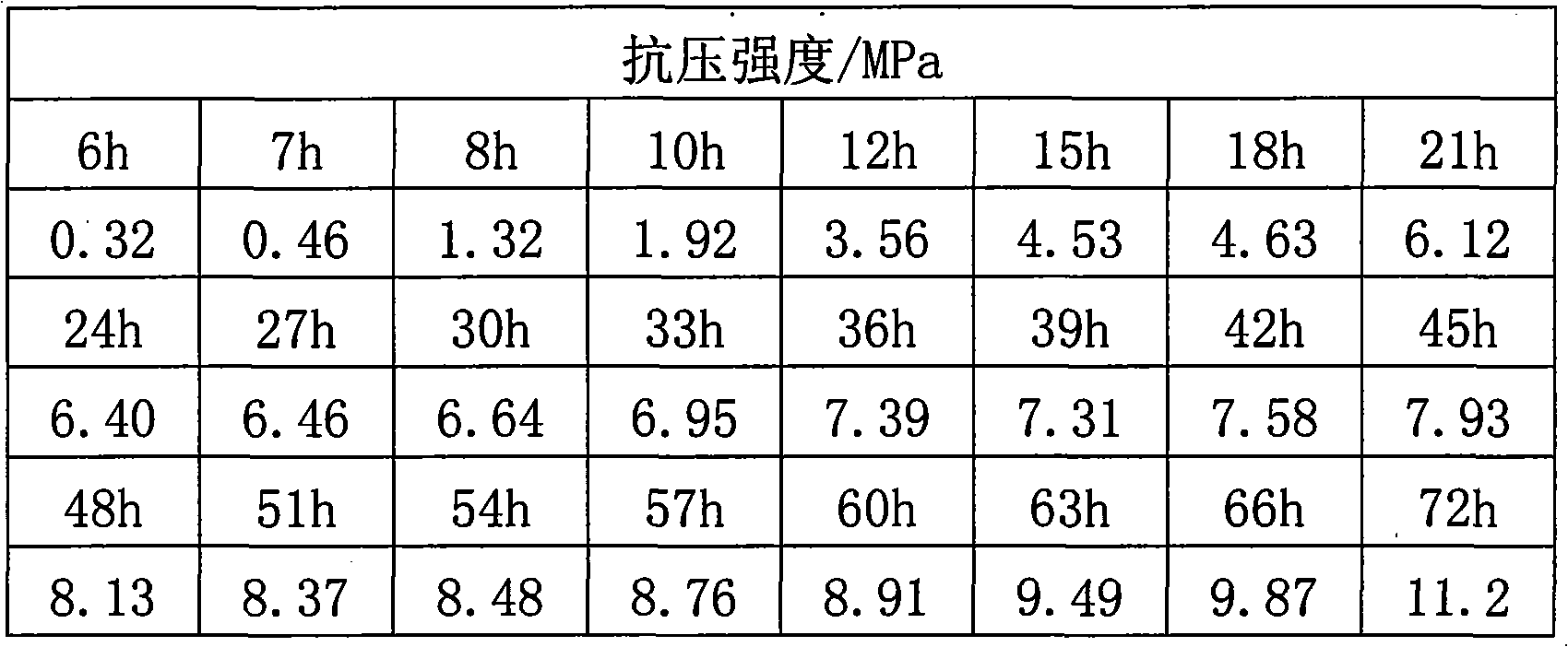

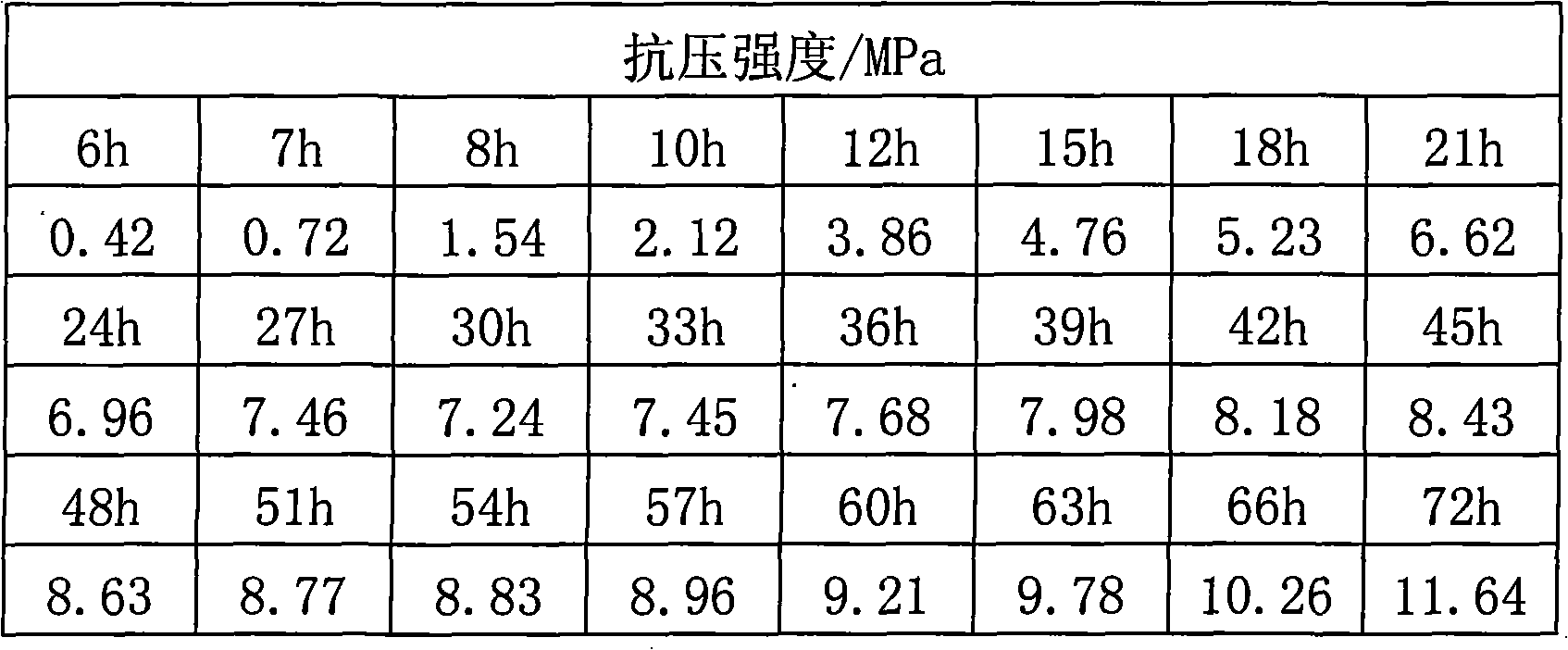

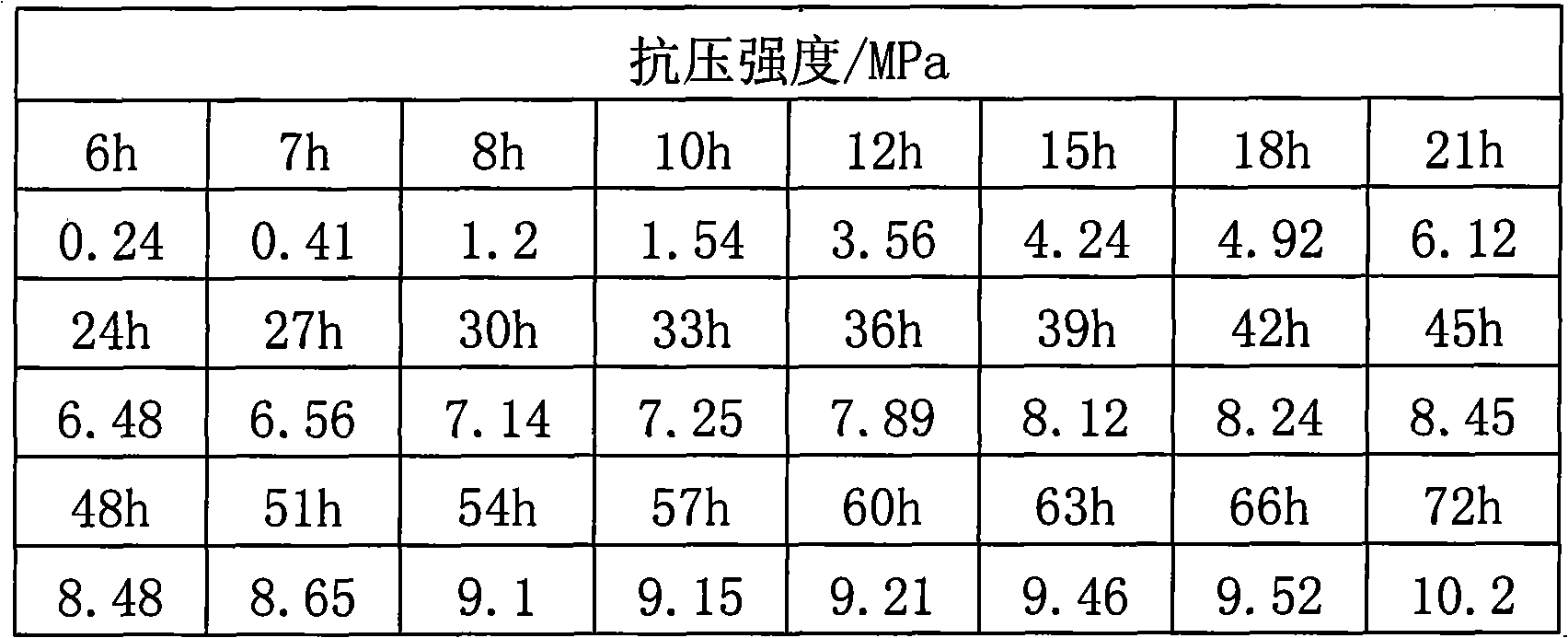

Injectable efficient suspended stable calcium phosphate cement and preparation method and application thereof

ActiveCN102049062AFor long-term storageImprove suspension stabilityImpression capsSurgeryTissue repairCompressive strength

The invention relates to injectable efficient suspended stable calcium phosphate cement and a preparation method and application thereof. The invention discloses the injectable efficient suspended stable calcium phosphate cement and the preparation method and the application thereof. When fumed silica and a modified product thereof are applied in the injectable calcium phosphate cement, the suspension stability of the original calcium phosphate cement is remarkably improved, the curing property of the calcium phosphate cement is kept on the basis that the operation is simple and convenient, and meanwhile the requirements of the injectable property and the compressive strength of the calcium phosphate cement are not reduced. The calcium phosphate cement has the advantages of low raw material cost, simple preparation, convenience for operation and the like, has good suspension stability, can be stored for a long term under certain conditions, and is expected to be used as a high-performance novel tissue repair material which realizes large-scale industrialized production and is applied to clinic.

Owner:EAST CHINA UNIV OF SCI & TECH

Curable low-density leaking stoppage working fluid and preparation method thereof

InactiveCN106967393AReduce hydrostatic injection pressureExtended stayDrilling compositionFiberWorking fluid

The invention provides a curable low-density leaking stoppage working fluid and a preparation method. The curable low-density leaking stoppage working fluid is prepared from, by weight, 100 parts of G-grade oil well cement, 44-60 parts of slag, 23-67 parts of lightening admixture, 8-12 parts of micro silicon, 0.4-1.2 parts of dispersant, 4-5 parts of fluid loss agent, 0.4 part of retarder, 1 part of fiber, 131-214 parts of water and 0.5 part of foaming agent. The density of the curable low-density leaking stoppage working fluid is 1.20-1.50 g / cm<3>, the curable low-density leaking stoppage working fluid is high in early strength and thixotropy, free of free water and good in system stability, and the technical problem that a curing body cannot be formed due to bridge plug leaking stoppage in a conventional leaking stoppage method and the cement leaking stoppage cutting body difficultly stays at a leaking layer is solved. After leaking stoppage is carried out, the formation pressure bearing capacity at the leaking layer can be improved, and the technical defects of the existing conventional leaking stoppage method are overcome.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Leak-stopping agent for oil-base drilling fluid

ActiveCN105441044AImprove lipophilicityImprove suspension stabilityDrilling compositionFiberJUGLANS REGIA SHELL

A related leak-stopping agent for an oil-base drilling fluid comprises the following compositions in percent by weight: 15-20% of fiber, 10-25% of juglans regia vshell, 20-40% of an oil-absorptin polymer particle, and 40-60% of an oil-base juglans-regia-shell expanding plugging agent. The leak-stopping agent for the oil-base drilling fluid is obtained by uniformly mixing the above raw materials. The leak-stopping agent is simple in preparation technology, good in lipophilicity, good in suspension stability and expanding performance, and good in plugging effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of alcohol-based flow coating paint for cast iron

ActiveCN103551497AUnique methodLight colorFoundry mouldsFoundry coresCrack resistanceSodium Bentonite

The invention relates to a production method of paint and in particular relates to a production method of an alcohol-based flow coating paint for cast iron. The production method of the alcohol-based flow coating paint for the cast iron comprises the following steps: adding a dissolved rosin liquid and a pretreated bentonite liquid into a dispersing kettle, then sequentially adding ethanol, a combustion-supporting agent, isopropyl alcohol and a thickening agent in residual content, carrying out electric stirring, sequentially adding polyvinyl butyral, a silicate composite suspending agent, a defoaming agent and a surface active agent into the dispersing kettle, regulating the stirring rate to be 500r / min after charging is finished, sequentially adding flake graphite and mullite into the dispersing kettle, regulating the stirring rate after charging is finished, dispersing, sequentially adding quartz powder and white corundum into the dispersing kettle, regulating the stirring rate to be 1200r / min after charging is finished, dispersing for 20 minutes, and discharging. The production method of the alcohol-based flow coating paint for the cast iron is unique, and the produced alcohol-based flow coating paint for the cast iron has the advantages of superior liquidity, good levelling property, high suspension stability, heat shock crack resistance, high temperature stability, sand burning resistance and low gas-forming property.

Owner:共享新材料(山东)有限公司

Early strength cement grout with low dehydration ratio for grouting

InactiveCN101628800AGuaranteed suspension stabilityImprove resistance to water dilutionSlurrySuspending Agents

The invention discloses early strength cement grout with low dehydration ratio for grouting. The stable early strength cement grout for pre-grouting of coal mineshaft surface comprises the following components in part by weight: 100 parts of silicate cement, 80-120 parts of water, 10-40 parts of suspending agent, 1 part of inorganic sodium salt and 0.03-0.1 part of organic alcohol early strength agent. The cement grout utilizes physical and chemical functions of composite admixture, improves the suspending stability of the cement grout and the early compression strength of a concretion body, improves the flow deformation feature and the movable shearing force of the grout and realizes controllable grout diffusion distance.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

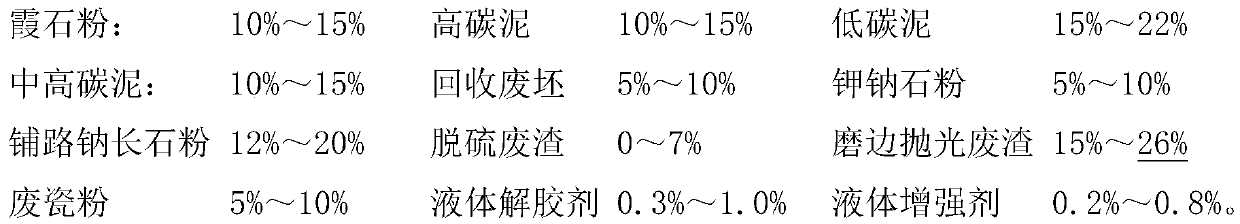

Silky fine matt ceramic tile and production method thereof

ActiveCN110204306AReduce consumptionSimplify product processCeramic shaping apparatusCeramic materials productionCeramic tilesPotassium

The invention relates to a silky fine matt ceramic tile and a production method thereof. The blank material of the ceramic brick comprises 10-15% of nepheline powder, 5-10% of high-carbon mud, 20-25%of low-carbon mud, 10-15% of medium-and-high-carbon mud, 5-10% of recovered waste blanks, 5-10% of potassium and sodium stone powder, 20-25% of paving albite powder, 5-10% of waste porcelain powder, 0-7% of desulfurization waste residues, 20-30% of edging and polishing waste residues, 0.3-1.0% of a liquid dispergator and 0.2-0.8% of a liquid reinforcing agent. The production method comprises the following processes: proportioning and ball milling of blank raw materials, spray drying, aging, blank compression molding, drying, blank polishing, water spraying, glazing, pattern decoration and firing.

Owner:JIANGXI HEMEI CERAMICS +4

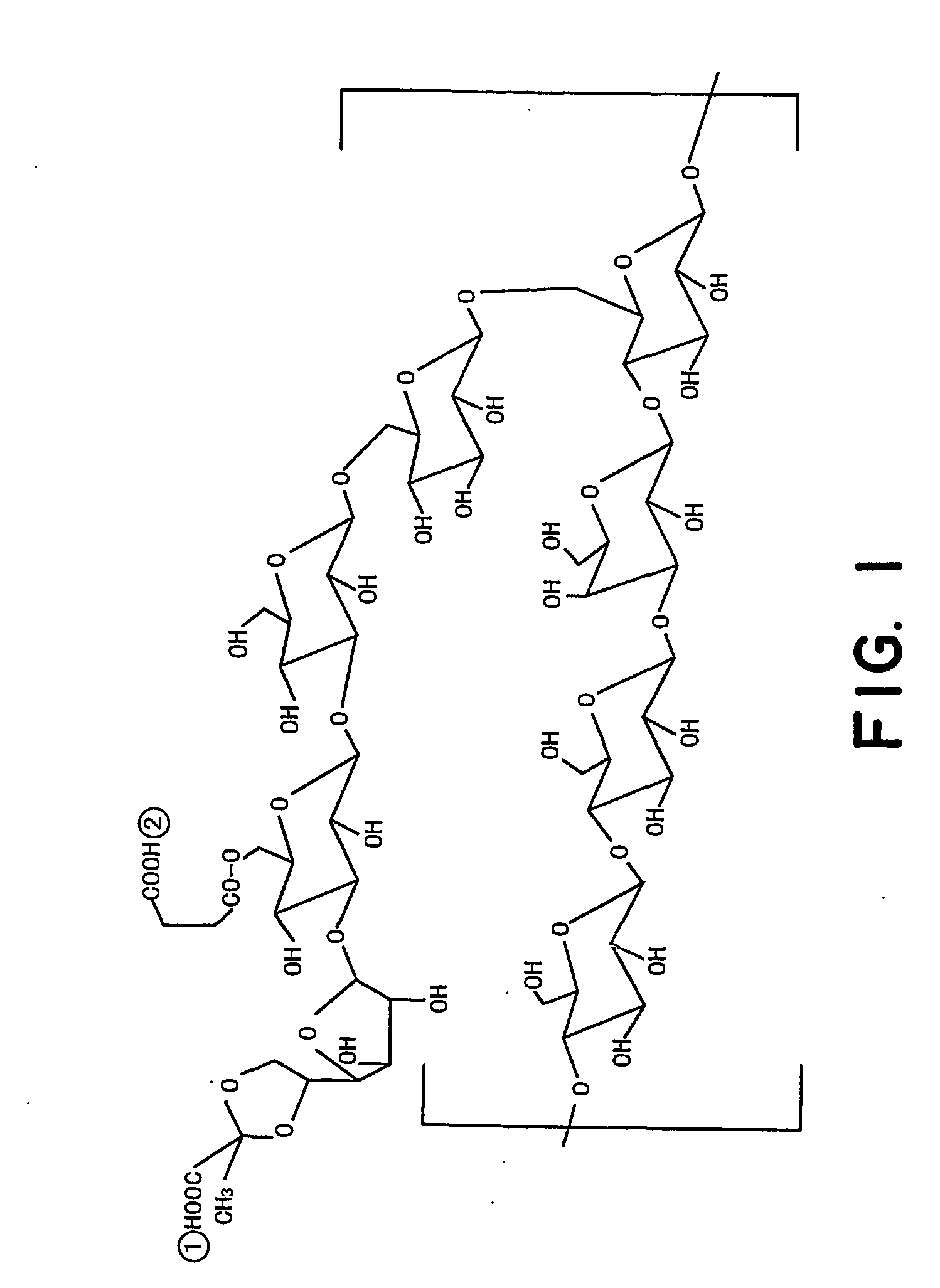

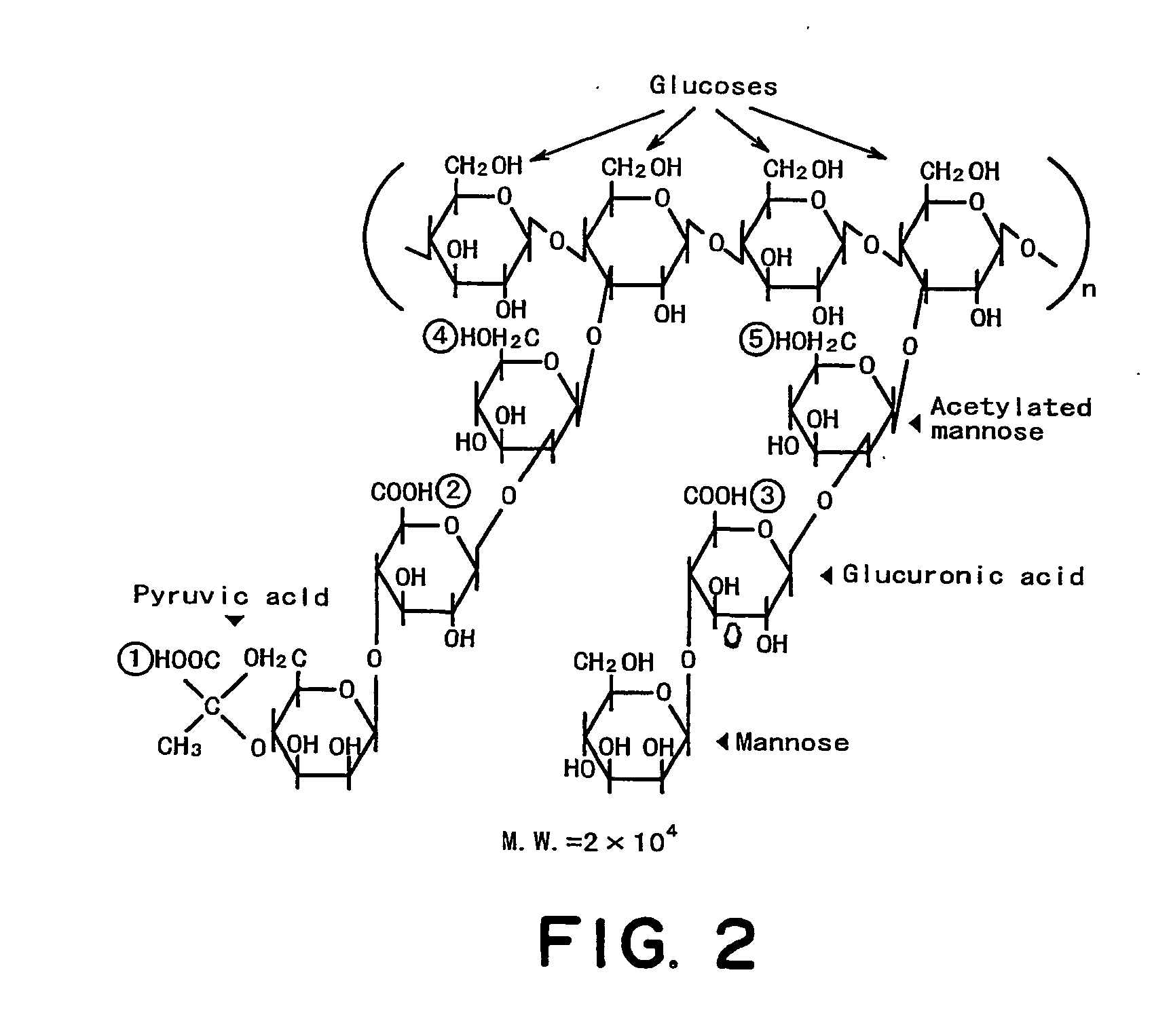

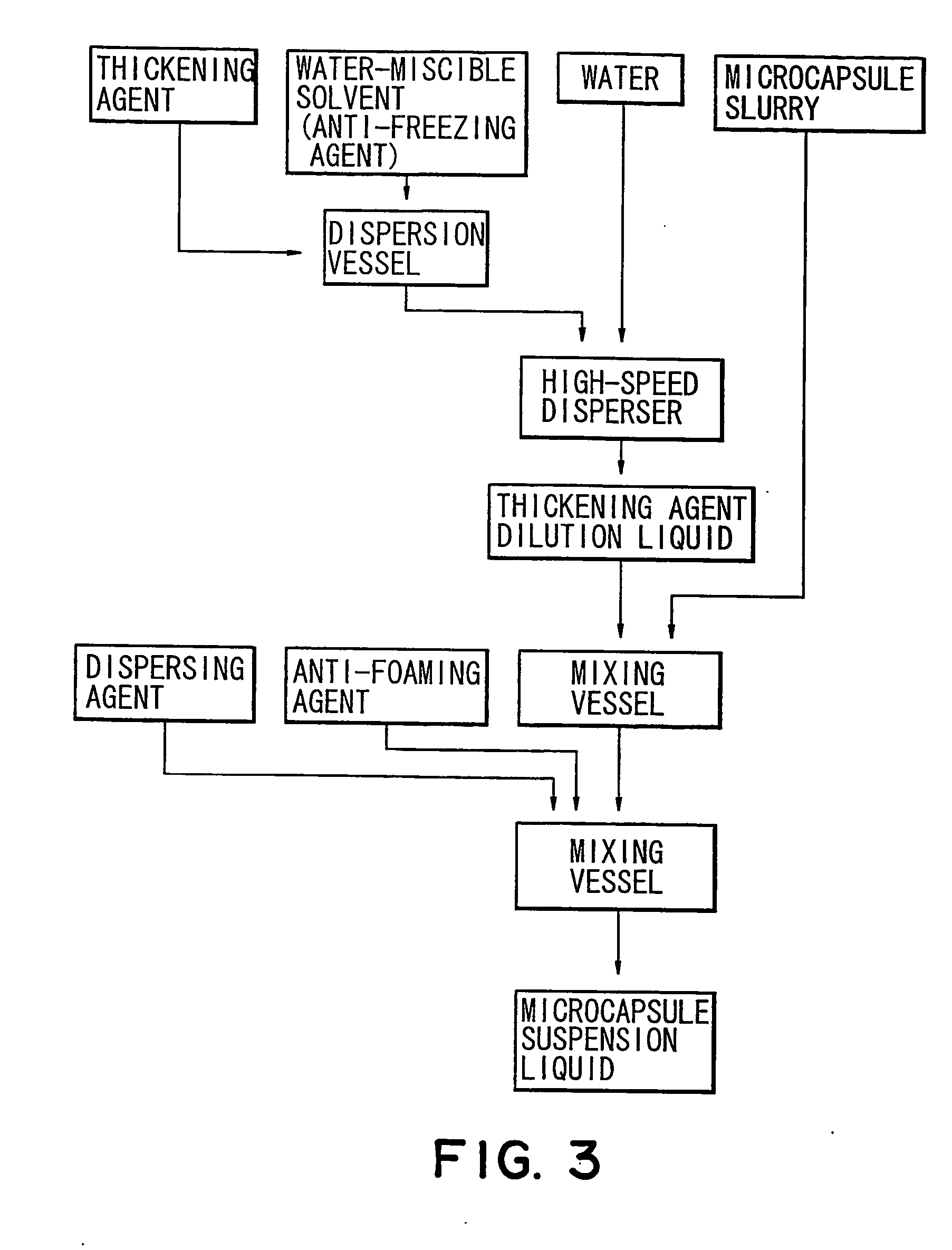

Microcapsule suspension liquid and process for production thereof

InactiveUS20050208144A1Improve suspension stabilityGood conditionBiocideLiquid surface applicatorsSlurryPolysaccharide

An aqueous microcapsule suspension liquid exhibiting an excellent (long-term) storage stability and allowing easy re-dispersion and dilution with water even after such a storage, is produced by adding a microorganism-fermented polysaccharide of succinoglycan type as a thickening agent into a microcapsule slurry, or by adding such a microorganism- fermented polysaccharide as a thickening agent to a microcapsule slurry after uniform dilution with water.

Owner:KUREHA KAGAKU KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com