Patents

Literature

147results about How to "Wide firing range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

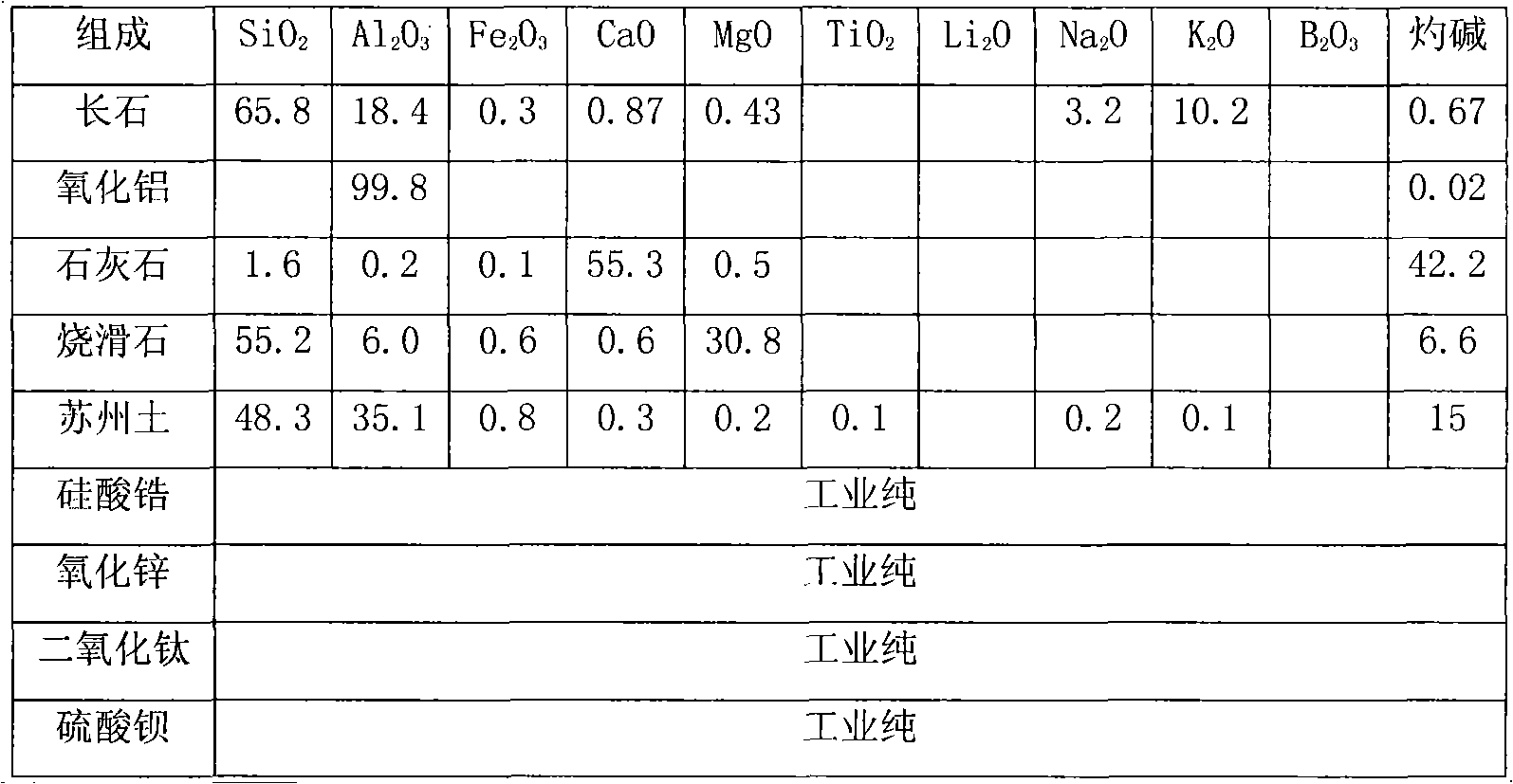

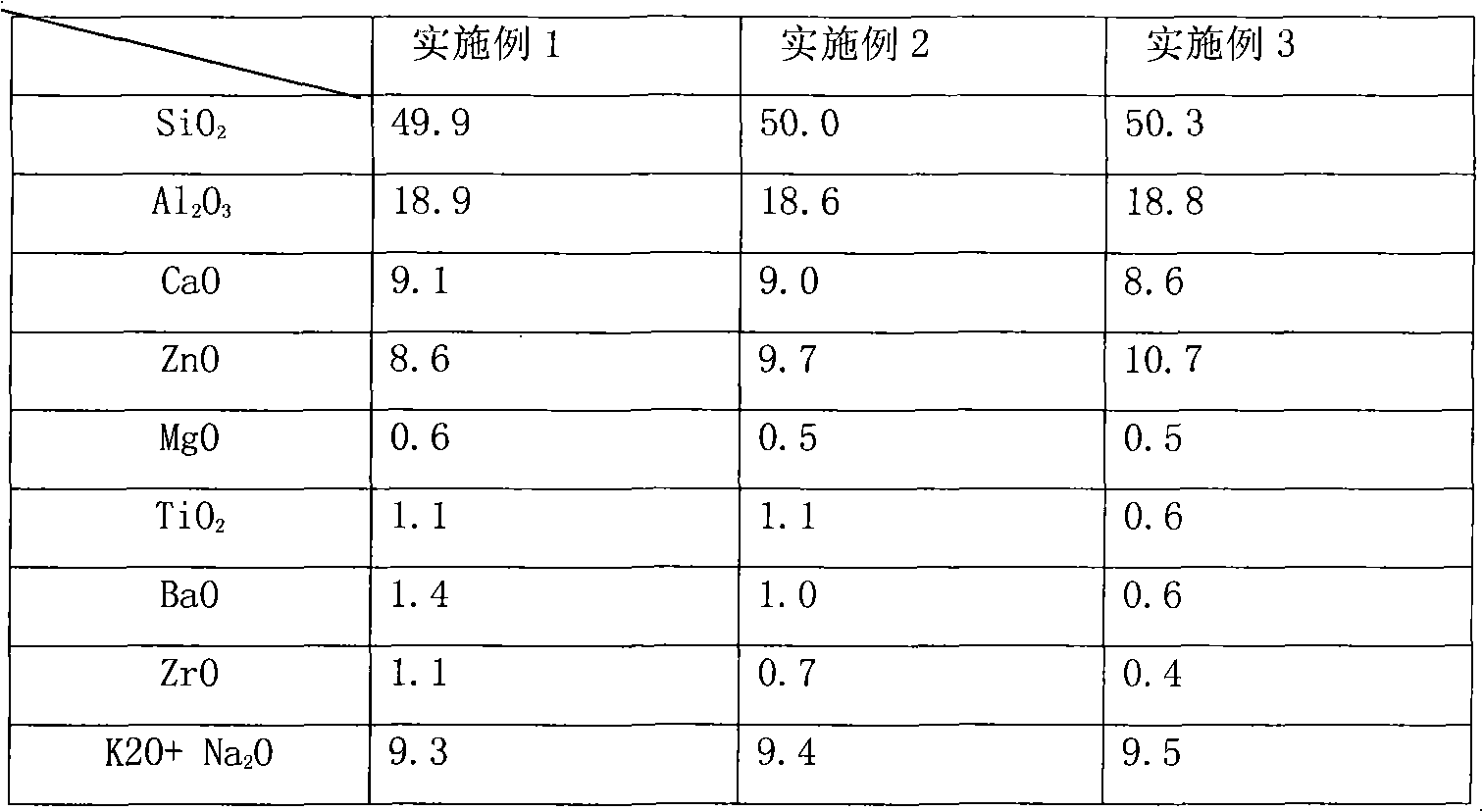

Raw material matting glaze

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

High and low-temperature resistant porcelain glaze for enamel

InactiveCN103274764AImprove smoothnessGood high and low temperature resistanceTemperature resistanceLead sulfate

The invention relates to porcelain glaze and in particular relates to high and low-temperature resistant porcelain glaze for enamel. According to the technical scheme, the highnd low-temperature resistant porcelain glaze for enamel is prepared from the following raw materials in parts by weight: 22-38 parts of sodium silicate with the modulus of 2-3.8, 11-19 parts of aluminum oxide, 10-20 parts of manganese dioxide, 6-9 parts of palladium oxide, 6-9 parts of high-boron calcium borate, 23-29 parts of lead sulfate, 2-4 parts of talc, 7-13 parts of calcium carbonate, 8-12 parts of barium sulfate, 12-19 parts of zinc sulfate and 2-9 parts of titanium oxide. The high and low-temperature resistant porcelain glaze has excellent ultralow-temperature resistance and high-temperature resistance.

Owner:XIANGFENG ZHEJIANG METAL PROD

Enamel glaze and preparation process thereof

The invention discloses an enamel glaze which belongs to the technical field of ceramic materials, and the enamel glaze comprises a colored glaze basic glaze, an enamel glaze basic glaze and coloring pigments. The invention further discloses a preparation process of the enamel glaze and an application of the enamel glaze. The preparation process can improve the firing temperature of the enamel colored glaze, expand the firing range of the glaze, improve the viscosity of the enamel colored glaze and ensure that coloring metal oxides can not be diffused or the color can not be dimmed due to the flowing of the glaze by optimizing the formula of the enamel colored glaze, adopting an appropriate amount of zinc oxide for replacing heavy metal flux materials, such as lead oxide and the like, integrating the applicable color development performances of a variety of coloring materials and introducing a rare earth compound of yttrium oxide. The preparation process can further ensure that the coloring metal oxides in the enamel glaze can not be oxidized by oxygen or water vapor in the air through the way of underglaze color, thereby further ensuring that a product can not change the color or fade forever, closing heavy metals contained in the coloring oxides for avoiding solventing-out and solving the problem of heavy metal pollution.

Owner:SHENZHEN YONG FENG YUAN IND

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

Environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and preparation method of electrode silver slurry

ActiveCN104934103AGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryResistor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

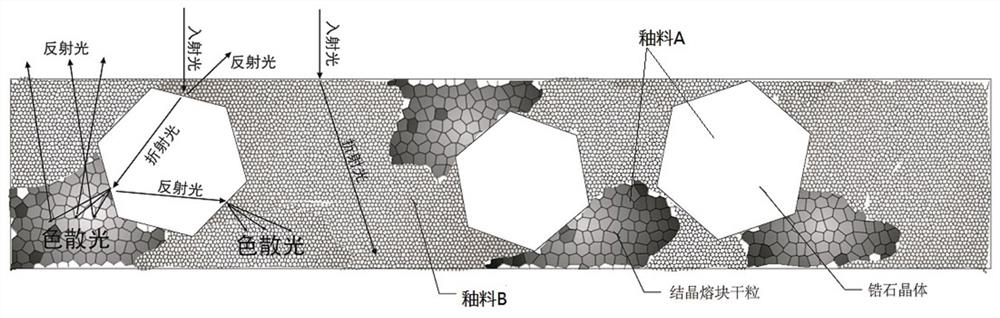

Preparation method of polished porcelain glazed tile with flashing effect

InactiveCN111923193AGood flash effectSimplify the polishing processCovering/liningsCeramic shaping apparatusGreen bodyKiln

The invention discloses a preparation method of a polished porcelain glazed tile with a flashing effect. The preparation method comprises the following steps of S1, mixing high-purity zircon sand andcrystallized frit dry particles to obtain glaze A; S2, taking marble polished glaze or transparent dry granular glaze as glaze B, and mixing the glaze A and the glaze B to obtain mixed glaze; S3, preparing a porcelain tile green body, and drying the porcelain tile green body; S4, applying a cover glaze to the porcelain tile green body dried in the step S3, performing ink-jet printing, and then sequentially applying a protective glaze and the mixed glaze; S5, drying the porcelain tile green body coated with the protective glaze and the mixed glaze in S4 in a drying kiln at 150-200 DEG C, and firing the porcelain tile green body by using a conventional porcelain tile firing method to obtain a semi-finished porcelain tile; and S6, polishing the semi-finished porcelain tile prepared in the S5.The preparation method adopts multiple reflection, dispersion and refraction methods of crystals in the glaze to realize the flashing effect, and meets the market demand.

Owner:佛山市蓝瓷创陶科技有限公司

Crystalline glaze of iron, zinc and augite and its material compounding process

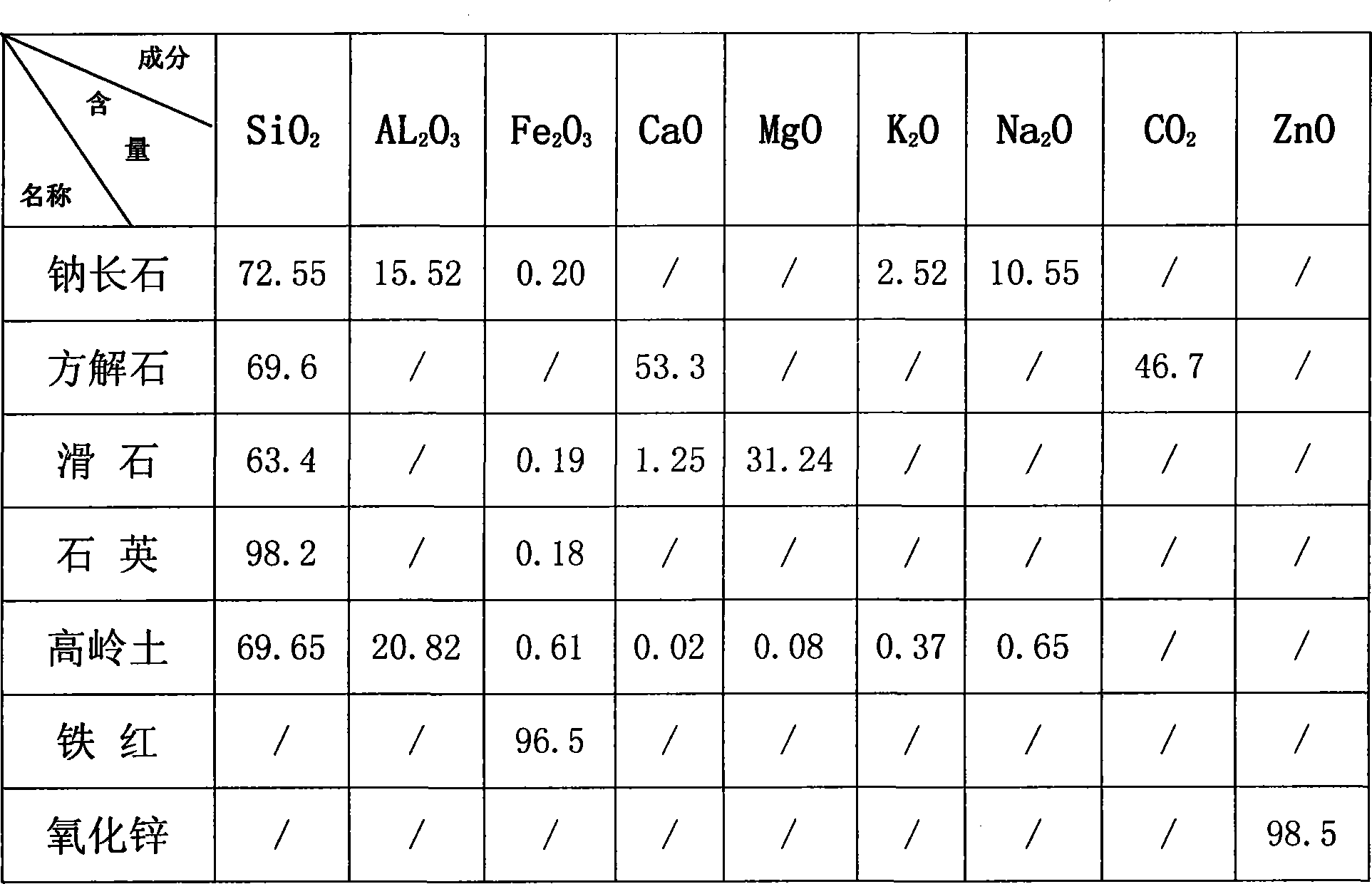

The iron and zinc augite crystalline glaze is prepared through introducing great amount of ferric oxide and zinc oxide into augite crystalline glaze and through a conventional color glaze sintering process. Chemically, the iron and zinc augite crystalline glaze consists of SiO2 50-60 wt%, AL2O3 5-8 wt%, K2O 0-1 wt%, Na2O 2.5-3.5 wt%, CaO 6-7 wt%, MgO 5 -6 wt%, Fe2O3 5-15 wt% and ZnO 3-10 wt%. The iron and zinc augite crystalline glaze is prepared with the materials including albite 20-35 weight portions, calcite 10-18 weight portions, talcum 15-25 weight portions, iron red 5-15 weight portions, zinc oxide 3-10 weight portions, kaolin 3-5 weight portions and quartz 20- 30 weight portions.

Owner:HUNAN HUALIAN CHINA IND

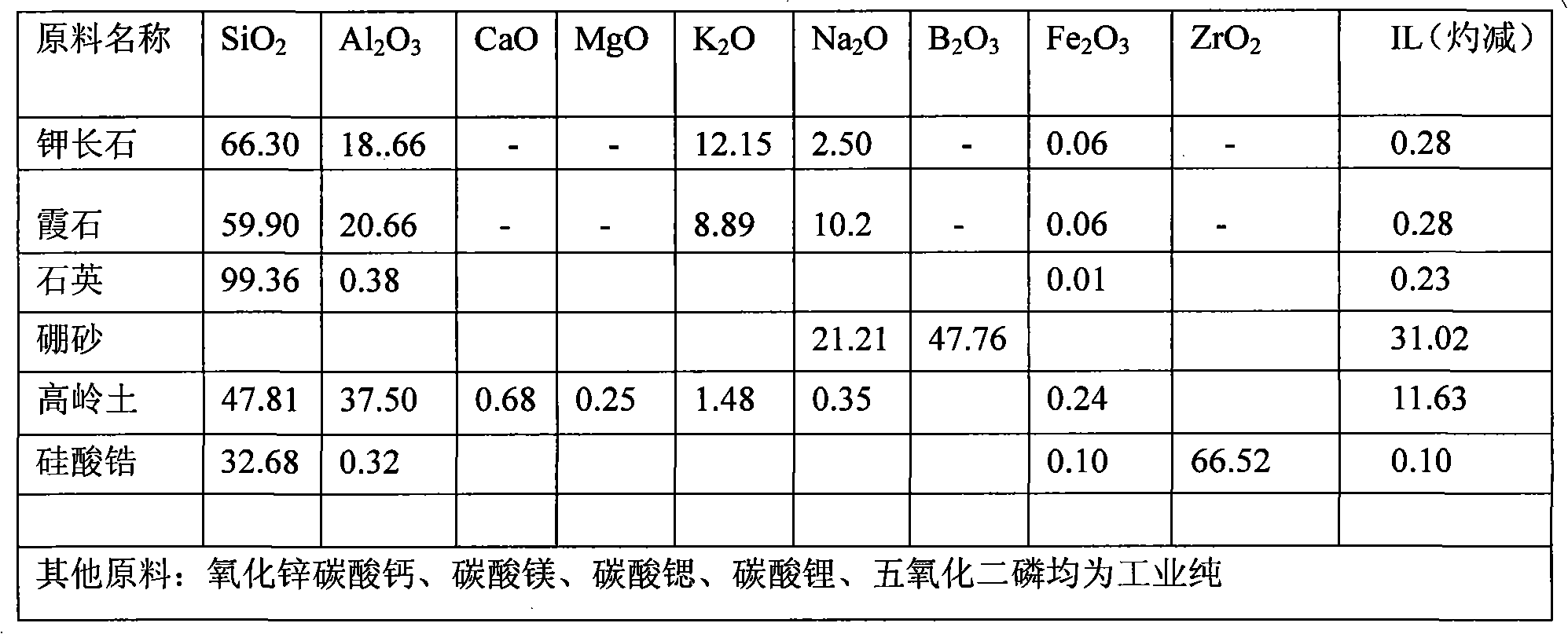

Lead-free and cadmium-free bone china glaze and preparation process thereof

The invention discloses a lead-free and cadmium -free bone china glaze and a preparation process thereof. The lead-free and cadmium-free bone china glaze comprises the following compositions in percentage by weight: 50.0 to 62.0 percent of SiO2, 6.0 to 10.0 percent of Al2O3, 6.0 to 10.0 percent of CaO, 0.5 to 4 percent of MgO, 0.0 to 2.0 percent of BaO, 0.5 to 3.0 percent of SrO, 6.0 to 10.0 percent of ZnO, 2.0 to 6.5 percent of K2O, 1.0 to 5.0 percent of Na2O, 0.2 to 3.0 percent of Li2O, 1.0 to 3.0 percent of B2O3, 1.0 to 3.5 percent of ZrO2, 0.2 to 1.0 percent of La2O3, and 0.1 to 2.0 percent of P2O5. By optimizing the glaze formula, the glaze has no lead and cadmium, so the glaze is non-toxic and environment-friendly. The lead-free and cadmium-free bone china glaze and the preparation process thereof have the advantages of reducing the consumption of zinc oxide, overcoming the defects of soft glaze, easy scratching and color disadvantage caused by high zinc oxide content, and improving the hardness of the glaze by optimizing the chemical compositions of the glaze.

Owner:SHENZHEN YONG FENG YUAN IND

Method for manufacturing ceramic of multi-layer structure

ActiveCN106116688ATight outer surfaceHigh light chromaCeramic materials productionCeramicwareWork in processCeramic tiles

The invention provides a method for manufacturing ceramic of a multi-layer structure. The method includes the following steps that a common ceramic brick material is used for manufacturing surface blank, a foamed ceramic bottom blank material is used for preparing foamed ceramic bottom blank, the surface blank and the foamed ceramic bottom blank are pressed into multiple layers in a spaced mode, the uppermost layer of a tile serves as the surface blank, and after the surface blank is dried, a semi-finished product is obtained; the semi-finished product is colored and subjected to one-time cofiring to form a ceramic tile of the multi-layer structure where the foamed ceramic bottom blank layer and the non-porous surface blank layer coexist. The ceramic tile of the multi-layer structure has the advantages that the ceramic tile is light and convenient to attach, the surface blank is compact, and photochromism is high.

Owner:XINLAILI CERAMIC DEV CO LTD

Leadless enamel blocks

A non-lead fritted glaze for ceramics is prepared from quartz, feldspar, borax, boric acid, barium carbonate, stalactite, zinc oxide, strontium carbonate, lithium carbonate, prepared talc, and aluminium hydroxide through proportionally mixing, fusing at 1300-1350 deg.C, quenching in water, and grinding. Its advantages are wide range of calcine temp, low calcine temp. high surface finish quality, no lead, and high antiwear performance.

Owner:SHANDONG JINLING MINING CO LTD

Medium-temperature hard fine porcelain with high whiteness, high transparency and high strength and preparation method of medium-temperature hard fine porcelain

InactiveCN105693202AGood visible light transmittanceSmall expansion coefficientClaywaresSlurryFineness

The invention relates to medium-temperature hard fine porcelain with high whiteness, high transparency and high strength and a preparation method of the medium-temperature hard fine porcelain. The medium-temperature hard fine porcelain with high whiteness, high transparency and high strength is prepared from the following chemical components in parts by weight: 66 to72 parts of SiO2, 23 to 28 parts of Al2O3, 0.5 to 4 parts of CaO, 0.3 to 3 parts of MgO, 1 to 5 parts of K2O, 0.5 to 2.5 parts of Na2O and 0.2 to 1 part of B2O3. The preparation method of the medium-temperature hard fine porcelain with high whiteness, high transparency and high strength comprises the following steps of firstly, burdening; secondly, performing ball milling; thirdly, detecting the fineness of slurry; fourthly, sieving and removing iron; fifthly, ageing; sixthly, performing slip casting; seventhly, primary drying; eighthly, fettling; ninthly, glazing; tenthly, performing secondary drying; eleventhly, firing.

Owner:南京豪祺新材料有限公司

Antique matte glaze with delicate texture and using method thereof

The invention discloses an antique matte glaze with delicate texture. The antique matte glaze with the delicate texture consists of a frit and raw materials, wherein the mass ratio of the frit to the raw materials is 1-1.5: 1. The invention also discloses a preparation method of the antique matte glaze with the delicate texture. The preparation method comprises the following steps of: applying a layer of base glaze on the surface of a brick blank, and applying a layer of the matte glaze; and sintering the brick blank at the temperature of 1150-1250 degrees centigrade to obtain a final product. The matte glaze provided by the invention consists of the frit with good high temperature fluidity and part of the raw materials, so that the glaze surface can flow levelly at high temperature quickly; through matching of different materials, the matte, smooth and delicate effects of the glaze surface are ensured; through the composition design of half raw material and half frit, the compositionis more stable and is applicable to different technical conditions and furnace temperatures; and the sintering temperature and the matte degree of the matte glaze are regulated by regulating the adding amount of aluminum oxide.

Owner:广东道氏陶瓷材料有限公司

Method for preparing colored foam glass ceramic material from lithium tailings

InactiveCN108191230ASimple preparation processWide firing rangeGlass shaping apparatusPore distributionSlag

The invention provides a method for preparing a colored foam glass ceramic material from lithium tailings. According to the method, the material is prepared from a main material, an auxiliary material, fluxing agents, pore forming agents and colorants by blending and one-time high-temperature sintering, wherein the lithium tailings serve as the main material; cullet serves as the auxiliary material; the fluxing agents comprise sodium fluoride, potassium carbonate, sodium silicate, mirabilite and borax; the pore forming agents comprise calcium carbonate and silicon carbide; the colorants comprise copper oxide, iron oxide, cobalt oxide, chromium oxide, manganese oxide and zinc oxide. The problems of industrial slag accumulation and secondary pollution can be solved effectively with the method, and recycling of resources is realized; the preparation process is simple, the cost is low, and prepared foam glass ceramic is small in bulk density, uniform in pore distribution, adjustable in color, high in compressive strength and high in added value and has good industrial prospect.

Owner:WUHAN UNIV OF TECH

Lithium-magnesium ceramic fired at low temperature and manufacturing method thereof

The invention provides lithium-magnesium ceramic fired at low temperature and a manufacturing method thereof. A lithium-magnesium ceramic blank comprises 15-25wt% of lithium material, 60-70wt% of magnesium material and 10-20wt% of clay and is required to comprise the following chemical components in percentage by weight: 55-65% of SiO2, 1-5% of Al2O3, 15-25% of MgO, 1-4% of CaO, less than 1% of Na2O, less than 1.5% of K2O, 4-6% of Li2O4 and not more than 0.3% of Fe2O3, wherein ignition loss is 5-7%. Compared with the prior art, in the invention, the lithium material is used as a main fluxing agent capable of greatly reducing firing temperature, thereby reducing fuel cost and improving market competitiveness of products; the magnesium material is a main skeleton-forming constituent capable of preventing firing deformation; and the clay is used as main bonding constituent so as to ensure that a plasticity index meets a forming requirement.

Owner:QUANZHOU KUNDA GIFT

Double-layered crystal glaze and preparation method thereof

The invention discloses double-layered crystal glaze and a preparation method thereof. The double-layered crystal glaze comprises bottom glaze and surface glaze, wherein the bottom glaze is prepared from the following components in parts by weight: 30-35 parts of feldspar, 21-23 parts of quartz, 7-12 parts of calcite, 4-5 parts of Guizhou soil, 3-5 parts of zinc oxide, 7.5-10 parts of zirconium silicate and 7-11 parts of strontium carbonate; the surface glaze is prepared from the following components in parts by weight: 22-25 parts of feldspar, 24-25 parts of borax, 5-10 parts of quartz, 12-15 parts of calcite, 4-5 parts of Guizhou soil, 23-25 parts of zinc oxide, 9-10 parts of zirconium silicate, 5-8 parts of dolomite and 0.5 part of chromophore. According to the invention, the sintering time of the crystal glaze can be shortened, so that the cost is lowered. The double-layered crystal glaze can be produced on a large scale, and the production quantity of the double-layered crystal glaze is improved.

Owner:LILING TAORUN INDAL DEV

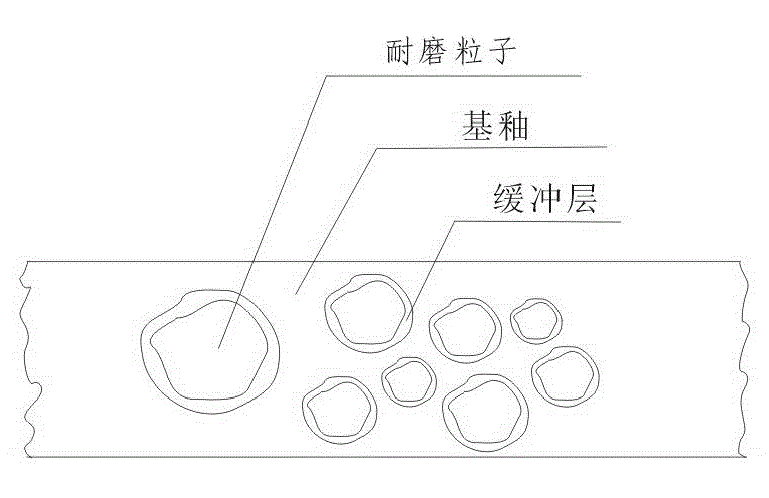

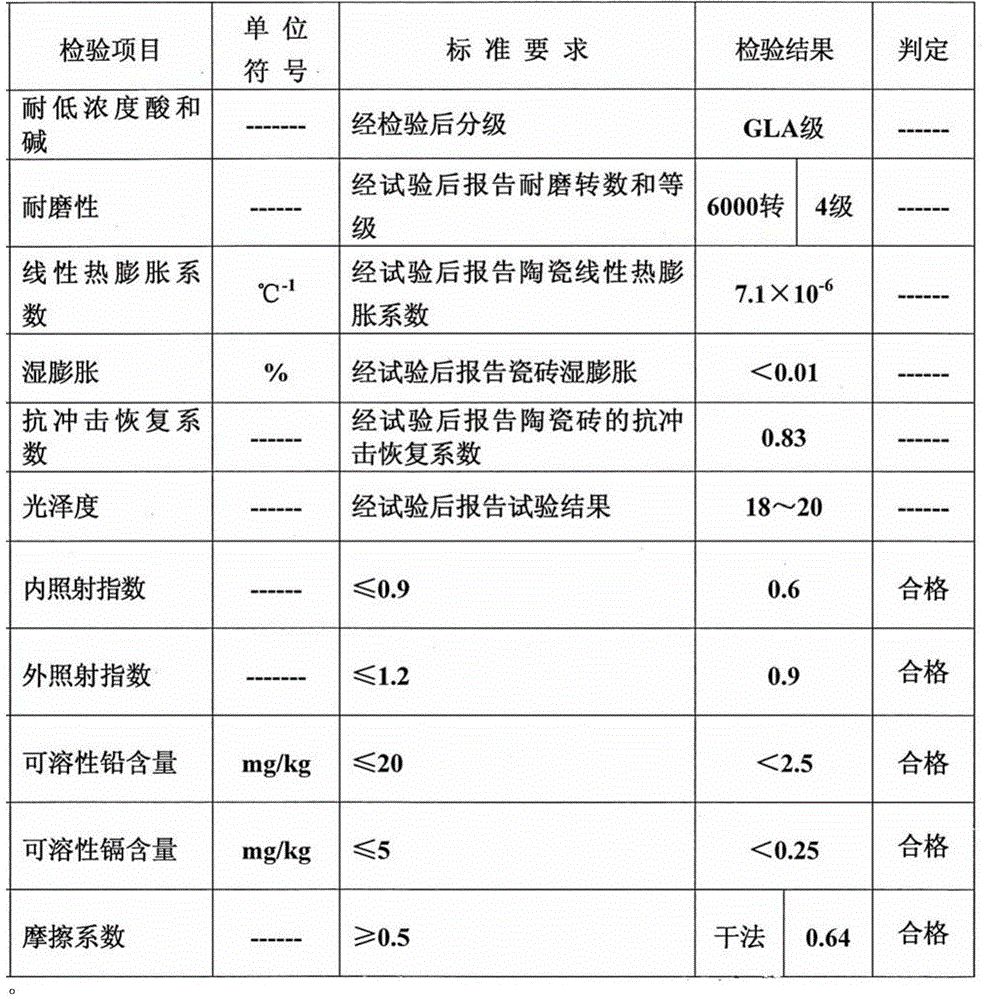

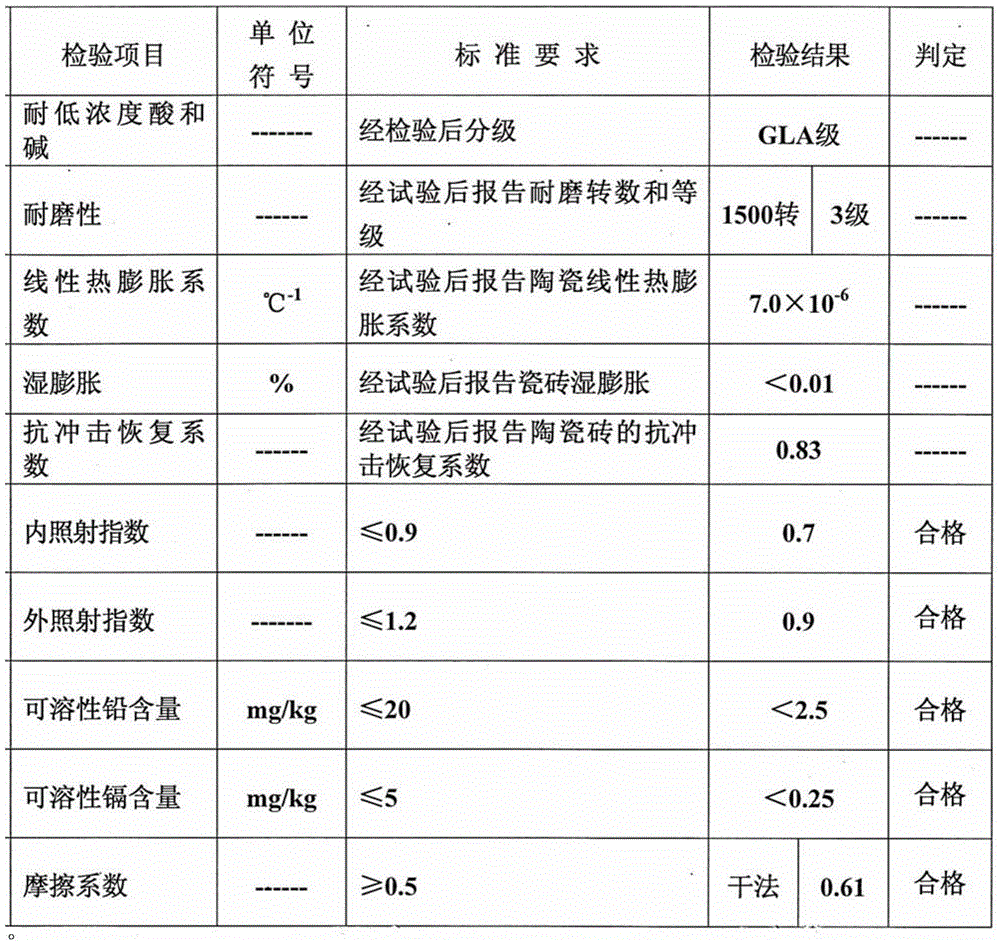

High wear resistance in-glaze decoration ceramic brick and preparation method thereof

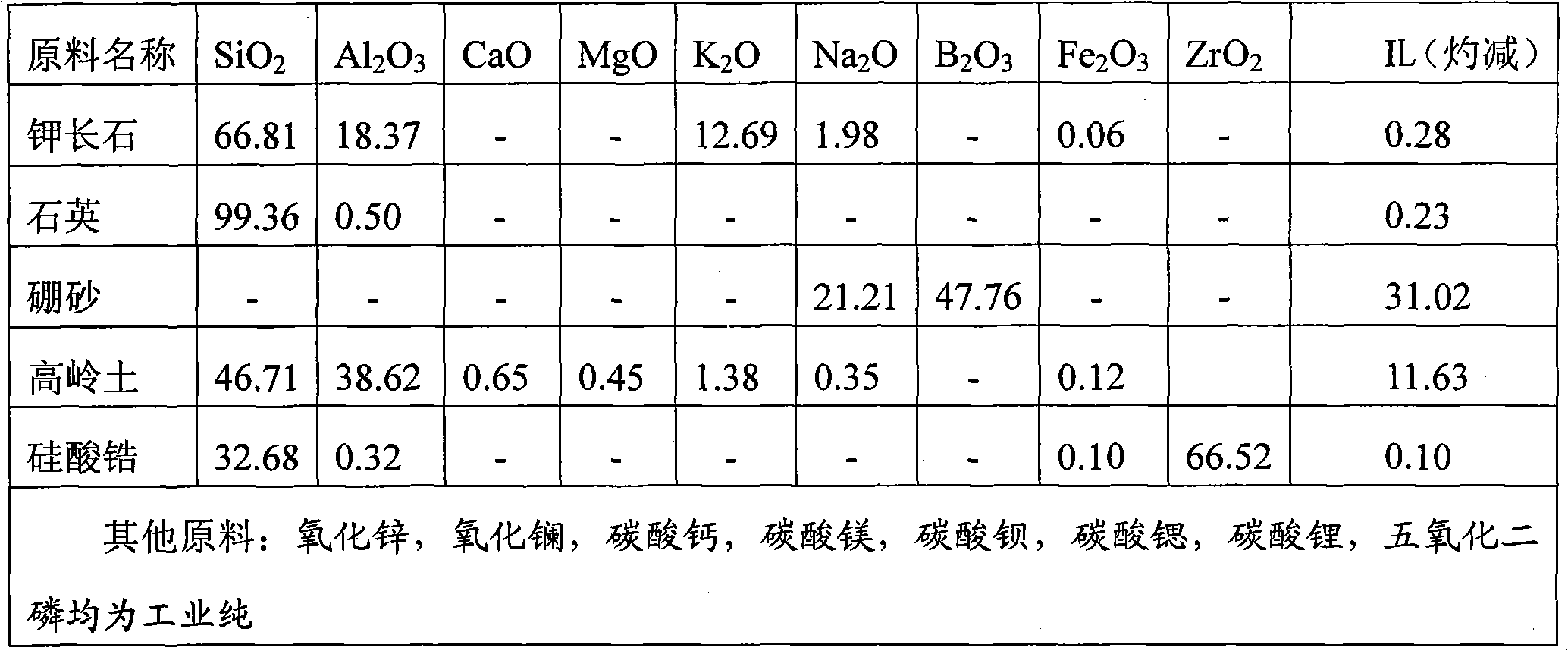

The present invention relates to a high wear resistance in-glaze decoration ceramic brick and a preparation method thereof. The high wear resistance in-glaze decoration ceramic brick comprises a billet body with printed patterns and a transparent glaze layer obtained by firing on the billet body with the printed patterns, wherein the transparent glaze layer comprises a transparent base glaze and high wear resistance transparent frit particles wrapped by the transparent base glaze, the fineness of the high wear resistance transparent frit particles is 130-180 mesh, and the high wear resistance transparent frit particles comprise 52-58 wt% SiO2, 25-30 wt% of Al2O3, 8-15 wt% of CaO, 0.2-0.5 wt% of MgO, 1-3 wt% of K2O, 0.5-2 wt% of Na2O, and 1-5 wt% of ZnO.

Owner:MONALISA GRP CO LTD

Metallic glaze and its preparation method

The invention discloses a metallic glaze. The metallic glaze comprises the following components: 5-25 parts by weight of feldspar, 10-30 parts by weight of albite, 25-40 parts by weight of quartz, 1-15 parts by weight of calcite, 5-20 parts by weight of kaolin, 15-40 parts by weight of frit powder, 0.1-5 parts by weight of titanium oxide, 0.5-5 parts by weight of vanadium pentoxide, 5-20 parts by weight of manganese dioxide, 0.1-5 parts by weight of copper oxide, 0.1-3 parts by weight of cobalt oxide and 0.1-5 parts by weight of nickel oxide, wherein the frit powder comprises potassium chloride, sodium chloride, silica, alumina, magnesia, boric acid and spodumene. The invention also discloses a preparation method for the metallic glaze. With the formula and preparation method for the metallic glaze, the prepared metallic glaze has excellent metallic luster and high glaze hardness and totally appears to be golden yellow.

Owner:湖南铜官海旭陶瓷有限公司

Mutton fat matt white glaze for ceramic decoration and preparation method of white glaze

The invention discloses mutton fat matt white glaze for a ceramic decoration and a preparation method of the white glaze. The white glaze is prepared from, by mass percentage, 15-25% of feldspar powder, 10-17% of calcium carbonate, 5-7% of dolomite, 6-12% of talc, 3-8% of barium carbonate, 15-20% of zirconium silicate, 10-15% of zirconium white frit, 0-6% of zinc oxide, 5-7% of aluminum oxide and 0-12% of kaolin. The components are weighed according to the formula, fully mixed and added into a grinding tank, water with the weight 45-50% that of dry powder is added for grinding for 10-15 h, then glaze slurry obtained after ball milling is subjected to iron removal and screening, and the concentration is adjusted till the true specific gravity is 50-54 degrees. A ceramic product is coated with the white glaze in a spraying mode or a soaking mode or other decoration modes. After drying, the ceramic product enters a kiln to be oxidized and fired for 8-11 h at the temperature of 1200-1235 DEG C, and the ceramic product is taken out of the kiln after being naturally cooled. The prepared mutton fat matt white glaze has the advantages of being high in processing property, high in operability and not prone to cracking.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

Preparation method for three-dimensional cover glaze

The invention provides a preparation method for three-dimensional cover glaze. The preparation method comprises the following steps: I, selecting at least one monochrome from an image to prepare a silk screen plate; II, applying cover glaze on a semi-finished blank in a silk screen printing pattern, wherein the cover glaze is powder; III, baking in a kiln to obtain ceramic with the three-dimensional cover glaze. In the preparation method for the three-dimensional cover glaze, an image pre-treating scheme is adopted, and the advantage of bright color of silk screen printing is utilized, so that a ceramic product with a bright image is obtained.

Owner:XINLAILI CERAMIC DEV CO LTD

A preparing method of cordierite self-glazed ceramic

The invention relates to a preparing method of cordierite self-glazed ceramic. A raw material formula of a green body comprises following components by weight: 20-30 wt% of burnt talc, 10-15 wt% of raw talc, 15-30 wt% of kaolin, 0-5 wt% of lithium feldspar, 5-12 wt% of feldspar, 2-5 wt% of bentonite, 15-18 wt% of aluminum oxide, and 0-5 wt% of quartz. A ceramic product in which a glaze layer is naturally formed on the surface of the green body is prepared by preparing the materials, ball milling, forming and firing. By adding the lithium feldspar and the quartz based on a formula of cordierite ceramic, the firing temperature is reduced, and the firing range is expanded. In addition, by a manner of prolonging the temperature maintaining time, more glass phases are formed on the surface of the green body, a glazing step in production is omitted, the production efficiency is increased, and the production cost is saved. The prepared ceramic product is good in transmissivity, high in whiteness and high in mechanical strength, so that the ceramic has a wide market.

Owner:江西帮企陶瓷股份有限公司

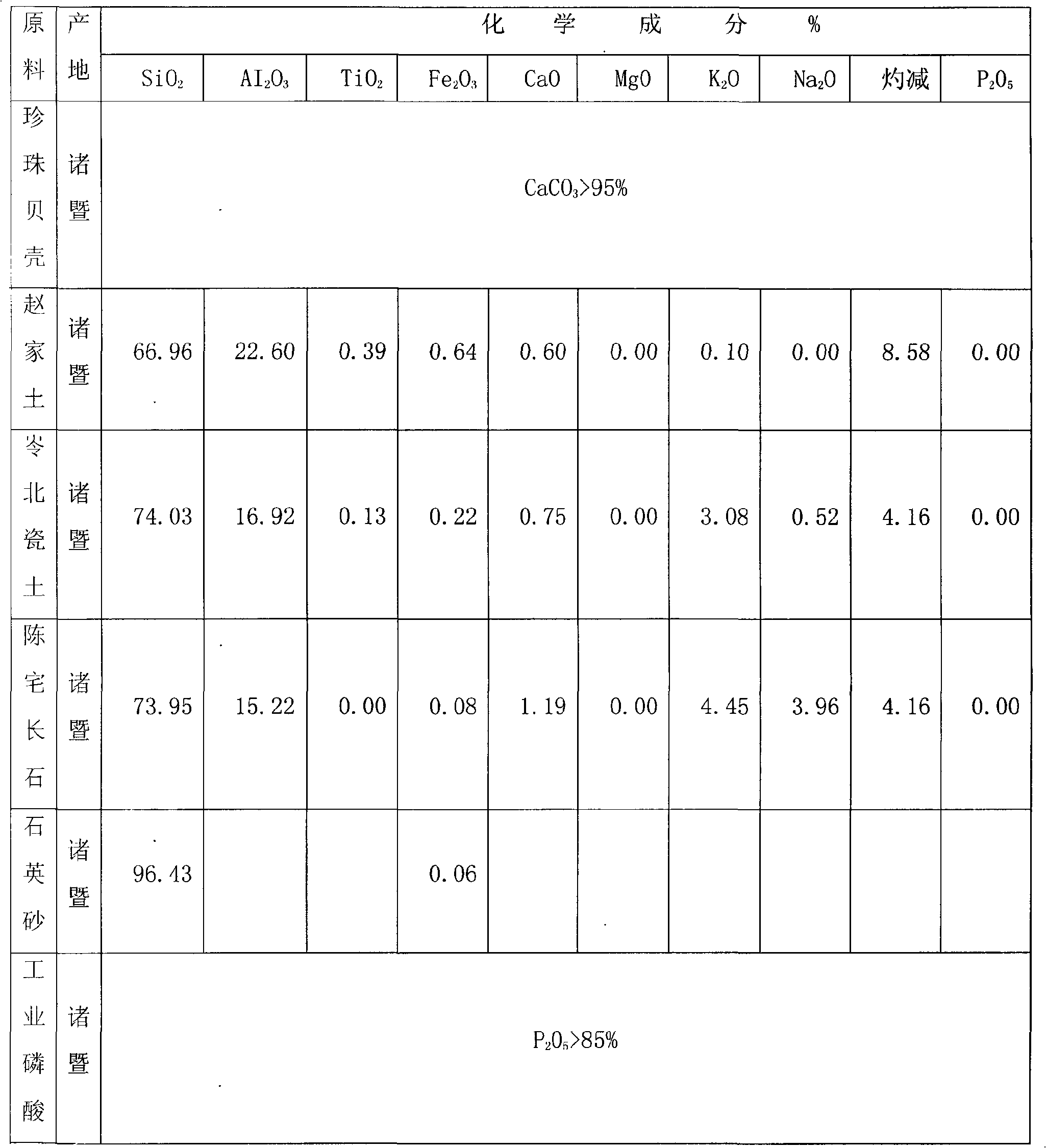

Pearl shell treating process as well as ceramic and glaze prepared by materials prepared by same

The invention discloses a treating process for preparing ceramic materials by pearl shells and wasted pearl bodies, and simultaneously further discloses a formula and a sintering technology for preparing daily-used ceramic and glaze by powder materials prepared by the treating process. The formula of shell porcelain body is as follows: 17-30 percent of mineral powder prepared by treatment, 10-20 percent of porcelain clay, 45-58 percent of kaoline, 0-5 percent of quartz, and 5-15 percent of feldspar; the formula of glaze of shell porcelain body is as follows: 1.36-4 percent of mineral powder prepared by treatment, 0,8-4 percent of porcelain clay, 3.6-11.6 percent of kaoline, 0-1 percent of quartz, 0.4-3 percent of feldspar, and 80-92 percent of high-boron high-zinc lead-free transparent frit; and the sintering technology of the shell porcelain is as follows: 1170-1220 DEG C of high-temperature plain temperature, and 1050-1100 DEG C of low-temperature glaze firing temperature. The invention has the advantages of energy conservation and consumption reduction, safety and environmental protection, and economy and practicalness.

Owner:ZHEJIANG DONGWEI CERAMICS

Glaze composition

The invention provides a glaze composition and belongs to the technical field of ceramic products. The glaze composition is prepared from the following raw materials in parts by weight: 7 to 10 parts of Longyan kaolin, 38 to 42 parts of potassium feldspar, 25 to 30 parts of quartz, 18 to 22 parts of wollastonite, 0.5 to 2 parts of bone ash and 1.02 to 2.1 parts of pigment. The glaze provided by the invention has high viscosity and low flowability in a firing process and the defects that the thickness of a glaze surface is not uniform and the color is not uniform, caused by glaze flowing and glaze stacking, are avoided; a firing method of the glaze provided by the invention has a high reduction temperature point and a relatively wide high-temperature firing temperature range; the yield of a product is easy to guarantee; furthermore, a ceramic product fired by the invention has high glaze surface glossiness, pure color, beautiful appearance and long implication.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Quick fired fine ceramics made in open flame roller hearth kiln and technical method

The present invention is a new ceramic material and new producing technology. The quick fired fie ceramic is produced with the material including kaolin 20-55 wt%, feldspar 10-20 wt%, and quartz 35-60 wt%, and through quick high temperature biscuit firing in an open flame roller hearth kiln and low temperature glaze firing. The low temperature glaze firing in reducing atmosphere can obtain bright and soft glaze with high transmittance, and product with high impact strength, high heat impact strength and high acid and alkali resistance; and the low temperature glaze firing in oxidizing atmosphere can obtain bright glaze without pinhole. The present invention has simple technological process, low cost, great output and low power consumption, and may be applied widely in ceramic industry.

Owner:张民

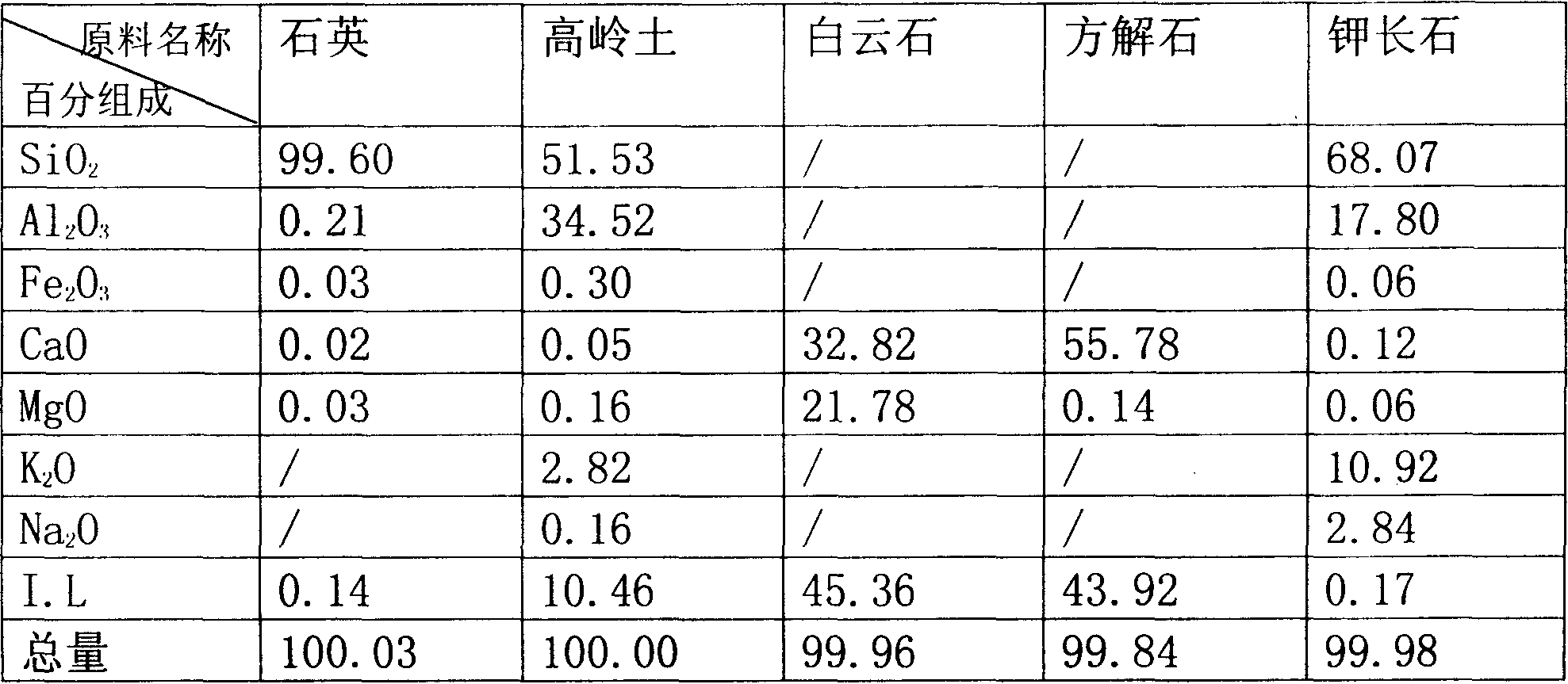

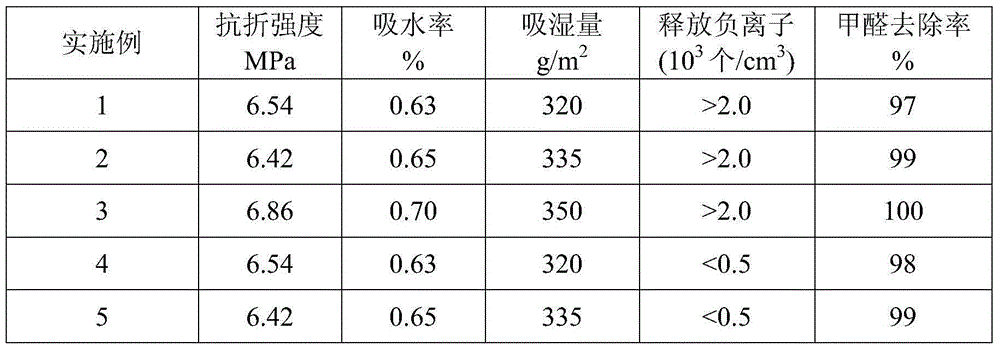

Diatomaceous earth breathing brick with high humidifying harm-reduction function and production method thereof

A diatomaceous earth breathing brick with a high humidifying harm-reduction function and a production method thereof are disclosed, through improvement of a formula, slurry with excellent performances can be prepared, a molding material is prepared by a spray granulation process, and the molding problem is overcome. The formula comprises, (wt%), 80%-90% of diatomaceous earth; 4%-14% of clay; 0.5%-1.5% of talc; 0.5%-1% of a ceramic body enhancer; 1%-2% of a ceramic sintering aid agent; 0.5%-1% of a superplasticizer; 0.5%-1.5% of nano titanium dioxide and 0.5%-1.5% of tourmaline powder. The production method is as follows: the raw materials are prepared into the slurry by adding of water, and by spray granulation, material distribution, molding and firing, the diatomaceous earth breathing brick with the high humidifying harm-reduction function is obtained. Compared with the prior art, the formula and the molding process are improved, the use amount of the diatomaceous earth is significantly increased, body cracking, deformation, stratification and other phenomena caused by inappropriate moisture content of raw materials, uneven material distribution and excessive local stress of a green body can be avoided, and the diatomaceous earth breathing brick has a higher humidifying harm-reduction function.

Owner:LIAONING SILICATE RES INST

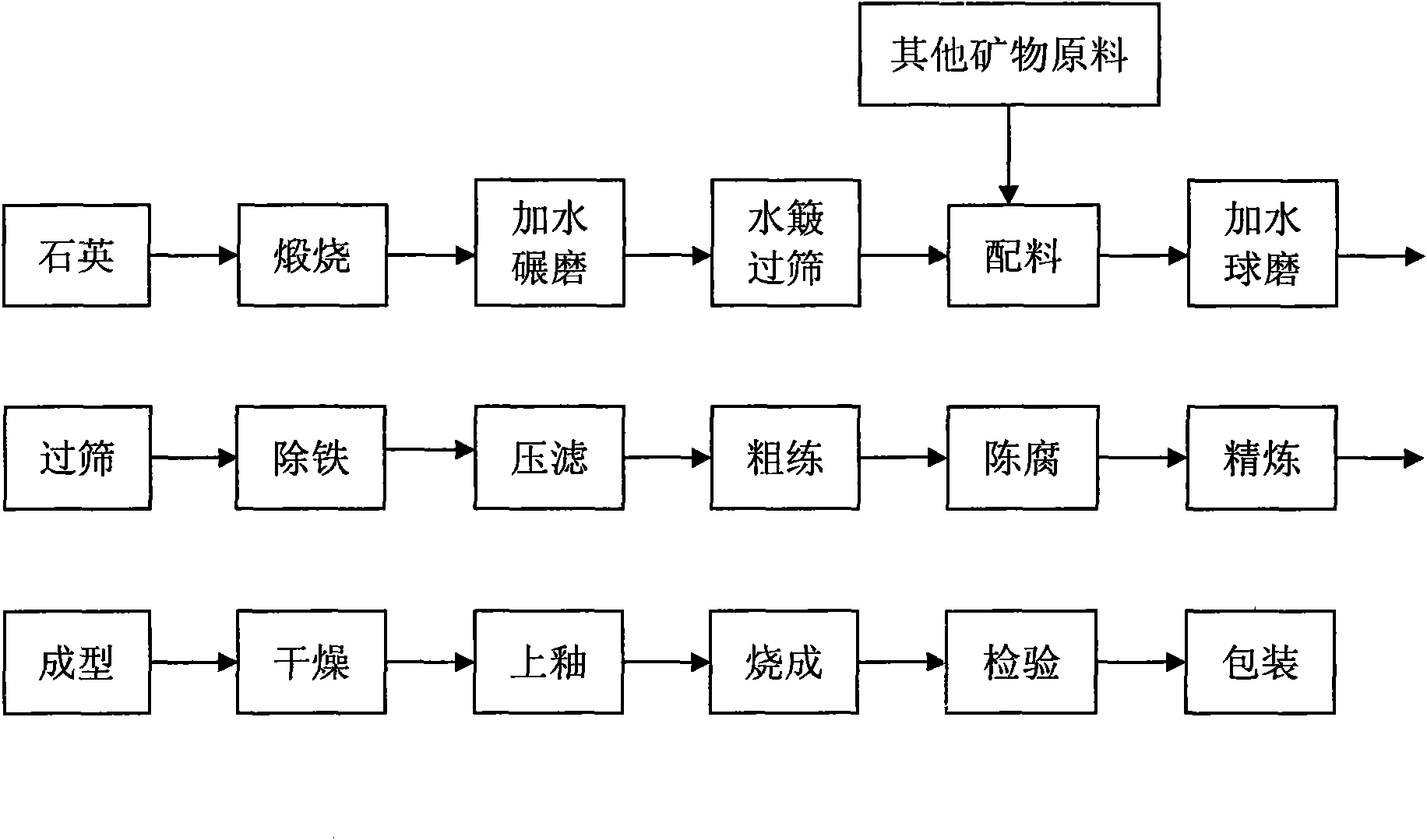

Bone jade porcelain and method for manufacturing same

The invention relates to a household porcelain and a method for manufacturing the same, in particular to a bone jade porcelain and a method for manufacturing same. The bone jade porcelain body comprises quartz, petalite, Australian alumina, Guizhou clay, Longyan kaolin braying and Huidong kaolin braying. The method for manufacturing the bone jade porcelain comprises the following steps of: calcining the quartz, grinding with water, sieving with levigation and preparing into quartz grain, dosing according to formula, ball milling, sieving, removing iron, dehydrating in a way of filter pressing, primary smelting, aging, refining, shaping, drying, glazing and finally baking with a kiln. The invention has the tactile sensation of a bone ash porcelain, lower manufacturing cost compared with the bone ash porcelain, higher thermal stability, wider baking ranging and convenient control.

Owner:CHAOZHOU ZHONGXIA PORCELAIN FACTORY

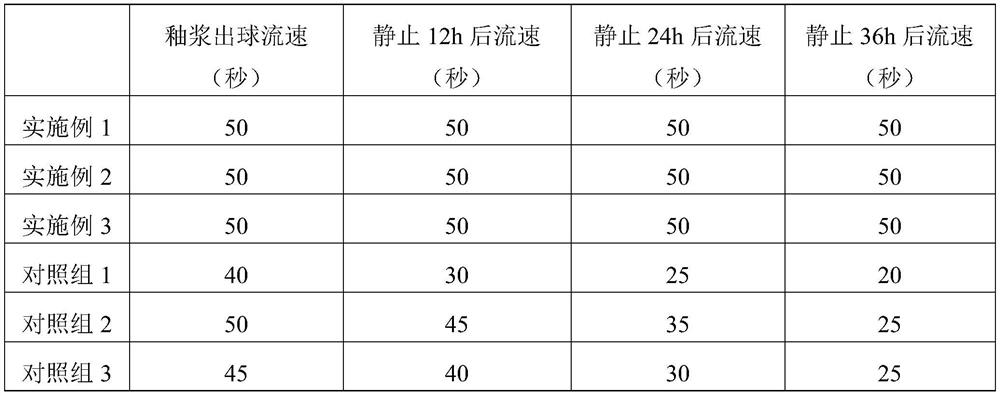

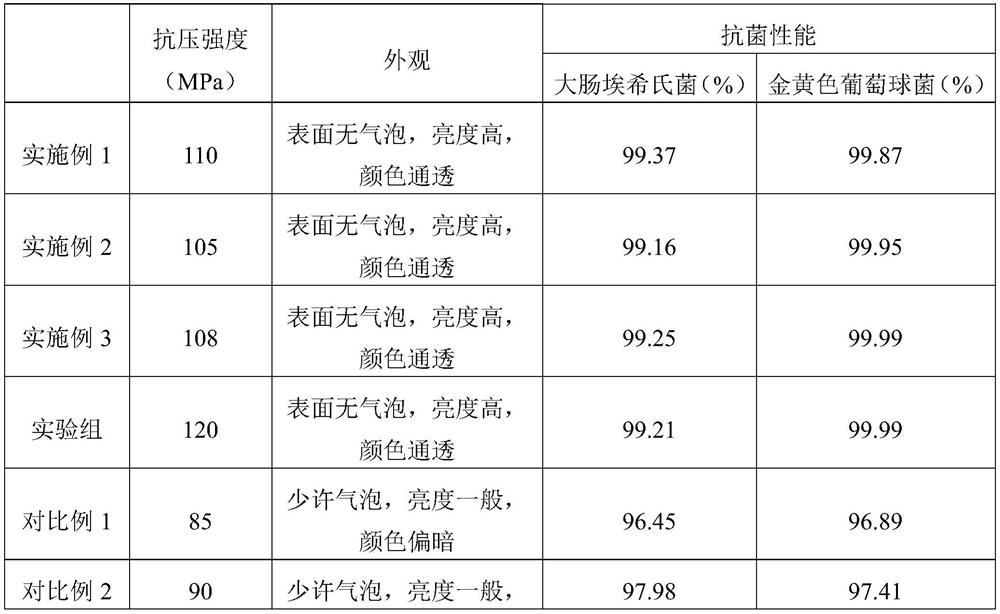

Antibacterial glaze, antibacterial brick and preparation method of antibacterial brick

PendingCN112239372ALow melting pointIncrease high temperature viscosityClaywaresKaolin clayAnti bacteria

The invention discloses an antibacterial glaze, an antibacterial brick and a preparation method of the antibacterial brick. The antibacterial glaze comprises the following raw materials in parts by weight: 25-35 parts of albite, 10-15 parts of potassium feldspar, 5-7 parts of kaolin, 5-15 parts of quartz, 3-5 parts of aluminum oxide, 5-10 parts of talc, 5-7 parts of zinc oxide, 10-20 parts of dolomite, 5-15 parts of wollastonite, 7-12 parts of strontium carbonate, 3-5 parts of barium carbonate and 4-6 parts of nano antibacterial powder. The antibacterial glaze is prepared through crushing, uniform mixing and ball milling, and then the surface of a green body layer is coated with the antibacterial glaze, so the antibacterial brick disclosed by the invention is prepared. The antibacterial effect of the antibacterial glaze reaches 99%, the firing temperature range is wide during ceramic tile preparation, and a prepared ceramic tile glaze layer is high in mechanical strength, almost free of bubbles, good in layering sense and capable of being suitable for a low-water-absorption green body and a high-water-absorption green body at the same time.

Owner:FOSHAN TAOYING NEW MATERIAL CO LTD

Ceramic product with self-cleaning glaze and making method thereof

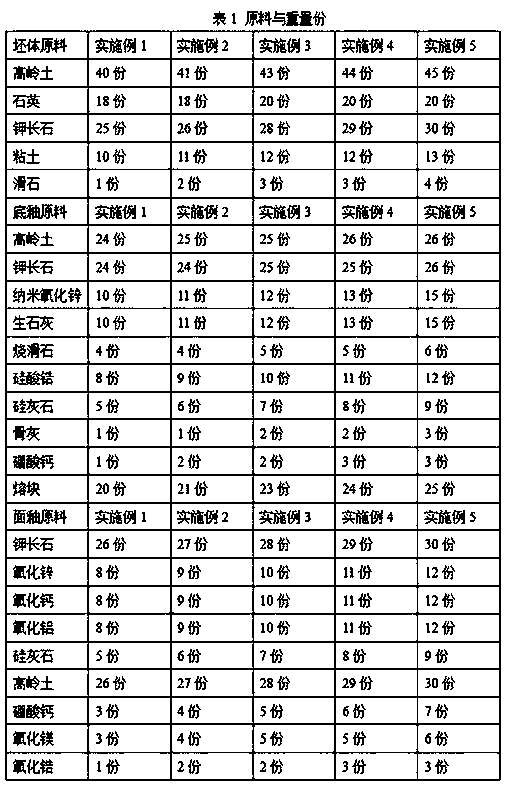

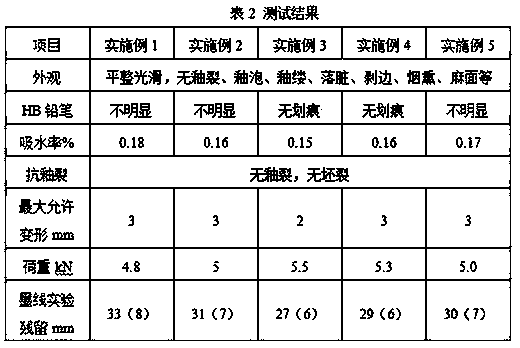

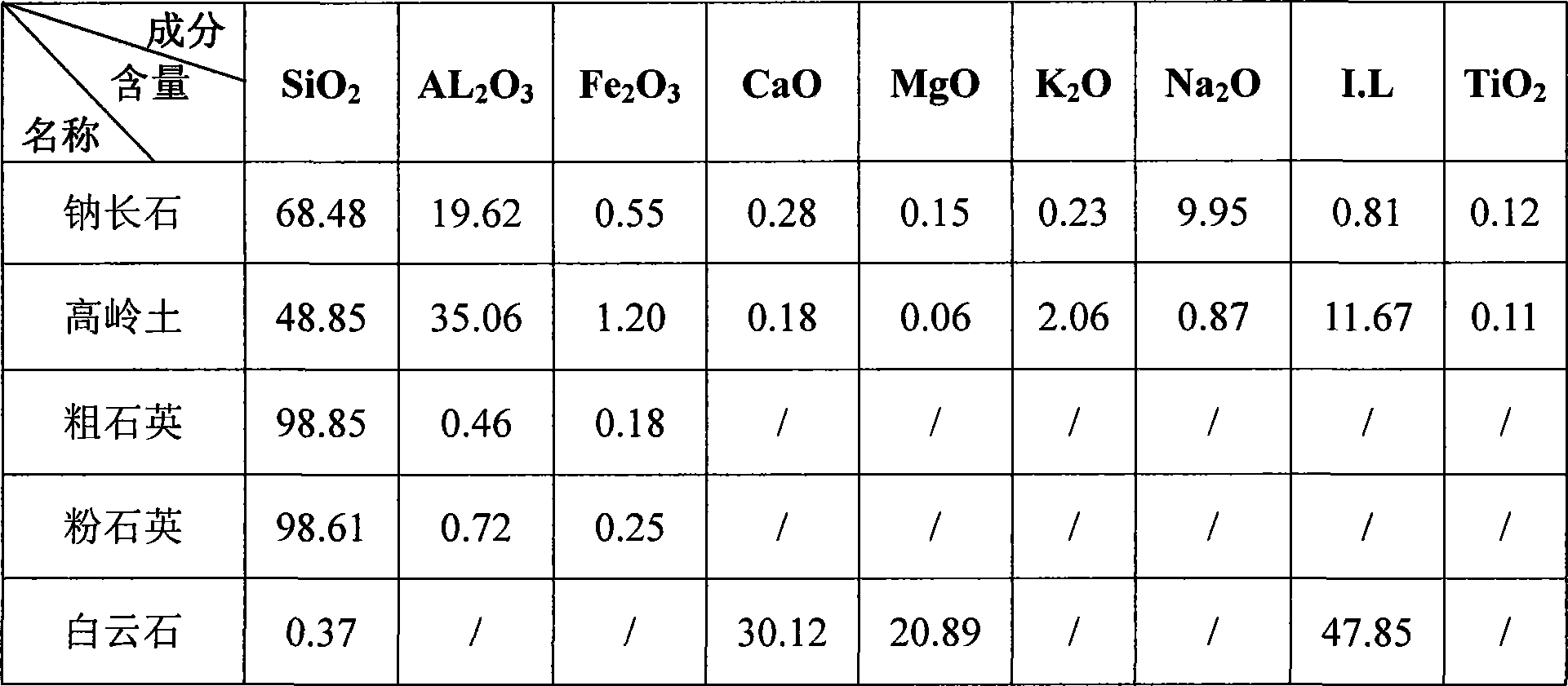

The invention provides a ceramic product with self-cleaning glaze. The ceramic product comprises a tire material and the glaze, wherein the tire material comprises kaolin, quartz, potassium feldspar,clay and talc; the glaze comprises ground glaze and cover glaze, wherein the ground glaze comprises the following raw materials: potassium feldspar, nano zinc oxide, calcium oxide, burning talc, zirconium silicate, wollastonite, kaolin, bone ash, calcium borate and frit; the cover glaze comprises the following raw materials: potassium feldspar, kaolin, wollastonite, zinc oxide, calcium oxide, aluminum oxide, magnesium oxide, zirconium oxide and calcium borate. A making method of the ceramic product with the self-cleaning glaze comprises the following steps: (1) respectively mixing the tire material and the glaze, adding water, wet-milling with a ball mill and sieving to obtain tire material slurry and glaze slurry; (2) making a green body with the tire material slurry for biscuit firing; (3) applying the ground glaze; (4) applying the cover glaze; (4) firing. The ceramic product made of the making method provided by the invention is fine and bright in glazed surface and can effectivelyprevent the accumulation of dirt and the formation of black spots.

Owner:福建省德化龙辉陶瓷有限公司

Petuntse used for preparing an exquisite ceramic cooker and method for preparing exquisite ceramic cooker from petuntse

The invention discloses petuntse used for preparing an exquisite ceramic cooker and a method for preparing the exquisite ceramic cooker from the petuntse. The petuntse comprises the following components, 25 to 27 parts by weight of halloysite, 14 to 16 parts by weight of sericite, 14 to 16 parts by weight of hypersthene, 8 to 10 parts by weight of sodium tripolyphosphate, 8 to 10 parts by weight of calcined vermiculite powder, 4 to 5 parts of howlite and 2 to 3 parts by weight of meerschaum; the calcined vermiculite powder is manufactured in the way that vermiculite is calcined for 1 to 1.2 hours at 1200 DEG C to 1220 DEG C, and is smashed and sieved by a 20-mesh sieve. The petuntse provided by the invention has the advantages that the firing temperature is lowered greatly, the firing range is broadened, the effects of environment friendliness and energy conservation are achieved, and the manufacturing cost is reduced; the manufactured exquisite ceramic cooker can not crack under the condition of heat exchange at 600 DEG C to 20 DEG C, and the application range of the product is wide.

Owner:潮州市阳光科技发展有限公司

Durable bone china and preparation method thereof

The invention relates to daily bone china, and in particular relates to durable bone china and a preparation method of the durable bone china. The green body of the durable bone china is prepared from the following raw materials in percentage by mass: 38.0-44.0% of animal ash, 3.5-7.5% of quartz sand, 7.0-12.0% of potassium feldspar, 4.0-8.0% of Suzhou clay, 8.0-12.0% of Longyan clay, 2.0-6.0% of Yi County clay, 2.0-7.0% of GF88 clay, 3.0-8.0% of K18 clay, 0.5-4.0% of alpha-aluminium oxide, 5.0-9.0% of limestone, and 0.5-8.0% of waste porcelain powder. The preparation method of the durable bone china comprises the following steps of: preparing a mixture from the above raw materials according to percentage by mass, ball-milling the mixture in a ball mill for 14.0-20.0 hours according to the mass ratio of the raw material to balls to water of 1:2.5:1, sieving the slurry using a 100-mesh sieve, removing ion, aging the resulting product for 3-7 days, squeezing the mud, adding certain water and dispersant into a mud cake for dispergation, carrying out slip casting, drying and trimming, firing the resulting product at 1230-1290 DEG C for 1.5-3.0 hours, and cooling the fired product to obtain the biscuit firing billet of the bone china. By adopting the durable bone china provided by the invention, the technical problems of the mutual interaction of the whiteness, the jade sense and the transparency, and the mutual interaction of the thickness, the strength, the hardness, and the thermal stability are solved.

Owner:NANJING UNIV OF TECH

Low temperature high silicon stoneware and its making process

The present invention is low temperature high silicon stone ware and its making process. The low temperature high silicon stone ware has great amount of quartz in different granularities introduced to increase the expansion coefficient of the biscuit. It is prepared with the materials including albite 15-35 wt%, kaolin 25-40 wt%, quartz 35-50 wt% and dolomite 1-5 wt%, and through a common stone ware baking process. The low temperature high silicon stone ware features the firing range of 1,175-1,225 deg.c and water absorption of 1-4 %.

Owner:HUNAN HUALIAN YIBAILI CERAMIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com