Color petuntse fired at temperature not higher than 1,150 DEG C and preparation method thereof

A color and porcelain clay technology, applied in the field of porcelain clay, can solve the problems of inability to further reduce, high energy consumption for firing, and high firing temperature, and achieves the effects of bright color, lower firing temperature, and energy and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

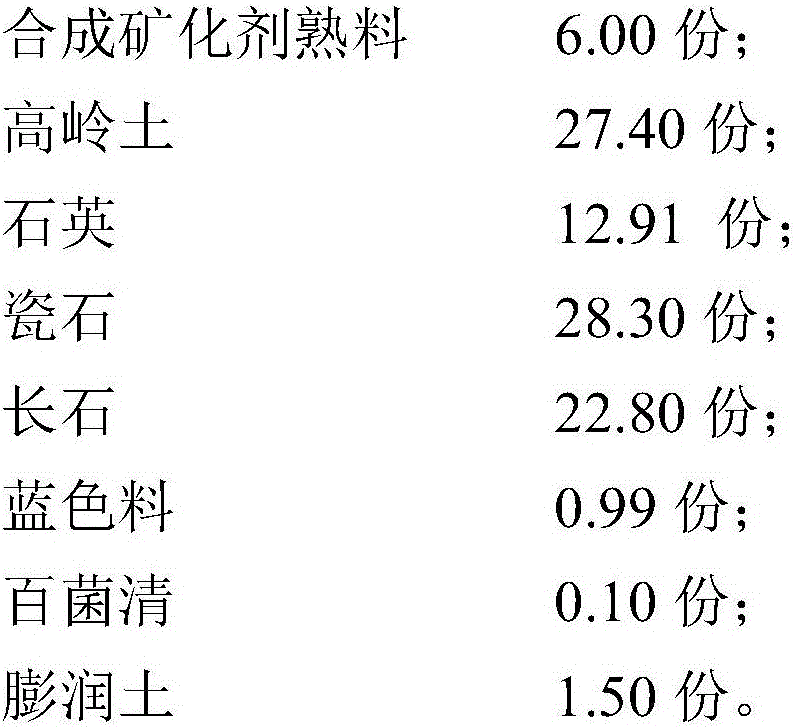

[0032] The colored porcelain clay fired below 1150°C provided by the invention comprises the following raw materials and parts by weight thereof:

[0033]

[0034] Wherein, in the synthetic mineralizer clinker, the weight ratio of lithium china stone and albite feldspar is 7:3, and it is made by calcination at 1080°C. In this embodiment, Li in the lithium china stone 2 The O content is 0.8%.

[0035] The preparation method of the colored porcelain clay fired below 1150°C comprises the following steps:

[0036] 1) After mixing lithium china stone and albite feldspar, they are calcined at 1080°C to make synthetic mineralizer clinker;

[0037] 2) After kaolin, quartz, porcelain stone, feldspar, and synthetic mineralizer clinker are mixed evenly, the ball mill is obtained to obtain a white mixture, the fineness of which is to pass through a 180-mesh sieve, and the sieve residue is 0.8%;

[0038] 3) Mix the blue material with about 5% of the white mixture until it becomes a c...

Embodiment 2

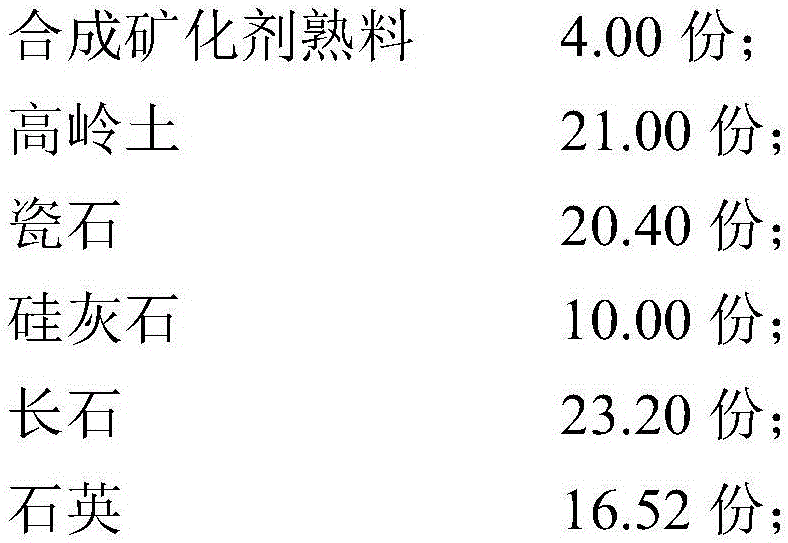

[0042] The colored porcelain clay fired below 1150°C provided by the invention comprises the following raw materials and parts by weight thereof:

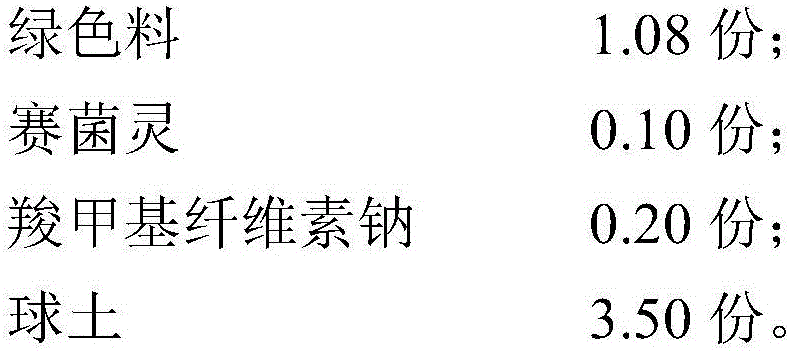

[0043]

[0044]

[0045] Wherein, in the synthetic mineralizer clinker, the weight ratio of lithium china stone to albite is 7.5:2.5, and it is made by calcining at 1100°C. In this embodiment, Li in the lithium china stone 2 The O content is 1.5%.

[0046] The preparation method of the colored porcelain clay fired below 1150°C comprises the following steps:

[0047] 1) After mixing lithium china stone and albite feldspar, they are calcined at 1100°C to make synthetic mineralizer clinker;

[0048] 2) Mix kaolin, quartz, porcelain stone, feldspar, wollastonite, and synthetic mineralizer clinker evenly, and then ball mill to obtain a white mixture. The fineness of the white mixture is 180 mesh sieve, and the sieve residue is 1.0% ;

[0049] 3) Mix the green material with about 6% of the white mixture until it becomes a unifo...

Embodiment 3

[0053] The colored porcelain clay fired below 1150°C provided by the invention comprises the following raw materials and parts by weight thereof:

[0054]

[0055] Wherein, in the synthetic mineralizer clinker, the weight ratio of lithium china stone to albite is 8:2, and it is calcined at 1075°C. In this embodiment, Li in the lithium china stone 2 The O content is 2.3%.

[0056] The preparation method of the colored porcelain clay fired below 1150°C comprises the following steps:

[0057] 1) After mixing lithium china stone and albite feldspar, they are calcined at 1075°C to make synthetic mineralizer clinker;

[0058] 2) Mix kaolin, quartz, porcelain stone, feldspar, wollastonite, and synthetic mineralizer clinker evenly, and then ball mill to obtain a white mixture. The fineness of the white mixture is 180 mesh sieve, and the remaining 0.7% is sieved ;

[0059] 3) Mix the yellow material with about 7.5% of the white mixture until it becomes a color paste with uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com