Silky fine matt ceramic tile and production method thereof

A technology for ceramic tiles and ceramic brick blanks, which is applied in ceramic molding machines, ceramic material production, clay products, etc., can solve the problems of complex manufacturing methods, unfavorable pattern decoration richness, yellowing of glaze, etc., and achieves low surface tension. , the effect of broadening the firing range and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with embodiment:

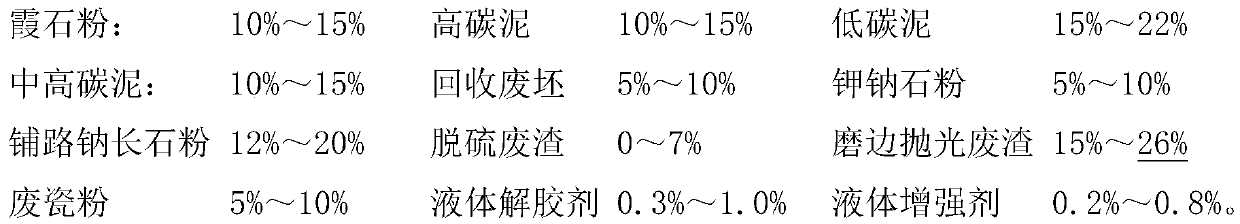

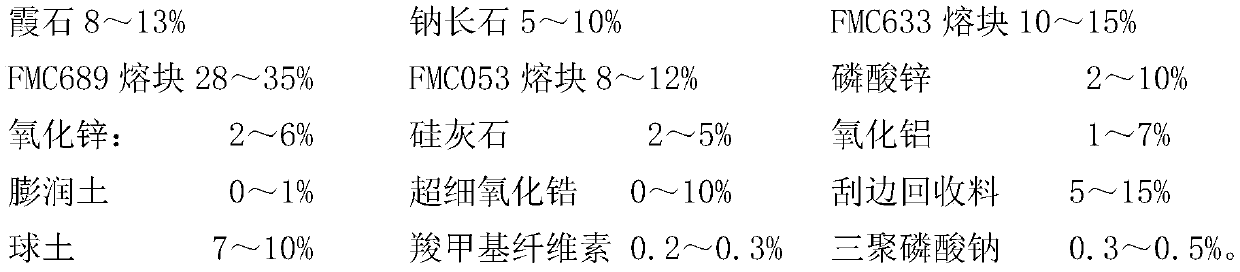

[0052] The silk fine and matte ceramic brick blank consists of the following components:

[0053]

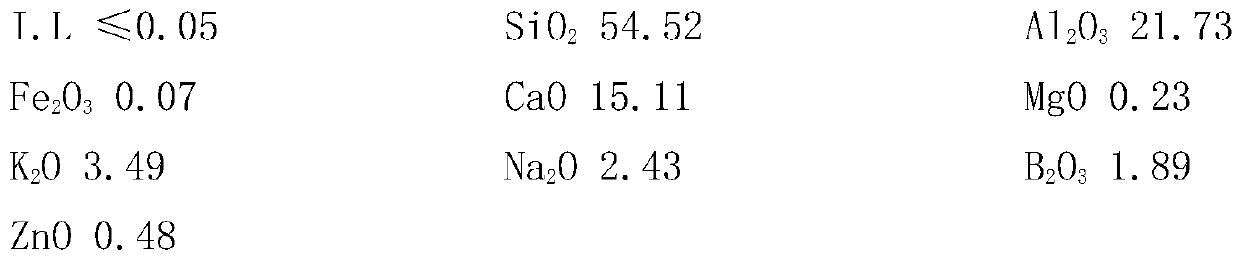

[0054] In this embodiment, the edging and polishing waste residue is selected from one or more of the following: SiO 2 、Al 2 o 3 , CaO, K 2 O, Na 2 O, MgO, MgCl 2 , SiC; the moisture content of the edging and polishing waste residue is 32-36%.

[0055] The edging and polishing waste mainly comes from the solid waste produced by flocculation, sedimentation and pressure filtration after a series of processes such as grinding, polishing, edging, and chamfering of ceramic tiles in the later stage of cold processing. These solid wastes include ceramic tiles. Fines that are polished or ground off—blanks, glazes, fine chips that have been ground off by grinding heads, etc.; the recycled waste blanks are mud blanks that have chipped corners or are broken during the manufactu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com