Patents

Literature

87 results about "Petuntse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petuntse (from 白墩子 in pinyin: bai2 dun1 zi0), also spelled petunse and bai dunzi, baidunzi, is a historic term for a wide range of micaceous or feldspathic rocks. However, all will have been subject to geological decomposition processes that result in a material which, after processing, is suitable as an ingredient in some ceramic formulations. The name means "little white bricks", referring to the form in which it was transported to the potteries (compare ball clay).

Making process of porcelain with twistable clay body

The present invention provides a making process of porcelain with twistable clay body, the making process includes raw material processing, molding, firing and other steps, the finished porcelains with twistable clay body are all porcelains with different textures, the porcelains with different textures comprise three or more than three kinds of colors, and are prepared by combining petuntse and by clay body twisting technique, the surface of the porcelains is artistically processed by veneer grafting, scarf patch repair, dry grafting, wet grafting, transfer-grafting and other techniques, smooth and natural line-decoration can be formed by traditional clay body twisting technique, modern art ceramic creation technique is used, the porcelain meets contemporary aesthetic taste, the picture color is controlled by pigment adding proportion, and the picture position is decided by mud cake sticking position, so that rich color changes can be produced, and the picture has a three-dimensional sense.

Owner:吴大立

Method for preparing high-strength, high-whiteness, high- thermal-shock-resistance petuntse

The present invention provides a method for preparing high-strength, high-whiteness, high-thermal-shock-resistance petuntse. The preparation method comprises the following production steps of (1) mechanically beating pyrophyllite, washing to remove mud and removing iron by magnetic separator and sieving; (2) mechanically beating kaolin, washing to remove mud and removing iron by magnetic separator and sieving; (3) according to the percentage by weight, weighting 28% of potassium feldspar, 12% of aluminum oxide, 10% of illite, 10% of montmorillonite and 30% of kaolin, mixing with 10% of pyrophyllite, ball milling, removing iron by magnetic separator and sieving to obtain petuntse materials; (4) press filtering the above sieved petuntse materials to obtain petuntse. The petuntse prepared by the invention is suitable for the production of ceramic products for daily use, product qualification rate is high. The strength, whiteness and thermal shock resistance of the product are superior to that of bone china, porcelain and highly siliceous magnesia porcelain, production cost is low, products are particularly applied in dishwashers, microwaves, refrigerators and sterilized cupboard.

Owner:CHAOZHOU RONGCHANG CERAMIC IND CO LTD

Petuntse used for preparing an exquisite ceramic cooker and method for preparing exquisite ceramic cooker from petuntse

The invention discloses petuntse used for preparing an exquisite ceramic cooker and a method for preparing the exquisite ceramic cooker from the petuntse. The petuntse comprises the following components, 25 to 27 parts by weight of halloysite, 14 to 16 parts by weight of sericite, 14 to 16 parts by weight of hypersthene, 8 to 10 parts by weight of sodium tripolyphosphate, 8 to 10 parts by weight of calcined vermiculite powder, 4 to 5 parts of howlite and 2 to 3 parts by weight of meerschaum; the calcined vermiculite powder is manufactured in the way that vermiculite is calcined for 1 to 1.2 hours at 1200 DEG C to 1220 DEG C, and is smashed and sieved by a 20-mesh sieve. The petuntse provided by the invention has the advantages that the firing temperature is lowered greatly, the firing range is broadened, the effects of environment friendliness and energy conservation are achieved, and the manufacturing cost is reduced; the manufactured exquisite ceramic cooker can not crack under the condition of heat exchange at 600 DEG C to 20 DEG C, and the application range of the product is wide.

Owner:潮州市阳光科技发展有限公司

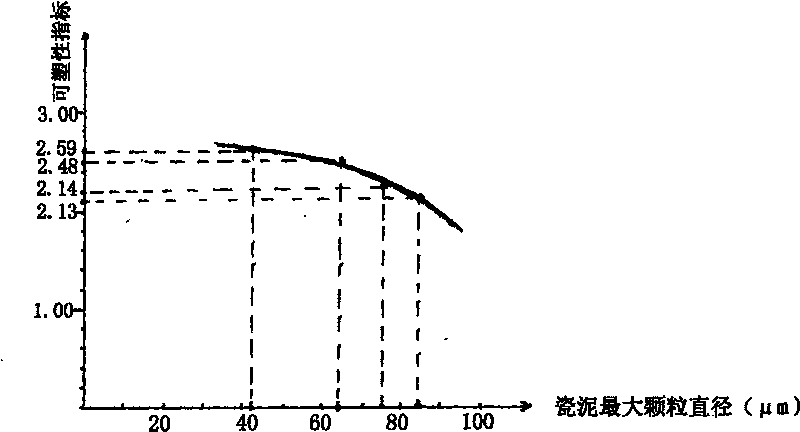

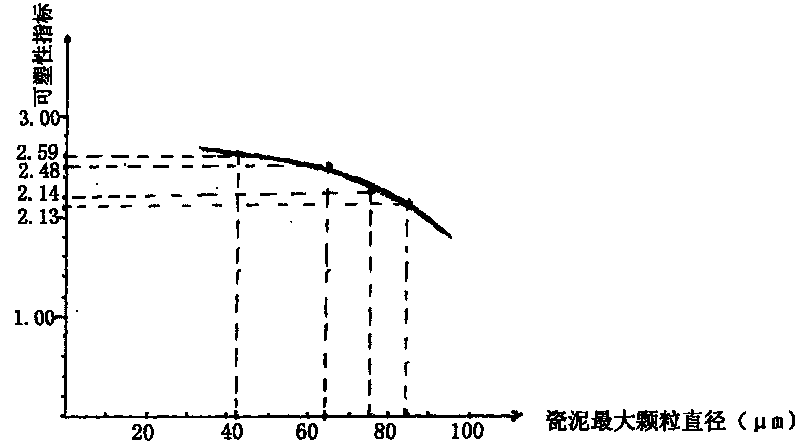

Method for producing petuntse from waste ceramics

The invention discloses a method for producing petuntse from waste ceramics, which comprises the following producing steps: taking the waste ceramics, pulverizing and ball milling, and then, sieving to obtain waste ceramic particles for standby, wherein the fineness of each ceramic particle is less than or equal to 50mu m; according to the percentage by weight, taking 7-12% of quartz, 8-13% of feldspar, 15-20% of mechanical pounded pug and 20-30% of kaolin to be uniformly mixed with 40-50% of waste ceramic particles for standby, putting the mixture in a ball mill for mixing and ball milling for 25-35 hours to obtain pug, wherein the ball milling fineness is controlled over 325 meshes, and the sieve residue is less than 0.2%; and sieving, de-ironing, filter-pressing and pugging the pug to obtain the petuntse. In the invention, by controlling the fineness of the petuntse, the plasticity of the petuntse is improved to meet the production requirements, the produced petuntse has good plasticity, the component types needed by producing the petuntse are reduced, various ceramic and porcelanic wastes can be recycled, and compared with the traditional method, the production cost of the method of the invention is greatly saved.

Owner:广东文化长城集团股份有限公司

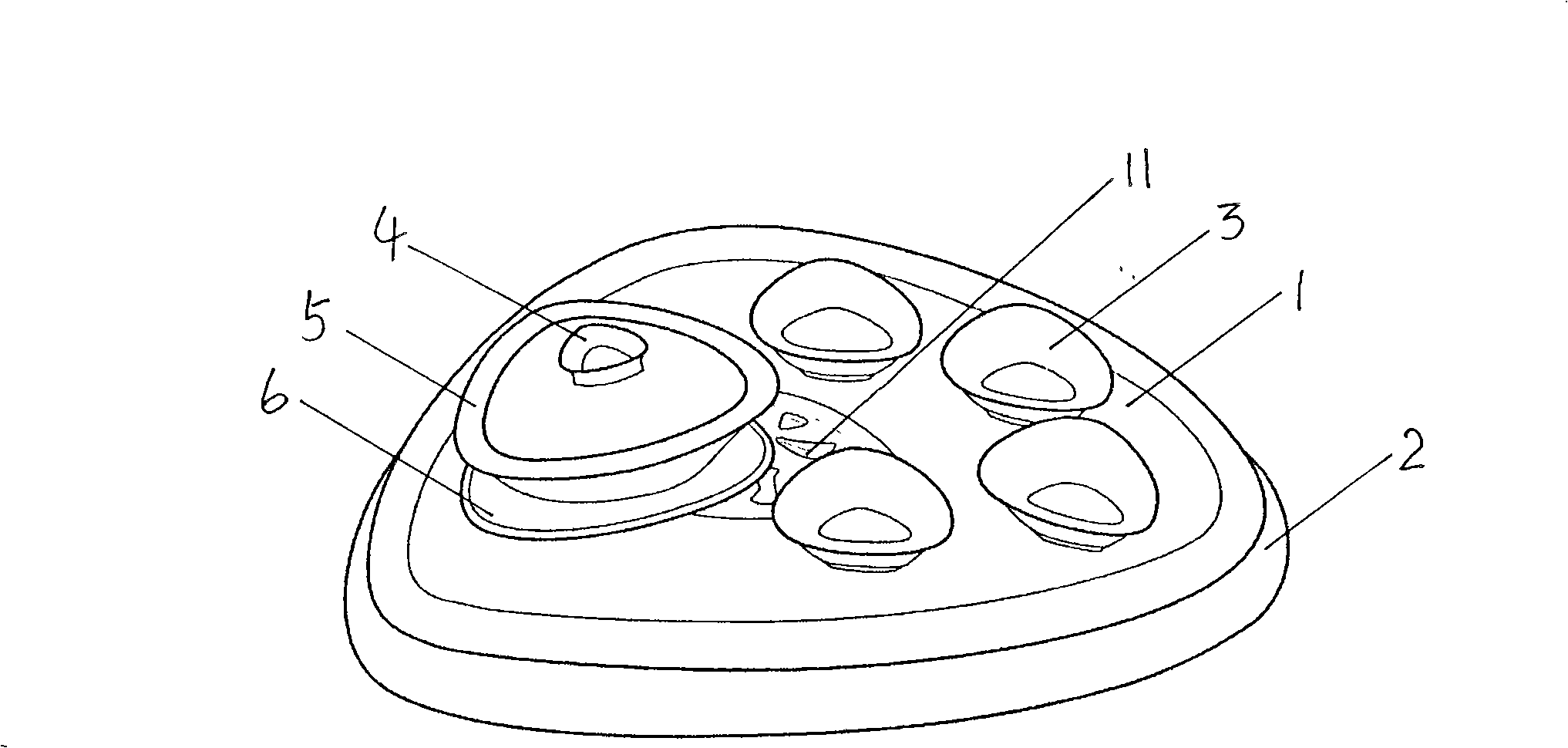

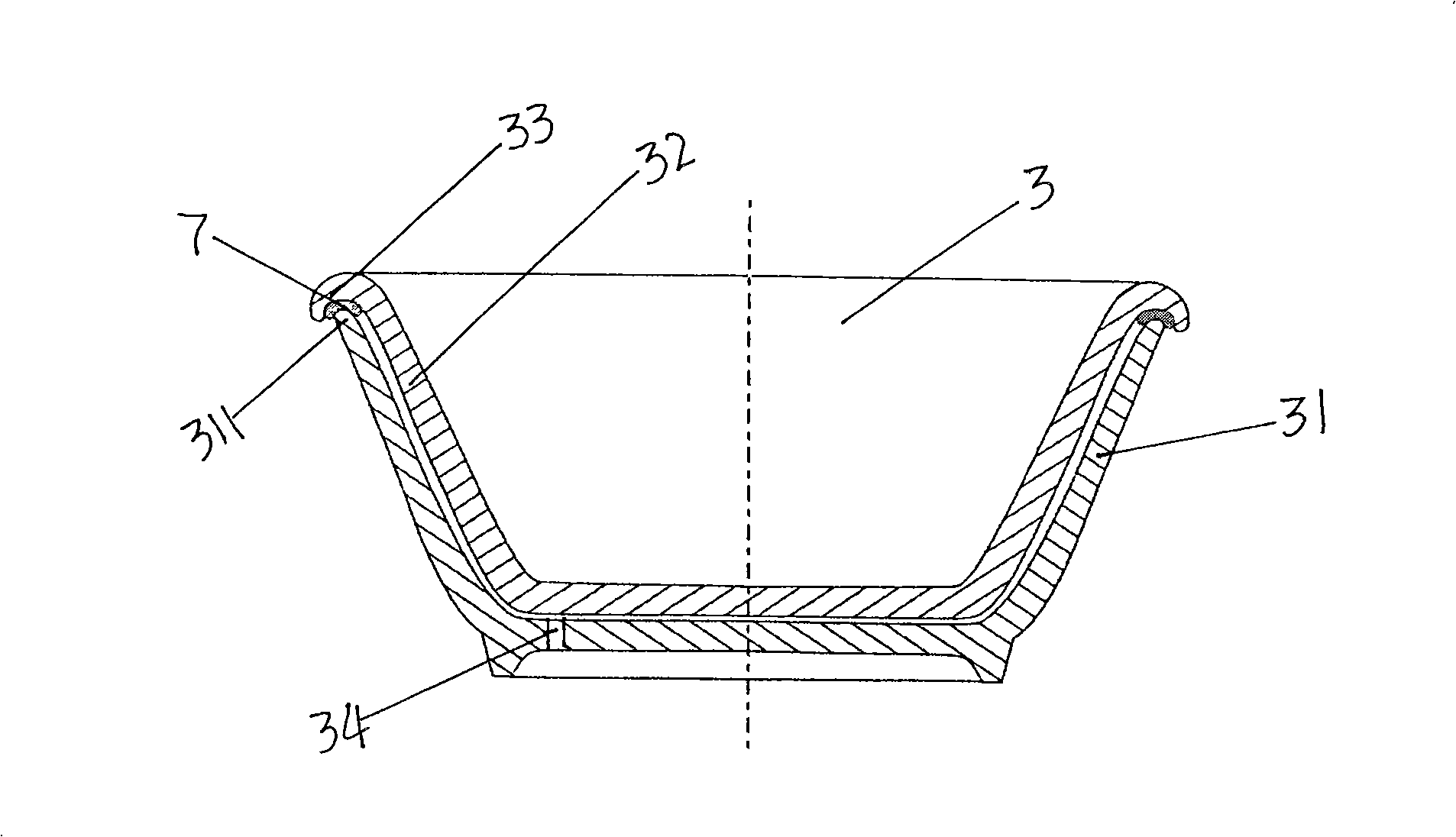

Pottery-porcelain double-layer congou tea set and preparation method thereof

InactiveCN101288542AImprove insulation effectGood heat insulationDomestic vesselsDrinking vesselsHuman bodyPetuntse

The invention provides a congou tea set with a pottery layer and a porcelain layer and a preparation method thereof. The tea set comprises a covered bowl, a tea board, a tea board bracket and a plurality of cups; wherein, the covered bowl consists of a tea cover, a tea bowl and a tea bracket; the tea cups and the tea bowl take on two-layered structure, an outer layer is white porcelain, an inner layer is purple sand ceramics, and port edges of the inner layer and the outer layer are bonded into a whole; the middle of the tea board is engraved with a through hole. The preparation comprises the following technological steps: selecting purple sand petuntse for manufacturing inner-layer green bodies of the tea board, the tea cover and the tea bowl, glazing and baking; selecting high-temperature white petuntse for manufacturing outer-layer green bodies of the tray, the tea bracket, the tea cups and the tea bowl, glazing and baking; nesting and bonding the inner layers and the outer layers of the tea cups and the tea bowl and braking. The tea set prepared by the invention has good heat preservation and heat insulation effect; the hands can not be burnt when making tea or drinking tea; by skillfully combining the purple sand with the white porcelain, the texture and the color has intense comparison and the lasting appeal is boundless, wherein, the purple sand is polished and refined, which not only absorbs tea aroma, but contains a plurality of beneficial elements, thus having healthcare function on human body; a triangular basic pattern is adopted, the unique pattern not only inherits the lasting appeal of the traditional congou tea set, but also increases fashion elements, thus having the advantages of enjoyment performance and collection value, etc.

Owner:邱欣昭

Color petuntse fired at temperature not higher than 1,150 DEG C and preparation method thereof

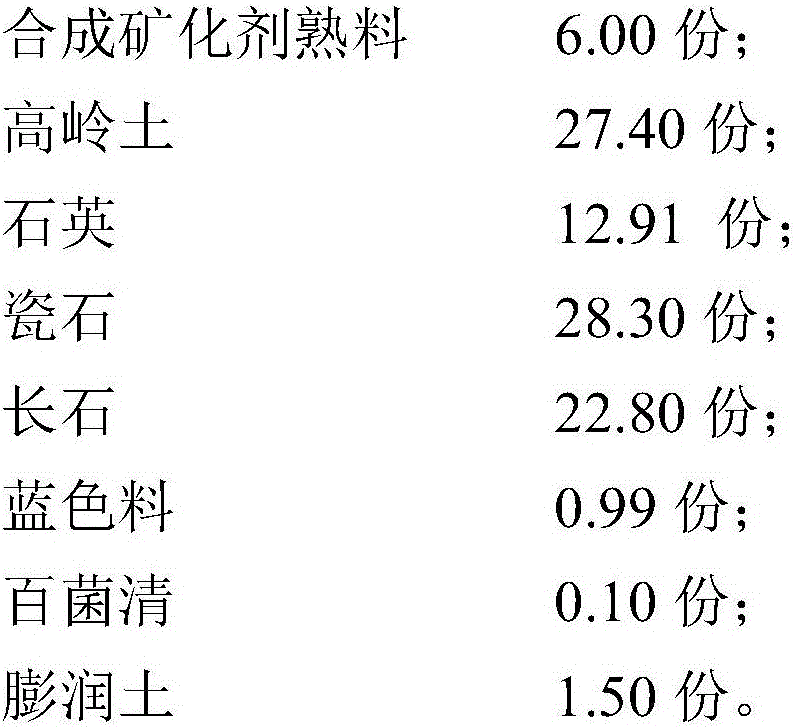

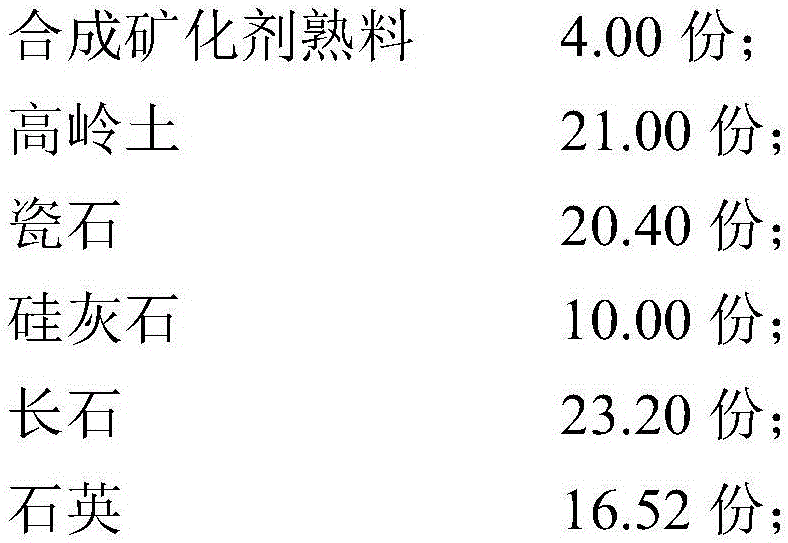

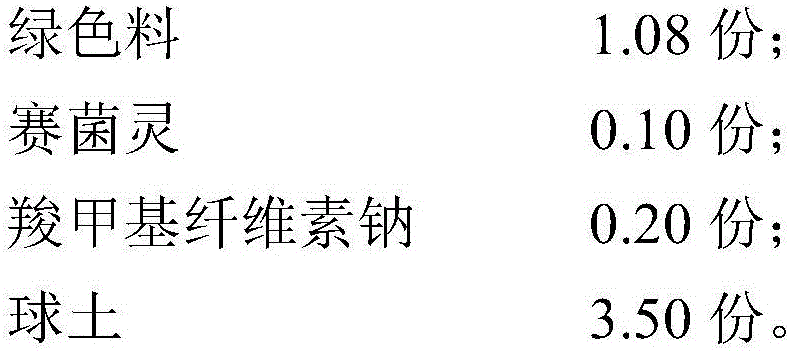

The invention discloses color petuntse fired at a temperature not higher than 1,150 DEG C and a preparation method thereof. The color petuntse comprises the following components in parts by weight: 1-10 parts of synthetic mineralizer clinker, 80-100 parts of white petuntse and 0.1-10 parts of pigment, wherein the synthetic mineralizer clinker is prepared by mixing lithium chinastone and albite and calcining. According to the color petuntse and preparation method thereof disclosed by the invention, the firing temperature can be effectively reduced by 30-50 DEG C, the energy and cost are saved, the glaze surface of the product is smoother, and the color is brighter.

Owner:董克勤

Intermediate temperature crackled glaze porcelain for daily use and preparation method thereof

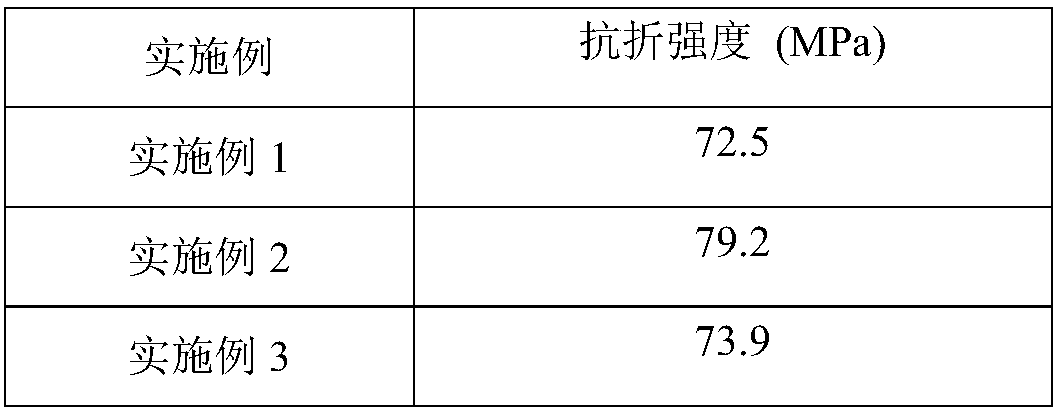

ActiveCN109516779AImprove flexural strengthLow expansion coefficientClaywaresAbsorption ratioPetuntse

The invention discloses intermediate temperature crackled glaze porcelain for daily use. The intermediate temperature crackled glaze porcelain for daily use comprises a blank and glaze, wherein the blank is prepared from the following components in parts by weight: 10-15 parts of washed quartz powder, 28-33 parts of feldspar, 50-55 parts of washed kaolin, 5-10 parts of petuntse, and 0.5-1 part ofdolomite mineralizer. The adopted blank can realize one-step fast firing, the firing period can be shortened to 5-8 h, the ball-milling time is shortened to 12 h, and on the basis of ensuring the strength of the green body, the preparation time of the intermediate temperature crackled glaze porcelain for daily use can be shortened, the quality of a final product is improved, the quality standard of the porcelain for daily use can be met, and the water absorption ratio of the prepared intermediate temperature crackled glaze porcelain for daily use is below 0.5%.

Owner:HUNAN HUALIAN CHINA IND

Method for manufacturing translucent porcelain and uses thereof

InactiveCN101318806ASimple preparation processReduce manufacturing costClaywaresPetuntseProduct modeling

The invention provides a method for preparing translucent porcelain. The process comprises the following steps that: petuntse is prepared by the compositions according to the ratio: 65 to 75 percent of SiO2, 20 to 28 percent of Al2O3, 0.1 to 0.3 percent of Fe2O3, 0.1 to 0.5 percent of CaO, 0.3 to 0.8 percent of MgO, 1 to 4 percent of K2O and 0.5 to 1.5 percent of NaO; the raw materials are mixed with water, water glass and sodium humate, the mixture is stirred to prepare slurry; the slurry is poured on a product modeling die; the mixture is dried and demoulded to produce the proximate matter; the proximate matter is finished, sun-dried or baked; the water is poured and the matter is polished, creamy white oil is poured; the sintering process is performed at a temperature of between 1250 and 1300 DEG C for 8 to 10 hours; and stained paper is stuck on and the second sintering process is performed at a temperature of between 720 and 770 DEG C for 4 to 6 hours. The method has simple preparation technology, low cost, wide applications, and good transmission effect; therefore, the translucent porcelain can be taken as a heat-resistant instrument in household such as a lamp holder, a lampshade, a candle shield, a candle cup and an essence oil burner and as an art display, thereby being a modern article integrating illumination and art into a whole.

Owner:蔡妙填

High alumina full ceramic ball arch

The invention discloses a high alumina full ceramic ball arch, comprising following raw materials: calcined alumina, active alumina, feldspar powder, Qingyuan petuntse, Fujian petuntse, Zuoyun soil and Handan soil. The preparation method of the high alumina full ceramic ball arch comprising the following steps: firstly, adding the calcined alumina, the active alumina, the feldspar powder, the Qingyuan petuntse, the Fujian petuntse, the Zuoyun soil and the Handan soil into a globe mill in a certain proportion and evenly mixing the mixture; secondly, mixing and ball milling the mixture with dolomite; thirdly, milling with proper amount of water to form sizing agent; and finally staling, extracting, molding, drying and firing the sizing agent to obtain the high alumina full ceramic ball arch. The high alumina full ceramic ball arch greatly improves the intensity of the ball arch, can lighten the weight of the ball arch, reduces the depth of small brick body, increases the superficial area of holes in the ball arc, and increases the percentage of opening of the ball arc to 68-72%, thereby being capable of reducing flow resistance in a tower, improving air velocity, enlarging the air flow of the tower, improving the work efficiency of the tower and improving yield by more than 10%, and being good for improving the whole carrying capacity of the ball arc, enlarging the area of thrust surface in the tower, more evenly dispersing pressure in the tower and extending the service life of the ball arc.

Owner:JIANGXI PINGXIANG LONGFA ENTERPRISE

Surface glazing technology for jun porcelain plate

The invention provides a surface glazing technology for a jun porcelain plate. A prepared plate-type green body is put in a ventilation environment at the room temperature, the inner surface of the plate-type green body is uniformly coated with a petuntse layer, a gridded indentation is pressed on the inner surface of the plate-type green body by a screen mesh, depth of the indentation is controlled in a range of 1-3 mm, the treated plate-type green body is placed in a thermal insulating chamber at the temperature of 50-80 DEG C and left to stand for 10-20 min, then the inner surface of the plate-type green body is coated with an overglaze layer, the thickness of glaze applied to the area without the indentation is controlled in a range of 0.5-1.5 mm on the basis that the indentation is filled with the glaze, the plate-type green body is aired for 20-30 min in the ventilation environment, the inner surface of the plate-type green body is coated with the overglaze layer again, meanwhile, the peripheral surface of the plate-type green body is uniformly coated with a ground glaze layer, and glazing is finished. The glazing technology for the jun porcelain plate is optimized, the glazeattached to inner and outer surfaces of the jun porcelain plate is in the optimum state, and through matching with the optimal overglaze and ground glaze materials, the appearance of the jun porcelain plate prepared with the technology achieves the best aesthetic effect.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Method for reclaiming and utilizing porcelain clay tailings and petuntse prepared by the same

InactiveCN101125750AReduce the amount addedIncrease costCeramic materials productionClaywaresPlasticizerPetuntse

The invention discloses a method for recycling porcelain clay gangue and the produced petuntse thereof, which is grinded by combinations of porcelain clay gangue, high alumina clay, magnesium mineral, and sodium fluxing agent and plasticizer and polo, wherein, the sodium fluxing agent is better to be waste glass. The invention solves the problem of gangue pollution, greatly applies the porcelain clay gangue to the production of household porcelain, technology porcelain and sanitaryware and reduces the cost of gangue of 20-30 percent compared with the existing common gangue.

Owner:GUANGDONG DONGBAO GRP

Method for manufacturing stockpile electroplated decorative furnishing art porcelain

Owner:GUANGDONG SITONG GROUP

Manufacturing method for electroplated display artistic porcelain decorated by boat snail shells

InactiveCN103113083AImprove the artistic effectReduce consumptionDecorative surface effectsClaywaresPetuntseEconomic benefits

The invention relates to a manufacturing method for electroplated display artistic porcelain decorated by boat snail shells. The manufacturing method comprises the following four steps of: selecting petuntse; processing porcelain blank; processing and treating boat snail shells; and decorating the porcelain by the boat snail shells. The display artistic porcelain manufactured by the manufacturing method disclosed by the invention has natural surface grains and strong third dimension; the manufacturing method is capable of recycling pure natural and waste boat snail shells, converting the waste materials into economic benefits, so that the production cost is saved, the energy resources are saved and the environment protection is facilitated.

Owner:GUANGDONG SITONG GROUP

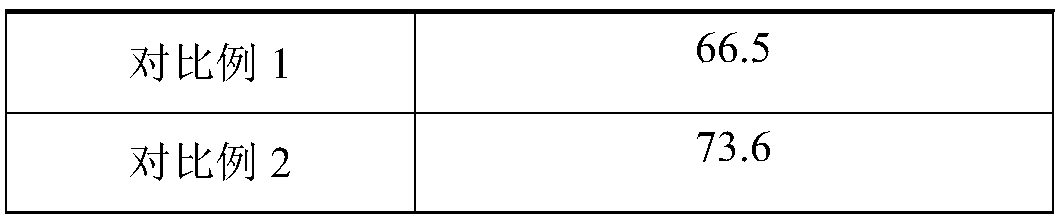

Porcelain prepared by combination of glass and ceramic and method thereof

The invention provides porcelain prepared by the combination of glass and ceramic and a preparation method thereof. The porcelain comprises a porcelain pot and a glass fitting. The pot surface of the porcelain pot is provided with a recessed surface, and the glass fitting is mounted on the recessed surface. The glass fitting and the porcelain pot of the porcelain can be combined together firmly, and the porcelain has a good aesthetic feeling. The method comprises the following steps: petuntse is ground to obtain required slurry; the slurry is injected into a mould to form a rough blank; the rough blank is repaired and glued; after the blank body to be moulded is dried, the recessed surface is made at the position where the glass fitting needs to be adhered to the blank surface; the finished blank body undergoes briscuit firing; the blank body which has undergone briscuit firing undergoes glazing; the blank body which has undergone glazing enters a kiln and undergoes high-temperature glaze firing; a moulded finished product obtained after glaze firing undergoes sole rubbing and mouth polishing; and the glass fitting is mounted and adhered to the recessed surface of the pot surface. By the above method, the problem that glass and porcelain cannot be cofired or firmly combined is overcome.

Owner:郑忠诚

Ceramic product for closestool, and preparation method thereof

The invention discloses a ceramic product for a closestool, and a preparation method thereof. The ceramic product comprises the following components in parts by weight: 14.5 parts of black soil, 15 parts of loess, 40 parts of ceramic powder, 7 parts of kaolin powder, 11 parts of half petuntse, 28 parts of feldspar powder, 30 parts of tourmaline, 20 parts of medical stone and 6 parts of zeolite.

Owner:潮州市嘉柏陶瓷有限公司

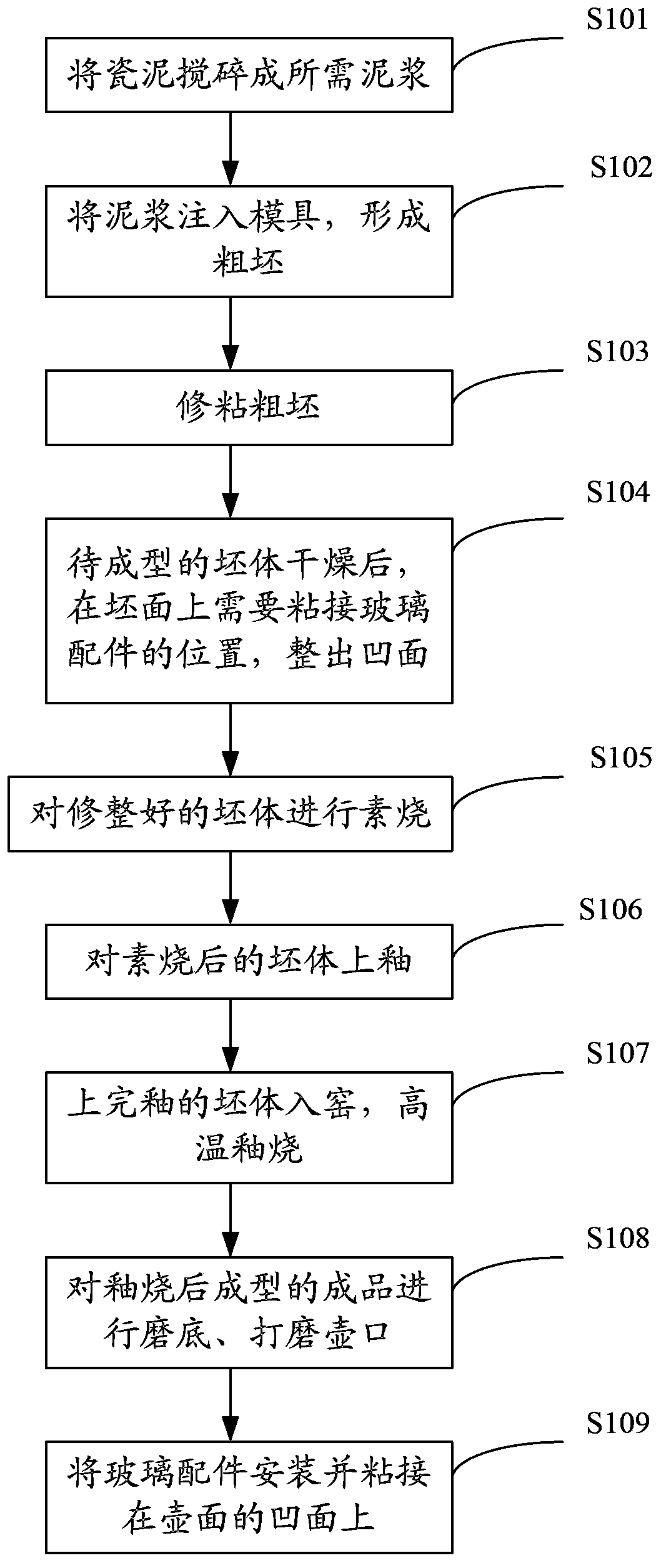

Ecological Ru porcelain petuntse

Ecological Ru porcelain petuntse is prepared from the following raw materials in parts by weight: 4-8 parts of charcoal dust, 8-12 parts of Fengxue soil, 55-80 parts of Banpo soil, 8-12 parts of kaolin, 4-8 parts of potash feldspar and 0.3-0.6 part of white alkali. The ecological Ru porcelain petuntse is calcined into a porcelain in a reducing atmosphere at the temperature of 1,220-1,225 DEG C, the porcelain quality is excellent, the charcoal dust is combusted and volatilized so that holes are formed in a blank and become crack sources of crackles of a glaze surface, the holes are connected with the crackles of the glaze surface, flow of air between the body and glaze of the Ru porcelain is improved, and peculiar effects of adsorbing smell in Ru porcelain utensil and improving taste are achieved, after tea water and wine are injected in an ecological Ru porcelain tea set and an ecological Ru porcelain wine set, the flavor of the tea water and the flavor of the wine are changed, and the tea water and the wine taste sweet and are smooth and soft. If cigarettes are placed in an ecological Ru porcelain smoke tank, part of harmful odor in the cigarettes can be sucked away after five days, and the cigarettes are not cruel or fierce when a user smokes, and are sweet, smooth and soft. Compared with Ru porcelain made of common pug, the porcelain made of the ecological Ru porcelain petuntse has high health maintenance and collection value.

Owner:李晓涓 +1

Preparation technology of jun porcelain plate

The invention provides a preparation technology of a jun porcelain plate. The preparation technology comprises steps as follows: a plate-type green body is prepared from petuntse which is prepared well; the plate-type green body is pre-heated; the surface of the pre-heated green body is glazed, and the glazed green body is put in a kiln for fire molding; the pre-heating step of the plate-type green body comprises a low-temperature biscuit firing step and a standing treatment step, and the operating method comprises the process as follow: firstly, the plate-type green body is put in a low-temperature kiln for 10-30 min, the temperature in the low-temperature kiln is controlled in a range of 50-150 DEG C, and the plate-type green body is taken out of the low-temperature kiln and left to stand for 1-3 h in the ventilation environment at the room temperature. The glazing technology for the jun porcelain plate is optimized, glaze attached to inner and outer surfaces of the jun porcelain plate is in the optimum state, and through matching with the early-stage pre-heating step and late-stage fire molding step, the appearance of the jun porcelain plate prepared with the technology achievesthe best aesthetic effect.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

Manufacturing method for tiny mosaic electroplated decoration display artistic ceramic

The invention relates to a manufacturing method for tiny mosaic electroplated decoration display artistic ceramic. The manufacturing method comprises the steps of selecting petuntse, processing china biscuit, processing and treating mosaic, decorating the china biscuit by using tiny mosaic and the like. The display artistic ceramic manufactured by the method is formed by recycling waste materials discarded in the market, so that the display artistic ceramic is lower in cost but has strong fashionable breath.

Owner:GUANGDONG SITONG GROUP

Lightweight reinforced ceramic corrugation structured filler

The invention discloses a light strengthen porcelain corrugated structured stuff, which is composed of laminated light porcelain stuff units with corrugated shapes, wherein the units are dried, selected and ball ground into petuntse, to be shaped into blank, dewatered, dried, calcined and refined. The light strengthen porcelain corrugated structured stuff unit contains 10-30% of high quality aluminum powder, 40-70% of high silicon clay, 5-15% of quartz and 10-15% of feldspar. The inventive light strengthen porcelain corrugated structured stuff has thin wall, low weight, simple application, high application efficiency, low pressure decrease, high processing capacity, low liquid hold up, no obvisou amplification and high operation flexibility, which is not easy to break and is easy to assemble. Compared with prior corrugated stuff, the strength of the invention is improved of at least 30% and the corrosion resistance is improved of at least 20%, to meet the technical demands of oil refining.

Owner:赖祖明

Ceramic tableware repairing method

The invention belongs to the field of ceramics and particularly relates to a ceramic tableware repairing method. The ceramic tableware repairing method comprises the following several working procedures: cleaning, treating bottom layers of notches, filling petuntse, spraying glaze and baking, wherein the petuntse filling step means petuntse is smeared at bottom layers of crevices, and after the petuntse is completely smeared in place, the operation is carried out in a stacking manner, the petuntse comprises a JL-01 type component and a JL-02 type component, and the JL-01 type component and the JL-02 type component are mixed for use in a ratio of the JL-01 type component to the JL-02 type component being 1: 2. The ceramic tableware repairing method has the advantages of low cost, simplicity and easiness in operation and low professional skill requirements and can be used for repairing ceramic tableware as like before, so that a lot of money can be saved for restaurants and hotels.

Owner:HANGZHOU JUELUN SCI & TECH

Method for manufacturing synthetic decorative display art porcelain by plastic and pearl powder

ActiveCN103085577ALow costImprove product added valueOrnamental structuresClaywaresPetuntseLacquerware

The invention relates to a method for manufacturing synthetic decorative display art porcelain by plastic and pearl powder. The method comprises the steps of: selecting petuntse, processing China biscuit, machining the plastic, decorating the China plain greys by the plastic and the pearl powder, and the like. The display art porcelain manufactured by using the method is good in third dimension, vivid, and true to nature; and the appearance of the art porcelain is like lacquer and metal, and caters to the aesthetic psychologies of pursuit of fashion and variety of moderns. By adopting the method, an energy source can be saved; the cost can be reduced; and the technical additional value of the art porcelain is improved.

Owner:GUANGDONG SITONG GROUP

Manufacturing method of novel porcelain artwork

The invention discloses a manufacturing method of a novel porcelain artwork, which comprises the following production steps of: preparing nano mixed pulp, preparing a green body from petuntse, and carrying out high-temperature biscuit firing, colored drawing and high-temperature color burning on the green body. According to the invention, by adding the nano mixed pulp in the petuntse and cooperating with various petuntse raw materials in specific proportions, through the working procedures of the invention, porcelains which are exquisite in texture and uniform in pigment adsorption can be prepared, so that the colored drawing process difficulty is greatly reduced, the production efficiency is improved while the quality of products is improved, and drawings on the surface of the porcelain artwork are more vivid.

Owner:LANZHOU JIAOTONG UNIV

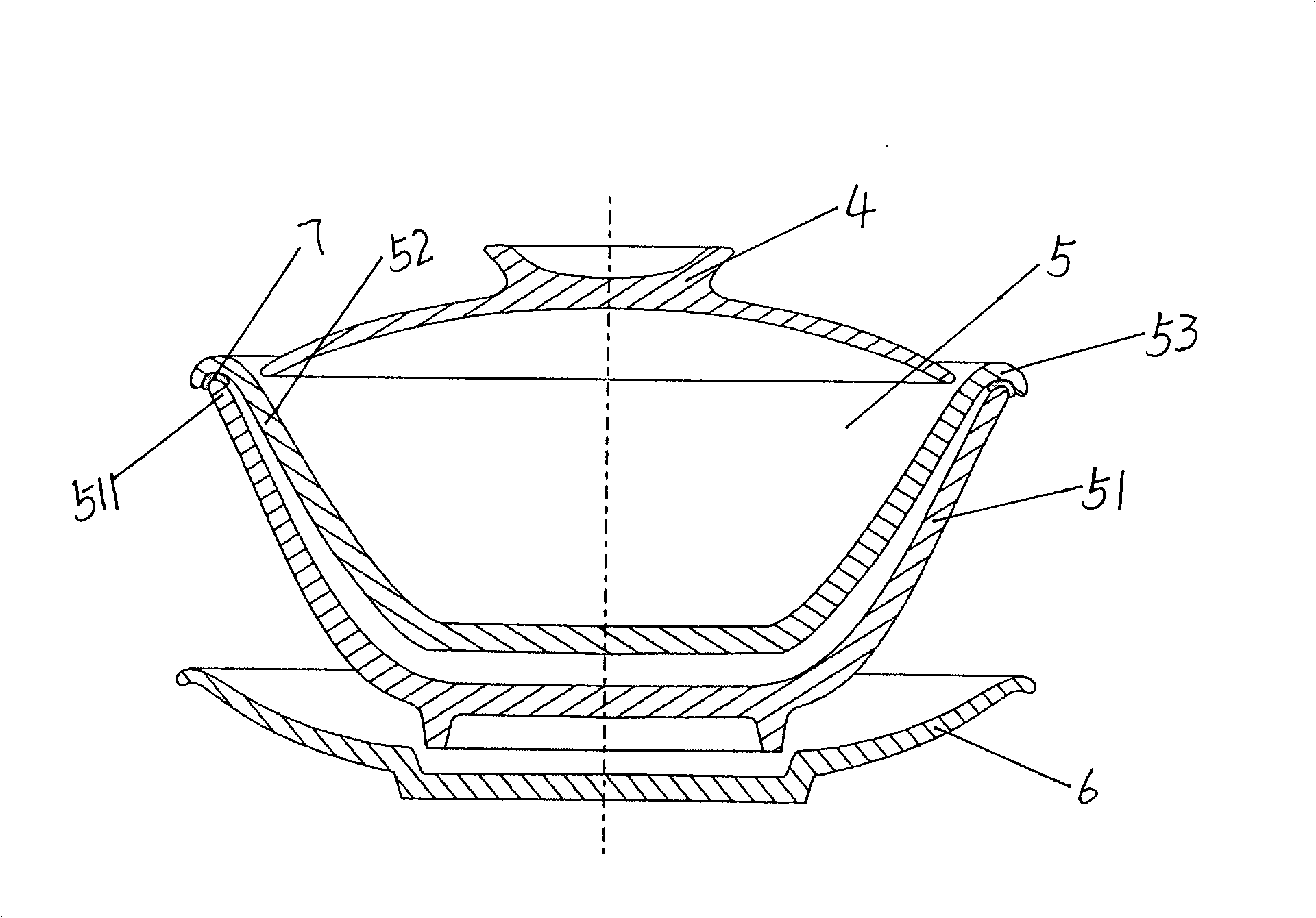

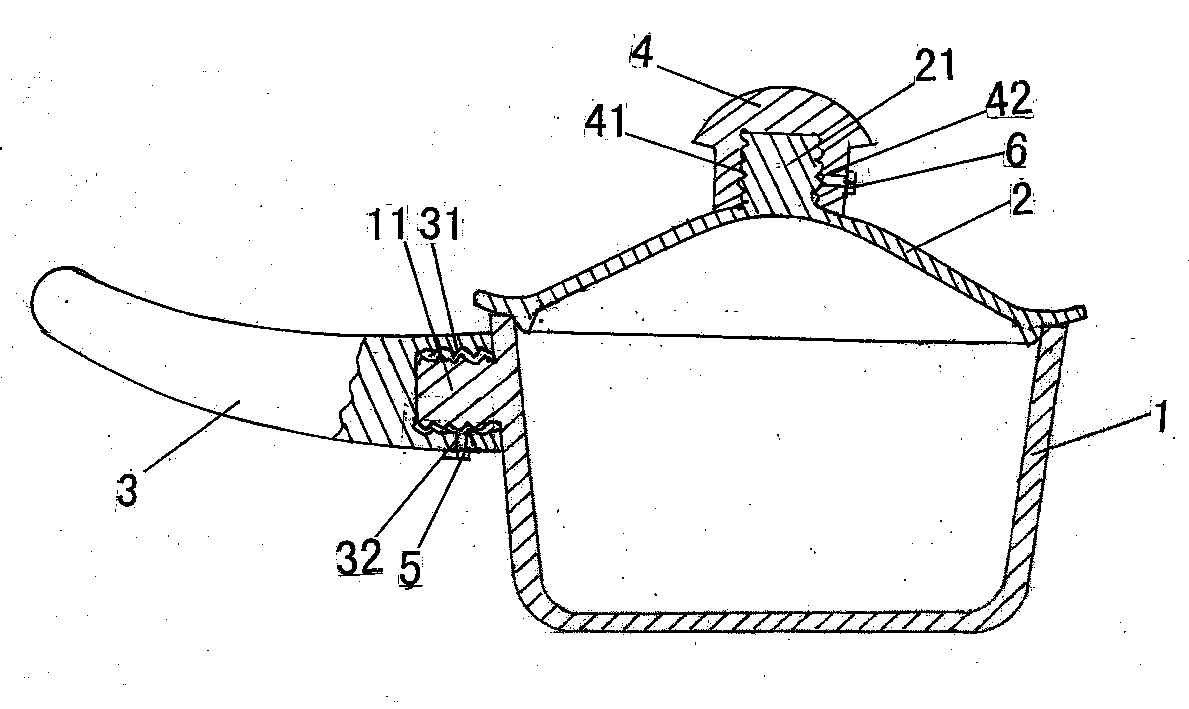

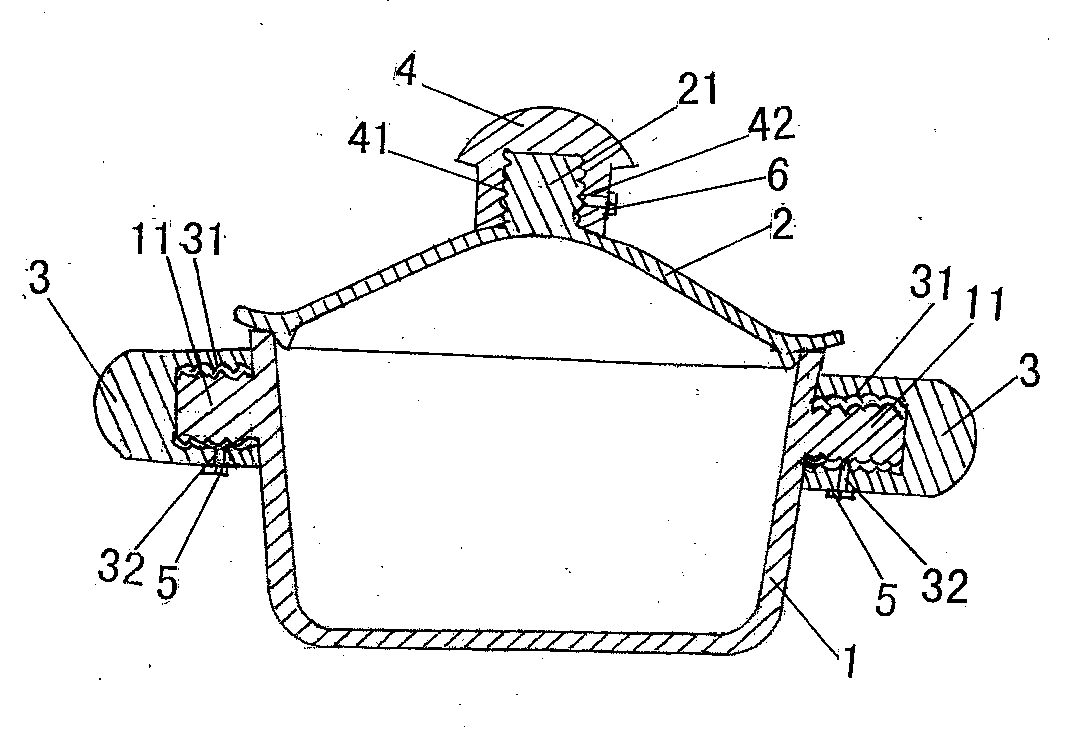

Heat-resisting ceramic cooker with connection seat and manufacture method of heat-resisting ceramic cooker

The invention provides a heat-resisting ceramic cooker with a connection seat and a manufacture method of the heat-resisting ceramic cooker. The heat-resisting ceramic cooker comprises a ceramic cooker body, a ceramic cooker cover, a handle and a lifting grip, wherein ceramic screws are arranged on the cooker body and at the top of the cooker cover in an integrating mode, the handle and the lifting grip are provided with screw holes, the handle is in threaded connection with the cooker body, the lifting grip is in threaded connection with the cooker cover, and fastening devices are arranged in the connection positions between the handle and the cooker body and between the lifting grip and the cooker cover. The manufacture method of the heat-resisting ceramic cooker includes manufacturing heat-resisting petuntse and heat-resisting ceramic glaze, forming green bodies of a container body and a cover body, forming green bodies of the ceramic screws, performing splicing, manufacturing the handle and the lifting grip, and sequentially performing fettling, stoving or airing, thread correction, bisque firing, glazing, glaze firing, assembling, and checking. According to the heat-resisting ceramic cooker with the connection seat and the manufacture method of the heat-resisting ceramic cooker, a connection structure of the cooker body, the cooker cover and the lifting grip is reasonable, connection positions are high in sealing and fastening performance, and disconnection and air leakage do not occur; the handle and the lifting grip are free from being rusted and aged, and durable in use; the application range is wide, and the manufactured heat-resisting cooker is applicable to frying, stir-frying, and stewing food under various heat sources and can be directly used in microwave ovens.

Owner:黄驰驰

Plate and making method therefor

InactiveCN101069976ASimple preparation processColor won't changeDomestic articlesFlat articlesPine resinPetuntse

The invention discloses woods for making furniture and bureaus and its preparation method. The products are formed by mixing the following components and weight ratio uniformly, rolling, molding, drying, grinding and polishing: petuntse powder (viscin thread mud) 40-60, orange skin powder 5-15, pine leaves powder 5-15, pine resin 10-25 and tung oil 10-25. The plates have no formaldehyde or other harmful substance. It is fireproof, durable, wear, anti- bristletail and anti-static. It also can form natural figure without decorating with other panels or any treatment on the surface. Its preparation technologies are simple, color can not change and it can be polished for renewal repeatedly.

Owner:曹廷亿

Manufacturing method of glass-and-jeweler decorated furnishing art porcelain

InactiveCN103145399ALow costExcellent decorative effectDecorative surface effectsClaywaresPetuntseCeramic

The invention relates to a manufacturing method of a glass-and-jeweler decoration furnishing art porcelain. The manufacturing method specifically comprises the following steps of: selecting petuntse, processing a porcelain biscuit, processing the glass, processing the jeweler, and decorating the porcelain biscuit by using the glass and the jeweler. The furnishing art porcelain manufactured by the method provided by the invention has remarkable decoration effect and low cost, due to the glass-and-jeweler decoration mode, the fastness of the ceramic is greatly improved, and the porcelain is hard to damage.

Owner:GUANGDONG SITONG GROUP

High-temperature black body porcelain and reduction flame firing preparation method thereof

The invention relates to high-temperature black body porcelain and a reduction flame firing preparation method thereof. The invention discloses the high-temperature black body porcelain which is prepared from a blank and a glaze material; production raw materials of the blank comprise: 15 to 20 weight percent of washing petuntse, 15 to 18 weight percent of plaster, 36 to 44 weight percent of whitemud, 18 to 25 weight percent of red purple sand shale, 16 to 20 weight percent of quartz and 3 to 6 weight percent of tillite; production raw materials of the glaze material comprise: 30 to 35 weightpercent of potassium feldspar, 31 to 37 weight percent of quartz, 10 to 15 weight percent of wollastonite, 3 to 5 weight percent of barium carbonate, 8 to 10 weight percent of talc, 8 to 10 weight percent of kaolin, 3 to 5 weight percent of alumina powder and 11 to 16 weight percent of red purple sand shale; the ceramic product not only is pure in color, attractive and excellent in surface artistic effect, but also is high in rate of fired finished products and stable in product performance and has glaze which is not cracked or opened.

Owner:醴陵市科镭陶瓷釉料有限公司

Continuous production process of 500KV insulating insulator

ActiveCN105503153AHigh strengthImprove impact resistanceInsulatorsClaywaresInterference resistanceRoom temperature

A continuous production process of 500KV insulating insulator comprises: selecting an insulating petuntse, unsaturated polyester resin and other auxiliaries for mixing to preparing suspensoid mixed slurry, pugging the unsaturated polyester resin to prepare a blank, performing ageing, secondary pugging and electric drying in the shade on the prepared blank, fettling the blank after the electric drying in the shade and performing ten-section heating calcinating, performing six-section cooling calcinating after the ten-section heating calcinating, standing the calcinated blank at room temperature for 3-5 days, performing finishing, trimming and surface processing to prepare the product. The insulating insulator prepared by the continuous production process is reasonable in structure, convenient to load and unload and high in environmental interference resistance, and stably works under 500KV ultrahigh voltage environment.

Owner:醴陵华鑫电瓷科技股份有限公司

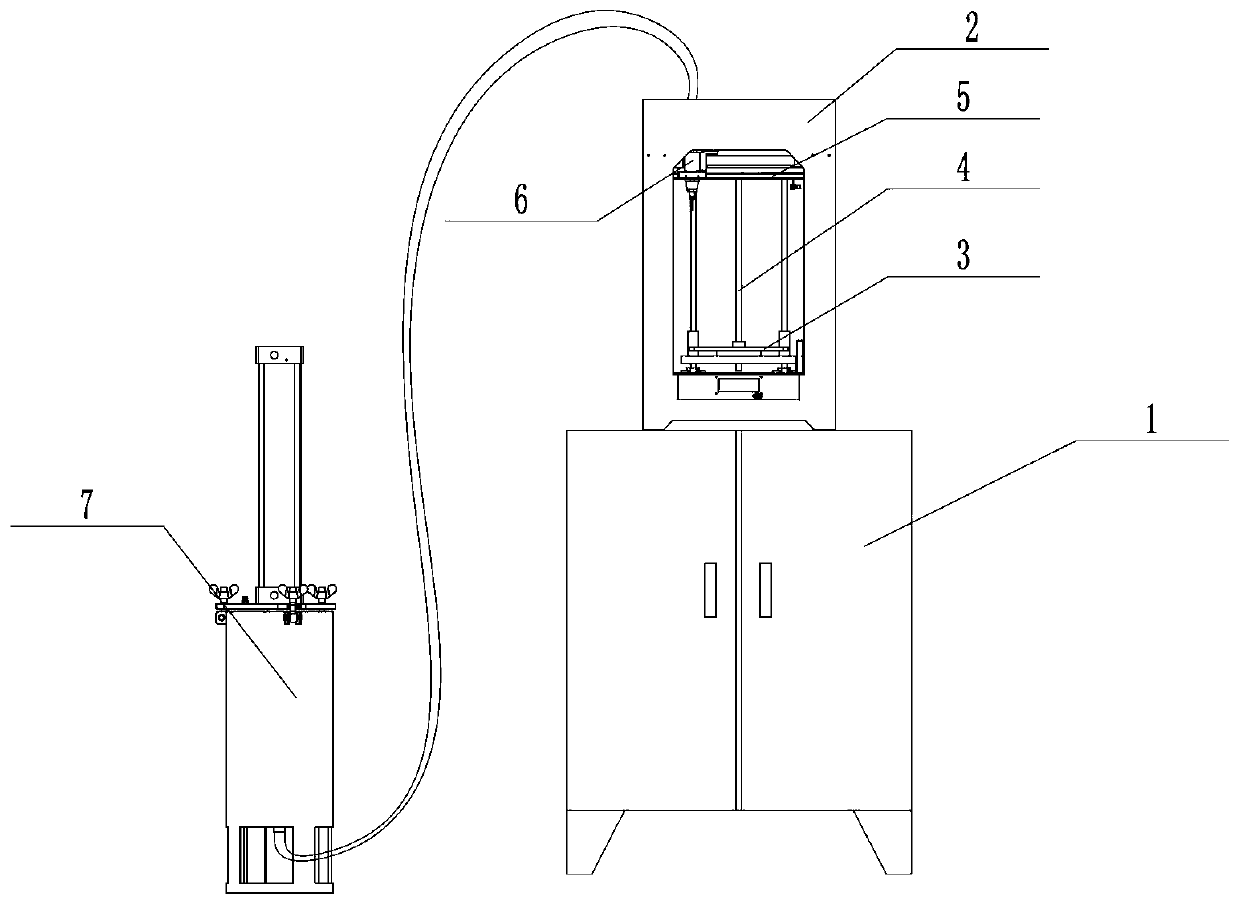

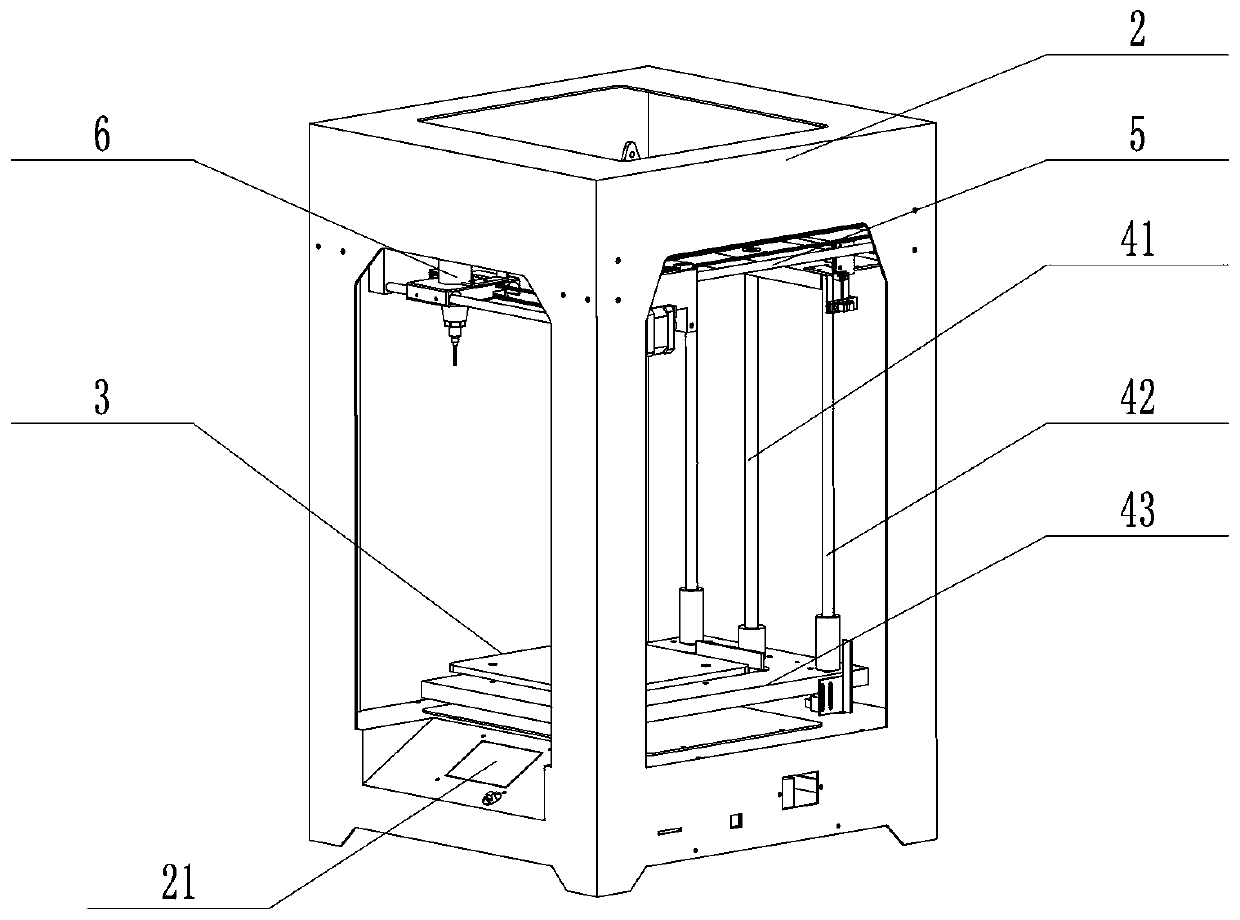

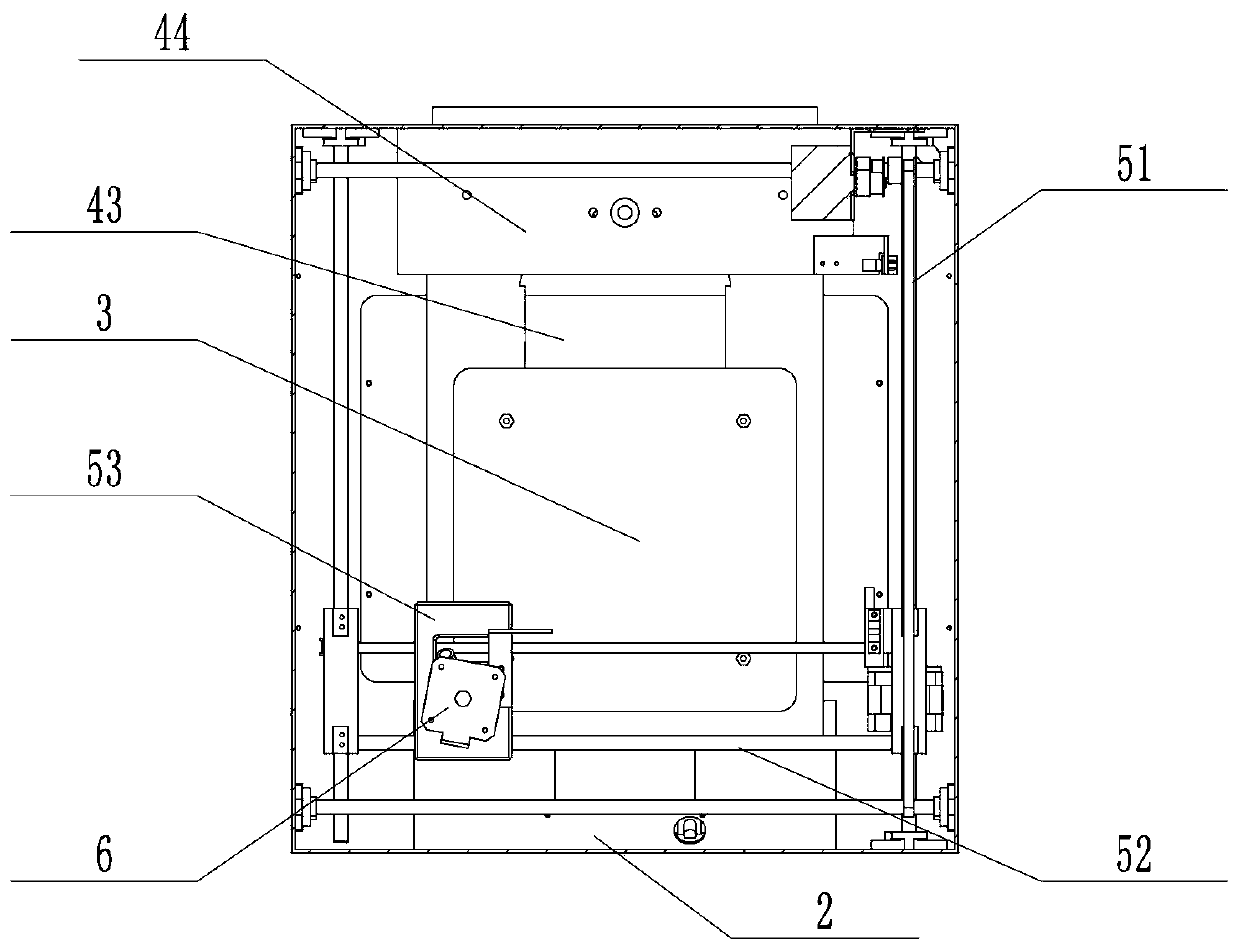

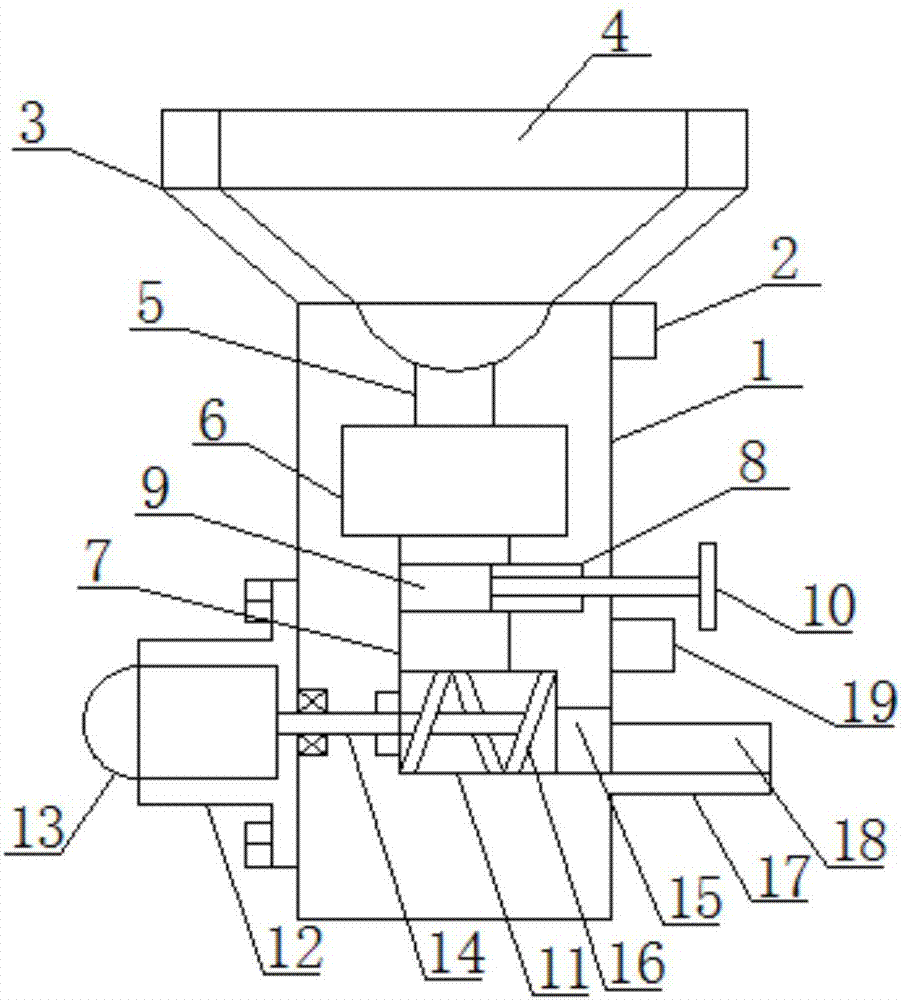

Precise ceramic 3D printer and printing method based on same

PendingCN109849149ASolve the defect of not being able to use porcelain clay as a raw material for 3D printingImprove design and production molding timeAdditive manufacturing apparatusCeramic shaping apparatusPetuntseEngineering

The invention discloses a precise ceramic 3D printer and a printing method based on the same. The precise ceramic 3D printer comprises a support, a printing framework, a printing bottom plate, a lifting rack, a printing head, a moving device and a material supplying barrel; the printing framework is arranged on the support; the lifting rack is fixedly arranged on the bottom of the printing framework; the printing bottom plate is fixedly arranged on the lifting rack; the moving device is fixedly arranged on the top of the printing framework; the printing head is arranged on the moving device; and the material supplying barrel is connected to a pipeline of the printing head. The invention further discloses a printing method based on the precise ceramic 3D printer. By adopting the printing method based on the precise ceramic 3D printer, the defect that an FDM type 3D printer cannot perform 3D printing using petuntse as a raw material is solved; besides, printing is performed directly in adigital modeling mode, so that manufacturing of ceramic products is precise; massive products that cannot be made in a traditional ceramic moulding mode can be produced; and variety and creativity ofceramic products are improved.

Owner:潮州市源润科技有限公司

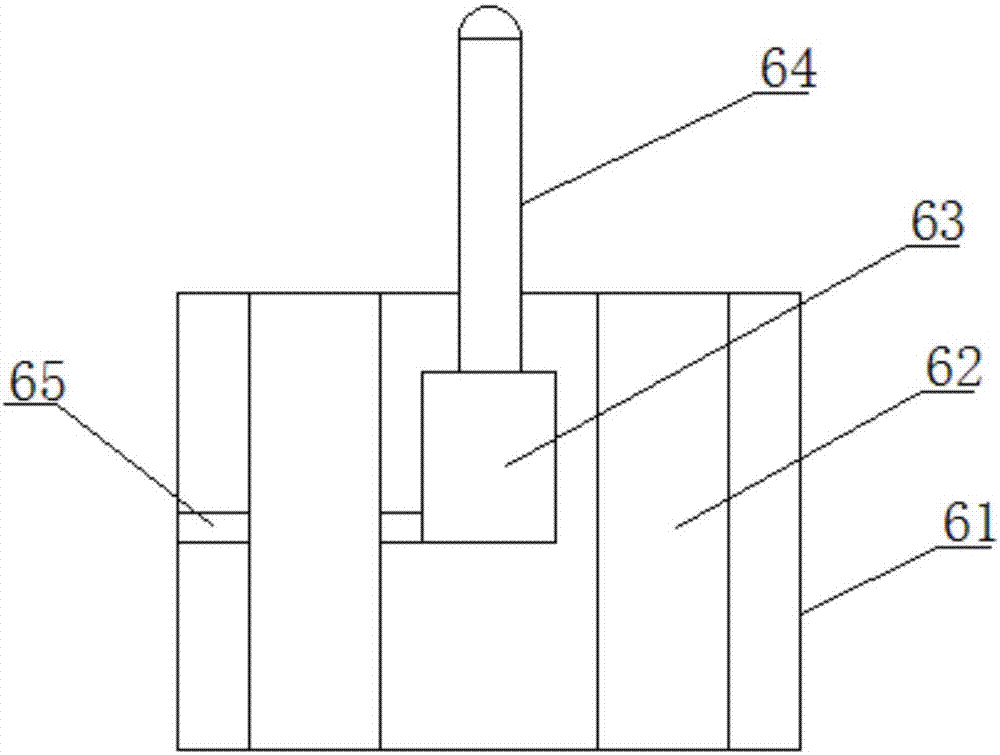

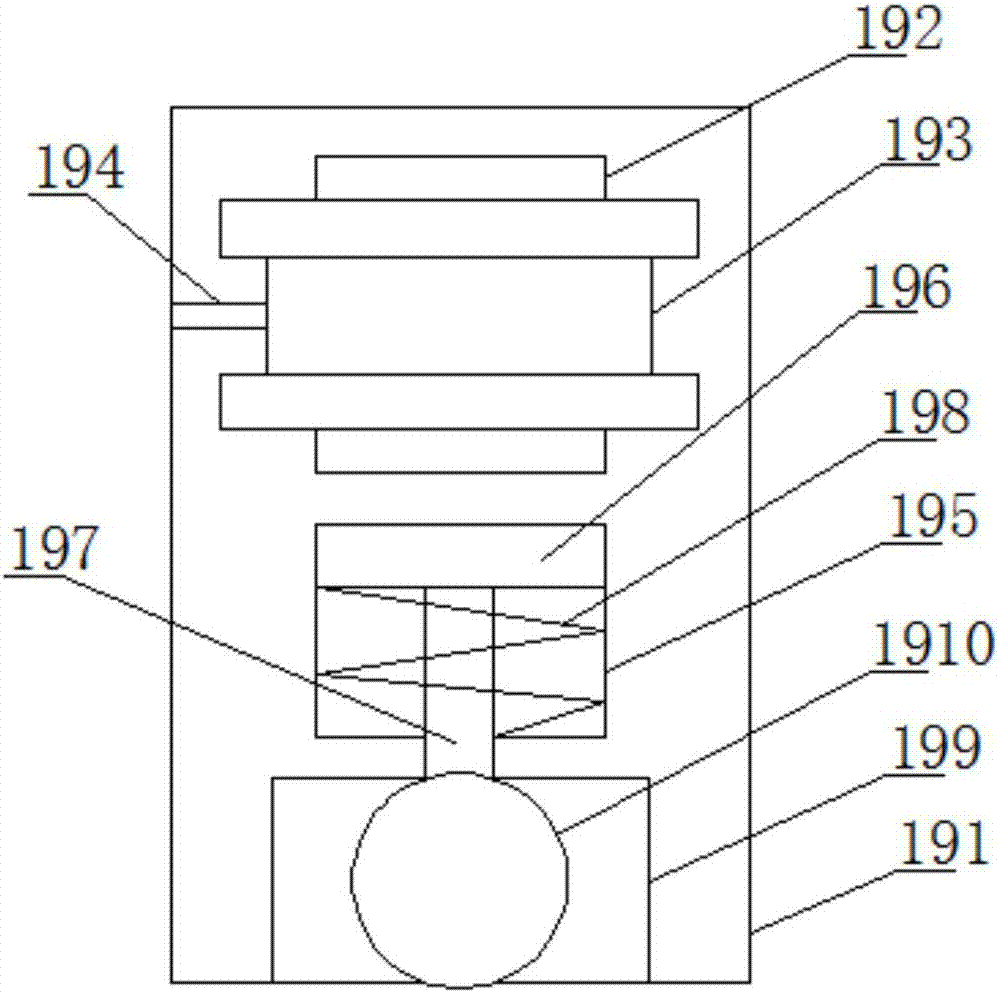

Cylindrical piled petuntse forming and cutting device

PendingCN107379241AReduce probabilityImprove performanceAuxillary shaping apparatusMicrocomputerMicrocontroller

The invention discloses a columnar mud stacking forming and cutting device, comprising a hollow shell, the top of the hollow shell is provided with a hopper shell integrally structured with it, and one side of the hollow shell is installed with a 51 Single-chip microcomputer, the inside of the hopper housing is provided with a funnel space, the center of the hollow housing is provided with a first feeding hole communicating with the funnel space, and the inside of the hollow housing is located at the first feeding hole The vibration mechanism, the hollow shell is located in the second feed hole located in the first feed hole, and the hollow shell is provided with a valve core plate movable space in the middle of the second feed hole. The present invention can shape and cut the softened soil, can quickly realize the process from shaping to cutting, and has high efficiency and fast working efficiency, thereby speeding up the time required for production. In addition, the device has a vibration mechanism, which can reduce the The presence of air bubbles inside the raw material improves the performance of the formed mud column.

Owner:华琦

Production method of vase

The invention provides a production method of a vase. The production method comprises the following steps of producing a vase bottom; producing a vase body; preparing mixed slurry; producing a green body; biscuiting at high temperature; performing colored drawing and color burning; airing; taking a mixed solution of a dispersing agent, deionized water and absolute ethyl alcohol and nano powder, putting the mixed solution and the nano powder into a high-speed homogenizer for homogenizing, and then performing ultrasonic dispersion, wherein the mass part ratio of the dispersing agent to the deionized water to the absolute ethyl alcohol to the nano powder is 5 to 30 to 20 to 55; forming the green body: petuntse is prepared from the following raw materials in percentage by weight: 5.3 percent of nano mixed slurry, silicon dioxide, aluminum oxide, iron oxide, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, phosphorus pentoxide, zirconia, boric oxide and yttria, putting the petuntse on the formed vase bottom, and molding by using the petuntse. The vase bottom of the vase produced by using the mode is firm and cannot be easily broken up.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com