Easy-cleaning ceramic glaze as well as preparation method and application thereof

A ceramic glaze and easy-to-clean technology is applied in the field of ceramic glaze to achieve the effects of smooth glaze surface, improved gloss, and improved glaze self-cleaning degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of Easy-to-Clean Ceramic Glaze

[0027] 1. Yijie ceramic glaze is composed of the following raw materials calculated by weight percentage: potassium feldspar 33-35%, kaolin 10-12%, calcium oxide 13-15%, magnesium oxide 8-10%, zinc oxide 6-8% , Quartz 24-26%.

[0028] 2. The preparation method of the above-mentioned easy-to-clean ceramic glaze comprises the following steps:

[0029] S1. According to the formula ratio, mix and pulverize each raw material, and perform wet ball milling to obtain glaze slurry;

[0030] S2. Remove iron from the glaze slurry in a 18000 Gauss iron remover;

[0031] S3. Pass the glaze slurry after iron removal through a 250-mesh sieve, and the sieve residue is less than 0.02%;

[0032] S4. Stale the sieved glaze slurry for 24-26 hours, and set aside;

[0033] S5. Prepare a ceramic glaze according to a conventional method.

Embodiment 2

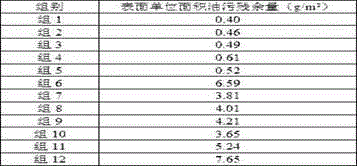

[0034] Example 2 Optimization of raw material formula for easy-to-clean ceramic glaze

[0035] 1. Experimental grouping

[0036] Group 1: Easy-to-clean ceramic glaze is composed of the following raw materials calculated by weight percentage: potassium feldspar 35%, kaolin 10%, calcium oxide 13%, magnesium oxide 10%, zinc oxide 6%, quartz 26%.

[0037] Group 2: Yijie ceramic glaze is composed of the following raw materials calculated by weight percentage: 34% potassium feldspar, 10% kaolin, 13% calcium oxide, 9% magnesium oxide, 6% zinc oxide, and 26% quartz.

[0038] Group 3: Yijie ceramic glaze is composed of the following raw materials calculated by weight percentage: 33% potassium feldspar, 12% kaolin, 15% calcium oxide, 8% magnesium oxide, 8% zinc oxide, and 24% quartz.

[0039] Group 4: Yijie ceramic glaze is composed of the following raw materials calculated by weight percentage: 35% potassium feldspar, 12% kaolin, 15% calcium oxide, 10% magnesium oxide, 8% zinc oxide...

Embodiment 3

[0068] Example 3 Optimization of aging time of glaze slurry

[0069] 1. The raw material formula of Yijie ceramic glaze is as follows: potassium feldspar 35%, kaolin 10%, calcium oxide 13%, magnesium oxide 10%, zinc oxide 6%, quartz 26%.

[0070] 2. Preparation steps:

[0071] (1) The preparation steps of Group 1 are as follows:

[0072] S1. Mix and pulverize the raw materials of Yijie daily-use ceramic glaze according to the proportion of the component formula, and perform wet ball milling. The wet ball mill is carried out according to material: stone: water = 1:1.8:1, and glaze slurry is obtained;

[0073] S2. The above-mentioned glaze slurry is deironed in a 18000 Gauss iron remover;

[0074] S3. Sieve the glaze slurry after iron removal, the fineness of the sieve is 250 mesh, and the sieve residue is less than 0.02%;

[0075] S4. Stale the sieved glaze slurry for 21 hours and set aside;

[0076] S5. Prepare a ceramic glaze according to a conventional method.

[0077...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com